Page 1

PXIS-2670

3U 14-Slot PXI Chassis

with 500W AC Power Supply

User’s Manual

Manual Rev. 2.01

Revision Date: December 21, 2006

Part No: 50-17022-1000

Advance Technologies; Automate the World.

Page 2

Copyright 2006 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Trademarks

NuDAQ, NuIPC, DAQBench are registered trademarks of ADLINK

TECHNOLOGY INC.

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc.

Please contact us should you require any service or assistance.

ADLINK TECHNOLOGY INC.

Web Site: http://www.adlinktech.com

Sales & Service: Service@adlinktech.com

TEL: +886-2-82265877

FAX: +886-2-82265717

Address: 9F, No. 166, Jian Yi Road, Chungho City,

Taipei, 235 Taiwan

Please email or FAX this completed service form for prompt and

satisfactory service.

Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX:

Web Site

Product Information

Product Model

OS:

Environment

M/B: CPU:

Chipset: BIOS:

Please give a detailed description of the problem(s):

Page 4

Page 5

Table of Contents

Table of Contents..................................................................... i

List of Tables.......................................................................... iii

List of Figures ........................................................................ iv

1 Introduction ........................................................................ 1

1.1 Unpacking Checklist ............................................................ 2

1.2 Features............................................................................... 3

1.3 OEM options ........................................................................ 4

Backplane ....................................................................... 4

Power Supply Unit .......................................................... 4

Chassis Color and Logo ................................................. 5

2 Installation .......................................................................... 7

2.1 Power Budget Consideration ............................................... 7

2.2 Steps for Installation ............................................................ 7

2.3 System monitoring ............................................................... 7

2.4 Grounding on the Mounting Holes ....................................... 9

3 Backplane Overview ........................................................ 11

3.1 Interoperability with CompactPCI ...................................... 11

3.2 System Controller Slot ....................................................... 11

3.3 Star Trigger Slot................................................................. 11

3.4 Peripheral Slots ................................................................. 12

3.5 Local Bus ........................................................................... 13

3.6 Trigger Bus ........................................................................ 13

3.7 System Reference Clock ................................................... 13

4 Troubleshooting and Preventative Maintenance .......... 15

4.1 Troubleshooting the PXIS-2670......................................... 15

4.2 Cleaning............................................................................. 16

Interior Cleaning ........................................................... 16

Exterior Cleaning .......................................................... 16

4.3 Temperature Detect........................................................... 17

4.4 Fan Hot-Swap Replacement.............................................. 17

A Specifications................................................................... 19

A.1 General .............................................................................. 19

Table of Contents i

Page 6

Electrical ....................................................................... 19

B Backplane Drawing and Pin Assignments ..................... 23

B.1 Backplane Drawing ............................................................ 23

B.2 Backplane xBP-3014L Connectors Pin Assignments ........ 24

PXI Connectors Pin Assignments ................................. 24

Miscellaneous Connectors Pin Assignments ................ 31

Important Safety Instructions............................................... 35

Warranty Policy ..................................................................... 37

ii Table of Contents

Page 7

List of Tables

Table 3-1: JP2: PXI 10MHz Reference Clock Control ............. 13

Table 4-1: Troubleshooting ...................................................... 15

