Page 1

TRACER 6000 SERIES

Integrated System Manual

12806410L2A TRACER 6410 2.4 GHz (High Power) System (Plan A)

12806410L2B TRACER 6410 2.4 GHz (High Power) System (Plan B)

12806420L1A TRACER 6420 5.8 GHz System (Plan A)

12806420L1B TRACER 6420 5.8 GHz System (Plan B)

12806420L2A TRACER 6420 5.8 GHz (High Power) System (Plan A)

12806420L2B TRACER 6420 5.8 GHz (High Power) System (Plan B)

612806420L1-1E

November 2005

Page 2

Trademarks TRACER 6000 Series Integrated System Manual

Trademarks

Any brand names and product names included in this manual are trademarks, registered trademarks, or

trade names of their respective holders.

To the Holder of the Manual

The contents of this manual are current as of th e date of publication. ADTRAN reserves the right to change

the contents without prior notice.

In no event will ADTRAN be liable for any special, incidental, or consequential damages or for

commercial losses even if ADTRAN has been advised thereof as a result of issue of this publication.

About this Manual

This manual provides a complete description of the TRACER 64x0 systems (TRACER 6410 and 6420)

and system software. The purpose of this manual is to provide the technician, system administrator, and

manager with general and specific information related to the planning, installation, operation, and

maintenance of the TRACER 64x0 systems. This manual is arranged so that needed information can be

quickly and easily found.

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

Copyright © 2005 ADTRAN, Inc.

All Rights Reserved.

Printed in U.S.A.

2 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 3

TRACER 6000 Series Integrated System Manual Revision History

Revision History

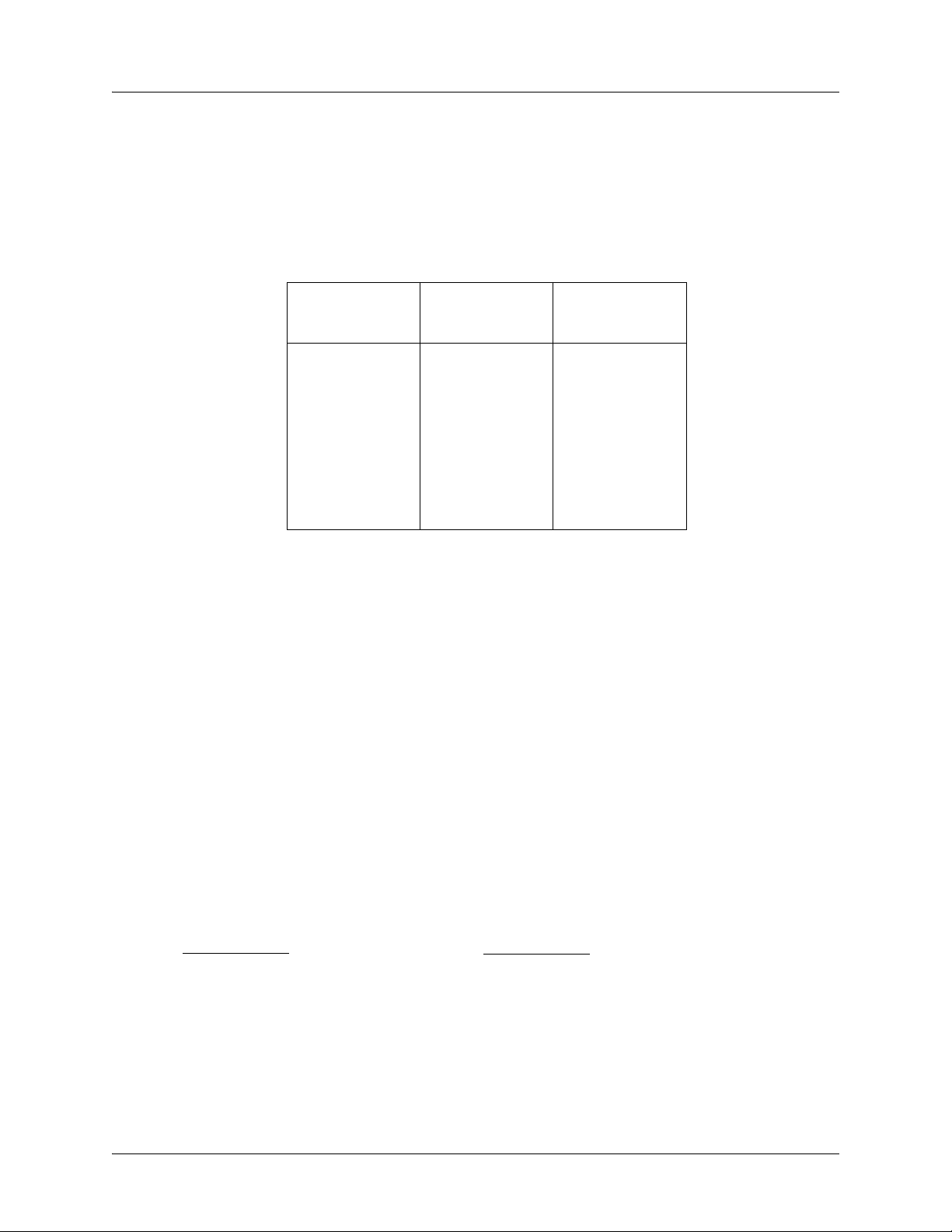

Document

Revision

A December 2004 Initial release of manual to include the TRACER 6420 (5.8 GHz

B March 2005 Include E1 and E1 breakout panel inform ation and add ne w RF link

C June 2005 Added new real-time power reporting and support for new

D September 2005 Include information for new product offering (TRACER 6410

E November 2005 Include information for new product offering (TRACER 6420

Date Description of Changes

integrated system) and the Quad T1 and Ethernet Switch modules.

management bridge functionality. Update the Troubleshooting

Guide to include E1 information.

Quad E1 (120Ω) module.

2.4 GHz (High Power) system). Update the User Iinterface Guide

and MIB sections to include new fan and temperature alarm

information. Made minor corrections to calculations in the

Microwave Path Engineering section.

5.8 GHz (High Power) system).

Notes provide additional useful information.

Cautions signify information that could prevent service interruption or damage to

equipment.

Warnings provide information that could prevent endangerment to human life.

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 3

Page 4

Safety Instructions TRACER 6000 Series Integrated System Manual

Safety Instructions

When using your telephone equipment, please follow these basic safety precautions to reduce the risk of

fire, electrical shock, or personal injury:

1. Do not use this product near water, such as a bathtub, wash bowl, kitchen sink, laundry tub, in a

wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical storm. There is a remote

risk of shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply, and/or batteries indicated in the manual. Do not dispose of

batteries in a fire. They may explode. Check with local codes for special disposal instructions.

Save These Important Safety Instructions

4 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 5

TRACER 6000 Series Integrated System Manual FCC-Required Information

FCC-Required Information

Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio frequencies. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC limits.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Radio Frequency Interface Statement

This equipment has been tested and found to comply with the limits for an intentional radiator, p ursuant to

Part 15, Subpart C of the FCC Rules. This equipment generates, uses, and can radiate radio frequency

energy. If not installed and used in accordance with the instructions, it may cause interference to radio

communications.

The limits are designed to provide reasonable protection against such interference in a residential situation.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the equipment

on and off, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna of the affected radio or television.

• Increase the separation between the equipment and the affected receiver.

• Connect the equipment and the affected receiver to power outlets on separate circuits.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by ADTRAN could void the user’s

authority to operate the equipment.

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 5

Page 6

FCC-Required Information TRACER 6000 Series Integrated System Manual

FCC Output Power Restrictions

The FCC does not require licensing to implement this device. License-free operation in the industrial,

scientific, and medical band is documented in FCC Rules Part 15.247. It is the responsibility of the

individuals designing and implementing the radio system to ensure compliance with any pertinent FCC

Rules and Regulations. This device must be professionally installed.

The FCC specifies the maximum transmitter power used for antennae of a given gain. FCC Rules Part 15,

Subpart 247 allow for a maximum power of 1 watt (30 dBm) into antennae of a gain less than or equal to 6

dBi. At 2.4 GHz (TRACER 6410), the 1-watt maximum transmitter power must be reduced by 1 dB for

every 3 dB of antenna gain over 6 dBi. This rule is shown in Table 5 on page 20. For the 5.8 GHz band

(TRACER 6420), the maximum output power is 1 watt (30 dBm) regardless of the gain of the attached

antenna. Since the TRACER 6420 L1 and L2 maximum transmit power is 100 milliwatts and

250 milliwatts, respectively, there is no reduction in transmitter output power required.

Exposure to Radio Frequency Fields

The TRACER 6410 is designed to operate at 2.4 GHz with 500 mW maximum transmit power, the

TRACER 6420L1 is designed to operate at 5.8 GHz with 100 mW maximum transmit power, and the

TRACER 6420L2 is designed to operate at 5.8 GHz with 250 mW maximum transmit power.

This level of RF energy is below the Maximum Permissible Exposure (MPE) levels specified in FCC OET

65:97-01. The installation of high gain antenna equipment in the system configuration may create the

opportunity for exposure to levels higher than recommended for the general population at a distance less

than 24 feet (7.3 meters) from the center of the antenna. The following precautions must be taken

during installation of this equipment:

Verify the antenna installation meets all regulations specified in the National Electric

Code (NEC) Article 810 with particular attention to clearances from power and lighting

conductors, mounting, grounding, and antenna discharge unit.

• The installed antenna must not be located in a manner that allows exposure of the general population to

the direct beam path of the antenna at a distance less than 24 feet (7.3 meters). Installation on towers,

masts, or rooftops not accessible to the general population is recommended; or

• Mount the antenna in a manner that prevents any personnel from entering the area within 24 feet

(7.3 meters) from the front of the antenna.

• It is recommended that the installer place radio frequency hazard warnings signs on the barrier that

prevents access to the antenna.

• Prior to installing the antenna to the TRACER output, make sure the power is adjusted to the settings

specified in Section 2 of this manual.

• During antenna installation, be sure that power to the TRACER equipment is turned off in order to

prevent the presence of microwave energy on the coaxial connector.

• During installation and alignment of the antenna, do not stand in front of the antenna assembly.

• During installation and alignment of the antenna, do not handle or touch the front of the antenna.

Per Industry Canada RSS210: “The installer of this radio equipment must ensure that the antenna is located

or pointed such that it does not emit RF field in excess of Health Canada limits for the general population;

consult Safety Code 6, obtainable from Health Canada’s website at www.hc-sc.gc.ca/rpb.These simple

precautions must be taken to prevent general population and installation personnel from exposure to RF

energy in excess of specified MPE levels.

6 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 7

TRACER 6000 Series Integrated System Manual Warranty and Customer Service Information

Warranty, Customer Service, Product Support Information, and T raining

ADTRAN will repair and return this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com/warranty.

A return material authorization (RMA) is required prior to returning equipment to ADTRAN. For service,

RMA requests, training, or more information, use the contact information given below.

Repair and Return

If you determine that a repair is needed, please contact our Customer and Product Service (CaPS)

department to have an RMA number issued. CaPS should also be contacted to obtain information

regarding equipment currently in house or possible fees associated with repair.

CaPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to the following address:

ADTRAN Customer and Product Service

901 Explorer Blvd. (East Tower)

Huntsville, Alabama 35806

RMA # _____________

Pre-Sales Inquiries and Applications Support

Your reseller should serve as the first point of contact for support. If additional pre-sales support is needed,

the ADTRAN Support website provides a variety of support services such as a searchable knowledge base,

latest product documentation, application briefs, case studies, and a link to submit a question to an

Applications Engineer. All of this, and more, is available at:

http://support.adtran.com

When needed, further pre-sales assistance is available by calling our Applications Engineering

Department.

