Page 1

®

Total Access® 1500 FXS/DPO Access Module

Installation and Maintenance Practice

CONTENTS

1. General .................................................................... 1

2. Installation............................................................... 2

3. Provisioning ............................................................ 3

4. Test Features ......................................................... 11

5. Maintenance .......................................................... 11

6. Specifications ........................................................ 11

7. Warranty and Customer Service ........................... 11

FIGURES

Figure 1. FXS/DPO..................................................... 1

Figure 2. DIP Switches Detail..................................... 6

Figure 3. FXS/DPO Menu Tree ................................ 10

TABL ES

Table 1. Compliance Codes ........................................ 2

Table 2. Front Panel LEDs and Switch....................... 3

Table 3. Time Slot and Wiring Interconnect............... 4

Table 4. DIP Switches................................................. 5

Table 5. FXS/DPO General Options........................... 7

Table 6. FXS/DPO Mode Options .............................. 8

Table 7. FXS/DPO Tandem Options........................... 9

Table 8. Specifications .............................................. 12

Section 61180403L1-5B

Issue 2, December 2004

CLEI Code: VAIMZ70J_ _

FXS/DPO

1180403L1

STAT US

REM

AP

Figure 1. FXS/DPO

1. GENERAL

This practice is an installation and maintenance guide

®

for the ADTRAN

Total Access® 1500 Foreign

Exchange Station/Dial Pulse Originate (FXS/DPO)

access module. Figure 1 illustrates the FXS/DPO

(P/N 1180403L1) front panel.

Revision History

This is the second revision of this practice. This release

of the document includes the addition of the NBOC

option and the TO w/SC operating mode precipitated by

Line Interface Unit (LIU) software updates to R36 or

later. Time slot and wiring interconnect information for

the 19-inch and 23-inch Total Access 1500 chassis and

hardware and software provisioning information has

been included. This revision reflects a general

document update and change to the Warranty information.

Description

The FXS/DPO is designed specifically for the Total

Access 1500 chassis and is not used in any other

product. The FXS/DPO provides for a 2-wire analog

interface between a Voice Frequency (VF) transmission

and signaling facility and the Total Access 1500 Pulse

Code Modulation (PCM) backplane. The FXS interface

provides for simultaneous signaling in each direction

for use with 2-wire Off-Premises Station Lines, carrier

extended PBX Trunks, or subscriber line Foreign

Exchanges using ground or loop start signaling systems.

The unit is multifunctional and can be hardware or

software provisioned to operate in any one of the

following modes:

• Loop Start

• Ground Start

• TR08 Single Party (SP)

• TR08 Universal Voice Grade (UVG)

•TR08 Auto

• Private Line Automatic Ringdown (PLAR) D4

61180403L1-5B 1

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

Page 2

•PLAR D3

•Tandem

•DPO

• FX Ringdown

• TO w/Sealing Code

Features

The basic features of the FXS/DPO include the

following:

µ-law encoding and decoding

•

• Supports ground start, loop start, PLAR, DPO, and

Tandem, TR08SP, TR08UVG, TR08AUTO, and

FX Ringdown

• Supports 900 ohms (+2.16

(+2.16

µF) 2-wire VF interfaces

µF) and 600 ohms

• Receive TLP range of -9.0 dB to 0.0 dB

• Transmit TLP range of -7.0 dB to +9.0 dB

• Supports CLASS

®

• Hot swappable

• Long loop capability: 1650 ohms nominal

• V.90 Modem compliant

• Extended temperature range of –40ºC to +65ºC

• Meets UL 60950, NEBS Level 3, PUB 43801, and

GR57

• Call Forward Disconnect

Compliance

Tabl e 1 shows the compliance codes for the FXS/DPO.

The FXS/DPO is NRTL listed to the applicable UL

standards. The FXS/DPO is to be installed in a restricted

access location and in a Type “B” or “E” enclosure

only.

The Total Access 1500 chassis frame ground terminal

must be connected to an earth ground to ensure that the

front panel of the FXS/DPO is properly grounded via

the backplane connector.

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation.

Changes or modifications not expressly approved by

ADTRAN could void the user’s authority to operate this

equipment.

2. INSTALLATION

C A U T I O N !

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

After unpacking the FXS/DPO, inspect it for damage. If

damage has occurred, file a claim with the carrier, then

contact ADTRAN Customer Service. Refer to the

Warranty and Customer Service section for further

information. If possible, keep the original shipping

container for returning the FXS/DPO for repair or for

verification of shipping damage.

