ADS Environmental Services QR 775004 A1 User Manual

ADS® FlowShark® Pulse Operation and Maintenance Manual

March 2009 QR 775004 A1

An introductory guide to the ADS® FlowShark® Pulse Meter

Valid as of Software Revision No. 4.10

1300 Meridian Street, Suite 3000

Huntsville, AL 35801 USA

(256) 430-3366

ii ADS FlowShark Pulse O&M Manual

© 2009 ADS® LLC. All rights reserved.

ADS®, ADS Environmental Services®, and FlowShark® are registered trademarks

of ADS LLC.

NIVUS® is a registered trademark of NIVUS GmbH.

Java™ is a trademark of Sun Microsystems, Inc.

All other brand and product names are trademarks or registered trademarks of their

respective holders.

Notice of Proprietary Information

The information contained herein represents the latest information available at the

time of publication. ADS LLC reserves the right to make any changes or

modifications to the content of this document, without notice, to reflect the latest

changes to the equipment. No part of this document may be reproduced in any form

without the written consent of ADS LLC.

Table of Contents iii

Table of Contents

Chapter 1 Warrant y and Certifications 1-1

Declaration of Conformity ................................................................................... 1-2

Product Warranty ................................................................................................. 1-3

New Product Warranty ................................................................................... 1-3

Out of Warranty Product Repairs ................................................................... 1-3

Troubleshooting Fee ...................................................................................... 1-3

Shipping ......................................................................................................... 1-3

Ex-Approval Transmitter ..................................................................................... 1-5

Ex-Approval Sensors ......................................................................................... 1-10

Chapter 2 Use and Specifications 2-1

Use in Accordance with the Requirements .......................................................... 2-2

Specifications ....................................................................................................... 2-4

Transmitter ..................................................................................................... 2-4

Combi Sensor/Pipe Insertion Sensor ............................................................. 2-5

Air-Ultrasonic Sensor .................................................................................... 2-7

Accessories (Option) ...................................................................................... 2-8

Chapter 3 Safety and Identification 3-1

Device Identification ............................................................................................ 3-2

Replacement Parts and Accessories ..................................................................... 3-3

Emergency and Safety Procedures ....................................................................... 3-4

User’s Responsibilities......................................................................................... 3-5

Chapter 4 System Overview and Operation 4-1

Combination Sensor ............................................................................................. 4-2

Water-Ultrasonic Depth Measurement .......................................................... 4-2

Pressure Depth Measurement......................................................................... 4-3

Flow Velocity Measurement .......................................................................... 4-3

Air-Ultrasonic Depth Sensor ................................................................................ 4-6

Pipe Insertion Sensor ........................................................................................... 4-7

Device Versions ................................................................................................... 4-8

Transmitter ..................................................................................................... 4-8

Sensors ........................................................................................................... 4-9

iv ADS FlowShark Pulse O&M Manual

Chapter 5 Delivery, Maintenance, and Handling 5-1

Delivery and Receipt ............................................................................................ 5-2

Maintenance ......................................................................................................... 5-3

Handling ............................................................................................................... 5-5

Storage ........................................................................................................... 5-5

Transport ........................................................................................................ 5-5

Disposal.......................................................................................................... 5-5

Chapter 6 Installation 6-1

Transmitter Installation and Connection .............................................................. 6-2

General ........................................................................................................... 6-2

Enclosure Dimensions ................................................................................... 6-3

Transmitter Connection ................................................................................. 6-3

Sensor Installation and Connection...................................................................... 6-6

Choosing a Suitable Location for Sensor Installation .................................... 6-6

Sensor Installation ........................................................................................ 6-10

Sensor Connection ....................................................................................... 6-17

FlowShark Pulse Power Supply ......................................................................... 6-25

Overvoltage Protection Precautions ................................................................... 6-27

Regulator Mode ................................................................................................. 6-30

General ......................................................................................................... 6-30

Setting up the Measurement Location ......................................................... 6-31

Connection ................................................................................................... 6-34

Control Algorithm ........................................................................................ 6-34

Communication .................................................................................................. 6-36

General ......................................................................................................... 6-36

Data Communication ................................................................................... 6-36

Communication Options .............................................................................. 6-36

Chapter 7 Initial Startup and Communication 7-1

Establishing Communication Through a Browser ............................................... 7-2

Operator Keypad .................................................................................................. 7-6

Display ................................................................................................................. 7-7

Operation Basics .................................................................................................. 7-8

Table of Contents v

Chapter 8 Parameter Settings 8-1

Quick Start Guide for Setting Parameters ............................................................ 8-2

Basics for Setting Parameters .............................................................................. 8-3

Operation Mode (RUN) ....................................................................................... 8-5

Display Menu (EXTRA) ...................................................................................... 8-9

Parameter Menu (PAR) ...................................................................................... 8-12

Parameter Menu: Measurement Place .......................................................... 8-12

Parameter Menu: Level ................................................................................ 8-19

Parameter Menu: Flow Velocity .................................................................. 8-24

Parameter Menu: Analog Inputs .................................................................. 8-28

Parameter Menu: Digital Inputs ................................................................... 8-30

Parameter Menu: Analog Outputs................................................................ 8-32

Parameter Menu: Digital Outputs ................................................................ 8-35

Parameter Menu: Flow Controller ............................................................... 8-38

Parameter Menu: Settings ............................................................................ 8-47

Parameter Menu: Memory Mode ................................................................. 8-49

Data Structure on the Memory Card ............................................................ 8-53

Parameter Menu: Communication ............................................................... 8-54

Signal Input/Output Menu (I/O)......................................................................... 8-58

I/O Menu: Analog Inputs ............................................................................. 8-58

I/O Menu: Digital Inputs .............................................................................. 8-59

I/O Menu: Analog Outputs .......................................................................... 8-59

I/O Menu: Relay Outputs ............................................................................. 8-60

I/O Menu: Sensors ....................................................................................... 8-60

I/O Menu: Interfaces .................................................................................... 8-63

I/O Menu: Controller ................................................................................... 8-63

I/O Menu: Memory Card ............................................................................. 8-64

Calibration and Calculation Menu (CAL) ......................................................... 8-67

CAL Menu: Level ........................................................................................ 8-67

CAL Menu: Velocity.................................................................................... 8-69

CAL Menu: Simulation ................................................................................ 8-73

Chapter 9 Parameter Tree 9-1

Chapter 10 Data Collection 10-1

Data Collection .................................................................................................. 10-2

Deleting Data Files............................................................................................. 10-4

Viewing Data ..................................................................................................... 10-5

vi ADS FlowShark Pul se O&M Manual

Chapter 11 Troubleshooting 11-1

Chapter 12 Materials and Chemical Resistance 12-1

Chemical Resistance Legend ............................................................................. 12-3

Resistance .................................................................................................... 12-3

Material Names ............................................................................................ 12-3

C H A P T E R 1

Warranty and Certifications

This chapter includes the Declaration of Conformity, the ADS® warranty, and all

required certifications for the ADS FlowShark

®

Pulse.

Please notice that the certifications included in this chapter identify

the FlowShark Pulse as the OCM Pro CF. The FlowShark Pulse is

®

a version of the NIVUS

ADS. In all aspects related to certification, the FlowShark Pulse is

OCM Pro CF designed specifically for

identical to the OCM Pro CF.

