Page 1

PXIS-2719A

19-slot 3U PXI Chassis

User’s Manual

Manual Rev.: 2.00

Revision Date: May 7, 2012

Part No: 50-17037-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

2.00 May 7, 2012 Initial Release

ii

Page 3

PXIS-2719A

Preface

Copyright 2012 ADLINK Technology, Inc.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect,

special, incidental, or consequential damages arising out of the

use or inability to use the product or documentation, even if

advised of the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component

damage, data loss, and/or program corruption when try-

CAUTION:

ing to complete a task.

Information to prevent serious physical injury, compo-

nent damage, data loss, and/or program corruption

when trying to complete a specific task.

iv Preface

Page 5

PXIS-2719A

Table of Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Tables......................................................................... vii

List of Figures........................................................................ ix

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 2

1.2 Specifications....................................................................... 3

1.3 Schematics .......................................................................... 5

1.4 Connectors, I/O, and Controls ............................................. 9

1.4.1 Front Panel ................................................................. 9

1.4.2 Rear Panel................................................................ 10

1.5 Backplane Overview .......................................................... 11

1.5.1 Interoperability with CompactPCI ............................. 11

1.5.2 System Controller Slot.............................................. 12

1.5.3 Star Trigger Slot ....................................................... 12

1.5.4 Peripheral Slots ........................................................ 12

1.5.5 Local Bus.................................................................. 13

1.5.6 Trigger Bus ............................................................... 13

1.5.7 System Reference Clock .......................................... 15

2 Getting Started ................................................................. 19

2.1 Package Contents ............................................................. 19

2.2 Cooling Considerations...................................................... 20

2.3 Hardware Installation ......................................................... 21

2.3.1 Installing the System Controller................................ 21

2.3.2 Installing Peripheral Modules ................................... 23

2.3.3 Powering Up the System .......................................... 26

Table of Contents v

Page 6

2.4 Rack Mounting ................................................................... 26

3 System Management........................................................ 29

3.1 Installing the Monitor Utility ................................................ 30

3.2 Connect Control ................................................................. 31

3.2.1 Com Port Setting ...................................................... 31

3.2.2 Chassis Status Log................................................... 32

3.3 Remote Status and Control................................................ 33

3.3.1 Remote On/Off.......................................................... 33

3.3.2 Chassis Status.......................................................... 35

4 Monitoring/Control Functions ......................................... 37

4.1 Data Structure.................................................................... 37

4.1.1 ChassisStatus........................................................... 37

4.1.2 ChassisSetting.......................................................... 38

4.1.3 MCUVersion ............................................................. 39

4.1.4 Data Structure Variables........................................... 39

4.2 Function Library ................................................................. 41

Appendix: Troubleshooting and Maintenance ................53

1 Installation Problems.......................................................... 53

2 Basic Troubleshooting ....................................................... 54

3 Maintenance ...................................................................... 54

3.1 Handling the Chassis................................................ 54

3.2 Cleaning the Exterior ................................................ 55

3.3 Power Requirements ................................................ 55

Important Safety Instructions............................................... 57

Getting Service...................................................................... 59

vi Table of Contents

Page 7

PXIS-2719A

List of Tables

Table 1-1: Front Panel Legend ......................................................... 9

Table 1-2: Front Panel Indicators.................................................... 10

Table 1-3: Rear Panel Legend........................................................ 11

Table 1-4: Trigger Bus Switch Functions........................................ 14

Table 1-5: Trigger Bus Settings ...................................................... 15

Table 1-6: 10MHZ Reference Clock Priority ................................... 16

Table 1-7: Clock Source Indicators Legend.................................... 16

Table 2-1: Rack Mount Assembly Legend ...................................... 27

Table 3-1: PXIS-219A Temperature Parameter Legend................. 34

Table 4-1: Data Structure Variables................................................ 41

vii

Page 8

viii

This page intentionally left blank.

Page 9

PXIS-2719A

List of Figures

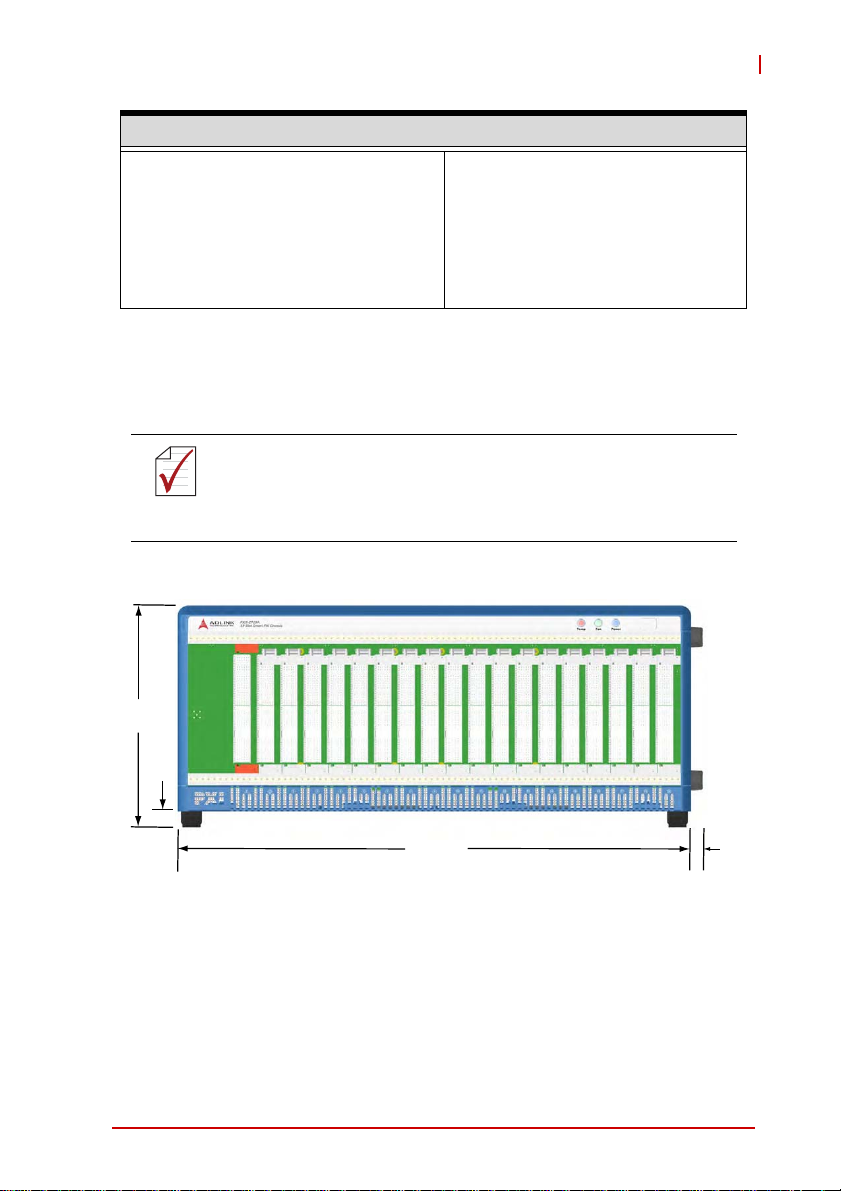

Figure 1-1: Front View .................................................................. 5

