Page 1

USB-2401

24-bit 2kS/s USB 2.0-Based Universal Input

DAQ Module

User’s Manual

Manual Rev.: 2.00

Revision Date: Apr 27, 2012

Part No: 50-1Z101-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

2.00 Apr 27, 2012 Initial release

ii

Page 3

USB-2401

Preface

Copyright 2012 ADLINK Technology, Inc.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component dam-

age, data loss, and/or program corruption when trying to com-

CAUTION:

WARNING:

plete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

iv Preface

Page 5

USB-2401

Table of Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Figures....................................................................... vii

List of Tables.......................................................................... ix

1 Introduction ........................................................................ 1

1.1 Overview.............................................................................. 1

1.2 Features............................................................................... 1

1.3 Applications ......................................................................... 2

1.4 Specifications....................................................................... 2

1.4.1 General Specifications................................................ 2

1.4.2 General Analog Input.................................................. 2

1.4.3 Analog Input Electrical................................................ 4

1.4.4 Digital Input/Output..................................................... 7

1.5 Software Support ................................................................. 8

1.6 Driver Support for Windows................................................. 8

1.7 Utilities for Windows .......................................................... 10

1.8 Overview and Dimensions ................................................. 11

1.8.1 Module...................................................................... 11

1.8.2 Module Stand ........................................................... 14

1.9 Connector Information ....................................................... 18

2 Getting Started ................................................................. 21

2.1 Connecting the USB-2401 Module .................................... 21

2.2 Device ID ........................................................................... 22

2.3 Hardware Configuration..................................................... 23

2.4 Device Mounting ................................................................ 23

2.4.1 Rail Mounting............................................................ 23

Table of Contents v

Page 6

2.4.2 Wall Mounting ........................................................... 25

3 Operation........................................................................... 27

3.1 Functional Layout............................................................... 27

3.2 Signal Sources................................................................... 27

3.2.1 Floating Signal Source.............................................. 27

3.2.2 Ground-Referenced Signal Source........................... 28

3.3 Signal Connection.............................................................. 28

3.3.1 Voltage Input Mode .................................................. 28

3.3.2 Current Input Mode................................................... 29

3.3.3 Full Bridge and Half Bridge Input Mode.................... 30

3.3.4 Thermocouple Input Mode........................................ 31

3.3.5 RTD Input Mode ....................................................... 32

3.3.6 Wire Resistance Mode.............................................. 34

3.4 AI Data Format................................................................... 35

3.5 ADC Sampling Rate........................................................... 36

3.5.1 Software Polling Data Transfer

(Non-Buffering Programmed I/O).............................. 36

3.5.2 Continuous Acquisition Mode ................................... 37

3.6 Programmable Function I/O............................................... 37

3.6.1 TTL DI/DO ................................................................ 37

3.6.2 General Purpose Timer/Counter............................... 38

3.6.3 General Purpose Timer/Counter Modes................... 39

4 Calibration......................................................................... 45

Important Safety Instructions............................................... 47

Getting Service...................................................................... 49

vi Table of Contents

Page 7

USB-2401

List of Figures

Figure 1-1: U-Test Interface ........................................................ 10

Figure 1-2: USB-2401 Module Rear View................................... 11

Figure 1-3: USB-2401 Module Side View ................................... 12

Figure 1-4: USB-2401 Module Front View .................................. 13

Figure 1-5: Module, Stand, Connector, and USB Cable ............. 14

Figure 1-6: Module, Stand, & Wall Mount Kit Side View (w/ Connec-

tions)......................................................................... 14

Figure 1-7: Module In Stand Front View ..................................... 15

Figure 1-8: Module Stand Top View ........................................... 16

Figure 1-9: Module Stand Side Cutaway View ........................... 17

Figure 1-10: Module Stand Front View ......................................... 17

Figure 2-1: USB-2401 Module in Windows Device Manager...... 21

Figure 2-2: Device ID Selection Control...................................... 22

Figure 2-3: Rail Mount Kit ........................................................... 23

Figure 2-4: Module Pre-Rail Mounting ........................................ 24

Figure 2-5: Module Rail-Mounted ............................................... 24

Figure 2-6: Wall Mount Holes ..................................................... 25

Figure 2-7: Module with Wall Mount Apparatus .......................... 25

Figure 3-1: USB-2401 Functional Block Diagram ....................... 27

Figure 3-2: Ground-Referenced Source and Differential Input ... 28

Figure 3-3: Floating Source and Differential Input ...................... 29

Figure 3-4: Current Source Connection ...................................... 30

Figure 3-5: Full Bridge and Half Bridge Connection ................... 31

Figure 3-6: Thermocouple Connection ....................................... 32

Figure 3-7: 4-Wire RTD Connection ........................................... 33

Figure 3-8: 3-Wire RTD Connection ........................................... 33

Figure 3-9: 2-wire RTD Connection ............................................ 34

Figure 3-10: 2-Wire Resistance Connection ................................. 35

Figure 3-11: Mode 1-Simple Gated-Event Calculation ................. 39

Figure 3-12: Mode 2-Single Period Measurement ........................ 40

Figure 3-13: Mode 3-Single Pulse-Width Measurement ............... 40

Figure 3-14: Mode 4-Single-Gated Pulse ..................................... 41

Figure 3-15: Mode 5-Single-Triggered Pulse................................ 42

Figure 3-16: Mode 6-Re-Triggered Single Pulse .......................... 42

Figure 3-17: Mode 7-Single-Triggered Continuous Pulse............. 43

Figure 3-18: Mode 8-Continuous Gated Pulse ............................. 43

Figure 3-19: Mode 9-Edge Separation Measurement................... 44

Figure 3-20: Mode 10-PWM Output.............................................. 44

List of Figures vii

Page 8

This page intentionally left blank.

viii List of Figures

Page 9

USB-2401

List of Tables

Table 1-1: U-Test Interface Legend................................................ 10

Table 1-2: USB-2401 Pin Assignment ............................................ 18

Table 1-3: I/O Signal Description .................................................... 19

Table 3-1: Analog Input Range and Output Digital Code................ 35

Table 3-2: Analog Input Range and Output Digital Code (cont’d)... 36

Table 3-3: TTL Digital I/O Pin Definition ......................................... 37

Table 3-4: Timer/Counter Pin Definition.......................................... 38

List of Tables ix

Page 10

This page intentionally left blank.

xList of Tables

Page 11

1 Introduction

1.1 Overview

The USB-2401 is a 24-bit, 4-channel simultaneous-sampling universal input USB DAQ module featuring built-in signal conditioning

and direct measurement of commonly used sensors, including

current output transducers, thermocouple, RTD, load cell, strain

gauge, and resistance. Individual channels can be programmed to

measure different signal types.

The USB-powered USB-2401 is equipped with removable

screw-down terminals for easy device connectivity, and the

included multi-functional stand fully supports desktop, rail, or wall

mounting.

The USB-2401 is suitable for basic measurement applications

requiring high resolution and accuracy, laboratory research and

material testing environments, and industrial temperature measurement. U-Test, a free ready-to-use testing program is included

to enable operation or testing of all ADLINK USB DAQ series functions with no programming requirements.

