Page 1

User’s

Manual

ADMAG TI Series

AXW Magnetic Flowmeter

[Size: 500 to 1800 mm (20 to 72 in.)]

Installation Manual

[Style: S1, S2]

Integral Flowmeter

(AXW###G)

Remote Transmitter

(AXG1A)

Remote Transmitter

(AXFA11G)

This manual outlines the basic guidelines for installation and

wiring procedures. For the items which are not covered in this

manual, see the user’s manuals and the general speci ca-

tions as listed in Table 1.1.

Remote Sensor

(AXW###G, AXW###W)

Remote Transmitter

(AXW4A)

IM 01E25A01-01EN

Contents

1. Introduction

1.1 For Safe Use of Product ................................................3

1.2 Warranty .........................................................................6

1.3 Combination for Remote Sensor and Remote

Transmitter .....................................................................6

2. Receiving and Storage

2.1 Model and Speci cations Check ...................................7

2.2 Storage Precautions ......................................................8

3. Installation

3.1 Piping Design Precautions ............................................9

3.2 Handling Precautions .................................................. 12

3.2.1 General Precautions ...................................... 12

3.2.2 Flowmeter Piping ........................................... 13

3.3 Integral Flowmeter and Remote Sensor Installation .. 13

3.4 Remote Transmitter Installation .................................. 19

3.4.1 Installation Location ....................................... 19

3.4.2 Mounting of AXW4A Transmitter ................... 19

3.4.3 Mounting of AXG1A Transmitter .................... 19

3.4.4 Mounting of AXFA11 Transmitter ................... 20

3.5 Changing Direction of Electrical Connection .............. 20

3.5.1 Integral Flowmeter ......................................... 20

3.5.2 Remote Sensor (Style: S1) ............................ 21

3.5.3 Remote Sensor (Style: S2) ............................ 22

3.6 Changing Direction of Display Unit ............................. 23

4. Wiring

4.1 Wiring Precautions ...................................................... 24

4.2 Cables ......................................................................... 25

4.3 Electrical Connections ................................................ 26

4.4 Connecting to External Instruments of Integral

Flowmeter and Remote Transmitter ........................... 30

4.5 Connecting to Remote Sensor and Remote

Transmitter (Sensor Side) ........................................... 36

4.6 Input and Output ......................................................... 39

5. Basic Operating Procedures

5.1 Operation by Display unit ............................................ 42

5.2 Display and Basic Con guration ................................. 42

5.3 Display Mode and Setting Mode ................................. 45

5.4 Parameter Setting from Display Panel ....................... 46

5.5 microSD Card Setting ................................................. 48

5.6 BRAIN Con guration Tool ........................................... 48

5.7 HART Con guration Tool ............................................ 49

5.8 Modbus Con guration Tool ......................................... 50

5.9 F

OUNDATION

eldbus Con guration Tool ..................... 51

6. Operation

6.1 Pre-operation Zero Adjustment ................................... 52

6.2 Zero Adjustment from Display Unit ............................. 52

6.3 Hardware Switch Setting ............................................ 53

7. Errors and Countermeasures (Display unit)

1

2

3

4

5

6

7

IM 01E25A01-01EN

6th Edition

Page 2

<1. Introduction>

NOTE

IMPORTANT

NOTE

1. Introduction

1

This manual provides the basic guidelines for installation,

wiring procedures and basic operation of ADMAG TI

(Total Insight) Series AXW magnetic owmeters (size:

500 to 1800 mm (20 to 72 in.)) with BRAIN, HART and

Modbus protocol.

For the items which are not covered in this manual,

read the applicable user’s manuals and general

specications as listed in Table 1.1. These documents

can be downloaded from the website of YOKOGAWA. To

ensure correct use of the instrument, read these manuals

thoroughly and fully understand how to operate the

instrument before operating it. For method of checking

the model and specications, read Chapter 2 and general

specications as listed in Table 1.1.

Website address: http://www.yokogawa.com/d/doc/

These manuals can be downloaded from the website

of YOKOGAWA or purchased from the YOKOGAWA

representatives.

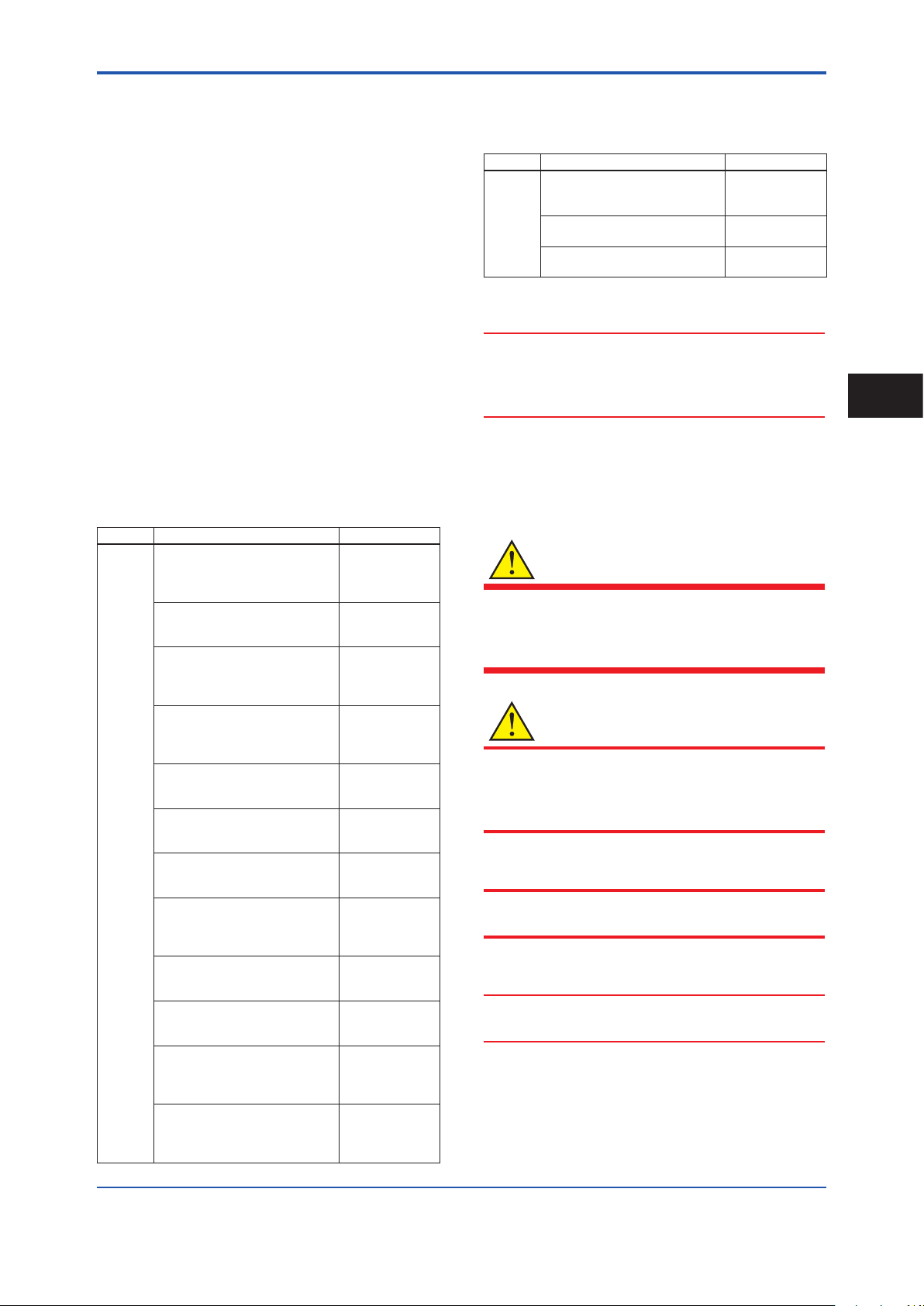

Table 1.1 Manual and General Specications List

Model Document Title Document No.

ADMAG TI Series

AXW###G

AXW###W

AXW4A

AXG1A

AX01C

AXG###, AXW###, AXG4A, AXW4A,

AXG1A Magnetic Flowmeter

Read Me First

ADMAG TI Series

AXG/AXW Magnetic Flowmeter

Safety Manual

ADMAG TI Series

AXW Magnetic Flowmeter

[Size: 500 to 1800 mm (20 to 72 in.)]

Installation Manual

ADMAG TI Series

AXW Magnetic Flowmeter

[Size: 25 to 1800 mm (1 to 72 in.)]

Maintenance Manual

ADMAG TI Series

AXG, AXW Magnetic Flowmeter

BRAIN Communication Type

ADMAG TI Series

AXG, AXW Magnetic Flowmeter

HART Communication Type

ADMAG TI Series

AXG, AXW Magnetic Flowmeter

Modbus Communication Type

ADMAG TI Series

AXG/AXW Magnetic Flowmeter

OUNDATION Fieldbus

F

Communication Type

ADMAG TI Series

AXG1A Magnetic Flowmeter

BRAIN Communication Type

ADMAG TI Series

AXG1A Magnetic Flowmeter

HART Communication Type

ADMAG TI Series

AXW Magnetic Flowmeter

[Size: 500 to 1800 mm (20 to 72 in.)]

General Specications

ADMAG TI Series

AXG1A Magnetic Flowmeter

Remote Transmitter

General Specications

IM 01E21A21-01Z1

IM 01E21A21-02EN

IM 01E25A01-01EN

(this manual)

IM 01E24A01-02EN

IM 01E21A02-01EN

IM 01E21A02-02EN

IM 01E21A02-05EN

IM01E21A02-03EN

IM 01E22C02-01EN

IM 01E22C02-02EN

GS 01E25D11-01EN

GS 01E22C01-01EN

Model Document Title Document No.

AXF Series

AXFA11G

AXFC

Magnetic Flowmeter

Read Me First

AXFA11G Remote Converter

[Hardware Edition/Software Edition]

AXFA11G Remote Converter

General Specications

IM 01E20A21-01Z1

IM 01E20C01-01E

GS 01E20C01-01E

When describing the model name like AXW###G in this

manual, “###” means any of the following.

500, 600, 700, 800, 900, 10L, 11L, 12L, 13L, 14L, 15L,

16L, 18L

Precautions Related to the Protection,

Safety, and Alteration of the Instrument

The following safety symbol marks are used in this

manual and instrument.

WARNING

A WARNING sign denotes a hazard. It calls attention to

procedure, practice, condition or the like, which, if not

correctly performed or adhered to, could result in injury

or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls attention

to procedure, practice, condition or the like, which, if

not correctly performed or adhered to, could result in

damage to or destruction of part or all of the product.

An IMPORTANT sign denotes that attention is required

to avoid damage to the instrument or system failure.

A NOTE sign denotes information necessary for

essential understanding of operation and features.

1

Introduction

All Rights Reserved, Copyright © 2017, Yokogawa Electric Corporation

IM 01E25A01-01EN6th Edition: Nov. 2020 (KP)

Page 3

<1. Introduction>

2

The following symbols are used in the Instrument and the

manual to indicate the accompanying safety precautions:

Protective grounding terminal

Functional grounding terminal (This terminal should

not be used as a protective grounding terminal.)

Alternating current

Direct current

Caution

This symbol indicates that the operator must refer to

an explanation in the user’s manual in order to avoid

the risk of injury or death of personnel or damage to

the instrument.

• For the protection and safe use of the instrument and

the system in which this instrument is incorporated,

be sure to follow the instructions and precautions

on safety that is stated in this manual whenever

you handle the instrument. Take special note that if

you handle the instrument in a manner that violated

these instructions, the protection functionality of the

instrument may be damaged or impaired. In such

cases, YOKOGAWA does not guarantee the quality,

performance, function, and safety of instrument.

• When installing protection and/or safety as lighting

protection devices and equipment for the instrument

and control system or designing or installing separate

protection and/or safety circuits for fool-proof design

and fail-safe design of the processes and lines that

use the instrument and the control system, the user

should implement these using additional devices and

equipment.

• Should use the parts specied by YOKOGAWA when

replacing. Please contact YOKOGAWA’s service

oce for fuse replacement.

• This instrument is not designed or manufactured

to be used in critical applications that directly aect

or threaten human lives. Such applications include

nuclear power equipment, devices using radioactivity,

railway facilities, aviation equipment, air navigation

facilities, aviation facilities, and medical equipment. If

so used, it is the user’s responsibility to include in the

system additional equipment and devices that ensure

personnel safety.

• Do not modify this instrument.

• YOKOGAWA will not be liable for malfunctions or

damage resulting from any modication made to this

instrument by the customer.

• The instrument should be disposed of in accordance

with local and national legislation/regulations.

Regarding This User’s Manual

• This manual should be provided to the end user.

• The contents of this manual are subject to change

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without YOKOGAWA’s written

permission.

• YOKOGAWA makes no warranty of any kind with

regard to this manual, including, but not limited to,

implied warranty of merchantability and tness for a

particular purpose.

• If any question arises or errors are found, or if any

information is missing from this manual, inform the

nearest YOKOGAWA sales oce.

• The specications covered by this manual are limited

to those for the standard type under the specied

model number break-down and do not cover custom-

made instruments.

• Note that changes in the specications, construction,

or component parts of the instrument may not

immediately be reected in this manual at the time

of change, provided that postponement of revisions

will not cause diculty to the user from a functional or

performance standpoint.

• This manual is intended for the following personnel;

Engineers responsible for installation and wiring of the

instrument.

Personnel responsible for normal daily operation of

the instrument.

• To ensure correct use, read this manual and

the applicable manuals as listed in Table 1.1

thoroughly before starting operation. Read the

general specications as listed in Table 1.1 for its

specication.

Trademarks:

• HART is a registered trademark of FieldComm Group.

• Modbus is a registered trademark of AEG Schneider.

• F

OUNDATION

Group.

• All the brands or names of Yokogawa Electric’s

products used in this manual are either trademarks

or registered trademarks of Yokogawa Electric

Corporation.

• All other company and product names mentioned

in this manual are trade names, trademarks or

registered trademarks of their respective companies.

• In this manual, trademarks or registered trademarks

are not marked with ™ or

is a registered trademark of FieldComm

®

.

IM 01E25A01-01EN

Page 4

<1. Introduction>

IMPORTANT

3

1.1 For Safe Use of Product

For the protection and safe use of the instrument and

the system in which this instrument is incorporated, be

sure to follow the instructions and precautions on safety

that is stated in this manual whenever you handle the

instrument. Take special note that if you handle the

instrument in a manner that violated these instructions,

the protection functionality of the instrument may be

damaged or impaired. In such cases, YOKOGAWA

shall not be liable for any indirect or consequential loss

incurred by either using or not being able to use the

Instrument.

(1) General

• This instrument conforms to EN61326-1, EN613262-3, EN61326-2-5, EN61000-3-2, and EN61000-3-3

(EMC standard).

• This instrument is an EN61326-1 (EMC standard),

Class A (for use in commercial, industrial, or business

environments).

• This instrument (General-purpose type) is complied

with IP66 and IP67 in the IP Protection Grade.

YOKOGAWA assumes no liability for the customer’s

failure to comply with these requirements.

• This instrument (Submersible type) is complied with

IP68 in the IP Protection Grade.

YOKOGAWA assumes no liability for the customer’s

failure to comply with these requirements.

• This instrument is designed for indoor and outdoor

use.

• This instrument is Micro Pollution Degree: 2.

• This instrument is Macro Pollution Degree: 4.

