Page 1

Express-BE

User’s Manual

Manual Revision: 1.00

Revision Date:

Part Number: 50-1J060-1000

May 7, 2015

Page 2

Revision History

Revision Description Date By

1.00 Initial release 2015-05-07 JC

Page 2 Express-BE

Page 3

Preface

Copyright 2015 ADLINK Technology, Inc.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by

any mechanical, electronic, or other means in any form without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior notice in order to improve reliability, design, and function and does not

represent a commitment on the part of the manufacturer. In no event will the manufacturer be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use or inability to use the product or documentation, even if advised of the possibility of such

damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global environmental preservation through compliance with the European Union's

Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE) directive. Environmental

protection is a top priority for ADLINK. We have enforced measures to ensure that our products, manufacturing processes, components, and

raw materials have as little impact on the environment as possible. When products are at their end of life, our customers are encouraged to

dispose of them in accordance with the product disposal and/or recovery programs prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks of their

respective companies.

Express-BE Page 3

Page 4

Table of Contents

Revision History ............................................................................................................ 2

Preface............................................................................................................................ 3

1. Introduction......................................................................................................... 8

2. Specifications....................................................................................................... 9

2.1. Core System..............................................................................................................................9

2.2. Expansion Busses......................................................................................................................9

2.3. SEMA Board Controller.............................................................................................................9

2.4. Debug Headers .........................................................................................................................9

2.5. Video...................................................................................................................................... 10

2.6. Audio...................................................................................................................................... 10

2.7. LAN ........................................................................................................................................ 10

2.8. Multi I/O and Storage............................................................................................................ 10

2.9. TPM (Trusted Platform Module) ........................................................................................... 10

2.10. Power Specifications ............................................................................................................. 11

2.11. Power Consumption.............................................................................................................. 11

2.12. Operating Temperatures ....................................................................................................... 11

2.13. Environmental ....................................................................................................................... 11

2.14. Specification Compliance ...................................................................................................... 11

2.15. Operating Systems................................................................................................................. 11

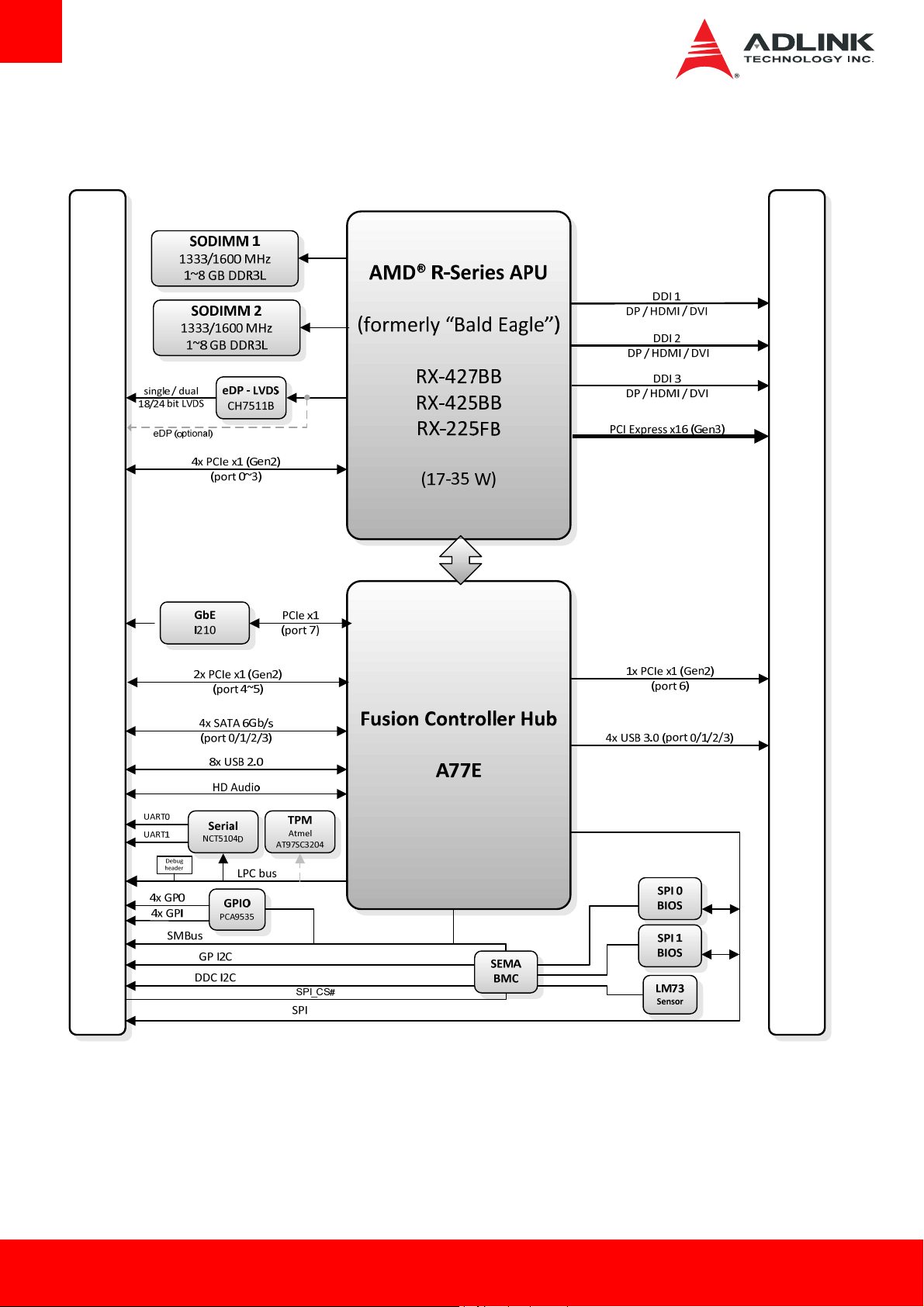

2.16. Functional Diagram................................................................................................................ 12

2.17. Mechanical Dimensions......................................................................................................... 13

3. Pinouts and Signal Descriptions......................................................................

3.1. AB/CD Pin Definitions............................................................................................................ 14

3.2. Signal Description Terminology............................................................................................. 17

14

3.3. AB Signal Descriptions ........................................................................................................... 18

3.3.1. Audio Signals ...............................................................................................................................18

3.3.2. Analog VGA (No VGA support)....................................................................................................18

3.3.3. LVDS ............................................................................................................................................18

3.3.4. Gigabit Ethernet ..........................................................................................................................19

3.3.5. SATA ............................................................................................................................................19

3.3.6. PCI Express ..................................................................................................................................20

3.3.7. Express Card................................................................................................................................21

3.3.8. LPC Bus ........................................................................................................................................21

3.3.9. USB ..............................................................................................................................................21

Page 4 Express-BE

Page 5

3.3.10. USB Root Segmentation ..............................................................................................................22

3.3.11. SPI (BIOS only).............................................................................................................................22

3.3.12. Miscellaneous..............................................................................................................................23

3.3.13. SMBus..........................................................................................................................................23

3.3.14. I2C Bus.........................................................................................................................................23

3.3.15. General Purpose I/O (GPIO) ........................................................................................................23

3.3.16. Serial Interface Signals ................................................................................................................24

3.3.17. Power and System Management ................................................................................................24

3.3.18. Power and Ground ......................................................................................................................25

3.4. CD Signal Descriptions ........................................................................................................... 26

3.4.1. USB 3.0 Extension .......................................................................................................................26

3.4.2. PCI Express x1..............................................................................................................................26

3.4.3. DDI Channels ...............................................................................................................................27

3.4.4. DDI to DP/HDMI Mapping...........................................................................................................29

3.4.5. PCI Express Graphics x16 (PEG)...................................................................................................30

3.4.6. Module Type Definition ..............................................................................................................31

3.4.7. Power and Ground ......................................................................................................................31

4. Module Interfaces and Configuration ............................................................ 32

4.1. Connector, Switch and LED Locations ................................................................................... 32

4.1.1. Express-BE and the DB40 Module connected.............................................................................32

4.2. 40-pin Multipurpose Connector ............................................................................................ 33

4.3. Status LEDs ............................................................................................................................ 34

4.4. Fan Connector ....................................................................................................................... 35

4.5. BIOS Setup Defaults Reset Button......................................................................................... 36

4.6. Express-BE Switch Settings .................................................................................................... 37

4.6.1. Switch Locations..........................................................................................................................37

4.6.2. SW1: BIOS Select and Mode Configuration Switch .....................................................................37

4.7. PCIe x 16-to-two-x8 Adapter Card......................................................................................... 38

5. Smart Embedded Management Agent (SEMA) ............................................. 39

5.1. Board Specific SEMA Functions ............................................................................................. 40

5.1.1. Voltages.......................................................................................................................................40

5.1.2. Main Current...............................................................................................................................40

5.1.3. BMC Status..................................................................................................................................40

5.1.4. Exception Codes ..........................................................................................................................41

5.1.5. BMC Flags....................................................................................................................................41

6. System Resources.............................................................................................. 42

6.1. System Memory Map ............................................................................................................ 42

Express-BE Page 5

Page 6

6.2. Direct Memory Access Channels ........................................................................................... 42

6.3. I/O Map.................................................................................................................................. 43

6.4. Interrupt Request (IRQ) Lines................................................................................................ 44

6.4.1. PIC Mode.....................................................................................................................................44

6.4.2. APIC Mode...................................................................................................................................45

6.5. PCI Configuration Space Map ................................................................................................ 46

6.6. PCI Interrupt Routing Map .................................................................................................... 47

6.7. SMBus Address Table ............................................................................................................ 47

7. BIOS Setup .........................................................................................................48

7.1. Menu Structure ..................................................................................................................... 48

7.2. Main....................................................................................................................................... 49

7.2.1. System Information.....................................................................................................................49

7.2.2. Memory Information...................................................................................................................49

7.2.3. System Management ..................................................................................................................49

7.2.4. System Date and Time.................................................................................................................52

7.3. Advanced ............................................................................................................................... 52

7.3.1. CPU..............................................................................................................................................52

7.3.2. Memory.......................................................................................................................................53

7.3.3. Graphics ......................................................................................................................................53

7.3.4. SATA ............................................................................................................................................54

7.3.5. USB ..............................................................................................................................................55

7.3.6. Network.......................................................................................................................................57

7.3.7. PCI and PCIe ................................................................................................................................57

7.3.8. Super IO.......................................................................................................................................62

7.3.9. ACPI and Power Management ....................................................................................................62

7.3.10. Sound ..........................................................................................................................................63

7.3.11. Serial Port Console ......................................................................................................................63

7.3.12. Thermal .......................................................................................................................................65

7.3.13. Miscellaneous..............................................................................................................................65

7.4. Boot ....................................................................................................................................... 65

7.4.1. Boot Configuration......................................................................................................................65

7.4.2. Boot Configuration > CSM16 Parameters ...................................................................................66

7.4.3. Boot Configuration > CSM Parameters .......................................................................................66

7.5. Security.................................................................................................................................. 67

7.5.1. Password Description..................................................................................................................67

7.6. Save & Exit ............................................................................................................................. 67

7.6.1. Save and Exit > Reset Options.....................................................................................................67

7.6.2. Save and Exit > Save Options ......................................................................................................67

Page 6 Express-BE

Page 7

7.6.3. Boot Override..............................................................................................................................67

8. BIOS Checkpoints, Beep Codes........................................................................ 68

8.1. Status Code Ranges ............................................................................................................... 69

8.2. Standard Status Codes........................................................................................................... 69

8.2.1. SEC Status Codes .........................................................................................................................69

8.2.2. SEC Beep Codes...........................................................................................................................70

8.2.3. PEI Status Codes..........................................................................................................................70

8.2.4. PEI Beep Codes............................................................................................................................72

8.2.5. DXE Status Codes ........................................................................................................................72

8.2.6. DXE Beep Codes ..........................................................................................................................75

8.2.7. ACPI/ASL Checkpoint...................................................................................................................75

8.3. OEM-Reserved Checkpoint Ranges ....................................................................................... 75

9. Mechanical Information ...................................................................................

9.1. Board-to-Board Connectors .................................................................................................. 76

9.2. Thermal Solution ................................................................................................................... 77

9.2.1. Heat Spreaders............................................................................................................................77

9.2.2. Heat Sinks....................................................................................................................................77

9.2.3. Installation...................................................................................................................................77

9.3. Mounting Methods................................................................................................................ 80

9.4. Standoff Types....................................................................................................................... 81

Safety Instructions ...................................................................................................... 82

Getting Service ............................................................................................................ 83

76

Express-BE Page 7

Page 8

1. Introduction

The Express-BE is a COM Express® COM.0 R2.1 Basic Size Type 6 module supporting the AMD R-Series APU (codename: Bald Eagle)

with A77E Fusion Controller Hub. The Express-BE is specifically designed for customers who need excellent graphics performance and

high-level processing performance with low power consumption in a long product life solution.

The Express-BE features the AMD R-Series APU supporting Heterogeneous System Architecture (HSA) and non-ECC type DDR3L dualchannel memory at 1333/1600 MHz to provide excellent overall performance.

AMD Radeon HD 9000 Graphics integrated on the APU includes features such as OpenGL 4.2, DirectX 11.1, OpenCL 1.2, OpenGLES 2.0,

OpenCV, and support for H.264, MPEG2, VC1, MPEG4, WMV9, and MVC hardware decode. Graphics outputs include dual-channel

18/24-bit LVDS and DDI ports supporting HDMI, DVI, DisplayPort and optional eDP

supported. The Express-BE is specifically designed for customers with high-performance processing and graphics requirements who want to

outsource the core logic of their systems for reduced development time.

The Express-BE has dual stacked SODIMM sockets for up to 16 GB non-ECC type DDR3L memory. In addition to the onboard integrated

graphics, a multiplexed PCI Express® x16 Graphics bus is available for discrete graphics expansion. Input/output features include a single

onboard Gigabit Ethernet port, USB 3.0 ports and USB 2.0 ports, and SATA 6 Gb/s ports. Support is provided for SMBus and I2C. The

module is equipped with SPI AMI EFI BIOS with CMOS backup, supporting embedded features such as remote console, hardware monitor,

and watchdog timer.

(TBD). In addition, up to four independent displays are

Page 8 Express-BE

Page 9

2. Specifications

2.1. Core System

¾ CPU: Dual or quad-core AMD R-Series APU (codename: Bald Eagle)

• RX-427BB 2.7 GHz (3.6 GHz boost), 35W (4C/8CU)

• RX-425BB 2.5 GHz(3.4 GHz boost), 35W (4C/6CU)

• RX-225FB 2.2 GHz (3.0 GHz boost), 17W (2C/3CU)

Supporting: AMD-V, Intel® SSE4.1 and SSE4.2, AMD Thermal Monitor (SB-TSI)

Note: The availability of the features may vary between processor SKUs.

