Page 1

TSU LT

USER MANUAL

Part Number 1203060L1

61203060L1-1A

April 2003

Page 2

Trademarks TSU LT User Manual

Trademarks

Any brand names and product names included in this manual are trademarks, registered trademarks, or

trade names of their respective holders.

T-Watch PRO

®

is a registered trademark of ADTRAN, Inc.

To the Holder of the Manual

The contents of this manual are current as of the date of publication. ADTRAN reserves the right to change

the contents without prior notice.

In no event will ADTRAN be liable for any special, incidental, or consequential damages or for

commercial losses even if ADTRAN has been advised thereof as a result of issue of this publication.

About this Manual

This manual provides a complete description of the TSU LT system and system software. The purpose of

this manual is to provide the technician, system administrator, and manager with general and specific

information related to the planning, installation, operation, and maintenance of the TSU LT. This manual is

arranged so that needed information can be quickly and easily found.

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

© 2003 ADTRAN, Inc.

All Rights Reserved.

Printed in U.S.A.

2 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 3

TSU LT User Manual Revision History

Revision History

Document

Revision

A April 2003 Initial release of new part number.

B

C

D

E

F

G

Conventions

Date Description of Changes

Notes provide additional useful information.

Cautions signify information that could prevent service interruption.

Warnings provide information that could prevent damage to the equipment or

endangerment to human life.

61203060L1-1A © 2003 ADTRAN, Inc. 3

Page 4

Safety Instructions TSU LT User Manual

Safety Instructions

When using your telephone equipment, please follow these basic safety precautions to reduce the risk of

fire, electrical shock, or personal injury:

1. Do not use this product near water, such as a bathtub, wash bowl, kitchen sink, laundry tub, in a

wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical storm. There is a remote

risk of shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply, and/or batteries indicated in the manual. Do not dispose of

batteries in a fire. They may explode. Check with local codes for special disposal instructions.

5. The socket-outlet shall be installed near the equipment and shall be easily accessible.

Double pole/neutral fusing.

Save These Important Safety Instructions

4 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 5

TSU LT User Manual Compliance Information

Compliance Information

Product: TSU LT

Model Numbers: 1203060L1

FCC Registration Number: US: HDCDENAN1203060L1

FCC regulations require that the following information be provided to the customer:

1. This equipment complies with Part 68 of the FCC rules. On the side or bottom of this equipment is

a label that contains, among other information, the FCC Registration Number and Ringer

Equivalence Number (REN), if applicable, for this equipment. If required, this information must

be given to the telephone company.

2. An FCC-compliant telephone cord and modular plug is provided with this equipment. This

equipment is designed to be connected to the telephone network or premises wiring using a

compatible modular jack which is Part 68-compliant. See installation instructions for details.

3. If your telephone equipment causes harm to the telephone network, the telephone company may

discontinue your service temporarily. If possible, they will notify you in advance. But if advance

notice isn’t practical, you will be notified as soon as possible. You will be advised of your right to

file a complaint with the FCC.

4. Your telephone company may make changes in its facilities, equipment, operations, or procedures

that could affect the proper operation of your equipment. If they do, you will be given advance

notice to give you an opportunity to maintain uninterrupted service.

5. If you experience trouble with this equipment, please contact ADTRAN at (256) 963-8722 for

repair/warranty information. The telephone company may ask you to disconnect this equipment

from the network until the problem has been corrected or until you are sure the equipment is not

malfunctioning.

6. This unit contains no user-serviceable parts.

7. The FCC recommends that the AC outlet to which equipment requiring AC power is to be installed

is provided with an AC surge arrester.

8. The REN is used to determine the quantity of devices which may be connected to the telephone

line. Excessive RENs on the telephone line may result in the devices not ringing in response to an

incoming call. In most, but not all areas, the sum of RENs should not exceed five (5.0). To be

certain of the number of devices that may be connected to a line, as determined by the total RENs,

contact the local telephone company.

9. The following information may be required when applying to your local telephone company for

leased line facilities.

Service Type REN/SOC FIC USOC

1.544 Mbps - SF 6.0 F 04DU9-BN RJ-48C

1.544 Mbps - SF and B8ZS 6.0 F 04DU9-DN RJ-48C

1.544 Mbps - ESF 6.0 F 04DU9-1KN RJ-48C

1.544 Mbps - ESF and B8ZS 6.0 F 04DU9-1SN RJ-48C

61203060L1-1A © 2003 ADTRAN, Inc. 5

Page 6

Federal Communications Commission Radio Frequency Interference Statement TSU LT User Manual

Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio frequencies. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC limits.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Affidavit Requirements for Connection to Digital Services

• An affidavit is required to be given to the telephone company whenever digital terminal equipment

without encoded analog content and billing protection is used to transmit digital signals containing

encoded analog content which are intended for eventual conversion into voiceband analog signals and

transmitted on the network.

• The affidavit shall affirm that either no encoded analog content or billing information is being

transmitted or that the output of the device meets Part 68 encoded analog content or billing protection

specifications.

• End user/customer will be responsible for filing an affidavit with the local exchange carrier when

connecting unprotected customer premise equipment (CPE) to 1.544 Mbps or subrate digital services.

• Until such time as subrate digital terminal equipment is registered for voice applications, the affidavit

requirement for subrate services is waived.

6 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 7

TSU LT User Manual Affidavit for Connection of Customer Premises Equipment

Affidavit for Connection of Customer Premises Equipment

to 1.544 Mbps and/or Subrate Digital Services

For the work to be performed in the certified territory of ___________________ (telco name)

State of ________________

County of ________________

I, _______________________ (name), ____________________________________ (business address),

____________________ (telephone number) being duly sworn, state:

I have responsibility for the operation and maintenance of the terminal equipment to be connected

to 1.544 Mbps and/or ________ subrate digital services. The terminal equipment to be connected

complies with Part 68 of the FCC rules except for the encoded analog content and billing protection

specifications. With respect to encoded analog content and billing protection:

( ) I attest that all operations associated with the establishment, maintenance, and adjustment of the digital

CPE with respect to analog content and encoded billing protection information continuously complies

with Part 68 of the FCC Rules and Regulations.

( ) The digital CPE does not transmit digital signals containing encoded analog content or billing

information which is intended to be decoded within the telecommunications network.

( ) The encoded analog content and billing protection is factory set and is not under the control of the

customer.

I attest that the operator(s)/maintainer(s) of the digital CPE responsible for the establishment,

maintenance, and adjustment of the encoded analog content and billing information has (have) been

trained to perform these functions by successfully having completed one of the following (check

appropriate blocks):

( ) A. A training course provided by the manufacturer/grantee of the equipment used to encode analog

signals; or

( ) B. A training course provided by the customer or authorized representative, using training materials

and instructions provided by the manufacturer/grantee of the equipment used to encode analog

signals; or

( ) C. An independent training course (e.g., trade school or technical institution) recognized by the

manufacturer/grantee of the equipment used to encode analog signals; or

( ) D. In lieu of the preceding training requirements, the operator(s)/maintainer(s) is (are) under the

control of a supervisor trained in accordance with _________ (circle one) above.

61203060L1-1A © 2003 ADTRAN, Inc. 7

Page 8

Affidavit for Connection of Customer Premises Equipment TSU LT User Manual

I agree to provide ______________________ (telco’s name) with proper documentation to demonstrate

compliance with the information as provided in the preceding paragraph, if so requested.