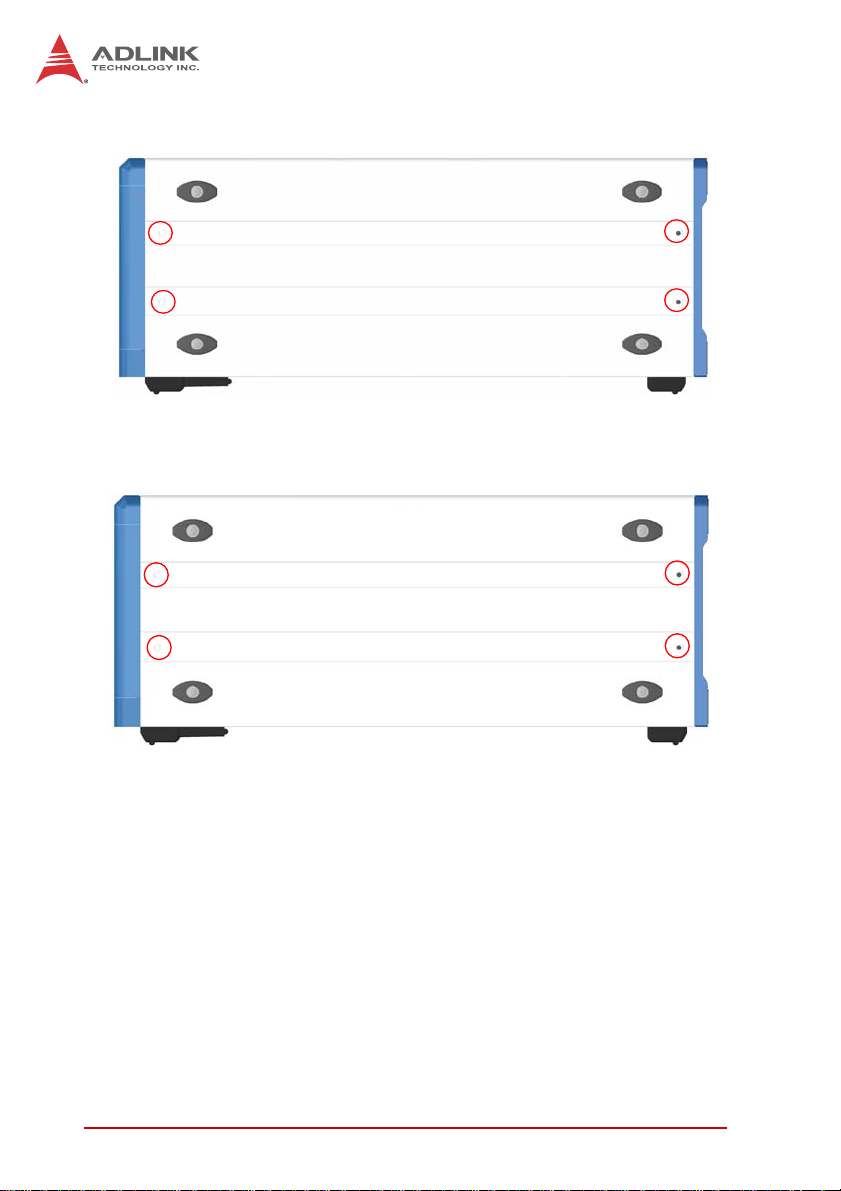

Figure 1-2: Right Side View (showing rackmount screw holes).... 6

Figure 1-3: Left Side View (showing rackmount screw holes) ...... 6

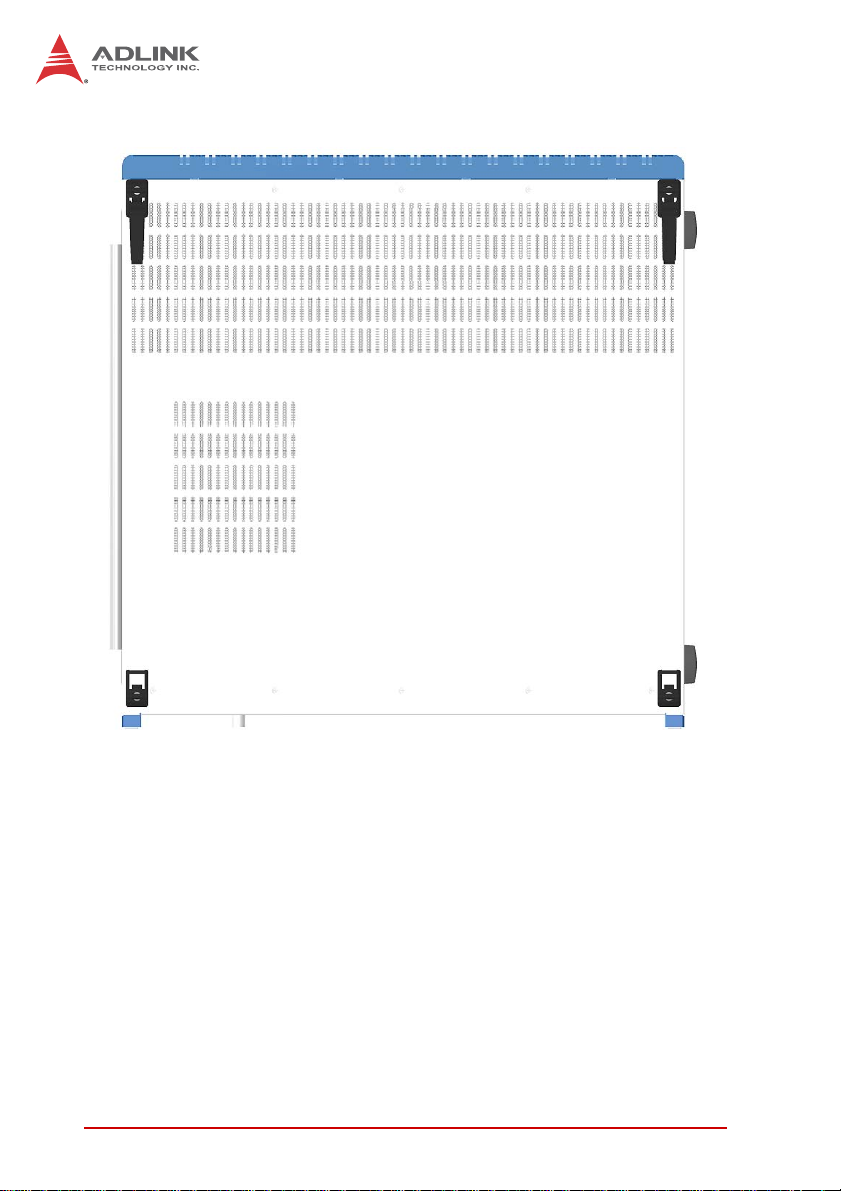

Figure 1-4: Rear View ................................................................... 7

Figure 1-5: Underside View .......................................................... 8

Figure 1-6: PXIS-2719A Front Panel ............................................ 9

Figure 1-7: PXIS-2719A Rear Panel........................................... 10

Figure 1-8: Instrument Signal Routing ........................................ 13

Figure 1-9: Trigger Bus Switching............................................... 14

Figure 1-10: Clock Source Indicators............................................ 16

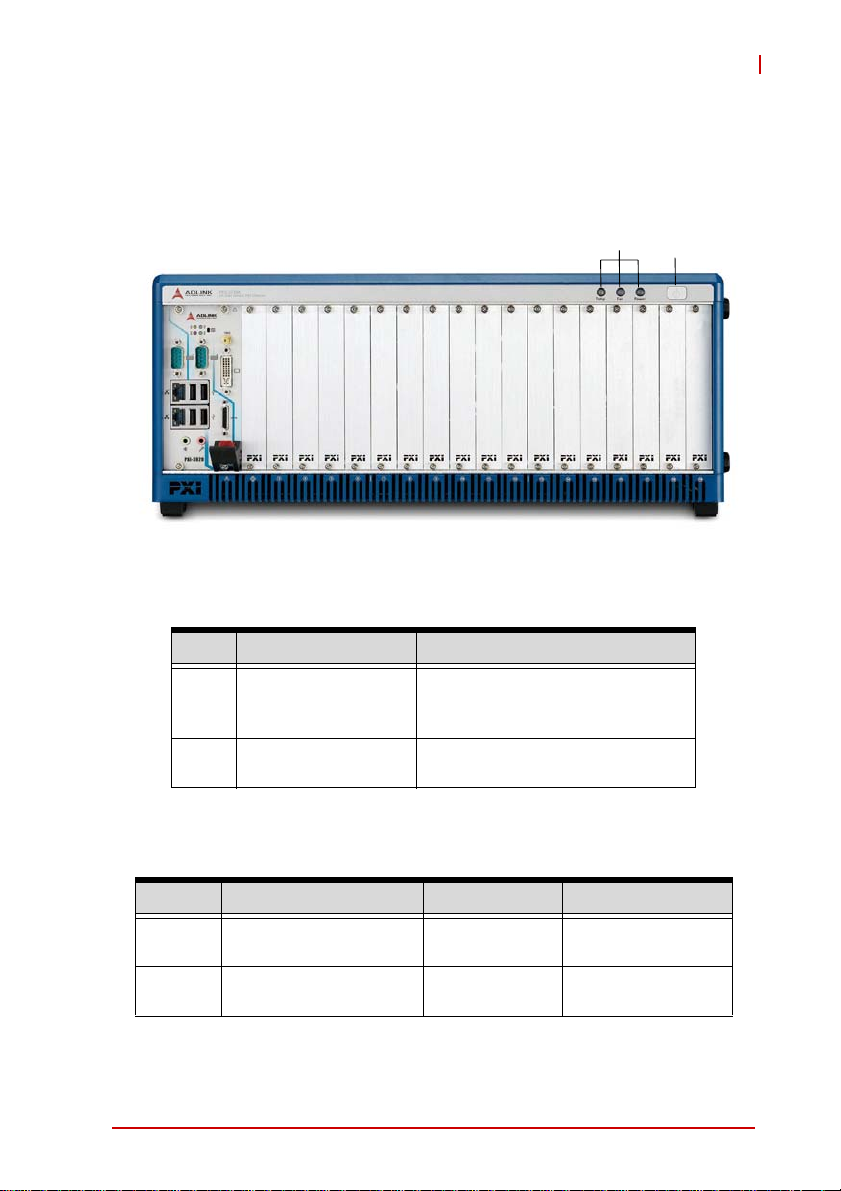

Figure 2-1: Rack Mount Assembly.............................................. 27

Figure 3-1: Remote Monitor Utility Interface ............................... 30

Figure 3-2: Log Options Dialog ................................................... 32

Figure 3-3: Remote Status and Control Interface ....................... 33

Figure 3-4: PXIS-219A Temperature Setting Parameters .......... 34

ix

Page 10

This page intentionally left blank.

x

Page 11

1 Introduction

The ADLINK PXIS-2719A is a 3U PXI chassis with advanced

features and function. Compliant with PXI and CompactPCI

specifications, the PXIS-2719A provides one system slot and

eighteen peripheral slots, and fully meets or exceeds demands

for large capacity, wide operating temperature range, uniformity of

heat dissipation and exceptional chassis weight and robustness.