• This instrument is designed for altitude at installation

Site Max. 2000 m above sea level.

• This instrument is installation Category (Overvoltage

category): II.

CAUTION

This instrument is a Class A instrument in the

EN61326-1(EMC standard). Operation of this

instrument in a residential area may cause radio

interference, in which case the user is required to take

appropriate measures to correct the interference.

The minimum ambient temperature is limited by the

minimum uid temperature of the sensor (the lining).

For more information, read the applicable general

specications as listed in Table 1.1.

The owmeter may be used in an ambient humidity

where the relative humidity ranges from 0 to 100%.

However, avoid long-term continuous operation at

relative humidity above 95%.

WARNING

• Purpose of use

This instrument is the Magnetic Flowmeter for use of

measuring the liquid ow. Do not use this instrument

for other purposes.

WARNING

• Installation, wiring and maintenance of the magnetic

owmeter must be performed by expert engineer

or skilled personnel. No operator shall be permitted

to perform procedures relating to installation, wiring

and maintenance.

• Wiring work should be done adequate wire, sleeve

crimp and torque force. Use terminal with insulating

cover for the power supply wiring and protective

grounding wiring. Do not pull the wires too much

strongly in order to prevent electric shocks caused

by their damage.

• Do not open the cover in wet weather or humid

environment. When the cover is open, stated

enclosure protection is not applicable.

• Ensure that the power supply is o in order to

prevent electric shocks.

• When opening the cover, wait for more than 20

minutes after turning o the power. Only expert

engineer or skilled personnel are permitted to open

the cover.

• When opening and closing the transmitter cover, be

sure to handle the transmitter cover carefully so that

there are no damage and foreign matter adhesion at

its threads and O-ring.

• This instrument employs the parts which are

aected by a function damage caused by static

electricity. Thus, you should do the antistatic work

using an anti-static wrist band for it and be careful

to avoid touching each electrical parts and circuitry

directly.

• When connecting the wiring, check that the supply

voltage is within the range of the voltage specied

for this instrument before connecting the power

cable. In addition, check that no voltage is applied to

the power cable before connecting the wiring.

• To prevent electric shocks, ensure the electrical

wiring cover is completely attached after the wiring

work.

• To prevent electric shocks, do not impress over

rated voltage to each input/output terminals.

• If there is any unused electrical connection, use

the blanking plug to cover which comes with this

instrument or which is supplied by YOKOGAWA.

The blanking plug should be fastened into the

unused electrical connection without any mistake. If

not, stated enclosure protection is not applicable.

1

Introduction

IM 01E25A01-01EN

Page 5

<1. Introduction>

4

(2) Installation

WARNING

• For AXG1A, impact resistance rating of glass on the

display cover is IK06, metal housing is IK08.

In the test method, the steel ball is dropped from a

height of 200 mm after pre-cooling the housing to

-40 degree C. (Impact on horizontal surface)

• The magnetic owmeter is a heavy instrument.

Be careful that no damage is caused personnel

through accidentally dropping it, or by exerting

excessive force on the magnetic owmeter. When

moving the magnetic owmeter, always use a trolley

and have at least two people carry it.

• Do not apply excessive weight, for example, a

person stepping on the magnetic owmeter.

• The magnetic owmeter must be installed within the

specication conditions.

• Connect the Protective Grounding Terminal

Ensure to connect the protective grounding to

prevent electric shock before turning on the power.

• Do Not Impair the Protective Grounding

Never cut o the internal or external protective

grounding wire or disconnect the wiring of the

protective grounding terminal. Doing so invalidates

the protective functions of the instrument and poses

a potential shock hazard.

• Do Not Operate with Defective Protective

Grounding

Do not operate the instrument if the protective

grounding might be defective. Also, ensure to check

them before operation.

• Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence

of ammable gas, vapors, or combustible dust.

Operation in such an environment constitutes a

safety hazard. Prolonged use in a highly dense

corrosive gas (H

malfunction.

• Ground the Instrument before Making External

Connections

Connect the protective grounding before connecting

to the item under measurement or control unit.

• Damage to the Protection

Operating the instrument in a manner neither

described in this manual nor the manuals as listed in

Table 1.1 may damage the instrument’s protection.

• The owmeter should be installed away from

electrical motors, transformers, and other power

sources in order to avoid interference with

measurement.

S, SOx, etc.) will cause a

2

WARNING

• Install an external switch or circuit breaker as a

means to turn the power o (capacitance: 15A,

conforming to IEC60947-1 and IEC60947-3).

Locate this switch either near the instrument or in other

places facilitating easy operation. Ax a "Power O

Equipment" label to this external switch or circuit breaker.

•

All procedures relating to installation must comply

with the electrical code of the country where it is used.

(3) Wiring

WARNING

• In cases where the ambient temperature exceeds

50°C, use external heat resistant wiring with a

maximum allowable temperature of 70°C or above.

• When wiring the conduits, pass the conduit through

the wiring connection port, and utilize the waterproof

gland to prevent water from owing in. Install a drain

valve at the low end of the vertical pipe, and open

the valve regularly.

•

Do not connect cables outdoors in wet weather in order

to prevent damage from condensation and to protect the

insulation, e.g. inside the terminal box of the owmeter.

• The transmitter case should be removed by

YOKOGAWA’s qualied personnel only. Opening

the transmitter case is dangerous, because some

areas inside the instrument have high voltages.

• The protective grounding must be connected

securely at the terminal with the

danger to personnel.

mark to avoid

(4) Operation

WARNING

Be sure to enable the write protect function to prevent

the overwriting of parameters after nishing parameter

setting.

In rare cases, the infra-red switches may respond

unexpectedly in such conditions as sticking ball of water

or extraneous substances on the surface of display

panel glass according to the principle of infra-red switch

operation. Its probability rises in such cases as sticking

rain water by storm or other similar situation and

washing up work near owmeter installation place.

Blinking light from a ashlight etc. to the infra-red

switches may result in the malfunction.

Read Section 6.3 for the hardware write protect

function, and the user's manual of applicable

communication type as listed in Table 1.1 for the

software write protect function.

IM 01E25A01-01EN

Page 6

<1. Introduction>

IMPORTANT

5

(5) Maintenance

WARNING

• When maintaining the instrument, read the

maintenance manual as listed in Table 1.1. Do not

perform the maintenance that is not described in the

manual. If necessary, contact YOKOGAWA.

• When the magnetic owmeter is processing hot

uids, the instrument itself may become extremely

hot. Take sucient care not to get burnt.

• Where the uid being processed is a toxic

substance, avoid contact with the uid and avoid

inhaling any residual gas, even after the instrument

has been taken o the piping line for maintenance

and so forth.

• If dirt, dust or other substances surfaces on the

glass of display cover, wipe them clean with a soft

dry cloth.

• Maintenance of this owmeter should be

implemented in a maintenance service shop where

the necessity tools and environment condition are

provided.

The necessity of this environmental condition is that

ambient temperature is 5 to 40°C (the maximum

relative humidity is 80 % for temperature 5 to 31°C,

and decreasing linearly to 50 % relative humidity at

40°C).

(6) Modication

• Do not modify this instrument.

• YOKOGAWA will not be liable for malfunctions or

damage resulting from any modication made to this

instrument by the customer.

(7) Product Disposal

The instrument should be disposed of in accordance

with local and national legislation/regulations.

(8) Power Supply

Ensure that the source voltage matches the voltage of

the power supply before turning on the power.

Power Supply Code 1:

• AC Type:

Rated Power Supply: 100 to 240 V AC, 50/60 Hz

• DC Type:

Rated Power Supply: 100 to 120 V DC

Power Supply Code 2:

• AC Type:

Rated Power Supply: 24 V AC, 50/60 Hz

• DC Type:

Rated Power Supply: 24 V DC

Power Consumption:

Integral Type: 13 W

Remote Type (with AXG4A): 13 W

Remote Type (with AXG1A): 32 W

Note: Power Consumption is independent of communication

and I/O specication.

Note: For AXFA11, read the applicable user’s manual as

listed in Table 1.1.

(9) microSD Card

• Do not store or use the microSD card in places

with static electricity, near electrically charged

objects, or where electrical noise is present. Doing

so can result in shock or damage.

• Do not disassemble or modify the microSD card.

• Do not physically shock, bend, or pinch the

microSD card.

• During reading/writing of data, do not turn o the

power, apply vibration or shock, or pull out the

card. Data can corrupt or be permanently lost.

• Use only micro SD cards sold by YOKOGAWA.

Operation cannot be guaranteed when other cards

are used.

• When inserting the microSD card into the

instrument, make sure to orient the microSD card

correctly (face up or down) and insert it securely. If

not inserted correctly, the microSD card will not be

recognized by the instrument.

• Do not touch the microSD card with wet hands.

• Do not use the microSD card if it is dusty or dirty.

• The microSD card comes formatted. If you want

to format the microSD card, use the instrument's

Format function.

• YOKOGAWA provides no warranty for damage

to, or loss of data recorded on the microSD card,

regardless of the cause of such damage or loss.

We recommend making backup copies of your

data.

1

Introduction

IM 01E25A01-01EN

Page 7

<1. Introduction>

IMPORTANT

NOTE

6

1.2 Warranty

• The warranty shall cover the period noted on the

quotation presented to the purchaser at the time of

purchase. Problems occurred during the warranty

period shall basically be repaired free of charge.

• In case of problems, the customer should contact

the YOKOGAWA representative from which

the instrument was purchased, or the nearest

YOKOGAWA oce.

• If a problem arises with this instrument, please inform

us of the nature of the problem and the circumstances

under which it developed, including the model

specication and serial number. Any diagrams,

data and other information you can include in your

communication will also be helpful.

• Responsible party for repair cost for the problems

shall be determined by YOKOGAWA based on our

investigation.

• The Purchaser shall bear the responsibility for

repair costs, even during the warranty period, if the

malfunction is due to:

- Improper and/or inadequate maintenance by the

purchaser.

- Failure or damage due to improper handling, use

or storage which is out of design conditions.

- Use of the product in question in a location

not conforming to the standards specied by

YOKOGAWA, or due to improper maintenance of

the installation location.

- Failure or damage due to modication or repair

by any party except YOKOGAWA or an approved

representative of YOKOGAWA.

- Malfunction or damage from improper relocation of

the product in question after delivery.

- Reason of force majeure such as res,

earthquakes, storms/oods, thunder/lightening,

or other natural disasters, or disturbances, riots,

warfare, or radioactive contamination.

1.3 Combination for Remote Sensor and Remote Transmitter

• The AXW remote sensor (sizes 500 to 1800 mm

(20 to 72 in.)) should be combined with a remote

transmitter according to Table 1.2.

• If the transmitter combined with the AXW magnetic

owmeter’s remote sensor is changed from the

original transmitter which was delivered the meter

factor of the remote sensor must be readjusted

according to its ow calibration.

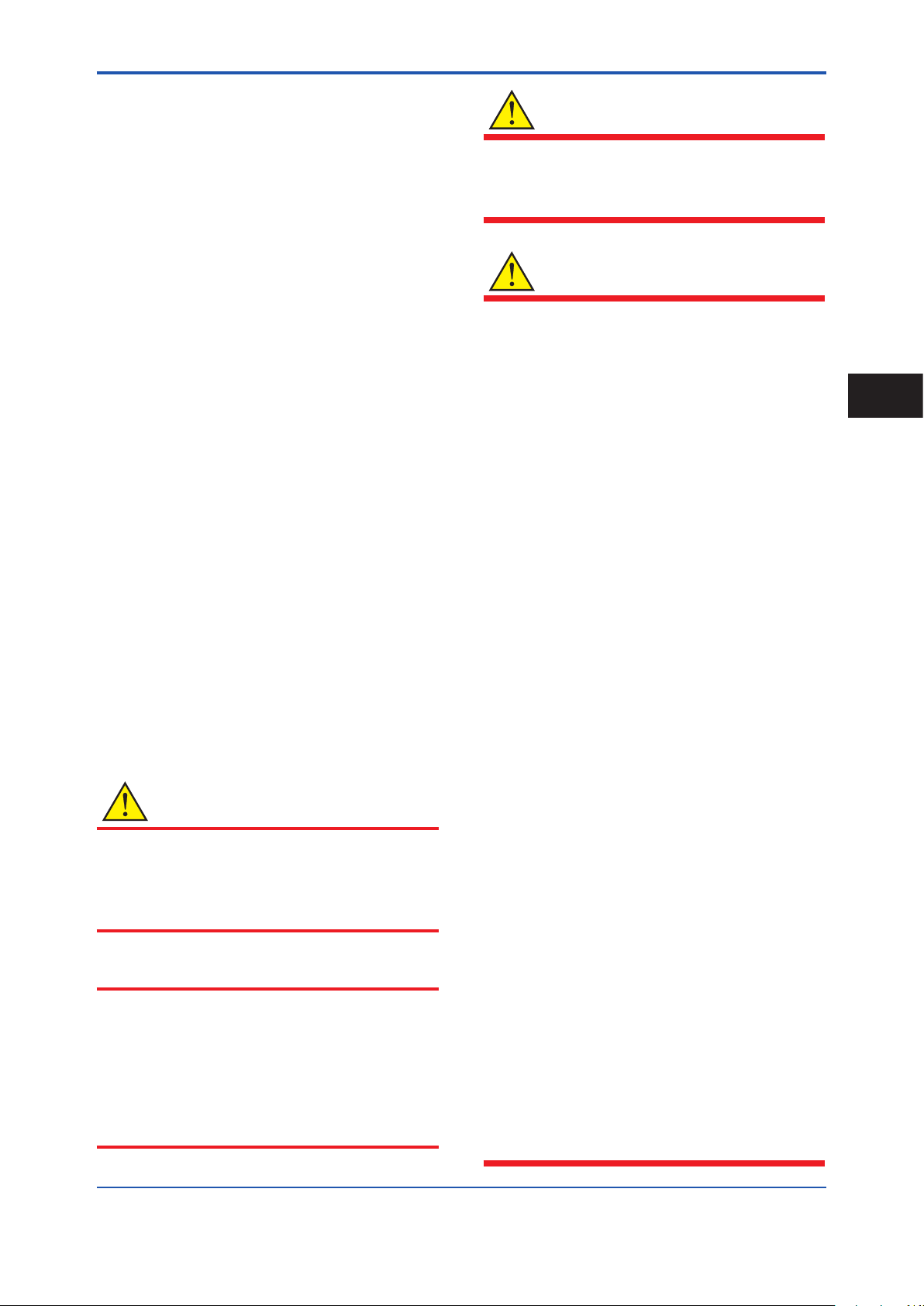

Table 1.2 Combination for sensor and transmitter

Remote Sensor

Model

AXW500G to AXW10LG

AXW500W to AXW10LW

AXW500G to AXW18LG

AXW500W to AXW18LW

AXW500G to AXW18LG

AXW500W to AXW18LW

Converter,

Communication,

I/O

-W AXW4A

-B AXG1A

-N AXFA11G

Contact YOKOGAWA before using it in combination with

transmitters other than those listed above.

In case of combination with AXFA11 remote transmitter,

select “ADMAG AXF” in the parameter “C30” of the

AXFA11 remote transmitter.

