Page 1

INSTALLATION

USE AND CARE

PARTS REPLACEMENT

Evaporative cooling works on the principle of heat absorption by moisture evaporation.

Your evaporative cooler draws outside air into specially made pads soaked with water, where the air is

cooled by evaporation, then circulated into your home.

Your MasterCool evaporative cooler has been designed to provide more efficient, consistent cooling

through use of a long-life MasterCool pad. It is a cellulose fiber treated with stiffening and wetting agents

to provide the most reliable evaporative pad ever devised.

Your cooler has two modules - wet and dry - which may be separated for service and cleaning, and

incorporates the most reliable components for long, trouble-free life.

MODELS:

MC43/44B

HC43/44A

MC63/64B

HC63/64A

REQUIRED: A special MasterCool motor kit is necessary for installation.

NOTE! READ AND SAVE THIS MANUAL -

"IMPORTANT SAFETY INSTRUCTIONS"

Model Number

Serial Number

The model and serial numbers for your unit

are located on the data plate attached to your cooler.

Record this information in the space allotted above.

This product covered by City of Los Angeles

Research Reports RR930224 (for all single

phase applications), or RR930190 (for 3 phase

applications) Electrical, and RR8141 Mechani-

cal. Copies of these reports are available from

the manufacturer upon request.

MasterCool" II, 1

Page 2

Installation and Start-Up ............................................................ ................................

Mounting and Securing ....................................................................... 3

Electrical Connections ........................................................................ 3

Grounding ............................................................. '.............................. 3

Installing Motor ................................................................................... 3

Installing Overflow Standpipe and Drain Line ...................................... 4

Connecting Water Supply ................................................................... 4

Faucet Use ......................................................................................... 4

Adjusting Water Level and Float Valve ............................................... 4

Installing Bleed-Off ............................................................................. 4

Installing Float Shield ......................................................................... 4

Maintenance Schedule

Annual Start-Up/Shut-Down ............................................................... 5

Required Exhaust Openings ............................................................... 5

Pre Start-Up Inspection ...................................................................... 5

Periodic Inspection ............................................................................. 5

Checklist ............................................................................................. 5

Cabinet Cleaning & Touch-Up ............................................................ 5

Scratches & Bare Metal ...................................................................... 5

Changing Pad ..................................................................................... 5

Adjusting Belt Tension ........................................................................ 6

Lubrication .......................................................................................... 6

Cleaning Water Pump ........................................................................ 6

Snugging Down Set Screws and Nuts ................................................ 6

Washing Pad ...................................................................................... 6

Parts Replacement

Motor .................................................................................................. 6

Pump .................................................................................................. 6

Float .................................................................................................... 6

Bleed-Off ........................................................................................... 6

Troubleshooting ........................................................................................................ 7

Getting the most from your cooler ...................... t................................................... 7

Maintenance ....................................................................................... 7

Add-On Coolers .................................................................................. 7

Insulation ............................................................................................ 7

Multi-Speed Motor .............................................................................. 7

Attic Vents .......................................................................................... 7

Thermostat Control .......................................................................... 3,7

2 • MastetCooP II

Page 3

Installation. and Start-Up

Read carefully before =nstalhng your MasterCo'bl evaporative cooler.

To install the unit the following tools are

needed:

• 5132" hax key allen wrench

Channel locks

• Pliers

• Adjustable wrenches

Tubing cutter

Screwdrivers

• Hammer

114"Socket wrench

• 7/16" Socket wrench

Before attempting to install the cooler,

make sure the following preparations have

been made:

• Assure that the mounting sudace is

strong enough to bear the weight of the

cooler when in use; remember that

when the system fillswith water, the

cooler will be much heavier than when

dry. The operating weight for MC units is

250 pounds, and for HC units is 295

pounds.

Make sure you have adequate means

for liftingthe cooler in place.

Make sure the mounting sudt_ceis level

in all directions.

• Make sure any ductworkandelectrical

needscomplywithlocal,state,county,

and federalcodes.

Caution: Aft electrical in-

stallations must comply

with local buflding and

safety codes, and must be

performed by qualified

personnel only. ,

Mounting

The blower module and the media module

can be separated before mounting by re-

moving tour bolts and one sh_ppingscrew

-see drawing below.

