ADS 310px Owner's Manual

the px story

Your 310px component subwoofer is the finest subwoofer ever from a/d/s/. Like other

models in the px system, the 310px sets a new standard of musical performance and precise

construction.

The philosophy behind px is to build products which are not compromised in any way by price

constraints or manufacturing simplicity. With all px series products, musical performance takes

precedence over all other considerations. Each design choice made during the engineering

process was made to provide optimum performance not attainable with conventional materials and construction.

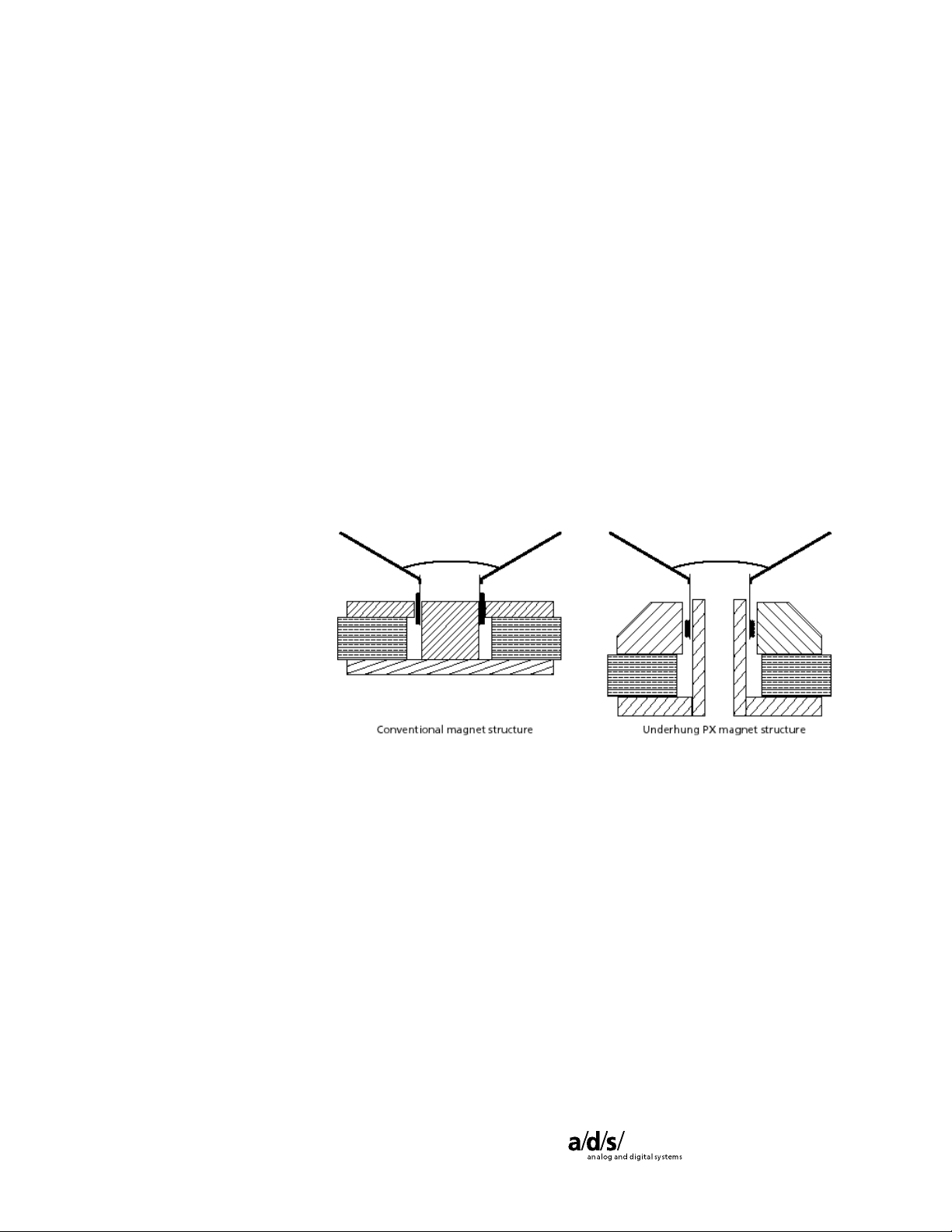

In the 310px, this philosophy results in a precisely machined frame of Aluminum, Brass, and

Stainless Steel. This frame is hand assembled to precise tolerances, assuring perfect alignment

of all of the moving parts. Additionally, the magnet and voice coil assembly are of an "underhung" design, which dramatically improves linearity and results in much lower harmonic distortion than with conventional woofers. The anodized aluminum cone and voice coil help dissipate heat from the motor structure, thereby improving power handling and reducing dynamic compression of the signal.

