Admiral NTW4880YQ0, NTW4600XQ0, ATW4475VQ1, NTW5100XQ0, NTW4800XQ0 Installation Instructions Manual

...Page 1

Washer Installation Instructions

Instructions pour l'installation de la laveuse

Table of Contents Table des mati_res

WASHER SAFETY ............................................................. 1 SECURITE DE LA LAVEUSE ............................................. 9

iNSTALLATiON REQUIREMENTS .................................... 2

Tools and Parts .................................................................... 2

Location Requirements ...................................................... 2

Drain System ....................................................................... 3

Electrical Requirements ..................................................... 4

INSTALLATION iNSTRUCTiONS ................................................ 4

Before you start: Remove shipping materials .................. 4

Connect Drain Hose ............................................................ 5

Connect INet Hoses ............................................................ 6

Level Washer ....................................................................... 7

COMPLETE iNSTALLATiON CHECKLIST ................................. 8

iNSTALLATiON NOTES

Date of purchase:

Date of installation:

Installer:

Model number:

Serial number:

Para obtener acceso al "lnstrucciones de installation" en espa_ol, o para obtener informaci6n adicional acerca

de su producto, visite:

www.whirlpool.com

Tenga listo su nOmero de modelo completo. Puede encontrar el ndmero de modelo y de serie dentro de la cavidad

superior de la puerta.

EXIGENCES D'INSTALLATION ......................................... 9

Outillage et pi_ces ............................................................... 9

Exigences d'emplacement ................................................ 10

Syst_me d'6vacuation ........................................................ 10

Sp6cifications 61ectriques ................................................. 11

iNSTRUCTiONS D'INSTALLATION ........................................... 12

Avant de commencer : retrait du mat6rial d'exp6dition. 13

Raccordement du tuyau de vidange ................................. 14

Raccordement des tuyaux d'ariv_e d'eau ....................... 15

(=tablissement de I'aplomb de la laveuse ......................... 15

ACHEVER L'INSTALLATION - LISTE DE VleRIFICATION ........ 16

NOTES CONCERNANT L'INSTALLATION

Date d'achat :

Date d'installation :

Installateur :

Num6ro de module :

Num6ro de s6rie :

WASHER S_ETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

W10200890C

W10200891C - SP

Page 2

INSTALLATION REQU[REMENW$

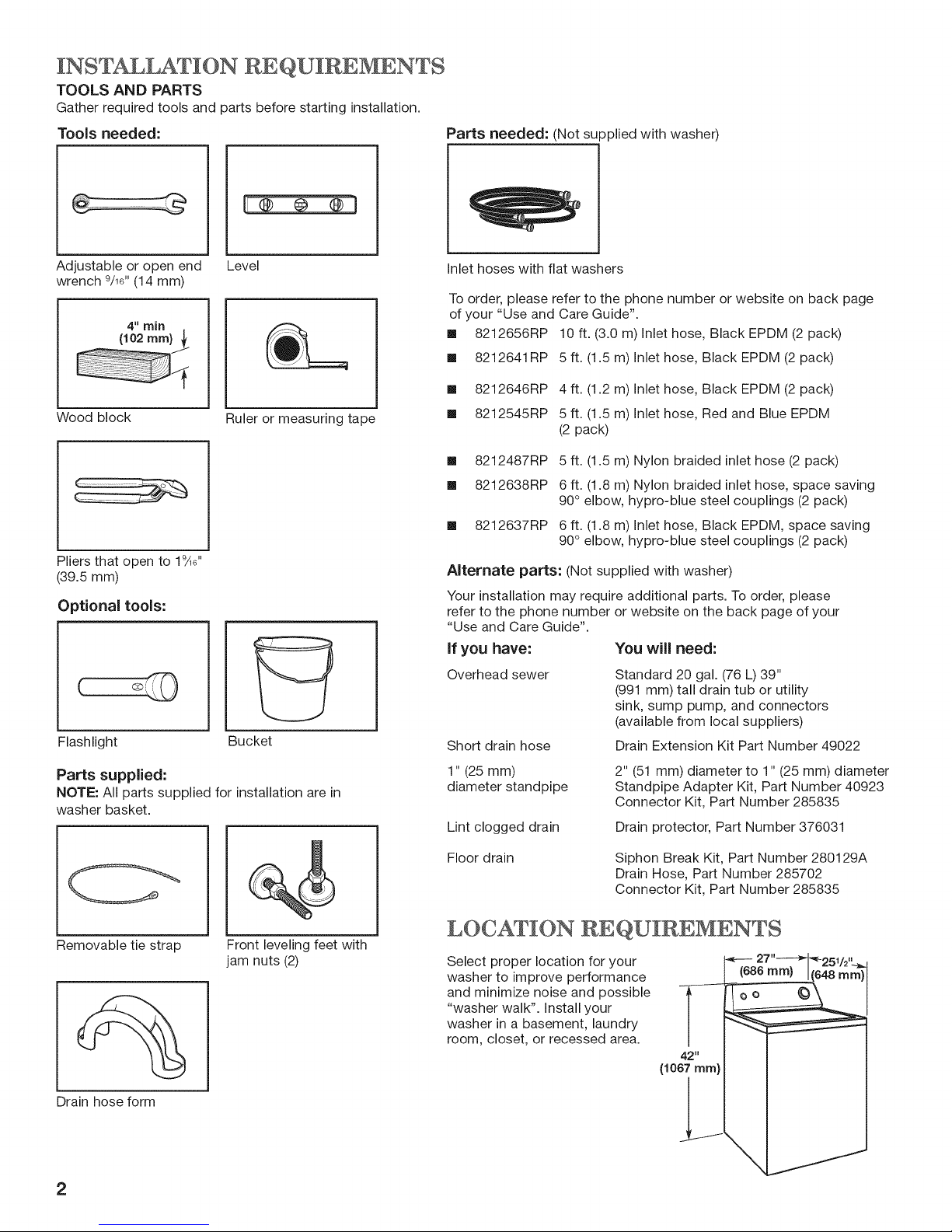

TOOLS AND PARTS

Gather required tools and parts before starting installation.

Tools needed: Parts needed: (Not supplied with washer)

m F®--®--®q

Adjustable or open end

wrench 9/16"(14 mm)

4" min

(102 mm}

Wood block

Pliers that open to 19_"

(39.5 mm)

Optional tools:

Flashlight

Level

Ruler or measuring tape

Bucket

Inlet hoses with flat washers

To order, please refer to the phone number or website on back page

of your "Use and Care Guide".