Placement and Securing

The duct opening for the 63/64 units

should be about 20" x 20"+ The cooler

discharge opening for these models is

19-3/4 x 19-3/4". For the 43/44 units the

duct opening should be about 18" x

15". The cooler discharge opening for

these models is 17-3/4" x 17-3/4".

If the cooler is to be mounted on the roof,

construct a suitable roof stand to support

the entire weight of the cooler. (The roof

jack or ducting should NOT be used to

support any weight ofthe unit). For models

MC63 or MC64 our #785 leg kit,sold sepa-

rately as an accessory, willadequately sup-

port the unit and secure it to the roof. For

High-Performance models HC43. HC44.

HC63 and HC64 we recommend that a full

stand be constructed in such a manner as

to support the entire perimeter of the

cooler. A leg kit only may not provide

adequate support forthese mode!s due to

their increased size and weight.

Place the cooler over the roof jack and

position so that it is level. Carefully seal

the space between the roof jack and bot-

tom of cooler with caulking compound,

silicone, asphalt or industrial sealing

tape to prevent air leakage, Then care-

fully seal the roof jack to roof with asphalt

or caulking compound to prevent air leak-

age from cooler or rain water from leaking

into mot. (See Figure 1). There should be

24 inches clearance on all sides of the

cooler for maintenance.

For maximum cooling performance

and even water distribution, the cooler

must be level. The base of the cooler

at the drain fitting should have at least

4" clearance to allow drain installation.

Electrical Connections

For the convenience of thermostat con-

trol, we recommend installing a

MasterStat TM Universal Cooler Control

Kit, Model CC1000A. Complete installa-

tion instructions are furnished with the

CC1000A Kit. For electrical connections

to a rotary wall switch, use the following

instructions:

Locate the junction box installed inthe dry

module. Junction box is to be installed

with the receptacle facing away from

the pad. Make certain all electrical cords

are clear of the belt, water, pulleys and

blower wheel. Note that there ere two

plug-ins, one for the motor and one forthe

pump. The building power supply must be

connected to this iunction box to provide

power to the motor and pump. The wiring

diagram in Figure 1 shows how the junc-

lion box receptacle should be connected

to the power supply. Make sure contro

switch and circuit breaker are in the OFF

position. Low voltage electrical supply

(below 105 V) may cause insufficient

water supply to pad,

®

Caution: Turn off afi elec-

trical power to the cooler

before attempting to in-

stall, open, or service

your cooler.

Grounding

Install a ground wire to suitable ground

according to local codes.

Install Motor

NOTE: A special MesterCool motor kit

Is necessary for installation due to the

custom designed receptacle In the

junction box.

1. Adjust motor cradle spacing.

2. Place motor in cradle (see Figure 2).

3, Place straps over each end, connect to

cradle and tighten.

4, Align sheave (motor pulley) with blower

pulley by moving sheave in and out on

motor shaft until visual alignment is

achieved. Tighten alignment set screw

to 125 in-lbs. Do not adjust to the point

where the motor sheave comes in con-

tact withthe motor face plate (see Figure

2). Belttensionshould be ad usted so the

beltwi defect 1/21o3/4 nchatthecenter

of the span per Figure 3. Re-adjust belt

tensionafter any pulley adjustment. Re-

place worn or damaged belts.

MOTOR STRAPS

_---'"-___U PPORT BRACKETS

AE_IUSTNENT

BRACKET

F/gure 3

Figure t

230 VOLT INSTALLATION

MasterCoot _ I/, 3

Page 4

Caution: Disconnect all

electrical power to the

cooler and insure that belt

is not rotating before ad-

justing belt tension. Do

not adjust belt tension by

changing dlamefer of ad-

justable sheave. Adjust

belt tension only by ad-

justing motor brackeL

Rotate blower wheel by hand to see that it

moves freely without rubbing against

housing.

Check motor mountinq to be sure all

screws and nuts are tightened down.

If cooler is connected to ductwork, air

delivery and motor amperage will be de-

creased due to increased duct resistance.

To compensate for this, the motor pulley is

adjusted out or in. using an ammeter to

check motor amperage. For maximum air

flow check motor amperage with all ser-

vice panels in place. To prevent overload-

ing of the motor, check amperage with all

windows and doors open and all relief

systems operating. Tighten pulley set

screw to 125 in-lbs.

A qualified serviceman is required to ad-

just motor before start-up.