These improvements add up to make the 310px the most musically accurate low frequency

driver we have ever produced.

using the

310px

2

The 310px was carefully engineered for optimum use installed in a small sealed enclosure in

a typical automotive environment. The parameters were chosen to yield a gentle low frequency rolloff, which combines with the typical vehicle transfer function to give extended low

frequency performance with excellent transient response. The optimum recommendations are

given in the specifications section of this manual.

The 310px may also be used in single-tuned bandpass or vented enclosures if different results

are desired, or if the application demands it. Using the 310px in a vented enclosure will typically give you higher SPL capability than in a sealed enclosure, but with the penalty of additional group delay and compromised transient response. Due to the effects of the vehicle's

transfer function, a typical vented enclosure will give you a slight bass emphasis above the

enclosures cutoff frequency, with a sharp rolloff below it. Most practical bandpass enclosures

will also share this characteristic, with the added disadvantage of signal compression and wind

noise through the port at high SPL. However, the vented option may be appropriate if you

value SPL above audiophile sound quality. A bandpass enclosure can sometimes be the best

choice if the bass must pass through a small panel, since you only need enough panel space

to pass the port through.

While the 310px is very rugged in use, some aspects of its design require careful handling

during installation. In particular, the voice coil is vented below the spider. This improves

power handling and linearity, but it also provides a path for particles to become lodged in

the voice coil.

• Keep the 310px in its protective plastic bag until you are ready to install it.

• Keep the unit away from sawdust and metal shavings.

• Thoroughly vacuum the inside of the enclosure before installing the woofer to

remove any sawdust or wood shavings.

• If using fiberglass or polyester filling in the enclosure, completely cover the rear of the

driver with a piece of cloth between the driver and the filling.

• Do not use wood screws to mount the woofer to the cabinet. Use "T"-nuts and

machine screws only.

• Do not press the dustcap! This will cause permanent deformation.

• Be careful handling the speaker frame to avoid scratching the cosmetic surface.

warnings

and tips

The 310px is unusually heavy and has very high capability. It demands above average enclosure construction to perform at its best. We recommend that you construct the enclosure from

MDF or laminated Baltic birch plywood at least 3/4" (20mm) thick. Whenever possible, 1"

(25mm) thick material is preferred. Due to the unusual beauty of the 310px frame, you may

want to show it off with one or more panels made from clear acrylic. All acrylic panels should

be at least 1" thick. Use "T"-nuts and machine screws to fasten the 310px to the enclosure.

Make certain all of the joints and panels in the enclosure are airtight and rattle-free. Seal any

terminals or wire access holes completely. Seal the driver's mounting surface with foam tape.

Some applications may demand a different solution than the above recommendations allow.

For example, you may need to construct an enclosure from Fiberglass, Kevlar, or Carbon Fiber

in order to fit into an irregularly shaped cavity. When using these materials, try to keep any

unsupported flat wall surfaces to a minimum. Add bracing whenever necessary to keep the

enclosure walls from flexing under pressure.

enclosure

construction

3

damping

material

Enclosure recommendations are given for enclosures with and without damping material as a

filler. Use of filler will yield the smallest enclosure size. If you are building with transparent panels, you will probably not want to use any filler material, so use the "no-filler" enclosure recommendations. For sealed enclosures, or the sealed portion of a bandpass enclosure, the

design recommendations assume fiberglass or polyester damping material installed at a density of 12oz. per cubic foot. It is VERY IMPORTANT that you place a piece of reasonably finetextured cloth between the back of the driver and the filler material. A piece of grill cloth will

work. This will prevent any of the fibers from the filler material from becoming lodged in the

voice coil.

All vented enclosures, sealed enclosures with transparent sides, and the vented chambers of

bandpass enclosures should have all non-transparent cabinet walls lined with 1" thick foam

damping material.

wiring

The terminals used on the 310px will accept up to AWG#8 speaker cable. We recommend

using AWG #12 OFC copper wire to connect the 310px to the amplifier.

For the best contact:

• Do not tin the wire before inserting it into the terminal.

• Do not use any pins or other terminations.

• Do strip the wire approximately 1/2" and insert it into the terminal. The wire will

conform to the inside of the terminal to provide the best contact surface.

4

Loading...

Loading...