Combined with the

Remote Transmitter

Model

IM 01E25A01-01EN

Page 8

<2. Receiving and Storage>

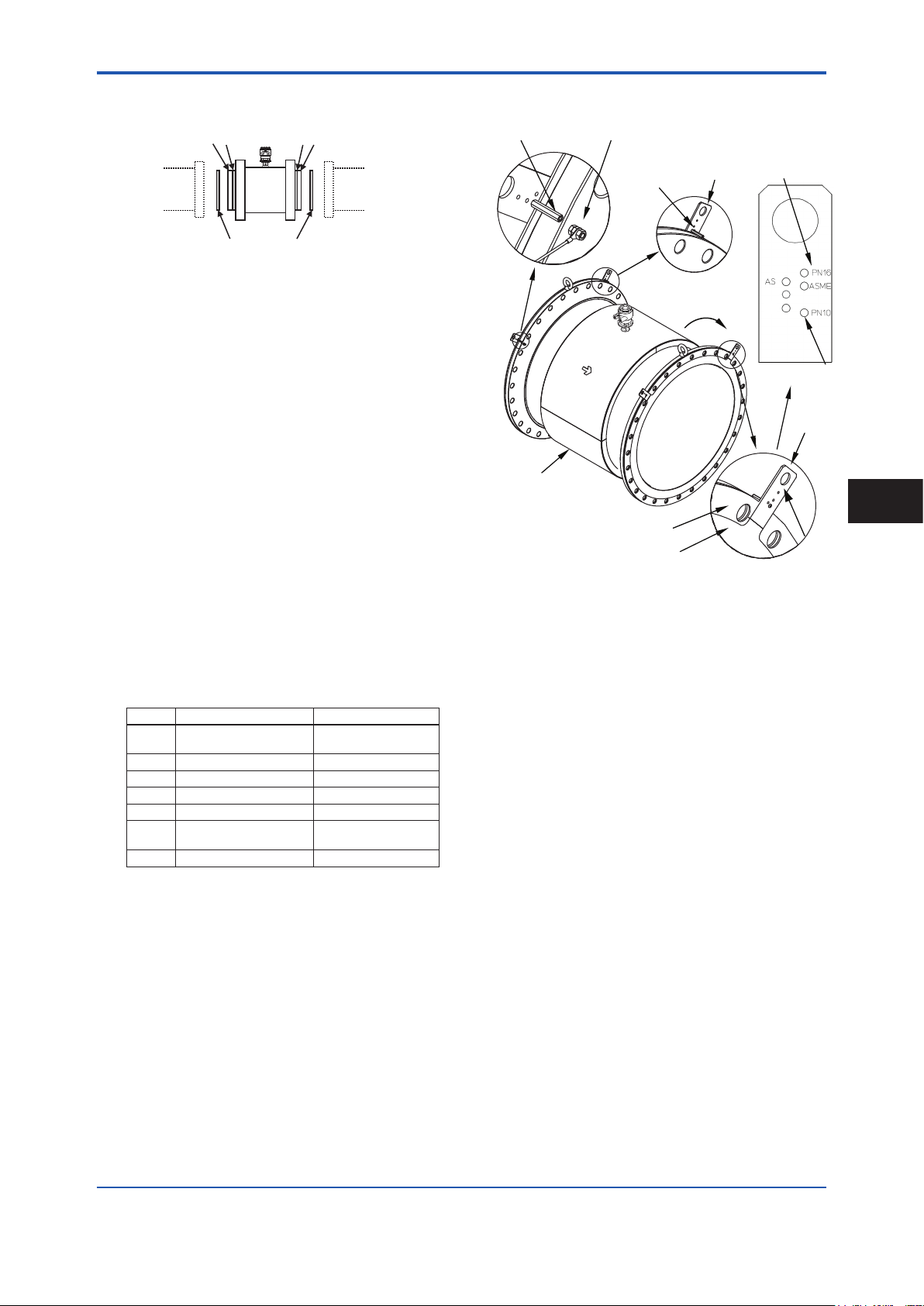

F0201.ai

F0202.ai

Style: S1

2. Receiving and Storage

7

When the instrument is delivered, check visually that no

damage has occurred during transportation. Also check

that all owmeters mounting hardware shown below is

included.

Integral Flowmeter

Model Part name Qty.

AXW###G Blanking Plug (*1) 0 to 2 pcs.

Remote Transmitter

Model Part name Qty.

AXW4A Mounting Bracket 1 set

Blanking Plug (*1) 0 to 2 pcs.

AXG1A Mounting Bracket 1 set

AXFA11G Mounting Bracket 1 set

*1: When the following code is specied for “Power Supply”

and “Converter, Communication, I/O”, the following

quantity of blind plug is attached.

Power Supply code

-1

-2

Communication and I/O code

-D, -E, -M, -F 1 pc.

Other than those above 0 pc.

-D or -E 2 pcs.

-P 0 pc.

Other than those above 1 pc.

Qty

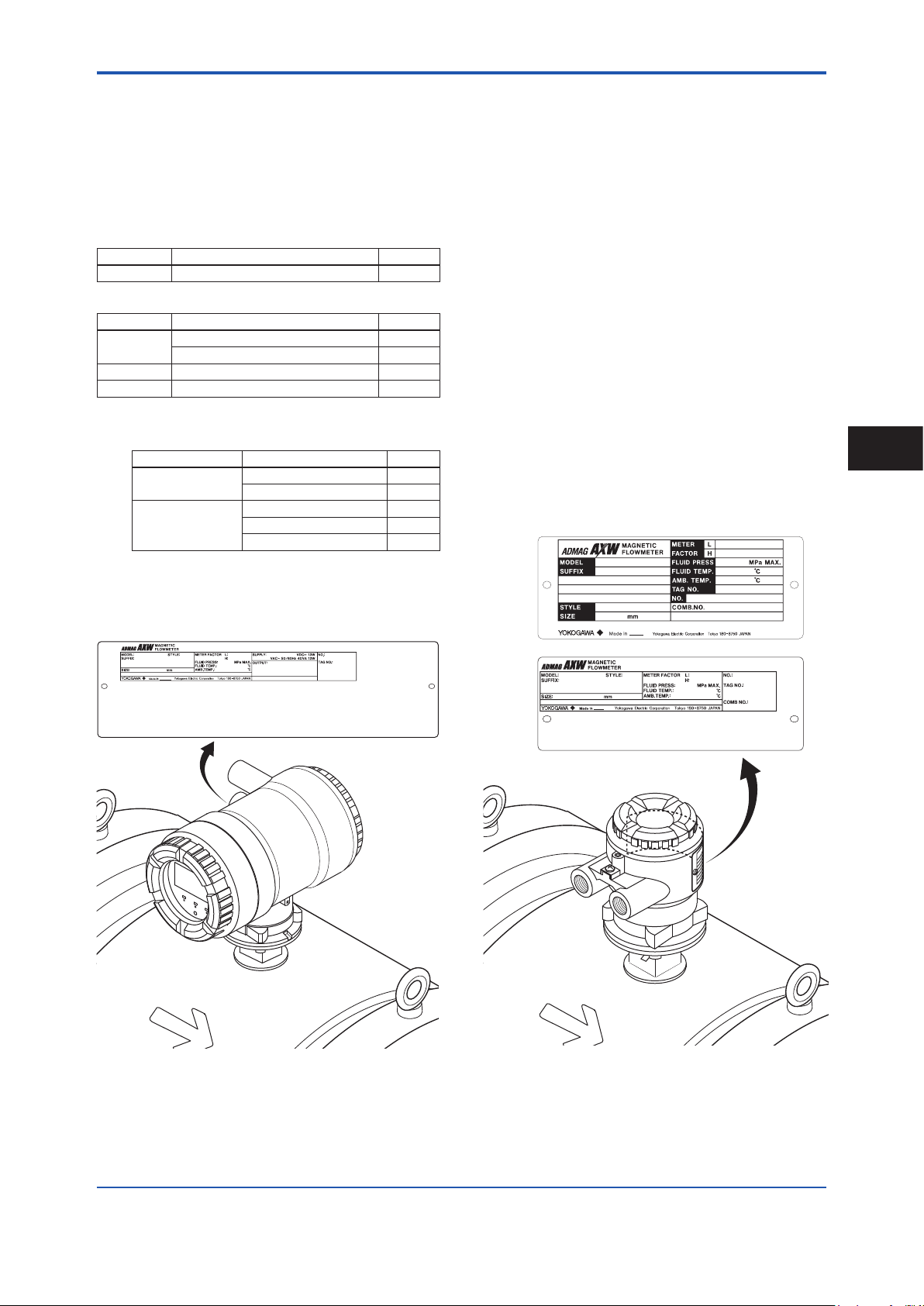

2.1 Model and Specications

Check

As shown in Figure 2.1 to Figure 2.5, the model, sux

code, serial number, meter factor, uid specication, and

device information are found on the name plate located on

the outside of the housing. And, this instrument can check

their information from parameters. Read the user’s manual

of applicable communication type as listed in Table 1.1 for

checking device information from parameters.

When checking the matching of model and specication you

ordered, see the applicable general specications as listed in

Table 1.1.

Be sure you have the model code and serial number

available when contacting YOKOGAWA.

Note: Description on the nameplate

- Made in _______: Country of origin

- COMB No.: Serial number of the combined remote

sensor or remote transmitter

2

Receiving and Storage

Figure 2.1 Name Plate (AXW Integral Flowmeter)

Style: S2

Figure 2.2 Name Plate (AXW Remote Sensor)

IM 01E25A01-01EN

Page 9

<2. Receiving and Storage>

F0204.ai

F0205.ai

F0203.ai

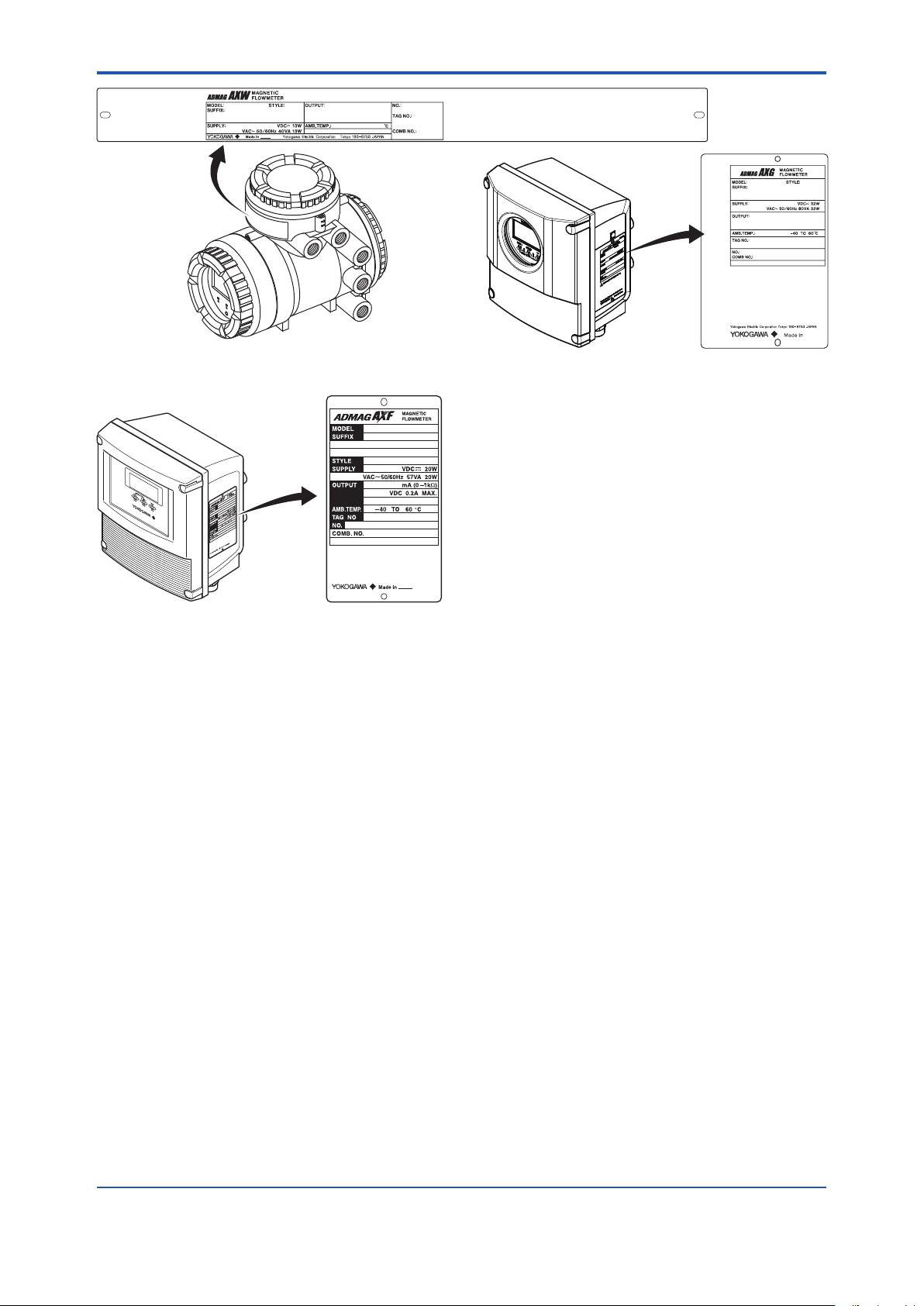

Figure 2.3 Name Plate (AXW4A Remote Transmitter)

Figure 2.4 Name Plate (AXG1A Remote Transmitter)

8

Figure 2.5 Name Plate (AXFA11 Remote Transmitter)

2.2 Storage Precautions

If the instrument is to be stored for a long period of time

after delivery, observe the following points.

The instrument should be stored in its original packing

condition in the storage location.

Select a storage location that fulls the following

conditions:

• A place where it will not be exposed to rain or water

• A place subject to minimal vibrations or shocks

•

Temperature and humidity levels should be as follows:

Temperature: -10 to 70°C

Humidity: 5 to 80% RH (no condensation)

The preferred ambient temperature and humidity

levels are 25°C and approximately 65% RH.

If the instrument is transferred to the installation site

and stored without being installed, its performance

may be impaired due to the inltration of rainwater

and so forth. Be sure to install and wire the instrument

as soon as possible after transferring it to the

installation location.

IM 01E25A01-01EN

Page 10

<3. Installation>

IMPORTANT

NOTE

IMPORTANT

IMPORTANT

3. Installation

9

WARNING

Installation of the magnetic owmeter must be

performed by expert engineer or skilled personnel.

No operator shall be permitted to perform procedures

relating to installation.

Installation Location Precautions

Select the installation location with consideration to the

following items to ensure long-term stable operation of

the instrument.

Ambient Temperature:

Avoid installing the instrument in locations with constantly

uctuating temperatures. If the location is subject to

radiant heat from the plant, provide heat insulation or

improve ventilation.

Atmospheric Condition:

Avoid installing the instrument in a corrosive atmosphere.

In situations where this is unavoidable, consider ways to

improve ventilation and to prevent rainwater from entering

and being retained in the conduit pipes.

Vacuum:

In the case of PTFE lining, avoid the negative pressure

inside the measuring pipe.

Vibrations or Shocks:

Avoid installing the instrument in a place subject to

shocks or vibrations.

3.1 Piping Design Precautions

Design piping correctly, referring to the following to

prevent damage to sensors and to assure accurate

measuring.

This section describes the remote sensor as an

example. The same attention must be paid to the

integral owmeter.

(1) Location

Install the owmeter in a location where it is not

exposed to direct sunlight. The minimum ambient

temperature is limited by the minimum uid temperature

of the sensor (the lining). For more information, read the

applicable general specication as listed inTable 1.1.