[] 8212656RP 10 ft. (3.0 m) Inlet hose, Black EPDM (2 pack)

[] 8212641RP 5 ft. (1.5 m) Net hose, Black EPDM (2 pack)

[] 8212646RP 4 ft. (1.2 m) Net hose, Black EPDM (2 pack)

[] 8212545RP 5 ft. (1.5 m) Inlet hose, Red and Blue EPDM

(2 pack)

[] 8212487RP

[] 8212638RP

[] 8212637RP

Alternate parts: (Not supplied with washer)

Your installation may require additional parts. To order, please

refer to the phone number or website on the back page of your

"Use and Care Guide".

If you have:

Overhead sewer

Short drain hose

5 ft. (1.5 m) Nylon braided inlet hose (2 pack)

6 ft. (1.8 m) Nylon braided inlet hose, space saving

90° elbow, hypro-blue steel couplings (2 pack)

6 ft. (1.8 m) Inlet hose, Black EPDM, space saving

90° elbow, hypro-blue steel couplings (2 pack)

You will need:

Standard 20 gal. (76 L) 39"

(991 mm) tall drain tub or utility

sink, sump pump, and connectors

(available from local suppliers)

Drain Extension Kit Part Number 49022

Parts supplied:

NOTE: All parts supplied for installation are in

washer basket.

Removable tie strap

Drain hose form

Front leveling feet with

jam nuts (2)

2

1" (25 mm)

diameter standpipe

Lint clogged drain

Floor drain

2" (51 mm) diameter to 1" (25 mm) diameter

Standpipe Adapter Kit, Part Number 40923

Connector Kit, Part Number 285835

Drain protector, Part Number 376031

Siphon Break Kit, Part Number 280129A

Drain Hose, Part Number 285702

Connector Kit, Part Number 285835

LOC,AT[ON REQU[REMENWS

Select proper location for your

washer to improve performance

and minimize noise and possible

"washer walk". Install your

washer in a basement, laundry

room, closet, or recessed area.

42"

(1067mm)

Page 3

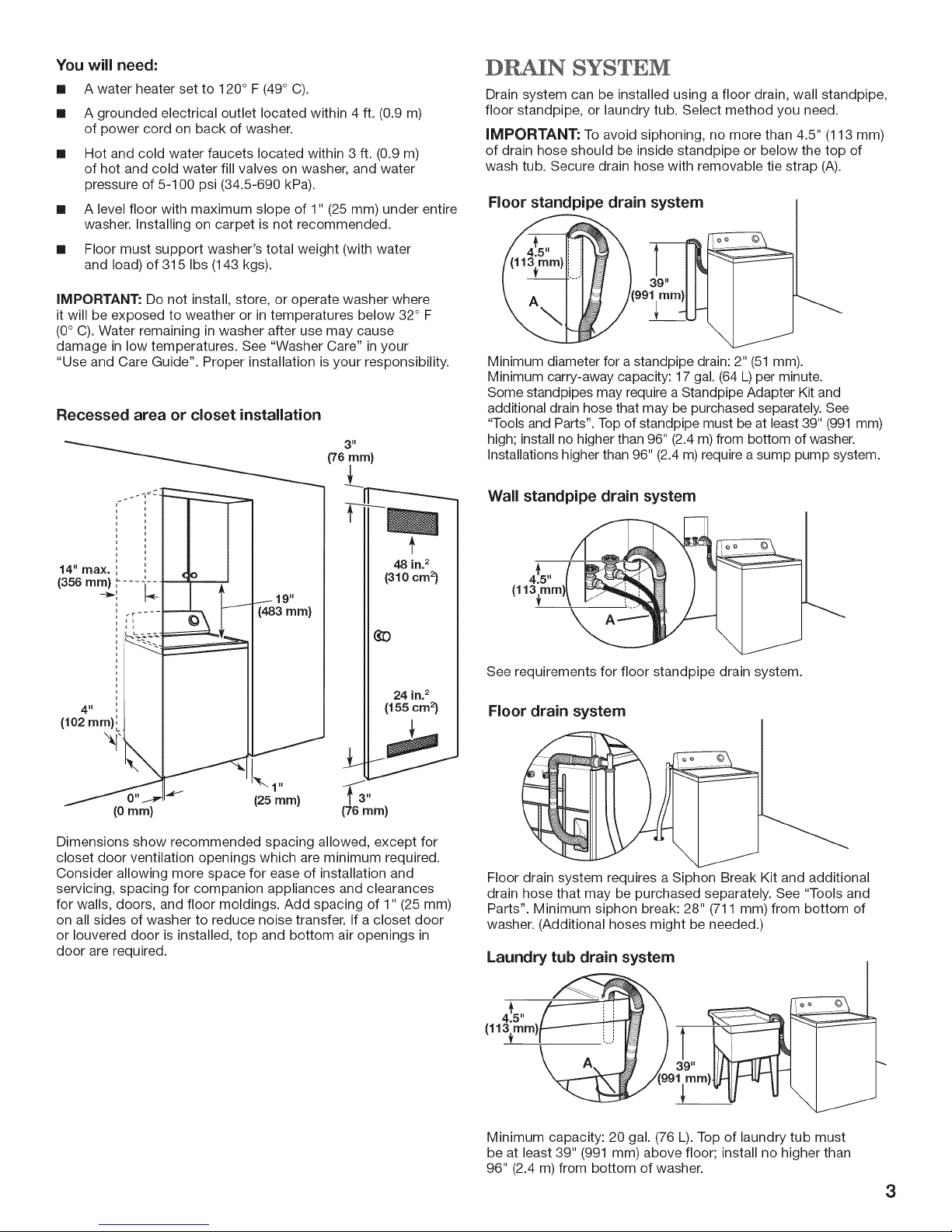

You will need:

[] A water heater set to 120 ° F (49° C).

[] A grounded electrical outlet located within 4 ft. (0.9 m)

of power cord on back of washer.

[] Hot and cold water faucets located within 3 ft. (0.9 m)

of hot and cold water fill valves on washer, and water

pressure of 5-100 psi (34.5-690 kPa).

[] A level floor with maximum slope of 1" (25 mm) under entire

washer. Installing on carpet is not recommended.

[] Floor must support washer's total weight (with water

and load) of 315 Ibs (143 kgs).

IMPORTANT: Do not install, store, or operate washer where

it will be exposed to weather or in temperatures below 32° F

(0° C). Water remaining in washer after use may cause

damage in low temperatures. See "Washer Care" in your

"Use and Care Guide". Proper installation is your responsibility.

Recessed area or closet instanation

3"

[76 ram)

SYSTEM

Drain system can be installed using a floor drain, wall standpipe,

floor standpipe, or laundry tub. Select method you need.

iMPORTANT: To avoid siphoning, no more than 4.5" (113 mm)

of drain hose should be inside standpipe or below the top of

wash tub. Secure drain hose with removable tie strap (A).

