Page 1

Page 2

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

INSTALLATION INSTRUCTIONS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

n Flat-blade screwdriver

n #2 Phillips screwdriver

n Adjustable wrench that

opens to 1" or hex-head

socket wrench (for

adjusting dryer feet)

n ¼" socket wrench or ¼"

nut driver

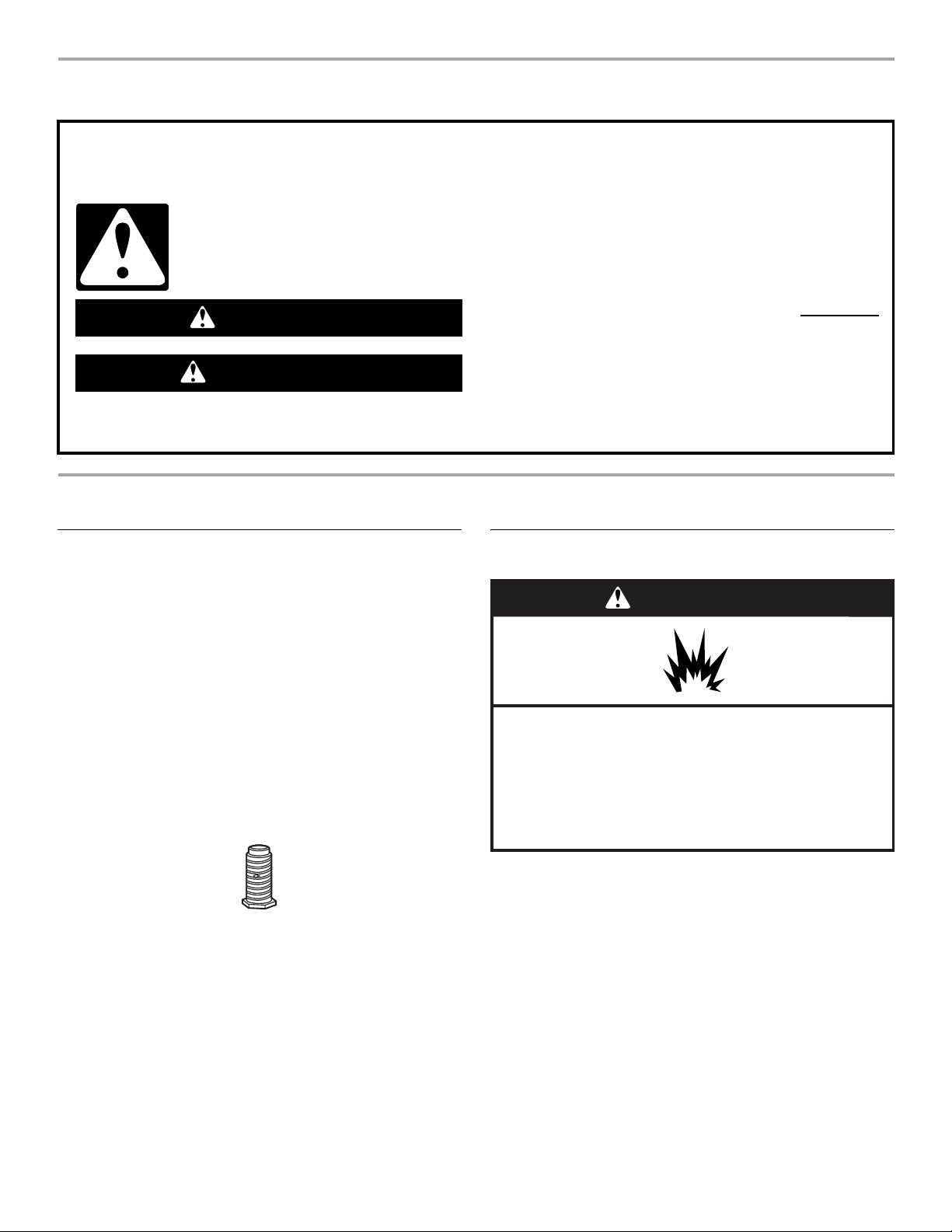

Parts supplied

Remove parts package from dryer drum. Check that all parts were

included.

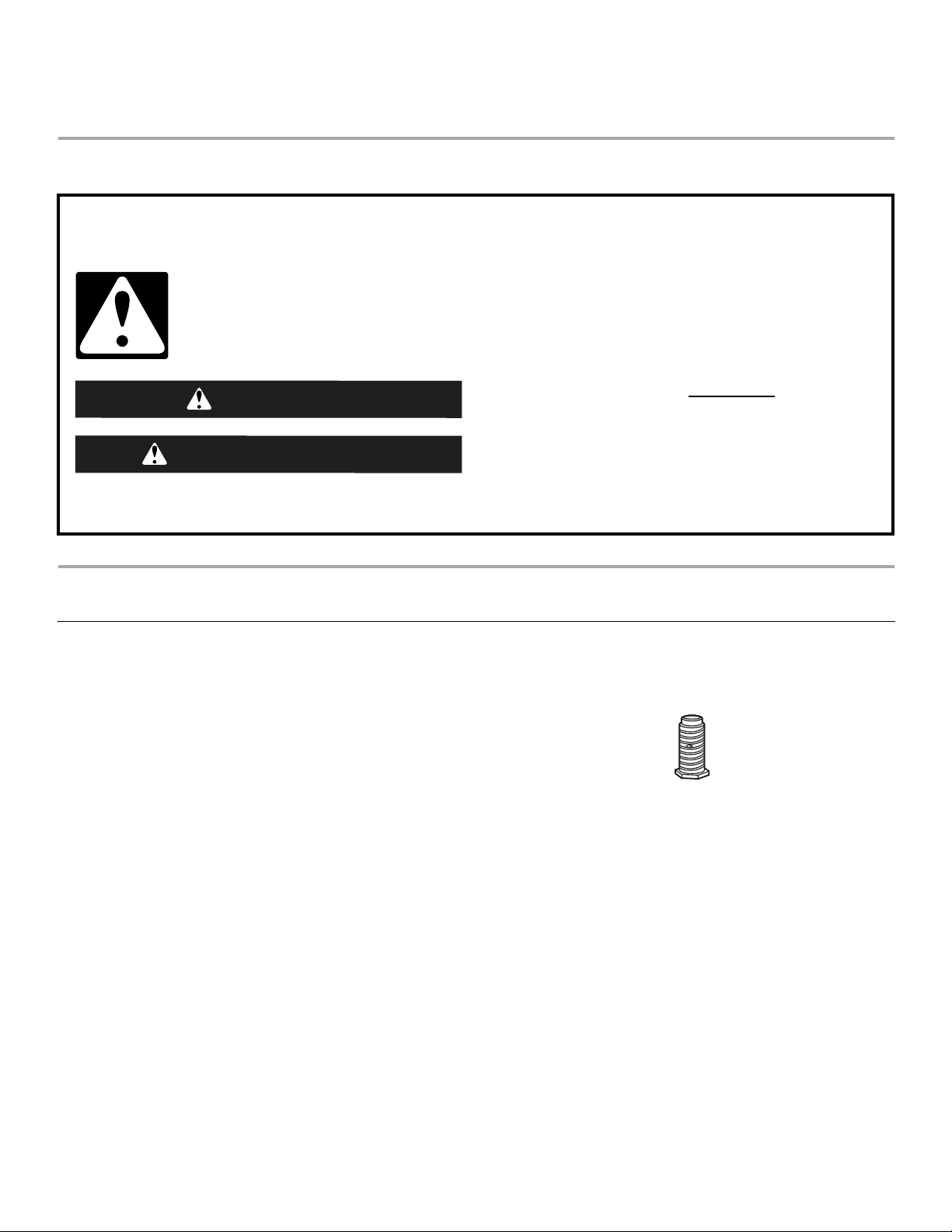

4 leveling legs

Parts needed:

Check local codes, check existing electrical supply and venting

and see “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

n Tin snips (new vent

installations)

n Level

n Vent clamps

n Caulking gun and

compound (for installing

new exhaust vent)

n Tape measure

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

n A location that allows for proper exhaust installation. See

“Venting Requirements.”

n A separate 30-amp circuit.

n A grounded electrical outlet located within 2 ft (61 cm) of

either side of the dryer. See “Electrical Requirements.”

n A sturdy floor to support the total weight (dryer and load) of

200 lbs (90.7 kg). The combined weight of a companion

appliance should also be considered.

n A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer. (If slope is greater than 1" [2.5 cm], install Extended

Dryer Feet Kit, Part Number 279810.) Clothes may not tumble

properly and models with automatic sensor cycles may not

operate correctly if dryer is not level.

Do not operate your dryer at temperatures below 45ºF (7ºC). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

2

Page 3

The dryer must not be installed or stored in an area where it will be

exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes or

sleeping quarters. Contact your local building inspector.

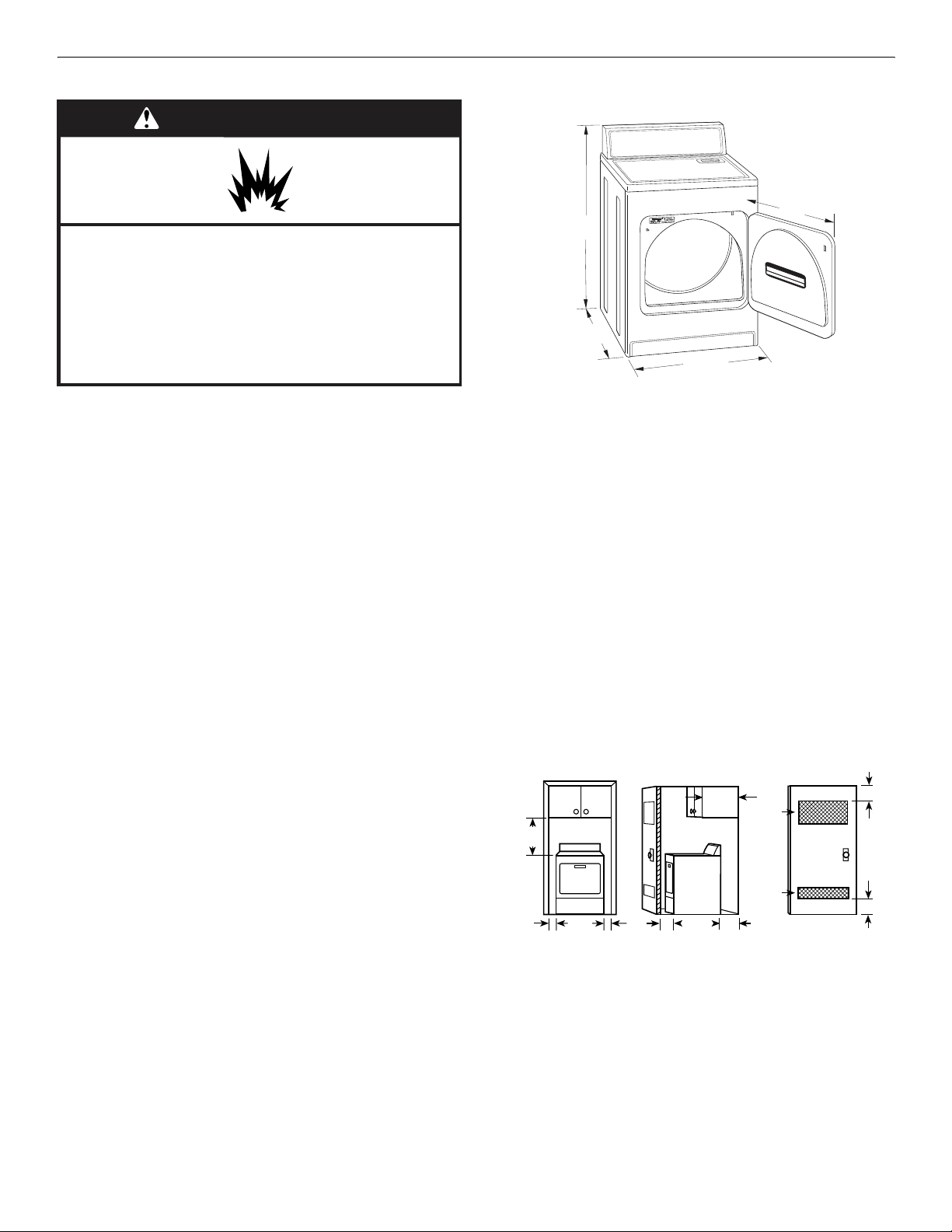

Installation Clearances

The location must be large enough to allow the dryer door to open

fully.