_________________________________Signature

_________________________________Title

_________________________________ Date

Transcribed and sworn to before me

This ________ day of _______________, _______

_________________________________

Notary Public

My commission expires:

_________________________________

8 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 9

TSU LT User Manual Industry Canada Compliance Information

Industry Canada Compliance Information

Notice: The Industry Canada label applied to the product (identified by the Industry Canada logo or the

“IC:” in front of the certification/registration number) signifies that the Industry Canada technical

specifications were met.

Notice: The Ringer Equivalence Number (REN) for this terminal equipment is supplied in the

documentation or on the product labeling/markings. The REN assigned to each terminal device indicates

the maximum number of terminals that can be connected to a telephone interface. The termination on an

interface may consist of any combination of devices subject only to the requirement that the sum of the

RENs of all the devices should not exceed five (5).

Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus

as set out in the interference-causing equipment standard entitled “Digital Apparatus,” ICES-003 of the

Department of Communications.

Cet appareil numérique respecte les limites de bruits radioelectriques applicables aux appareils numériques

de Class A prescrites dans la norme sur le materiel brouilleur: “Appareils Numériques,” NMB-003 edictee

par le ministre des Communications.

61203060L1-1A © 2003 ADTRAN, Inc. 9

Page 10

Warranty TSU LT User Manual

Warranty

ADTRAN will replace or repair this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com/warranty.

Product Registration

Registering your product helps ensure complete customer satisfaction. Please take time to register your

products on line at www.adtran.com. Click Service/Support on the top of the page, and then click Product

Registration under Support.

Customer Service, Product Support Information, and Training

ADTRAN will replace or repair this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com/warranty.

A return material authorization (RMA) is required prior to returning equipment to ADTRAN. For service,

RMA requests, training, or more information, use the contact information given below.

Repair and Return

If you determine that a repair is needed, please contact our Customer and Product Service (CAPS)

department to have an RMA number issued. CAPS should also be contacted to obtain information

regarding equipment currently in house or possible fees associated with repair.

CaPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to the following address:

ADTRAN Customer and Product Service

901 Explorer Blvd. (East Tower)

Huntsville, Alabama 35806

RMA # _____________

Pre-Sales Inquiries and Applications Support

Your reseller should serve as the first point of contact for support. If additional pre-sales support is needed,

the ADTRAN Support web site provides a variety of support services such as a searchable knowledge

base, latest product documentation, application briefs, case studies, and a link to submit a question to an

Applications Engineer. All of this, and more, is available at:

http://support.adtran.com

When needed, further pre-sales assistance is available by calling our Applications Engineering

Department.

Applications Engineering (800) 615-1176

10 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 11

TSU LT User Manual Customer Service, Product Support Information, and Training

Post-Sale Support

Your reseller should serve as the first point of contact for support. If additional support is needed, the

ADTRAN Support web site provides a variety of support services such as a searchable knowledge base,

updated firmware releases, latest product documentation, service request ticket generation and troubleshooting tools. All of this, and more, is available at:

http://support.adtran.com

When needed, further post-sales assistance is available by calling our Technical Support Center. Please

have your unit serial number available when you call.

Technical Support (888) 4ADTRAN

Installation and Maintenance Support

The ADTRAN Custom Extended Services (ACES) program offers multiple types and levels of installation

and maintenance services which allow you to choose the kind of assistance you need. This support is

available at:

http://www.adtran.com/aces

For questions, call the ACES Help Desk.

ACES Help Desk (888) 874-ACES (2237)

Training

The Enterprise Network (EN) Technical Training Department offers training on our most popular products.

These courses include overviews on product features and functions while covering applications of

ADTRAN's product lines. ADTRAN provides a variety of training options, including customized training

and courses taught at our facilities or at your site. For more information about training, please contact your

Territory Manager or the Enterprise Training Coordinator.

Training Phone (800) 615-1176, ext. 7500

Training Fax (256) 963-6700

Training Email training@adtran.com

61203060L1-1A © 2003 ADTRAN, Inc. 11

Page 12

Customer Service, Product Support Information, and Training TSU LT User Manual

12 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 13

Table of Contents

Chapter 1 Introduction ...........................................................................................................19

TSU LT Overview .......................................................................................................................................................19

TSU LT Physical Description ...............................................................................................................................19

TSU LT Features ..................................................................................................................................................20

TSU LT Interfaces ................................................................................................................................................20

TSU LT Bridge/Router Application ............................................................................................................................20

Chapter 2 Inspection and Installation ...................................................................................21

TSU LT Shipment ........................................................................................................................................................21

Inspecting for Damages ........................................................................................................................................21

Shipping Contents .................................................................................................................................................21

Installing the TSU LT ..................................................................................................................................................21

Power Connection .................................................................................................................................................21

Grounding Instructions .........................................................................................................................................21

TSU LT Rear Panel ...............................................................................................................................................23

TSU LT Interfaces ................................................................................................................................................23

Power Up Testing & Initialization ...............................................................................................................................24

Self-Test ................................................................................................................................................................24

Chapter 3 Operation ................................................................................................................27

Front Panel ...................................................................................................................................................................27

LCD Window ...............................................................................................................................................................28

Main Menus .................................................................................................................................................................28

Status .....................................................................................................................................................................29

Config (Configuration) .........................................................................................................................................29

Util (Utility) ..........................................................................................................................................................30

Test ........................................................................................................................................................................30

Example Menu Operations ...........................................................................................................................................31

Selecting a Main Menu Item .................................................................................................................................31

Selecting a Submenu .............................................................................................................................................32

Setting Data Fields ................................................................................................................................................32

Viewing Display-Only Data Fields .......................................................................................................................32

Exiting Any Menu Field Operation or Display ....................................................................................................32

Alternate Method of Control from TSU LT .................................................................................................................33

T-Watch PRO Management Software Program ...................................................................................................33

Chapter 4 Status Menu ............................................................................................................35

NI Perf Rpts menu ........................................................................................................................................................35

Curr Err/Alm Menu ......................................................................................................................................................36

Err/Alm Hist Menu ......................................................................................................................................................37

Chapter 5 Config Menu ...........................................................................................................39

Network (NI) Menu .....................................................................................................................................................39

61203060L1-1A © 2003 ADTRAN, Inc. 13

Page 14

Table of Contents TSU LT User Manual

Clock Sources and Timing ....................................................................................................................................40

Unit Menu ....................................................................................................................................................................42

Cntrl Port Submenu ..............................................................................................................................................43

Alarms Submenu ...................................................................................................................................................43

Port Menu .....................................................................................................................................................................44

Chapter 6 Utility Menu ...........................................................................................................47

Software Rev ................................................................................................................................................................47

Reinit Unit ....................................................................................................................................................................47

Address .........................................................................................................................................................................47

Set Passcode .................................................................................................................................................................48

Keypad .........................................................................................................................................................................48

Fact Restore ..................................................................................................................................................................48

Chapter 7 Test Menu ...............................................................................................................49

Network Tests ..............................................................................................................................................................49

Local Loopback ....................................................................................................................................................49

Remote Loopback .................................................................................................................................................50

Test Pattern ...........................................................................................................................................................51

CLR Errors ............................................................................................................................................................51

Insert 511 Errors ...................................................................................................................................................51

Run Self-Test ...............................................................................................................................................................51

Port Tests ......................................................................................................................................................................52

Chapter 8 Circuit Testing .......................................................................................................53

Far End Looped Back Test ...................................................................................................................................53

Appendix A TSU LT Menu Tree .............................................................................................55

Appendix B DTE Data Rate Chart ..........................................................................................57

Appendix C Pinouts...................................................................................................................59

Network (USOC RJ-48C) ............................................................................................................................................59

Control Chain In (RJ-48) .............................................................................................................................................59

Control Chain Out (RJ-48) ...........................................................................................................................................60

