ADS Environmental Services QR 775027 A3 User Manual

ADS Intrinsically-Safe TRITON+™

Installation, Operation, and

Maintenance Manual

November 2014 QR 775027 A3

1300 Meridian Street, Suite 3000

Huntsville, Alabama 35801

(256) 430-3366

www.adsenv.com

ii ADS TRITON+ Manual

2014 ADS

LLC. All rights reserved.

ADS , ADS Environmental Services, IntelliServe,

TRITON+

, XBUS, XIO, and Qstart are either trademarks or

registered trademarks of ADS LLC.

Microsoft, Windows, and Excel are registered trademarks of

Microsoft Corporation.

Scotchkote is a trademark of 3M.

Teflon is a registered trademark of E.I. du Pont de Nemours and

Company.

Telit is a registered trademark of Telit Communications PLC.

All other brand and product names are trademarks or registered

trademarks of their respective holders.

Notice of Proprietary Information

The information contained herein represents the latest information

available at the time of publication. ADS LLC reserves the right to

make any changes or modifications to the content of this document,

without notice, to reflect the latest changes to the equipment. No

part of this document may be reproduced in any form without the

written consent of ADS LLC.

Table of Contents iii

Table of Contents

Chapter 1 Introduction…….. ..................... 1-1

Intrinsic Safety ............................................................... 1-2

TRITON+ System Certification .............................. 1-3

Installation and IS Considerations .......................... 1-5

Special Conditions for Safe Use ............................. 1-6

Other Conditions for Safe Use ................................ 1-7

Maintenance Restrictions ............................................... 1-8

Warnings, Certifications, Cellular Modem

Compliance, and Conformity ......................... 1-10

Changes or Modifications ..................................... 1-10

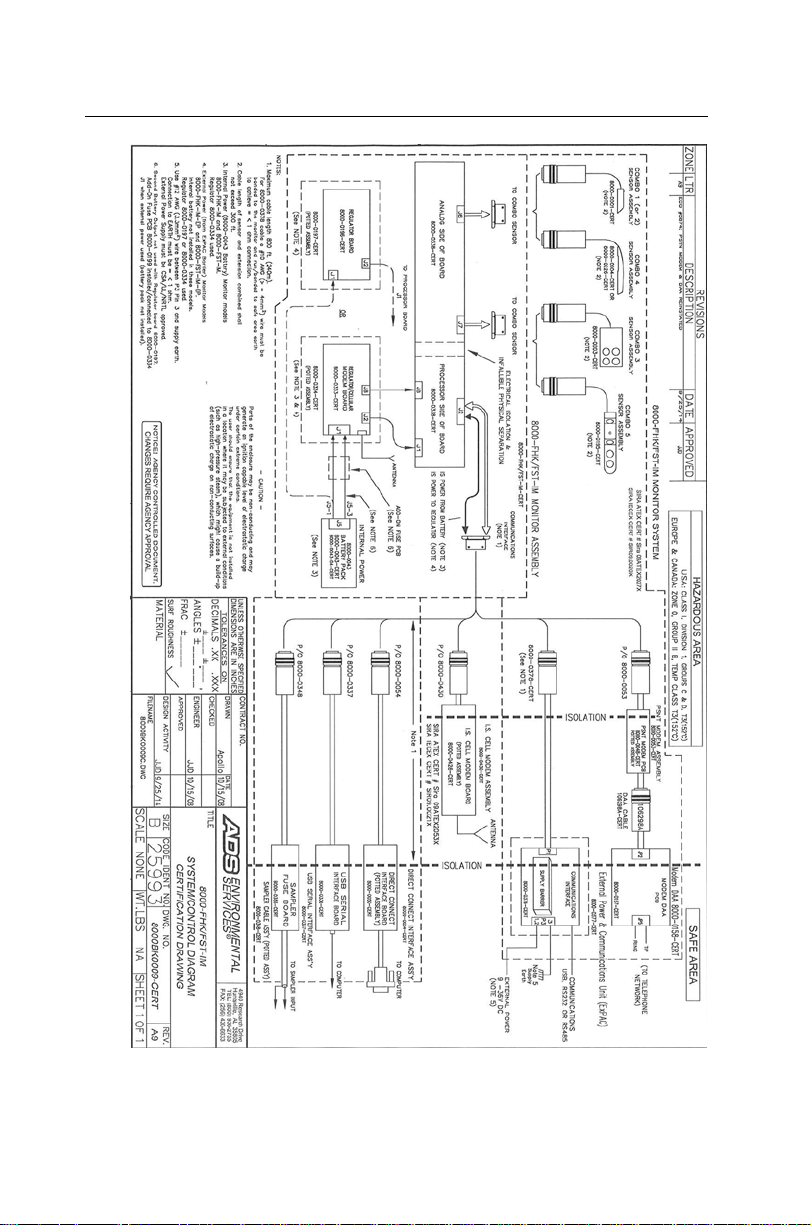

Control Drawing ................................................... 1-11

European ATEX Hazardous Area Compliance ..... 1-13

IECEx (International Electrotechnical

Commission Explosive) Hazardous Area

Compliance .................................................... 1-19

CSA Hazardous Area Compliance ........................ 1-21

Declaration of Conformity .................................... 1-24

Installation and Configuratio n ...................................... 1-26

Product Warranty ......................................................... 1-28

New Product Warranty .......................................... 1-28

Out-of-Warranty Product Repairs ......................... 1-28

Troubleshooting Fee ............................................. 1-29

Shipping ................................................................ 1-29

Service .................................................................. 1-30

Chapter 2 System Overview ..................... 2-1

TRITON+ Flow Monitor ................................................ 2-4

Communications ..................................................... 2-4

Processor Board ...................................................... 2-5

Connector Ports ....................................................... 2-7

SIM Card Enclosure ................................................ 2-8

Power .................................................................... 2-10

Sensors ......................................................................... 2-15