CAUTION

Electronic modules can be damaged by ESD.

When handling modules, wear an antistatic

discharge wrist strap to prevent damage to

electronic components. Place modules in

antistatic packing material when transporting

or storing. When working on modules, always

place them on an approved antistatic mat that is

electrically grounded.

Table 1. Compliance Codes

Code Input Output

Power Code (PC) C C

Telecommunication Code (TC) – X

Installation Code (IC) A –

2 Issue 2, December 2004 61180403L1-5B

Page 3

Instructions for Installing the Module

To install the FXS/DPO, perform the following steps:

1. If present, remove the Access Module Blank (P/N

1175099L1) from the appropriate access module

slot of the Total Access chassis.

2. Pull the ejector latch, located on the lower lefthand side of the FXS/DPO front panel, from its

closed position.

3. Hold the FXS/DPO by the front panel while

supporting the bottom edge of the module with the

ejector latch opened to engage the chassis edge.

4. Align the module edges to fit in the lower and

upper guide grooves for the access module slot.

5. Slide the module into the access module slot.

Simultaneous thumb pressure at the top (above the

STATUS LED) and at the bottom (below the

electrostatic caution symbol) of the module will

ensure that the module is firmly positioned against

the backplane of the chassis.

6. Secure the FXS/DPO in place by pushing in on the

ejector latch.

Table 2. Front Panel LEDs and Switch

Label Condition Description

BUSY

REM

Switch Description

AP

Recessed pushbutton toggles between

hardware provisioning and software

provisioning

Off

Green

Yellow

Red

Green

Off

Module is in an on-hook or

idle condition

Module is in an off-hook or

busy condition

Module is in a digital or

metallic test

Module failure has been

detected

Module software provisioned

by Line Interface Unit (LIU)

Module hardware provisioned

by Dip Switches

SW3, and SW4

SW1, SW2,

When the FXS/DPO first powers up it performs the

power up self-tests. Once the power up self-test is

complete, the status LEDs will reflect the true state of

the hardware.

Front Panel LEDs

The FXS/DPO provides front panel LEDs to display

status information. See Table 2 for a listing of the front

panel LEDs and their indications.

Time Slot Assignment

For time slot assignments in the Dual T1 mode and in

the Quad T1 mode, see Tab le 3 on page 4. The Total

Access 1500 platform can have multiple time slots in

the T1 data stream assigned to each physical slot in the

channel bank. The Total Access 1500 allows craftselectable time slots using the electronic provisioning

interface. The system will automatically map DS0s in

the T1 as determined by the Line Interface Unit (LIU)

operational configuration. Manual mapping is available

via the LIU menu.

Connections

Four 50-pin male amphenol connectors on the 23-inch

Total Access 1500 backplane and three on the 19-inch

chassis packplane provide the interconnect wiring for

each of the access module physical slots. The FXS/DPO

requires

19-inch chassis, Slots 1-6 use

Slots 13-18 use

P1 (Pair 1 T/R) on the 23-inch chassis. In the

P1, Slots 7-12 use P2, and

P3. See Table 3 on page 4 for wiring

interconnect details.

3. PROVISIONING

Provisioning options are either hardware provisioned;

using DIP switches on the FXS/DPO printed circuit

board, or software provisioned; using the craft interface

(

ADMIN) on the System Controller Unit (SCU).

Selection of hardware or software provisioning is determined by the front panel recessed pushbutton

AP (see

Table 2).

61180403L1-5B Issue 2, December 2004 3

Page 4

Table 3. Time Slot and Wiring Interconnect

Associated T1/DS0

Physical

Slot

1 A1 A1 A1 1 P1 - 26/1 P1 - 26/1 T/R

2 A3 A5 A9 1 P1 - 27/2 P1 - 30/5 T/R

3 A5 A9 A17 1 P1 - 28/3 P1 - 34/9 T/R

4 A7 A13 A2 1 P1 - 29/4 P1 - 38/13 T/R

5 A9 A17 A10 1 P1 - 30/5 P1 - 42/17 T/R

6 A11 A21 A18 1 P1 - 31/6 P1 - 46/21 T/R

7 A13 B1 B1 1 P1 - 32/7 P2 - 26/1 T/R

8 A15 B5 B9 1 P1 - 33/8 P2 - 30/5 T/R

9 A17 B9 B17 1 P1 - 34/9 P2 - 34/9 T/R

10 A19 B13 B2 1 P1 - 35/10 P2 - 38/13 T/R

11 A21 B17 B10 1 P1 - 36/11 P2 - 42/17 T/R

12 A23 B21 B18 1 P1 - 37/12 P2 - 46/21 T/R

13 B1 C1 C1 1 P1 - 38/13 P3 - 26/1 T/R

Dual T1

Quad T1

(D4)

