ADS Environmental Services QR 775016 A0 User Manual

ADS® PrimeProbe®2 User Manual

October 2009 QR 775016 A0

ADS LLC

4940 Research Drive

Huntsville, Alabama 35805

Telephone: 1-800-430-3366 / Fax: 1-800-430-6633

www.adsenv.com

PrimeProbe2 User Manual

Copyright © 2009 ADS® LLC. All rights reserved.

ADS® is a registered trademark of ADS LLC.

PrimeProbe®, PrimeLog®, and PrimeWorks® are registered trademarks of Primayer

Limited.

All other brand and product names are trademarks or registered trademarks of their

respective holders.

Notice of Proprietary Information

The information contained herein represents the latest information available at the time of

publication. ADS reserves the right to make any changes or modifications to the content

of this document, without notice, to reflect the latest changes to the equipment. No part

of this document may be reproduced in any form without the written consent of ADS.

ii

PrimeProbe2 User Manual

Table of Contents

Chapter 1 Introduction ......................................................................1

System Components.....................................................................................2

Compact.................................................................................................2

Remote...................................................................................................3

PrimeProbe2 Length Dimensions..........................................................3

Technical Specifications........................................................................4

Chapter 2 Installation ........................................................................5

Turning On the Unit.....................................................................................6

Compact Version (units acquired since June 2008)..............................6

Compact Version (units acquired prior to June 2008)..........................6

Remote Version .....................................................................................6

Site Selection ...............................................................................................7

Installation and Operational Considerations................................................8

International Standard of Flow Measurement......................................10

Mechanical Considerations for Sensor Installation ...................................11

Plastic or AC Pipes (Fitting Gate Valve).............................................11

Steel Pipes (Fitting Gate Valve) ..........................................................11

Measuring the Internal Diameter of the Pipe.............................................12

Pipe Thickness Gauge..........................................................................12

Gauging Rod........................................................................................12

Installing the PrimeProbe2.........................................................................14

Installation Procedure ..........................................................................15

Grounding the Sensor and the Converter.............................................15

Flow Direction.....................................................................................16

Connecting the Converter to the Sensor ....................................................17

Pulse Output Characteristics................................................................18

Powering-up the PrimeProbe2 Sensor.................................................19

Menu Access System.................................................................................22

Factory Presets.....................................................................................22

QUICK START...................................................................................23

Main Menu...........................................................................................23

Converter Functions...................................................................................31

Default Values .....................................................................................32

Entry Definitions................................................................................333

Chapter 3 Operation ........................................................................38

Software Setup...........................................................................................39

iii

PrimeProbe2 User Manual

Setup Wizard........................................................................................39

Chapter 4 Part Numbers..................................................................41

PrimeProbe2 (Compact) Part Numbers .....................................................42

PrimeProbe2 (Remote) Part Numbers........................................................43

Chapter 5 Battery Life......................................................................44

Chapter 6 Index… ............................................................................45

iv

C H A P T E R 1

Introduction

The PrimeProbe®2 flow meter measures flow rate in closed pipes with

clean water having a conductivity greater than 5 microsiemens. It is not

suitable for measuring wastewater, gases, petroleum, or other fluids with

low conductivity.

1

System Components

Note: Please be careful when removing the PrimeProbe2 product

from its original container. Fully inspect the equipment for

damage. If damage exists, notify the carrier and ADS immediately.

The system consists of two primary components: the insertion-type sensor

and the converter. Two types of PrimeProbe2 are available:

Compact

Remote

Compact

For the compact version, the converter is integrated into the sensor. This

version is battery powered.

PrimeProbe2 User Manual

2

Remote

PrimeProbe2 User Manual

For the remote version, the converter connects to the sensor by a cable.

This unit can be battery or externally powered.