USB-2401

1.2 Features

X High-speed USB 2.0

X USB powered

X 4-CH simultaneous-sampling analog input

X Built-in signal conditioning for high voltage/current/thermo-

couple/RTD/strain gauge/load cell/resistance measurement

X Sample rate from 20 S/s to 2 kS/s

X Functional digital I/O

X Removable screw-down terminal

X Lockable USB cable for secure connectivity

X Ready-to-use testing application (U-Test) provided

Introduction 1

Page 12

1.3 Applications

X Automotive testing

X Laboratory research

X Biotech measurement

X I/O control

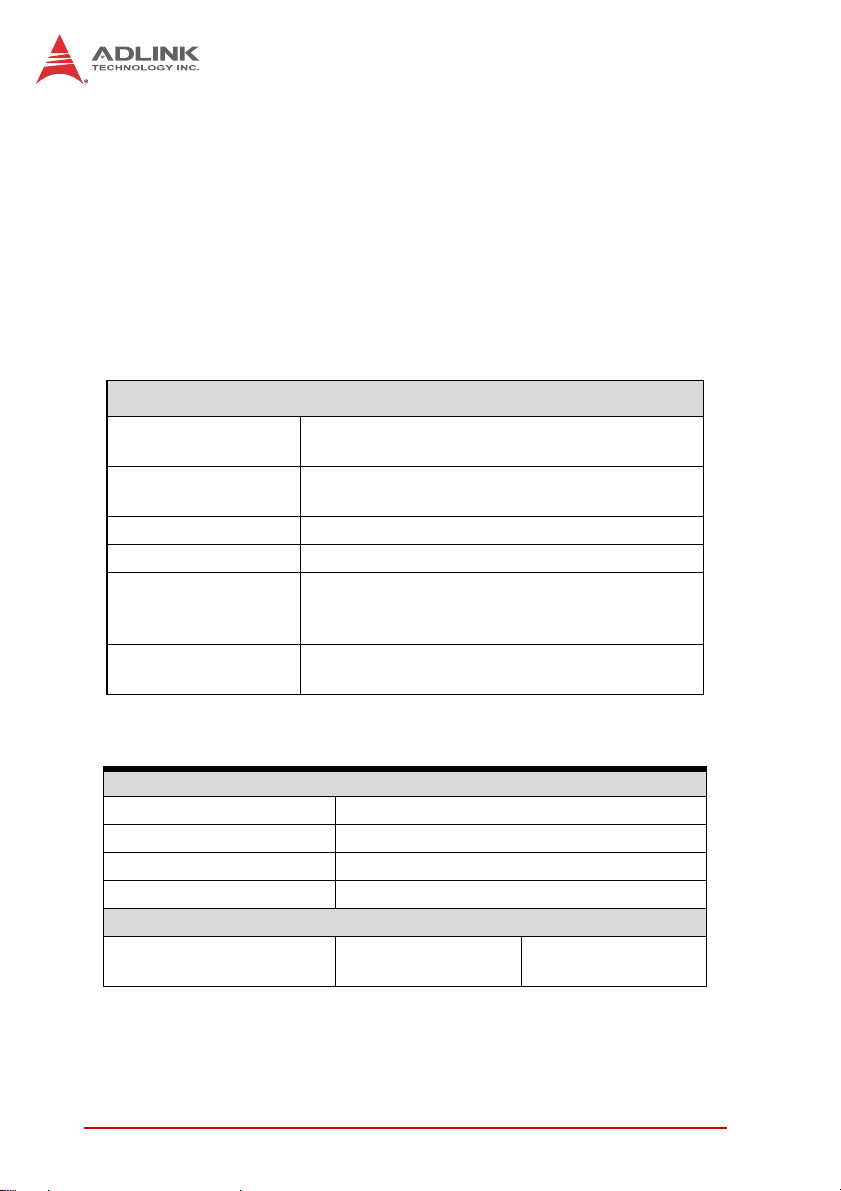

1.4 Specifications

1.4.1 General Specifications

Physical, Power, and Operating Environment

Interface

Dimensions

I/O Connector Two 20-pin removable screw-down terminals

Power requirement USB power (5 V @ 400 mA)

Operating

environment

Storage environment

High speed USB 2.0 compatible, mini-USB

connector

156 (L) x 114 (W) x 41 (H) mm (6.14 X 4.49 X

1.61 in.)

Ambient temperature: 0 to 55°C

Relative humidity: 10% to 90%,

non-condensing

Ambient temperature: -20 to 70 °C

Relative humidity: 5% to 95%, non-condensing

1.4.2 General Analog Input

General

Number of channels: 4 differential input (simultaneous-sampling)

Sampling rate (sample/sec) 20, 40, 80, 160, 320, 500, 1000, 2000

Resolution 24-bit

Input coupling DC

Input mode and range

Input range or

supporting type

2Introduction

Actual input range

Page 13

USB-2401

Voltage ±25V

±12.5V

±2.5V

±312.5mV

Current ±20mA 2.5V

Thermocouple K, J, N, R, S, B, T, E 78.125mV

RTD (3-wire, 4-wire) Pt 100, Pt 1000 2.5V

Half-Bridge (120Ω, 350Ω) Max. 30mV/V 78.125mV

Full-Bridge (120Ω, 350Ω) Max. 30mV/V 78.125mV

2-Wire Resistance 30kΩ 2.5V

Excitation voltage 2.5V (for half/full-bridge mode only)

Excitation current 0.5mA for RTD mode

0.05mA for Resistance mode

Cold junction compensation

(CJC) accuracy

Operational common mode

voltage range

Overvoltage protection Power on:

FIFO buffer size 4k samples

Data transfers Programmed I/O, continuous (bulk transfer

Input impedance 1.009M for voltage input mode

± 0.5°C (after 15 minute warmup)

Voltage input mode: Vcm+Vpp/2 ≦ input

range (25V/12.5V/2.5V/ 0.3125V)

Current input mode: Vcm ≦24V

Voltage input mode: 30V

Current input mode: 60mA

Sensor input mode enable: no protection

Sensor input mode disable: 30V

Excitation voltage (EX+) and AGND: no

protection

mode)