Quad T1

(D1D)

Port

Amphenol Connections

23” Chassis

1180001L1

19” Chassis

1180019L1

Interconnect

Wiring

14 B3 C5 C9 1 P1 - 39/14 P3 - 30/5 T/R

15 B5 C9 C17 1 P1 - 40/15 P3 - 34/9 T/R

16 B7 C13 C2 1 P1 - 41/16 P3 - 38/13 T/R

17 B9 C17 C10 1 P1 - 42/17 P3 - 42/17 T/R

18 B11 C21 C18 1 P1 - 43/18 P3 - 46/21 T/R

19 B13 D1 D1 1 P1 - 44/19 N/A T/R

20 B15 D5 D9 1 P1 - 45/20 N/A T/R

21 B17 D9 D17 1 P1 - 46/21 N/A T/R

22 B19 D13 D2 1 P1 - 47/22 N/A T/R

23 B21 D17 D10 1 P1 - 48/23 N/A T/R

24 B23 D21 D18 1 P1 - 49/24 N/A T/R

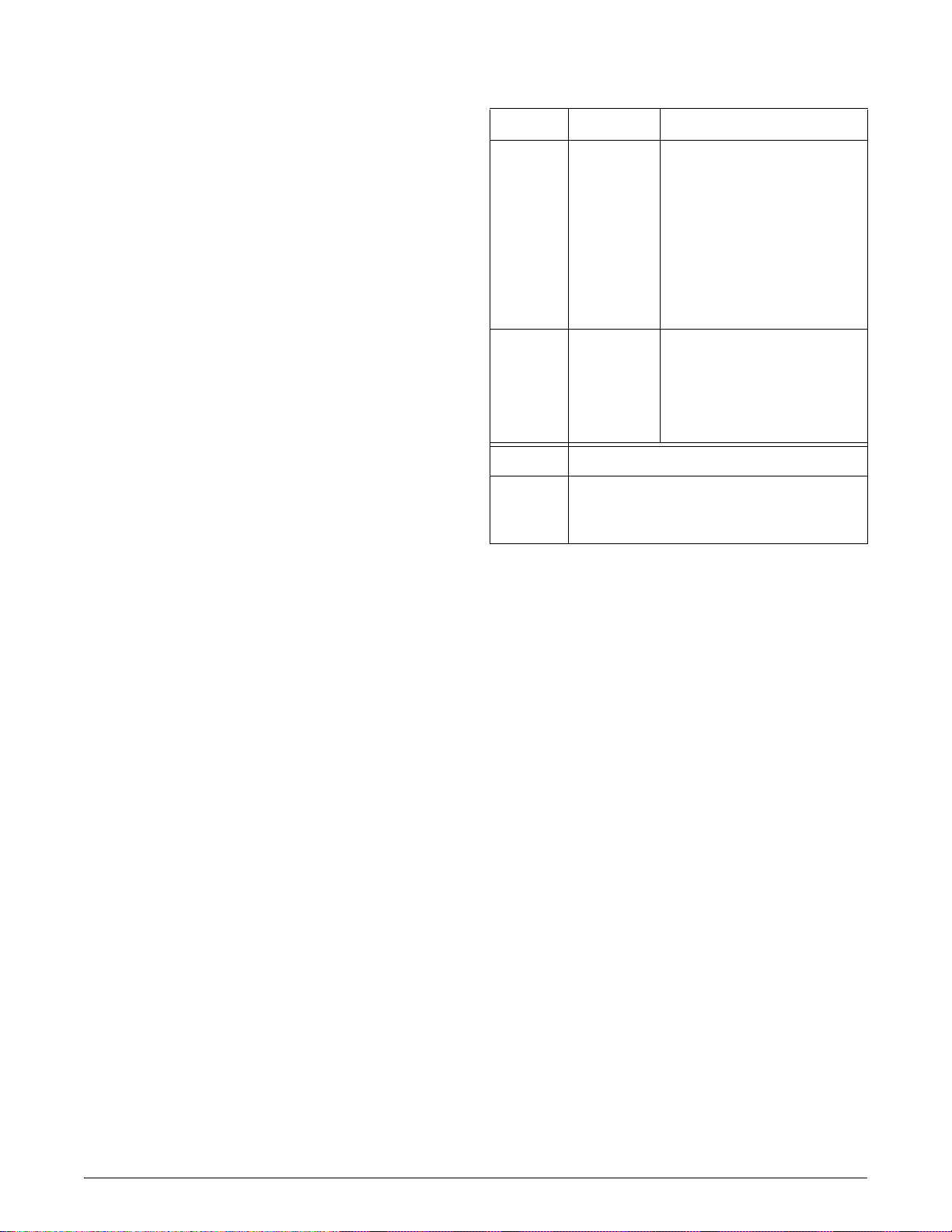

Hardware Provisioning

DIP switches

provision many of the FXS/DPO options. Tab le 4 on

page 5 summarizes the options provisioned by the DIP

switches. Figure 2 on page 6 provides a graphic detail

of the four switches and the printed circuit board

markings.

SW1, SW2, SW3, and SW4 are used to

NOTE

Manual switches can only be used for the

negative portion of the TLP range. For

example, a switch setting of TX32 corresponds

to –3.2 dB.

4 Issue 2, December 2004 61180403L1-5B

Page 5

Table 4. DIP Switches

Sw.-Segment Label Function/Description

1-1 D3/D4 D3 or D4 Signaling (PLAR only)

1-2

1-3

1-4 GS/LS Ground Start or Loop Start

1-5 AUTO_TERM/OFF Reserved for future use

1-6 900/600 Selects the Impedance of the 2-wire interface:

1-7 RTG/OFF Ringback Tone Generation (tandem and PLAR modes only)

1-8 DTG/OFF Dialtone Generation (tandem and PLAR modes only)

2-1 DPC/OFF Reserved for future use

2-2

2-3

2-4

2-5

2-6

2-7

2-8

MODE 1/OFF

MODE 2/OFF

RX64/OFF

RX32/OFF

RX16/OFF

RX08/OFF

RX04/OFF