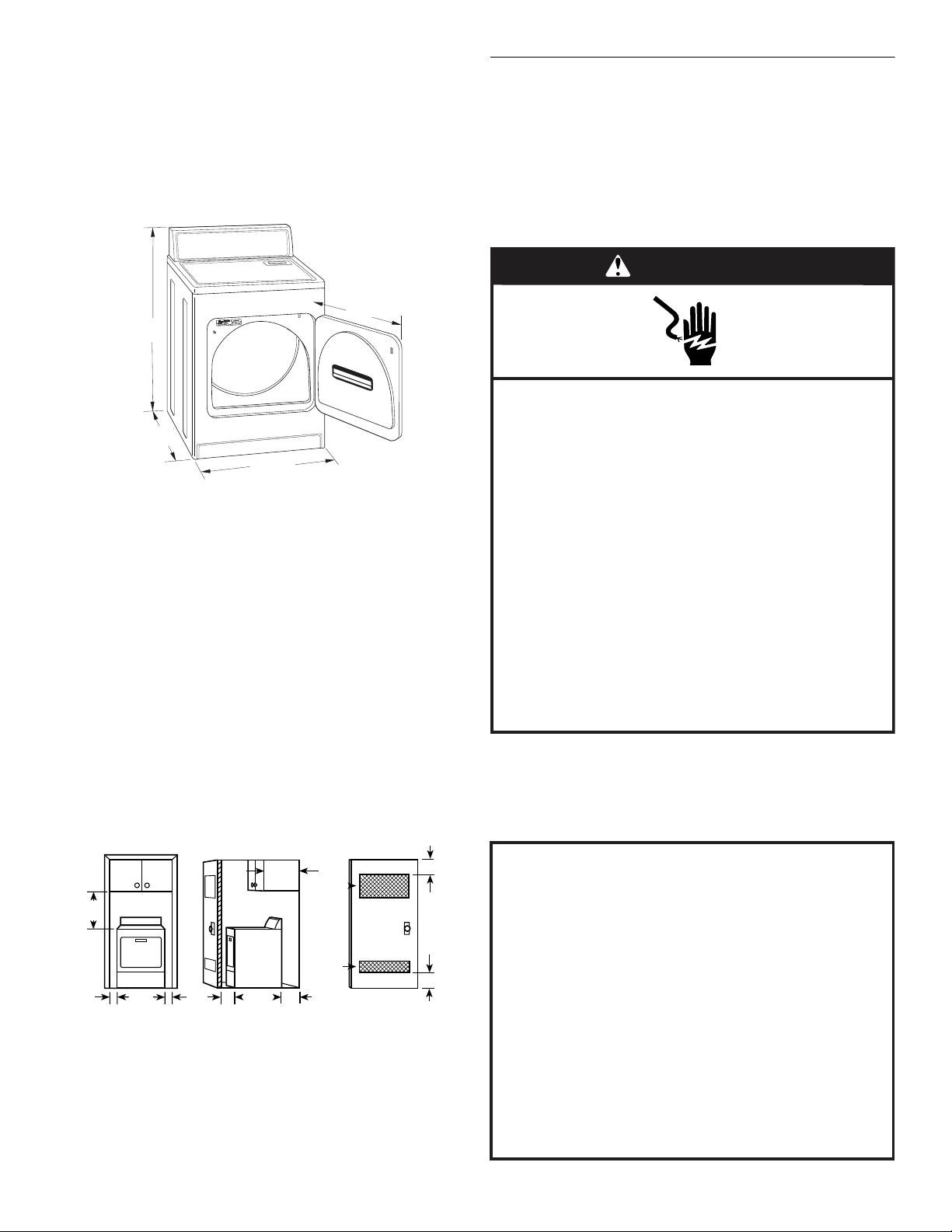

Dryer Dimensions

22³⁄₄"

43³⁄₈"

(110 cm)

*27³⁄₄"

(70.5 cm)

29"

(73.66 cm)

(57.8 cm)

*Most installations require a minimum 5" (12.7 cm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of 0" (0 cm)

clearance on the sides and rear. Recommended spacing should

be considered for the following reasons:

n Additional spacing should be considered for ease of

installation and servicing.

n Additional clearances might be required for wall, door and

floor moldings.

n Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

n For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

n Companion appliance spacing should also be considered.

3"*

(7.6 cm)

3"*

(7.6 cm)

18"*

(45.7 cm)

29"

1"

(73.66 cm)

(2.5 cm)

A

*Required spacing

1"

(2.5 cm)

1"*

(2.5 cm)

14" max.*

(35.6cm)

27¾"

(70.5 cm)

5"*

(12.7 cm)

2

48 in.

*

2

(310 cm )

2

*

24 in.

2

(155 cm )

B

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

C

Electrical Requirements

It is your responsibility

n To contact a qualified electrical installer to assure that the

electrical installation is adequate and is in conformance with

all local codes and ordinances.

n To supply the required 2 wire, single phase, 230 volt, 50 Hz.,

AC only electrical supply on a separate 30-amp circuit. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit.

WARNING

Electrical Shock Hazard

Electrical ground is required on this dryer.

Do not ground to a gas pipe.

Do not change the power supply cord plug. If it does

not fit the outlet, have a proper outlet installed by a

qualified electrician.

Do not have a fuse in the neutral or grounding circuit.

Do not use an extension cord with this dryer.

Check with a qualified electrician to be sure the dryer is

properly grounded.

Do not connect plug end of power supply cord into a

live receptacle before connecting power supply cord to

dryer terminal block.

Do not reuse old power supply cord.

Failure to follow these instructions could result in

death, fire, or serious injury.

n To minimize possible shock hazard, the cord must be plugged

into a mating receptacle. Be sure wall receptacle is within

reach of dryer's final location.

For information on ordering parts, see the “Assistance or Service”

section of the Dryer User Instructions.

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

3

Page 4

Venting Requirements

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling or a concealed space of a building.

If using an existing vent system

Rigid metal vent

n For best drying performance, rigid metal vents are

recommended.

n Rigid metal vent is recommended to avoid crushing and

kinking.

Flexible metal vent

n Flexible metal vents are acceptable only if accessible for

cleaning.

n Flexible metal vent must be fully extended and supported

when the dryer is in its final location.

n Remove excess flexible metal vent to avoid sagging and

kinking that may result in reduced airflow and poor

performance.

n Do not install flexible metal vent in enclosed walls, ceilings or

floors.

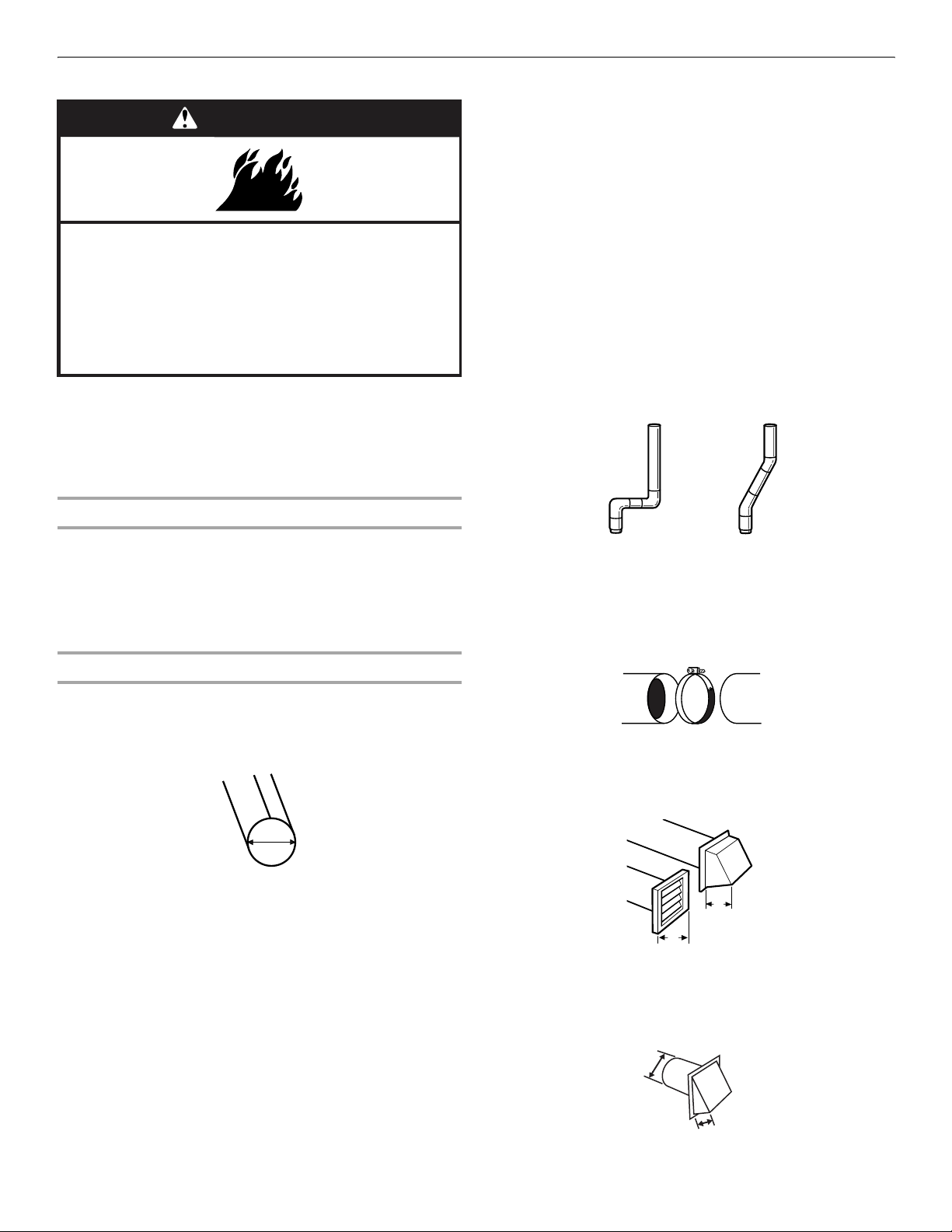

Elbows

45° elbows provide better airflow than 90° elbows.

n Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

n Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

n Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance.