1-2 ADS FlowShark Pulse O&M Manual

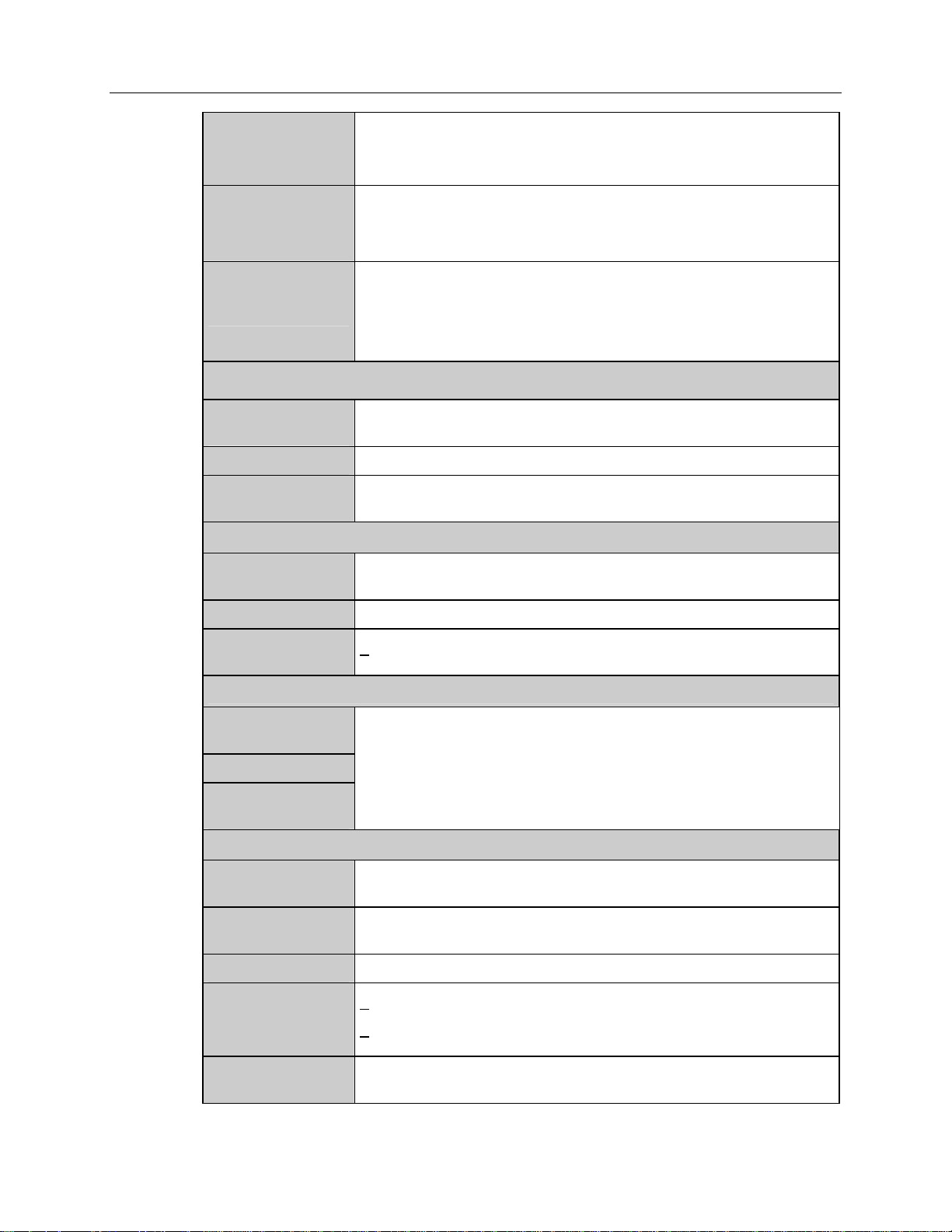

Declaration of Conformity

EC Declaration of Conformity

Pursuant to

z the EC Low Voltage Directive 73/23/EEC, Annex III

z the EC EMC Directive 89/336/EEC, Annex I and II

z the EC Directive 94/9/EC: Equipment and protective systems intended for use

in potentially explosive atmospheres (ATEX)

We hereby declare that the design of the

Description: Measuring device OCM Pro with active sensor

as delivered complies with the above regulations and following EC directives and

DIN EN standards:

Directive/

Standard

73/23/ EC EC Low Voltage Directive

EN 61010-1 Safety requirements for electrical equipment for measurement,

control and laboratory use – Part 1: General requirements

89/336/EC EC EMC Directive

EN 61000-6-2 Electromagnetic compatibility – Generic immunity standard – Industrial

environment

EN 61000-6-4 Electromagnetic compatibility – Generic immunity standard – Industrial

environment

Title

94/9/EC

(ATEX 100a)

EN 1127-1 Explosive atmospheres – Explosion prevention and protection –

EN 50014 Electrical apparatus for potentially explosive atmospheres – General

EN 50020 Electrical apparatus for potentially explosive atmospheres – Intrinsic

EC Directive: Equipment and protective systems intended for use in

potentially explosive atmospheres

Part 1: Basic concepts and methodology

requirements

safety "i"

Unauthorized changes to the device invalidate this declaration.

Eppingen, March 15

th

, 2007 ..............................................

Heinz Ritz

Head of Quality Management

Product Warranty

This section includes warranty information for the ADS FlowShark Pulse.

New Product Warranty

All new products manufactured by ADS will be free from defects in material and

workmanship for up to two (2) years following the date of shipment from ADS.

During this warranty period, upon satisfactory proof of a defect, the product may be

returned for repair or replacement, at ADS’s sole option. No returns will be accepted

unless the Owner has prepaid shipping and has received a prior authorization return

number from ADS. Please contact ADS to obtain an authorization return number.

Warranty repairs and replacements will be performed only by ADS. Any

unauthorized repair or replacement will void this product warranty. Any repair or

replacement will be covered by this new product warranty for ninety (90) days from

the date that such repaired or replaced product is shipped from ADS. This warranty

is available only if the product has been setup and operated in accordance with the

procedures outlined in the ADS Operations and Maintenance Manual. This warranty

does not apply to damage by catastrophes of nature, fire, explosion, acts of God

(including, but not limited to, lightning damage and power surges), accidents,

improper use or service, damage during transportation, or other similar causes beyond

ADS’s control.

Warranty and Certifications 1-3

Out of Warranty Product Repairs

After the new product warranty expires, a product may be returned, at the owner’s

prepaid expense, to ADS for repair. The owner will pay for all parts and labor

associated with the repair. Any repair part will be covered by the new product

warranty for 90 days from the date of shipment from ADS.

Troubleshooting Fee

ADS will charge a troubleshooting fee if the reported product defect cannot be found

and/or the reported defect is not due to a defect in materials or workmanship.

Shipping

All repaired products will be returned via surface transportation prepaid by ADS.

Import duties, fees, taxes, and other related charges are the responsibility of the

owner.

1-4 ADS FlowShark Pulse O&M Manual

THIS IS THE ONLY WARRANTY FOR ADS PRODUCTS. NO OTHER

WARRANTY IS EXPRESSED OR IMPLIED, INCLUDING FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY. PRODUCT REPAIR

OR REPLACEMENT IS THE ONLY REMEDY. IN NO EVENT WILL ADS

BE RESPONSIBLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, OR

SPECIAL DAMAGES.