¾ Cache: 4MB L2 cache for RX-427BB and RX-425BB, 2MB L2 cache for RX-225FB

¾ Memory: Dual channel non-ECC 1333/1600 MHz DDR3L memory up to 16GB in dual stacked SODIMM sockets

Note: The lower SODIMM slot must be populated.

¾

Chipset: AMD A77E Fusion Controller Hub (codename: Bolton-E4)

¾ Embedded BIOS: AMI EFI with CMOS backup in 8 MB SPI BIOS

2.2. Expansion Busses

¾ PCI Express x 16 Gen3 (can be configured to 2 x8 or 1 x8 and 1 x4)

Note: These lanes are intended for use with a graphics card.

¾ 6 PCI Express x1 (AB): Lanes 0/1/2/3/4/5 (Lanes 0-3 from APU, L anes 4-5 from FCH)

¾ 1 PCI Express x1 (CD): Lane 6 (from FCH)

2

¾ LPC bus, SMBus (system) , I

C (user)

2.3. SEMA Board Controller

¾ Type: ADLINK Smart Embedded Management Agent (SEMA)

¾ Supports:

• Voltage/Current monitoring

• Power sequence debug support

• AT/ATX mode control

• Logistics and Forensic information

• Flat Panel Control

• General Purpose I2C

• Failsafe BIOS (dual BIOS )

• Watchdog Timer and Fan Control

2.4. Debug Headers

¾ 40-pin multipurpose flat cable connector, used in combination with DB-40 debug module providing BIOS POST code LED, BMC

access, SPI BIOS flashing, power testpoints, debug LEDs

Express-BE Page 9

Page 10

2.5. Video

¾ GPU Feature Support: Radeon HD 9000 Series supporting four independent displays and Heterogeneous System Architecture

• 3D graphics hardware acceleration

• Support for DirectX 11.1, OpenCL 1.2, OpenGL 4.2, OpenGLES 2.0 and OpenCV

• Video decode hardware acceleration (UVD 4.2) including support for H.264, MPEG2, VC-1, MPEG4, WMV9 and MVC formats

• Video encode hardware acceleration (VCE 2.0) including support for H.264, SVC formats and specific support for video conferencing and

wireless display applications

• AMD Eyefinity technology

• AMD Dual Graphics technology

Note: the availability of the features may vary between OS (Win 7/8, WES 7/8, Linux)

¾ Display Interface support

• DDI1: supports

• DDI2: supports

• DDI3: supports

DisplayPort, HDMI, DVI (eDP TBD)

DisplayPort, HDMI, DVI

DisplayPort, HDMI, DVI (eDP TBD)

• LVDS: supports up to dual-channel 18/24-bit LVDS (through eDP to LVDS bridge IC)

Note: Display priority follows APU settings, and cannot be defined by the user. The priority is DP0 > DP1 > DP2 > DP3.

à DP0 (from APU) mapped to DDI1

à DP1 (from APU) mapped to DDI3

à DP2 (from APU) mapped to LVDS

à DP3 (from APU) mapped to DDI2

2.6. Audio

¾ Audio Codec: located on carrier Express-BASE6 (ALC886 standard support)

2.7. LAN

¾ Intel MAC/PHY: Intel® i210 Ethernet controller

¾ Interface: 10/100/1000 Mbit/s connection

2.8. Multi I/O and Storage

¾ Integrated in APU and FCH

¾ USB:

• 4x USB 1.1/2.0/3.0 (USB 0,1,2,3)

• 4x USB 1.1/2.0 (USB 4,5,6,7)

¾ SATA: four ports SATA 6Gb/s (SATA 0,1,2,3)

Note: SATA repeater/redriver on carrier board is required for SATA 6Gb/s

¾ Serial: 2 UART ports COM 0/1 with console redirection

¾ GPIO: 4 GPO and 4 GPI with interrupt

2.9. TPM (Trusted Platform Module)

¾ Chipset: Atmel AT97SC3204

¾ Type: TPM 1.2

Page 10 Express-BE

Page 11

2.10. Power Specifica tions

¾ Power Modes: AT and ATX mode (AT mode startup controlled by SEMA)

¾ Standard Voltage Input: ATX @ 12V±5%,/ 5Vsb ±5% or AT @ 12V ±5%

¾ Wide Voltage Input: ATX @ 8.5-20V, 5Vsb ±5% or AT @ 8.5-20V

¾ Power Management: ACPI 4.0 compliant, Smart Battery support

¾ Power States: supports C0, C1, C1E, C6, CC6, S0, S3, S5, S5 ECO mode (Wake-on-USB S3, WOL S3/S5)

¾ ECO mode: supports deep S5 for 5Vsb power saving

2.11. Power Consumption

TBD

2.12. Operating Temperatures

¾ Standard Operating Temperature: °C to 60°C (wide voltage input)

2.13. Environmental

¾ Humidity: 5-90% RH operating, non-condensing

5-95% RH storage (and operating with conformal coating).

¾ Shock and Vibration: IEC 60068-2-64 and IEC-60068-2-27

MIL-STD-202F, Method 213B, Table 213-I, Condition A and Method 214A, Table 214-I, Condition D

