Page 1

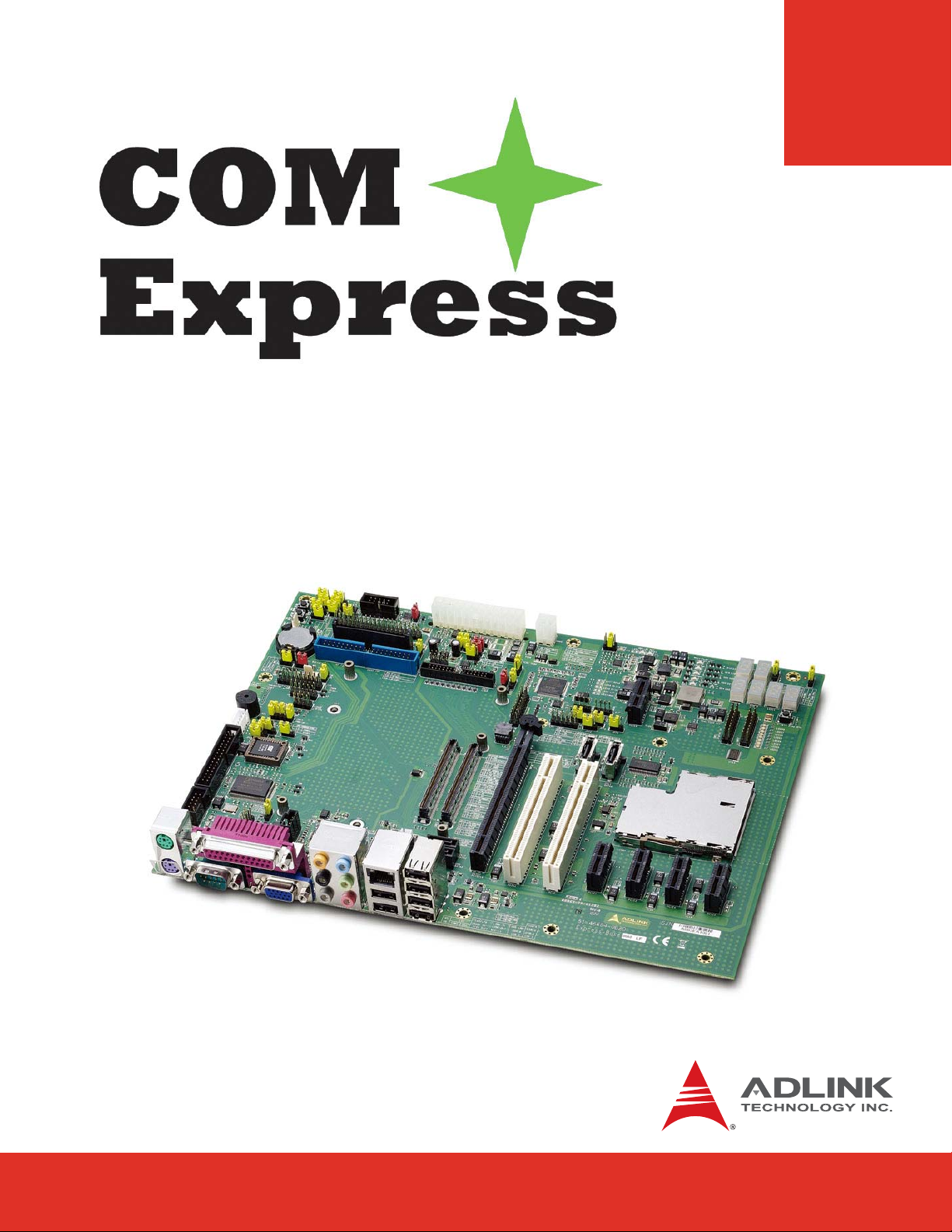

Express-BASE

User’s Manual

Manual Revision: 2.30

Revision Date: July 6, 2011

Part Number: 50-1J012-1030

Page 2

Revision History

Release Date Change

2.00 2006/9/15 Initial Release

2.10 2007/10/19 Updated ETXexpress/Express name changes

2.20 2009/03/05 Updated Engineering Specifications (B2)

2.21 2010/06/11 Updated to D1 PCB version

2.30 2011/07/06 Updated to D2 PCB version: Removed TV-out, extended power

Updated company contact information

(compatible with PICMG COM Express Carrier Design Guide)

connectors; added LVDS panel control header and jumpers, SPI BIOS

socket and Secondary BIOS instructions, ATX 12V 4-pin connector, ATX

power connector info

Express-BASE User’s ManualPage 2

Page 3

Table of Contents

Preface ............................................................................................................................5

1 Introduction...............................................................................................................7

2 Special Features .......................................................................................................8

2.1 Primary LPC based Super I/O...............................................................................................8

2.2 Secondary BIOS ...................................................................................................................8

2.3 Integrated Debug Port with Single Step Execution ...............................................................8

2.4 Onboard Audio......................................................................................................................8

2.5 Information LEDs ..................................................................................................................8

