Page 1

CT-61

Rugged Conduction Cooled Low Power 6U CompactPCI

Processor Blade with Intel® Core™ i7 and Two PMC Sites

User’s Manual

Manual Rev. 1.00

Revision Date: September 25, 2014

Part No: 50-1Y002-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

1.00 2014/09/25 Initial release

Page 3

CT-61

Preface

Copyright 2014 ADLINK Technology Inc.

This document contains proprietary infor mation protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufa cturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component damage, data loss, and/or program corruption when trying to com-

CAUTION:

WARNING:

plete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

iv Preface

Page 5

CT-61

Table of Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Tables......................................................................... vii

List of Figures........................................................................ ix

1 Overview ............................................................................. 1

1.1 Introduction.......................................................................... 1

1.2 Features............................................................................... 2

1.3 Block Diagram ..................................................................... 3

1.4 Product List............................. ... .......................................... 4

2 Specifications..................................................................... 5

2.1 CT-61 Specifications............................................................ 5

2.2 Power Requirements.................... ... .... ... ... ... ... .... ... ... ... .... ... 7

2.3 Thermal Management Features .......................................... 9

3 Functional Description .................................................... 11

3.1 Processor........................................................................... 11

3.2 Chipset............................................................................... 12

3.3 Super I/O ........................................................................... 13

3.4 Battery ............................................................................... 13

3.5 PMC/XMC Sites................................................................. 13

3.6 BIOS Recovery.................................................... .............. 14

4 Board Interfaces............................................................... 15

4.1 CT-61 Board Layout - Top Side......................................... 15

4.2 CT-61 Board Layout - Bottom Side.................................... 16

4.3 Connector Pin Assignments .............................................. 17

4.4 Switch and Jumper Settings.............................................. 25

Table of Contents v

Page 6

5 Getting Started.................................................................. 29

5.1 CT-61 Blade Installation..................................................... 29

5.2 PMC/XMC Module Installation........................................... 30

6 Driver Installation.............................................................. 31

6.1 Driver Installation Procedure.............................................. 31

7 Utilities............................................................................... 33

7.1 Watchdog Timer................................................................. 33

7.2 Preboot Execution Environment (PXE).............................. 38

7.3 BIOS Recovery........................ .... ... ... ... .... ... ... ... ... ............. 39

7.4 Programming NT Mode EEPROM Map............................. 41

8 BIOS Setup Utility............................................................. 43

8.1 Starting the BIOS............................................................... 43

8.2 Main Setup......................................................................... 46

8.3 Advanced BIOS Setup....................................................... 47

8.4 Chipset Configuration ........................................................ 57

8.5 Boot Configuration............................................................. 60

8.6 Security Setup.................................................................... 62

8.7 Save & Exit ........................................................................ 63

9 IPMI User Guide ................................................................ 65

9.1 Introduction........................................................................ 65

9.2 Summary of Commands Supported by BMR-AVR-cPCI... 65

9.3 OEM Commands Summary Table............ ... ... ... ... ....... ... ... 69

9.4 CompactPCI Address Map ................................................ 73

9.5 Communications with IPMC............................................... 74

9.6 IPMI Sensors List............................................................... 74

9.7 Relevant Documents................................. ... ... ... ... .... ... ... ... 74

Important Safety Instructions............................................... 75

Getting Service...................................................................... 77

vi Table of Contents

Page 7

CT-61

List of Tables

Table 2-1: CT-61 Specifications ................................................ 6

Table 2-2: CompactPCI Input Voltage Characteristics .............. 7

Table 2-3: Idle Mode Power Consumption ................................ 8

Table 2-4: 100% CPU Usage Power Consumption ................... 8

Table 4-1: XMC Connector Pin Definition ................................ 17

Table 4-2: PMC Connector Pin Definitions .............................. 18

Table 4-3: CompactPCI J1 Connector Pin Definition ............... 20

Table 4-4: CompactPCI J2 Connector Pin Definition ............... 21

Table 4-5: CompactPCI J3 Connector Pin Definition ............... 22

Table 4-6: CompactPCI J4 Connector Pin Definition ............... 23

Table 4-7: CompactPCI J5 Connector Pin Definition ............... 24

Table 4-8: Mode Switch Settings .. ... ... ... .... ... ... ... ... .... ... ... ... .... . 26

Table 4-9: PMC Bandwidth/Clock Switch Settings .................. 26

List of Tables vii

Page 8

This page intentionally left blank.

viii List of Tables

Page 9

CT-61

List of Figures

Figure 1-1: CT-61 Block Diagram ................................................ 3

Figure 4-1: CT-61 Board Layout - Top Side............................... 15

Figure 4-2: CT-61 Board Layout - Bottom Side ......................... 16

List of Figures ix

Page 10

This page intentionally left blank.

xList of Figures

Page 11

1Overview

1.1 Introduction

The CT-61 is a conduction cooled 6U CompactPCI single board

computer in single slot width (4HP) form factor supporting 32nm

Intel® Core™ i7 SV, LV, ULV processors with integrated graphics

and ECC memory controller onboard. The CT-61 provides up to

8GB of dual channel DDR3-800/1066 ECC memory soldered

onboard and implements the Mobile In tel® QM57 Express Chipset

to provide a full feature set and optimal performance per watt.

The CT-61 provides a 64bit/66MHz CompactPCI bus, up to two

PMC sites with 64-bit/133MHz PCI-X bus supporting rear I/O

(PIM), and one PCI Express x8 XMC site (shared with inner PMC

site). Rear I/O provides versatile additional I/O including two

PICMG 2.16 GbE, USB, COM, High Definition Audio, and SATA

interfaces.

For flexibility of use, the CT-61 can be installed in a standard CompactPCI system slot as system master, or peripheral slot as a PCI

device. Through hardware switch setting, the CT-61 optionally

supports operation in system or per ipheral slots as a standalone

blade. The CT-61 is ideally suited for military, aviation, communication and other industrial applications.

CT-61

Overview 1

Page 12

1.2 Features

X 6U CompactPCI SBC in 4HP width form factor

X µFC-BGA package Intel® Core™ i7 processor, up to 2.53GHz

X Mobile Intel® BD82QM57 PCH (Platform Controller Hub)

X Dual Channel DDR3 ECC SDRAM at 800 or 1066MHz sol-

dered onboard, up to 8GB

X 64-bit/66MHz CompactPCI Interface based on PCI specifica-

tions, 3.3V and 5V signaling

X Supports operation in system slot as system master or in

peripheral slot with connectivity to CompactPCI bus* (optional

isolation from CompactPCI bus)

X Dual PMC sites with 64-bit/133MHz PCI bus

X Single XMC site with PCIe x8 lane (shared with inner PMC

site)

X -40°C to 85°C operating temperature (at wedge locks)

X RTM models available with multiple I/O options: SATA, HD

audio, COM, USB, Gigabit Ethernet, PS/2 KB/MS, PIM, SAS,

SCSI, CF, SD socket

X Hardware RAID on SCSI, SAS interfaces supported (depen-

dent on RTM module)

*See “Programming NT Mode EEPROM Map” on page 41 for

instructions on how to set the PCIe-to-PCI bridge on the CT-61

NOTE:

NOTE:

to NT-mode to allow operation in a peripheral slot.

