Page 1

Air-Conditioning of the future

Service Manual

Residential A/Cs

Page 2

CONTENTS

Please find CAS, CAD, CAM (R or I), CMP, etc.. in separate papers!

1. DIAGNOSTIC CHART 1

2. The service rules of the R407C(R410a) product 5

3. MAS 8

4. MES 45

5. CES/CED/CEM 65

6. GES 97

7. GIS 115

8. LIS 127

9. CUS 139

10. BES 157

11. CES I 178

12.

CED I & CEM I

197

Page 3

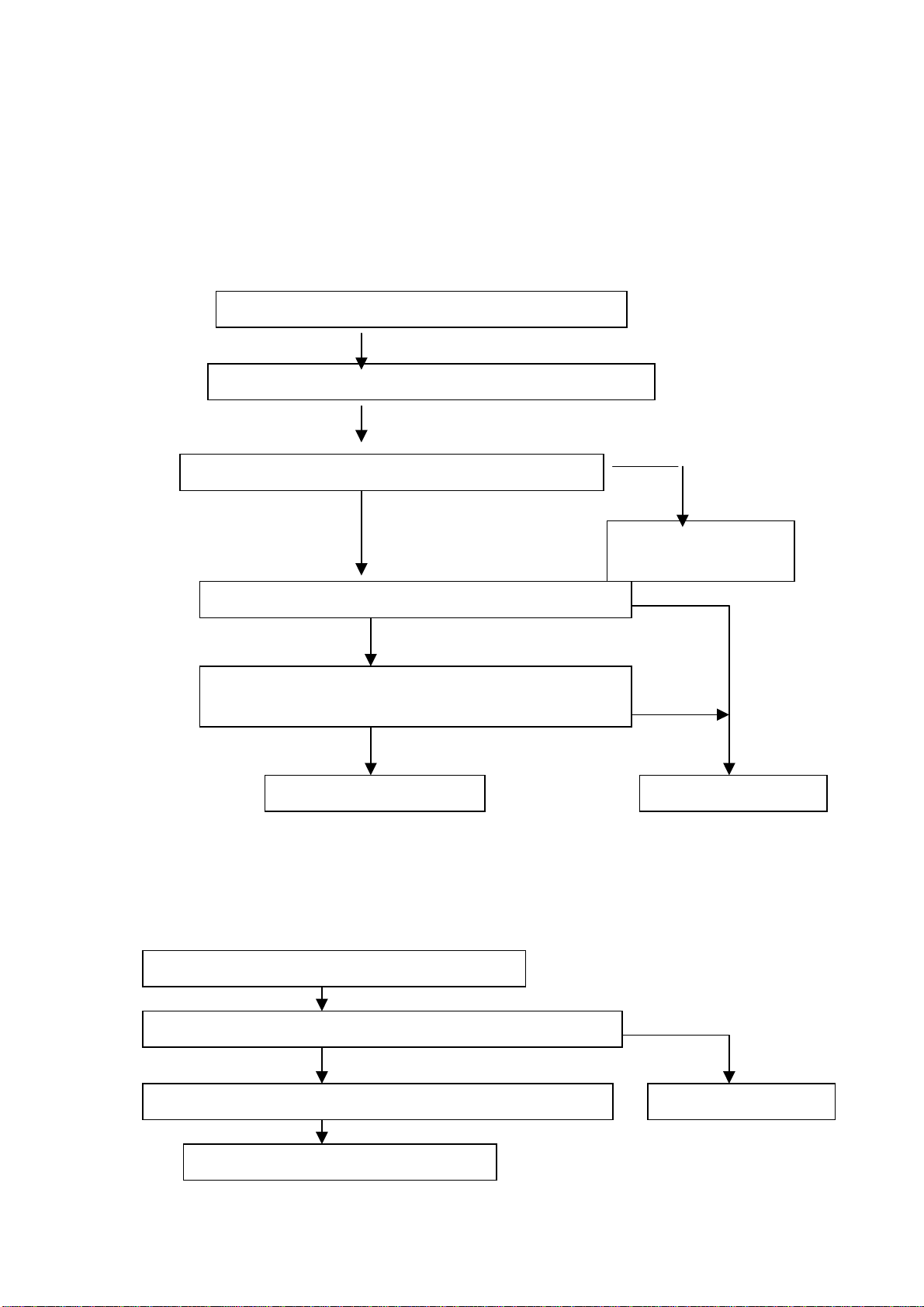

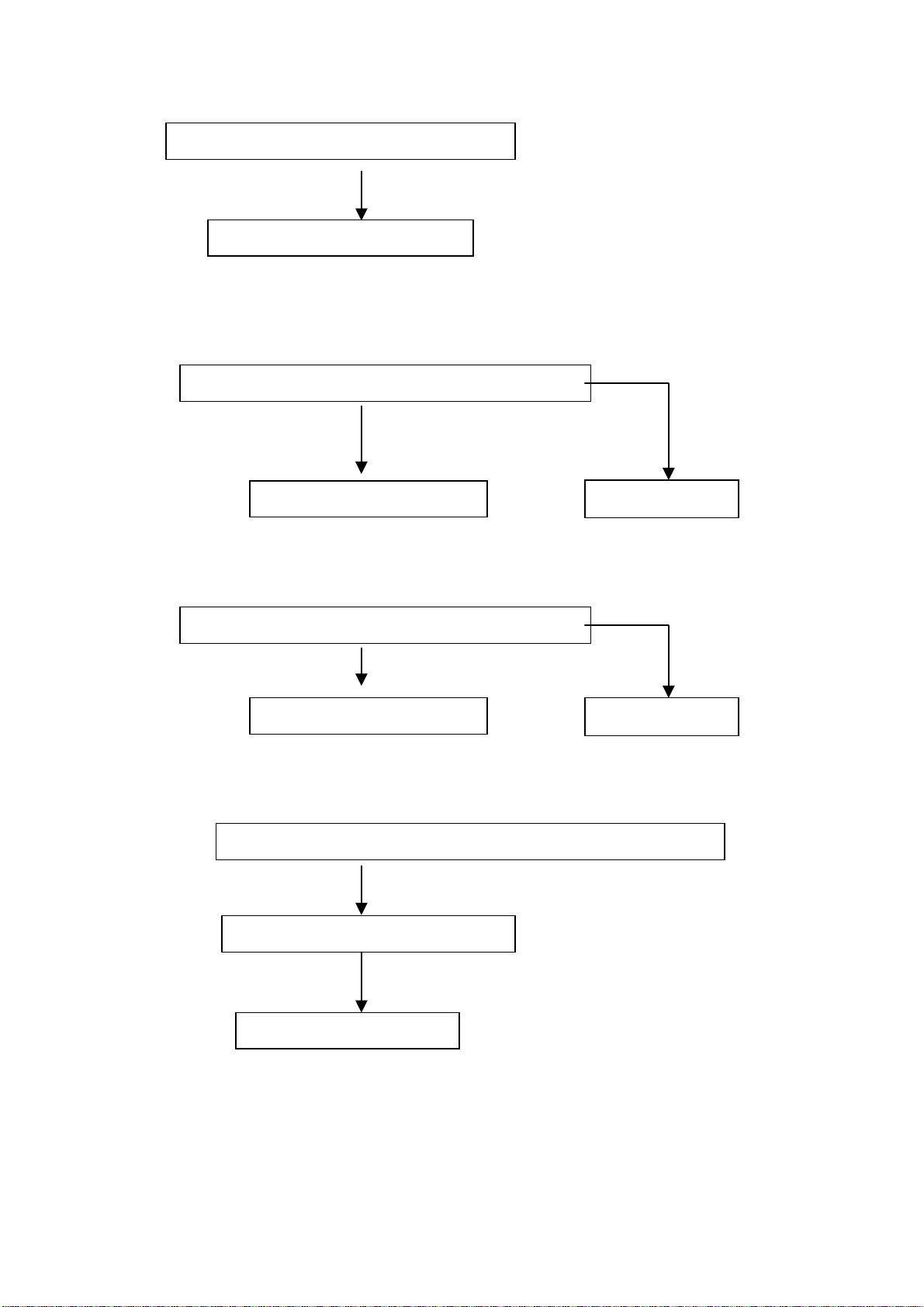

Diagnostic Chart(5000Btu/h-12000Btu/h)

1. Self-diagnose the failure

COOLWEX units have self-diagnose function.

Note: for the following series

CES

CED

CEM

2. After energizing, no indicator is lighted and the air conditioner can’t be operated.

After energizing, the air conditioner can’t be operated

Check if AC220V power supply outputs to Indoor PCB.

Yes

Check if AC220V exists at the primary coil of transformer.

Yes No

Indoor PCB is defective

Or current fuse is melt.

Check if AC14.5V exists at the secondary coil of transformer.

Take off the secondary plug of transformer, and then check if

AC14.5V exists at the secondary coil of transformer.

No Yes

Yes

No

The transformer is defective. Indoor PCB is defective

3. Resetting phenomenon often occurs during operation. (That is automatically entering to

the status when power is on.)

The reason is that the instantaneous voltage of main chip is less than 4.5V. Check

according to the following procedure:

Resetting phenomenon often occurs during operation.

After changing Indoor PCB, check if the failure releases.

No Yes

After changing indoor fan motor, check if the failure releases.

Power supply circuit has problems.

No

Indoor PCB is defective

1

Page 4

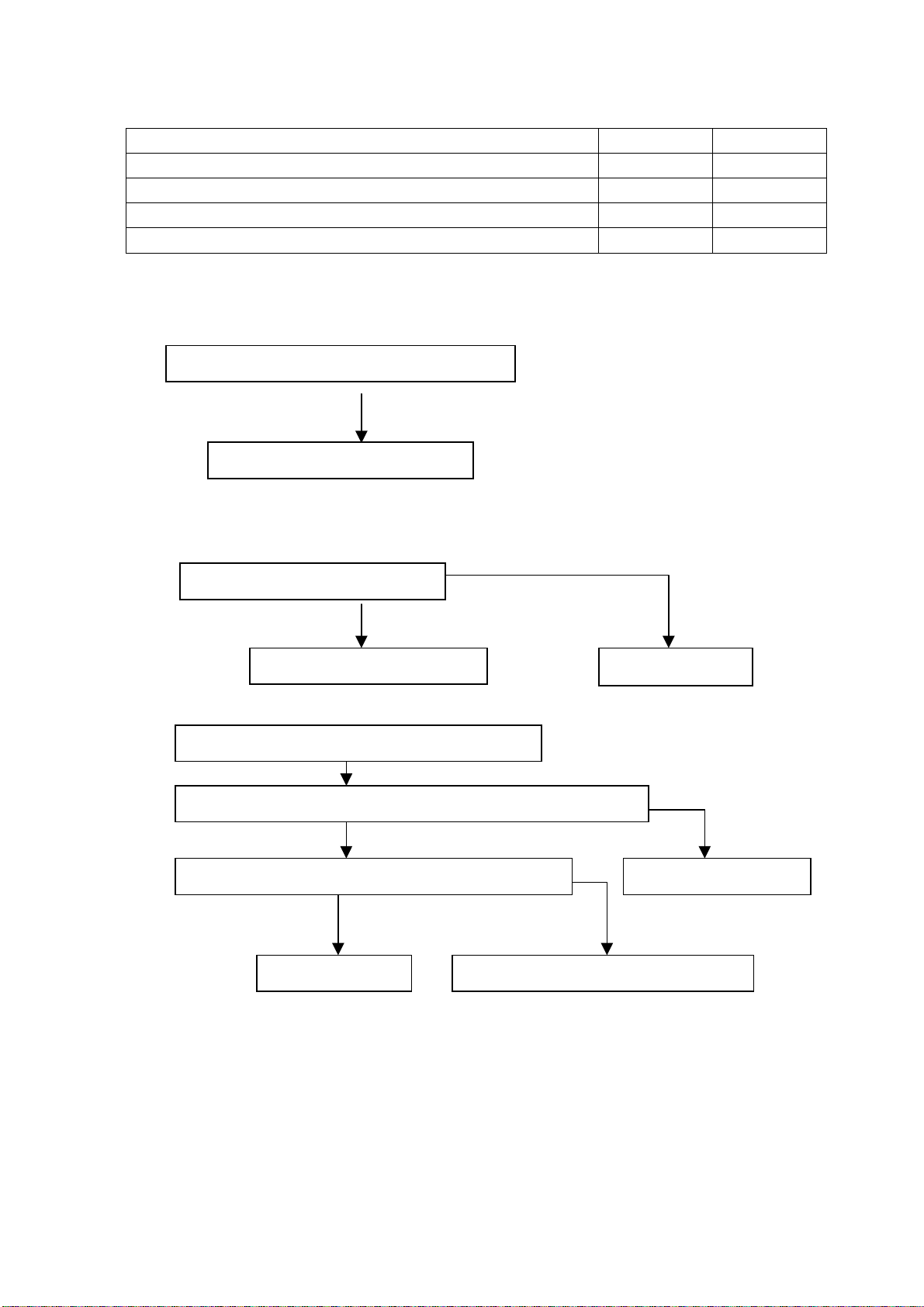

A

4.

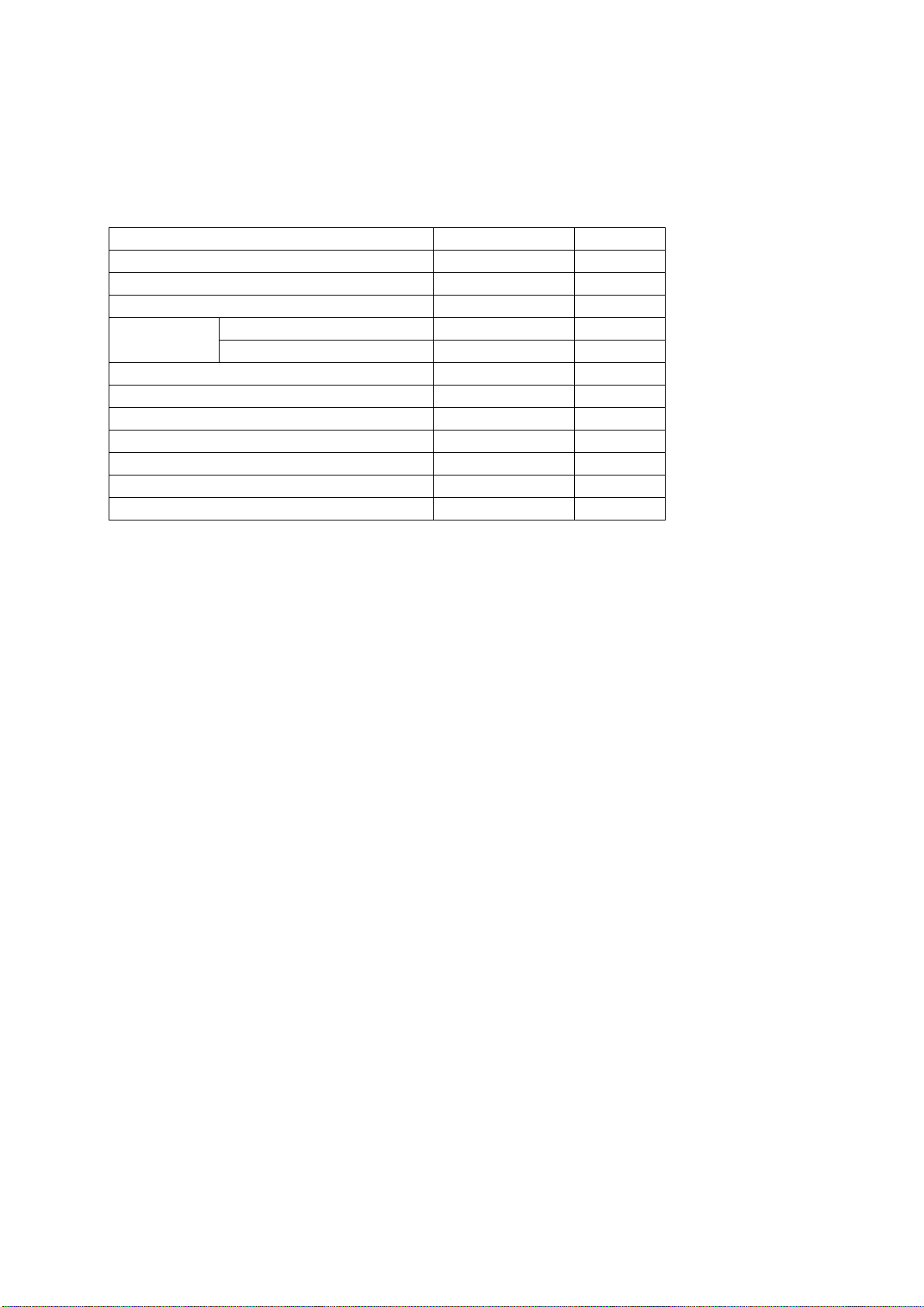

Failure phenomenon for cooling only type

Failure phenomenon Operation lamp Timer lamp

Indoor fan speed has been out of control for over 1 minute

Indoor room temp. or evaporator sensor is open circuit or short circuit

Over current protection of the compressor occurs 4 times X

EEPROM error On

r Extinguish

☆ Flash at 5Hz

☆

☆

4.1 Operation lamp flashes and Timer lamp off.

Operation lamp flashes and Timer lamp off.

Yes

Change the main control board

4.2 Operation lamp flashes and Timer lamp on.

Is connection to connector good?

yes No

Replace the sensor

Repair connector

4.3 Operation lamp off and Timer lamp flashes

Operation lamp off and Timer lamp flashes

fter changing the main control board, check if the failure releases.

No Yes

The voltage of power supply is too low (less than 187V)?

Indoor PCB is defective

Yes No

Power supply fault Outdoor unit fault (such as the compressor)

4.4 Operation lamp on and Timer lamp flashes

EEPROM error, indoor PCB is defective.

X

On

☆

☆

2

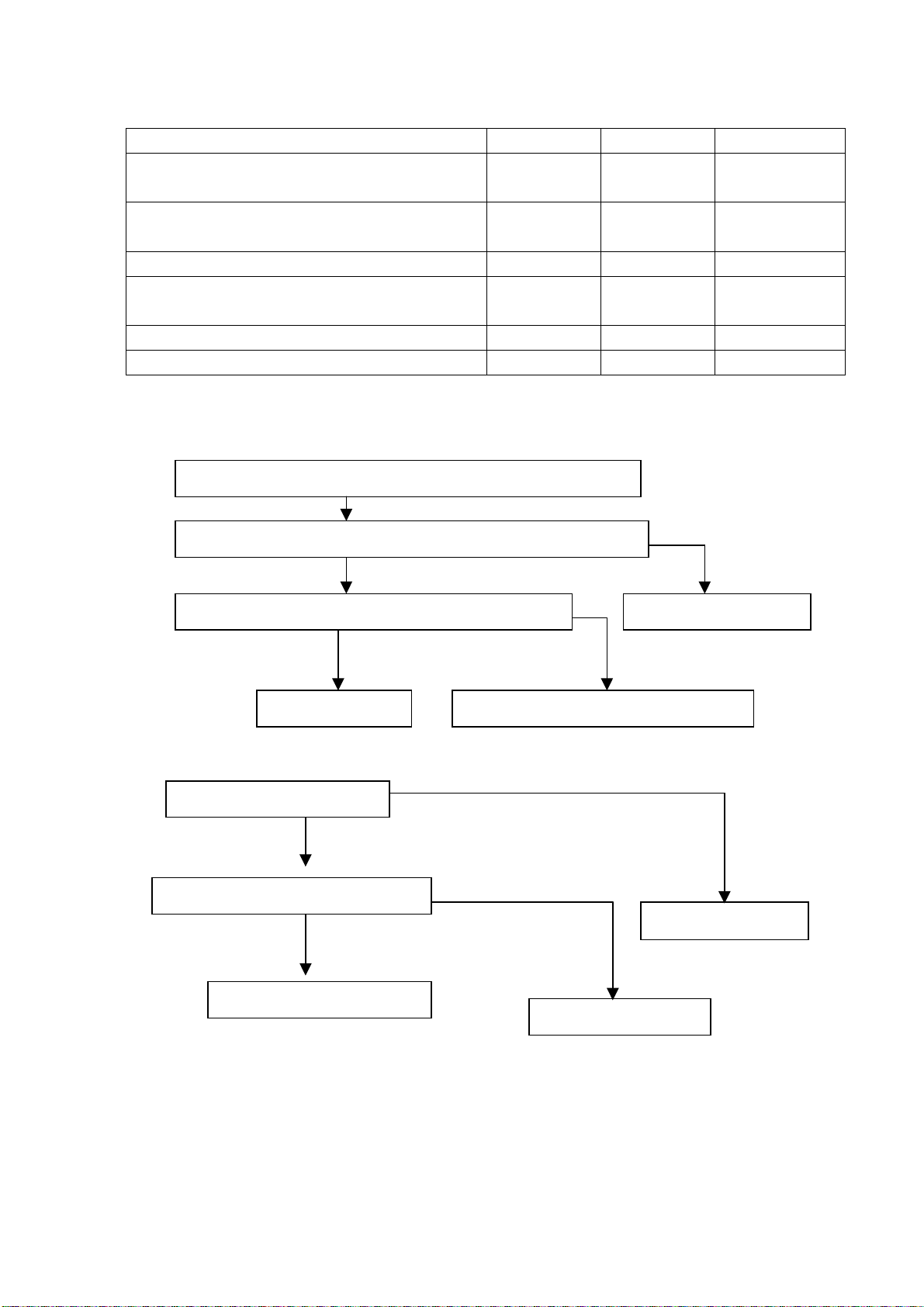

Page 5

A

5.

