Page 1

INDUSTRIAL DIRECT AND INDIRECT/DIRECT EVAPORATIVE COOLING

Engineer designed to satisfy your design requirements.

Modular Components

• Air Handling Modules in side, down or up

discharge and single or dual inlet design.

• Evaporative Media Modules with standard 8” or

Hi-Performance 12” media.

• Indirect Cooling Modules for added cooling

with no moisture added (optional).

Durable Construction

• Galvanized steel with our exclusive

POLYBOND® polyester epoxy powder

based coating ensures years of dependable

service.

Effi ciency

• Choice of media modules allows cooling

effi ciencies tailored to your design

requirements.

Cost Effectiveness

• Competitive fi rst cost combined with substantial

energy savings over refrigerated air units results in

quick payback. Plus, the simplicity of design allows

low maintenance requirements.

Other Features

• Precision balanced blower wheel.

• Solid shaft for rugged durability.

• AdobeAir motors and pumps are U.L. Recognized.

• City of Los Angeles (C.O.L.A.) approved.

• AMCA Licensed ratings

• U.L. Classifi ed

• U.L. Listed

Dual Inlet

Models MD628, MS628, and MU628 U.L. Classified

Shown with 12” media modules DM120

Models UD980 and US980 U.L. Listed

Shown with 12” media modules UM120

AdobeAir, Inc. certifies that the evaporative air cooling products

shown herein are licensed to bear the AMCA Seal. The ratings

shown are based on tests and procedures performed in

accordance with AMCA Publication 211 and comply with the

requirements of the AMCA Certified Ratings Program.

Single Inlet

Models MD524 and MS524 U.L. Classified

Shown with 12” media modules DM080

Models UD960 and US960 U.L. Listed

Shown with 12” media modules UM080

Page 2

SINGLE-STAGE INDUSTRIAL EVAPORATIVE COOLING

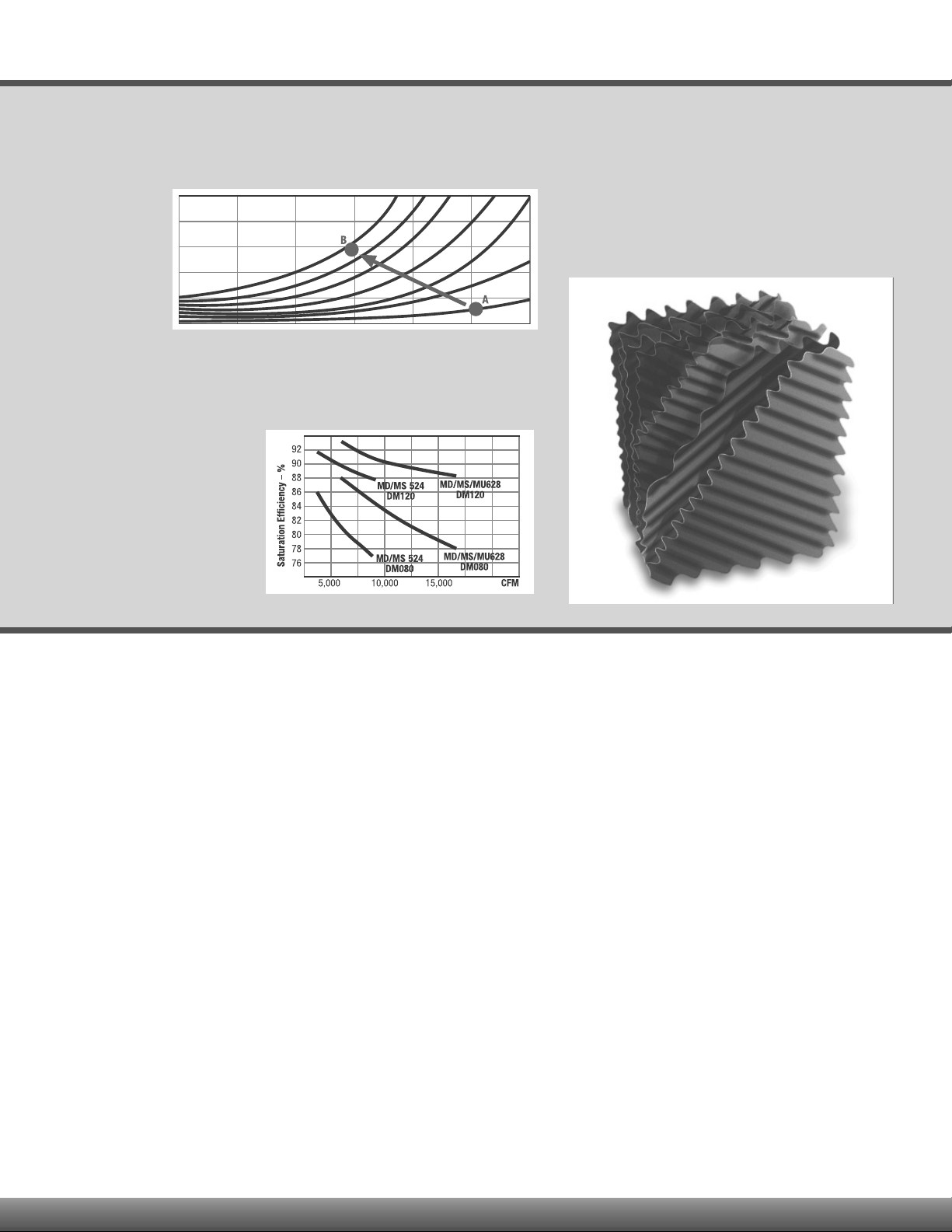

Direct Evaporative Cooling Process

Direct evaporative cooling exchanges sensible heat for latent heat,

and follows upward along a constant wet-bulb temperature line on the

Psychrometric

Chart. The result

is a dry-bulb

temperature of

the leaving air

(B) approaching

the wet-bulb

temperature of the

entering air (A).