Nx56K/64K DTE (V.35) ..............................................................................................................................................61

Index..............................................................................................................................................63

14 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 15

List of Figures

Figure 1-1. TSU LT - Front Panel ............................................................................................................19

Figure 1-2. TSU LT - Rear Panel .............................................................................................................19

Figure 1-3. Simple Bridge Application on a T1 or an FT1 Circuit ..........................................................20

Figure 2-1. TSU LT Rear Panel ................................................................................................................23

Figure 2-2. TSU LT Interfaces .................................................................................................................24

Figure 3-1. TSU LT Front Panel ...............................................................................................................27

Figure 3-2. TSU LT Main Menu Screen ...................................................................................................28

Figure 3-3. TSU LT Main Menus .............................................................................................................29

Figure 3-4. Cursor on Menu Item .............................................................................................................31

Figure 3-5. Submenu Fields ......................................................................................................................31

Figure 4-1. Status Menu Tree ...................................................................................................................35

Figure 4-2. Severely Errored Seconds Screen ..........................................................................................36

Figure 4-3. Loss of Signal (Current Errors/Alarms) Screen .....................................................................36

Figure 4-4. Clear History Screen ..............................................................................................................37

Figure 5-1. Configuration Menu Tree .......................................................................................................39

Figure 5-2. Network Submenu ..................................................................................................................40

Figure 5-3. Network Timed Clock Source ................................................................................................41

Figure 5-4. DTE Clock Source .................................................................................................................41

Figure 5-5. Internal Clock Source .............................................................................................................42

Figure 5-6. Configuration Submenu .........................................................................................................42

Figure 5-7. Inband Remote Configuration ................................................................................................ 46

Figure 6-1. Utility Menu Tree ...................................................................................................................47

Figure 6-2. Address Screen .......................................................................................................................48

Figure 7-1. Test Menu Tree ......................................................................................................................49

Figure 7-2. Network Loopback Tests .......................................................................................................50

Figure 7-3. Self Test Results Screen .........................................................................................................51

Figure 7-4. Port Loopback Tests ...............................................................................................................52

Figure A-1. TSU LT Menu Tree (Status and Config) ................................................................................55

Figure A-2. TSU LT Menu Tree (Util and Test)........................................................................................56

61203060L1-1A © 2003 ADTRAN, Inc. 15

Page 16

List of Figures TSU LT User Manual

16 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 17

List of Tables

Table 1-1. TSU Family of Single-port CSU/DSUs................................................................................. 19

Table 2-1. Number Identification for TSU LT Rear Panel ..................................................................... 23

Table 3-1. Number Identification for TSU LT Front Panel .................................................................... 27

Table 3-2. LCD Features ......................................................................................................................... 28

Table 4-1. Network Interface Performance Reports (15 Min / 24 Hours) .............................................. 36

Table 4-2. Alarms and Errors (Current and Historical)........................................................................... 37

Table 5-1. Network Interface Submenus................................................................................................. 40

Table 5-2. Normal Mode Operation ........................................................................................................ 46

Table B-1. DTE Data Rate Chart..............................................................................................................57

Table C-1. Network Pin Assignments.......................................................................................................59

Table C-2. Chain In Pin Assignments.......................................................................................................59

Table C-3. Chain Out Pin Assignments ....................................................................................................60

Table C-4. V.35 Pin Assignment ..............................................................................................................61

61203060L1-1A © 2003 ADTRAN, Inc. 17

Page 18

List of Tables TSU LT User Manual

18 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 19

Chapter 1

Introduction

TSU LT OVERVIEW

The TSU LT belongs to the ADTRAN T1 single-port CSU/DSU family offering complete flexibility in

connecting various data sources to T1 or FT1 facilities (see Table 1-1).

Table 1-1. TSU Family of Single-port CSU/DSUs

Product Description

TSU ACE T1 CSU/DSU with a single Nx56/64K serial port that offers front panel configuration only.

TSU LT T1 CSU/DSU with a single Nx56/64K serial port that offers terminal, front panel, or T-Watch PRO

configuration options.

The TSU LT serves as the link between user data sources such as local area network (LAN) bridges and

routers, computers, CAD systems, and teleconferencing equipment. The amount of bandwidth allocated to

the port is custom programmable. The data terminal equipment (DTE) data can occupy contiguous or

alternate channels in the T1 stream, and the channels may start at any position.

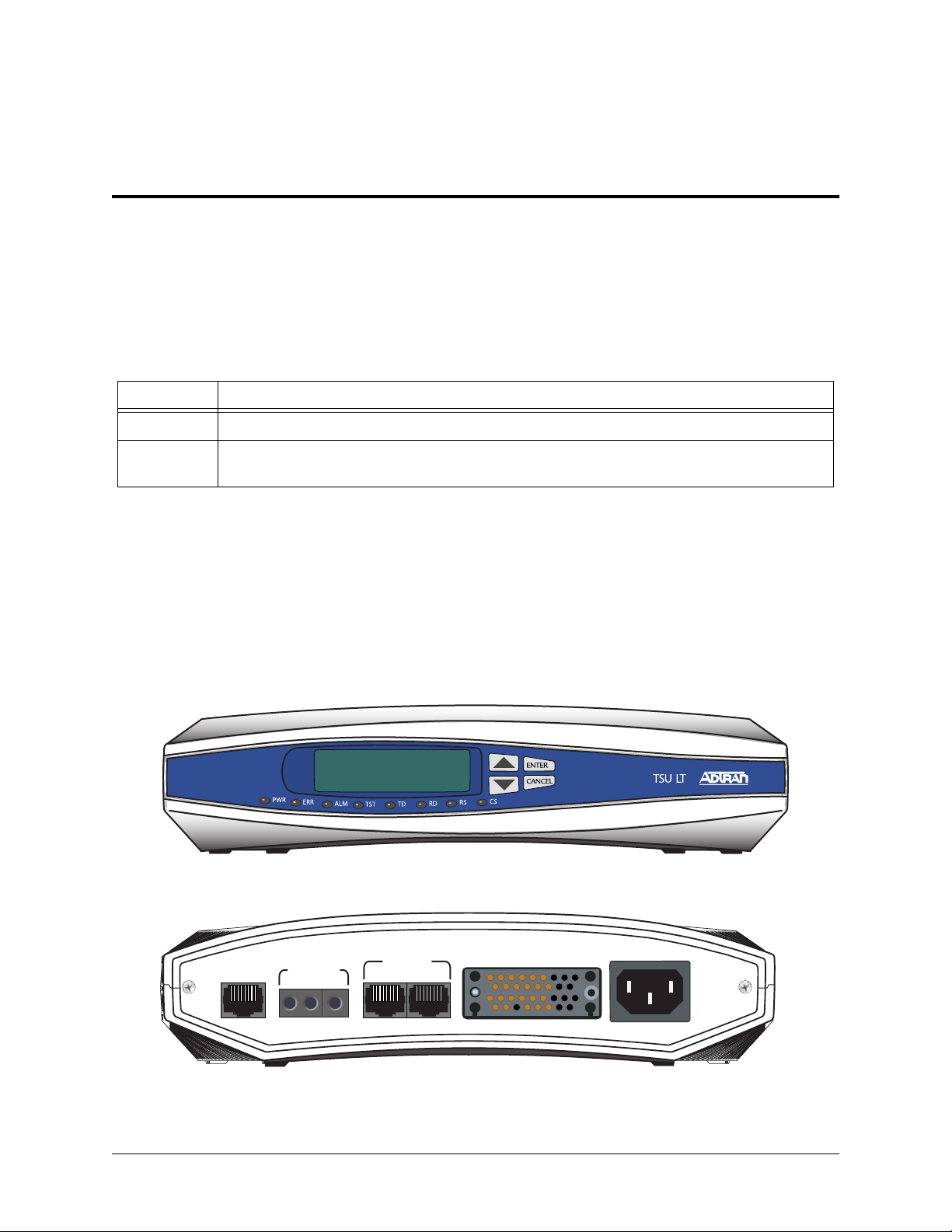

TSU LT Physical Description

Figure 1-1 shows the TSU LT front panel and Figure 1-2 shows the rear panel.