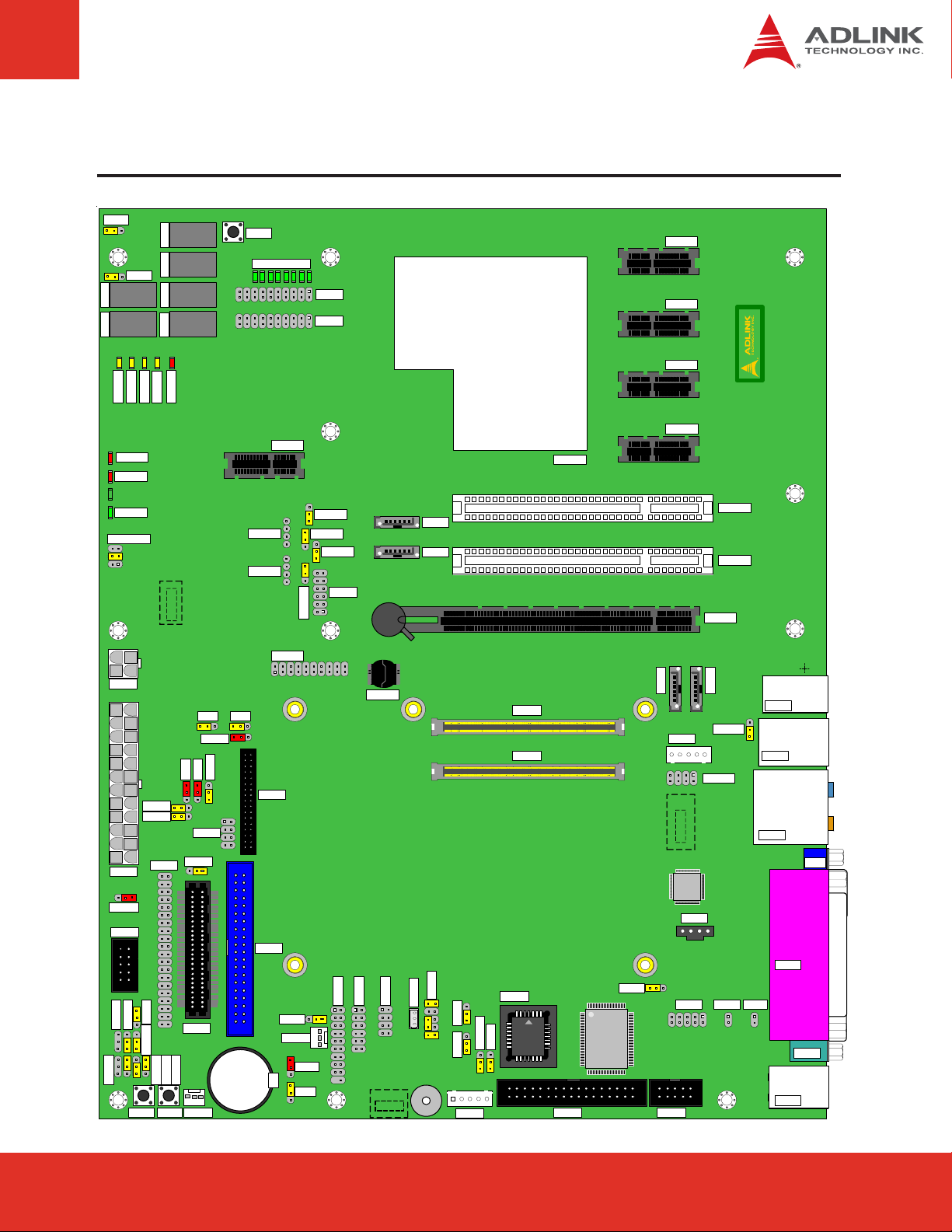

3 Component Location................................................................................................9

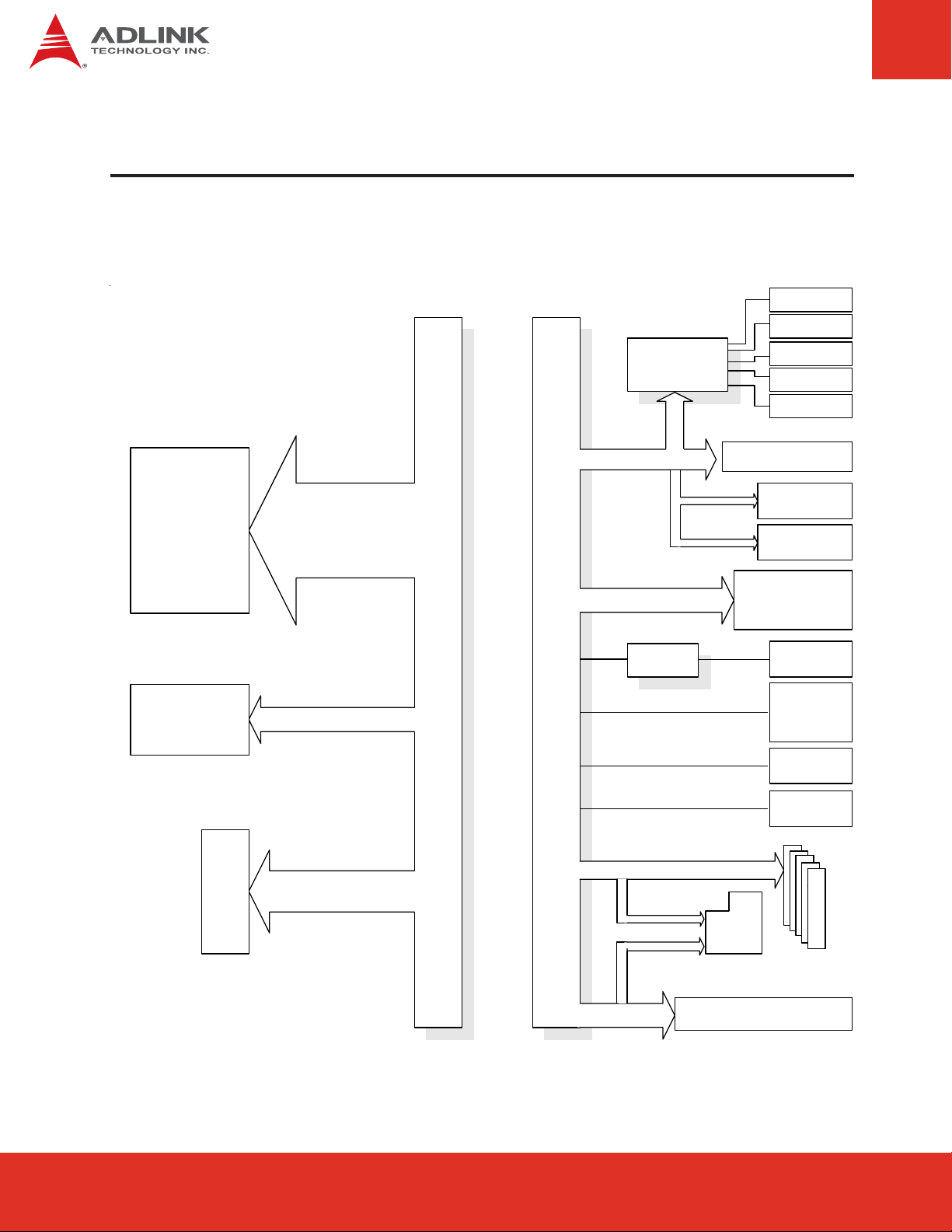

4 Function Block Diagram ........................................................................................10

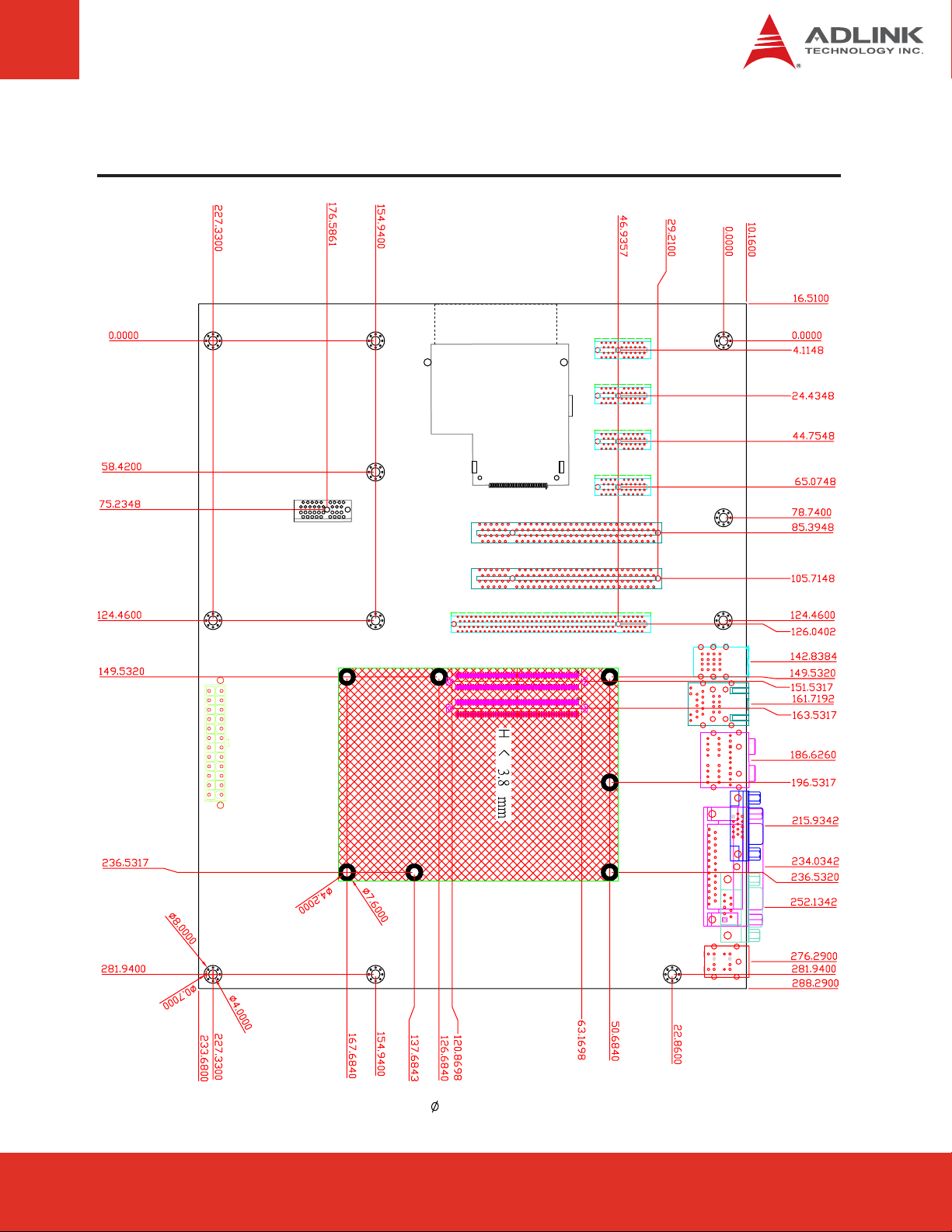

5 Mechanical Dimensions......................................................................................... 11

6 Connectors and Pin-outs.......................................................................................12

6.1 Carrier Board Signals..........................................................................................................12

6.2 Connector and Pinout Compatibility....................................................................................12

6.3 Carrier Board Design ..........................................................................................................12

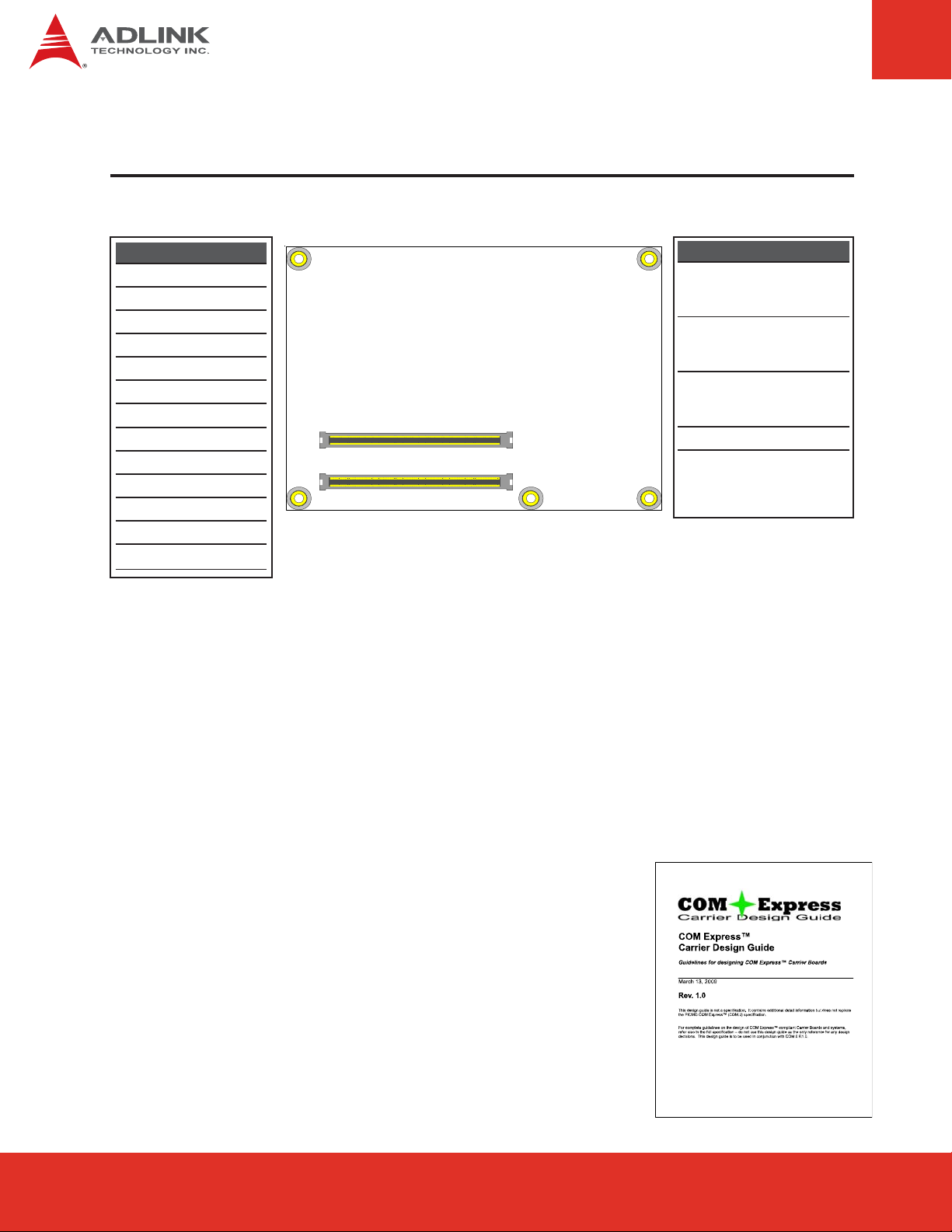

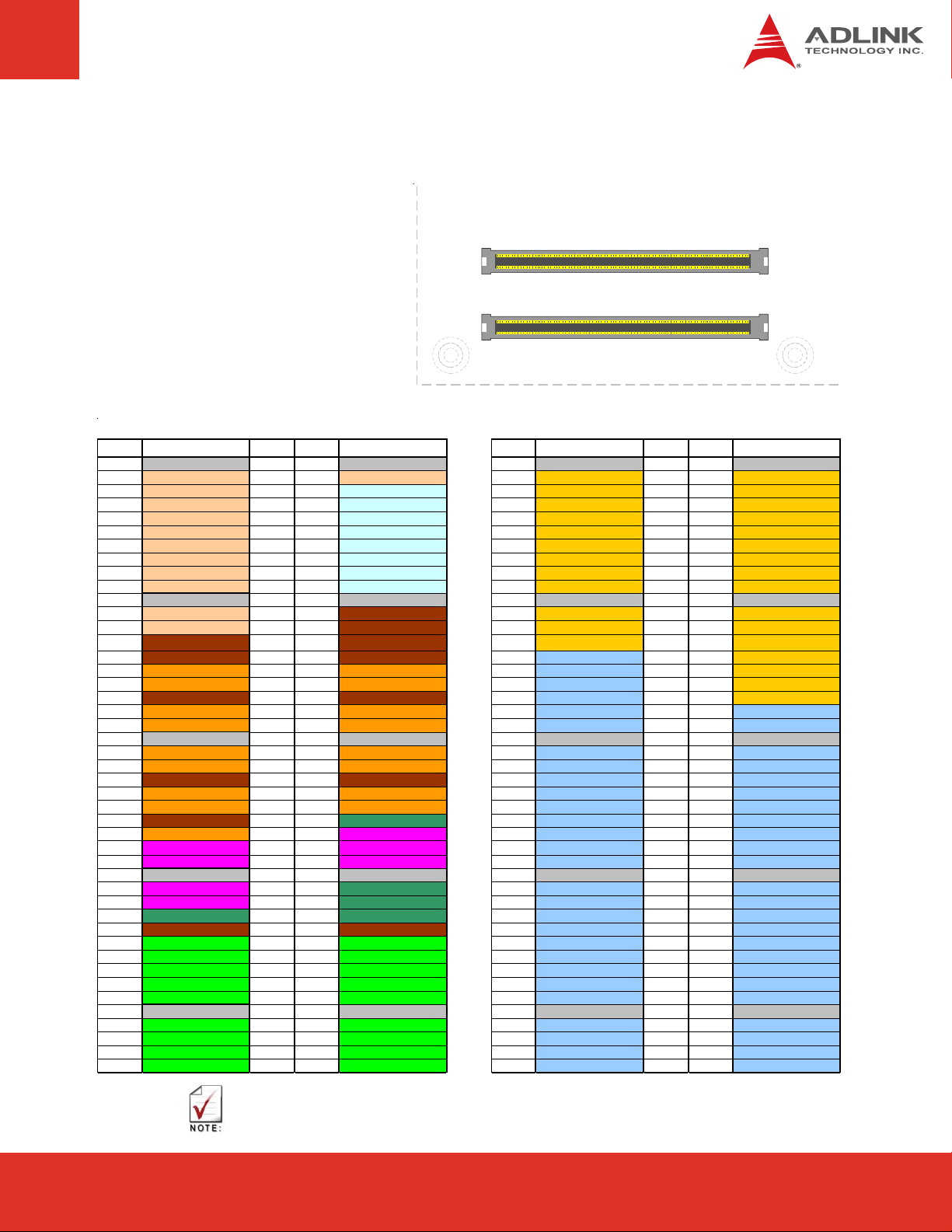

6.4 COM Express Board-to-Board Connectors.........................................................................13

6.5 PCI Express and PCI Express Graphic (PEG) Slots...........................................................15

6.6 PCI Slots.............................................................................................................................18