Failure phenomenon(heat pump)

Failure phenomenon Operation lamp Timer lamp Defrosting lamp

Over current protection of the compressor occurs 4

times

Indoor fan speed has been out of control for over 1

minute

No over-zero signal

Temp. sensor on indoor evaporator is open circuit or

short circuit

Indoor room temp. sensor is open circuit or short circuit X

EEPROM error On

☆

X

☆ ☆ ☆

X X

X

☆ ☆

☆

☆

☆

☆

X

X

r Extinguish

☆ Flash at 5Hz

5.1 Operation lamp flashes ,Timer lamp off and Defrosting lamp flashes.

Operation lamp flashes ,Timer lamp off and Defrosting lamp flashes

fter changing the main control board, check if the failure releases.

No Yes

The voltage of power supply is too low (less than 187V)?

Indoor PCB is defective

Yes No

Power supply fault Outdoor unit fault (such as the compressor)

5.2 Operation lamp off, Timer lamp flashes and Defrosting lamp flashes.

Is connector connection good?

No Yes

Is voltage being applied to the fan motor?

Yes No

Repair the connector

Fan motor is defective

Indoor PCB is defective

5.3 Operation lamp flashes, Timer lamp flashes and Defrosting lamp flashes .

This is alarm signal when the main chip can’t detect over-zero signal. When such

failure occurs, the main control board must have fault.

3

Page 6

Operation lamp flashes and Timer lamp off.

Yes

Change the main control board

5.4 Operation lamp off ,Timer lamp off and Defrosting lamp flashes.

Is connection to connector good?

yes No

Replace the sensor

Repair connector

5.5 Operation lamp off, Timer lamp flashes and Defrosting lamp off

Is connection to connector good?

yes No

Replace the sensor

Repair connector

5.6 Operation lamp on, Timer lamp flashes and Defrosting lamp off

EEPROM error, main PCB has fault.

Temporarily turn off the power supply and turn it on again in about 1 minutes

Does the trouble occur again?

Yes

Replace the indoor PCB

4

Page 7

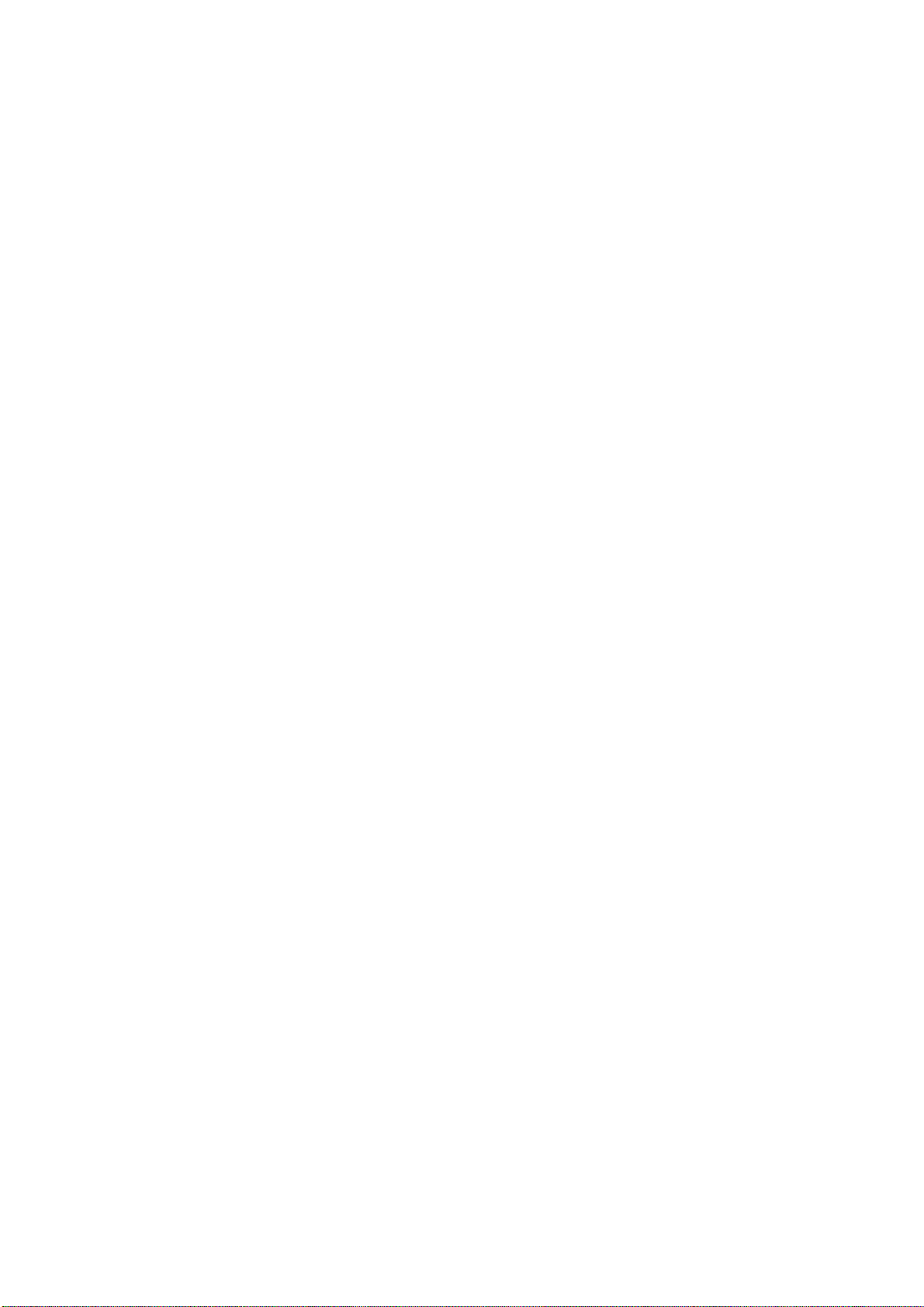

The service rules of the R407C product

The service rules of the R410A product

1. The service rules of the new refrigerant R407C product

COOLWEX uses the green refrigerant R407C firstly in China.

Its thermal characters are similar to R22, but there is little difference between them.

1.1 The main difference between R407C and R22:

R407C R22

Component HFC32/125/134a HCFC22

The ratio of mix Wt% 23/25/52 100

The saturation liquid density Kg/m

3

1136 1191

Normal pressure kj/kg.k 0.835 0.622 Specific heat

The saturation liquid kj/kg.k 1.554 1.256

Evaporating pressure kpa 499 498

Condensing pressure kpa 2112 1943

Temperature slippage ℃ 4.3-7.1 0

Heating capacity w 92-97 100

Input power w 106 100

COP 97 100

The consistent with the oil Fat oil Mineral oil

1.2 Service precautions:

1.2.1 Because R407C is a mixture composed of three kinds of matter, when vapor phase and liquid

phase coexist, the component of the vapor phase is different from the liquid phase. When we fill

the refrigerant, we must ensure to fill it in liquid phase, in order to maintain the stability of the

character.

1.2.2 The leakage of the refrigerant is from vapor side or liquid side, and the leakage from vapor side

could make the component change and impact the character seriously. So when the amount of

the leakage is up to 5%, we need discharge all refrigerant in the system, and fill liquid

refrigerant according to amount in nameplate.

1.2.3 Because the lubricant fit for refrigerant R407C is ester refrigerating engine oil (POE) or ether

refrigerating engine oil (PVE). The mineral lubricant fit for refrigerant CFC and HCFC is weak in

consistent with the HFC, and it doesn’t fit for the refrigerant HFC. So when the compressor

using new refrigerant R407C is worn out, to replace it by compressor of CFC or HCFC is

forbidden.

1.2.4 When the connection of the refrigerant pipe is finished, before the system start up we should

vacuum the indoor unit by cut-off valve or discharge the indoor unit air by refrigerant R407C

bottle. Discharged the air in system by outdoor unit refrigerant is forbidden.

1.2.5 Ester oil could adsorb the water in the air. In order to removemoisture in refrigeration system,

avoid capillary jammed by ice and the ester lubricant oil decomposed with water, we use

desiccant in system. Artificial zeolite (molecular sieve R etc.) is the effective water sorbent.

Toavoid absorb refrigerant but only absorbmoisture, we use the molecular sieve whose

aperture is smaller than the molecule of the refrigerant. For R407C we should adopt XH-11

rather than XH-9AK and 4A-NRG.

1.2.6 Because the corrosion of R407C and POE to high molecular material is different from R22 and

mineral oil, the airproof material inside high/low pressure valve and foul-way valve needs to be

changed in refrigeration system, such as R407C, polyurethane rubber etc. The high/low

pressure valve and four-way valve which are fit for R22 couldn’t be used in service.

1.2.7 When there is leakage, filling with other kind of refrigerant is forbidden.

1.2.8 When we need to vacuum the system, we should use the special quick joint, but use the quick

joint of other refrigerant is forbidden lest pollute by mixing refrigerant. The time for vacuuming is

5

Page 8

about 30 minutes, and vacuity is less than 133Pa.

1.3 Precautions:

1.3.1 Regulations

Being liquefied vapor, R-407C and R-410A are high-pressure vapor , the high-pressure gas regulation is

applicable. Before use it, please refer to high-pressure gas regulation. To prevent the high-pressure

vapor from causing damage, the regulation should be followed.

1.3.2 Usage of vessel

Being high-pressure vapor, R-407C and R-410A are contained in high-pressure vessel. The

safety condition of vessel is good, but if you don’t use it carefully, you may damage the vessel

and cause accident.

1.3.3 Storage

Although R-407C and R-410A are nonflammable, when they are stored with the normal

high-pressure gas, we should place them in the good ventilation area.

In addition, there are safe devices in the high-pressure vessel. Please note that when the

temperature (fusible valve) or pressure (spring safe valve) is up to a certain value, it will eject

vapor.

1.3.4 Ventilation

Because R-407C and R-410A are heavier then air, they will go down. If room is full of the

leakage vapor, the density of oxygen will decrease, and cause people suffocated.

In addition, if you light the fire when there is R-407C in the air, it will produce the toxic gas with

pungent odor and corrosiveness.

1.3.5 Precautions about health

For R-407C, R-410A and normal liquefied high-pressure vapor, please don’t contact with skin

directly, and prevent being splashed into eyes and avoid drinking.

1.3.6 The following are the urgent disposal methods:

Splash into eyes:

Wash eyes with pure water for more than 15 minutes, and don’t knead the eyes or blink.

Please wash eyes with watery boric acid water if the ache gets heavy.

To avoid the accident, please ensure that you wear the protection glasses.

Contact with skin directly

The temperature will decrease rapidly by evaporation if R-407C and R-410A expose to air in

liquid phase. So if the liquid contacts with skin directly, it may cause frostbite. If there are freeze

burns, please go to see the doctor immediately.

2. The service rules of the R410A product

2.1 There are some differences between air conditioner of R410A s and that of R22:

2.1.1 The compressor used is different, it is a new refrigerant compressor (special);

2.1.2 The air conditioner of new refrigerant R410A has a drier, while the A/C of R22 doesn’t have.

2.1.3 There is no difference between the evaporator, condenser and system pipe of new refrigerant

R410A A/C and that of R22 A/C in appearance. The requirement of new refrigerant R410A A/C

for craft is higher , and the amount of moisture and impurity in the system is less than that of A/C

using R22. The resistance to pressure is higher.

2.1.4 The manufacture process is different, the requirement of air conditioner using R410A for craft is

high.

2.2 Refrigerant system:

2.2.1 The high pressure of refrigerant system is 3.0 Mpa, and the low pressure is 1.2 Mpa. (The

value is 1.5 times more than that of R22 under the same condition)

2.2.2 When installing the split type of new refrigerant R410A, all connecting pipes must be special

pipes of R410A. Discharging air must use refrigerant R410A, and couldn’t misuse the

connecting pipe and refrigerant of A/C using R22. Otherwise, it will destroy the stability of A/C.

2.2.3 Because the compressor of refrigerant R410A split type uses POE oil, which can react with

moisture to form water and acid. The water produced by reaction could react further, and if the

6

Page 9

chain reaction proceeds continually , the water in the system will be more and more. It will cause

the capillary ice blocking; at the same time, acidity of working substance circulated in the

system will be higher and higher (the value of PH is lower and lower), and it may corrode the

components and parts in the system. The phenomenon of copperizing would happen. When

installing A/C, the action should be prompt, and after opening the plug of connecting pipe we

must tighten the nut in 5 minutes. The time of discharging air should be enough. When

installing A/C, the sweat drops into the connecting pipe is forbidden; the infusible impurity

mixed in the system is forbidden. It is better to install the A/C of refrigerant R410A split type in

fine weather, do not do it in rainy day, nor humid weather.

2.2.4 The chlorine ion could react with POE oil to form acid, and the acid corrodes the components

and parts of refrigerant system. So pollute the system with chlorine ion in installation is

forbidden, such as sweat beads and other impurities that contain chlorine ion.

2.2.5 Whatever the reason we must change the drier, if the refrigerant system is exscinded in service,

after we exscind the refrigerant system, we must use something to wrap the fracture lest the

moisture in air enters into the system. The time that refrigerant system expose to air should be

less than 5 minutes.

2.2.6 Must weld the drier into system in 5 minutes in order to isolate the air when changing it.

Otherwise it will influence the performance of the drier.

2.2.7 Must use special pump after service. The lubricant should be the grease. The pump couldn’t be

used to vacuum the A/C of refrigerant R22, otherwise it would cause the contamination of

refrigerant, and influence the performance of A/C. The time of vacuuming must be over 25

minutes, Otherwise the moisture in system will be too high, and affect the stability of A/C.

2.2.8 If need to change the components and parts, must use the special one of R410A in service.

Using the components and parts of R22 is forbidden; otherwise it would affect the stability of

A/C.

The refrigerant R410A should be placed in environment under 30℃. If the refrigerant has been

placed in environment above 30℃, it is necessary to store the refrigerant in the environment below

30℃ for more than 24 hours. Otherwise the component of refrigerant would be changed and it

affects the performance of A/C.

7

Page 10

CES, CED & CEM

1. Features 66

2. Specification 67

3. Dimensions 73

4. Refrigeration cycle diagram 77

5. Operation limits 78

6. Wiring diagram 79

7. Troubleshooting 86

8. Electronic function 86

Page 11

1.Features

1.1 Compact design

1.2 High efficiency and quiet operation

66

Page 12

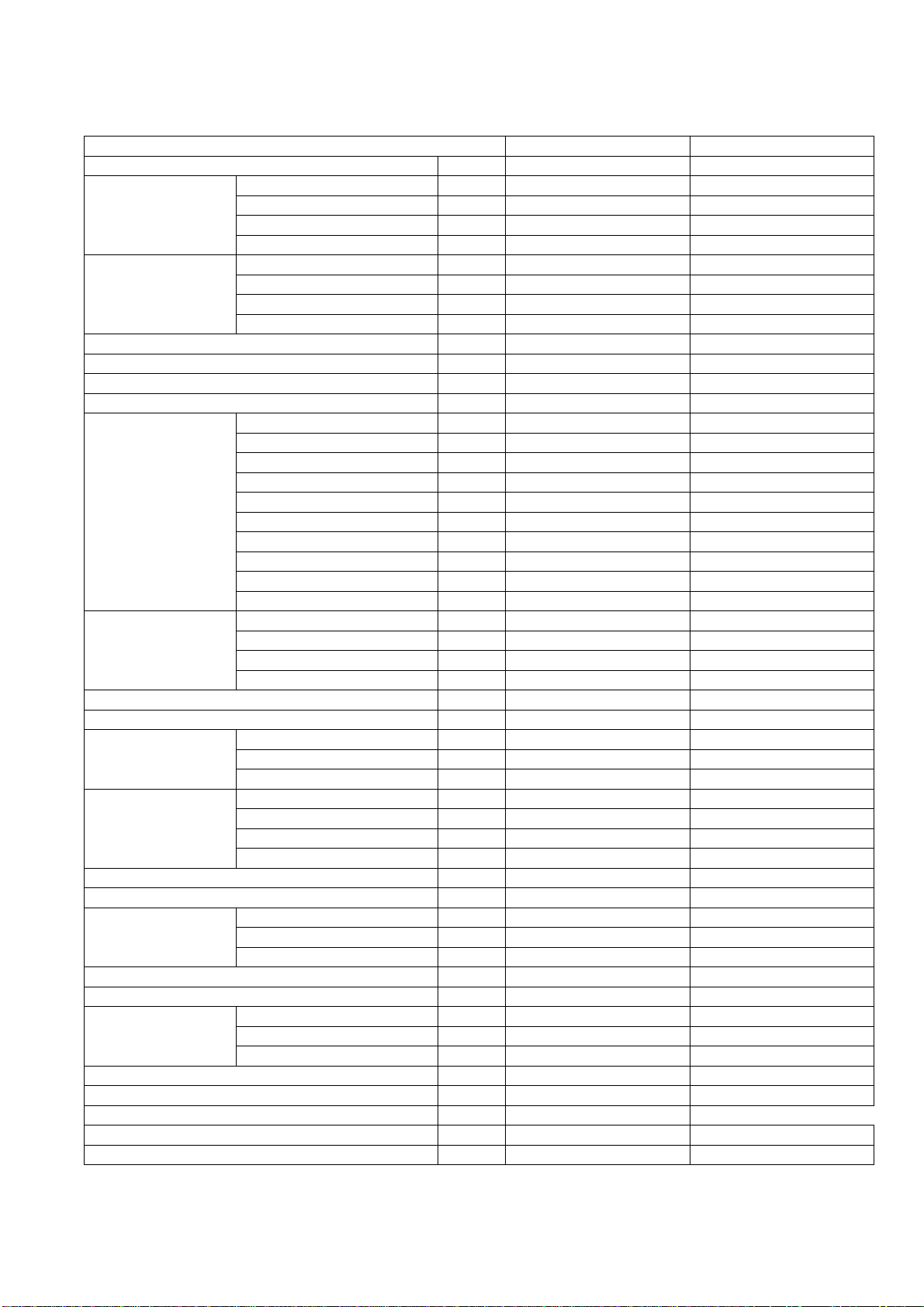

2.Specification

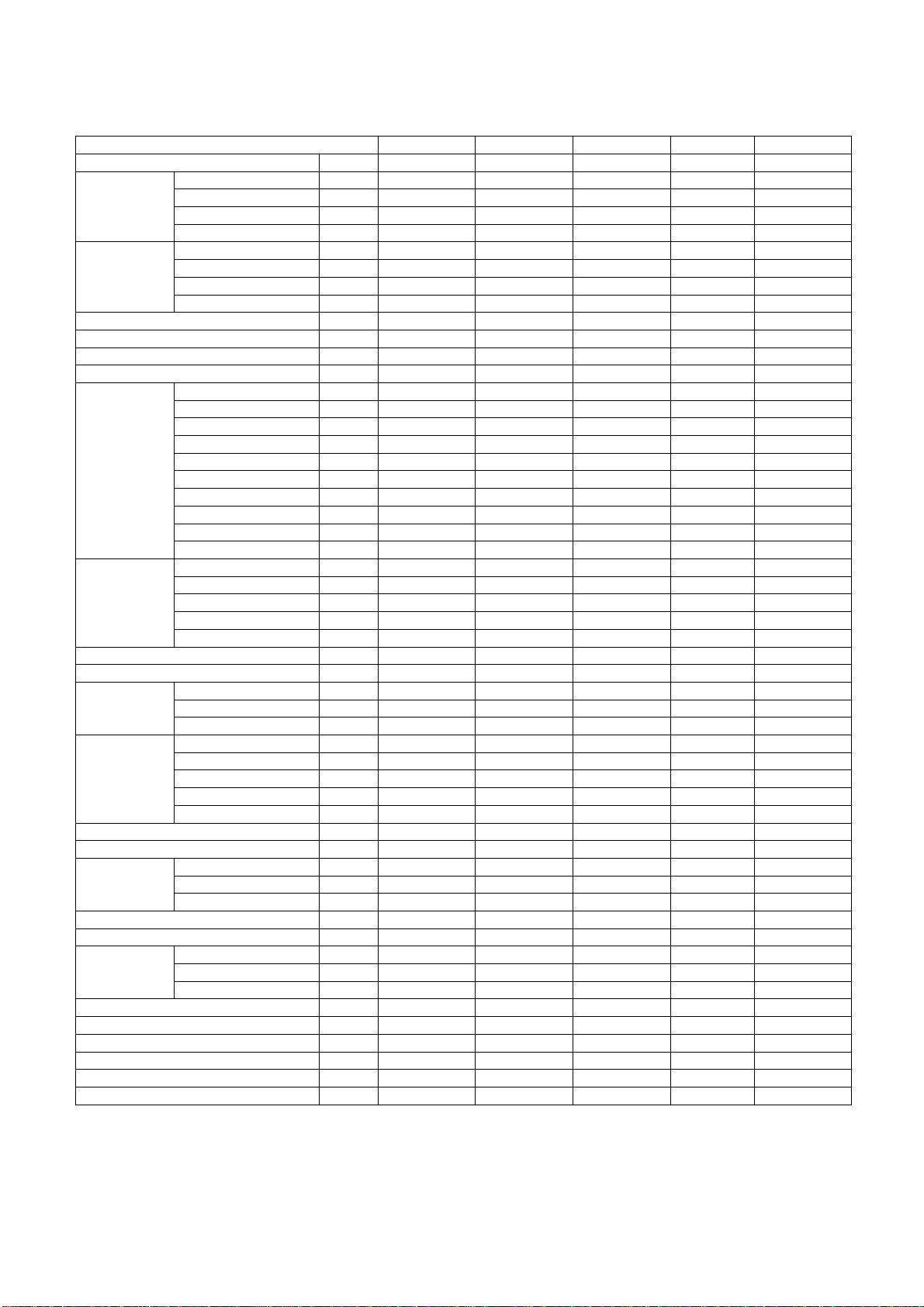

Model CES-05.R.....................CES-07.R.........................CES-07.RC...................CES-09.R....................CES-09.RC