Standard and Hi-Performance Models

The fl exibility of modular components allows selection of CFM and

saturation effi ciencies producing the sensible heat capacities needed to

meet design requirements. For

many applications, our standard

8” media continues to be an

economical choice, with an 80%

saturation effi ciency at 450 FPM.

For more demanding design

conditions, our 12” media offers

90% effi ciency at around 450

FPM.

MasterCool Evaporative Media

MasterCool evaporative media is constructed

of special cellulose material, impregnated with

insoluble anti-rot salts and rigidifying saturants.

The cross-fl uted design continually directs

water to the air-entering side, inducing a highly

turbulent mixing of air and water for optimum

heat and moisture transfer.

Direct Evaporative Cooling

Put simply, whenever water is evaporated, heat

is absorbed. This basic principle underlies the design

of the MasterCool direct evaporative cooler.

High Quality Construction

Hot-dipped galvanized steel, welded for maximum

strength is combined with our exclusive POLYBOND®

fi nish that protects the whole system – cabinet

pans, distributor covers, louvers, and all other parts

contacting water. The electrostatically applied

polyester epoxy powder-based coating is cured at high

temperature and is so durable that these models are

backed by the best warranty in the industry.

Energy Efficient...

Environmentally Friendly

With no compressors or condensors, MasterCool

evaporative coolers offer signifi cant energy savings

over mechanical refrigeration units; and, with no

CFC’s, do not contribute to depletion of the ozone

layer. Their air washing effect improves indoor air

quality with fresh, fi ltered air constantly brought into

the cooled space...forcing stale air out.

Comfort Levels

Not only does evaporative cooling lower the temperature

in the space to be cooled, it also lowers the temperature

you feel. Rapid air movement produced by the

MasterCool increases skin evaporation which causes you

to feel 3-5° effectively cooler than the temperature read

from a thermometer. Evaporative cooling can provide

effective temperatures acceptable in most commercial/

industrial applications throughout the world.

Typical Applications

The Industrial MasterCool is used for area cooling or

spot cooling. In many areas it can replace or supplement

mechanical refrigeration needs in agricultural,

institutional, commercial, and industrial applications.

Applications such as kitchens, laundries, gymnasiums,

heat treating areas, and dry cleaning plants requiring

large quantities of fresh air moving through the building

are ideal candidates for evaporative cooling.