249.5 for current input mode

±25V

±12.5V

±2.5V

±312.5mV

Introduction 3

Page 14

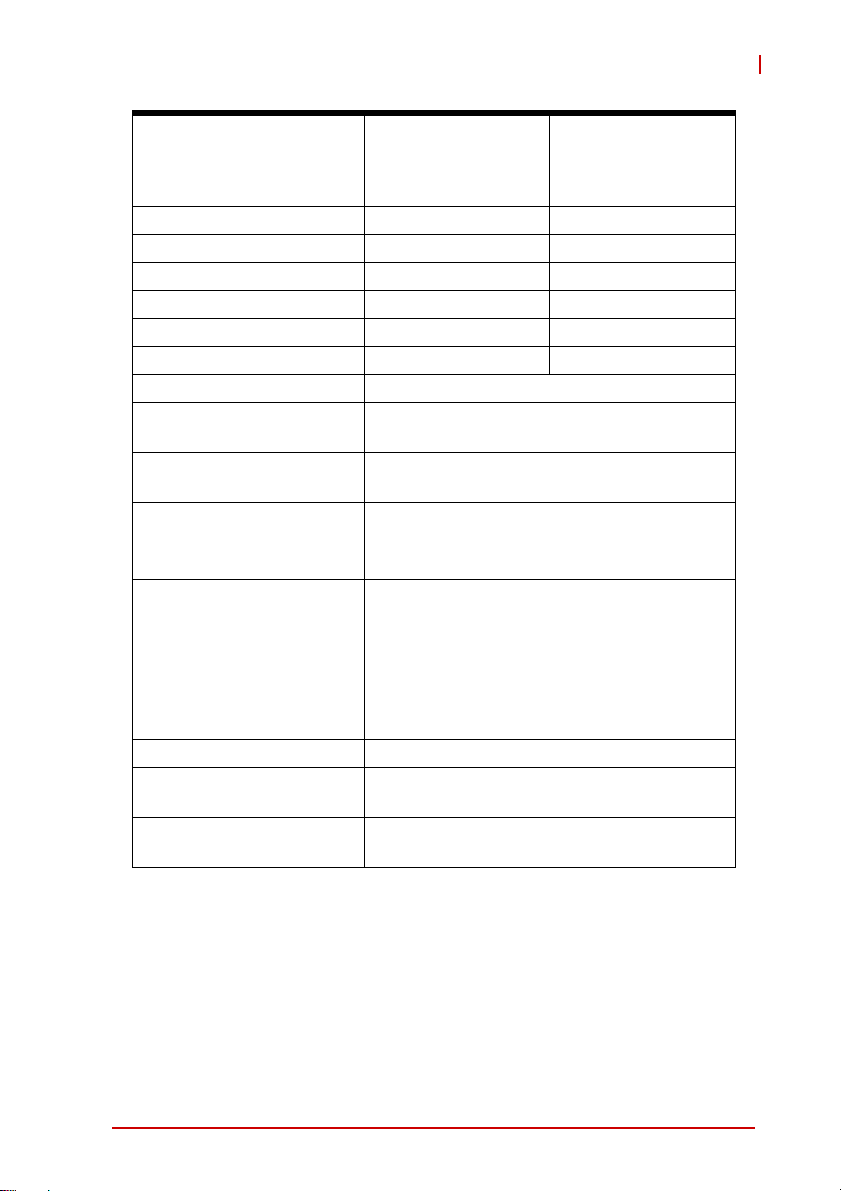

1.4.3 Analog Input Electrical

Temperature Draft @20SPS, in ppm/°C

Mode Gain drift Offset drift

Voltage (±25V) 1.389055871 0.043023355

Voltage (±12.5V) 1.37552178 0.075556565

Voltage (±2.5V) 1.662727273 0.030882956

Voltage (±312.5mV) 21.92878977 0.110084412

Current (±20mA) 3.270369091 0.282946284

Full-bridge 28.00370355 30.90013157

Half-bridge 33.48025514 1.750342188

Thermocouple 62.9978196 0.164409864

2-wire RTD 2.842575758 0.522492944

3-wire RTD 2.879839489 0.258840329

4-wire RTD 2.902723485 0.018656382

2-wire resistance 3.026166667 0.03246755

Temperature Draft @160SPS, in ppm/°C

Mode Gain drift Offset drift

Voltage (±25V) 1.533312973 0.084457938

Voltage (±12.5V) 1.520465436 0.134715279

Voltage (±2.5V) 1.732148674 0.054557101

Voltage (±312.5mV) 20.94809375 0.130828487

Current (±20mA) 3.488472439 0.305882921

Full-bridge 26.72626394 17.74701205

Half-bridge 35.27328612 1.748929398

4Introduction

Page 15

Mode Gain drift Offset drift

Thermocouple 105.3142618 0.193622785

2-wire RTD 2.965409564 0.512440163

3-wire RTD 2.996320076 0.240909456

4-wire RTD 2.854513258 0.086721521

2-wire resistance 3.40709375 0.06209485

Temperature Draft @2000SPS, in ppm/°C

Mode Gain drift Offset drift

Voltage (±25V) 1.620950284 0.105635778

Voltage (±12.5V) 1.584251894 0.11027477

Voltage (±2.5V) 1.701225379 0.067356314

Voltage (±312.5mV) 20.52684091 0.113061874

USB-2401

Current (±20mA) 3.771356399 0.338399386

Full-bridge 30.71138027 50.00179464

Half-bridge 35.58911174 1.862124485

Thermocouple 117.7077884 0.435895845

2-wire RTD 3.047327178 0.452466872

3-wire RTD 3.124556345 0.189605804

4-wire RTD 3.216423295 0.088365093

2-wire resistance 3.386921402 0.04574323

Introduction 5

Page 16

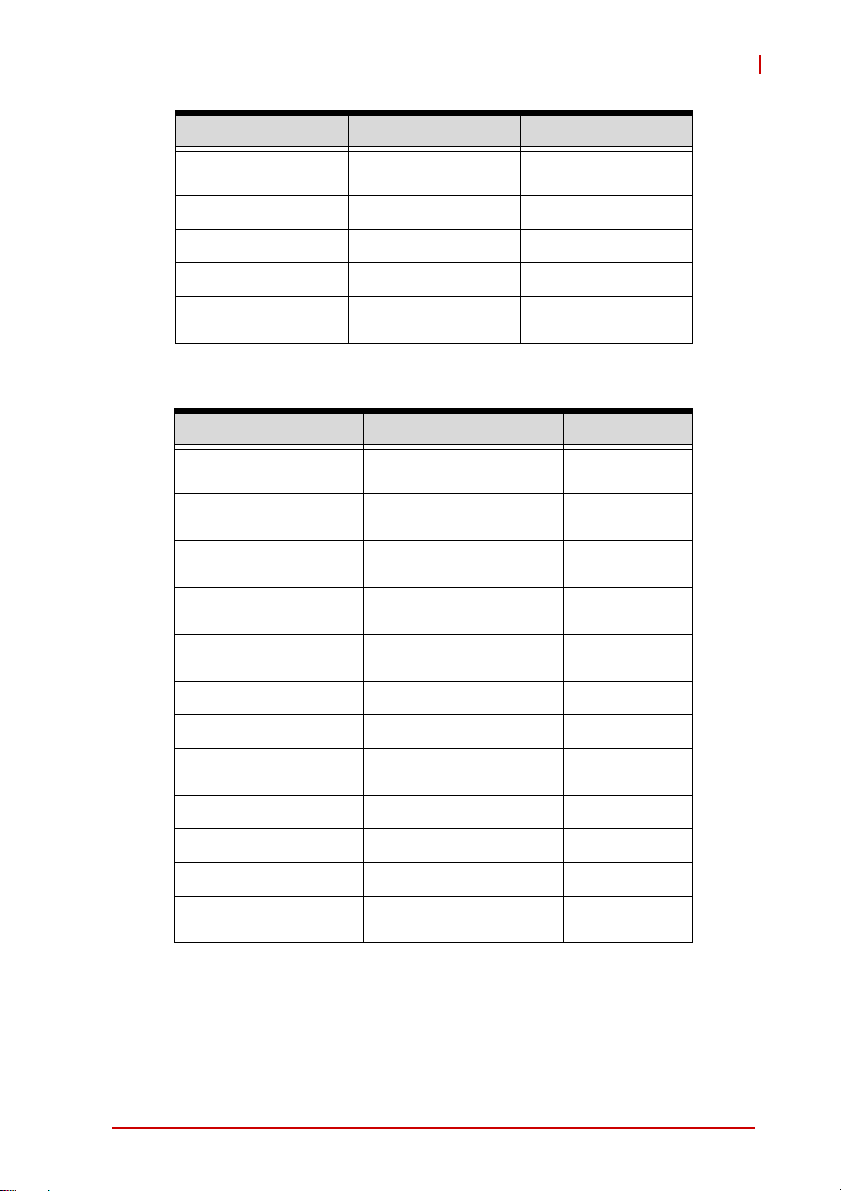

System Noise, in LSB (Typical, 25°C): 20 SPS to 160 SPS

Mode Sampling Rate (SPS)

20 40 80 160

Voltage (±25V) 9.443641 13.58713513 22.225423 47.06011713

Voltage (±12.5V) 10.45022375 15.55506725 23.934448 50.668689

Voltage (±2.5V) 8.941254375 12.75718938 19.522499 46.11391238

Voltage

(±312.5mV)

Current (±20mA) 29.50086975 33.76906888 39.179197 53.86180763

Full/Half-bridge 58.669068 33.97045388 41.628525 67.98029188

Thermocouple 28.24161013 41.73502813 51.59679 76.21635225

2-wire RTD 8.00126525 11.64115513 16.869046 33.30653975

3-wire RTD 8.407154625 12.01619113 16.528028 33.69525963

4-wire RTD 9.043779125 12.47814688 16.762287 45.44077163

2-wire

resistance

11.115466 15.1842875 19.108748 39.44412825

9.318955625 13.208205 18.829651 43.74764375

System Noise, in LSB (Typical, 25°C): 320 SPS to 2000 SPS

Mode Sampling Rate (SPS)

