Page 1

ADVANCE ADAPTERS INC. P/N: 477021

P.O. Box 247, 4320 Aerotech Center Way New Item: (12/01)

Paso Robles, CA 93447 PAGE 1 OF 14

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 02-23-11

TOYOTA LOW GEAR 4.7:1 21 SPLINE

For Gear-Driven T ransfer Cases ONLY

The installation of this gear set requires you to almost completely disassemble the transfer case. We have provided

illustrative assembly and disassembly instructions. If your transfer case is in need of a rebuild, now would be the time

to do it.

Here are a couple of points to keep in mind that will make the installation much easier if you've never disassembled a

Toyota transfer case:

1.) Keep all bolts separated into groups as you remove them and label their container.

2.) Keep all small parts in separate containers and label as to location and origin.

3.) Make sure you have plenty of time and a clean, spacious area to perform the installation.

4.) You might want to have a qualified machine shop remove and install the bearings and seals on the new gears,

input shaft and in the case.

5.) The Trail Tamer instructions (in TT001) are to be used as a guide. The official Toyota shop manual is strongly

recommended for your particular application. See Pages 3 & 4 on this instruction sheet to identify your

style transfer case & see what modifications are needed to your transfer case.

TOOLS YOU WILL NEED:

12mm, 14mm and 30mm Metric sockets and ratchet driver

6mm Allen (hex) head wrench

Snap-ring pliers

3/16" (4mm) drift / roll pin punch

Plastic soft blow hammer

Bearing / gear puller with long fingers

Bearing press device

Die grinder

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components will

void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly recommend

that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We recommend that a

service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally available at automotive

dealerships and parts stores.

Page 2

ADVANCE ADAPTERS INC. P/N: 477021

P.O. Box 247, 4320 Aerotech Center Way New Item: (12-01)

Paso Robles, CA 93447 PAGE 2 OF 14

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 02-23-11

TOYOTA LOW GEAR 4.7:1 21 SPLINE

For Gear-Driven T ransfer Cases ONLY

SNAP RING LIST:

This is a list of Toyota snap rings that may be needed for your installation should your stock snap rings

become distorted during disassembly or assembly. These snap rings are stock Toyota parts and can be

obtained at a Toyota parts dealership. Advance Adapters does not carry these components.

36221C

90520-28242 1.50-1.55mm

90520-28248 1.60-1.65mm

36223A

90520-30215 2.10mm

90520-30217 2.20mm

36231F

90520-71221 1.65mm with 71.1mm ID

90520-36250 2.40-2.45mm

90520-36251 2.45-2.50mm

90520-36252 2.50-2.55mm

90520-36253 2.55-2.60mm

90520-36254 2.60-2.65mm

90520-36255 2.65-2.70mm

36212D

90520-72001 1.45mm

90520-72002 1.50mm

90520-72003 1.55mm

90520-72004 1.60mm

90520-72005 1.65mm

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components will

void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly recommend

that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We recommend that a

service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally available at automotive

dealerships and parts stores.

Page 3

ADVANCE ADAPTERS INC. P/N: 477021

P.O. Box 247, 4320 Aerotech Center Way New Item: (12-01)