¾ Halt: Thermal Stress, Vibration Stress, Thermal Shock and Combined Test

2.14. Specification Compliance

¾ PICMG COM.0: Rev 2.1 Type 6, Basic size 125 x 95 mm

2.15. Operating Systems

¾ Standard Support: Windows 7/8.1 32/64-bit, Linux 32/64-bit

¾ Extended Support (BSP): WES 7/8, Linux

Express-BE Page 11

Page 12

2.16. Functional Diagram

AB

UMI

CD

Page 12 Express-BE

Page 13

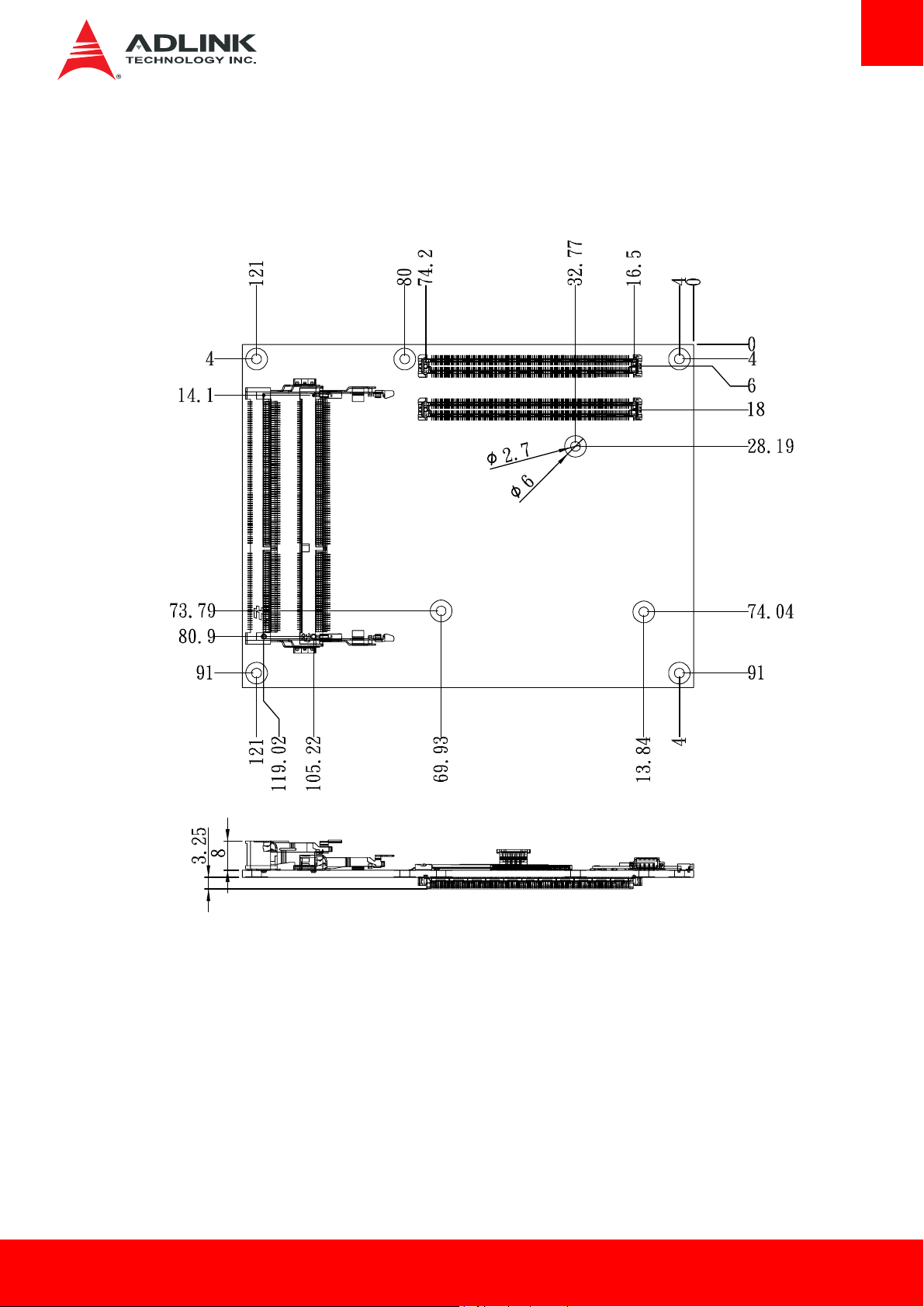

2.17. Mechanical Dimensions

Top View

Side View

All Ø tolerances ± 0.05 mm

Other tolerances ± 0.2 mm

Dimensions in mm

Express-BE Page 13

Page 14

3. Pinouts and Signal Descriptions

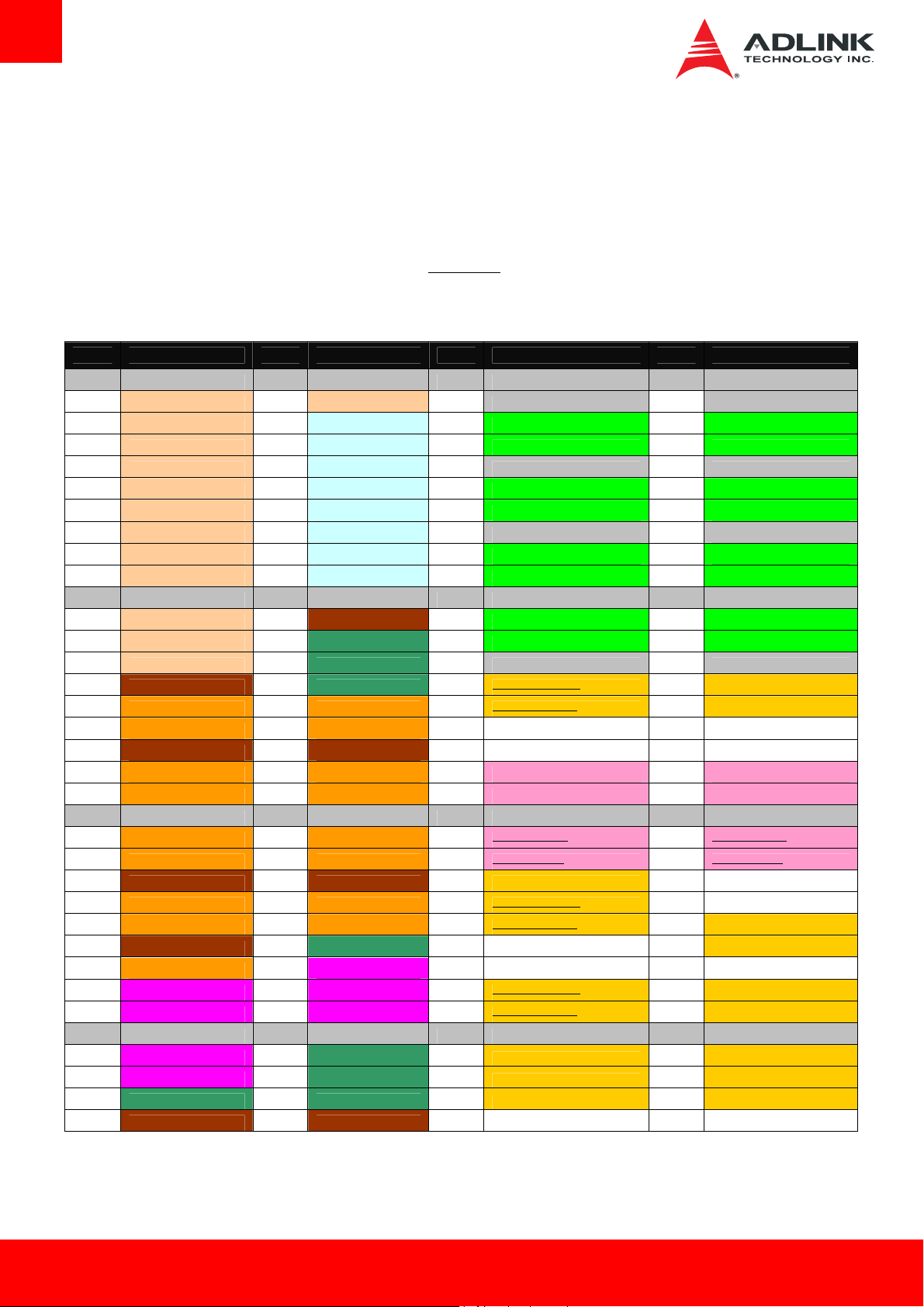

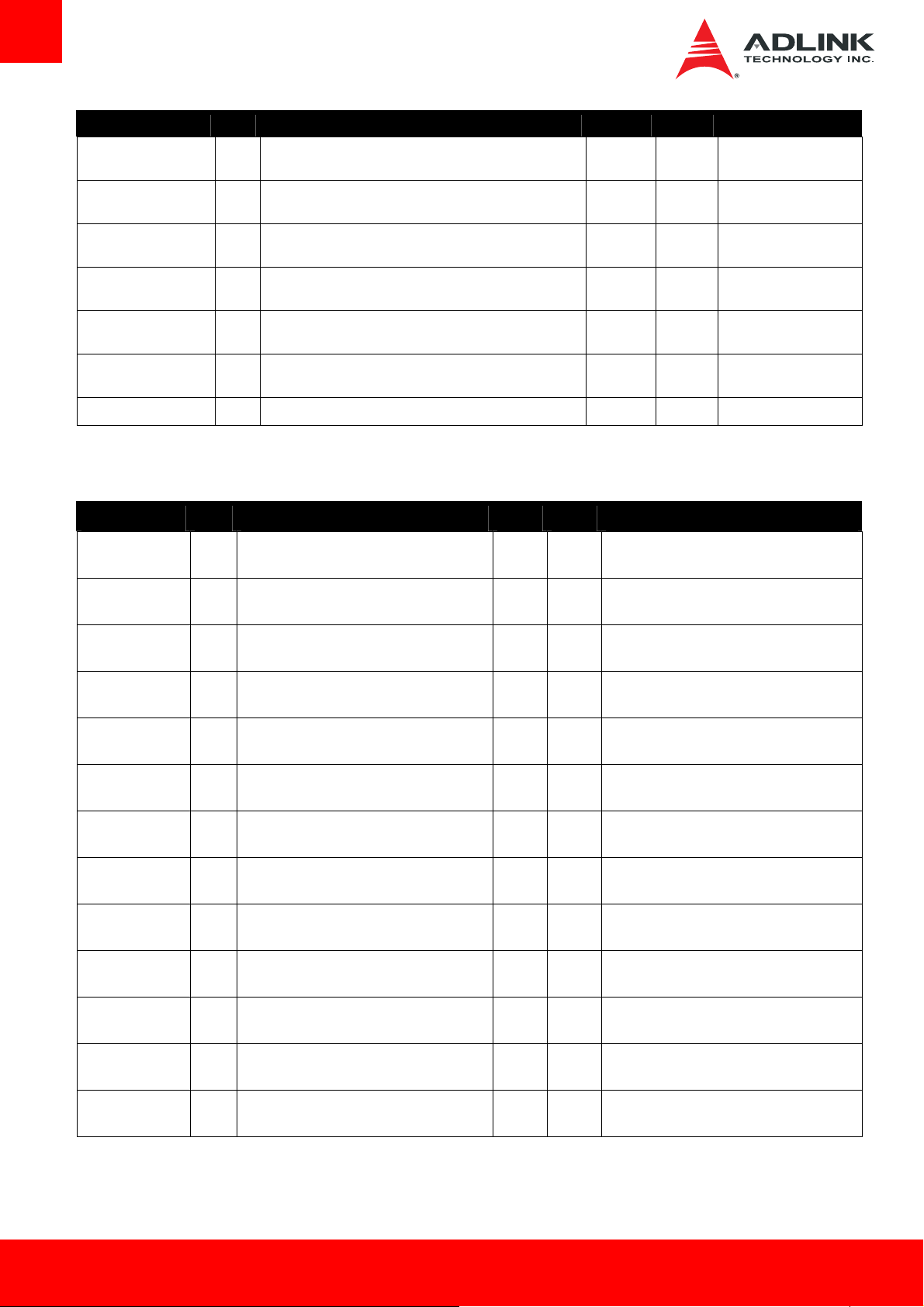

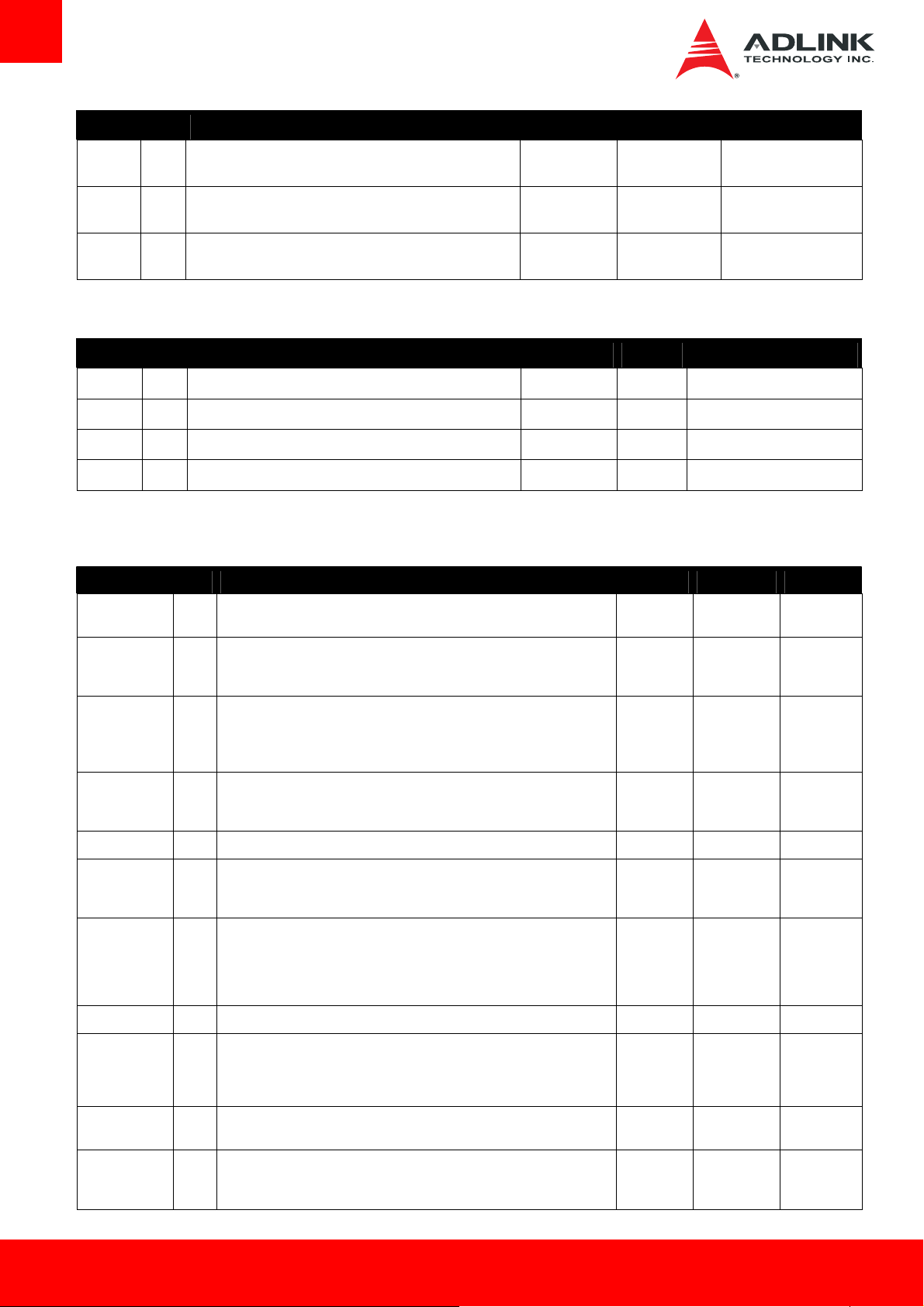

3.1. AB/CD Pin Definitions

The Express-BE is a Type 6 module supporting USB 3.0 and DDI channels on the CD connector. In the table below, all standard pins of the

COM Express specification are described, including those not supported on the Express-BE.

Note: Signals not supported on the Express-BE module are crossed out

Row A Row B Row C Row D

Pin Name Pin Name Pin Name Pin Name

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

GND (fixed)

GBE0_MDI3GBE0_MDI3+

GBE0_LINK100#

GBE0_LINK1000#

GBE0_MDI2GBE0_MDI2+

GBE0_LINK#

GBE0_MDI1GBE0_MDI1+

GND (fixed)

GBE0_MDI0GBE0_MDI0+

GBE0_CTREF

SUS_S3#

SATA0_TX+

SATA0_TX-

SUS_S4#

SATA0_RX+

SATA0_RXGND (fixed)

SATA2_TX+

SATA2_TXSUS_S5#

SATA2_RX+

SATA2_RX-

BATLOW#

(S)ATA_ACT#

AC/HDA_SYNC

AC/HDA_RST#

GND (fixed)

AC/HDA_BITCLK

AC/HDA_SDOUT

BIOS_DIS0#

THRMTRIP#

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

GND (fixed)

GBE0_ACT#

LPC_FRAME#

LPC_AD0

LPC_AD1

LPC_AD2

LPC_AD3

LPC_DRQ0#

LPC_DRQ1#

LPC_CLK

GND (fixed)

PWRBTN#

SMB_CK

SMB_DAT

SMB_ALERT#

SATA1_TX+

SATA1_TX-

SUS_STAT#

SATA1_RX+

SATA1_RXGND (fixed)

SATA3_TX+

SATA3_TXPWR_OK

SATA3_RX+

SATA3_RX-

WDT

AC/HDA_SDIN2

AC/HDA_SDIN1

AC/HDA_SDIN0

GND (fixed)

SPKR

I2C_CK

I2C_DAT

THRM#

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

C33

C34

C35

GND (fixed)

GND

USB_SSRX0USB_SSRX0+

GND

USB_SSRX1- D6 USB_SSTX1USB_SSRX1+ D7 USB_SSTX1+

GND D8 GND

USB_SSRX2- D9 USB_SSTX2USB_SSRX2+ D10 USB_SSTX2+

GND (fixed) D11 GND (fixed)

USB_SSRX3- D12 USB_SSTX3USB_SSRX3+ D13 USB_SSTX3+

GND

DDI1_PAIR6+

DDI1_PAIR6RSVD

RSVD

PCIE_RX6+ D19 PCIE_TX6+

PCIE_RX6- D20 PCIE_TX6GND (fixed)

PCIE_RX7+

PCIE_RX7-

DDI1_HPD

DDI1_PAIR4+

DDI1_PAIR4RSVD

RSVD

DDI1_PAIR5+

DDI1_PAIR5GND (fixed)

DDI2_CTRLCLK_AUX+

DDI2_CTRLDATA_AUXDDI2_DDC_AUX_SEL

RSVD

D1

D2

D3

D4

D5

D14

D15

D16

D17

D18

D21

D22

D23

D24

D25

D26

D27

D28

D29

D30

D31

D32

D33

D34

D35

GND (fixed)

GND

USB_SSTX0USB_SSTX0+

GND

GND

DDI1_CTRLCLK_AUX+

DDI1_CTRLDATA_AUX

RSVD

RSVD

GND (fixed)

PCIE_TX7+

PCIE_TX7RSVD

RSVD

DDI1_PAIR0+

DDI1_PAIR0RSVD

DDI1_PAIR1+

DDI1_PAIR1GND (fixed)

DDI1_PAIR2+

DDI1_PAIR2-

DDI1_DDC_AUX_SEL

RSVD

Page 14 Express-BE

Page 15

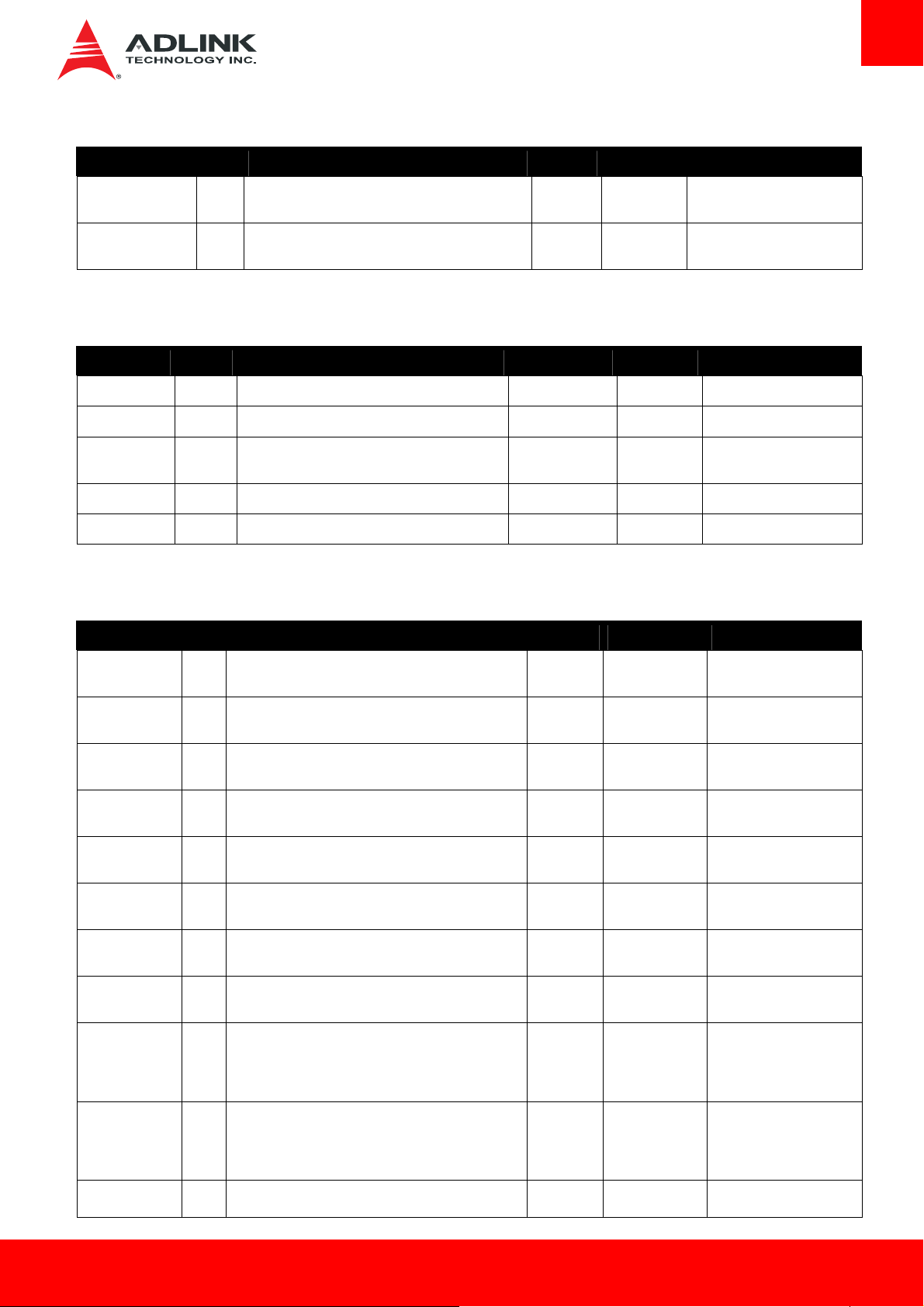

Row A Row B Row C Row D

Pin Name Pin Name Pin Name Pin Name

A36

A37

A38

A39

A40

A41

A42

A43

A44

A45

A46

A47

A48

A49

A50

A51

A52

A53

A54

A55

A56

A57

A58

A59

A60

A61

A62

A63

A64

A65

A66

A67

A68

A69

A70

A71

A72

A73

A74

A75

A76

A77

A78

A79

USB6USB6+

USB_6_7_OC#

USB4USB4+

GND (fixed)