List of Tables iii

Page 8

List of Figures

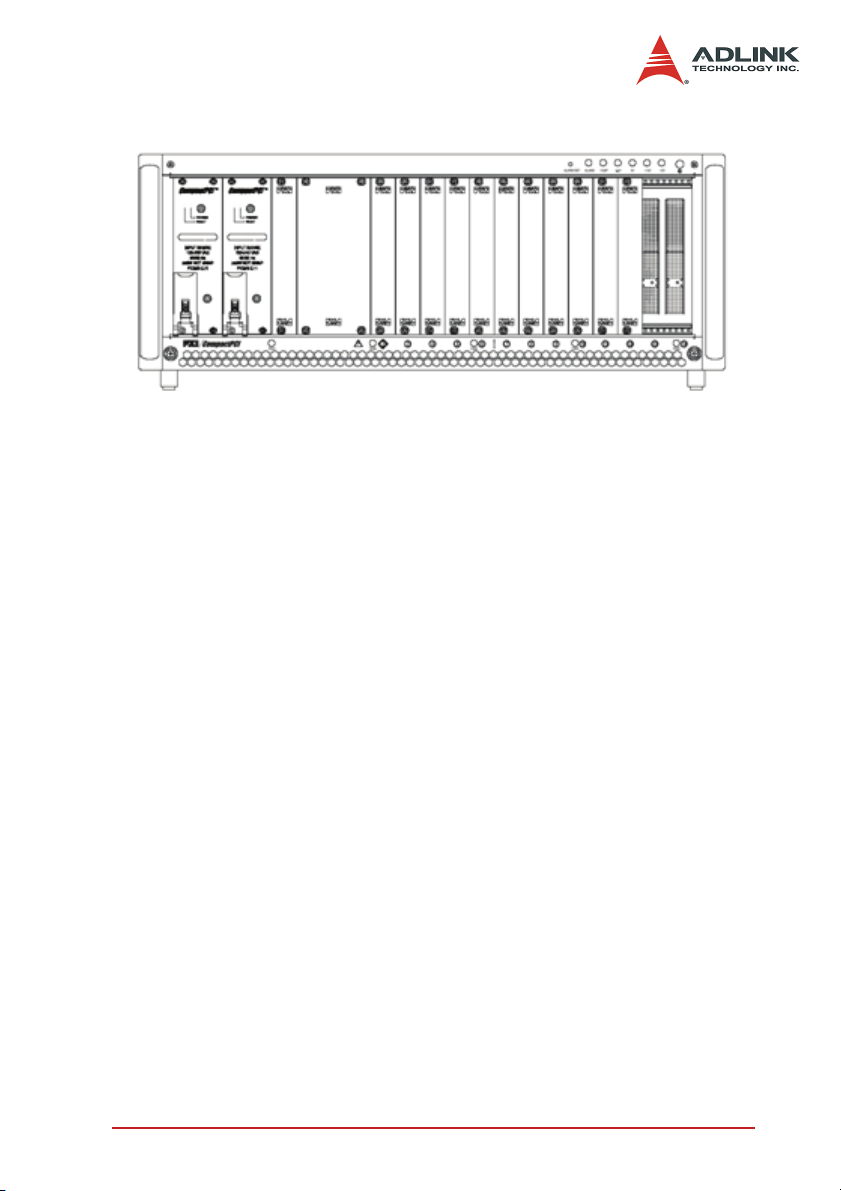

Figure 1-1: Front View of the PXIS-2670 Chassis ....................... 3

Figure 1-2: Rear View of the PXIS-2670 Chassis ........................ 4

Figure 1-3: Optional power supply (redundant AC/DC cPCI PSU) 5

Figure 3-1: PXI Local Bus and Star Trigger Routing.................. 12

Figure B-1: XBP-3014L front view drawing ............................... 23

Figure B-2: XBP-3014L rear view drawing ................................. 23

iv List of Figures

Page 9

1 Introduction

The ADLINK PXIS-2670 is a 19" 3U PXI chassis providing one

PXI system slot and 13 PXI peripheral slots in a system. This

chassis is compliant with PXI and CompactPCI specifications.

Both PXI and CompactPCI modules can be used in the chassis.

Compliant with PXI specifications, the internal 10MHz reference

clock or external reference clock is available on all of the 13 PXI

slots, as well as the star trigger functions, PXI trigger bus, and PXI

local bus.

The PXIS-2670 is equipped with an industrial-grade, 2U ATX

500W AC power supply to provide reliable power to the system.

The status of system power supply, temperature, and cooling fans

are monitored by the alarm module assembled in the chassis.

Once a failure is detected, a LED and buzzer will be actuated. The

failure fans can be removed from the front panel and are hot

swappable, which effectively reduces MTTR (Mean-Time-ToRepair).

The PXIS-2670 chassis is designed to accommodate a 3-slot or 4slot PXI controller module. ADLINK PXI-3800/PXI-3710 (3-slot PXI

controller) and PXI-3710F (4-slot PXI controller, with floppy disk

drive) are recommended for the PXIS-2670 chassis. With its powerful features, the PXIS-2670 is ideal for applications which need

high performance, robust and compact chassis.

Introduction 1

Page 10

1.1 Unpacking Checklist

Check the shipping carton for any damage. If the shipping carton

and contents are damaged, notify the local dealer or sales for a

replacement. Retain the shipping carton and packing material for

inspection by the dealer.

Check for the following items in the package. If there are any missing items, contact your local dealer or sales.

X PXIS-2670: 14-slot 3U PXI/CompactPCI instrument chassis

with a 500W AC power supply installed

X This User’s Manual

X Power Cord

Note: The package of the PXI-2670 OEM version (non-standard

configuration, functionality, or package) may vary according

to custom requests. The assigned controller or peripheral

modules may be pre-installed and shipped with the chassis.

Please check with the dealer for more options.

2Introduction

Page 11

1.2 Features

X Accepts both 3U PXI and CompactPCI modules

X One system slot and 13 PXI/CompactPCI peripheral slots

X PXI specifications Rev. 2.2 compliant

X IEEE 1101.10 mechanical packaging compliant

X Filtered, forced-air cooling

X Industrial-grade 500W AC power supply

X Temperature, voltage, and fan monitoring LED

X 4U high rackmount and benchtop installation

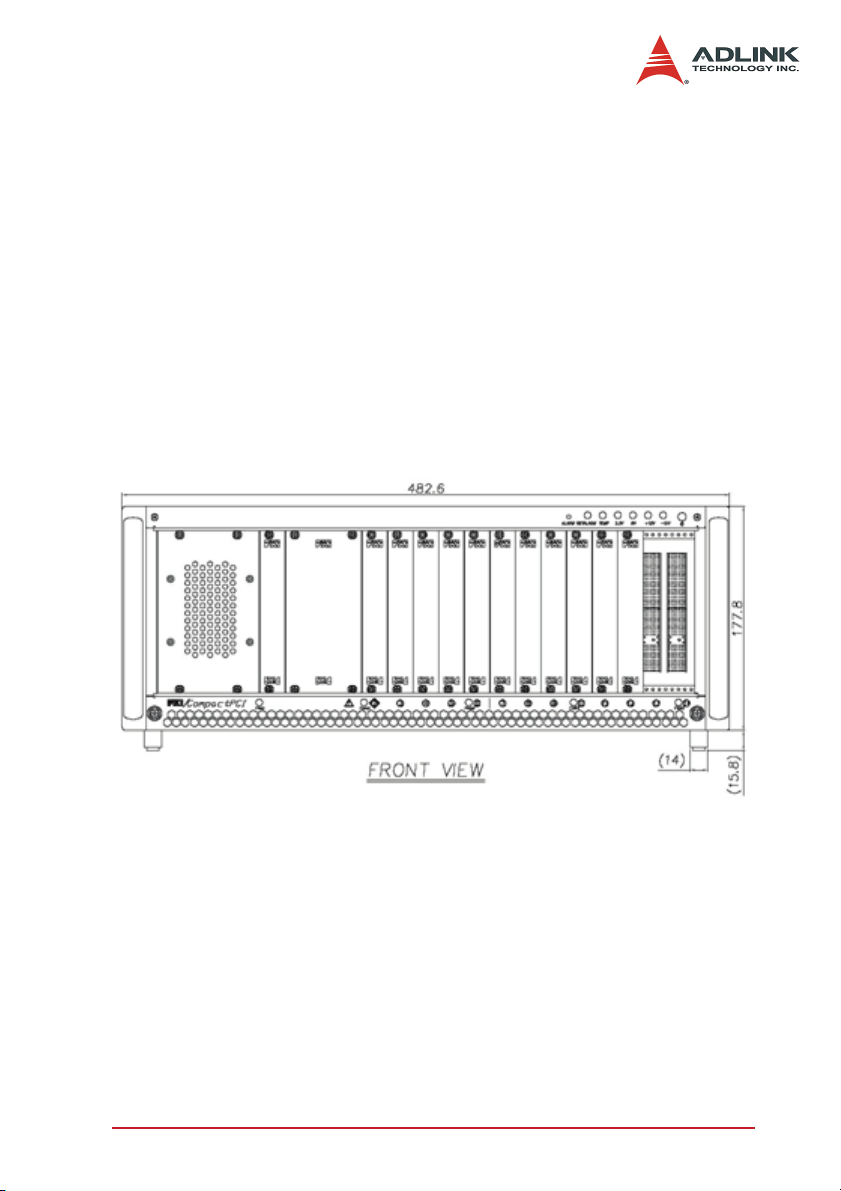

Figures 1-1 and 1-2 show some of the features and components of

the PXIS-2670 chassis. Figure 1-1 shows the front view of the

PXIS-2670. Figure 1-2 shows the rear view of the PXIS-2670.