.

NETWORK

PWR

TEST JACKS

IN OUT MON

ERR

ALM

TST

TD

Figure 1-1. TSU LT - Front Panel

CONTROL

CHAIN IN

CHAIN OUT

CS

RS

V.35 Nx56/64

115VAC 60HZ .15A

Figure 1-2. TSU LT - Rear Panel

61203060L1-1A © 2003 ADTRAN, Inc. 19

Page 20

Chapter 1 Introduction TSU LT User Manual

TSU LT Features

• Easy configuration capabilities using simplistic menus displayed in a liquid crystal display (LCD)

window operated by a front panel keypad.

• Timing is selectable from the network, from the Nx56/64 DTE port, or internally.

• Variety of test patterns: all ones, all zeros, 511, 1:8.

• Extensive self-testing and monitoring ensures proper operation.

• Flexible channel allocation (any starting channel and alternate or contiguous).

TSU LT Interfaces

The TSU LT is equipped with four interfaces:

• Network DS1 interface per AT&T 62411

• Nx56/64 serial V.35

• Control input (EIA-232)/Chain port input

• Chain port output

TSU LT BRIDGE/ROUTER APPLICATION

A bridge or router can be interfaced to the network by using the V.35 DTE interface. The bandwidth used

is programmable at Nx56 or Nx64 data rates for T1 or FT1 service. The bandwidth can be selected as

contiguous or alternate. Figure 1-3 shows a simple bridge application.

TSU LT TSU LT

PWR

PWR

ERR

ERR

ALM

ALM

TST

TST

TSU LT

CS

CS

RSRS

RD

TD

TD

PWR

PWR

ERR

ERR

ALM

ALM

TST

TST

Figure 1-3. Simple Bridge Application on a T1 or an FT1 Circuit

TSU LT

CS

CS

RSRS

RD

TD

TD

20 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 21

Chapter 2

Inspection and Installation

TSU LT SHIPMENT

Inspecting for Damages

Carefully inspect the TSU LT for any shipping damage. If damage is suspected, file a claim immediately

with the carrier and then contact ADTRAN Customer Service. If possible, keep the original shipping

container for use in shipping the TSU LT back for repair or for verification of damage during shipment.

Shipping Contents

The following items are included in the ADTRAN shipment:

• TSU LT unit

• Power cable

• RJ-48 T1 Cable

• Documentation CD

• Loopback plug

Customers must provide the DTE cable as well as a cable for the chain port, if it is used.

INSTALLING THE TSU LT

Power Connection

Each TSU LT unit comes with an eight-foot power cord, terminated by a three-prong plug which connects

to a grounded power receptacle.

Power to the TSU LT must be from a grounded 115 VAC, 60 Hz power source.

Grounding Instructions

Grounding instruction information from the Underwriters' Laboratory UL 1950 3rd Edition is provided in

this section. An equipment grounding conductor that is not smaller in size than the ungrounded

branch-circuit supply conductors is to be installed as part of the circuit that supplies the product or system.

61203060L1-1A © 2003 ADTRAN, Inc. 21

Page 22

Chapter 2 Inspection and Installation TSU LT User Manual

Bare, covered, or insulated grounding conductors are acceptable. Individually covered or insulated

equipment grounding conductors shall have a continuous outer finish that is either green, or green with one

or more yellow stripes. The equipment grounding conductor is to be connected to ground at the service

equipment.

The attachment-plug receptacles in the vicinity of the product or system are all to be of a grounding type,

and the equipment grounding conductors serving these receptacles are to be connected to earth ground at

the service equipment. A supplementary equipment grounding conductor shall be installed between the

product or system and ground that is in addition to the equipment grounding conductor in the power supply

cord.

The supplementary equipment grounding conductor shall not be smaller in size than the ungrounded

branch-circuit supply conductors. The supplementary equipment grounding conductor shall be connected

to the product at the terminal provided, and shall be connected to ground in a manner that will retain the

ground connection when the product is unplugged from the receptacle. The connection to ground of the

supplementary equipment grounding conductor shall be in compliance with the rules for terminating

bonding jumpers at Part K or Article 250 of the National Electrical Code, ANSI/NFPA 70. Termination of

the supplementary equipment grounding conductor is permitted to be made to building steel, to a metal

electrical raceway system, or to any grounded item that is permanently and reliably connected to the

electrical service equipment ground.

Bare, covered, or insulated grounding conductors are acceptable. A covered or insulated grounding

conductor shall have a continuous outer finish that is either green, or green with one or more yellow

stripes.

The supplemental grounding conductor shall be connected to the equipment using a number 8 ring

terminal. The terminal should be fastened to the grounding lug provided on the rear panel of the

equipment. The ring terminal should be installed using the appropriate crimping tool (AMP P/N 59250

T-EAD Crimping Tool or equivalent).

22 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 23

TSU LT User Manual Chapter 2 Inspection and Installation

TSU LT Rear Panel

To install the TSU LT, make the appropriate connections using Figure 2-1, Table 2-1, and TSU LT

Interfaces as guides.

123456 7 8

115VAC 60HZ .15A

NETWORK

TEST JACKS

IN OUT MON

CHAIN IN

CONTROL

CHAIN OUT

V.35 Nx56/64

Figure 2-1. TSU LT Rear Panel

Table 2-1. Number Identification for TSU LT Rear Panel

No. Item Function

1 Network T1-FT1 network interface

2 In Bantam test jack

3 Out Bantam test jack

4 MON (Monitor) Bantam test jack

5 Chain In Interface of Chain In (Hyperterminal <Ctrl +PTT>, etc.)

6Chain Out

7 V.35 Nx56/64 DTE port

8 115 VAC 60 Hz 0.15A

Power Receptacle

Connects to Chain In of another TSU LT

Accepts 3-prong power cord (included with shipment)

TSU LT Interfaces

Figure 2-2 on page 24 illustrates the four interfaces that come with the TSU LT and how they might be

connected. The interfaces include the following, and Appendix B , on page 57 shows the pinouts.

• Network DS1 interface per AT&T 62411

• Control input (EIA-232)/chain port input

• Chain port output

• Nx56/64 serial V.35

61203060L1-1A © 2003 ADTRAN, Inc. 23

Page 24

Chapter 2 Inspection and Installation TSU LT User Manual

PC or Modem

Network

Control

Input

NI

Nx56/64

TSU

Chain

Output

Chain

Input

NI

Nx56/64

Chain

Output

TSU

Figure 2-2. TSU LT Interfaces

Network Interface (NI)

The Network Interface (NI) port provides the connection to the T1/FT1. It complies with the applicable

ANSI and AT&T standards.

Control Port Input (Chain In)

The control port input provides an EIA-232 input from a PC or a modem for control of the TSU LT. You

can also use it as a Chain input from any ADTRAN unit with a Chain port or as input for PC proxy agent

control.

Chain Port Output (Chain Out)

The chain port output include provides an EIA-232 output to chain control to other TSU LTs.

V.35 Nx56/64 Serial Interface

The Nx56/64 serial interface operates at the following data rates: N*56K or N*64K, where N=1 to 24

(DS0s).