Paso Robles, CA 93447 PAGE 3 OF 14

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 02-23-11

TOYOTA LOW GEAR 4.7:1 21 SPLINE

For Gear-Driven T ransfer Cases ONLY

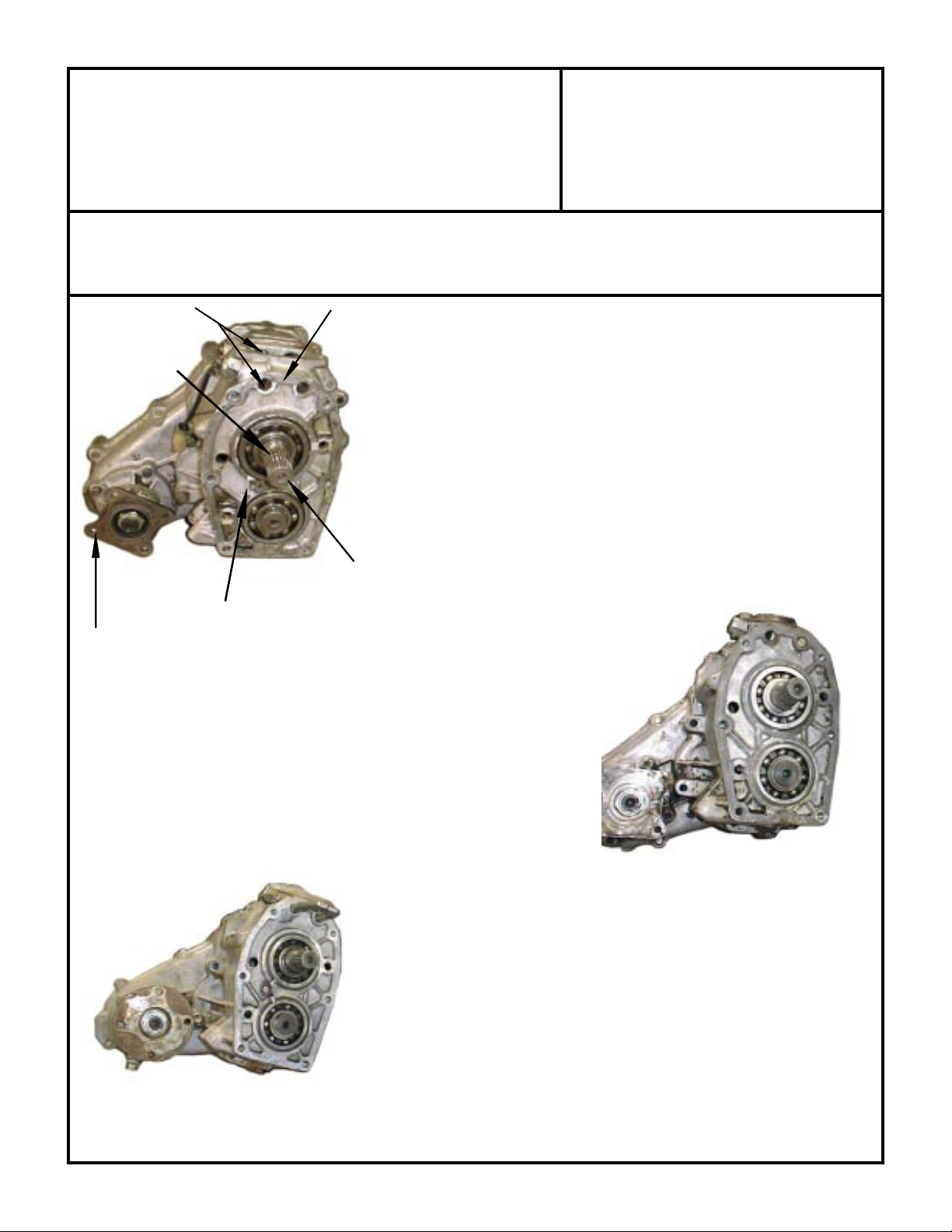

BD

1979-80 4SP TRANSFER CASE

A

E

C

Identification points on this transfer case

are the same on the transfer cases below.

A. Extended splines on input shaft.

B. Short Case (.400).

C. 8.125 Front driveline bolts.

D. Transfer case shifter in top of T-case. Short shift rails.

E. Noisy run gears (no front retainer clip).

F. 21 spline input shaft.

Modification Notes:

This transfer case will require modifications to the shift forks. Refer to Assembly

Step A-12 of the in the Toyota Truck Instruction Manual.

The transfer case reduction box may need to be relieved due to core shift. Refer

to Assembly Step A-11 of the in the Toyota Truck Instruction Manual.

F

1981 to (April) 1983 5SP TRANSFER CASE

B. Short Case (.400).

C. 8.125 Front driveline bolts.

D. Transfer case shifter in top of T-case. Short shift rails.

E. Noisy run gears (no front retainer clip).

F. 21 spline input shaft.

Modification Notes:

This transfer case will require modifications to the shift forks. Refer to

Assembly Step A-12 of the in the Toyota Truck Instruction Manual.