Figure 1-1: Front View of the PXIS-2670 Chassis

Introduction 3

Page 12

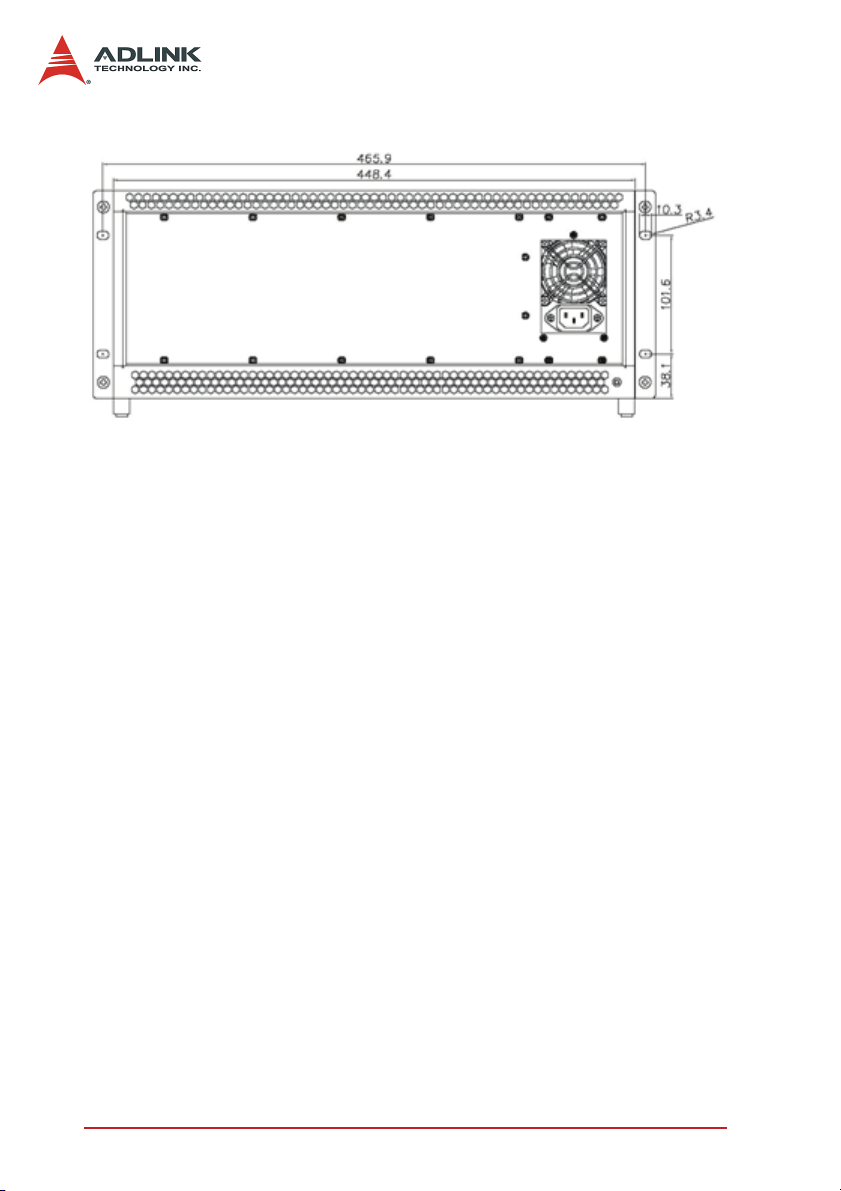

Figure 1-2: Rear View of the PXIS-2670 Chassis

1.3 OEM options

The standard PXIS-2670 chassis includes backplanes and a

power supply unit in addition to the enclosure metal parts. The following sections depict the standard parts used in the PXIS-2670

and OEM options.

Backplane

The PXIS-2670 has a 14-slot PXI backplane xBP-3014L inside.

The backplane is used to accommodate PXI/CompactPCI controller and peripheral modules. The xBP-3014L is designed to support

both 32-bit/33MHz and 64-bit/66MHz PXI bus.

Power Supply Unit

PXIS-2670 equips one industrial-grade, 2U ATX 500W AC power

supply to provide reliable power to the system.

Various OEM models that accommodate different AC or DC input

are available. This makes PXIS-2670 suitable for wide variety of

applications such as communication signal analysis and transportation computer, which require 24V/48V DC power supply. Please

contact us for other power supply options that fit your applications.

4Introduction

Page 13

Figure 1-3: Optional power supply (redundant AC/DC cPCI PSU)

Chassis Color and Logo

The standard color of PXI-2670 is beige. ADLINK provides custom

chassis color or paint specific logo for OEMs, with minimum order

requirement. Please contact us for more details.

Introduction 5

Page 14

6Introduction

Page 15

2 Installation

The chapter depicts the procedure of installation PXIS-2670 chassis.

2.1 Power Budget Consideration

Prior to installing any modules into the PXIS-2670 chassis, please

calculate the system power requirement. The power budget for

every DC outputs shall also be checked, including +5V, +3.3V,

+12V, -12V supply rail.

2.2 Steps for Installation

Follow the step to power on the chassis.

1. Make sure the power switch is in the OFF position.

2. Plug in the AC power cord.

3. Install your controller. Please check the ejector/injector

handle is pushed down. Align the controller edge to the

“RED” card guide, sliding in to the rear of the chassis.

Push up on the ejector/injector handle to fully inject the

card into the chassis. Secure the screws on the module’s front panel.