USB2USB2+

USB_2_3_OC#

USB0USB0+

VCC_RTC

EXCD0_PERST#

EXCD0_CPPE#

LPC_SERIRQ

GND (fixed)

PCIE_TX5+

PCIE_TX5-

GPI0

PCIE_TX4+

PCIE_TX4GND

PCIE_TX3+

PCIE_TX3GND (fixed)

PCIE_TX2+

PCIE_TX2GPI1

PCIE_TX1+

PCIE_TX1GND

GPI2

PCIE_TX0+

PCIE_TX0GND (fixed)

LVDS_A0+

LVDS_A0-

LVDS_A1+

LVDS_A1-

LVDS_A2+

LVDS_A2-

LVDS_VDD_EN

LVDS_A3+

LVDS_A3-

B36

B37

B38

B39

B40

B41

B42

B43

B44

B45

B46

B47

B48

B49

B50

B51

B52

B53

B54

B55

B56

B57

B58

B59

B60

B61

B62

B63

B64

B65

B66

B67

B68

B69

B70

B71

B72

B73

B74

B75

B76

B77

B78

B79

USB7USB7+

USB_4_5_OC#

USB5USB5+

GND (fixed)

USB3USB3+

USB_0_1_OC#

USB1USB1+

EXCD1_PERST#

EXCD1_CPPE#

SYS_RESET#

CB_RESET#

GND (fixed)

PCIE_RX5+

PCIE_RX5-

GPO1

PCIE_RX4+

PCIE_RX4GPO2

PCIE_RX3+

PCIE_RX3GND (fixed)

PCIE_RX2+

PCIE_RX2GPO3

PCIE_RX1+

PCIE_RX1-

WAKE0#

WAKE1#

PCIE_RX0+

PCIE_RX0GND (fixed)

LVDS_B0+

LVDS_B0-

LVDS_B1+

LVDS_B1-

LVDS_B2+

LVDS_B2-

LVDS_B3+

LVDS_B3-

LVDS_BKLT_EN

C36

C37

C38

C39

C40

C41

C42

C43

C44

C45

C46

C47

C48

C49

C50

C51

C52

C53

C54

C55

C56

C57

C58

C59

C60

C61

C62

C63

C64

C65

C66

C67

C68

C69

C70

C71

C72

C73

C74

C75

C76

C77

C78

C79

DDI3_CTRLCLK_AUX+

DDI3_CTRLDATA_AUX-

DDI3_DDC_AUX_SEL

DDI3_PAIR0+

DDI3_PAIR0GND (fixed)

DDI3_PAIR1+

DDI3_PAIR1DDI3_HPD

RSVD

DDI3_PAIR2+

DDI3_PAIR2RSVD

DDI3_PAIR3+

DDI3_PAIR3GND (fixed)

PEG_RX0+ D52 PEG_TX0+

PEG_RX0- D53 PEG_TX0-

TYPE0#

PEG_RX1+ D55 PEG_TX1+

PEG_RX1- D56 PEG_TX1-

TYPE1#

PEG_RX2+ D58 PEG_TX2+

PEG_RX2- D59 PEG_TX2GND (fixed) D60 GND (fixed)

PEG_RX3+ D61 PEG_TX3+

PEG_RX3- D62 PEG_TX3RSVD D63 RSVD

RSVD D64 RSVD

PEG_RX4+ D65 PEG_TX4+

PEG_RX4- D66 PEG_TX4RSVD D67 GND

PEG_RX5+ D68 PEG_TX5+

PEG_RX5- D69 PEG_TX5GND (fixed) D70 GND (fixed)

PEG_RX6+ D71 PEG_TX6+

PEG_RX6- D72 PEG_TX6GND D73 GND

PEG_RX7+ D74 PEG_TX7+

PEG_RX7- D75 PEG_TX7GND D76 GND

RSVD D77 RSVD

PEG_RX8+ D78 PEG_TX8+

PEG_RX8- D79 PEG_TX8-

D36

D37

D38

D39

D40

D41

D42

D43

D44

D45

D46

D47

D48

D49

D50

D51

D54

D57

DDI1_PAIR3+

DDI1_PAIR3RSVD

DDI2_PAIR0+

DDI2_PAIR0GND (fixed)

DDI2_PAIR1+

DDI2_PAIR1DDI2_HPD

RSVD

DDI2_PAIR2+

DDI2_PAIR2RSVD

DDI2_PAIR3+

DDI2_PAIR3GND (fixed)

PEG_LANE_RV#

TYPE2#

Express-BE Page 15

Page 16

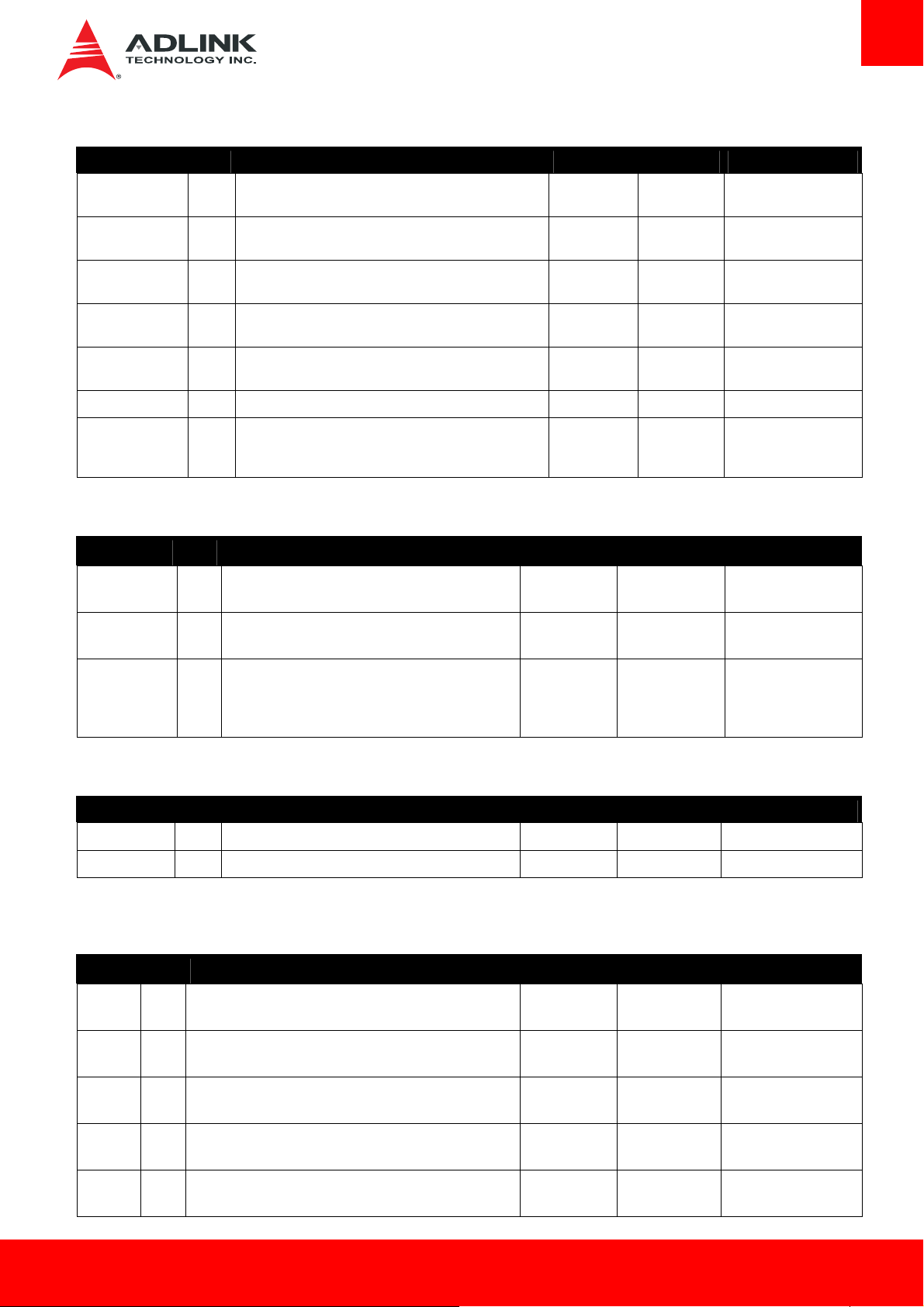

Row A Row B Row C Row D

Pin Name Pin Name Pin Name Pin Name

A80

A81

A82

A83

A84

A85

A86

A87

A88

A89

A90

A91

A92

A93

A94

A95

A96

A97

A98

A99

A100

A101

A102

A103

A104

A105

A106

A107

A108

A109

A110

GND (fixed)

LVDS_A_CK+

LVDS_A_CK-

LVDS_I2C_CK

LVDS_I2C_DAT

GPI3

RSVD

RSVD

PCIE0_CK_REF+

PCIE0_CK_REF-

GND (fixed)

SPI_POWER

SPI_MISO

GPO0

SPI_CLK

SPI_MOSI

TPM_PP

TYPE10#

SER0_TX / CAN_TX

SER0_RX / CAN_RX

GND (fixed)

SER1_TX

SER1_RX

LID# ** B103 SLEEP# **

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

GND (fixed)

B80

B81

B82

B83

B84

B85

B86

B87

B88

B89

B90

B91

B92

B93

B94

B95

B96

B97

B98

B99

B100

B101

B102

B104

B105

B106

B107

B108

B109

B110

GND (fixed)

LVDS_B_CK+

LVDS_B_CK-

LVDS_BKLT_CTRL

VCC_5V_SBY

VCC_5V_SBY

VCC_5V_SBY

VCC_5V_SBY

BIOS_DIS1#

VGA_RED C89

GND (fixed)

VGA_GRN C91

VGA_BLU C92

VGA_HSYNC C93

VGA_VSYNC C94

VGA_I2C_CK C95

VGA_I2C_DAT C96

SPI_CS#

RSVD

RSVD

GND (fixed)

FAN_PWMOUT

FAN_TACHIN

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

GND (fixed)

C80

C81

C82

C83

C84

C85

C86

C87

C88

C90

C97

C98

C99

C100

C101

C102

C103

C104

C105

C106

C107

C108

C109

C110

GND (fixed)

PEG_RX9+ D81 PEG_TX9+

PEG_RX9- D82 PEG_TX9TPM_PP D83 RSVD

GND D84 GND

PEG_RX10+ D85 PEG_TX10+

PEG_RX10- D86 PEG_TX10GND D87 GND

PEG_RX11+ D88 PEG_TX11+

PEG_RX11- D89 PEG_TX11GND (fixed) D90 GND (fixed)

PEG_RX12+ D91 PEG_TX12+

PEG_RX12- D92 PEG_TX12GND D93 GND

PEG_RX13+ D94 PEG_TX13+

PEG_RX13- D95 PEG_TX13GND D96 GND

RSVD D97 RSVD

PEG_RX14+ D98 PEG_TX14+

PEG_RX14- D99 PEG_TX14GND (fixed) D100 GND (fixed)

PEG_RX15+ D101 PEG_TX15+

PEG_RX15- D102 PEG_TX15GND D103 GND

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

GND (fixed)

D80

D104

D105

D106

D107

D108

D109

D110

GND (fixed)

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

VCC_12V

GND (fixed)

Page 16 Express-BE

Page 17

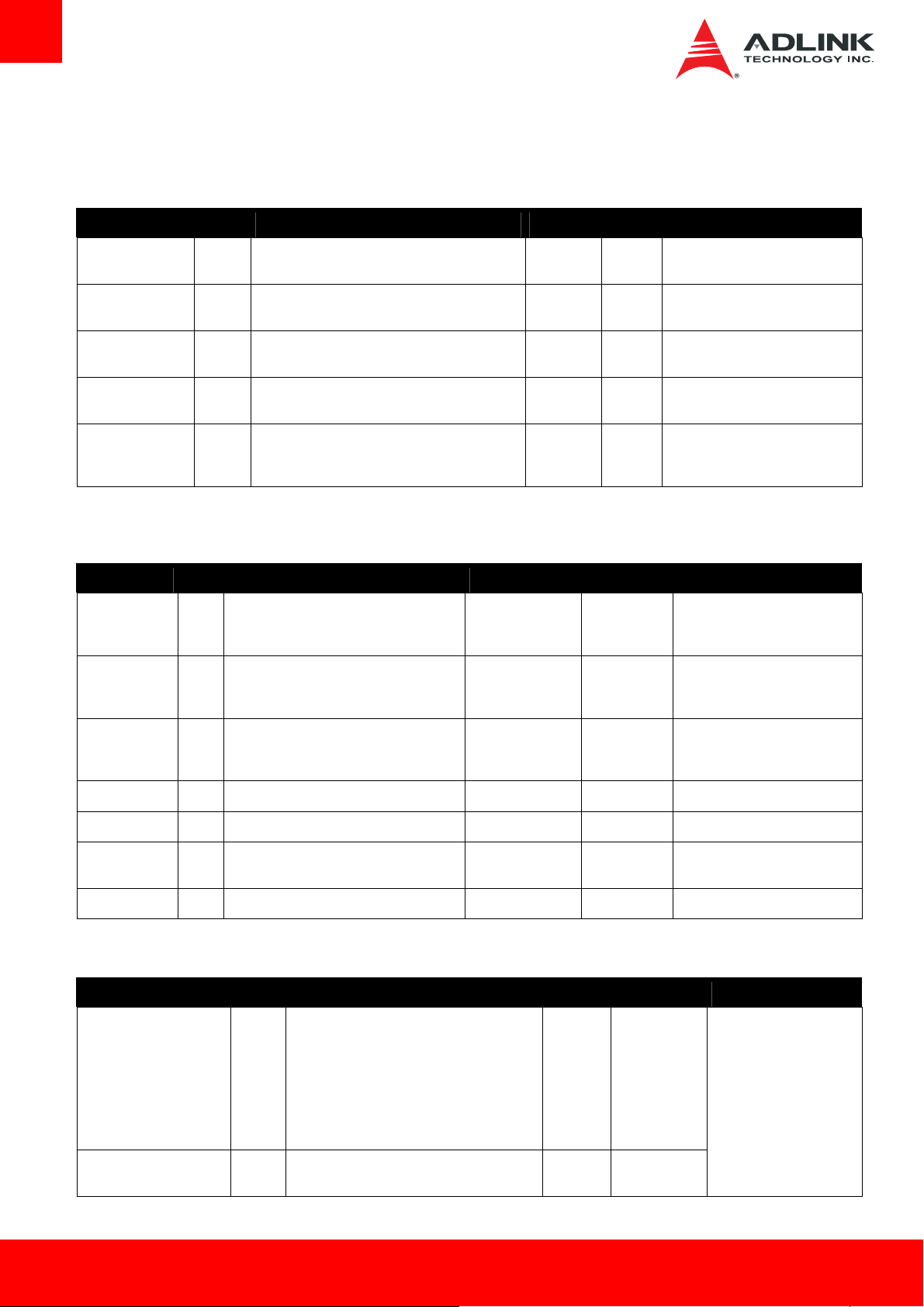

3.2. Signal Description Terminology

The following terms are used in the COM Express AB/CD Signal Descriptions below.