6.7 LPC Debug .........................................................................................................................19

6.8 I2C and SMB Bus (for user access)...................................................................................20

6.9 USB and LAN......................................................................................................................22

6.10 Audio...................................................................................................................................23

6.11 VGA, LVDS ......................................................................................................................... 24

6.12 LVDS Jumper Settings........................................................................................................25

6.13 Keyboard & Mouse .............................................................................................................26

6.14 Serial and IrDA Ports ..........................................................................................................26

6.15 Parallel Port ........................................................................................................................27

6.16 Storage: SATA, PATA, FDD, CF..........................................................................................27

6.18 Power Connectors ..............................................................................................................30

Page 3Express-BASE User’s Manual

Page 4

6.19 Power Jumper Settings.......................................................................................................32

6.17 Other Connectors................................................................................................................33

6.20 Other Jumper Settings........................................................................................................35

7 Secondary BIOS......................................................................................................37

7.1 FWH Secondary BIOS - COM.0 Rev. 1.0 ...........................................................................37

7.2 SPI Secondary BIOS - COM.0 Rev. 2.0..............................................................................38

8 Switches, POST, LEDs & Power ............................................................................39

8.1 On/Off and RESET .............................................................................................................39

8.2 POST & Module Type Display.............................................................................................39

8.3 Indicator LEDs ....................................................................................................................40

8.4 Digital I/O LEDs ..................................................................................................................40

8.5 ATX Power Connectors.......................................................................................................41

8.6 AT Power Mode ..................................................................................................................42

Important Safety Instructions .....................................................................................43

Getting Service.............................................................................................................44

Express-BASE User’s ManualPage 4

Page 5

Preface

Copyright 2006-2011 ADLINK Technology, Inc.

This document contains proprietary information protected by copyright. All rights are reserved. No

part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior notice in order to improve

reliability, design, and function and does not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential

damages arising out of the use or inability to use the product or documentation, even if advised

of the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global environmental preservation

through compliance with the European Union's Restriction of Hazardous Substances (RoHS)

directive and Waste Electrical and Electronic Equipment (WEEE) directive. Environmental

protection is a top priority for ADLINK. We have enforced measures to ensure that our products,

manufacturing processes, components, and raw materials have as little impact on the

environment as possible. When products are at their end of life, our customers are encouraged to

dispose of them in accordance with the product disposal and/or recovery programs prescribed by

their nation or company.

Trademarks

COM Express™ and PICMG® are registered trademarks of the PCI Industrial Computer

Manufacturers Group.

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks of their respective companies.

Page 5Express-BASE User’s Manual

Page 6

Conventions

Take note of the following conventions used throughout this manual to make sure that users

perform certain tasks and instructions properly.

Additional information, aids, and tips that help users perform tasks.

Information to prevent minor physical injury, component damage, data loss,

and/or program corruption when trying to complete a task.

Information to prevent serious physical injury, component damage, data

loss, and/or program corruption when trying to complete a specific task.

Express-BASE User’s ManualPage 6

Page 7

1 Introduction

The COM Express approach of custom carrier combined with off the shelf system cores is an

excellent solution when you need to customize but lack the time or quantity for a complete

redesign. It fits most system integration projects with production volumes from 500 to 10,000 pcs

per year. The COM Express concept has a great many advantages over full custom designs, it

reduces engineering complexity, lowers the threshold for total project quantity and last but not

least brings your product to the market in no time. The average time to design a carrier board is

less than half the time of a full custom OEM board.

Express-BASE is a standard ATX size carrier board. Together with the COM Express module of

your choice and off the shelf add-on cards you can quickly emulate the functionality of your

desired end product for software development and hardware verification.

To build a functional prototype of your target system you will need:

f COM Express module

f Express-BASE carrier board

f PCI Express or PCI add on cards

f PATA / SATA storage or Flash disk solution

The Express-BASE is compatible with Basic and Compact form factor Type 2 pinout COM

Express modules and accommodates up to five PCI Express x1 slots, one PCI Express Graphics

x16 slot, one ExpressCard slot and two PCI slots.

The Express-BASE is based on the PICMG COM Express™ (COM.0 Rev. 2.0) specification and

is compatible with the PICMG COM Express™ Carrier Design Guide (see 6.3 Carrier Board

Design on page 12).

Page 7Express-BASE User’s Manual

Page 8

2 Special Features

2.1 Primary LPC based Super I/O

COM Express modules do not have a Super I/O chip onboard as this is considered legacy.

Therefore, a Super I/O is placed on the carrier board as an optional item. The Express-BASE

uses a Winbond W83627HG-AW that supports FDD, LPT, COM and PS/2 Keyboard and Mouse.

2.2 Secondary BIOS

The Express-BASE using firmware hub (FWH) for COM.0 Rev. 1.0 modules and Serial Peripheral

Interface (SPI) for COM.0 Rev. 2.0 modules. Selection of active BIOS can be made by jumper

setting.

2.3 Integrated Debug Port with Single Step Execution

In addition to a two-digit POST code display, the board also provides a four-digit address display.

By jumper selection the board can be switched into single step BIOS execution mode. Steps are

executed using a manually operated onboard mini switch.

2.4 Onboard Audio

The Express-BASE has a Realtek ALC888 audio codec onboard. Audio I/O is provided by a sixjack connector.

2.5 Information LEDs

General information is obtained through signaling LEDs for HDD, Power and Watchdog status.

Additionally the Express-BASE gives information about module types being plug into the board.

See 8.2 POST & Module Type Display on page 40 and 8.3 Indicator LEDs on page 41.

Express-BASE User’s ManualPage 8

Page 9

3 Component Location

JP1

LED14LED13

LED15

LED21

LED2

LED20

CNY6

CN42

CN41

JPY10

CNY9

JPY14

JPA6

JPA2

88

LED16

LED17

LED18

JPZ2

JPZ1

CNY4

JP6

JPY13

JPY12

JPA5

SW3 SW1

SW2

LEDX8 – X1

CNY2

CN30

CN31

CNY5

PCIE6

CN32

CNY3

PCIE3

JPY4

JPY5

JPY2

CNY1

JPY3

UZ3

CN11

CN12

CN21

CN20

88 88

LED10 LED11 LED12

LED9

LED19

CN40

JP4

JP3

JPZ3

JP8

JP7

JPY9

CNY8

JPZ4

PCIE5

PCIE4

PCIE2

PCIE1

CN17

CN13

CN16

ALC

CN15

883

PCIA1

PCIE7

CN9

JPY11

CNZ1

PCI2

CN6

CN7

CN2

51-46604-0D20

Express-BASE

CN1

CN35

CN5

CNY7

CN29

CNZ2

JPA4

JPA3

CN37

JPY8

CN33

JPY1

JP5

CN25

CN28

CN26

CN43

CN24

U14

JPZ5

JP2

JPY7 JPY6

CN19 CN18

JPA1

CN8CN10CN14

Winbond

W83627HG-AW

CN3

CN4

Page 9Express-BASE User’s Manual

Page 10

4 Function Block Diagram

W83627HG

Primary

Super I/O

LPT1

COM1

COM2

KB/MS

FDD

PCI Express x16

onboard slot

Onboard IDE

Connector

PCI

2

PCI Express

Graphics x16

PATA

32-bit PCI

CD

AB

LPC

SATA

ALC888

Codec

PCI Express

Debug Header

SATA headers

Express

Card

Secondary

BIOS

POST Code

Display

4 onboard

Audio on

Rear I/O

Gigabit

Ethernet

Rear I/O

CRT VGA

Rear I/O

LVDS

headers

P

P

P

C

P

C

P

C

I

C

I

C

I

E

I

E

I

E

1

E

1

E

1

1

5

USB

6x USB on Rear I/O

1x USB on header

Express-BASE User’s ManualPage 10

Page 11

5 Mechanical Dimensions

All tolerances ± 0.05 mm

Other tolerances ± 0.2 mm

Page 11Express-BASE User’s Manual

Page 12

6 Connectors and Pin-outs

6.1 Carrier Board Signals

AB Connector

1 Gigabit Ethernet port

LPC interface

4 Serial ATA channels

High Definition Audio

8 USB 2.0 ports

6 PCI Express Lanes x1

Dual 24-bit LVDS channels

Analog VGA

TV-out ports (SDTV/HDTV)

8 GPIO pins

SMB and I2C bus

+12V primary power input

+5V standby and 3V RTC

C D

A B

6.2 Connector and Pinout Compatibility

Connectors positions and pinouts comply with pinout and signal descriptions in the “PICMG®

COM.0 - COM Express Module Base specification, Revision 2”. This document includes:

description of pinouts, signal descriptions and mechanical characteristics of the COM Express

specification. The Express-BASE is compatible with COM Express modules in Basic and

Compact form factor, Type 2 pinout, COM.0 Rev. 1.0 and Rev. 2.0 .

CD Connector

Parallel ATA, IDE port

alternate definition assigns this to

2 additional Gigabit Ethernet ports

32-bit PCI v2.3 bus

alternate definition assigns this to

10 additional PCI Express x1 lanes

PCI Express x16 for Graphics

these pins can also be assigned to

two SDVO extensions (multiplexed)

+12V primary power input

6.3 Carrier Board Design

The Express-BASE closely follows the PICMG COM Express™

Carrier Design Guide (CDG). Please note that the CDG gives

design advice, and contains unverified reference schematics. The

Express-BASE design and schematics are fully verified, and we

recommend that you follow them as a reference for your carrier

board design.

The CDG and Express-BASE Rev. D2 Schematics and

Mechanical files can be downloaded from the ADLINK

Express-BASE product webpage:

http://www.adlinktech.com/PD/web/PD_detail.php?cKind=&pid=705

Express-BASE User’s ManualPage 12

Page 13

6.4 COM Express Board-to-Board Connectors

R

Signals and Pinout for:

Basic form factor, Type 2.