The PXIS-2719A also offers intelligent chassis control, enabling

automatic fan speed according to inner chassis temperature, and

monitoring of DC voltage, fan speed, and inner temperature, with

results exportable to a remote computer via a standard RS-232

port.

The ADLINK PXIS-2719A features an innovative cooling mechanism for superior heat dissipation. Three 185.9CFM fans in the

rear section of the chassis draw cooling air through apertures on

the bottom and front of the chassis, with airflow past PXI modules,

for exhaust to the rear. This cooling mechanism provides not only

exceptional heat dissipation efficiency, but also improved uniformity for each PXI slot.

The PXIS-2719A provides an industrial grade AC power supply for

reliability, a BNC connector for an external 10 MHz reference

clock input, front panel LEDs, and easy-access PXI/CompactPCI

slots with card guides for convenient installation and use. It is

designed to accommodate a 3-slot PXI controller, with ADLINK

PXI-3950/3920 PXI controllers highly recommended. With innovative features and robust design, the PXIS-2719A provides an

excellent choice for a PXI platform meeting all test and measurement requirements.

PXIS-2719A

Introduction 1

Page 12

1.1 Features

X PXI Specification Rev. 2.2-compliant

X Rack-mountable 19-slot PXI chassis with one system slot

and eighteen PXI/CompactPCI peripheral slots

X Advanced forced-cooling mechanism for efficient and uni-

form heat dissipation

X External 10 MHz reference clock input via BNC connector

X 0 to 55°C extended operating temperature range

Z Intelligent chassis monitoring/control

Z Automatic fan speed control

Z Chassis status monitoring and exporting

Z Remote chassis power on/off control

X 600 W industrial-grade AC power supply

X Power, temperature and fan monitoring LEDs

2Introduction

Page 13

PXIS-2719A

1.2 Specifications

The PXIS-2719A complies with PXI Specification Rev. 2.2 and

accepts modules compliant with CompactPCI and PICMG 2.0

specifications.

General Specifications

Power Supply

AC Input (*guaranteed by power supply design)

Input voltage range 100 to 240 VAC

Operating voltage range* 85 to 264 VAC

Input voltage frequency 50 to 60 Hz

Operating voltage frequency* 47 to 63 Hz

Input current rating

115 VAC 12 A

230 VAC 12 A

DC Output

Maximum total usable power 600 W

VDC Maximum Load Regulation Maximum Ripple & Noise

+5V 45.0 A ±3% 20 mV

+12V 15.0 A ±3% 50 mV

+3.3V 42.0 A ±3% 20 mV

-12V 4.75 A ±3% 50 mV

10 MHz System Reference Clock (10 MHz REF)

Maximum clock skew between slots 300 ps

Built-in 10 MHz clock accuracy ±50 ppm

External 10 MHz clock source input requirements

Frequency input 10 MHz ±100 PPM

Input signal (10MHz REF In BNC) 100 mVPP to 5 VPP (square or sine)

Input impedance (10MHz REF In BNC) 50 Ω ±5 Ω

Input signal (PXI_CLK10_IN on second

slot)

Cooling

Fans 3 sets of 185.9 CFM fans

5 V or 3.3 V TTL signal

Introduction 3

Page 14

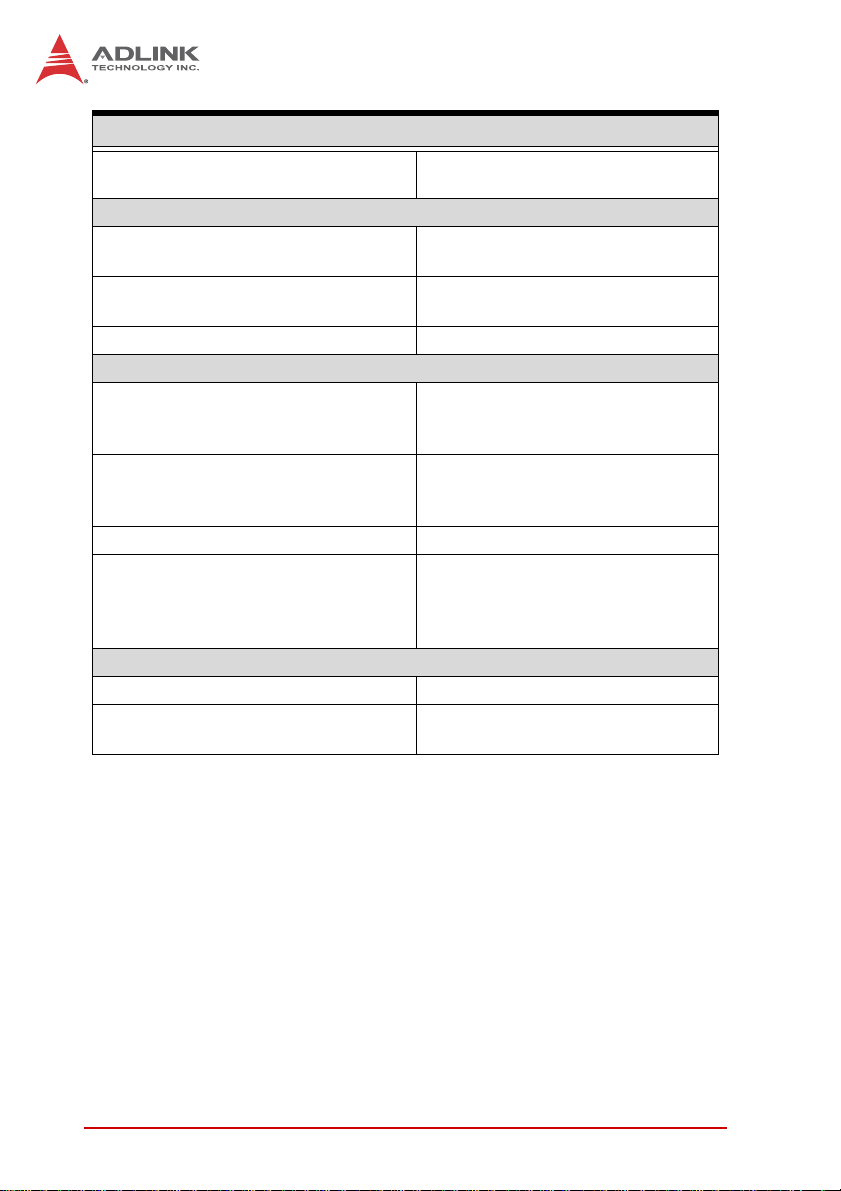

General Specifications

Per-slot cooling capacity 25 W (verified by 55°C chamber

test)

Physical

Slots 19

(1 x system slot, 18 peripheral slots)

Dimensions 444.4 (W) x 177.8 (H) x 455 (D) mm

(17.5 x 7 x 17.9 in.)

Weight 14.5 kg (31.9 lb)

Environmental

Storage Ambient temperature: -20 to 70°C

Relative humidity: 10 to 90%,

noncondensing

Operating Ambient temperature: 0 to 55°C

Relative humidity10 to 90%,

noncondensing

Functional shock 30 G, half-sine, 11 ms pulse duration

Random Vibration Operating: 5 to 500 Hz, 0.31 Grms,

3 axes

Nonoperating: 5 to 500 Hz, 2.46

Grms, 3 axes

Certification

Safety EN 61010-1

Electromagnetic Compatibility Emissions: EN 55011 Class A

Immunity: EN 61326-1

4Introduction

Page 15

PXIS-2719A

General Specifications

CE Compliance Meets essential requirements of

applicable European Directives, as

amended for CE Marking:

Low-Voltage Directive (safety): 73/

23/EEC

Electromagnetic Compatibility

Directive (EMC): 9/336/EEC

1.3 Schematics

Please note that all dimensions shown are in mm (millimeters).