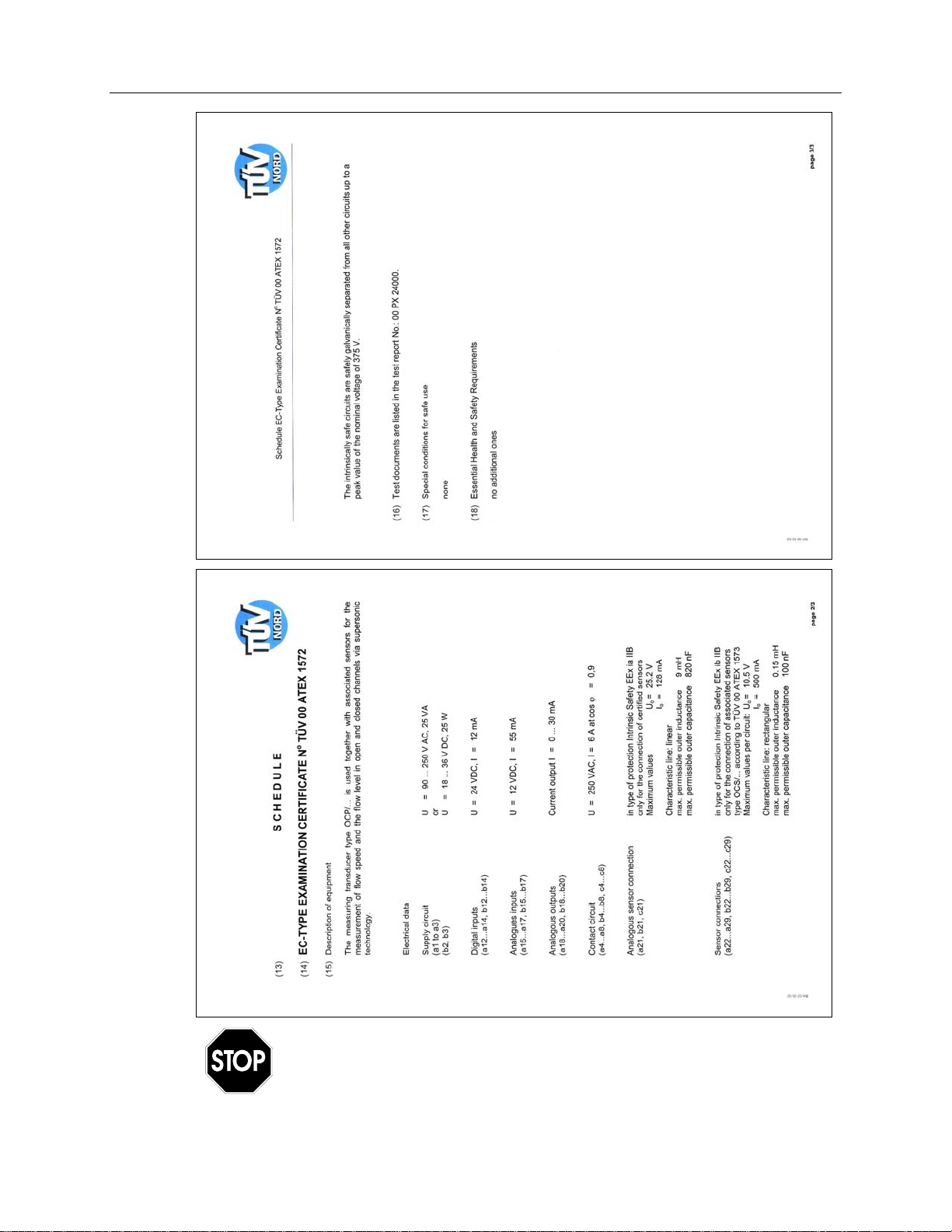

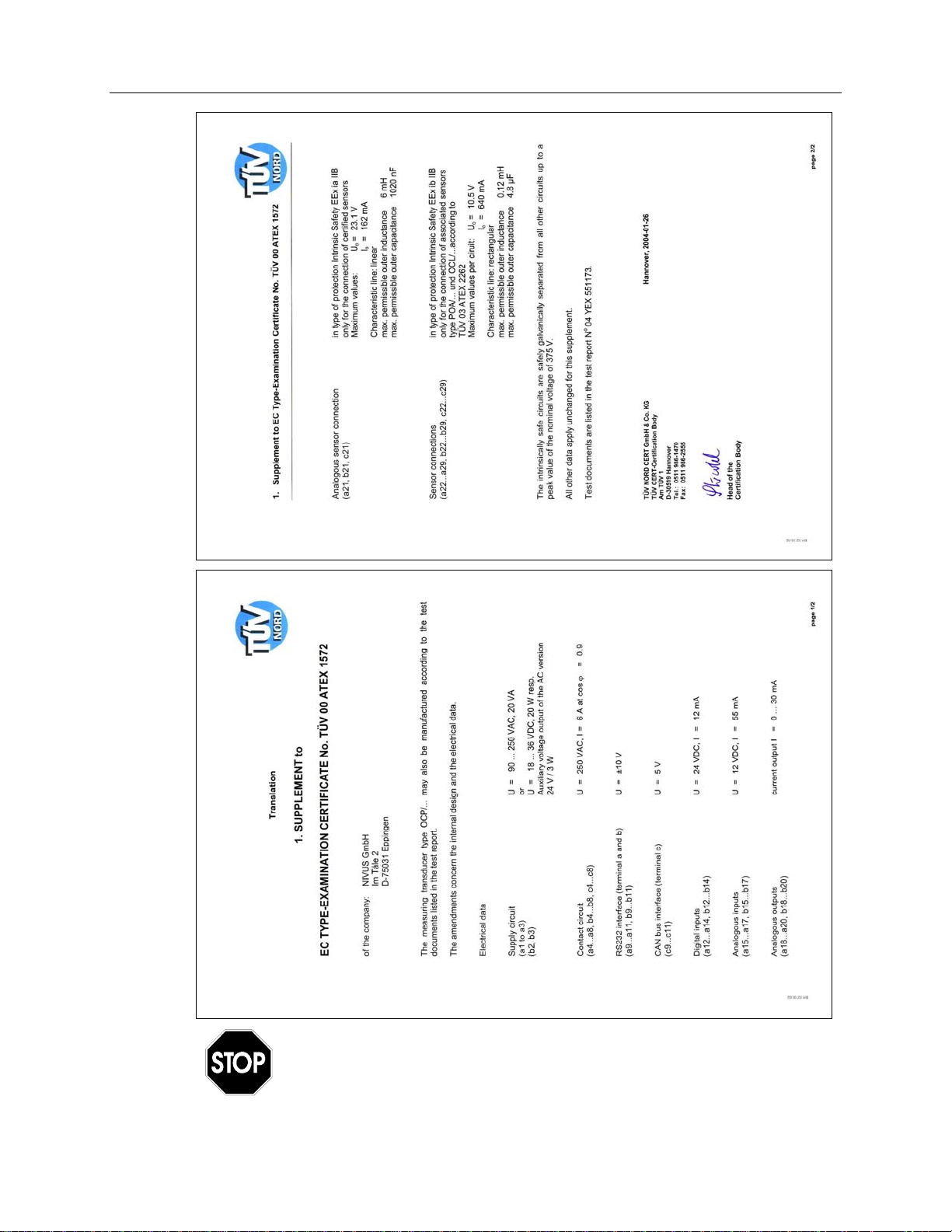

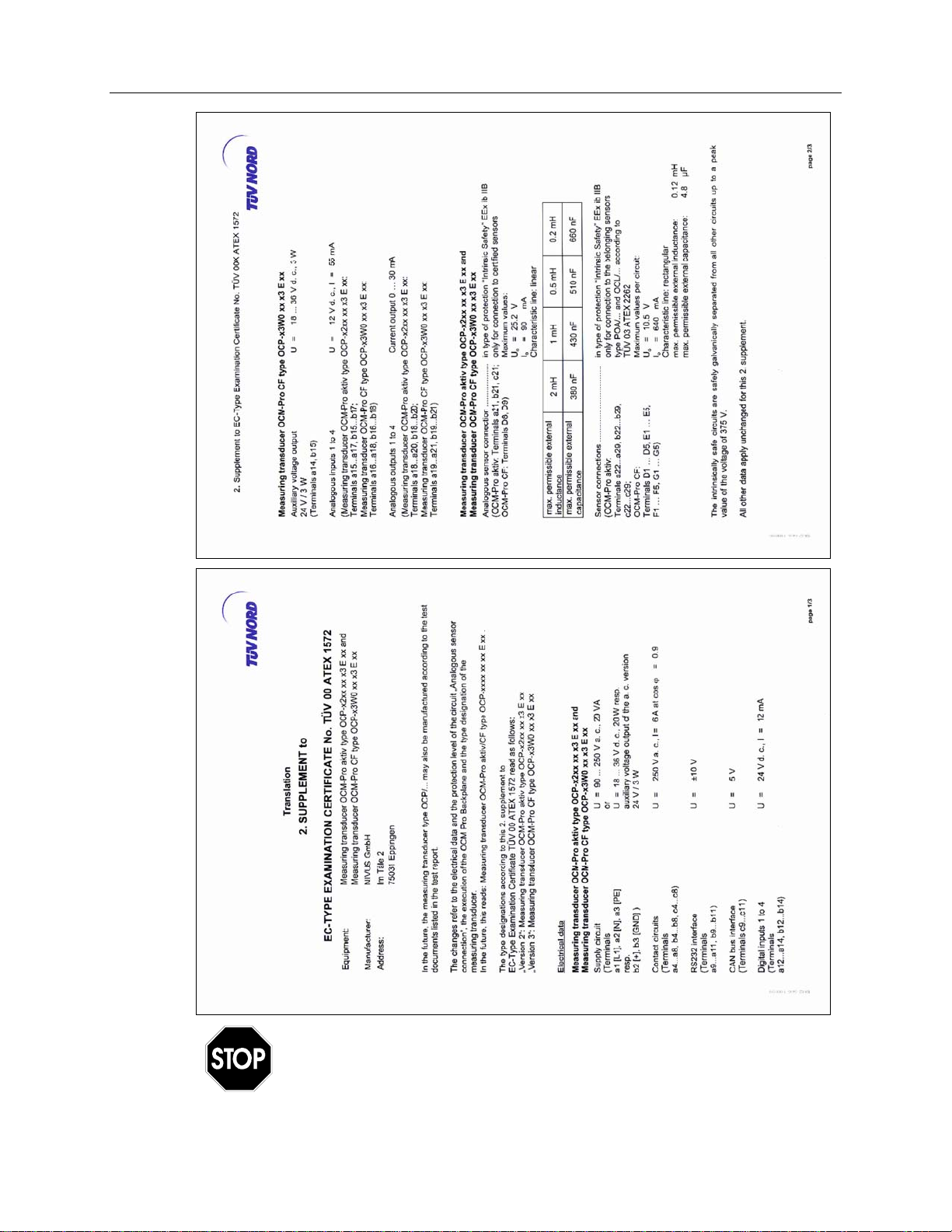

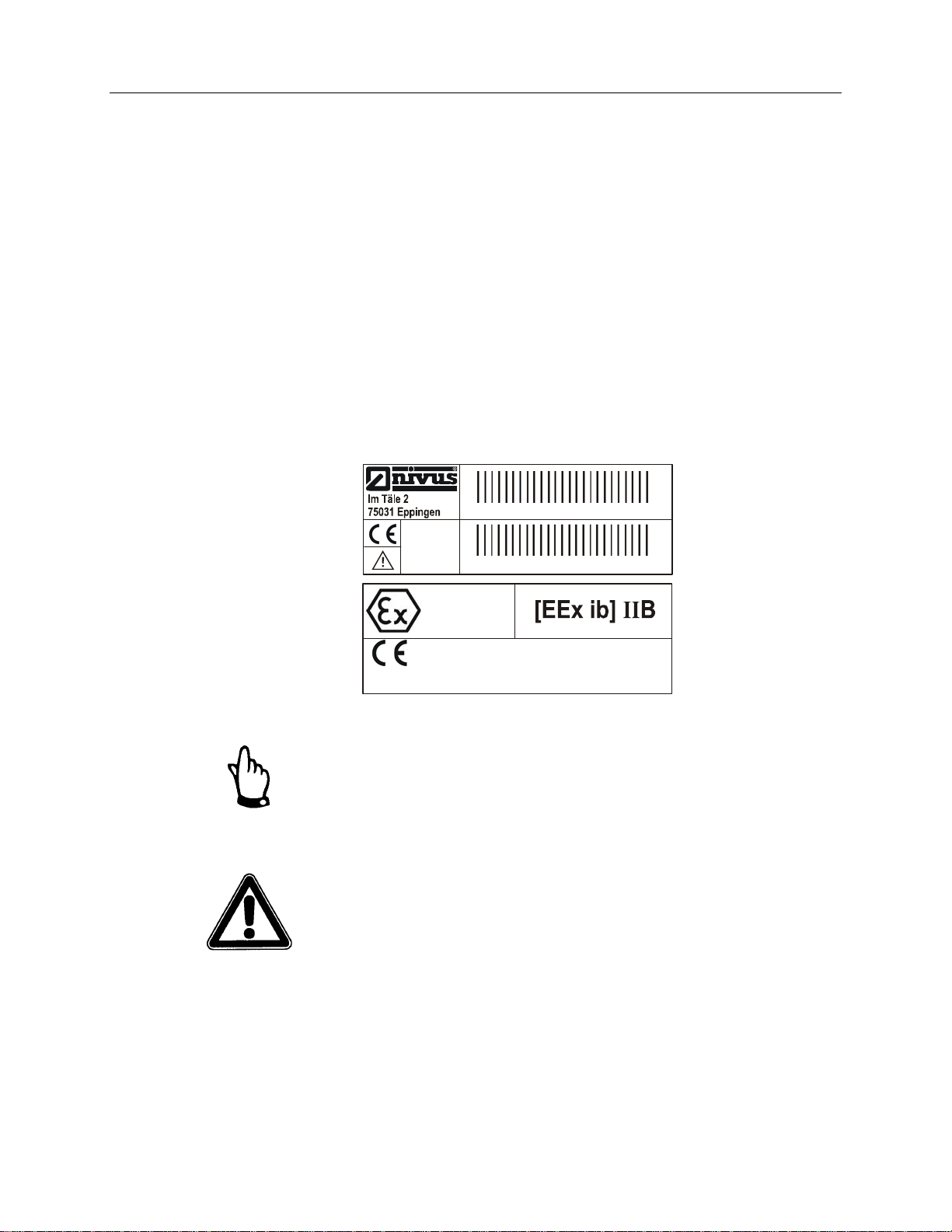

Ex-Approval Transmitter

Warranty and Certifications 1-5

The approval is valid only when the corresponding indicator

displays on the transmitter nameplate.

1-6 ADS FlowShark Pulse O&M Manual

The approval is valid only when the corresponding indicator displays

on the transmitter nameplate.