Peak Combo Sensor .............................................. 2-15

Ultrasonic Depth Sensor ....................................... 2-18

Surface Combo Sensor .......................................... 2-19

iv ADS TRITON+ Manual

I/O and Modbus Capability .......................................... 2-23

Analog Inputs and Outp uts.................................... 2-23

Digital Inp uts and Outp uts .................................... 2-24

Modbus ................................................................. 2-24

Chapter 3 Sensor Installation and

Investigating Site Characterist ic s ................................... 3-4

Flow Hydraulics ...................................................... 3-4

Pipe and Manhole Characteristics ........................... 3-5

Installing the Sensors in the Pipe ................................... 3-7

Standard Installation ............................................... 3-7

Special Installations .............................................. 3-38

Securing the Sensor Cables in the Pipe and Manhole .. 3-64

Connecting the Sensors and Sampler to the Monitor ... 3-67

Securing the Dryer Tub e to the Monitor ............... 3-69

Chapter 4 Communication…… ................. 4-1

Cellular-Based Wireless Communication ...................... 4-3

Installing the Antenna and SIM Card ............................. 4-5

Gathering Parts and Supplies .................................. 4-5

Installing the Wireless Antenn a .............................. 4-7

Installing the SIM Card ......................................... 4-11

Connecting the Antenna to the Monit or ................ 4-14

Connecting t o the Monitor in the Field ........................ 4-16

Connecting Directly to the Monitor ...................... 4-17

Connecting t o the Monitor through t he ExPAC .... 4-18

Connection.. ..................... 3-1

Chapter 5 External Power……. ................. 5-1

Installation ...................................................................... 5-2

DC Power Requirements and Consumption ............ 5-3

Mounting the XIO or XBU S ................................... 5-4

Mounting the Recommended Power Supply ........... 5-6

Mounting the ExPAC ............................................ 5-10

Wiring the AC Power Source to the

Recommended Power Supply ........................ 5-15

Wiring the Power Suppl y to the ExPAC ............... 5-18

Running the Ground Wires ................................... 5-22

Table of Contents v

Wiring the ExPAC/XBUS/XIO to the Monitor .... 5-29

Final Instructions .................................................. 5-36

Chapter 6 Configuration and Activation .. 6-1

Hardware and Software Compatibility .................... 6-2

Starting Qstart ......................................................... 6-2

Setting Up the Qstart Parameters ............................ 6-3

Configuring the Monitor Location ................................. 6-7

Create and Configure the Monitor Location ........... 6-7

Configure the Monitoring Point(s) ........................ 6-10

Assigning and Editing Devices ............................. 6-12

Activating the Monitor ................................................. 6-72

Setting Up the RTU to Retrieve the Current Data

through Modbus ............................................. 6-74

Designating the Data for Retrieval ........................ 6-74

Verifying the Modbus Output Data ....................... 6-74

Running Se nsor Diagnostics ........................................ 6-76

Performing Confirmations............................................ 6-79

Collecting Data from the Monitor ................................ 6-82

Upgrading the Monitor Firmware ................................ 6-85

Viewing Diagnostic and Data Logs.............................. 6-87

Chapter 7 Monitor Installation .................. 7-1

Mounting the Monitor on Manhole R ung ...................... 7-3

Mounting the Monitor to the Manhole Wall .................. 7-4

Mounting the Monitor to the Manhole Rim ................... 7-7

Chapter 8 Analog and Digital Inputs and

Outputs…….. .................... 8-1

Analog Inputs ................................................................. 8-3

Connecting a Third-Party Instrument to an

Analog Input on the XIO ................................. 8-3

Analog Outputs .............................................................. 8-8

Connecting a Third-Party Device to an Analog

Output on the XIO ........................................... 8-8

Digital Inputs ................................................................ 8-13

Connecting a Third-Party Device to a Digital

Input on the XIO ............................................ 8-13

vi ADS TRITON+ Manual

Digital Outputs ............................................................. 8-16

Connecting a Third-Party Device to a Digital

Output on the XIO ......................................... 8-16

Chapter 9 Modbus………….. ..................... 9-1

Establishing a Modbus Connectio n ................................ 9-2

Setting Up a Serial Connection ............................... 9-2

Setting Up a Wireless Connection .......................... 9-9

Configuring the Monitor for Modbus Applications ..... 9-10

Modbus Data Registers ................................................ 9-11

Register Addresse s for Entit y Data ....................... 9-11

Chapter 10 Maintenance and

Maintaini ng the System Components........................... 10-2

Gathering Replacement Parts and Supplies........... 10-2

Inspecting the Monitor .......................................... 10-3

Inspecting, Cleaning, and Handling the

Sensors ......................................................... 10-18

Replacing the SIM Card ...................................... 10-21

Replacing the Fuses in the Monitor..................... 10-25

Interpret ing the Diag nostic LED Codes on the

ExPAC ......................................................... 10-31

Troubleshooting ......................................................... 10-33

General Monitor Problems .................................. 10-34

Communication Problems ................................... 10-38

Ultrasonic Depth Subsystem ............................... 10-42

Upward Depth Subsystem ................................... 10-47

Peak Velocity Subsystem .................................... 10-50

Surface Velocity Subsystem ............................... 10-53

Pressure Depth Subsyst em .................................. 10-55

Temperature Subsystem ...................................... 10-56

External Power, I/O, and Modbus S ubsystems ... 10-57

Troubleshooting ............ 10-1

Appendix A Specifications… .................... A-1

TRITON+ Flow Monitor ............................................... A-1

Intrinsically-Safe Sensors .............................................. A-5

USB Serial Interface ................................................... A-10

Table of Contents vii

ExPAC ........................................................................ A-11

Power Supply .............................................................. A-12

XBUS .......................................................................... A-13

XIO ............................................................................. A-14

Appendix B Part Numbers……. ................ B-1

Appendix C Monitor Activity Codes ......... C-1

Appendix D System Configuration and

Setup to Support the

Telog Ru-33……. .............. D-1

Configuring the Monitor to Support the Ru-33 ............. D-2

Connecting the Monitor to the Ru-33 ............................ D-2

C H A P T E R 1

Introduction

The ADS Intrinsically-Safe TRITON+™ flow monitor measures

open channel flow in sanitary sewers, storm sewers, combined

sewers, and other environments to assist municipalities and other

industry in addressing the following issues:

Planning sewer systems (sizing and rehabilitation)

Reducing infiltration and inflow (I/I)

Monitoring combined sewer overflows (CSOs)

Detecting and monitoring surchar ges

1-1

Managing inter-agency billing

Monitoring sewage handling facilities (wastewater treatment

plants and pump stations)

The battery- or externally-powered TRITON+ monitor provides

exceptional accuracy and reliability in measuring open-channel flow

depth and velocity to determine flow rate (quantity) in pipes. This

flow data is the essential element required to successfully p er form

investigative, analytical, and reporting activities.