I Input to the Module

O Output from the Module

I/O Bi-directional input/output signal

OD Open drain output

I 3.3V Input 3.3V tolerant

I 5V Input 5V tolerant

O 3.3V Output 3.3V signal level

O 5V Output 5V signal level

I/O 3.3V Bi-directional signal 3.3V tolerant

I/O 5V Bi-directional signal 5V tolerant

I/O 3.3Vsb Input 3.3V tolerant active in standby state

P Power Input/Output

REF Reference voltage output that may be sourced from a module power plane.

PDS Pull-down strap. This is an output pin on the module that is either tied to GND or not connected.

The signal is used to indicate the PICMG module type to the Carrier Board.

PU ADLINK implemented pull-up resistor on module

PD ADLINK implemented pull-down resistor on module

Express-BE Page 17

Page 18

3.3. AB Signal Descriptions

3.3.1. Audio Signals

Signal Pin # Description I/O PU/PD Comment

AC_RST# /

HDA_RST#

AC_SYNC /

HDA_SYNC

AC_BITCLK /

HDA_BITCLK

AC _SDOUT /

HDA_SDOUT

AC _SDIN[2:0]

HDA_SDIN[2:0]

A30 Reset output to CODEC, active low. O 3.3VSB

A29 Sample-synchronization signal to the CODEC(s). O 3.3V

A32 Serial data clock generated by the external

CODEC(s).

A33 Serial TDM data output to the CODEC. O 3.3V

B28

B30

Serial TDM data inputs from up to 3 CODECs. I/O 3.3VSB AC_SDIN0: supported

I/O 3.3V

AC_SDIN1: supported

AC_SDIN2: supported

3.3.2. Analog VGA (No VGA support)

Signal Pin # Description I/O PU/PD Comment

VGA_RED B89 Red for monitor.

Analog DAC output, designed to drive a

37.5-Ohm equivalent load.

VGA_GRN B91 Green for monitor

Analog DAC output, designed to drive a

37.5-Ohm equivalent load.

O Analog

O Analog

PD 150R

PD 150R

shall also be terminated on the

carrier with 150Ω resistor to

ground close to VGA connector

shall also be terminated on the

carrier with 150Ω resistor to

ground close to VGA connector

VGA_BLU B92 Blue for monitor.

Analog DAC output, designed to drive a

37.5-Ohm equivalent load.

VGA_HSYNC B93 Horizontal sync output to VGA monitor O 3.3V

VGA_VSYNC B94 Vertical sync output to VGA monitor O 3.3V

VGA_I2C_CK B95 DDC clock line (I²C port dedicated to identify

VGA monitor capabilities)

VGA_I2C_DAT B96 DDC data line. I/O OD 3.3V PU 2k2 3.3V

O Analog

I/O OD 3.3V PU 2k2 3.3V

PD 150R

shall also be terminated on the

carrier with 150Ω resistor to

ground close to VGA connector

3.3.3. LVDS

Signal Pin # Description I/O PU/PD Comment

LVDS_A0+ / eDP_TX2+

LVDS_A0- / eDP_TX2-

LVDS_A1+ / eDP_TX1+

LVDS_A1- / eDP_TX1LVDS_A2+ / eDP_TX0+

LVDS_A2- / eDP_TX0-

LVDS_A3+

LVDS_A3-

LVDS_A_CK+ / eDP_TX3+

LVDS_A_CK- / eDP_TX3-

A71

A72

A73

A74

A75

A76

A78

A79

A81

A82

LVDS Channel A differential pairs O LVDS

LVDS Channel A differential clock O LVDS

Page 18 Express-BE

Page 19

Signal Pin # Description I/O PU/PD Comment

LVDS_B0+

LVDS_B0-

LVDS_B1+

LVDS_B1-

LVDS_B2+

LVDS_B2-

LVDS_B3+

LVDS_B3-

LVDS_B_CK+

LVDS_B_CK-

LVDS_VDD_EN A77 LVDS panel power enable O 3.3V

LVDS_BKLT_EN B79 LVDS panel backlight enable O 3.3V

LVDS_BKLT_CTRL B83 LVDS panel backlight brightness control O 3.3V

LVDS_I2C_CK A83 DDC lines used for flat panel detection and

LVDS_I2C_DAT A84 DDC lines used for flat panel detection and

B71

B72

B73

B74

B75

B76

B77

B78

B81

B82

LVDS Channel B differential pairs O LVDS

LVDS Channel B differential clock O LVDS

O 3.3V PU 2k2 3.3V

control.

I/O 3.3V PU 2k2 3.3V

control.

3.3.4. Gigabit Ethernet

Gigabit Ethernet Pin # Description I/O PU/PD Comment

GBE0_MDI0+

GBE0_MDI0-

GBE0_MDI1+

GBE0_MDI1-

GBE0_MDI2+

GBE0_MDI2-

GBE0_MDI3+

GBE0_MDI3-

GBE0_ACT# B2 Gigabit Ethernet Controller 0 activity indicator, active low. O 3.3VSB PU 10k

GBE0_LINK# A8 Gigabit Ethernet Controller 0 link indicator, active low. O 3.3VSB

GBE0_LINK100# A4 Gigabit Ethernet Controller 0 100Mbit/sec link indicator, active low. O 3.3VSB

GBE0_LINK1000# A5 Gigabit Ethernet Controller 0 1000Mbit/sec link indicator, active low. O 3.3VSB

GBE0_CTREF A14 Reference voltage for Carrier Board Ethernet channel 1 and 2 magnetics

A13

Gigabit Ethernet Controller 0: Media Dependent Interface Differential Pairs

A11

0, 1, 2, 3. The MDI can operate in 1000, 100, and 10Mbit/sec modes.

A10

Some pairs are unused in some modes according to the following:

A9

1000 100 10

A7

MDI[0]+/- B1_DA+/- TX+/- TX+/-

A6

MDI[1]+/- B1_DB+/- RX+/- RX+/-

A3

MDI[2]+/- B1_DC+/-

A2

MDI[3]+/- B1_DD+/-

center tap. The reference voltage is determined by the requirements of the

Module PHY and may be as low as 0V and as high as 3.3V. The reference

voltage output shall be current limited on the Module. In the case in which

the reference is shorted to ground, the current shall be 250 mA or less.

I/O Analog Twisted pair

3.3VSB

GND min

3.3V max

Floating on

3.3.5. SATA

signals for

external

transformer.

module, N.C.

pin

Signal Pin # Description I/O PU/PD Comment

SATA0_TX+

SATA0_TX-

SATA0_RX+

SATA0_RX-

A16

Serial ATA channel 0, Transmit Output differential pair. O SATA AC coupled on Module

A17

A19

Serial ATA channel 0, Receive Input differential pair. I SATA AC coupled on Module

A20

Express-BE Page 19

Page 20

Signal Pin # Description I/O PU/PD Comment

SATA1_TX+

SATA1_TX-

SATA1_RX+

SATA1_RX-

SATA2_TX+

SATA2_TX-

SATA2_RX+

SATA2_RX-

SATA3_TX+

SATA3_TX-

SATA3_RX+

SATA3_RX-

(S)ATA_ACT# A28 ATA (parallel and serial) or SAS activity indicator, active low. O 3.3V

B16

Serial ATA channel 1, Transmit Output differential pair. O SATA AC coupled on Module

B17

B19

Serial ATA channel 1, Receive Input differential pair. I SATA AC coupled on Module

B20

A22

Serial ATA channel 2, Transmit Output differential pair. O SATA AC coupled on Module

A23

A25

Serial ATA channel 2, Receive Input differential pair. I SATA AC coupled on Module

A26

B22

Serial ATA channel 3, Transmit Output differential pair. O SATA AC coupled on Module

B23

B25

Serial ATA channel 3, Receive Input differential pair. I SATA AC coupled on Module

B26

3.3.6. PCI Express

Signal Pin # Description I/O PU/PD Comment

PCIE_TX0+

PCIE_TX0-

PCIE_RX0+

PCIE_RX0-

A68

PCI Express channel 0, Transmit Output

A69

differential pair.

B68

PCI Express channel 0, Receive Input

B69

differential pair.

O PCIE AC coupled on Module

I PCIE AC coupled off Module

PCIE_TX1+

PCIE_TX1-

PCIE_RX1+

PCIE_RX1-

PCIE_TX2+

PCIE_TX2-

PCIE_RX2+

PCIE_RX2-

PCIE_TX3+

PCIE_TX3-

PCIE_RX3+

PCIE_RX3-

PCIE_TX4+

PCIE_TX4-

PCIE_RX4+

PCIE_RX4-

PCIE_TX5+

PCIE_TX5-

PCIE_RX5+

PCIE_RX5-

A64

PCI Express channel 1, Transmit Output

A65

differential pair.

B64

PCI Express channel 1, Receive Input

B65

differential pair.

A61

PCI Express channel 2, Transmit Output

A62

differential pair.

B61

PCI Express channel 2, Receive Input

B62

differential pair.

A58

PCI Express channel 3, Transmit Output

A59

differential pair.

B58

PCI Express channel 3, Receive Input

B59

differential pair.

A55

PCI Express channel 4, Transmit Output

A56

differential pair.

B55

PCI Express channel 4, Receive Input

B56

differential pair.

A52

PCI Express channel 5, Transmit Output

A53

differential pair.

B52

PCI Express channel 5, Receive Input

B53

differential pair.

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module

I PCIE AC coupled off Module

PCIE_CLK_REF+

PCIE_CLK_REF-

A88

PCI Express Reference Clock output for all PCI

A89

Express and PCI Express Graphics Lanes.

O PCIE

Page 20 Express-BE

Page 21

3.3.7. Express Card

Signal Pin # Description I/O PU/PD Comment

EXCD0_CPPE#

EXCD1_CPPE#

EXCD0_PERST#

EXCD1_PERST#

A49

B48

A48

B47

PCI ExpressCard: PCI Express capable card request I 3.3V PU 10k 3.3V

PCI ExpressCard: reset O 3.3V

3.3.8. LPC Bus

Signal Pin # Description I/O PU/PD Comment

LPC_AD[0:3] B4-B7 LPC multiplexed address, command and data bus I/O 3.3V

LPC_FRAME# B3 LPC frame indicates the start of an LPC cycle O 3.3V

LPC_DRQ0#

LPC_DRQ1#

LPC_SERIRQ A50 LPC serial interrupt I/O OD 3.3V PU 8k2 3.3V

LPC_CLK B10 LPC clock output –33MHz nominal O 3.3V

B8

B9

LPC serial DMA request I 3.3V

3.3.9. USB

Signal Pin # Description I/O PU/PD Comment

USB0+

USB0-

USB1+

USB1-

USB2+

USB2-

USB3+

USB3-

USB4+

USB4-

USB5+

USB5-

USB6+

USB6-

USB7+

USB7-

USB_0_1_OC# B44 USB over-current sense, USB ports 0 and 1. A pull-up

A46

USB differential data pairs for Port 0 I/O 3.3VSB USB 1.1/ 2.0 compliant

A45

B46

USB differential data pairs for Port 1 I/O 3.3VSB USB 1.1/ 2.0 compliant

B45

A43

USB differential data pairs for Port 1 I/O 3.3VSB USB 1.1/ 2.0 compliant

A42

B43

USB differential data pairs for Port 2 I/O 3.3VSB USB 1.1/ 2.0 compliant

B42

A40

USB differential data pairs for Port 3 I/O 3.3VSB USB 1.1/ 2.0 compliant

A39

B40

USB differential data pairs for Port 4 I/O 3.3VSB USB 1.1/ 2.0 compliant

B39

A37

USB differential data pairs for Port 5 I/O 3.3VSB USB 1.1/ 2.0 compliant

A36

B37

USB differential data pairs for Port 6 I/O 3.3VSB USB 1.1/ 2.0 compliant

B37

for this line shall be present on the module. An open

drain driver from a USB current monitor on the carrier

board may drive this line low.

I 3.3VSB PU 10k 3.3VSB Do not pull high on carrier

USB_2_3_OC# A44 USB over-current sense, USB ports 2 and 3. A pull-up

for this line shall be present on the module. An open

drain driver from a USB current monitor on the carrier

board may drive this line low. .

USB_4_5_OC# B38 USB over-current sense, USB ports 4 and 5. A pull-up

for this line shall be present on the module. An open

I 3.3VSB PU 10k 3.3VSB Do not pull high on carrier

I 3.3VSB PU 10k 3.3VSB Do not pull high on carrier

Express-BE Page 21

Page 22

Signal Pin # Description I/O PU/PD Comment

drain driver from a USB current monitor on the carrier

board may drive this line low.

USB_6_7_OC# A38 USB over-current sense, USB ports 6 and 7. A pull-up

for this line shall be present on the module. An open

drain driver from a USB current monitor on the carrier

board may drive this line low.