POWER UP TESTING & INITIALIZATION

Self-Test

When shipped from the factory, the TSU LT is set to factory default conditions. When you first power-up,

the unit automatically executes self-tests followed by an initialization sequence which sets up the unit. The

self-test checks the integrity of the internal operation of the electronic components by performing memory

tests and by sending and verifying data test patterns through all internal interfaces. Although actual user

data cannot be passed during these tests, the self-test can run with the network and DTE interfaces in place,

without disturbing any external interface.

The self-test automatically executes upon power-up. It can also be commanded from a front panel menu or

from the control port.

24 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 25

TSU LT User Manual Chapter 2 Inspection and Installation

In addition to the specified self-tests, background tests are run on various parts of the internal electronics.

These run during normal operation to confirm continued correct functioning. The background tests include

the following:

• Monitoring the phase-locked loop for lock.

• Standard background network performance monitoring.

The self-test works as follows:

If... Then...

a power-up (or commanded) self-test occurs the LCD displays ADTRAN TSU INITIALIZING and the LEDs

illuminate sequentially.

the self-test completes with no failures detected the LCD momentarily displays ALL TESTS PASSED.

a failure is detected it is displayed in the LCD window.

The automatic self-test consists of the following tests:

• Board level tests

• Random access memory (RAM) tests; erasable programmable read only memory (EPROM) checksum

• On-board data path. Sending a known test pattern through an on-board loop

• Unit level tests

• Front panel LED verification

• Phase lock loop verification

61203060L1-1A © 2003 ADTRAN, Inc. 25

Page 26

Chapter 2 Inspection and Installation TSU LT User Manual

26 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 27

Chapter 3

Operation

FRONT PANEL

The front panel monitors operation and controls the unit configuration. Figure 3-1 illustrates the TSU LT

front panel. Use the

menu level, pressing

returns the system to the main menus. You can configure and control the TSU LT from either the local

front panel or from a PC using the T-Watch PRO management software. Table 3-1 lists the unit features

identified by number in Figure 3-1.

U

P

C

and D

ANCEL

arrows on the front panel to access the menus and data fields. At every

OWN

returns the system to the previous menu level. Repeatedly pressing C

11 10 9

ANCEL

PWR

ERR

ALM

112

TST

TD

63524 78

CS

RS

Figure 3-1. TSU LT Front Panel

Table 3-1. Number Identification for TSU LT Front Panel

Item Displays Function

1PWR

LED ON when power is received by TSU LT.

2 ERR LED ON when error event occurred in the last second (for example, BPV).

3 ALM LED ON when an alarm condition exists.

4 TST LED ON when unit is in test mode.

5 TD LED ON when DTE data is being transmitted.

6 RD LED ON when DTE data is being received.

7 RS LED ON when request to send (RTS) active from DTE.

8CS

LED ON when TSU LT has clear to send (CTS) active toward DTE.

A 2X16 LCD window that displays menu items used in configuration and

9LCD

displays information useful in monitoring the unit. See also LCD Window on

page 28.

61203060L1-1A © 2003 ADTRAN, Inc. 27

Page 28

Chapter 3 Operation TSU LT User Manual

Table 3-1. Number Identification for TSU LT Front Panel (Continued)

Item Displays Function

Operation Keys

10 Up/Down

Keyboard arrows used to travel up/down menu trees. Arrows increase/decrease

numeric values and scroll through selections.

11 Enter Used to choose paths and make selections.

12 Cancel Used to exit selections or menu tree branches.

LCD WINDOW

The TSU LT uses a multilevel menu structure containing both menu items and data fields. The opening

(main) menus are the access points to all other operations. The TSU LT front panel LCD displays these

numbered menus and data fields. Table 3-2 lists features you should look for in the LCD when viewing the

menus and data fields.

Table 3-2. LCD Features

Feature Description

Data Fields

Display Field

Arrows

A menu item followed by a colon (:) identifies an editable data field.

A menu field followed by alarm or error information (read-only).

Menus that display small up or down arrows in the lower right corner of the window

indicate there are more menu items than are viewable on a two-line LCD. The additional

menu items are accessed with the front panel U

P

or D

OWN

arrows.

MAIN MENUS

Each main menu has several submenus to identify and access specific parameters. The four main menus

include

LCD window. Figure 3-3 on page 29 shows the menu tree for main menus and first-level submenus.

(Appendix A, TSU LT Menu Tree, on page 55 contains the complete TSU LT menu tree.)

28 © 2003 ADTRAN, Inc. 61203060L1-1A

1)S

TATUS

, 2)C

ONFIG

, 3)U

, and 4)T

TIL

. Figure 3-2 shows the main menus in the front panel’s

EST

Figure 3-2. TSU LT Main Menu Screen

Page 29

TSU LT User Manual Chapter 3 Operation

1) NI PERF REPORTS

1) STATUS 2) CURR ERR/ALM

3) ERR/ALM HIST

1) NETWORK (NI)

TSU LT Main Menus 2) CONFIG 2) UNIT

3) PORT 1) SOFTWARE REV

3) UTIL 2) REINIT UNIT

3) ADDRESS

1) NETWORK TESTS 4) SET PASSCODE

4) TEST 2) RUN SELFTEST 5) KEYPAD

3) PORT TESTS 6) FACT RESTORE

Figure 3-3. TSU LT Main Menus

Status

Use the S

menu to view the operational status of the TSU LT. (Also see Status Menu on page 35.)

TATUS

This menu includes the following submenus:

NI PERF RPTS

Use to view and reset the user set of data on the Network Interface Performance

Reports. These reports are in compliance with ANSI T1.403 and AT&T

document TR54016.

CURR ERR/ALM

ERR/ALM HIST

Use to view current errors and alarms as reported by the TSU LT.

Use to view and clear the history of errors and alarms.

Config (Configuration)

Use the C

ONFIGURATION

page 39.) This menu includes the following submenus:

NETWORK (NI)

UNIT

PORT

menu to set the TSU LT operational configuration. (Also see Config Menu on

Use to set all of the parameters associated with the network interface.

Use to control the TSU LT control-port baud rate and to set up the dial-out

function.

Use to configure the parameters associated with the DTE (V.35) port.

61203060L1-1A © 2003 ADTRAN, Inc. 29

Page 30

Chapter 3 Operation TSU LT User Manual

Util (Utility)

Use the U

menu to view and to set system parameters. (Also see Utility Menu on page 47.) This menu

TIL

includes the following submenus:

SOFTWARE REV

Displays the version number of the current software revision level. This

information is required when requesting assistance from ADTRAN Customer

Service or when updates are needed.

REINIT UNIT

Reinitializes the unit (runs a self-test). This menu does not restore the factory

default settings.

ADDRESS

Use to view and change the current unit address used for control-port access.

Acceptable addresses are 0002 through 9999.

SET PASSCODE

KEYPAD

Sets a passcode for use with K

EYPAD

.

Use to lock the front panel keypad so that no accidental changes are made to the

menus. Enter the passcode to unlock the keypad (see Set Passcode on page 48).

FACT RESTORE

Restores factory default settings for all unit parameters.

Test

Use the T

LCD window. (Also see Test M en u on page 49.) The menu contains three submenus:

menu to initiate different types of unit tests and to view test results which are displayed in the

EST

NETWORK TESTS

RUN SELF TEST

PORT TESTS

Test execution disrupts some normal operations. See the individual test menu descriptions

before executing a test.

Use to control the activation of loopbacks and the initiation of data test patterns.

Use to execute an internal self-test.

Use for testing the DTE (V.35) port.