This manual offers detailed instructions on installing, operating,

maintaining, and tr oubleshooting the TRITON+ flow monitor,

sensors, and communication hardware.

1-2 ADS TRITON+ Manual

United States

Germany

Poland

Australia

Hungary

Romania

Canada

Italy

Singapore

China

Japan

Slovenia

Croatia

Korea

South Africa

Finland

New Zealand

Turkey

France

Norway

United Kingdom

Intrinsic Safety

Intrinsic safety is an electronic hardware pr o tection concept that

ensures there a re no conditions under which the equipment can

operate that could cause a release of energy sufficient to ignite a

hazardous gas or dust mixture. Devices that meet the low power,

current-limited design criteria are deemed Intrinsically Safe (IS).

Special design, testing, quality, and inspection rules apply to

manufacturers and users of IS equipment due to the critical nature

of its deployment in hazardous areas. Areas where hazardous

conditions can be expected to be present on a constant basis are

classified (rated) as Zone 0 (equivalent to Class I, Division 1, in

North America).

The TRITON+ flow monitor (Model 8000-FST-IM) is certified for

use in North America in areas where the Class/Division system is

observed. The TRITON+ has been tested to worldwide IECEx

(International Electrotechnical Commission Explosive) standards

and is certified for use in areas requiring Class I, Division 1,

equipment. The IECEx scheme allows demonstrated compliance

for use in Zone 0 (equivalent to Class I, Division 1, in North

America) areas in the following countries:

Brazil India Russia

Czech Republic Malaysia Sweden

Denmark Netherlands Switzerland

The TRITON+ has also been certified for use in Zone 0 via testing

to ATE X (Atmosphere Explosibles) standards. It is certified to

ATEX standards in Europe and for use in all classified (hazardous)

sanitary sewer and industrial hazardous areas. Many rest-of-world

countries accept ATEX certification in lieu of their country-specific

requirements.

The TRITON+ flow monitor has been tested to CSA (Canadian

Standards Association) standards and certified for use in Canada in

Intrinsically Safe and Non-Incendive Systems – For Hazardous

Locations. The CSA certification allows demonstrated compliance

for use in Ex ia IIB T3 (152 C) areas in Canada.

It is the customer’s responsibility to ensure that the certification(s)

provided for the ADS equipment meets the applicable regulatory

requirements.

Note: TRITON+ models include the 8000-FST-IM and

8000-FST-IM-EP.

TRITON+ System Certification

Introduction 1-3

The TRITON+ unit and associated telemetry equipment are

certified for use only with approved ADS battery packs, sensors,

communication cables, and telemetry equipment. Connection of

any non-approved devices could result in unsafe operation and will

immediately void the warranty and IS certification.

Note: Connecting the Telog® Ru-33 to the ADS

TRITON+ is an approved application and, therefore, will

not void the TRITON+ warranty. However, because the

Telog unit is not IS certified, the installation will not be

considered intrinsically safe if the Ru-33 is installed in the

manhole with the monitor.

1-4 ADS TRITON+ Manual

Sensors

The TRITON+ monitor supports several approved IS sensors that

vary in measurement methodology, redundancy, and other features.

The monitor is approved for accommodating up to two of the same

or different types of IS sensors. Following are the approved IS

sensors:

Peak Combo Sensor Performs upward ultrasonic depth,

pressure depth, and peak velocity measurement and mounts at

or near the bottom of the pipe under the flow surface (ADS p/n

8K-CS4-05-35, 8K-CS4-15-35, or 8K-CS4-30-1H).

Surface Combo Sensor Performs downward ultrasonic

depth, surcharge pressure depth, surcharge peak velocity, and

surface velocity measurement and mounts at the top (or crown)

of the pipe above the flow (ADS p/n 8K-CS5-V2-05-30, 8KCS5-V2-15-30, or 8K-CS5-V2-30-1H).

Ultrasonic Depth Sen sor Performs downward ultrasonic

depth measurement alone and mounts at the top (or crown) of

the pipe above the flow (ADS p/n 8K-CS5-D1-00-30).

Extension cables are available for these sensors in lengths up to a

maximum of 300 feet (91 m). .

Note: Detailed descriptions and specifications for the

sensors are available in Chapter 2, System Overview, and

Appendix A, Specifications

Power

The TRITON+ flow monitor is powered by an internal 12-volt IS

battery pack (ADS p/n 8000-0043) or an external DC power source

through an external power and communications unit (ExPAC, ADS

p/n 8000-0377), external Modbus interface unit (XBUS

9000-0427), or an external i nput/output device (XIO

8000-0400).

Note: Using a battery pack that is not supplied by ADS

will void the warranty and IS certification of the monitor.

™

™

, ADS p/n

, ADS p/n

Introduction 1-5

Telemetry

Wireless communication is available to the TRITON+ monitor

through an antenna and internal UMTS/HSPA+/GSM modem. The

antenna through which wireless communication occ urs may be

located either inside or outside the manhole; however, ADS

recommends installi ng the antenna outside the manhole to maximize

signal strength.

Many antennas are available to mitigate signal strength issues.

While ADS offers two proven antenna options, customers also may

obtain their own antennas to accommodate specific project needs or

requirements. However, when assessing a third-party antenna,

please consult an ADS or IETG, as applicable, representative prior

to installing the antenna to verify the antenna can adequately

support monitor communications.

Connecting the TRITON+ to the Telog RTU (Model Ru-33) also

supports wirel ess communication via the Telog “passthrough”

mode. The Telog is mounted next to the TRITON+ in the

hazardous area and connected to the monitor using the Triton-Telog

Comm Cable (ADS p/n 8000-0054-01). However, please note that,

because the Telog unit does not possess IS certification, the

installation will not be considered intrinsically safe if the Telog unit

is installed in the manhole with the monitor.