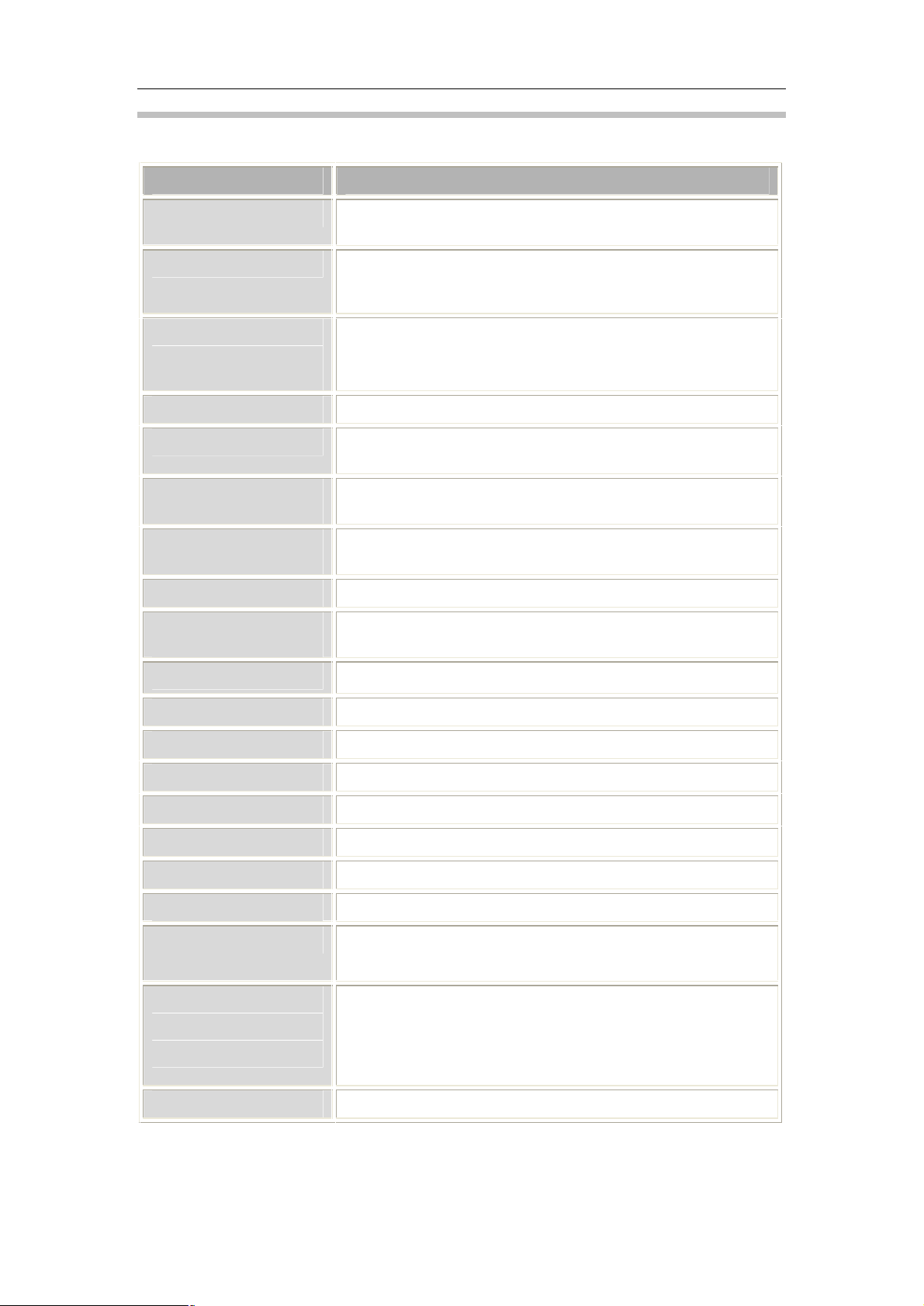

PrimeProbe2 Length Dimensions

Model Insertion Length Overall Length

(Compact)

Size 1 11.8 inches

(300 mm)

Size 2 19.7 inches

(500 mm)

Size 3 27.6 inches

(700 mm)

Size 4 39.4 inches

(1000 mm)

* Assumes operation on the centerline of the pipe

29.0 inches

(737 mm)

36.9 inches

(937 mm)

44.8 inches

(1137 mm)

56.6 inches

(1437 mm)

Overall Length

(Remote)

30.2 inches

(767 mm)

38.1 inches

(967 mm)

45.9 inches

(1167 mm)