Caution: Do not exceed

maximum amperage out-

put as stamped on the mo-

tor specification plate or

motor can overload. Only

qualified persons with proper electrical

equipment and knowledge should ad-

just variable pitch sheaves. Do not allow

water to get on the motor, as it will burn

out the windings.

Note on multi-speed switches: A switch

with separate terminals for the pump is

recommended.

Install Overflow

Standpipe and Drain Line

Install overflow drain bushing in bottom

wet section onthe rightside. Screw plastic

overflow standpipe into the drain bushing

and tighten snugly. Slide rubber washer

over drain bushing, push through bottom

of cooler, and tighten nut, Connect a per-

manent drain (copper/pvc/garden hose) to

the drain bushing for draining the unit and

overflow protection. Drain should be in

accordance with local plumbing codes.

FTgure4

WASHER

4 • MesterCooP II

Connect Water Supply

Connect water line to cooler as follows:

• A water valve should be installed at a

convenient location, to allow the water

supply to be turned onand off. 1/4"tubing

is used to provide water to the cooler. A

water connector kit, availubte from your

dealer provides the necessary items.

• Install float valve in the side panel of the

wet section opposite the pump.

• Place tube nut and ferrule over end of

tubing.

• Insert tube into float valve, and tighten to

Secure.

qOTE: Soft water equipment should not be

mttached to any water lines going "to a

ooler. "Soft Water" will cause corrosion

md decrease effective life of cooler.

Figure $

COMPRESSION NUT

FERRULE • _.

_RULE___

Fasten 1/4 inch water supply line to cooler

stand using tubing clamp and self-drilling

screw. Locate tubing clamp 18 inches or

less from water supply line entry intocabi-

net. (See Figure 5A)

f

SI_LF-DRtLUNG

SCREW

1/4" WATER

SUPPlyLINE

Faucet Use

Connect water line to water supply, as fol-

lows (refer to Figure 6).

• Install a sillcock and water valve on

faucet, as shown. Place tubing nut and

ferrule on tube end and insed in valve.

Tighten nuts on valve and tube.

l( faucet is not to be used for water supply,

installvalve on water lineto be used. Follow

instructions above for securing tubing to

valve.

Figure6 .,_,_ |t_--TUBING FROM

FAUCET , • "

F.nau.E

vW',v .

SILLCOCK

Adjusting Water Level

and Float Valve

Fillreservoir as follows:

• Turn water supply on. Check for good

pressure and flow from float valve.

• When float valve shuts off. check water

level. Water level should be from 1/2 to

1 inch below top edge of overflow

standpipe. It may be necessary toadjust

float valve by bending the rod (refer to

Figure 5).

• Check reservoir and all connections for

leaks.

Install Bleed-Off

A bleed-off system is provided with your

MastsrCoo| cooler. We recommend the

bleed-off be installed and maintained

while operating this unit. Its purpose is to

eliminate a small quantity of water from

recirculatlon thus reducing scale build-up.

Rgure 7

Install bleed-off as

follows:

• Install 1/4" black

plastic tubing into

pump as shown in

Figure 7.

• Insert smaller

black plastic

tubing into 114"

tubing as shown

in Figure 7.

Adjust bleed-off by shortening smalltube to

get the proper bleed rate shown below.

Disposal ofbleed-off water shouldcomply

with local codes. Use of chemical additives

or any water treatment otherthan bleed-off

isnot recommended forthiscooler. Failure

to use the bleed-off with MasterCool pad

greatly increases the mineral deposits and

reduces the expected life of the

MasterCool pad. and could result in early

replacement of pad at your expense.

SECONDSTOFILLA 12OZ.CAN

Model

MC43/44

MC43/44

HC43144

HC43/44

MC63;64

MC63/64

HC63/64

HC63/64

Motor Hp Seconds to fill

1/2 100

3/4 80

1/2 80

3/4 65

3i4 70

1,0 60

314 60

1.0 50

Install Float Shield

• Installshield overfloat valve as shown in

F)gure 8.

• Loop of cotter pin fits into hole in shield.

• Cotter pin loop and hole must face

MasterCool pad.

IEIIT'_p R PIN

Page 5

Required Exhaust

Openings

Using standard CFM ratings, a common [[_.L_

method of determining how much to open

doors or windows for proper exchange is:

2 square feet per 1000 CFM.