D1

C1

D110

C D

C110

B1

A1

B110

A110

A B

Row ARow BRow CRow D

Pin No. Pin Na me Pin N o. Pin Name Pi n No. Pin Name Pin No. Pin Name

A1 GND (FIXED) B1 GND (FIXED) C1 GND FIXED) D1 GND FIXED)

A2 GBE0_MDI3- B2 GBE0_ACT# C2 IDE_D7 D2 IDE_D5

A3 GBE0_MDI3+ B3 LPC_FRAME# C3 IDE_D6 D3 IDE_D10

A4 GBE0_LINK100# B4 LPC_AD0 C4 IDE_D3 D4 IDE_D11

A5 GBE0_LINK1000# B5 LPC_AD1 C5 IDE_D15 D5 IDE_D12

A6 GBE0_MDI2- B6 LPC_AD2 C6 IDE_D8 D6 IDE_D4

A7 GBE0_MDI2+ B7 LPC_AD3 C7 IDE_D9 D7 IDE_D0

A8 GBE0_LINK# B8 LPC_DRQ0# C8 IDE_D2 D8 IDE_REQ

A9 GBE0_MDI1- B9 LPC_DRQ1# C9 IDE_D13 D9 IDE_IOW#

A10 GBE0_MDI1+ B10 LPC_CLK C10 IDE_D1 D10 IDE_ACK#

A11 GND (FIXED) B11 GND (FIXED) C11 GND (FIXED) D11 GND (FIXED)

A12 GBE0_MDI0- B12 PWRBTN# C12 IDE_D14 D12 IDE_IRQ

A13 GBE0_MDI0+ B13 SMB_CK C13 IDE_IORDY D13 IDE_A0

A14 GBE0_CTREF B14 SMB_DAT C14 IDE_IOR# D14 IDE_A1

A15 SUS_S3# B15 SMB_ALERT# C15 PCI_PME# D15 IDE_A2

A16 SATA0_TX+ B16 SATA1_TX+ C16 PCI_GNT2# D16 IDE_CS1#

A17 SATA0_TX- B17 SATA1_TX- C17 PCI_REQ2# D17 IDE_CS3#

A18 SUS_S4# B18 SUS_STAT# C18 PCI_GNT1# D18 IDE_RESET#

A19 SATA0_RX+ B19 SATA1_RX+ C19 PCI_REQ1# D19 PCI_GNT3#

A20 SATA0_RX- B20 SATA1_RX- C20 PCI_GNT0# D20 PCI_REQ3#

A21 GND (FIXED) B21 GND (FIXED) C21 GND (FIXED) D21 GND (FIXED)

A22 SATA2_TX+ B22 SATA3_TX+ C22 PCI_REQ0# D22 PCI_AD1

A23 SATA2_TX- B23 SATA3_TX- C23 PCI_RESET# D23 PCI_AD3

A24 SUS_S5# B24 PWR_OK C24 PCI_AD0 D24 PCI_AD5

A25 SATA2_RX+ B25 SATA3_RX+ C25 PCI_AD2 D25 PCI_AD7

A26 SATA2_RX- B26 SATA3_RX- C26 PCI_AD4 D26 PCI_C/BE0#

A27 BATLOW# B27 WDT C27 PCI_AD6 D27 PCI_AD9

A28 (S)ATA_ACT# B28 AC/HDA_SDIN2

A29 AC/HDA_SYNC B29 AC/HDA_SDIN1

A30 AC/HDA_RST# B30 AC/HDA_SDIN0

A31 GND (FIXED) B31 GND (FIXED) C31 GND (FIXED) D31 GND (FIXED)

A32 AC/HDA_BITCLK

A33 AC/HDA_SDOUT

A34 BIOS_DIS0#

A35 THRMTRIP# B35 THRM# C35 PCI_LOCK# D35 PCI_TRDY#

A36 USB6- B36 USB7- C36 PCI_DEVSEL# D36 PCI_FRAME#

A37 USB6+ B37 USB7+ C37 PCI_IRDY# D37 PCI_AD16

A38 USB_6_7_OC# B38 USB_4_5_OC# C38 PCI_C/BE2# D38 PCI_AD18

A39 USB4- B39 USB5- C39 PCI_AD17 D39 PCI_AD20

A40 USB4+ B40 USB5+ C40 PCI_AD19 D40 PCI_AD22

A41 GND (FIXED) B41 GND (FIXED) C41 GND (FIXED) D41 GND (FIXED)

A42 USB2- B42 USB3- C42 PCI_AD21 D42 PCI_AD24

A43 USB2+ B43 USB3+ C43 PCI_AD23 D43 PCI_AD26

A44 USB_2_3_OC# B44 USB_0_1_OC# C44 PCI_C/BE3# D44 PCI_AD28

A45 USB0- B45 USB1- C45 PCI_AD25 D45 PCI_AD30

B32 SPK

B33 I2C_CK C33 PCI_C/BE1# D33 PCI_SERR#

B34 I2C_DAT C34 PCI_PERR# D34 PCI_STOP#

C28 PCI_AD8 D28 PCI_AD11

C29 PCI_AD10 D29 PCI_AD13

C30 PCI_AD12 D30 PCI_AD15

C32 PCI_AD14 D32 PCI_PAR

Pin definitions that are new for COM.0 Rev. 2.0 are highlighted in bold.

Page 13Express-BASE User’s Manual

Page 14

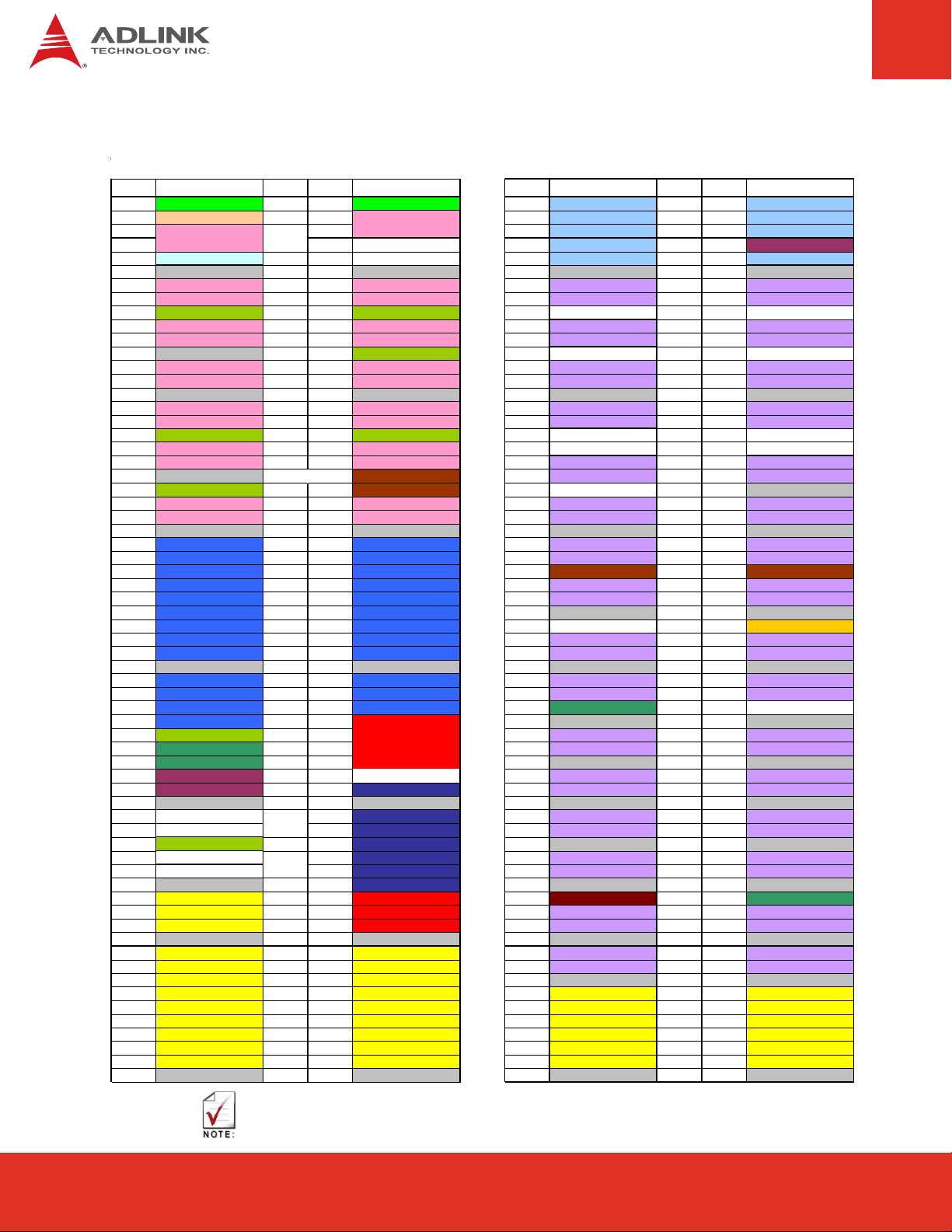

COM Express Board-to-Board Connectors (cont'd):

Row ARow BRow CRow D

Pin No. Pin Name Pin No. Pin Name Pin No. Pin Name Pin No. Pin Name

A46 USB0+ B46 USB1+ C46 PCI_AD27 D46 PCI_IRQC#

A47 VCC_RTC B47 EXCD1_PERST# C47 PCI_AD29 D47 PCI_IRQD#

A48 EXCD0_PERST# B48 EXCD1_CPPE# C48 PCI_AD31 D48 PCI_CLKRUN#

A49 EXCD0_CPPE# B49 SYS_RESET# C49 PCI_IRQA# D49 PCI_M66EN

A50 LPC_SERIRQ B50 CB_RESET# C50 PCI_IRQB# D50 PCI_CLK

A51 GND (FIXED) B51 GND (FIXED) C51 GND (FIXED) D51 GND (FIXED)

A52 PCIE_TX5+ B52 PCIE_RX5+ C52 PEG_RX0+ D52 PEG_TX0+

A53 PCIE_TX5- B53 PCIE_RX5- C53 PEG_RX0- D53 PEG_TX0A54 GPI0 B54 GPO1 C54 TYPE0# D54 PEG_LANE_RV#

A55 PCIE_TX4+ B55 PCIE_RX4+ C55 PEG_RX1+ D55 PEG_TX1+

A56 PCIE_TX4- B56 PCIE_RX4- C56 PEG_RX1- D56 PEG_TX1A57 GND B57 GPO2 C57 TYPE1# D57 TYPE2#

A58 PCIE_TX3+ B58 PCIE_RX3+ C58 PEG_RX2+ D58 PEG_TX2+

A59 PCIE_TX3- B59 PCIE_RX3- C59 PEG_RX2- D59 PEG_TX2A60 GND (FIXED) B60 GND (FIXED) C60 GND (FIXED) D60 GND (FIXED)

A61 PCIE_TX2+ B61 PCIE_RX2+ C61 PEG_RX3+ D61 PEG_TX3+

A62 PCIE_TX2- B62 PCIE_RX2- C62 PEG_RX3- D62 PEG_TX3A63 GPI1 B63 GPO3 C63 RSVD D63 RSVD

A64 PCIE_TX1+ B64 PCIE_RX1+ C64 RSVD D64 RSVD

A65 PCIE_TX1- B65 PCIE_RX1- C65 PEG_RX4+ D65 PEG_TX4+

A66 GND B66 WAKE0# C66 PEG_RX4- D66 PEG_TX4A67 GPI2 B67 WAKE1# C67 RSVD D67 GND

A68 PCIE_TX0+ B68 PCIE_RX0+ C68 PEG_RX5+ D68 PEG_TX5+

A69 PCIE_TX0- B69 PCIE_RX0- C69 PEG_RX5- D69 PEG_TX5A70 GND (FIXED) B70 GND (FIXED) C70 GND (FIXED) D70 GND (FIXED)