2Overview

Page 13

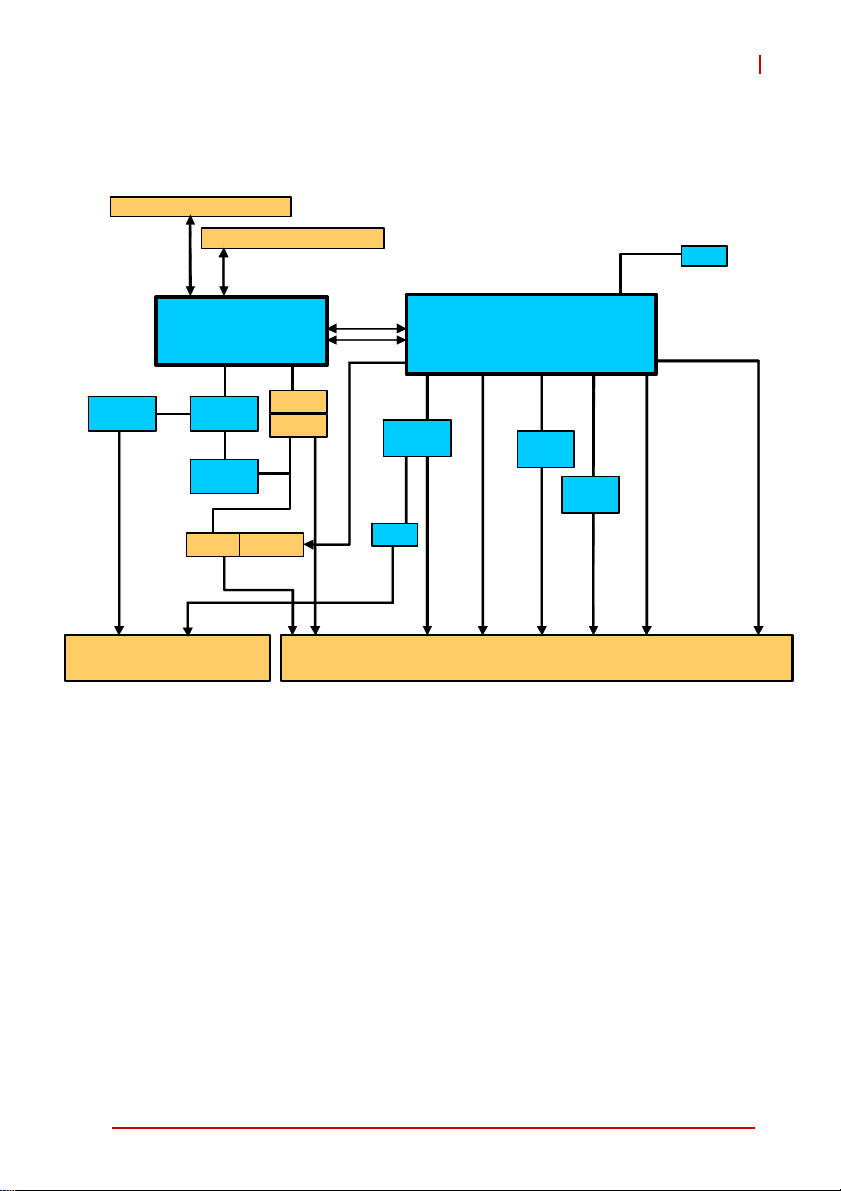

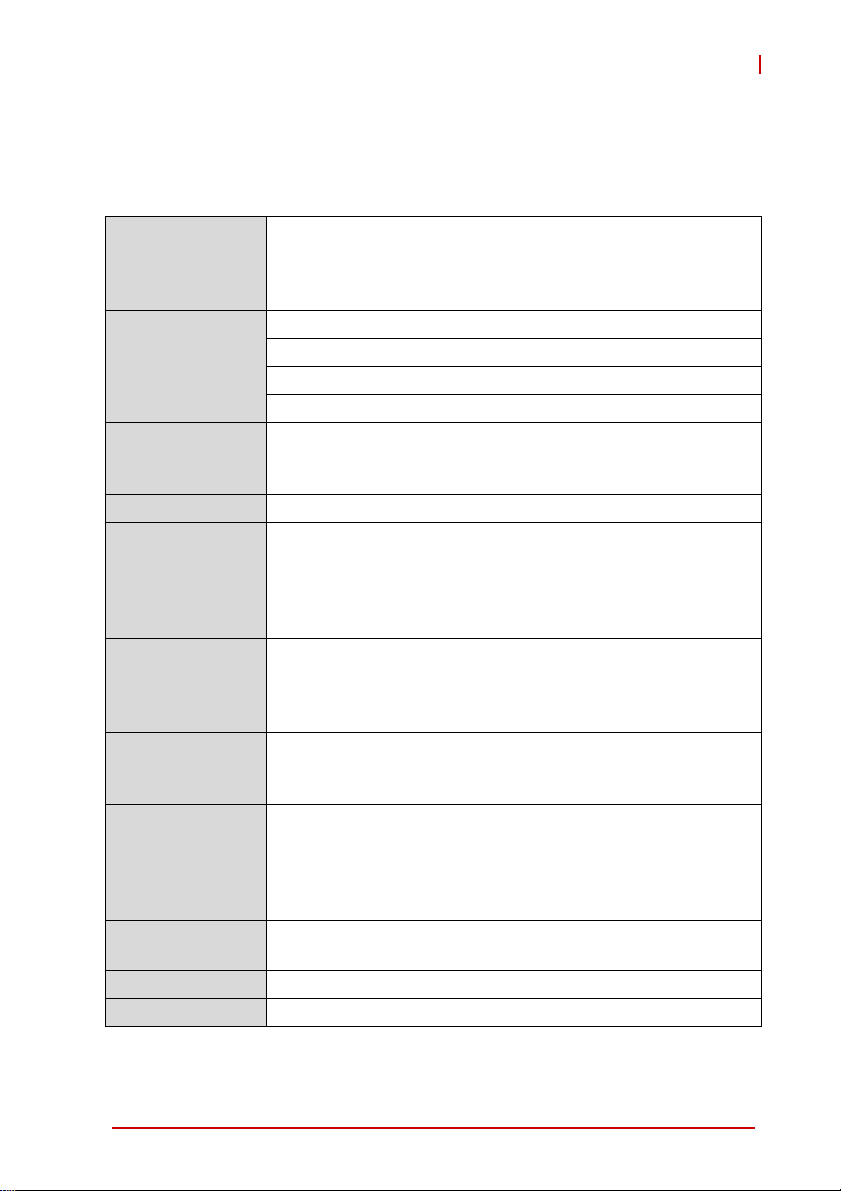

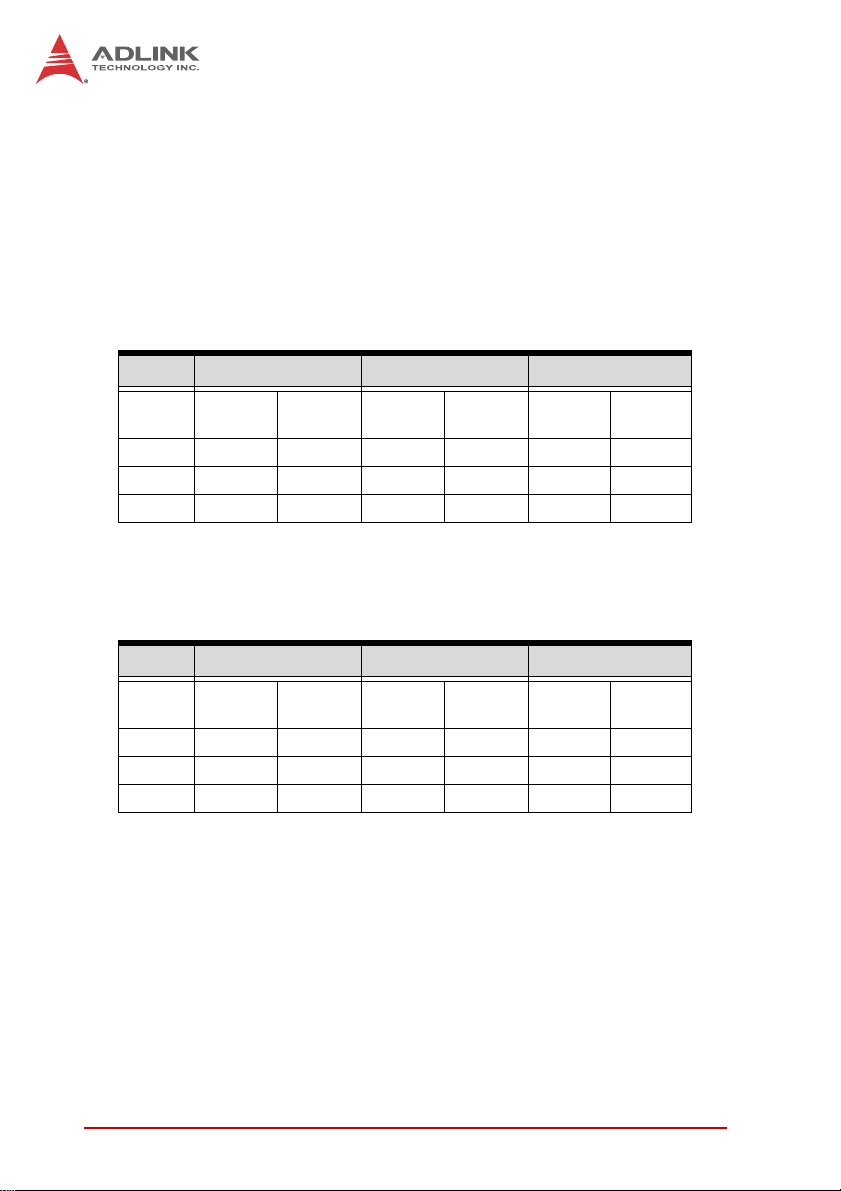

1.3 Block Diagram

Soldered w/ ECC, max. 4GB

Soldered w/ ECC, max. 4GB

DDR3 800/10 66

SPI

CT-61

BIOS

Pericom

PI7C9X13

PCI 64b/66M

Intel® Cor e™i7

PCIe x8

PCIe

Switch

PCIe x4

PCIe x4

Pericom

PI7C9X13

PCI-X 64b/133M

PMC 2

Rear I/O

XMC

PMC 1

2.5” HDD

PCIe x8

Rear I/O

DMI

SATA1

COM4

IPMB 0/1

ITE8783

BMC

SIO

LPC

KB/MS

2x COM

J1/J2 J3/J4/J5

Figure 1-1: CT-61 Block Diagram

QM57 PCH

Intel

82574L

6x USB

3x SAT A

HDA

5x GPIO

RTC

PCIe x4

LVDS

Intel

82574L

PCIe x1 PCIe x1

GbE3 GbE4

TMDSB

RGB

Overview 3

Page 14

1.4 Product List

Products included in the CT-61 include:

Processor Blade

X CT-61: 4HP width (single-slot) 6U CompactPCI blade fea-

turing single Intel® Core™i7 processor, dual channel

DDR3-800/1066 soldered onboard SDRAM with ECC,

2x PMC

Rear Transition Modules

X cPCI-R6002: 4HP width RTM with DVI-I, 2x COM, 3x USB, 2x

GbE, 2xSATA

X cPCI-R6100: 4HP width RTM with 4x GbE, 4x USB, 2xSATA,

DVI, VGA, PS/2 KB/MS, CF & SD sockets

X cPCI-R6110: 4HP width RTM with 2x GbE, 4x USB, 3x SATA,

VGA, PS/2 KB/MS, CF, & SD sockets

X cPCI-R6200: 8HP width RTM with 2x GbE, 2x COM, 4x USB,

DVI-I, 3x SATA, Mic-in, Line-out, PS/2 KB/MS, 8x SAS

X cPCI-R6210: 4HP width RTM with 2xUSB, DVI-I, COM,

2x SATA, 2x PIM

The contents of non-standard CT-61 configurations may vary

depending on customer requests.

NOTE:

NOTE:

This product must be protected from static discharge and physical shock. Never remove any of the components except at a

CAUTION:

4Overview

static-free workstation. Use the anti-static bag shipped with the

product when putting the board on a surface. Wear an

anti-static wrist strap properly grounded on one of the system's

ESD ground jacks when installing or servicing system components.

Page 15

2 Specifications

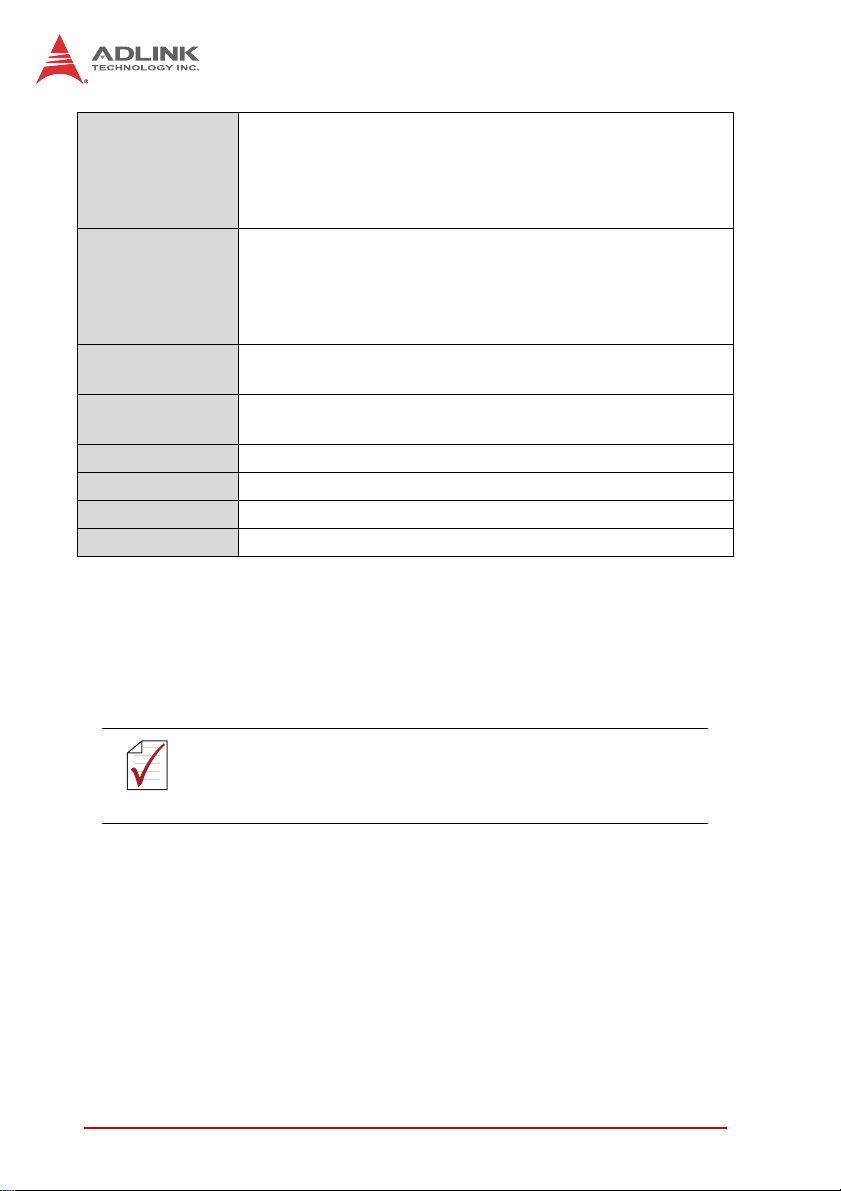

2.1 CT - 61 Specifications

PICMG® 2.0 CompactPCI® Rev. 3.0

CompactPCI

Standard

Mechanical

Processor

Chipset Intel® QM57 Platform Controller Hub (PCH)

Memory

CompactPCI Bus

PMC/XMC

Graphics

Ethernet

Serial Ports Two serial ports routed to rear I/O

BIOS AMI® EFI BIOS 64Mbit SPI flash memory

PICMG® 2.1 Hot Swap Specification Rev.2.0

PICMG® 2.9 System Management Bus Rev. 1.0

PICMG® 2.16 Packet Switching Backplane Rev.1.0

Standard 6U CompactPCI®

Board size: 233.23 mm x 160mm

Single slot (4HP, 20.32mm) width

CompactPCI® connectors J1, J2, J3, J4 and J5

µFC-BGA Intel® Core™i7-610E, 4MB L2 cache, 2.53GHz

µFC-BGA Intel® Core™i7-620LE, 4MB L2 cache, 2.0GHz

µFC-BGA Intel® Core™i7-620UE, 4MB L2 cache, 1.06GHz

Dual channel DDR3-800/1066 soldered onboard SDRAM

with un-buffered ECC

DDR3-800 for Core™i7-620UE processor

DDR3-1067 for Core™i7-610E/620LE processors

Maximum 8GB capacity

PCI 64-bit/ 66MHz; V(I/O) 3.3V and 5V signaling

Supports operation in system slot or in peripheral slot with

connectivity to CompactPCI bus (Universal Mode)

Optional Satellite mode by switch setting

Two PCI 64-bit/133MHz PMC sites, V(I/O) 3.3V (contact

ADLINK for 5V support)

One PCIe x8 XMC site (shared with inner PMC site)

Integrated in Intel® Core™i7 processor

Analog RGB signal to rear

DVI port routed to rear

Supports dual independent display

Analog RGB up to QXGA

PCIe x1 Intel® 82574L GbE controllers

Two 10/100/1000BASE-T ports to J3

CT-61

1

Specifications 5

Page 16

Supports PICMG® 2.9 secondary system management bus

IPMI functions implemented as defined by IPMI Spec. v1.5 ;

IPMI Interface

ATmega128L-8AU Baseboard Management Controller

(BMC) with 128KB programmable in-system flash, 4KB

EEPROM, and 4KB internal SDRAM

Microsoft® Windows® 7 Ultimate

Microsoft® Windows® Vista Enterprise

Supported OS

Microsoft® Windows® XP Professional SP3

Fedora™ 12

Other OS support upon request

Operating

Temperature

Storage

temperature

-40°C to +85°C at wedge lock

-40°C to 85°C

Humidity 20% to 95% non-condensing

Shock 20G peak-to-peak, 11ms duration, non-operating

Vibration Operating: 20Grms. 5 to 500Hz, each axis

Compliance CE EN55022, FCC Class A

T able 2-1: CT-61 Specifications

Notes:

1. See 7.4 "Programming NT Mode EEPROM Map" on page 41

for instructions on how to set the PCIe-to-PCI bridge on the

CT-61 to Non-Transparent mode to allow operation in a peripheral slot.