Power supply Ph-V-Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz

Capacity Btu/h 5000 7000 7000 9000 9000

Cooling

Heating

Moisture Removal L/h 0.6 0.8 0.8 1 1

Max. input consumption W 800 1050 1050 1300 1300

Max. current A 3.8 5 5 7 7

Starting current A 16 18 18 25 25

Compressor

Indoor fan motor

Indoor air flow (Hi/Mi/Lo) m3/h 300/270/240 380/350/320 380/350/320 450/420/ 390 450/420/390

Indoor noise level (Hi/Mi/Lo) dB(A) 32/28/25 32/28/25 32/28/25 33/31/27 33/31/27

Indoor unit

Outdoor fan motor

Outdoor air flow m3/h 1400 1400 1400 1500 1500

Outdoor noise level dB(A) 49 49 49 49 49

Outdoor unit

Refrigerant type R22 g 480 620 580 650 580

Design pressure MPa 2.6 2.6 2.6 2.6

Refrigerant piping

Connection wiring No No No No No

Plug type 10A 10A 10A 10A 10A

Thermostat type Electronic control Electronic control Electronic control Electronic control Electronic control

Operation temp ℃ 17-30 17-30 17-30 17-30 17-30

Ambient temp ℃ 18-45 -7-45 18-45 -7-45 18-45

Application area m2 8-12 10--14 10-14 14-21 14-21

Input W 560 760 760 1000 1000

Rated current A 2.6 3.6 3.6 4.5 4.5

EER Btu/w.h 8.6 8.8 8.8 9 9

Capacity Btu/h 7600 10000

Input W 760 980

Rated current A 3.4 4.4

COP w/w 2.9 3.0

Model KH104VFHC 2P14C235ANA 2P14C235ANA PH170X1C-4DZ2 PH170X1C-4DZ2

Type Rotary Rotary Rotary Rotary Rotary

Brand SHANGHAI SENLIN GD Matsushita GD Matsushita GD Toshiba GD Toshiba

Capacity Btu/h 5700 7500 7500 10000 10000

Input W 590 725 725 970 970

Rated current(RLA) A 2.7 3.4 3.4 4.5 4.5

Locked rotor Amp(LRA) A 13 15 15 24 24

Thermal protector BF540-KB MRA98854 MRA98854 UP3QE0591-T61 UP3QE0591-T61(int

Capacitor uF 15 25 25 25 25

Refri

gerant oil ml MS-56 270 AT OMOS M60 270 ATOMOS M60 270 SUNISO 350 SUNISO 350

Model RPG13H RPG13H RPG13H RPG 13H RPG13H

Brand WELLING WELLING WELLING W ELLING WELLING

Input W 36.5 36.5 36.5 36.5 36.5

Capacitor uF 1.2µF/450V 1.2µF/450V 1.2µF/450V 1.2µF/450V 1. 2µF/450V

peed(hi/mi/lo) r/min 1020/ 960/ 900 1020/ 960/ 900 1020/ 960/ 900 1100/1020/950 1100/1020/950

S

Dimension (W*H*D) mm 750×250×188 750×250×188 750×250×188 750×250×188 750×250×188

Packing (W*H*D) mm 830X336X280 830X336X280 830X336X280 830X336X280 830X336X280

Net/Gross wei

Model YDK24-6T YDK24-6T YDK24-6T YDK24-6T YDK24-6T

Brand WELLING WELLING WELLING W ELLING WELLING

Input W 70 70 70 70 70

Capacitor uF 3 3 3 3 3

peed r/min 850 850 850 850 850

S

Dimension(W*H*D) mm 700×535×235 700×535×235 700×535×235 700×535×235 700×535×235

Packing (W*H*D) mm 815×580×325 815×580×325 815×580×325 815×580×325 815×580×325

Net/Gross wei

Liquid side/ Gas side mm(inch) Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53

Max. refr igerant pipe length m 10 10 10 10 10

Max. difference in level m 5 5 5 5 5

ght Kg 8/9.5 8.5/10 8.5/10 8. 5/10 8.5/10

ght Kg 26/29 28/31 27/30 30/33 29/32

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient condition.

67

Page 13

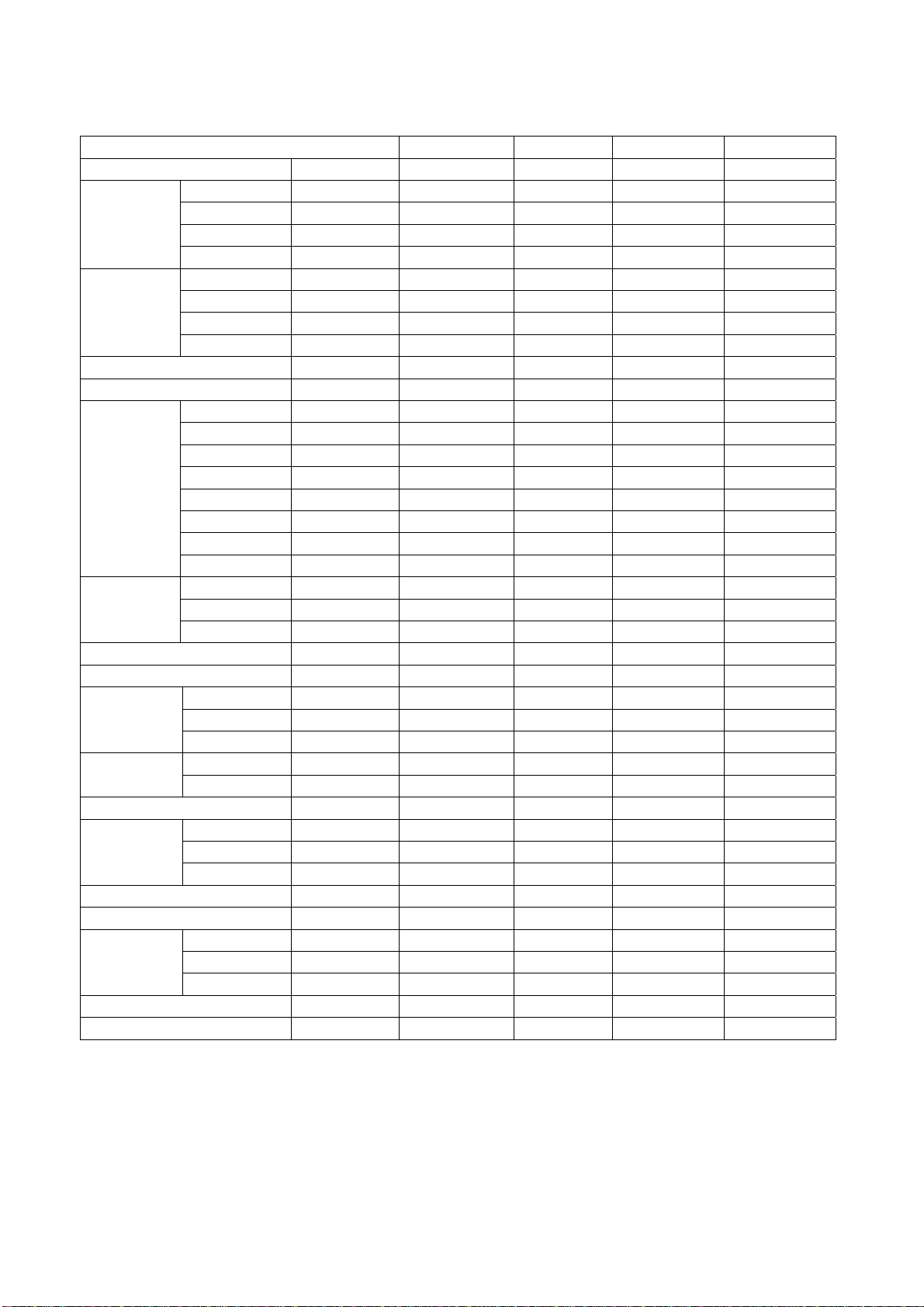

Model CES-12.RC CES-12.R CES-18.RC CES-18.R

Power supply Ph-V-Hz 220-240V,50HZ 220-240V,50HZ 220-240V~,50Hz 220-240V~,50Hz

Capacity Btu/h 12000 12000 18000 18000

Cooling

Heating

Moisture Removal L/h 1.2 1.2 1.5 1.5

Max. input consumption W 1650 1690 2040 2080

Compressor

Indoor fan motor

Indoor air flow (Hi/Mi/Lo) m3/h 550 550 750/710/650 750/710/650

Indoor noise level (Hi/Mi/Lo) dB(A) 36/33/30 36/33/30 41/38/35 41/38/35

Indoor unit

Outdoor fan motor

Outdoor noise level dB(A) 51 51 53 53

Outdoor unit

Refrigerant type g R22/750 R22/820 1110 1370

Design pressure MPa 2.6 2.6 2.6 2.6

Refrigerant piping

Plug type 16A 16A 15 15

Application area m2 18-26 18-26 25-35 25-35

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient condition.

Input W 1230 1230 18000 18000

Rated current A 5.7 5.7 1820 1800

EER Btu/w.h 9.8 9.8 8.5 8.4

Capacity Btu/h 13000 10.0,2.9

Input W 1290 19000

Rated current A 6 1800

COP w/w 3.0 3.1

Model PH200X2C-8FTC PH225X2C-4FT PH290X2C-4FT1 PH290X2C-4FT1

Capacity Btu/h 11840 13610 17435 17435

Input W 1135 1305 1670 1670

Rated current(RLA) A 5.2 6.1 8.0 8.0

Locked rotor Amp(LRA) A 26 41.2 41.2

Thermal protector Internal External Internal Internal

Capacitor uF 25 35 35 35

Refrigerant oil ml 440 430 520 520

Input W 36.5 36.5 53 53

Capacitor uF 1.2 1.2 1.5uF/450V 1.5uF/450V

Speed(hi/mi/lo) r/min 1350 1350 1180 1180

Dimension (W*H*D) mm 750X250X188 750X250X188 906×286×235 906×286×235

Packing (W*H*D) mm 830X336X280 830X336X280 1020X380X328 1020X 380X328

Net/Gross weight Kg 8.5/10 8.5/10 13.5/16.5 13.5/16.5

Input W 70 70 96 96

Capacitor uF 2.5 2.5 2.5µF/450V 2.5µF/450V

Dimension(W*H*D) mm 780X540X250 780X540X250 780X540X250 780X540X250

Packing (W*H*D) mm 910X575X335 910X 575X335 910X575X335 910X575X335

Net/Gross weight Kg 34/37 36/39 43/47 44/48

Liquid side/ Vapor side mm(inch) Ф6.35/Ф12.7 Ф6.35/Ф12.7 Ф6.35/Ф12.7 Ф6. 35/Ф12.7

Max. refrigerant pipe length m 10 10 15 15

Max. difference in level m 5 5 8 8

68

Page 14

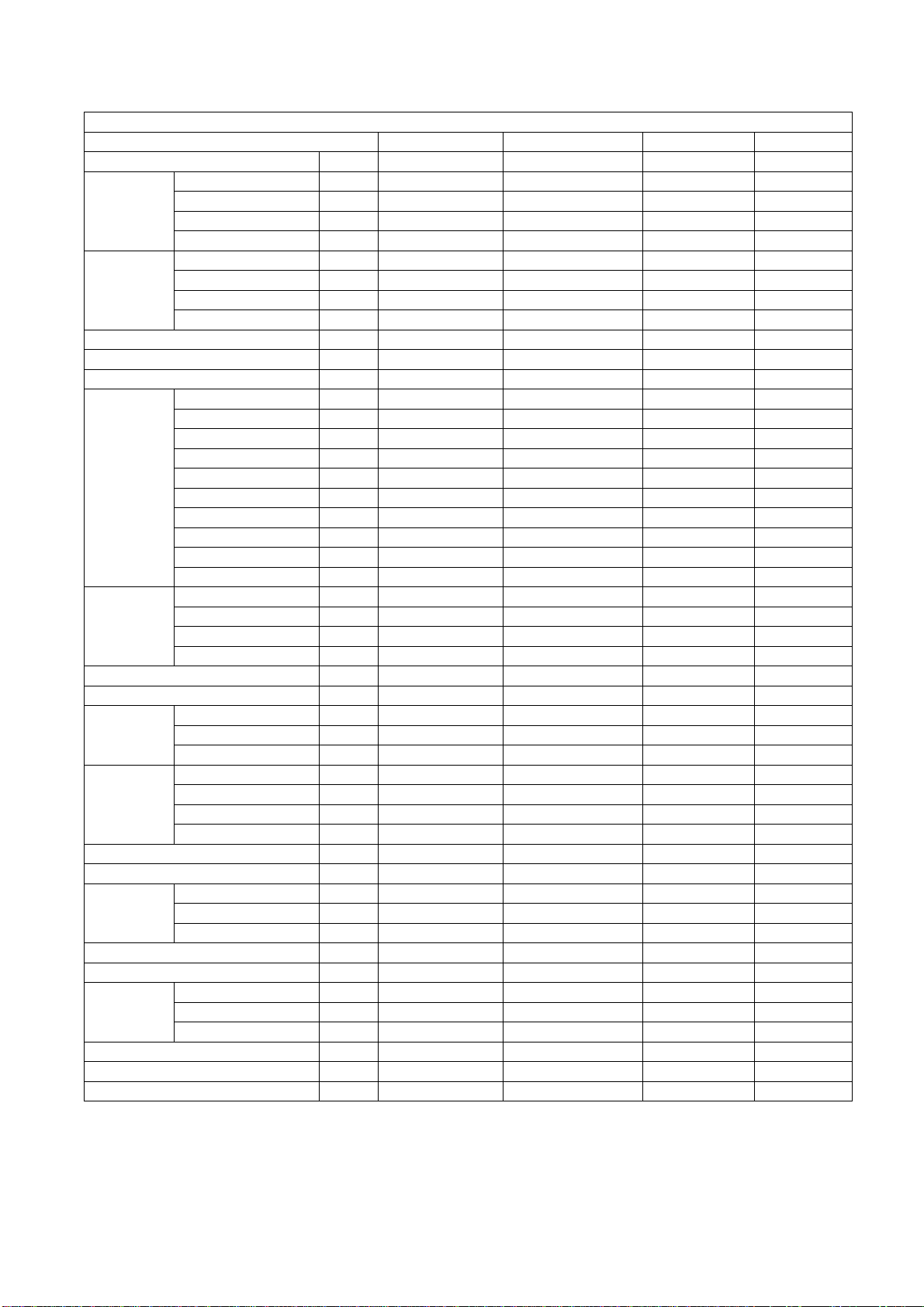

Model

Power supply Ph-V-Hz 220-240V~,50Hz 220-240V~,50Hz

Capacity Btu/h 21000 21000

Cooling

Heating

Moisture Removal L/h 2.0 2.0

Max. input consumption W 2500 2600

Max. current A 11.3 14.5

Starting current A 42 42

Compressor

Indoor fan motor

Indoor air flow (Hi/Mi/Lo) m3/h 920\760\700 920\760\700

Indoor noise level (Hi/Mi/Lo) dB(A) 41/37/33 41/37/33

Indoor unit

Outdoor fan motor

Outdoor air flow m3/h 2600 2600

Outdoor noise level dB(A) 53 53

Outdoor unit

Refrigerant type R22 g 1220 1740

Design pressure MPa 2.6 2.6

Refrigerant piping

Thermostat type Electronic control Electronic control

Operation temp

Ambient temp

Application area m2 34-49 34-49

Input W 2300 2300

Rated current A 10.5 10.5

EER Btu/w.h 9.1 9.1

Capacity Btu/h 23500

Input W 2400

Rated current A 11.0

COP w/w 2.9

Model 2V36S225AUD 2V36S225AUD

Type rotary rotary

Capacity Btu/h 20600 20600

Input W 2010 2010

Rated current(RLA) A

Locked rotor Amp(LRA) A 42 42

Thermal protector INNER INNER

Capacitor uF 50 50

Refrigerant oil ml 680 680

Model RPG25 RPG25

Brand WELLING WELLING

Input W 53 53

Capacitor uF 1.5uF/450V 1.5uF/450V

Speed(hi/mi/lo) r/min 1325 1325

Dimension (W*H*D) mm 906×286×235 906×286×235

Packing (W*H*D) mm 1020X380X328 1020X380X328

Net/Gross weight Kg 13.5/16.5 13.5/16.5

Model YDK53-6 YDK53-6

Input W 100 100

Capacitor uF

Speed r/min 640 640

Dimension(W*H*D) mm 845×695×335 845×695×335

Packing (W*H*D) mm 970×770×395 970×770×395

Net/Gross weight Kg 52/57 55/60

Liquid side/ Gas side mm(inch)

Max. refrigerant pipe length m 15 15

Max. difference in level m 8 8

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient condition.

CES-21.RC CES-21.R

9。5 9。5

2.5μF/450V 2.5μF/450V

Ф6.35/Ф12.7 Ф6.35/Ф12.7

℃

℃

17-30 17-30

10-43 (-5~43)

69

Page 15

Comfort

Model CES-07_R7______________CES-07_R7C____________CES-09_R7_________CES-09_R7C

Power supply Ph-V-Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz

Capacity Btu/h 7000 7000 9000 9000

Cooling

Heating

Moisture Removal L/h 0.6 0.6 0.8 0.8

Max. input consumption W 1000 1000 1330 1330

Max. current A 4.4 4.4 6 6

Compressor

Indoor fan motor

Indoor air flow (Hi/Mi/Lo) m3/h 430/400/370 430/400/370 470/440/410 470/440/410

Indoor noise level (Hi/Mi/Lo) dB(A) 35/32/30 35/32/30 36/32/30 36/32/30

Indoor unit

Outdoor fan

motor

Outdoor air flow m3/h 1600 1600 1900 1600

Outdoor noise level dB(A) 49 49 49 49

Outdoor unit

Refrigerant type R407C g 740 650 840 770

Design pressure MPa 2.8 2.8 2.8 2.8

Refrigerant

piping

Operation temp ℃ 17 30 17 30 17 30 17 30

Ambient temp ℃ -7-45 18-45 -7-45 18-45

Application area m2 10-14 10-14 14-21 14-21

Input W 800 800 1050 1050

Rated current A 3.5 3.5 4.6 4.6

EER Btu/w.h 8.8 8.8 8.6 8.6

Capacity Btu/h 8500 10000

Input W 880 1050

Rated current A 4 4.6

COP w/w 2.9 2.93

Model PG135X1C-4DZ2 PG135X1C-4DZ2 PG180X1C-4DZ3 PG180X1C-4DZ3

Type Rotary Rotary Rotary Rotary

Brand TOSHIBA TOSHIBA TOSHIBA TOSHIBA

Capacity Btu/h 8086/8172 8086/8172 10800 10800

Input W 765/785 765/785 1015 1015

Rated current(RLA) A 3.52/3.34 3.52/3.34 4.5 4.5

Locked rotor Amp(LRA) A

Thermal protector UP3SE0591-T71 UP3SE0591-T71 UP3SE0591-T61 UP3SE0591-T61

Capacitor uF 25 25 30 30

Refrigerant oil ml 400 400 400 400

Model RPG13H RPG13H RPG13H RPG13H

Input W 36.5 37.5 38.5 39.5

Capacitor uF 1.2 1.2 1.2 1.2

Speed(hi/mi/lo) r/min 1020/960/900 1020/960/900 1100/1020/950 1100/1020/950

Dimension (W*H*D) mm 750×250×188 750×250×188 750×250×188 750×250×188

Packing (W*H*D) mm 830×336×280 830×336×280 830×336×280 830×336×280

Net/Gross weight Kg 8.5/10.5 8.5/10.5 8.5/10.5 8.5/10.5

Model YDK24-6T YDK24-6T YDK24-6T YDK24-6T

Input W 70 70 70 70

Capacitor uF 3 3 3 3

Speed r/min 850 850 850 850

Dimension(W*H*D) mm 700X535X235 700X535X235 700X535X235 700X535X235

Packing (W*H*D) mm 815X580X325 815X580X325 815X580X325 815X580X325

Net/Gross weight Kg 30/33 29/32 29/32 30/33

Liquid side/ Gas side mm(inch Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53

Max. refrigerant pipe length m 10 10 10 10

Max. difference in level m 5 5 5 5

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient condition.

70

Page 16

Model CES-12_R7C____________________________CES-12_R7

Power supply Ph-V-Hz 1, 220-240V~, 50Hz 1, 220-240V~, 50Hz

Capacity Btu/h 12000 12000

Cooling

Heating

Moisture Removal L/h 1.2 1.2

Max. input consumption W 1800 1800

Max. current A 7.8 7.8

Starting current A

Compressor

Indoor fan motor

Indoor air flow (Hi/Mi/Lo) m3/h 620/550/520 620/550/520

Indoor noise level (Hi/Mi/Lo) dB(A) 37/34/31 37/34/31

Indoor unit

Outdoor fan motor

Outdoor air flow m3/h 1900 1900

Outdoor noise level dB(A) 54 54

Outdoor unit

Refrigerant type R407C g 830 1150

Design pressure MPa 2.8 2.8

Refrigerant piping

Plug type 16A 16A

Thermostat type Electronic control Electr onic control

Operation temp

Ambient temp

Application area m2 18-26 18-26

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient condition.