320 640 1000 2000

Voltage (±25V) 72.508028 142.60307 71.11201 119.26144

Voltage (±12.5V) 81.44560913 139.01469 77.924207 128.36732

Voltage (±2.5V) 66.64280488 136.24263 71.915341 122.92882

Voltage

(±312.5mV)

Current (±20mA) 77.58907738 131.06695 80.416917 126.239

Full/Half-bridge 92.8294875 144.14509 175.67111 202.15501

6Introduction

48.83473638 79.888989 86.157589 128.4315

Page 17

USB-2401

Mode Sampling Rate (SPS)

Thermocouple 107.9735725 143.46202 198.49927 202.17693

2-wire RTD 44.53668125 77.870435 71.369319 127.45831

3-wire RTD 42.00570563 87.738238 72.70806 123.21166

4-wire RTD 72.2785775 155.50389 72.168651 123.65813

2-wire

resistance

72.76746238 153.9091 71.566314 122.28421

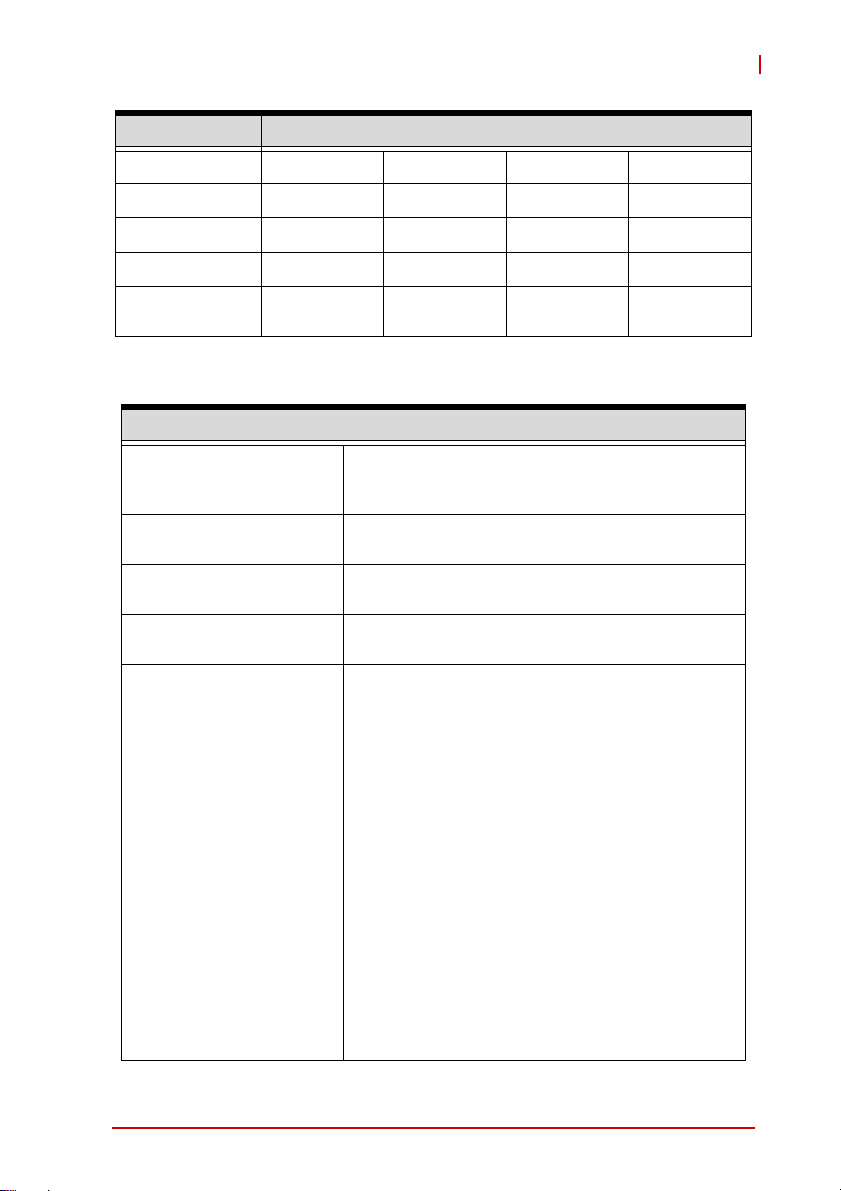

1.4.4 Digital Input/Output

I/O Specifications

Number of channels 4-CH programmable function digital input (DI)

2-CH programmable function digital output

(DO)

Compatibility TTL (single-end) (supports 3.3V and 5 V DI but

3.3V DO)

Input voltage Logic low: VIL = 0.8 V max; IIL = 0.2 mA max.

Logic high: VIH = 2.0 V min.; IIH = 0.2 mA max.

Output voltage Logic low: VOL = 0.5 V max; IOL = 10 mA max.

Logic high: VOH = 2.6V min.; IIH = 10 mA max.

Supporting modes (only

one can be selected and

function at the same time,

please see Section 4.6:

Programmable Function

I/O)

X 4-CH TTL DI and 2-CH TTL

DO

X 1-CH 32-bit general-purpose

timer/counters:

Z Clock source: internal or

external

Z Max source frequency:

internal: 80 MHz; external:

10 MHz

X 1-CH PWM outputs:

Z Duty cycle:1-99% (please

see Section 4.6.3: Mode 10:

PWM Output) Modulation

frequency: 20 MHz to

0.005Hz

Introduction 7

Page 18

I/O Specifications

Data transfers Programmed I/O

1.5 Software Support

ADLINK provides comprehensive software drivers and packages

to suit various user approaches to system building. In addition to

programming libraries, such as DLLs, for most Windows-based

systems, ADLINK also provides drivers for other application environments such as LabVIEW® and MATLAB®. ADLINK also provides ActiveX component ware for measurement and

SCADA/HMI, and breakthrough proprietary software. All software

options are included in the ADLINK All-in-One CD.

Be sure to install the driver & utility before using the USB-2401

module.

1.6 Driver Support for W indows

1.6.1 UD-DASK

UD-DASK is composed of advanced 32/64-bit kernel drivers for

customized DAQ application development. USB-DASK enables

you to perform detailed operations and achieve superior performance and reliability from your data acquisition system. DASK

kernel drivers now support Windows 7/Vista® OS.

1.6.2 DAQPilot

DAQPilot is a SDK with a graphics-driven interface for various

application development environments. DAQPilot represents

ADLINK's commitment to full support of its comprehensive line of

data acquisition products and is designed for the novice to the

most experienced programmer.

As a task-oriented DAQ driver, SDK and wizard for Windows systems, DAQPilot helps you shorten development time while accelerating the learning curve for data acquisition programming.

You can download and install DAQPilot at:

http://www.adlinktech.com/TM/DAQPilot.html

8Introduction

Page 19

USB-2401

Please note that only DAQPilot versions 2.3.0.712 and later can

support the USB-2401.

Introduction 9

Page 20

1.7 Utilities for Windows

1.7.1 U-Test

U-Test is a free and ready-to-use utility which can assist instant

testing and operation of all ADLINK USB DAQ series functions

with no programming. In addition to providing data collection and

monitoring functions, U-Test also supports basic FFT analysis and

provides direct control of analog output and digital I/O with a

user-friendly interface.