A71 LVDS_A0+ B71 LVDS_B0+ C71 PEG_RX6+ D71 PEG_TX6+

A72 LVDS_A0- B72 LVDS_B0- C72 PEG_RX6- D72 PEG_TX6A73 LVDS_A1+ B73 LVDS_B1+ C73 SDVO_DATA D73 SDVO_CLK

A74 LVDS_A1- B74 LVDS_B1- C74 PEG_RX7+ D74 PEG_TX7+

A75 LVDS_A2+ B75 LVDS_B2+ C75 PEG_RX7- D75 PEG_TX7A76 LVDS_A2- B76 LVDS_B2- C76 GND D76 GND

A77 LVDS_VDD_EN B77 LVDS_B3+ C77 RSVD D77 IDE_CBLID#

A78 LVDS_A3+ B78 LVDS_B3- C78 PEG_RX8+ D78 PEG_TX8+

A79 LVDS_A3- B79 LVDS_BKLT_EN C79 PEG_RX8- D79 PEG_TX8A80 GND (FIXED) B80 GND (FIXED) C80 GND (FIXED) D80 GND (FIXED)

A81 LVDS_A_CK+ B81 LVDS_B_CK+ C81 PEG_RX9+ D81 PEG_TX9+

A82 LVDS_A_CK- B82 LVDS_B_CK- C82 PEG_RX9- D82 PEG_TX9A83 LVDS_I2C_CK B83 LVDS_BKLT_CTRL C83 RSVD D83 RSVD

A84 LVDS_I2C_DAT B84 VCC_5V_SBY C84 GND D84 GND

A85 GPI3 B85 VCC_5V_SBY C85PEG_RX10+ D85PEG_TX10+

A86 KBD_RST# B86 VCC_5V_SBY C86PEG_RX10- D86PEG_TX10A87 KBD_A20GATE B87 VCC_5V_SBY C87 GND D87 GND

A88 PCIE_CLK_REF+

A89 PCIE_CLK_REF- B89 VGA_RED C89PEG_RX11- D89PEG_TX11A90 GND (FIXED) B90 GND (FIXED) C90 GND (FIXED) D90 GND (FIXED)

A91 SPI_POWER

A92 SPI_MISO

A93 GPO0 B93 VGA_HSYNC C93 GND D93 GND

A94 SPI_CLK

A95 SPI_MOSI

A96 GND B96 VGA_I2C_DAT C96 GND D96 GND

A97 TYPE10# B97 SPI_CS#

A98 RSVD B98 RSVD

A99 RSVD B99 RSVD

A100 GND (FIXED) B100 GND (FIXED) C100 GND (FIXED) D100 GND (FIXED)

A101 RSVD B101 RSVD

A102 RSVD B102 RSVD

A103 RSVD B103 RSVD

A104 VCC_12V B104 VCC_12V C104 VCC_12V D104 VCC_12V

A105 VCC_12V B105 VCC_12V C105 VCC_12V D105 VCC_12V

A106 VCC_12V B106 VCC_12V C106 VCC_12V D106 VCC_12V

A107 VCC_12V B107 VCC_12V C107 VCC_12V D107 VCC_12V

A108 VCC_12V B108 VCC_12V C108 VCC_12V D108 VCC_12V

A109 VCC_12V B109 VCC_12V C109 VCC_12V D109 VCC_12V

A110 GND (FIXED) B110 GND (FIXED) C110 GND (FIXED) D110 GND (FIXED)

B88 BIOS_DIS1#

B91 VGA_GRN C91PEG_RX12+ D91PEG_TX12+

B92 VGA_BLU C92PEG_RX12- D92PEG_TX12-

B94 VGA_VSYNC C94PEG_RX13+ D94PEG_TX13+

B95 VGA_I2C_CK C95PEG_RX13- D95PEG_TX13-

C88PEG_RX11+ D88PEG_TX11+

C97 RSVD D97 PEG_ENABLE#

C98PEG_RX14+ D98PEG_TX14+

C99PEG_RX14- D99PEG_TX14-

C101 PEG_RX15+ D101 PEG_TX15+

C102 PEG_RX15- D102 PEG_TX15C103 GND D103 GND

Pin definitions that are new for COM.0 Rev. 2.0 are highlighted in bold.

Express-BASE User’s ManualPage 14

Page 15

6.5 PCI Express and PCI Express Graphic (PEG) Slots

PCI Express x1:

PCIE1

PCIE2

PCIE4

PCIE5

PCIE6

B1

B11

B12

B18

A1

A11

A12

A18

Pin Signal Pin Signal

B1 + 12V A1 NC

B2 + 12V A2 + 12V

B3 NC A3 + 12V

B4 GND A4 GND

B5 SMB_CK A5 TCK

B6 SMB_DAT A6 TDI

B7 GND A7 NC

B8 + 3.3V A8 TMS

B9 TRST# A9 + 3.3V

B10 +3.3VSB A10 + 3.3V

B11 WAKE# A11 PERST#

B12 NC A12 GND

B13 GND A13 REFCLK+

B14 PETp0 A14 REFCLKB15 PETn0 A15 GND

B16 GND A16 PERp0

B17 NC A17 PERn0

B18 GND A18 GND

CN44: ExpressCard (PCIE3, USB7)

Pin Signal Pin Signal

1 GND 14 +3.3V

2 USBD- 15 +3.3V

3 USBD+ 16 CLKREQ#

4 CPUSB# 17 CPPE#

5 RESERVED 18 REFCLK6 RESERVED 19 REFCLK+

7 SMB_CK 20 GND

8 SMB_DAT 21 PERn0

9 +1.5V 22 PERp0

10 +1.5V 23 GND

11 WAKE# 24 PETn0

12 +3.3VSB 25 PETp0

13 PERST# 26 GND

Page 15Express-BASE User’s Manual

Page 16

A1A11A12A82

B1B11B12B82

PCIE7: PCI Express x16 mode

See the JP6 jumper description for PCI Express x16 mode and SDVO mode settings on p. 35.

Pin Signal Pin Signal

B1 + 12V A1 NC

B2 + 12V A2 + 12V

B3 NC A3 + 12V

B4 GND A4 GND

B5 SMB_CK A5 TCK

B6 SMB_DAT A6 TDI

B7 GND A7 NC

B8 + 3.3V A8 TMS

B9 TRST# A9 + 3.3V

B10 +3.3VSB A10 + 3.3V

B11 WAKE# A11 PERST#

B12 NC A12 GND

B13 GND A13 REFCLK+

B14 PETp0 A14 REFCLKB15 PETn0 A15 GND

B16 GND A16 PERp0

B17 RSVD A17 PERn0

B18 GND A18 GND

B19 PETp1 A19 NC

B20 PETn1 A20 GND

B21 GND A21 PERp1

B22 GND A22 PERn1

B23 PETp2 A23 GND

B24 PETn2 A24 GND

B25 GND A25 PERp2

B26 GND A26 PERn2

B27 PETp3 A27 GND

B28 PETn3 A28 GND

B29 GND A29 PERp3

B30 NC A30 PERn3

B31 RSVD A31 GND

B32 GND A32 NC

B33 PETp4 A33 NC

B34 PETn4 A34 GND

B35 GND A35 PERp4

B36 GND A36 PERn4

B37 PETp5 A37 GND

B38 PETn5 A38 GND

B39 GND A39 PERp5

B40 GND A40 PERn5

B41 PETp6 A41 GND

Pin Signal Pin Signal

B42 PETn6 A42 GND

B43 GND A43 PERp6

B44 GND A44 PERn6

B45 PETp7 A45 GND

B46 PETn7 A46 GND

B47 GND A47 PERp7

B48 NC A48 PERn7

B49 GND A49 GND

B50 PETp8 A50 NC

B51 PETn8 A51 GND

B52 GND A52 PERp8

B53 GND A53 PERn8

B54 PETp9 A54 GND

B55 PETn9 A55 GND

B56 GND A56 PERp9

B57 GND A57 PERn9

B58 PETp10 A58 GND

B59 PETn10 A59 GND

B60 GND A60 PERp10

B61 GND A61 PERn10

B62 PETp11 A62 GND

B63 PETn11 A63 GND

B64 GND A64 PERp11

B65 GND A65 PERn11

B66 PETp12 A66 GND

B67 PETn12 A67 GND

B68 GND A68 PERp12

B69 GND A69 PERn12

B70 PETp13 A70 GND

B71 PETn13 A71 GND

B72 GND A72 PERp13

B73 GND A73 PERn13

B74 PETp14 A74 GND

B75 PETn14 A75 GND

B76 GND A76 PERp14

B77 GND A77 PERn14

B78 PETp15 A78 GND

B79 PETn15 A79 GND

B80 GND A80 PERp15

B81 NC A81 PERn15

B82 NC A82 GND

Express-BASE User’s ManualPage 16

Page 17

PCIE7: SDVO mode

A1A11A12A82

B1B11B12B82

See the JP6 jumper description for PCI Express x16 mode and SDVO mode settings on p. 35.

Pin Signal Pin Signal

B1 + 12V A1 NC

B2 + 12V A2 + 12V

B3 NC A3 + 12V

B4 GND A4 GND

B5 SMB_CK A5 TCK

B6 SMB_DAT A6 TDI

B7 GND A7 NC

B8 + 3.3V A8 TMS

B9 TRST# A9 + 3.3V

B10 +3.3VSB A10 + 3.3V

B11 WAKE# A11 PERST#

B12 NC A12 GND

B13 GND A13 REFCLK+

B14 SDVOB_RED+ A14 REFCLKB15 SDVOB_RED- A15 GND

B16 GND A16 SDVO_TVCLKIN+

B17 SDVO_CLK A17 SDVO_TVCLKINB18 GND A18 GND

B19 SDVOB_GRN+ A19 NC

B20 SDVOB_GRN- A20 GND

B21 GND A21 SDVOB_INT+

B22 GND A22 SDVOB_INTB23 SDVOB_BLU+ A23 GND

B24 SDVOB_BLU- A24 GND

B25 GND A25 SDVO_FLDSTALL+

B26 GND A26 SDVO_FLDSTALLB27 SDVOB_CK+ A27 GND

B28 SDVOB_CK- A28 GND

B29 GND A29 RSVD

B30 NC A30 RSVD

B31 SDVO_DAT A31 GND

B32 GND A32 NC

B33 SDVOC_RED+ A33 NC

B34 SDVOC_RED- A34 GND

B35 GND A35 RSVD

B36 GND A36 RSVD

B37 SDVOC_GRN+ A37 GND

B38 SDVOC_GRN- A38 GND

B39 GND A39 RSVD

B40 GND A40 RSVD

B41 SDVOC_BLU+ A41 GND

Pin Signal Pin Signal

B42 SDVOC_BLU- A42 GND

B43 GND A43 RSVD

B44 GND A44 RSVD

B45 SDVOC_CK+ A45 GND

B46 SDVOC_CK- A46 GND

B47 GND A47 RSVD

B48 NC A48 RSVD

B49 GND A49 GND

B50 RSVD A50 NC

B51 RSVD A51 GND

B52 GND A52 RSVD

B53 GND A53 RSVD

B54 RSVD A54 GND

B55 RSVD A55 GND

B56 GND A56 RSVD

B57 GND A57 RSVD

B58 RSVD A58 GND

B59 RSVD A59 GND

B60 GND A60 RSVD

B61 GND A61 RSVD

B62 RSVD A62 GND

B63 RSVD A63 GND

B64 GND A64 RSVD

B65 GND A65 RSVD

B66 RSVD A66 GND

B67 RSVD A67 GND

B68 GND A68 RSVD

B69 GND A69 RSVD

B70 RSVD A70 GND

B71 RSVD A71 GND

B72 GND A72 RSVD

B73 GND A73 RSVD

B74 RSVD A74 GND

B75 RSVD A75 GND

B76 GND A76 RSVD

B77 GND A77 RSVD

B78 RSVD A78 GND

B79 RSVD A79 GND

B80 GND A80 RSVD

B81 NC A81 RSVD

B82 NC A82 GND

Page 17Express-BASE User’s Manual

Page 18

6.6 PCI Slots

PCI interrupts

OnboardDevice Pin INTA# Pin INTB# Pin INTC# Pin INTD# IDSEL

PCIA1 X1_INTA# X1_INTB# X1_INTC# X1_INTD# AD20

PCI2 X1_INTB# X1_INTC# X1_INTD# X1_INTA# AD21

A1

PCIA1, PCI2: 32-bit PCI slot

B1

A Signal B Signal

1 TRST_L 1 -12V

2 +12V 2 TCK

3 TMS 3 Ground

4 TDI 4 TDO

5 +5V 5 +5V

6 INTA_L 6 +5V

7 INTC_L 7 INTB_L

8 +5V 8 INTD_L

9 Reserved 9 PRSNT1_L

10 +5V 10 Reserved

11 Reserved 11 PRSNT2_L

12 Ground 12 Ground

13 Ground 13 Ground

14 Reserved 14 Reserved

15 RST_L 15 Ground

16 +5V 16 CLK

17 GNT_L 17 Ground

18 Ground 18 REQ_L

19 Reserved 19 +5V

20 AD[30] 20 AD[31]

21 +3.3V 21 AD[29]