NOTE:

NOTE:

177.8

13.6

444.4 10

Figure 1-1: Front View

Introduction 5

Page 16

Figure 1-2: Right Side View (showing rackmount screw holes)

Figure 1-3: Left Side View (showing rackmount screw holes)

6Introduction

Page 17

Figure 1-4: Rear View

PXIS-2719A

Introduction 7

Page 18

Figure 1-5: Underside View

8Introduction

Page 19

1.4 Connectors, I/O, and Controls

1.4.1 Front Panel

Figure 1-6: PXIS-2719A Front Panel

PXIS-2719A

BA

Feature Details

A Power Powers the chassis on/off (when

INHIBIT on rear panel (not

shown) is set to “DEF”)

B Chassis Status Temperature, Fan, and Power (L

to R), functions as follows

Table 1-1: Front Panel Legend

Status Temperature (Amber) Fan (Green) Power (Blue)

On (Lit) N/A Fans operating

normally

Off Temperature is normal Chassis is

powered down

Introduction 9

DC voltage supply

is normal

Chassis is powered

down

Page 20

Status Temperature (Amber) Fan (Green) Power (Blue)

Blinking One or more

temperature sensors

exceeds threshold

temperature (default

70°C)

One or more

fans falls below

threshold

speed (default

is 800RPM)

One or more power

rails exceeds

threshold settings

(defaults are +5%, 3% for 5V and 3.3V

±5% for +12V and 12V)

Table 1-2: Front Panel Indicators

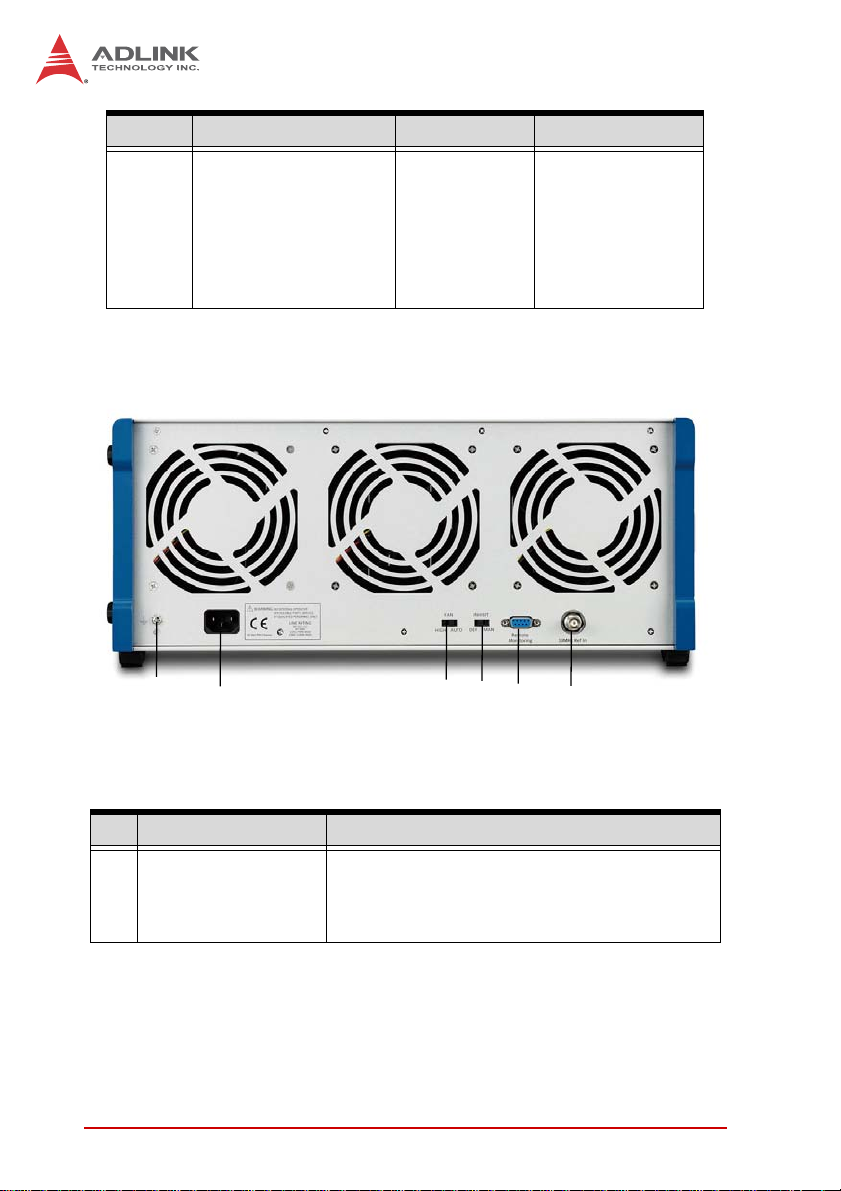

1.4.2 Rear Panel

F

E

D

B

C

A

Figure 1-7: PXIS-2719A Rear Panel

Feature Details

A 10MHz Reference

Clock Input

The BNC connector acts as a 10MHz reference

clock input, whereby the backplane 10MHz

clock is overridden in the presence of an

external 10MHz clock

10 Introduction

Page 21

PXIS-2719A

Feature Details

B Remote Monitoring

Connector

C Inhibit Switch In the DEF (default) position, the front panel

D Fan Switch In the HIGH position, fans operate at maximum

E Universal Power Inlet Accepts C13 power outlet-equipped connection

F Chassis Ground Lug The ground wire can be crimped to the ground

The D-sub9 connector acts as a remote

monitoring connector. To remotely monitor and

control the PXIS-2719A, the remote monitoring

port must be connected to a remote computer

using a standard RS-232 cable.

X Note: The remote monitor port is

Rx-Tx/Tx-Rx crossed, such that a

RS-232 cable with Rx-Rx/Tx-Tx

connection must be used for

remote monitoring.

power button turns the power supply on/off, and

in the MAN (manual) position, the remote

controller turns the power supply on/off via RS232 connection (D)

speed, and in AUTO, the fans run based on the

monitored chassis temperature

lug, using a crimp tool of the appropriate size,

with the other end connected to ground

Table 1-3: Rear Panel Legend

1.5 Backplane Overview

1.5.1 Interoperability with CompactPCI

PXIS-2719A is compatible for use with both PXI-compatible products and standard CompactPCI products, with PXI Specification

Rev. 2.2-compliant backplanes.

Signals on the P1 connector of the backplane meet the requirements of the CompactPCI specification for both peripheral and

system modules.

The PXI-specific signals are located on P2. Only the signals

reserved or not used in the CompactPCI 64-bit specification are

found on PXI-specific signals. Therefore, peripheral modules that

Introduction 11

Page 22

meet the requirements of the CompactPCI 64-bit specification will

function in the PXIS-2719A.

CompactPCI peripheral modules which operate with rear I/O

modules can NOT be installed in the PXIS-2719A, due to pos-

NOTE:

NOTE:

sible conflict between rear I/O signals and PXI-specific signals

on J2.

1.5.2 System Controller Slot

The System Controller slot is Slot 1 as defined by the PXI specification. The PXIS-2719A chassis can accommodate a PXI system

controller occupying up to 3 slots. As defined in the PXI specification, two controller expansion slots allow the controller to expand

to the left to avoid occupying peripheral slots.

1.5.3 Star Trigger Slot

The Star Trigger (ST) slot is Slot 2. This slot has dedicated trigger

lines between ST slot itself and slots 3-15. The star trigger functionality provides a precise trigger signal to the peripheral modules

by installing a specific star trigger controller module in the ST slot.

The star trigger slot can be also used as a general peripheral slot if

star trigger functionality is not required.

1.5.4 Peripheral Slots

The PXIS-2719A provides 18 peripheral slots (including the Star

Trigger controller slot). Each peripheral slot can accommodate a

3U PXI/CompactPCI peripheral module.

DO NOT install a 3U CompactPCI module with rear I/O function in the PXIS-2719A chassis.System damage may result.

CAUTION:

12 Introduction

Page 23

PXIS-2719A

Figure 1-8: Instrument Signal Routing

1.5.5 Local Bus

The local bus on a PXI backplane is a daisy-chained bus that connects each peripheral slot with adjacent peripheral slots to the left

and right. Each local bus has 13 lines and can transmit analog or

digital signals between modules. It can also provide a high-speed

sideband communication path that does not affect the PCI bandwidth.

In accordance with the PXI specification, the local bus connects all

adjacent slots except slots 1 and 2.

1.5.6 Trigger Bus

The trigger bus is an 8-line bus that connects all PXI slots in the

same PCI segment. The trigger bus can be used to provide intermodule synchronization. PXI modules can transmit trigger or

clock signals to one another through the trigger bus, allowing precisely timed responses to asynchronous external events the system is monitoring or controlling.

The PXIS-2719A provides three trigger bus segments, connected

by two trigger bus buffers. The first segment is from slot 1 to slot 6,

Introduction 13

Page 24

the second from slot 7 to slot 12, and the last from slot 13 to slot

19. Switch SWY1 shown is the on-board switch, controlling the

configuration of these two buffers.

Switch Function

P2 on switch

P3 on switch

P4 on switch

P5 on switch

Enables/Disables (On/Off) bus buffer between first and

second segments

Enables/Disables (On/Off) bus buffer between second

and third segments

Determines direction of the bus buffer between first and

second segments, with high left to right and low right to

left

Determines direction of the bus buffer between second

and third segments, with high left to right and low right to

left

Table 1-4: Trigger Bus Switch Functions

P1 P2 P3 P4 P5

ON

1

14 Introduction

234

Figure 1-9: Trigger Bus Switching

5

Page 25

PXIS-2719A

P2 P3 P4 P5 Configuration Description

xxxxN/A N/A

OFF OFF x x All Segments

Isolated

ON ON ON ON 1 → 2 → 3 Segment 1 to 2 & 3

ON OFF ON OFF 1 → 2 Segment 1 to 2

ON OFF OFF OFF 1 ← 2 Segment 2 to 1

OFF ON OFF ON 2 → 3 Segment 2 to 3

OFF ON OFF OFF 2 ← 3 Segment 3 to 2

ON ON OFF OFF 1 ← 2 ← 3 Segment 3 to 1 & 2

ON ON OFF ON 1 ← 2 → 3 Segment 2 to 1 & 3

Table 1-5: Trigger Bu s Settings

All Segments Isolated

1.5.7 System Reference Clock

The PXIS-2719A supplies a PXI 10MHz system reference clock

(PXI_CLK10) to each peripheral slot for inter-module synchronization. An independent buffer (having source impedance matched to

the backplane and a skew of less than 1 ns between slots) drives

the clock signal generated from a high-precision oscillator to each

peripheral slot.