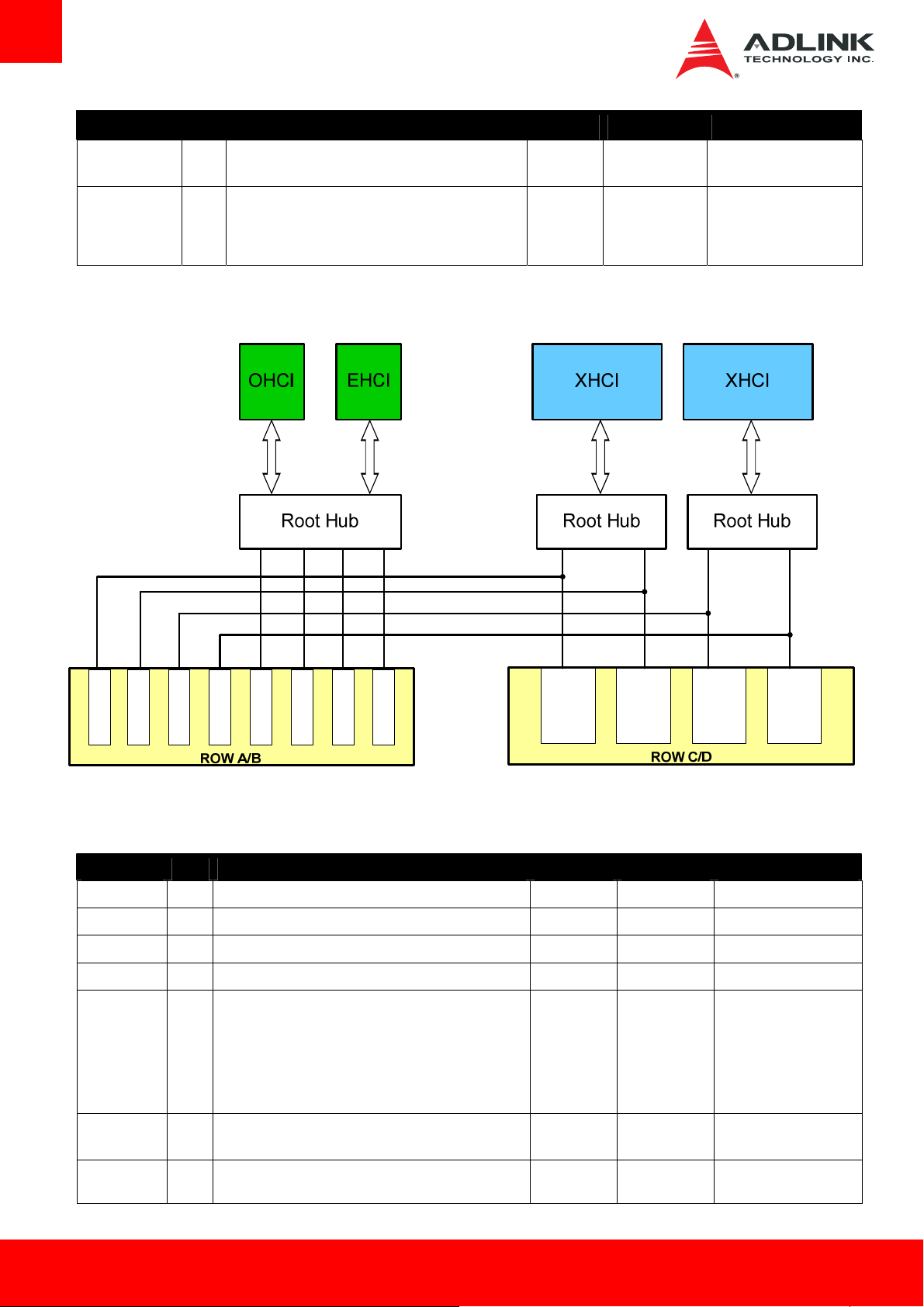

3.3.10. USB Root Segmentation

I 3.3VSB PU 10k 3.3VSB Do not pull high on carrier

USB_SSRX2+ / C10

USB_SSRX0+ / C4

USB_SSTX0+ / D4

USB_SSRX0- / C3

USB0+ / A46

USB1+ / B46

USB2+ / A43

USB3+ / B43

USB4+ / A40

USB5+ / B40

USB6+ / A37

USB0- / A45

USB1- / B45

USB2- / A42

USB3- / B42

USB4- / A39

USB5- / B39

USB6- / A36

USB7+ / B37

USB7- / B36

USB_SSTX0- / D3

USB_SSRX1+ / C7

USB_SSTX1+ / D7

USB_SSRX1- / C6

USB_SSTX1- / D6

USB_SSTX2+ / D10

USB_SSTX2- / D9

3.3.11. SPI (BIOS only)

Signal Pin # Description I/O PU/PD Comment

SPI_CS# B97 Chip select for Carrier Board SPI BIOS Flash. O 3.3VSB

SPI_MISO A92 Data in to module from carrier board SPI BIOS flash. I 3.3VSB

SPI_MOSI A95 Data out from module to carrier board SPI BIOS flash. O 3.3VSB

SPI_CLK A94 Clock from module to carrier board SPI BIOS flash. O 3.3VSB

SPI_POWER A91 Power supply for Carrier Board SPI – sourced from Module

– nominally 3.3V.

The Module shall provide a minimum of 100mA on

SPI_POWER.

Carriers shall use less than 100mA of SPI_POWER.

SPI_POWER shall only be used to power SPI devices on

the Carrier

O P 3.3VSB

USB_SSRX3+ / C13

USB_SSTX3+ / D13

USB_SSRX3- / C12

USB_SSRX2- / C9

USB_SSTX3- / D12

BIOS_DIS0# A34 Selection strap to determine the BIOS boot device. I PU 10K 3.3VSB Carrier shall pull to GND

or leave not- connected.

BIOS_DIS1# B88 Selection strap to determine the BIOS boot device. I PU 10K 3.3VSB Carrier shall pull to GND

or leave not- connected

Page 22 Express-BE

Page 23

3.3.12. Miscellaneous

Signal Pin # Description I/O PU/PD Comment

SPKR B32 Output for audio enunciator, the “speaker” in PC-AT

systems

WDT B27 Output indicating that a watchdog time-out event has

occurred.

THRM# B35 Input from off-module temp sensor indicating an over-temp

situation.

THRMTRIP# A35 Active low output indicating that the CPU has entered

thermal shutdown.

FAN_PWMOUT B101 Fan speed control. Uses the Pulse Width Modulation

(PWM) technique to control the fan’s RPM.

FAN_TACHIN B102 Fan tachometer input for a fan with a two pulse output. I OD 3.3V PU 10k 3.3V

TPM_PP C83 Trusted Platform Module (TPM) Physical Presence pin.

Active high. TPM chip has an internal pull down. This

signal is used to indicate Physical Presence to the TPM.

O 3.3V

O 3.3V

I 3.3V

O 3.3V PU 10k 3.3V

O OD 3.3V

I 3.3V

PD 10k 3.3V PD only when TPM on

module

3.3.13. SMBus

Signal Pin # Description I/O PU/PD Comment

SMB_CK B13 System Management Bus bidirectional clock line. Power

sourced through 5V standby rail and main power rails.

SMB_DAT# B14 System Management Bus bidirectional data line. Power

sourced through 5V standby rail and main power rails.

I/O OD 3.3VSB PU 2k2 3.3VSB

I/O OD 3.3VSB PU 2k2 3.3VSB

SMB_ALERT# B15 System Management Bus Alert – active low input can

be used to generate an SMI# (System Management

Interrupt) or to wake the system. Power sourced

through 5V standby rail and main power rails.

I 3.3VSB PU 10k 3.3VSB

3.3.14. I2C Bus

Signal Pin # Description I/O PU/PD Comment

I2C_CK B33 General purpose I²C port clock output/input I/O OD 3.3VSB PU 2k2 3.3VSB Source SEMA BMC

I2C_DAT B34 General purpose I²C port data I/O line I/O OD 3.3VSB PU 2k2 3.3VSB Source SEMA BMC

3.3.15. General Purpose I/O (GPIO)

Signal Pin # Description I/O PU/PD Comment

GPO[0] A93 General purpose output pins. O 3.3V PU 10K 3.3V After hardware RESET

output low

GPO[1] B54 General purpose output pins. O 3.3V PU 10K 3.3V After hardware RESET

output low

GPO[2] B57 General purpose output pins. O 3.3V PU 10K 3.3V After hardware RESET

output low

GPO[3] B63 General purpose output pins. O 3.3V PU 10K 3.3V After hardware RESET

output low

GPI[0] A54 General purpose input pins.

Pulled high internally on the module.

I 3.3V PU 10K 3.3V

Express-BE Page 23

Page 24

Signal Pin # Description I/O PU/PD Comment

GPI[1] A63 General purpose input pins.

Pulled high internally on the module.

GPI[2] A67 General purpose input pins.

Pulled high internally on the module.

GPI[3] A85 General purpose input pins.

Pulled high internally on the module.

I 3.3V PU 10K 3.3V

I 3.3V PU 10K 3.3V

I 3.3V PU 10K 3.3V

3.3.16. Serial Interface Signals

Signal Pin # Description I/O PU/PD Comment

SER0_TX A98 General purpose serial port transmitter (TTL level output) O CMOS Power rail tolerance 5V, 12V

SER0_RX A99 General purpose serial port receiver (TTL level input) I CMOS Power rail tolerance 5V, 12V

SER1_TX A101 General purpose serial port transmitter (TTL level output) O CMOS Power rail tolerance 5V, 12V

SER1_RX A102 General purpose serial port receiver (TTL level input) I CMOS Power rail tolerance 5V, 12V

3.3.17. Power and System Management

Signal Pin # Description I/O PU/PD Comment

PWRBTN# B12 Power button to bring system out of S5 (soft off), active on falling edge. I 3.3VSB PU 10k

3.3VSB

SYS_RESET# B49 Reset button input. Active low request for module to reset and reboot. May

be falling edge sensitive. For situations when SYS_RESET# is not able to

reestablish control of the system, PWR_OK or a power cycle may be used.

CB_RESET# B50 Reset output from module to Carrier Board. Active low. Issued by module

chipset and may result from a low SYS_RESET# input, a low PWR_OK

input, a VCC_12V power input that falls below the minimum specification, a

watchdog timeout, or may be initiated by the module software.

PWR_OK B24 Power OK from main power supply. A high value indicates that the power is

good. This signal can be used to hold off Module startup to allow carrier

based FPGAs or other configurable devices time to be programmed.

SUS_STAT# B18 Indicates imminent suspend operation; used to notify LPC devices. O 3.3VSB

SUS_S3# A15 Indicates system is in Suspend to RAM state. Active-low output. An inverted

copy of SUS_S3# on the carrier board (also known as “PS_ON”) may be

used to enable the non-standby power on a typical ATX power supply.

SUS_S4# A18 Indicates system is in Suspend to Disk state. Active low output. O 3.3VSB

SUS_S5# A24 Indicates system is in Soft Off state. O 3.3VSB

WAKE0# B66 PCI Express wake up signal. I 3.3VSB PU 10k

I 3.3VSB PU 10k

3.3VSB

O 3.3VSB

I 3.3V PU 100k

3.3VSB

O 3.3VSB

3.3VSB

Not

supported

connected to

SUS_S5#

Not supported

connected to

WAKE1#

WAKE1# B67 General purpose wake up signal. May be used to implement wake-up on

PS/2 keyboard or mouse activity.

BATLOW# A27 Battery low input. This signal may be driven low by external circuitry to

signal that the system battery is low, or may be used to signal some other

external power-management event.

I 3.3VSB PU 10k

3.3VSB

I 3.3VSB PU 10k

3.3VSB

Page 24 Express-BE

Page 25

Signal Pin # Description I/O PU/PD Comment

LID# A103 LID button. Low active signal used by the ACPI operating system for a LID

switch.

SLEEP# B103 Sleep button. Low active signal used by the ACPI operating system to bring

the system to sleep state or to wake it up again.

I OD

3.3VSB

I OD

3.3VSB

PU 10k

3.3VSB

PU 10K

3.3VSB

Emulated on

GPIO (BIOS)

Emulated on

GPIO (BIOS)

3.3.18. Power and Ground

Signal Pin # Description I/O PU/PD Comment

VCC_12V A104-A109

B104-B109

VCC_5V_SBY B84-B87 Standby power input: +5.0V nominal. See section 7 “Electrical

VCC_RTC A47 Real-time clock circuit-power input. Nominally +3.0V. P

GND A1, A11, A21, A31, A41, A51,

A57, A66, A80, A90, A96, A100,

A110, B1, B11, B21 ,B31, B41,

B51, B60, B70, B80, B90, B100,

B110

Primary power input: +12V nominal (wide range 5 ~ 20V).

All available VCC_12V pins on the connector(s) shall be used.

Specifications“ for allowable input range. If VCC5_SBY is used,

all available VCC_5V_SBY pins on the connector(s) shall be

used. Only used for standby and suspend functions. May be left

unconnected if these functions are not used in the system design.

Ground - DC power and signal and AC signal return path. P

P 8.5~20 V

P 5Vsb ±5%

Express-BE Page 25

Page 26

3.4. CD Signal Descriptions

3.4.1. USB 3.0 Extension

Signal Pin Description I/O PU/PD Comment

USB_SSRX0-

USB_SSRX0+

USB_SSTX0-

USB_SSTX0+

USB_SSRX1-

USB_SSRX1+

USB_SSTX1-

USB_SSTX1+

USB_SSRX2-

USB_SSRX2+

USB_SSTX2-

USB_SSTX2+

USB_SSRX3-

USB_SSRX3+

USB_SSTX3-

USB_SSTX3+

C3

C4

D3

D4

C6

C7

D6

D7

C9

C10

D9

D10

C12

C13

D12

D13

Additional Receive signal differential pairs for the

SuperSpeed USB data path on USB0

Additional Transmit signal differential pairs for the

SuperSpeed USB data path on USB0

Additional Receive signal differential pairs for the

SuperSpeed USB data path on USB1

Additional Transmit signal differential pairs for the

SuperSpeed USB data path on USB1

Additional Receive signal differential pairs for the

SuperSpeed USB data path on USB2

Additional Transmit signal differential pairs for the

SuperSpeed USB data path on USB2

Additional Receive signal differential pairs for the

SuperSpeed USB data path on USB3

Additional Transmit signal differential pairs for the

SuperSpeed USB data path on USB3

I PCIE AC coupled off module

O PCIE AC coupled on module

I PCIE AC coupled off module

O PCIE AC coupled on module

I PCIE AC coupled off module

O PCIE AC coupled on module

I PCIE AC coupled off module

O PCIE AC coupled on module

3.4.2. PCI Express x1

Signal Pin # Description I/O PU/PD Comment

PCIE_TX6+

PCIE_TX6-

PCIE_RX6+

PCIE_RX6-

D19

D20

C19

C20

PCI Express channel 6, Transmit Output differential pair. O PCIE

PCI Express channel 6, Receive Input differential pair. I PCIE

AC coupled on module

AC coupled off module

PCIE_TX7+

PCIE_TX7-

PCIE_RX7+

PCIE_RX7-

D22

D23

C22

C23

PCI Express channel 7, Transmit Output differential pair. O PCIE Not supported

PCI Express channel 7, Receive Input differential pair. I PCIE Not supported

Page 26 Express-BE

Page 27

3.4.3. DDI Channels

DDI 1

Signal Pin Description I/O PU/PD Comment

DDI1_PAIR0+

DDI1_PAIR0DDI1_PAIR1+

DDI1_PAIR1DDI1_PAIR2+

DDI1_PAIR2DDI1_PAIR3+

DDI1_PAIR3DDI1_PAIR4+

DDI1_PAIR4DDI1_PAIR5+

DDI1_PAIR5DDI1_PAIR6+

DDI1_PAIR6-

DDI1_HPD C24 Digital Display Interface Hot-Plug Detect I PCIE PD 100K

DDI1_DDC_AUX_SEL D34 Selects the function of

D26

D27

D29

D30

D32

D33

D36

D37

C25

C26

C29

C30

C15

C16

Digital Display Interface1 differential pairs O PCIE Pair 4 to Pair 6

IF DDI1_DDC_AUX_SEL is floating I/O PCIe DP1_AUX+ DDI1_CTRLCLK_AUX+ D15

IF DDI1_DDC_AUX_SEL pulled high I/O OD 3.3V HDMI1_CTRLCLK

IF DDI1_DDC_AUX_SEL is floating I/O PCIe DP1_AUX+ DDI1_CTRLCLK_AUX- D16

IF DDI1_DDC_AUX_SEL pulled high I/O OD 3.3V HDMI1_CTRLDATA

I/O OD 3.3V PD 1M

DDI1_CTRLCLK_AUX+ and

DDI1_CTRLDATA_AUX-. This pin shall

have a 1M pull-down to logic ground on

the Module. If this input is floating the

AUX pair is used for the DP AUX+/signals. If pulled-high the AUX pair

contains the CRTLCLK and CTRLDATA

signals.