Specifications are subject to change without prior notice.

NOTE:

NOTE:

6 Specifications

Page 17

CT-61

2.2 Power Requirements

In order to guarantee a stable functionality of the system, it is recommended to provide more power than the system requires. An

industrial power supply unit should be able to provide at least

twice as much power as the entire system requires of each

voltage. An ATX power supply unit should be able to provide at

least three times as much power as the entire system requires.

The tolerance of the voltage lines described in the CompactPCI

specification (PICMG 2.0 R3.0) is +5%/ -3% for 5, 3.3 V and ±5%

for ±12V. This specification is for power delivered to each slot an d

it includes both the power supply and the backplane tolerance.

Voltage

5V +5.0 VDC +5% / -3% 50 mV

3.3V +3.3 VDC +5% / -3% 50 mV

+12V +12 VDC +5% / -5% 240 mV

-12V -12 VDC +5% / -5% 240 mV

V I/O (PCI I/O

Buffer Voltage)

GND

Table 2-2: Comp actPCI Input Voltage Characteristics

Nominal

Value

+3.3 VDC or

+5 VDC

Tolerance

+5% / -3% 50 mV

Max. Ripple

(P - P)

Specifications 7

Page 18

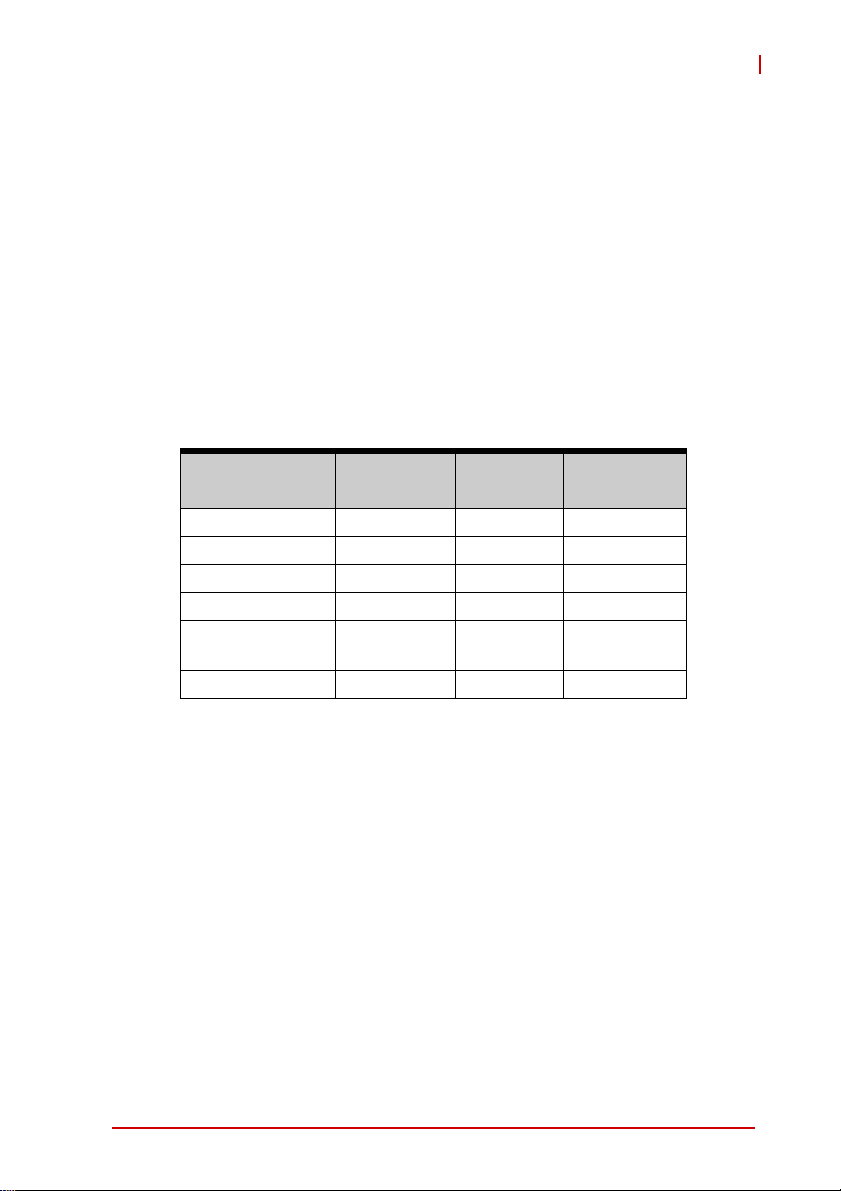

Power Consumption

This section provides information on the power consumption of the

CT-61 with different CPUs, 2GB DDR3-800/1066 soldered memory, and 100GB SATA HDD. The system was tested in Idle Mode

and Full Load Mode under Windows XP running Burn-in Test 6.0.

The CT-61 is powered by 5V and 3.3V.

Idle Mode under Windows XP

CPU Core™ i7 610E Core™ i7 620LE Core™ i7 620UE

Voltage

+3.3 4.19 13.82 4.12 18.41 3.85 12.71

Total 19.51 23.76 17.96

100% CPU Usage under Windows XP

CPU Core™ i7 610E Core™ i7 620LE Core™ i7 620UE

Voltage

+3.3 6.09 20.10 5.83 19.25 5.31 17.52

Total 42.31 37.08 27.87

Current

(V)

+5 1.14 5.69 1.07 5.35 1.05 5.25

(V)

+5 4.44 22.21 3.57 17.83 2.07 10.35

(A)

Table 2-3: Idle Mode Power Consumption

Current

(A)

Power

(W)

Power

(W)

Current

(A)

Current

(A)

Power

(W)

Power

(W)

Current

(A)

Current

(A)

Power

(W)

Power

(W)

T able 2-4: 100% CPU Usage Power Consumption

8 Specifications

Page 19

CT-61

2.3 Thermal Management Features

When the CPU temperature exceed s its maximum junction temperature (T

reduce power consumption (and thus performance) in an attempt

to reduce the core junction temperature. Use of the CPU’s thermal

management features is intended for short periods of time when

running power intensive applications. If the system is operated

under conditions below the TDP curves above, activation of the

thermal management features will be minimal and reduction in

CPU performance will be minor.

However, if the operating conditions are outside the limits set out

above, the CPU temperature may exceed T

periods, resulting in noticeable performance loss and reduced reliability of the processor.

In extreme situations, the thermal management features may be

incapable of cooling the processor. If the CPU temperature

exceeds approximately 130°C, a catastrophic cooling failure will

be detected and the processor will automatically shut down to prevent physical damage to the processor.

), the CPU’s thermal management features will

j,Max

for prolonged

j,Max

Prolonged operation above the CPU’s maximum junction temperature (Tj,Max=105°C) may damage the CPU and/or reduce

WARNING:

Specifications 9

its long term reliability. Be sure to follow the thermal guidelines

set out in this document.

Page 20

This page intentionally left blank.

10 Specifications

Page 21

3 Functional Description

The following sections describe the CT-61 features and functions.

3.1 Processor

Intel® Core™ i7 Processor

The Intel® Core™ i7-620LE/UE and i7-610E are 64-bit, multi-core

mobile processors built on a 32 nanometer process technology.

The processors are designed for a two-chip platform consisting of

a processor and the Platform Controller Hub (PCH) and enables

higher performance, lower cost, easier validation, and improved

x-y footprint. The Intel® Core™ i7-620LE/UE and i7-610E processors are offered in a BGA1288 package and include an integrated

graphics and memory controller die on the same package as the

processor core die.

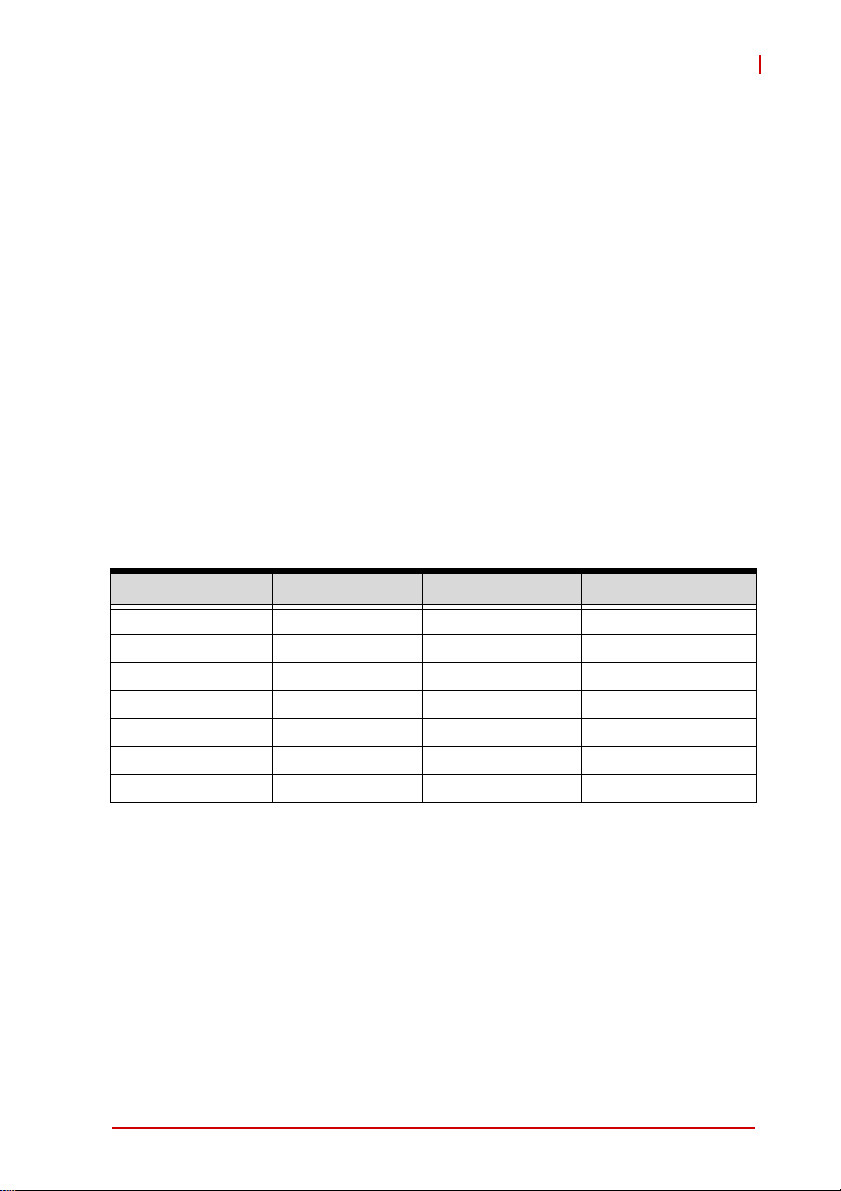

The following table lists the processors supported by the CT-61

and their specifications.

Features SV Core i7-610E LV Core i7-620LE ULV Core i7-620UE

Clock 2.53GHz 2.0GHz 1.06GHz

Max. Turbo Freq. 3.2GHz 2.8GHz 2.13GHz

L2 cache 4MB 4MB 4MB

Max. Power (TDP1)

2

T

j,Max

Process 32nm 32nm 32nm

# of cores/threads 2/4 2/4 2/4

Notes:

1. The highest expected sustainable power while running known

power intensive applications. TDP is not the maximum power

that the processor can dissipate.

2. Maximum junction temperature (T

ported operating temperature.