Floor standpipe drain system

Minimum diameter for a standpipe drain: 2" (51 mm).

Minimum carry-away capacity: 17 gal. (64 L) per minute.

Some standpipes may require a Standpipe Adapter Kit and

additional drain hose that may be purchased separately. See

"Tools and Parts". Top of standpipe must be at least 39" (991 mm)

high; install no higher than 96" (2.4 m) from bottom of washer.

Installations higher than 96" (2.4 m) require a sump pump system.

Wall standpipe drain system

14" max. ',

1356 m , - - -

1 19"

(483 ram)

48 in.2

(31ocm_)

¢3

4"

10ram)

Dimensions show recommended spacing allowed, except for

closet door ventilation openings which are minimum required.

Consider allowing more space for ease of installation and

servicing, spacing for companion appliances and clearances

for walls, doors, and floor moldings. Add spacing of 1" (25 mm)

on all sides of washer to reduce noise transfer. If a closet door

or Iouvered door is installed, top and bottom air openings in

door are required.

(25ram}

176 ram)

24 in.2

(155cm2)

,t,,,(

(113{turn)/

See requirements for floor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit and additional

drain hose that may be purchased separately. See "Tools and

Parts". Minimum siphon break: 28" (711 mm) from bottom of

washer. (Additional hoses might be needed.)

Laundry tub drain system

\ 9 /3o,,lil rmH

Minimum capacity: 20 gal. (76 L). Top of laundry tub must

be at least 39" (991 mm) above floor; install no higher than

96" (2.4 m) from bottom of washer.

3

Page 4

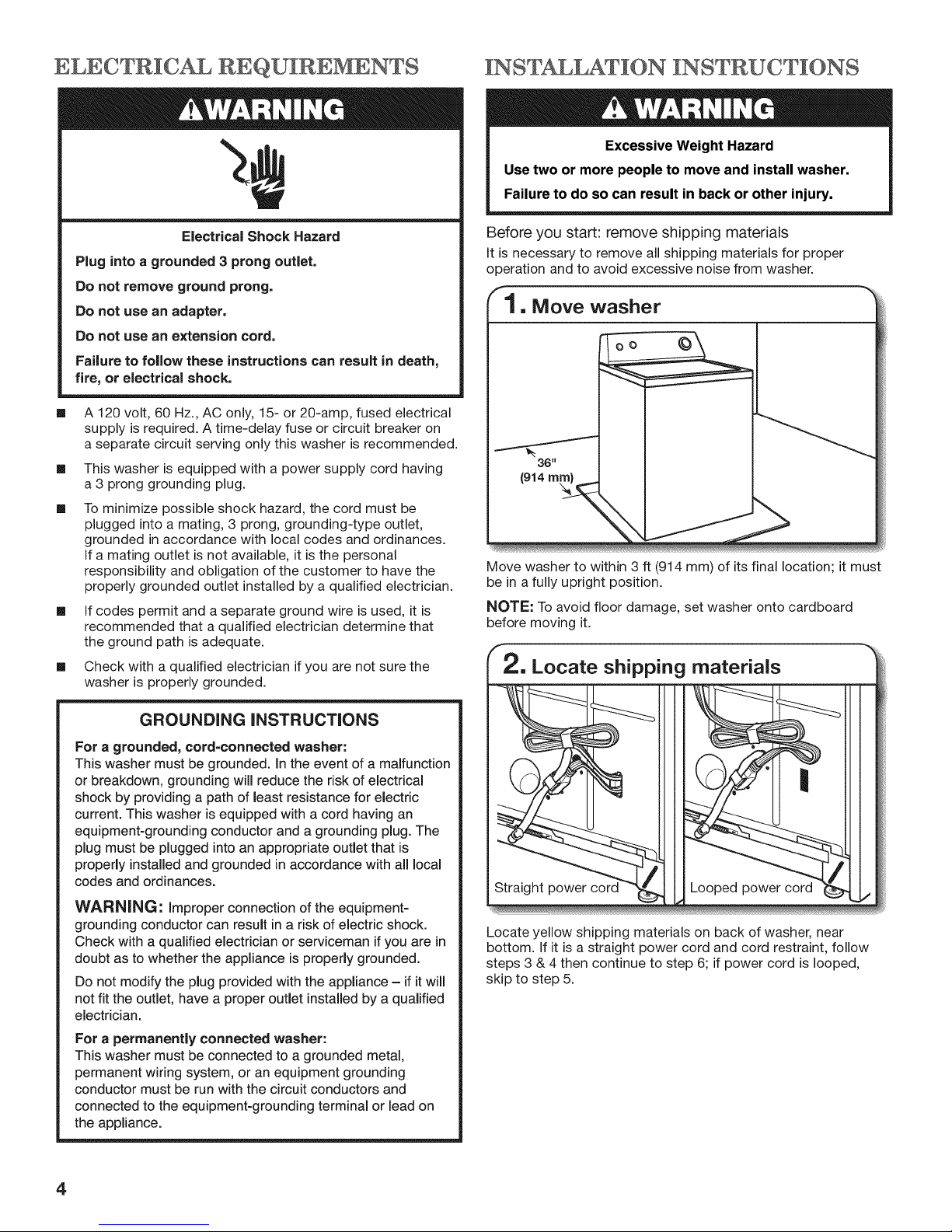

ELECTRICAL REQU[REMENT$

INS LATION INSTRUC%IONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[]

A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker on

a separate circuit serving only this washer is recommended.

[]

This washer is equipped with a power supply cord having

a 3 prong grounding plug.

[]

To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualified electrician.

[]

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

[] Check with a qualified electrician if you are not sure the

washer is properly grounded.

Before you start: remove shipping materials

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

1. Move washer

oo

Move washer to within 3 ft (914 mm) of its final location; it must

be in a fully upright position.

NOTE: To avoid floor damage, set washer onto cardboard

before moving it.

GROUNDING INSTRUCTIONS

For a grounded, cord=connected washer:

This washer must be grounded, in the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

Locate yellow shipping materials on back of washer, near

bottom. If it is a straight power cord and cord restraint, follow

steps 3 & 4 then continue to step 6; if power cord is looped,

skip to step 5.