Installati on a nd IS Considerations

When installing the TRITON+ flow monitor, carefully follow any

local regulations for the installation of IS equipment. For example,

many clients only allow the use of special hazardous area tools

(flashlights, radios, etc.) in manholes. Some clients will not allow

the use of an electric drill, either battery-powered or AC-powered,

in a manhole. In this case, air (i.e., pneumatic) tools must be used.

When in doubt as to the applicable regulations, check with the client

or the client’s designated safety representative.

1-6 ADS TRITON+ Manual

Special Conditi ons f or Safe Use

During the ATEX /IECEx/CSA approval process, certain conditions

are set fort h t hat must be observed when using the certified

equipment. These Special Conditions for Safe Use can be found in

the body of each certification (referenced in this manual), as well as

on a page attached to the Declaration of Conformity. Following is a

summary of these Safe Use Instructions:

Parts of the enclosure may be non-conducting and may generate

an ignition-capable level of electrostatic charge under certain

extreme conditions. Therefore, do not install this equipment in

a location where it may b e subject to external conditions (such

as high-pressure steam or dust) that may cause a buildup of

electrostatic charge on non-conducting surfaces.

As aluminum is used at the accessible surface of this unit, in the

event of rare incidents, ignition sources due to impact and

friction sparks may occur. This shall be considered when it is

being installed, particularly in locations that require equipment

with a Group II Ga level of protection.

The equipment (ADS Model 8000-FST-IM) shall be used in

the hazardous area only when fully assembled. Do not perform

any maintenance of internal parts, replacement of battery packs,

or replacement of fuses unless the unit is located in a safe area.

Applicable to the USB Serial Interface : Measures shall be

taken to limit transient over voltages to the USB Serial

Interface to an appropriately low level in accordance with

Overvoltage Category 1 (IEC 60664-1).

The equipment shall be installed as per installation drawing

8000BK0009.

The External Power and Communications Unit (ExPAC) may

only be mounted in a non-hazardous location.

The IS Modem DAA is only permitted to be connected to a

“Public Switched Telephone Netwo rk”.

The 8000-FHK/FST-IM Monitor Assembly common line is

connected to the metal enclosure. Therefore, when it is

powered by the “External Power and Communications Unit”

(ExPAC), the Monitor Assembly shall be bonded to the ExPAC

earth with a conductor having a minimum cross-sectional area

of 4 mm

2

, to achieve a resistance ≤1 Ω.

Other Conditions f or Sa fe Use

The ADS Model 8000-FST-IM shall use only the 12-volt IS

Battery Pack (ADS p/n 8000-0043) for internal power.

Only ADS-approved sensors shall be connected to the ADS

Model 8000-FST-IM: ADS sensor types 8K-CS4 and 8K-CS5.

The only communication devices that may be connected to the

COMM + EXT PWR connector on the TRITON+ are the

USB Serial Interface (ADS p/n 8000-0337), the

ExPAC/XBUS/XIO power cable (ADS p/n 8000-378-10/25),

the Direct Connect Interface (ADS p/n 8000-0054), and the

Sampler Cable (ADS p/n 8000-0348).

Introduction 1-7

Note: The Triton-Telog Comm Cable (ADS p/n 8000-

0054-01) also may be connected to the COMM + EXT

PWR connector on the TRITON+ to provide

communication between the Telog Ru-33 and the monitor.

However, because the Ru-33 is not certified for IS

operation, an installation involving a connection between

these units will not be considered intrinsically safe, unless

the Telog unit is installed outside the hazardous area.

1-8 ADS TRITON+ Manual

Maintenance Restrictions

As mentioned earlier, all ADS TRITON+ flow monitors are

manufactured to meet IS standards. The monitor’s IS certification

can be voided instantly if proper maintenance and service

procedures are not followed. ADS must restrict certain

maintenance tasks to ADS IS-certified technicians.

ADS-certified technicians carefully inspect and document their

repairs of IS monitors. This inspection and documentation process

provides legal protection should the monitor's performance or safety

be in question.

If you experience trouble with this equipment, please refer to this

manual for troub l eshooting guidel ines. The following maintenance

procedures may be performed in the field, but they must be

performed as described in this manual:

Installing and swapping monitor

Installing and swapping sensors

Installing and swapping battery pack

Swapping fuses in power regulator in monitor

Installing and swapping SIM card on monitor port

Replacing pressure depth sensor dryer tube and desiccant beads

Installing and swapping ExPAC (applicable only when not

housed within an XBUS or XIO), XBUS, or XIO

Cleaning sensors

Confirming sensors

Note: Please note that, in all applications, only ADS IScertified Service Technicians are authorized to perform

component-level service on the TRITON+.

If you have any questions about the procedures, warranty

information, or level of service you are allowed to perform on a

Introduction 1-9

monitor, please contact ADS (or IETG, when applicable) through

the contact information listed at the end of this chapter.

1-10 ADS TRITON+ Manual

Warnings, Certifications, Cellular Modem Compliance, and Conf ormity

Manhole and sewer system work involves confined space entry and

is inherently dangerous. Therefore, installers and technicians

should comply with all federal, state, and municipal regulations

concerning confined space entry.

In addition, personnel installing and maintaining this equipment

should follow all gui delines presented in this manual concerning

monitor installation and maintenance. Failure to strictly adhere to

these guidelines can result in personal injury and/or damage to the

monitor.

Changes or Modifications

Changes or modifications to the TRITON+ flow monitor not

expressly approved by the party responsible for compliance will

void the IS certification.

Personnel performing installation of the TRITON+ flow monitor

should carefully follow the guidelines contained in this manual

when installing and maintaini ng the monitor. Failure to str ic tly

adhere to these guidelines can result in personal injury and can

cause damage to the monitor, which would invalidate its warranty.

The TRITON+ flow monitor is designed to be installed in combined

and sanitary sewer lines and manholes. This installation work is

inherently danger ous. All applicable safety guidelines should be

followed and carried out by at least two fully trained and qualified

persons.