22 AD[28] 22 Ground

23 AD[26] 23 AD[27]

24 Ground 24 AD[25]

25 AD[24] 25 +3.3V

26 IDSEL 26 C/BE[3]_L

27 +3.3V 27 AD[23]

28 AD[22] 28 Ground

29 AD[20] 29 AD[21]

30 Ground 30 AD[19]

31 AD[18] 31 +3.3V

A62

B62

A Signal B Signal

32 AD[16] 32 AD[17]

33 +3.3V 33 C/BE[2]_L

34 FRAME_L 34 Ground

35 Ground 35 IRDY_L

36 TRDY_L 36 +3.3V

37 Ground 37 DEVSEL_L

38 STOP_L 38 Ground

39 +3.3V 39 LOCK_L

40 Reserved 40 PERR_L

41 Reserved 41 +3.3V

42 Ground 42 SERR_L

43 PAR 43 +3.3V

44 AD[15] 44 C/BE[1]_L

45 +3.3V 45 AD[14]

46 AD[13] 46 Ground

47 AD[11] 47 AD[12]

48 Ground 48 AD[10]

49 AD[09] 49 Ground

50 KEYWAY 50 KEYWAY

51 KEYWAY 51 KEYWAY

52 C/BE[0]_L 52 AD[08]

53 +3.3V 53 AD[07]

54 AD[06] 54 +3.3V

55 AD[04] 55 AD[05]

56 Ground 56 AD[03]

57 AD[02] 57 Ground

58 AD[00] 58 AD[01]

59 +5V 59 +5V

60 REQ64_L 60 ACK64_L

61 +5V 61 +5V

62 +5V 62 +5V

Express-BASE User’s ManualPage 18

Page 19

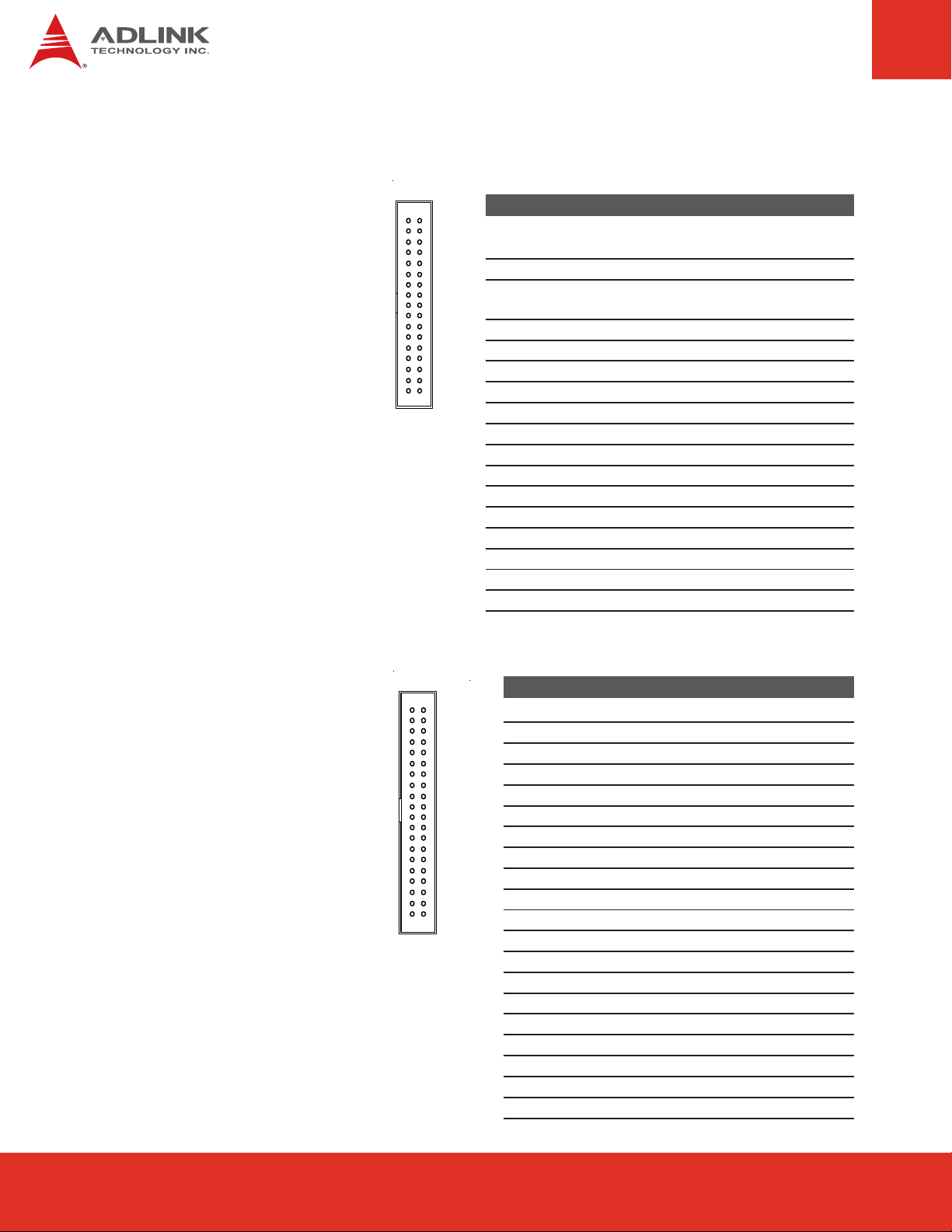

6.7 LPC Debug

CN32: LPC Debug header

12

19 20

CNY1: LPC Test Connector

(compatible with ADLINK

LPC Debug Card)

Pin Signal Pin Signal

1 LPC_CLK 2 GND

3 LPC_FRAME# 4 KEY

5 LPC_RST# 6 + 5V

7 LPC_AD3 8 LPC_AD2

9 + 3.3V 10 L_AD1

11 LPC_AD0 12 GND

13 SMB_CK 14 SMB_DAT

15 SPD_A1 (See JP3) 16 SPD_A0 (See JP4)

17 GND 18 LPC_SERIRQ

19 KBRST# 20 A20GATE#

Pin Signal Pin Signal

1 LPC_DRQ0# 2 LPC_AD0

3 LPC_DRQ1# 4 LPC_AD1

5 LPC_SERIRQ 6 LPC_AD2

7 LPC_FRAME# 8 LPC_AD3

9 LPC_RST# 10 GND

11 LPC_CLK 12 GND

External LPC EEPROM Address Selection

JP3 & JP4 configure the address of the external EEPROM connected to the LPC Debug header (CN32)

JP3: EEPROM Address A0 Selection

1

2

3

JP4: EEPROM Address A1 Selection

1

2

3

NOTE: <<<< indicates default setting

Jumper Status

1-2 High "1" <<<<

2-3 Low "0"

Jumper Status

1-2 High "1" <<<<

2-3 Low "0"

Page 19Express-BASE User’s Manual

Page 20

6.8 I2C and SMB Bus

(for user access)

CN31: I2C Bus

1

CN30: SMB Bus

1

Pin Signal

1 +5V

2 I2C_DAT

3 I2C_CK

4 GND

Pin Signal

1 +5V

2 SMB_DAT

3 SMB_CK

4 GND

I2C/SMBus Buffers

These buffers settings are for isolation of the I2C and SMBus - test feature only.

ON: I2C/SMBus passes through LTC4300A-2 Buffer

OFF: Bypass Buffer

JPY2: I2C BUFFER (data)

1

2

3

Jumper Status

1-2 ON

2-3 OFF <<<<

JPY3: I2C BUFFER (clock)

JPY4: SMBus BUFFER (data)

JPY5: SMBus BUFFER (clock)

1

2

3

1

2

3

1

2

3

Jumper Status

1-2 ON

2-3 OFF <<<<

Jumper Status

1-2 ON

2-3 OFF <<<<

Jumper Status

1-2 ON

2-3 OFF <<<<

NOTE: <<<< indicates default setting

Express-BASE User’s ManualPage 20

Page 21

I2C EEPROM Address Selection

JPY12 to JPY14 configure the address of the A0, A1 and A2 bits of the I2C EEPROM

JPY12: I2C EEPROM A0

JPY13: I2C EEPROM A1

JPY14: I2C EEPROM A2

1

2

3

1

2

3

1

2

3

Jumper Status

1-2 A0_HIGH "1"

2-3 A0_LOW "0" <<<<

Jumper Status

1-2 A1_HIGH "1"

2-3 A1_LOW "0" <<<<

Jumper Status

1-2 A2_HIGH "1"

2-3 A2_LOW "0" <<<<

NOTE: <<<< indicates default setting

Page 21Express-BASE User’s Manual

Page 22

6.9 USB and LAN

CN6: USB x4 Connector

CN7: RJ-45 Gbe LAN

+ USB

Pin Signal

1 +5V

2 USB3 USB+

4 Ground

Pin Signal

1 MDI[0]+

2 MDI[0]3 MDI[1]+

4 MDI[1]5 MDI[2]+

6 MDI[2]7 MDI[3]+

8 MDI[3]-

CN13: USB Header

1

Pin Signal

1 +5V

2 USB3 USB+

4 Ground

Pin Signal

1 +5V

2 USB3 USB+

4 Ground

Express-BASE User’s ManualPage 22

Page 23

6.10 Audio

CN2: Six-in-One

Audio Phone Jack

CN14: Audio Pin Header

9

1

CN8: SPDIF Input Header

1

Color Signal

BLUE Line-In

GREEN Line-Out

PINK MIC-In

ORANGE Center/Subwoofer

BLACK Rear Speaker Out

GRAY Side Speaker Out

Pin Signal Pin Signal

1 MIC-In-L 2 AGND

3 MIC-In-R 4 ACZ Detect

5 Line-In-R 6 MIC-In Detect

7 Front I/O Sense 8 Key

9 Line-In-L 10 Line-In Detect

Pin Signal Pin Signal

1 SPDIF-In 2 GND

CN10: SPDIF Output Header

1

Pin Signal Pin Signal

1 SPDIF-Out 2 GND

CN15: CD Audio-out Connector

CNZ1: AC’97 Pin Header

1

7

Pin Signal Pin Signal

1 GND 2 AC_SYNC

3 AC_SDOUT 4 AC_RST#

5 AC_BITCLK 6 GND

7 AC_SDIN0 8 NC

Pin Signal

1 LINR

2 AGND

1

3 AGND

4 LINL

Page 23Express-BASE User’s Manual

Page 24

6.11 VGA, LVDS

CN1: VGA

CNY5: LVDS Flat Panel Connector

Pin Signal Pin Signal

1 Red 2 Green

3 Blue 4 NC

5 GND 6 GND

7 GND 8 GND

9 NC 10 GND

11 DDC Power 12 DDC2B Data

13 HSYNC 14 Vsync

15 DDC2B clock

Pin Signal Pin Signal

1 LVDS_I2C_DAT 2 LVDS_I2C_CK

3 N.C 4 N.C

5 GND 6 LVDS_A07 LVDS_A0+ 8 LVDS_VDD_EN

9 LVDS_A1- 10 LVDS_A1+

11 LVDS_BKLT_EN 12 LVDS_A2+

13 LVDS_A2- 14 N.C

15 LVDS_A_CK- 16 LVDS_A_CK+

17 N.C 18 LVDS_A3+

19 LVDS_A3- 20 GND

21 LVDS_B0- 22 LVDS_B0+

23 GND 24 LVDS_B125 LVDS_B1+ 26 GND

27 LVDS_B2- 28 LVDS_B2+

29 GND 30 LVDS_B_CK+

31 LVDS_B_CK- 32 N.C

33 LVDS_B3+ 34 LVDS_B3-

CNY8: Backlight Control

See 6.12 LVDS Jumper Settings for Panel Power Voltage (JP8), Backlight Power Voltage

(JP7) and other LVDS jumper settings.