If this is a new vent system

Vent material

n Use a heavy metal vent. Do not use plastic or metal foil vent.

n 4" (10.2 cm) heavy metal exhaust vent and clamps must be

used.

4"

10.2 cm

4" (10.2 cm) heavy metal exhaust vent

For more information, see the “Assistance or Service” section

of the Dryer User Instructions.

Good Better

Clamps

n Use clamps to seal all joints.

n Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

duct. Do not use duct tape.

Clamp

Exhaust

Recommended hood styles are shown here.

B

A

4"

(10.2 cm)

4"

(10.2 cm)

A. Louvered hood style

B. Box hood style

The angled hood style (shown here) is acceptable.

4"

(10.2 cm)

2½"

(6.4 cm)

4

Page 5

n An exhaust hood should cap the vent to keep rodents and

G

insects from entering the home.

n Exhaust hood must be at least 12" (30.5 cm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

n Do not use an exhaust hood with a magnetic latch.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

Plan Vent System

Choose your exhaust installation type

Recommended exhaust installations

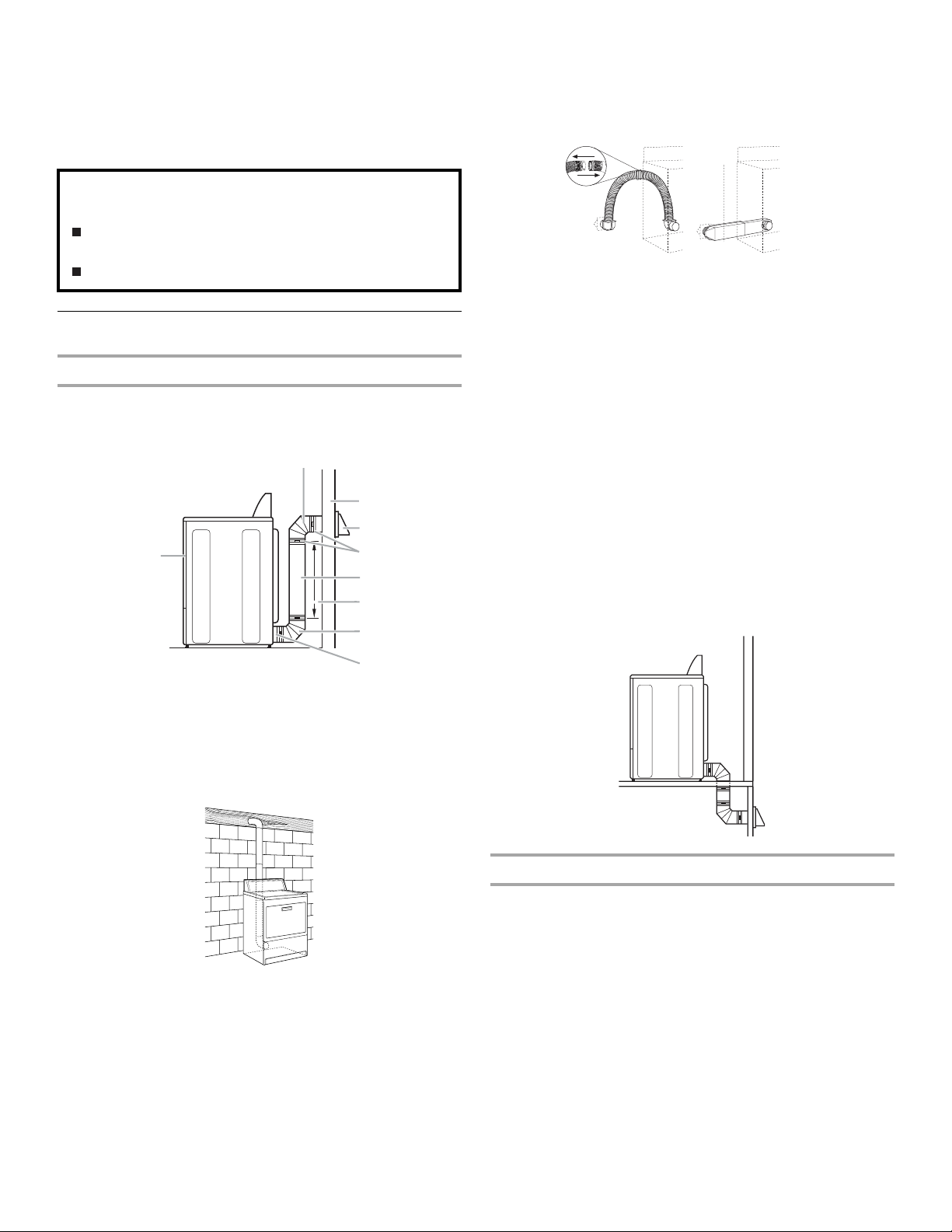

Typical installations vent the dryer from the rear of the dryer. Other

installations are possible.

B

C

D

A

E

F

B

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

A

A. Over-the-top installation (also available

with one offset elbow)

B. Periscope installation

NOTE: The following kits for close clearance alternate installations

are available for purchase. Please see the “Assistance or Service”

section of the Dryer User Instructions.

n Over-the-Top Installation:

Part Number 4396028

n Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 4396037 - 0" (0 cm) to 18" (45.72 cm) mismatch

Part Number 4396011 - 18" (45.72 cm) to 29" (73.66 cm)

mismatch

Part Number 4396014 - 29" (73.66 cm) to 50" (127 cm)

mismatch

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

B

H

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Standard exhaust installation with rigid metal or flexible

metal vent

Determine vent path

n Select the route that will provide the straightest and most

direct path outdoors.

n Plan the installation to use the fewest number of elbows and

turns.

n When using elbows or making turns, allow as much room as

possible.

n Bend vent gradually to avoid kinking.

n Use the fewest 90° turns possible.

5

Page 6

Determine vent length and elbows needed for best

drying performance

Install Leveling Legs

n Use the Vent system chart below to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified in the

Vent system chart. Exhaust systems longer than those

specified will:

n Shorten the life of the dryer.

n Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system chart provides venting requirements that will help

to achieve the best drying performance.

Vent system chart

NOTE: Side and bottom exhaust installations have a 90º turn

inside the dryer. To determine maximum exhaust length, add one

90º turn to the chart.

Number of

90º turns

or elbows

0 Rigid metal

1 Rigid metal

2 Rigid metal

3 Rigid metal

4 Rigid metal

For vent systems not covered by the vent specifications chart, see

Whirlpool Service Manual, “Exhausting Whirlpool Dryers,” Part

Number LIT603197, available from your Whirlpool parts

distributor.

Type of

vent

Flexible metal

Flexible metal

Flexible metal

Flexible metal

Flexible metal

Box or

louvered

hoods

64 ft (20 m)

36 ft (11 m)

54 ft (16.5 m)

31 ft (9.4 m)

44 ft (13.4 m)

27 ft (8.2 m)

35 ft (10.7 m)

25 ft (7.6 m)

27 ft (8.2 m)

23 ft (7 m)

Angled

hoods

58 ft (17.7 m)

28 ft (8.5 m)

48 ft (14.6 m)

23 ft (7 m)

38 ft (11.6 m)

19 ft (5.8 m)

29 ft (8.8 m)

17 ft (5.2 m)

21 ft (6.4 m)

15 ft (4.6 m)

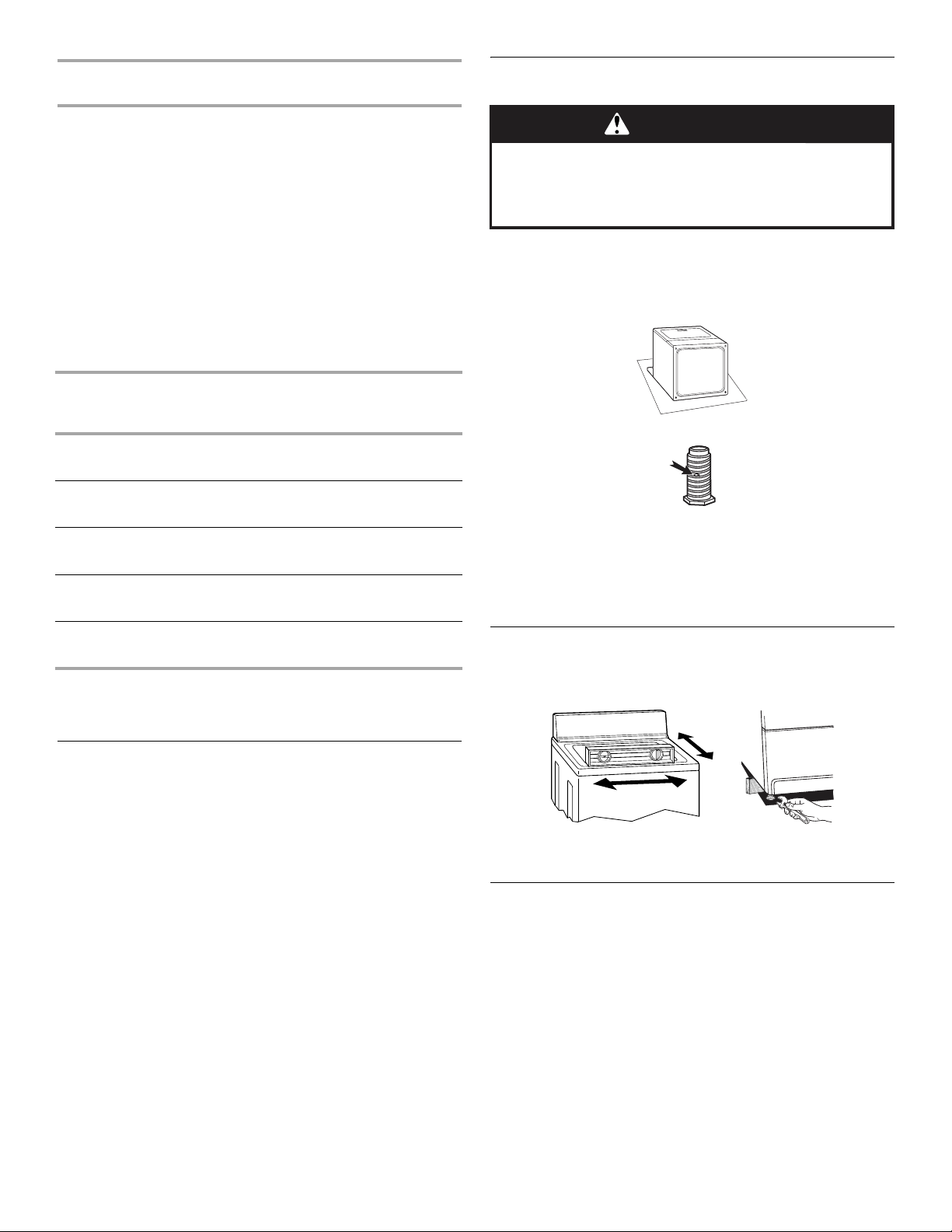

WARNING

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. To protect the floor, use a large, flat piece of cardboard from

the dryer carton. Place cardboard under the entire back side

of the dryer.

2. Firmly grasp the body of the dryer (not the top or console

panel). Gently lay the dryer on the cardboard. See illustration.

3. Examine the leveling legs. Find the diamond marking.

4. Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

5. Place a carton corner post from dryer packaging under each

of the 2 dryer back corners. Stand the dryer up. Slide the

dryer on the corner posts until it is close to its final location.