Not supported

Express-BE Page 27

Page 28

DDI 2

Signal Pin Description I/O PU/PD Comment

DDI2_PAIR0+

DDI2_PAIR0DDI2_PAIR1+

DDI2_PAIR1DDI2_PAIR2+

DDI2_PAIR2DDI2_PAIR3+

DDI2_PAIR3-

DDI2_HPD D44 PD 100K

DDI2_DDC_AUX_SEL C34 Selects the function of DDI2_CTRLCLK_AUX+ and

D39

D40

D42

D43

D46

D47

D49

D50

Digital Display Interface2 differential pairs

IF DDI2_DDC_AUX_SEL is floating I/O PCIe DP2_AUX+ DDI2_CTRLCLK_AUX+ C32

IF DDI2_DDC_AUX_SEL pulled high I/O OD 3.3V HDMI2_CTRLCLK

IF DDI2_DDC_AUX_SEL is floating I/O PCIe DP2_AUX+ DDI2_CTRLCLK_AUX- C33

IF DDI2_DDC_AUX_SEL pulled high I/O OD 3.3V HDMI2_CTRLDATA

PD 1M

DDI2_CTRLDATA_AUX-. This pin shall have a 1M

pull-down to logic ground on the Module. If this input

is floating the AUX pair is used for the DP AUX+/signals. If pulled-high the AUX pair contains the

CRTLCLK and CTRLDATA signals.

DDI 3

Signal Pin Description I/O PU/PD Comment

DDI3_PAIR0+

DDI3_PAIR0DDI3_PAIR1+

DDI3_PAIR1DDI3_PAIR2+

DDI3_PAIR2DDI3_PAIR3+

DDI3_PAIR3-

DDI3_HPD C44 PD 100K

DDI3_DDC_AUX_SEL C38 Selects the function of DDI3_CTRLCLK_AUX+

C39

C40

C42

C43

C46

C47

C49

C50

Digital Display Interface3 differential pairs

IF DDI3_DDC_AUX_SEL is floating I/O PCIe DP2_AUX+ DDI3_CTRLCLK_AUX+ C36

IF DDI3_DDC_AUX_SEL pulled high I/O OD 3.3V HDMI2_CTRLCLK

IF DDI3_DDC_AUX_SEL is floating I/O PCIe DP2_AUX+ DDI3_CTRLCLK_AUX- C37

IF DDI3_DDC_AUX_SEL pulled high I/O OD 3.3V HDMI2_CTRLDATA

PD 1M

and DDI3_CTRLDATA_AUX-. This pin shall

have a 1M pull-down to logic ground on the

Module. If this input is floating the AUX pair is

used for the DP AUX+/- signals. If pulled-high

the AUX pair contains the CRTLCLK and

CTRLDATA signals.

Page 28 Express-BE

Page 29

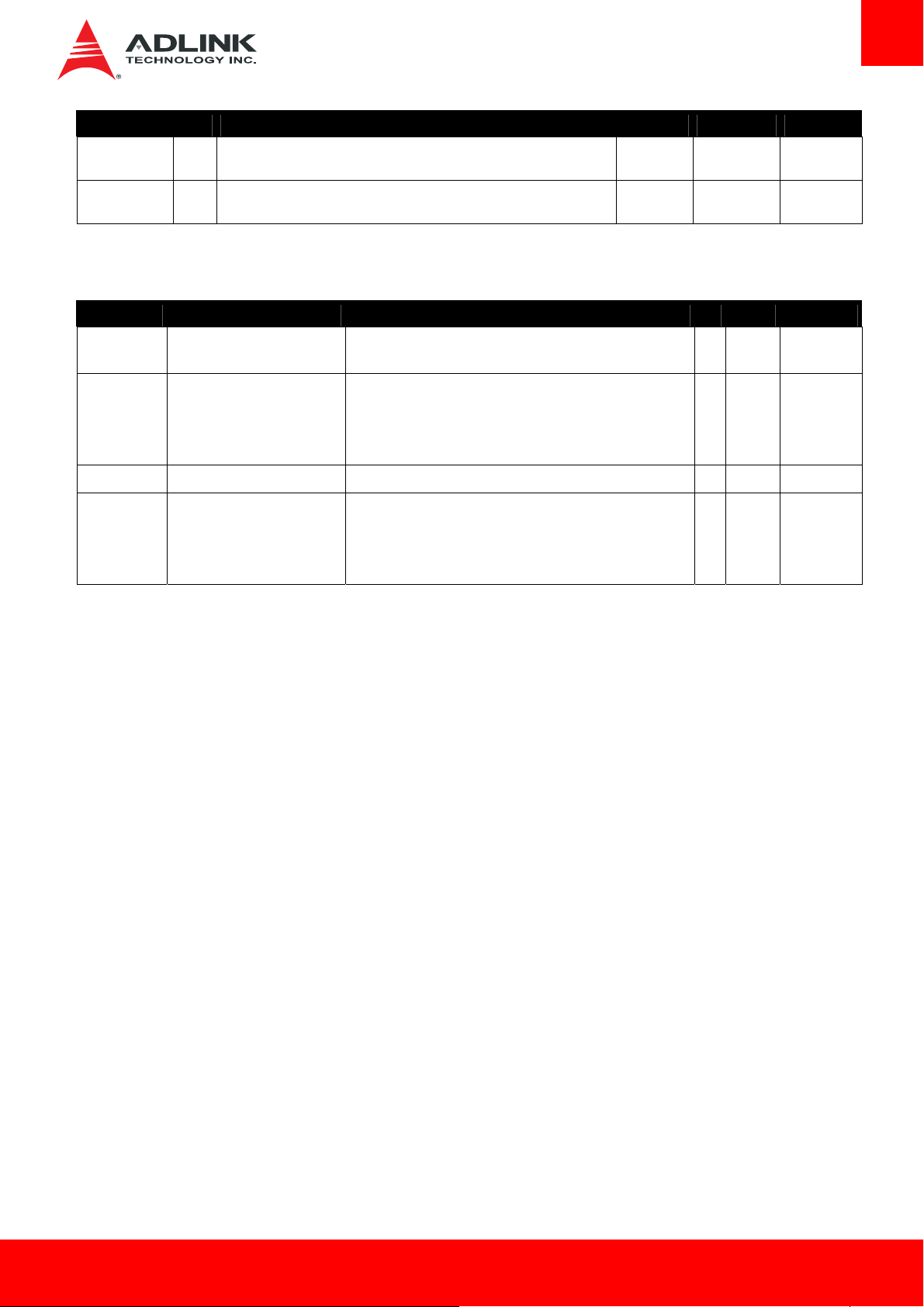

3.4.4. DDI to DP/HDMI Mapping

Pin Pin Name DP HDMI \ DVI

D26 DDI1_PAIR0+ DP1_LANE0+ TMDS1_DATA2+

D27 DDI1_PAIR0- DP1_LANE0- TMDS1_DATA2D29 DDI1_PAIR1+ DP1_LANE1+ TMDS1_DATA1+

D30 DDI1_PAIR1- DP1_LANE1- TMDS1_DATA1D32 DDI1_PAIR2+ DP1_LANE2+ TMDS1_DATA0+

D33 DDI1_PAIR2- DP1_LANE2- TMDS1_DATA0D36 DDI1_PAIR3+ DP1_LANE3+ TMDS1_CLK+

D37 DDI1_PAIR3- DP1_LANE3- TMDS1_CLKC25 DDI1_PAIR4+

C26 DDI1_PAIR4-

C29 DDI1_PAIR5+

C30 DDI1_PAIR5-

C15 DDI1_PAIR6+

C16 DDI1_PAIR6-

C24 DDI1_HPD DP1_HPD HDMI1_HPD

D15 DDI1_CTRLCLK_AUX+ DP1_AUX+ HMDI1_CTRLCLK

D16 DDI1_CTRLDATA_AUX- DP1_AUX- HMDI1_CTRLDATA

D34 DDI1_DDC_AUX_SEL

D39 DDI2_PAIR0+ DP2_LANE0+ TMDS2_DATA2+

D40 DDI2_PAIR0- DP2_LANE0- TMDS2_DATA2D42 DDI2_PAIR1+ DP2_LANE1+ TMDS2_DATA1+

D43 DDI2_PAIR1- DP2_LANE1- TMDS2_DATA1D46 DDI2_PAIR2+ DP2_LANE2+ TMDS2_DATA0+

D47 DDI2_PAIR2- DP2_LANE2- TMDS2_DATA0D49 DDI2_PAIR3+ DP2_LANE3+ TMDS2_CLK+

D50 DDI2_PAIR3- DP2_LANE3- TMDS2_CLKD44 DDI2_HPD DP2_HPD HDMI2_HPD

C32 DDI2_CTRLCLK_AUX+ DP2_AUX+ HDMI2_CTRLCLK

C33 DDI2_CTRLDATA_AUX- DP2_AUX- HDMI2_CTRLDATA

C34 DDI2_DDC_AUX_SEL

Express-BE Page 29

Page 30

3.4.5. PCI Express Graphics x16 (PEG)

Signal Pin Description I/O PU/PD Comment

PEG_RX0+

PEG_RX0-

PEG_RX1+

PEG_RX1-

PEG_RX2+

PEG_RX2-

PEG_RX3+

PEG_RX3-

PEG_RX4+

PEG_RX4-

PEG_RX5+

PEG_RX5-

PEG_RX6+

PEG_RX6-

PEG_RX7+

PEG_RX7-

PEG_RX8+

PEG_RX8-

PEG_RX9+

PEG_RX9-

PEG_RX10+

PEG_RX10-

PEG_RX11+

PEG_RX11-

PEG_RX12+

PEG_RX12-

PEG_RX13+

PEG_RX13-

PEG_RX14+

PEG_RX14-

PEG_RX15+

PEG_RX15

PEG_TX0+

PEG_TX0-

PEG_TX1+

PEG_TX1-

PEG_TX2+

PEG_TX2-

PEG_TX3+

PEG_TX3-

PEG_TX4+

PEG_TX4-

PEG_TX5+

PEG_TX5-

PEG_TX6+

PEG_TX6-

PEG_TX7+

PEG_TX7-

PEG_TX8+

PEG_TX8-

PEG_TX9+

PEG_TX9-

PEG_TX10+

PEG_TX10-

PEG_TX11+

PEG_TX11-

PEG_TX12+

PEG_TX12-

PEG_TX13+

PEG_TX13-

PEG_TX14+

PEG_TX14-

PEG_TX15+

PEG_TX15-

C52

C53

C55

C56

C58

C59

C61

C62

C65

C66

C68

C69

C71

C72

C74

C75

C78

C79

C81

C82

C85

C86

C88

C89

C91

C92

C94

C95

C98

C99

C101

C102

D52

D53

D55

D56

D58

D57

D61

D62

D65

D66

D68

D69

D71

D72

D74

D75

D78

D79

D81

D82

D85

D86

D88

D89

D91

D92

D94

D95

D98

D99

D101

D102

PCI Express Graphics transmit differential pairs. I PCIE AC couple off module

PCI Express Graphics receive differential pairs. O PCIE AC couple on module

Page 30 Express-BE

Page 31

Signal Pin Description I/O PU/PD Comment

PEG_LANE_RV# D54 PCI Express Graphics lane reversal input strap.

Pull low on the Carrier board to reverse lane order.