A

B

C

D

Figure 1-1: U-Test Interface

A Main Menu

B Device Viewer

C AI Data View & AO, DIO Control Panel

D Analog Input Configuration

Table 1-1: U-Test Interface Legend

You can download and install U-Test at: http://www.adlinktech.com/

10 Introduction

Page 21

1.8 O verview and Dimensions

All dimensions shown are in millimeters (mm)

NOTE:

NOTE:

1.8.1 Module

USB-2401

114

41.3

Figure 1-2: USB-2401 Module Rear View

Introduction 11

Page 22

Figure 1-3: USB-2401 Module Side View

12 Introduction

Page 23

114

USB-2401

41.3

Figure 1-4: USB-2401 Module Front View

Introduction 13

Page 24

1.8.2 Module Stand

The multi-function USB-2401 stand is compatible with desk, rail, or

wall mounting. To fix the module in the stand, slide the module

body into the stand until a click is heard. To remove the module

from the stand, twist the bottom of the stand in a back-and forth

motion and separate from the module.

Figure 1-5: Module, Stand, Connector, and USB Cable

200.1

169.4

156.5

Figure 1-6: Module, Stand, & Wall Mount Kit Side View (w/ Connections)

14 Introduction

Page 25

USB-2401

Figure 1-7: Module In Stand Front View

Introduction 15

Page 26

26

B

20.4

Figure 1-8: Module Stand Top View

16 Introduction

20.4

Page 27

1.5

3.4

6

USB-2401

5.89

Figure 1-9: Module Stand Side Cutaway View

100

Figure 1-10: Module Stand Front View

Introduction 17

Page 28

1.9 Connector Information

The USB-2401 module is equipped with 40-pin removable

screw-down terminal connectors, with pin assignment and signal

description as follows.

Pin Function Pin Function

20 GPO0 40 GPO1

19 GPI1 39 GPI3

18 GPI0 38 GPI2

17 NC 37 DGND

16 GND1 36 GND3

15 SC1- 35 SC3-

14 SC1+ 34 SC3+

13 EXC1 33 EXC3

12 CI1- 32 CI3-

11 CI1+ 31 CI3+

10 AI1- 30 AI3-

9 AI1+ 29 AI3+

8 GND0 28 GND2

7 SC0- 27 SC2-

6 SC0+ 26 SC2+

5 EXC0 25 EXC2

4CI0- 24CI2-

3CI0+ 23CI2+

2 AI0- 22 AI2-

1 AI0+ 21 AI2+

Table 1-2: USB-2401 Pin Assignment

18 Introduction

Page 29

USB-2401

Signal Name Reference Direction Description

GND<0..3> -------- Ground of excitation

voltage/current, with

GND<0..3> and DGND

connected on board

DGND -------- Digital ground, DGND and

GND<0..3> are connected

on board

AI<0..4> GND I Differential analog Input

channels 0~3

CI<0..4> GND I Current input channel 0~3.

EXC<0..3> GND O Excitation output for channel

0~3; can be configured to

voltage output (2.5V) or

current output (1mA) by

software, with corresponding

ground pin GND<0..3>

SC<0..3> GND I Sensor (small signal) input

channel 0~3

GPI<0..3> DGND I Function digital input <0..3>

GPO<0..3> DGND O Function digital output <0,1>

N/C N/C N/C No connection

Table 1-3: I/O Signal Description

Introduction 19

Page 30

This page intentionally left blank.

20 Introduction

Page 31

2 Getting Started

The appropriate driver must be installed before you can connect the USB DAQ to the computer system. Refer to

WARNING:

2.1 Connecting the USB-2401 Module

Section 1.6: Driver Support for Windows for driver support

information.

1. Turn on the computer.

2. Connect the USB-2401 module to one USB 2.0 port on

the computer using the included USB cable.

3. The first time the USB-2401 module is connected, a New

Hardware message appears. It will take around 6 seconds to load the firmware. When loading is complete, the

LED indicator on the rear of the USB DAQ module

changes from amber to green and the New Hardware

message closes.

4. The USB-2401 module can now be located in the hardware Device Manager, as shown.

USB-2401

Figure 2-1: USB-2401 Module in Windows Device Manager

Getting Started 21

Page 32

If the USB-2401 module cannot be detected, the power provided

by the USB port may be insufficient. The USB-2401 module is

exclusively powered by the USB port and requires 400 mA @ 5 V.

2.2 Device ID

A rotary control on the rear of the module (as shown) controls

device ID setting and can be set from 1 to 8. The device ID allows

dedicated control of the USB-2401 module irrespective of the connected USB port. When more than one USB module of the same

type is connected, each must be set to a different ID to avoid conflicts and errors in operation.

Figure 2-2: Device ID Selection Control

22 Getting Started

Page 33

USB-2401

2.3 H ardware Configuration

All remaining hardware configurations are software

programmable, including sampling/update rate, input/output

channel, input range, and others. Please see the UD-DASK

Function Reference manual for details.

2.4 Device Mounting

2.4.1 Rail Mounting

The multi-function stand can be mounted on the DIN rail using the

rail-mount kit as shown.

Figure 2-3: Rail Mount Kit

Getting Started 23

Page 34

Figure 2-4: Module Pre-Rail Mounting

Figure 2-5: Module Rail-Mounted

24 Getting Started

Page 35

USB-2401

2.4.2 Wall Mounting

The multi-function stand can be fixed to a wall using four flush

head screws as shown. The four screw holes should be

approximately 3.4 mm in diameter.

20.4

13.0

Figure 2-6: Wall Mount Holes

Figure 2-7: Module with W al l Moun t Apparatus

Getting Started 25

Page 36

This page intentionally left blank.

26 Getting Started

Page 37

3 Operation

Operation of the USB-2401 is described here to assist in

configuration and programming of the module. Functions

described include A/D conversion, programmable function I/O,

and others

3.1 Functional Layout

The USB-2401 provides 4-channel 24-bit universal analog inputs

and supports seven input modes, including voltage input, current

input, thermocouple, RTD, full bridge, half bridge, and resistance

measurement. The four channels sample simultaneously, and

while each can be configured to a different input mode, all active

channels must be configured to the same sampling rate. In

addition, the USB-2401 also provides 6-channel programmable

digital I/O and can be configured to GPIO, GPTC, or PWM mode.

USB-2401

ADC

ADLINK

USB BUS

+5V Supply

EEPROM

Calibration

Data/

Control

3.3 2.5 1.2V

Supply

data

24MHz XTAL

Cypress

CY7C68013A

8051 Core 12/

24/48MHz

DATA

Power

DDR2 SDRAM

circuit

3.3V Supply

+5V Supply

AIn+, AIn-

CIn+, CIn-

SCn+, SCn-

INTERFACE

40P CONNECTOR

EXCn

(Cold Junction

Compensation)

CJC

4DI , 2DO

Mode

Voltage

Current

Bridge-based

RTD

Resistor

Thermocouple

Excitation Source

Current (0.5mA, 0.05mA)

±4,±2.5V

Voltage (2.5V)

AFI

ADC Front end

24 Bit

Sigma-

AFI

delta ADC

Functional I/O

GPIO

GPTC

PWM

3.3/2.5/1.2V

Control signal

n=0 ~3

AI Data and

Power

circuit

Control

I2C

Interface

Digital I/O

Controller

Calibration

Controller

FPGA Core

8051 Core

Function

Interface

Figure 3-1: USB-2401 Functional Block Diagram

3.2 S ignal Sources

3.2.1 Floating Signal Source

Not connected in any way to the existing ground system.

Devices with isolated output are floating signal sources, such as

optical isolator outputs, transformer outputs, and thermocouples.