Warranty and Certifications 1-7

The approval is valid only when the corresponding indicator displays

on the transmitter nameplate.

1-8 ADS FlowShark Pulse O&M Manual

The approval is valid only when the corresponding indicator displays

on the transmitter nameplate.

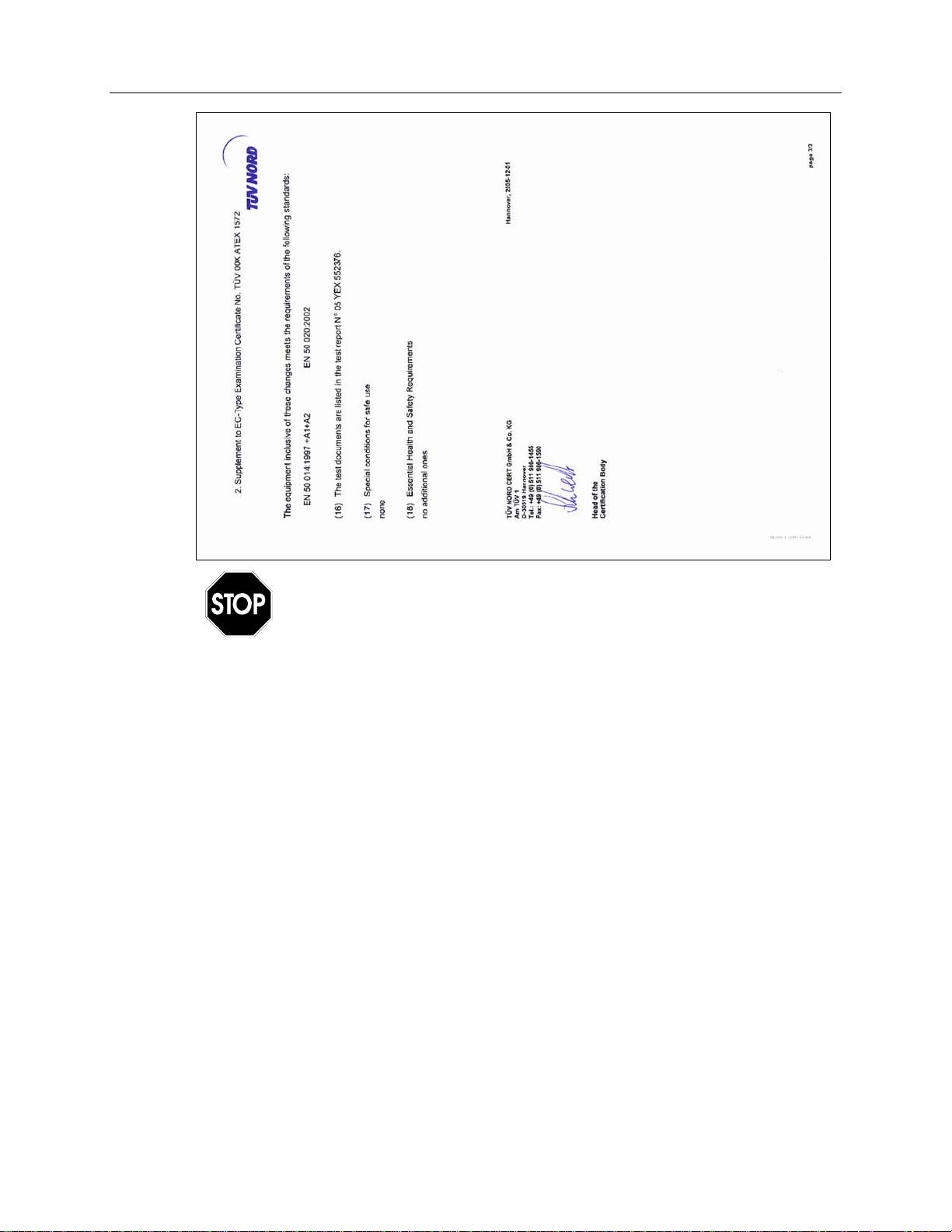

Warranty and Certifications 1-9

The approval is valid only when the corresponding indicator displays

on the transmitter nameplate.