Applications Engineering (800) 615-1176

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 7

Page 8

Warranty and Customer Service Information TRACER 6000 Series Integrated System Manual

Post-Sale Support

Your reseller should serve as the first point of contact for support. If additional support is needed, the

ADTRAN Support website provides a variety of support services such as a searchable knowledge base,

updated firmware releases, latest product documentation, service request ticket generation and

trouble-shooting tools. All of this, and more, is available at:

http://support.adtran.com

When needed, further post-sales assistance is available by calling our Technical Support Center. Please

have your unit serial number available when you call.

Technical Support (888) 4ADTRAN

Training

The Enterprise Network (EN) Technical Training Department offers training on our most popular

products. These courses include overviews on product features and functions while covering applications

of ADTRAN's product lines. ADTRAN provides a variety of training op tions, including customized

training and courses taught at our facilities or at your site. For more information about training, please

contact your Territory Manager or the Enterprise Training Coordinator.

Training Phone (800) 615-1176, ext. 7500

Training Fax (256) 963-6700

Training Email training@adtran.com

8 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 9

TRACER 6000 Series Integrated System Manual Table of Contents

Table of Contents

Section 1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

This section of ADTRAN’s TRACER 6000 Series Integrated System Manual is designed for

use by network engineers, planners, and designers for overview information about the

TRACER 64x0 systems.

Section 2 Microwave Path Engineering Basics . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Explains the basics of analyzing a wireless microwave link or path. Defines significant

parameters and makes several installation recommendations.

Section 3 Engineering Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Provides information to assist network designers with incorporating the TRACER 64x0 system

into their networks.

Section 4 Network Turnup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Provides shipment contents list, grounding instructions, mounting options, and specifics of

supplying power to the unit.

Section 5 User Interface Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Provides detailed descriptions of all menu options and configuration parameters available for

the TRACER 64x0.

Section 6 Detail Level Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Provides detailed instructions on performing common system tasks such as connecting to the

system and upgrading firmware.

DLP-1 Connecting a VT100 Terminal or PC to the CRAFT Port . . . . . . . . . . . . . . . . . . . . . . 91

DLP-2 Logging into the TRACER 64x0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

DLP-3 Setting IP Parameters for the TRACER 64x0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

DLP-4 Verifying Communications Over an IP LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

DLP-5 Updating the Firmware Using TFTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

DLP-6 Updating the Firmware Using XMODEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Section 7 MIBs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Provides a listing of SNMP Management Information Bases (MIBs) supported by the

TRACER 64x0. This section also lists traps supported for each MIB.

Section 8 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Provides helpful information for troubleshooting common configuration problems for the

TRACER 64x0.

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 9

Page 10

Table of Contents TRACER 6000 Series Integrated System Manual

10 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 11

SYSTEM DESCRIPTION

This section of ADTRAN’s TRACER 6000 Series Integrated System Manual is designed for use by

network engineers, planners, and designers for overview information about the TRACER 64x0 systems.

It contains general information and describes physical and operational concepts, network relationships,

provisioning, testing, alarm status, and system monitoring. This section should be used in conjunction with

Section 3, Engineering Guidelines, of this manual.

CONTENTS

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Configuration and Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operational . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Available Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

E1 Network Module with 120Ω Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

E1 Network Module with 75Ω Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

T1 Network Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Quad Ethernet Switch Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 11

Page 12

Section 1 System Description TRACER 6000 Series Integrated System Manual

1. SYSTEM OVERVIEW

The TRACER 64x0 provides license-free scalable connectivity for service providers and corporate

networks. These radios feature two modular network interface ports tha t c an accommodate various

combinations of T1, E1, and Ethernet option cards up to 8xT1/E1 (16.384 Mbps). This flexibility provides

customized time division multiplexed (TDM) and packet solutions for voice and data applications in a

single platform. The TRACER 6410 and TRACER 6420 (L1 and L2) provide carrier class point-to-point

connectivity up to thirty miles in the 2.4 GHz and 5.8 GHz license-free Industrial, Scientific, and Medical

(ISM) bands, respectively.

Complete network management is supported via simple network management protocol (SNMP), Telnet

access, and a VT100 terminal interface (

T1/E1/Ethernet alarm conditions, enabling remote installations to report outages without requiring a truck

roll to diagnose problems. Version 2 standard management information bases (MIBs) are supported for all

interface cards, while an enterprise-specific MIB is provided for radio functionality. Triple-DES (3DES)

security provides additional protection from unauthorized access without requiring any additional external

security appliances. Encryption can also be disabled altogether. Future upgrades and e nhan cemen ts ca n be

added through FLASH firmware downloads via trivial file transfer protocol (TFTP) (on the Ethernet

interface) or XMODEM on the

CRAFT port.

Receive sensitivity is optimized through the use of extensive forward error correction and

high-performance receiver design techniques. Dynamic receive sensitivity allows the user to increase

receiver performance by decreasing the delivered bandwidth and increasing forward error correction. This

feature maximizes link performance by customizing the delivered bandwidth to the specific needs of the

installation. Three software selectable channel plans are supported to simplify frequency coordination at

co-located sites. Channel plans are easily changed via any of the software management interfaces without

the added expense of hardware upgrades or spare filter assemblies.

CRAFT port). SNMP traps are implemented for all RF link and

TRACER 64x0 wireless solutions maximize equipment density through the combination of compact size

(only 1U rack space required), low power consumption, and high thermal transfer. TRACER 64x0 systems

can be deployed at twice the density of other available wireless products.

2. FEATURES AND BENEFITS

The following is a brief list of the TRACER 64x0 features and benefits:

Configuration and Management

• Easy-to-use VT100 control port (RS-232 interface) for configuration and monitoring

• End-to-end management bridging for forwarding management traffic across the RF link management

channel

• Remote configuration of both ends of the wireless link, from each end of the link

Operational

• No license required per FCC Rules Part 15.247

• Dual module slots for network connectivity

• Up to 8xT1 or E1 bandwidth (16.384 Mbps) using two 4xT1 or 4xE1 network modules

• TRACER 6410 Frequency: 2.400 to 2.483 GHz

• TRACER 6420 (L1 and L2) Frequency: 5.725 to 5.850 GHz

12 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 13

TRACER 6000 Series Integrated System Manual Section 1 System Description

• Point-to-point transmission, up to 30 miles

• 1U high unit for easy rack mounting

Available Interface Modules

• Quad T1 Module (P/N 1280040L1)

• Quad E1 Module with 120Ω Interface (P/N 1280044L1)

• Quad E1 Module with 75Ω Interface (P/N 1280044L2)

• Quad Ethernet Switch Module (P/N 1280050L1)

E1 Network Module with 120Ω Interface

• Four E1 circuits provided through four RJ-45 connectors

• Complies with CCITT G.703, G.704, and G.823 standards

• E1 circuit alarm reporting capability

• Testing support through local and remote line and link loopbacks

E1 Network Module with 75Ω Interface

• Four E1 circuits provided through a single DB-25, 75Ω connector

• Complies with CCITT G.703, G.704, and G.823 standards (with the BNC breakout panel)

• E1 circuit alarm reporting capability

• Testing support through local and remote line and link loopbacks

•75Ω E1 breakout panel (P/N 1280060L1) provides BNC interfaces for E1 connections

T1 Network Module

• Four T1 circuits provided through four RJ-45 connectors

• Complies with ANSI T1.403 and AT&T 54016 and 62411

• T1 circuit alarm reporting capability

• Testing support through local and remote line and link loopbacks

Quad Ethernet Switch Module

• Four 10/100BaseT/TX interfaces provided through four RJ-45 connectors

• Auto MDI/MDIX crossover on all interfaces

• Back-pressure flow control on all half-duplex interfaces

• Pause-frame flow control on all full-duplex interfaces

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 13

Page 14

Section 1 System Description TRACER 6000 Series Integrated System Manual

14 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 15

MICROWAVE PATH ENGINEERING BASICS

Explains the basics of analyzing a wireless microwave link or path. Defines significant parame ters and

makes several installation recommendations.

CONTENTS

Line-of-Sight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Decibels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Calculating the Fade Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Receiver Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Antenna Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transmitted Power (PT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Carrier Wavelength (l). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Path Distance (d) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Losses (L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Path Loss (LP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Receiver Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Antenna Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Antenna Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TRACER RSSI Test Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Real-time Signal Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Antenna Beam Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fresnel Zones, Earth Curvature, and Antenna Heights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Other Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Path Availability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FIGURES

Figure 1. Example Microwave Path with Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 2. Typical Antenna Beam Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TABLES

Table 1. Antenna Gain for Given Dish Diameters with k = 0.55 (Standard) . . . . . . . . . . . . . . . . . 19

Table 2. Antenna Gain for Given Dish Diameters with k = 0.55 (Metric) . . . . . . . . . . . . . . . . . . . 19

Table 3. Antenna Gain for Given Dish Diameters with k = 0.40 (Standard) . . . . . . . . . . . . . . . . . 19

Table 4. Antenna Gain for Given Dish Diameters with k = 0.40 (Metric) . . . . . . . . . . . . . . . . . . . 19

Table 5. Transmit Power Reduction for Various Antennae Gains . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6. Typical Coaxial Loss for Common Cable Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 7. Path Loss for Given Path Lengths (miles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 8. Path Loss for Given Path Lengths (kilometers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 9. Receiver Sensitivity for the TRACER 64x0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 10. Minimum Antenna Height for Given Path Lengths (miles and ft) . . . . . . . . . . . . . . . . . . 26

Table 11. Minimum Antenna Height for Given Path Lengths (km and m) . . . . . . . . . . . . . . . . . . . . 27

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 15

Page 16

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

1. LINE-OF-SIGHT

The TRACER 6410 and TRACER 6420 systems are designed for operation in the license-free 2.400 to

2.483 GHz and 5.725 GHz to 5.850 GHz industrial, scientific, and medical (ISM) bands, respectively.

Radio wave propagation in these bands exhibits microwave characteristics which are ideally suited for

point-to-point, line-of-sight communications. Line-of-sight requires that the transmitting antenna and

receiving antenna are able to “see” each other, and that the straight-line path between the two antennas is

free of obstructions such as buildings, trees, mountains, and in longer paths, even the curvature of the

earth. For maximum signal strength, the area around the visual line-of-sight where microwave signals

reflect (Fresnel zone) must also be free of obstructions. Fresnel zones are discussed in more detail on

page 25.

Terminology

Point-to-Point Wireless communication from a single site to another individual

site. Contrast with point-to-multipoint.

Line-of-Sight An unobstructed, direct path exists between the transmitting and

the receiving antennas.

2. DECIBELS

Understanding the decibel (dB) format is key when discussing microwave path engineering because the

received signal power is often expressed in decibel format. In general, any quantity can be expressed in

decibels. If the quantity x is a power level (in watts), the decibel equivalent is defined as

x

dB

10 log10x()

⋅

=

(dB)

If the quantity x, expressed in milliwatts (mW), is referenced to a mW, then the decibel-milliwatt (dBm) is

used instead of a generic decibel.

x

dBm

=

10 log

⋅

⎛⎞

------------ -

10

⎝⎠

1mW

(dBm)

x

Using the decibel format simplifies power calculations by reducing multiplication and division operations

into addition and subtraction operations.