This common reference clock signal can synchronize multiple

modules in a PXI chassis. The 10 MHz reference clock is important to the PXI specification for inter-module synchronization. PXI

modules which have phase-locker loop circuit can lock the 10

MHz reference clock to generate an in-phase timebase.

The PXIS-2719A PXI chassis automatically selects the source of

the 10 MHz reference clock from

X Built-in accurate 10 MHz oscillator

X External 10 MHz clock through a BNC connector

X PXI_CLK10_IN pin on the star trigger slot

Introduction 15

Page 26

Priority of the 10MHz reference clock is as shown.

System Timing

Slot (2nd slot)

No clock present No clock present

No clock present

10MHz clock

present

10MHz clock

present

Table 1-6: 10MHZ Reference Clock Priority

Three indicators on the backplane indicate the 10MHz clock

source driven to all peripheral slots, as shown.

BNC connector on

rear panel

10MHz clock

present

No clock present

10MHz clock

present

10MHz clock driven to

peripheral slots

The 10MHz clock is

generated by backplane.

Clock from BNC

connector is driven to all

the peripheral slots

Clock from system

timing slot is driven to all

the peripheral slots

Clock from system

timing slot is driven to all

the peripheral slots

A

B

LED1

R300

Figure 1-10: Clock Source Indicators

ALEDs

BResistors

Table 1-7: Clock Source Indicators Legend

16 Introduction

LED2

R301

LED3

R302

Page 27

PXIS-2719A

The right indicator lights when the clock is generated by backplane, the middle when the 10MHz clock from BNC connector is

the source of the 10MHz clock, and the left when the 10MHz clock

is present on the system timing slot.

Introduction 17

Page 28

18 Introduction

Page 29

2 Getting Started

This chapter describes procedures for installing the PXIS-2719A

and making preparations for its operation. Please contact ADLINK

or authorized dealer if there are any problems during the installation.

Diagrams and illustrated equipment are for reference only.

Actual system configuration and specifications may vary.

NOTE:

NOTE:

2.1 Package Contents

Before unpacking, check the shipping carton for any damage. If

the shipping carton and/or contents are damaged, inform your

dealer immediately. Retain the shipping carton and packing materials for inspection. Obtain authorization from your dealer before

returning any product to ADLINK.

Please ensure that the following items are included in the package.

X PXIS-2719A Chassis

X Power cords

X Filler panel kit for unused/reserved slots including one 3-slot

panel and eighteen 1-slot panels

X ADLINK All-in-One CD

X User's Manual

PXIs-2719A

If any of these items are missing or damaged, contact the dealer

from whom you purchased the product. Save the shipping materials and carton in case you want to ship or store the product in the

future.

Do not install or apply power to equipment that is damaged or

missing components. Retain the shipping carton and packing

materials for inspection. Please contact your ADLINK dealer/

vendor immediately for assistance and obtain authorization

before returning any product.

Getting Started 19

Page 30

2.2 Cooling Considerations

The PXIS-2719A features an innovative design for heat dissipation, with cooling fans in the rear section of the chassis, drawing

cool air through apertures on the bottom for exhaust through the

back. This design provides uniform airflow for each PXI slot and

exceptional cooling capability. When the chassis is installed in a

rack, the cooling design minimizes drawing of hot air from the rear

area, where other devices exhaust, while maintaining a steady

temperature inside the chassis. For optimal cooling efficiency,

retain support feet.

When rack mounting the PXIS-2719A, at least 1U (44.5 mm/1.75

in.) clearance below the intake apertures is required. Also keep

other objects or equipment at a minimum of 76.2 mm (3 in.) away

from the outlet apertures in the rear region of the chassis.

To maintain expected airflow, please always install filler panels

in unused slots. The filler panels can be found in the chassis

NOTE:

NOTE:

package.

20 Getting Started

Page 31

PXIs-2719A

2.3 Hardware Installation

2.3.1 Installing the System Controller

The PXIS-2719A provides a system controller slot supporting a 3slot wide PXI system controller. We recommend the following system controllers for use with the PXIS-2719A:

X ADLINK PXI-3950 Core 2 Duo PXI controller

X ADLINK PXI-3920 Pentium M PXI controller

1. Ensure the CPU, memory module(s), and storage

device(s) are properly installed on the system controller.

2. Locate the system controller slot (Slot 1).

3. Depress the system controller module’s latch to release.

Getting Started 21

Page 32

4. Align the module’s top and bottom edges with the card

guides, and carefully slide the module into the chassis.

5. Lift the latch until the module is securely seated in the

chassis backplane.

6. Fasten the screws on the module front panel, and connect all devices to the system controller.

22 Getting Started

Page 33

PXIs-2719A

2.3.2 Installing Peripheral Modules

The PXIS-2719A supports up to eighteen PXI/CompactPCI

peripheral modules, including a star trigger module.

The PXIS-2719A chassis does not support installation of a 3U

CompactPCI module with rear I/O function.

CAUTION:

1. Select an available peripheral slot (2 to19)

2. Depress the peripheral module’s latch and align the

module’s top and bottom edges with the card guides.

3. Carefully slide the module into the chassis.

Getting Started 23

Page 34

24 Getting Started

Page 35

PXIs-2719A

4. Lift the latch until the module is securely seated in the

chassis backplane.

5. Fasten the screws on the module’s front panel.

Getting Started 25

Page 36

6. Repeat steps 1 to 5 to install additional PXI peripheral

modules.

To improve efficiency of heat dissipation, after installing all PXI

modules, please install filler plates for any unused slots.

NOTE:

NOTE:

2.3.3 Powering Up the System

The PXIS-2719A is equipped with a 100 VAC to 240 VAC universal power supply unit requiring no input voltage selection.

1. Connect one end of the supplied power cord to the

power inlet located at the rear side of the chassis.

2. Plug the other end of the AC power cord to a properly

grounded wall socket or power strip.

3. Press the standby power switch. The Power LED (blue)

lights up immediately

4. To power off the chassis, press the standby power

switch.

2.4 Rack Mounting

ADLINK provides hardware for optional installation of the PXIS2719A to a rack. The rack-mount kit flexibly recesses the PXIS2719A in the rack, accommodating external mechanical parts on

the front side, such as cables and mass interconnect modules.

26 Getting Started

Page 37

PXIs-2719A

A

C

D

B

C

Figure 2-1: Rack Mount Assembly

A Carrying Handle

B Rubber Feet

C Handles

D Mounting Brackets

Table 2-1: Rack Mount Assembly Legend

1. Unscrew and remove the carrying handle from the left

side

2. Remove the four rubber feet from the right side

3. Fasten both handles to the mounting brackets using the

provided M4 screws

4. Install the mounting brackets to both sides of the chas-

sis using the provided M4 screws. Position of the mounting brackets can be adjusted to recess the chassis in the

rack by any distance

Getting Started 27

Page 38

5. Install the chassis in the rack using eight screws (not

included).

28 Getting Started

Page 39

3 System Management

The PXIS-2719A provides advanced remote monitoring and control of chassis status, including internal temperature, fan speed,

and DC voltages, all exported via a standard RS-232 port, allowing the system to be monitored on a remote computer. The remote

computer can also be used to turn the system on or off through the

monitoring port via software commands.

Remote monitoring and control of the PXIS-2719A requires connection of the remote monitoring port to a remote computer by a

standard RS-232 cable.

The remote monitor port is Rx-Tx/Tx-Rx crossed, requiring a

Rx-Rx/Tx-Tx connected RS-232 cable for remote monitoring.

NOTE:

NOTE:

ADLINK provides an interface-based program (PXISRemoteMonUtil.exe) to monitor the status of PXIS-2719A via a remote computer. As shown, the utility is divided into three interface

categories:

PXIS-2719A

X Connect Control

X Threshold & Control

X Chassis Status.

System Management 29

Page 40

Figure 3-1: Remote Monitor Utility Interface

3.1 Installing the Monitor Utility

The remote monitoring utility and function library are provided on

the ADLINK All-in-One CD.

To install the monitoring utility:

1. Connect a USB CD-/DVD-ROM drive to the system controller.

2. Place the ADLINK All-in-Once CD in the drive.

3. Locate the monitoring utility in the folder

X:\Driver Installation\PXI Platform\PXI chassis\PXIS2719A\RemoteMon\

(where X: denotes the CD-ROM drive)

4. Double-click the Setup.exe file to begin installation.

30 System Management

Page 41

PXIS-2719A

3.2 Connect Control

The Connect Control section connects and disconnects the link

between the PXIS-2719A and the remote computer, displays

chassis status log data, and saves and loads threshold settings.

3.2.1 Com Port Setting

To establish a connection between the remote computer and

the PXIS-2719A:

1. Ensure functional connection between the remote moni-

toring port of the PXIS-2719A and the remote computer

2. Launch PXISRemoteMonUtil.exe on the remote com-

puter.