The transfer case reduction box may need to be relieved due to core shift.

Refer to Assembly Step A-11 of the in the Toyota Truck Instruction Manual.

1984-88 CARBURETED 5SP TRANSFER CASE

B. Tall Case (.580).

C. 10.125 Front driveline bolts.

D. Transfer case shifter in top of transmission with forward shift rails.

E. Quiet run gears (front retainer clip).

F. 21 spline input shaft.

Modification Notes:

The transfer case reduction box may need to be relieved due to core shift. Refer

to Assembly Step A-11 of the in the Toyota Truck Instruction Manual.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we

strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 4

ADVANCE ADAPTERS INC. P/N: 477021

P.O. Box 247, 4320 Aerotech Center Way New Item: (12-01)

Paso Robles, CA 93447 PAGE 4 OF 14

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 02-23-11

TTOYOTA LOW GEAR 4.7:1 21 SPLINE

For Gear-Driven T ransfer Cases ONLY

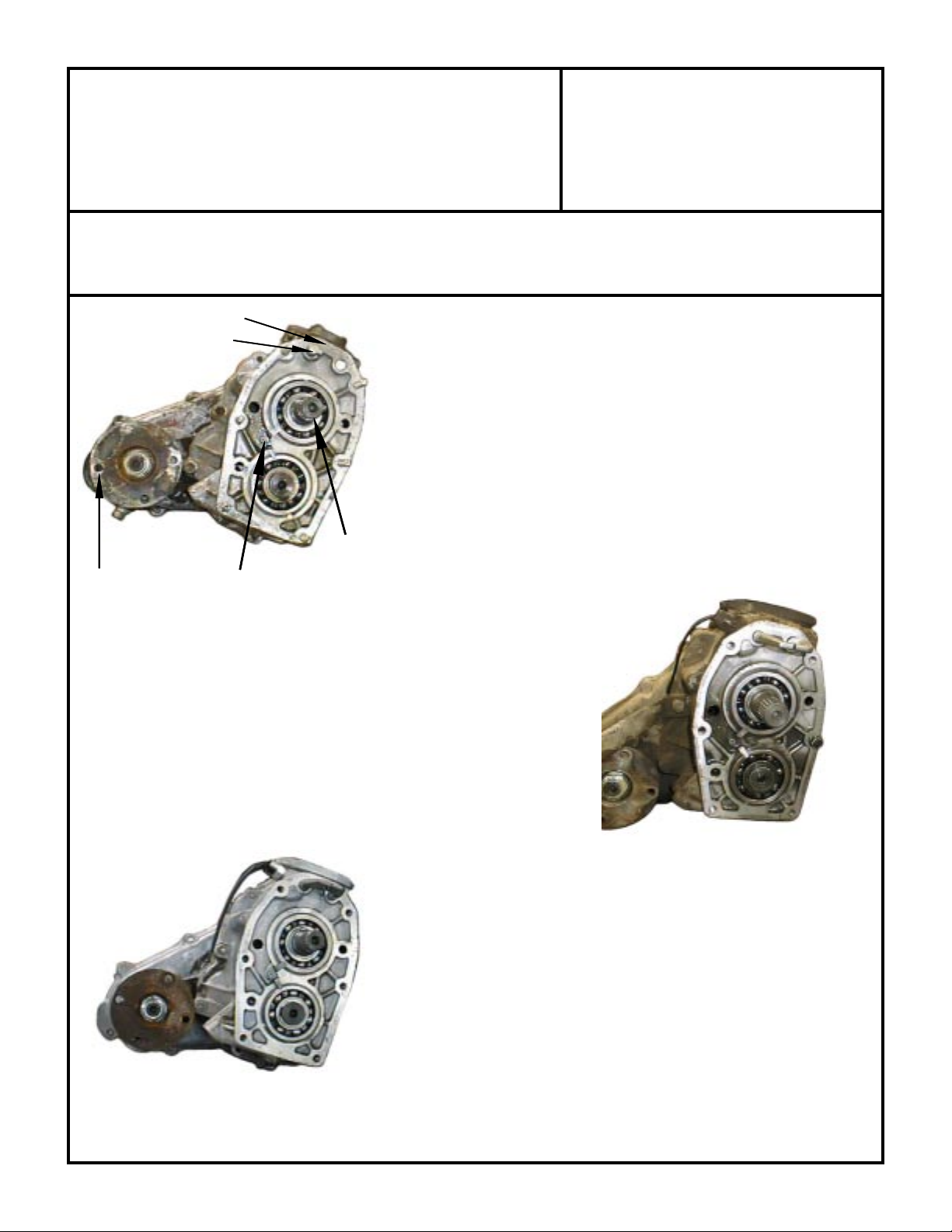

B

D

CE

Identification points on this transfer case

are the same on the transfer cases below.

1985-88 E.F.I. 5SP TRANSFER CASE

B. Tall Case (.580).

C. 10.125 Front driveline bolts.

D. Transfer case shifter in top of T-case. Short shift rails with low-range

shifter rod proturding out approximately .500.

1985 to August 1988

E. Quiet run gears (front retainer clip).

F. 21 spline input shaft.

Modification Notes:

This transfer case will require modifications to the shift forks. Refer to

Assembly Step A-12 of the in the Toyota Truck Instruction Manual.

F

The transfer case reduction box may need to be relieved due to core shift. Refer

to Assembly Step A-11 of the in the Toyota Truck Instruction Manual.

1989-95 E.F.I. 5SP TRANSFER CASE

B. Tall Case (.580)

C. 10.125 Front driveline bolts.

D. Transfer case shifter in top of transmission with forward shift rails. The

shifter rods are 1/2" shorter than the 1984-88 Carbureted T/C.

E. Quiet run gears (front retainer clip).

F. 21 spline input shaft.

Modification Notes:

The transfer case reduction box may need to be relieved due to core shift.

Refer to Assembly Step A-11 of the in the Toyota Truck Instruction Manual.

Carburated T-cases had shifter in transmission.

1986-87 TURBO E.F.I. 5SP TRANSFER CASE

1988-95 V6 5SP TRANSFER CASE

B. Tall Case (.580)

C. 10.125 Front driveline bolts.

D. Transfer case shifter in top of transmission with forward shift rails.

E. Quite run gears (front retainer clip).

F. 23 spline input shaft.

Modification Notes:

The transfer case reduction box may need to be relieved due to core shift.

Refer to Assembly Step A-11 of the in the Toyota Truck Instruction Manual.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we

strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 5

ADVANCE ADAPTERS INC. P/N: 477021

P.O. Box 247, 4320 Aerotech Center Way New Item: (12-01)