57.8 inches

(1467 mm)

Use in Pipe

Sizes*

≤ 23.6 inches

(600 mm)

≤ 39.4 inches

(1000 mm)

≤ 55.1 inches

(1400 mm)

≤ 78.7 inches

(2000 mm)

3

Technical Specifications

Parameter Specification

PrimeProbe2 User Manual

Pipe Sizes

Measurement Range

Accuracy; Point

Velocity

Flow

Repeatability

Flow Determination

Measurement

Sampling

Minimum Fluid

Conductivity

Process Connection

Pipeline Pressure

Rating

3.2 to 315.0 inches (80 mm to 8000 mm) – at 1/8 pipe

diameter (insertion depth) installation

Bi-directional from 0.03 to 16.40 feet per second (0.01 m/s

to 5 m/s) (Maximum may be lower based on insertion length

and pipe position.)

±0.0066 feet per second (± 2mm/sec) or ± 2%, whichever is

the greater.

Refer to ISO 7145-1982

± 0.5% of velocity

Assumes fully developed flow profile; ISO 7145-1982

reference

Continuous or programmable from 1 to 90 seconds

5µS/cm

1-inch (25-mm) BSP (British Standard Pipe)

232 psi

Sensor Material

Body Material

Electrode Materials

Flow Temperature

Safety

Pressure Tapping

Adjustment Method

Protection

Batteries

Output: Signal

Units

Connection

Communications

PTFE (polytetrafluoroethylene)

SS304

SS316

32º to 176º F (0 to 80º C)

Probe fitted with anti-bounce chain

Female quick-release connector

5 mm Allen key (supplied by ADS) – fits all screws

IP68

Type: Lithium batteries

Life: ≤3 years (depending on sampling period and usage)

Pulses proportional to velocity/flow rate - maximum frequency

32 Hz

User-selectable

MIL-spec connector

USB

4

C H A P T E R 2

Installation

This chapter provides instructions on powering up the PrimeProbe2,

determining the appropriate length and position for the insertion sensor,

selecting a suitable location for measurement, and installing the

PrimeProbe2.

PrimeProbe2 User Manual

5

PrimeProbe2 User Manual

Turning On the Unit

ADS delivers the PrimeProbe2 in the OFF condition. The user must turn

it on before going to the first installation site, as described in the following

sections.

Compact Version (units acquired since June 2008)

1. Launch the PrimeWorks® software.

2. Connect the PrimeProbe2 to the PC/laptop running the software

using the communications cable.

3. Select the PrimeProbe2 > Shipping > Wake up menu option.

The software will initiate communications with the PrimeProbe2 to

bring it out of Sleep mode. The probe is now ready for use.

Compact Version (units acquired prior to June 2008)

1. Using the 5mm Allen key (supplied by ADS), remove the 4 screws

securing the rear cover of the converter.

2. Locate the two small switches left of center of the circuit board and

in front of the battery. Place them in the LEFT position.

3. Replace the cover and the 4 screws, and then tighten the screws

with the Allen key securely and evenly.

Remote Version

1. Using the 5mm Allen key (supplied by ADS), remove the 4 screws

securing the rear cover of the converter.

2. Locate the two small switches immediately behind the

communications jack socket. Place these switches in the LEFT

position.

3. Replace the cover and the 4 screws, and then tighten the screws

with the Allen key securely and evenly.

Note: Tighten all the screws fully to prevent water ingress from

occurring.