3. Select “COM Port” on the remote computer connected to

the PXIS-2719A

4. Select “Connect” to initiate connection

5. Select “Run” to commence monitoring system status

6. Select “Stop” to cease monitoring

7. Selecting Start initializes monitoring, and selecting Stop

ends the operation.

System Management 31

Page 42

3.2.2 Chassis Status Log

With the Chassis Status Log function, monitored data can be

recorded. Clicking Log Chassis Status opens the Log Options

dialog, as shown.

Figure 3-2: Log Options Dialog

The name of the log file can be entered, and overwrite or

append to operations selected. The log period can further be

entered, in seconds. Clicking Start begins the log.

Over Threshold Statistics, when selected, displays information

regarding threshold being exceeded.

Save/Load Threshold

All Threshold & Control settings can be saved or loaded here.

Clicking Save Threshold Settings saves all current settings.

Clicking Load Threshold Settings loads all settings from the

saved file. Clicking Load Default Threshold resets all threshold

settings to the default values.

Version Info

Displays the current firmware version.

32 System Management

Page 43

PXIS-2719A

3.3 Remote Status and Control

Sets operations and threshold settings for PXIS-2719A, including

remote chassis on/off, target temperature, fan mode, and threshold settings for DC voltage, temperature, and cooling fan speed.

Figure 3-3: Remote Status and Control Interface

3.3.1 Remote On/Off

On/off status of the PXIS-2719A is displayed. Choosing “Power

ON” or “Power OFF” and selecting “Set” directly powers the

chassis on or off.

Target Temperature

Fans run at different speeds based on the monitored temperature, when the Fan switch on the rear panel is set to AUTO.

Target Temp indicates the temperature when the fans are at

100%. Using the default 50°C as an example, fans run at 40%

when all temperature readings are less than 25°C, and begin

System Management 33

Page 44

rampup when any reading exceeds 25°C. The fans run 100%

speed if any temperature reading exceeds 50°C (Target Temperature). Target temperature setting operations are as shown.

Target Temp can be set by entering the desired target temperature value in the field and clicking Set.

E

D

100

40

Fan

voltage

duty

cycle

(%)

0

A B

0

10 252015 30 35

5

Highest temperature (°C) reported by the 8 backplane sensors

40 45 50

55 60

C

65 70

Figure 3-4: PXIS-219A Temperature Setting Parameters

Temp Parameter

A 0°C Minimum chassis temperature at which the fan

speeds begin ramp-up to the 25°C setting above

B 45°C Maximum chassis temperature at which the fan

speeds begin ramp-up to the 70°C setting above

C 70°C Highest maximum chassis temperature at which fans

reach maximum speed

D 25°C to

70°C

45° range within which maximum chassis temperature

(at which the fans reach maximum speed) can be set

E 25°C Lowest maximum chassis temperature at which fans

reach maximum speed

Table 3-1: PXIS-219A Temperature Parameter Legend

34 System Management

Page 45

Fan Speed

Auto/Full status of the PXIS-2719A is shown here, Auto is displayed when the cooling fans are set to auto mode and Full

when the fans are set to run full speed. Selection of Auto or

Full values and clicking Set directly changes cooling fan mode.

Alarm Threshold

Active alarm threshold settings are shown, including DC voltage, temperature, and fan speeds. The updated threshold setting can also be set here, by entering the desired value and

clicking Set Threshold Settings.

3.3.2 Chassis Status

DC Voltage

The monitored 5V AUX, 3.3V, 5V, 12V, and -12V power rail

readings are shown here. The status shows as normal when

the readings are within the threshold range, and abnormal

when the readings exceed the threshold range.

Chassis Temperature

PXIS-2719A

Eight temperature sensors on the top of the backplane, T1 to

T8 from left to right, provide readings, with status showing normal when the readings are within the threshold value (70°C in

the figure), and abnormal when the readings exceed the

threshold value.

Fan Speed

Monitored readings of the three cooling fans appear here. Status shows as normal when readings exceed threshold value

(800 RPM in the figure), and abnormal when the readings fall

below the threshold value.

System Management 35

Page 46

This page intentionally left blank.

36 System Management

Page 47

4 Monitoring/Control Functions

The monitoring/control function library can be used to create a

customized program for monitoring and controlling the PXIS2719A. The data structure and function library follow.

4.1 Data Structure

In the function library, 3 data structures are defined, as follows.

4.1.1 ChassisStatus

Includes Power, Fan Status, Temperature Status, and Power Status:

typedef struct tagChassisStatus

{

BYTEPowerStatus;//Power On/Off status

//Fan status and speed in RPM

BYTEFan1Status;//Fan#1 status

BYTEFan2Status;//Fan#2 status

BYTEFan3Status;//Fan#3 status

intFan1RPM;//Fan#1 speed in RPM

intFan2RPM;//Fan#2 speed in RPM

intFan3RPM;//Fan#3 speed in RPM

//Temperature sensor status and reading in degree cen-

tigrade

BYTETemp1Status;//Temperature sensor#1 status

BYTETemp2Status;//Temperature sensor#2 status

BYTETemp3Status;//Temperature sensor#3 status

BYTETemp4Status;//Temperature sensor#4 status

BYTETemp5Status;//Temperature sensor#5 status

BYTETemp6Status;//Temperature sensor#6 status

BYTETemp7Status;//Temperature sensor#7 status

BYTETemp8Status;//Temperature sensor#8 status

floatTemp1Reading;//Temperature sensor#1 reading (°C)

floatTemp2Reading;//Temperature sensor#2 reading (°C)

floatTemp3Reading;//Temperature sensor#3 reading (°C)

PXIs-2719A

Monitoring/Control Functions 37

Page 48

floatTemp4Reading;//Temperature sensor#4 reading (°C)

floatTemp5Reading;//Temperature sensor#5 reading (°C)

floatTemp6Reading;//Temperature sensor#6 reading (°C)

floatTemp7Reading;//Temperature sensor#7 reading (°C)

floatTemp8Reading;//Temperature sensor#8 reading (°C)

//DC status and reading

BYTEDC1Status;//DC 5Vsb status

BYTEDC2Status;//DC 3.3V status

BYTEDC3Status;//DC 5V status

BYTEDC4Status;//DC 12V status

BYTEDC5Status;//DC -12V status

floatDC1Reading;//DC 5Vsb voltage

floatDC2Reading;//DC 3.3V voltage

floatDC3Reading;//DC 5V voltage

floatDC4Reading;//DC 12V voltage

floatDC5Reading;//DC -12V voltage

} ChassisStatus;

4.1.2 ChassisSetting

Includes Target Temperature, Temperature Threshold, Fan Speed

Threshold and Power Threshold:

typedef struct tagChassisSetting

{

int TargetTemp;//Target Temerature

int ThresholdTemp;//Temperature Threshold

int ThresholdFan;//Fan Speed Threshold

int Threshold5V_H;//5V High Threshold

int Threshold5V_L;//5V Low Threshold

int Threshold3V3_H;//3.3V Hight Threshold

int Threshold3V3_L;//3.3V Low Threshold

int Threshold12V_H;//12V High Threshold

int Threshold12V_L;//12V Low Threshold

int ThresholdN12V_H;//-12V High Threshold

int ThresholdN12V_L;//-12V Low Threshold

38 Monitoring/Control Functions

Page 49

PXIs-2719A

BYTE FanFullSpeed; //Fan in Full or Auto

Speed Mode

} ChassisSetting;

4.1.3 MCUVersion

Includes MCU Code Version, Major Number, and Minor Number

typedef struct tagMCUVersion

{

BYTE MajorNo;

BYTE MinorNo;

} MCUVersion;