4

Page 5

f

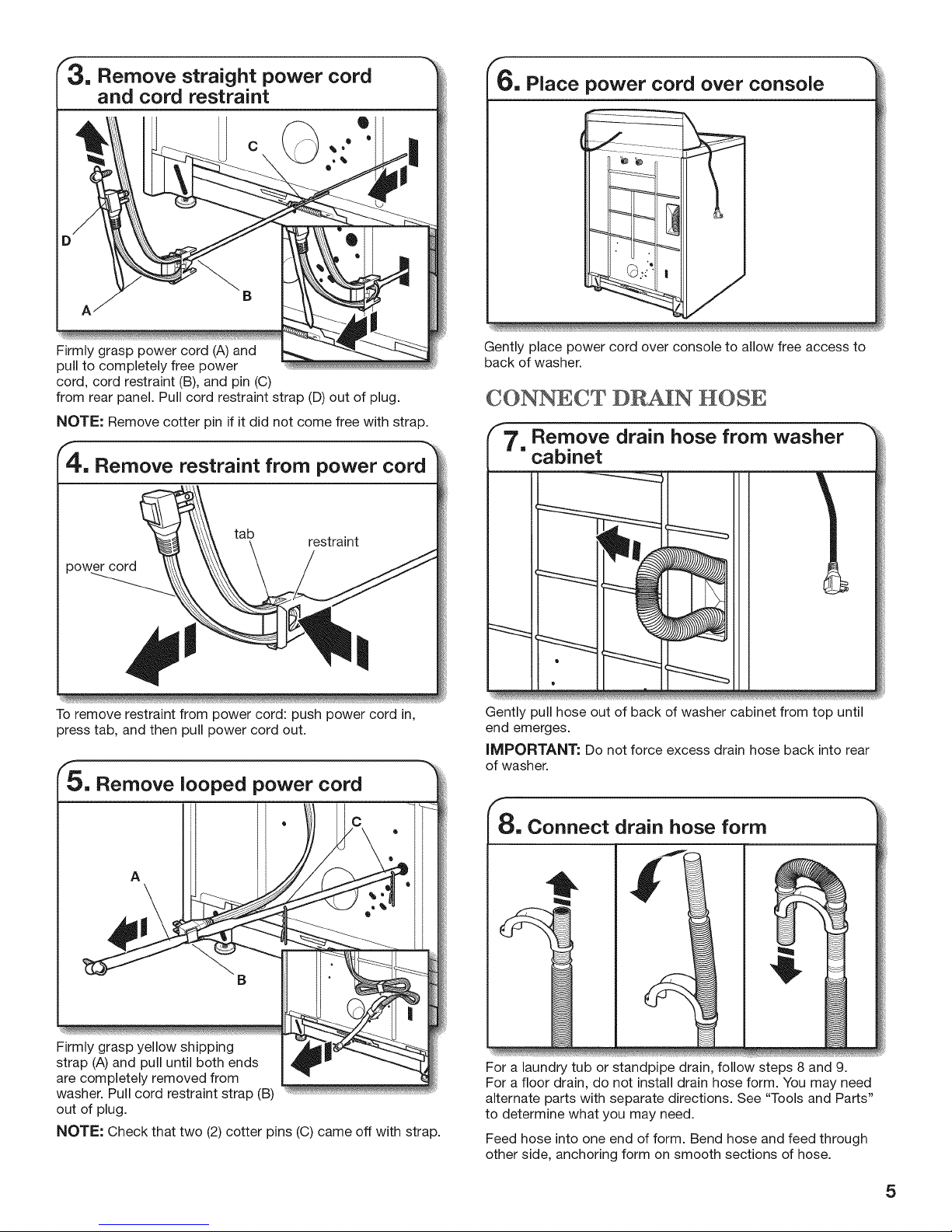

3. Remove straight power cord

and cord restraint

B

6, Place power cord over console

Firmly grasp power cord (A) and

pull to completely free power

cord, cord restraint (B), and pin (C)

from rear panel. Pull cord restraint strap (D) out of plug.

NOTE: Remove cotter pin if it did not come free with strap.

, Remove restraint from power cord

tab

power cord

%, ...... _

To remove restraint from power cord: push power cord in,

press tab, and then pull power cord out.

restraint

_, Remove looped power cord

Gently place power cord over console to allow free access to

back of washer.

CONNECT DR_N HOSE

7, Remove drain hose from washer

cabinet

Gently )ull hose out of back of washer cabinet from top until

end emerges.

iMPORTANT: Do not force excess drain hose back into rear

of washer.

A

Firmly grasp yellow shipping

strap (A) and pull until both ends

are completely removed from .......

washer. Pull cord restraint strap (B)

out of plug.

NOTE: Check that two (2) cotter pins (C) came off with strap.

8, Connect drain hose form

For a laundry tub or standpipe drain, follow steps 8 and 9.

For a floor drain, do not install drain hose form. You may need

alternate parts with separate directions. See "Tools and Parts"

to determine what you may need.

Feed hose into one end of form. Bend hose and feed through

other side, anchoring form on smooth sections of hose.

5

Page 6

Place hose into standpipe (shown in picture) or over side of

laundry tub.

iMPORTANT: No more than 4.5" (113 mm) of drain hose

should be inside standpipe; do not force excess hose into

standpipe or lay on bottom of laundry tub. Drain hose form

must be used.

CONNECT INLET HOSES

iMPORTANT: Check that your water inlet hoses have flat

washers at both ends. Washer must be connected to water

faucets with new inlet hoses with flat washers (not provided).

Do not use old hoses. Do not use hoses without washers.

1 1, Clear water lines

Run water for a few seconds through hoses into a laundry

tub, drainpipe, or bucket to prevent clogs. Water should run

until clear.

fl 2, Connect inlet hoses to washer

faucets

Attach hose to hot water faucet. Screw on coupling by hand

until it is seated on washer. Use pliers to tighten couplings an

additional two-thirds turn. Repeat this step with second hose

for cold water faucet.

iMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

HELPFUL TIP: Make note of which hose is connected to hot

water to help in attaching hoses to washer correctly.

Attach hot water hose to hot water inlet valve. Screw coupling

by hand until it is snug. Use pliers to tighten couplings an

additional two-thirds turn. Repeat with cold water inlet valve.

iMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

iMPORTANT: To reduce risk of hose failure, replace the hoses

every 5 years. Record hose installation or replacement dates for

future reference.

[] Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

NOTE: Inlet valves may be arranged vertically or horizontally

depending on your model.

0

6

Turn on water faucets to check for leaks from faucet and at

washer connection. A small amount of water may enter washer.

This is normal; it will drain later.

Page 7

"14, Secure drain hose

"17. Engage rear leveling feet

Laundry Tub Standpipe

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with removable tie strap (A). This will

help reduce the chance of drain water splashing on the floor.

Wall

LEVEL WASHER

IMPORTANT: Leveling your washer properly reduces excess

noise and vibration.

"15, Prepare to install leveling feet

©©

Tilt washer forward; self-adjusting rear feet will click into place.