Input W 1320 1320

Rated current A 5.8 5.8

EER Btu/w.h 9.1 9.1

Capacity Btu/h 14000

Input W 1360

Rated current A 6

COP w/w 3.02

Model 4KS225EBA 4KS225EBA

Type Rotary Rotary

Brand MATSUSHITA-WABAO MATSUSHITA-W ABAO

Capacity Btu/h 13000 13000

Input W 1260 1260

Rated current(RLA) A 5.7 5.7

Locked rotor Amp(LRA) A 30 30

Thermal protector

Capacitor uF 35 35

Refrigerant oil ml 480 480

Model RPG20D RPG20D

Input W 49.2 49. 2

Capacitor uF 1.5 1.5

Speed(hi/mi/lo) r/min 1180/1000/ 900 1180/1000/900

Dimension (W*H*D) m m 815X280X195 815X280X195

Packing (W*H*D) mm 915X360X275 915X360X275

Net/Gross weight Kg 10.5/13.5 10.5/13.5

Model YDK25-6C YDK25-6C

Input W

Capacitor uF

Speed r/min 900 900

Dimension(W*H*D) mm 780X540X250 780X540X250

Packing (W*H*D) mm 910X575X335 910X575X335

Net/Gross weight Kg 34/38 37/41

Liquid side/ Gas side mm(inch)

Max. refrigerant pipe length m 10 10

Max. difference in level m 5 5

℃

℃

85 85

2.5 2.5

Ф6.35/Ф12.7 Ф6.35/Ф12.7

17-30 17-30

18-45 —7-45

71

Page 17

Comfort

Model CES-07_R7______________CES-07_R7C____________CES-09_R7________CES-09_R7C

Power supply Ph-V-Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz 220-240V~,50Hz

Capacity Btu/h 7000 7000 9000 9000

Cooling

Heating

Moisture Removal L/h 0.6 0.6 0.8 0.8

Max. input consumption W 1000 1000 1330 1330

Max. current A 4.4 4.4 6 6

Compressor

Indoor fan motor

Indoor air flow (Hi/Mi/Lo) m3/h 430/400/370 430/400/370 470/440/410 470/440/410

Indoor noise level (Hi/Mi/Lo) dB(A) 35/32/30 35/32/30 36/32/30 36/32/30

Indoor unit

Outdoor fan

motor

Outdoor air flow m3/h 1600 1600 1900 1600

Outdoor noise level dB(A) 49 49 49 49

Outdoor unit

Refrigerant type R407C g 740 650 840 770

Design pressure MPa 2.8 2.8 2.8 2.8

Refrigerant

piping

Operation temp ℃ 17 30 17 30 17 30 17 30

Ambient temp ℃ -7-45 18-45 -7-45 18-45

Application area m2 10-14 10-14 14-21 14-21

Input W 800 800 1050 1050

Rated current A 3.5 3.5 4.6 4.6

EER Btu/w.h 8.8 8.8 8.6 8.6

Capacity Btu/h 8500 10000

Input W 880 1050

Rated current A 4 4.6

COP w/w 2.9 2.93

Model PG135X1C-4DZ2 PG135X1C-4DZ2 PG180X1C-4DZ3 PG180X1C-4DZ3

Type Rotary Rotary Rotary Rotary

Brand TOSHIBA TOSHIBA TOSHIBA TOSHIBA

Capacity Btu/h 8086/8172 8086/8172 10800 10800

Input W 765/785 765/785 1015 1015

Rated current(RLA) A 3.52/3.34 3.52/3.34 4.5 4.5

Locked rotor Amp(LRA) A

Thermal protector UP3SE0591-T71 UP3SE0591-T71 UP3SE0591-T61 UP3SE0591-T61

Capacitor uF 25 25 30 30

Refrigerant oil ml 400 400 400 400

Model RPG13H RPG13H RPG13H RPG13H

Input W 36.5 37.5 38.5 39.5

Capacitor uF 1.2 1.2 1.2 1.2

Speed(hi/mi/lo) r/min 1020/960/900 1020/960/900 1100/1020/950 1100/1020/950

Dimension (W*H*D) mm 750×250×188 750×250×188 750×250×188 750×250×188

Packing (W*H*D) mm 830×336×280 830×336×280 830×336×280 830×336×280

Net/Gross weight Kg 8.5/10.5 8.5/10.5 8.5/10.5 8.5/10.5

Model YDK24-6T YDK24-6T YDK24-6T YDK24-6T

Input W 70 70 70 70

Capacitor uF 3 3 3 3

Speed r/min 850 850 850 850

Dimension(W*H*D) mm 700X535X235 700X535X235 700X535X235 700X535X235

Packing (W*H*D) mm 815X580X325 815X580X325 815X580X325 815X580X325

Net/Gross weight Kg 30/33 29/32 29/32 30/33

Liquid side/ Gas side mm(inch Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53 Ф6.35/Ф9.53

Max. refrigerant pipe length m 10 10 10 10

Max. difference in level m 5 5 5 5

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient condition.

70

Page 18

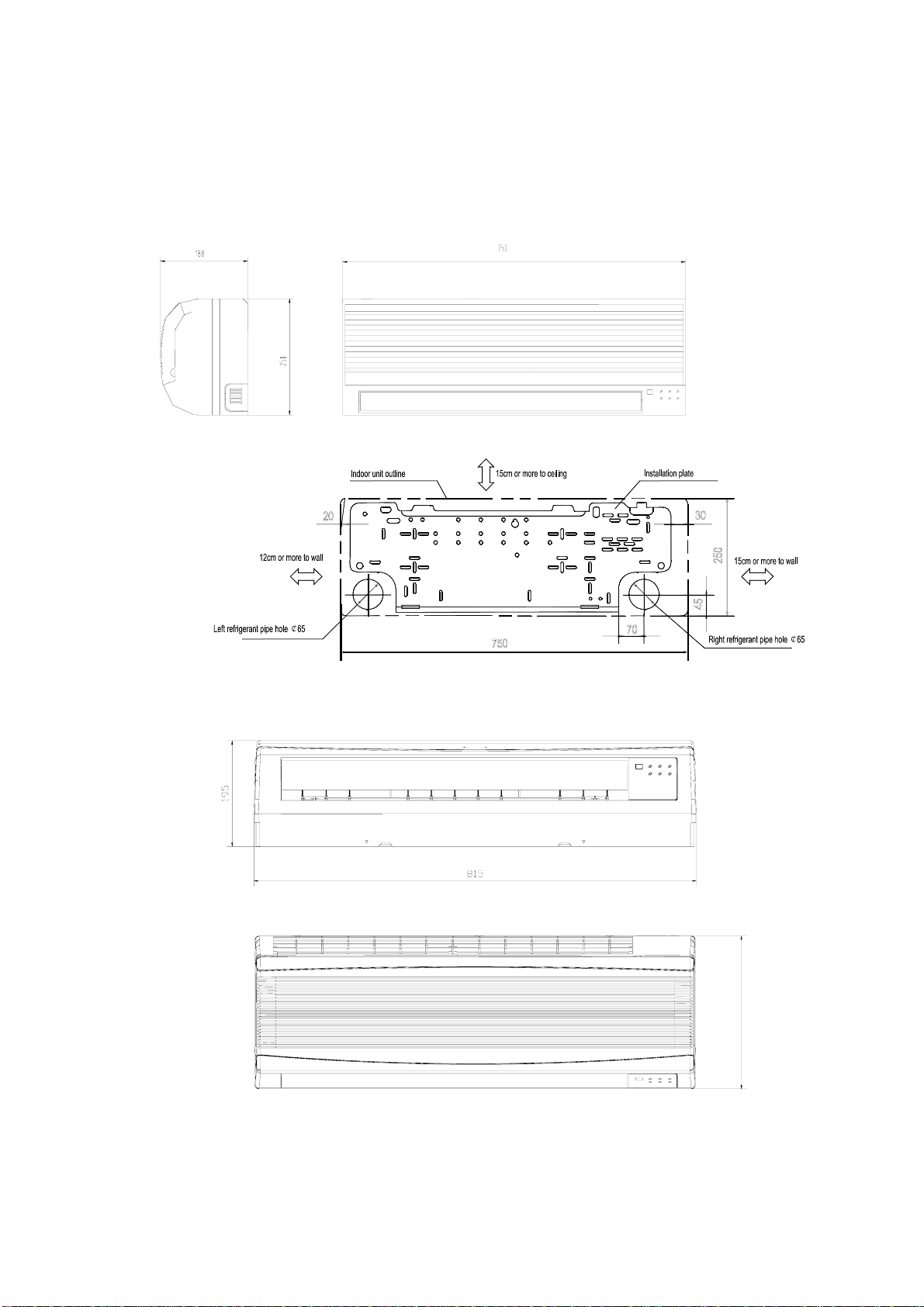

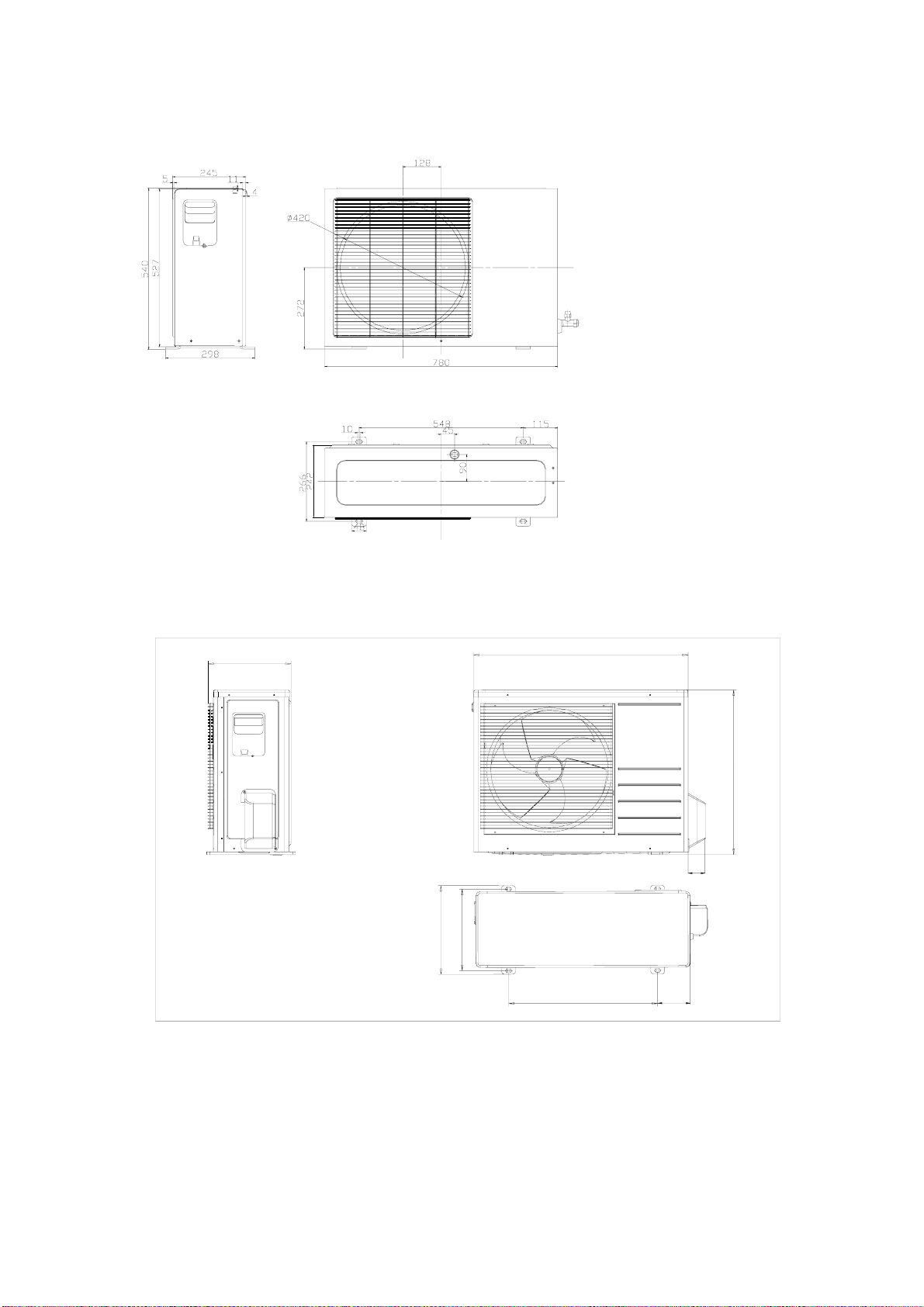

3.Dimensions

3.1 Indoor unit

CES-05/07/09_R(7)(C),CES-12_R(7)(C)

3.2 Indoor unit CES-12_R(7)(C)

280

73

Page 19

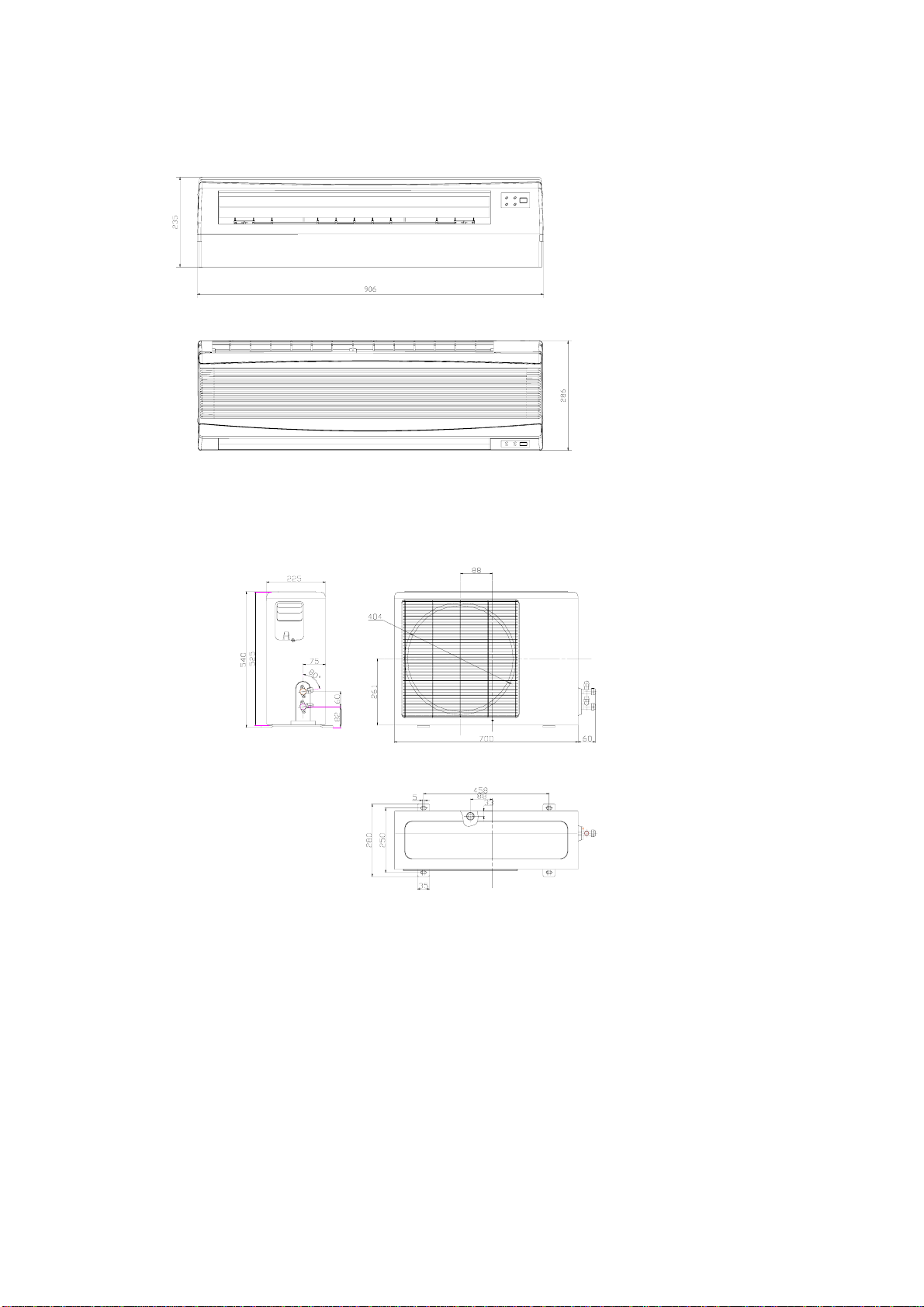

3.3 Indoor unit CES-18/21_R(7)(C))

3.4 Outdoor unit CES-05/07/09_R(7)(C),

74

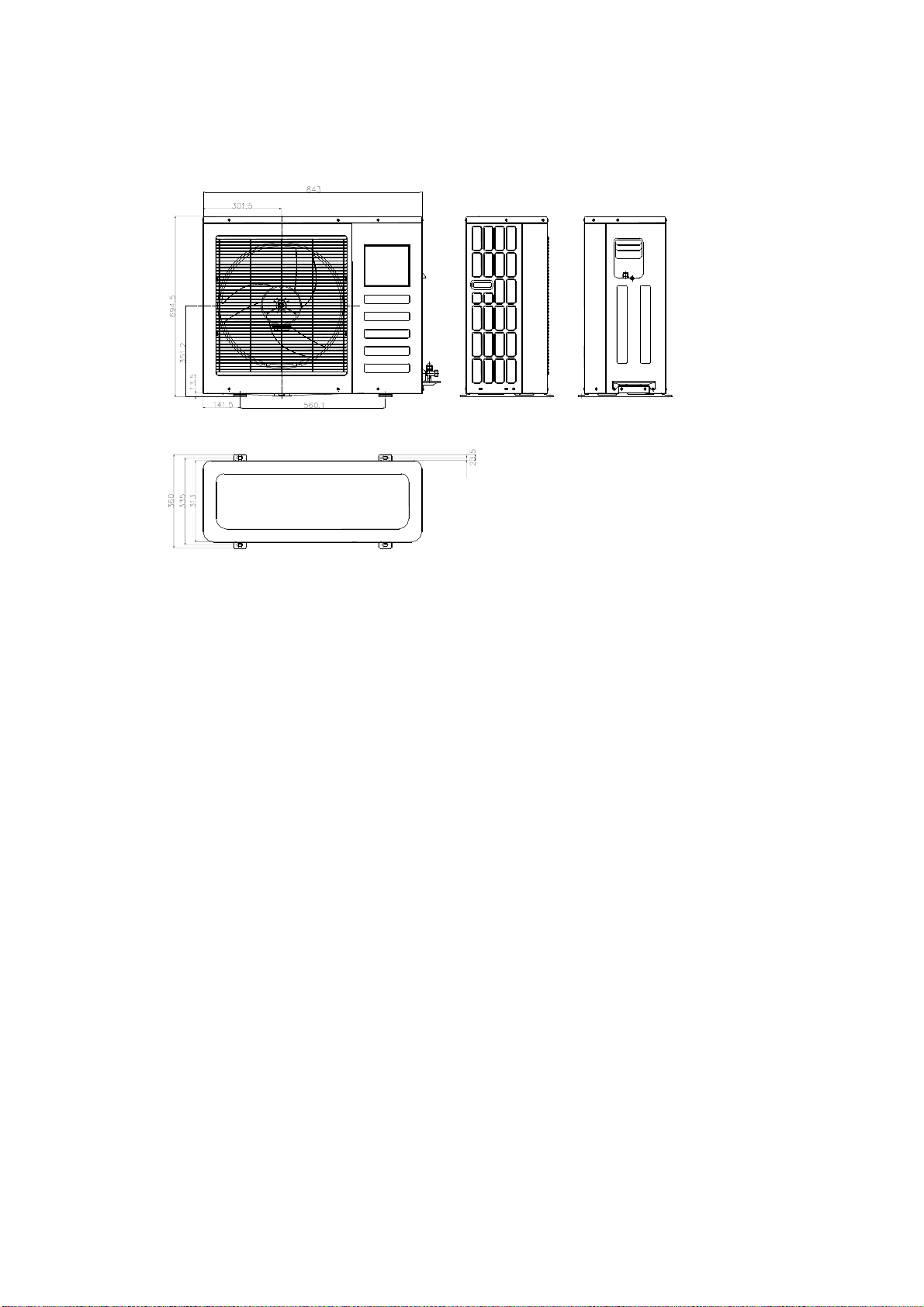

Page 20

3.5 Outdoor unit CES-12_R(7)(C) & CES-18_R(7)(C)

3.6 Outdoor unit CES-18_R(7)(C)

285

315

290

750

590

62

530

110

75

Page 21

3.7 Outdoor unit CES-21_R(7)(C)

12.5

76

Page 22

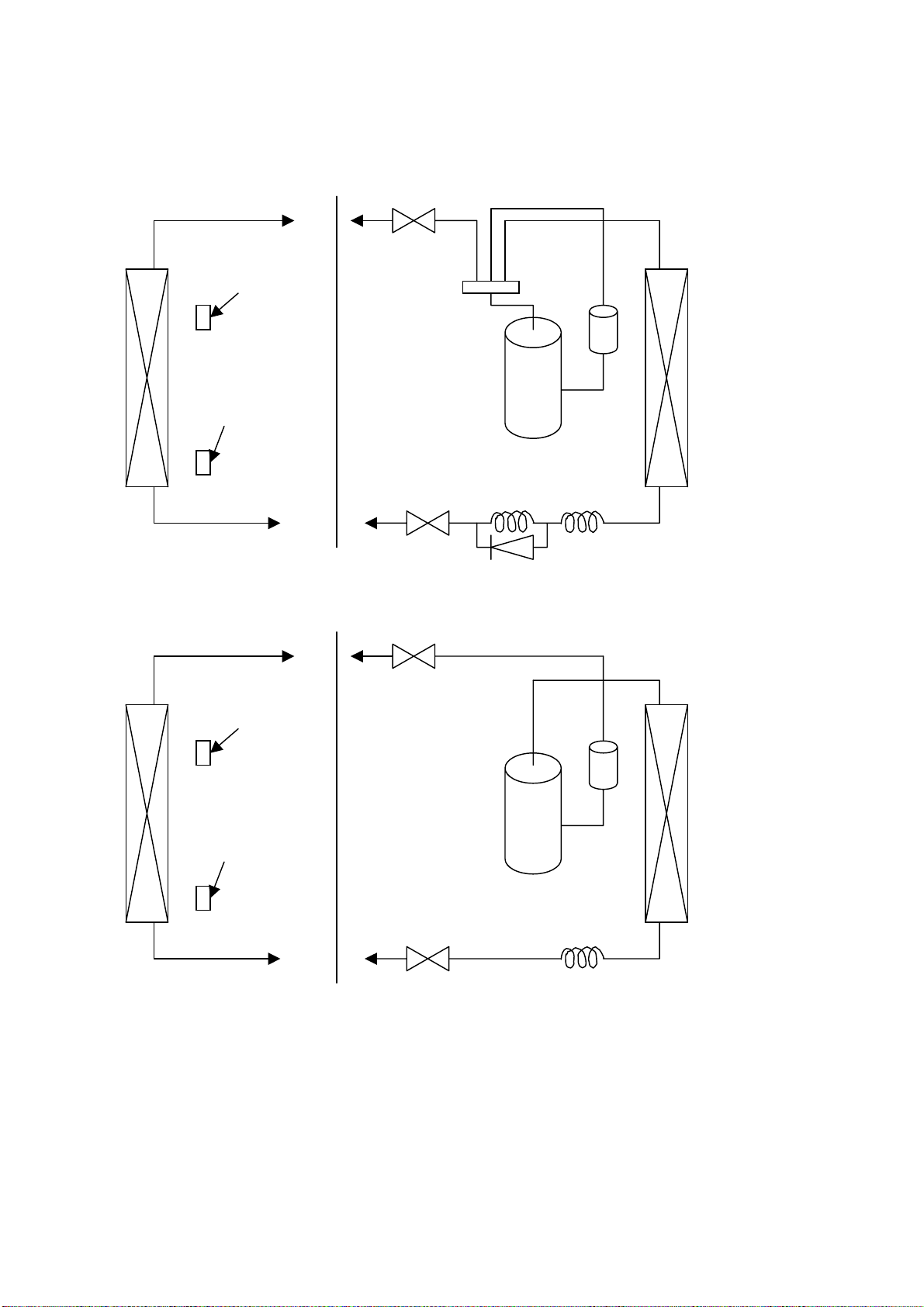

4.Refrigeration cycle diagram

4.1 Cooling/heating

Indoor unit outdoor unit

. 4 way valve

Sensor of room temp

Val ve

Heat exchanger Heat exchanger

Sensor of heat exchanger temp

.