4. Install peripheral modules if any.

5. Press the power switch on the front panel to power on

the chassis.

6. Check the LED to make sure the power input is ready.

There are four Green LED indicators (3.3V, 5V, +12V,

and -12V). The four LEDs will light when power turn on.

The fans should become operational as well.

Note: If the chassis does not power on, see Chapter 4, Trouble-

shooting and Preventative Maintenance.

2.3 System monitoring

There are LEDs on the front panel for system monitoring, including

powers, temperature, and fans. Please refer to following for the

detail meaning of display status on LEDs.

Installation 7

Page 16

System Monitoring

X Power LED (Voltage : 3.3V, 5V, +12V, -12V)

Z Color: Green

Z ON while supplied

X Temperature LED

Z Color: Amber

Z ON for normal condition

Z Flashes if exceeds temperature

X Fan LED

Z Color: Green

Z ON while normal fan speed

Z Flashes if abnormal fan speed

X Alarm LED

Z Color: Red

Z ON while normal condition

Z Flashes if alarm occurs

The Alarm Buzzer beeps continuously if any alarm occurs. When

the Alarm Buzzer beeps, users can check the LED on the front

panel to find out which kind of alarm occurs.

There is a black button labeled Alarm RST near by the Alarm LED

on the front panel. When the Alarm LED flashes and the Alarm

Buzzer continues beeping, you can push Alarm RST button to

stop beeping.

Refer to Chapter 4 for Troubleshooting.

8Installation

Page 17

2.4 Grounding on the Mounting Holes

There are two kinds of grounding for the mounting holes of the

backplane. The mounting holes labeled as “GND” with “circle soldering mask” connected to the logic ground plane of the backplane. The mounting holes labeled as “FGND” with “square

soldering mask” not connected to the ground plane therefore providing isolation between the logic ground and the chassis ground.

The backplane is mounted on the PXIS-2670 through all mounting

holes by default, therefore the chassis ground is shorted to the

logic ground. For applications that require isolation between the

logic ground and the chassis ground, users can remove the

screws on the GND mounting holes.

Installation 9

Page 18

10 Installation

Page 19

3 Backplane Overview

3.1 Interoperability with CompactPCI

The PXIS-2670 backplane XBP-3014L can use both PXI-compatible products and standard CompactPCI products.

The signals on the P1 connector of the backplane meet the

requirements of the CompactPCI specification for both the peripheral and system modules.

The PXI-specific signals are located on P2. Only the signals that

are reserved or not used in the CompactPCI 64-bit specification

are found on PXI-specific signals. Therefore, all modules that

meet the requirements of the CompactPCI 64-bit specification will

function in the PXIS-2670.

3.2 System Controller Slot

The System Controller slot is Slot 1 of the chassis as defined by

the PXI specification. It has three controller expansion slots, which

are used for system controller modules that are wider than one

slot. As defined in the PXI specification, these slots allow the controller to expand to the left to prevent the controller from using up

peripheral slots.

3.3 Star Trigger Slot

The Star Trigger (ST) slot is Slot 2. This slot has a dedicated trigger line between itself and slots 3-14 is intended for modules with

ST functionality that can provide individual triggers to the peripherals.

Backplane Overview 11

Page 20

3.4 Peripheral Slots

There are 7 peripheral slots including the Star Trigger controller

slot.

Figure 3-1: PXI Local Bus and Star Trigger Routing

12 Backplane Overview

Page 21

3.5 Local Bus

The local bus of PXI backplane XBP-3014L is a daisy-chained bus

that connects each peripheral slot with its adjacent peripheral slots

to the left and right. Each local bus is 13 lines wide and can pass

analog signals between modules or provide a high-speed sideband communication path that does not affect the PXI bandwidth.

In accordance with the PXI specification, the local bus connections

between all slots except slots 1 and 2.

3.6 Trigger Bus

ADLINK PXIS-2670 has PXI trigger bus. Users can use triggers to

synchronize the operation of several different PXI peripheral modules, or use one module to control carefully timed sequences of

operations performed on other modules in the system. Modules

can pass triggers to one another through trigger bus, allowing precisely timed responses to asynchronous external events the system is monitoring or controlling.

3.7 System Reference Clock

The PXIS-2670 supplies the PXI 10MHz system clock signal

(PXI_CLK10) independently to every peripheral slot. An independent buffer (having source impedance matched to the backplane

and a skew of less than 1ns between slots) drives the clock signal

to each peripheral slot. Users can use this common reference

clock signal to synchronize multiple modules in a measurement or

control system or drive PXI_CLK10 from an external source

through the PXI_CLK10_IN pin on the P2 connector of the star

trigger slot.

Users can select the internal or external clock by setting the

jumper JP2.

JP2 Description

Pin 1-2 External clock through the PXI_CLK10_IN on star trigger slot

Pin 2-3 Internal 10MHz system clock PXI_CLK10

Table 3-1: JP2: PXI 10MHz Reference Clock Control

Backplane Overview 13

Page 22

14 Backplane Overview

Page 23

4 Troubleshooting and Preventative

Maintenance

4.1 Troubleshooting the PXIS-2670

Please refer to Table 4-1 to troubleshoot the PXIS-2670 chassis.

The table lists possible causes for power failure and recommends

ways to correct the problem.

Possible Cause What to Do

PXIS-2670 is not connected to

power source.

Power switch is not switched on. Make sure the power switch is set to the ON position.

Power supply has failed. Contact ADLINK for repair.

The Alarm Buzzer is beeping

Make sure that the PXIS-2670 is connected to a live

electrical outlet. Try operating another piece of equipment from this outlet.

Push Alarm RST button to stop beeping and refer to

Chapter 2.3 to find out which alarm occurs.

X Temperature LED flashes:

X Cool down the PXIS-2670 system

under 50

X Fan LED flashes:

X Refer to Chapter 4.4 for the fan hot-

°C.

swap replacement.

Table 4-1: Troubleshooting

Troubleshooting and Preventative Maintenance 15

Page 24

4.2 Cleaning

Cleaning procedures consist of two parts: interior and exterior

cleaning of the chassis. Refer to your module user documentation

for information about cleaning the individual CompactPCI or PXI

modules.