To avoid damage to the display panel, be sure to set the Panel Power Voltage (JP8) and

Backlight Power Voltage (JP7) to the correct values for your display.

12

Pin Signal Pin Signal

1 GND 2 Panel PWR

3 Backlight CTRL 4 GND

5 Backlight Enable 6 GND

7 NC 8 Backlight PWR

Express-BASE User’s ManualPage 24

Page 25

6.12 LVDS Jumper Settings

JP7: Backlight Power Voltage

Selects the Backlight Power voltage on CNY8

Backlight Control pin header (pin 8).

JP8: Panel Power Voltage

Selects the Panel Power voltage on CNY8

Backlight Control pin header (pin 2).

JPZ1: Brightness Control

Sets the Panel Brightness Control (CNY8 pin 3:

Backlight CTRL) to Voltage Level or PWM .

When set to Voltage Level, the Backlight CTRL

signal can be varied from 0~5V in 0.5V

increments.

JPZ2: Brightness PWM Source

Sets the Panel Brightness PWM Source

to GPU or LVDS I2C. When Brightness PWM

Source is set to LVDS I2C, the user will be able

to use the AIDI Library AidiVgaSetBacklight

command to control the PWM pulse to the panel

backlight.

1

2

3

1

2

3

1

2

3

1

2

3

Jumper Status

1-2 + 12V

2-3 + 5V <<<<

Jumper Status

1-2 + 3.3V <<<<

2-3 + 5V

Jumper Status

1-2 Voltage Level

2-3 PWM <<<<

Jumper Status

1-2 GPU

2-3 LVDS I2C <<<<

JPY9: Backlight Enable Signal Type

Sets the Backlight Enable Signal to "Normal"

1

2

3

or "Inverse" type.

NOTE: <<<< indicates default setting

Jumper Status

1-2 Inverse

2-3 Normal <<<<

Page 25Express-BASE User’s Manual

Page 26

6.13 Keyboard & Mouse

CN4: Mouse (top)

Keyboard (bottom)

6.14 Serial and IrDA Ports

CN3: COM1 (DB9)

65

4

21

65

4

21

3

3

Pin Signal Pin Signal

6 DSR 1 DCD#

7 RTS# 2 RXD

8 CTS# 3 TXD

9 RI# 4 DTR#

Pin Signal

1 MSDAT

2NC

3 GND

4 KB5V

5 MSCLK

6NC

Pin Signal

1 KBDAT

2NC

3 GND

4 KB5V

5 KBCLK

6NC

5 GND

CN18: COM2 (header)

CN24: IrDA Connector

Pin Signal Pin Signal

5

1

1

1 DCD# 6 DSR

2 RXD 7 RTS#

3 TXD 8 CTS#

4 DTR# 9 RI#

5 GND 10 NC

Pin Signal

1 +5V

2 No connect

3 IrRXD

4 Ground

5 IrTXD

Express-BASE User’s ManualPage 26

Page 27

6.15 Parallel Port

CN5: DB25

Pin Signal Pin Signal

1 STROBE# 14 AUTOFD#

2 DATA0 15 ERROR#

3 DATA1 16 INIT#

4 DATA2 17 SELIN#

5 DATA3 18 GND

6 DATA4 19 GND

7 DATA5 20 GND

8 DATA6 21 GND

9 DATA7 22 GND

10 ACK# 23 GND

11 BUSY 24 GND

12 PAPER EMPTY 25 GND

13 SEL 26 N/C

6.16 Storage: SATA, PATA, FDD, CF

CN9/11/12/17: SATA

1 7

Pin Signal Pin Signal

1 GND 2 Tx+

3 Tx- 4 GND

5 Rx- 6 Rx+

7 GND

Page 27Express-BASE User’s Manual

Page 28

CN19: FDD Connector

1 2

33 34

Pin Signal Pin Signal

1 Ground 2 Drive density selection

0

3 Ground 4 N.C.

5 N.C. 6 Drive density selection

1

7 Ground 8 Index

9 Ground 10 Motor enable 0 (1)

11 Ground 12 Drive select 1

13 Ground 14 Drive select 0 (1)

15 Ground 16 Motor enable 1

17 Ground 18 Direction

19 Ground 20 Step

21 Ground 22 Write data

23 Ground 24 Write gate

25 Ground 26 Track 00

27 Ground 28 Write protect

29 Ground 30 Read data

31 Ground 32 Side 1 select

33 Ground 34 Diskette change

CN35: IDE Connector

1 2

39 40

Pin Signal Pin Signal

1 Reset IDE 2 GND

3 IDE Data 7 4 IDE Data 8

5 IDE Data 6 6 IDE Data 9

7 IDE Data 5 8 IDE Data 10

9 IDE Data 4 10 IDE Data 11

11 IDE Data 3 12 IDE Data 12

13 IDE Data 2 14 IDE Data 13

15 IDE Data 1 16 IDE Data 14

17 IDE Data 0 18 IDE Data 15

19 Ground 20 KEY

21 DREQ0 22 GND

23 IDEIOW# 24 GND

25 IDEIOR# 26 GND

27 IDEIORDY 28 CBSEL

29 DACK0# 30 GND

31 IDEIRQ14 32 NC

33 IDE Address 1 34 PDIAG#

35 IDE Address 0 36 IDE Address 2

37 IDE Chip select 1# 38 IDE Chip select 3#

39 IDE activity 40 GND

Express-BASE User’s ManualPage 28

Page 29

CNZ2: CF Socket

Pin Signal Pin Signal

1 GND 2 IDE_D3

3 IDE_D4 4 IDE_D5

5 IDE_D6 6 IDE_D7

7 IDE_CS1J 8 GND

9 GND 10 GND

11 GND 12 GND

13 5VCC 14 GND

15 GND 16 GND

17 GND 18 IDE_A2

19 IDE_A1 20 IDE_A0

21 IDE_D0 22 IDE_D1

23 IDE_D2 24 IOIS16J

25 GND 26 GND

27 IDE_D11 28 IDE_D12

1

29 IDE_D13 30 IDE_D14

31 IDE_D15 32 IDE_CS3J

33 GND 34 IDE_IORJ

35 IDE_IOWJ 36 CFWE

37 IDE_IRQ 38 5VCC

39 CFSCSEL 40 NC

41 PLTRSTJ 42 IDE_IORDY

43 IDE_REQJ 44 IDE_ACKJ

45 IDE_ACTJ 46 IDE_66DECT

47 IDE_D8 48 IDE_D9

49 IDE_D10 50 GND

JPZ4: CF Master/Slave Setting

The default setting is CF slot (CNZ2) Master

and IDE Slave (CN35).

1

2

3

Jumper Status

1-2 CF Master <<<<

2-3 CF Slave

Page 29Express-BASE User’s Manual

Page 30

6.18 Power Connectors

CN33/37: 12 V Fan Power

321

Pin Signal

1 FAN Tach output

2 12 V

3 GND

CN41: ATX 24-pin Power Connector

+3.3 V

Connect the ATX 24-pin (or 20-pin) connector

to supply power to the Express-BASE carrier.

-12 V

COM

PWR_ON

COM

COM

COM

-5 V

+5 V

+5 V

+5 V

COM

+3.3 V

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

+3.3 V

Ground

+5 V

Ground

+5 V

Ground

PWR_GOOD

+5 V

SB

+12 V

+12 V

+3.3 V

CN42: ATX 12V 4-pin Connector

Connect the ATX 12V 4-pin connector to

supply power to the COM Express module.

All 12V power for the COM Express module is provided by the ATX 12V 4-pin connector.

The system will not power up if CN42 is not connected to the power supply.

To avoid damage to the carrier board and installed components, be sure to connect the

ATX power supply to the correctly connectors. See 8.5 ATX Power Connectors on page 42

for detailed information.

Pin Signal

24

1

3

1 GND

2 GND

3 +12V

4 +12V

Express-BASE User’s ManualPage 30

Page 31

CN43: 5 Volt FAN Power

321

CNY9: Smart Battery

Pin Signal

15 V

2 GND

3 FAN Tach output

Connects to Smart Battery

module

Pin Signal Pin Signal

1 I2C_CK 6 SUS_S45#

2 I2C_DAT 7 +12V

3 PWRBTN# 8 +5VSB

4 BATLOW# 9 SUS_STAT#

5 PS_ON# 10 GND

Page 31Express-BASE User’s Manual

Page 32

6.19 Power Jumper Settings

CNY6: PWR_OK Config

CNY7: Power Up Config

*The Super I/O detects a power button event using the 'PSIN' pin. When a power button event occurs, the powerup logic of the Super I/O sets 'PSOUT#' low and asserts 'PWRBTN#' of the module's chipset. The Super I/O also

sets the 'PWRCTL#' pin to low, which asserts the 'PS_ON#' signal and switches on the ATX power supply.

JPY1: AT/ATX MODE

In AT mode, JPY1 shorts PS_ON# to ground

Jumper Status

1-2 Add 3.3V Pullup with 10K to signal PWR_OK

3-4 Connect PWRGOOD of ATX power supply <<<<

5-6 Connect PWRGOOD of onboard DCDC regulator

Jumper Status

101

1-10

5-6 Power-up by module <<<<

8-9

2-9

3-8 Power-up by Super I/O*

5

6

4-7

1

2

3

Jumper Status

1-2 A TX Mode <<<<

2-3 A T Mode

directly to force power on.

JPY10: PS_ON# Signal Source

All ADLINK modules support S3 mode and

1

2

3

Jumper Status

1-2 SUS_S3# <<<<

2-3 SUS_S5#

consecutive power down of ATX power supply.

For modules that connect the S3 signal, PS_ON#

should always be set to SUS_S3# as source (even when S3 mode is disabled in the BIOS). For

modules that do not bring out the S3 signal, PS_ON# should be set to SUS_S5# as source.

JPZ3: AT Power 5V Setting

With an AT power supply is connected to

1

2

3

Jumper Status

1-2 AT without P5V <<<<

2-3 AT with P5V

the Express-BASE, JPZ3 can be used to

provide 5VSB to the COM module from

the carrier board.