Compressor

Val ve Capillary

4.2 Cooling only

Indoor unit outdoor unit

.

Sensor of room temp

Val ve

Heat exchanger Heat exchanger

Sensor of heat exchanger temp

.

Compressor

Val ve Capillary

77

Page 23

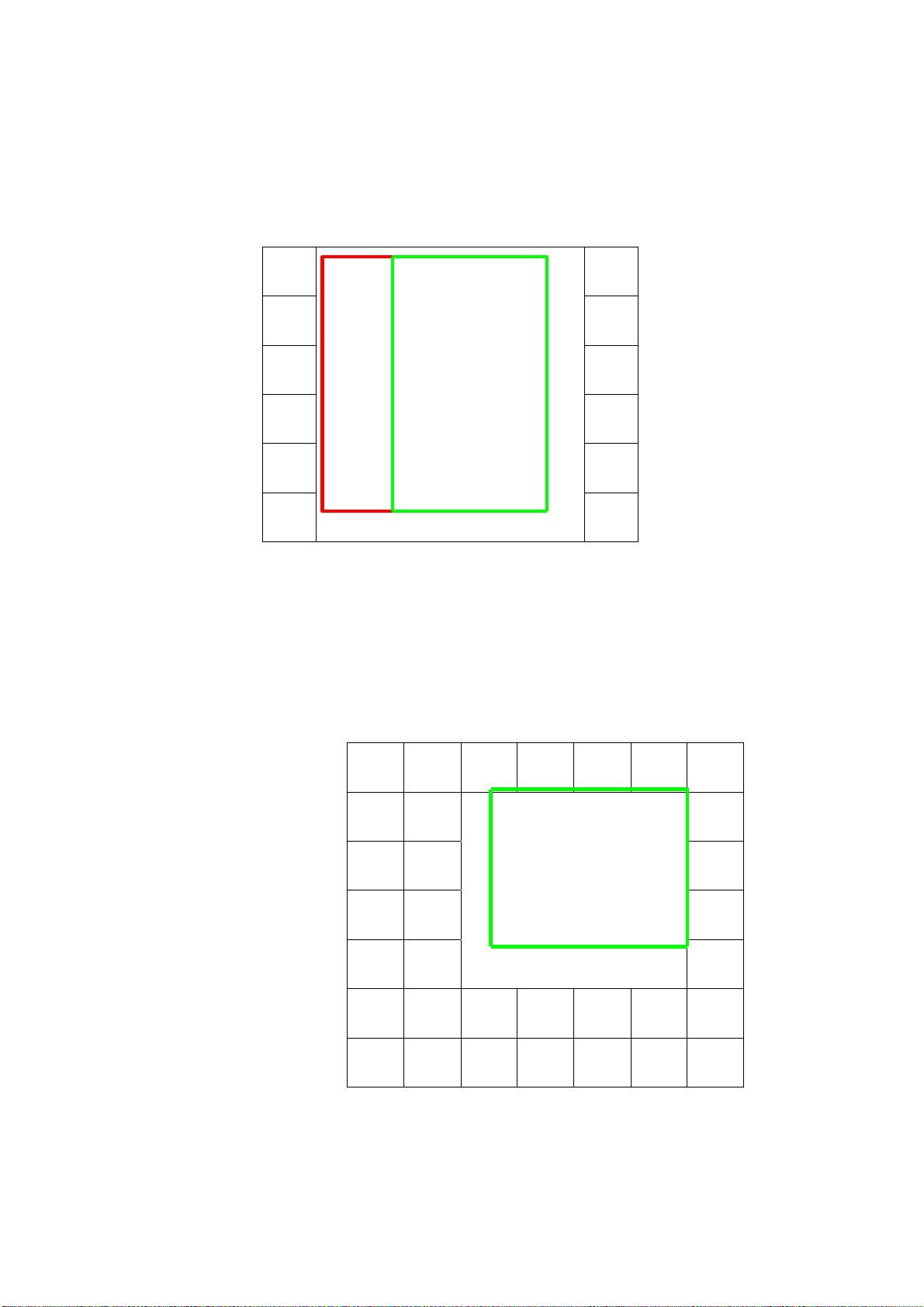

5.Operation limits

5.1Cooling operation

Outdoor unit air temp.℃ DB

45

40

35

30

25

20

Indoor air temp.

Note : The chart is the result from the continuous operation under constant air temperature

conditions. However, excludes the initial pull-down stage.

5.2Heating operation

DRY COOLING

10 15 20 25 30 35 40

℃ DB

Indoor air temp. ℃ DB

30

25

20

15

10

5

Note : The chart is the result from the continuous operation under constant air

temperature conditions. However, excludes the initial pull-down stage.

-5 5 15 25

Outdoor unit air temp.

78

℃ DB

Page 24

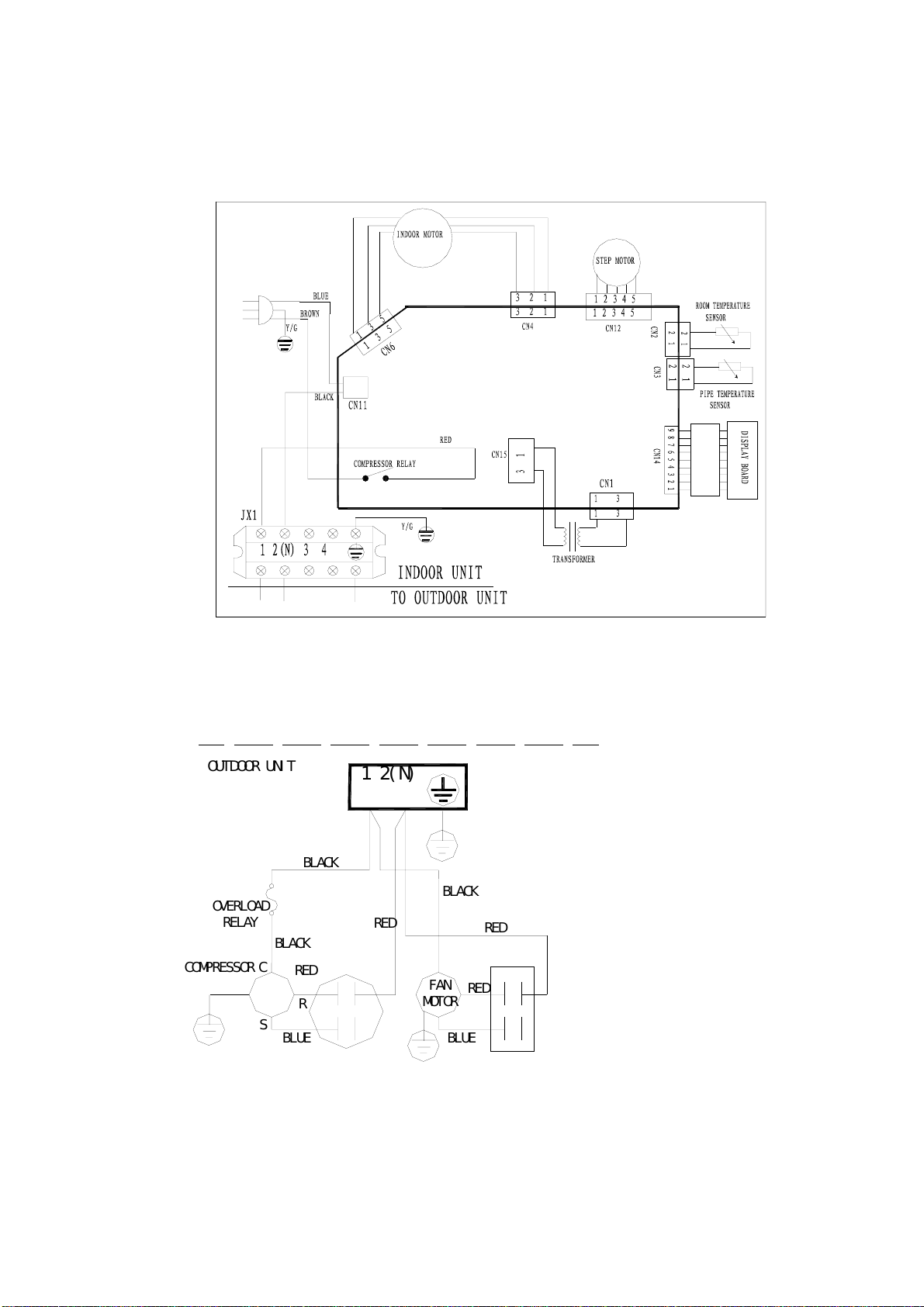

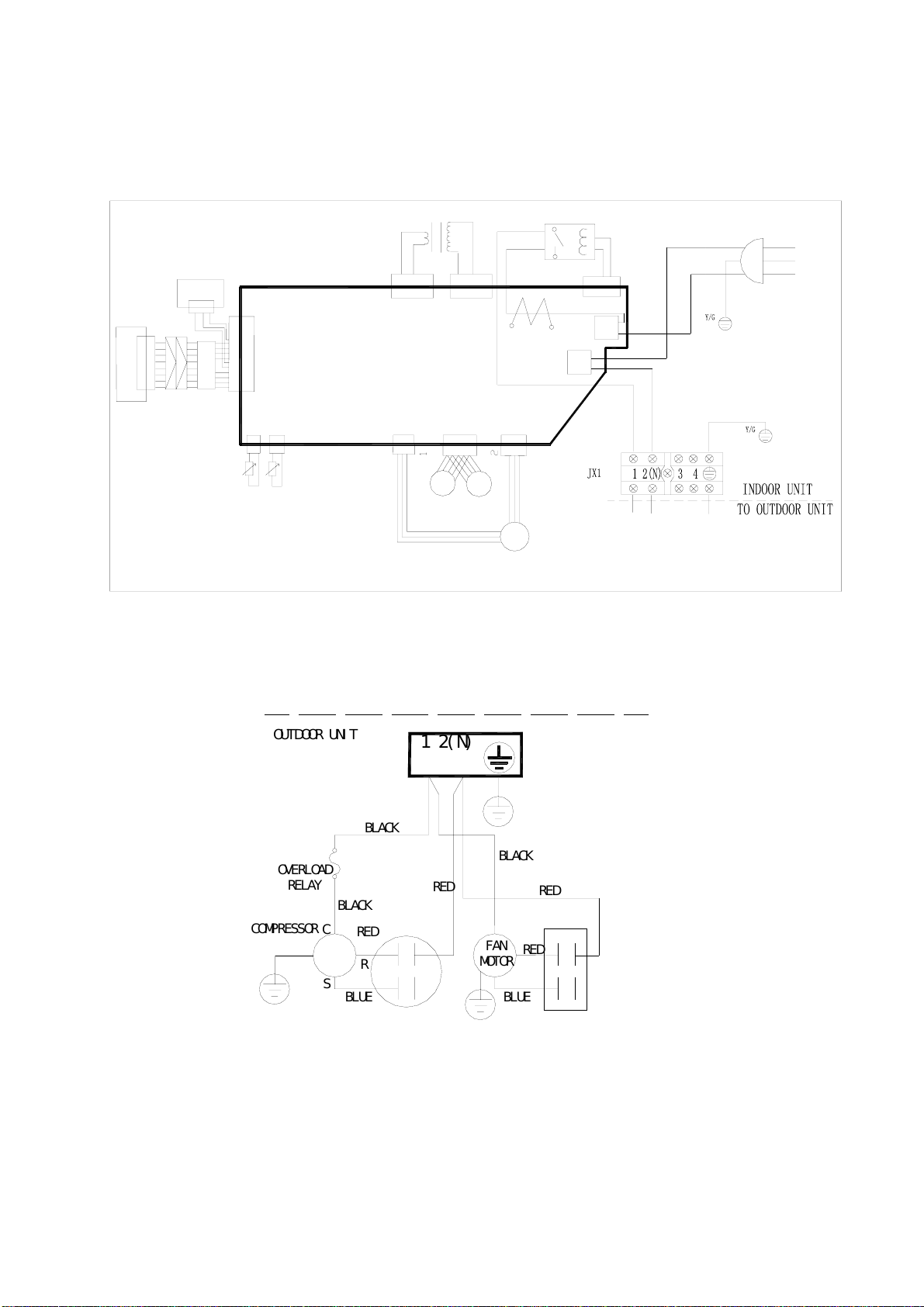

6.Wiring diagram

6.1 Cooling only

6.1.1 CES-05_R(7)(C) Indoor unit

POWER SUPPLY

INDOOR UNIT

OUTDOOR UNI

OVERLOAD

RELAY

COMPRESSO

Y&G

T

BLACK

BLACK

R

C

RED

R

S

BLU

E

1 2(N)

RED

COMPRESSOR

CAPACITOR

Y&G

FAN

MOTOR

BLACK

BLU

Y&G

RED

RED

E

FAN

CAPACITOR

79

Page 25

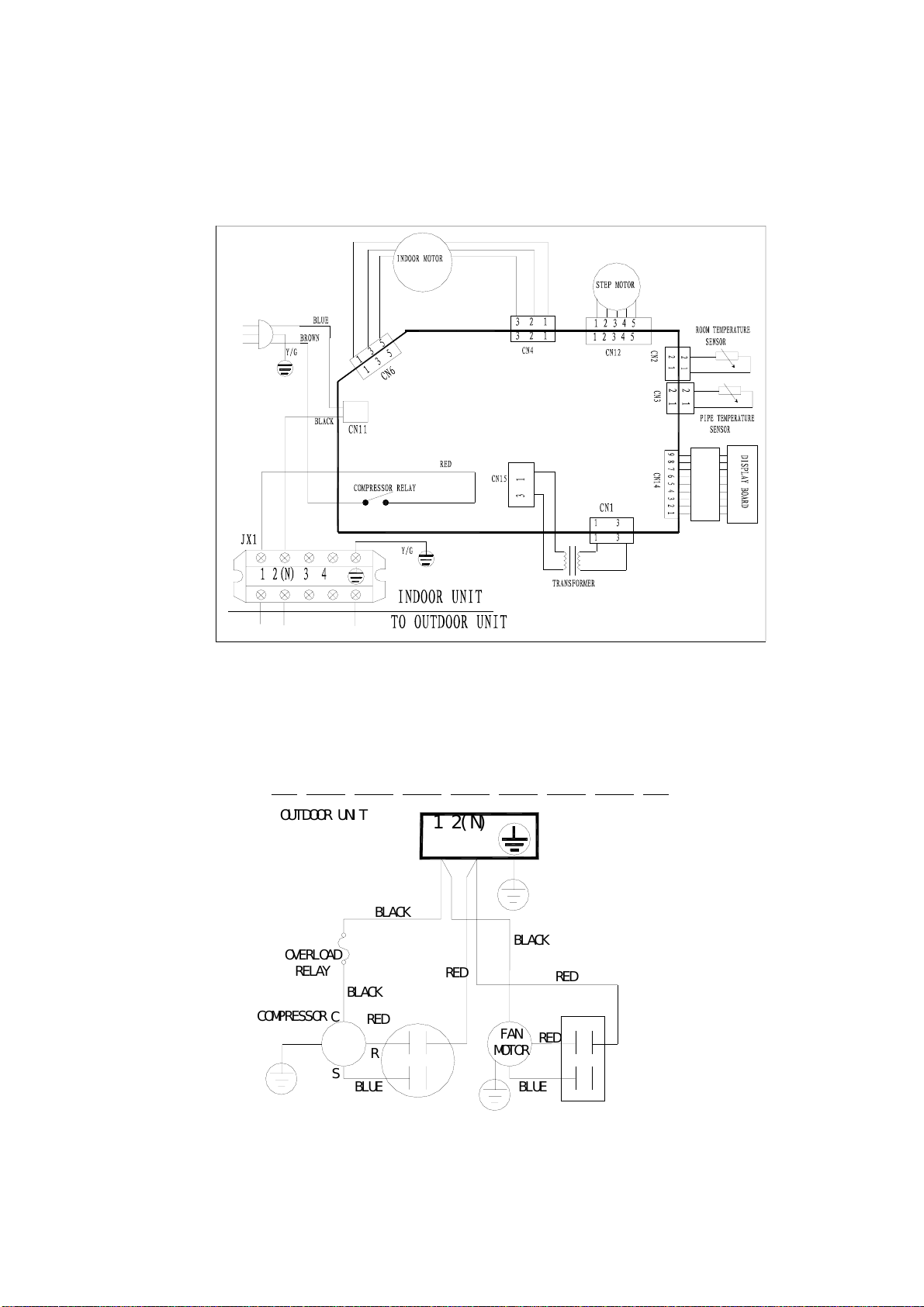

6.1.2 CES-07_R(7)(C) & CES-09_R(7)(C)

POWER SUPPLY

INDOOR UNIT

OUTDOOR UNI

OVERLOAD

RELAY

COMPRESSO

Y&G

T

BLACK

BLACK

R

C

RED

R

S

BLU

E

1 2(N)

RED

Y&G

FAN

MOTOR

BLACK

BLU

Y&G

RED

RED

E

COMPRESSOR

CAPACITOR

80

FAN

CAPACITOR

Page 26

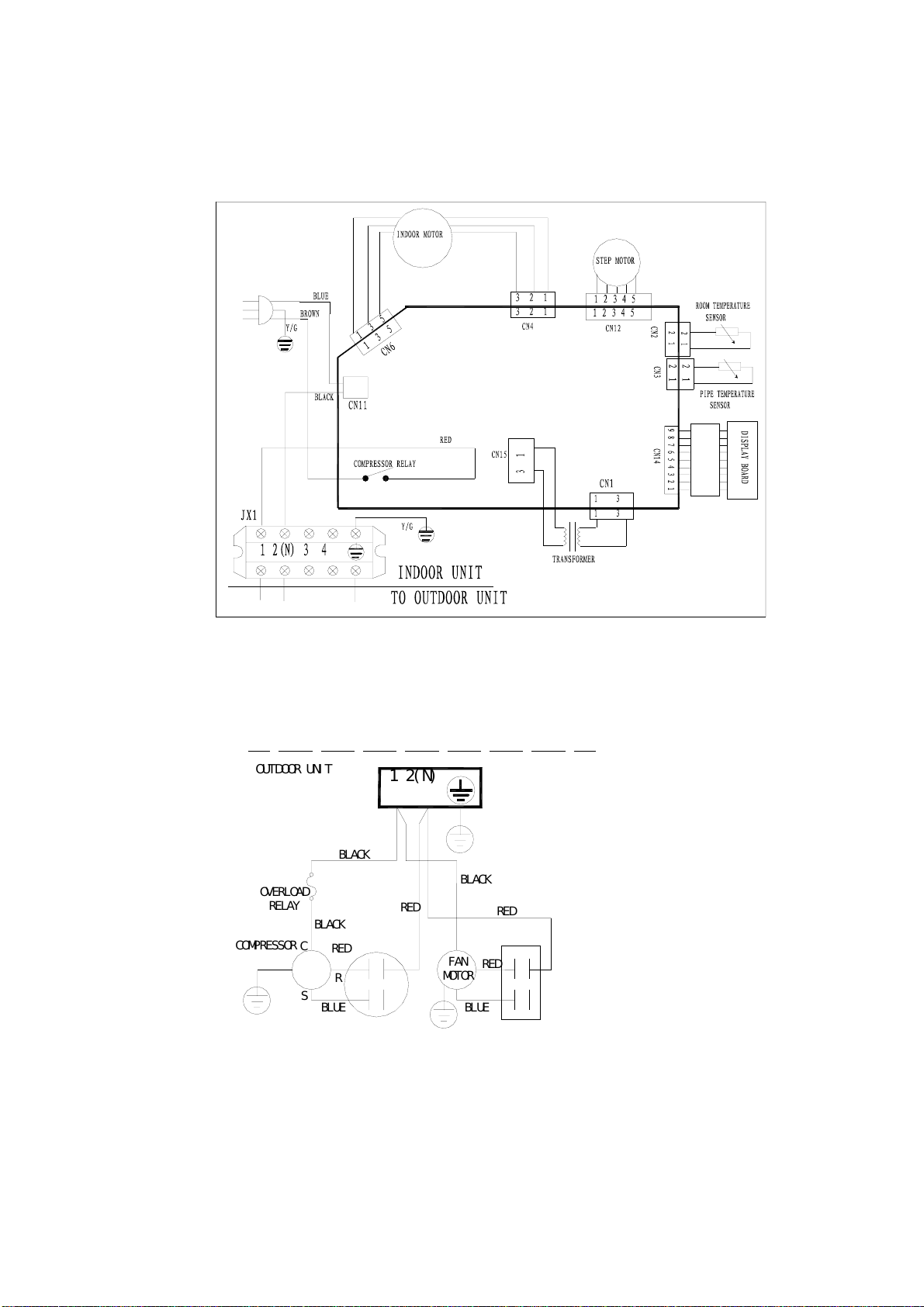

6.1.3 CES-12_R(7)(C) Indoor unit (A Type)

POWER SUPPLY

INDOOR UNIT

OUTDOOR UNI

OVERLOAD

RELAY

COMPRESSO

Y&G

T

BLACK

BLACK

R

C

RED

R

S

BLU

E

1 2(N)