Leave enough room to connect the exhaust vent.

Level Dryer

Check the levelness of the dryer. Check levelness first side to

side, then front to back.

Install Vent System

1. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp.

3. Run vent to dryer location. Use the straightest path possible.

See “Determine vent path” in “Plan Vent System.” Avoid 90º

turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior

of the vent to secure vent.

6

If the dryer is not level, prop up the dryer using a wood block. Use

a wrench to adjust the legs up or down and check again for

levelness.

Connect Vent

1. Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Check that the vent is secured

to exhaust hood with a 4" (10.2 cm) clamp.

2. Move dryer into its final location. Do not crush or kink vent.

3. (On gas models) Check that there are no kinks in the flexible

gas line.

4. Once the exhaust vent connection is made, remove the corner

posts and cardboard.

Page 7

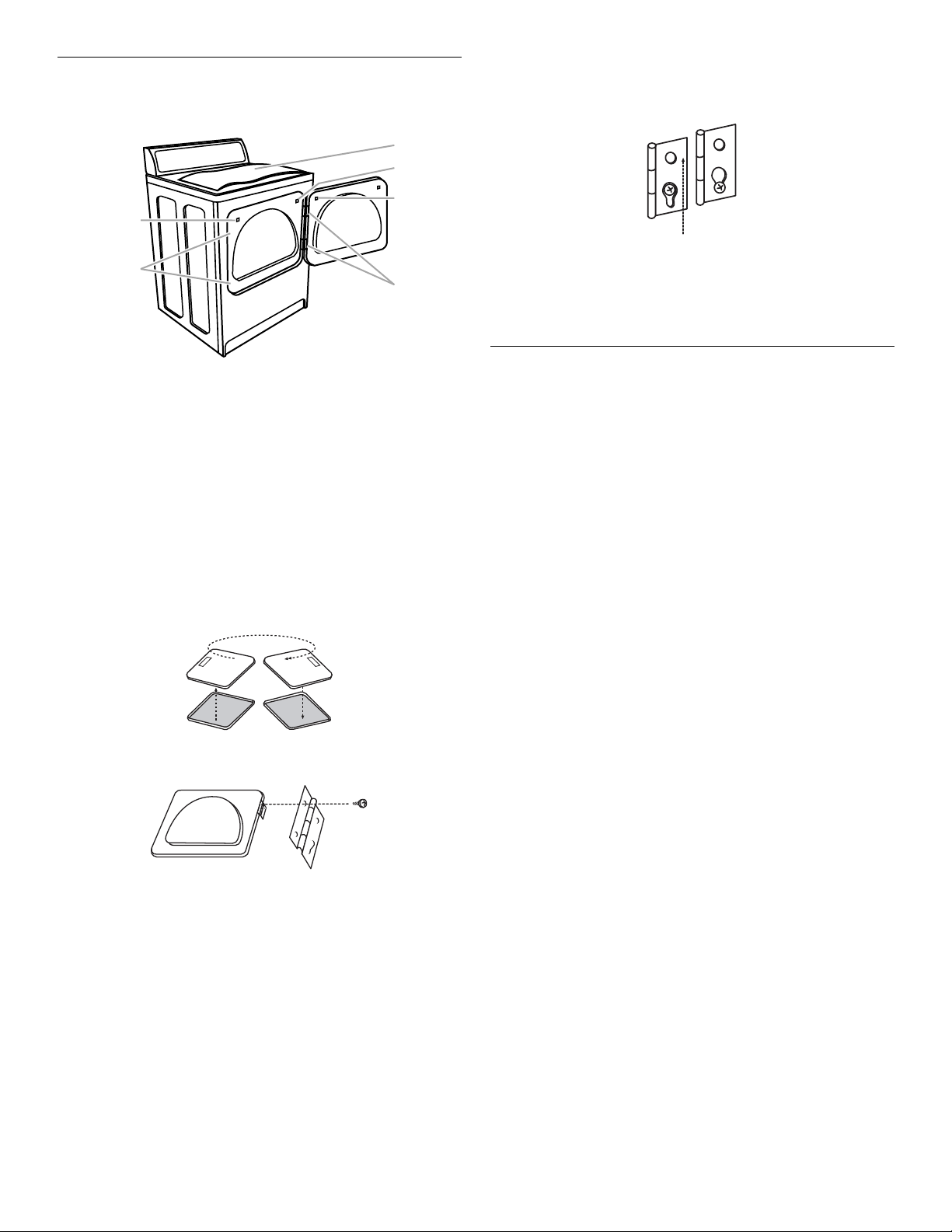

Reverse Door Swing (Optional)

A

C

D

You can change your door swing from a right-side opening to a

left-side opening, if desired.

B

E

9. Insert screws into bottom holes on left side of cabinet. Tighten

screws halfway. Position door so large end of door hinge slot

is over screws. Slide door up so screws are in bottom of slots.

Tighten screws. Insert and tighten top screws in hinges.

F

1. Place towel (A) on top of dryer to protect surface.

2. Open dryer door. Remove bottom screws from cabinet side of

hinges (D). Loosen (do not remove) top screws from cabinet

side of hinges.

3. Lift door until top screws in cabinet are in large part of hinge

slot. Pull door forward off screws. Set door (handle side up) on

top of dryer. Remove top screws from cabinet.

4. Remove screws attaching hinges to door.

5. Remove screws at top, bottom and side of door (4 screws).

Holding door over towel on dryer, grasp sides of outer door

and gently lift to separate it from inner door. Do not pry apart

with putty knife. Do not pull on door seal or plastic door

catches.

6. Be certain to keep cardboard spacer centered between doors.

Reattach outer door panel to inner door panel so handle is on

the side where hinges were just removed.

7. Attach door hinges to dryer door so that the larger hole is at

the bottom of the hinge.

8. Remove door strike (E) from cabinet. Use a small, flat-blade

screwdriver to gently remove 4 hinge hole plugs (F) on left side

of cabinet. Insert plugs into hinge holes on right side of

cabinet.

10. Remove door strike plug (B). Insert the door strike you

removed in Step 8 into hole and secure with screw. Insert door

strike plug into original door strike hole and secure with screw.

11. Close door and check that door strike aligns with door catch

(C). If it is needed, slide door catch left or right within slot to

adjust alignment.

Complete Installation

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check the dryer’s final location. Be sure the vent is not

crushed or kinked.

5. Check that the dryer is level. See “Level Dryer.”

6. Plug into a grounded 2 prong outlet. Turn on power.

7. Remove the blue protective film on the console and any tape

remaining on the dryer.

8. Read “Dryer Use” in the Dryer User Instructions.

9. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

10. Set the dryer on a full heat cycle (not an air cycle) for

20 minutes and start the dryer.

If the dryer will not start, check the following:

n Controls are set in a running or “On” position.

n Start button has been pushed firmly.

n Dryer is plugged into an outlet and/or electrical supply

is on.

n Household fuse is intact and tight, or circuit breaker has

not tripped.

n Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you feel heat, cancel cycle and

close the door.

If you do not feel heat, turn off the dryer and check the

following:

n Check that the fuse is intact and tight, or that the circuit

breaker has not tripped. If the problem continues, contact

a qualified technician.

NOTE: You may notice a burning odor when the dryer is first

heated. This odor is common when the heating element is first

used. The odor will go away.

7

Page 8

INSTRUCCIONES DE INSTALACIÓN PARA LA

SECADORA ELÉCTRICA DE 29" (73,7 CM)

SEGURIDAD DE LA SECADORA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el símbolo de advertencia de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

PELIGRO

ADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

INSTRUCCIONES DE INSTALACIÓN

Herramientas y piezas

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación. Lea y siga las instrucciones provistas con cualquiera

de las herramientas nombradas a continuación:

n Destornillador de hoja

plana

n Destornillador Phillips # 2

n Llave inglesa que se abra a

1" pulgada o una llave de

cubo de cabeza hexagonal

(para regular las patas de la

secadora)

n Llave inglesa con apertura

de ¼", o un destornillador

giratuercas con apertura

de ¼"

n Tijeras cortachapas (para

instalar el nuevo conducto

de ventilación)

n Nivel

n Abrazaderas para

ventilación

n Pistola y masilla para

calafateo (para instalar el

nuevo conducto de

escape)

n Cinta de medir

Piezas suministradas:

Retire el paquete de piezas del tambor de la secadora. Verifique

que estén todas las piezas.

4 patas niveladoras

Piezas necesarias:

Verifique los códigos locales. Verifique el suministro eléctrico

existente y la ventilación y vea “Requisitos eléctricos” y

“Requisitos de ventilación” antes de comprar las piezas.

8

Page 9

Requisitos de ubicación

ADVERTENCIA

Peligro de Explosión

Mantenga los materiales y vapores inflamables, como

la gasolina, lejos de la secadora.

Coloque la secadora a un mínimo de 46 cm sobre

el suelo para la instalación en un garaje.

No seguir estas instrucciones puede ocasionar

la muerte, explosión o incendio.

Dimensiones de la secadora

43³⁄₈"

(110 cm)

*27³⁄₄"

(70,5 cm)

29"

(73,66 cm)

22³⁄₄"

(57,8 cm)

Usted necesitará

n Una ubicación que permita una instalación adecuada del

conducto de escape. Consulte “Requisitos de ventilación”.

n Un circuito separado de 30 amperios.

n Un enchufe con conexión a tierra ubicado a unos 2 pies

(61 cm) de cualquiera de los lados de la secadora. Vea

“Requisitos eléctricos”.

n Un suelo resistente para soportar la secadora con un peso

total (secadora y carga) de 200 lbs (90,7 kg). También se debe

considerar espacio adicional para otro electrodoméstico que

le acompañe.

n Un suelo nivelado con una inclinación máxima de 1" (2,5 cm)

debajo de la secadora completa. (Si la inclinación es mayor

que 1" [2,5 cm], instale el Juego de extensión de patas de la

secadora, Pieza No. 279810.) La ropa quizás no rote

adecuadamente y los modelos con ciclos de sensor

automático posiblemente no funcionen debidamente si la

secadora no está nivelada.

No ponga a funcionar su secadora a temperaturas inferiores a

45ºF (7ºC). A temperaturas inferiores, es posible que la secadora

no se apague al final de un ciclo automático. Los tiempos de

secado pueden prolongarse.

No debe instalarse ni guardarse la secadora en un área en donde

pueda estar expuesta al agua y/o a la intemperie.

Verifique los requisitos de los códigos. Algunos códigos limitan, o

no permiten, la instalación de la secadora en garajes, armarios,

casas rodantes o en dormitorios. Póngase en contacto con el

inspector de construcciones de su localidad.

*La mayoría de las instalaciones requieren un espacio mínimo de

5" (12,7 cm) detrás de la secadora para acomodar el conducto

de escape con codo. Vea “Requisitos de ventilación”.

Espacio para la instalación en un lugar empotrado o en un

armario

Se recomiendan las siguientes medidas de espacio para esta

secadora. Esta secadora ha sido puesta a prueba para espacios

de 0" (0 cm) en los costados y en la parte posterior. El espacio

recomendado debe ser considerado por los siguientes motivos:

n Debe considerarse el espacio adicional para facilitar la

instalación y el servicio técnico.

n Se podrían necesitar espacios libres adicionales para las

molduras de la pared, puerta y suelo.

n Se debe considerar agregar espacio adicional en todos los

lados de la secadora para reducir la transferencia de ruido.

n Para la instalación en armario de una puerta, se requieren

aperturas de ventilación mínimas en la parte superior e inferior

de la puerta. Se aceptan puertas tipo persianas con aperturas

de ventilación equivalentes.

n También se debe considerar espacio adicional para otro

electrodoméstico que le acompañe.