RX02/OFF

RX01/OFF

SW1-2 SW1-3 Mode Selected

OFF OFF FXS

OFF MODE 2 DPO

MODE 1 OFF Tandem

MODE 1 MODE 2 PLAR

900 + 2.16 µF or 600 + 2.16 µF

Receive attenuation in 0.1 dB increments (values are additive up to a total

of 9.0 dB)

Example:

RX32 = 3.2 dB

RX01 = 0.1 dB

3.3 dB Total receive attenuation

3-1 SD/OFF Selects signaling on the loop during a Carrier Fail Alarm (CFA)

SD = Busy during CFA

OFF = Idle during CFA

3-2

3-3

3-4

3-5

3-6

3-7

3-8

4-1 IMM/WINK Tandem start mode: Immediate or Wink Start

4-2 REV/NORM Tandem battery mode: Reverse or Normal battery

4-3

4-4

4-5

4-6

4-7

4-8

TX64/OFF

TX32/OFF

TX16/OFF

TX08/OFF

TX04/OFF

TX02/OFF

TX01/OFF

NB64/OFF

NB32/OFF

NB16/OFF

NB08/OFF

NB04/OFF

NB02/OFF

Transmit attenuation in 0.1 dB increments (values are additive up to a

total of 7.0 dB)

Example:

TX32 = 3.2 dB

TX01 = 0.1 dB

3.3 dB Total transmit attenuation

Network Build Out Capacitance (NBOC) in 2 µF increments (values are

additive)

61180403L1-5B Issue 2, December 2004 5

Page 6

A

SW4SW3SW2SW1

12345678

D3

MODE 1

MODE 2

GS

UTO_TERM

900

RTG

DTG

12345678

ON

C & K

SD08

D4

OFF

OFF

LS

OFF

600

OFF

OFF

DPC

RX64

RX32

RX16

RX08

RX04

RX02

RX01

12345678

ON

C & K

SD08

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

SD

TX64

TX32

TX16

TX08

TX04

TX02

TX01

12345678

ON

C & K

SD08

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

IMM

REV

NB64

NB32

NB16

NB08

NB04

NB02

Switches SW1 through SW4 are used to select/deselect a particular “State” vice the labeled switch nomenclature of on/off.