The owmeter may be used in an ambient humidity

where the relative humidity ranges from 0 to 100%.

However, avoid long-term continuous operation at

relative humidity 95% or higher.

(2) Noise Avoidance

3

Installation

The owmeter should be installed away from electrical

motors, transformers, and other power sources in

order to avoid interference with measurement. When

installing two or more magnetic owmeters, provide a

distance of at least 5D (D is size of model code) each

other. If diameters of them are dierent, let D be the

larger one.

IM 01E25A01-01EN

Page 11

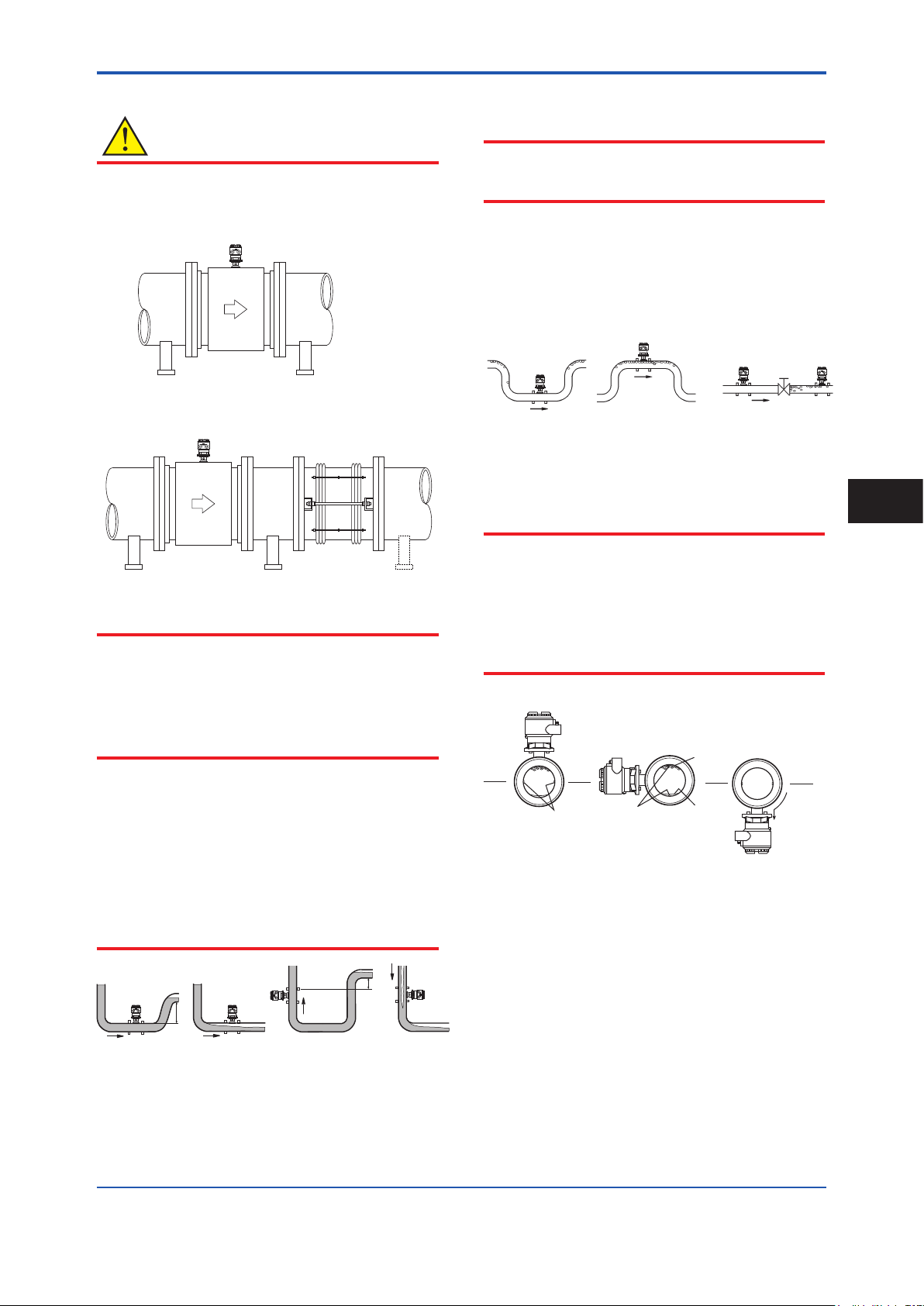

F0301.ai

D: Sensor Size

2D or more

IMPORTANT

F0302.ai

(Incorrect)

Upstream side

(Correct)

Downstream side

IMPORTANT

F0303.ai

Bypass valve

Block

valve

<3. Installation>

10

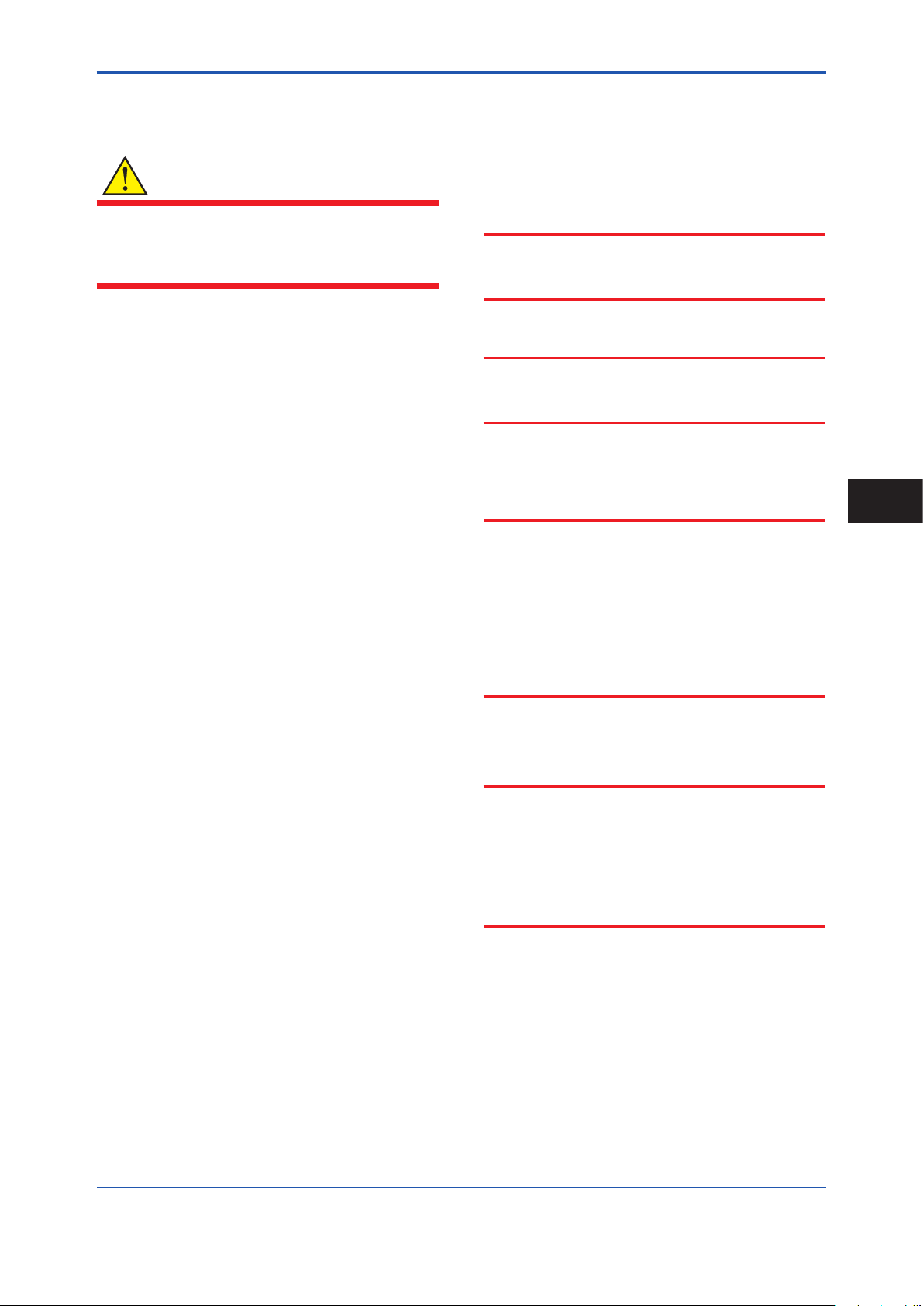

(3) Required Straight Pipe Length

Based on JIS B 7554 “Electromagnetic Flowmeters” and

our piping condition test data, we recommend the piping

conditions as shown in the following gures. This is not

always enough when the piping line incorporates multiple

conditions at the same time.

Gate valve

fully open

5D or more2Dor more

Tee

0 is allowable.5D or more 0 is allowable.5D or more

Figure 3.1.1 Required Straight Pipe Length

*1: Do not install anything in the vicinity that may interfere

with the magnetic eld, induced signal voltages, or ow

velocity distributions of the owmeter.

*2: A straight run may not be required on the downstream

side of the owmeter. However, if a downstream valve

or other tting causes irregularity or deviation in ows,

provide a straight run of 2D to 3D on the downstream side.

*3: The valves shall be mounted on the downstream side so

that deviated ows do not occur in the sensor and to avoid

startup from an empty condition.

*4: In case the piping conditions are compounded, install

on the straight pipe section where the upstream part is

suciently rectied.

Reducer

pipe

0 is allowable. 0 is allowable.

90-degree bend

Expander

pipe

10D or more

Various valves

10D or more

2D

or more

(4) Maintaining Stable Fluid Conductivity

(5) Precautions for Use of Liquid Sealing

Compounds

Care must be taken in using liquid sealing compounds

on the piping, as it may have a negative inuence on

the ow indications by owing out and covering the

surfaces of an electrode or grounding ring. In particular,

care must be taken if a liquid sealing compound is used

in the case of vertical piping.

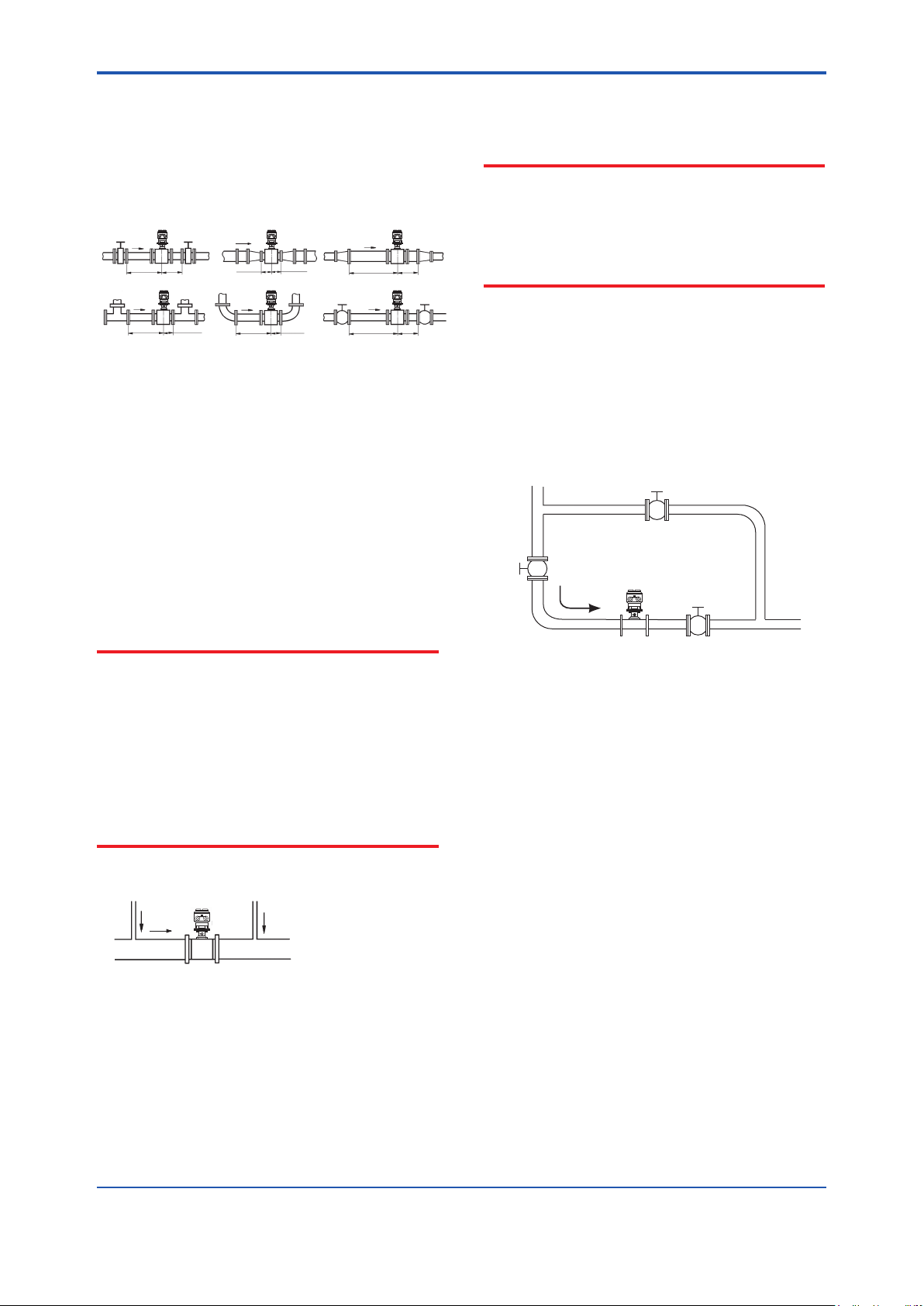

(6) Service Area

Select locations where there is adequate space to service

installing, wiring, overhauling, etc.

(7) Bypass Line

It is recommended to install a bypass line to facilitate

maintenance and zero adjustment.

Block valve

Do not install the owmeter where uid conductivity

tends to become uneven. If chemicals are fed near

the upstream side of a magnetic owmeter, they may

aect the ow rate’s indications. To avoid this situation,

it is recommended that the chemical feed ports be

located on the downstream side of the owmeter. If

it is unavoidable that chemicals must be fed on the

upstream side, provide a sucient straight pipe length

(approximately 50D or more) to ensure the proper

mixture of uids.

Figure 3.1.2 Chemical Injection

Figure 3.1.3 Bypass Line

IM 01E25A01-01EN

Page 12

<3. Installation>

F0304.ai

Abutment Abutment

F0305.ai

IMPORTANT

F0306.ai

(Incorrect)

IMPORTANT

F0307.ai

(Incorrect)

IMPORTANT

F0308.ai

Correct

the terminal

11

(8) Supporting the Flowmeter

CAUTION

Do not secure the owmeter separately to prevent the

vibrations, shocks, and expansion and contraction forces

of the piping from aecting it. Fix the pipes rst, then

support the owmeter with the pipes.

Magnetic flowmeter

To release the load from installing the owmeter to the

pipeline, set a expansive pipe in the downstream side.

Magnetic flowmeter

Abutment Abutment

For vertical mounting, make sure that the weight of piping

does not weigh on the owmeter.

(9) Mounting Positions

Expansive pipe

Avoid air bubbles.

If air bubbles enter a measurement pipe, ow rate

indications may be aected and measurement errors

may be caused.

In cases where uids contain air bubbles, piping must

be designed to prevent them from accumulating in the

measurement pipe of a sensor.