6

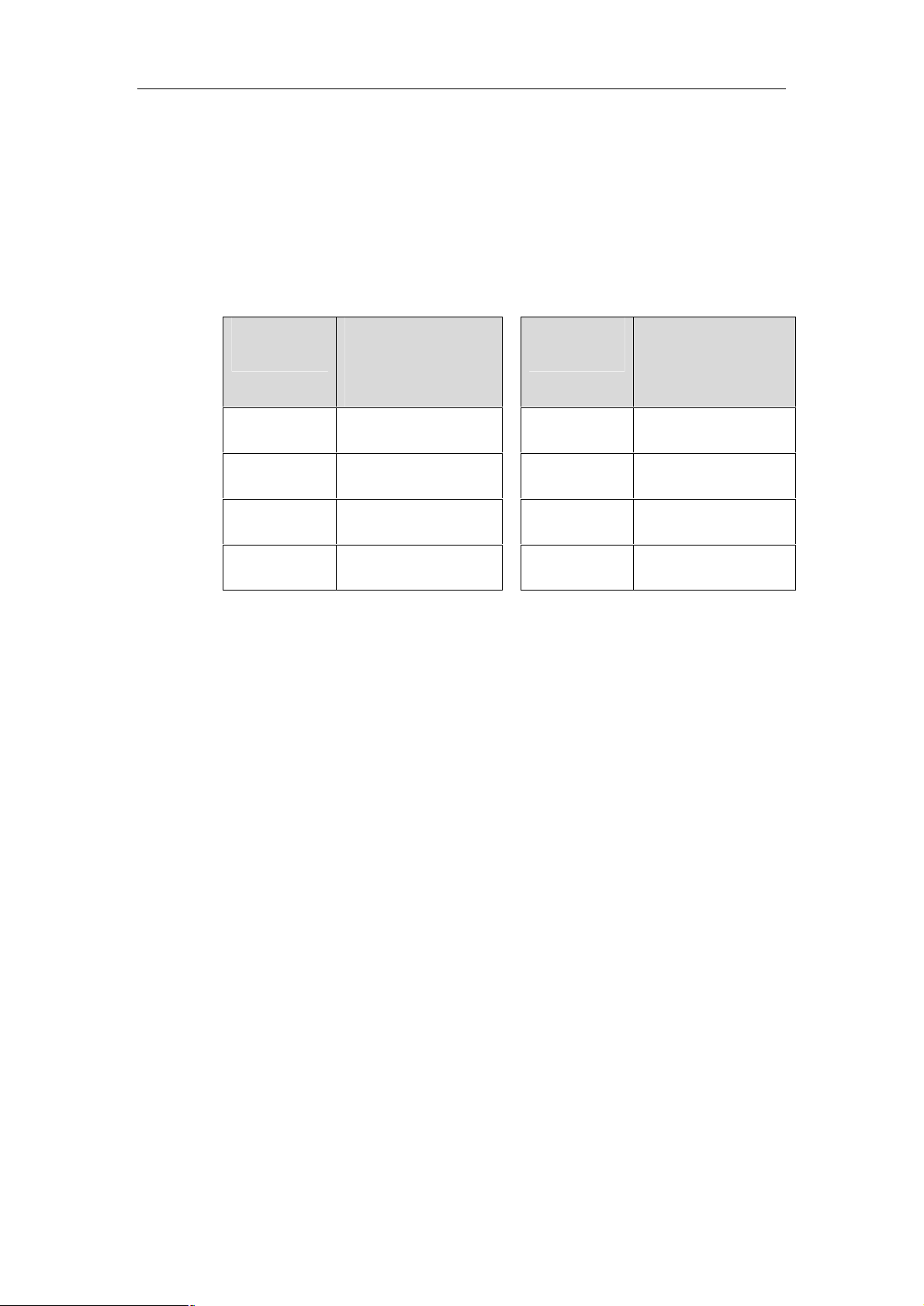

Site Selection

3.15 to 220.47 inches

3.15 to 314.96 inches

The PrimeProbe2 can be used on pipes with internal diameters from 3.15

to 314.96 inches (80 to 8000mm) at 1/8 diameter insertion depth, based on

the insertion length of the selected probe. The following table indicates

the 4 different insertion lengths of the PrimeProbe2 and the pipe sizes in

which they can operate. The PrimeProbe2 can be located at one of three

depth positions: ½-pipe diameter, 1/8-pipe diameter, or 7/8-pipe diameter.