1-10 ADS FlowShark Pulse O&M Manual

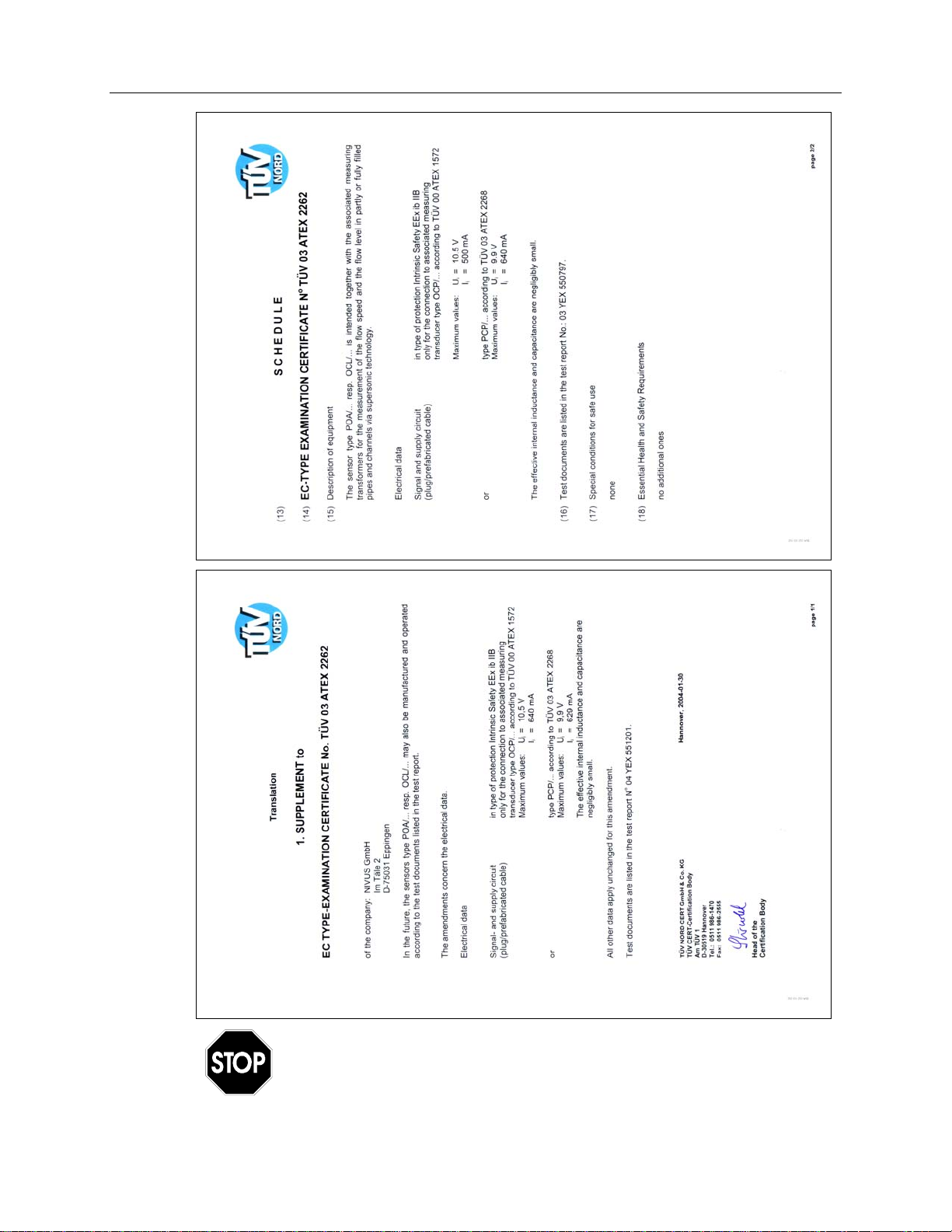

Ex-Approval Sensors

The approval is valid only when the corresponding indicator

displays on the transmitter nameplate.

Warranty and Certifications 1-11

The approval is valid only when the corresponding indicator displays

on the transmitter nameplate.

C H A P T E R 2

Use and Specifications

Please read this instruction manual thoroughly. It contains all the information

necessary to configure and operate the FlowShark Pulse for proper operation. This

manual is written primarily for qualified technical staff that have adequate knowledge

of measurement technology, automation technology, information technology, and

wastewater hydraulics. Reading and following the instructions in this manual before

initial start-up will help ensure success in device configuration. Do not initiate startup until installation is verified and complete.