If a valve exists near the owmeter, try to mount the

owmeter on the valve’s upstream side in order to

prevent a possible reduction of pressure inside the pipe,

thereby avoiding the possibility of air bubbles.

(Correct)

(Incorrect)

Figure 3.1.5 Avoiding Air Bubbles

(Correct)

Valve

Mounting orientation

Install the magnetic owmeter so that the electrodes

position is not perpendicular to the ground. Otherwise it

may cause the measuring errors because air bubbles at

upper side or slurry at downside covers the electrode.

Mount the terminal box of a remote sensor and the

transmitter of an integral owmeter above the piping to

prevent water from entering them.

3

Installation

Pipes must be fully lled with liquids.

It is essential that pipes remain fully lled at all times,

otherwise ow rate indications may be aected and

measurement errors may be caused.

Piping shall be designed so as to maintain the interior of

the sensor lled with uids.

Vertical mounting is eective in such cases as

when uids tend to separate or solid matter may be

precipitated. When employing vertical mounting, direct

the uids from the bottom to the top to ensure that the

pipes remain fully lled.

(Correct)

Figure 3.1.4 Mounting Positions

(Incorrect)

h

h>0

(Correct)

h>0

h

Incorrect

Electrode

Figure 3.1.6 Mounting Orientation

Electrode

Air bubble

Precipitate

Incorrect

Water can

seep into

box.

IM 01E25A01-01EN

Page 13

NOTE

F0309.ai

IMPORTANT

IMPORTANT

IMPORTANT

<3. Installation>

12

3.2 Handling Precautions

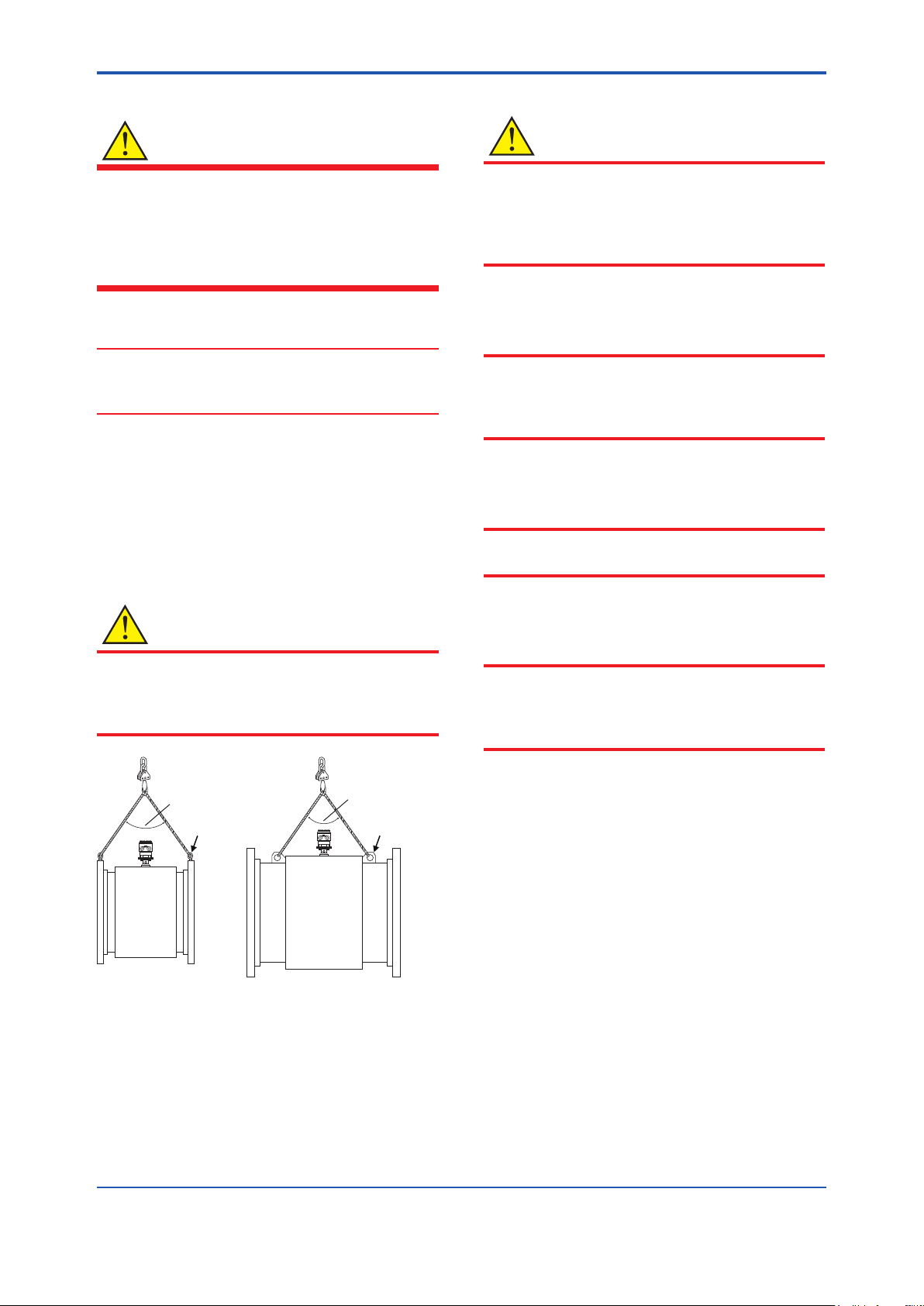

WARNING

The magnetic owmeter is a heavy instrument.

Be careful that no damage is caused to personnel

through accidentally dropping it, or by exerting

excessive force on the magnetic owmeter. When

moving the magnetic owmeter, always use a trolley

and have at least two people carry it.

This section describes the remote sensor as an

example. The same attention must be paid to the

integral owmeter.

3.2.1 General Precautions

(1) Precaution during Transportation

The magnetic owmeter is packed tightly. When

it is unpacked, pay attention to prevent damaging

the owmeter. To prevent accidents while it is being

transported to the installing location, transport it to the site

in its original packing.

CAUTION

(2) Avoid Shocks from Impact

CAUTION

Care should be taken not to drop the owmeter or

expose it to excessive shock. In particular, be careful

not to subject the ange surface to shock. This may

lead to lining damage which will result in inaccurate

readings.

(3) Flange Protection Covers

Keep the protective covering (i.e. the corrugated

cardboard or other cushioning material) in place over

the ange except when mounting the owmeter to the

pipe.

(4) Terminal Box Cover

As it is possible that the insulation will deteriorate, do

not open the terminal box cover until it is time to wire it.

(5) Long-term Non-use

When lifting the magnetic owmeter, use the lifting rings

(eye bolts or eye plates) as in Figure 3.2.1.

Never lift it using a bar passed through the magnetic

owmeter as this damages the liner severely.

90 degrees or less

Eye bolt Eye plate

Figure 3.2.1 Lifting Flowmeter

90 degrees or less

It is not desirable to leave the owmeter unused

for a long term after installation. If this situation is

unavoidable, take care of the owmeter by observing

the following.

Conrmation of sealing conditions for the

owmeter

Conrm that the terminal box screw and electrical

connections are well sealed. Equip the conduit piping

with drain plugs or waterproof glands to prevent moisture

or water from penetrating into the owmeter through the

conduit.

Regular inspections

Inspect the sealing conditions as mentioned above, and

the inside of the terminal box at least once a year.

Also, due to rain, etc. when it is suspected that water may

have penetrated into the inside of the owmeter, perform

supplementary inspections.

IM 01E25A01-01EN

Page 14

<3. Installation>

F0310.ai

NOTE

NOTE

IMPORTANT

13

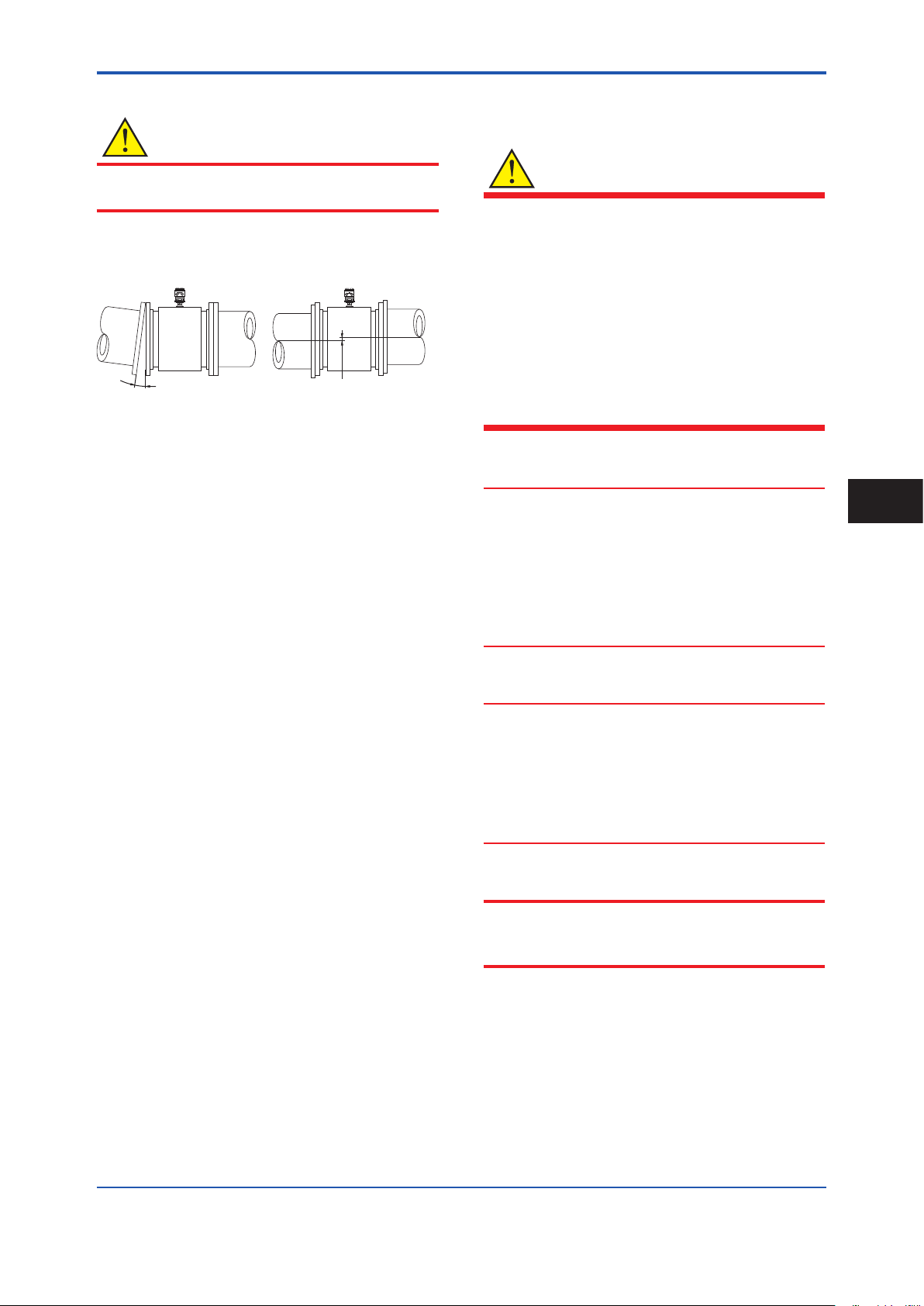

3.2.2 Flowmeter Piping

CAUTION

Misaligned or slanted piping can lead to leakage and

damage to the anges.

(1) Correct any misaligned or slanted piping, and any

gaps that may exist between mounting anges before

installing the owmeter (see Figure 3.2.2).

Slanted

Figure 3.2.2 Slanted and Misaligned Flowmeter Piping

(2) Inside a newly installed pipeline, there may be some

foreign substances such as residue from welding

or wood chips. Remove them by ushing the piping

before mounting the owmeter. This prevents the

lining from being damaged, as well as the occurrence

of erroneous measured signals resulting from foreign

substances passing through the sensor during

measurement.

Misaligned

3.3 Integral Flowmeter and Remote Sensor Installation

WARNING

• All gaskets used for piping of Magnetic Flowmeters

should be prepared by customers except in some

cases.

With the option of grounding ring, if the lining is

natural hard rubber or PTFE, gaskets must be

placed between each the grounding ring and the

sensor to avoid uid leakage. These gaskets are

to be supplied by customer. Do not forget those

gaskets also when ordering and attaching the

grounding rings later additionally.

• Use the gasket of the equivalent hardness for

gasket (customer pipe) and gasket (sensor).

• The tightening torque of gaskets varies by the

type and external dimensions of the lining and the

gasket. The tightening torque values should be

decided by referring to Table 3.3.1.

• For uids capable of potentially permeating PTFE

linings (such as nitric acid, hydrouoric acid, or

sodium hydrate at high temperatures), do not use

the PTFE lining type.

3

Installation

• The PTFE lining has a structure adhering PTFE to

the metal inner face of the sensor. When tightening

bolts and nuts to install to the piping, be careful not

to bring unequal stress or torque to the PTFE lining.

• For the PTFE lining, it is recommendedo be installed

with grounding rings, or to be installed with short

pipes at upstream and downstream sides.

Use bolts and nuts in compliance with the ange

ratings. When choosing the gaskets, be sure to choose

sheet gaskets designed to t for ange standard.

IM 01E25A01-01EN

Page 15

IMPORTANT

IMPORTANT

A

A

<3. Installation>

14

(1) Mounting Direction

Mount the owmeter so that the ow direction of the uid

to be measured is in line with the direction of the arrow

mark on the owmeter. It may be especially dicult to

move large size sensors after bringing them into the pit.

Check directions before bringing.

If it is impossible to match the direction of the arrow

mark, the direction of the electrical connection can be

changed. Read Section 3.5.

In case the uid being measured ows against the

arrow direction, change the value from “Forward” to

“Reverse” at the parameter “Flow direct”. Read the

user’s manual of the applicable communication type

(for AXW/AXW4A/AXG1A) or the hardware/software

edition (for AXFA11) as listed in Table 1.1.

Display Menu Path (AXW/AXW4A/AXG1A):

Device setup ► Detailed setup ► AUX calculation ► Flow direct

(2) Lifting

90 degrees or less

90 degrees or less

(4) Applying Gasket and optional Grounding

Rings

Gasket:

Necessary gaskets for piping connection are as

below depending on the choice of grounding rings.

Use sheet gaskets designed to t for the ange

ratings ad uid specications. The GF type-1

gaskets by JIS G 3443-2 should be used for the JIS

F12 ange models in sizes 1100 mm (44 in.) and

above. In this case, the gasket groove is required on

the customer pipe anges.

The thickness of gasket should be 2 mm (0.08 in.)

to 5 mm (0.2 in.) for sizes up to 1000 mm (40 in.),

and 5 mm (0.2 in.) or more for larger sizes. Use

soft rubber gasket, PTFE-sheathed non-asbestos

gasket, or its equivalent in hardness.

1. Standard (no grounding rings)

Customer

pipe

A A

Gaskets A supplied by customer

Figure 3.3.2 Installation without Grounding Rings

Customer

pipe

F0312.ai

Eye bolt

Figure 3.3.1 Lifting

Eye plate

F0311.ai

CAUTION

• When carrying the magnetic owmeter, use the

lifting rings (eye bolts or eye plates).