Gently lower washer to floor.

"18, Check levelness of washer

oo ©

Place level here

Prop up front of washer about 4" (102 mm) with a wood block or

similar object that will support weight of washer. Then screw jam

nut onto each foot to within 1" (25 mm) of foot base.

"16, Install front leveling feet

Screw feet into threaded holes at front

corners of washer until jam nuts touch washer, but are not tight.

Tilt washer back, remove wood block. Gently lower washer to

floor and slide washer to its final location. Remove cardboard

used to protect floor.

Place a level on top edges of washer, checking each side

and front. Rock washer back and forth to make sure all four

feet make solid contact with floor. If not level, tip washer and

adjust feet up or down, repeating as necessary.

Not Level LEVEL Not Level

7

Page 8

f

1 9, Tighten leveling feet

A

When washer is level, hold the leveling foot to keep it from

turning and use a 9/16" or 14 mm open-end or adjustable

wrench to tighten jam nut (A) counterclockwise on foot

securely against washer cabinet.

HELPFUL TiP: You may want to prop washer again with

wooden block, then make sure to recheck for levelness.

COMFLEWE INS%ALLAWION

CHECKLIST

[]

Check electrical requirements. Be sure you have correct

electrical supply and recommended grounding method.

m

Check that all parts are now installed. If there is an extra

part, go back through steps to see what was skipped.

m

Check that you have all of your tools.

m

Check that yellow shipping materials were completely

removed from back of washer.

Check that both water faucets are on.

[]

[]

Check for leaks around faucets and inlet hoses.

[]

Remove film from console and any tape remaining

on washer.

[]

Check that washer is plugged into a grounded

3 prong outlet.

[]

Dispose of/recycle all packaging materials.

[]

Read "Washer Use" in your "Use and Care Guide".

[]

Totest and clean your washer, measure 1/2 of normal

recommended amount of powdered or liquid detergent

and pour it into washer basket or detergent dispenser

(on some models). Close lid. Select any cycle. Start washer

and allow to complete full cycle.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

20, Plug into a grounded

3 prong outlet

8

Page 9

p p

$NCURXTN DE LA LA_USN

Votre s_curit_ et celle des autres est tr_s importante.

Nous donnons de nombreux messages de securit6 importants dans ce manuel et sur votre appareil m6nager. Assurez-vous de

toujours lire tous les messages de securit6 et de vous y conformer.

Voici le symbole d'alerte de s6curit&

Ce symbole d'alerte de s6curit6 vous signale les dangers potentiels de d6c_s et de blessures graves & vous

et & d'autres.

Tousles messages de s_curit6 suivront le symbole d'alerte de securit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas imm_diatement les instructions,

Risque possible de d_c_s ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de securit6 vous diront quel est le danger potentiel et vous disent comment r6duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

EXXGENCNS D'XN$ LATXON

OUTILLAGE ET PIECES

Rassembler les outils et pieces n6cessaires avant de

commencer I'installation.

Outillage n_cessaire :

Pi_ces fournies :

REMARQUE : Toutes les pieces fournies pour

I'installation se trouvent darts le panier de la laveuse.

@

CI6 plate ou r6glable Niveau

de 9/16"(14 mm)

4"" rain

(102 ram))

Cale en bois

Pince avec ouverture jusqu'&

19/16'' (39,5 mm)

Outillage facultatif :

Regle ou metre ruban

Attache de fixation

amovible

Bride de retenue pour

tuyau de vidange

Pi_ces n_cessaires

Tuyaux d'arriv6e d'eau

avec rondelles plates

Pieds de nivellement avant

avec contre-6crous (2)

(Non fournies avec la laveuse)

Lampe de poche Seau

9

Page 10

Pour commander, consulter les num@os d'appel sans frais

figurant sur la couverture arriere des Instructions d'utilisation

de la laveuse.

[] 8212656RP Tuyau d'arriv6e d'eau de 10 pi (3 m),

EPDMnoirs (lot de 2)

[] 8212641RP Tuyau d'arriv6e d'eau de 5 pi (1,5 m), EPDM

noirs (lot de 2)

[] 8212646RP Tuyau d'arriv6e d'eau de 4 pi (1,2 m), EPDM

noirs (lot de 2)

[] 8212545RP Tuyau d'arriv6e d'eau de 5 pi (1,5 m), EPDM

rouge et bleu (lot de 2)

[] 8212487RP Tuyau d'arriv6e en nylon tress6 de 5 pi (1,5 m)

(lot de 2)

[] 8212638RP Tuyau d'arriv6e en nylon tress6 de 6 pi (1,8 m),

coude compact de 90°, raccords hypro-blue

en acier (lot de 2)

[] 8212637RP

Tuyau d'arriv6e de 6 pi (1,8 m), EPDM noir,

coude compact de 90°, raccords hypro-blue

en acier (lot de 2)

Autres pi_ces : (Non fournies avec la laveuse)

IIse peut que I'installation n6cessite des pieces suppl6mentaires.

Pour commander, consulter les num@os d'appel sans frais

figurant sur la couverture arriere des Instructions d'utilisation

de la laveuse.

SJ vous avez :

Un egout surelev6

II vous faudra :

Tuyau de vidange standard de 20 gal.

(76 L) de 39" (991 mm) de haut ou

evier de decharge, pompe de puisard

et connecteurs (disponibles chez les

vendeurs de mat@iel de plomberie

Iocaux)

Un tuyau de vidange

trop court

Un tuyau rigide de rejet

I'egout de 1" (25 mm)

de diametre

Ensemble de raccord de tuyau

d'evacuation - N° de piece 49022

Un ensemble d'adaptateur de 2" (51ram)

1" (25mm) de diametre pour letuyau

rigide de rejet a I'egout, N° de piece 40923

Ensemble de raccord, N° de piece 285835

Le systeme d'evacuation

obstrue par de la charpie

Un tuyau d'evacuation

au plancher

Protecteur de canalisation,

N° de piece 376031

Ensemble de brise-siphon,

N° de piece 280129A

Tuyau d'evacuation, N° de piece 285702

Ensemble de raccord, N° de piece 285835

EXIGENCES D'EMPLACEMENT

Le choix d'un emplacement

appropri6 pour la laveuse

en am61iore le rendement

et r6duit au minimum

le bruit et le "d6placement"

possible de la laveuse. La

laveuse peut _tre install6e

dans un sous-sol, une salle

de buanderie, un placard

ou un encastrement.

42"

(1067ram)

II vous faudra :

[]

Un chauffe-eau r6g16& 120° F (49° C).

