ADS 312rs Installation Manual

automotive

subwoofer

introduction

Thank you for selecting an a/d/s/ subwoofer for your car stereo installation. Your subwoofer was

engineered and built to provide you with exceptional performance which is not only powerful, but

musical as well. Bass extension, detail, and transient response are remarkable. Narrow voice coil

gaps and suspension systems that allow long, linear throw enable these subwoofers to provide the

best performance available in their intended applications.

The A-series and 3-series are comparable in quality. Do not think of one line as the “step-up”

from the other, merely that they are optimized for different applications. The higher cost of the 3series is the result of the dual voice-coils and different materials used to optimize its performance

for smaller enclosures.

· The A-series subwoofers; A8s, A10s and A12s are the optimum choice for vented and bandpass

enclosures, or for infinite-baffle use. They are also a good choice for moderate to large

sealed enclosures.

· The 3-series: 308rs, 310rs and 312rs is best for small sealed and vented enclosures, or for

small single-tuned bandpass applications. The 3-series is not recommended for infinite-

baffle applications.

Both series feature rugged, cast aluminum frames. These assure precise alignment of all the parts

and also help conduct heat away from the voice-coil. All models use massive high efficiency vented

magnet structures with extended center poles for excellent linearity and high power handling.

The A-series utilize a single 4-Ohm voice coil wound with oxygen-free copper wiring and bonded

to a Kapton former with Thermoset adhesives. The 3-series feature Bifilar wound dual 4-Ohm

voice coils on anodized aluminum formers. The mineral filled injection-molded cones of the Aseries are light and rigid, guaranteeing high SPL capability without cone breakup in vented enclosures or when used infinite baffle. The 3-series use anodized aluminum cones chosen for their

extreme stiffness and higher mass, making them ideal for small sealed enclosures.

getting the most from your subwoofers

As with any subwoofer, how you use it is as important as the qualities of the woofer itself. The

enclosure in which you mount the driver, is vital to it’s resulting performance. There are a variety

of different enclosure designs to choose from, each with their unique benefits and disadvantages.

Of the myriad of choices, the most common designs used in car audio are:

· Infinite Baffle - sometimes called “free-air”.

· Sealed enclosure - a.k.a. “acoustic suspension”.

· Vented enclosure - a.k.a. “bass reflex”