• To assure safety, keep lifting angle less than 90

degrees as shown in Figure 3.3.1

(3) Transportation and Positioning

Bring in the magnetic owmeter, place it and use a jack to

adjust its position.

When using the GF type-1 gaskets, the gasket

groove is required as mentioned above.

2. With optional grounding rings (code GR1)

Optional grounding rings

Customer

pipe

B

Gaskets A and B supplied by customer

Figure 3.3.3 Installation with Grounding Rings GR1

B

Customer

pipe

F0313.ai

It is recommended to use the same gasket for A

and B. Both gaskets A and B are to be supplied

by customer.

When polyurethane or natural soft rubber lining,

the gaskets B are not necessary.

Apply the jack to the anges of the magnetic

owmeter.

In addition, adjust any misalignment when the

magnetic owmeter is brought in, as the jack can

adjust vertical position, but not horizontal one.

IM 01E25A01-01EN

Page 16

<3. Installation>

15

3. With optional grounding rings (code GR2)

Optional grounding rings

with integrated gaskets B included

B

Customer

pipe

A A

Gaskets A supplied by customer

Figure 3.3.4 Installation with Grounding Rings GR2

B

Customer

pipe

F0314.ai

This is available for the models with process

connection JIS F12 (JIS 75M) in sizes 1100 mm

(44 in.) and above. Only gaskets A are to be

supplied by customer. Use soft rubber gasket,

PTFE-sheathed non-asbestos gasket, or its

equivalent in hardness.

The grounding rings are installed and locked

onto the magnetic owmeter with gaskets B

when shipped from factory.

Mounting Procedure (no Grounding Rings):

Connect the magnetic owmeter’s ange and the

customer’s pipe which contact process uid by

some wire supplied by customer.

Mounting Procedure (with optional Grounding

Rings GR1 for sizes up to 1000 mm (40 in.)):

1. Handles of the grounding ring have some holes

which correspond to outer diameter of each

ange type. There are printings near each hole.

The printings show types of ange. See the

table below.

5. Install the magnetic owmeter into the

customer’s pipe with the gaskets A.

Centering Pin

Magnetic Flowmeter

Note : Gasket A and B are also placed concentrically with

Figure 3.3.5 Mounting Procedure with Grounding Rings

Screw & Nut : Connect the wire from the

grounding ring or the customer’s pipe

Centering Pin

Clockwise

Gasket B

Grounding Ring

the magnetic owmeter.

GR1 for sizes up to 1000 mm

(40 in.)

Handle

Printing of

Flange Type

F12

10K

Hole

Handle

Printed

Surface

F0315.ai

3

Installation

Printing

ASME -CA1

AWWA -CB1 AWWA C207 Class D

PN10 -CE1 EN1092-1 PN10

PN16 -CE2 EN1092-1 PN16

10K -CJ1 JIS B2220 10K

AS -CS1, -CS2, -CT1

F12 -CG1 JIS F12 (JIS 75M)

Process Connection Code

Flange Standard

ASME B16.5 Class 150,

ASME B16.47 Class 150

AS2129 table D, E

AS4087 PN16

2. Conrm the centering pin is xed to the hole

corresponding to ange or x the centering pin

to the correct hole.

3. Hang the grounding rings with their ange type

printings outer side of the magnetic owmeter.

Set the angle of both handles symmetrically to

be 45 degree from top. If there are any boltholes under the handles, turn the grounding

rings clockwise in order to locate handles

between bolt-holes. Center the grounding ring

to the center of the magnetic owmeter.

4. Connect the wire from the grounding ring to the

screw of the magnetic owmeter’s ange and

x the wire by the nut. This procedure (item

1 to 4) must be done for the both sides of the

magnetic owmeter.

Mounting Procedure (with optional Grounding

Rings GR1 for sizes 1100mm (44 in.)) and above :

1. The grounding ring is temporarily xed onto

the magnetic owmeter by four bolts. Hang the

grounding ring up using a crane or a hoist so

that it would not fall down from the magnetic

owmeter while setting the gasket B.

2. Unfasten the bolts and remove the grounding

ring o from the magnetic owmeter.

3. Place the gasket B to the magnetic owmeter.

Cut out holes on the gasket B if necessary, so

that the bolts can go through. Fix the grounding

ring to the magnetic owmeter by the four bolts

again.

4. Connect the wire from the grounding ring to the

screw at the ange and x the wire by the nut.

This procedure (item 1 to 4) must be done for

the both sides of the magnetic owmeter.

IM 01E25A01-01EN

Page 17

<3. Installation>

5. Install the magnetic owmeter into the

customer’s pipe with the gaskets A.

Screw & Nut : Connect the wire from the

grounding ring or the customer’s pipe.

Magnetic Flowmeter

Hang the grounding

ring up with this point.

Unfasten the bolts and

remove the grounding rings.

Cut out some holes on the

gasket B when necessary.

Wire

16

Grounding Ring

F0316.ai

Note : Gasket A and B should be placed concentrically with

the magnetic owmeter.

Figure 3.3.6 Mounting Procedure with Grounding Rings

GR1 for sizes 1100 mm (44 in.) and above

Mounting Procedure (with optional Grounding

Rings GR2):

The grounding rings are installed and locked onto

the magnetic owmeter with gaskets B when

shipped from factory. Install the magnetic owmeter

into the customer’s pipe with gaskets A supplied by

customer.

(5) Tightening Nuts

Pass the bolts from pipe line side, not magnetic owmeter

side, and tighten the nuts according to the torque values

for the metal piping in Table 3.3.1 or Table 3.3.2.

CAUTION

• Be sure to tighten the nuts according to the

prescribed toeque values. Tighten them diagonally

with the same torque values, step by up to the

prescribed torque value.

IM 01E25A01-01EN

Page 18

<3. Installation>

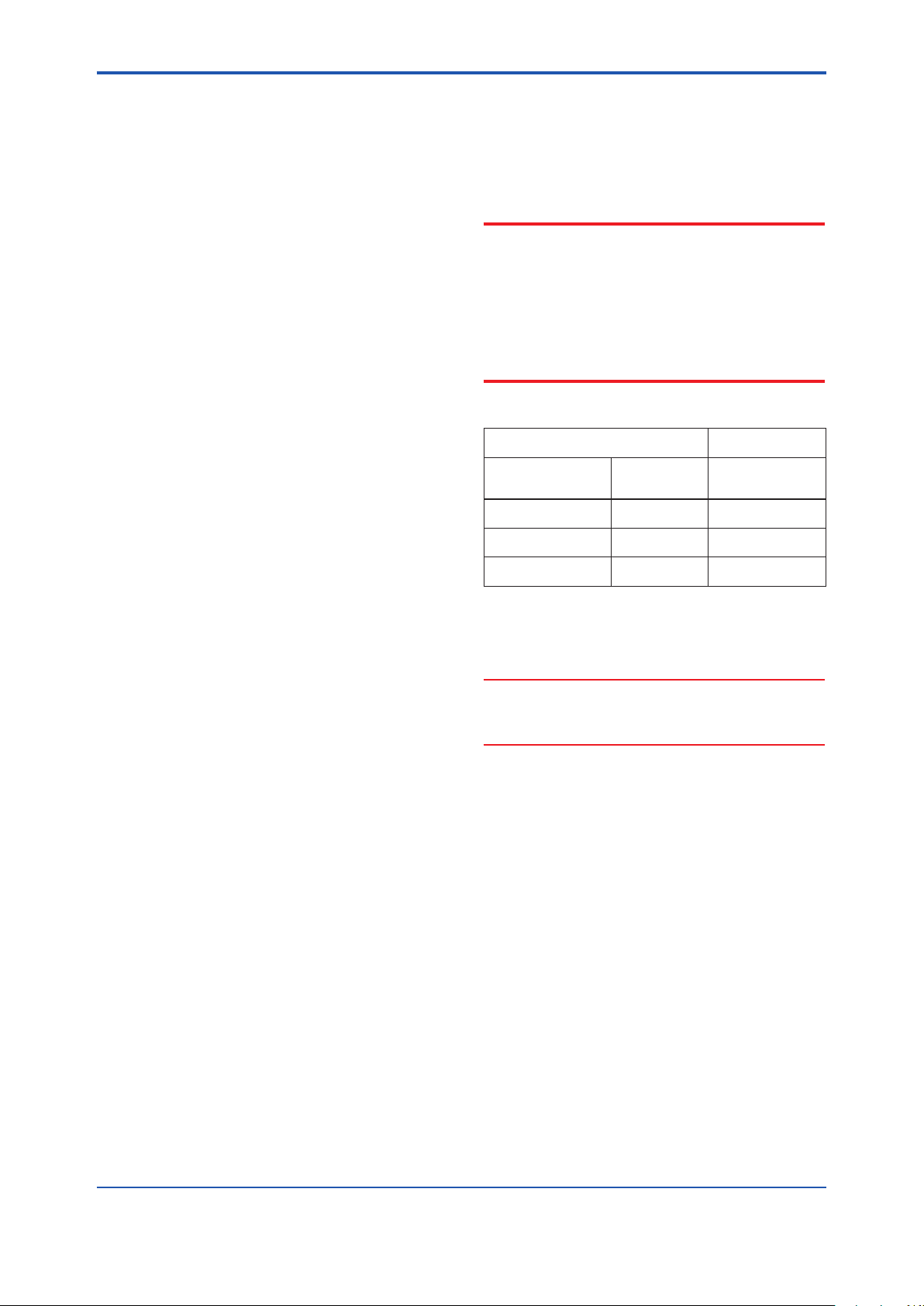

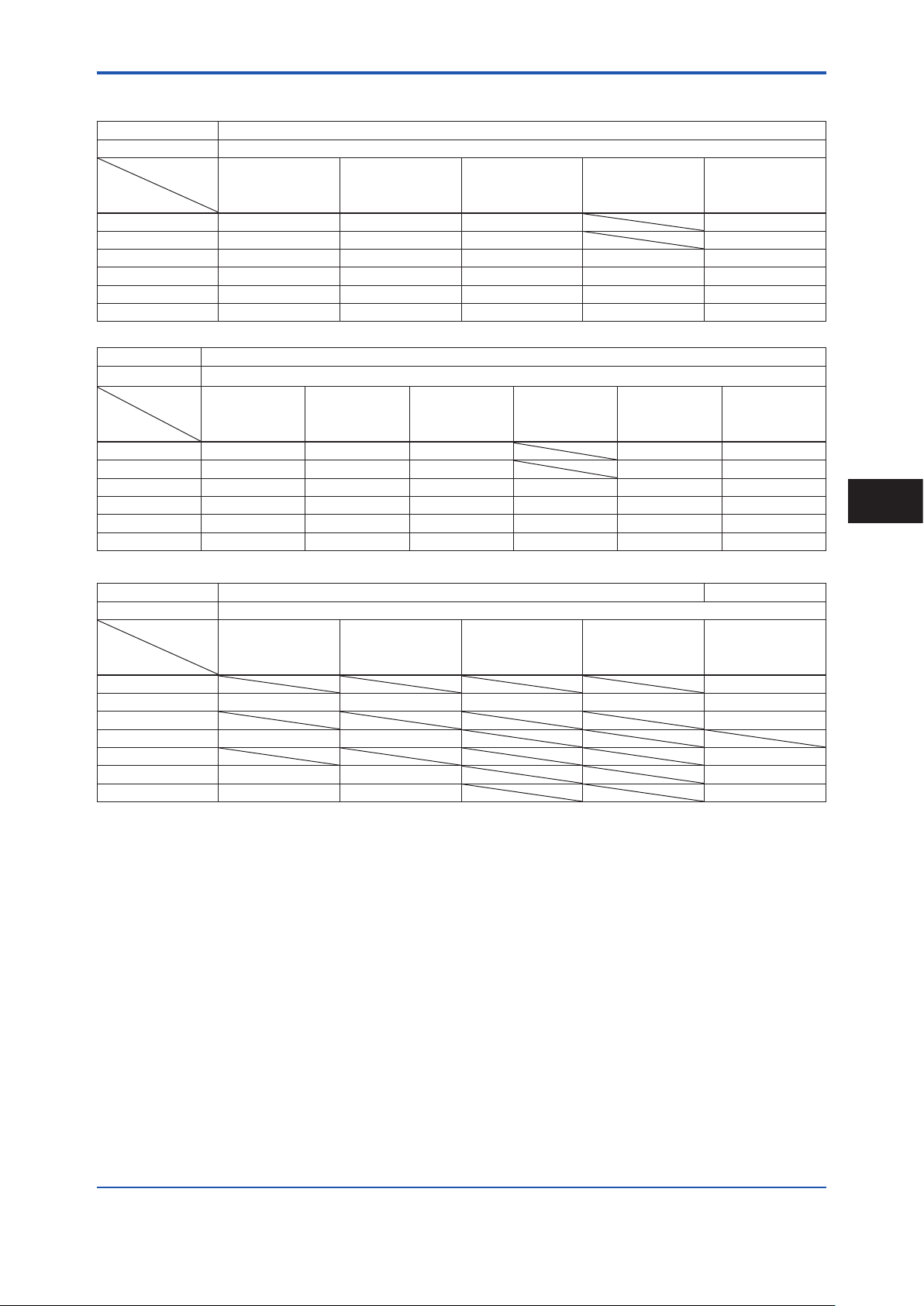

Table 3.3.1 Tightening Torque Values for Metal Piping (N-m)

Lining type

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

Size

mm (inch)

Size

mm (inch)

connection

500 (20) 99 to 166 85 to 140 143 to 238 151 to 233

600 (24) 144 to 240 108 to 175 218 to 363 239 to 331

700 (28) 168 to 281 176 to 266 180 to 300 176 to 293 240 to 333

800 (32) 259 to 432 212 to 302 236 to 393 246 to 410 400 to 612

900 (36) 274 to 457 206 to 338 224 to 373 258 to 430 399 to 604

1000 (40) 274 to 457 277 to 422 307 to 512 286 to 477 422 to 587

Lining type Polyurethane rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

500 (20) 71 to 118 60 to 99 74 to 123 76 to 123 131 to 218

600 (24) 97 to 162 82 to 126 101 to 168 118 to 171 124 to 206

700 (28) 125 to 208 135 to 202 146 to 244 120 to 200 167 to 242 202 to 337

800 (32) 176 to 294 160 to 229 190 to 316 169 to 281 218 to 348 197 to 328

900 (36) 170 to 283 151 to 251 178 to 296 161 to 268 200 to 317 221 to 369

1000 (40) 175 to 291 206 to 314 220 to 367 165 to 275 253 to 370 218 to 363

B16.5 (500, 600)

B16.47 (700-1000)

ASME

B16.5 (500, 600)

B16.47 (700-1000)

Class 150

ASME

EN1092-1 PN10

JIS B2220 10K

Class 150

PTFE / Natural hard rubber / Natural soft rubber

EN1092-1 PN10

JIS B2220 10K

EN 1092-1 PN16

EN 1092-1 PN16

AWWA C207

Class D

AWWA C207

Class D

AS2129 Table D, E

AS4087 PN16

AS2129 Table D, E

17

Unit: N-m

AS4087 PN16

Unit: N-m

JIS F12

(JIS 75M)

3

Installation

Lining type Natural hard rubber Polyurethane rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

Size

connection

mm (inch)