RED

COMPRESSOR

CAPACITOR

Y&G

FAN

MOTOR

BLACK

BLU

Y&G

RED

RED

E

FAN

CAPACITOR

81

Page 27

6.1.4 CES-12_R(7)(C) (B Type)

INDOOR UNIT

OUTDOOR UNI

OVERLOAD

RELAY

COMPRESSO

Y&G

T

BLACK

BLACK

R

C

RED

R

S

BLU

E

1 2(N)

RED

COMPRESSOR

CAPACITOR

Y&G

FAN

MOTOR

BLACK

BLU

Y&G

RED

RED

E

FAN

CAPACITOR

82

Page 28

6.1.5 CES-18_R7(C) & CES-21_R7(C)

DISPLAY BOARD

SWITCH BOARD

CN12

CN8

AMBIENT SENSOR

CN7

HEAT EXCHANGER

TRANSFORMER

CN9

CN10

SENSOR

CN4

CN6

LOUVER MOTOR

INDOOR MOTOR

COMPRESSOR RELAY

WHITE

CURRENT DETECTOR

CN1

CN5

LOUVER MOTOR

CN14

CN2

WHITE

BLUE

BROWN

BLACK

INDOOR UNIT

OUTDOOR UNI

OVERLOAD

RELAY

COMPRESSO

Y&G

T

1 2(N)

Y&G

BLACK

BLACK

RED

RED

BLACK

R

C

RED

R

S

BLU

E

COMPRESSOR

CAPACITOR

Y&G

FAN

MOTOR

BLU

RED

E

FAN

CAPACITOR

83

Page 29

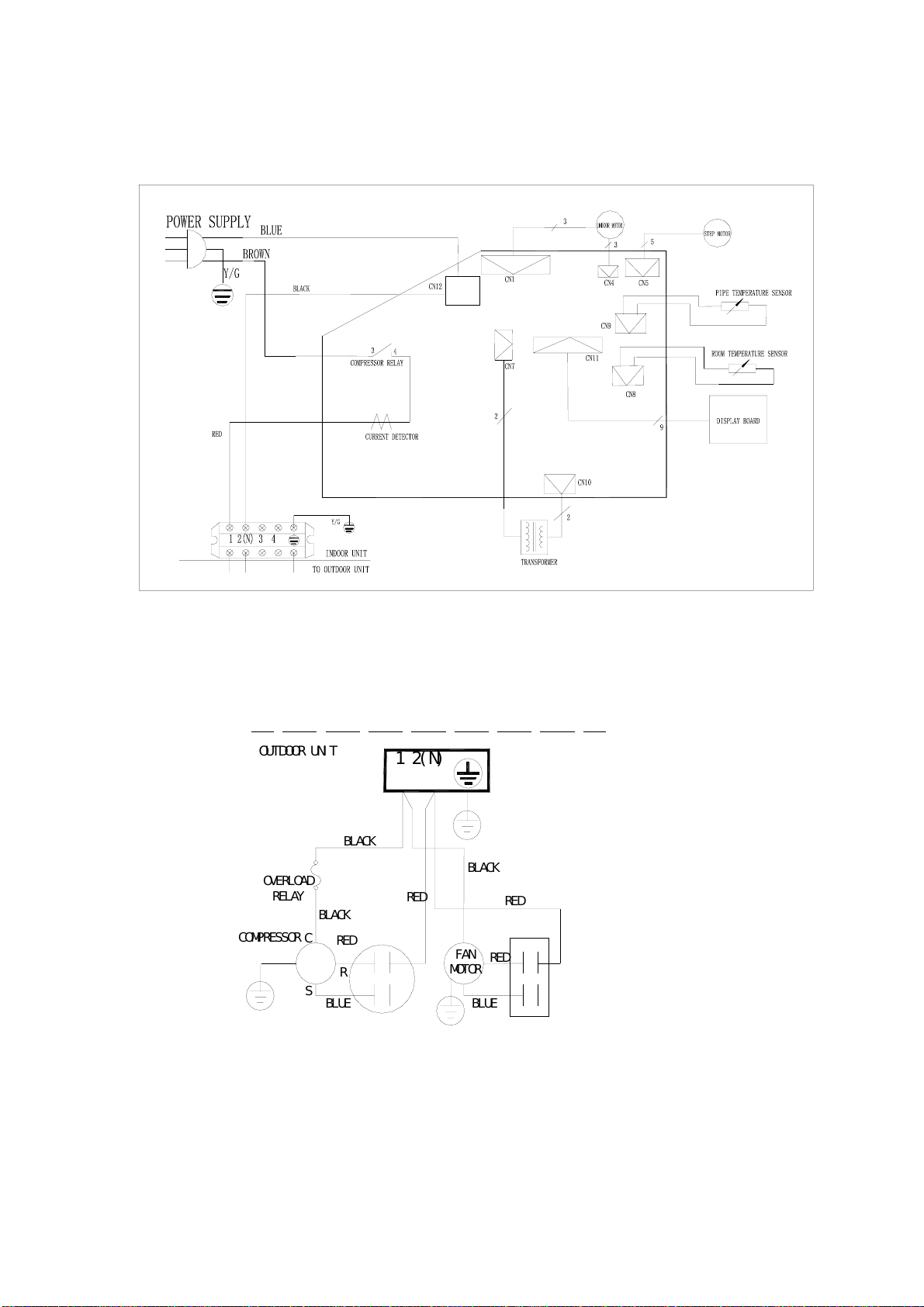

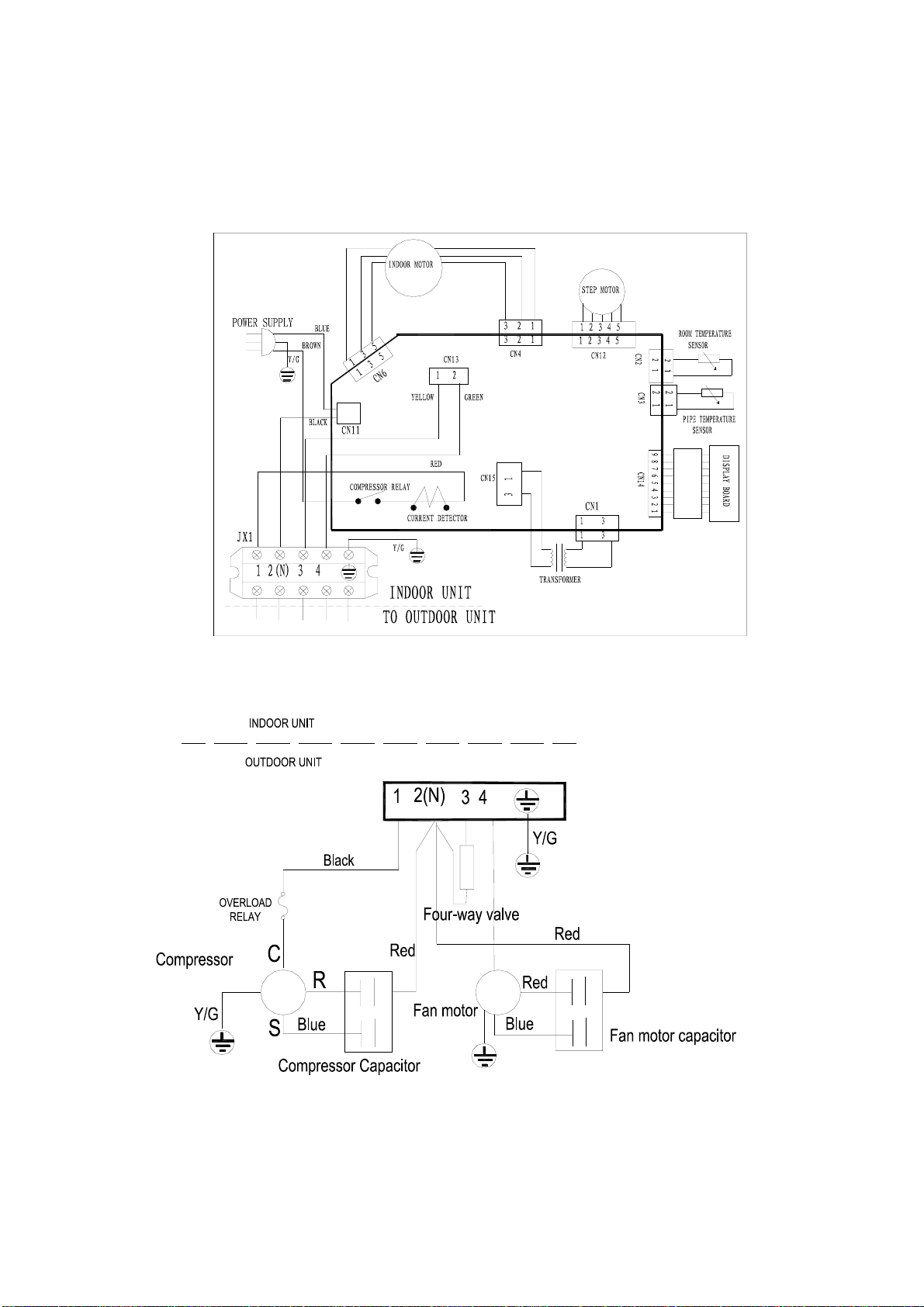

6.2 Heating/cooling

6.2.1 CES-07_R(7),CES-09_R(7) & CESG-09HRN2,

84

Page 30

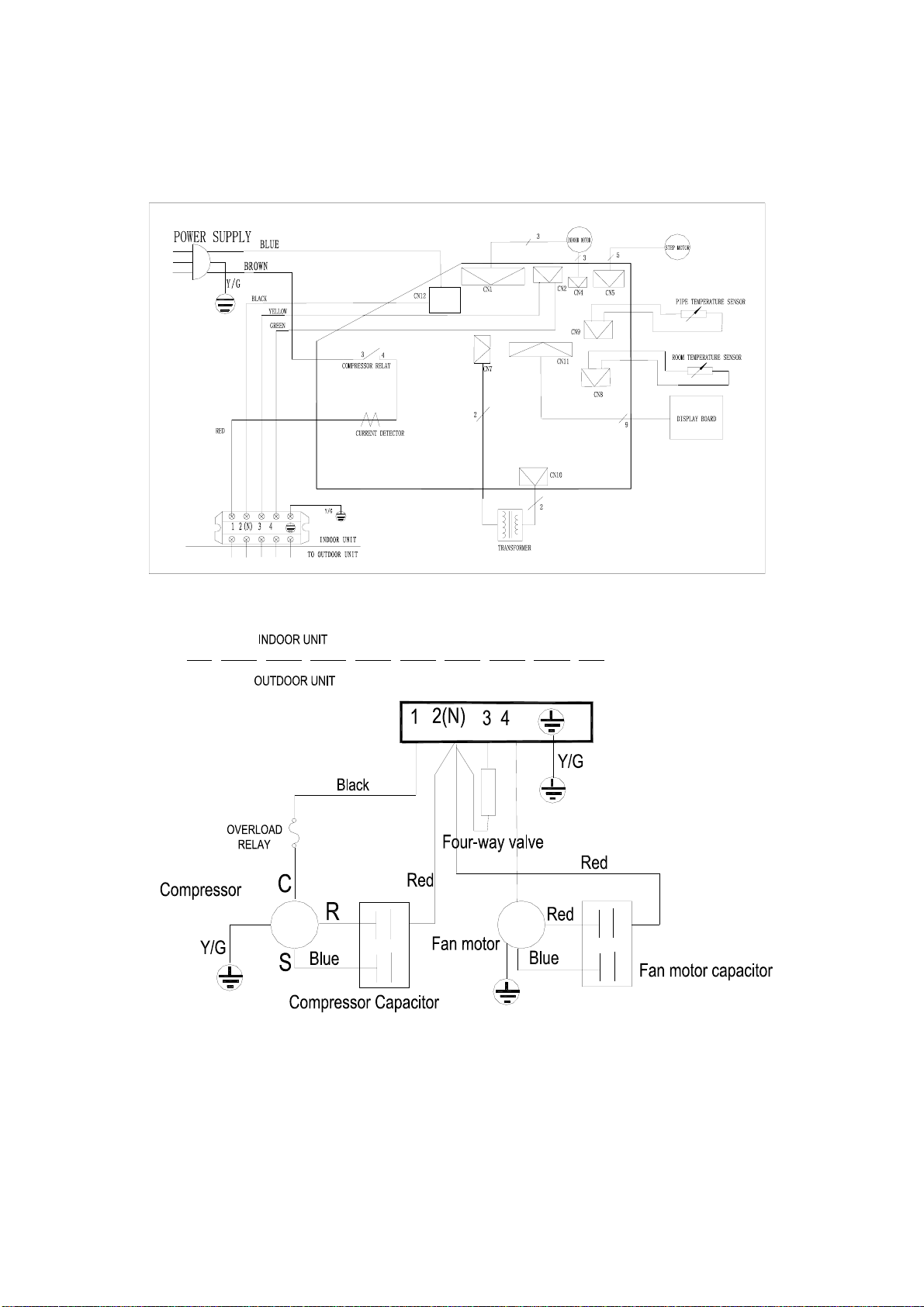

6.2.2 CES-12_R7(B TYPE) & CES-12_R7

85

Page 31

6.2.3 CES-18_R(7) & CES-21_R(7)

DISPLAY BOARD

SWITCH BOARD

CN8

AMBIENT SENSOR

CN12

CN7

TRANSFORMER

CN9

CN3

SENSOR

HEAT EXCHANGER

CN10

CN4

CN6

LOUVER MOTOR

INDOOR MOTOR

COMPRESSOR RELAY

WHITE

CURRENT DETECTOR

CN1

CN5

LOUVER MOTOR

CN14

CN2

WHITE

BLUE

BROWN

YELLOW

GREEN

BLACK

86

Page 32

7.Troubleshooting

7.1 For all cooling only model

Failure phenomenon Operation lamp Timer lamp

Indoor fan speed has been out of control for over 1 minute ☆ X

Indoor room temp. or evaporator sensor is open circuit or short

circuit

Over current protection of the compressor occurs 4 times X ☆

EEPROM error On ☆

No over-zero signal ☆ ☆

r Extinguish

☆ Flash at 5Hz

7.2 For all heat pump model

Failure phenomenon Operation lamp Timer lamp Defrosting lamp

Over current protection of the compressor occurs 4 times ☆ X ☆

Indoor fan speed has been out of control for over 1 minute X ☆ ☆

No over-zero signal ☆ ☆ ☆

Temp. sensor on indoor evaporator is open circuit or short circuit X X ☆

Indoor room temp. sensor is open circuit or short circuit X ☆ X

EEPROM error On ☆ X

☆ On

r Extinguish

☆ Flash at 5Hz

8 Electronic function

8.1 Electric Control working environment

8.1.1 input voltage: 175~253V

8.1.2 Input power frequency:50Hz

8.1.3 Ambient temperature: -7°C~+43°C

8.1.4 Indoor fan normal working amp is less than 1A,

8.1.5 Outdoor fan. Normal working amp is less than 1.5A

8.1.6 Four-way valve normal working amp is less than 1A.

8.1.7 Swing motor: DC12V.

8.1.8 Compressor: single-phase power supply. Its normal working amp is less than 15A

8.2 Proper symbols and their meanings:

TA: Indoor ambient temperature

TE: Indoor evaporator temperature

TS: Setting temperature through the remote controller

I

: Self-protection amp of compressor, continue three seconds until turns off the compressor.

3sec

I

: Self-protection amp of compressor, continue five minutes until turns off the compressor.

5MIN

I

: Self-protection amp of outdoor fan/indoor fans when they change from higher wind to lower wind.

FAN

I

RESTORE

TH

TM

TL

TE1: Anti-cold wind, from Fan Off to Breeze temperature

87

: Amp self-protection return value

DEFROST

DEFROST

DEFROST

: High wind, defrosting temperature difference

: Middle wind, defrosting temperature difference

: Low wind, defrosting temperature difference

Page 33

TE2: Anti-cold wind, from Breeze to Setting Fan Speed temperature

TE3: Anti-cold wind, from Setting Fan Speed to Breeze temperature

TE4: Anti-cold wind, from Breeze to Fan Off temperature

TE5: Evaporator low temperature protection entering temperature

TE6: Evaporator low temperature protection restoring temperature

TE7: Evaporator high temperature protection, compressor off temperature

TE8: Evaporator high temperature protection, fan off temperature

TE9: Evaporator high temperature protection, restoring temperature

8.3 Systematic functions

Remote receiving

Testing and forced run

Position set for indoor unit wind vane

LED displaying and alarm

On or off Timer

Protection for the compressor

Current protection

High temperature protection of indoor heat exchanger at heating mode

Auto defrosting and heating recovery at heating mode

Anti cold air at heating mode

Anti frozen at heating mode

8.4 Protection

8.4.1 The compressor functions protection with a delay of three minutes.

8.4.2 Sensor protection at open circuit and breaking disconnection

8.4.3 Temperature Fuse break protection

8.4.4 Fan Speed is out of control. When Indoor Fan Speed is too high(higher than High Fan+300RPM)or

too low(lower than 400RPM), the unit stops and LED displays failure information and can’t returns to

normal operation automatically.

8.4.5 Cross Zero signal error warning. If there is no Cross Zero signals in 4 minutes, the unit stops and LED

displays failure information and can’t returns to normal operation automatically.

8.4.6 The current protection of the compressor

Condition Indoor fan Compressor Outdoor fan Remark

Current up

Current down

I< I

RESTORE

I

FAN

I

5MIN

I

5MIN

I

FAN

RESTORE

I< I

On On On

RESTORE

<I< I

FAN

<I<I

Off Off After 5 Minutes

5MIN

<I< I

Off Off After 3 Seconds

3SEC

<I< I

Off Off After 3 Seconds

3SEC

<I<I

Off Off After 5 Minutes

5MIN

<I< I

FAN

On On On

RESTORE

On On Off Heating mode I

Low speed On On Cooling mode

On On Off Heating mode I

Low speed On On Cooling mode

If compressor turns off for continuously 4 times due to current protection in 5 minutes from

Compressor On, the unit stops and LED displays failure information and can’t returns to normal

operation automatically.

88

Page 34

8.5 Fan-only mode

Fan speed is high/mid/low/ Auto

8.6 Cooling mode

The 4-way valve is closed at cooling mode.

The action of the compressor and the outdoor fan:

Condition Compressor Outdoor fan

T> Ts+1 On On Temp. up

T<Ts+1 Off Off

T> Ts On On Temp. down

T<Ts Off Off

Auto fan at cooling mode:

Condition

T=Indoor Temp.-Setting Temp.

Temp. up

Temp. down

T<3℃ Low

3℃<T<5℃ Med.

T>5℃ High

T> 3℃ High

1℃<T<3℃ Med.

T<1℃ Low

Indoor fan speed

Anti-freezing control to indoor evaporator at cooling mode( T: evaporator temp. )

Condition

Temp. Time

T> TE6 On On Temp. up

T< TE6 >5 Minutes Off Off

T> TE5 On On Temp. down

T< TE5 >5 Minutes Off Off

Compressor Outdoor fan

8.7 Dehumidifying mode

8.7.1 The 4-way valve is off in dehumidifying mode

8.7.2 Compressor and Indoor Fan actions in dehumidifying mode

NO Conditions Indoor Fan Compressor and Outdoor Fan

1

2

3

TA ≥ TS+2

TS ≤TA <TS+2

TA < TS

LOW

BREEZE

LOW

BREEZE

LOW

BREEZE

ON 6minutes

OFF 4minutes

ON 5minutes

OFF 5minutes

ON 4minutes

OFF 6minutes

Repeat on and off cycle.

89

Page 35

8.7.3 Low room temperature protection:

When room temperature decreases to below 10℃, compressor and outdoor fan will stop(indoor fan

is Breeze). Dehumidifying operation will be resumed when room temperature restores to over 13℃.

8.7.4 At dehumidifying mode, the anti-freezing function of the indoor heat exchanger is the same as that

of cooling mode.