Pre-Start-Up Inspection

Assure that:

• Cooler mounting is level; duct is sealed.

• Cabinet issecurely fastenndto mounting.

• Cooler cabinet is grounded. Electrical

connections are safe and secure.

• Motor, pump, and float installed. Motor

and pump plugged into junction box.

• Pump impeller turnsfreely. Remove pump

and basket. Remove impeller cover (see

FigurelO and spin the impeller to assure

free rotation).

• Water line connectedsecurelywithout

leaks.Water supplyturnedon.

• Floatadjusted forproperwaterlevel.

• Blower, shaft, collar, and pulley set bolts

are snug (do not overllghtan pulley boll).

• Pulley alignment okay; belt tension okay

(see page 3 for instructions).

• Blowerbearingsarelubricated.Filloilcup

witha goodgrade SAE2OWor30W oil

• Pad is pre-soaked. Check to see that

pump starts and pad is evenly Wet.

• Open windows or vents in house.

• In case of trouble in any oi these stag_,

refer to the Troubleshooting Chad on

page 7.

Caution: Never operate unit

with service panels, pad

or inlet _ter removed This

will result In am overloaded

€ondition and may damage

the blower motor.

Periodic Inspection

In addition to the planned maintenance

schedule, regular inspection of your

MasterCool cooler willenhance the chance

for longtrouble-free service life.

Checklist

Check for leaks

0 Is cooler level?

0 Are there dry spots on the pad when

cooler is in operation?

CI Does blower turn freely?

0 Isthere 25 Ibs.tension (models 63/64)

20 It=. tension (models 43/44) on drive

belt?

0 Are bolts, nuts, and set screws snug?

0 Is float set correctly?

0 Iswater pan clean?

Cabinet Cleaning and

Touch-up

The cabinet and all internal parts except

blower and drives are fumlehed with a hard

appliance-type Polybond• coating. This

surface ishighly resistantto scale and cor-

rosion.A softcloth, warm water, and a mild

cleanser will bdng all surfaces back to like

new appearance. Avoidsteel wool or sand-

paper in normal cleaning ofthe cabinet.

Scratches and Bare Metal

In the unlikely event that scratches or bare

metal areasoccur, sand orrub the area with

steel wool to prepare the finish. Paint with

standard paint or touch-up paint available

through your dealer.

Changing Pad

This should be done after 5 years or if

passages are clogged.

NOTE: Hosing off inlet face of pad can

unclog passages of dust, and minerals ac-

cumulated there. Light ecrapinge of the in-

take edges of the pad will not harm its

openings and will remove more stubborn

scale.

Caution: Avoid splashing

water on blower motor.

• Remove wet section top.

• Remove water distdbutor assembly,

disconnecting hose.

• Lift out used pad sections.

• Replace wllh new MastarCool pad only,

available from your dealer. Aspen and

other evaporative pads WILL NOT

WORK.

Maintenance Schedule

Regular maintenance isa key to long successful service ofyour MasterCool cooler. The selvice schedule willhelp you maintain an efficient

unit with good appearance.

MAINTENANCE REQUIREMENTS ANNUAL ANNUAL

(LOCATION IN MANUAL) START-UP SHUT DOWN

Changing pad (p. 5) At beginning of6th

year or ifpassages

are blocked.

Cleaning & touch-up (p. 5) X

Cleaning water pump (!o.6) X

Lubrication (p. 6) X

Adjusting bell tehsion (p. 6) X As needed

Periodic inspection (p. 5) Duringcoolingseason Duringcoolingseason

Snugging downset screws & nuts(p. 6) X

Adjustingblend-off(p.4) X

Washing down pad withhose (p. 6) X

Drain allwater lines to and fromthe

cooler to prevent freezing X

NOTES:

DO NOT UNDERCOAT THE WATER

RESERVOIR.

Your MastarCoolIIcooler'swater reser-

voirisfinishedwitha Polybond®appliance

type finish. It is so hard, asphalt type

coolerundercoatwillnotstickto it.Under-

coat willbreak free and clog pump and

waterdistributor.

Do not use cooler cleaners,

cooler treatments, or other

additives in this evaporative

cooler. The use of any of

these products will void your

warranty and may impair the

life of your evaporative cooler.