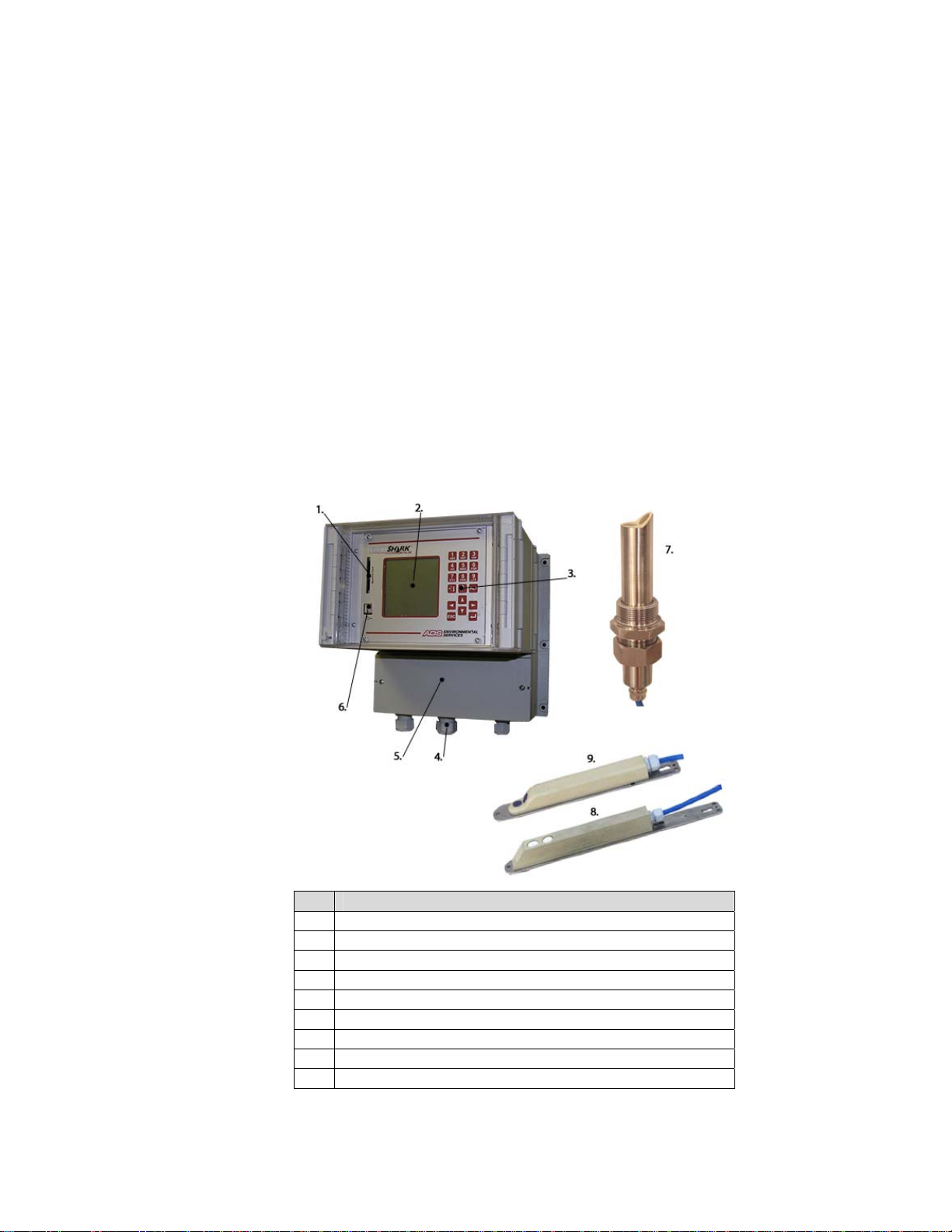

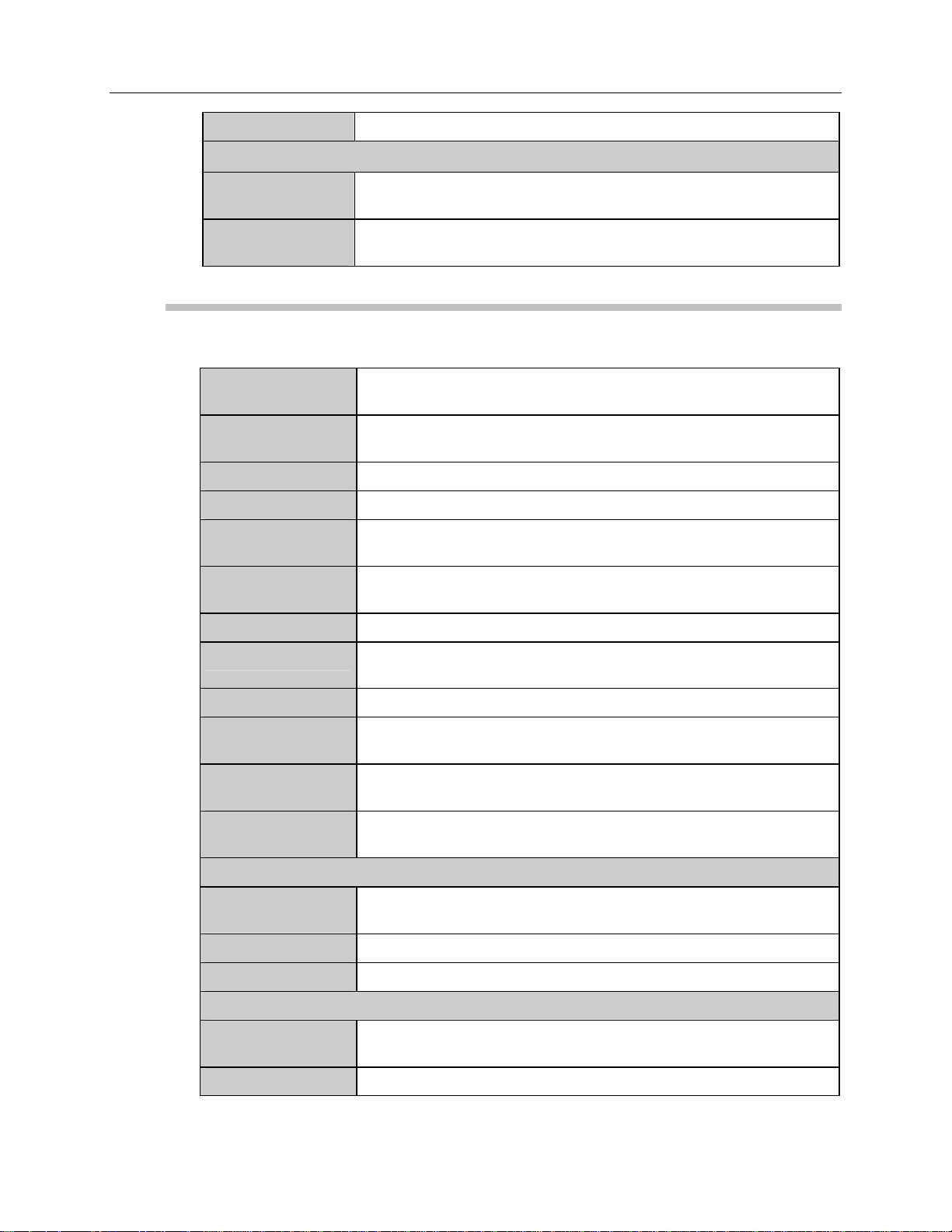

Part Description

1 Memory Card Slot

2 Display

3 Keypad

4 Cable Glands

5 Terminal Clamp Housing

6 USB Interface

7 Pipe Insertion Sensor

8 Air-Ultrasonic Sensor

9 Combi Sensor (Flow Velocity, Water Ultrasonic, and Pressure Depth)

Figure 2-1 Overview

2-2 ADS FlowShark Pulse O&M Manual

Use in Accordance with the Requirements

The ADS FlowShark Pulse and corresponding sensors are designed for measuring

slightly- to heavily-polluted flow in partially-filled and full pipes or other similar

applications. Please adhere to the measurement specifications designated in this

chapter. Monitoring flow under conditions falling outside the documented

specifications of the equipments’ capabilities without prior written permission of

ADS occurs at the owner’s risk.

Modifying or using this equipment for purposes other than the

intended use (described above) without the prior written consent of

the manufacturer will be considered outside the specifications of

the equipment. Therefore, any resulting damages that may occur

will be at the user’s risk or expense.

This equipment has an estimated lifetime of 10 years. Therefore,

inspect and overhaul equipment exceeding 10 years in age.

Ex-Protection

The Ex-version of the FlowShark Pulse active sensor is designed for use in explosive

environments (zone 1).

Always install the transmitter outside Ex-zones!

Approval

Sensor:

Transmitter:

II 2 G EEx ib IIB T4

II(2)G [EEx ib] IIB

Electronic Specifications

Analog sensor connections: Ignition protection type intrinsically-safe

EEx ia IIB

Clamps D8, D9 for connecting certified sensors only

Max values:

U

I

= 23.1 V

0

= 162 mA

0

linear characteristic

Use and Specifications 2-3

Max. outer inductivities allowed 2 mH 1 mH 0.5 mH 0.2 mH

Max. outer capacities allowed 380 nF 430 nF 510 nF 660 nF

Sensor connections Ignition protection type intrinsically-safe

EEx ia IIB

Clamps D1...D5, E1...E5 for connection of accompanying sensors only

F1...F5, G1...G5 Type POA/...OCL/... according to TÜV 03

ATEX 2262

Max. values per circuit:

U

I

= 10.5 V

0

= 640 mA

0

rectangular characteristic

Max. outer inductivities allowed: 0.12 mH

Max. outer capacities allowed: 4.8 µF

The intrinsically-safe circuits are isolated galvanically safe from the remaining

circuits up to a peak voltage of 375 volts.

The certification is valid only when the corresponding label exists

on the transmitter or sensor nameplate.

For installation and initial start-up, perform all work in

accordance with the appropriate certificates of conformity and

testing from the respective authorities.

2-4 ADS FlowShark Pulse O&M Manual

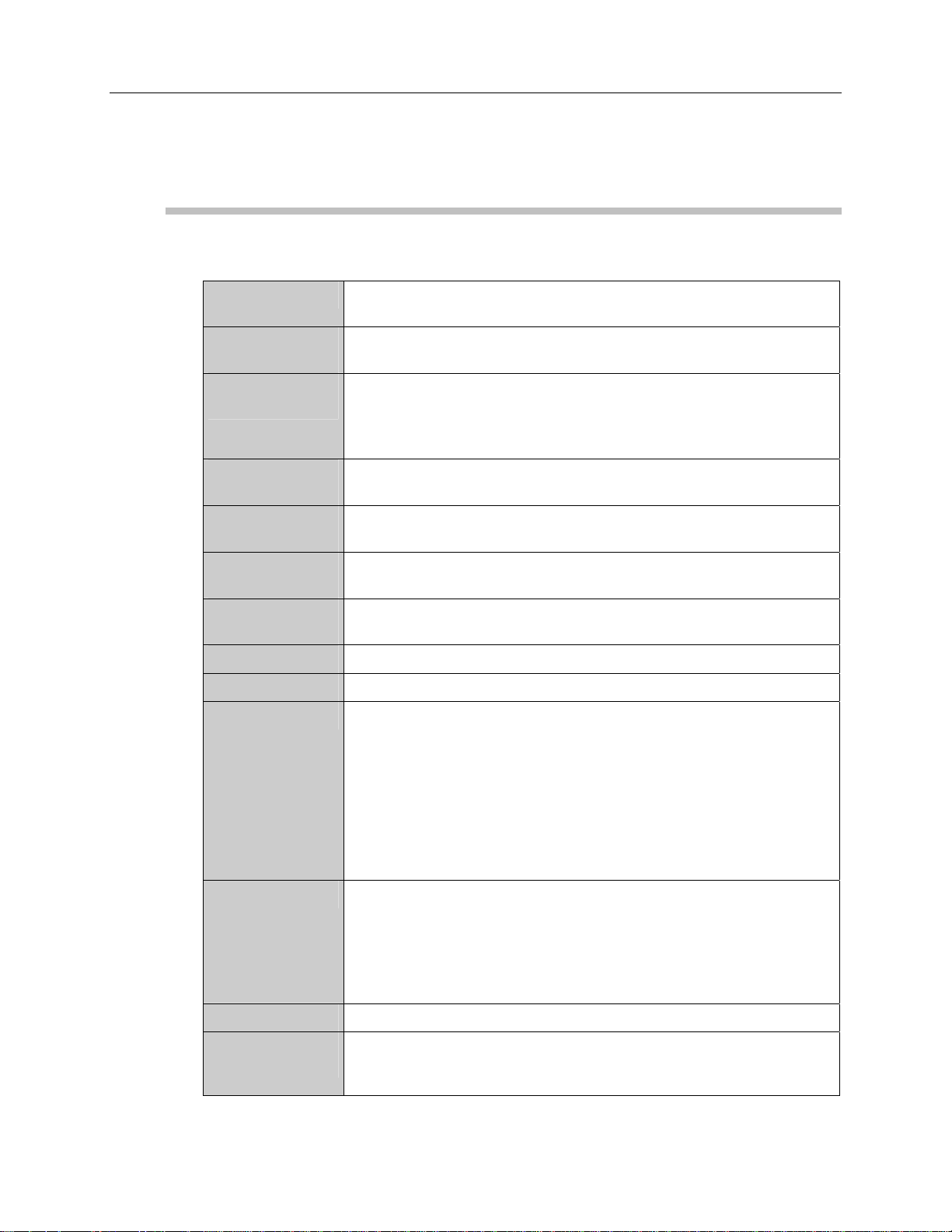

Specifications

Transmitter

Power Supply

Power

Consumption

Wall-Mount

Enclosure

Ex-Approval

(optional)

Operating

Temperature

Storage

Temperature

Maximum

Humidity

Display

Operation

Inputs

100 to 240 V AC, +10% /-15%, 47 to 63 Hz

or 24 V DC ± 15%, 5% residual fluctuation

Maximum 20 VA

• Material: Polycarbonate

• Weight: approximately 6.4 pounds

• Protection: IP65

II(2)G [EEx ib] IIB

-4° to 122° F (-20° to +50° C)