NOTE: <<<< indicates default setting

Express-BASE User’s ManualPage 32

Page 33

6.17 Other Connectors

CN25: GPIO Header

GPIOs of CN25 come from

the COM Express module.

CN29: Miscellaneous

Connector

12

78

1 11

10 20

Pin Signal Pin Signal

1 GPI0 2 GPO0

3 GPI1 4 GPO1

5 GPI2 6 GPO2

7 GPI3 8 GPO3

Pin Signal Pin Signal

1 Power LED 11 Speaker

2 Power LED 12 Speaker

3 Power LED 13 Speaker

4 Keyboard Lock 14 Speaker

5 Keyboard Lock 15 RESET

6 NC 16 RESET

7 NC 17 HDD LED

8 NC 18 HDD LED

9 NC 19 Power Button

10 NC 20 Power Button

CNY2-3: Digital I/O

The Express-Base provides

GPIO expansion for I²C

applications via a Phillips

PCA955 with 16-bit I²C

I/O port and interrupt.

Pin Signal Pin Signal

1 I/O 0 11 GND

2 I/O 1 12 GND

3 I/O 2 13 GND

4 I/O 3 14 GND

5 I/O 4 15 GND

6 I/O 5 16 GND

7 I/O 6 17 GND

8 I/O 7 18 GND

9 INT# 19 BATLOW#

10 3V3 20 +3.3V

Page 33Express-BASE User’s Manual

Page 34

CNY4: Feature Connector

12

39 40

Pin Signal Pin Signal

1 +5V 2 +5VSB

3 +5V 4 Hard Disk Activity

5 I2C_DAT 6 SMBCLK_SB

7 I2C_CK 8 SMBDATA_SB

9 Internal use 10 GPO0

11 Internal use 12 GPO1

13 PS_ON# 14 GPO2

15 SUS_S3# 16 GPO3

17 GND 18 GND

19 THRMTRIP# 20 SMBALRT#

21 GPI1 22 SUS_S4#

23 SUS_STAT# 24 GPI0

25 GPI2 26 SUS_S5#

27 WDTRIG 28 THRM#

29 GPI3 30 PCI_M66EN

31 BATLOW# 32 WAKE1#

33 PEG_ENABLE# 34 PEG_LANE_RV#

35 KBINH# 36 SYS_RESET#

37 GND 38 GND

39 PWBTN# 40 PWR_OK

UZ3: Secondary SPI BIOS Socket

See JP2/JPZ5 BIOS Selection Jumpers

on page 35 and 7.2 SPI Secondary BIOS

on page 38 for detailed information.

Pin Signal

1 CS#

2DO

3 WP#

4 GND

5DI

6 CLK

7 HOLD#

8 +3.3V

Express-BASE User’s ManualPage 34

Page 35

6.20 Other Jumper Settings

JP1: LPC Port 80

Free Run: BIOS will complete the boot process

1

2

3

Jumper Status

1-2 Free Run <<<<

2-3 Single Step

Single Step: BIOS will execute step-by-step by

pressing SW2 button

JP2/JPZ5: BIOS Selection

See 7 Secondary BIOS on page 37 for

a detailed description.

JP5: CMOS Clear

To clear CMOS, shut down the power and short

1

2

3

JPZ5 JP2 Status

1-2 1-2 Module BIOS <<<<

1-2 2-3 Carrier FWH BIOS

2-3 1-2 Carrier SPI BIOS

2-3 2-3 Reserved

1

2

3

Jumper Status

1-2 Normal <<<<

2-3 Clear CMOS

pins 2 and 3 (shorts VBA T to ground).

JP6: External PEG/Internal Graphics with SDVO Selection

This jumper controls PCIE7: PCI Express x16 mode and SDVO mode. Enables/disables internal

graphics or external graphics on the x16 PCI Express Graphics (PEG) port. If the PEG port is

enabled, both the internal graphics and SDVO will be disabled.

1

2

3

JPY6: TPM Signal Jumper

Configuring the jumper to "ON" pulls the

Jumper Enable

1-2 Internal Graphics with SDVO <<<<

2-3 PCI Express x16 slot graphics

1

2

3

Jumper Status

1-2 ON

2-3 OFF <<<<

TPM signal high and "OFF" does nothing

to the TPM signal. Dependent upon module's

design for the TPM signal.

NOTE: <<<< indicates default setting

Page 35Express-BASE User’s Manual

Page 36

JPY11: Ethernet Mode

Configure the jumper to "10/100/1000" for

modules with Gigabit Ethernet, to "10/100" for

modules with Fast Ethernet

1

2

3

Jumper Status

1-2 10/100/1000 <<<<

2-3 10/100

JPA1: Super I/O

Enables/disables the Super IO. By default, the

Express-BASE enables the onboard W83627HGAW Super I/O. To disable the Onboard Super I/O,

short pins 2-3 of Jumper JP A1.

JPY7, JPY8: Reserved

1

2

3

Jumper Status

1-2 Enable <<<<

2-3 Disable

NOTE: <<<< indicates default setting

Express-BASE User’s ManualPage 36

Page 37

7 Secondary BIOS

The Express-BASE supports Secondary BIOS using firmware hub (FWH) for COM.0 Rev. 1.0

modules and Serial Peripheral Interface (SPI) for COM.0 Rev. 2.0 modules. Secondary BIOS

solutions can be used as an alternative to the on-module BIOS and provide support for the

following:

f Testing new BIOS versions

f Development of firmware modifications

f Recovery if soldered BIOS on module is corrupted

7.1 FWH Secondary BIOS - COM.0 Rev. 1.0

The firmware hub (FWH) is supported by PICMG COM.0 Rev. 1.0 to provide a Secondary BIOS

f

or COM Express Rev. 1.0 modules that support a FWH Secondary BIOS (not supported by

COM.0 Rev.1.0 modules with SPI BIOS).

When using the FWH Secondary BIOS, the soldered BIOS on the module does not need

to be removed.

To use the BIOS on the module:

f Short pins 1-2 on both JPZ5 and JP2.

To use the FWH BIOS on the carrier board:

f Short pins 1-2 on JPZ5 and pins 2-3 on JP2.

Page 37Express-BASE User’s Manual

Page 38

7.2 SPI Secondary BIOS - COM.0 Rev. 2.0

SPI is supported by PICMG COM.0 Rev. 2.0 to provide a Secondary BIOS for COM Express

Rev 2.0 modules that support a SPI Secondary BIOS.

When using SPI Secondary BIOS, the FWH BIOS chip must be removed from the carrier

board. If the FWH BIOS chip is not removed, the COM Express module may not boot

correctly.

To use the BIOS on the module:

f Short pins 1-2 on both JPZ5 and JP2.

To use the SPI BIOS on the carrier board:

f Short pins 2-3 on JPZ5 pins 1-2 on JP2.

Open the SPI BIOS socket and insert the

secondary BIOS flash chip.

Express-BASE User’s ManualPage 38

Page 39

8 Switches, POST, LEDs & Power

8.1 On/Off and RESET

The top left corner of the board contains two

mini switches.

The SW3 switch is the ATX power button.

This switch can be used to power up and

power down the system with an ATX power

supply.

The SW1 switch is the RESET button.

8.2 POST & Module Type Display

COM Express type:

1-2, 3, 4, 5 or wrong pinout

An LPC based POST display is added for

debugging.

The top two LEDs shows the actual

POST data and a bottom row of four LEDs

shows the address

The POST circuitry allows you to execute the

BIOS step-by-step.

JP1 short 2-3 results in single step BIOS

execution. A single step can be executed by

pressing the SW2 mini switch

To the left of the POST display a column of 5

mini LEDs indicate what type of COM Ex-

press module is installed on Express-BASE.

Page 39Express-BASE User’s Manual

Page 40

8.3 Indicator LEDs

8.4 Digital I/O LEDs

A row of mini LEDs to the left of the POST

display indicates the following:

LED20 5Vsb:ATX power attached

on standby or active

LED2 HDD: Hard disk activity

(SATA and PATA)

LED21 WDT: programmable LED to debug

watchdog during count down

LEDX1 - LEDX8 are indicators for the

Digital I/O Connector CNY2. When the I/O

signal is high, the LED will light. The I/O 0

signal corresponds to LEDX1, and the I/O 7

signal corresponds to LEDX8.

Express-BASE User’s ManualPage 40

Page 41

8.5 ATX Power Connectors

ATX 24-pin

Connector

ATX 12V 4-pin

Connector

The nanoX-BASE has one ATX 24-pin

connector to supply power to the carrier board

and one ATX 12V 4-pin connector to supply

power to the COM Express module.

The system will not power on unless

an ATX 12V 4-pin connector is

connected.

If your power supply has a 24-pin A TX

connector, then attach the connectors as

shown.

ATX 20-pin

Connector

ATX 12V 4-pin

Connector

If your power supply has a 20-pin ATX

connector, then attach the connectors as

shown.

DO NOT plug the ATX 12V 4-pin

connector into the ATX 24-pin power

connector.

Page 41Express-BASE User’s Manual

Page 42

8.6 AT Power Mode

To operate the system in AT Mode with an ATX power supply, use the AT mode PSU converter

cable (no 5Vsb) to connect the ATX 20/24-pin power connector to the carrier board as shown.

Set the ATX/AT Mode jumper JP1 to AT Mode as described in 6.24 Power Jumper Settings.

Express-BASE User’s ManualPage 42

Page 43

Important Safety Instructions

For user safety, please read and follow all instructions, warnings, cautions, and notes marked

in this manual and on the associated equipment before handling/operating the equipment.

f Read these safety instructions carefully.

f Keep this user’s manual for future reference.

f Read the specifications section of this manual for detailed information on the operating

environment of this equipment.

f When installing/mounting or uninstalling/removing equipment:

- Turn off power and unplug any power cords/cables.

f To avoid electrical shock and/or damage to equipment:

- Keep equipment away from water or liquid sources;

- Keep equipment away from high heat or high humidity;

- Keep equipment properly ventilated (do not block or cover ventilation openings);

- Make sure to use recommended voltage and power source settings;

- Always install and operate equipment near an easily accessible electrical socket-outlet;

- Secure the power cord (do not place any object on/over the power cord);

- Only install/attach and operate equipment on stable surfaces and/or recommended

mountings; and,

- If the equipment will not be used for long periods of time, turn off and unplug the

equipment from its power source.

f Never attempt to fix the equipment. Equipment should only be serviced by qualified

personnel.

f A Lithium-type battery may be provided for uninterrupted, backup or emergency power.

Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries

according to the instructions.

f Equipment must be serviced by authorized technicians when:

- The power cord or plug is damaged;

- Liquid has penetrated the equipment;

- It has been exposed to high humidity/moisture;

- It is not functioning or does not function according to the user’s manual;

- It has been dropped and/or damaged; and/or,

- It has an obvious sign of breakage.

Page 43Express-BASE User’s Manual

Page 44

Getting Service

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing, 100085 China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

Express-BASE User’s ManualPage 44

Page 45

ADLINK Technology (Europe) GmbH

Address: Nord Carree 3, 40477 Duesseldorf, Germany

Tel: +49-211-495-5552

Fax: +49-211-495-5557

Email: emea@adlinktech.com

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1506-25 穢壊 B/D 2 猻

2F, Hando B/D, 1506-25, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: No. 1357, "Anupama", Sri Aurobindo Marg, 9th Cross,

JP Nagar Phase I, Bangalore - 560078, India

Tel: +91-80-65605817

Fax: +91-80-22443548

Email: india@adlinktech.com

Page 45Express-BASE User’s Manual

Page 46

Loading...

Loading...