Figure 2. DIP Switches Detail

ON

C & K

SD08

WINK

NORM

OFF

OFF

OFF

OFF

OFF

OFF

Software Provisioning

The FXS/DPO is provisioned by connecting a VT100

terminal or a computer running a terminal emulation

program to the craft interface

ADMIN port located on the

System Controller Unit (SCU) front panel. Connection

to the port is made via a RS-232, DB-9 cable with a

male connector.

Craft port settings are as follows:

• 9600 Baud

• No parity

• 8 Data bits

• 1 Stop bit

• No Flow Control

The provisioning options for the FXS/DPO access

module are described in the following tables:

• Tabl e 5 , FXS/DPO General Options on page 7

• Tabl e 6 , FXS/DPO Mode Options on page 8

• Tabl e 7 , FXS/DPO Tandem Options on page 9

Password and User ID

Password protection is a function of the SCU and is

factory disabled. If password authentication is enabled,

then the SCU will display the

Logon screen. A valid

User Name and Password are required to access the

menus.

The default User Name is “user”, and the default

Password is “password”. The User Name and Password

are not case sensitive.

Menu Navigation

To traverse through the menus, select the desired entry,

and press

the

ENTER. To work backward in the menu, press

ESC (escape) key.

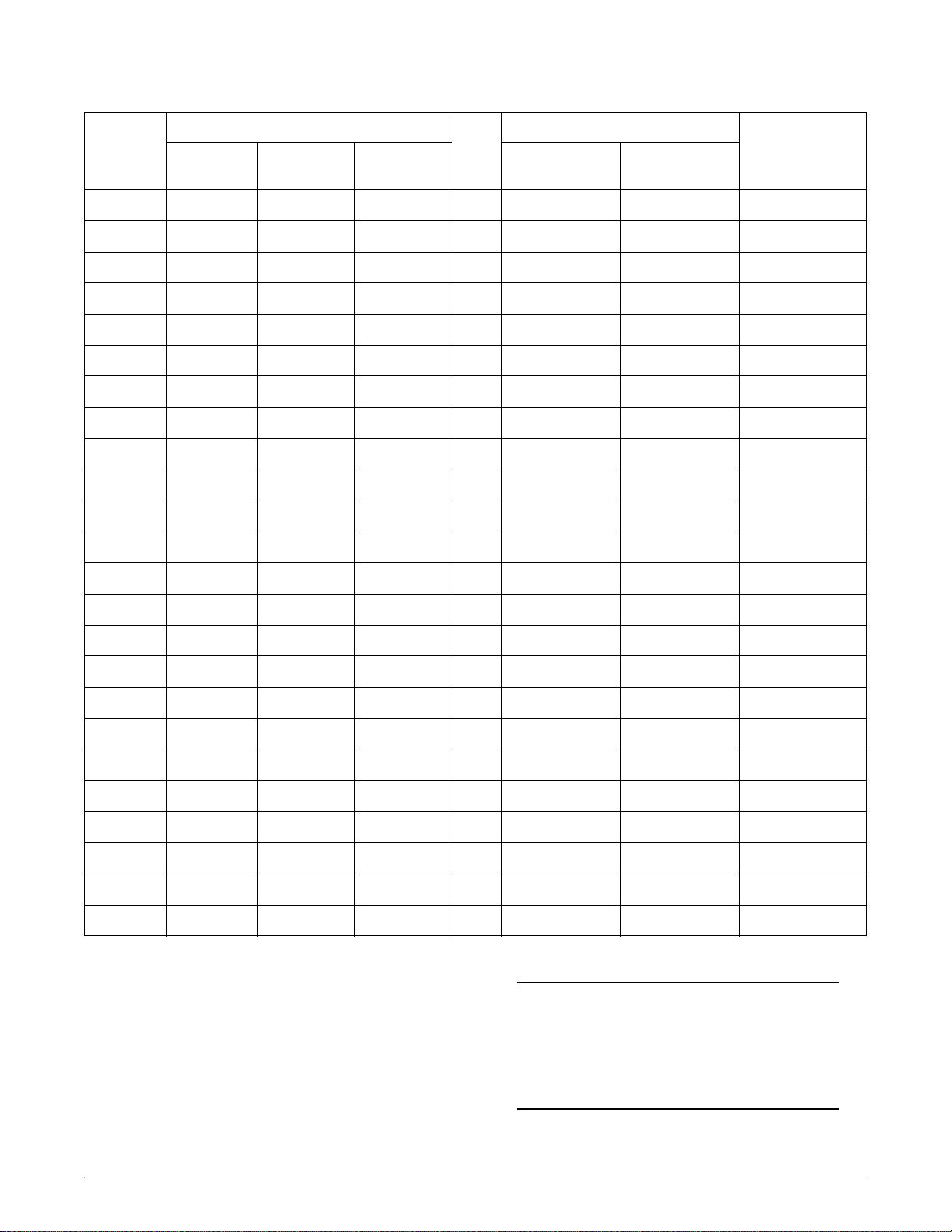

The menu tree in Figure 3 on page 10 illustrates the

path to every provisioning, performance, and test access

point in the Total Access 1500 FXS/DPO menu

6 Issue 2, December 2004 61180403L1-5B

Page 7

.

Table 5. FXS/DPO General Options

Function Option Description

Mode Loop Start

Ground Start

TR08 Single Party

TR08 Universal VG

TR08 Auto

(3)

(3)

(3)

This option selects the signaling mode of the FXS/DPO.

See Table 6 for detailed descriptions of Mode Options.

PLAR D4

PLAR D3

Tand em

(3)

DPO

FX Ringdown

TO w/SC

2-Wire Termination 600 ohms + 2.16 µF

900 ohms + 2.16 µF

(3)

(3)

This option selects the impedance of the 2-wire

interface.

Transmit TLP –7.0 to +9.0 dB (+0.0) This is the transmit channel attenuation in 0.1 dB steps.

Receive TLP –9.0 to +0.0 dB (+0.0) This is the receive channel attenuation in 0.1 dB steps.

Trunk Processing Busy in CFA

Idle in CFA

On-Hook Messaging Disabled

Enabled

This option selects signaling on the loop during a

Carrier Fail Alarm (CFA).

When On-Hook Messaging is Disabled, full battery

voltage is provided to the loop when on-hook. This is

utilized to provide compatibility with some station sets.

Note that except for Caller ID, this prevents