USB 2.0

High-Speed

USB BUS

USB 2.0 INTERFACE

Operation 27

Page 38

3.2.2 Ground-Referenced Signal Source

Connected in some way to the existing ground system, to a

common ground point with respect to the USB DAQ, when the

computer is connected to the same power system. Non-isolated

output of instruments and devices connected to the existing

power systems are ground-referenced signal sources.

3.3 Signal Connection

Each analog input channel can be configured to different input

modes by the software API. Details of signal connection in

different input modes follow.

3.3.1 Voltage Input Mode

The properties of the signal to be measured must be considered.

The differential input mode provides two inputs that respond to

signal voltage difference between them. If the signal source is

ground-referenced, the differential mode can be used for the

common-mode noise rejection.

Connection of ground-referenced signal sources under differential

input mode is as shown.

USB-2401

AI+

Ground reference

signal source

AI-

Common mode noise

& ground potential

Figure 3-2: Ground-Referenced Source and Differential Input

Vcm

GND

Amplifier

Amplifier

For floating signal sources, addition of a resistor at each channel

provides a bias return path. The resistor value should be about

28 Operation

Page 39

USB-2401

100 times the equivalent source impedance, such that if the

source impedance is less than 100, the negative side of the

signal needs only be connected to GND as well as the negative

input of the Instrumentation Amplifier without any resistors.

Connection of a floating signal source to the USB-2401 in

differential input mode is as shown.

USB-2401

AI+

Floating signal source

AI-

GND

Figure 3-3: Floating Source and Differential Input

Amplifier

Amplifier

3.3.2 Current Input Mode

Current signal source can be floating or grounded reference,

converted to voltage through a precision 249.5 resistor.

Cross-voltage on the precision resistor is considered differential

signal. The differential signal pair passes through differential

amplifier buffers and is measured by the analog-to-digital

converter chip (ADC) with ±2.5 V input range.

The formula to calculate voltage-to-current conversion is:

)()(voltV

mACurrent =

6701527.18

Operation 29

Page 40

I

Figure 3-4: Current Source Connection

ƻ

3.3.3 Full Bridge and Half Bridge Input Mode

A bridge-based transducer is a passive device, requiring voltage

excitation to convert the resistive change to an electrical signal.

The USB-2401 provides a steady 2.5V excitation voltage for each

analog input channel in full bridge and half bridge modes. For

half-bridge transducer, USB-2401 has built-in precision 20k

resistors to compensate the circuit as a full-bridge transducer

measurement.

Also provided is a moving average function, a common and useful

digital filtering method of smoothing fluctuation caused by noise.

The averaging number for data can be set to 0, 2, 4, 8, or 16,

where 0 represents disabling the moving average function.

A typical four-wire connection is shown.

A dotted line represents the connection and circuit of full-bridge

mode.

NOTE:

NOTE:

30 Operation

Page 41

EXC

SC+

USB-2401

USB-2401

DC 2.5V

20kƻ

SC-

20kƻ

GND

MUX

Figure 3-5: Full Bridge and Half Bridge Connection

3.3.4 Thermocouple Input Mode

A thermocouple consists of two different conductors that produce

a voltage proportional to a temperature difference between either

end of the pair of conductors. The USB-2401 uses 78.125mV

input range to acquire the thermocouple signal, and provides a

precision built-in digital temperature sensor for cold junction compensation (CJC). CJC reading is available by software API with

data in °C. The CJC is in the USB-2401 module.

The CJC temperature sensor is housed in the USB-2401 and

requires 15 minutes’ warmup to stabilize.

NOTE:

NOTE:

Operation 31

Page 42

USB-2401

SC+

SC-

Thermocouple

Figure 3-6: Thermocouple Connection

MUX

ADC

3.3.5 RTD Input Mode

The resistance temperature detector (RTD) measures temperature by correlating the resistance of the RTD element with temperature. The USB-2401 can generate a steady 0.5 mA excitation

current source to each channel in RTD input mode to measure

cross-voltage on the RTD. The actual input range is ±2.5V with a

formula of voltage to RTD resistance conversion of:

V(volt)

)( =ΩRTD

0.0005

Since the excitation current can only drive cross-voltage up to

1.5V with good linearity, the maximum equivalent value of the RTD

resistor is limited to 3k.

The USB-2401 can support two, three, and four-wire RTD measurement. Adopting three- and four-wire connections rather than

two-wire can eliminate connection lead resistance effects from

measurement. Three-wire connection is sufficient for most purposes and most universal industrial applications. Four-wire connections are used for the most precise application requirements.

32 Operation

Page 43

USB-2401

RTD

RTD

EXC

0.5mA

SC+

MUX

SC-

GND

Figure 3-7: 4-Wire RTD Connection

0.5mA

EXC

SC+

MUX

SC-

GND

Figure 3-8: 3-Wire RTD Connection

Operation 33

Page 44

0.5mA

EXC

X

SC+

X

RTD

SC-

X

GND

X

Figure 3-9: 2-wire RTD Connection

3.3.6 Wire Resistance Mode

The USB-2401 can source precision 0.05 mA excitation current to

the resistor to be measured and use a 2.5V input range to acquire

cross-voltage on the resistor. The formula of voltage to resistance

conversion is:

MUX

USB-2401

ADC

V(volt)

)( =ΩR

0.00005

Since the excitation current can only drive the cross-voltage up to

1.5V with good linearity, the maximum equivalent value of the

resistor is limited to 30k.