3. CALCULATING THE FADE MARGIN

It is imperative to determine whether the proposed microwave path is suitable (at a

minimum) for ideal, nondistorted signals before attempting installation.

The fade margin (F ) is a value in decibels (dB) that represents the amount of signal reduction that can be

tolerated before the link exceeds the specified bit error rate (BER). Fade margin is simply the difference

between the available signal power at the receiver (P

FP

16 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

–=

RPsens

= PT + GT + GR - L - LP - P

) and the receiver sensitivity (P

R

sens

(dB)

sens

).

Page 17

TRACER 6000 Series Integrated System Manual Section 2 Microwave Path Engineering Basics

where the variables in the equations are defined as

P

P

P

G

G

R

sens

T

T

R

received power (dBm)

receiver sensitivity (dBm)

transmitted power (adjustable up to 20, 24, or 27 dBm maximum – depending on product)

transmit antenna gain (decibels referenced to an isotropic source – dBi)

receive antenna gain (dBi)

L other losses (RF coaxial cable, etc. – dB)

L

P

path loss (dB)

Higher levels of fade margin indicate stronger protection against signal fading and a more reliable link . For

most applications, 20 to 30 dB of fade margin should ensure a reliable link. ADTRAN provides a free

wireless link planner tool on the ADTRAN website (www.adtran.com

– see Service/Support > Tec hnical

Support > TRACER Products).

The following sections further discuss the necessary power calculations and their components.

4. RECEIVER POWER

The viability of a particular microwave path is determined by the power of the transmitted microwave

signal, the transmit and receive antenna gain, distance, and accumulated system losses (such as RF coaxial

cable losses and path loss).

The equation relating received signal power to the other microwave parameters is

2

PTGTG

P

------------------------------=

R

()2d2L

4

λ

R

π

or (in decibel notation)

P

= PT + GT + GR - L - L

R

where the variables in the equations are defined as

P

R

P

T

G

T

G

R

received power (dBm)

transmitted power (adjustable up to 20, 24, or 27 dBm maximum – depending on product)

transmit antenna gain (decibels referenced to an isotropic source – dBi)

receive antenna gain (dBi)

λ carrier wavelength (meters)

d path distance (meters)

L other losses (RF coaxial cable, etc. – dB)

L

P

path loss (dB)

When using decibel notation, all quantities must be individually converted to decibels

prior to performing addition and subtraction.

(watts, W)

(decibels referenced to a milliwatt, dBm)

P

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 17

Page 18

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

P

L

L

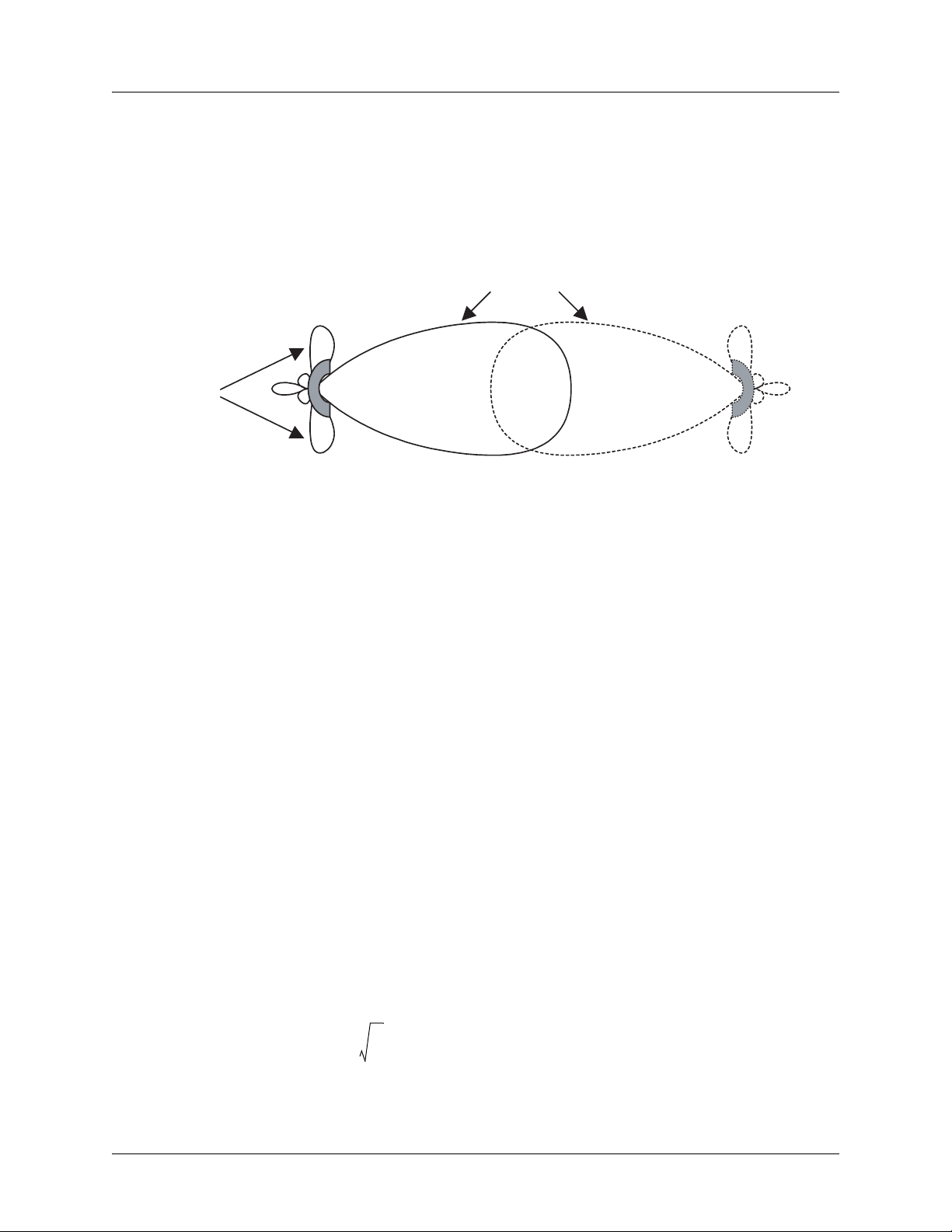

Figure 1 illustrates a wireless link configuration containing all the parameters necessary for the power

budget analysis.

λ

G

T

d, L

P

G

R

T

Figure 1. Example Microwave Path with Parameters

The following sections further discuss the power budget analysis and its components.

P

R

Antenna Gain

Actual transmit and receive antenna gain values depend strictly upon the physical characteristics of the

antennas installed for each link. In other words, the size of the dish determines the antenna gain. Using a

parabolic dish antenna results in the best performance. Antenna gains are specified in terms of decibels of

gain referenced to an isotropic source (dBi). An isotropic source is a hypothetical antenna having equal

radiation in all directions. The equation for calculating gain over isotropic radiation is

G 10 log k

where

⎛⎞

⎛⎞

⋅=

⋅

⎜⎟

⎝⎠

⎝⎠

π D⋅

----------- -

λ

2

(dBi)

k dish efficiency factor (usually 0.55)

λ carrier wavelength (c / f)

D dish diameter

The carrier wavelength (λ) and dish diameter (D) can be metric or standard units of

measure. Use the same unit of measure for both variables. For example, a carrier

wavelength of 0.124 meters requires a dish diamet er in meters as well.

The dish efficiency factor (k) is used to estimate how efficiently the dish reflector passes energy to the

feedhorn. The “standard” factor is 0.55 (measured performance of prime-focus dishes with a pyrimidal

waveguide feedhorn with no aperture blockage). Other dishes and feedhorn designs may have better or