MasterCooP II* 5

Page 6

Adjust Belt Tension

Each time you inspect your cooler, be sure to

check belt tension on motor/blower assem-

bly. Check belt condition and replace it if

frays or defects appear: Check alignment of

blower pulley with motor pulley.

Lubrication

Blower shaft bearings need periodic lubri-

cation. The oil cups on the blower shaft

bearings should be filled with a good grade

SAI= 20W or30W oilwhen necessary. Under

normal use, oiling is required every three

months of operation. DO NOT OVER OIL.

The pump and blower motor do not require

lubrication.

Four

Rgure 9

tabs

Cleaning Water Pump

Disassemble and clean water pump as

follows:

• Disconnect pump from electrical box.

• Remove pump

• To Prevent breakage, carefully release

the four snap-out tabs, and lift impeller

base plate from the pump body.

• Using a mild detergent solution, wash

all deposits from inside around impeller

and impeller base plate.

• Spin impeller to dislodge any foreign

material.

• Rinse and reinstall impeller base.

• Reinstall pump.

• Make sure to usa a pump screen or

basket. Check to sea if old one needs

replacing due to clogging

®

Caution: Do not allow pump

to topple over and become

submerged; water will

damage pump motor.

Snugging Down Set

Screws and Nuts

Location of set screws and hardware that

should be snugged down.

• Pulley set screw (150 in-lbs)

• Blower set screws (150 in-lbs)

• Wet and dry module connection bolts

Washing Pad

Annually, mineral a.ccumulation and dust

should be washed off the intake sudsce of

the pad. Use garden hose and nozzle. A

paint scrapper may be used to remove hard-

ened scale from edges of intake passages in

pad.

Parts Replacement

Motor

Removingold motor

• Disconnectpowertocooler

• Unplugfromjuncflonbox-4 pinplug

• Loosenalignmentset_:mw on

motorpuney(onmotorsideofpulley)

andmmevebaitand motorpulley,

• Flemovemotorstrap6.

• Pul motorfrombrackets,

Replacing motor

• Reverseproceduretoinstall

new motor,

Pump

Removing old pump

• Disconnectpowerto cooler.

• Unplugfromju_ box(3pinping),

• Unscrewpumpbracket.

• Liftoutpump.

Replacing pump

• Remove impeller base plate at

bottom or pump by releasing tour

tabs,

• Spin impeller to assure free

rotation.

• Reinstall impeller base plata.

• Clean old pump basket or replace.

• Race pump in basket.

• Attach bracket to cabinet.

• Connect pump plug to junction

box (3 pin receptacle).

• Connect pump hose to hose

fitting.

Bleed-off

Removal of old bleed-off

• Replacebleedlineif necessary.

Installation of bleed-off

assembly

• To installbleedline topumpsee

Rgere7.

• Bleedllneshouldfilla 12ounse

beveragecanasindicatedinchart

onpage4.

• Adjustblasd rate byshoriening

smallbleedtuba.

Float

Removing old float

• Removefloatshield

• Removenutand ferrulefrom

waterline.

• Removelockwasherand nutfrom

valve.

• Liftfloatout o!cabineL

Replacing or installing float

valves:

• Secure nutand lockwasher

holdingfloatto cabinet.

• Placetubanutandferruleoverend

oftubing.

• Inserttubeintofloat valveand

tightentosecure.

• Turnon lauoatallowingwaterto

enterthroughvalve,

• Fill from1/2 to I inchbelowtop

edgeof overflewstandpipe.

• Adjustfloatballby bandingthe

float armwitha pairol pliersto

achieve correctangle.

• Reinstallfloatshield.