transmission in the on-hook state. When Enabled, a

small amount of overhead voltage is reserved for AC

transmission.

NBOC 0 - 126 µF (0 µF) This option selects setting for Network Build Out

Capacitance to balance the FXS/DPO access module to

the loop. Setting should be equivalent to the additional

capacitance added due to the length of the cable.

Tandem Mode Options

(1)

Conversion Mode

Supervision

See Table 7 for a detailed description of Tandem

options.

Tandem Battery

Dial Tone Generation

Ringback Tone Generation

Forward Disconnect

DNIS Protocol

(4)

This option is used in PLAR D3, PLAR D4, or FX

Ringdown modes only. When Enabled, the FXS/DPO

Ringback Tone Generation

(2)

DNIS Delay

Disabled

Enabled

provides ringback tone toward the Network.

Defaults are in bold type.

(1)

Only available if Tandem Mode is selected.

(2)

Only available if PLAR D3, PLAR D4, or FX Ringdown Mode is selected.

(3)

Only provisionable through software provisioning (reference Software Provisioning on page 6).

(4)

Only available if DNIS Protocol is set to DNIS Enabled or DNIS Enabled-No Answer.

61180403L1-5B Issue 2, December 2004 7

Page 8

Table 6. FXS/DPO Mode Options

Mode Description

Loop Start This option selects ANSI T1.403 FXS Loop Start mode of operation.

Ground Start This option selects ANSI T1.403 FXS Ground Start mode of operation.

TR08 Single Party This option selects GR-08-Core Loop Start mode of operation.

TR08 Universal VG This option selects GR-08-Core Ground Start mode of operation.

TR08 Auto This option selects automatic detection of TR08 Single Party or TR08 Universal VG, based

on incoming signalling.

PLAR D4 This option selects Private Line Automatic Ringdown where onhook = 00. Signaling must

match the PLAR unit at the distant end.

PLAR D3 This option selects Private Line Automatic Ringdown where onhook = 11. Signaling must

match the PLAR unit at the distant end.

Tandem This option selects A/B signaling on the Network side for use with a Class 4 Tandem switch.

DPO This option selects Dial Pulse Originate for Direct-Outward Dial applications.

FX Ringdown This is the PLAR mode of operation that allows for a FXS Loop Start unit on the distant end.

TO w/SC This option disables signaling for Transmission Only with Sealing Current enabled. Used in 2

w/TO applications where the Network Customer Termination Equipment (NCTE) or

Customer premise equipment provide for termination of the sealing current (sealing current

sink).