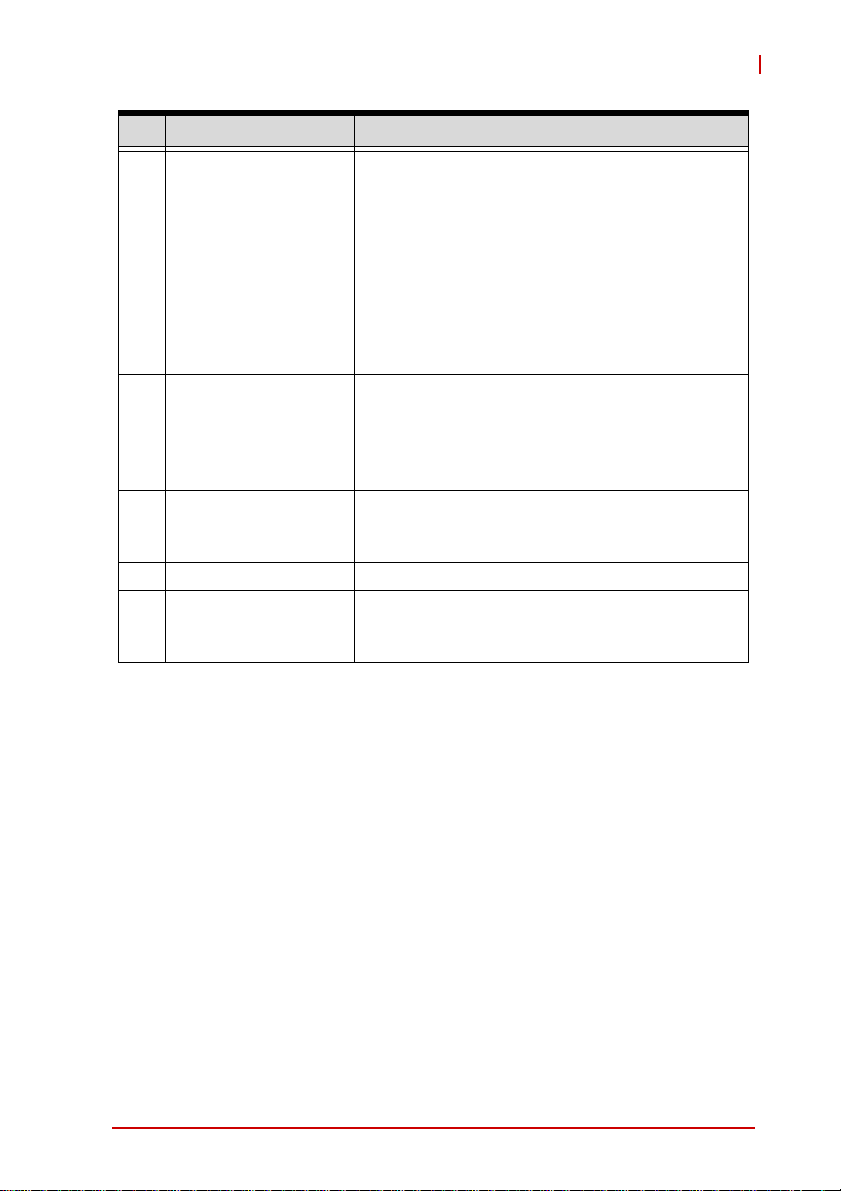

4.1.4 Data Structure Variables

Variables in the Data Structure are as follows

Variable Description Type Value

PowerStatus Power On/Off status BYTE 0: Off

1: On

Fan1Status Fan#1 operating status BYTE 0: Normal

Fan2Status Fan#2 operating status BYTE

Fan3Status Fan#3 operating status BYTE

Fan1RPM Fan#1 speed in RPM int

Fan2RPM Fan#2 speed in RPM int

Fan3RPM Fan#3 speed in RPM int

Temp1Status Temperature sensor #1 status BYTE

Temp2Status Temperature sensor #2 status BYTE

Temp3Status Temperature sensor #3 status BYTE

Temp4Status Temperature sensor #4 status BYTE

Temp5Status Temperature sensor #5 status BYTE

Temp6Status Temperature sensor #6 status BYTE

Temp7Status Temperature sensor #7 status BYTE

Temp8Status Temperature sensor #8 status BYTE

1: Abnormal

2: Disabled

3: Stopped

RPM value

0: Normal

1: Abnormal

Monitoring/Control Functions 39

Page 50

Variable Description Type Value

Temp1Reading Reading of temperature

sensor#1 in °C

Temp2Reading Reading of temperature

sensor#2 in °C

Temp3Reading Reading of temperature

sensor#3 in °C

Temp4Reading Reading of temperature

sensor#4 in °C

Temp5Reading Reading of temperature

sensor#5 in °C

Temp6Reading Reading of temperature

sensor#6 in °C

Temp7Reading Reading of temperature

sensor#7 in °C

Temp8Reading Reading of temperature

sensor#8 in °C

DC1Status DC 5 V standby status BYTE

DC2Status DC 3.3 V status BYTE

DC3Status DC 5 V status BYTE

DC4Status DC 12 V status BYTE

DC5Status DC -12 V status BYTE

DC1Reading DC 5 V standby voltage reading float

DC2Reading DC 3.3 V voltage reading float

DC3Reading DC 5 V voltage reading float

DC4Reading DC 12 V voltage reading float

DC5Reading DC -12 V voltage reading float

TargetTemp Target Temperature in °C int Temperature

ThresholdTemp Temperature Threshold in °C int Temperature

ThresholdFan Fan Speed Threshold in RPM int RPM value

Threshold5V_H 5V High Threshold int 0.01 Voltage

Threshold5V_L 5V Low Threshold int 0.01 Voltage

Threshold3V3_H3.3V High Threshold int 0.01 Voltage

float

float

float

float

float

float

float

float

Temperature

value

0: Normal

1: Abnormal

Voltage value

value

value

Threshold3V3_L3.3V Low Threshold int 0.01 Voltage

40 Monitoring/Control Functions

Page 51

PXIs-2719A

Variable Description Type Value

Threshold12V_H12V High Threshold int 0.01 Voltage

Threshold12V_L12V Low Threshold int 0.01 Voltage

ThresholdN12V_H-12V High Threshold int 0.01 Voltage

ThresholdNV12_L-12V Low Threshold int 0.01 Voltage

FanFullSpeed Fan in Full Speed BYTE 1:Full, 0:Auto

MajorNo MCU code Version Major

Number

MinorNo MCU code Version Minor

Number

Table 4-1: Data Structu r e Variables

BYTE Number

BYTE Number

4.2 Function Library

InitCOM

Description

Initializes the remote computer COM port connected to the

remote monitoring port of the PXIS-2719A.

Syntax

HANDLE InitCOM(LPCSTR com)

Parameter

com:

A string denotes the COM port. Can be COM1 ~

COM8

Return Value

A handle to the initialized COM port. If the function returns

NULL, the initialization of COM port failed.

Monitoring/Control Functions 41

Page 52

Example

HANDLEhCOM;

hCOM= InitCOM(“COM1”);

GetChassisStatus

Description

Acquires chassis status and stores the result in a ChassisStatus structure. Can be invoked periodically to update chassis

status.

Syntax

BOOL GetThreshold(HANDLE hCom, ChassisSetting*

setting)

Parameters

hCom:

The initialized COM port.

Status:

ChassisStatus data structure that stores the chassis status in which PowerStatus, Fan1Status, Fan2Status,

Fan3Status, Fan1RPM, Fan2RPM, Fan3RPM,

Temp1Status ~ Temp8Status, Temp1Reading ~

Temp8Reading, DC1Status ~ DC5Status, DC1Reading

~ DC8Reading will be updated.

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

ChassisStatus status; BOOL ret;

ret= GetChassisStatus(hCom, &status);

42 Monitoring/Control Functions

Page 53

GetThreshold

Description

Acquires chassis fan speed, temperature, and voltage threshold settings and stores the results in a ChassisSetting structure.

Syntax

WD_AD_Auto_Calibration_ALL (ByVal CardNumber

As Integer) As Integer

Parameters

hCom:

The initialized COM port.

Status:

ChassisSetting data structure that stores the chassis

status in which TargetTemp, ThresholdTemp, ThresholdFan, Threshold5V_H, Threshold5V_L, Threshold3V3_H,

Threshold3V3_L, Threshold12V_H, Threshold12V_L,

ThresholdN12V_H, ThresholdN12V_L will be updated

PXIs-2719A

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

ChassisSettingsetting; BOOLret;

ret= GetThreshold(hCom, &setting);

GetMCUVersion

Description

Acquires the MCU code version number and stores the result

in a ChassisStatus structure.

Syntax

BOOL GetMCUVersion(HANDLE hCom, MCUVersion *

Version)

Monitoring/Control Functions 43

Page 54

Parameters

hCom:

The initialized COM port.

Status:

ChassisStatus data structure that stores the chassis status in which MajorNo, MinorNo will be updated.

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

MCUVersionversion; BOOLret;

ret= GetMCUVersion(hCom, &version);

SetChassisPowerOn

Description

Powers on the PXIS-2719A

Syntax

BOOL SetChassisPowerOn (HANDLE hCom)

Parameter

com:

The initialized COM port.

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

ret= SetChassisPowerOn (hCom);

44 Monitoring/Control Functions

Page 55

SetChassisPowerOff

Description

Powers off the PXIS-2719A.

The system controller should be shut down via the operating

system before turning off chassis power.

NOTE:

NOTE:

Syntax

BOOL SetChassisPowerOff (HANDLE hCom)

Parameter

com:

The initialized COM port.

Return Value

TRUE if the function succeeded, FALSE if failed.

PXIs-2719A

Example

BOOL ret;

ret= SetChassisPowerOff (hCom);

SetFanSpeedMax

Description

Sets fan speed to Max mode (forcing fans to operate at full

speed)

Syntax

BOOL SetFanSpeedMax (HANDLE hCom)

Parameters

com:

An initialized COM port.

Monitoring/Control Functions 45

Page 56

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

ret= SetFanSpeedMax (hCom);

SetFanSpeedAuto

Description

Sets fan speed to Auto mode (automatically adjusting fan

speed according to internal temperature)

Syntax

BOOL SetFanSpeedAuto (HANDLE hCom)

Parameter

com:

An initialized COM port.

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

ret= SetFanSpeedAuto (hCom);

SetTargetTemp

Description

Sets a Chassis target temperature that fan speed will automatically adjust to meet.

Syntax

BOOL SetTargetTemp(HANDLE hCom ,int temp)

46 Monitoring/Control Functions

Page 57

Parameters

com:

An initialized COM port.

temp:

Target temperature (from 25 to 70°C)

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

int temp = 50;

ret= SetTargetTemp(hCom,temp);

SetFanAlarm

Description

Sets chassis fan speed threshold, fan speeds under which will

trigger the alarm.