Paso Robles, CA 93447 PAGE 5 OF 14

Telephone: (800) 350-2223 Fax: (805) 238-4201 Page Rev. Date: 02-23-11

TOYOTA LOW GEAR 4.7:1 21 SPLINE

For Gear-Driven T ransfer Cases ONLY

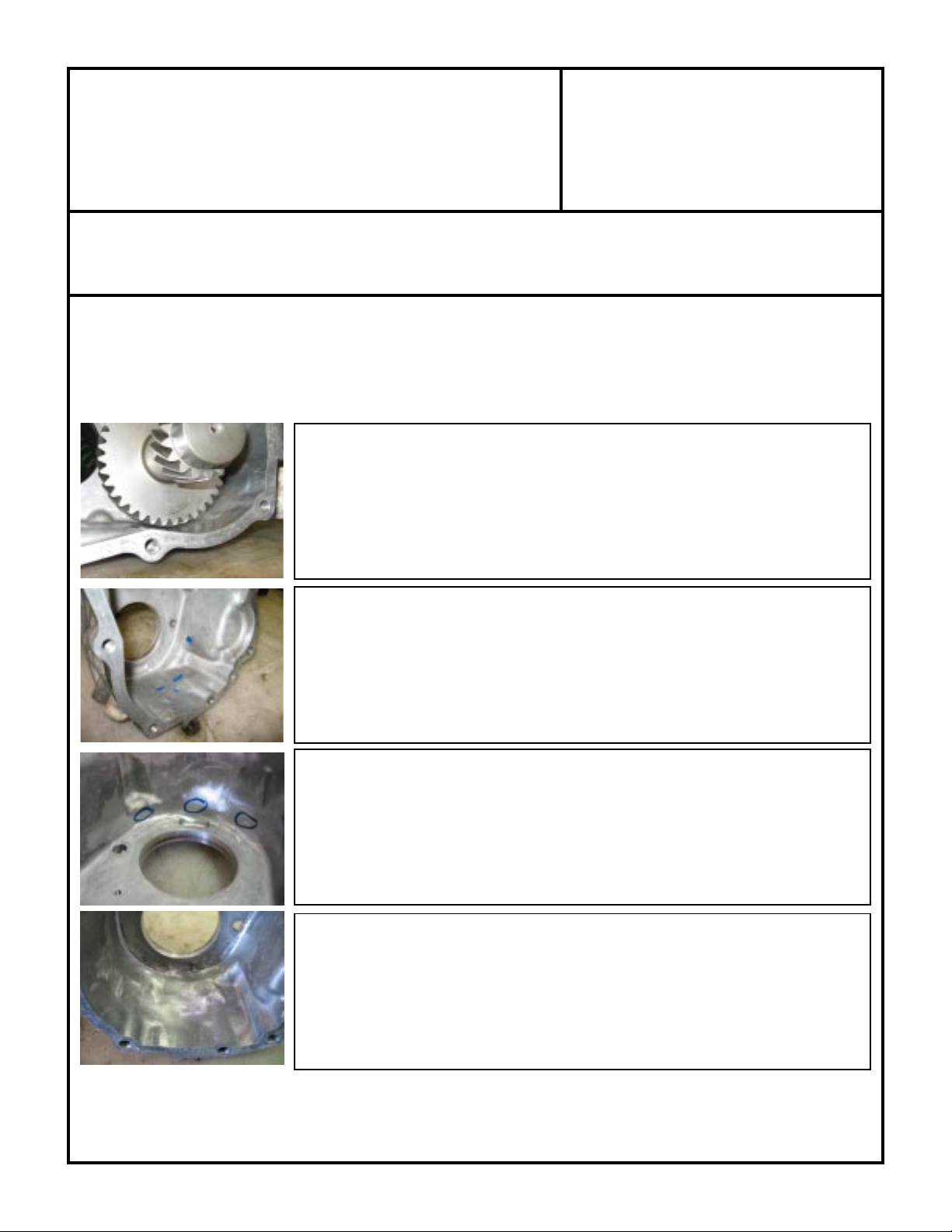

Installation Tips: For those who do not have access to a mill, here is an easy way to clearance your reduction

housing. This procedure requires only some marking fluid and a small angled grinder. This should take you about

1 hour, but remember to take your time and do it slowly. If you do not feel comfortable making these modifications,

we offer P/N 51-5911. This is a heavy duty housing that has been pre-clearanced for these gear sets.

First, test fit your new gear set into your reduction housing. You will notice that the

gears will interfere with the casting in multiple locations. Lightly tap the gear into

the casting. This will score the casting at the interference locations. Now using

marking fluid (paint pen, permanent marker, etc.), take the time to carefully mark

all locations where contact is made.

Now that all your marks have been made, it's time to start slowy removing material

from the casting. Using the grinder equipped with a 50 grit disc, begin to work away

at your marked areas. Remember to take mental note of how much each section

of the casting was contacting the gear. Take special care at this point not to remove

too much material.

After the marked areas have been ground away, go ahead and re-test fit the gears

back into the housing. Make sure to rotate the gear and that it has 360 degree

clearance with all areas of the housing. At this point, it may be necessary to re mark

areas where the gear is still contacting the housing. Repeating this procedure a few

times will insure proper fit and you will avoid the possibility of grinding a hole through

the casting.