Page 7

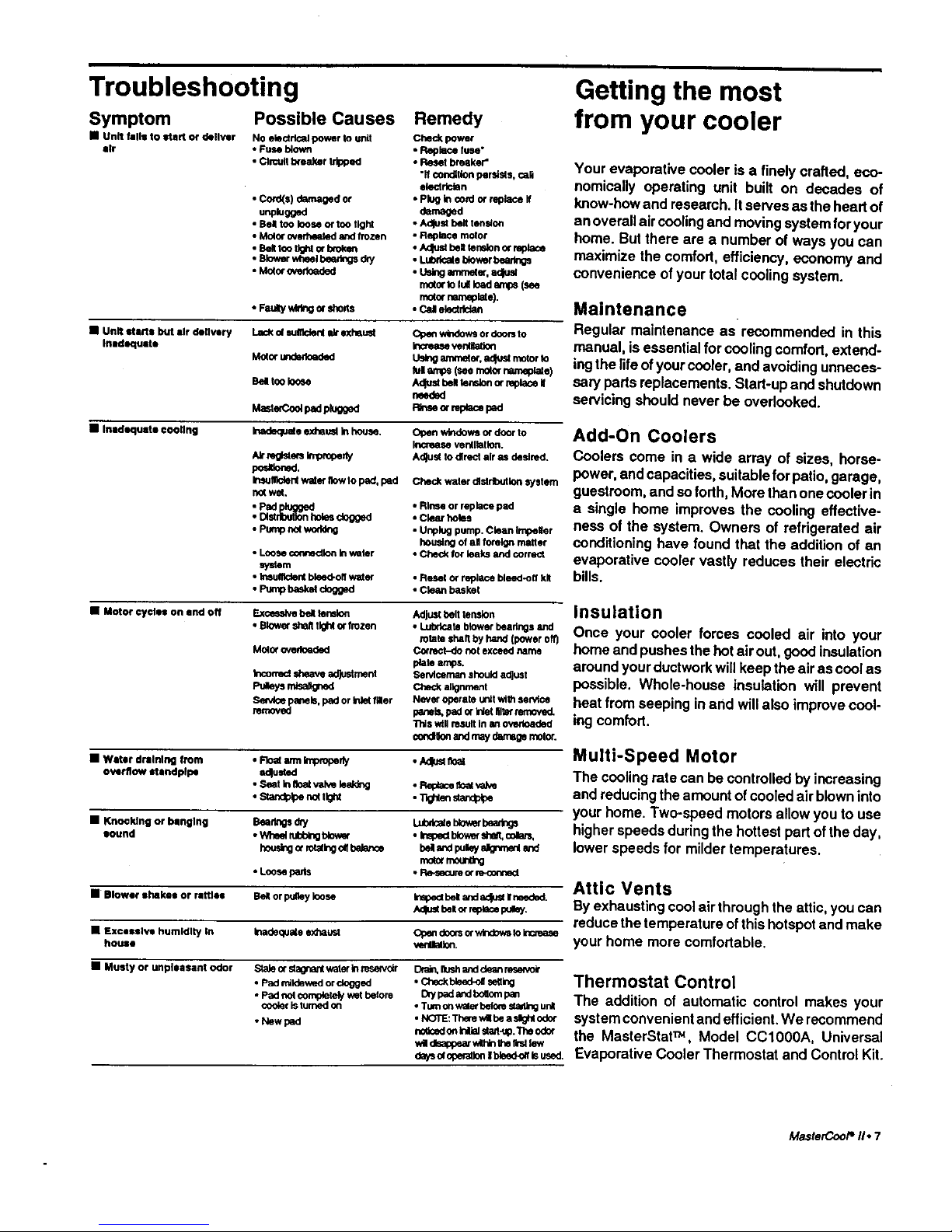

Troubleshooting

Symptom Possible Causes

• Unit fells to Itart of deliver NO elactrlcal power io unit

Ilr • Fuse blown

• _N breaker_ed

• Co_s) damagedor

unplugged

• Bel toolooseortootlgnt

• M_ cve_ andfrozen

• _t_m

• Blowerwileelbeadngsd_y

• Meleeoverloaded

• Fauly wiriogm _lofts

Remedy

Checkpower

• Replacetuse"

• Resetbreaker"

•ffcondition_s, can

eleclrk_n

• PlugInco_ or replaceIf

damaged

• Adjust_n ten_

• Replace motor

• Adjustbel tensionor replace

• Lubdc=sblowerbearlr_s

• Us_g =nm_ef, adlua

rnolcrio lull bad amps(see

motetnamep_e).

• cal einctddan

• Unit lUlrts but eir delivery

Inidequete

_ _ s_e_ U exheu_

Motor

Be4ioo bose

MamrCo¢padp_

alum windows or doors to

Increaseventkellon

Usingamm_er,aclu_ motorto

lull_ (seemotornamep_e)

AdJu_be#lanslonm replaceN

needed

R_seormp_cepad

• I_dequete cooling

_lao ex_uM In house,

Alrreg_siers_robe_

pos_oned.