I 3.3V

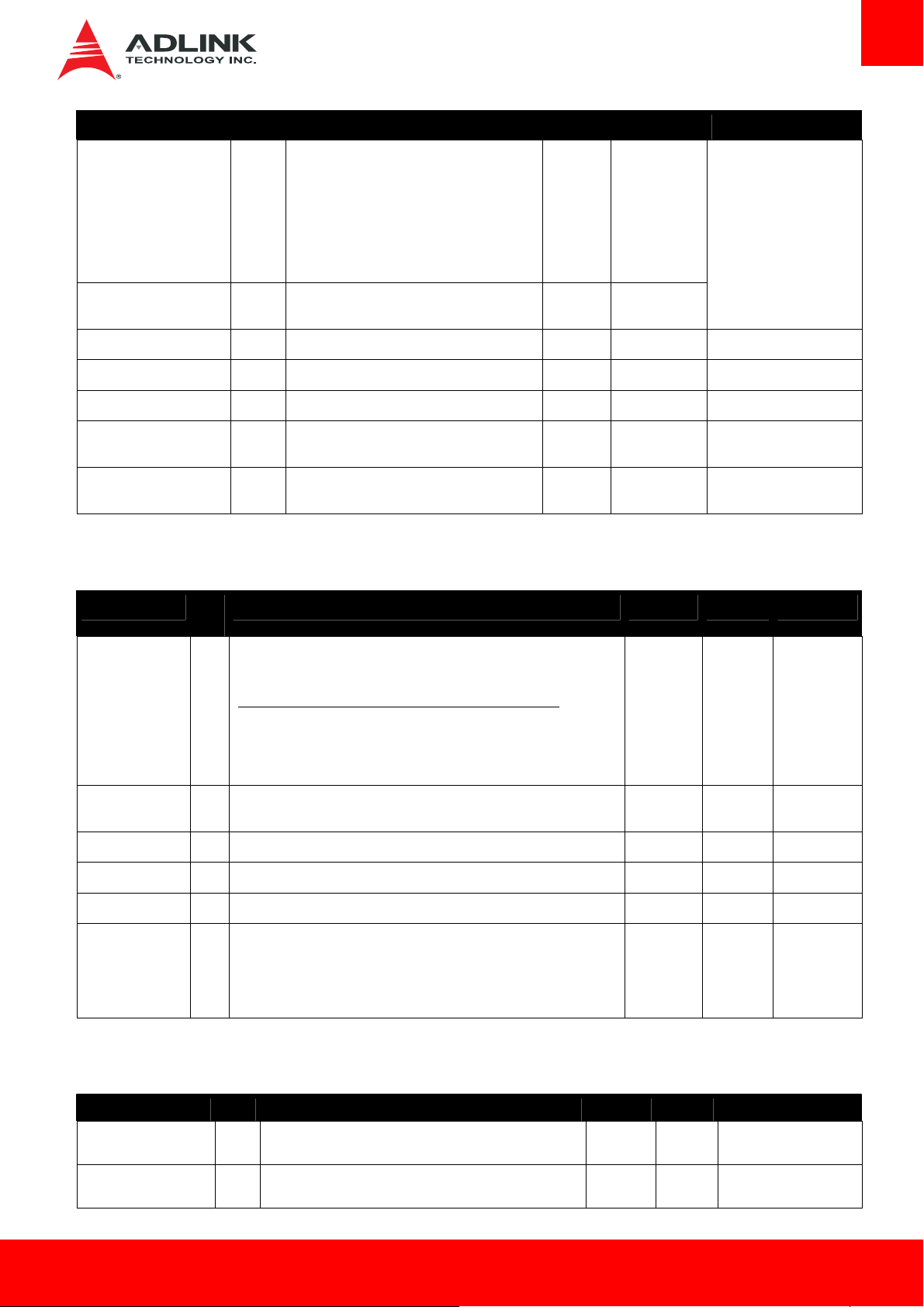

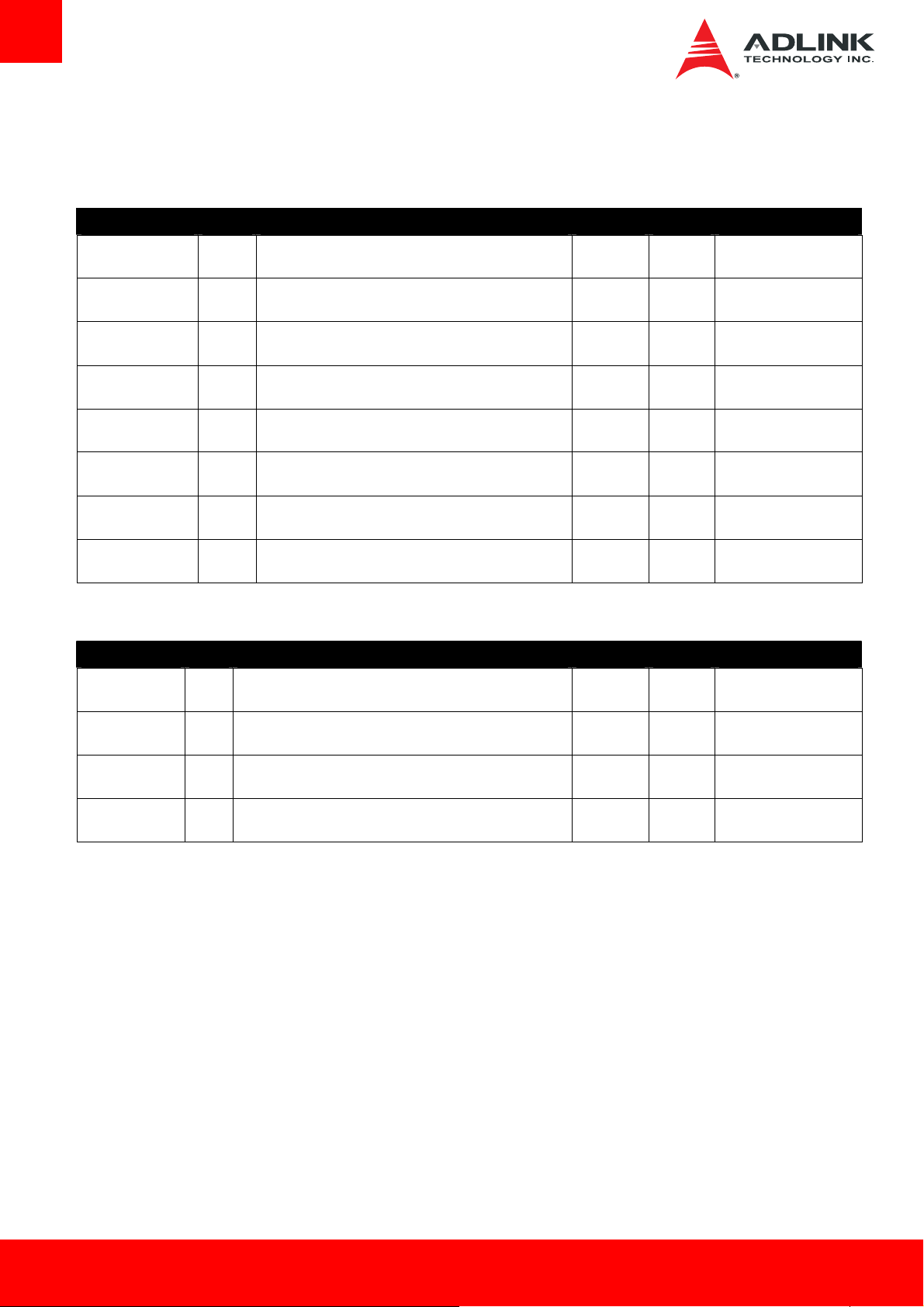

3.4.6. Module Type Definition

Signal Pin # Description I/O Comment

TYPE0#

TYPE1#

TYPE2#

C54

C57

D57

The TYPE pins indicate to the Carrier Board the Pin-out Type that is implemented on

the module. The pins are tied on the module to either ground (GND) or are noconnects (NC). For Pinout Type 1, these pins are don’t care (X).

TYPE2# TYPE1# TYPE0#

X X X Pinout Type 1

NC NC NC Pinout Type 2

NC NC GND Pinout Type 3 (no IDE)

NC GND NC Pinout Type 4 (no PCI)

NC GND GND Pinout Type 5 (no IDE, no PCI)

GND NC NC Pinout Type 6 (no IDE, no PCI)

The Carrier Board should implement combinatorial logic that monitors the module

TYPE pins and keeps power off (e.g deactivates the ATX_ON signal for an ATX power

supply) if an incompatible module pin-out type is detected. The Carrier Board logic

may also implement a fault indicator such as an LED.

Type 6

3.4.7. Power and Ground

Signal Pin # Description I/O PU/PD Comment

VCC_12V C104-C109

D104-D109

GND C1, C11, C21, C31, C41,

C51, C60, C70, C76, C80,

C84, C87, C90, C93, C96,

C100, C103, C110, D1,

D11, D21, D31, D41, D51,

D60, D67, D70, D76, D80,

D84, D87, D90, D93, D96,

D100, D103, D110

Primary power input: +12V nominal (wide range 5 ~ 20V).

All available VCC_12V pins on the connector(s) shall be used

Ground - DC power and signal and AC signal return path.

All available GND connector pins shall be used and tied to carrier

board GND plane.

P 8.5 ~ 20V

P

Express-BE Page 31

Page 32

4. Module Interfaces and Configuration

This chapter describes connectors and pinouts, LEDs and switches that are used on the module but are not included in the standard PICMG

specification.

4.1. Connector, Switch and LED Locations

BIOS

Defaults

Reset

Switch

Fan

4-pin

Fan

40-pin Multi-

Purpose

CD

AB

4.1.1. Express-BE and the DB40 Module connected

Page 32 Express-BE

Page 33

4.2. 40-pin Multipurpose Connector

¾ FPC Connector type: FCI 59GF Flex 10042867

¾ Pin Orientation:

1 40

¾ Pin Definitions (on COMe module)

Pin Interface Signal Remark Pin Interface Signal Remark

1 VCC_SPI_IN SPI Power Input from flash tool to

SPI

Program

interface

2 GND 22 RXD6

3 SPI_BIOS_CS0# 23 FUMD0

4 SPI_BIOS_CS1# 24 RESET_IN#

5 SPI_BIOS_MISO 25 DATA

6 SPI_BIOS_MOSI 26 CLK

7

8 3V3_LPC System power 3.3V provide from

LPC Bus

9 GND 29 PWRBTN#

10 BIOS_DIS0 30 SYS_RESET#

11 RST# 31 CB_RESET#

12 CLK33_LPC 32 CB_PWROK

13 LPC_FRAME# 33 SUS_S3#

SPI_BIOS_CLK 27 OCD0A Include a jumper to connect

module. HW need add MOS FET

to switch SPI power for SPI ROM

COM module

21 TXD6

28

BMC Program

interface

(continued)

OCD0A via 1K0 pull-up to

3.3V_BMC

OCD0B Include a jumper to connect

OCD0A via 1K0 pull-up to

3.3V_BMC

Test points

14 LPC_AD3 34 SUS_S4#

15 LPC_AD2 35

16 LPC_AD1 always power 3.3V provide from

COM module

17

BMC

18

Program

interface

19 3.3V_BMC always power 3.3V provide from

20

LPC_AD0 37 SEL_BIOS Connect to Jumper for

3.3V_BMC always power 3.3V provide from

COM module

COM module

GND 40 Reserved

36 POSTWDT_DIS# Connect to Jumper for

38 BIOS_MODE Connect to Jumper for

39

BMC Debug

signals

SUS_S5#

Debug

Debug

Debug

BMC_STATUS

Note: the pin description on the Debug Module is the inverse of that on the COM Express module.

Express-BE Page 33

Page 34

4.3. Status LEDs

To facilitate easier maintenance, status LED’s are mounted on the board.

LED1 LED2 LED3

¾ LED Descriptions:

Name Color Connection Function

LED1 Blue BMC output Power Sequence Status Code (BMC)

Power Changes, RESET

(see 5.1.4 Exception Codes below)

LED2 Green Power Source 3Vcc S0 LED ON

S3/S4/S5 LED OFF

ECO mode LED OFF

LED3 Red BMC output

and same signal as WDT

(B27) on BtB connector

Module power up LED OFF

Watchdog counting LED OFF

Watchdog timed out LED ON

Watchdog RESET LED ON

Rebooted after WD RESET LED ON

Rebooted after PWRBTN LED ON

Rebooted after RESET BTN LED OFF

Note: only a RESET not initiated by the BMC can clear the WD LED (user action)

Page 34 Express-BE

Page 35

4.4. Fan Connector

¾ Connector Type: JVE 24W1125A-04M00

¾ Pin Orientation:

1 2 3 4

¾ Pin Definitions:

Pin Signal

1 FAN_PWMOUT

2 FAN_TACHIN

3 Ground

4 5V

Express-BE Page 35

Page 36

4.5. BIOS Setup Defaults Reset Button

To perform a hardware reset of BIOS default settings, perform the following steps:

1. Shut down the system.

2. Press the BIOS Setup Defaults Reset Button continuously and boot up the system. You can release the button when the BIOS

prompt screen appears

3. The BIOS prompt screen will display a confirmation that BIOS defaults have been reset and request that you reboot the system.

Page 36 Express-BE

Page 37

4.6. Express-BE Switch Settings

4.6.1. Switch Locations

4.6.2. SW1: BIOS Select and Mode Configuration Switch

The module has two BIOS chips and BIOS operation can be configured to "PICMG" and dual-BIOS "Failsafe" modes using SW1, Pin 2.

Setting the module to PICMG mode will configure the BIOS chips on the module as SPI0 and SPI1. In PICMG mode, a BIOS chip cannot

placed in the SPI0 slot on the carrier.

In dual-BIOS Failsafe mode, both BIOS chips on the module are configured as SPI1. Only one of the two is connected to the SPI bus at any

given time. In case of failure of the primary SPI1 BIOS, the system will reboot and switch to the secondary SPI1 BIOS on the module. In

Failsafe mode, the SPI0 BIOS socket on the carrier can be populated.

In either mode, SW1 Pin 1 is used to select whether to boot from SPI0 or SPI1.

Mode Pin 1 Pin 2

Boot from SPI0 (default) On —

Boot from SPI1 Off —

Set BIOS to PICMG mode — On

Set BIOS to Failsafe BIOS mode (default) — Off

be

Express-BE Page 37

Page 38

4.7. PCIe x16-to-two-x8 Adapter Card

The Express-BE can be used with the PCIe x16-to-two-x8 Adapter Card on the Express-BASE6 Reference Carrier to support bifurbication of

the CPU's PEG interface (PCIe x16). The card reroutes the PCIe x16 to two x8 and allows testing of two independent PCIe add-on cards

with x8/x4/x2/x1 width. To use the card, set BIOS > Advanced > Graphics > GFX LINK CFG to "2 x8 " as described in

53.

page

PCIex16-to-two-x8 Adapter Card

(Model: P16TO28, Part No.: 91-79301-0010)

7.3.3 .Graphics on

Page 38 Express-BE

Page 39

5. Smart Embedded Management Agent (SEMA)

The onboard microcontroller (BMC) implements power sequencing and Smart Embedded Management Agent (SEMA) functionality.

The microcontroller communicates via the System Management Bus with the CPU/chipset.

The following functions are implemented

¾ Total operating hours counter counts the number of hours the module has been run in minutes.

¾ On-time minutes counter counts the seconds since last system start.

¾ Temperature monitoring of CPU and board temperature minimum and maximum temperature values of CPU and board are stored in

flash.

¾ Power cycles counter

¾ Boot counter counts the number of boot attempts.

¾ Watchdog Timer (Type-II) Set, Reset, Disable Watchdog Timer. Features auto-reload at power-up.

¾ System Restart Cause Power loss, BIOS Fail, Watchdog, Internal Reset, External Reset

¾ Fail-safe BIOS support In case of a boot failure, hardware signals tells external logic to boot from fail-safe BIOS.

¾ Flash area 1kB Flash area for customer data

¾ 128 Bytes Protected Flash area Keys, IDs, etc. can be stored in a write- and clear-protectable region.

¾ Board Identify Vendor, Board, Serial number, Production Date

¾ Main-current & voltage monitors drawn current and main voltages

For a detailed description of SEMA features and functionality, please refer to the SEMA Technical Manual and SEMA Software Manual,

downloadable at:

http://www.adlinktech.com/PD/web/PD_detail.php?cKind=&pid=1274

Express-BE Page 39

Page 40

5.1. Board Specific SEMA Functions

5.1.1. Voltages

The BMC of the Express-BE implements a voltage monitor and samples several onboard voltages. The voltages can be read by calling the

SEMA function “Get Voltages”. The function returns a 16-bit value divided into high-byte (MSB) and low-byte (LSB).