Note: Always power-off the chassis and disconnect the power cord

before cleaning of servicing the chassis.

Interior Cleaning

Use a dry, low-velocity stream of air for cleaning the interior of the

chassis. Clean around components with a soft-bristle brush. If you

must use a liquid for minor interior cleaning, use a 75% isopropyl

alcohol solution and rinse with deionized water.

Exterior Cleaning

Use a dry lint-free cloth or a soft-bristle brush to clean the exterior

surfaces of the chassis. If any dirt remains, moisten a cloth to wipe

the exterior surfaces of the chassis in a mild soap solution. Wiping

with a cloth moistened with clear water to remove any soap residue. Do not use abrasive compounds on any part of the chassis.

16 Troubleshooting and Preventative Maintenance

Page 25

4.3 Temperature Detect

If the system overheats, an Amber Temp LED flashes and a

buzzer beeps continuously. There are three values of temperature

setting, 50

ADLINK if you need to change setting.

°C, 60°C, and 70°C. The default is 50°C. Contact

4.4 Fan Hot-Swap Replacement

There is a LED for each fan for system monitoring. When any one

of the fans is defective, the corresponding LED flashes and the

alarm buzzer keep beeping. Please refer to the following for the

fan hot-swap replacement.

Fan Hot-Swap Replacement Procedure

1. Press the Alarm RST button on the front panel to stop

the beeping.

2. Remove the front panel cover of fans.

3. Pull out the defective fan.

4. Replace with a new fan.

5. Cover back the fans panel cover.

Troubleshooting and Preventative Maintenance 17

Page 26

18 Troubleshooting and Preventative Maintenance

Page 27

A Specifications

A.1 General

Complies with PXI specifications and accepts modules compliant

with CompactPCI, PICMG 2.0 specifications.

Electrical

AC Power Supply

X Input voltage: 100 to 240 ±10%

X Input frequency: 50Hz to 60Hz ±5% Hz

X Output

Maximum usable power: 500W

VDC Maximum

+5V 50.0A

+3.3V 28.0A

+12V 35.0A

-12V 0.8A

The maximum +5V and +3.3V power source outputs must not

exceed 250W.

System Monitoring

X Power LED

Z Voltage : +5V, +3.3V, +12V, -12V

Z Color : Green

X ON while power suppliedTemperature LED

Z Temperature setting: 50°C, 60°C, 70°C

Z Color: Amber

Z ON for normal condition

Z FLASH if exceeds temperature

X Fan LED

Z Fan speed monitoring

Z Color: Green

19

Page 28

Z ON while normal fan speed

Z FLASH while abnormal fan speed

X Alarm LED

Z Color: Red

Z ON while normal condition

Z FLASH if any alarm occurs

X Alarm Buzzer

Z Beep if any alarm occurs

X Alarm reset button

Z Reset the alarm monitor system

Cooling

Fans:

X Front-access hot swappable fan trays

X Five 31CFM fans trays at the bottom of the chassis

X Fan speed: 2900 ±300RPM

X Power: 12 VDC @ 0.17 A each fan

X Noise: 36dB(A)

X Air filter: removable from the bottom of the chassis

Physical

X Number of PXI/CompactPCI slots: 14 (1 system slot, 13

peripheral slots)

X Number of controller expansion slots: 3 (left of controller

slot)

X Dimensions:

Z 258mm x 448.4mm x 177.8 mm (L x W x H, w/o handle)

X Weight

Z 14 Kg

Operating Environment

X Ambient temperature range: 0 to 50ºC

X Relative humidity: 10 to 90%, noncondensing

20

Page 29

Storage Environment Temperature

X Ambient temperature range: -20 to 70ºC

X Relative humidity: 5 to 95%, noncondensing

Backplane

X Backplane bare-board material: UL 94V-0 rated

X Backplane connectors: Conforms to IEC-917 and IEC 1076-

4-101, UL 94V-0 rated

X Number of PXI/CompactPCI slots: 14 (1 controller, 13

peripherals)

Shock and Vibration

X Shock: 15 G

X Random Vibration

Z Operating: 5 to 500 Hz, 0.5 G

Z Nonoperating: 5 to 500 Hz, 1.88 G

peak-to-peak

, 11 ms duration, non-operation

, each axis

RMS

, each axis

RMS

Safety and EMC/EMI Compliance

EMC/EMI: CE, FCC Class A

21

Page 30

22

Page 31

B Backplane Drawing and Pin

Assignments

B.1 Backplane Drawing

The following figures show the two parts of the backplanes and

Mechanical Drawing.

Figure B-1: XBP-3014L front view drawing

Figure B-2: XBP-3014L rear view drawing

23

Page 32

B.2 Backplane xBP-3014L Connectors Pin Assignments

PXI Connectors Pin Assignments

System Slot (Slot #1) P1 Pin Assignment

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND AD[1] +5V V(I/O) AD[0] ACK64# GND