Page 3

2-STAGE INDUSTRIAL EVAPORATIVE COOLING

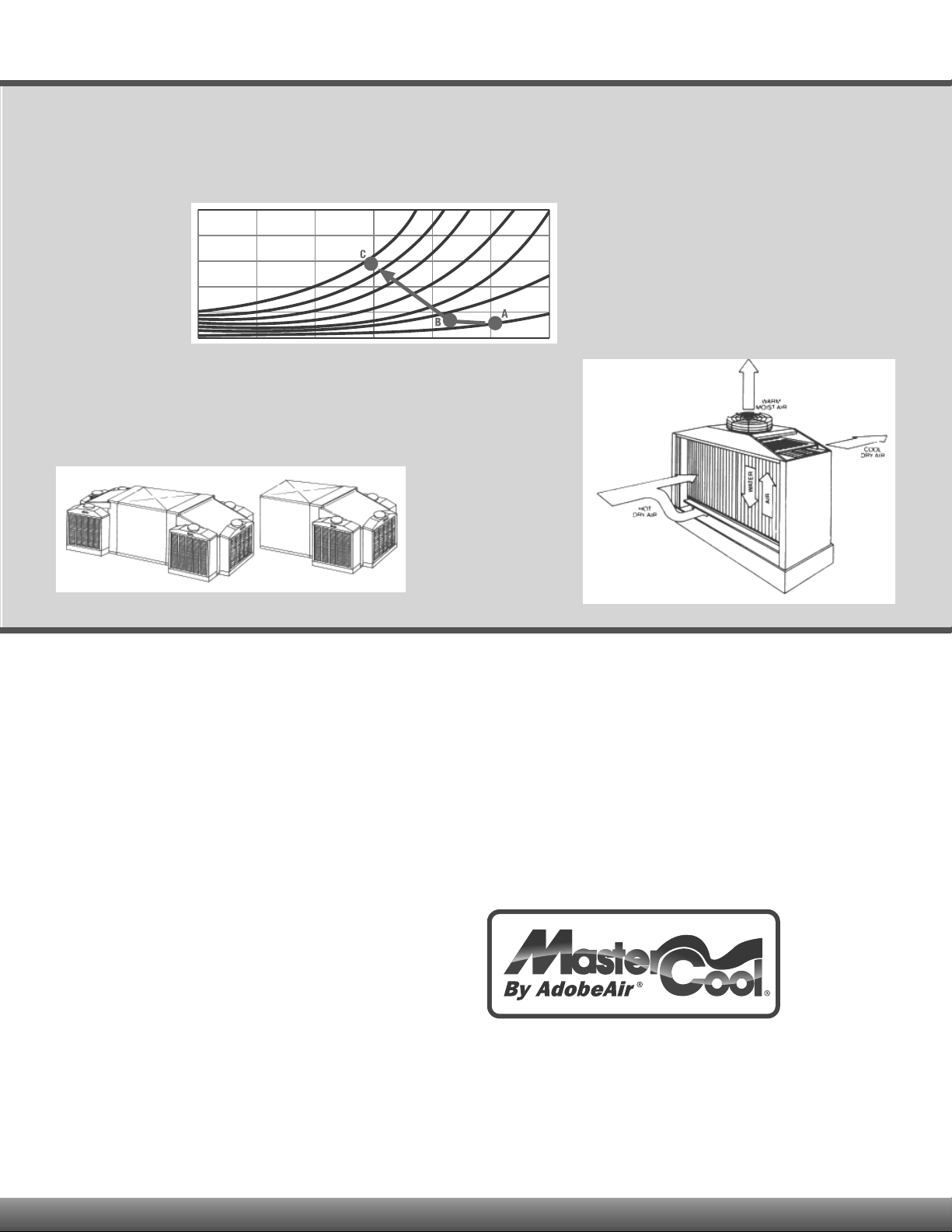

Indirect/Direct Evaporative Cooling Process

In the indirect cooling stage, entering air is cooled along a horizontal

humidity ratio line on the Psychrometric Chart (A to B) without adding

moisture. In the next cooling stage, this air is further cooled along a new

wet-bulb line (B

to C), resulting in

a lower dry-bulb

temperature of

leaving air than

can be achieved

with single stage

direct evaporative

cooling alone.

Typical Confi gurations

Many confi gurations of 2-Stage Industrial MasterCool are possible.

Typical fi eld-assembled components include 2 or 3 Indirect Cooling

Modules with Models MD/MS524 and 4 or 6 ICM’s with models MD/MS/

MU628 Contact your

local MasterCool

representative for

assistance in sizing.

Models shown with

three ICM’s at each

inlet location.

The Indirect Cooling Module

Outside air is drawn into the ICM. A fan

draws air through the inside of vertical fi ns

(which have water running inside them). The

air picks up heat and is expelled from the

ICM while the fi ns are cooled by evaporation.

Other outside air is drawn across the outside

surfaces of the cooled fi ns, and is cooled

without coming in contact with water. This

cooled air, with no humidity added, then

enters the direct evaporative section of the

Industrial MasterCool for fi nal cooling.

2-Stage Indirect/Direct

Evaporative Cooling

2-Stage cooling allows you to use energy-saving

evaporative cooling technology for design conditions

where direct evaporative cooling alone is not adequate.

A 2-stage cooler results in greater cooling power, less

affected by higher ambient temperature and humidity.

In the indirect cooling stage, outside entering air

is cooled sensibly reducing its total enthalpy. This

“precooled” air is then evaporatively cooled in the direct

cooling stage, approaching its new, lower

wet-bulb temperature.

The end result is discharge temperatures near or

even slightly below the wet-bulb temperature.

More importantly, these lower discharge temperatures

translate into customer comfort at a fraction of the cost

of refrigerated air conditioning.

Applications

With its substantial increase in cooling capacity, the

indirect/direct 2-stage Industrial MasterCool can replace

mechanical refrigeration in many applications.

KoolKalk...

Computer Aided Sizing

The sizing method described in this brochure can be used

for general sizing of direct evaporative Industrial MasterCool

units.

For more accurate sizing, and for sizing indirect/direct units,

we recommend the use of KoolKalk... an IBM compatible

computer program designed specifi cally for AdobeAir

Evaporative Coolers. For more information please visit the

AdobeAir, Inc. website at www.AdobeAir.com.