PrimeProbe2 User Manual

Size of

PrimeProbe2

11.81 inches

(300 mm)

19.69 inches

(500 mm)

27.56 inches

(700 mm)

39.37 inches

(1000 mm)

Internal Diameters

of Pipes at 1/8

Diameter Insertion

Depth

3.15 to 78.74 inches

(80 to 2000 mm)

3.15 to 78.74 inches

(80 to 2000 mm)

(80 to 5600 mm)

(80 to 8000 mm)

Size of

PrimeProbe2

11.81 inches

(300 mm)

19.69 inches

(500 mm)

27.56 inches

(700 mm)

39.37 inches

(1000 mm)

Internal Diameters

of Pipes at 1/2

Diameter Insertion

Depth

3.15 to 23.62 inches

(80mm to 600mm)

3.15 to 39.37 inches

(80 to 1000 mm)

3.15 to 55.12 inches

(80 to 1400 mm)

3.15 to 78.74 inches

(80 to 2000 mm)

Before installing the PrimeProbe2, determine the direction of the flow in

the pipe. The PrimeProbe2 must be installed in the correct direction.

Using the symbols on the nameplate of the sensor (– to +) for reference,

the PrimeProbe2 is installed correctly when the flow in the pipe travels

from – to +.

7

PrimeProbe2 User Manual

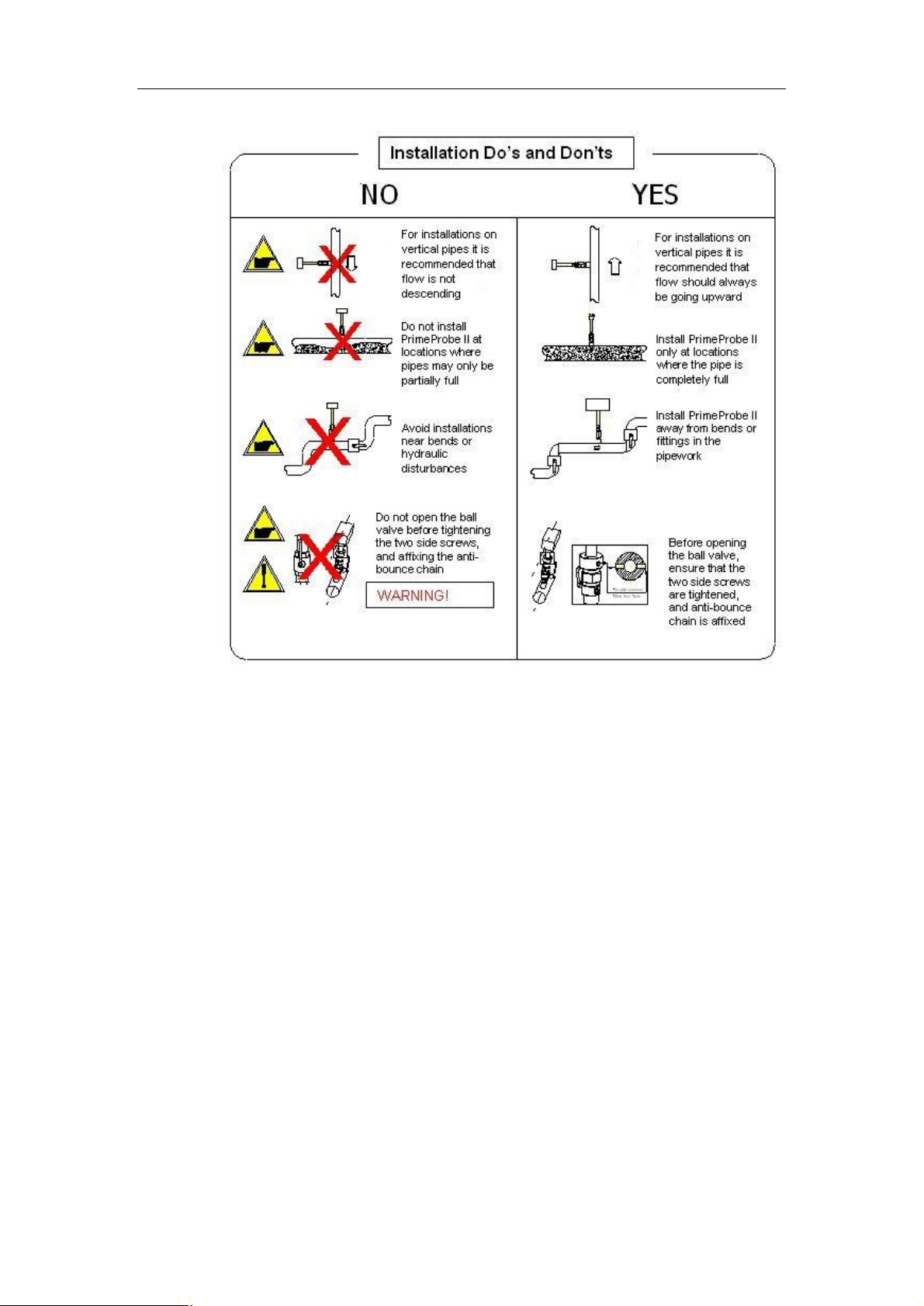

Installation and Operational Considerations

Install the sensor away from any bends in the pipe and hydraulic

fittings (disturbances). For the best results, install the sensor of the

PrimeProbe2 at a location with at least 25 times the pipe diameter

in distance of straight unrestricted pipe upstream of the sensor and

10 times the pipe diameter in distance of straight unrestricted pipe

downstream of the sensor.

Operate the PrimeProbe2 only in full pipes. The converter

performs flow calculations based on full pipe.

Before opening the valve to insert the PrimeProbe2, make sure the

safety mechanism is engaged. Some pipes are under considerable

pressure. Failure to lock-down the probe could allow pressure to

force the sensor upward like a projectile, potentially causing injury

to the installer.

Although it is not always necessary to install the sensor at the 12

o’clock position on the pipe, it is always necessary to install the

probe at a 90° angle to the length of the pipe.

The PrimeProbe2, configured with a remote converter, can receive

power from an AC mains supply. When using AC power, terminal

connections with the mains supply should be made only by

qualified technicians familiar with all current procedures and local