30 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 31

TSU LT User Manual Chapter 3 Operation

EXAMPLE MENU OPERATIONS

The following examples show you how to select a main menu item and submenu item; how to set a data

field; how to view a data field and how to exit any menu or display.

Selecting a Main Menu Item

To select a main menu, perform the following steps:

1. Use the front panel

2) CONFIG. See Figure 3-4.

E

.

2. Press

NTER

U

P

and D

arrows to place the cursor on a main menu item; in this example,

OWN

The unit responds by displaying the first two available submenu fields (see Figure 3-5). The cursor

is on the first field. If there are more than two menu fields, a down arrow is visible on the lower

right corner. Use the front panel

D

arrow to access these.

OWN

Figure 3-4. Cursor on Menu Item

Arrow indicates that

more submenus are

available.

Figure 3-5. Submenu Fields

3. To exit out of a main menu, press C

61203060L1-1A © 2003 ADTRAN, Inc. 31

ANCEL

.

Page 32

Chapter 3 Operation TSU LT User Manual

Selecting a Submenu

To select a submenu, perform the following steps:

1. Follow the same steps used to select a main menu.

U

2. Use the front panel

1)NETWORK (NI).

and D

P

arrows to place the cursor on a menu; in this example,

OWN

3. Press

E

NTER

.

The unit responds by displaying the first two available data field items. The cursor is on the number of the

first item. When there are more than two data field items for the selected submenu, a down arrow is visible

on the lower right corner.

Use the front panel

D

OWN arrow to access these.

Setting Data Fields

Data fields that are available for editing are preceded by a colon (:). For this example, set the F

1. Follow this path:

2. Press E

NTER

2) CONFIG > 1)NETWORK (NI) > 1)FORMAT:

while the cursor is located on 1)FORMAT:. The cursor moves to the current data field

(to the right of the submenu item name).

You can now use the

and D

P

arrows to scan the available settings, which display in the data

OWN

U

field position one at a time.

3. When the appropriate value is in the data field position, press

E

to set the value.

NTER

The unit is set for the value shown in the data field and the cursor moves back to the submenu item

position indicating the operation is complete. You can select another submenu field or press

to return to the submenu.

CEL

ORMAT

type.

CAN-

C

is available any time during the operation. If used prior to pressing Enter after

ANCEL

making a data change, the original data value is restored and the cursor returns to the

submenu field.

Viewing Display-Only Data Fields

To view an example of a D

1. Select

2. Select submenu

LOSS OF SIGNAL INACTIVE/ACTIVE is displayed giving the current state of the alarm.

S

TATUS

from the main menu.

CURR ERR/ALM.

ISPLAY ONLY

data field, navigate through the following menus:

Exiting Any Menu Field Operation or Display

1. Press C

32 © 2003 ADTRAN, Inc. 61203060L1-1A

as many times as required to return to a menu level.

ANCEL

Page 33

TSU LT User Manual Chapter 3 Operation

ALTERNATE METHOD OF CONTROL FROM TSU LT

T-Watch PRO Management Software Program

T-Watch PRO is the ADTRAN management software program that allows the user to control the TSU LT

from a PC. It provides complete control over the configuration of the TSU LT using a graphic interface.

The T-Watch PRO program displays the same status and performance data as the front panel LCD. This

data is displayed as tables and graphs. In addition, T-Watch PRO has the following capabilities:

• A modem interface permits dialing into a remote TSU LT location to configure the unit, read the unit’s

status, or check its performance.

• The performance data read from the units can be exported to a file which is compatible with common

spreadsheet programs.

61203060L1-1A © 2003 ADTRAN, Inc. 33

Page 34

Chapter 3 Operation TSU LT User Manual

34 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 35

Chapter 4

Status Menu

The S

TATUS

complete

menu branch lets you view the operational status of the TSU LT. Figure 4-1 shows the

S

1) STATUS YELLOW ALARM

TATUS

menu tree.

RESET PERF CNTRS

SES 15MIN/24HR

ES 15MIN/24HR

1)NI PERF RPTS %AV 15MIN/24HR

%EF 15MIN/24HR LOSS OF SIGNAL

CVs 15MIN/24HR AIS ALARM

2)CURR ERR/ALM OUT OF FRAME

CLEAR HISTORY RED ALARM

LOSS OF SIGNAL CODE VIOLATIONS

AIS ALARM BIPOLAR VIOL

OUT OF FRAME FRAME BIT ERRORS

YELLOW ALARM PLL ALARM

3)ERR/ALM HIST RED ALARM

CODE VIOLATIONS

BIPOLAR VIOL

FRAME BIT ERRORS

PLL ALARM

Figure 4-1. Status Menu Tree

NI PERF RPTS MENU

This branch (network interface performance reports) displays the user copy of the performance data. The

TSU LT also maintains this performance data on the network in compliance with ANSI T1.403 and AT&T

document TR54016. The data displayed is data accumulated over the last 15 minutes and over the last 24

hours.

These fields cannot be edited, only viewed or cleared. To clear the counters move to the

C

menu and press E

NTRS

performance data is cleared. Figure 4-2 on page 36 shows the LCD for an

shows the other data types available from the

61203060L1-1A © 2003 ADTRAN, Inc. 35

. To exit the menu, press the front panel C

NTER

NI PERF RPTS menu.

key. Only the user copy of

ANCEL

SES menu. Table 4-1 on page 36

R

ESET PERF

Page 36

Chapter 4 Status Menu TSU LT User Manual

a

Error Type

Figure 4-2. Severely Errored Seconds Screen

Table 4-1. Network Interface Performance Reports (15 Min / 24 Hours)

Data Type Description

SES Number of severely errored seconds

ES Number of errored seconds

%AV Percentage of available seconds

%EF

CVs

Percentage of error free seconds

Number of code violations

Since only the user’s copy of performance data is cleared by the TSU LT, the data

displayed here might be different from the data being sent to the network as performance

report message (PRM) data.

CURR ERR/ALM MENU

Use this branch for viewing currently active or inactive errors and alarms. Use the front panel UP and

D

arrows to move through the errors and alarms. Figure 4-3 shows an LOS alarm. Table 4-2 on page

OWN

37 provides a complete list of the errors and alarms.

Alarm Type

State (Active/In

Figure 4-3. Loss of Signal (Current Errors/Alarms) Screen

36 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 37

TSU LT User Manual Chapter 4 Status Menu

ERR/ALM HIST MENU

Use this branch for viewing a history of errors and alarms. If an alarm has occurred since the last C

H

selection, the menu condition is active; otherwise it is inactive (see Figure 4-4). Table 4-2

ISTORY

provides a complete list of the errors and alarms.

Figure 4-4. Clear History Screen

Table 4-2. Alarms and Errors (Current and Historical)

Errors and Alarms Meaning

Loss of Signal

AIS Alarm Unframed All-Ones received at NI

Out of Frame No framing pattern sync at NI

No pulses received at NI

LEAR

Yellow Alarm Receiving yellow alarm pattern from NI

Red Alarm Loss of signal/out of frame (LOS/OOF) causing red alarm at NI

Code Violations Cyclic redundancy check (CRC) errors in ESF, or bipolar violations (BPVs) in Superframe

Format (SF) were received at NI

Bipolar Violations BPVs (the presence of two consecutive bits of the same polarity) in SF or ESF

Frame Bit Errors

PLL Alarm Unable to sync up to selected clock

Frame Bits received incorrectly at NI

61203060L1-1A © 2003 ADTRAN, Inc. 37

Page 38

Chapter 4 Status Menu TSU LT User Manual

38 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 39

Chapter 5

Config Menu

Use the C

menus to set the TSU LT operational configuration, including all of the network interface

ONFIG

parameters, the allocation of the DS0s, and the port parameters. This menu includes three branches:

N

ETWORK

.