3"*

(7,6 cm)

18"*

(45,7 cm)

14" máx.*

(35,6cm)

48 pulg.

2

(310 cm )

2

*

Espacios para la instalación

La ubicación debe ser lo suficientemente grande para poder abrir

completamente la puerta de la secadora.

1"

(2,5 cm)

29"

(73,66 cm)

A

A. Lugar empotrado

B. Vista lateral - armario o lugar confinado

C. Puerta del armario con orificios de ventilación

*Espacio necesario

1"

(2,5 cm)

1"*

(2,5 cm)

27¾"

(70,5 cm)

B

24 pulg.

(155 cm )

5"*

(12,7 cm)

2

*

2

3"*

(7,6 cm)

C

9

Page 10

Requisitos eléctricos

Usted es responsable de

n Ponerse en contacto con un instalador eléctrico calificado

para asegurarse de que la instalación eléctrica sea adecuada

y de conformidad con todos los códigos y ordenanzas

locales.

n Proveer el suministro eléctrico requerido de 2 alambres,

monofásico, de 230 voltios, 50 Hz, CA solamente, en un

circuito separado de 30 amperios. Se recomienda un fusible

retardado o un cortacircuitos. Conéctelo a un circuito

derivado individual.

ADVERTENCIA

Peligro de descarga eléctrica

Se requiere una conexión eléctrica a tierra para esta

secadora.

No conecte a tierra a una tubería de gas.

No cambie la clavija del cable de suministro de energía.

Si no cabe en el enchufe, consulte a un electricista

cualificado para instalar un enchufe adecuado.

No tenga un fusible en el circuito neutro o de conexión

a tierra.

No use un cable eléctrico de extensión con esta

secadora.

Compruebe con un electricista cualificado que la

secadora está conectada a tierra como es debido.

No conecte el extremo de la clavija del cable de

suministro eléctrico a un enchufe activado, antes de

conectar el cable de suministro eléctrico al terminal de

la secadora.

No vuelva a usar un cable de suministro eléctrico viejo.

No seguir estas instrucciones puede ocasionar la

muerte, incendio o lesiones graves.

n Para reducir al mínimo el peligro de posibles descargas

eléctricas, el cable debe ser enchufado en un enchufe

apropiado. Cerciórese de que haya un enchufe de pared

dentro del alcance de la ubicación final de la secadora.

Para obtener información sobre la compra de piezas, vea la

sección “Ayuda o servicio técnico” en las Instrucciones para el

usuario de la secadora.

INSTRUCCIONES DE PUESTA A TIERRA

■

Para la conexión de una secadora mediante cable

eléctrico conectado a tierra:

Esta secadora debe estar conectada a tierra. En el caso de

funcionamiento defectuoso o avería, la conexión a tierra

reducirá el riesgo de descarga eléctrica al proporcionar una

vía de menor resistencia para la corriente eléctrica. La

clavija del cable de suministro eléctrico debe conectarse a

un enchufe apropiado, que esté debidamente instalado y

conectado a tierra de acuerdo con todos los códigos y

ordenanzas locales.

ADVERTENCIA: La conexión inadecuada del

conductor a tierra del equipo puede provocar riesgo de

descarga eléctrica. Si no está seguro de que la conexión a

tierra de la secadora es la adecuada, verifíquela con un

electricista o representante o personal de servicio

cualificado. No modifique la clavija del cable de suministro

eléctrico provisto con la secadora: si no cabe en el enchufe,

consulte a un electricista cualificado para instalar un

enchufe adecuado.

GUARDE ESTAS INSTRUCCIONES

Requisitos de ventilación

ADVERTENCIA

Peligro de Incendio

Use un conducto de escape de metal pesado.

No use un conducto de escape de plástico.

No use un conducto de escape de aluminio.

No seguir estas instrucciones puede ocasionar

la muerte o incendio.

ADVERTENCIA: Para reducir el riesgo de incendio, esta

secadora DEBE TENER SALIDA DE VENTILACIÓN AL EXTERIOR.

IMPORTANTE: Observe todas las normas y ordenanzas vigentes.

El conducto de escape de la secadora no debe conectarse en

ningún conducto de escape de gas, chimenea, pared, techo o el

espacio oculto de un edificio.

10

Si usa un sistema de ventilación existente

n Limpie la pelusa que está en toda la longitud del sistema y

asegúrese de que la capota de ventilación no esté obstruida

con pelusa.

n Reemplace cualquier conducto de escape de plástico o de

hoja de metal por uno de metal pesado rígido o flexible.

n Vuelva a consultar el cuadro del sistema de ventilación.

Modifique el sistema de ventilación existente si fuera

necesario para lograr el mejor rendimiento de la secadora.

Page 11

Si éste es un nuevo sistema de ventilación

G

Material de ventilación

n Use un conducto de escape de metal pesado. No use

conducto de escape de plástico o de hoja de metal.

n Se debe usar un conducto de escape de metal pesado de

4" (10,2 cm) y abrazaderas.

4"

10,2 cm

Conducto de escape de metal pesado de 4" (10,2 cm)

Para más información, vea la sección “Ayuda o servicio

técnico” de las Instrucciones para el usuario de la secadora.

Conducto de escape de metal rígido

n Para un óptimo rendimiento de secado, se recomiendan

conductos de escape de metal rígido.

n Se recomienda el ducto de escape de metal rígido para evitar

que se aplaste o se tuerza.

Ducto de escape de metal flexible

n Los ductos de escape de metal flexible son aceptables

únicamente si se puede acceder a los mismos para limpiarlos.

n El ducto de escape de metal flexible debe extenderse y

sostenerse por completo cuando la secadora está en su

ubicación final.

n Quite el exceso del ducto de metal flexible para evitar que se

doble y se tuerza, lo cual podría dar lugar a una reducción del

flujo de aire y a un rendimiento insuficiente.

n No instale el ducto de escape de metal flexible en paredes,

techos o suelos confinados.

Codos

Los codos de 45° proveen un mejor flujo de aire que los

codos de 90°.

Respiradero

Los estilos recomendados de capotas de ventilación se

ilustran aquí.

B

A

4"

(10,2 cm)

4"

(10,2 cm)

A. Estilo de capota con ventilación tipo persiana

B. Estilo de capota con ventilación tipo caja

El estilo de capota de ventilación angular (que se ilustra aquí)

es aceptable.

4"

(10,2 cm)

2½"

(6,4 cm)

n Una capota de ventilación debe tapar el conducto de escape

para evitar la entrada de roedores e insectos a la casa.

n La capota de ventilación debe estar por lo menos a

12" (30,5 cm) de distancia del suelo o de cualquier objeto que

pudiese estar en el trayecto del ducto de escape (como flores,

rocas o arbustos, límite de nieve, etc).

n No use capotas de ventilación con pestillos magnéticos.

La ventilación inadecuada puede ocasionar la

acumulación de humedad y pelusa en la casa, lo cual

puede dar como resultado:

Daños de humedad en la carpintería, muebles, pintura,

empapelado, alfombras, etc.

Problemas en la limpieza de la casa y de salud.

Bien Mejor

Abrazaderas

n Utilice abrazaderas para sellar todas las juntas.

n No debe conectarse ni asegurarse el conducto de escape con

tornillos ni con ningún otro dispositivo de sujeción que se

extienda hacia el interior de dicho conducto. No utilice cinta

adhesiva para conductos.

Abrazadera

Planificación del sistema de ventilación

Seleccione su tipo de instalación de ventilación

Instalaciones recomendadas de escape

Las instalaciones típicas tienen la ventilación en la parte posterior

de la secadora. Otras instalaciones son posibles.

B

C

D

A

A. Secadora

B. Codo

C. Pared

D. Capota de ventilación

E. Abrazaderas

F. Conducto de metal rígido o de metal

flexible

G. Longitud necesaria del conducto de

escape para conectar los codos

H. Salida de ventilación

E

F

B

H

11

Page 12

Instalación con salida de ventilación estándar con un

conducto de escape de metal rígido o flexible

Determinación de la vía del conducto de escape

n Seleccione la vía que proporcione el trayecto más recto y

directo al exterior.

n Planifique la instalación a fin de usar el menor número posible

de codos y vueltas.

n Cuando use los codos o haga vueltas, deje todo el espacio

que sea posible.

n Doble el ducto gradualmente para evitar torceduras.

n Use la menor cantidad posible de vueltas de 90°.

Instalaciones alternas para espacios limitados

Los sistemas de ventilación vienen en una amplia gama.

Seleccione el tipo más apropiado para su instalación. A

continuación se ilustran dos tipos de instalación para espacios

limitados. Consulte las instrucciones del fabricante.

A

A. Instalación en la parte superior (también está

disponible con un codo de desviación)

B. Instalación de periscopio

B

NOTA: Se pueden adquirir los siguientes juegos para

instalaciones alternas en espacios limitados. Por favor vea la

sección “Ayuda o servicio técnico” en las Instrucciones para el

usario de la secadora.

n Instalación en la parte superior:

Pieza número 4396028

n Instalación de periscopio (Para usar si hay discordancia entre

el conducto de escape de la pared y el conducto de

ventilación de la secadora):

Pieza número 4396037 - Discordancia de 0" (0 cm) a

18" (45,72 cm).

Pieza número 4396011 - Discordancia de 18" (45,72 cm) a 29"

(73,66 cm).

Pieza número 4396014 - Discordancia de 29" (73,66 cm) a 50"

(127 cm).

Previsiones especiales para las instalaciones en casas

rodantes

El ducto de escape deberá sujetarse firmemente en un lugar no

inflamable de la estructura de la casa rodante y no debe terminar

debajo de la casa rodante. El conducto de escape debe terminar

en el exterior.

Determinación de la longitud del conducto de escape y

de los codos necesarios para obtener un óptimo

rendimiento de secado

n Use el cuadro del sistema de ventilación a continuación para

determinar el tipo de material para conducto y la combinación

de capota aceptable a usar.

NOTA: No use tendidos de conducto de escape más largos

que los especificados en el cuadro del sistema de ventilación.

Los sistemas de ventilación más largos que los especificados:

n Acortarán la vida de la secadora.

n Reducirán el rendimiento, dando lugar a tiempos de

secado más largos y un aumento en el consumo de

energía.

El cuadro del sistema de ventilación indica los requisitos de

ventilación que le ayudarán a alcanzar el mejor rendimiento de

secado.

Cuadro del sistema de ventilación

NOTA: Las instalaciones de ventilación laterales e inferiores

tienen una vuelta de 90º dentro de la secadora. Para determinar la

longitud máxima de ventilación, agregue una vuelta de 90º al

cuadro.