With all the grinding done, test fit the gear set one last time making sure that every

thing spins freely and that there are no hang ups or tight spots. In addition to the

case, also remember that the shift rails will require some modifications due to gear

interference. This would be the optimal time to complete this procedure as well.

Make sure that the shift detents are installed to insure proper shift location for

modifications to be made.

SPECIAL NOTE: The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we

strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

Page 6

TOYOTA TRANSFER CASE

ASSEMBLY & DISASSEMBLY PROCEDURES

These gears are ideal for the avid Toyota Truck rock crawler. These gears are designed for the Toyota Truck gear-driven transfer

case. Depending on the model of your transfer case, some additional modifications may be required. Please refer to the Transfer

Case information section for proper transfer case identification and possible modifications.

The installation of the Toyota gear sets requires you to almost completely disassemble the transfer case. We have provided

illustrative disassembly and assembly instructions to assist you. These instructions are to be used as a guide. The official Toyota

shop manual is strongly recommended for additional information. If your transfer case is in need of a rebuild, now would be the

time to do it.

DISASSEMBLY

(Step D-1)

(1)

The transfer case must be in 2WD High before

starting the disassembly procedures.

nut with a 30mm socket and then remove the flange.

(Step D-2)

(2) Remove the 7 bolts that retain the rear extension housing

with a 14mm metric socket.

a separate container. This will reduce the chances of

placing the bolts in the wrong location on reassembly.

(Step D-3)

(3) With the rear extension

housing removed, you

will see the oil pump

and speedometer drive

gears. Slide the gears

off of the rear output

shaft. Take note of the

orientation of the oil

pump and the speedometer gear.

the speedometer drive gear. Make sure you store it in a

bag or some other kind of container. These little parts can

walk away.

NOTE: There is a small ball bearing under

HINT: Keep these bolts in

Remove the

(Step D-4)

(4) Remove the rear output shaft bearing.

(Step D-5)

(5) Remove outer bearing C-clip by reaching inside case and

pushing up on gear, while lightly tapping on the case with

a plastic soft blow mallet.

(Step D-6)

(6) Remove the 10 bolts retaining the rear case cover with a

14mm socket. Retain these separately to avoid any confusion during assembly.

Note their location before removal!

Some bolts are different lengths.

Page 7

(Step D-7)

(7) Pull case off. Remove the two lubrication tubes located on

either side of the main shaft.

Note their orientation!

(Step D-11)

(11)Remove the thick spacer found behind the front wheel drive

gear and be aware of the small ball bearing underneath it.

(Step D-8)

(8) Using a 3/16" (4mm) punch, drive the roll pin out that holds

the front wheel drive shift fork.

(Step D-9)

(9) Slide the fork and clutch sleeve off the shift rail.

(Step D-10)

(10)Remove the front wheel drive gear and it's caged needle

roller bearing assembly.

(Step D-12)

(12)Use a 12mm socket to remove the four bolts that retain the

shift fork cover. With a 5mm Allen wrench, remove the shift

detent screw plugs found on both sides of the case.

(Step D-13)

(13)With the screw plugs removed, the shift ball and spring

assemblies can be removed from both sides.

(Step D-14)

(14)Drive the roll pin out that

retains the high/low shift

fork using a 3/16" (4mm)

punch. Occasionally the

pin will fall into the case.

Don't worry. You will be

able to retrieve the pin

later. On 1979-83 and

1985-88 fuel injected

model transfer cases,

DO NOT REMOVE roll

pin.

Page 8

This interlock pin is located between the two

shift rail detent assembly

chambers.

(Step D-15)

(15)Remove the shift rails,

being careful not to

lose the interlock pin

that might fall out.

(Step D-16)

(16)Remove the 4WD in-

dicator switch with a

22mm wrench.

(Step D-19)

(19)Remove the high/low shift fork

with the clutch sleeve and

needle bearing from the input

shaft.

(Step D-20)

(20)Here are the gears that you will be replacing with the new

Trail Tamer set.