8 Issue 2, December 2004 61180403L1-5B

Page 9

Table 7. FXS/DPO Tandem Options

Function Option Description

Conversion Mode Tandem Inactive

Loop Start

Ground Start

Supervision Immediate Start

Wink Start

Tandem Battery Normal Battery

Reverse Battery

Dial Tone Generation Disabled

Enabled

RingBack Tone

Generation

Disabled

Enabled

This option sets the conversion from E&M (2-state) signaling

on the PCM interface to loop start or ground start signaling on

the loop. This option MUST be configured for channel

operation, as the default value (Tandem Inactive) will not run

the state machine.

This option configures the E7M trunk as immediate or wink

start for both the RX and TX direction. With wink start, a

wink is sent back to the network from the FXS/DPO card

before ringing to signal line seizure for inbound calls. For

outgoing calls, a wink must be received from the switch to the

FXS/DPO card to indicate trunk seizure for the call.

This option configures answer supervision for the associated

voice port. Answer supervision is indicated by reverse battery

polarity when Reverse Battery option is set. This is valid for

outbound calls only.

This option is used to generate a 5-second dial tone from the

associated FXS/DPO port when off-hook is detected. The dial

tone provided by the FXS/DPO times out after 5 seconds and

is not broken by digit input.

When this option is enabled, a ringback tone is provided

toward the Network.

Forward Disconnect 250 msec

500 msec

This option configures the amount of time battery is removed

during far-end disconnect.

750 msec

1 second

2 seconds

DNIS Protocol Disabled

DNIS Enabled

This option selects or deselects DNIS support for appropriate

voice/data port applications.

DNIS Enabled - No Answer

DNIS Delay* 0.5 seconds

1.0 second

1.5 seconds

When DNIS is activated, this option defines the delay time

between the transmitted DNIS wink, which signals off-hook/

loop closure, and the off-hook sent in signaling bits.

2.0 seconds

2.5 seconds

3.0 seconds

3.5 seconds

4.0 seconds

* Only available if DNIS Protocol is set to Enabled or Enabled-No Answer.

61180403L1-5B Issue 2, December 2004 9

Page 10

Figure 3. FXS/DPO Menu Tree

1. Configuration

2. Provisioning

Unit Name

CLEI Code

Part Number

Software Revision

1. Mode

2. 2-Wire Termination

3. Transmit TLP

4. Receive TLP

5. Trunk Processing

6. On-Hook Messaging

7. NBOC

8. Tandem

8. Ringback Tone Generation

(1)

1. 600 + 2.16

2. 900 + 2.16

Enter Value (-7.0...+9.0)

Enter Value (-9.0...+0.0)

1. Busy in CFA

2. Idle in CFA

1. Disabled

2. Enabled

Enter Value (0...126)

1. Disabled

(2)

2. Enabled

1. Conversion Mode

2. Supervision

3. Tandem Battery

4. Dial Tone Generation

5. Ringback Tone Generation

6. Forward Disconnect

7. DNIS Protocol

8. DNIS Delay

(3)

1. Tandem Inactive

2. Loop Start

3. Ground Start

1. Immediate Start

2. Wink Start

1. Normal Battery

2. Reverse Battery

1. Disabled

2. Enabled

1. Disabled

2. Enabled

1. Disabled

2. DNIS Enabled

3. DNIS Enabled - No Answer

1. Loop Start

2. Ground Start

3. TR08 Single Party

4. TR08 Universal VG

5. TR08 Auto

6. PLAR D4

7. PLAR D3

8. Tandem

9. DPO

10. FX Ringdown

11. TO w/SC

1. 250 msec

2. 500 msec

3. 750 msec

4. 1 second

5. 2 seconds

1. 0.5 seconds

2. 1.0 seconds

3. 1.5 seconds

4. 2.0 seconds

5. 2.5 seconds

6. 3.0 seconds

7. 3.5 seconds

8. 4.0 seconds

3. Status

4. Test

(1) Only appears if Tandem Mode is selected.

(2) Only appears if PLAR D3, PLAR D4, or FX Ringdown Mode is selected.

(3) Only appears if DNIS Protocol is enabled.