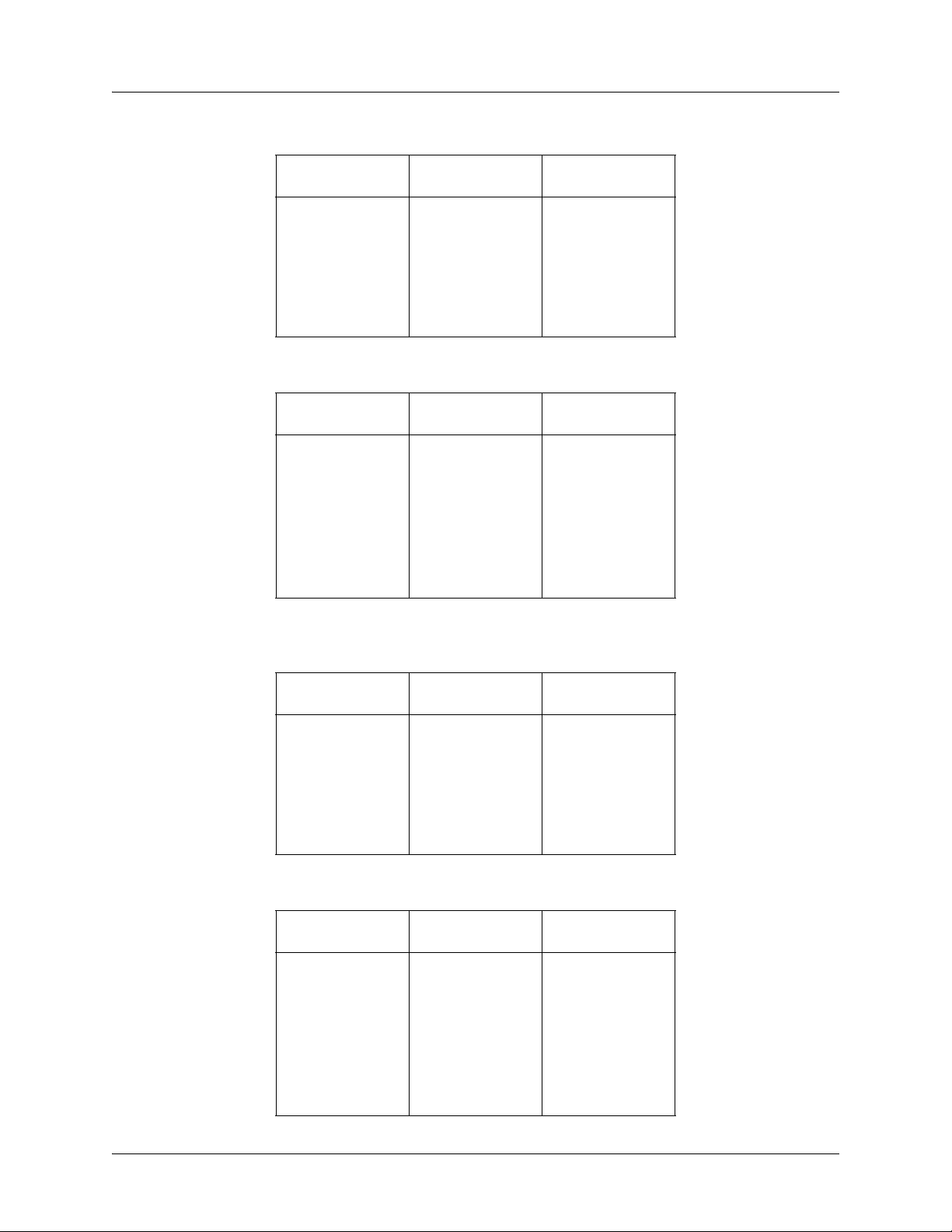

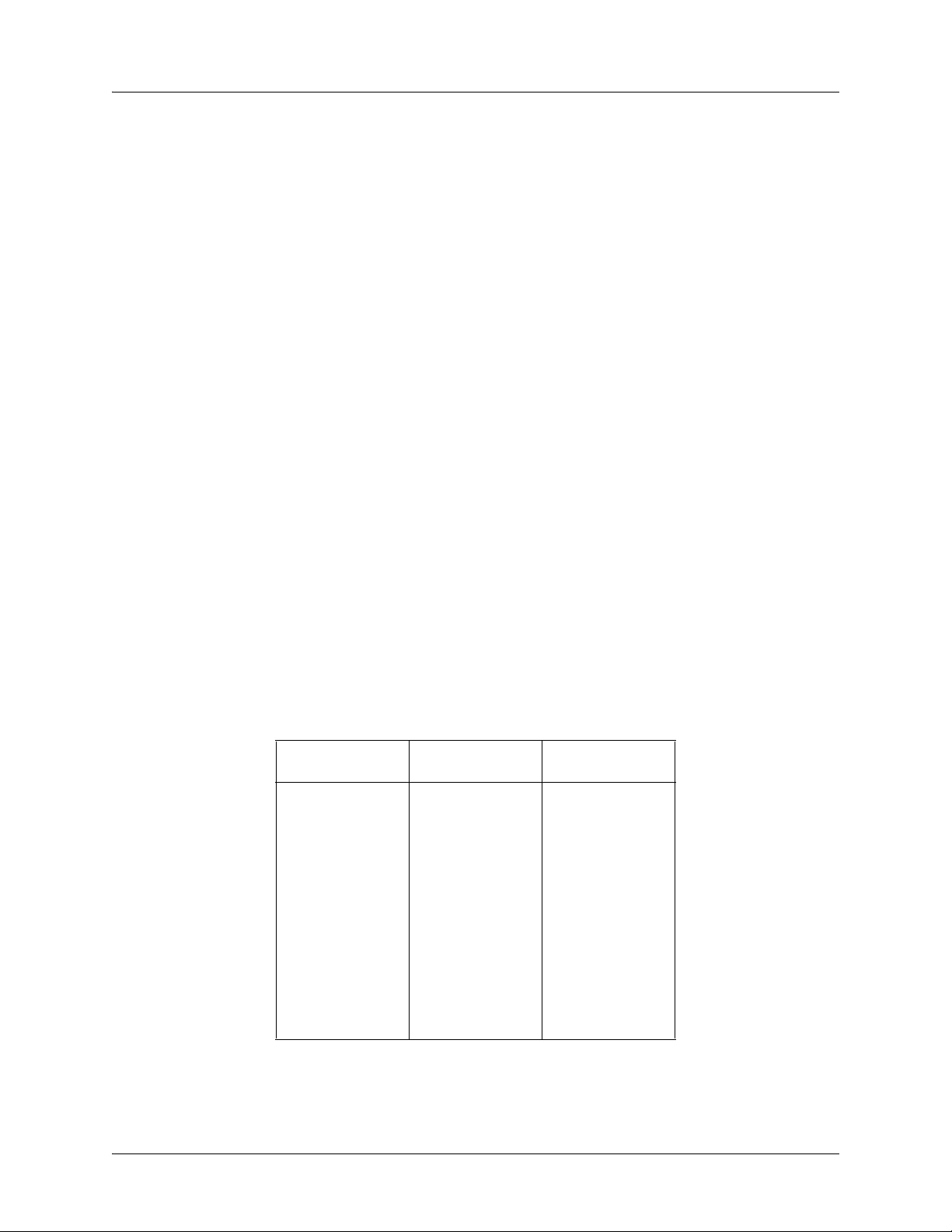

worse efficiency. Table 1 on page 19 (standard) an d Table 2 on page 19 (metric) provide gains using a 0.55

dish efficiency factor. Table 3 on page 19 (standard) and Table 4 on page 19 (metric) provide gains using a

0.40 dish efficiency factor. Dish manufacturers can provide gains for specific types of antennas.

18 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 19

TRACER 6000 Series Integrated System Manual Section 2 Microwave Path Engineering Basics

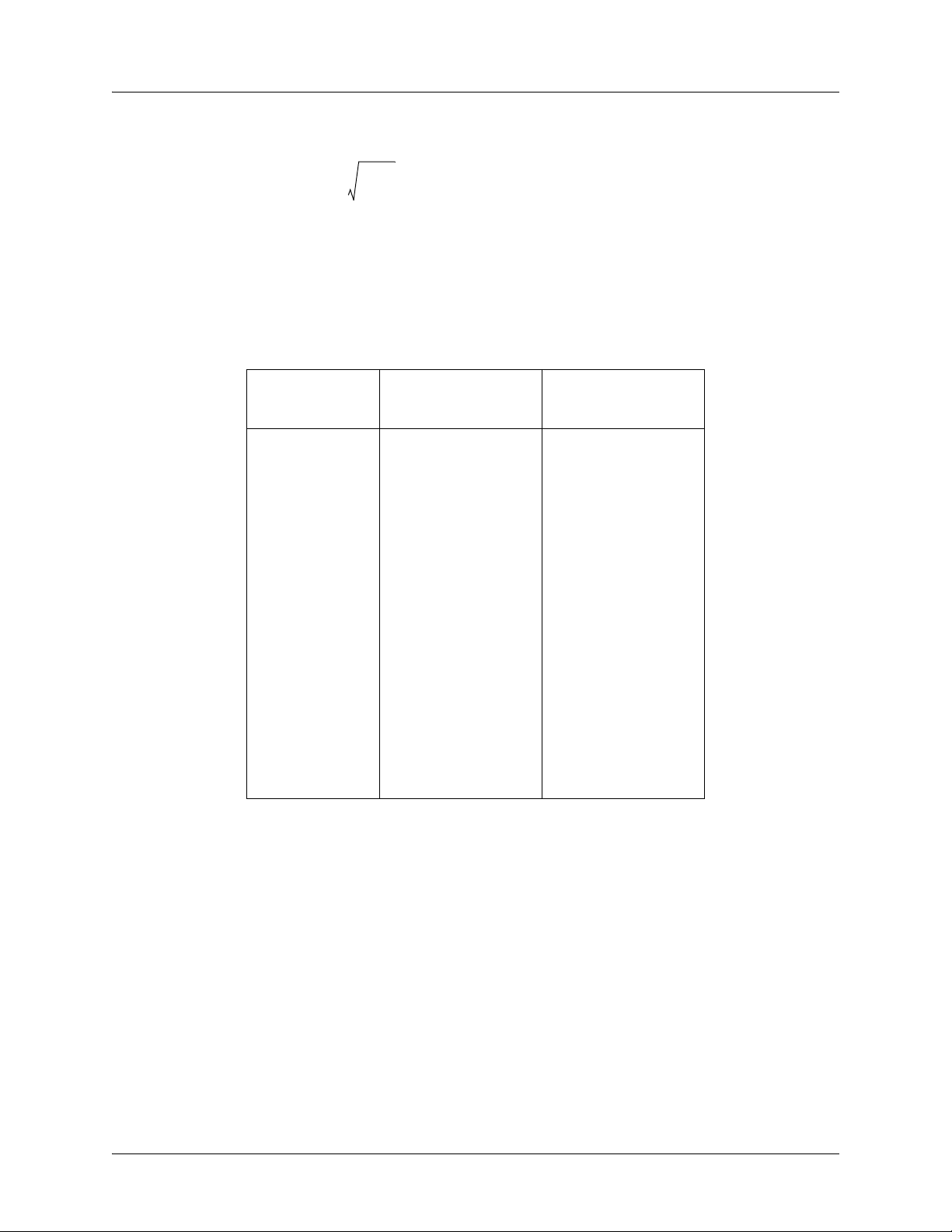

Table 1. Antenna Gain for Given Dish Diameters with k = 0.55 (Standard)

Dish Diameter

(in feet)

Gain at 2.4 GHz

(in dBi)

Gain at 5.8 GHz

(in dBi)

2 21.1 28.8

4 27.2 34.8

6 31.7 38.3

8 33.2 40.8

10 35.2 42.7

12 36.7 44.3

Table 2. Antenna Gain for Given Dish Diameters with k = 0.55 (Metric)

Dish Diameter

(in meters)

Gain at 2.4 GHz

(in dBi)

Gain at 5.8 GHz

(in dBi)

0.6 21.0 28.6

0.8 23.5 31.1

1.0 25.5 33.1

1.2 27.1 34.7

1.5 28.9 36.6

1.8 30.6 38.2

2.0 31.5 39.1

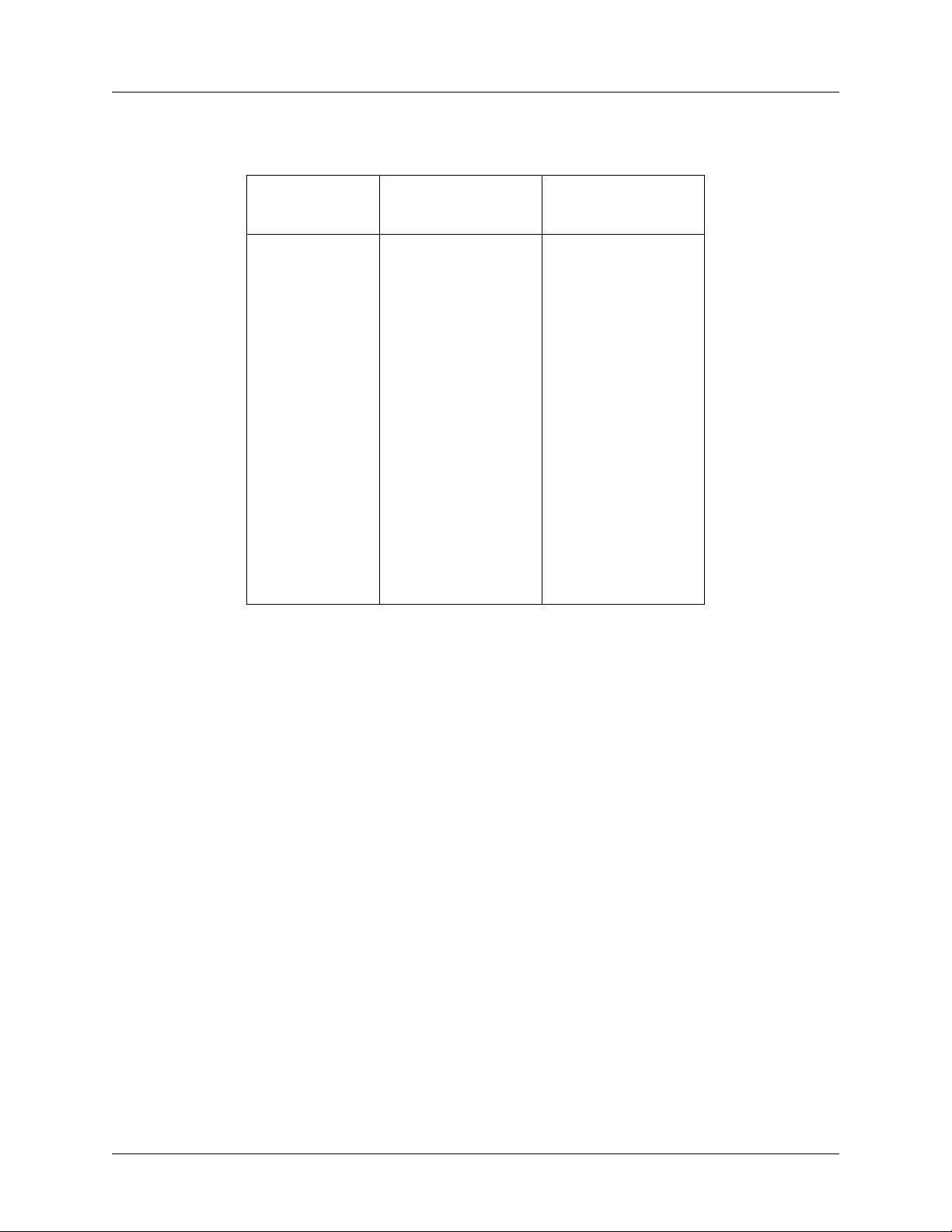

Table 3. Antenna Gain for Given Dish Diameters with k = 0.40 (Standard)