8.8 Heating mode

8.8.1 Generally, the 4-way valve is open in heating mode, but it is closed in defrosting mode. 4-way valve

must delay 2 minutes compared with compressor if the compressor changed into non-heating mode

or turned off. 4-way valve doesn't delay in dehumidifying mode.

8.8.2 Generally, the outdoor fan is turned off with the on-off action of compressor in heating mode, except

for the defrosting mode or the end of defrost.

8.8.3 Action of compressor and outdoor fan motor at heating mode: compressor must run for 7 minutes

after starting and then judge temperature. Meanwhile other protections are still valid.

Condition Compressor Outdoor fan

T> Ts+3 Off Off Room temp. up

T<Ts+3 On On

T< Ts+2 On On Room temp. down

T>Ts+2 Off Off

8.8.4 Indoor Fan actions at heating mode

Indoor Fan can be set at HIGH/MID/LOW/AUTO by using a remote controller, but Anti-cold wind

function prevails.

Anti-cold wind control function at heating mode

Condition

T= Indoor exchanger temp.

Indoor exchanger temp. up

Indoor exchanger temp. down

T<TE1 Off

TE1<T<TE2 Breeze

T>TE2 Setting fan speed

T> TE3 Setting fan speed

TE3<T<TE4 Breeze

T<TE4 Off

8.8.5 Auto wind at heating mode

Condition

T=Indoor Temp.-Setting Temp.

T<2℃ High Room temp. up

T>2℃ Med.

T> 0℃ Med. Room temp. down

T<0℃ High

Indoor fan speed

Indoor fan speed

90

Page 36

8.8.6 Indoor evaporator high-temperature protection at heating mode

Condition

T= Indoor exchanger temp.

Indoor exchanger temp. up

T<TE8 On On

TE8<T<TE7 On Off

T>TE7 Off Off

T>TE9 Off Off Indoor exchanger temp. down

T<TE9 On On

8.9 Defrosting operation (Available for heating only).

8.9.1 Defrosting condition: Defrosting starts when either of the following ①&②:

① A and B are satisfied:

A: The compressor keeps running for 40 minutes or more.

B: The temperature difference of evaporator and room temperature meets one of the following:

℃

Fan speed is high ≤TH

Fan speed is mid ≤TM

Fan speed is low ≤TL

Breeze Meet only if it is Breeze

Temp. of evaporator---room temp.

Compressor Outdoor fan

DEFROST

DEFROST

DEFROST

② Calculate from the end of latest defrost, evaporator high temp. protection only closes outdoor fan

with the compressor still running. Add up to 90 minutes.

8.9.2 Defrosting time

If the temp. difference condition ① is satisfied for less than 40 minutes, this can be regarded as

severe frosting. The defrosting time is 10 minutes.

If the temp. difference condition ② is satisfied for more than 40 minutes, the defrosting time is 6

minutes.

If the temp. difference condition ① is satisfied out of 40 minutes, generally the defrosting time is 6

minutes, after three continuous 6-minute defrost, the fourth should be 10 minutes defrost. The

circulation is as following:

→6-minute defrost → 6-minute defrost→6-minute defrost→10-minute defrost→

8.9.3 Ending condition of defrosting

If one of following conditions is satisfied, end the defrost and turn into heating mode:

A. The defrost time has reached to 6 or 10 minutes.

B. The compressor current has reached to I

DEFROST

or above, I

DEROST

differs in different models.

91

Page 37

8.9.4 Defrosting Actions:

45S 25S

Compressor

4-way Valve 23S

40S

Outdoor Fan

Indoor Fan

10S

Defrost 10or 6minutes

8.9.7 Turn into heating mode, turn off the heating mode in 7 minutes.

8.10 Automatic operation mode

8.10.1 The air conditioner automatically selects one of the following operation modes: cooling, heating or

fan only according to the temp. difference between room temp. (TA) and set temp. (TS).

TA—TS Operation mode

TA—TS>2℃ Cooling

-1℃≤TA—TS≤+2℃ Fan-only

TA—TS<-1℃ Heating (air-only for cooling only type)

8.10.2 The indoor fan blows automatically in corresponding selected mode.

8.10.3 The motion of indoor fan’s blade should accord with the selected operation mode.

8.11 Forced cooling function

8.11.1 Select forced cooling function with the forced cooling button or the switch.

8.11.2 The compressor is unconditionally turned on, after 30 minutes cooling operation whose fan mode is

set as low, the A/C operates at the DRY mode with a set temp. of 24℃.

8.11.3 All protections of remote control cooling are available at forced cooling operation.

8.12 Forced Auto function

Select forced auto function with the forced auto button or the switch.

In forced auto status the A/C operates at remote control mode with a set temp. of 24℃.

8.13 Timer Function

8.14 Economic Running

8.14.1 The economic running function is available at cooling, heating or auto mode.

8.14.2 Cooling:

The set temperature rise 1℃ per hour. Two hours later, the set temperature will maintain as a

constant and the fan speed is kept at low speed.

8.14.3 Heating:

92

Page 38

The set temperature decrease 1℃ per hour. Two hours later, the set temperature will maintain as a

constant and the air circulation is kept at low speed (Cold air proof function takes precedence over

all).

8.14.4 Auto:

The economic running function operates in accordance with selected running mode by auto mode.

8.15 Auto restart function

In case of a sudden power failure, this function automatically sets the unit to previous settings before

the power failure when power returns.

93

Page 39

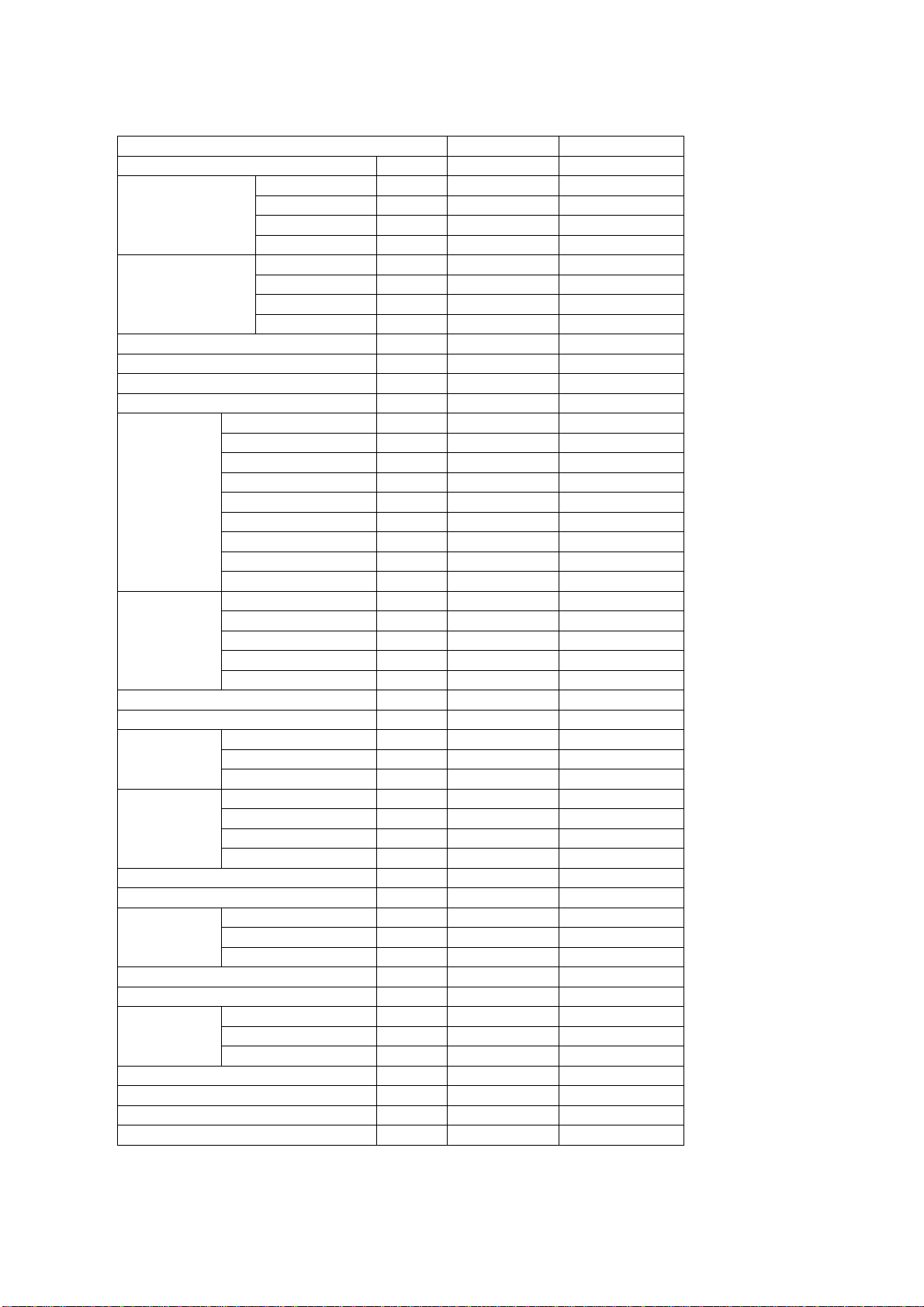

8.16 Models and Parameters

Model CES-07_RC CES-07_R CES-09_RC CES-09_R CES-12_RC CES-12_R

I3SEC 8.5A 8.5A 10.0A 10.0A 11 .0A 11 .0A

I5MIN 6.2A 6.2A 7.5A 7.5A 10.0A 10.0A

IFAN 5.2A 5.2A 5.5A 5.5A 8.0A 8.0A

IRESTORE 4.2A 4.2A 4.5A 4.5A 6.0A 6.0A

IDEFROST 3.2A 3.5A 5.5A

TE1 28℃ 28℃ 28℃

TE2 32℃ 32℃ 32℃

TE3 30℃ 30℃ 30℃

TE4 26℃ 26℃ 20℃

TE5 2℃ 2℃ 2℃ 2℃ 3℃ 3℃

TE6 7℃ 7℃ 7℃ 7℃ 8℃ 8℃

TE7 60℃ 60℃ 60℃

TE8 53℃ 53℃ 53℃

TE9 50℃ 50℃ 50℃

ANGLCOOL 200° 200° 200° 200° 200° 200°

ANGLHEAT 0° 0° 0°

ANGLOFF 124° 124° 124° 124° 124° 124°

TH

16°C 14°C 14°C

DEFROST

TM

17°C 15°C 15°C

DEFROST

TL

18°C 16°C 16°C

DEFROST

94

Page 40

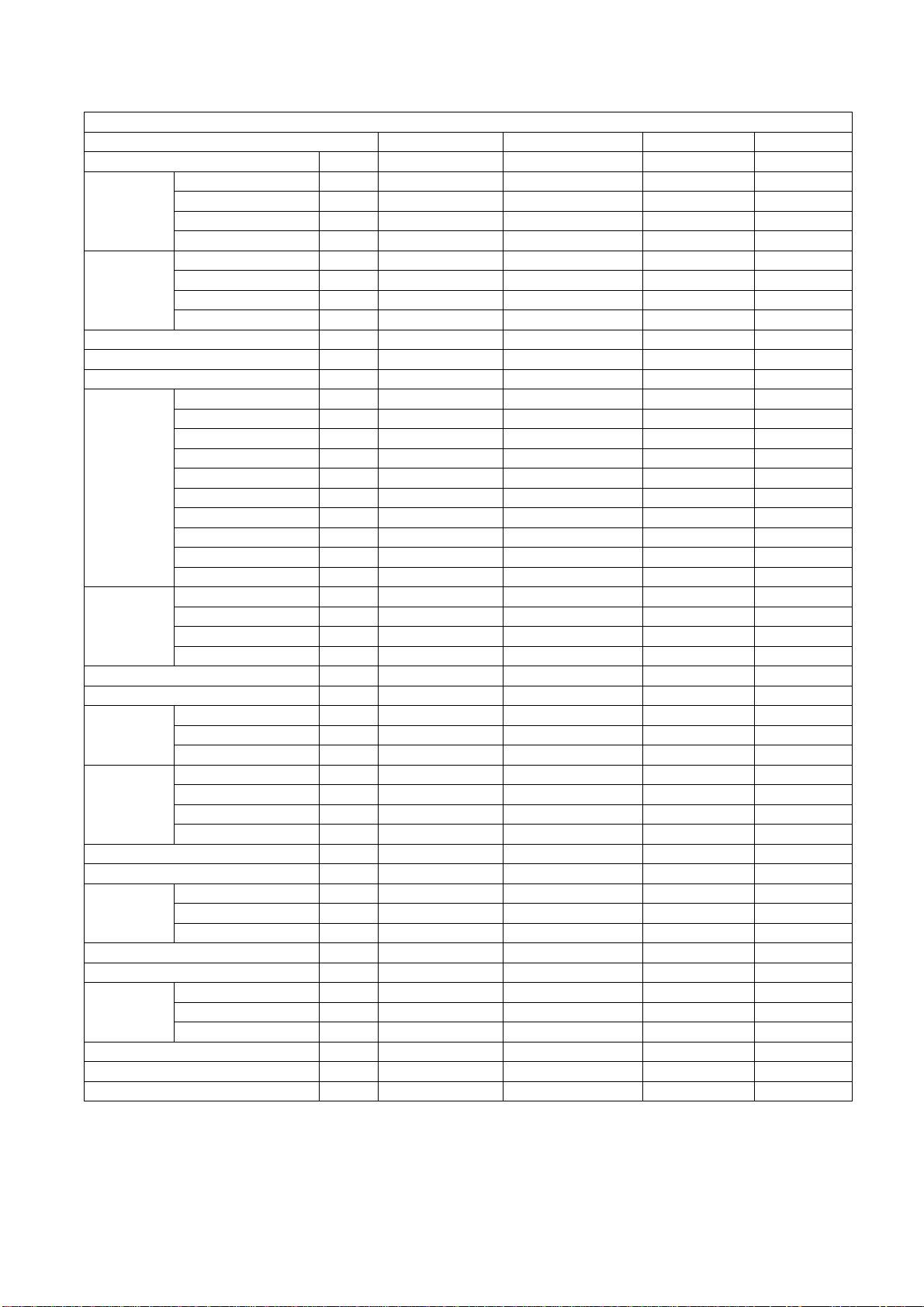

Model CES-07_R7C CES-07_R7 CES-09_R7C CES-09_R7

I3SEC 8.5A 8.5A 10.0A 10.0A

I5MIN 6.2A 6.2A 7.5A 7.5A

IFAN 5.2A 5.2A 5.5A 5.5A

IRESTORE 4.2A 4.2A 4.5A 4.5A

IDEFROST 3.2A 3.5A

TE1 28℃ 28℃

TE2 32℃ 32℃

TE3 30℃ 30℃

TE4 26℃ 26℃

TE5 4℃ 4℃ 4℃ 4℃

TE6 10℃ 10℃ 10℃ 10℃

TE7 60℃ 60℃

TE8 53℃ 53℃

TE9 50℃ 50℃

ANGLCOOL 200° 200° 200° 200°

ANGLHEAT 0° 0°

ANGLOFF 124° 124° 124° 124°

TH

TM

TL

14°C 14°C

DEFROST

15°C 15°C

DEFROST

16°C 16°C

DEFROST

95

Page 41

Model CES-12_RC

(B type)

CES-12_R7C______CES-12_R7________CES-18_R7C_______CES-18_R7_______CES-21_R7C_____CES-21_R7

I3SEC 14.5A 14.5A 16.0A 16.0A 17.0A 17.0A

I5MIN 13.5A 13.5A 13.0A 13.0A 16.0A 16.0A

IFAN 9.5A 9.5A 11.0 A 11. 0A 14.0A 14.0A

IRESTORE 8.5A 8.5A 9.5A 9.5A 12A 12A

IDEFROST 6.5A 6.5A 7A

TE1 34℃ 34℃ 34℃

TE2 37℃ 36℃ 36℃

TE3 33℃ 30℃ 30℃

TE4 22℃ 20℃ 20℃

TE5 2℃ 2℃ 3℃ 3℃ 3℃ 3℃

TE6 7℃ 7℃ 10℃ 10℃ 10℃ 10℃

TE7 62℃ 60℃ 64℃

TE8 56℃ 52℃ 56℃

TE9 50℃ 50℃ 50℃

ANGLCOOL 40° 40° 50° 50° 50° 50°

ANGLHEAT 197° 105° 105°

ANGLOFF 100° 100° 0° 0° 0° 0°

TH

TM

TL

17°C 17°C 20°C

DEFROST

18°C 18°C 21°C

DEFROST

19°C 19°C 22°C

DEFROST

CES-12_R*

(B type)

CES-18_R_C CES-18_R CES-21_RC CES-21_R

96

Page 42

COOLWEX Group USA

SPLIT TYPE, HEAT PUMP AIR CONDITIONERS

Technical & service manual 2005

CES Inverter Type (50Hz) R407C Wall Mounted

[Models]

CES 7 I7

CES 7 I7

CES 12 I7

Page 43

Contents

1. Features 2

2. Specification 3

3. Dimensions 4

4. Refrigeration cycle diagram 6

5. Operation limits 7

6. Wiring diagram 8

7. Troubleshooting 10

8. Electronic function 11

1

Page 44

1.Features

1.1 Powerful at cooling/heating, 1.3 times and 1.6 times relatively higher than normal same type of

models.

1.2 Low voltage start-up function, even at 160 V it can normally start.

1.3 Anti-icing function at cooling mode.

1.4 Anti-cold air function at heating mode.

1.5 Auto-defrosting and heating recovering function at heating mode.

1.6 Outdoor whole electric current protection

1.7 Temperature protection of the outdoor compressor top.

1.8 Restart protection for the compressor.

1.9 24 hours on/off mode time setting.

1.10 Error self diagnosis function.

1.11 Protection against over-load or too-low current inputted through alternating current.

2

Page 45

2. Specification

Model Item CES 7 I7 CES 9 I7 CES 12 I7

Power source 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz

Capacity BTU/H 7000(2700~9000) 9000(2730~10600) 12000(3070~13300)

Cooling

Heating

Max. input consumption W 2100 2300 2600

Compressor

Refrigerant R407C g 800 800 1150

Design pressure MPa 2.6 2.6 2.6

Indoor fan

motor

Air flow

(indoor)

Noise level

(indoor)

motor

Noise

(outdoor)

Indoor unit

Outdoor unit

★1 The noise date is base on anechoic chamber, during actual operation, these values are normally somewhat different as a result of ambient

condition.

Input W 780(250~1200) 1000(270~1470) 1320(310~1710)

Running current A 4.8(1.35~6.2) 4.5(1.2~6.6) 5.8(1.60~7.60)

EER BTU/W.H 9.0, 2.6 9.0, 2.6 9.1, 2.6

Capacity BTU/H 9000(2700~11000) 12000(2730~14000) 15000(3070~17060)

Input W 1010(250~1300) 1250(270~1800) 1560(300~2380)

Running current A 4.4(1.35~6.7) 5.5(1.45~9.3) 6.8(1.6~10.6)

Model BG130X1C-20FZ BG130X1C-20FZ BG130X1C-20FZ

Type Rotary Inverter Rotary Inverter Rotary Inverter

Brand MIDEA TOSHIBA MIDEA TOSHIBA MIDEA TOSHIBA

Refrigerant oil ml 370 370 370

Refrigerant oil type R407C R407C R407C

Input W RPG13H 36 RPG13H 36 RPG13C 50

Capacitor uF 1.2uF/≥450VAC 1.2uF/≥450VAC 1.5uF/≥450VAC

Speed level 3 3 3

Hi speed( rpm) 1100 1100 1060

Mid speed( rpm) 1000 1000 900

Low speed( rpm) 800 800 800

High fan m3/h 500 520 560

Middle fan m3/h 430 430 460

Low fan m3/h 330 330 380

dB(A) 35/32/26

Input W YDK23-6G 63 YDK23-6G 63 YDK23-6G 63 Outdoor fan

Capacitor uF 2.5uF/≥450VAC 2.5uF/≥450VAC 2.5uF/≥450VAC

High dB(A) ≤51 ≤51 ≤53

dimension(W*H*D) 750*250*188 750*250*188 815*280*195

Packing (W*H*D) 830*336*280 830*336*280 915*360*275

Net weight kg 8.5 8.5 11

dimension(W*H*D) 780*520*240 780*520*240 780*520*240

Packing (W*H*D) 910*575*335 910*575*335 910*575*335

Net weight kg 37 37 40

36/32/26 36/32/26

3

Page 46

3. Dimensions

3.1 Indoor Unit

CES 7 I7, CES 9 I7

3.2 Indoor Unit

CES 12 I7

4

Page 47

3.3 Outdoor Unit

CES 7 I7, CES 9 I7, CES 12 I7

5

Page 48

4. Refrigeration Cycle Diagram

Indoor unit outdoor unit

Sensor

Heat exchanger Sensor of temp

. 4 way valve

Sensor of heat exchanger temp

Sensor of room temp Heat exchanger

. Sensor of heat exchanger temp

Val ve

Compressor

Val ve Capillary

6

Page 49

5. Operation Limits

5.1 Cooling operation

Outdoor unit air temp.℃

60

50

40

30

20

10

10 17 25 30 35 40

Indoor air temp.

℃

Note :the chart is the result from the continuous operation under constant air temperature

conditions. however, excludes the initial pull-down stage.

5.2 Heating operation

Indoor air temp. ℃

30

20

10

5

-5

-15

Note :the chart is the result from the continuous operation under constant air

temperature conditions. however, excludes the initial pull-down stage.

-15 -5 5 15 25 30

Outdoor unit air temp.

℃

7

Page 50

6.