34 Operation

Page 45

USB-2401

0.05mA

USB-2401

SC +

X

Resistor

MUX

SC -

ADC

X

Figure 3-10: 2-Wire Resistance Connection

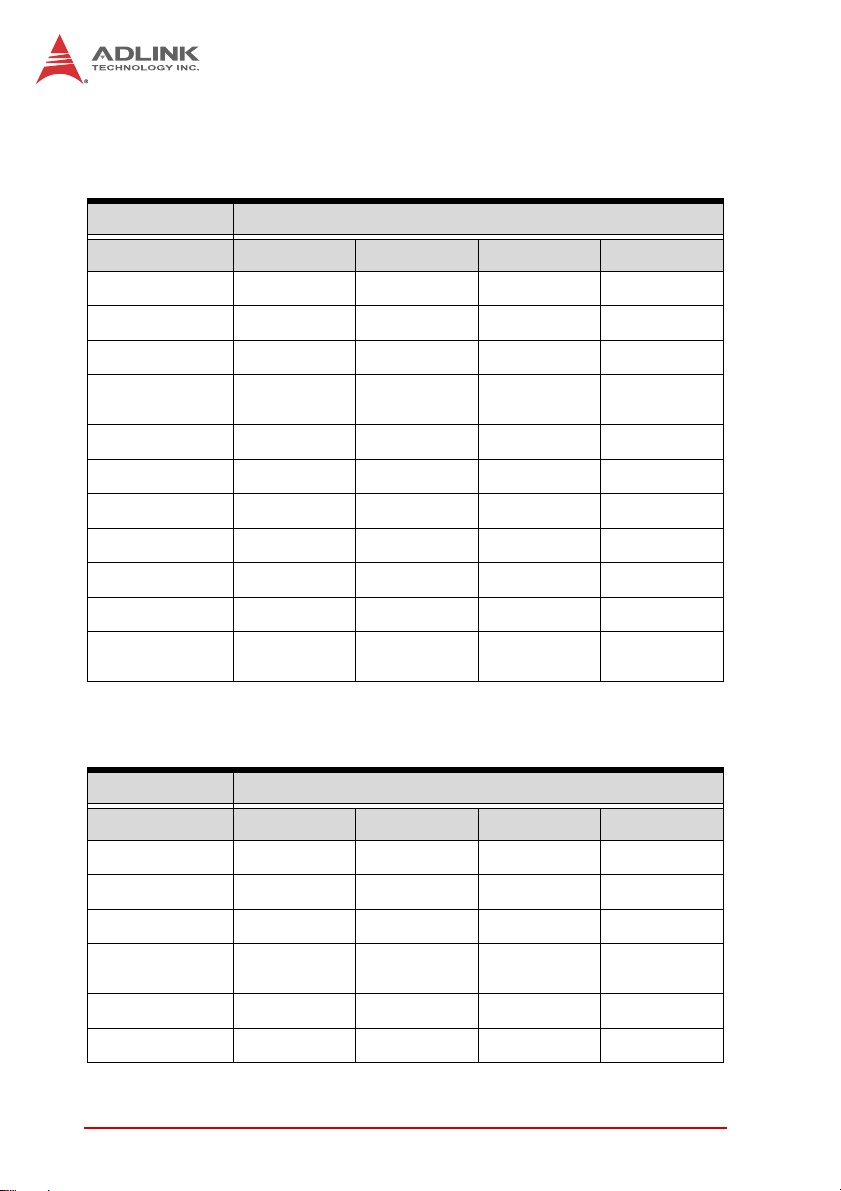

3.4 A I Data Format

The acquired 24-bit A/D data is 2’s complement coded data format. Valid input ranges and optimum transfer characteristics are

as shown.

Description Bipolar Analog Input Range

Full-scale

range

Least

significant bit

FSR-1LSB 24.999997V12.4999985V2.4999997V0.3124999V 7FFFFF

±25 V ±12.5 V ±2.5 V ±0.3125V N/A

2.98uV 1.49uV 0.298uV 0.037uV N/A

Digital

Code

Midscale

+1LSB

Midscale 0 V 0 V 0 V 0 V 000000

Midscale

-1LSB

-FSR -25 V -12.5 V -2.5 V -0.3125V 800000

2.98uV 1.49uV 0.298uV 0.037 uV 000001

-2.98uV -1.49uV -0.298uV -0.3124999uV FFFFFF

Table 3-1: Analog Input Range and Output Digital Code

Operation 35

Page 46

Description

Full-scale range ±78.125 mV N/A

Least significant

bit

FSR-1LSB 78.1249907 mV 7FFFFF

Midscale

+1LSB

Midscale 0 V 000000

Midscale

-1LSB

-FSR -78.125mV 800000

Table 3-2: Analog Input Range and Output Digital Code (cont’d)

Bipolar Analog

Input Range

9.313nV N/A

9.313nV 000001

-9.313nV FFFFFF

Digital Code

3.5 ADC Sampling Rate

Sampling Rate refers to ADC internal conversion speed as set by

the user. When programming through a software API, the desired

ADC sampling rate must be set, whether for single value, using a

software polling command, or block data in continuous buffer

mode. Available sampling rates are 20SPS, 40SPS, 80SPS,

160SPS, 320SPS, 500SPS, 1000SPS, and 2000SPS.

Accuracy frequently deteriorates with increased ADC sampling

rate.

NOTE:

NOTE:

3.5.1 Software Polling Dat a Transfer (Non-Buffering Programmed I/O)

Polling mode benefits flexible timing and is suitable for retrieving

the latest data without FIFO buffering latency. The USB-2401 continuously updates the latest acquired data onto a data port for specific channels. Data not retrieved in time is overwritten with new

data without notice. As the software polling rate (here equaling

data rate) of a PC may exceed the ADC sampling rate, it is possible to receive multiple identical data before a new conversion has

36 Operation

Page 47

USB-2401

completed. Please refer to UD-DASK function reference for the

details of corresponding software API instruction.

3.5.2 Continuous Acquisition Mode

Differs from software polling mode only in the generation of block

data in continuous acquisition mode without the need to consider

data overwriting or acquiring repeat data in software polling mode.

This mode is suitable for when continuous data is to be acquired in

a fixed and precise time interval. Please note the data buffer size

must be a multiple of 128 in continuous acquisition mode. Please

refer to UD-DASK function reference for details of corresponding

software API instruction.

3.6 Programmable Function I/O

The USB-2401 supports powerful programmable I/O function provided by an FPGA chip, configurable as TTL DI/DO, 32-bit

timer/counters, and PWM output. These signals are single-ended

and 5V TTL-compliant.

3.6.1 TTL DI/DO

Programmable function I/O can be used as static TTL-compliant

4-CH digital input and 2-CH digital output. The I/O lines can be

updated by software polling, with sample and update rate fully

controlled by software timing.

Pin Function Pin Function

20 GPO0 40 GPO1

19 GPI1 39 GPI3

18 GPI0 38 GPI2

17 NC 37 DGND

Table 3-3: TTL Digital I/O Pin Definition

Operation 37

Page 48

3.6.2 General Purpose Timer/Counter

The USB-2401 is equipped with one general purpose timer/counter featuring:

X Count up/down controllable by hardware or software

X Programmable counter clock source (internal clock up to

80MHz, external clock up to 10 MHz)

X Programmable gate selection (hardware or software con-

trol)

X Programmable input and output signal polarities (high active

or low active)

X Initial Count loaded from a software API

X Current count value readable by software without affecting

circuit operation.

Pin Function Pin Function

20 GPTC_OUT0 (GPO0) 40 GPTC_OUT1 (GPO1)

19 GPTC_UD (GPI1) 39 GPTC_AUX (GPI3)

18 GPTC_CLK (GPI0) 38 GPTC_GATE (GPI2)

17 NC 37 DGND

Table 3-4: Timer/Counter Pin Definition

The timer/counter has three inputs that can be controlled via

hardware or software, clock input (GPTC_CLK), gate input

(GPTC_GATE), and up/down control input (GPTC_UD). The

GPTC_CLK input provides a clock source input to the timer/counter. Active edges on the GPTC_CLK input increment or decrement

the counter. The GPTC_UD input directs the counter to count up

or down (high: count up; low: count down), while the GPTC_GATE

input is a control signal acting as a counter enable or counter trigger signal in different applications. The GPTC_OUT then generates a pulse signal based on the timer/counter mode set.

All input/output signal polarities can be programmed by software

application. For brevity, all GPTC_CLK, GPTC_GATE, and

GPTC_OUT in the following illustrations are assumed to be active

high or rising-edge triggered.

38 Operation

Page 49

USB-2401

3.6.3 General Purpose Timer/Counter Modes

Ten programmable timer/counter modes are available. All initialize

following a software-start signal set by the software. The GPTC

software reset initializes the status of the counter and reloads

the initial value to the counter. The operation remains halted

until software start is executed again. Operations under different

modes are as follows.

Mode 1: Simple Gated-Event Counting

In this mode, the counter calculates the number of pulses on

the GPTC_CLK after a software start. Initial count can be

loaded from the software application. Current count value can

be read back by software any time with no influence on calculation. GPTC_GATE enables/disables calculation. When

GPTC_GATE is inactive, the counter halts the current count

value. Operation in which initial count = 5, countdown mode is

shown.

Software start

Gate

CLK

Count value

Figure 3-11: Mode 1-Simple Gated-Event Calculation

55 432110 ffff

Mode 2: Single Period Measurement

The counter calculates the period of the signal on

GPTC_GATE in terms of GPTC_CLK. The initial count can be

loaded from the software application. After software start, the

counter calculates the number of active edges on GPTC_CLK

between two active edges of GPTC_GATE. After the completion of the period interval on GPTC_GATE, GPTC_OUT outputs high and then current count value can be read by the

Operation 39

Page 50

software application. Operation in which initial count = 0,

count-up mode is shown.

Software start

Gate

CLK

Count value

Figure 3-12: Mode 2-Single Period Measurement

00 1234555

Mode 3: Single Pulse-Width Measurement

The counter calculates the pulse-width of the signal on

GPTC_GATE in terms of GPTC_CLK. Initial count can be

loaded from the software application. After software start, the

counter calculates the number of active edges on GPTC_CLK

when GPTC_GATE is in its active state.