Page 4

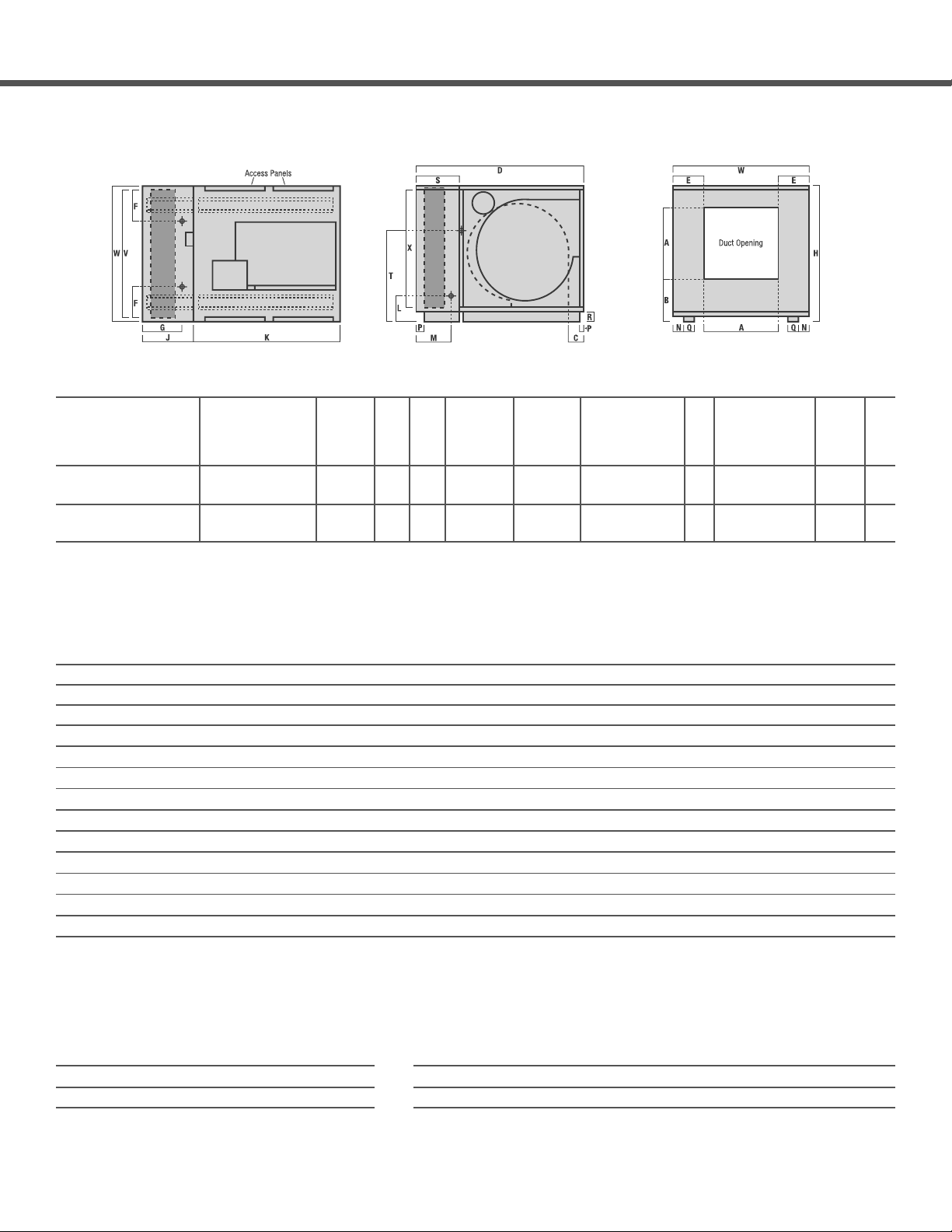

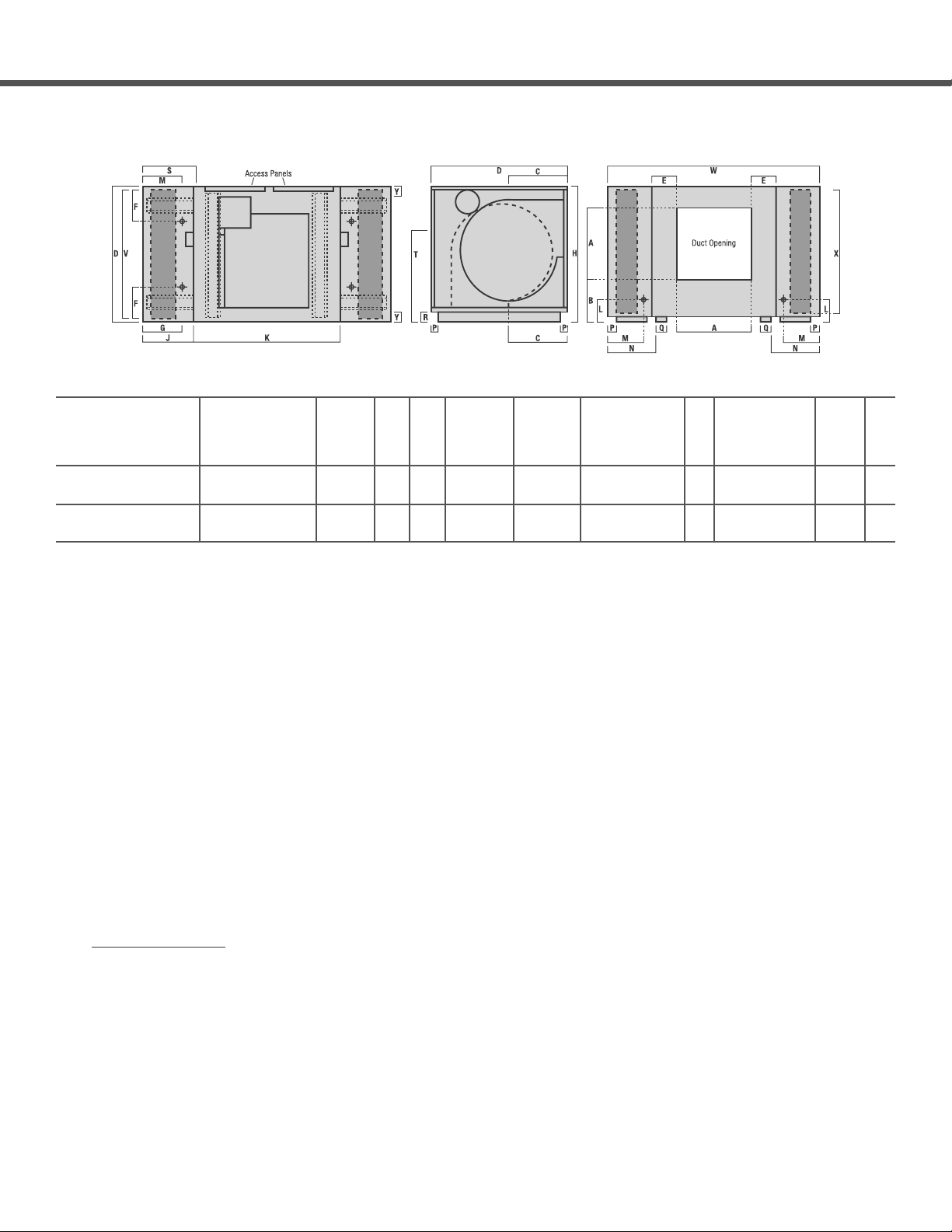

DIMENSIONS AND SPECIFICATIONS

Single Inlet Model Dimensions MD524 or UD960 (Down Discharge) and MS524 or US960 (Side Discharge)

Top View Side View Front View

MD/MS524 or UD/US960

Media Section Cabinet Duct Location Drain1 Media Blower Water2 Electric3 Blower Wheel

Model Number Location Cabi- Cabi- Service Service

1 Required Side Down net net Location Location Pitch

H W D A B C E F G J K L M S T Dia. Width Shaft Dia. N P Q R X V Sq.Ft.