Dish Diameter

(in feet)

Gain at 2.4 GHz

(in dBi)

Gain at 5.8 GHz

(in dBi)

2 19.8 27.4

4 25.8 33.4

6 29.3 36.9

8 31.8 39.4

10 33.8 41.4

12 35.3 42.9

Table 4. Antenna Gain for Given Dish Diameters with k = 0.40 (Metric)

Dish Diameter

(in meters)

Gain at 2.4 GHz

(in dBi)

Gain at 5.8 GHz

(in dBi)

0.6 19.7 27.2

0.8 22.2 29.7

1.0 24.1 31.1

1.2 25.7 33.3

1.5 27.6 35.2

1.8 29.2 36.8

2.0 30.1 37.7

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 19

Page 20

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

Transmitted Power (PT)

The FCC specifies the maximum transmitter power used for antennae of a given gain. FCC Rules Part 15,

Subpart 247 allow for a maximum power of 1 watt (30 dBm) into antennae of a gain less than or equal to

6 dBi. At 2.4 GHz (TRACER 6410), the 1-watt maximum transmitter power must be reduced by 1 dB for

every 3 dB of antenna gain over 6 dBi. This rule is shown in Table 5.

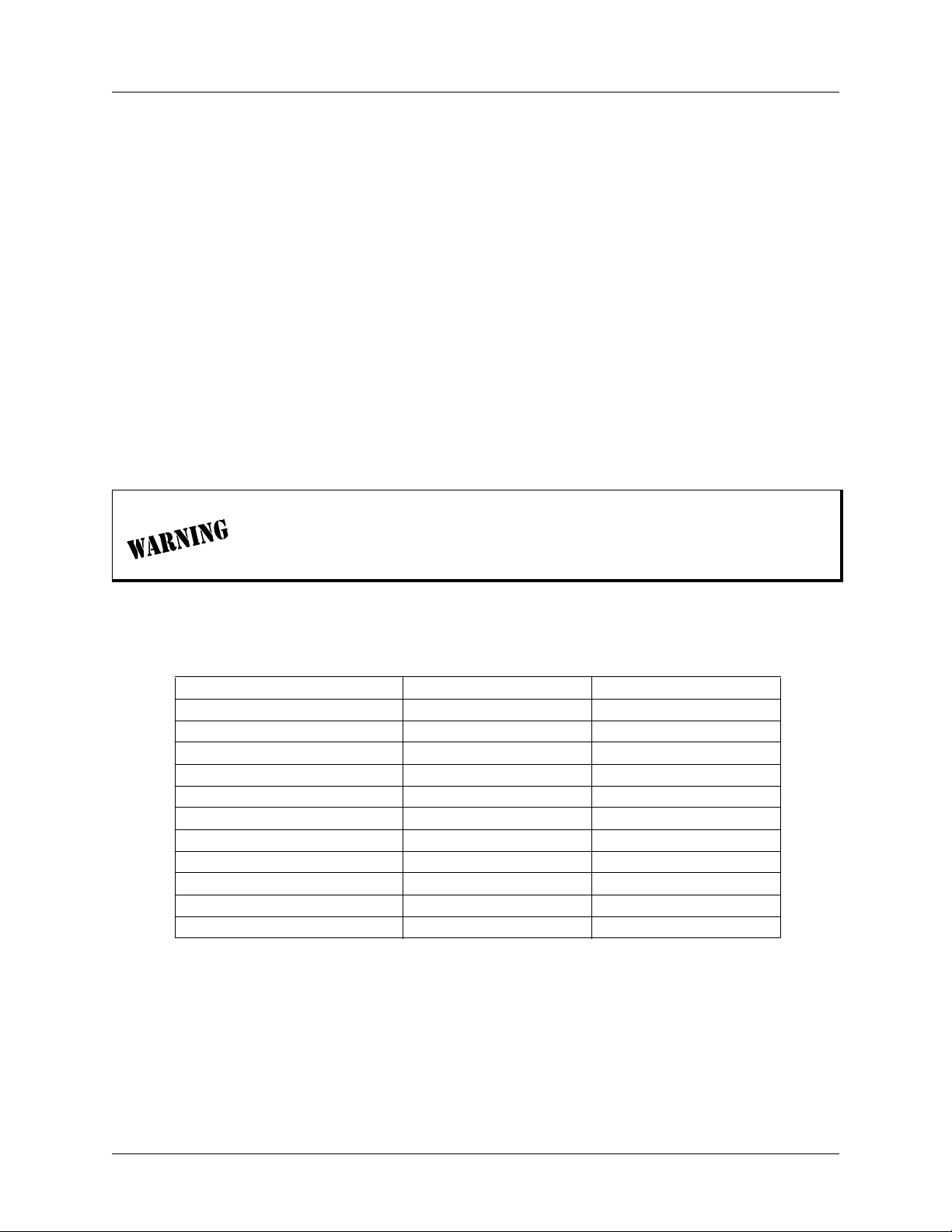

Table 5. Transmit Power Reduction for Various Antennae Gains

Output Power

(dBm)

27 15 42

26 18 44

25 21 46

24 24 48

23 27 50

22 30 52

21 33 54

20 36 56

Maximum

Antenna Gain

(dBi)

Maximum EIRP

(dBm)

For the 5.8 GHz band (TRACER 6420 L1 and L2), the maximum output power is 1 watt (30 dBm) regardless

of the gain of the attached antenna. Since the TRACER 6420 L1 and L2 maximum transmit powers are

100 milliwatts and 250 milliwatts, respectively, there is no reduction in transmitter output power required.

Carrier Wavelength (λ)

The carrier wavelength is the physical wavelength of the main RF carrier being used for communication, and

is usually approximated at the center frequency of the band (which is 2421.7 MHz for TRACER 6410 and

5787.5 MHz for the TRACER 6420). The carrier wavelength calculations follow.

λ = c / f (meters)

where

c = speed of light (in meters)

f = frequency (in Hz)

resulting in the following carrier wavelengths

TRACER 6410

λ = 3.00 x 108 / 2421.7 x 10

6

= 0.124 m or 12.4 cm

= 4.88 in

20 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

TRACER 6420

λ = 3.00 x 108 / 5787.5 x 10

= 0.0518 m or 5.18 cm

= 2.04 in

6

Page 21

TRACER 6000 Series Integrated System Manual Section 2 Microwave Path Engineering Basics

Path Distance (d)

The path distance is the physical distance between the transmit and receive antennas. For the

TRACER 64x0, these distances can range up to 30 miles (48.27 kilometers).

System Losses (L)

System losses are defined by RF coaxial cable loss, connector losses, and losses added from any additional

lightning protection devices for the power budget an alysis. Coaxial cable is required to attach the TRACER

64x0 to the antenna. The length of the cable varies from a few feet to hundreds of feet, depending upon

your application and the proximity of the TRACER 64x0 to the antenna. Various grades of coaxial cable

will work sufficiently for connecting the TRACER 64x0 unit to the antenna. A low-loss coaxial cable will

minimize cable losses.

One end of the coaxial cable requires an N-type male connector (plug) to mate with the TRACER 64x0

unit. The other end of the coaxial cable requires a connector compatible with the antenna chosen for the

installation (usually an N-type male connector). Additionally, ADTRAN recommends that the outdoor

connector on the coaxial cable be weatherproofed to prevent corrosion and electrical shorting.

In areas wher e lightning strikes are frequent, a lightning arrestor should be installed

directly on the antenna coaxial cable. Installing lightning arrestors helps protect the

RF electronics (including the TRACER 64x0 unit) in the downstream path from

damaging voltages and currents.

Table 6 gives typical loss figures for some of the more common coaxial cable types (per 100 feet).

Table 6. Typical Coaxial Loss for Common Cable Types

Cable Type 2.4 GHz Loss/100 ft (in dB) 5.8 GHz Loss/100 ft (in dB)

RG58 80 Not recommended

RG8 (air) 20 Not recommended

RG8 (foam) 9 Not recommended

1/4-inch Coax 5.91 11.36

3/8-inch Coax 5.76 9.65

1/2-inch Coax 3.83 6.49

5/8-inch Coax 2.98 4.90

7/8-inch Coax 2.2 Not suitable

1 1/4-inch Coax 1.62 Not suitable

1 5/8-inch Coax 1.41 Not suitable

5.8 GHz Elliptical Waveguide Not suitable 1.23

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 21

Page 22

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

Path Loss (LP)

Path loss is the estimated attenuation between the transmit and receive antennas caused by signal

separation and scattering. The path loss is considered basic transmission loss over the microwave link. The

following expression calculates path loss:

4πd

⎛⎞

L

P

20 log

⋅=

--------- -

⎝⎠

λ

where

f carrier frequency (Hz)

λ carrier wavelength (c / f) (meters)

d path distance (meters)

c speed of light, free-space (meters)

or

L

P

+=

96.6 20 log10d() 20·log+

where d is expressed in miles and f in GHz.

(dB)

⋅

10

f()

(dB)

Path loss, as shown here, increases rapidly as either the path length increases or the carrier wavelength

decreases (which happens as the carrier frequency increases). Therefore, longer microwave paths naturally

experience more path loss than shorter paths. Likewise, higher frequency microwave communication

experiences more path loss than lower frequency microwave communication.

The path loss values for various path lengths for the TRACER 64x0 2.4 and 5.8 GHz systems are listed in

T able 7 (miles) and Table 8 on page 23 (kilometers).Values not listed in the tables can be interpolated from

those listed.

Table 7. Path Loss for Given Path Lengths (miles)

Path Length

(miles)

1104112

2110118

3114121

4116124

5118126

10 124 132

15 128 135

20 130 138

25 132 140

30 134 141

35 135 143

Path Loss (dB)

at 2.4 GHz

Path Loss (dB)

at 5.8 GHz

22 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 23

TRACER 6000 Series Integrated System Manual Section 2 Microwave Path Engineering Basics

Table 8. Path Loss for Given Path Lengths (kilometers)

Path Length

(kilometers)

1 100 108

2 106 114

3 110 117

4 112 120

5 114 122

10 120 128

15 124 131

20 126 134

25 128 136

30 130 137

35 131 139

Path Loss (dB)

at 2.4 GHz

Path Loss (dB)

at 5.8 GHz

5. RECEIVER SENSITIVITY

Receiver sensitivity is a value expressed in decibels referenced to one milliwatt (dBm) that corresponds to

the minimum amount of signal power needed at the receiver to achieve a given bit error rate (BER).

Receiver sensitivity is usually a negative number of decibels, and smaller receiver sensitivity (higher

quantity negative number) is better for a given BER. Several factors affect receiver sensitivity, including

the data bandwidth of the wireless link and the amount of additional signal degradation introduced in the

receiver electronics.