1100 (44) 285 to 476

1200 (48) 180 to 300 327 to 546 298 to 497 400 to 582 281 to 468

1350 (54) 397 to 662

1400 (56) 233 to 388 379 to 632

1500 (60) 421 to 702

1600 (64) 238 to 397 532 to 886 532 to 887

1800 (72) 291 to 485 552 to 919 468 to 779

EN1092-1 PN6 EN1092-1 PN10

AWWA C207

Class D

AS2129 Table D, E

AS4087 PN16

JIS F12

(JIS 75M)

Unit: N-m

IM 01E25A01-01EN

Page 19

<3. Installation>

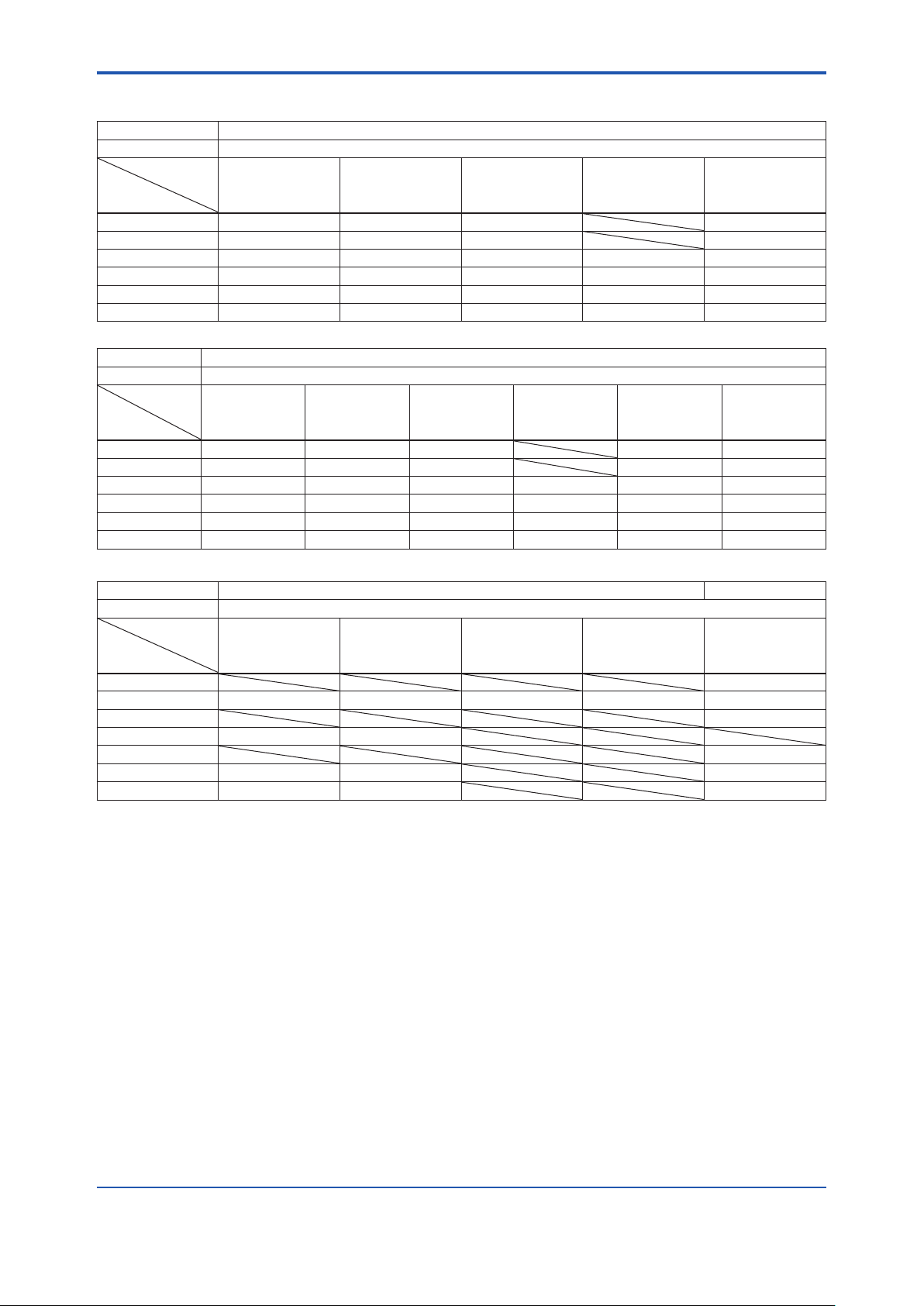

Table 3.3.2 Tightening Torque Values for Metal Piping (lbf-in)

Lining type

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

Size

mm (inch)

Size

mm (inch)

connection

500 (20) 880 to 1467 748 to 1239 1266 to 2110 1332 to 2062

600 (24) 1275 to 2125 955 to 1546 1928 to 3214 2113 to 2932

700 (28) 1490 to 2483 1561 to 2357 1594 to 2657 1558 to 2596 2123 to 2943

800 (32) 2292 to 3820 1880 to 2671 2085 to 3475 2176 to 3627 3538 to 5413

900 (36) 2426 to 4043 1821 to 2991 1980 to 3301 2285 to 3809 3535 to 5346

1000 (40) 2426 to 4043 2450 to 3739 2717 to 4528 2534 to 4224 3734 to 5265

Lining type Polyurethane rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

500 (20) 626 to 1044 527 to 876 652 to 1087 674 to 1089 1159 to 1931

600 (24) 862 to 1436 727 to 1113 894 to 1490 1043 to 1512 1095 to 1825

700 (28) 1106 to 1843 1193 to 1791 1295 to 2159 1061 to 1769 1478 to 2142 1788 to 2980

800 (32) 1562 to 2603 1420 to 2024 1680 to 2800 1494 to 2491 1926 to 3076 1739 to 2899

900 (36) 1505 to 2508 1340 to 2218 1571 to 2619 1422 to 2370 1773 to 2808 1958 to 3263

1000 (40) 1546 to 2577 1824 to 2781 1951 to 3251 1459 to 2432 2239 to 3274 1928 to 3213

B16.5 (500, 600)

B16.47 (700-1000)

ASME

B16.5 (500, 600)

B16.47 (700-1000)

Class 150

ASME

EN1092-1 PN10

JIS B2220 10K

Class 150

PTFE / Natural hard rubber / Natural soft rubber

EN1092-1 PN10

JIS B2220 10K

EN 1092-1 PN16

EN 1092-1 PN16

AWWA C207

Class D

AWWA C207

Class D

AS2129 Table D, E

AS4087 PN16

AS2129 Table D, E

18

Unit: lbf-in

AS4087 PN16

Unit: lbf-in

JIS F12

(JIS 75M)

Lining type Natural hard rubber Polyurethane rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

Size

connection

mm (inch)

1100 (44) 2527 to 4211

1200 (48) 1594 to 2657 2898 to 4830 2639 to 4398 3539 to 5149 2484 to 4139

1350 (54) 3517 to 5862

1400 (56) 2060 to 3434 3358 to 5597

1500 (60) 3729 to 6215

1600 (64) 2109 to 3515 4705 to 7842 4713 to 7854

1800 (72) 2576 to 4293 4883 to 8138 4138 to 6897

EN1092-1 PN6 EN1092-1 PN10

AWWA C207

Class D

AS2129 Table D, E

AS4087 PN16

JIS F12

(JIS 75M)

Unit: lbf-in

IM 01E25A01-01EN

Page 20

<3. Installation>

IMPORTANT

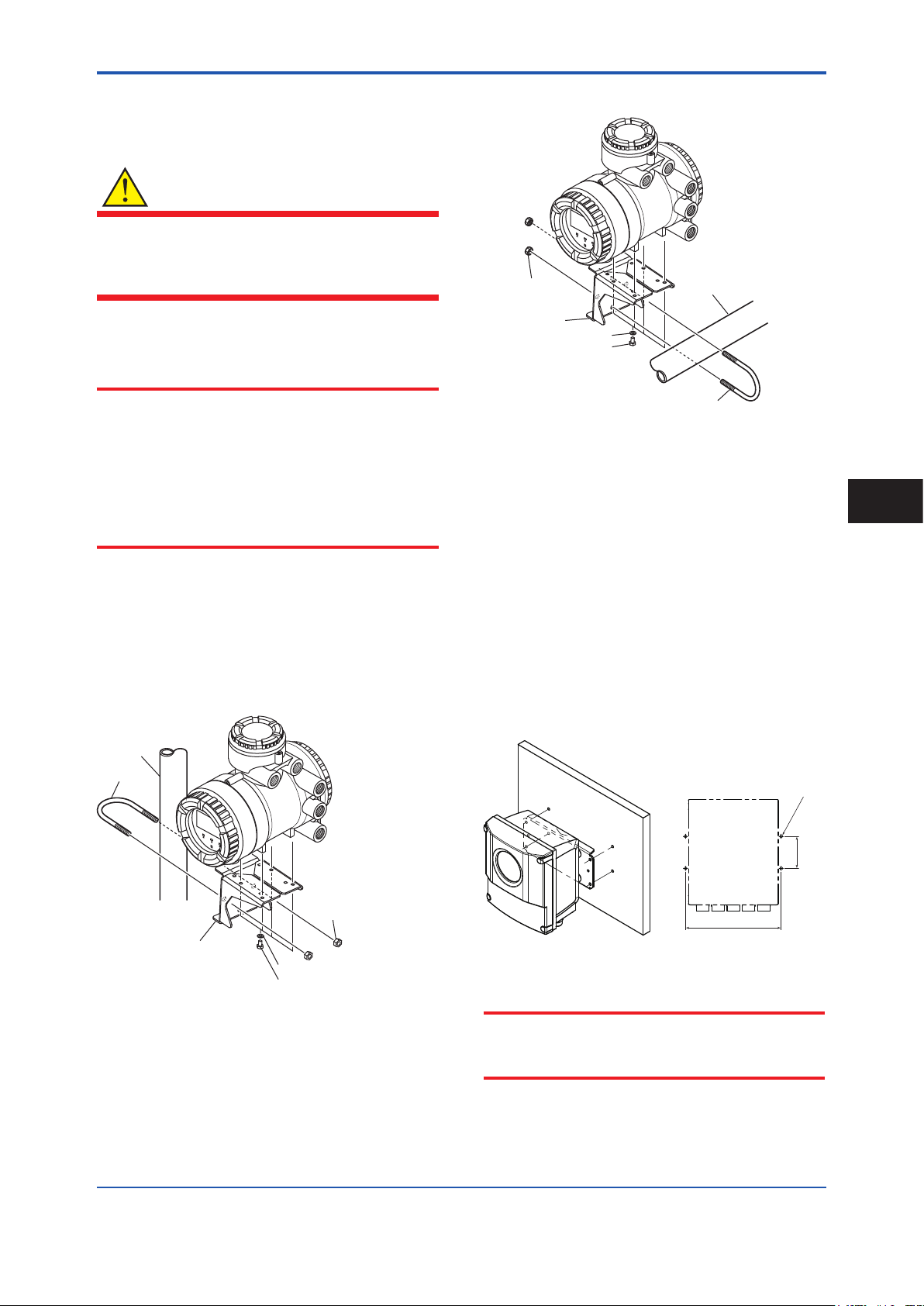

F0317.ai

F0318.ai

Mounting fixture

4-ø6 Hole or

F0319.ai

Unit: mm

(approx. inch)

IMPORTANT

19

3.4 Remote Transmitter Installation

WARNING

Installation of the magnetic owmeter must be

performed by expert engineer or skilled personnel.

No operator shall be permitted to perform procedures

relating to installation.

3.4.1 Installation Location

Install the instrument in a location where it is not

exposed to direct sunlight. For ambient temperature,

read the applicable general specications as listed in

Table 1.1.

The instrument may be used in an ambient humidity

where the RH ranges from 0 to 100%. However, avoid

long-term continuous operation at relative humidity

above 95%.

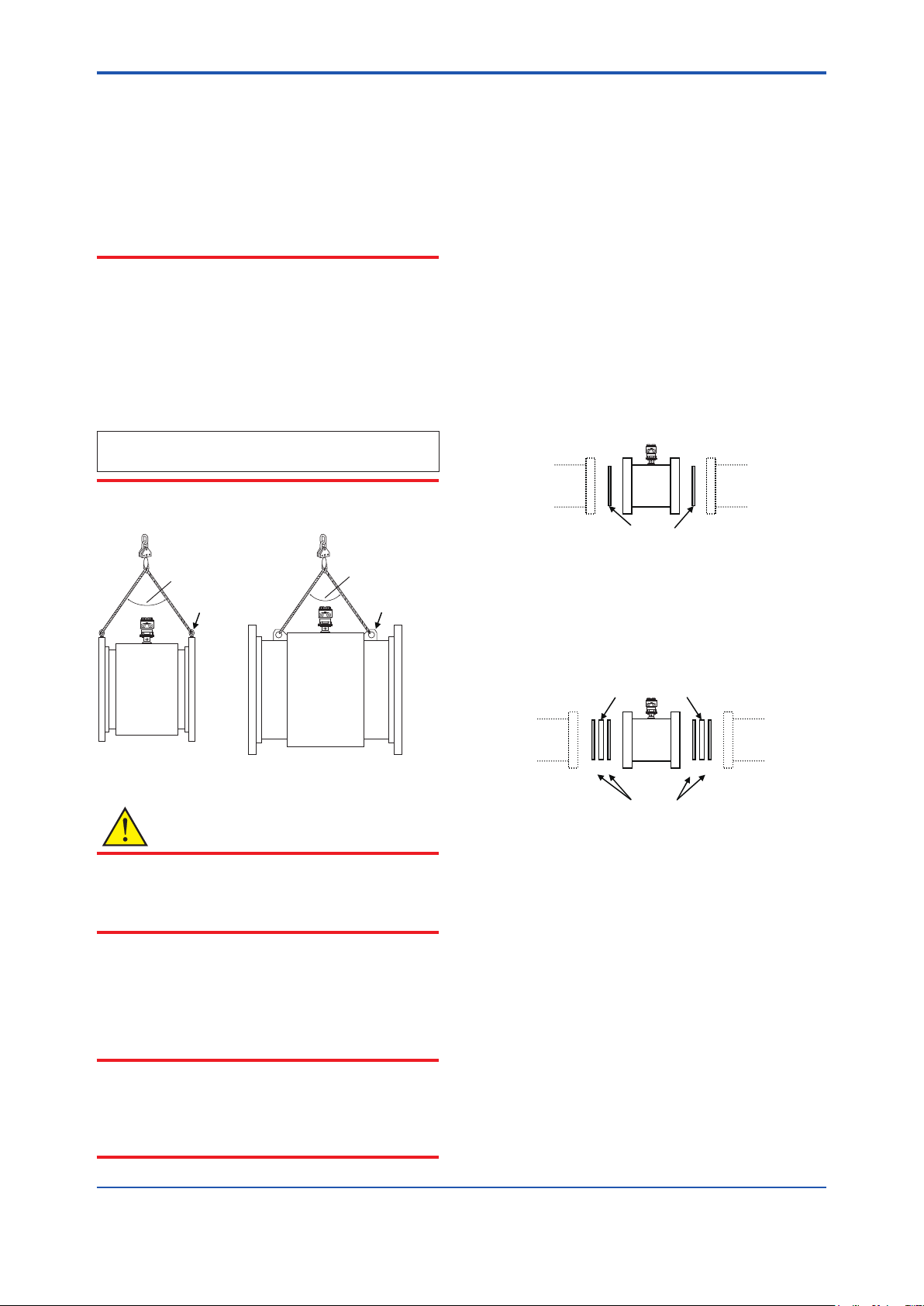

Horizontal Pipe Mounting

Nut

Washer

Screw

Figure 3.4.2 2-inch Pipe Horizontal Mounting

1. Fix the instrument on the mounting xture using four

screws.