No. de

vueltas

Tipo de

conducto

de 90º o

codos

0 Metal rígido

Metal flexible

1 Metal rígido

Metal flexible

2 Metal rígido

Metal flexible

3 Metal rígido

Metal flexible

4 Metal rígido

Metal flexible

Capotas de

ventilación de

caja o tipo

persianas

64 pies (20 m)

36 pies (11 m)

54 pies (16,5 m)

31 pies (9,4 m)

44 pies (13,4 m)

27 pies (8,2 m)

35 pies (10,7 m)

25 pies (7,6 m)

27 pies (8,2 m)

23 pies (7 m)

Capotas

angulares

58 pies (17,7 m)

28 pies (8,5 m)

48 pies (14,6 m)

23 pies (7 m)

38 pies (11,6 m)

19 pies (5,8 m)

29 pies (8,8 m)

17 pies (5,2 m)

21 pies (6,4 m)

15 pies (4,6 m)

12

Para los sistemas de escape que no estén cubiertos en el cuadro

de especificación de la ventilación, vea el Manual de servicio de

Whirlpool, “Ventilación de secadoras Whirlpool”, Pieza N°

LIT603197, disponible en el distribuidor de partes Whirlpool.

Page 13

Instalación del sistema de ventilación

A

C

D

1. Instale la capota de ventilación. Emplee una masilla de

calafateo para sellar la apertura de la pared externa alrededor

de la capota de ventilación.

2. Conecte el conducto de escape a la capota de ventilación. El

conducto de escape debe encajar dentro de la capota de

ventilación. Asegure el conducto de escape a la capota de

ventilación con una abrazadera de 4" (10,2 cm).

3. Extienda el conducto de escape a la ubicación de la

secadora. Use la trayectoria más recta posible. Vea

“Determinación de la vía del ducto de escape” en

“Planificación del sistema de ventilación”. Evite giros de 90º.

Use abrazaderas para sellar todas las juntas. No use cinta

adhesiva para conductos, tornillos ni otros dispositivos de

fijación que se extiendan dentro del conducto de escape, para

fijar el mismo.

Nivelación de la secadora

Revise la nivelación de la secadora. Verifique primero de lado a

lado y luego del frente hacia atrás.

Si la secadora no está nivelada, apuntale la secadora, usando un

bloque de madera. Use una llave inglesa para regular las patas

hacia arriba o hacia abajo y verifique nuevamente si la secadora

está nivelada.

Instalación de las patas niveladoras

ADVERTENCIA

Peligro de Peso Excesivo

Son necesarias dos o más personas para mover e

instalar la secadora.

No seguir esta instrucción puede ocasionar una

lesión en la espalda u otro tipo de lesiones.

1. Para proteger el suelo, use un pedazo de cartón grande y

plano del embalaje de la secadora. Coloque el cartón debajo

de todo el borde posterior de la secadora.

2. Sujete con firmeza el cuerpo de la secadora (no la parte

superior o el panel de la consola). Coloque la secadora

cuidadosamente sobre el cartón. Vea la ilustración.

3. Examine las patas niveladoras. Localice la marca en forma de

diamante.

Conexión del conducto de escape

1. Usando una abrazadera de 4" (10,2 cm), conecte el conducto

de escape a la salida de aire de la secadora. Si se conecta a

un conducto de escape existente, asegúrese de que el mismo

esté limpio. El conducto de escape de la secadora debe

encajar sobre la salida de aire de la secadora y dentro de la

capota de ventilación. Cerciórese de que el conducto de

escape esté asegurado a la capota de ventilación con una

abrazadera de 4" (10,2 cm).

2. Mueva la secadora a su posición final. No aplaste ni retuerza

el conducto de escape.

3. (En modelos a gas) Asegúrese de que no hayan torceduras en

la línea de gas flexible.

4. Una vez que la conexión del conducto de escape esté lista,

quite los esquinales y el cartón.

Cómo invertir el cierre de la puerta

(opcional)

Si lo desea, puede cambiar la dirección del cierre de la puerta del

lado derecho al lado izquierdo.

B

E

4. Atornille con la mano las patas en los orificios de las patas.

Use una llave inglesa para terminar de atornillar las patas

hasta que la marca en forma de diamante no quede visible.

5. Coloque un esquinal de cartón del embalaje de la secadora

debajo de cada una de las 2 esquinas posteriores de la

secadora. Ponga la secadora de pie. Deslice la secadora

sobre los postes esquinales hasta que quede cerca de su

ubicación final. Deje suficiente espacio para conectar el

conducto de escape.

F

1. Coloque una toalla (A) encima de la secadora para proteger la

superficie.

2. Abra la puerta de la secadora. Extraiga los tornillos inferiores

de las bisagras del lado del gabinete (D). Afloje (no extraiga)

los tornillos superiores de las bisagras del lado del gabinete.

3. Levante la puerta hasta que los tornillos inferiores del

gabinete estén en la parte grande de la ranura de la bisagra.

Tire de la puerta hacia adelante para separarla de los tornillos.

Coloque la puerta (con el lado de la manija hacia arriba)

encima de la secadora. Extraiga los tornillos superiores del

gabinete.

4. Extraiga los tornillos que unen a las bisagras con la puerta.

13

Page 14

5. Extraiga los tornillos en la parte superior, inferior y lateral de la

puerta (4 tornillos). Sosteniendo la puerta sobre la toalla en la

secadora, sujete los costados de la parte exterior de la puerta

y levante cuidadosamente para separarla de la parte interior

de la puerta. No los separe utilizando una espátula. No tire del

burlete de la puerta ni de los ganchos plásticos de la misma.

6. Asegúrese de mantener los espaciadores de cartón centrados

entre las puertas. Vuelva a unir el panel exterior de la puerta al

panel interior de la misma de manera que la manija se

encuentre en el lado de donde se acaban de extraer las

bisagras.

7. Fije las bisagras de la puerta a la puerta de la secadora de

manera que el orificio más grande quede en la parte inferior

de la bisagra.

8. Extraiga el tope de la puerta (E) del gabinete. Use un

destornillador pequeño de hoja plana para quitar

cuidadosamente los 4 tapones para los orificios de la bisagra

(F) que se encuentran al lado izquierdo del gabinete.

Introduzca los tapones en los orificios de la bisagra en el lado

derecho del gabinete.

9. Introduzca los tornillos en los orificios inferiores en el lado

izquierdo del gabinete. Atorníllelos por la mitad. Coloque la

puerta de tal forma que el extremo grande de la ranura de la

bisagra esté sobre los tornillos. Deslice la puerta hacia arriba

para que los tornillos estén en la parte de abajo de las

ranuras. Apriete los tornillos. Introduzca y apriete los tornillos

superiores en las bisagras.

Complete la instalación

1. Compruebe de que todas las piezas estén instaladas. Si hay

alguna pieza extra, vuelva a revisar todos los pasos para ver

cuál se omitió.

2. Verifique si tiene todas las herramientas.

3. Deshágase de todos los materiales de embalaje o recíclelos.

4. Revise la ubicación final de la secadora. Asegúrese de que el

ducto de escape no esté aplastado o retorcido.

5. Verifique si la secadora está nivelada. Vea “Nivelación de la

secadora”.

6. Conecte la secadora a un enchufe con dos orificios y

conexión a tierra. Encienda la secadora.

7. Quite la película protectora azul que está en la consola y

cualquier cinta adhesiva que haya quedado en la secadora.

8. Lea “Uso de la secadora” en las Instrucciones para el usuario

de la secadora.

9. Limpie el interior del tambor de la secadora meticulosamente

con un paño húmedo para quitar residuos de polvo.

10. Fije la secadora en un ciclo completo de calor (no en un ciclo

de aire) por 20 minutos y póngala en marcha.

Si la secadora no funciona, revise lo siguiente:

n Que los controles estén fijados en una posición de

funcionamiento o encendido (“On”).

n Que se haya presionado con firmeza el botón de puesta

en marcha.

n Que la secadora esté conectada a un enchufe y/o el

suministro de energía eléctrica está encendido.

n Que el fusible de la casa esté intacto y ajustado, o que no

se haya disparado el cortacircuitos.

n Que la puerta de la secadora esté cerrada.

11. Después de que la secadora haya estado funcionando

durante 5 minutos, abra la puerta y fíjese si está caliente. Si

siente calor, cancele el ciclo y cierre la puerta.

Si no está caliente, apague la secadora y revise lo

siguiente:

n Compruebe que el fusible de la casa esté intacto y

ajustado, o que no se haya disparado el cortocircuitos. Si

el problema continúa, póngase en contacto con un

técnico cualificado.

NOTA: Cuando la secadora se caliente por primera vez quizás

sienta un olor a quemado. Este olor es común cuando se usa por

primera vez el elemento de calefacción. El olor desaparecerá.

10. Extraiga el tapón del tope de la puerta (B). Introduzca el tope

de la puerta que usted quitó en el paso 8 en el orificio, y

asegúrelo con un tornillo. Introduzca el tapón del tope de la

puerta en el orificio original del tope de la puerta y asegúrelo

con un tornillo.

11. Cierre la puerta y asegúrese de que el tope de la misma esté

alineado con el gancho de la puerta (C). Si es necesario,

deslice el gancho de la puerta hacia la izquierda o derecha

dentro de la ranura a fin de ajustar la alineación.

14

Page 15

INSTRUCTIONS POUR L’INSTALLATION DU SECHE-LINGE

ELECTRIQUE DE 29" (73,7 CM)

SECURITE DU SECHE-LINGE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

INSTRUCTIONS D’INSTALLATION

Outillage et pièces nécessaires

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et suivre les instructions fournies avec les outils

indiqués ici.

n Tournevis à lame plate

n Tournevis Phillips n

n Clé à molette avec

ouverture jusqu’à 1" ou

clé à douille hexagonale

(pour ajuster les pieds du

sèche-linge)

n Tourne-écrou ou clé à

douille de ¼"

n Cisaille de ferblantier

(pour l’installation d’un

nouveau conduit)

o

2

n Niveau

n Brides de serrage pour

conduit d’évacuation

n Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation d’un

nouveau circuit

d'évacuation)

n Mètre ruban

Pièces fournies :

Retirer le sachet de pièces du tambour du sèche-linge. Vérifier

que toutes les pièces de la liste sont présentes.

4 pieds de nivellement

Pièces nécessaires :

Consulter les codes locaux, vérifier l’alimentation électrique et le

circuit d’évacuation existants, et consulter les sections

“Installations électriques” et “Exigences concernant l’évacuation”

avant d’acheter les pièces nécessaires.

15

Page 16

Exigences d’emplacement

)

AVERTISSEMENT

Risque d'explosion

Garder les matières et les vapeurs inflammables, telle

que l’essence, loin du sèche-linge.

Placer le sèche-linge au moins 46 cm au-dessus du

plancher pour une installation dans un garage.

Le non-respect de ces instructions peut causer un

décès, une explosion ou un incendie.

Dimensions du sèche-linge

43³⁄₈"

(110 cm)

*27³⁄₄"

(70,5 cm)

29"

(73,66 cm)

22³⁄₄"

(57,8 cm)

On a besoin de

n Un emplacement permettant une évacuation appropriée. Voir

“Exigences concernant l'évacuation”.

n Un circuit séparé de 30 ampères.

n Une prise électrique avec liaison à la terre située à moins de

2 pi (61 cm) de l’un des côtés du sèche-linge. Voir

“Spécifications électriques”.

n Un plancher robuste capable de supporter un poids total

(sèche-linge et charge) de 200 lb (90,7 kg). Le poids combiné

d’un appareil voisin doit également être pris en compte.

n Un plancher horizontal avec une pente maximale de

1" (2,5 cm) sous l’ensemble du sèche-linge. (Si la pente est

supérieure à 1" [2,5 cm], installer l’ensemble de pieds longs

o

n

de pièce 279810.) Si le sèche-linge n’est pas d’aplomb, le

linge peut ne pas culbuter convenablement et les

programmes commandés par des détecteurs automatiques

peuvent ne pas fonctionner correctement.