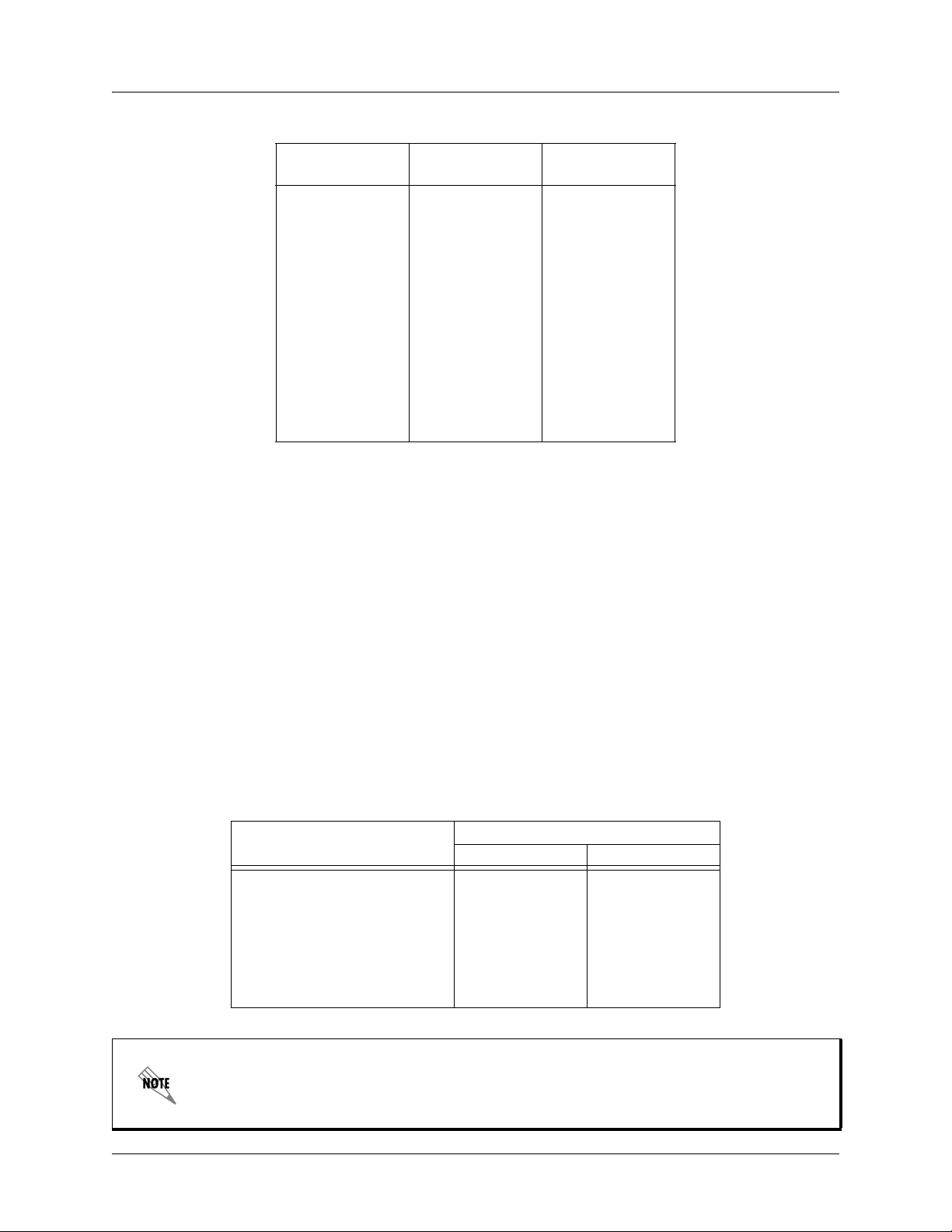

Receiver sensitivity of the TRACER 64x0 is dynamic as a function of the desired bandwidth; receiver

sensitivity improves as delivered bandwidth decreases. TRACER bandwidth is provided in the form of

eight channels available for mapping to the support modules. For T1 and E1 modules, each channel

mapped represents a single T1 or E1 interface. For Quad Ethernet Switch modules, each channel mapped

represents 2 Mb of Ethernet data delivered to the module. In situations where eight-channel connectivity is

not required, the delivered bandwidth can be decreased to four or two channels, and the receiver sensitivity

improves as follows:

Table 9. Receiver Sensitivity for the TRACER 64x0

Receiver Sensitivity

Delivered Bandwidth

8xT1 -86 dBm -85 dBm

4xT1 -90 dBm -89 dBm

2xT1 -93 dBm -92 dBm

8xE1 or 16 Mbps Ethernet -84 dBm -83 dBm

4xE1 or 8 Mbps Ethernet -88 dBm -87 dBm

2xE1 or 4 Mbps Ethernet -91 dBm -90 dBm

TRACER 6410 TRACER 6420

Should an interferer be present nearby, three software-selectable band plans are provided

for frequency agility. Changing the TRACER 64x0 band plan does not require additional

components or opening of the radio. See > RF Link Configuration > RF Band Plan on

page 64 for additional details.

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 23

Page 24

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

6. ANTENNA INFORMATION

The overall wireless system is directly affected by the antenna selection and installation, discussed in the

following sections.

Verify the antenna installation meets all regulations specified in the National Electric

Code (NEC) Article 810 with particular attention to clearances from power and lighting

conductors, mounting, grounding, and antenna discharge unit.

Antenna Alignment

With line-of-sight microwave communications, optimum system performance requires that the

transmitting and receiving antennas are properly aligned. This ensures maximum received signal power at

each receiver. Antenna alignment must be achieved in both azimuth (along a horizontal plane) and

elevation (along a vertical plane). By ensuring maximum received signal strength, a received signal

strength indicator (RSSI) helps the equipment installer determine when alignment is maximized.

TRACER RSSI Test Points

RSSI for the TRACER 64x0 system is provided through the VT100 terminal menus accessed through the

RS-232 interface, and it is presented as a series of bars indicating signal strength. More bars means more

RSSI, which ensures greater received signal strength and better link performance.

If both the local and remote end of the system are operational, the remote TRACER 64x0 receive power

can be viewed from the local TRACER 64x0 VT100 terminal menu interface.

An RSSI test point located on the front panel provides a DC voltage level (relative to the

GND test point)

that corresponds to the amount of signal being received from the far end’s transmitter. The voltage at this

test point can vary from approximately 0 to 5 VDC. An RSSI calibration sheet is shipped with the system

to provide the installer a cross-reference between actual received signal level (in dBm) and RSSI voltage.

This sheet is useful for verifying link budget calculations and ensuring proper equipment installation.

Real-time Signal Values

The TRACER 64x0 system displays real-time signal values for RX QUALITY, RX POWER, and TX POWER

(for both the local and remote units).

with 0 corresponding to poor signal quality and 100 corresponding to exceptional signal quality.

RX POWER values are displayed in dBm within ±5 dBm accuracy and can vary with extreme temperatures.

TX POWER values are displayed in dBm within ±1 dBm accuracy.

Real-time signal values are not supported on all TRACER 64x0 systems. Systems must be

ADTRAN calibrated to provide readings for Rx or Tx Power signal levels.

RX QUALITY values are displayed as a numerical value from 0 to 100,

24 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 25

TRACER 6000 Series Integrated System Manual Section 2 Microwave Path Engineering Basics

Antenna Beam Patterns

Antennas used with the TRACER 64x0 system have a particular beam shape, determined in part by the

physical construction and geometry of the antenna. The antenna beam patterns are characterized by a

dominant main lobe, which is the preferred lobe to use for point-to-point communications, and several side

lobes, as shown in Figure 2. When setting up a microwave link, antenna alignment is nothing more than

steering the main lobes of both antennas until the main lobe of one transmitter is centered on the receiving

element of the receiving antenna.

main lobe

side lobes

Figure 2. Typical Antenna Beam Pattern

Antennas are also designed to radiate RF energy efficiently for a specific range of frequencies. Please

consult the data sheet for your particular antenna make and model to ensure that it is specified to operate in

the 2400 MHz to 2483.5 MHz (TRACER 6410) or 5725 MHz to 5850 MHz (TRACER 6420) frequency

bands for your TRACER 64x0 system.

Fresnel Zones, Earth Curvature, and Antenna Heights

Fresnel zones correspond to regions in the microwave path where reflections of the intended signal occur

and combine in both constructive and destructive manners with the main signal, thereby either enhancing

or reducing the net power at the receiver.

In general, the odd numbered Fresnel zones (1, 3, 5, ...) add constructively at the receiver, while the even

numbered Fresnel zones (2, 4, 6, ...) add destructively at the receiver.

The first Fresnel zone corresponds to the main lobe, 60 percent of which must be free of physical

obstructions for the path calculations to be valid. Since the main lobe contains the vast majority of the

microwave energy, this zone is typically used to determine proper antenna heights when placing antennas

on towers or buildings.

The curvature of the Earth becomes a legitimate obstruction for path lengths of 7 miles (11 kilometers) or

greater, and must also be accounted for when determining minimum antenna heights.

The aggregate expression for minimum antenna height that incorporates both the 60 percent first Fresnel

zone and the Earth’s curvature is given by

d

h72.1

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 25

---- 4f

0.125d

+=

2

(feet)

Page 26

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

where f is in GHz and d is in miles or

h 21.975

d

------------ -

6.436f

0.0147d

+=

2

(meters)

where f is in GHz and d is in kilometers.

The minimum antenna heights for given path lengths are displayed in Table 10 (feet/miles) and Table 11

on page 27 (kilometers/meters).

Table 10. Minimum Antenna Height for Given Path Lengths (miles and ft)

Min. Antenna Height

Path Length

(miles)

2 33 22

4 48 32

6 61 41

8 73 50

10 85 60

14 111 81

16 124 92

18 138 104

20 153 117

22 169 131

24 185 145

26 202 161

28 220 177

30 239 194

32 259 213

34 279 232

36 300 252

at 2.4 GHz

(ft)

Min. Antenna Height

at 5.8 GHz

(ft)

26 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 27

TRACER 6000 Series Integrated System Manual Section 2 Microwave Path Engineering Basics

Table 11. Minimum Antenna Height for Given Path Lengths (km and m)

Min. Antenna Height

Path Length

(kilometers)

2 8.0 5.1

4 11.4 7.4

6 14.2 9.3

8 16.8 11.1

10 19.2 12.8

14 23.8 16.3

16 26.1 18.2

18 28.5 20.0

20 30.9 22.0

22 33.3 24.0

24 35.9 26.1

26 38.4 28.3

28 41.1 30.6

30 43.9 32.9

32 46.7 35.4

34 49.6 38.0

36 52.6 40.6

at 2.4 GHz

(meters)

Min. Antenna Height

at 5.8 GHz

(meters)

7. OTHER CONSIDERATIONS Path Availability

The path availability of a wireless link is a metric that expresses the fractional amount of time a link is

available over some fixed amount of time, and depends on several factors. Path availability is expressed as

A12.510

=

()abfd310

where the parameters are

a terrain factor

b climate factor

f carrier frequency (GHz)

d path length (miles)

F fade margin (dB)

or

A1

=

6.00 10

()abfd310

6–

×

7–

×

F10

⁄

–

()–[]100%

F10

–

()–[]100%

×

⁄

×

(%)

(%)

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 27

Page 28

Section 2 Microwave Path Engineering Basics TRACER 6000 Series Integrated System Manual

where the parameters are

a terrain factor

b climate factor

f carrier frequency (GHz)

d path length (kilometers)

F fade margin (dB)

Terrain Factor (a)

The terrain factor is a quantity that compensates the link availability for different types of terrain.