35W 25W 18W

105°C 105°C 105°C

). The maximum sup-

j,Max

CT-61

Functional Description 11

Page 22

System Memory Support

X Two channels of DDR3 memory soldered onboard

X Memory DDR3 data transfer rates of 800 and 1066 MT/s

X 64-bit wide channels (72-bit wide including ECC)

X Supports ECC unbuffered DDR3 memory

X Theoretical maximum memory bandwidth of:

Z

12.8 GB/s in dual-channel mode assuming DDR3 800 MT/s

Z

17.1 GB/s in dual-channel mode assuming DDR3 1066 MT/s

X 1-Gb and 2-Gb DDR3 DRAM technologies for x8 devices

X Using 2Gb device technologies, the largest memory capac-

ity is 8GB

3.2 Chipset

Mobile Intel® QM57 Express Chipset

The CT-61 incorporates the Mobile Intel® QM57 Express Chipset,

also referred to as PCH (Platform Controller Hub), to provide

extensive I/O support. Functions and capabilities include:

X PCI Express Base 2.0 Specification support for up to eight

ports

X 4 PCI Express x1 connected to LAN controllers

X 4 PCI Express x1 are configured to PCI Express x4 and

routed to J5 for I/O expansion

X ACPI Power Management Logic Support

X Two integrated SATA host controllers with up to six ports,

supporting independent DMA operation and dat a transfer

rates of up to 3.0GB/s (the CT-61 supports up to four SATA

ports)

X Supports Advanced Host Controller Interface (AHCI)

X Intel Rapid Storage Technology provides high performance

RAID 0, 1, 5, and 10 functionality

X High speed USB 2.0 allows data transfers up to 480 Mb/s

X Provides Intel Virtualization Technology with Directed I/O

(Intel VT-d) support.

12 Functional Description

Page 23

CT-61

3.3 Super I/O

The ITE IT8783F Super I/O is on a Low Pin Count interface supporting PS/2 keyboard/mouse, 16C550-compatible serial ports,

floppy drive interface, hardware monitor function to monitor CPU

voltage, CPU temperature, power supply voltages and system temperature, and Watchdog Timer with time resolution from minimum 1

second or minute to maximum 65,535 se co nd s or minutes.

3.4 Battery

The CT-61 is p ro vided with a 3.0V/0.2F gold ca p for th e Rea l Time

Clock (RTC). The gold cap supports a 12-hour theoretically life.

3.5 PMC/XMC Sites

The CT-61 supports two PMC sites for front panel I/O expansion.

The PMC sites provides a maximum 64bit/133MHz PCI-X bus link

using a Pericom PI7C9X130 PCIe-to-PCI bridge and PCIe x4 link.

The PMC/XMC sites support +3.3V signaling and 5V VPWR by

default. For optional 5V signaling and 12V VPWR support, contact

your ADLINK sales representative.

The JN1/5 and JN2/6 connectors provide the signals for the 32-bit

PCI bus. The JN3/7 connector provides the 64 bit extension for the

PMC interface. The JN3/7 connectors support user defined I/O

signals and are routed to the CompactPCI J4/5 connectors to rear

I/O.

The CT-61 provides a PCIe x8 XMC interface sharing the same

space as the inner PMC site for high speed I/O e xpansion, such as

10GbE or high-end graphics.

Functional Description 13

Page 24

3.6 BIOS Recovery

The CT-61 features AMI® EFI BIOS with BIOS recovery. If the

BIOS becomes corrupted and you are unable to boot your system,

follow the instructions in Section 7.3 “BIOS Recovery” on page 39.

14 Functional Description

Page 25

4 Board Interfaces

This chapter describes the board layout, connector pin assignments, and jumper settings of the CT-61.

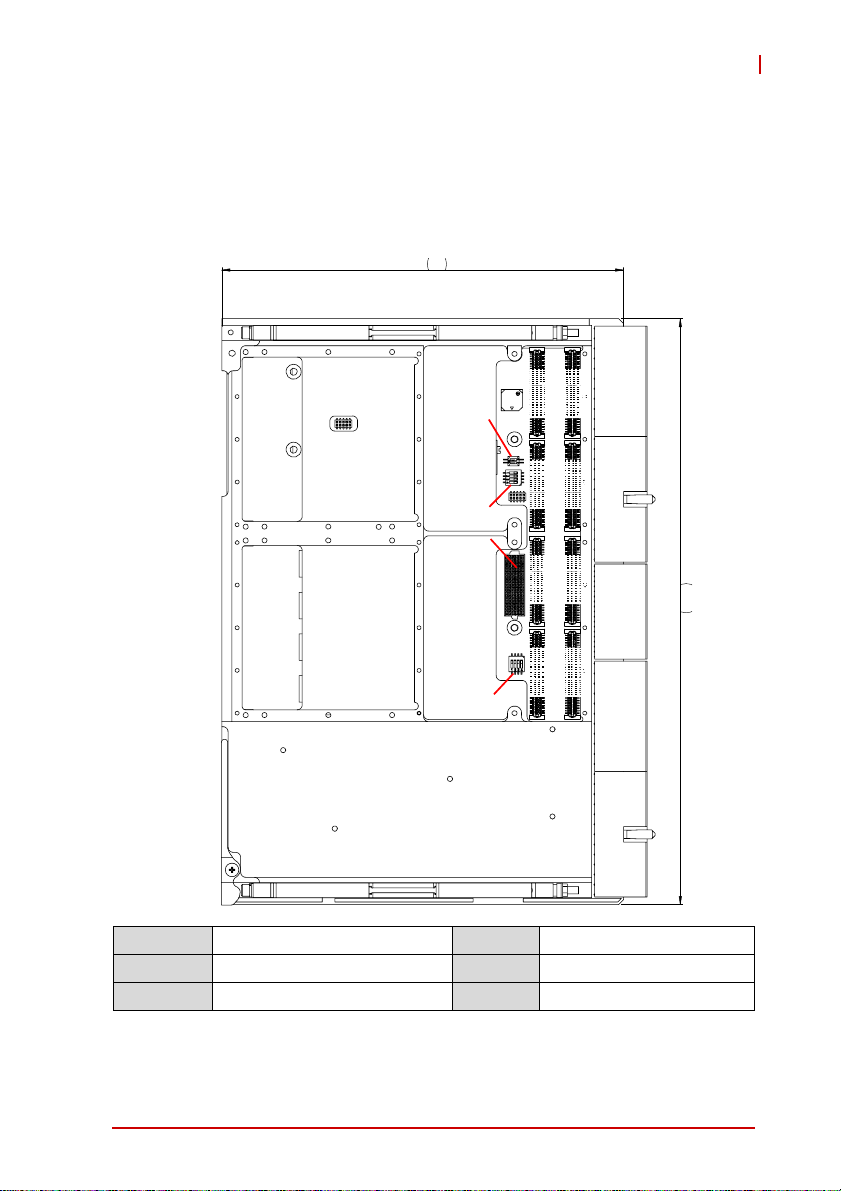

4.1 CT-61 Board Layout - Top Side

160

CT-61

JN5 JN7

J5

JN6 JN8

SW1

J4

SW2

CN8

JN1 JN3

JN2 JN4

J3

SW3

J2

J1

CN8 XMC conne ctor SW1 Reserved

J1-5 CompactPCI connectors SW2 Mode Switch

JN1-8 PMC connectors SW3 PMC Clock Switch

233.2

Figure 4-1: CT-61 Board Layout - Top Side

Board Interfaces 15

Page 26

4.2 CT- 61 Board Layout - Bottom Side

SW6 SW4

SW4 Reserved SW6 Clear CMOS

Figure 4-2: CT-61 Board Layout - Bottom Side

16 Board Interfaces

Page 27

CT-61

4.3 Connector Pin Assignments

Refer to “CT-61 Board Layout - Top Side” on page 15 and “CT-61

Board Layout - Bottom Side” on page 16 for connector locations.

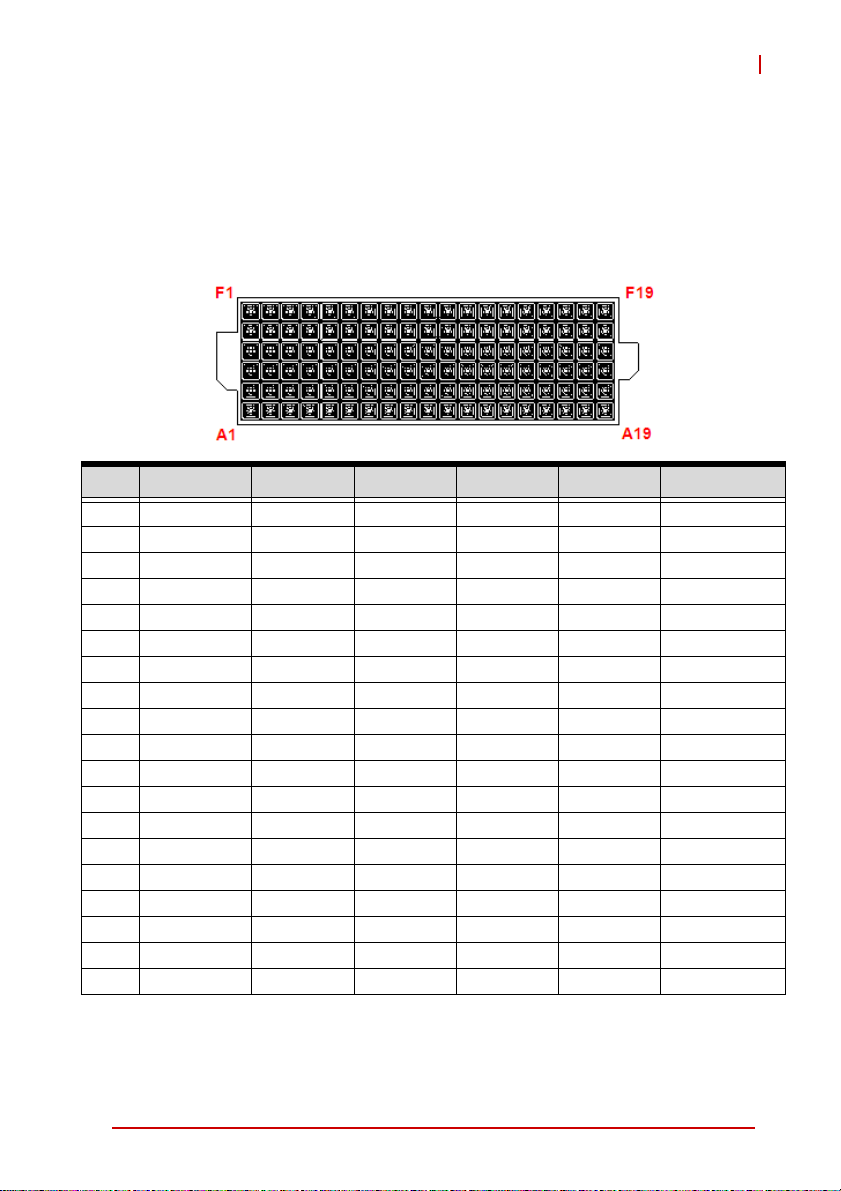

XMC Connector (CN8)

Pin# A B C D E F

1 PETp0 PETn0 3.3V PETp1 PETn1 VPWR

2 GND GND TRST# GND GND MRSTI#

3 PETp2 PETn2 3.3V PETp3 PETn3 VPWR

4 GND GND TCK GND GND MRSTO#

5 PETp4 PETn4 3.3V PETp5 PETn5 VPWR

6 GND GND TMS GND GND +12V

7 PETp6 PETn6 3.3V PETp7 PETn7 VPWR

8 GND GND TDI GND GND -12V

9NC NCNCNCNCVPWR

10 GND GND TDO GND GND GA0

11 PERp0 PERn0 MBIST# PERp1 PERn1 VPWR

12 GND GND GA1 GND GND MPRESENT#

13 PERp2 PERn2 3.3V AUX PERp3 PERn3 VPWR

14 GND GND GA2 GND GND MSDA

15 PERp4 PERn4 NC PERp5 PERn5 VPWR

16 GND GND MVMRO GND GND MSCL

17 PERp6 PERn6 NC PERp7 PERn7 NC

18 GND GND NC GND GND NC

19 REFCLK+0 REFCLK-0 NC WAKE# ROOT0# NC

Table 4-1: XMC Connector Pin Definition

Board Interfaces 17

Page 28

PMC Connector (JN1/5, JN2/6, JN3/7, JN4/8)