DM080

or UM080 51

DM120

or UM120 51

1. Drain is 3/4” male hose thread.

2. Water service can be left or right for 1/4” tubing.

3. 7/8” knockout for running electrical service.

½ 491/8 66 26¾ 17 3 11¼ 13 133/8 17 491/8 7¼ 123/8 18 35½ 24 24 13/16 13 2 15/8 4 2½ 445/8 48 14.8

½ 491/8 70 26¾ 17 3 11¼ 13 173/8 21 491/8 7¼ 163/8 22 35½ 24 24 13/16 13 2 15/8 4 2½ 445/8 48 14.8

Blower

Skid Location Media Pad

Pulley

Dimension Area

Electrical Specifi cations

HP Speed Phase Voltage Amperage NEMA Frame Shaft Diameter Motor Kit #

¾ 1 1 115/230 12.5/6.2 56 5/8 EJ006

¾ 2 1 230 5.9 56 5/8 EJ020

¾ 1 3 208-230/460 3.0/1.5 56 5/8 EJ883

1 1 1 115/230 15.1/ 7.5 56

1 2 1 230 7.3 56

1 1 3 208-230/460 3.6/1.7 143T

1½ 1 1 115/230 14.5/6.3 143T

1½ 1 3 208-230/460 4.6/2.2 143T

2 1 1 115/230 19.0/8.5 143T

2 1 3 208-230/460 7.1/3.3 143T

3 1 3 208-230/460 8.7-8.4/4.2 182T 1

5 1 3 208-230/460 14.2-13.0/6.5 184T 1

7½ 1 3 208-230/460 20.9-19.2/9.6 213T 1

• Amperage from National Electric Code. • See nameplate on actual motor for amperage in fi guring overload protector.

• Single phase motors rated 230 volts can be operated at nameplate amps at 208 volts. • All 3-phase motors listed are suitable for use on evaporative coolers at 200 volts.

5

/8 EJ007

5

/8 EJ021

7

/8 EJ665

7

/8 EJ212

7

/8 EJ666

7

/8 EJ213

7

/8 EJ667

1

/8 EJ668

1

/8 EJ659

3

/8 EJ675

Pump Specifi cations

Pump Volts Amps Watts GPH

Model# At 4’ Head

CP280 115 1.2 80 300

CP480 230 .6 80 300

Note: Pumps are available in 115 volt and 230 volt models. As a

result, transforming or separate circuiting may be required for

other voltages.