(Step D-17)

(17)Remove the interlock

pin from the shifter

detent chamber, if you

haven't already done

so in Step #D-15.

(Step D-18)

(18)Use a 14mm socket to remove the 4 bolts that retain the

front case to the reduction case. Split the cases. Now you

can retrieve the roll pin that might have fallen in as noted on

Step #D-14.

(Step D-21)

(21)Remove the output shaft from

the front case by removing the

4 bolts with a 12mm socket.

Remove the bearing retainer and snap ring.

(Step D-22)

(22)Remove the snap rings that retain the input shaft and

cluster gear bearings and remove the two from the case.

You might have to use a slight tap from a soft plastic

hammer to help them fall out.

Page 9

(Step D-23)

(23)Remove the low range gear by removing the snap ring that

retains the roller bearing onto the rear shaft. Press the roller

bearing off of the shaft.

ASSEMBLY

(Step D-24)

(24)Now that the roller bearing is removed, you will see a

spacer. Remove the spacer, being careful not to lose the

ball bearing underneath it. Remove the low range gear and

needle bearing. You will be replacing this gear with the new

low gear.

(Step A-1)

(1) Notice that the cluster / counter gear does not incorporate

the stock sub-gear and spring washer. These are not used!

(Step A-2)

(2) Install the cage needle bearing on the output shaft. Use

assembly lube provided in the kit!

(Step A-4)

(4) Install the ball bearing and spacer. Use a drop of assembly

lube to hold the small ball bearing in place during assembly.

(Step A-5)

(5) Reinstall the original roller bearing on the output shaft.

Note snap ring groove orientation on bearing!

(Step A-3)

(3) Install the new low range gear. Apply a small amount of

assembly lube to the caged roller bearing.

(Step A-6)

(6) Install the snap ring that retains the output shaft bearing in

place.

Page 10

(Step A-7)

(7) Install the output shaft assembly into the case. You might

have to tap it in gently with a soft plactic hammer.

(Step A-8)

(8) Install a new snap ring (provided in the kit) that holds in the

bearing for the output shaft.

4.77 cluster interference

(Step A-11)

(11) Install the cluster and input gears into the reduction case.

A slight tap from a soft plastic hammer should be all it takes to

get them seated. Note: On the 4.77 & 5.0 gears, the case must

be machined to provide

clearance for the cluster gear. On some 4.0

cluster gears, we have

found that the case will

need to be relieved due

to core shift. Spin the

cluster gear to check for

interference.

You can grind the necessary

clearance; however, it is recommended to machine the

case for this clearance. We

used a 1” coarse pitch

roughing end mill and took

approximately .050” off the

inside case wall. (We also

offer a new front housing that

has the proper gear clearance, P/N 51-5911)

(Step A-9)

(9) Install the bearing retainer into its original position. Apply

Loctite 242 and install the 4 bolts removed earlier. Torque

evenly to 13 ft./lbs.

(Step A-10)

(10)Press on the cluster / counter gear and input gear bearings.

Be sure to install new snap rings that retain the bearings

on the shafts.

(Step A-12)

(12)If your case uses the large E-clip, remove and replace with

the new C-clip (supplied in kit).

See Photo A-12a. The shift

fork/rail assembly should be test fit before proceeding with

the assembly. Some grinding on the fork rail boss may be

required to clear the larger gear. See Photo A-12b for

grinding locations.

As a final check, reinstall shift

rails/fork assembly over new

gear and temporarily install

mating case so that the shift

rails are indexed into the case.

The gear should rotate easily

with no interference. Now remove case half and go on to

Step 13.

r

New style

C-clip

supplied.

Photo A-12a

r

Discard this

E-clip.

Photo A-12b

Page 11

(Step A-13)

(13)Install new snap rings that retain the cluster / counter and

input gear assemblies in place.

(Step A-14)

(14)Install the output

shaft "pocket" needle

bearing. Apply assembly lube!

(Step A-15)

(15)Install the clutch sleeve

and the high/low shift

fork set into position.

(Step A-17)

(17)Apply Loctite 242 to the 4

bolts that secure the reduction case to the front case.