Pin# JN1/5 Signal JN2/6 Signal JN3/7 Signal JN4/8 Signal

1 PMC_TCK P12V NC PIO1

2 N12V PMC_TRST-L GND PIO2

3 GND PMC_TMS GND PIO3

4 PCIX_INTA-L NC (PMC_TDO) PCIX_CBE-L7 PIO4

5 PCIX_INTB-L PMC_TDI PCIX_CBE-L6 PIO5

6 PCIX_INTC-L GND PCIX_CBE-L5 PIO6

7 PMC_MOD-L1 GND PCIX_CBE-L4 PIO7

8P5V NC GND PIO8

9 PCIX_INTD-L NC PMC_VIO PIO9

10 NC NC PCIX_PAR64 PIO10

11 GND PMC_MOD-L2 PCIX_AD63 PIO11

12 P3V3_PMCAUX P3V3 PCIX_AD62 PIO12

13 CLK66_PCIX_PMC PMC_RST-L PCIX_AD61 PIO13

14 GND PMC_MOD-L3 GND PIO14

15 GND P3V3 GND PIO15

16 PCIX_GNT-L0 PMC_MOD-L4 PCIX_AD60 PIO16

17 PCIX_REQ-L0 PMC_PME-L PCIX_AD59 PIO17

18 P5V GND PCIX_AD58 PIO18

19 PMC_VIO PCIX_AD30 PCIX_AD57 PIO19

20 PCIX_AD31 PCIX_AD29 GND PIO20

21 PCIX_AD28 GND GND PIO21

22 PCIX_AD27 PCIX_AD26 PCIX_AD56 PIO22

23 PCIX_AD25 PCIX_AD24 PCIX_AD55 PIO23

24 GND PCIX_AD23 PCIX_AD54 PIO24

25 GND PMC_IDSEL PCIX_AD53 PIO25

26 PCIX_CBE-L3 PCIX_AD23 GND PIO26

27 PCIX_AD22 P3V3 GND PIO27

28 PCIX_AD21 PCIX_AD20 PCIX_AD52 PIO28

29 PCIX_AD19 PCIX_AD18 PCIX_AD51 PIO29

30 P5V GND PCIX_AD50 PIO30

31 PCIX_FRAME-L PCIX_AD16 PCIX_AD49 PIO31

32 PCIX_AD17 PCIX_CBE-L2 GND PIO32

6364

12

Table 4-2: PMC Connector Pin Definitions

18 Board Interfaces

Page 29

Pin# JN1/5 Signal JN2/6 Signal JN3/7 Signal JN4/8 Signal

33 PCIX_FRAME-L GND GND PIO33

34 GND NC PCIX_AD48 PIO34

35 GND PCIX_TRDY-L PCIX_AD47 PIO35

36 PCIX_IRDY-L P3V3 PCIX_AD46 PIO36

37 PCIX_DEVSEL-L GND PCIX_AD45 PIO37

38 P5V PCIX_STOP-L GND PIO38

39 PCIX_PCIXCAP PCIX_PERR-L GND PIO39

40 PCIX_LOCK-L GND PCIX_AD44 PIO40

41 NC P3V3 PCIX_AD43 PIO41

42 NC PCIX_SERR-L PCIX_AD42 PIO42

43 PCIX_PAR PCIX_CBE-L1 PCIX_AD41 PIO43

44 GND GND GND PIO44

45 PMC_VIO PCIX_AD14 GND PIO45

46 PCIX_AD15 PCIX_AD13 PCIX_AD40 PIO46

47 PCIX_AD12 PCIX_M66EN PCIX_AD39 PIO47

48 PCIX_AD11 PCIX_AD10 PCIX_AD38 PIO48

49 PCIX_AD9 PCIX_AD8 PCIX_AD37 PIO49

50 P5V P3V3 GND PIO50

51 GND PCIX_AD7 GND PIO51

52 PCIX_CBE-L0 NC PCIX_AD36 PIO52

53 PCIX_AD6 P3V3 PCIX_AD35 PIO53

54 PCIX_AD5 NC PCIX_AD34 PIO54

55 PCIX_AD4 NC PCIX_AD33 PIO55

56 GND GND GND PIO56

57 PMC_VIO NC GND PIO57

58 PCIX_AD3 NC PCIX_AD32 PIO58

59 PCIX_AD2 GND NC PIO59

60 PCIX_AD1 NC NC PIO60

61 PCIX_AD0 PCIX_ACK64-L NC PIO61

62 P5V P3V3 GND PIO62

63 GND GND GND PIO63

64 PCIX_REQ64-L NC NC PIO64

Table 4-2: PMC Connector Pin Definitions (cont’d)