Bleed Rates GPH per Media Module

Blower Model Blower Motor HP

524 or 960 7 8 9 10 10 – –

628 or 980 – 11 13 14 16 18 20

¾ 1 1½ 2 3 5 7½

Page 5

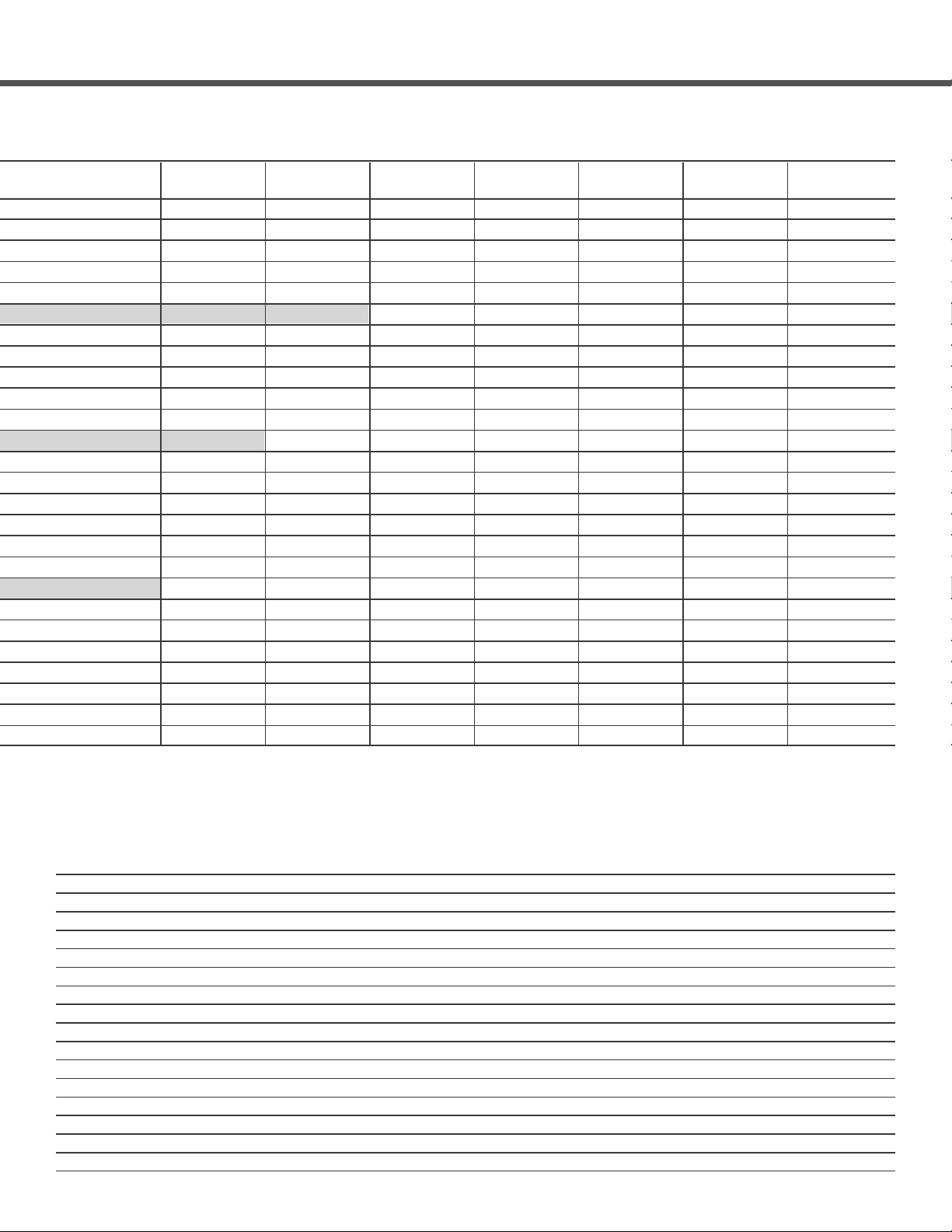

Dual Inlet Model Dimensions MD628 or UD980 (Down Discharge), MS628 or US980 (Side Discharge) and MU628 (Up Discharge)

Top View Side View - Blower Section Front View

(UP)

(DOWN)

MD/MS/MU628 or UD/US980

Media Section Cabinet Duct Location Drain1 Media Blower Water2 Electric3 Blower Wheel Blower Skid Location Media Pad

Model Number Location Cabi- Cabi- Service Service Pulley Dimension Area

1 Required Side Down net net Location Location Pitch

H W D A B C E F G J K L M S T Dia. Width Shaft Dia. N P Y Q R X V Sq.Ft.

DM080

or UM080 51

DM120

or UM120 51

1. Drain is 3/4” male hose thread.

2. Water service can be left or right for 1/4” tubing.

3. 7/8” knockout for running electrical service.

½ 831/8 491/8 31¾ 17¾ 15¼ 8¾ 13 133/8 17 491/8 71⁄4 123/8 18 35½ 28 28 13/16 18 19 15/8 2 4 2½ 445/8 48 14.8

½ 911/8 491/8 31¾ 17¾ 15¼ 8¾ 13 173/8 21 491/8 71⁄4 163/8 22 35½ 28 28 13/16 18 23 15/8 4 4 2½ 445/8 48 14.8

Sizing Instructions

Follow these steps to properly size the Industrial MasterCool. The performance or

Sensible Heat Capacity of any cooler is a function of both the CFM and saturation

effi ciency (which determines the delivered air discharge temperature). Sizing by

only considering CFM may result in an improperly sized application.

1. Determine design conditions:

Outdoor Dry-Bulb DB1

Outdoor Wet-Bulb WB1

Indoor Dry-Bulb T1

2. Determine design sensible heat load (Btuh)

3. Determine leaving air temperature (LAT):

LAT = DB1 - [(DB1 - WB ) * EFF]

where EFF ‘ 0.80 for 8” media or 0.90 for 12” media

4. Determine CFM required:

CFM = 0.925 * Sensible Heat Load

(T1 - LAT)

5. Determine the cooler(s) required:

Refer to the specifi cation / air fl ow charts on next page.

6. Use KoolKalk to account for various losses:

This will result in more accurate sizing.

Motor Sheave Selection

1. Determine the external static pressure of the air delivery system.

2. Determine the motor (H.P., Voltage and Phase) required to deliver the design

airfl ow.

3. Determine the shaft size for the motor selected.

Refer to the Electrical Specifi cations chart on facing page.

4. Determine the RPM that will deliver the required airfl ow (CFM) at the static

pressure of the system.

Refer to the Certifi ed Air Delivery CFM chart for the chosen cooler and selected

motor HP.

5. Determine the sheave, and the number of turns open, that is closest to the

desired RPM.

Refer to the Sheave Selection charts on the next page. Find the selected motor HP,

shaft size, and desired RPM (See Steps 2-4 above). You might need to look at more

than one sheave before fi nding the correct RPM.

6. Specify the sheave and sheave setting (turns open) for the installer.

Ordering

When ordering your cooler, you should know this information.

• System design static pressure.

• Desired air volume at system design.

• Electrical power supply available.

• Stability of structure to support operating weight of unit.

Complete systems consist of the following components, and are sold separately

for application versatility.

• Cabinet – 1 blower section

• Wet media section (1 for 524’s - 2 for 628’s)

• Motor

• Motor sheave

• Pulley-belt kit

• Pump (one required for each media section)

NOTE: Motor starters, internal wiring and over-current protection are not supplied.

Page 6

DIMENSIONS

Certifi ed Air Delivery CFM at Various External Static Pressures

Inches Water Gauge. AMCA Licensed Ratings.