Generally speaking, the smoother an area’s terrain, the less availability a wireless link running over that

terrain will have, primarily due to multipath reflections. In contrast, secondary microwave signals will be

randomly dispersed over rough terrain and will not interfere with the main signal lobe as badly as in the

smooth terrain case. The terrain factor values normally used are listed below:

Terrain Terrain Factor Description

Smooth 4 water, flat desert

Average 1 moderate roughness

Mountainous 1/4 very rough, mountainous

Climate Factor (b)

The climate factor is a quantity that compensates the link availability for different types of climates

(weather). In general, microwave links operating in areas with high humidity will have less availability

than those in arid areas, primarily because water is a dispersive mechanism to microwave energy and

causes the main signal lobe to refract and disperse away from the receiver location. The climate factor

values normally used are listed below:

Climate Climate Factor Description

Very Dry 1/8 desert regions

Temperate 1/4 mainland, interior region

Humid 1/2 humid and coastal regions

28 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 29

ENGINEERING GUIDELINES

Provides information to assist network designers with incorporating the TRACER 64x0 system into their

networks.

CONTENTS

Equipment Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reviewing the Front Panel Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

RSSI Monitoring Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

AUX RS232 Interface (RJ-45). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CRAFT Port (DB-9). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Reviewing the TRACER 64x0 Rear Panel Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

MGMT 10/100BaseT/TX Connection (RJ-48C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DC Power Connection (Plug-In Terminal Block). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Alarm Contacts (Plug-In Terminal Block) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Antenna Interface (N-Type Connector). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Network Module Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4xT1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Quad Ethernet Switch Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4xE1 Module with 120Ω Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4xE1 Module with 75Ω Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

At-A-Glance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LIST OF FIGURES

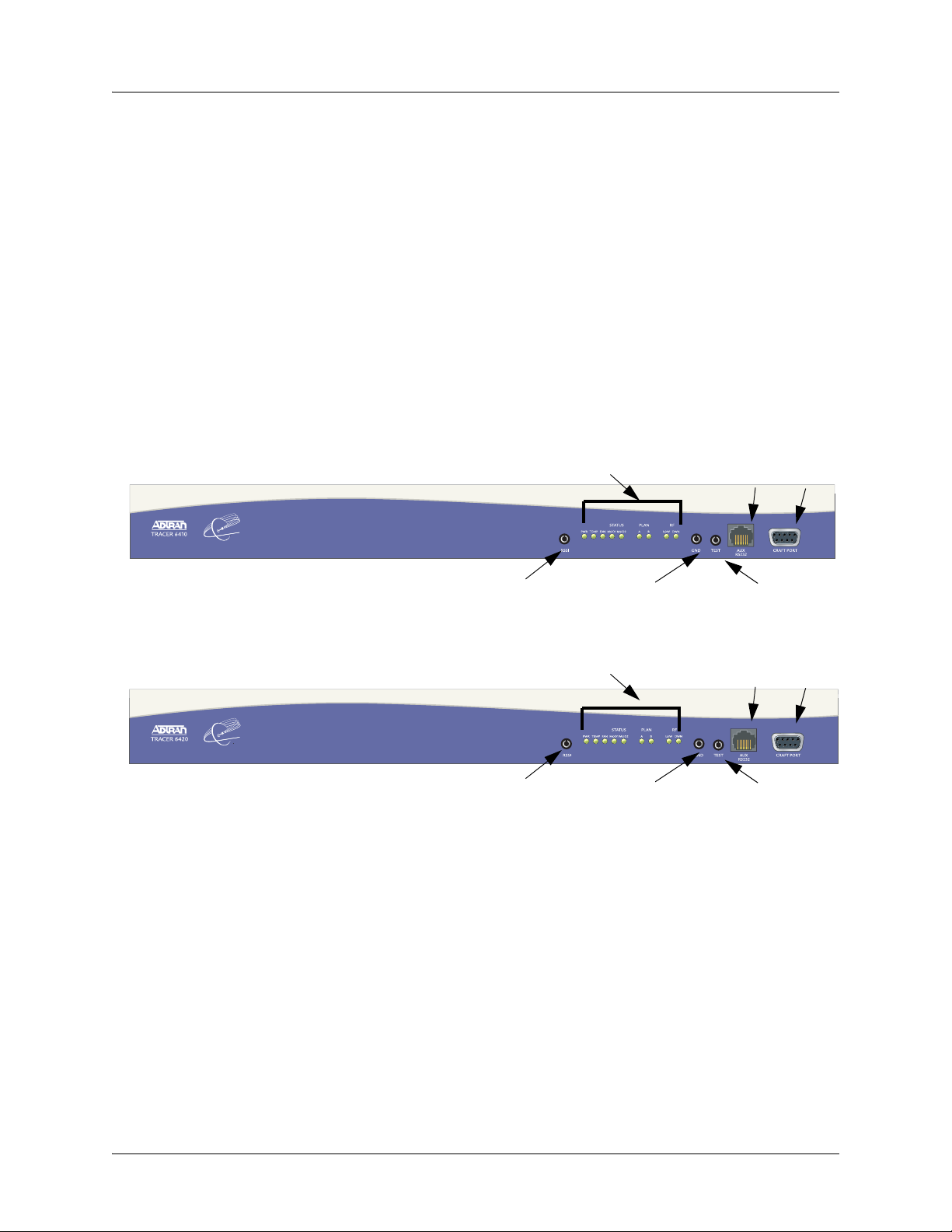

Figure 1. TRACER 6410 and TRACER 6420 (L2) Front Panel Layout. . . . . . . . . . . . . . . . . . . . . 30

Figure 2. TRACER 6420 (L1) Front Panel Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 3. TRACER 64x0 Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 4. E1 Breakout Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LIST OF TABLES

Table 1. TRACER 64x0 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2. TRACER 64x0 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 3. AUX RS232 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 4. CRAFT Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 5. Null-Modem Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 6. Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 7. MGMT 10/100BaseT/TX Interface Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 8. DC Power Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 9. Alarm Contact Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 10. 4xT1 Module RJ-45 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 11. Quad Ethernet Switch RJ-45 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 12. 4xE1 Module with 120 Ω Interface RJ-45 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . 38

Table 13. 4xE1 Module with 75Ω Interface DB-25 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . 39

Table 14. DB-25 to 75Ω Unbalanced Cable Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 15. At-A-Glance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 29

Page 30

Section 3 Engineering Guidelines TRACER 6000 Series Integrated System Manual

1. EQUIPMENT DIMENSIONS

The TRACER 64x0 integrated radio is 17.2 inch (43.7 cm) W, 11.4 inch (28.9 cm) D, and

1.7 inch (4.4 cm) H, weighs 7 pounds (3.18 kg), and can be used in rackmount configurations.

2. POWER REQUIREMENTS

The TRACER 64x0 radio has a maximum power consumption of 25 W and a maximum current draw of

1.1 A (at 21 VDC).

3. REVIEWING THE FRONT PANEL DESIGN

The front panel contains an RSSI monitoring interface, a GND interface for reference with RSSI, a TEST

interface for factory use only, a DB-9

interface (RJ-45) that provides an end-to-end serial port interface (at 9600 bps), and status LEDs to provide

visual information about the TRACER 64x0 system. Figure 1 identifies the various interfaces and LEDs for

the TRACER 6410 and TRACER 6420 (L2). Figure 2 identifies the various interfaces and the LEDs for the

TRACER 6420 L1. Table 1 on page 31 provides a brief description of each interface.

CRAFT PORT for management and configuration, an AUX RS232

B

A

Figure 1. TRACER 6410 and TRACER 6420 (L2) Front Panel Layout

C

B

A

Figure 2. TRACER 6420 (L1) Front Panel Layout

C

E

E

F

D

F

D

30 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 31

TRACER 6000 Series Integrated System Manual Section 3 Engineering Guidelines

Table 1. TRACER 64x0 Front Panel Description1

Name Connector Description

A

RSSI bantam DC voltage indicating strength of the received signal at

the antenna

B

Status LEDs N/A Visual status information about the system

C

GND bantam Ground reference for the RSSI interface

D

TEST 3.5 mm mini-jack Factory use only

E

AUX RS232 RJ-45 Serial interface for a 9600 bps connection between the

local and remote systems over the RF link

F

CRAFT PORT DB-9 RS-232 interface for connection to a VT100 terminal or

PC with terminal emulation software

1 Detailed discussions (including pinouts) of front panel components (where applicable) follow the table.

RSSI Monitoring Interface

The RSSI voltage is a function of the signal strength at the receiver and is used to measure the received

signal strength. RSSI varies from approximately 0 to 5 VDC. An RSSI calibration sheet is shipped with the

system to provide the installer a cross-reference between actual received signal level (in dBm) and RSSI

voltage. This sheet is useful for verifying link budget calculations and ensuring proper equipment

installation.

Front Panel LEDs

With the TRACER powered-on, the front panel LEDs provide visual information about the status of the

system. Table 2 describes the LEDs.

Table 2. TRACER 64x0 LEDs

For these LEDs... This color light... Indicates that...

PWR Green (solid) the TRACER is connected to a power source.

Off the TRACER is not currently powered up.

TEMP

*TRACER 64x0 high

power system only

FAN

*TRACER 64x0 high

power system only

TST

*TRACER 6420 (L1) only

Green (solid) the TRACER 64x0 high power system temperature is within

normal range.

Red (solid) the TRACER 64x0 high power system has an active temperature

alarm.

Green (solid) the TRACER 64x0 high power system fans are working properly.

Red (solid) the TRACER 64x0 high power system fans are not functioning.

Amber (flashes once) powe r-up self-test is in progress. If the LED continuously flashes

or remains on (solid) after 10 seconds, the unit has failed

self-test.

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 31

Page 32

Section 3 Engineering Guidelines TRACER 6000 Series Integrated System Manual

Table 2. TRACER 64x0 LEDs (Continued)

For these LEDs... This color light... Indicates that...

STATUS

MOD1 and MOD2

PLAN A

PLAN B

RF LO Red (solid)

RF DWN Red (solid)

Green the module is installed and functioning properl y.

Red (solid) a port on the installed module is currently in alarm.

Off no module occupies the slot.

Green (solid) the TRACER is transmitting on Frequency Plan A.

Off the TRACER is not transmitting on Frequency Plan A.

Green (solid) the TRACER is transmitting on Frequency Plan B.

Off the TRACER is not transmitting on Frequency Plan B.

the RSSI level is below suggested minimum threshold

(approximately 10 dBm above the minimum receive sensitivity).

there is a communication problem between the local and remote

TRACERs.

AUX RS232 Interface (RJ-45)

The AUX RS232 interface provides a female RJ-45 terminal connection (wired as a DCE interface), used

for a 9600 bps point-to-point connection between the local and remote systems (over the RF link). Ta ble 3

shows the pinout.

Table 3. AUX RS232 Pinout

Pin Name Source Description

1 GND Common Signal ground

2 RTS Attached Equipment Request to send (unused)

3 TXDATA Attached Equipment Transmit data (from attached equipment)

4 DSR TRACER Data set ready

5 RXDATA TRACER Received data (to attached equipment)

6 CTS TRACER Clear to send

7 DTR Attached Equipment Data terminal ready (unused)

8 CD TRACER Carrier detect

32 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 33

TRACER 6000 Series Integrated System Manual Section 3 Engineering Guidelines

CRAFT Port (DB-9)

The CRAFT connector provides a female DB-9 terminal connection (wired as a DCE interface), used for

terminal access to the TRACER system. Table 4 shows the pinout. A null modem cable is necessary for

connecting the

modem cable.