Ne pas faire fonctionner le sèche-linge à une température

inférieure à 45ºF (7ºC). A des températures inférieures, le

sèche-linge risque de ne plus s’arrêter à la fin d’un programme

automatique. Les temps de séchage risquent alors d’augmenter.

Le sèche-linge ne doit pas être installé ou remisé dans un endroit

où il sera exposé à l’eau et/ou aux intempéries.

Vérifier les règlements locaux. Certains codes limitent ou

n’autorisent pas l’installation des sèche-linge dans un garage, un

placard, une maison mobile ou une chambre à coucher.

Communiquer avec l’inspecteur des bâtiments local.

Dégagements de séparation à respecter

L’emplacement doit être assez grand pour permettre d’ouvrir

complètement la porte du sèche-linge.

*La plupart des installations requièrent un espace minimum de

5" (12,7 cm) derrière le sèche-linge pour le conduit d’évacuation

avec coude. Voir “Exigences concernant l'évacuation”.

Espacement minimum pour une installation dans un

encastrement ou dans un placard

On recommande les dimensions d'espacement suivantes pour ce

sèche-linge. Ce sèche-linge a été testé pour une installation avec

dégagement de 0" (0 cm) sur les côtés et à l'arrière.

L'espacement recommandé doit être considéré pour les raisons

suivantes :

n On prévoira un peu plus d’espace pour faciliter l’installation et

l’entretien.

n Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

n Un espace supplémentaire de tous les côtés du sèche-linge

est recommandé pour réduire le transfert du bruit.

n Si une porte de placard est installée (pour une installation

encastrée), on doit prévoir des orifices d’entrée d’air en haut

et en bas de la porte. Les portes à claire-voie offrant une

surface équivalente de passage de l’air sont acceptables.

n Il faut aussi prendre en compte l’espace requis entre les

appareils voisins.

3"*

(7,6 cm

3"*

(7,6 cm)

18"*

(45,7 cm)

1"

(2,5 cm)

29"

(73,66 cm)

A

1"

(2,5 cm)

1"*

(2,5 cm)

14" max*

(35,6cm)

27¾"

(70,5 cm)

B

48 po

(310 cm )

24 po

(155 cm )

5"*

(12,7 cm)

2

*

2

2

*

2

C

16

A. Encastrement

B. Vue latérale – placard ou endroit exigu

C. Porte du placard avec orifices d’entrée d’air

*Espacement requis

Page 17

Spécifications électriques

C’est à l’utilisateur qu’incombe la responsabilité de

n Contacter un installateur qualifié pour s’assurer que

l’installation électrique réponde à tous les codes et

réglements locaux.

n S'assurer que l'appareil est alimenté uniquement par un circuit

monophasé à 2 fils de 230 V CA, 50 Hz, sur un circuit séparé à

30 ampères. On recommande l’emploi d’un disjoncteur ou

fusible temporisé. On recommande également que cet

appareil soit alimenté par un circuit indépendant.

AVERTISSEMENT

Risque de choc électrique

Ce sèche-linge doit être relié à la terre.

Ne pas utiliser une tuyauterie de gaz pour le

raccordement à la terre.

Ne pas changer la prise du cordon d'alimentation. Si

elle ne correspond pas à la prise de sortie, faire

installer la prise appropriée par un électricien qualifié.

Ne pas avoir de fusible dans le circuit neutre ou de

liaison à la terre.

Ne pas utiliser un câble de rallonge avec ce sèchelinge.

Consulter un électricien qualifié pour s'assurer que le

sèche-linge est correctement relié à la terre.

Ne pas connecter le cordon d'alimentation à une prise

sous tension avant de le connecter au boîtier de

connexion du sèche-linge.

Ne pas réutiliser un cordon d'alimentation usagé.

Le non-respect de ces instructions peut causer un

décès, un incendie ou une blessure grave.

n Pour minimiser les risques de choc électrique, le cordon

d’alimentation électrique doit être branché sur une prise de

courant appropriée. Veiller à ce que la prise murale se trouve à

proximité de l'emplacement définitif du sèche-linge.

Pour des renseignements sur la commande de pièces, consulter

la section “Assistance ou service” qui se trouve dans les

Instructions d’utilisation du sèche-linge.

INSTRUCTIONS DE LIAISON À LA TERRE

■

Pour un sèche-linge relié à la terre et connecté par un

cordon :

Ce sèche-linge doit être relié à la terre. En cas d'anomalie

de fonctionnement ou de panne, la liaison à la terre réduira

le risque de choc électrique en offrant au courant électrique

un itinéraire d'évacuation de moindre résistance.

La fiche doit être branchée sur une prise de courant

appropriée qui est bien installée et reliée à la terre

conformément à tous les codes et règlements locaux.

AVERTISSEMENT : Un raccordement inapproprié

du conducteur de liaison à la terre peut causer un risque de

choc électrique.En cas de doute concernant la liaison à la

terre du sèche-linge, consulter un électricien qualifié, un

agent ou personnel d'entretien. Ne pas modifier la fiche

fournie avec le sèche-linge; si elle ne s'adapte pas à la

prise, faire installer une prise appropriée par un électricien

qualifié.

CONSERVEZ CES INSTRUCTIONS

Exigences concernant l'évacuation

AVERTISSEMENT

Risque d’incendie

Utiliser un conduit d’évacuation en métal lourd.

Ne pas utiliser un conduit d’évacuation en plastique.

Ne pas utiliser un conduit d’évacuation en feuille

de métal.

Le non-respect de ces instructions peut causer

un décès ou un incendie.

AVERTISSEMENT : Pour réduire le risque d'incendie, ce

sèche-linge doit EVACUER L'AIR A L'EXTERIEUR.

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur.

Le conduit d'évacuation du sèche-linge ne doit pas être connecté

à une évacuation de gaz, une cheminée, un mur, un plafond ou un

vide de construction.

En cas d'utilisation du système d'évacuation existant

n Eliminer la charpie sur toute la longueur du système et veiller à

ce que le clapet de décharge ne soit pas obstrué par une

accumulation de charpie.

n Remplacer tout conduit de plastique ou de feuille métallique

par un conduit de métal lourd rigide ou souple.

n Examiner le tableau de longueur du conduit d'évacuation.

Apporter les modifications nécessaires au système

d'évacuation pour atteindre le meilleur rendement de

séchage.

17

Page 18

En cas de nouveau système d'évacuation

Matériel pour l'évacuation

n Utiliser un conduit d'évacuation en métal lourd. Ne pas utiliser

un conduit de plastique ou en feuille métallique.

n Utiliser un conduit d'évacuation en métal lourd de 4" (10,2 cm)

et des brides de serrage.

4"

10,2 cm

Conduit d'évacuation en métal lourd de 4" (10,2 cm)

Pour plus de renseignements, voir la section “Assistance ou

service” dans les instructions d'utilisation du sèche-linge.

Conduit métallique rigide

n Pour un meilleur rendement de séchage, on recommande

d'utiliser des conduits métalliques rigides.

n On recommande d'utiliser un conduit métallique rigide pour

réduire les risques d'écrasement et de déformation.

Conduit métallique flexible

n Les conduits métalliques flexibles sont acceptables

seulement dans la mesure où ils sont accessibles en vue du

nettoyage.

n Un conduit métallique flexible doit être totalement déployé et

soutenu lorsque le sèche-linge est à sa position finale.

n Enlever tout excès de conduit flexible pour éviter tout

affaissement ou déformation susceptible de réduire la

capacité d'évacuation et le rendement.

n Ne pas installer le conduit métallique flexible dans les cavités

fermées des murs, plafonds ou planchers.

Coudes

Les coudes à 45° permettent une meilleure circulation de l'air

que les coudes à 90°.

Brides de serrage

n Utiliser des brides pour sceller tous les joints.

n Le conduit d'évacuation ne doit pas être connecté ou fixé

avec des vis ou avec tout autre dispositif de serrage qui se

prolonge à l'intérieur du conduit. Ne pas utiliser de ruban

adhésif pour conduit.

Bride de serrage

Evacuation

Les styles de clapets recommandés sont illustrés ci-dessous.

B

A

4"

(10,2 cm)

4"

(10,2 cm)

A. Clapet à persiennes

B. Clapet de type boîte

Le clapet incliné de type boîte ci-dessous est acceptable.

4"

(10,2 cm)

2½"

(6,4 cm)

n Terminer le conduit d'évacuation par un clapet de décharge

pour empêcher les rongeurs et insectes d'entrer dans

l'habitation.

n Le clapet de décharge doit être situé à au moins 12" (30,5 cm)

au-dessus du sol ou de tout autre objet susceptible de se

trouver sur le trajet de l'air humide rejeté (par exemple, fleurs,

roches ou arbustes, limite de la neige, etc.)

n Ne pas utiliser un clapet d'évacuation à fermeture

magnétique.

18

Bon Meilleur

Une mauvaise évacuation de l'air peut causer de

l'humidité et une accumulation de charpie à l'intérieur de

la maison, ce qui peut provoquer :

Dommages par l'humidité aux boiseries, meubles, peinture,

papier-peint, tapis, etc.

Problèmes de nettoyage dans la maison et problèmes

de santé.

Page 19

Planification du système d’évacuation

G

Choisir un type de système d’évacuation

Installations d’évacuation recommandées

Les installations typiques consistent à acheminer le conduit

d’évacuation à l’arrière du sèche-linge. D'autres installations sont

possibles.

B

C

D

A

A. Sèche-linge

B. Coude

C. Mur

D. Clapet de décharge

E. Brides

F. Conduit métallique rigide ou souple

G. Longueur de conduit nécessaire pour

raccorder les coudes

H. Bouche de décharge

E

F

B

H

n Installation de périscope (pour l’utilisation en cas de non-

concordance de la bouche de décharge du sèche-linge avec

le clapet) :

Pièce numéro 4396037 - 0" (0 cm) à 18" (45,72 cm) de

décalage

Pièce numéro 4396011 - 18" (45,72 cm) à 29" (73,66 cm) de

décalage

Pièce numéro 4396014 - 29" (73,66 cm) à 50" (127 cm) de

décalage

Dispositions spéciales pour les installations dans une

maison mobile

Le système d'évacuation doit être solidement fixé à une section

non combustible de la structure de la maison mobile et ne doit

pas se terminer en-dessous de la maison mobile. Faire en sorte

que le système d'évacuation se termine à l'extérieur.

Installations standard du conduit d’évacuation à l’aide d’un

conduit métallique rigide ou souple

Autres installations où le dégagement est réduit

Il existe de nombreux types de systèmes d’évacuation. Choisir le

type qui convient le mieux à l’installation. Deux installations à

dégagement réduit sont illustrées. Voir les instructions du

fabricant.