-4° to 158° F (-20° to +70° C)

80%, non-condensing

Back-lit graphic display, 128- x 128-pixel

18 keys, menu-driven in English, German, French, and Italian

• 1 x 4 – 20 mA for external depth measurement (2-wire sensor)

• 1 x RxTx-Bus for ADS air-ultrasonic sensor (Type LUS)

Outputs

Data Storage

Data

Transmission

• 1 (Model 10 transmitter) or 4 (Model 20 transmitter) x 0/4 – 20

mA, 12-bit resolution for external depth measurement, external

setpoints, and data storage setpoint

• 4 digital inputs (Model 20 only)

• 1 (Model 10) or 2/3 (Model 20) velocity sensors connectable

• 1 (Model 10) or 4 (Model 20) x 0/4 – 20 mA, load 500 Ohm, 12-bit

resolution, accuracy greater than 0.1%

• 2 (Model 10) or 5 (Model 20) switchable relays, loadable up to

230V AC / 2 A (cos ϕ0.9)

• RJ45 for Internet communication

Plug-in Compact Flash Card up to 128 MB

Via Compact Flash Card; open protocol via RS 485; direct connection

over a TCP/IP network, internal ISDN, or external GSM/GPRS

gateway

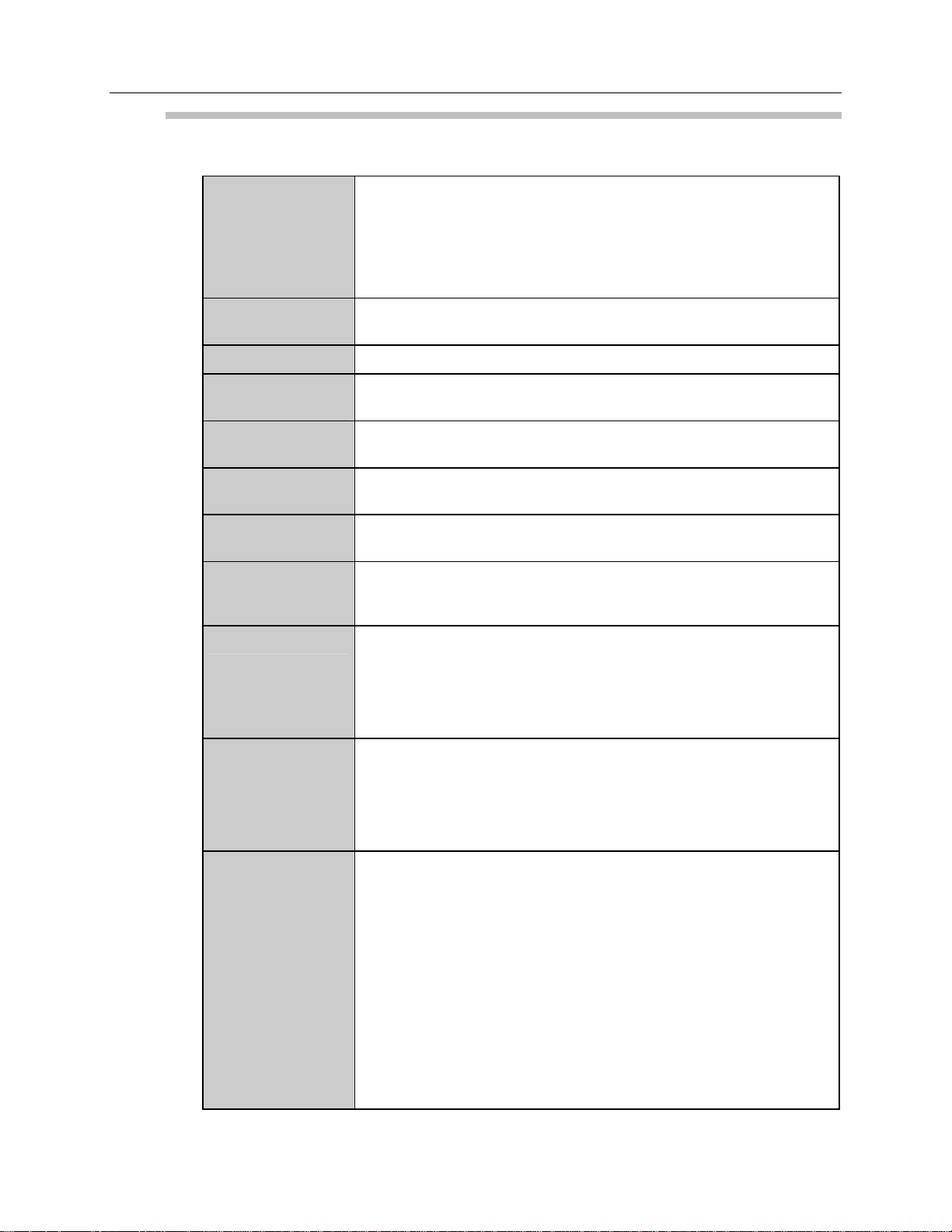

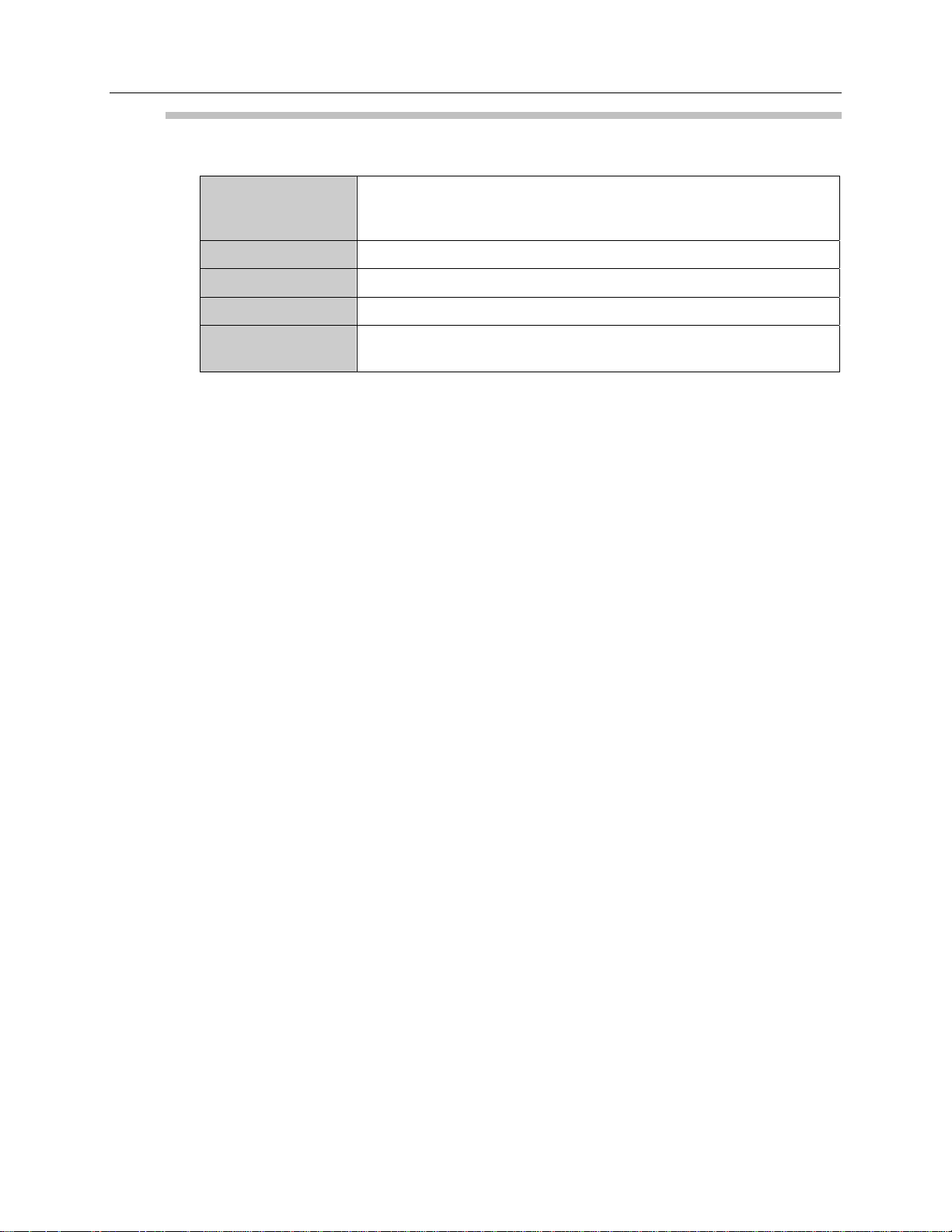

Combi Sensor/Pipe Insertion Sensor

Use and Specifications 2-5

Measurement

Principle

Measurement

Frequency

Protection Rating

Ex-Approval

(optional)