PXIs-2719A

Syntax

BOOL SetFanAlarm(HANDLE hCom ,int speed)

Parameters

com:

An initialized COM port.

speed:

Fan speed threshold (in rpm, multiples of 100, such as

500, 600, 700…, range 0 to 10000)

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

int speed = 1000;

Monitoring/Control Functions 47

Page 58

ret= SetFanAlarm(hCom,speed);

SetTempAlarm

Description

Sets chassis temperature threshold, which, if exceeded in a

sensor reading, triggers the temperature alarm.

Syntax

BOOL SetTempAlarm(HANDLE hCom ,int temp)

Parameters

com:

An initialized COM port.

temp:

Temperature alarm threshold ( unit: °C, range : 0~100)

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

int temp = 60;

ret= SetTempAlarm(hCom,temp);

Set5VAlarm

Description

Sets the chassis DC 5V threshold, beyond which the DC 5V

voltage triggers the alarm.

Syntax

BOOL Set5VAlarm(HANDLE hCom ,float H, float L)

Parameters

com:

48 Monitoring/Control Functions

Page 59

An initialized COM port.

H:

DC 5V alarm upper threshold (voltage, range 0 to 1.0)

L:

DC 5V alarm lower threshold (voltage, range 0 to 1.0)

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

floathigh = 0.25;

floatlow = 0.25;

ret= Set5VAlarm(hCom, high, low);

Set3V3Alarm

Description

Sets the chassis DC 3.3V threshold, beyond which the DC 5V

voltage triggers the alarm.

PXIs-2719A

Syntax

BOOL Set3V3Alarm(HANDLE hCom ,float H, float

L)

Parameters

com:

An initialized COM port.

H:

DC 3.3V alarm upper threshold (voltage, range 0 to

0.66)

L:

DC 3.3V alarm lower threshold (voltage, range 0 to 0.66)

Monitoring/Control Functions 49

Page 60

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

floathigh = 0.15;

floatlow = 0.15;

ret= Set3V3Alarm(hCom, high, low);

Set12VAlarm

Description

Sets the chassis DC 12V threshold, beyond which the DC 12V

voltage triggers the alarm.

Syntax

BOOL Set12VAlarm(HANDLE hCom ,float H, float

L)

Parameters

com:

An initialized COM port.

H:

DC 12V alarm upper threshold (voltage, range 0 to 2.4)

L:

DC 12V alarm lower threshold (voltage, range 0 to 2.4)

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

floathigh = 0.6;

floatlow = 0.6;

ret= Set12VAlarm(hCom, high, low);

50 Monitoring/Control Functions

Page 61

SetN12VAlarm

Description

Sets the chassis DC -12V threshold, beyond which the DC

-12V voltage triggers the alarm.

Syntax

BOOL SetN12VAlarm(HANDLE hCom ,float H, float

L)

Parameters

com:

An initialized COM port.

H:

DC 12V alarm upper threshold (voltage, range 0 to 2.4)

L:

DC 12V alarm lower threshold (voltage, range 0 to 2.4)

Return Value

PXIs-2719A

TRUE if the function succeeded, FALSE if failed.

Example

BOOL ret;

floathigh = 0.6;

floatlow = 0.6;

ret= SetN12VAlarm(hCom, high, low);

CloseCOM

Description

Closes the initialized COM port.

Syntax

BOOL CloseCOM(HANDLE hCom)

Monitoring/Control Functions 51

Page 62

Parameters

com:

The initialized COM port.

Return Value

TRUE if the function succeeded, FALSE if failed.

Example

ret= CloseCOM (hCom);

52 Monitoring/Control Functions

Page 63

PXIS-2719A

Appendix - Troubleshooting and Mainte-

nance

This Appendix describes basic troubleshooting techniques, as well

as instructions for the maintenance of the PXIS-2719A chassis.

1 Installation Problems

Inability to start the system frequently results from incorrect installation of the system controller, peripheral modules, and other components. Before starting the system, please ensure that:

X The system controller is properly installed and secured

X All peripheral modules are properly seated on the slots

X All cables are properly connected to the system controller

and peripheral modules

X All installed peripheral modules are compatible for use in

the chassis

X The power cord is securely plugged into the chassis power

connector and power outlet/wall socket/power strip

If the system fails to start when all installation conditions are met,

remove all installed peripheral modules and try again. If the system starts normally, instal one peripheral module at a time followed by powering up. You may also try installing the modules into

different slots until the desired result is obtained

Troubleshooting and Maintenance 53

Page 64

2 Basic Troubleshooting

Problem Ensure that:

System fails to

power up

No video output in

the external display

Power LED (blue) is

blinking

Fan LED (green) is

blinking

Temperature LED

(amber) is blinking

X The power cord is securely

plugged into the chassis power

connector and wall socket/power

strip

X The wall socket/power strip is live

X The main power switch on the

back of the chassis is turned on

X The standby power button on the

chassis front panel is turned on

X The external display is function-

ing properly

X Display settings support external

video

There is no short circuit by removing all PXI

modules (PXI controller and peripheral modules)

If the signal persists, contact your dealer for further

assistance

The fan is unobstructed

If the signal persists, contact your dealer for further

assistance.

Airflow from the outlet apertures is unobstructed

and steady; if not, ensure that adequate clearance

for the intake apertures is provided

If the temperature of exhausted air is normal (below

50°C) but the temperature LED is still blinking,

contact your dealer for further assistance.

3 Maintenance

3.1 Handling the Chassis

The PXIS-2719A is designed for both rack-mount and benchtop

use. When transporting or carrying the chassis, it is recom-

54 Troubleshooting and Maintenance

Page 65

PXIS-2719A

mended that the handle be used, being designed to support the

weight of the chassis for superior portability and balance.

The PXIS-2719A weighs 14.5 kg. Please be careful when moving

the chassis to avoid any possible injury.

3.2 Cleaning the Exterior

Make sure that the system is turned off before cleaning the chassis exterior. Wipe the exterior with a clean cloth starting from areas

that easily accumulate dust or dirt such as the area in and around

the chassis and power supply air intake apertures.

3.3 Power Requirements

Make sure that the power cord is in good condition before plugging

it into the system. It is important to check the reliability of the

power source. The PXIS-2719A power supply is capable of handling 100 to 240 V AC within the 50 Hz to 60 Hz range. Do not

connect the PXIS-2719A to an already overloaded circuit.

Troubleshooting and Maintenance 55

Page 66

This page intentionally left blank.

56 Troubleshooting and Maintenance

Page 67

PXIS-2719A

Important Safety Instructions

For user safety, please read and follow all instructions,

WARNINGS, CAUTIONS, and NOTES marked in this manual and

on the associated equipment before handling/operating the

equipment.

X Read these safety instructions carefully.

X Keep this user’s manual for future reference.

X Read the specifications section of this manual for detailed

information on the operating environment of this equipment.

X When installing/mounting or uninstalling/removing

equipment:

Z Turn off power and unplug any power cords/cables.

X To avoid electrical shock and/or damage to equipment:

Z Keep equipment away from water or liquid sources;

Z Keep equipment away from high heat or high humidity;

Z Keep equipment properly ventilated (do not block or

cover ventilation openings);

Z Make sure to use recommended voltage and power

source settings;

Z Always install and operate equipment near an easily

accessible electrical socket-outlet;

Z Secure the power cord (do not place any object on/over

the power cord);

Z Only install/attach and operate equipment on stable

surfaces and/or recommended mountings; and,

Z If the equipment will not be used for long periods of time,

turn off and unplug the equipment from its power source.

Important Safety Instructions 57

Page 68

X Never attempt to fix the equipment. Equipment should only

be serviced by qualified personnel.

X A Lithium-type battery may be provided for uninterrupted,

backup or emergency power.

Risk of explosion if battery is replaced with an incorrect type;

please dispose of used batteries appropriately.

X Equipment must be serviced by authorized technicians

when:

Z The power cord or plug is damaged;

Z Liquid has penetrated the equipment;

Z It has been exposed to high humidity/moisture;

Z It is not functioning or does not function according to the

user’s manual;

Z It has been dropped and/or damaged; and/or,

Z It has an obvious sign of breakage.

58 Important Safety Instructions

Page 69

Getting Service

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing, 100085 China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

PXIS-2719A

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

ADLINK Technology (Europe) GmbH

Address: Nord Carree 3, 40477 Duesseldorf, Germany

Tel: +49-211-495-5552

Fax: +49-211-495-5557

Email: emea@adlinktech.com

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Getting Service 59

Page 70

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1675-12 微汾瘶捒娯 8猻

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: 1st Floor, #50-56 (Between 16th/17th Cross) Margosa Plaza,

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80-23464606

Email: india@adlinktech.com

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

8F Mointer B/D,1675-12, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Singapore 349584

Margosa Main Road, Malleswaram, Bangalore-560055, India

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 6 Hasadna St., Kfar Saba 44424, Israel

Tel: +972-9-7446541

Fax: +972-9-7446542

Email: israel@adlinktech.com

60 Getting Service

Loading...

Loading...