Control Drawing

This drawing depicts the interconnections allowed for the

TRITON+. It is intended for use by inspection professionals for

audit certificate compliance; however, it is a good tool for

understanding t he structure of the TRITON+ flow monitoring

system.

Introduction 1-11

1-12 ADS TRITON+ Manual

Control Drawing

Introduction 1-13

Note: This is an excerpt from an agency-controlled

document for ill ustration purposes only. Changes t o the

base controlled document require agency approval. For a

full-size copy of this drawing, please contact ADS and

request dra wing number 8000BK0009-CERT.

Note: The Telog R u-33 can be connected to the COMM

+ EXT PWR port on the TRITON+ monitor using the

Telog-Triton Comm Cable (ADS p/n 8000-0054-01).

However, this co nfi guration has not been included on this

drawing because the Telog unit is not certified for IS

operation. Therefore, a n installation involving this

configuration will not be considered intrinsically safe,

unless the Ru-33 is installed outside the hazardous area.

Cellular Modem Information and Compliance

Wireless telemetry is provided via a third-pa rty, F CC- and carrierapproved, commercial HSPA+/GSM or CDMA/EV-DO modem

inside the TRITON+ monitor and a corresponding antenna. Two

antenna options are available through ADS. However, customers

may obtain their own antennas to accommodate specific needs or

requirements. If a customer-supplied antenna is preferable or

required, consult an ADS or IETG, as applicable, representative

prior to installing the antenna to ensure it will adequately support

TRITON+ monitor communications and compliance.

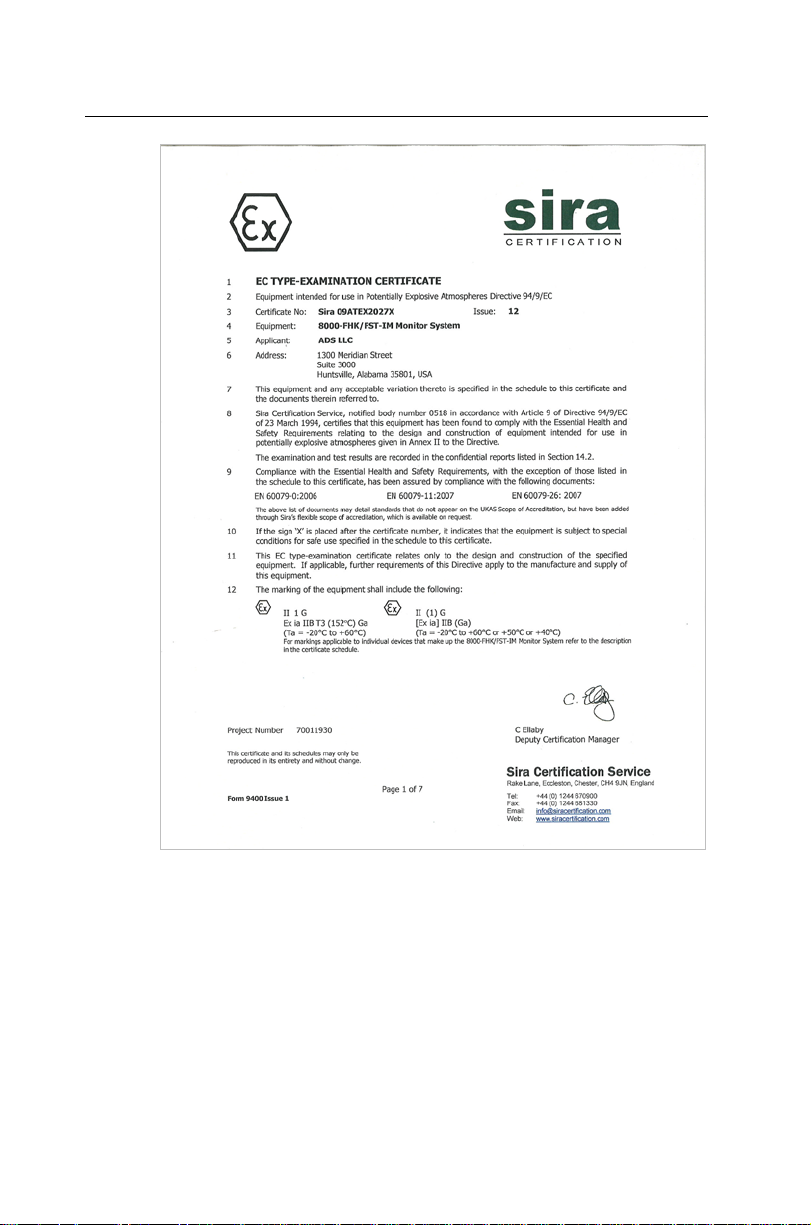

European ATEX Hazardous Area Compliance

The following instructions apply to equipment covered by the

certificate numbered Sira 09ATEX2027X (TRITON+, USB Serial

Interface, and Combo Sensors CSX Series). Reference European

ATEX Directive 94/9/EC, Annex II, 1.0.6:

The equipment may be used with flammable gases and vapors

with apparatus groups IIA and IIB and with temperature classes

T3 (152

o

C), T4, T5, and T6.

1-14 ADS TRITON+ Manual

The equipment is only certified for use in ambient temperatures

in the range of -20

o

C to +60oC and should not be used outside

this range.

The certificate number has an ‘X’ suffix, which indicates that

special conditions apply to installation and use. Those

installing or inspecting this equipment must have access to the

contents of the certificate.

Installation shall be carried out in accordance with the

applicable code of practice by suitably-trained personnel.

Repair of this equipment shall be carried out in accordance

with the applicable code of practice.

If the equipment is likely to come into contact with aggressive

substances, then it is the responsibility of the user to take

suitable precautions that prevent it from being adversely

affected, thus ensuring that the type of protection is not

compromised.

Aggressive substances such as acidic liquids or gases that

may attack metals, or solvents that may affect polymer ic

materials

Suitable precautions such as regular checks as part of

routine inspections or establishing from the material’s data

sheet that it is resistant to specific chemicals

There are no special inspections or maintenance conditions

other than a periodic check.