23 GND +3.3V AD[4] AD[3] +5V AD[2] GND

22 GND AD[7] GND +3.3V AD[6] AD[5] GND

21 GND +3.3V AD[9] AD[8] GND C/BE[0]# GND

20 GND AD[12] GND V(I/O) AD[11] AD[10] GND

19 GND +3.3V AD[15] AD[14] GND AD[13] GND

18 GND SERR# GND +3.3V PAR C/BE[1]# GND

17 GND +3.3V IPMB_SCL IPMB_SDA GND PERR# GND

16 GND DEVSEL# GND V(I/O) STOP# LOCK# GND

15 GND +3.3V FRAME# IRDY# GND TRDY# GND

12-14 Key

11 GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

10 GND AD[21] GND +3.3V AD[20] AD[19] GND

9 GND C/BE[3]# GND AD[23] GND AD[22] GND

8 GND AD[26] GND V(I/O) AD[25] AD[24] GND

7 GND AD[30] AD[29] AD[28] GND AD[27] GND

6 GND REQ# (1) GND +3.3V CLK (1) AD[31] GND

5 GND BRSVP1A5 BRSVP1B5 PCIRST# GND GNT# (1) GND

4 GND IPMB_PWR GND V(I/O) INTP INTS GND

3 GND INTA# (1) INTB# (1) INTC# (1) +5V INTD# (1) GND

2 GND TCK +5V TMS TDO TDI GND

1 GND +5V -12V TRST# +12V +5V GND

Pin Z A B C D E F

24

Page 33

System Slot (Slot #1) P2 Pin Assignment

Pin Z A B C D E F

22 GND PXI_BRSVA22 PXI_BRSVB22 PXI_BRSVC22 PXI_BRSVD22 PXI_BRSVE22 GND

21 GND CLK6 GND NC NC NC GND

20 GND CLK5 GND NC GND NC GND

19 GND GND GND SMBDATA SMBCLK SMBALERT- GND

18 GND PXI_TRIG3 PXI_TRIG4 PXI_TRIG5 GND PXI_TRIG6 GND

17 GND PXI_TRIG2 GND PRST# REQ6# GNT6# GND

16 GND PXI_TRIG1 PXI_TRIG0 DEG# GND PXI_TRIG7 GND

15 GND PXI_BRSVA15 GND FAL# REQ5# GNT5# GND

14 GND AD[35] AD[34] AD[33] GND AD[32] GND

13 GND AD[38] GND V(I/O) AD[37] AD[36] GND

12 GND AD[42] AD[41] AD[40] GND AD[39] GND

11 GND AD[45] GND V(I/O) AD[44] AD[43] GND

10 GND AD[49] AD[48] AD[47] GND AD[46] GND

9 GND AD[52] GND V(I/O) AD[51] AD[50] GND

8 GND AD[56] AD[55] AD[54] GND AD[53] GND

7 GND AD[59] GND V(I/O) AD[58] AD[57] GND

6 GND AD[63] AD[62] AD[61] GND AD[60] GND

5 GND C/BE[5]# GND V(I/O) C/BE[4]# PAR64 GND

4 GND V(I/O) PXI_BRSVB4 C/BE[7]# GND C/BE[6]# GND

3 GND CLK4 GND GNT3# REQ4# GNT4# GND

2 GND CLK2 CLK3 GND (SYS#) GNT2# REQ3# GND

1 GND CLK1 GND REQ1# GNT1# REQ2# GND

Pin Z A B C D E F

25

Page 34

Star Trigger Slot (Slot #2) P1 Pin Assignment

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND AD[1] +5V V(I/O) AD[0] ACK64# GND

23 GND +3.3V AD[4] AD[3] +5V AD[2] GND

22 GND AD[7] GND +3.3V AD[6] AD[5] GND

21 GND +3.3V AD[9] AD[8] M66EN C/BE[0]# GND

20 GND AD[12] GND V(I/O) AD[11] AD[10] GND

19 GND +3.3V AD[15] AD[14] GND AD[13] GND

18 GND SERR# GND +3.3V PAR C/BE[1]# GND

17 GND +3.3V IPMB_SCL IPMB_SDA GND PERR# GND

16 GND DEVSEL# GND V(I/O) STOP# LOCK# GND

15 GND +3.3V FRAME# IRDY# GND TRDY# GND

12-14 Key

11 GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

10 GND AD[21] GND +3.3V AD[20] AD[19] GND

9 GND C/BE[3]# IDSEL (1) AD[23] GND AD[22] GND

8 GND AD[26] GND V(I/O) AD[25] AD[24] GND

7 GND AD[30] AD[29] AD[28] GND AD[27] GND

6 GND REQ# (1) GND +3.3V CLK (1) AD[31] GND

5 GND BRSVP1A5 BRSVP1B5 PCIRST# GND GNT# (1) GND

4 GND IPMB_PWR GND V(I/O) INTP INTS GND

3 GND INTA# (1) INTB# (1) INTC# (1) +5V INTD# (1) GND

2 GND TCK +5V TMS TDO TDI GND

1 GND +5V -12V TRST# +12V +5V GND

Pin Z A B C D E F

26

Page 35

Star Trigger Slot (Slot #2) P2 Pin Assignment

Pin Z A B C D E F

22 GND PXI_BRSVA22 PXI_BRSVB22 PXI_BRSVC22 PXI_BRSVD22 PXI_BRSVE22 GND

21 GND PXI_LBR0 GND PXI_LBR1 PXI_LBR2 PXI_LBR3 GND

20 GND PXI_LBR4 PXI_LBR5 PXI_STAR0 (2) GND PXI_STAR1 (2) GND

19 GND PXI_STAR2 (2) GND PXI_STAR3 (2) PXI_STAR4 PXI_STAR5 GND

18 GND PXI_TRIG3 PXI_TRIG4 PXI_TRIG5 GND PXI_TRIG6 GND

17 GND PXI_TRIG2 GND N/C PXI_CLK10_IN PXI_CLK10 GND

16 GND PXI_TRIG1 PXI_TRIG0 N/C GND PXI_TRIG7 GND

15 GND PXI_BRSVA15 GND N/C PXI_STAR6 PXI_LBR6 GND

14 GND AD[35] AD[34] AD[33] GND AD[32] GND

13 GND AD[38] GND V(I/O) AD[37] AD[36] GND

12 GND AD[42] AD[41] AD[40] GND AD[39] GND

11 GND AD[45] GND V(I/O) AD[44] AD[43] GND

10 GND AD[49] AD[48] AD[47] GND AD[46] GND

9 GND AD[52] GND V(I/O) AD[51] AD[50] GND

8 GND AD[56] AD[55] AD[54] GND AD[53] GND

7 GND AD[59] GND V(I/O) AD[58] AD[57] GND

6 GND AD[63] AD[62] AD[61] GND AD[60] GND

5 GND C/BE[5]# GND V(I/O) C/BE[4]# PAR64 GND

4 GND V(I/O) PXI_BRSVB4 C/BE[7]# GND C/BE[6]# GND

3 GND PXI_LBR7 GND PXI_LBR8 PXI_LBR9 PXI_LBR10 GND

2 GND PXI_LBR11 PXI_LBR12 N.C (SYS#) PXI_STAR7 PXI_STAR8 GND

1 GND PXI_STAR9 GND PXI_STAR10 PXI_STAR11 PXI_STAR12 GND

Pin Z A B C D E F

27

Page 36

General Peripheral Slot (Slot #3~#6) P1 Pin Assignment

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND AD[1] +5V V(I/O) AD[0] ACK64# GND