(NI), U

, and P

NIT

2) CONFIG 2) OUTPUT

. Figure 5-1 shows the complete menu tree.

ORT

1) FORMAT

2) CODE

3) YEL ALRM

1) NETWORK (NI) 4) XMIT PRM

5) CLOCK SOURCE

6) SET LBO 1) POSITION

1) CNTRL PORT 3) DATA RATE

2) UNIT

2) ALARMS 1) TRAPS

1) RATE 56/64

2) CHANNELS

3) DTE TX CLK

4) START CHAN

3) PORT 5) # OF CHAN

6) DATA

7) CTS

8) DCD

9) DSR

10) INBAND

2) MODEM INIT

3) TEL NUM

Figure 5-1. Configuration Menu Tree

NETWORK (NI) MENU

Use this menu to access the configuration of parameters associated with the network interface in the

TSU LT. This branch includes six submenus (see Table 5-1 on page 40). Figure 5-2 on page 40 shows one

submenu.

61203060L1-1A © 2003 ADTRAN, Inc. 39

Page 40

Chapter 5 Config Menu TSU LT User Manual

Table 5-1. Network Interface Submenus

Submenu Description

FORMAT Sets the frame format for the NI.

Choices: D4, ESF, AUTO

a

CODE

YEL ALRM

XMIT ALRM

CLOCK SOURCE

SET LBO

a D4 is equivalent to Superframe Format (SF).

b For more information on clock sources and timing, see Clock Sources and Timing on page 40.

Sets the line code for the NI.

Choices: AMI, B8ZS

Enables and disables the transmitting of yellow alarms.

Choices: ENA (enable), DISA (disable)

Enables and disables the transmitting of performance report message (PRM) data on the

facility data link (FDL). The PRM data continues to be collected even if XMIT PRM is disabled

(possible only with ESF Format).

Choices: ENA (enable), DISA (disable)

b

Selects the clock source for transmission toward the network from the NI.

Choices: NETWORK, DTE, INTERNAL

Selects the line build-out (amount of attenuation, in dB) for the network interface.

Choices: 0, 7.5, 15, 22.5

Figure 5-2. Network Submenu

Clock Sources and Timing

The TSU LT operates from various clock sources, permitting it to perform properly in many different

applications. Use the

clocking options (network, DTE, or internal timing). See the descriptions for Network Timing on page 41,

DTE Timing on page 41, and Internal Timing on page 42.

40 © 2003 ADTRAN, Inc. 61203060L1-1A

C

ONFIG

> N

ETWORK

(NI) > 5)C

LOCK SOURCE

: menu to set the network interface

The clocking option selected always designates the clock source for transmission.

Clocking necessary for receiving data is always recovered from incoming data.

Page 41

TSU LT User Manual Chapter 5 Config Menu

Network Timing

The network is the source of timing. The received data clocking is looped back to the network where it is

used to determine the transmission timing. This option is also referred to as looped timed as the

transmission clock is derived from the received clock. See Figure 5-3.

Figure 5-3. Network Timed Clock Source

DTE Timing

The DTE is the source of timing. The TSU LT uses the incoming DTE clock to determine the transmission

timing. This is typically used in applications such as limited distance line drivers, where it is necessary to

have the DTE as the primary clock source (see Figure 5-4).

Figure 5-4. DTE Clock Source

61203060L1-1A © 2003 ADTRAN, Inc. 41

Page 42

Chapter 5 Config Menu TSU LT User Manual

Internal Timing

The TSU LT is the source of timing. The TSU LT is configured to use its own internal oscillator as the

source of timing. Applications include private line driver circuits where one end is set to network and the

other to internal. See Figure 5-5.

UNIT MENU

Use the U

submenus to change control port and alarm options. Figure 5-6 shows a sample LCD window.

NIT

Figure 5-5. Internal Clock Source

Figure 5-6. Configuration Submenu

42 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 43

TSU LT User Manual Chapter 5 Config Menu

Cntrl Port Submenu

Use to set up the unit as the master or slave on a chain of units, and to initialize a modem and the control

port data rate.

POSITION

[of TSU LT]

This option determines if the TSU LT is at the head of a chain of units (directly

connected to the modem or PC). The head of the chain is referred to as the master

unit. Units down the chain are referred to as slaves or a slave unit.

Setting the position is only necessary when you are using a modem, in which case

the head unit should be

M

ASTER

. For all other cases, select S

. (The master is

LAVE

in charge of control of the modem.)

Choices: MASTER, SLAVE

MODEM INIT

Use this option to initialize a modem, but only when the TSU LT is serving as the

M

unit. The modem should be physically connected to the TSU LT with the

ASTER

power turned on prior to initialization. At this point, an industry-standard AT

command string is used to initialize the modem. The string is also used following

future power-up sequences.

Choices: ENA (enable), DISA (disable)

DATA RATE

Selects the data rate for the control port. The data rate should be consistent with all

units on a chain and with the modem and/or PC/Proxy Agent serial port.

Choices: 1200, 2400, 9600

Alarms Submenu

Use these submenus to initialize the method by which the control port handles alarm conditions.

TRAPS

Determines if alarm conditions should automatically trigger an alarm message (trap)

to the controlling PC/Proxy Agent. The setting is for this unit, or for slaves if this unit

is a master. For applications where the A

should only be enabled with the Inband selection set to ON or OFF.

RAPS

T

UTO INBAND

selection is not acceptable,

Choices: ENA (enable), DISA (disable)

OUTPUT

Selects whether the alarm traps (if enabled) are sent directly, or if the telephone

number stored in the TSU LT should be dialed first (industry-standard AT dial

command sent to modem).

Choices: DIRECT, DIAL

61203060L1-1A © 2003 ADTRAN, Inc. 43

Page 44

Chapter 5 Config Menu TSU LT User Manual

TEL NUM

Sets the telephone number to be dialed to send alarm traps. The string can be up to 20

characters in length and is terminated with a semicolon (;) as the last character. A

colon (:) character is used to represent a pause in the dial string.

For example, for number 9:5551212; dial 9, pause momentarily and then dial

5551212. This pause could be necessary to access an outside line, such as a PBX.

When editing a specific character, the arrows are used to scroll from 0 to 9, then colon

(:) and semicolon (;). The new telephone number is entered into the TSU LT only after

typing the semicolon and pressing

Choices: 20 digits (

0-9, :, and ;)

E

NTER

.

The ALARM > TEL NUM menu only accepts the typed digits after pressing E

PORT MENU

Use this menu to select and configure the parameters associated with the V.35 port.

NTER

.

RATE 56/64

CHANNELS

DTE TX CLK

Sets the base rate of the interface. The actual data rate depends on the number of

DS0s assigned to the Nx port. The DTE data rate versus the number of DS0s appears

in Appendix B, DTE Data Rate Chart, on page 57.

Choices: 56K, 64K

Sets the unit to use A

LTERNATE

more than 12 channels are used, then

A

LTERNATE

channels may be used to meet pulse density requirements (this is only

or C

ONTIGUOUS

C

ONTIGUOUS

channels in the T1 data stream. If

must be used. Otherwise,

necessary for Nx 64 without B8ZS). If other than a private network, the carrier must

be notified of this choice.

Choices: ALT (alternate), CONT (contiguous)

Controls the clock used by the TSU LT to accept the transmit (TX) data from the

DTE. Most applications will allow for this to be set to

cable is long (causing a phase shift in the data) the clock can be selected as

I

NTERNAL

. If the interface

INT-I

NV

(Internal/Inverted - the factory default setting). This switches the phase of the clock

which should compensate for a long cable.