[]

Une prise 61ectrique reli6e & la terre et situ6e &moins

de 4 pi (0,9 m) du cordon d'alimentation situ6 & I'arriere

de la laveuse.

[]

Des robinets d'eau chaude et d'eau froide situ6s a moins

de 3 pi (0,9 m) des 61ectrovannes de remplissage d'eau

chaude et d'eau froide situ6es sur la laveuse et une

pression d'eau de 5-100 Ib/po 2(34,5 a 690 kPa).

[]

Un plancher de niveau avec une pente maximale

de 1" (25 mm) sous I'ensemble de la laveuse. Uinstallation

sur de la moquette n'est pas recommand6e.

[]

Un plancher capable de supporter le poids total

de 315 Ib (143 kg) de la laveuse (eau et charge compris).

iMPORTANT : Ne pas installer, remiser ou faire fonctionner la

laveuse & un emplacement oQelle sera expos6e aux intemp6ries

ou & des temp6ratures inf6rieures & 32° F (0° C). De I'eau rest6e

dans la laveuse apres utilisation peut causer des dommages

&basse temp6rature. Voir "Entretien de la laveuse" dans les

Instructions d'utilisation de la laveuse pour des renseignements

sur I'hiv6risation.

C'est &I'utilisateur qu'incombe la responsabilit6 de r6aliser une

installation correcte.

installation darts un encastrement ou un placard

3 ml

(76 mm)

.q=2]

14" max. ', I

(356mm) .... "---

/ 19"

(463 mm)

48 in. _

(310 cm 2)

¢3

24 in. _

(155cm2)

J

k,,,

(6 ram)

(25mm)

Les dimensions repr6sentent les d6gagements recommand6s

permis, hormis pour les ouvertures de ventilation de la porte

du placard qui correspondent aux dimensions minimales

n6cessaires. On peut 6ventuellement laisser davantage

de d6gagement pour faciliter I'installation et I'entretien,

des distances de s6paration pour les appareils m6nagers

voisins et des d6gagements pour les murs, portes et plinthes.

Ajouter un espace suppl6mentaire de 1" (25 mm) de tousles

c6t6s de la laveuse pour r6duire le transfert de bruit. Si I'on

installe une porte de placard ou une porte a persiennes, des

ouvertures d'a@ation au sommet et au bas de la porte sont

n6cessaires.

f3"

(76ram)

10

Page 11

SYS%EME DE VID GN

Le systeme de vidange de la laveuse peut 6tre install6

& I'aide d'un conduit d'6vacuation au plancher, un tuyau

de rejet a 1'6gout au plancher ou mural ou un 6vier

de buanderie. S61ectionner la m6thode a utiliser.

IMPORTANT." Pour 6viter un effet de siphon, ne pas

introduire plus de 4.5" (113 ram) de tuyau de vidange

& I'int@ieur du tuyau de rejet & 1'6gout ou sous la partie

sup@ieure de la cuve de lavage. Immobiliser le tuyau

de vidange avec I'attache de fixation amovible (A).

Syst_me de vidange avec tuyau de rejet _ 1'6gout

au plancher

Diametre minimal pour un tuyau de rejet & 1'6gout : 2" (51 mm).

Capacit6 minimale d'acheminement : 17 gal. (64 L) par minute.

Certains tuyaux rigides de rejet a 1'6gout peuvent n6cessiter

un ensemble d'adaptateur pour tuyau rigide de rejet & 1'6gout

et un tuyau d'6vacuation suppl6mentaire qui peuvent 6tre

achet6s s@ar6ment. Voir "Outillage et pieces". Le sommet

du tuyau de rejet & 1'6gout dolt avoir une hauteur d'au moins

39" (991 mm); ne pas I'installer & plus de 96" (2,4 m) du fond

de la laveuse. Si on dolt I'installer & plus de 96" (2,4 m)

de hauteur, un systeme de pompe de puisard est n6cessaire.

Syst_me de vidange avec tuyau de rejet

1'6gout mural

Syst_me de vidange dans un 6vier de buanderie

Capacit6 minimale : 20 gal. (76 L). Le sommet de 1'6vier de

buanderie dolt se trouver & au moins 39" (991 mm) du plancher;

ne pas I'installer & plus de 96" (2,4 m) du fond de la laveuse.

SPNCIFIC,ATION$ NLECTAIQUES

Risque de choc 61ectrique

Brancher sur une prise/_ 3 alv6oles reli6e a la terre.

Ne pas enlever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c_ble de rallonge.

Le non=respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

Voir les exigences pour le systeme de vidange avec tuyau

de rejet & 1'6gout au plancher.

Syst_me de vidange au plancher

Le systeme de vidange au plancher n6cessite un ensemble

de brise-siphon et un tuyau de vidange suppl6mentaire qui

peuvent 6tre achet6s s@ar6ment. Voir "Outillage et pieces".

Dimension minimale pour le brise-siphon : 28" (711 mm)

&partir du fond de la laveuse. (Des tuyaux suppl6mentaires

peuvent 6tre requis).

Une alimentation de 120 volts, 60 Hz, CA seulement,

de 15 ou 20 amperes, prot6g6e par un fusible est requise.

Une alimentation de 120 volts, 60 Hz, CA seulement,

de 15 ou 20 amp@es, prot6g6e par un fusible est requise.

On recommande I'emploi d'un fusible ou d'un disjoncteur

temporis& II est recommand6 de raccorder la laveuse

sur un circuit distinct exclusif & cette laveuse.

[]

Cette laveuse comporte un cordon d'alimentation

61ectrique & trois broches pour liaison & la terre.

[]

Pour minimiser les risques de choc 61ectrique, on

dolt brancher le cordon sur une prise de courant de

configuration correspondante, b,3 alv6oles, reli6e b, laterre

et install6e conform6ment aux codes et reglements Iocaux.

Si une prise de courant de configuration correspondante

n'est pas disponible, le client a la responsabilit6 et

I'obligation de faire installer par un 61ectricien qualifi6 une

prise de courant correctement reli6e &la terre.

Si les codes le permettent et si I'on utilise un conducteur

distinct de liaison & la terre, il est recommand6 qu'un

61ectricien qualifi6 v&ifie la qualit6 de la liaison & la terre.

En cas de doute quant b,la qualit6 de la liaison & la terre

de la laveuse, consulter un 61ectricien qualifi&

11

Page 12

iNSTRUCTiONS DE LiAiSON A LA TEl:IRE

Pour une laveuse reli_e _ la terre et connect_e par

un cordon :

Cette laveuse dolt 6tre reli6e &la terre. En cas d'anomalie

de fonctionnement ou de panne, la liaison &la terre r6duira

le risque de choc 61ectrique en offrant au courant 61ectrique

un itin6raire d'6vacuation de moindre r6sistance. Cette

laveuse est aliment6e par un cordon electrique comportant

un conducteur reli6 & la terre et une fiche de branchement

munie d'une broche de liaison & la terre. La fiche doit 6tre

branch6e sur une prise de courant appropri6e qui est bien

install6e et reli6e & Jaterre conform6ment & tous Jes codes

et reglements Iocaux.