Operating Belt information .0 .0 .1 .1 .2 .2

Model Weight BHP Quantity Down Side Up CFM RPM CFM RPM CFM RPM

524 with DM080 or 960 with UM080 — 8” Media

560 ¾ 1 AX78 AX80 6390 298 6070 310 5710 320

570 1 1 AX78 AX80 7030 329 6760 339 6420 349

575 1½ 1 AX78 AX80 8050 376 7810 385 7530 394

580 2 1 AX78 AX80 8860 414 8640 422 8400 430

590 3 1 AX78 A82* 9050 422 9050 440 9050 459

524 with DM120 or 960 with UM120 — 12” Media

600 ¾ 1 AX78 AX80 6250 298 5900 309 5550 321

610 1 1 AX78 AX80 6880 328 6560 338 6250 349

615 1½ 1 AX78 AX80 7880 376 7600 384 7320 393

620 2 1 AX78 AX80 8670 414 8420 421 8160 429

630 3 1 AX78 A82* 9050 422 9050 439 9050 458

628 with two DM080 or 980 with two UM080 — 8” Media

818 1 1 A95* A95* A95 9720 214 9320 224 8650 235

823 1½ 1 A95* A95* A95 11130 245 10720 254 10230 263

828 2 1 A95* A95* A95 12250 270 11890 278 11460 286

838 3 2 A97 A97 A95 14020 309 13720 316 13350 323

858 5 2 A97 A97 A95 16620 367 16390 371 16080 378

898 7½ 2 A100* A100* A95 18100 406 18100 418

628 with two DM120 or 980 with two UM120 — 12” Media

908 1 1 A95* A95* A95 9680 216 9080 226 8530 237

913 1½ 1 A95* A95* A95 11080 248 10540 256 10080 265

918 2 1 A95* A95* A95 12190 273 11700 280 11260 288

928 3 2 A97 A97 A95 13950 312 13510 318 13130 325

948 5 2 A97 A97 A95 16540 370 16050 375 15820 380

988 7½ 2 A100* A100* A95 18100 406 18100 409 18100 428

Shaded Areas: Do not exceed listed RPM, water entrainment may result.

NOT RECOMMENDED

*Not supplied: MS524 coolers with a 3 HP motor require the purchase of one A82 belt

(AX78 belt included with unit). MD628 and MS628 coolers with 1, 11⁄2 or 2 HP motor

requires one A95 belt (two A97 belts included with unit). MD628 and MS628 coolers

1

with 7

⁄2 HP motor require two A100 belts (two A97 belts included with unit).