Wiring Diagram

6.1 Indoor unit(CES 7 I7, CES 9 I7)

6.2 Indoor unit(CES 12 I7)

8

Page 51

6.3 Outdoor unit (CES 7 I7 / CES 9 I7 / CES 12 I7)

S

NL

9

Page 52

7.Troubleshooting

7.1 Indoor Unit Error Display Function

LED4 operation LED2 defrosting LED1 timer LED4 auto

LED2

defrost

X X O ☆ Mold protection

O X X ☆ Compressor top protection against temperature

X O X ☆ Open or short circuit of outdoor temperature sensor

X O O ☆ Over load or too low voltage protection

O O O ☆

O O ☆ ☆ Fan speed beyond control

☆ X O ☆ Zero-crossing examination error

☆ O X ☆ Temperature fuse protection

X X ☆ ☆ EEPROM data error

☆ O X ☆ Types doesn't match

☆ ☆ ☆ ☆ Indoor / outdoor units communication protection

LED1

Timer

LED3

Auto

LED4

LED STATUS

operation

Room temperature or evaporator temperature sensor open

or short circuit of

O (on) X (off) ☆ (flash)

7.2.Outdoor Unit Error Self-diagnosis Display

Outdoor Unit Error: if L4 flashes at 1Hz.

Outdoor unit works: L4 on

Outdoor unit Stand by: if L4 flashes at 0.5Hz

10

Page 53

8 .Electronic Function

8.1 General Protection

8.1.1 Temperature Protection of Compressor Top

8.1.2 3 minutes Delayed Starting Protection of the Compressor

8.1.3 Voltage Protection

8.1.4 The frequency Up-Down speed at which the compressor starts, operates and shuts off will be

subject to the following principles (outdoor chip):

HZ

1HZ/S

92Hz 2HZ/S

57Hz 1HZ/S

1HZ/S

6HZ/S

time

50 Sec

2 min

8.1.5 Frequency Converter Mold Protection (outdoor chip):

The Frequency Converter Mold itself has a protection function against current, voltage and

temperature, if there are 4 times of above mentioned protection functioning within 1 hour (when

the compressor's consecutive operation lasts more than 10 minutes, the fore-mentioned 4

counts will be cleared), the whole machine will shut off and the mold protection gives an alarm.

8.2 Fan-only Mode Function Requirement

8.2.1 The compressor, 4 way valve and outdoor fan are off at Fan-only mode.

8.2.2 Temperature setting function is cancelled, the set temperature can not be displayed, nor

adjusted.

8.2.3 The rotational speed of indoor fan can be optionally chosen by remote control as

High/Mid/Low/Auto.

8.2.4 The indoor fan vanes at Fan-only mode perform the same as those at cooling mode.

11

Page 54

8.2.5 Performance at Auto mode at Fan-only status is the same as that at Auto mode at cooling status,

provided that the set temperature is 24°c.

°C

27.5 High

27.0

25.5 Mid

25.0

Low

8.3 Cooling Mode Function Requirement

8.3.1 At cooling mode the 4 way valve is off.

8.3.2 Anti-icing Control for Indoor Evaporator

When the temperature of indoor heat exchanger drops to ≤ 4°c, the frequency will reduce one

step down (including F0) and last for 1 minute every time until the temperature is kept between 4

- 7°c. If the temperature rises to ≥ 7°c, the limitation then will be removed.

When the temperature of indoor heat exchanger drops to < 0°c, shut off the compressor and it

will resume when the temperature rises up to > 5°c.

8.3.3 Outdoor Unit Current Control When Cooling:

Shut off the compressor

(10.2A) 8.0 A

frequency down

(8.8A) 6.8 A

frequency unchanged

(7.4A) 5.4 A

resume to normal

Note: The frequency down at the diagram is in accordance with the present frequency dropping

down, to determine every 2 seconds whether the frequency is keeping going down or is

recovering.

12

Page 55

8.3.4 Indoor fan operates in accordance with the following principles:

8.3.4.1 When indoor fan is in operation, it can be remote controlled to High/Mid/Low/Auto modes.

8.3.4.2 The fan speed at Auto mode in cooling status is subject to the following:

°C room temperature - set temperature

+4.0 High

+3.0

+1.5 Mid

+1.0

Low

8.3.5 Indoor fan vanes at cooling mode will swing in accordance with the following:

When just plugged in for cooling, the vanes will open to the standard angle 50°.

The vane angle can be set by remote control at any angle between 50° and 105° (every setting

can adjust 6°) or set swinging (swinging angle will be 25°).

8.4 Dehumidifying Mode Requirements

8.4.1 At dehumidifying mode, the 4 way valve is shut off

8.4.2 At dehumidifying mode, the indoor fan is fixed in Breeze status and not adjustable.

8.4.3 At dehumidifying mode, the compressor operates in accordance with the following principles:

Room temperature - set temperature

2.5 F3

2.0

1.5 F2

1.0

0.5 F1

0.0

F1

8.4.4 Too-low room temperature protection

During dehumidifying, when room temperature drops down < 10°c, the compressor will shut off,

and when the room temperature rises up than 12°c, the compressor resumes operation.

8.4.5 At dehumidifying mode, the anti-icing function of indoor heat exchanger applies.

13

Page 56

8.4.6 At dehumidifying mode, the power voltage and outdoor temperature limitation to the highest

frequency when compressor starts and operates is the same as that at cooling mode.

8.5 Heating Mode Function Requirement

8.5.1 At heating mode, the 4 way valve is on, during defrosting operation, it is off.

8.5.2 Outdoor fan usually turns on or off in accordance with the action of compressor, except for

defrosting and ending of the defrost.

8.5.3 Indoor fan action:

Anti-cold air control

Temperature of heat exchanger

37°c

Set rotational speed

34°c

33°c

breeze

18°c

fan off

8.5.4 Indoor fan can be set by remote control to any mode like High/Mid/Low/Auto, however anti-cold

air function comes first.

Auto fan

Room temperature - set temperature

-0.5

Low

-1.0

-1.5 Mid

-2.0

High

14

Page 57

8.5.5 Outdoor Unit current control when heating

Note:

The frequency in the table

Compressor off

goes down in accordance

(11.5A) 10.0A

with the present frequency,

frequency down

determine every 2 seconds

whether it keeps going

(10.5A) 8.8A

down or it is recovering.

frequency unchanged

(9.2A) 7.4A

8.5.6 Indoor evaporator protection against high temperature

When the temperature of indoor heat exchanger is higher than 53°c, the frequency will reduce one

step and last for 20 seconds every time until the temperature drops down lower than 53°c. If the

temperature drops down < 48°c, the limitation then will be removed (the frequency will not going

down further when reaching 35Hz).

When the temperature of indoor heat exchanger is higher than 63°c, shut off the compressor.

8.5.7 Indoor fan vanes at heating mode will swing in accordance with the following:

When just plugged in for heating, the vanes will open to the standard angle 220°.

The vane angle can be set by remote control at any angle between 0° and 220° (every setting can

adjust 6°) or set swinging (swinging angle will be 25°).

8.5.8 Defrosting operation

8.5.8.1 Defrosting precondition:

Defrosting starts when meeting one of the three conditions:

① The temperature of outdoor heat exchanger remains consecutively lower than 3°c for more than

40 minutes, and the temperature remains consecutively Ti1 for more than 3 minutes.

Model Ti1:

CES 9 I : -4°c

CES 12 I : -6°c

CES 9 I7 : -9°c

CES 9 I7 : -9°c

15

Page 58

② The temperature of outdoor heat exchanger remains consecutively lower than 3°c for more than

80 minutes, and the temperature remains consecutively Ti2 for more than 3 minutes.

Model Ti2:

CES 9 I : -2°c

CES 12 I : -4°c

CES 9 I7 : -7°c

CES 9 I7 : -7°c

③ The temperature of outdoor heat exchanger remains consecutively lower than 3°c for more than

120 minutes, and the temperature remains consecutively Ti3 for more than 3 minutes.

Model Ti3:

CES 9 I : -0°c

CES 12 I : -2°c

CES 9 I7 : -5°c

CES 9 I7 : -5°c

Note: The time period starts to count when outdoor heat exchanger temperature is lower than

3°c, the defrosting operation starts when the exchanger temperature remains lower than the

starting temperatures which are Ti3, Ti2, Ti1.

8.5.8.2 Conditions of defrost ending

Defrosting ends when meeting any of the following three conditions and it turns to normal

heating operation.

① When the temperature of outdoor heat exchanger rises up to 12°c.

② When the temperature of outdoor heat exchanger rises up to 8°c and this continues for more

than 80 seconds.

③ When defrosting action continues for 10 minutes.

8.5.8.3 Defrosting Action

Max 10 mins

30 sec.

ON 10 sec. ON 30 sec

Compressor OFF

ON ON

4 way valve OFF

ON ON

Outdoor fan OFF

ON ON

Indoor fan OFF

The indoor fan operates in anti-

cold air mode when it recovers

16

Page 59

8.5.9 Set Function Test

When it is detected that the outdoor temperature is between 5 - 9°c and room temperature is

between 18 - 22°c, provided that the heating operation remains consecutively more than 30

minutes, the compressor's highest operational frequency is FMAX=F8=96HZ. If any of the above

conditions is not met, it will quit from set frequency operation.

8.6 Auto Mode Function

Using remote control to choose auto mode, under which the set temperature can be adjusted in a

range of 17 - 30°c.

8.6.1 When entering auto mode, the A/C will choose cooling, heating or fan only according to the

difference between room temperature (TA) and set temperature (TS).

TA - TS Operation status

TA -TS > 1°c Cooling

-1°c ≤TA - TS ≤+1°c Fan only

TA - TS < -1°c Heating

8.6.2 At auto mode, the indoor fan will choose auto fan in corresponding mode.

8.6.3 At auto mode, the vane action of indoor fan is the same as that of chosen mode.

8.6.4 Once a mode is chose, it will take 5 minutes after shutting off the compressor to re-choose

another mode according to the difference between room temperature and set temperature, or

you can re-choose mode when set temperature is changed.

8.7 Forced Operation Function

8.7.1 Forced operation is controlled by the switch on switch board and divided into forced cooling and

forced auto. Remote control doesn't work at forced operation control.

8.7.2 At forced operation status, all protection functions in general protection fore-mentioned apply.

8.7.3 At forced cooling mode, the compressor operates at a fixed frequency of F2=42HZ, indoor fan is

Breeze, anti-icing control and general current control of cooling outdoor unit work; forced

operation will transfer to auto mode whose set temperature is 24°c automatically after 30

minutes.

8.7.4 At forced auto mode, the remote control controls in a set temperature of 24°c.

8.8 Timer Function Requirement

8.8.1 The maximum length of timer is 24 hours and the minimum resolving power is 15 minutes.

8.8.2 Timer on function: first turn off the A/C, the A/C will be automatically on at the set time.

8.8.3 Timer off function: first turn on the A/C, the A/C will be automatically off at the set time.

8.8.4 Timer on/off function( on time is earlier than off time): first turn off the A/C, it will be automatically

on at set time, and later be off at the set time.

8.8.5 Timer off/on function( off time is earlier than on time): first turn on the A/C, it will be automatically

off at set time, and later be on at the set time.

8.8.6 Timer function execution is applicable upon one operation only.

8.8.7 Timer error is less than 1 min/h.

17

Page 60

INVERTER COMFORT - Multiple

1. Product features 198

2. Specification 199

3. Dimensions 203

4. Refrigeration cycle diagram 204

5. Operation limits 205

6. Capacity table 206

7. Wiring diagram 208

8. Electric control functions 210

197

Page 61

1. Product Features

Both indoor units can be operated either simultaneously or separately through the utilization of the advanced

converter technique and microcomputer control.

The flowing volume of refrigerant is adjustable through the electronic expansion valve.

High Cooling and Heating capacity is facilitated through the famous-brand frequency converter compressor.

Indoor noise is minimized through the optimization of the air flow system design, a four-folded evaporator and a

big diameter Cross Flow Fan.

The system is operable under low-voltage.

Effective and prompt defrosting correlates into no cold feelings.

High heating effects under extremely low temperatures.

The systems purging function improves the quality of the air in the room.

Wireless remote controlled function:

---A Manual Switch can operate the air conditioner when the remote controller is misplaced and the batteries are

exhausted.

---Horizontal and vertical louvers can swing automatically and the customized setting flows the air as desired.

---Grounding's have been connected and are safe to use.

---Compressor protection function enabled.

Indoor unit:

1) 4-Bend heat exchanger.

2) Trapeziform innergroove copper.

3) Hydrophilic Aluminum Fin.

4) Two-direction air vane technology.

5) Sleep mode.

6) Anti-rust cabinet.

7) Easy-cleaned panel.

8) Self-diagnosis auto-protection function.

198

Page 62

2. Specification

Model CED 9-9 I7

Indoor unit 7000Btu/h 9000Btu/h 12000Btu/h

Power supply Ph-V-Hz 1Ph, 220-240V~, 50Hz

Capacity Btu/h single: 7000-12000; Twin:16000-24000

Cooling

Heating

Moisture Removal L/h 0.7 0.9 1.2

Max. input consumption W single: 1800W; Twin:3200W

Max. current A single: 13A; Twin:20A

Starting current A 10

Compress

or

Input W single: 1000W-1350W; Twin:2570W-2900W

Rated current A single: 4.8A-6.7A; Twin:11.7A-13.8A

EER Btu/w.h single: 7.0-8.9; Twin:6.2-8.3

Capacity Btu/h single: 10000-14000; Twin:24000-27000

Input W single: 1300W-1650W; Twin:2100W-2800W

Rated current A single: 6.3A-8.0A; Twin:11.0A-13.5A

COP Btu/w.h single: 7.7-8.5; Twin:11.4-9.6

Model

Type Rotary inverter

Brand GD T oshiba

Capacity Btu/h 18000

Input W 1690

Rated current(RLA) A 11.6

BG240X2CS-20KU

Indoor

fan motor

Indoor

coil

Locked rotor Amp(LRA) A 60

Thermal protector Internal

Capacitor uF 85UF/250V

Refrigerant oil ml RB68AF/α68TF/T-68 750 ml

Model

Brand

Input W

Capacitor uF

Speed(hi/mi/lo) r/min 1050/950/750 1100/1000/800 1060/900/800

Number of rows 2 2

Tube pitch(a)x row pitch(b) mm 21×13.37 21×13.37

Fin spacing mm 1.5 1.5

Fin type (code)

Tube outside dia.and type mm

Coil length x height x width mm 578×252×27.34 578×252×27.34

RPG13H RPG13H RPG13C

Welling Welling Matsushita

36

1.2uF/≥450VAC 1.2uF/≥450VAC 1.5uF/≥450VAC

36

50

2

21×13.37

1.3

Hydrophilic

aluminium

φ7, innergroove tube

Hydrophilic

aluminium

φ7, innergroove

tube

Hydrophilic

aluminium

φ7, innergroove

tube

635×315×27.34

199

Page 63

Indoor air flow (Hi/Mi/Lo) m3/h 500/410/320 520/430/330

Indoor noise level (Hi/Mi/Lo) dB(A) 35/32/26 36/32/26

Indoor

unit

Number of circuits 2 2

Dimension (W*H*D) mm

Packing (W*H*D) mm

Net/Gross weight kg

Model YDK53-6M

750*250*188 750*250*188 815*280*195

830*336*280 830*336*280 915*360*275

8.5/11 8.5/11 11/14

2

560/460/380

36/32/26

Outdoor

fan motor

Outdoor

coil

Outdoor air flow m3/h 2500

Outdoor noise level dB(A) 60

Outdoor

unit

Refrigerant type R407C g 2200

Brand Welling

Input W 148

Capacitor uF 3.0

Speed r/min 775

Number of rows 1.5

Tube pitch(a)x row pitch(b) mm 25.4×22

Fin spacing mm 1.7

Fin type (code) Hydrophilic aluminium

Tube outside dia.and type mm φ9.53 innergroove trube

Coil length x height x width mm 776×660×22

Number of circuits 2

Dimension(W*H*D) mm 845X695X335

Packing (W*H*D) mm 975X772X405

Net/Gross weight kg 71/74

Design pressure(Hi/Lo) MPa 2.8/1.2

Refrigera

nt piping

Connection wiring No

Plug type No

Controller Remote

Operation temp ℃ 17~30

Ambient temp ℃ 18~43(cooling); -15~24(heating)

Application area m2

Notes: 1. Nominal cooling capacities are based on the following conditions:

Indoor temp: 27°CDB, 19°CWB; Outdoor temp: 35°CDB; Equivalent ref. Piping: 8m(horizontal)

2. Nominal heating capacities are based on the following conditions:

Indoor temp: 20°CDB; Outdoor temp: 7°CDB, 6°CWB; Equivalent ref. Piping: 8m(horizontal)

Liquid side/ Gas side mm Ф6.35/Ф9.53 Ф6.35/Ф9.53

Max. refrigerant pipe length m 10 10 10

Max. difference in level m 5 5 5

14-18 18-24 20-30

3. Actual noise level may differ, depending on the room structure, etc, since these noise values are from an

anechoic room.

Ф6.35/Ф12.7

200

Page 64

Model CAM 9-9-9 I7

Indoor unit 7000Btu/h 9000Btu/h 12000Btu/h

Power supply Ph-V-Hz 1Ph, 220-240V~, 50Hz

Capacity Btu/h single: 7000-12000; Twin:16000-24000; Three:24000

Cooling

Heating

Moisture Removal L/h 0.7 0.9 1.2

Max. input consumption W 3200

Max. current A 20

Starting current A 10

Compress

or

Input W single: 1000W-1350W; Twin:2570W-2900W; Three:2900W

Rated current A single: 4.8A-6.7A; Twin:11.1A-13.8A; Three: 13.8A

EER Btu/w.h single: 7.0-8.9; Twin: 6.2-8.3; Three: 8.3

Capacity Btu/h single: 10000-14000; Twin: 24000-27000; Three: 27000

Input W single: 1300W-1650W; Twin: 2100W-2800W; Three: 2800W

Rated current A single: 6.3A-8.0A; Twin: 11.0A-13.5A; Three: 13.5A

COP Btu/w.h single: 7.7-8.5; Twin: 11.4-9.6; Three: 9.6

Model

Type Rotary inverter

Brand GD T oshiba

Capacity Btu/h 18000

Input W 1690

Rated current(RLA) A 11.6

BG240X2CS-20KU

Locked rotor Amp(LRA) A 60

Thermal protector Internal

Capacitor uF 85UF/250V

Refrigerant oil ml RB68AF/α68TF/T-68 750 ml

Model

Indoor

fan motor

Indoor

coil

201

Brand

Input W

Capacitor uF

Speed(hi/mi/lo) r/min 1050/950/750 1100/1000/800 1060/900/800

Number of rows 2 2

Tube pitch(a)x row pitch(b) mm 21×13.37 21×13.37

Fin spacing mm 1.5 1.5

Fin type (code)

1.2uF/≥450VAC 1.2uF/≥450VAC 1.5uF/≥450VAC

RPG13H RPG13H RPG13C

Welling Welling Matsushita

36

36

50

2

21×13.37

1.3

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydr0philiC

aluminium

Page 65

Indoor air flow (Hi/Mi/Lo) m3/h 500/410/320 520/430/330

Indoor noise level (Hi/Mi/Lo) dB(A) 35/32/26 36/32/26

Indoor

unit

Tube outside dia.and type mm

Coil length x height x width mm 578×252×27.34 578×252×27.34

Number of circuits 2 2

Dimension (W*H*D) mm 750*250*188 750*250*188 815*280*195

Packing (W*H*D) mm

Net/Gross weight Kg

Model YDK53-6M

φ7, innergroove tube φ7, innergroove tube

830*336*280 830*336*280 915*360*275

8.5/11 8.5/11 11/14

φ7, innergroove tube

635×315×27.34

2

560/460/380

36/32/26

Outdoor

fan motor

Outdoor

coil

Outdoor air flow m3/h 2500

Outdoor noise level dB(A) 60

Outdoor

unit

Refrigerant type R407C g 2400

Brand Welling

Input W 148

Capacitor uF 3.0

Speed r/min 775

Number of rows 1.5

Tube pitch(a)x row pitch(b) mm 25.4×22

Fin spacing mm 1.7

Fin type (code) Hydrophilic aluminium

Tube outside dia.and type mm φ9.53 innergroove trube

Coil length x height x width mm 776×660×22

Number of circuits 2

Dimension(W*H*D) mm 845X695X335

Packing (W*H*D) mm 975X772X405

Net/Gross weight Kg 72/76

Design pressure(Hi/Lo) MPa 2.8/1.2

Refrigera

nt piping

Connection wiring No

Plug type No

Controller Remote

Operation temp ℃ 17~30

Ambient temp ℃ 18~43(cooling); -15~24(heating)

Application area m2

Notes: 1. Nominal cooling capacities are based on the following conditions:

Indoor temp: 27°CDB, 19°CWB; Outdoor temp: 35°CDB; Equivalent ref. Piping: 8m(horizontal)

2. Nominal heating capacities are based on the following conditions:

Indoor temp: 20°CDB; Outdoor temp: 7°CDB, 6°CWB; Equivalent ref. Piping: 8m(horizontal)

202

Liquid side/ Gas side mm Ф6.35/Ф9.53 Ф6.35/Ф9.53

Max. refrigerant pipe length m 10 10 10

Max. difference in level m 5 5 5

14-18 18-24 20-30

Ф6.35/Ф12.7

Page 66

3. Actual noise level may differ, depending on the room structure, etc, since these noise values are from an

anechoic room.

3 Dimensions

1. Indoor unit 7/9K

2. Indoor Unit 12K

3. Outdoor unit

203

Page 67

4 Refrigeration Cycle Diagram

Refrigeration circuit drawing of inverter trinary type

indoor unit

heat

exchanger

heat

exchanger

heat

exchanger

filter

filter

filter

filter