· Single-reflex bandpass

2

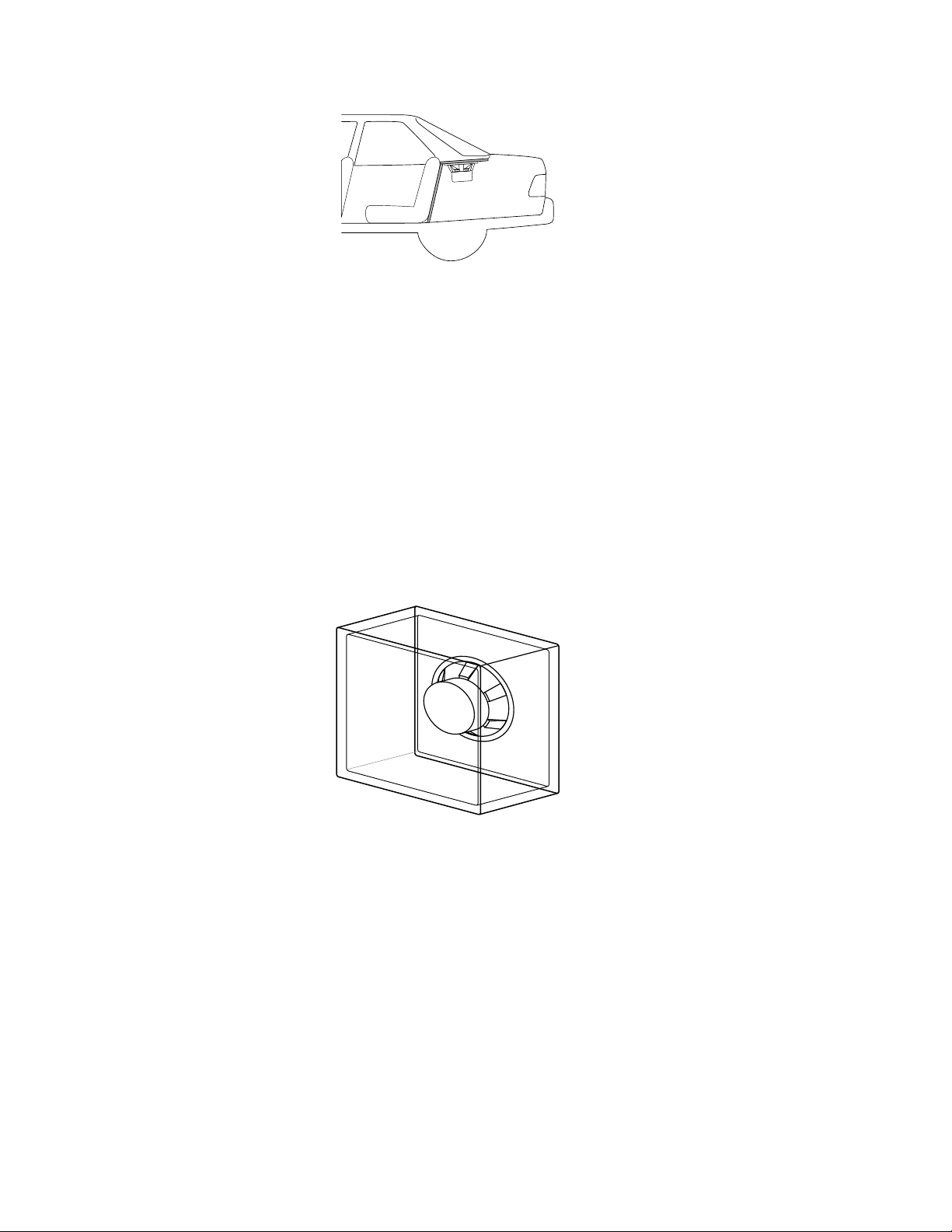

infinite baffle

An infinite-baffle system has no separate enclosure, per-se. In effect, it uses the trunk of the

automobile as the enclosure. When installed properly, this system acts like a large sealed enclosure, without occupying any trunk space. In

theory, the trunk is so large, that it’s effect on the

woofer’s frequency response is insignificant, and

the output is essentially the same as the driver

alone. Virtually all the sonic characteristics of

sealed systems are valid for infinite baffle installations. Installation time is typically less than other

systems because no enclosure is constructed.

Excellent performance can be achieved this way,

at the expense of maximum SPL.

This is because all of the other enclosure types help control woofer cone motion at low frequencies or high output levels. In an infinite-baffle installation, the woofer’s suspension and motor

assembly are the only forces controlling the cone motion, so high signal levels are more likely to

cause woofer bottoming.

To use an A-series woofer this way, we recommend a baffle board be constructed from at least ¾”

thick MDF (medium density fiberboard). The baffle is most commonly mounted to the underside of

the rear package shelf, or behind the rear seat. It should be sealed against the vehicle structure

with gasket material, so that it is completely isolates the sound from the rear of the woofer from

the sound from the front. If there is a solid metal panel between the woofer and the vehicle

interior, it must be perforated for the sound to get through. Do not cut large areas of metal out of

the shelf since it acts as a structural support in most cars. Instead, perforate it with small diameter

holes. Some automobiles have solid metal between the trunk and the back of the rear seat which

provides adequate isolation. With other seats, especially the fold down type, another piece of

MDF should be installed as an isolation wall.

sealed

Sealed enclosures, sometimes called “acoustic

suspension” systems provide extremely accurate

musical reproduction. They are easy to construct

and provide the most consistent results. Maximum SPL is somewhat lower than vented systems, but the gradual response roll-off of these

systems works well in concert with the acoustic

loading of automobile interiors. This means that

they often provide deeper bass response in the

automotive environment than vented systems.

Acoustic suspension systems also typically provide

the best musical detail and definition.

3

Loading...

Loading...