TRITON+ monitors delivered outside the U.S. must bear the

following label to substantiate conformance to ATEX and CSA

standards as certified thro ugh Sira Certification Services:

Introduction 1-15

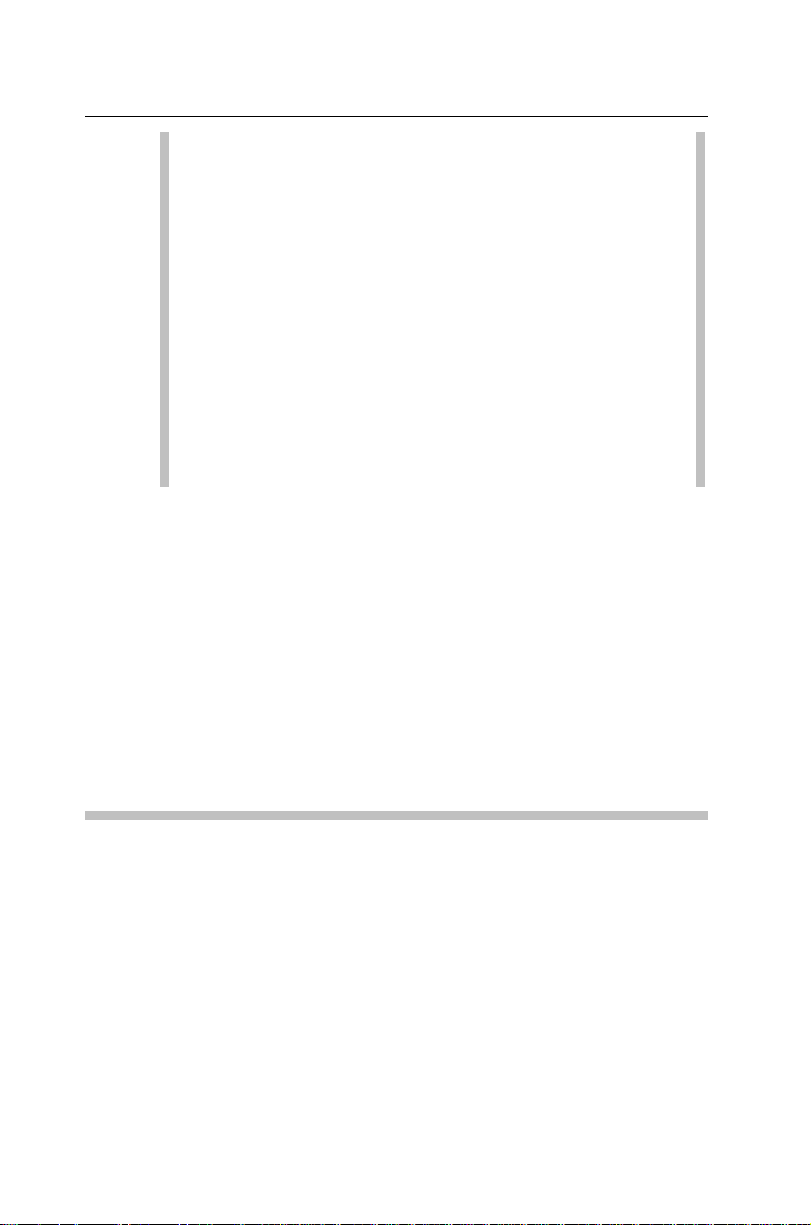

Sira TRITON+ Certifi cation Label

CSA TRITON+ Certification Label

Sira Combo Sensor CSX Series Certif i cation Label

1-16 ADS TRITON+ Manual

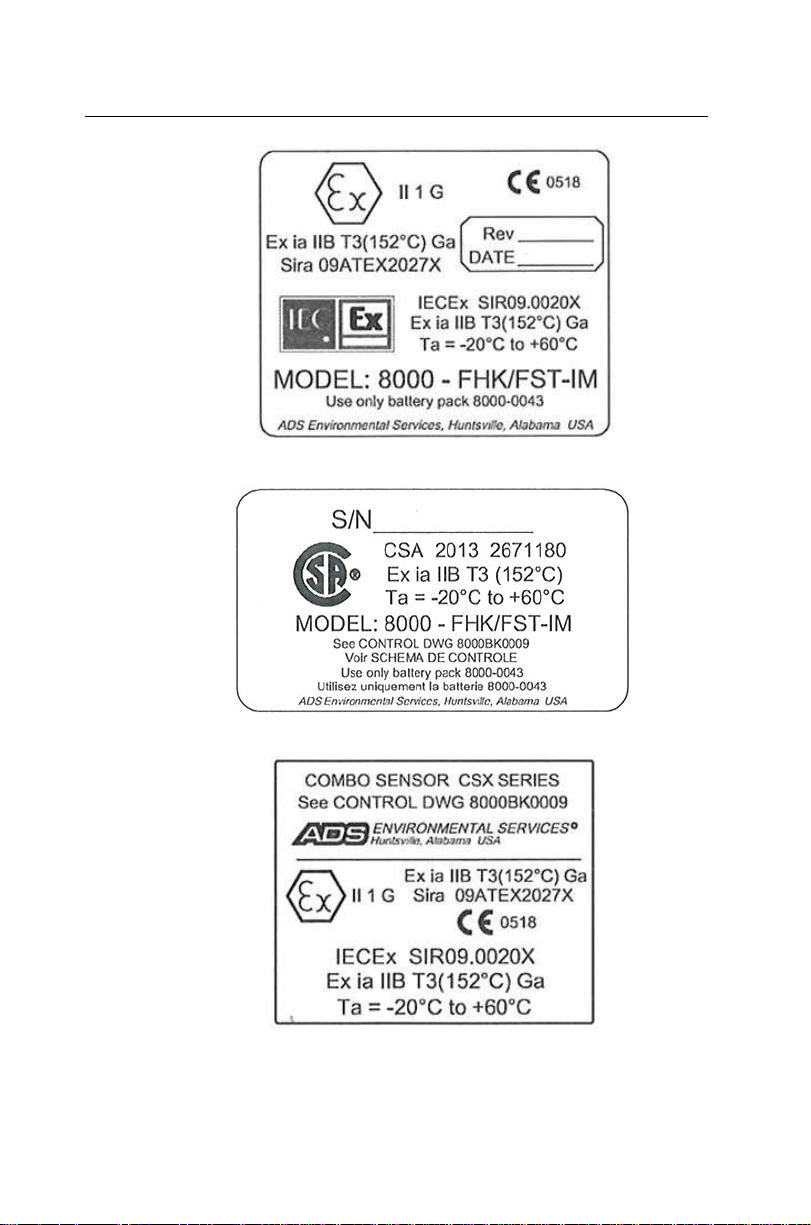

CSA Sensor Certificat i on Label

Sira USB Serial Interface Certification Label

CSA USB Serial Interface Certification Label

Introduction 1-17

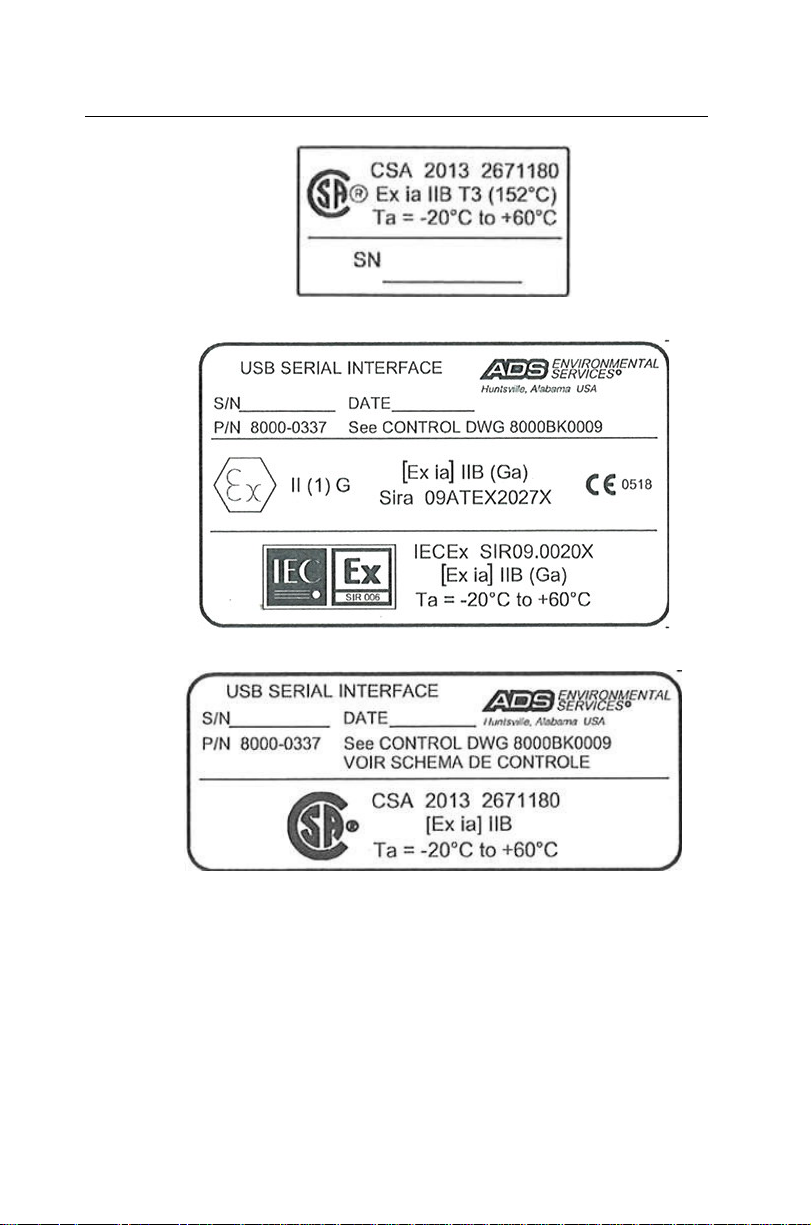

Sira ExPAC Certification Label

Sira Sampler Cable Certification Label

EC Type Examination Certificate Sira 09ATEX2027X can also be

used to substa ntiate conformance to applicable EU laws for IS

equipment. T he following page is a copy of the first page of the

certificate.

Note: This copy was current at the time of publication of

this manual. To access the latest version and entire content

of the certificate, please contact ADS.

1-18 ADS TRITON+ Manual

First page of the TRITON+ ATEX Certificate

Introduction 1-19

IECEx (International Electrotechnical Commission Explos ive) Hazardous Area Compliance

The TRITON+ is covered by certificate IECEx SIR 09.0020X

(TRITON+). Reference IECEx standards IEC 60079-0 : 2004; IEC

60079-11 : 2006; and IEC 60079-26 : 2006. This IECEx certificate

can also be used to substantiate conformance to applicable

international standards for IS equipment. The following page is a

copy of the first page of the certificate.

Note: This copy was current at the time of publication of

this manual. To access the latest version and entire content

of the certificate, please contact ADS.