MD/MS 524 or UD/US 960 Sheave Selection

Motor HP Browning Bore Blower RPM / Sheave Turns Open MasterCool

Part # 5 4 ½ 4 3 ½ 3 2 ½ 2 1 ½ 1 ½ 0 Package #

Single Phase Motor Blower RPM @ 1725 Motor RPM / Sheave Turns Open

¾, 1 1VL34 5/8 252 265 279 292 305 318 332 345 358 372 385 EL114

¾, 1 1VL40 5/8 318 332 345 358 372 385 398 411 425 438 451 EL110

1½, 2 1VL40 7/8 318 332 345 358 372 385 398 411 425 438 451 EL112

¾, 1 1VL44 5/8 372 385 398 411 425 438 451 464 478 491 504 ESH2411

1½, 2 1VL44 7/8 372 385 398 411 425 438 451 464 478 491 504 EL685

1½, 2 1VP50 7/8 451 464 478 491 504 518 531 544 557 571 584 686

Three Phase Motor Blower RPM @ 1750 Motor RPM / Sheave Turns Open

¾ 1VL34 5/8 256 269 283 296 310 323 337 350 363 377 390 EL114

1 1VL34 7/8 256 269 283 296 310 323 337 350 363 377 390 EL116

¾ 1VL40 5/8 323 337 350 363 377 390 404 417 431 444 458 EL110

1, 1½, 2 1VL40 7/8 323 337 350 363 377 390 404 417 431 444 458 EL112

¾ 1VL44 5/8 377 390 404 417 431 444 458 471 485 498 512 ESH2411

1, 1½, 2 1VL44 7/8 377 390 404 417 431 444 458 471 485 498 512 EL685

3 1VL44 11/8 377 390 404 417 431 444 458 471 485 498 512 684

1½, 2 1VP50 7/8 458 471 485 498 512 525 538 552 565 579 592 686

3 1VP50 11/8 458 471 485 498 512 525 538 552 565 579 592 685

Page 7

.3 .3 .4 .4 .5 .5 .6 .6 .7 .7 .8 .8 .9 .9 1.0 1.0

CFM RPM CFM RPM CFM RPM CFM RPM CFM RPM CFM RPM CFM RPM CFM RPM

5320 333 4850 348 4200 373 3670 391 3200 408 2770 426 2400 443 2060 460

6080 359 5720 371 5280 386 4660 409 4160 426 3720 442 3310 458 2940 473

7250 402 6930 412 6630 422 6240 434 5840 449 5260 471 4830 485 4440 499

8140 438 7880 446 7590 455 7310 464 6970 475 6630 487 6140 505 5660 523

9050 475 9050 491 9050 508 8820 516 8570 524 8330 532 8030 542 7730 552

5170 334 4720 349 4070 371 3590 390 3140 407 2740 423 2340 441 1980 458

5910 360 5540 373 5130 386 4510 408 4060 425 3650 441 3270 455 2900 471

7040 403 6740 413 6430 424 6070 435 5620 450 5110 469 4710 484 4350 498

7920 438 7650 447 7380 456 7100 466 6760 476 6440 487 5930 505 5510 520

9050 475 9050 492 8820 509 8570 518 8340 526 8080 534 7790 544 7520 553

8030 246 7380 260 6670 276 5240 308 4540 326 3840 345 3290 363 2740 379

9700 273 9160 283 8600 294 7990 307 7030 329 5890 354 5290 371 4690 387

10980 294 10510 303 10010 313 9500 323 8960 335 8360 348 6990 379 6280 395

12960 330 12540 337 12130 345 11690 353 11250 362 10800 371 10330 382 9810 393

15770 384 15450 390 15090 396 14730 402 14390 409 14020 416 13660 423 13280 430

18100 431 18030 440 17760 445 17440 450 17130 455 16820 461 16520 467 16210 473

7930 248 7220 261 6490 279 5130 310 4390 329 3810 345 3220 361 2630 376

9570 274 9030 285 8420 296 7810 310 6930 330 5760 358 5130 374 4600 388

10830 297 10350 306 9860 315 9310 325 8730 337 8110 353 6900 379 6150 398

12760 332 12370 340 11960 348 11530 356 11070 364 10580 373 10070 384 9630 396

15510 386 15190 393 14890 399 14530 406 14190 412 13820 419 13460 426 13060 433

18010 437 17730 443 17450 448 17190 454 16900 459 16590 465 16300 471 15970 477

• Power ratings (BHP) does not include drive losses. • Performance ratings include the effects of evaporative media in the airstream.

• Belt tension should be 20 pounds for “A” section belts. • Performance shown is for installation type B: Free Inlet, Ducted Outlet.

MD/MS/MU 628 or UD/US 980 Sheave Selection

Motor HP Browning Bore Blower RPM / Sheave Turns Open MasterCool

Part # 5 4 ½ 4 3 ½ 3 2 ½ 2 1 ½ 1 ½ 0 Package #

Single Phase Motor Blower RPM @ 1725 Motor RPM / Sheave Turns Open

1 1VL40 5/8 230 240 249 259 268 278 288 297 307 316 326 EL110

1½, 2 1VL40 7/8 230 240 249 259 268 278 288 297 307 316 326 EL112

1 1VL44 5/8 268 278 288 297 307 316 326 335 345 355 364 ESH2411

1½, 2 1VL44 7/8 268 278 288 297 307 316 326 335 345 355 364 EL685

1 1VP50 5/8 326 335 345 355 364 374 383 393 403 412 422 693

1½, 2 1VP50 7/8 326 335 345 355 364 374 383 393 403 412 422 686

Three Phase Motor Blower RPM @ 1750 Motor RPM / Sheave Turns Open

1, 1½, 2 1VL34 7/8 185 194 204 214 224 233 243 253 263 272 282 EL116

1, 1½, 2 1VL40 7/8 233 243 253 263 272 282 292 301 311 321 331 EL112

1, 1½, 2 1VL44 7/8 272 282 292 301 311 321 331 340 350 360 369 EL685

1, 1½, 2 1VP50 7/8 331 340 350 360 369 379 389 399 408 418 428 686

3 2VP42 11/8 253 263 272 282 292 301 311 321 331 340 350 687

3, 5 2VP50 11/8 331 340 350 360 369 379 389 399 408 418 428 688

5 2VP60 11/8 408 418 428 438 447 457 467 476 486 496 506 689

7½ 2VP60 13/8 408 418 428 438 447 457 467 476 486 496 506 692

Page 8

Project Submittal Sheet Models MD/MS 524, MD/MS/MU 628 — U.L. Classifi ed or UD/US 960, UD/US 980 — U.L. Listed

Project SHL*

Location

Architect

Engineer

Contractor

Submitted By Date

*Total design sensible heat load of project.

Blower Section – Motor – Motor Sheave – Pulley and Belt Kit

Blower Section Motor Specifi cations Kits

Ref. No. Qty. Model No. Motor HP Volts Phase Amps Motor Sheave Belt

1

2

3

4

*NOTE: Each unit (ready to operate) consists of one blower section, one blower motor, one pulley-belt kit, one motor sheave.

Wet Section – Pump

Wet Section Pump

Ref. No. Qty. Model No. Quantity Volts Amps GPM

1

2

3

4

*NOTE: Each wet section (ready to operate) consists of one wet module and one pump.

Your local MasterCool Representative of AdobeAir, Inc., is ready to

assist you in unit selection and application.

The world leader in evaporative cooling technology, AdobeAir, Inc. is continually involved in

the process of product improvement. AdobeAir, Inc. therefore reserves the right to change

specifi cations and/or design without prior notice. To obtain the most current product information

and/or specifi cations, visit the AdobeAir, Inc. web site at www.AdobeAir.com.

Manufactured in Mexico by:

AdobeAir, Inc.

1450 East Grant St.

Phoenix, AZ 85034

www.AdobeAir.com

MasterCool evaporative coolers and components are designed and tested in accordance with

one or more of the following standards or agencies:

Air Delivery: Data published derived from tests conducted in accordance with A.M.C.A. (Air Move-

ment and Control Assoc.) Standard 210.

Sealant: Water Immersion: per ASTM D870. Flexibility: per ASTM D756. Corrosion Resistance: per

ASTM B117. Cycle Freeze/Thaw: per ASTM C117.

POLYBOND®: Corrosion Resistance: per ASTM B117. Pencil Hardness: per ASTM D3363. Adhesion:

per ASTM D3359. Impact Resistance: per ASTM D2794. Flexibility: per ASTM D522. Specular Gloss:

per ASTM D523. Surface Burning Characteristics of Building Materials (best rating) per U.L. 723

and ASTM E-84.

Pumps: Recognized under the U.L. component recognition program for the application – construction, thermal overload, running overload, and locked rotor protection.

Blower Motors: U.L. Recognized general purpose drip-proof.

Polymeric Materials: Tested in accordance with U.L. 94 and 746C. Covered by City of Los Angeles

Research Reports (C.O.L.A.) RR930224 (for all single phase applications), or RR930190 (for 3

phase applications) Electrical, and RR8141 Mechanical.

L900799A March 2007

Loading...

Loading...