A

A. Installation au-dessus du sèche-linge (aussi disponible

avec un coude décalé)

B. Installation de périscope

REMARQUE : On peut acheter les trousses suivantes pour les

installations où le dégagement est réduit. Veuillez consulter la

section “Assistance ou service” dans les Instructions pour

l’utilisateur du sèche-linge.

n Installation au-dessus du sèche-linge :

Pièce numéro 4396028

B

Déterminer l'itinéraire d'acheminement du conduit

n Choisir l'itinéraire d'acheminement vers l'extérieur qui sera le

plus direct et le plus rectiligne.

n Planifier l'installation pour introduire le nombre minimal de

coudes et de changements de direction.

n Si des coudes ou des changements de direction sont utilisés,

prévoir autant d'espace que possible.

n Plier le conduit graduellement pour éviter de le déformer.

n Utiliser le moins possible de changements de direction à 90°.

Déterminer la longueur du conduit et les coudes

nécessaires pour la meilleure performance de séchage

n Utiliser le tableau des systèmes d'évacuation ci-dessous pour

déterminer le type de matériel à utiliser pour le conduit et les

combinaisons de clapet acceptables.

REMARQUE : Ne pas utiliser un conduit de longueur

supérieure à la valeur spécifiée dans le tableau des systèmes

d'évacuation. Si la longueur du circuit est supérieure à la

valeur spécifiée dans le tableau, on observera :

n Une réduction de la longévité du sèche-linge.

n Une réduction du rendement, avec temps de séchage

plus longs et une plus grande consommation d'énergie.

Le tableau des systèmes d'évacuation fournit les exigences

d'évacuation qui vous aideront à atteindre la meilleure

performance de séchage.

19

Page 20

Tableau des systèmes d'évacuation

REMARQUE : Les installations d’évacuation du conduit par le

côté ou par le bas comportent un changement de direction à 90º

à l’intérieur du sèche-linge. Pour établir la longueur maximale du

conduit, ajouter un changement de direction à 90º au tableau.

Nombre de

changements de

direction à

90° ou

coudes

0 Métallique

1 Métallique

Type de

conduit

rigide

Métallique

souple

rigide

Métallique

souple

Clapets de

type boîte ou

à persiennes

64 pi (20 m)

36 pi (11 m)

54 pi (16,5 m)

31 pi (9,4 m)

Clapets

inclinés

58 pi (17,7 m)

28 pi (8,5 m)

48 pi (14,6 m)

23 pi (7 m)

Installation des pieds de nivellement

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer le sèche-linge.

Le non-respect de cette instruction peut causer

une blessure au dos ou d’autre blessure.

1. Pour protéger le sol, utiliser un grand morceau de l’emballage

en carton du sèche-linge. Placer le carton sous le bord arrière

du sèche-linge.

2. Saisir fermement le sèche-linge par la caisse (ni par le dessus

ni par le panneau de commande). Déposer délicatement le

sèche-linge sur le carton. Voir l’illustration.

2 Métallique

rigide

Métallique

souple

3 Métallique

rigide

Métallique

souple

4 Métallique

rigide

Métallique

souple

Pour les systèmes d’évacuation non illustrés dans le tableau des

spécifications, voir dans le Manuel d’entretien Whirlpool la section

“Evacuation des sèche-linge Whirlpool”, pièce n° LIT603197,

disponible chez votre revendeur de pièces Whirlpool.

44 pi (13,4 m)

27 pi (8,2 m)

35 pi (10,7 m)

25 pi (7,6 m)

27 pi (8,2 m)

23 pi (7 m)

38 pi (11,6 m)

19 pi (5,8 m)

29 pi (8,8 m)

17 pi (5,2 m)

21 pi (6,4 m)

15 pi (4,6 m)

Installation du système d’évacuation

1. Installer le clapet d’évacuation. Utiliser du composé de

calfeutrage pour sceller l’ouverture murale à l’extérieur autour

du clapet d’évacuation.

2. Raccorder le conduit d’évacuation au clapet. Le conduit doit

être inséré à l’intérieur du clapet. Fixer ensemble le conduit et

le clapet avec une bride de serrage de 4" (10,2 cm).

3. Acheminer le conduit d’évacuation jusqu’à l’emplacement du

sèche-linge. Utiliser l’itinéraire le plus rectiligne possible. Voir

“Déterminer l'itinéraire d'acheminement du conduit” dans

“Planification du système d'évacuation”. Eviter les

changements de direction à 90º.

pour sceller tous les joints. Ne pas utiliser de ruban adhésif

pour conduit, des vis ou autres dispositifs de fixation qui se

prolongent à l’intérieur du conduit pour fixer celui-ci.

Utiliser des brides de serrage

3. Examiner les pieds de nivellement. Trouver le symbole de

repérage (losange).

4. Engager manuellement les vis des pieds dans les trous.

Utiliser une clé à molette pour visser les pieds jusqu'à ce que

le symbole de repérage (losange) ne soit plus visible.

5. Placer une cornière de carton provenant de l’emballage du

sèche-linge sous chacun des 2 coins arrière du sèche-linge.

Redresser le sèche-linge. Faire glisser le sèche-linge sur les

cornières près de son emplacement définitif. Laisser

suffisamment d’espace pour connecter le conduit

d’évacuation.

Mise à niveau du sèche-linge

Contrôler l’aplomb du sèche-linge. Contrôler l’aplomb tout

d’abord transversalement, puis dans le sens avant/arrière.

Si le sèche-linge n’est pas de niveau, le déposer sur un bloc de

bois. Utiliser une clé à molette pour ajuster les pieds vers le haut

ou vers le bas, et vérifier à nouveau s'il est de niveau.

20

Raccordement du conduit d’évacuation

1. A l’aide d’une bride de serrage de 4" (10,2 cm), relier le

conduit d’évacuation à la bouche d’évacuation du

sèche-linge. Si on utilise un système d’évacuation existant,

s’assurer qu’il est propre. Le conduit d’évacuation du

sèche-linge doit être fixé sur la bouche d’évacuation du

sèche-linge et dans le clapet d’évacuation. S’assurer que le

conduit d’évacuation est fixé au clapet d’évacuation à l’aide

d’une bride de serrage de 4" (10,2 cm).

2. Placer le sèche-linge à son emplacement final. Ne pas

écraser ni déformer le conduit d’évacuation.

Page 21

3. (Sur les modèles à gaz) Vérifier que le tuyau de gaz flexible

A

C

D

n'est pas déformé ou écrasé.

4. Une fois que le conduit d’évacuation est raccordé, retirer les

cornières et le carton.

Inversion du sens d'ouverture de la porte

(facultatif)

On peut changer l’ouverture de la porte du côté droit au côté

gauche si désiré.

9. Insérer les vis dans les trous inférieurs du côté gauche de la

caisse. Serrer les vis à moitié. Placer la porte de telle sorte que

la partie élargie du trou de charnière se trouve au-dessus des

vis. Glisser la porte vers le haut de telle sorte que les vis se

trouvent au bas des fentes. Serrer les vis. Insérer les vis

supérieures dans les charnières et les serrer.

B

E

F

1. Placer une serviette (A) su le sèche-lingee pour protéger la

surface.

2. Ouvrir la porte du sèche-linge. Ôter les vis inférieures fixant les

charnières (D) sur la caisse. Desserrer (sans les ôter) les vis

supérieures fixant les charnières sur la caisse.

3. Soulever la porte suffisamment pour que les vis supérieures

de la caisse se trouvent dans la partie élargie des trous des

charnières. Tirer la porte vers l’avant pour la dégager des vis.

Placer la porte (poignée vers le haut) sur le dessus du sèchelinge. Ôter les vis supérieures de la caisse.

4. Enlever les vis qui fixent les charnières sur la porte.

5. Enlever les vis au sommet, en bas et sur le côté de la porte

(4 vis). En tenant la porte au-dessus de la serviette sur le

sèche-linge, saisir les côtés de la section externe de la porte

et soulever prudemment pour la séparer de la section interne

de la porte. Ne pas essayer de séparer les deux sections avec

un couteau à mastic. Ne pas tirer sur le joint de la porte ou sur

les loquets de plastique de la porte.

6. Veiller à maintenir la plaque de carton d’espacement centrée

entre les deux sections de la porte. Réassembler la section

externe et la section interne de la porte de telle manière que la

poignée soit orientée du côté où les charnières viennent d’être

enlevées.

7. Fixer les charnières de porte à la porte du sèche-linge de

façon à ce que le trou le plus gros se trouve dans la partie

inférieure de la charnière.

8. Enlever la gâche de la porte (E) de la caisse. Utiliser un petit

tournevis à lame plate pour ôter soigneusement 4 bouchons

d’obturation (F) du côté gauche de la caisse. Insérer les

bouchons dans les trous de charnière du côté droit de la

caisse.

10. Enlever le bouchon d’obturation de la gâche de la porte (B).

Insérer dans le trou la gâche qui a été enlevée à l’étape 8; fixer

la gâche avec la vis. Insérer le bouchon d’obturation dans le

trou d’où la gâche avait été initialement extraite; fixer le

bouchon avec la vis.

11. Fermer la porte; vérifier que la gâche de la porte est alignée

avec le loquet (C). Au besoin, déplacer la gâche de la porte

vers la gauche ou vers la droite dans son logement pour

ajuster l’alignement.

Achever l’installation

1. Vérifier que toutes les pièces sont installées. S’il reste une

pièce, passer en revue les différentes étapes pour découvrir

laquelle aurait été oubliée.

2. S’assurer d’avoir tout l’outillage nécessaire.

3. Jeter ou recycler tout le matériel d’emballage.

4. Vérifier l’emplacement définitif du sèche-linge. S’assurer que

le conduit d’évacuation n’est pas écrasé ou déformé.

5. Vérifier que le sèche-linge est de niveau. Voir “Mise à niveau

du sèche-linge”.

6. Brancher sur une prise à 2 alvéoles reliée à la terre. Mettre le

courant.

7. Retirer la pellicule de protection bleue sur le panneau de

commande et le ruban resté sur le sèche-linge.

8. Lire “Utilisation du sèche-linge” dans les Instructions pour

l’utilisateur du sèche-linge.

9. Essuyer soigneusement le tambour du sèche-linge avec un

chiffon humide pour éliminer toute trace de poussière.

10. Régler le sèche-linge sur un programme de séchage complet

(pas le programme de séchage sans chaleur) de 20 minutes et

mettre le sèche-linge en marche.

Si le sèche-linge ne démarre pas, vérifier ce qui suit :

n Les commandes sont réglées à la position de marche ou

“On”.

n

Le bouton Start (mise en marche) a été enfoncé fermement

n Le sèche-linge est branché sur une prise reliée à la terre

et/ou l’alimentation électrique est connectée.

n Les fusibles du domicile sont intacts et serrés, ou le

disjoncteur n’est pas déclenché.

n La porte du sèche-linge est fermée.

11. Après 5 minutes de fonctionnement, ouvrir la porte du

sèche-linge et voir s’il y a de la chaleur. En cas de chaleur,

annuler le programme et fermer la porte.

Si aucune chaleur n'est perceptible, désactiver le

sèche-linge et vérifier ce qui suit :

n Vérifier que les fusibles du domicile sont intacts et serrés

ou que le disjoncteur n’est pas déclenché. Si le problème

persiste, contacter un électricien qualifié.

REMARQUE : Il est possible que le sèche-linge dégage une

odeur de brûlé lors du chauffage initial. Cette odeur est normale

lorsque l’élément chauffant est utilisé pour la première fois.

L’odeur disparaîtra.

.

21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Loading...

Loading...