1-20 ADS TRITON+ Manual

First page of the TRITON+ IECEx Certificate of Conformity

Introduction 1-21

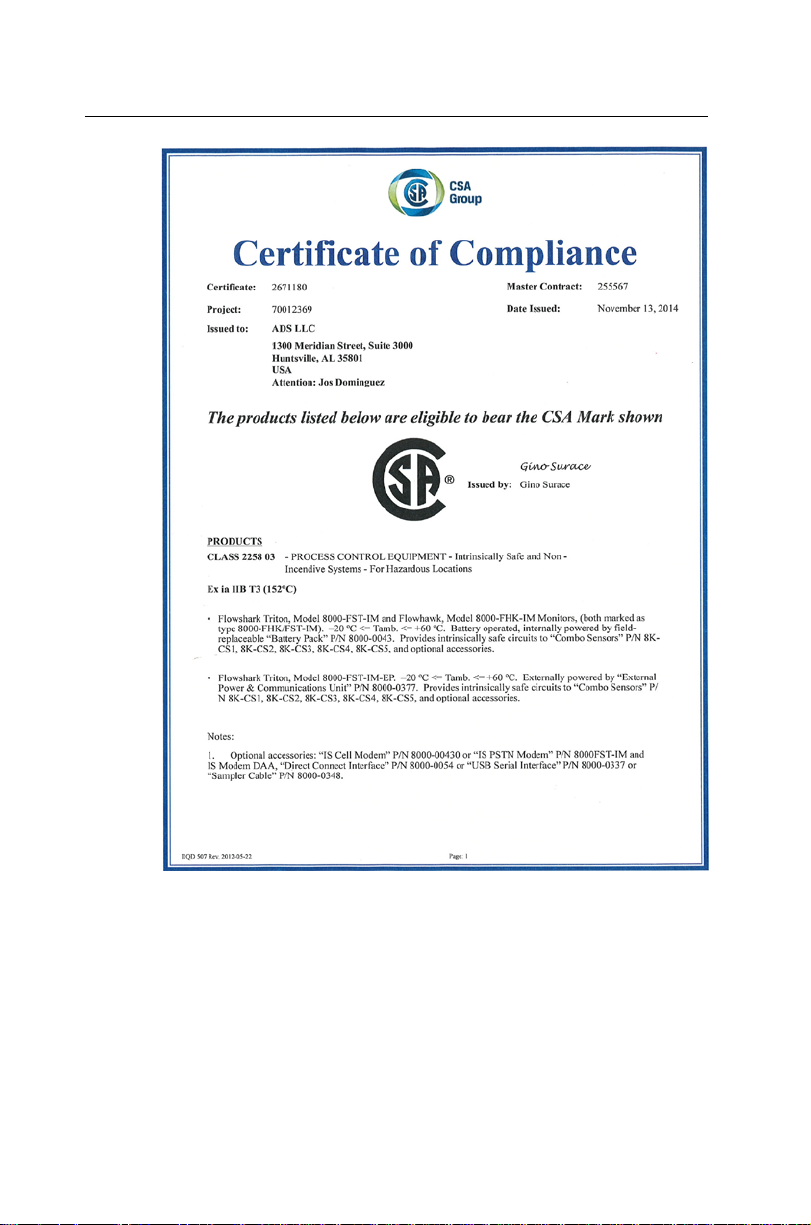

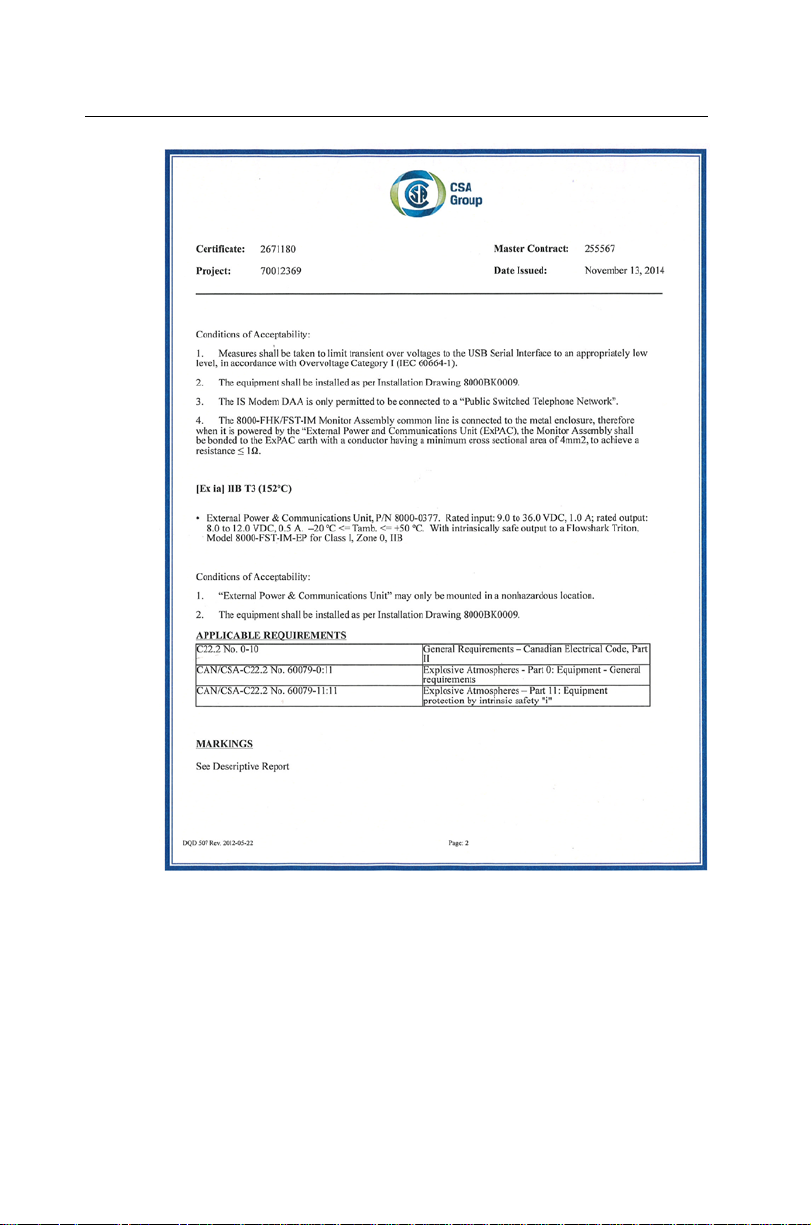

CSA Hazardous Area Compliance

The TRITON+ is covered by certificate CSA 2671180 (TRITON+

and Combo Sensors, and USB Serial Interface). Reference CSA

requirements C22.2 No. 0-10; CAN/CSA-C22.2 No. 60079-0:11;

and CAN/CSA-C22.2 No. 60079-11:11.

The following CSA certificate can also be used to substantiate

conformance to applicable Canadian standards for IS equipment:

Note: The certificate displayed on the following pages

was current at the time of publication of this manual. To

access the latest certificates, please contact ADS.

1-22 ADS TRITON+ Manual

CSA Certificate of Compliance – Page 1

Introduction 1-23

CSA Certificate of Compliance – Page 2

Loading...

Loading...