23 GND +3.3V AD[4] AD[3] +5V AD[2] GND

22 GND AD[7] GND +3.3V AD[6] AD[5] GND

21 GND +3.3V AD[9] AD[8] M66EN C/BE[0]# GND

20 GND AD[12] GND V(I/O) AD[11] AD[10] GND

19 GND +3.3V AD[15] AD[14] GND AD[13] GND

18 GND SERR# GND +3.3V PAR C/BE[1]# GND

17 GND +3.3V IPMB_SCL IPMB_SDA GND PERR# GND

16 GND DEVSEL# GND V(I/O) STOP# LOCK# GND

15 GND +3.3V FRAME# IRDY# GND TRDY# GND

12-14 Key

11 GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

10 GND AD[21] GND +3.3V AD[20] AD[19] GND

9 GND C/BE[3]# IDSEL (1) AD[23] GND AD[22] GND

8 GND AD[26] GND V(I/O) AD[25] AD[24] GND

7 GND AD[30] AD[29] AD[28] GND AD[27] GND

6 GND REQ# (1) GND +3.3V CLK (1) AD[31] GND

5 GND BRSVP1A5 BRSVP1B5 PCIRST# GND GNT# (1) GND

4 GND IPMB_PWR GND V(I/O) INTP INTS GND

3 GND INTA# (1) INTB# (1) INTC# (1) +5V INTD# (1) GND

2 GND TCK +5V TMS TDO TDI GND

1 GND +5V -12V TRST# +12V +5V GND

Pin Z A B C D E F

28

Page 37

General Peripheral Slot (Slot #3~#14) P2 Pin Assignment

Pin Z A B C D E F

22 GND PXI_BRSVA22 PXI_BRSVB22 PXI_BRSVC22 PXI_BRSVD22 PXI_BRSVE22 GND

21 GND PXI_LBR0 GND PXI_LBR1 PXI_LBR2 PXI_LBR3 GND

20 GND PXI_LBR4 PXI_LBR5 PXI_LBL0 GND PXI_LBL1 GND

19 GND PXI_LBL2 GND PXI_LBL3 PXI_LBL4 PXI_LBL5 GND

18 GND PXI_TRIG3 PXI_TRIG4 PXI_TRIG5 GND PXI_TRIG6 GND

17 GND PXI_TRIG2 GND N/C PXI_STAR (2) PXI_CLK10 GND

16 GND PXI_TRIG1 PXI_TRIG0 N/C GND PXI_TRIG7 GND

15 GND PXI_BRSVA15 GND N/C PXI_LBL6 PXI_LBR6 GND

14 GND AD[35] AD[34] AD[33] GND AD[32] GND

13 GND AD[38] GND V(I/O) AD[37] AD[36] GND

12 GND AD[42] AD[41] AD[40] GND AD[39] GND

11 GND AD[45] GND V(I/O) AD[44] AD[43] GND

10 GND AD[49] AD[48] AD[47] GND AD[46] GND

9 GND AD[52] GND V(I/O) AD[51] AD[50] GND

8 GND AD[56] AD[55] AD[54] GND AD[53] GND

7 GND AD[59] GND V(I/O) AD[58] AD[57] GND

6 GND AD[63] AD[62] AD[61] GND AD[60] GND

5 GND C/BE[5]# GND V(I/O) C/BE[4]# PAR64 GND

4 GND V(I/O) PXI_BRSVB4 C/BE[7]# GND C/BE[6]# GND

3 GND PXI_LBR7 GND PXI_LBR8 PXI_LBR9 PXI_LBR10 GND

2 GND PXI_LBR11 PXI_LBR12 N/C (SYS#) PXI_LBL7 PXI_LBL8 GND

1 GND PXI_LBL9 GND PXI_LBL10 PXI_LBL11 PXI_LBL12 GND

Pin Z A B C D E F

29

Page 38

Note 1: Please refer the following table for the routing of the Bus

Mastering (REQ/GNT), IDSEL, PCI CLK, and Interrupt signals.

IDSEL

Slot 1(SYS) - - - INTA# INTB# INTC# INTD#

Slot 2 AD30 1 5 INTC# INTD# INTA# INTB#

Slot 3 AD29 2 1 INTB# INTC# INTD# INTA#

Slot 4 AD28 3 3 INTA# INTB# INTC# INTD#

Slot 5 AD27 4 4 INTD# INTA# INTB# INTC#

Slot 6 AD26 5 0 INTC# INTD# INTA# INTB#

Slot 7 AD25 6 6 INTB# INTC# INTD# INTA#

Slot 8 S1_AD31 S1_0 0 INTC# INTD# INTA# INTB#

Slot 9 S1_AD30 S1_1 1 INTB# INTC# INTD# INTA#

Slot10 S1_AD29 S1_2 2 INTA# INTB# INTC# INTD#

Slot11 S1_AD28 S1_3 3 INTD# INTA# INTB# INTC#

Slot12 S1_AD27 S1_4 4 INTC# INTD# INTA# INTB#

Slot13 S1_AD26 S1_5 5 INTB# INTC# INTD# INTA#

Slot14 S1_AD25 S1_6 6 INTA# INTB# INTC# INTD#

REQ#

/GNT#

PCI

CLK

PXI P1

Pin A3

PXI P1

Pin B3

PXI P1

Pin C3

PXI P1

Pin E3

30

Page 39

Note 2: Please refer the following table for the routing of the

PXI_STAR addressing signals from the trigger slot to peripheral slots.