After the completion of the pulse-width interval on

GPTC_GATE, GPTC_OUT outputs high and current count

value can be read by the software application. Operation in

which initial count = 0, count-up mode is shown.

Software start

Gate

CLK

Count value

Figure 3-13: Mode 3-Single Pulse-Width Measurement

40 Operation

00 1234555

Page 51

USB-2401

Mode 4: Single-Gated Pulse Generation

This mode generates a single pulse with programmable delay

and programmable pulse-width following software start. The

two programmable parameters can be specified in terms of

periods of the GPTC_CLK input by the software application.

GPTC_GATE enables/disables calculation. When

GPTC_GATE is inactive, the counter halts the current count

value. Generation of a single pulse with a pulse delay of two

and a pulse-width of four is shown.

Software start

Gate

CLK

Count value

OUT

Figure 3-14: Mode 4-Single-Gated Pulse

22 1032210

Mode 5: Single-Triggered Pulse

This mode generates a single pulse with programmable delay

and programmable pulse-width following an active

GPTC_GATE edge. These programmable parameters can be

specified in terms of periods of the GPTC_CLK input. When the

first GPTC_GATE edge triggers the single pulse, GPTC_GATE

has no effect until software start is executed again. Generation

of a single pulse with a pulse delay of two and a pulse-width of

four is shown.

Operation 41

Page 52

Gate

CLK

Software start

Count value

22103210

OUT

Figure 3-15: Mode 5-Single-Triggered Pulse

Mode 6: Re-Triggered Single Pulse Generation

This mode is similar to Mode 5 except that the counter generates a pulse following every active edge of GPTC_GATE. After

software start, every active GPTC_GATE edge triggers a single

pulse with programmable delay and pulse width. Any

GPTC_GATE triggers that occur when the prior pulse is not

completed are ignored. Generation of two pulses with a pulse

delay of two and a pulse width of four is shown.

S o f t w a r e s t a r t

G a t e

C L K

C o u n t v a l u e

O U T

22 1032102

Figure 3-16: Mode 6-Re-Triggered Single Pulse

I g n o r e d

210

32102

2

Mode 7: Single-Triggered Continuous Pulse Generation

This mode is similar to Mode 5 except that the counter generates continuous periodic pulses with programmable pulse interval and pulse-width following the first active edge of

GPTC_GATE. When the first GPTC_GATE edge triggers the

counter, GPTC_GATE has no effect until software start is executed again. Generation of two pulses with a pulse delay of

four and a pulse-width of three is shown.

42 Operation

Page 53

S o f t w a r e s t a r t

G a t e

C L K

C o u n t v a l u e

O U T

44 4321021

0321021

Figure 3-17: Mode 7-Single-Triggered Continuous Pulse

Mode 8: Continuous Gated Pulse Generation

This mode generates periodic pulses with programmable pulse

interval and pulse-width following software start. GPTC_GATE

enables/disables calculation. When GPTC_GATE is inactive,

the counter halts the current count value. Generation of two

pulses with a pulse delay of four and a pulse-width of three is

shown.

S o f t w a r e s t a r t

G a t e

C L K

C o u n t v a l u e

O U T

44 3321021

0321021

USB-2401

032

103

Figure 3-18: Mode 8-Continuous Gated Pulse

Mode 9: Edge Separation Measurement

Measures the time differentiation between two different pulse

signals. The first pulse signal is connected to GPTC_GATE

and the second signal is connected to GPTC_AUX. Clocks that

pass between the rising edge signal of two different pulses

through the 40 MHz internal clock or external clock are calculated. You can calculate the time period via the known clock

frequency. The maximum counting width is 32-bit. Decrease of

Operation 43

Page 54

the counter value in Edge Separation Measurement mode is

shown.

S o f t w a r e s t a r t

G a t e

A U X

C L K

C o u n t v a l u e

1313 12 11 9 8 7 6

10

5432111111

Figure 3-19: Mode 9-Edge Separation Measurement

Mode 10: PWM Output

The USB-1900 Series timer/counter can also simulate a PWM

(Pulse Width Modulation) output. By setting a varying amount

of Pulse_initial_cnt and Pulse_length_cnt, varying pulse frequencies (Fpwm) and duty cycles (Dutypwm) can be obtained.

PWM output is shown.

P u l s e _ I n i t i a l _ c n t = 0 x 7 P u l s e _ I e n g t h _ c n t = 0 x B

P W M O U T

T I M E B A S E

Figure 3-20: Mode 10-PWM Output

Calculation of the PWM frequency and duty cycle is as follows.

F

=

F

PWM

Duty

PWM

=

44 Operation

Timeba se

+

+

cntlengthPulsecntinitialPulse

____

cntlengthPulse

__

cntlengthPulsecntinitialPulse

____

Page 55

4 Calibration

The USB-2401 is factory-calibrated before shipment. The associated calibration constants of the TrimDACs firmware are written to

the onboard EEPROM. TrimDACs firmware is the algorithm in the

FPGA. Loading calibration constants entails loading the values of

TrimDACs firmware stored in the onboard EEPROM.

The recommended re-calibration interval is one year. Please contact your local dealer to request calibration service.

USB-2401

Calibration 45

Page 56

This page intentionally left blank.

46 Calibration

Page 57

USB-2401

Important Safety Instructions

For user safety, please read and follow all instructions,

WARNINGS, CAUTIONS, and NOTES marked in this manual

and on the associated equipment before handling/operating the

equipment.

X Read these safety instructions carefully.

X Keep this user’s manual for future reference.

X Read the specifications section of this manual for detailed

information on the operating environment of this equipment.

X When installing/mounting or uninstalling/removing

equipment:

Z Turn off power and unplug any power cords/cables.

X To avoid electrical shock and/or damage to equipment:

Z Keep equipment away from water or liquid sources;

Z Keep equipment away from high heat or high humidity;

Z Keep equipment properly ventilated (do not block or

cover ventilation openings);

Z Make sure to use recommended voltage and power

source settings;

Z Always install and operate equipment near an easily

accessible electrical socket-outlet;

Z Secure the power cord (do not place any object on/over

the power cord);

Z Only install/attach and operate equipment on stable

surfaces and/or recommended mountings; and,

Z If the equipment will not be used for long periods of time,

turn off and unplug the equipment from its power source.

Important Safety Instructions 47

Page 58

X Never attempt to fix the equipment. Equipment should only

be serviced by qualified personnel.

A Lithium-type battery may be provided for uninterrupted, backup

or emergency power.

Risk of explosion if battery is replaced with an incorrect type;

please dispose of used batteries appropriately.

WARNING:

X Equipment must be serviced by authorized technicians

when:

Z The power cord or plug is damaged;

Z Liquid has penetrated the equipment;

Z It has been exposed to high humidity/moisture;

Z It is not functioning or does not function according to the

user’s manual;

Z It has been dropped and/or damaged; and/or,

Z It has an obvious sign of breakage.

48 Important Safety Instructions

Page 59

Getting Service

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

USB-2401

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

Getting Service 49

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing, 100085 China

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Page 60

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1675-12 微汾瘶捒娯 8猻

8F Mointer B/D,1675-12, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: 1st Floor, #50-56 (Between 16th/17th Cross) Margosa Plaza,

Margosa Main Road, Malleswaram, Bangalore-560055, India

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80-23464606

Email: india@adlinktech.com

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 6 Hasadna St., Kfar Saba 44424, Israel

Tel: +972-9-7446541

Fax: +972-9-7446542

Email: israel@adlinktech.com

50 Getting Service

Loading...

Loading...