CT-61

Board Interfaces 19

Page 30

CompactPCI J1 Connector Pin Assignment

Pin Z A B C D E F

1 GND +5V -12V TRST# +12V +5V GND

2 GND TCK# +5V TMS# NC TDI# GND

3 GND IRQA# IRQB# IRQC# +5V IRQD# GND

4 GND +5V_IPMB HEALTHY# V(I/O) NC NC GND

5 GND NC NC RESET# GND GNT0# GND

6 GND REQ0# GND +3.3V CLK0 AD31 GND

7 GND AD30 AD29 AD28 GND A D27 GND

8 GND AD26 GND V(I/O) AD25 AD24 GND

9 GND CBE3# IDSEL AD23 GND AD22 GND

10 GND AD21 GND +3.3V AD20 AD19 GND

11 GND AD18 AD17 AD16 GND CBE2# GND

12-14 Key

15 GND +3.3V FRAME# IRDY# BDSEL# TRDY# GND

16 GND DEVSEL# PCIXCAP V(I/O) STOP# LOCK# GND

17 GND +3.3V IPMB_CLK IPMB_DAT GND PERR# GND

18 GND SERR# GND +3.3V PAR CBE1# GND

19 GND +3.3V AD15 AD14 GND AD13 GND

20 GND AD12 GND VIO AD11 AD10 GND

21 GND +3.3V AD9 AD8 M66EN CBE0# GND

22 GND AD7 GND +3.3V AD6 AD5 GND

23 GND +3.3V AD4 AD3 +5V AD2 GND

24 GND AD1 +5V V(I/O) AD0 ACK64# GND

25 GND +5V REQ64# ENUM# +3.3V +5V GND

Table 4-3: CompactPCI J1 Connector Pin Definition

20 Board Interfaces

Page 31

CT-61

CompactPCI J2 Connector Pin Assignment

Pin Z A B C D E F

1 GND CLK1 GND REQ1# GNT1# REQ2# GND

2 GND CLK2 CLK3 SYSEN# GNT2# REQ3# GND

3 GND CLK4 GND GNT3# REQ4# GNT4# GND

4 GND V(I/O) NC CBE7# GND CBE6# GND

5 GND CBE5# GND V(I/O) CBE4# PAR64 GND

6 GND AD63 AD62 AD61 GND AD60 GND

7 GND AD59 GND V(I/O) AD58 AD57 GND

8 GND AD56 AD55 AD54 GND AD53 GND

9 GND AD52 GND V(I/O) AD51 AD50 GND

10 GND AD49 AD48 AD47 GND AD46 GND

11 GND AD45 GND V(I/O) AD44 AD43 GND

12 GND AD42 AD41 AD40 GND AD39 GND

13 GND AD38 GND V(I/O) AD37 AD36 GND

14 GND AD35 AD34 AD33 GND AD32 GND

15 GND NC GND FAL# REQ5# GNT5# GND

16 GND NC NC DEG# GND NC GND

17 GND NC GND RSTBTN# REQ6# GNT6# GND

18 GND NC NC NC GND NC GND

19 GND GND GND NC NC NC GND

20 GND CLK5 GND NC GND NC GND

21 GND CLK6 GND NC NC NC GND

22 GND GA4 GA3 GA2 GA1 GA0 GND

Table 4-4: CompactPCI J2 Connector Pin Definition

Board Interfaces 21

Page 32

CompactPCI J3 Pin Assignment

Pin Z A B C D E F

1GNDHDA_RST# HDA_SYNC HDA_BIT_CLK HDA_SDOUT HDA_SDIN0 GND

2GND

3GND

4GND

5 GND GND GND NC GND GND GND

6GND

7GND

8GND

9GND

10 GND

11 GND

12 GND

13 GND

14 GND

15 GND

16 GND

17 GND

18 GND

19 GND P5V P5V P12V P5V P5V GND

HDA_SDIN1 HDA_SDIN2 NC

KBDATA KBCLK NC MSDATA MSCLK GND

SATA-TX4+ SATA-TX4- GND SATA-TX3+ SATA-TX3- GND

SATA-RX4+ SATA-RX4- GND SATA-RX3+ SATA-RX3- GND

COM4-TX COM4-RX COM3-DCD# IPMB_CLK IPMB_DAT GND

COM3-RX COM3-TX COM3-DTR# COM3-DSR# COM3- RTS# GND

COM3-CTS# COM3-RI# RGB-BLUE RGB-RED RGB-GREEN GND

USB-OC3# RGB-DDCCLK RGB-DDCDAT RGB-HSYNC RGB-VSYNC GND

USB-P3+ USB-P3- GND USB-P4+ USB-P4- GND

USB-P5+ USB-P5- GND USB-P6+ USB-P6- GND

USB-P7+ USB-P7- GND USB-P8+ USB-P8- GND

USB-OC4# USB-OC5# USB-OC6# USB-OC7# USB-OC8# GND

LAND_TXD1+ LAND_TXD1- GND LAND_TXD3+ LAND_TXD3- GND

LAND_TXD0+ LAND_TXD0- GND LAND_TXD2+ LAND_TXD2- GND

LANC_TXD1+ LANC_TXD1- GND LANC_TXD3+ LANC_TXD3- GND

LANC_TXD1+ LANC_TXD0- GND LANC_TXD2+ LANC_TXD2- GND

HDA_DOCK_EN#

HAD_DOCK_RST#

GND

Table 4-5: CompactPCI J3 Connector Pin Definition

High Definition audio

Keyboard/Mouse

Serial ATA

Serial ports

USB ports

Ethernet ports

RGB

22 Board Interfaces

Page 33

CT-61

CompactPCI J4 Connector Pin Assignment

Pin Z A B C D E F

1 GND NC PMC1 IO:64 PMC1 IO:63 PMC1 IO:62 PMC1 IO:61 GND

2 GND PMC1 IO:60 PMC1 IO:59 PMC1 IO:58 PMC1 IO:57 PMC1 IO:56 GND

3 GND PMC1 IO:55 PMC1 IO:54 PMC1 IO:53 PMC1 IO:52 PMC1 IO:51 GND

4 GND PMC1 IO:50 PMC1 IO:49 PMC1 IO:48 PMC1 IO:47 PMC1 IO:46 GND

5 GND PMC1 IO:45 PMC1 IO:44 PMC1 IO:43 PMC1 IO:42 PMC1 IO:41 GND

6 GND PMC1 IO:40 PMC1 IO:39 PMC1 IO:38 PMC1 IO:37 PMC1 IO:36 GND

7 GND PMC1 IO:35 PMC1 IO:34 PMC1 IO:33 PMC1 IO:32 PMC1 IO:31 GND

8 GND PMC1 IO:30 PMC1 IO:29 PMC1 IO:28 PMC1 IO:27 PMC1 IO:26 GND

9 GND PMC1 IO:25 PMC1 IO:24 PMC1 IO:23 PMC1 IO:22 PMC1 IO:21 GND

10 GND PMC1 IO:20 PMC1 IO:19 PMC1 IO:18 PMC1 IO:17 PMC1 IO:16 GND

11 GND PMC1 IO:15 PMC1 IO:14 PMC1 IO:13 PMC1 IO:12 PMC1 IO:11 GND

12-14 Key

15 GND PMC1 IO:10 PMC1 IO:9 PMC1 IO:8 PMC1 IO:7 PMC1 IO:6 GND

16 GND PMC1 IO:5 PMC1 IO:4 PMC1 IO:3 PMC1 IO:2 PMC1 IO:1 GND

17 GND NC PMC2 IO:64 PMC2 IO:63 PMC2 IO:62 PMC2 IO:61 GND

18 GND PMC2 IO:60 PMC2 IO:59 PMC2 IO:58 PMC2 IO:57 PMC2 IO:56 GND

19 GND PMC2 IO:55 PMC2 IO:54 PMC2 IO:53 PMC2 IO:52 PMC2 IO:51 GND

20 GND PMC2 IO:50 PMC2 IO:49 PMC2 IO:48 PMC2 IO:47 PMC2 IO:46 GND

21 GND PMC2 IO:45 PMC2 IO:44 PMC2 IO:43 PMC2 IO:42 PMC2 IO:41 GND

22 GND PMC2 IO:40 PMC2 IO:39 PMC2 IO:38 PMC2 IO:37 PMC2 IO:36 GND

23 GND PMC2 IO:35 PMC2 IO:34 PMC2 IO:33 PMC2 IO:32 PMC2 IO:31 GND

24 GND PMC2 IO:30 PMC2 IO:29 PMC2 IO:28 PMC2 IO:27 PMC2 IO:26 GND

25 GND PMC2 IO:25 PMC2 IO:24 PMC2 IO:23 PMC2 IO:22 PMC2 IO:21 GND

Table 4-6: CompactPCI J4 Connector Pin Definition

Board Interfaces 23

Page 34

CompactPCI J5 Pin Assignment

Pin Z A B C D E F

1GNDPCIE-TX0+ PCIE-TX0- GND PCIE-RX0+ PCIE-RX0- GND

2GND

3GND

4GND

5 GND GND GND GND GND GND GND

6GND

7 GND GND GND RTC GND GND GND

8GND

9GND

10 GND

11 GND

12 GND

13 GND

14 GND PMC2 IO:20 PMC2 IO:19 GND

15 GND PMC2 IO:18 PMC2 IO:17 GPIO6

16 GND PMC2 IO:16 PMC2 IO:15 GPIO7 PMC2 IO:14 PMC2 IO:13 GND

17 GND PMC2 IO:12 PMC2 IO:11 GPIO8 PMC2 IO:10 PMC2 IO:9 GND

18 GND PMC2 IO:8 PMC2 IO:7 DETECT# PMC2 IO:6 PMC2 IO:5 GND

19 GND PMC2 IO:4 PMC2 IO:3 NC PMC2 IO:2 PMC2 IO:1 GND

20 GND

21 GND

22 GND NC

PCIE-TX1+ PCIE-TX1- GND PCIE-RX1+ PCIE-RX1- GND

PCIE-TX2+ PCIE-TX2- GND PCIE-RX2+ PCIE-RX2- GND

PCIE-TX3+ PCIE-TX3- GND PCIE-RX3+ PCIE-RX3- GND

PCIE-CLK+ PCIE-CLK- G ND RESET# NC GND

LVDS_DATA3- LVDS_DATA3+ NC LVDS_CLK LVDS_DATA GND

GPIO1 GPIO2 GPIO3 GPIO4 GPIO5 GND

TDC0+ TDC0- GND TDC1+ TDC1- GND

TDC2+ TDC2- GND TLC+ TLC- GND

DVI_DATA DVI_CLK DVI_HTPLG NC NC GND

LAND_100# LANC_100# NC LANC_1G# LAND_1G# GND

SATA-TX5+ SATA-TX5- GND

SATA-RX5+ SATA-RX5- GND

LVDS_DATA0- LVDS_DATA0+ GND LVDS_DATA1- LVDS_DATA1+ GND

LVDS_DATA2- LVDS_DATA2+ GND LVDS_CLK- LVDS_CLD+ GND

LAND_LINK_ACT#

+3.3V

LANC_LINK_ACT#

+3.3V GND

Table 4-7: CompactPCI J5 Connector Pin Definition

PCI-Express x4

GPIO

DVI

Ethernet port

LVDS

Serial ATA

24 Board Interfaces

Page 35

4.4 Switch and Jumper Settings

Refer to “CT-61 Board Layout - Top Side” on page 15 and “CT-61

Board Layout - Bottom Side” on page 16 for switch locations.

SW1 & SW4 (Debug use only)

The switches SW1 & 4 are for debugging purposes and should

be left in the default settings. The default setting of SW1 is all

OFF; the default setting of SW4 is Pin 1 OFF and Pin 2 ON.

Mode Switch (SW2)

Switch SW2 is a multi purpose switch that allows users to

define the board operating mode. Four pins independently control the mode setting. All are set to OFF by default.

Pin# Status Description

Universal Mode:

bus communication with the host board in the system slot. The

OFF

CT-61 can boot-up in a peripheral slot and be recognized by the

1

2

host board in the system slot as a PCI device.

Satellite Mode:

CompactPCI bus communication with the host board in the system

ON

slot. The CT-61 behaves a as standalone blade in the peripheral

slot.

When the system does not include a CMM (Chassis

OFF

Management

"without CMM mode".

When the system includes a CMM, set this pin to ON to allow

ON

IPMI to run in "with CMM mode".

The CT-61 in a peripheral slot has CompactPCI

The CT-61 in a peripheral slot has no

Module), set this pin to OFF to allow IPMI to run in

CT-61

Board Interfaces 25

Page 36

Pin# Status Description

OFF

3

OFF

4

The CT-61 cannot boot-up when installed in a peripheral slot if

there is no host board in the system slot.

The CT-61 is able to boot-up when installed in a peripheral slot if

there is no host board in the system slot. The CT-61 behaves as a

ON

system board in all slots. (Set this pin to "ON" if the CT-61 is

installed in a blade server backplane).

The CT-61 power on/off is state is controlled by the ejector handle

state.

ON

Force the ejector handle state to "closed".

Table 4-8: Mode Switch Settings

PMC Bandwidth/Clock Switch (SW3)

Switch SW3 allows the user to force the PCI bus to lower bandwidth and clock settings. All are set OFF by default to support

PCI-X mode up to 64bit/133MHz maximum with the bandwidth

and clock determined by the PCI device attached.

PIN ON OFF

1 Force the PCI bandwidth to 32bit

2 Force the PCI clock to 66MHz

Force the PCI bus to PCI mode

3

(no PCI-X mode support)

Force the PCI clock to

4

PCI-X 100MHz

Table 4-9: PMC Bandwidth/Clock Switch Settings

26 Board Interfaces

Auto Negotiation

Page 37

CT-61

Clear CMOS Switch (SW6)

Press switch SW6 to clear the CMOS and reset the CMOS values to default.

Board Interfaces 27

Page 38

This page intentionally left blank.

28 Board Interfaces

Page 39

5 Getting Started

This chapter describes the installation of the following component s

to the CT-61.

X CT-61 Blade installation

X PMC/XMC module installation

5.1 CT-61 Blade Installation

1. Carefully align the edges of the blade with the edges of

the slot.

2. Check that all the wedge locks lie flat against the board.

3. Slide the blade into the slot.

4. Tighten the wedge locks using a hex torque screwdriver

set to 6.0 ±0.5 kgf·cm (0.59 ±0.05 N·m).

To remove the cond uc tio n- co ole d bla d e, use th e fo llo wing steps:

1. Loosen the wedge locks using a hex screwdriver.

2. Use the ejection levers to disengage the lock.

CT-61

3. Carefully remove the blade from the conduction-cooled

chassis.

Getting Started 29

Page 40

5.2 PMC/XMC Module Installation

The CT-61 provides one PMC and one PMC/XMC slot. The

PMC/XMC slots support 3.3V V(I/O) and 5V VPWR only. For

optional 5V V(I/O) and 12V VPWR support, please contact

ADLINK.

Installing a PMC/XMC Module

1. Align the male connectors of the PMC/XMC card (component-side down) to the female connectors of the

CT-61 and press down.

2. Secure th e PMC/XMC card to the CT-61 by attaching the

screws provided with the card from the bottom side of

the board.

30 Getting Started

Page 41

6 Driver Installation

The CT-61 drivers can be found on the ADLINK All-In-One CD at

X:\cPCI\CT-61\ or from the ADLINK website (http://www.adlinktech.com). ADLINK provides validated drivers for chipset, graph-

ics and LAN on Windows XP Professional, Windows Vista, and

Windows 7.

6.1 Driver Installation Procedure

The following describes the driver installation procedures for Windows XP.

1. Install the Windows operating system before installing

any driver. Most standard I/O device drivers are installed

during Windows installation.

2. Install the chipset driver by extracting and running the pro-

gram in ...\Chipset\

Intel_INF_Update_Utility_WinAllOS_v9.1.1.1023.zip.

3. Install the graphics driver and utilities by extracting and run-

ning the program in ...\Graphics\

Intel_Graphics_Adapter_WinXP32_v6.14.10.5237.zip.

4. Install the LAN drivers by extracting and running the pro-

gram in

…\LAN\Intel_Network_Adapter_WinXP32_v11.4.7.0.zip.

We recommend using the drivers provided on the ADLINK

All-in-One CD or downloading them from the ADLINK website to

ensure compatibility. The Vxw orks BSP can be downloaded from

the CT-61 product page on the ADLINK website

(http://www.adlinktech.com).

CT-61

Driver Installation 31

Page 42

This page intentionally left blank.

32 Driver Installation

Page 43

7 Utilities

7.1 Watchdog Timer

This section describes the operation of the CT-61’s watchdog

timer (WDT). The primary function of the WDT is to monitor the

CT-61's operation and to reset the system if a software application

fails to function as programmed. The following WDT functions may

be controlled using a software application:

X enabling and disabling

X reloading timeout value

The CT-61 custom WDT circuit is implemented using the internal

IO of the ITE Super I/O IT8783 which is at address 2Eh of LPC.

The basic functions of the WDT include:

X Starting the timer countdown

X Enabling or disabling WDT

X Enabling or disabling WDT countdown LED ON

X Reloading the timeout value to keep the watchdog from timing

out

X Setting the range of the timeout period from 1 to 15300 seconds

or minutes

X Sending a RESET signal to the system when the watchdog

times out

CT-61

Using the Watchdog in an Application

The following section describes using the WDT functions in an

application. The WDT reset function is explained in the previous

section. This can be controlled through the registers in the CT-61's

Super I/O.

An application using the reset fe ature enab les the watch dog func tion, sets the count-down period, and reloads the timeout value

periodically to keep it from resetting the system. If the timer countdown value is not reloaded, the watchdog resets the system hardware after its counter reaches zero.

Utilities 33

Page 44

For a detailed programming sample, refer to the sample code provided on the ADLINK All-In-One CD. You can find it in the following

directory: X:\cPCI\CT-61\WDT.

Sample Code

The sample program written in C shown below offers an interactive

way to test the Watchdog Timer under DOS.

#include<stdio.h>

#include<dos.h>

#define IT8783_ID1 0x87

#define IT8783_ID2 0x83

static unsigned int IT8783_ioPort = 0x2e;

//Check index port

void Enter_IT8783_Config(unsigned int flag)

{

if(flag) IT8783_ioPort = 0x4e;

switch(IT8783_ioPort)

{

case 0x2E: //Address port = 0x2E, enter keys =

0x87, 0x01, 0x55, 0x55

outportb(0x2E, 0x87);

outportb(0x2E, 0x01);

outportb(0x2E, 0x55);

outportb(0x2E, 0x55);

break;

case 0x4E: //Address port = 0x4E, enter keys =

0x87, 0x01, 0x55, 0xAA

outportb(0x4E, 0x87);

outportb(0x4E, 0x01);

outportb(0x4E, 0x55);

outportb(0x4E, 0xAA);

break;

default:

break;

}

}

34 Utilities

Page 45

CT-61

//Exit index port

void Exit_IT8783_Config(unsigned int flag)

{

if(flag) IT8783_ioPort = 0x4e;

outportb(IT8783_ioPort, 0x02);

outportb(IT8783_ioPort+1, 0x02);

}

//Check chip

void Get_IT8783_ID(unsigned int &ID1, unsigned int &ID2)

{

outportb(IT8783_ioPort, 0x20);

ID1 = inportb(IT8783_ioPort+1);

outportb(IT8783_ioPort, 0x21);

ID2 = inportb(IT8783_ioPort+1);

}

//WDT and LED program

void IT8783_3_WDTRun(unsigned int count_value, unsigned

int PLEDflag) //for CT-61

{

unsigned long tempCount;

unsigned int registerValue;

outportb(IT8783_ioPort, 0x07);

outportb(IT8783_ioPort+1, 0x07);// Device 7

outportb(IT8783_ioPort, 0xf8);

outportb(IT8783_ioPort+1, 0x00);// PLED mapping to

nothing, disable PLED function

if(PLEDflag == 1)

{

outportb(IT8783_ioPort, 0x2D);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0x01; // set Pin109 is

GPIO function GP60

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0xC5);

registerValue = inportb(IT8783_ioPort + 1);

Utilities 35

Page 46

registerValue &= 0xfe; // set GP60 is

alternate function

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0xCD);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0x01; // set GP60 is output

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0xf8);

outportb(IT8783_ioPort+1, 0x30);// PLED

mapping to GP60

outportb(IT8783_ioPort, 0xf9);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0x02;

registerValue &= 0xfb;

outportb(IT8783_ioPort+1, registerValue);

}

outportb(IT8783_ioPort, 0x71);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0xD0; // set Mouse & Keyboard

interrupt Enable

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0x73);

outportb(IT8783_ioPort+1, count_value);

// set WDT count LSB

tempCount = tempCount >> 8;

outportb(IT8783_ioPort, 0x74);

outportb(IT8783_ioPort+1, count_value);

// set WDT count MSB

if(count_value >= 60)

{

outportb(IT8783_ioPort, 0x72);

registerValue = inportb(IT8783_ioPort+1);

registerValue &= 0x8f;

registerValue |= 0x10; //enable WDT output

through PowerOK!

outportb(IT8783_ioPort+1, registerValue);

// set WDT count is minute

36 Utilities

Page 47

tempCount = count_value / 60;

if((count_value%60) > 30)

tempCount++;

if(tempCount > 65535)

tempCount = 65535;

printf("WDT timeout in %d minutes.\n",

tempCount);

}

else

{

outportb(IT8783_ioPort, 0x72);

registerValue = inportb(IT8783_ioPort+1);

registerValue |= 0x80;

tempCount = count_value;

if(tempCount != 0)

{

printf("WDT timeout in %d seconds.\n",

tempCount);

registerValue |= 0x40; //Enable WDT

output through KBRST

}

else

{

printf("WDT is Disabled.\n");

registerValue &= 0xbf; //Disable WDT

output through KBRST

}

CT-61

outportb(IT8783_ioPort+1, registerValue);

// set WDT count is second

}

}

Utilities 37

Page 48

7.2 Preboot Execution Environment (PXE)

The CT-61 supports the Intel® Preboot Execution Environment

(PXE) that is capable of booting up or executing an OS installation

through an Ethernet port. To use PXE, there must be a DHCP

server on the network with one or more servers running PXE and

MTFTP services. It could be a Windows® 2003 server running

DHCP, PXE, and MTFTP services or a dedicated DHCP server

with one or more additional servers running PXE and MTFTP services.