Physical Slot Number PXI_STAR (P2-D17)

Slot 2 (Star Trigger Slot) PXI_STAR0 ~ PXI_STAR11

Slot 3 PXI_STAR0

Slot 4 PXI_STAR1

Slot 5 PXI_STAR2

Slot 6 PXI_STAR3

Slot 7 PXI_STAR4

Slot 8 PXI_STAR5

Slot 9 PXI_STAR6

Slot 10 PXI_STAR7

Slot 11 PXI_STAR8

Slot 12 PXI_STAR9

Slot 13 PXI_STAR10

Slot 14 PXI_STAR11

Miscellaneous Connectors Pin Assignments

CN1 & CN2: ATX DC Power input connectors

Signal Name Pin # Pin # Signal Name

V2SENSE 1 11 V2 (+3.3V)

V2 (+3.3V) 2 12 V4 (-12V)

GND 3 13 GND

V1 (+5V) 4 14 INH#

GND 5 15 GND

V1 (+5V) 6 16 SRTN

GND 7 17 GND

FAL#1 8* 18* V3SENSE

DEG#1 9* 19 V1SENSE

V3 (+12V) 10 20 V1 (+5V)

Note: Pin #8, #9, and #18 are not standard ATX power definition.

31

Page 40

J1 INH#: DC power inhibit signal

J1 Pin # Signal Name

1 INH#

2GND

J2 FAL#: Power supply fail input

J2 Pin # Signal Name

1FAL#

2GND

J3 PRST#: System reset signal

J3 Pin # Signal Name

1RST#

2GND

J4: Connector for LED power status

Name Pin # Pin # Name

J4

GND 8 7 +3.3V

GND 6 5 +5V

GND 4 3 -12V

GND 2 1 +12V

CN5: SMB (system managing bus) connector

Pin # Name

CN5

1 IPMB_CLK

2GND

3 IPMB_DATA

4 IPMB_PWR

5ALERT

Note: The SMB is connected to the P2 of the system slot.

32

Page 41

JP3: PXI Bus Speed Control

JP3 Pin 1-2 Description

Short (default) Short M66EN to ground to force PCI bus run 33MHz

Open PCI bus speed defined by M66EN on the PXI bus

JP2: PXI 10MHz Reference Clock Control

JP2 Description

Pin 1-2 External clock through the PXI_CLK10_IN on star trigger slot

Pin 2-3 Internal 10MHz system clock PXI_CLK10

33

Page 42

34

Page 43

Important Safety Instructions

Please read and follow all instructions marked on the product and

in the documentation before operating the system. Retain all

safety and operating instructions for future use.

X Please read these safety instructions carefully.

X Please keep this User’s Manual for future reference.

X The equipment should be operated in an ambient tempera-

ture between 0 to 50

X The equipment should be operated only from the type of

power source indicated on the rating label. Make sure the

voltage of the power source is correct when connecting the

equipment to the power outlet.

X If the user’s equipment has a voltage selector switch, make

sure that the switch is set to the proper position for the area.

The voltage selector switch is set at the factory to the correct voltage.

X For pluggable equipment, ensure they are installed near a

socket-outlet that is easily accessible.

X Secure the power cord to prevent unnecessary accidents.

Do not place anything over the power cord.

X If the equipment will not be in use for long periods of time,

disconnect the equipment from mains to avoid being damaged by transient overvoltage.

X All cautions and warnings on the equipment should be

noted.

X Please keep this equipment away from humidity.

X Do not use this equipment near water or a heat source.

X Place this equipment on a reliable surface when installing.

A drop or fall could cause injury.

X Never pour any liquid into the opening, this could cause fire

or electrical shock.

°C.

Important Safety Instructions 35

Page 44

X Openings in the case are provided for ventilation. Do not

block or cover these openings. Make sure there is adequate

space around the system for ventilation when setting up the

work area. Never insert objects of any kind into the ventilation openings.

X To avoid electrical shock, always unplug all power and

modem cables from the wall outlets before removing covers.

X Lithium Battery provided (real time clock battery)

“CAUTION - Risk of explosion if battery is replaced by

an incorrect type. Dispose used batteries as instructed

in the instructions”

X The equipment should be checked by service personnel if

one of the following situation arises:

Z The power cord or plug is damaged.

Z Liquid has penetrated the equipment.

Z The equipment has been exposed to moisture.

Z The equipment is not functioning or does not function

according to the user’s manual.

Z The equipment has been dropped and damaged.

Z If the equipment has obvious sign of breakage.

X Never open the equipment. For safety reasons, the equip-

ment should only be opened by qualified service personnel.

36 Important Safety Instructions

Page 45

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and

enjoy all the after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow the instructions exactly. When sending in

damaged products for repair, please attach an RMA application form which can be downloaded from: http://

rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for products bought in China:

X The warranty period starts on the day the product is

shipped from ADLINK’s factory.

X Peripherals and third-party products not manufactured

by ADLINK will be covered by the original manufacturers' warranty.

X For products containing storage devices (hard drives,

flash cards, etc.), please back up your data before sending them for repair. ADLINK is not responsible for any

loss of data.

X Please ensure the use of properly licensed software with

our systems. ADLINK does not condone the use of

pirated software and will not service systems using such

software. ADLINK will not be held legally responsible for

products shipped with unlicensed software installed by

the user.

X For general repairs, please do not include peripheral

accessories. If peripherals need to be included, be certain to specify which items you sent on the RMA Request

& Confirmation Form. ADLINK is not responsible for

items not listed on the RMA Request & Confirmation

Form.

Warranty Policy 37

Page 46

3. Our repair service is not covered by ADLINK's guarantee

in the following situations:

X Damage caused by not following instructions in the

User's Manual.

X Damage caused by carelessness on the user's part dur-

ing product transportation.

X Damage caused by fire, earthquakes, floods, lightening,

pollution, other acts of God, and/or incorrect usage of

voltage transformers.

X Damage caused by unsuitable storage environments

(i.e. high temperatures, high humidity, or volatile chemicals).

X Damage caused by leakage of battery fluid during or

after change of batteries by customer/user.

X Damage from improper repair by unauthorized ADLINK

technicians.

X Products with altered and/or damaged serial numbers

are not entitled to our service.

X This warranty is not transferable or extendible.

X Other categories not protected under our warranty.

4. Customers are responsible for shipping costs to transport

damaged products to our company or sales office.

5. To ensure the speed and quality of product repair, please

download an RMA application form from our company website: http://rma.adlinktech.com/policy. Damaged products

with attached RMA forms receive priority.

If you have any further questions, please email our FAE staff:

service@adlinktech.com.

38 Warranty Policy

Loading...

Loading...