AVERTISSEMENT : Le raccordement incorrect de cet

appareiJ au conducteur de liaison & Jaterre peut susciter un

risque de choc eJectrique. En cas de doute quant & la qualit6

de la liaison & la terre de I'appareil, consulter un eJectricien

ou technicien d'entretien qualifi&

Ne pas modifier la fiche de branchement fournie avec

J'appareil - si la fiche ne correspond pas & la configuration

de Ja prise de courant, demander & un 6Jectricien quaJifi6

d'instaJler une prise de courant convenable.

Pour une laveuse raccord_e en permanence :

Cette laveuse dolt 6tre raccord6e & un syst_me de c&blage

permanent en m6tal reli6 & la terre ou un conducteur reli6 &

la terre doit 6tre en fonction avec les conducteurs de circuit

et raccord6s & la borne de liaison & la terre ou la borne sur

I'appareil m6nager.

REMARQUE : Pour 6viter d'endommager le plancher, installer

la laveuse sur un carton avant de la d6placer.

Rep@er I'emplacement du mat@iel d'exp6dition jaune situe

&I'arriere de la laveuse, pros du fond. S'il s'agit d'un cordon

d'alimentation droit et d'un dispositif d'immobilisation du cordon

d'alimentation, suivre les 6tapes 3 et 4, puis passer & 1'6tape 6; s'il

s'agit d'un cordon d'alimentation en boucle, passer a 1'6tape 5.

Oter le cordon d'alimentation droit

et le dispositif d'immobilisation du

cordon d'alimentation.

INSTRUCTIONS D'INS LAT[ON

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_placer et

installer la laveuse.

Le non=respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

Avant de commencer : retirer le mat6riel d'exp6dition

II est necessaire de retirer tout le mat@iel d'exp6dition pour un

fonctionnement correct et pour 6viter que la laveuse ne fasse

trop de bruit.

"1, D_placer ia laveuse

oo ©

Saisir fermement le cordon

d'alimentation (A) et tirer pour le d6gager

completement ainsi que le dispositif

d'immobilisation (B) et la broche (C) du panneau arriere.

Oter I'attache de retenue du cordon d'alimentation (D)

hors de la prise.

REMARQUE : Oter la goupille si elle n'a pas 6t6 d6gag6e en

m_me temps que I'attache.

D6placer la laveuse a moins de 3 pi (914 mm) de son

emplacement final, elle dolt _tre en position completement

verticale.

12

Page 13

4, Retirer i'attache du cordon

d'alimentation

onglet

attache

cordon

d'alimentation

Pour retirer I'attache du cordon d'alimentation " enfoncer

le cordon d'alimentation, appuyer sur I'onglet, puis extraire

le cordon d'alimentation.

5, Retirer le cordon d'alimentation

en boucle

_CCORDNMENT DU TUYAU

DE ¥_D,_GE

Lib_rer le tuyau de vidange de la

caisse de ia iaveuse

Extraire d61icatement le tuyau de I'arri_re de la caisse de la

laveuse a partir du sommet jusqu'a ce que le bout apparaisse.

IMPORTANT : Ne pas forcer I'exc6dent du tuyau de vidange

dans I'arriere de la laveuse.

8, Raccorder la bride de retenue pour

tuyau de vidange

A

B

Saisir fermement la sangle

d'exp6dition jaune (A) et tirer

jusqu'a ce que les deux

extr6mit6s soient completement

d6gag6es de la laveuse. Oter I'attache de retenue

du cordon d'alimentation (B) hors de la prise.

REMARQUE : V6rifier que deux (2) goupilles ont 6t6

retir6es (C)avec la sangle.

Placer ie cordon d'alimentation par

dessus la console

Pour un 6vier de buanderie ou un tuyau de rejet a 1'6gout, suivre

les 6tapes 8 et 9. Pour un conduit d'6vacuation au plancher, ne

pas installer de bride de retenue pour tuyau de vidange. Des

pieces suppl6mentaires avec des directives distinctes seront

peut-_tre n6cessaires. Voir "Outillage et pieces".

Ins6rer le tuyau dans I'une des extr6mit6s de la bride de retenue,

plier le tuyau et continuer d'ins6rer le tuyau jusqu'a I'autre c6t6

tout en fixant la bride de retenue aux sections lisses du tuyau.

Placer d61icatement le cordon d'alimentation par dessus la

console pour permettre le libre acc_s a I'arriere de la laveuse.

13

Page 14

Placer le tuyau dans le tuyau de rejet a 1'6gout (illustr6 sur

I'image) ou par-dessus le c6t6 de 1'6vier de buanderie.

IMPORTANT : IIne dolt pas y avoir plus de 4,5" (113 mm) de

tuyau de vidange a I'int@ieur du tuyau de rejet a 1'6gout; ne pas

forcer I'exc6dent de tuyau dans le tuyau de rejet a 1'6gout ni

le placer dans 1'6vier de buanderie. On doit utiliser la bride de

retenue pour tuyau de vidange.

_CCORDEMENT DES T X

D_ARRI¥_E D_EAU

1 "1, Purger les canalisations d'eau

Faire couler I'eau par les tuyaux dans 1'6vier de buanderie, le

tuyau de rejet a 1'6gout ou le seau pendant quelques secondes

pour 6viter toute obstruction. On dolt laisser couler I'eau jusqu'&

ce qu'efle soit limpide.

fl 2, Raccorder les tuyaux d'arriv_e

d'eau a la laveuse.

IMPORTANT : V@ifier que les tuyaux d'arriv6e d'eau ont

les rondelles plates aux deux extr6mit6s. La laveuse dolt _tre

raccord6e aux robinets d'eau a I'aide des nouveaux tuyaux

d'arriv6e d'eau avec les rondelles plates (non fournis). Ne

pas utiliser de tuyaux usag6s. Ne pas utiliser de tuyaux sans

rondelles.

Raccorder les tuyaux d'arriv6e

d'eau aux robinets

Fixer le tuyau au robinet d'eau chaude. Visser le raccord & la

main pour qu'il repose sur la rondelle. Serrer les raccords de

deux tiers de tour suppl6mentaires a I'aide d'une pince. R6p6ter

cette 6tape avec le deuxieme tuyau pour le robinet d'eau froide.