To build a network environment with PXE support:

1. Setup a DHCP server with PXE tag configuration

2. Install the PXE and MTFTP services

3. Make a boot image file on the PXE server (i.e. the boot server)

4. Enable the PXE boot function on the client computer

38 Utilities

Page 49

CT-61

7.3 BIOS Recovery

The CT-61 features AMI® EFI BIOS with BIOS recovery. If the

BIOS becomes corrupted and you are unable to boot your system,

the system will sound 4 beeps. Follow the instructions below to

re-flash the BIOS and recover the system.

1. Download the BIOS recovery file “C6510000.ROM” from the

product website at :

detail.php?cKind=&pid=1017

2. Prepare a bootable USB flash drive and copy the recovery file “C6510000.ROM” to the root directory.

3. Insert the USB flash drive into the CT-61 and power up

the system.

4. The system will sound 4 beeps to indicate boot failure,

and then it will sound 2 beeps to indicate it is entering

Recovery Mode. You will see the screen below:

http://www.adlinktech.com/PD/web/PD_

5. Select “Proceed with flash update” and press Enter.

Utilities 39

Page 50

6. During the BIOS recovery process, you will see the following:

7. Af ter the flash update is completed, power down the syste m

and restart. The system should now boot up normally.

40 Utilities

Page 51

CT-61

7.4 Programming NT Mode EEPROM Map

The CT-61 supports operation in peripheral slot as PCI device with

PCI bus communication with the system board (Universal Mode).

To operate in a peripheral slot in Non-Transparent mode, the

PCIe-to-PCI bridge on the CT-61 should be set to Non-Transparent

mode by programming the NT mode EEPROM map. The EEPROM

map can be downloaded from the CT-61 product page on the

ADLINK website:

http://www.adlinktech.com/PD/web/PD_detail.php?cKind=&pid=1017

To set the PCIe-to-PCI bridge on the CT-61 to NT mode, perform

the following steps:

1. Download the EERPOM map cPCI-6510_NT.rar from

the CT-61 product website under Utilities.

2. Prepare a bootable USB flash drive and extract the con-

tents of the folder cPCI-6510_NT into the root directory.

3. Insert the USB flash drive into the CT-61 in system slot

and power up the system.

4. Execute the file NT.bat to program the bridge to

Non-Transparent mode. The board will then operate in a

peripheral slot as a PCI device.

5. To return the CT-61 to Transparent mode, execute the

file TR.bat.

Utilities 41

Page 52

This page intentionally left blank.

42 Utilities

Page 53

8 BIOS Setup Utility

The following chapter describes basic navigation for the

AMIBIOS®8 BIOS setup utility.

8.1 Starting the BIOS

To enter the setup screen, follow these steps:

1. Power on th e motherboard

2. Press the < Delete > key on your keyboard when you

see the following text prompt:

< Press DEL to run Setup >

3. After you press the < Delete > key, the main BIOS setup

menu displays. You can access the other setup screens

from the main BIOS setup menu.

CT-61

Note: In most cases, the < Delete > key is used to invoke the setup

screen. There are several cases that use other keys, such as

< F1 >, < F2 >, and so on.

BIOS Setup Utility 43

Page 54

Setup Menu

The main BIOS setup menu is the first screen that you can navigate. Each main BIOS setup menu option is described in this

user’s guide.

The Main BIOS setup menu screen has two main frames. The left

frame displays all the options that can be configured. “Grayed”

options cannot be configured, “Blue” options can be.

The right frame displays the key legend. Above the key legend is

an area reserved for a text message. When an option is selected

in the left frame, it is highlighted in white. Often a text message will

accompany it.

44 BIOS Setup Utility

Page 55

CT-61

Navigation

Note: There is a hot key legend located in the right frame on most

setup screens.

Keyboard Commands

Enter Selects the highlighted option or submenu.

< > The Left and Right “Arrow” keys allow you to select a setup

screen.

^ v The Up and Down “Arrow” keys allow you to select a setup

screen.

+ - The Plus and Minus keys allow you to change the field value

Tab Moves the cursor to the next configurable item or to the next

Esc The Esc key allows you to discard any changes you ha ve

BIOS Setup Utility 45

of a particular setup item.

field.

made and exit the Setup menu. Press the Esc key to exit

the Setup menu without saving your changes. Press the

Enter key to discard changes and exit. You can also use the

“Arrow” keys to select Cancel and then press the Enter key

to abort this function and return to the previous screen.

Page 56

8.2 Main Setup

When you first enter the Setup Utility , you will enter the Main setup

screen. You can always re turn to the Ma in setup screen by selecting the Main tab. There are two Main Setup options. They are

described in this section. The Main BIOS Setup screen is shown

below.

System Language

Choose the system default language.

System Time/System Date

Use this option to change the system time and date. Highlight System Time or System Date using the < Arrow > keys. En ter new values using the keyboard. Press the < Tab > key or the < Arrow >

keys to move between fields. The date must be entered in

MM/DD/YY format. The time is entered in HH:MM:SS format.

Note: The time is in 24-hour format. For example, 5:30 A.M. ap-

46 BIOS Setup Utility

pears as 05:30:00, and 5:30 P.M. as 17:30:00.

Page 57

CT-61

8.3 Advanced BIOS Setup

Select the Advanced tab from the setup screen to enter the

Advanced BIOS Setup screen. You can select any of the items in

the left frame of the screen, such a s SuperIO Conf iguration, to go

to the sub menu for that item. You can display an Advanced BIOS

Setup option by highlighting it using the < Arrow > keys. The

Advanced BIOS Setup screen is shown below.

The sub menus are described on the following pages.

Launch PXE OpROM

Boot option for legacy network devices. Options: LAN1, LAN2,

LAN3, LAN4, Disabled.

Launch Storage OpROM

Boot option for legacy mass storage devices with Option ROM.

Options: Enabled/Disabled.

BIOS Setup Utility 47

Page 58

PCI Subsystem Settings

PCI Latency Timer

Value to be programmed into PCI Latency Timer Register.

Options: 32 PCI Bus Clocks, 64 PCI Bus Clocks, 96 PCI Bus

Clocks, 128 PCI Bus Clocks, 160 PCI Bus Clocks, 192 PCI Bus

Clocks, 224 PCI Bus Clocks, 248 PCI Bus Clocks.

ASPM Support

Set the ASPM (Active State Power Management) level. Options:

X Disabled: Disable ASPM

X Auto: BIOS auto configure

X Force L0: Force all links to L0 State

48 BIOS Setup Utility

Page 59

CPU Configuration

Hyper-Threading

Enables/disables Hyper-Threading Technology.

Active Processor Cores

Number of cores to enable in each processor package.

Options: All, 1, 2.

CT-61

Intel Virtualization

Enables/disables Intel Virtualization Technology.

Power Technology

Power management feature. Options: Disabled, Energy Efficient,

Custom.

TDC Limit

Turbo-XE Mode Processor TDC Limit in 1/8 A granularity.

0 means use the factory-configured value.

TDP Limit

Turbo-XE Mode Processor TDP Limit in 1/8 W granularity.

0 means use the factory-configured value.

BIOS Setup Utility 49

Page 60

SATA Configuration

SATA Mode

The SATA can be configured as a legacy IDE, RAID and AHCI

mode.

Serial ATA Controller 0

This item specifies whether SATA Controller 0 is initialized in

Compatible or Enhanced mode of operation. The settings are

Disabled, Compatible and Enhanced.

Serial ATA Controller 1

This item specifies whether SATA Controller 1 is initialized in

Compatible or Enhanced mode of operation. The settings are

Disabled, Compatible and Enhanced.

50 BIOS Setup Utility

Page 61

Intel IGD SWSCI OpRegion Configuration

DVMT/FIXED Memory

Select DVMT/FIXED Mode Memory size used by internal

Graphics Device. Options: 128MB, 256MB, Maximum.

IGD – Boot Type

Selects the Video Device(s) to be activated during POST. This

option has no effect if external graphics pr es en t. Op tio ns : CRT,

DVI, TV, CRT+DVI.

CT-61

BIOS Setup Utility 51

Page 62

USB Configuration

Legacy USB Support

Legacy USB Support refers to USB mouse and keyboard support. Normally if this option is not enabled, any attached USB

mouse or keyboard will not become available until a USB compatible operating system is fully booted with all USB drivers

loaded. When this option is enabled, any attached USB mouse

or keyboard can control the system even when there is no USB

driver loaded on the system. Set this value to enable or disable

the Legacy USB Support.

EHCI Hand-off

This is a workaround for OSes without EHCI hand-off support.

The EHCI ownership change should be claimed by the EHCI

driver. Options: En able, Disable.

Device Reset Timeout

USB mass storage device Start Unit command timeout.

52 BIOS Setup Utility

Page 63

Super IO Configuration

Serial Port 1/2/4 Configuration

Sub-menu allows you to Enable/Disable and set the parameters of Serial Ports 1, 2, 4.

CT-61

BIOS Setup Utility 53

Page 64

PC Health Configuration

54 BIOS Setup Utility

Page 65

Console Redirection

The settings specify how the host computer and the remote

computer will exchange data. Both computers should have the

same or compatible settings.

The user can enable one serial port for Console Redirection.

Only one port can be used for Console Redir ecti on at any tim e.

CT-61

BIOS Setup Utility 55

Page 66

Terminal Type

VT-UTF8 is the preferred terminal type for out-of-band management. The next best choice is VT100+ and then VT100.

Options: VT100, VT100+, VT-UTF8, ASNI.

Bits per Second

Select the bit rate (bits/second) you want the ser ial port to use

for console redirection. Options: 115200, 57600, 19200, 9600.

Data Bits

Select the data bits you want the serial port to use for console

redirection. Set this value to 7 or 8.

Parity

Set this option to select Parity for console redirection. The settings for this value are None, Even, Odd, Mark, Space.

Stop B its

Stop bits indicate the end of a serial data packet. (A start bit

indicates the beginning). The standard setting is 1 stop bit.

Communication with slow devices may require more than 1

stop bit. Set this value to 1 or 2.

Flow Control

Set this option to select Flow Control for console redirection.

The settings for this value are None, Hardware, Software.

Terminal Resolution

Remote Terminal Resolution. Options: 80x25, 100x31.

56 BIOS Setup Utility

Page 67

CT-61

8.4 Chipset Configuration

Select the Chipset tab from the setup screen to enter the Chipset

BIOS Setup screen. You can select any of Chipset BIOS Setup

options by highlighting it using the < Arrow > keys. The Chipset

BIOS Setup screen is shown below.

Memory Information and Display Configuration

BIOS Setup Utility 57

Page 68

Initial Graphic Adapter

Allows you to select which graphics controller to use as the primary boot device. Configuration options: IGD, PCI/IGD,

PCI/PEG, PEG/IGD, PEG/PCI.

IGD Memory

IGD shared memory size. Options: Disabled, 32M, 64M, 128M.

PCH Configuration

SMBus Controller

The SMBus controller. Set this value to Enable/Disable.

Azalia HD Audio

The onboard HDA Controller. Set this value to Enable/Disable.

58 BIOS Setup Utility

Page 69

USB Configuration

All USB Devices

All USB Devices. Set this value to Enabled/Disabled.

EHCI Controller 1

USB 2.0 (EHCI) support. Set this value to Enabled/Disabled.