Insufnclari w_. liow Io pad. pad

r_o(weA.

:Pad

_'_n h_ _

• Loose¢o_¢fk_ In _ler

mm

• _ b_fl w_

O_oen w_dows or door to

InceNse ventliollon.

AdJusl to direct air as _slmd.

Check water Q_n wstem

• Rinse orrep_ce pad

• C_ _Ins

• U_ pump.Cban Im_Uer

_ ofaNfo_ m_er

• Check for leeksand corre_

• Rasel orreplacebleed-offkit

• Cio;mbasket

• .ot_ cycles on and off Exceesk,e b_dllenslon

• Blow_•heirtighto_frozen

Meleeoverloaded

Incormd sheaveadjustment

P_eys mba_gned

_panels, padorInio_liter

Adjustbelttension

• Lubrk:atebk)werbeadngsand

rotatesha_by hand(poweroff)

Correct-donot exceedname

plataamps.

Servlcernanshouldadjust

Ct_eckaNgnment

Neveroperateu_t withsauce

paneb,pador'_et flllarremoved.

INs wiNresultIn anevade•bed

€o_dl_ andmaydamagemeier.

• Wear dmlnl_ from • FIO_[arm Improperly • Ad_sl

overflow standpipe e_Justed

• ,_-_eatio IInatvalveleak_g *_ lanai',_ve

• _r_t_ ._e_

• Knocking or banging Bearings dr/ Lubd_e blowerbea/_lgs

sound • Wbeelrul_r,gt_v,w * Irebedblowxabet.eol_,

hous_orro_k_o_beJ_ce _ e_ puky.N_vner_an_

• L_ • R_o_ _d

• Blower shakes or rattles Bck or pulley loose Inspectbelland ad_ I needed.

,,wt_ben_-rit_acepuny.

• Excessive humldl_ In _a_e e_lau_ Op_ _x_ Or_ la

harms vengei_on.

i Mu_y or unpleasant odor _ain _ s_ wal_ In _oir Dm_ Ilushand dean re_wo_

• Pad_ldewed or clogged • Checkbleed-_ seeing

• Pad notcomplatel)'v_t beiore D_ypadanclbogotapan

coolerIsturnedon *Turnonwale_beioms_adlngu_

• Newpad * NOTE:Themwillbea sl_l ode€"

noticedonInNlaJs_-up. Tbeodo¢

wEdlsappeaJ-vAhhthe11mtk_v

dayso_opera_bnI bleedolfIs used.

Getting the most

from your cooler

Your evaporative cooler is a finely crafted, eco-

nomically operating unit built on decades of

know-how and reseamh. It serves as the head of

an overall air cooling and moving system for your

home. Butthere are a number of ways you can

maximize the comfort, efficiency, economy and

convenience of your total cooling system.

Maintenance

Regular maintenance as recommended in this

manual, isessential for cooling comfort, extend-

ingthe life of yourcooler, and avoiding unneces-

se_/pads replacements. Start-up and shutdown

servicing should never be ovedooked.

Add-On Coolers

Coolers come in a wide array of sizes, horse-

power, and capacities, suitableforpatio, garage,

guestroom, and so fodh, More than one coolerin

a single home improves the cooling effective-

ness of the system. Owners of refrigerated air

conditioning have found that the addition of an

evaporative cooler vastly reduces their electric

bills.

Insulation

Once your cooler forces cooled air into your

home and pushes the hot air out, good insulation

around your ductwork will keep the air as cool as

possible. Whola-house insulation will prevent

heat from seeping in and will also improve cool-

ing comfort.

Multi-Speed Motor

The cooling rate can be controlled by increasing

and reducing the amount of cooled air blowninto

your home. Two-speed motors allow youto use

higher speeds during the hottest pad of the day,

lower speeds for milder temperatures.

Attic Vents

By exhausting cool air through the attic, you can

reduce the temperature ofthis hotspot and make

your home more comfodable.

Thermostat Control

The addition of automatic control makes your

system convenient and efficient. We recommend

the MasterStat TM, Model CC1000A, Universal

Evaporative Cooler Thermostat and Control Kit.

MasterCooP I1.7

Page 8

AdobeAir, Inc. * 500 S. 15th Street • Phoenix, AZ85034

L411004A • 1/96

Loading...

Loading...