1. Digital Network Loopback

2. 1004 Hz Tone Test

3. Network Hook Test

4. Customer Ringing Test

1. No Test

2. On-Hook

3. Off-Hook

1. Inactive

2. Active

1. No Test

2. Ringing

1. No Test

2. To Network

3. To Loop

4. To Loop and Network

1. Circuit

2. Mode

3. 2-Wire Termination

4. Transmit TLP

5. Receive TLP

6. Trunk Processing

7. On-Hook Messaging

8. NBOC

9. Signal Bits Tx/Rx

10. Digital Test

Page 11

4. TEST FEATURES

The FXS/DPO supports the following tests for each

port:

5. MAINTENANCE

The Total Access FXS/DPO does not require routine

maintenance for normal operation.

• Digital Network Loopback

• 1004 Hz Tone Generation

• Network Hook Test

• Customer Ringing Test

These test are used to support circuit turn-up and

maintenance efforts. Test functions can be activated

locally via the

ADMIN port on the SCU, or remotely via

Telnet or SNMP and are initiated on an individual port

basis. The test are described below.

Digital Network Loopback Test

The Digital Network Loopback test activates a

loopback path that takes the DS0 data received from the

network and transmits it back to the network in the

appropriate transmit time slot.

1004 Hz Tone Generation Test

The 1004 Hz Tone Generation Test generates a 1004 Hz

Digital Reference Signal (DRS) tone toward the T1

network (0 dBm fixed), toward the customer loop (RX

TLP setting), or both directions simultaneously. While

sending the DRS tone toward the customer loop the

transmit audio path (towards the T1 network) will be

interrupted.

Network Hook Test

The Network Hook Test forces the AB signaling states

towards the T1 network. The bits are set based upon the

operating mode of the channel unit.

ADTRAN does not recommend that repairs be

attempted in the field. Repair services may be obtained

by returning the defective unit to ADTRAN. Refer to

the Warranty and Customer Service section for further

information.

6. SPECIFICATIONS

Specifications for the Total Access FXS/DPO are

detailed in Tabl e 8 on page 12.

7. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within the

warranty period if it does not meet its published specifications or fails while in service. Warranty information

can be found at www.adtran.com/warranty

.

Refer to the following subsections for sales, support,

Customer and Product Service (CAPS) requests, or

further information.

ADTRAN Sales

Pricing/Availability:

800-827-0807

ADTRAN Technical Support

Pre-Sales Applications/Post-Sales Technical

Assistance:

800-726-8663

Standard hours: Monday - Friday, 7 a.m. - 7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

Customer Ringing Test

The Customer Ringing Test will activate the ports ring

relay in a 2-second on and 4-second off cadence,

ADTRAN Repair/CAPS

Return for Repair/Upgrade:

(256) 963-8722

providing ringing toward the customer’s loop.

Repair and Return Address

NOTE

The tests cannot run simultaneously. If a test is

in progress and another test is initiated, the first

test will be terminated when the new test starts.

Contact CAPS prior to returning equipment to

ADTRAN.

ADTRAN, Inc.

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

61180403L1-5B Issue 2, December 2004 11

Page 12

Table 8. Specifications

Performance

Loop Current:

Transmit TLP:

Receive TLP:

Terminating Impedance:

Return Loss:

TransHybrid Loss:

Longitudinal Balance:

Frequency Response:

Idle Channel Noise:

PCM Encoding/Decoding:

DC Supervisory Range:

Power

Current Draw: 0.034 amps maximum @ –48 VDC

23 mAmp nominal

20 mAmp minimum

–7.0 to +9.0 dBm

–9.0 to 0.0 dBm

900 ohms +2.16 µF

600 ohms +2.16 µF

ERL ≥ 28 dB

SRL ≥ 20 dB

ERL ≥ 34 dB

SRL ≥ 20 dB

≥ 58 dB @ 200 to 1000 Hz

≥ 53 dB @ 3000 Hz

±0.25 dB @ 300-3000 Hz

≤ 20 dBrnCO

µ-law

1250 ohms

Physical

Dimensions:

Weight:

Environment

Operating Temperature:

Storage Temperature:

Relative Humidity:

Maximum Heat Dissipation:

Compliance

Regulatory Agency Requirements: UL 60950

Part Number

Total Access 1500 Foreign Exchange Station/Dial

Pulse Originate Access Module:

Height: 3.125 inches

Width: 0.62 inches

Depth: 10.1 inches

< 0.5 pound

–40°C to 65°C

–40°C to 85°C

95 percent maximum @ 50°C, noncondensing

1.389 watts maximum

NEBS Level 3

FCC 47CFR Part 15, Class A

1180403L1

12 Issue 2, December 2004 61180403L1-5B

Loading...

Loading...