codes. Connection to mains power should always occur through a

RCD (residual current device) and should be the last step in the

installation process.

8

PrimeProbe2 User Manual

9

PrimeProbe2 User Manual

International Standard of Flow Measurement

The following table has been reproduced, with permission, from ISO 7145

(BS 1042) Section 2.2 1982. Complete copies are available from BSI

Publications, Linford Wood, Milton Keynes, MK14 6LE.

Type of Disturbance

Upstream from the Cross-

Section of Measurement

90-degree elbow or a t-bend 50 25

Several 90-degree coplanar

bends

Several 90-degree non-

coplanar bends

Total angle convergent 18 to

36 degrees

Total angle convergent 14 to

28 degrees

Fully-opened butterfly valve 45 25

Fully-opened plug valve 30 15

* Expressed in multiples of the diameter of the conduit.

Minimum Upstream Straight Length*

For Measurement

at the Point of

Mean Axial

Velocity

50 25

80 50

30 10

55 25

For Measurement

on the Axis of the

Conduit

10

PrimeProbe2 User Manual

Mechanical Considerations for Sensor Installation

Install the probe into the pipe through a pre-drilled 1-inch (25-mm) hole in

the pipe using a 1-inch (25-mm) Ball Valve (included). A 1.5-inch or 2inch ball valve may be used with reducers.

Installing in plastic or AC (asbestos cement) pipes with smaller diameters

and steel pipes with larger diameters requires different methods.

Plastic or AC Pipes (Fitting Gate Valve)

Plastic or AC pipes require a gate valve; however, no welding is required

to install the gate valve onto a 7.87- to 15.75-inch (200- to 400-mm)

diameter plastic or AC pipe. Simply mount a saddle to the existing pipe,

tighten the lug nuts, and connect the 1.57-inch (40-mm) gate valve. Note

that a 1.57-inch (40-mm) drill bit must be used when boring a hole in the

pipe. Do not install reducers if they will interfere with a protruding drill

bit.

Steel Pipes (Fitting Gate Valve)

To connect a gate valve to a large-diameter steel pipe, first weld a carbon

steel boss directly to the pipe. After welding the boss to the pipe and

pressure-testing the weld, attach a 1.57-inch (40-mm) gate valve.

Note: A carbon steel boss cannot be welded effectively to a

ductile iron pipe. When using the PrimeProbe2 with ductile iron

pipes, use a pipe saddle.

11

Loading...

Loading...