IMPORTANT : Ne pas serrer excessivement ni utiliser de

ruban adh6sif ou de dispositif d'6tanch6Jt6 sur la valve lots

de la fixation aux robinets ou a la laveuse. Cela pourrait

entraTner des dommages.

Fixer le tuyau d'eau chaude au robinet d'arriv6e d'eau chaude.

Visser le raccord a la main jusqu'a ce qu'il soit bien serr& Serrer

les raccords de deux tiers de tour suppl6mentaires a I'aide d'une

pince. R6p6ter pour le robinet d'eau froide.

IMPORTANT : Ne pas serrer excessivement ni utiliser de

ruban adh_sif ou de dispositif d'6tanch6it6 sur la valve lots de la

fixation aux robinets ou a la laveuse. Cela pourrait entraTner des

dommages.

IMPORTANT : Pour r6duire le risque de d6faillance des tuyaux,

remplacer les tuyaux tousles 5 ans. Inscrire la date d'installation

ou de remplacement des tuyaux pour r6f@ence ult@ieure.

Ill Inspecter p6riodiquement les tuyaux et les remplacer

en cas de renflement, de d6formation, de coupure, d'usure

ou sJune fuite se manifeste.

REMAROUE : Les robinets d'arriv6e d'eau peuvent _tre install6s

verticalement ou horizontalement selon le modele.

CONSEIL UTILE : Rep@er quel tuyau est raccord6 & I'eau

chaude pour permettre une fixation correcte des tuyaux

& la laveuse.

14

Ouvrir les robinets d'eau pour v@ifier qu'il n'y a pas de fuite.

Une petite quantit6 d'eau peut entrer dans la laveuse. C'est

normal. Elle s'6vacuera plus tard.

Page 15

Tuyauderejet&

1'6gout

Mur

1 7, Engager les pieds de

=_

arrlere

geaupie( erie,

autuyauderejeta1'6goutouauxtuyauxd'arriv6ed'eaupour

letuyauderejeta1'6goutmuralavecI'attachedefixation

amovible(A).Ceciaideraar6duirelapossibilit6deI'eaude

vidange6claboussantsurleplancher.

LISSEMENT DE L'APLOr_B

DE LA L USE

IMPORTANT : L'6tablissement correct de I'aplomb de la

laveuse permet de r6duire les nuisances sonores et de limiter

les vibrations.

5, Pr6parer i'instailation des pieds _

de nivellement

K

m

Faire basculer la laveuse vers I'avant; les pieds auto-r6glables

arriere s'embofteront. Abaisser d61icatement la laveuse pour la

faire reposer sur le sol.

1 8, Contr61er i'aplomb de ia iaveuse

oo Q

placer le niveau

&cet endroit

Placer un niveau sur les bords sup6rieurs de la laveuse en

contr61ant chaque c6t6 et I'avant. Faire bouger la laveuse

d'avant en arriere pour s'assurer que les quatre pieds sont

bien en contact avec le plancher. Si elle n'est pas d'aplomb,

faire basculer la laveuse et r6gler les pieds vers le haut ou

vers le bas puis recommencer si n6cessaire.

Soulever I'avant de la laveuse d'environ 4" (102 mm) a I'aide

d'une cale en bois ou d'un objet similaire qui soutiendra le poids

de la laveuse. Visser ensuite le contre-6crou sur chaque pied

jusqu'a moins de 1" (25 mm) de la base du pied.

"1 6, Installer les pieds de nivellement

avant

Visser les pieds dans les trous filet6s aux

angles avant de la laveuse, jusqu'a ce clue les contre-6crous

soient en contact avec la laveuse mais sans _tre serr6s. Faire

basculer la laveuse vers I'arriere, retirer la cale en bois. Abaisser

d61icatement la laveuse pour la faire reposer sur le sol puis

la faire glisser jusqu'& son emplacement final. Oter le morceau

de carton utilis6 pour prot6ger le plancher.

Pas d'aplomb APLOMB Pas d'aplomb

15

Page 16

f

1 9, Serrer les pieds de nivellernent

Lorsque la laveuse est d'aplomb, tenir le pied de nivellement

pour empecher le pied de tourner, et utiliser une cl6 r6glable

ou plate de 9/16" ou de 14 mm pour serrer dans le sens

antihoraire le contre-6crou (A) du pied solidement contre la

caisse de la laveuse.

CONSEIL UTILE : On devra peut-_tre de nouveau relever la

laveuse a I'aide d'une cale de bois, puis v6rifier de nouveau le

bon aplomb de la laveuse.

LISTS DE ¥_RIFICATION

POUR UACHE_MENT

DE UINS%ALLATION

[]

Consulter les sp6cifications 61ectriques. S'assurer de disposer

d'une source d'61ectricit6 appropri6e et d'une liaison a la terre

conforme a la m6thode recommand6e.

[]

V6rifier que toutes les pieces sont maintenant install6es. S'il

reste une piece, passer en revue les diff6rentes 6tapes pour

d6couvrir laquelle aurait 6t6 oubli6e.

[]

V6rifier la pr6sence de tousles outils.

[]

V6rifier que tout le mat6riel d'exp6dition jaune a 6t6 retir6 de

I'arriere de la laveuse.

[]

V6rifier que touts les deux robinets d'eau sont ouverts.

[]

V6rifier qu'il n'y a pas de fuite autour des robinets et des

tuyaux d'arriv6e d'eau.

[]

Oter la pellicule de la console et tout ruban adh6sif rest6 sur

la laveuse.

[]

V6rifier que la laveuse est branch6e sur une prise de courant

3 alv6oles reli6e a la terre.

[]

#liminer/recycler tousles mat6riaux d'emballage.

[]

Life "Utilisation de la laveuse" dans les Instructions

d'installation de la laveuse.

[]

Pour tester et nettoyer la laveuse, mesurer la moiti6 de la

quantit6 normale recommand6e de d6tergent en poudre

ou liquide et la verser dans le panier de la laveuse ou le

distributeur de d6tergent (sur certains modeles). Fermer le

couvercle. S61ectionner n'importe quel programme. Mettre

la laveuse en marche et la laisser ex6cuter un programme

complet.

Risque de choc _lectrique

Brancher sur une prise & 3 alv_oles reli_e _ la terre.

Ne pas enlever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c&ble de rallonge.

Le non=respect de ces instructions peut causer

un d_c_s, un incendie ou un choc _lectrique.

r

20, Brancher sur une prise

_ 3 alv6oles reli6e a la terre.

W102008900

W102008910 = SP

02010

All rights reserved

Tous droits r6serv6s.

16

08/1 0

Printed in U.S.A.

Imprim6 aux #.-U.

Loading...

Loading...