A

setting allows the TSU LT to automatically detect the delay from the DTE

UTO

The

device to the TSU LT and set the proper phase of the clock. This feature

automatically selects between the

provides a clock with TX data, the clock selection is set to

I

NTERNAL

and I

settings. If the DTE

NT-INV

E

XTERNAL

. The TSU LT

depends on an externally supplied clock to accept the TX data.

Choices: INT-INV, INTERNAL, EXTERNAL, AUTO

44 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 45

TSU LT User Manual Chapter 5 Config Menu

START CHAN

# OF CHAN

DATA

CTS

DCD

DSR

Sets the starting channel for the T1 stream. This setting must be consistent with the

carrier if using a public network.

Choices: 01 through 24

Sets the number of DS0s (channels) to be used. The corresponding DTE rate will be

this number times 56K or 64K, depending on the setting of

1)R

ATE

56/64.

Choices: 01 through 24

Controls the inversion of DTE data. This inversion can be useful when operating

with an HDLC protocol. Often used as a means to ensure ones (1s) density. TSU LTs

on both ends must have identical option settings.

Choices: NORMAL, INVERT

Clear To Send - signal sent from the receiving station to the transmitting station that

indicates it is ready to accept data.

Choices: NORMAL (see Table 5-2 on page 46), FORCE ON

Data Carrier Detect - Indicates to the DTE when a valid signal is being received at

the Network Interface.

Choices: NORMAL (see Table 5-2 on page 46), FORCE ON

Data Set Ready - Indicates to the DTE when the DCE is turned ON and ready for

operations.

INBAND

Choices: NORMAL (see Table 5-2 on page 46), FORCE ON.

Inband Configuration Channel - Use to enable/disable an 8-kbps remote

configuration channel (see Figure 5-7 on page 46). When this option is set to

O

, the

N

first DS0 occupied operates in 56K mode and the DTE clock rate is reduced by

8 kbps. The TSU LT uses this 8-kbps channel to send and receive configuration data

across a T1 span. As shown in Figure 5-7, this feature allows the PC connected to

the Chain In port on TSU LT A to monitor and configure both TSU LT A and B.

This feature is useful when FDL connectivity is not available across the T1 span.The

8-kbps channel is only taken out of the first DS0. If two 64K DS0s are mapped, the

DTE rate would be 120 kbps instead of 128 kbps.

This menu option can also be set to

A

which activates the Inband Channel only

UTO

when commands are sent from T-Watch PRO to the remote unit (TSU LT B in

Figure 5-7). If no T-Watch PRO activity is detected for 10 minutes, the Inband

Channel is deactivated.

61203060L1-1A © 2003 ADTRAN, Inc. 45

Page 46

Chapter 5 Config Menu TSU LT User Manual

Table 5-2. Normal Mode Operation

NORMAL MODE OPERATION

Conditions which cause the Port Control Signals to be deactivated

SIGNAL RTS V.54 LOOP BK 511 TST ON SELF-TEST

ACTIVE

CTS Follows OFF OFF OFF OFF OFF OFF

DCD — — — OFF — OFF OFF

DSR — OFF OFF OFF OFF OFF —

Where “ — “ = don’t care

NETWK TEST

ACTIVE

NO DS0

MAPPED

NETWORK

ALARM

Figure 5-7. Inband Remote Configuration

46 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 47

Chapter 6

Utility Menu

Use the U

branch to view the unit’s software revision, to reinitialize the unit, to set system

TILITY

parameters, and to restore factory default settings (see Figure 6-1).

1) SOFTWARE REV

2) REINIT UNIT

UTIL 3) ADDRESS

4) SET PASSCODE

5) KEYPAD

6) FACT RESTORE

Figure 6-1. Utility Menu Tree

SOFTWARE REV

Displays the current software revision level. This information is required when requesting assistance from

ADTRAN Customer Service or when updates are needed.

REINIT UNIT

Reinitializes the unit. Do not use this submenu to restore the factory default settings for all parameters;

instead, use the factory restore submenu (number 6).

ADDRESS

Displays and changes the unit address setting. To view the address navigate to this menu. To change the

address, highlight

After changing a digit, press

is blinking on that digit. Unit identification numbers must be between 0002 and 9999. See Figure 6-2 on

page 48.

61203060L1-1A © 2003 ADTRAN, Inc. 47

A

DDRESS

and press E

E

to move to the next digit. To skip a digit, press E

NTER

. Then use the UP and D

NTER

arrow keys to change the digits.

OWN

while the cursor

NTER

Page 48

Chapter 6 Utility Menu TSU LT User Manual

Figure 6-2. Address Screen

SET PASSCODE

The TSU LT uses passcodes for front panel security and T-Watch PRO access. Use S

ET PASSCODE

change, or delete a passcode. Acceptable codes are 0000 through 9999. Four question marks (

to add,

????)

indicate the keypad is locked.

To alter the passcode, highlight

change the digits. After changing a digit, press

E

while the cursor is blinking on that digit.

NTER

P

ASSCODE

and press E

E

NTER

. Then use the UP and D

NTER

arrow keys to

OWN

to move to the next digit. To skip a digit, press

KEYPAD

Allows the user to lock or unlock the front panel keypad. This feature keeps the unit configuration from

being changed by unauthorized personnel. When the keypad is L

not changed (unless the passcode is entered). When the keypad is U

OCKED, option settings can be viewed but

NLOCKED

, the menus can be changed

at will. If an incorrect passcode is entered, the unit remains locked.

FACT RESTORE

Use the F

ACTORY RESTORE

submenu to restore the factory default setting for all unit parameters.

48 © 2003 ADTRAN, Inc. 61203060L1-1A

Page 49

Chapter 7

Test Menu

The T

(see Figure 7-1). This menu contains three branches:

submenus initiate different types of unit tests and let you view test results in the LCD window

EST

N

ETWORK TEST

Test execution will disrupt some of the unit’s normal operation. See individual menu items

concerning tests before executing.

1) LOCAL LOOPBK LINE ON NO LOOPBACK

2) REM LB ANSI FDL LLB

1)NETWORK TESTS AT&T INBAND LLB

3) TEST PATTERN NO PATTERN ANSI FDL PLB

4)TEST ALL ZEROS

4) CLR ERRS

, R

UN SELFTEST

NO LOOPBACK

PAYLOAD ON V.54 INBAND PLB

1:8 ALL DS0s AT&T PLB

511 ACT. DS0s

ALL ONES

, and P

ORT TESTS

.

5) INSERT 511 ERR

2)RUN SELFTEST

3)PORT TESTS 1) DTE LOOPBK

2) DATA LOOPBK

Figure 7-1. Test Menu Tree

NETWORK TESTS

Network tests control the activation of loopbacks and the initiation of data test patterns. They run on the

network interface (NI). Options include

ERRS

5) INSERT 511 ERR

, and

.

Local Loopback

The three choices available for setting the local loopback include N

61203060L1-1A © 2003 ADTRAN, Inc. 49

1) LOCAL LOOPBK, 2) REM LB, 3) TEST PATTERN, 4) CLR

O LOOPBACK

, L

INE ON

, and

Page 50

Chapter 7 Test Menu TSU LT User Manual

P

AYLOADON

No Loopback

Line On

Payload On

. Figure 7-2 shows an illustration of how the tests work.

Deactivates the loopback.

Activates the line loopback which loops all of the received data back toward the

network. The transmitted data is the identical line code that was received, including

any bipolar violations or framing errors.