Torque them evenly to 29 foot/pounds using a 14mm

socket.

(Step A-18)

(18)Install the high/low range shift rail. Use assembly lube!

(Step A-16)

(16)Before mating the surfaces of the reduction box and the

front case, apply a

few

thin

dabs of RTV blue silicon

sealant to the new gasket that installs between them.

(Step A-19)

(19)The shifter must be in 4WD High to install the interlock pin.

Make sure it slides freely into place. Use that assembly

lube!

(Step A-20)

(20)Install the roll pin that retains the high/low shift fork in place

on the shift rail.

Page 12

(Step A-21)

(21)Notice that the cluster / counter gear does not incorporate

the stock sub-gear and spring washer. These are not used!

(Step A-22)

(22)Install the detent plugs (with Loctite 242), spring and ball

assembly on both sides of the assembly cases. This will

position the shift rails once the retaining plugs are installed. Torque the detent plugs to 9 ft./lbs. Use assembly

lube!

(Step A-25)

(25)Install the spacer onto the output shaft.

(Step A-26)

(26)Install the 2 caged needle roller bearings on the output

shaft. Use assembly lube.

(Step A-23)

(23)Apply a drop of assembly lube on the tip of the 4WD indicator

switch and install it into its original position on the reduction

case.

(Step A-24)

(24)Install the small ball bearing in the machined pocket on the

output shaft. Use a drop of assembly lube to hold it in place.

(Step A-27)

(27)Install the transfer gear onto the output shaft. Use assem-

bly lube!

(Step A-28)

(28)Before proceeding, make sure you have installed these

snap rings!

Page 13

(Step A-29)

(29)Install the shift fork and shift hub sleeve onto the output

shaft.

(Step A-30)

(30)Install the roll pin that holds the front wheel drive shift fork

in place.

(Step A-33)

(33)Install the drive gear for the speedometer onto the output

shaft. Make sure the orientation is correct. The hardened

side goes against the bearing.

(Step A-34)

(34)Install the ball bearing onto the pocket on the output shaft

using a drop of assembly lube to hold it in place. Install the

oil pump drive gear.

(Step A-31)

(31)Install the clutch hub onto the output shaft.

(Step A-32)

(32)Install the bearing onto the output shaft.

(Step A-35)

(35)Install the two lubrication tubes into the case. Note the

orientation shown in the photo above.

(Step A-36)

(36)Apply a very thin coat of silicone gasket sealant to the rear

case gasket, and position the rear case. Apply Loctite 242

to the threads and install the 10 bolts that retain the case

with a 14mm socket

loosely

. You will tighten these later,

after the centering of the case is performed in the following

procedures.

Page 14

(Step A-37)

(37)Replace the outer seal in the rear tail housing. Apply a thin

film of assembly lube to sealing lip of seal.

(Step A-38)

(38)Apply a

few thin dabs

of silicone gasket sealant to the rear tail extension gasket and

position the rear tail

extension. Apply Loctite 242 to the threads

and install loosely the

7 bolts that retain the

tail extension with a 14mm socket. You will also tighten

these later, after the centering of the case is performed.

(Step A-41)

(41)Install the speedometer drive assembly and the retainer.

(Step A-42)

(42)Apply a thin film of RTV sealant to the cover plate mating

surface. Install the 4 bolts that hold it in place and tighten

firmly.

We do not recommend using the stock gasket

in this location.

On occasion we have found this gasket

to slip out of position and cause a serious leak.

(Step A-39)

(39)Insert the rear drive shaft flange. This will center the cases

on the seals in the rear tail extension. Use assembly lube

where seal rides on driveshaft flange.

(Step A-40)

(40)Now, with the seals centered on the rear shaft, torque the

bolts to 34 ft./lbs.

(Step A-43)

(43)Clean and apply a bead of RTV black silicone sealant to

about the middle of the spline area and slide the rear drive

shaft flange into position. Install the retainer nut and torque

to 90 ft./lbs. Using a chisel and hammer, fold the lip of the

nut to lock it in place.

Loading...

Loading...