2. Fix the mounting xture with the instrument installed

on a 2-inch pipe using a U-bolt.

2-inch pipe

U-bolt

3

Installation

3.4.2 Mounting of AXW4A Transmitter

AXW4A Remote Transmitter can be mounted on a 2-inch

pipe in a vertical or horizontal position depending on the

installation site.

Vertical Pipe Mounting

2-inch pipe

U-bolt

Nut

Mounting fixture

Washer

Screw

Figure 3.4.1 2-inch Pipe Vertical Mounting

1. Fix the instrument on the mounting xture using four

screws.

2. Fix the mounting xture with the instrument installed

on a 2-inch pipe using a U-bolt.

3.4.3 Mounting of AXG1A Transmitter

AXG1A Remote Transmitter can be mounted using surface

mounting, 2-inch pipe mounting, or panel mounting.

Surface Mounting (Wall Mounting)

For surface mounting, use the mounting

fixture provided, using M6 screws.

These M6 screws must be provided by the user.

M6 Screw

65

(2.56)

194 (7.64)

Figure 3.4.3 Surface Mounting

Mounting xture on equipment intended to be mounted

on a wall or ceiling shall withstand a force of four times

the weight of the equipment (AXG1A: 3.5 kg (7.7 lb)).

IM 01E25A01-01EN

Page 21

F0320.ai

Unit: mm

(approx. inch)

F0321.ai

IMPORTANT

<3. Installation>

20

2-inch Pipe Mounting

2-inch pipe

Mounting fixture

Washer

Clamp screw

Figure 3.4.4 2-inch Pipe Mounting

1. Pass the four clamp screws through the mounting

xture.

2. position it on the 2-inch pipe, and then fasten the

AXG1A in place.

Panel Mounting

3.5 Changing Direction of Electrical Connection

3.5.1 Integral Flowmeter

(1) The following tool is required.

• Hexagonal wrench (nominal size 5)

(2) Turn o the power to the owmeter.

(3) Using the wrench, unscrew the four hexagonal bolts

at the neck of transmitter.

Panel cutout

Mounting fixture

172 (6.8)

R3MAX

Washer

Screw

Clamp screw

Figure 3.4.5 Panel Mounting

1. Fit the AXG1A into the panel.

2. Attach the mounting xture to the AXG1A using the

screw and the washer, and secure the instrument with

the two clamp screws.

3.4.4 Mounting of AXFA11 Transmitter

AXFA11 Remote Transmitter can be mounted using

surface mounting, 2-inch pipe mounting, or panel

mounting, by the same process of AXG1A. Please refer

3.4.3. for the process.

203 (8.0)

AXW Integral Flowmeter

F0322.ai

CAUTION

Do not loosen the screw at the opposite side of electrical

connection (see the gure below).

F0323.ai

Mounting xture on equipment intended to be

mounted on a wall or ceiling shall withstand a force of

four times the weight of the equipment (AXFA11: 3.4

kg (7.5 lb)).

IM 01E25A01-01EN

Page 22

<3. Installation>

NOTE

IMPORTANT

NOTE

21

(4) Rotate the transmitter in the desired direction.

The direction can be changed to -90 degrees, +90

degrees or +180 degrees.

The transmitter and the terminal box can be rotated -90

degrees to +180 degrees at every 90 degrees from the

arrow mark indicating the ow direction. Do not exceed

these angle.

(5) Tighten diagonally the four hexagonal bolts with the

hexagonal wrench, and then be sure to check that the

transmitter was rmly xed to the sensor.

+90 degrees

Upstream

side

±0 degrees

+180 degrees

-90 degrees

Downstream

side

3.5.2 Remote Sensor (Style: S1)

The following types can not be changed direction of

electrical connection after delivery.

• Submersible Type (Model: AXWW)

• For District Heating and Cooling or Condensation-

proof (Optional code: DHC)

(1) The following tools are required.

• Hexagonal wrench (nominal size 1.5)

• Spanner (nominal size 46)

(2) Turn o the power to the owmeter.

(3) Using the spanner, loosen the hexagonal nuts at the

neck of remote sensor.

3

Installation

AXW Integral Flowmeter

F0324.ai

F0325.ai

(4) Using the hexagonal wrench, loosen the screw at the

neck.

(5) Rotate the terminal box in the desired direction.

The terminal box can be rotated -140 degrees to

+180 degrees from the arrow mark indicating the ow

direction. Do not exceed these angle.

(6) Using the hexagonal wrench, retighten the screw at

the neck.

+180 degrees-140 degrees

F0326.ai

(7) Using the spanner, retighten the hexagonal nut at the

neck, and then be sure to check that the terminal box

was rmly xed to the sensor.

IM 01E25A01-01EN

Page 23

IMPORTANT

NOTE

<3. Installation>

22

3.5.3 Remote Sensor (Style: S2)

The following types can not be changed direction of

electrical connection after delivery.

• Submersible Type (Model: AXWW)

• For District Heating and Cooling or Condensation-

proof (Optional code: DHC)

(1) The following tools are required.

• Hexagonal wrench (nominal size 5)

(2) Turn o the power to the owmeter.

(3) Using the wrench, unscrew the four hexagonal bolts

at the neck of remote sensor.

(4) Rotate the transmitter or the terminal box in the

desired direction. The direction can be changed to -90

degrees, +90 degrees or +180 degrees.

The terminal box can be rotated -90 degrees to +180

degrees at every 90 degrees from the arrow mark

indicating the ow direction. Do not exceed these

angle.

(5) Tighten diagonally the four hexagonal bolts with the

hexagonal wrench, and then be sure to check that the

terminal box was rmly xed to the sensor.

+90°

±0°

+180°

-90°

F0327.ai

AXW Remote Sensor

CAUTION

Do not loosen the screw at the opposite side of electrical

connection (see the gure below).

F0328.ai

AXW Remote Sensor

F0329.ai

IM 01E25A01-01EN

Page 24

<3. Installation>

IMPORTANT

IMPORTANT

23

3.6 Changing Direction of

Display Unit

(1) Removing the Cover

• The following tool is required.

Hexagonal wrench (nominal size 3)

• Turn o the power to the owmeter.

• Using the wrench, loosen the cover locking screw

(1) (See Figure 3.6.1 and Figure 3.6.2) clockwise

to unlock the cover. Upon shipment from the

manufacturing plant, the cover is locked. Hold the

owmeter with your hand. Remove the cover by

rotating it counterclockwise.

(1)

Cover locking screw

(2) Changing Display Unit Direction 90 degrees

• Hold the display unit with your hand and loosen

the two mounting screws.

• Rotate the display unit 90 degrees clockwise and

conrm the assembling position, taking care of the

connector and wire of the display unit.

At this time, do not remove the connector.

• Secure the display unit using its two mounting

screws.

Mounting screw

(two screws)

3

Installation

Figure 3.6.1 Removing the Display Cover

(Integral Flowmeter)

(1)

Cover locking screw

Figure 3.6.2 Removing the Display Cover

(AXW4A Remote Transmitter)

F0330.ai

F0331.ai

Clockwise 90 degrees

Figure 3.6.3 Changing Display Unit Direction 90 degrees

To preserve the safety, do not touch the electrical circuit

and cable of shaded area.

F0332.ai

(3) Installing the Cover

• Install the cover to the owmeter by rotating the

cover clockwise.

• Tighten cover locking screw (1) (See Figure

3.6.1 and Figure 3.6.2) counterclockwise using

a hexagonal wrench (nominal size 3) to lock the

cover.

Be sure to screw the cover rmly into the housing

without any space between them.

IM 01E25A01-01EN

Page 25

<4. Wiring>

4. Wiring

24

WARNING

The wiring of the magnetic owmeter must be

performed by expert engineer or skilled personnel.

No operator shall be permitted to perform procedures

relating to wiring.

CAUTION

Once all wiring is completed, check the connections

before applying power to the instrument. Improper

arrangements or wiring may cause a unit malfunction or

damage.

4.1 Wiring Precautions

Be sure to observe the following precautions when wiring:

CAUTION

• When opening the terminal box, wait for more than

20 minutes after turning o the power.

• In cases where the ambient temperature exceeds

50°C, use external heat resistant wiring with a

maximum allowable temperature of 70°C or above.

• Do not connect cables outdoors in wet weather in

order to prevent damage from condensation and to

protect the insulation, e.g. inside the terminal box of

the owmeter.

• Before turning the power on, tighten the terminal

box cover securely.

• For the remote type, do not splice the cable

between the transmitter and the sensor terminal

when it is too short. Replace it with a complete

cable of the appropriate length.

• For the remote type, ground the remote sensor and

the transmitter separately.

• Terminate all the cable nish with crimp terminal of

a round or rod shape (depending on the shape of

the terminal block), and connect them reliably.

• Always route the power and output signal cables

in separate steel conduit tubes, except when the

power supply voltage is 24 V and four-core cables

are used for wiring. For the remote type, route the

excitation cable and the signal cable in separate

steel conduit tubes. Keep conduits or exible tubes

watertight using sealing tape.

• If there is any unused electrical connection, use

the blanking plug to cover which comes with this

instrument or which is supplied by YOKOGAWA.

The blanking plug should be fastened into the

unused electrical connection without any mistake.

If not, stated enclosure protection is not applicable.

One or two blanking plug is provided depending on

the specications (24 V for power supply voltage or

I/O selection).

• The signal cables must be routed in separate steel

conduit tubes 16 (JIS C 8305) or exible conduit

tubes 15 (JIS C 8309).

• When waterproof glands or union equipped

waterproof glands are used, avoid tightening the

glands with an excessive torque.

• For the instruction of removing/installing the housing

covers and handling the locking screws, read

Section 4.4 and Section 4.5.

IM 01E25A01-01EN

Page 26

<4. Wiring>

IMPORTANT

Unit : mm

(approx. inch)

F0401.ai

NOTE

Inner jacket

Unit : mm

(approx. inch)

Conductors (A and B)

IMPORTANT

25

For the remote type, prepare the excitation cable

(supplied by customer) and the signal cable of almost

the same length. It is recommended to lay them

together closely.

4.2 Cables

4.2.1 Recommended Cable for Excitation, Power and Input/Output:

JIS C 3401 control cable equivalent

JIS C 3312 power cable equivalent

14 AWG Belden 8720 equivalent

Outer Diameter:

With no gland option:

6.5 to 12 mm (0.26 to 0.47 in.)

With waterproof gland (optional code EG, EG, EU,

EU, EW):

For excitation cable:

10.5 or 11.5 mm (0.41 or 0.45 in.)

For power and input/output cable:

7.5 to 12 mm (0.30 to 0.47 in.)

With plastic gland (optional code EP, EP:

6 to 12 mm (0.24 to 0.47 in.)

Nominal Cross Section:

Single wire; 0.5 to 2.5 mm

Stranded wire; 0.5 to 1.5 mm

Excitation cable for submersible use and optional

code DHC:

Heat resistant vinyl resin sheath cable

Outer diameter ø 10.5 mm

In case of power cable, Green/Yellow covered conductor

shall be used only for connection to PROTECTIVE

CONDUCTOR TERMINALS. Conform to IEC227,

IEC245 or equivalent national authorization.

2

2

Crimp terminal

• For excitation cable and power cable, always use a

crimp terminal with an insulation cover.

• Use crimp tools supplied by the manufacturer of the

crimp terminal you want to use to connect the crimp

terminal and cable.

• Use crimp tools that are appropriate for the diameter

of the cable to be connected.

4.2.2 Dedicated Signal Cable (AX01C)

Shields (SA and SB)

Tape

Outer jacket

Shield (C)

Inner jacket

Figure 4.2.2 Dedicated Signal Cable

The ow signal is transmitted via this dedicated cable.

The cable is constructed with double shielding over the

two conductors, and heat-resistant vinyl is used for the

outer jacket material.

Finished diameter: 10.5 mm (0.413 in.)

Maximum length:

Combination with the AXG1A/AXFA11 transmitter:

200 m (660 ft)

Combination with the AXW4A transmitter:

100 m (330 ft)

Maximum temperature: 80°C (176°F)

If the cable is longer than required, cut o any extra

length rather than coiling it up, and terminate the

conductors as shown in Figure 4.2.3.

Avoid using junction terminal boards to extend the cable

length, as this will interrupt the shielding.

10.5 (0.413)

F0402.ai

4

Wiring

EX1

Figure 4.2.1 Cable Finish for Excitaiton Cable

EX2

85 (3.35)

On the transmitter side

85 (3.35)

On the sensor side

EX1

EX2

IM 01E25A01-01EN

Page 27

<4. Wiring>

Unit: mm (approx. in.)

F0403.ai

Cable Finish: Finished

4.3 Electrical Connections

E

ACB

SA

(WHITE)

TRANSMITTER

Specication Code

AX01C-C

AX01C-B

AX01C-D

SB

F

G

D

(RED)(BLACK)

±5

8(0.31)Max.

150

(5.91)

L (Specified Length)

20(0.79)

D E F G

60 (2.4) 25 (1.0) 70 (2.8) 50 (2.0) For AXW4A

70 (2.8) 25 (1.0) 50 (2.0) 60 (2.4) For AXG1A

70 (2.8) 25 (1.0) 50 (2.0) 60 (2.4) For AXFA11

Length

Cable Finish: Unfinished

CAP

L (Specified Length) + 340(13.39) (Length for Cable Finish)

ø10.5(0.41)

Figure 4.2.3 Cable Finish for Signal Cable

ACB

90(3.54)

(WHITE)

±5

8(0.31)Max.

150

(5.91)

ø10.5(0.41)

55(2.17)

(BLACK) (RED)

SENSOR

Description

F404.ai

90(3.54)

This instrument is of watertight construction as stipulated

in JIS C 0920. It is shipped with a wiring bracket

(waterproof gland, waterproof gland with union or a

plastic gland attached), only in cases where an optional

specication is selected for the electrical connection.

Cable gland has the following kinds depending on the

type and size.

Integral Type Flowmeter

AXW (Size: 500 to 1000 mm (20 to 40 in.))

Optional

Code

EG2 2 pcs. of waterproof gland, and a blanking plug

EG3 3 pcs. of waterproof gland

2 pcs. of waterproof gland with union joint, and a blanking

EU2

plug

EU3 3 pcs. of waterproof gland with union joint

EP2 2 pcs. of plastic gland, and a blanking plug

EP3 3 pcs. of plastic gland

Description

Remote Sensor

AXW (Size: 500 to 1800 mm (20 to 72 in.))

Optional

Code

EW 2 pcs. of waterproof gland with JIS G3/4 female

EG 2 pcs. of waterproof gland

EU 2 pcs. of waterproof gland with union joint

Description

26

• As crimp terminals A, B, SA, SB and C have their

• To prevent a shield from coming in contact with

4.2.3 Recommended Cable for Modbus

3-Wire cable (twisted pair and Common) with shield

should be used.

Wire gauge: AWG24 or wider

Characteristic Impedance of cable: 100Ω or more

4.2.4 Recommended Cable for FOUNDATION

Fieldbus type-A specication cable should be used.

CAUTION

own electrical potentials, securely insulate them so

as not to come in contact with one another.

another shield or the case, cover each shield with a

vinyl tube or wrap it in vinyl tape.

communication