CRAFT port to a modem for remote dial-up access. Table 5 shows the pinout for a null

Table 4. CRAFT Pinout

Pin

1CD

2RXDATA

3 TXDATA Attached Equipment Transmit data (from attached equipment)

4 DTR Attached Equipment Data terminal ready (unused)

5 GND Common Signal ground

6DSR

7 RTS Attached Equipment Request to send (unused)

8CTS

9RI

Name

Source Description

TRACER Carrier detect

TRACER Received data (to attached equipment)

TRACER Data set ready

TRACER Clear to send

TRACER Ring indicator (unused)

Table 5. Null-Modem Pinout

Modem

Pin

1 (CD) Unconnected

2 (RXD) 3 (TXD)

3 (TXD) 2 (RXD)

4 (DTR) 6 (DSR)

5 (GND) 5 (GND)

6 (DSR) 4 (DTR)

TRACER 64x0

Pin

7 (RTS) 8 (CTS)

8 (CTS) 7 (RTS)

9 (RI) Unconnected

4. REVIEWING THE TRACER 64X0 REAR PANEL DESIGN

Figure 3 on page 34 identifies the features of the TRACER rear panel, an d Table 6 on page 34 provides a

brief description of each interface.

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 33

Page 34

Section 3 Engineering Guidelines TRACER 6000 Series Integrated System Manual

A

Network

Module Slots

B

Ethernet

Interface

Figure 3. TRACER 64x0 Rear Panel

Table 6. Rear Panel Description

Name Connector Description

A Network Module

Slots

B

C DC Power Terminal block 21 to 60 VDC power source connection (either polarity

D Fuse N/A 2A, 250 V, 2-inch slo-blo fuse

E Alarm Terminal blo ck External alarm monitoring system connection

F Antenna N-type (female) Antenna feedline cable connection

G Ground Lug N/A Earth ground connection

MGMT RJ-45

N/A Dual network module slots for system flexibility (shown

with a single 4xT1 module and a Quad Ethernet Switch

module installed)

10/100BaseT/TX Ethernet interface for SNMP, TFTP, and

Telnet access

referenced to ground)

C

DC Power

Connection

D

Fuse

E

Alarm

Contacts

1

F

Antenna

Connector

G

Ground

Lug

1 Detailed discussions (including pinouts) of rear panel components (where applicable) follow the table.

MGMT 10/100BaseT/TX Connection (RJ-48C)

The physical Ethernet interface is provided by a single RJ-48C jack (labeled MGMT) that delivers

10/100BaseT/TX for LAN connectivity. The

is not a router interface. The

MGMT port has a green LINK LED to indicate a valid link and an amber ACT

LED that flashes with data activity on the interface. Table 7 shows the pinout.

Table 7. MGMT 10/100BaseT/TX Interface Pinout

Pin Name Description

1

2 TX2 Transmit negative

3 RX1 Receive positive

4,5 — Unused

6 RX2 Receive negative

7, 8 — Unused

34 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

TX1 Transmit positive

MGMT port is used for Telnet, SNMP, and TFTP access and

Page 35

TRACER 6000 Series Integrated System Manual Section 3 Engineering Guidelines

DC Power Connection (Plug-In Terminal Block)

The TRACER 64x0 can operate from a supply between 21 and 60 VDC, with either polarity referenced to

ground, and consumes less than 25 W. Power supplies should be able to provide up to 25 W at the selected

voltage. Current required (in amps) is determined by dividing the power consumed (in watts) by the applied

voltage (in volts). For example, at 48 V, TRACER 64x0 would draw approximately 0.52 A

(25 W/48 V). Table 8 shows the DC power connection pinout.

Applying power to the radio without a 50Ω load attached to the antenna interface can

damage the system. Verify the 50

When using a power source that has the positive terminal or the negative terminal

connected to earth ground, the grounded terminal must be attached to the TRACER 64x0

power input that is identified with the ground symbol. Otherwise, equipment damage will

occur. When using a power source that has neither terminal connected with earth ground

(floating), either terminal may be connected to the TRACER 64x0 power input identified

with the ground symbol.

Table 8. DC Power Connector Pinout

Ω

load is attached before powering the radio.

Pin Name Description

1 +/– Voltage

2 GND Ground

Fuse

The fuse holder, accessible from the rear panel of the TRACER 64x0, accepts a generic 2 A, 250 V, 2-inch

slow-blo fuse.

Alarm Contacts (Plug-In Terminal Block)

An RF link down condition is indicated with both normally open (NO) and normally closed (NC) alarm

contacts on the rear panel of the TRACER 64x0 system. In normal operation, the NC contact is electrically

connected to the common contact (COM) and the NO contact is isolated. When the RF link drops, the NC

contact becomes isolated and the NO is electrically connected to COM. This allows RF down conditions to

be reported to external alarm monitoring systems. Table 9 provides the alarm contact pinout.

Table 9. Alarm Contact Connector Pinout

Pin Name Description

1 COM Common Contact

2 NO Norm ally- O pe n Co ntact

3 NC Normally-Closed Contact

Antenna Interface (N-Type Connector)

The ANTENNA interface (N-type connector) connects to the customer-supplied antenna using standard

antenna feedline cable. When determining the cable specifications for your application, refer to Section 2,

Microwave Path Engineering Basics (System Losses (L) on page 21) for a discussion on cable length and

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 35

Page 36

Section 3 Engineering Guidelines TRACER 6000 Series Integrated System Manual

loss factors.

Applying power to the radio without a 50Ω load attached to the antenna interface can

damage the system. Verify the 50

Ω

load is attached before powering the radio.

36 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 37

TRACER 6000 Series Integrated System Manual Section 3 Engineering Guidelines

5. NETWORK MODULE INTERFACES 4xT1 Module

The 4xT1 network module has four T1 interfaces (through four RJ-45 ports) that provide the following

functions:

®

• ANSI T1.403 and AT&T

• AMI or B8ZS coding

• Extended Super Frame (ESF) and Super Frame (SF) framing support

• Manual line build out

• Network performance monitoring and reporting

• Test loopbacks (both line and link)

Table 10 provides the RJ-45 interface pinout for the 4xT1 network module.

Table 10. 4xT1 Module RJ-45 Connector Pinout

Pin Name Description

1 R Transmit data (ring) towards the network

54016 and 62411 compliant

2 T Transmit data (tip) towards the network

3, 6-8 UNUSED —

4 R1 Receive data (ring) toward the network

5 T1 Receive data (tip) from the network

Quad Ethernet Switch Module

The Quad Ethernet Switch module has four 10/100BaseTX interfaces (through four RJ-45 ports) that

provide the following functions:

• IEEE 802.3 and 802.3u compliant

• Auto MDI/MDIX crossover

• Back-pressure flow control on all full-duplex interfaces

• Link and activity LEDs for each port

Table 11 provides the RJ-45 interface pinout for the Quad Ethernet Switch module.

Table 11. Quad Ethernet Switch RJ-45 Connector Pinout

Pin Name Source Description

1 RX1 Attached Equipment Receive Positive 2 RX2 Attached Equipment Receive Negative 3 TX1 Module Transmit Positive 4, 5 Unused N/A — 6 TX2 Module Transmit Negative 7, 8 Unused N/A —

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 37

Page 38

Section 3 Engineering Guidelines TRACER 6000 Series Integrated System Manual

4xE1 Module with 120Ω Interface

The 4xE1 network module provides four E1 interfaces (through four RJ-45 connec tors) that provide the

following functions:

• AMI or HDB3 coding

• Framed, multi-framed, and unframed framing support

• Network performance monitoring and reporting

• Test loopbacks (both line and link)

Table 12 provides the RJ-45 interface pinout for the 4xE1 network module.

Table 12. 4xE1 Module with 120Ω Interface RJ-45 Connector Pinout

Pin Name Description

1 TX Tip Transmit signal (Tip)

2 TX Ring Transmit signal (Ring)

3Unused—

4 RX Tip Receive signal (Tip)

5 RX Ring Receive signal (Ring)

6–8 Unused —

4xE1 Module with 75Ω Interface

The 4xE1 network module provides four E1 interfaces (through a si ngl e DB-25 interface) that provide the

following functions:

• AMI or HDB3 coding

• Framed, multi-framed, and unframed framing support

• Network performance monitoring and reporting

• Test loopbacks (both line and link)

Table 13 on page 39 provides the DB-25 interface pinout for the 4xE1 network module. A separate

breakout panel is available to provide 75Ω BNC unbalanced interfaces (see Table 14 on page 39 for the

pinout of the 75Ω cable). Figure 4 displays the E1 breakout panel.

38 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 39

TRACER 6000 Series Integrated System Manual Section 3 Engineering Guidelines

Table 13. 4xE1 Module with 75Ω Interface DB-25 Connector Pinout

Pin Name Description

1 E1D RX Receive signal for E1 D interface

2 E1D TX Output signal for E1 D interface

3 GND Ground

4 E1C RX Receive signal for E1 C interface

5 E1C TX Output signal for E1 C interface

6 GND Ground

7 E1B RX Receive signal for E1 B interface

8 E1B TX Output signal for E1 B interface

9 GND Ground

10 E1A RX Receive signal for E1 A interface

11 E1A TX Output signal for E1 A interface

12-25 GND Ground

Table 14. DB-25 to 75Ω Unbalanced Cable Pinout

E1 Cable Interface

DB-25 Male

(TRACER Side)

DB-25 Male

(Breakout Panel)

Channel 1 Input 10 14

Channel 1 Output 11 3

Channel 2 Input 7 17

Channel 2 Output 8 6

Channel 3 Input 4 20

Channel 3 Output 5 9

Channel 4 Input 1 23

Channel 4 Output 2 12

Ground All other pins All other pins

612806420L1-1E Copyright © 2005 ADTRAN, Inc. 39

Page 40

Section 3 Engineering Guidelines TRACER 6000 Series Integrated System Manual

Figure 4. E1 Breakout Panel

6. AT-A-GLANCE SPECIFICATIONS

Table 15 on page 40 contains a list of specifications for the TRACER 64x0 system.

Table 15. At-A-Glance Specifications

Hardware Description Specification

Transmitter

Output Power +27 dBm, maximum (TRACER 6410 L2)

+20 dBm, maximum (TRACER 6420 L1)

+24 dBm, maximum (TRACER 6420 L2)

Frequency Range 2400 to 2483.5 MHz (TRACER 6410 L2)

5725 to 5850 MHz (TRACER 6420 L1 and L2)

Receiver

Receive Level,

Minimum

Receive Level, Maximum -30 dBm

Receive Level, Nominal -55 dBm

TRACER 6410

-86 dBm @ 8xT1

-90 dBm @ 4xT1

-93 dBm @ 2xT1

TRACER 6420

-85 dBm @ 8xT1

-89 dBm @ 4xT1

-92 dBm @ 2xT1

-84 dBm @ 8xE1/16Mbps Ethernet

-88 dBm @ 4xE1/8 Mbps Ethernet

-91 dBm @ 2xE1/4 Mbps Ethernet

-83 dBm @ 8xE1/16Mbps Ethernet

-87 dBm @ 4xE1/8 Mbps Ethernet

-90 dBm @ 2xE1/4 Mbps Ethernet

40 Copyright © 2005 ADTRAN, Inc. 612806420L1-1E

Page 41

TRACER 6000 Series Integrated System Manual Section 3 Engineering Guidelines

Table 15. At-A-Glance Specifications (Continued)