Operating

Temperature

Storage

Temperature

Operating

Pressure

Cable Length

Cable Types

• Ultrasonic transit time (depth measurement) – Combi Sensor

only

• Piezoresistive pressure measurement (depth measurement) –

Combi sensor only

• Correlation with digital pattern detection (flow velocity)

1 MHz

IP 68

II 2 G EEx ib IIB T4

-4° to 122° F (-20° to +50° C) (104° F (40° C) in Ex Zone 1)

-22° to 158° F (-30° to +70° C)

Maximum 58 psi (4 bar) (combi sensor with pressure element

maximum 14 psi (1 bar))

33/66/99/165 feet (10/20/30/50 m), extendable up to 820 feet (250

m); sensors with pressure measurement require pressure

compensation element junction box

• Sensors with pressure measurement:

Outside Cable

Diameter

Sensor Types

LiYC11Y 2x1.5 + 1x2x0.34 + PA 1.5/2.5

• Sensors without pressure measurement:

LiYC11Y 2x1.5 + 1x2x0.34

• Sensors with pressure measurement:

0.34 ±0.01 inches (8.7 ±0.25 mm)

• Sensors without pressure measurement:

0.3 ±0.01 inches (7.6 ±0.25 mm)

• Flow velocity sensor with velocity measurement using cross-

correlation and temperature measurement to compensate for the

effect of temperature on the velocity of sound

• Combi sensor with flow velocity sensor using cross-correlation,

depth measurement via water-ultrasonic, and temperature

measurement to compensate for the effect of temperature on the

velocity of sound (combi sensor only)

• Combi sensor with flow velocity sensor using cross-correlation,

depth measurement via pressure, and temperature

measurement to compensate for the effect of temperature on the

velocity of sound (combi sensor only)

• Combi sensor with flow velocity sensor using cross-correlation,

2-6 ADS FlowShark Pulse O&M Manual

depth measurement via water-ultrasonic (and redundant

pressure measurement), and temperature measurement to

compensate for the effect of temperature on the velocity of

sound (combi sensor only)

Types of

Construction

Medium

Contacting

Materials

Measurement

Range

Zero Point Drift

Measurement

Error

Measurement

Range

Zero Point Drift

Measurement

Error

• Wedge sensor for installation on pipe bottom

• Insertion sensor for installation through pipe wall with nozzle and

cutting ring

Polyurethane, stainless steel 1.4571, PPO GF30, PA (combi sensor

only)

Option: Sensor made of PEEK, resistant against chemical

substances, Hastelloy mounting plate, Titanium mounting plate, FEP

coated cable

Depth Measurement – Water-Ultrasonic

0 to 6.56 feet (0 to 200 cm), lowest absolutely measurable depth

0.13 feet (4 cm)

Absolutely stable

Less than ±0.08 inches (±2 mm)

Depth Measurement – Pressure

0 to 11.5 feet (0 to 350 cm)

Maximum 0.75% of final value (32 °F to 122 °F (0 – 50 °C))

0.5% of final value

<

Measurement

Range

Zero Point Drift

Measurement

Error

Measurement

Range

Number of Scan

Layers

Zero point drift

Error Limits

(per scan layer)

Number of

Sensors

Depth Measurement – External Sensor

Based on device

Flow Velocity Measurement

-3.28 to 19.7 feet per second (-100 to +600 cm/s)

16 (maximum)

Absolutely stable zero point

1% of measurement value (v >3.28 feet per second (1 m/s))

<

0.5 % of measurement value 0.2 inches per second (+5 mm/s) (v

<

<3.28 feet per second (1 m/s))

1 to 3 per transmitter

Use and Specifications 2-7

Sonic Beam Angle

Measurement

Range

Measurement

Error

±5 degrees

-4° to 140° F (-20° to +60° C)

±0.5 K

Air-Ultrasonic Sensor

Measurement

Principle

Measurement

Frequency

Protection Rating

Ex-Approval

Operating

Temperature

Ultrasonic transit time

120 kHz

IP68

II 2 G EEx ib IIB T4

-4° to 122° F (-20 to +50° C) (104° F (+40° C) in Ex Zone 1)

Temperature Measurement

Storage

Temperature

Operating Pressure

Cable Length

Cable Type

Outside Cable

Diameter

Type of

Construction

Medium Contacting

Materials

Measurement

Range

Dead Band

Measurement Error

-22° to 158° F (-30° to +70° C)

Maximum 14 psi (1 bar)

33/66/99/165 feet (10/20/30/50 m), extendable up to 820 feet

(250 m) maximum

LiYC11Y 2x1.5 + 1x2x0.34

0.3 ± 0.01 inches (7.6 ±0.25 mm)

Wedge sensor for installation at top of pipe

Polyurethane, stainless steel 1.4571, PPO GF30, PA

Depth Measurement

0 to 6.56 feet (0 to 200 cm)

0.33 feet (10 cm)

less than ±0.2 inches (5 mm)

Temperature Measurement

Measurement

Range

Measurement Error

-4° to 140° F (-20° to +60° C)

±0.5 K

2-8 ADS FlowShark Pulse O&M Manual

Accessories (Option)

Pressure

Compensation

Element

Memory Card

Read-out Adapter

Read-out Uunit

Pipe Mounting

System

For connection of sensors with integrated pressure measurement

cell

SanDisk compact flash card with 128-MB maximum capacity

Adapter for PCMCIA interfaces, primarily for data read-out via laptop

USB interface for PC connection

For temporarily clamping air-ultrasonic or combi sensors in pipes

DN 200 - 800 (~ID 6 – 32 inches)

C H A P T E R 3

Safety and Identification

Following are the descriptions or interpretations for the general safety or danger

symbols corresponding to the special notes referenced throughout this manual.

Represents cautionary information to observe

Represents special notes

Represents information regarding present dangers associated

with electric voltage

Represents special warnings

To avoid accidents, observe the following information, regulations (such as Exregulations), and safety requirements during installation, initial start-up, and

operation of the FlowShark Pulse.

To ensure safety and maintain the product warranty, ADS must perform all operations

that extend beyond the installation, connection, or configuration procedures

designated in this manual for this device.

Due to the wastewater environment in which the transmitter,

sensors, and cables are installed and operate in the field, this

equipment may become coated with potentially dangerous diseases

and germs. Therefore, please take precautionary measures to

protect human health.

3-2 ADS FlowShark Pulse O&M Manual

Device Identification

The instructions in this manual pertain only to the FlowShark Pulse. The nameplate

affixed to the bottom of the unit contains the following information:

z Name and address of the manufacturer

z CE label

z Type and serial number

z Year of manufacture

z Ex-label (applies only to Ex-version equipment), as noted in Chapter 2

To expedite processing, please specify the article number and serial number of the

respective transmitter or sensor when inquiring about products or ordering

replacement parts.

100-240V~

20VA

Art. Nr. OCP-x3WO xx x3 E xx

Ser. Nr. JKW xx yyzz

II

(2)G

NR. 0032

TÜV 00 ATEX 1572

Figure 3-1: FlowShark Pulse Nameplate

Elektrische Daten

siehe Bescheinigung

This instruction manual is an essential component of the

FlowShark Pulse; therefore, ADS recommends keeping this manual

accessible at all times.

Please follow all safety instructions contained in this manual.

ADS strictly prohibits disabling or altering the function of the

safety devices in any way.

Replacement Parts and Accessories

ADS does not certify replacement parts or accessories that are not supplied by ADS.

Installing and/or using such products could adversely affect the operation of the

equipment. Therefore, users are responsible for all damages incurred as a result of

using parts or accessories supplied by any manufacturer other than ADS.

Safety and Identification 3-3

3-4 ADS FlowShark Pulse O&M Manual

Emergency and Safety Procedures

In case of an emergency, terminate power in one of the following ways:

z Turn off power at the source from the which the FlowShark Pulse is receiving

power.

z Set the slide switch for power on the FlowShark Pulse to the OFF position.

When performing maintenance, cleaning, and making repairs (authorized personnel

only), disconnect the unit from its power source and take the appropriate measures to

prevent it from powering up accidentally during these activities.

User’s Responsibilities

Obtain all local operating permits required and observe the provisions contained

within the permits. In addition, observe all local laws and regulations concerning the

following:

z Personnel safety (accident prevention regulations)

z Work material and tool safety (safety equipment and maintenance)

z Product disposal (laws on wastes)

z Cleaning (cleansing agents and disposal)

z Environmental protection

Before operating this equipment, all personnel involved in installation and initial

start-up activities must consider and acknowledge all local regulations, such as

performing operations in sanitary sewer environments.

Safety and Identification 3-5

Loading...

Loading...