USB Port

CT-61

USB Port 0~7.Set this value to Enabled/Disabled.

BIOS Setup Utility 59

Page 70

8.5 Boot Configuration

Select the Boot tab from the setup screen to enter the Boot Configuration screen. You can select any of the items in the left frame

of the screen to go to the sub menu for that item. You can display

a Boot Configuration option by highlighting it using the < Arrow >

keys. The Boot Configuration screen is shown below:

Quiet Boot

When this feature is enabled, the BIOS will display the OEM logo

during the boot-up sequence, hiding normal POST messages.

When it is disabled, the BIOS will display the normal POST messages, instead of the OEM logo.

Fast Boot

Enabling this setting will cause the BIOS Power-On Self Test routine to skip some of its tests during bootup for faster system boot.

Setup Prompt Timeout

Number of seconds to wait for setup activation key. 65535

(0xFFFF) means indefinite waiting.

60 BIOS Setup Utility

Page 71

CT-61

Bootup Num-Lock

This option sets the Num Lock status when the system is powered

on. Setting it to On will turn on the Num Lock key when the system

is booted up. Setting it to Off will not enable the Num Lock key on

bootup.

GateA20 Active

Upon Request: GA20 can be disabled using BIOS services.

Always: do not allow disabling GA20; this option is useful when

any RT code is executed above 1MB.

Interrupt 19 Capture

Allows Option ROMs to trap Int 19. Set this value to Enabled or

Disabled.

Boot Option #1

Set the boot device options to determine the sequence in which

the computer checks which device to boot from.

BBS Priorities

Selects the boot devices available for each device type to be used

for Boot Option Priorities settings.

BIOS Setup Utility 61

Page 72

8.6 Security Setup

Administrator Password

Use this option to set a password for administrators with full control of the BIOS setup utility.

User Password

Use this option to set a password for users with limited access to

the BIOS setup utility.

62 BIOS Setup Utility

Page 73

CT-61

8.7 Save & Exit

Select the Save & Exit tab from the setup screen to enter the Sa ve

& Exit setup screen. You can display a Save & Exit BIOS setup

option by highlighting it using the < Arrow > keys. The Save & Exit

BIOS setup screen is shown below.

Save Changes and Reset

When you have completed the system configuration changes,

select this option to leave Setup and reboot the computer so the

new system configuration parameters can take effect.

Discard Changes and Reset

Select this option to quit Setup without making any permanent

changes to the system configuration.

Restore Defaults

Restore/Load Defaults values for all the setup options.

Boot Override

Use the up/down arrow keys to highlight a boot device to immediately exit the BIOS Setup and boot from the selected device.

BIOS Setup Utility 63

Page 74

This page intentionally left blank.

64 BIOS Setup Utility

Page 75

9 IPMI User Guide

9.1 Introduction

This chapter is written for those who already have a basic understanding of the newest implementation of the baseboard management controller (BMC) of the Intelligent Platform Management

Interface (IPMI) specification rev. 2.0. It also describes the OEM

extension IPMI command usages which are not listed in the IPMI

specification.

9.2 Summary of Commands Supported by

BMR-AVR-cPCI

The table below lists all the commands supported by the

BMR-AVR-cPCI. For detailed information on supported commands, please refer to the Intelligent Platform Management Interface Specification downloadable from the Intel we bsite

(http://www.intel.com/design/servers/ipmi/spec.htm).

CT-61

Command

IPM Device “Global” Commands

Get Device ID 20.1 App 0 1h

Cold Reset 20.2 App 02h

Warm Reset 20.3 App 03h

Get Self Test

Results

Get Device GUID 20.8 App 08h

IPMI User Guide 65

IPMI

Spec

NetFn CMD Description

20.4 App 04h

This command is used to retrieve the

Intelligent Device’s Hardware Revision,

Firmware/Software Revision, and Sensor

and Event Interface Command

specification revision information.

This command directs the Responder to

perform a ‘Cold Reset’ of itself.

This command directs the Responder to

perform a ‘Warm Reset’ of itself.

This command directs the device to

return its Self Test results, if any.

This command returns a GUID (Globally

Unique ID), also referred to as a UUID

(Universally Unique IDentifier), for the

management controller.

Page 76

Command

Broadcast “Get

Device ID”

IPMI Messaging Support Commands

Send Message 22.7 App 34h

BMC Watchdog Timer

Reset Watchdog

Timer

Set Watchdog

Timer

Get Watchdog

Timer

Event Commands

Set Event Receiver 29.1 S/E 00h

Get Event Receiver 29.2 S/E 01h

Platform Event

Message

IPMI

Spec

NetFn CMD Description

20.9 App 01h

27.5 App 22h

27.6 App 24h

27.7 App 25h

29.3 S/E 02h

This is a broadcast version of the ‘Get

Device ID’ command that is provided for

the ‘discovery’ of Intelligent Devices on

the IPMB

The Send Message command is us ed for

bridging IPMI messages between

channels, and between the system

management software (SMS) and a given

channel.

The Reset Watchdog Timer command is

used for starting and restarting the

Watchdog Timer from the initial

countdown value that was specified in the

Set Watchdog Timer command.

The Set Watchdog Timer command is

used for initializing and configuring the

watchdog timer. The command is also

used for stopping the timer.

This command retrieves the current

settings and present countdown of the

watchdog timer.

This global command tells a controller

where to send Event Messages.

This global command is used to retrieve

the present setting for the Event Receiver

Slave Address and LUN. This command

is only applicable to management

controllers that act as IPMB Event

Generators.

This command may be thought of as a

request for the BMC to process the event

data that the command contains.

Typically, the data will be logged to the

System Event Log (SEL).

66 IPMI User Guide

Page 77

CT-61

Command

Sensor Device Commands

Get Device SDR

Info

Get Device SDR 35.3 S/E 21h

Reserve Device

SDR Repository

Set Sensor

Hysteresis

Get Sensor

Hysteresis

Set Sensor

Threshold

Get Sensor

Threshold

Set Sensor Event

Enable

Get Sensor Event

Enable

Get Sensor Event

Status

IPMI

Spec

35.10 S/E 28h

35.11 S/E 29h

35.13 S/E 2Bh

NetFn CMD Description

35.2 S/E 20h

35.4 S/E 22h

35.6 S/E 24h

35.7 S/E 25h

35.8 S/E 26h

35.9 S/E 27h

This command returns general

information about the collection of

sensors in a Dynamic Sensor Device.

The ‘Get Device SDR’ command allows

SDR information for sensors for a Sensor

Device (typically implemented

in a satellite management controller) to

be returned.

This command is used to obtain a

Reservation ID.

This command provides a mechanism for

setting the hysteresis values associated

with the thresholds of a sensor

that has threshold based event

generation.

This command retrieves the present

hysteresis values for the specified

sensor.

This command is used to set the

specified threshold for the given sensor.

This command retrieves the threshold for

the given sensor.

This command provides the ability to

disable or enable Event Message

Generation for individual sensor events.

The command is also used to enable or

disable sensors in their entirety using the

disable scanning bit.

This command returns the enabled/

disabled state for Event Message

Generation from the selected sensor. The

command also returns the enabled/

disabled state for scanning on the sensor.

The Get Sensor Event Status command

is provided to support systems where

sensor polling is used in addition to, or

instead of, Event Messages for event

detection.

IPMI User Guide 67

Page 78

Command

Get Sensor

Reading

Get Sensor Type 35.16 S/E 2Fh

FRU Device Commands

Get FRU Inventory

Area Info

Read FRU Data 34.2

Write FRU Data 34.3

IPMI

Spec

35.14 S/E 2Dh

NetFn CMD Description

34.1

Stora

ge

Stora

ge

Stora

ge

10h

11h

12h

This command returns the present

reading for sensor. The sensor device

may return a stored version of a

periodically updated reading, or the

sensor device may scan to obtain the

reading after receiving the request.

This command is used to assign the

Sensor Type and Event/Reading Type to

a specified sensor.

Returns overall the size of the FRU

Inventory Area in this device, in bytes.

The command returns the specified data

from the FRU Inventory Info area.

The command writes the specified byte

or word to the FRU Inventory Info area.

68 IPMI User Guide

Page 79

CT-61

9.3 OEM Commands Summary Table

Command NetFn Code Cmd Code

OemShowRevision OEM (C0h) 12h

OemRescanGaInput OEM (C0h) 22h

OemTestFunction OEM (C0h) 30h

OemSetBlueLEDLongBlinking OEM (C0h) 31h

OemReportGeoAddress OEM (C0h) F0h

OemEnableSmbus OEM (C0h) F2h

OemDisableSmbus OEM (C0h) F3h

OemDispDebugVariable OEM (C0h) F4h

OemResetHost OEM (C0h) F5h

OemPowerOff OEM (C0h) F6h

OemPowerOn OEM (C0h) F7h

OemShowRevision

This command is used to show the current information of the firmware including the firmware revision, the product ID, and addi-

tional features.

Action Byte Value Description

Request

Response

IPMI User Guide 69

0 C0h NetFn/LUN for OEM

1 12h OEM defined command

0 Complete Code 00h means OK

1 A5h Internal check byte. Always A5h

2 *Firmware Rev ‘V’ in ASCII code for verification

3 *Firmware Rev Revision info high byte

4 *Firmware Re v Revision info low byte

5 *Product ID ‘P’ in ASCII code for verification

6 *Product ID Product info high byte

7 *Product ID Product info low byte

8 *Special info ‘S’ in ASCII code for verification

9 *Special info Addition info byte

10 5Ah Internal check byte. Always 5Ah

Page 80

OemRescanGaInput

This command is used to rescan the geo-address input pins and

reset the IPMB address according to the input value.

Action Byte Value Description

Request

Response

0 C0h NetFn/LUN for OEM

1 22h OEM defined command

0 Complete Code 00h means OK

1 New IPMB address New IPMB address value

OemTestFunction

Internal test purposes only.

OemSetBlueLEDLongBlinking

This command is used to enable or disable the slow blink of the

blue HotSwap LED when a voltage is detected to be over ±5% out

of range for five seconds (see Table 4-1 on page 22).

This function

is set to enabled by default.

Action Byte Value Description

0 C0h NetFn/LUN for OEM

Request

Response 0 Complete Code 00h means OK

1 31h OEM defined command

2 00h or 01h

00h: disable slow blink capability

01h: enable slow blink capability

70 IPMI User Guide

Page 81

OemReportGeoAddress

This command can report the IPMB address, the GA pin input status, and the event forwarding control value.

Action Byte Value Description

Request

Response

0 C0h NetFn/LUN for OEM

1 F0h OEM defined command

0 Complete Code 00h means OK

1 IPMB address IPMB address value

2 GA value GA pin input status

3 Control value Current control value of event forwarding

OemEnableSmbus

This command is used to turn on the I2C bus when it is off during

boot up process. Usually BIOS will perform this command after

booting in boards with ServerWorks chipset.

Action Byte Value Description

Request

Response 0 Complete Code 00h means OK

0 C0h NetFn/LUN for OEM

1 F2h OEM defined command

CT-61

OemDisableSmbus

This command is used to shut down I2C bus access.

Action Byte Value Description

Request

Response 0 Complete Code 00h means OK

IPMI User Guide 71

0 C0h NetFn/LUN for OEM

1 F3h OEM defined command

Page 82

OemDispDebugVariable

This command can report up t o 5 interval values for debug purposes. For developers only.

Action Byte Value Description

Request

Response

0 C0h NetFn/LUN for OEM

1 F4h OEM defined command

0 Complete Code 00h means OK

1 *Debug variable 1

2 *Debug variable 2

3 *Debug variable 3

4 *Debug variable 4

5 *Debug variable 5

OemResetHost

This command is implemented to control the system’s status if

rebooting is required. Operators can control the system remotely.

Action Byte Value Description

Request

Response 0 Complete Code 00h means OK

0 C0h NetFn/LUN for OEM

1 F5h OEM defined command

OemPowerOff

This command is implemented to control the system’s status if

power-off is required. Operators can control the system remotely.

Action Byte Value Description

Request

Response 0 Complete Code 00h means OK

72 IPMI User Guide

0 C0h NetFn/LUN for OEM

1 F6h OEM defined command

Page 83

CT-61

OemPowerOn

This command is implemented to control the system’s status if

power-on is required. Operators can control the system remotely.

Action Byte Value Description

Request

Response 0 Complete Code 00h means OK

0 C0h NetFn/LUN for OEM

1 F7h OEM defined command

9.4 CompactPCI Address Map

Since more than one system may be installed in a single chassis,

we allocate each IPMB address based on GA input as peripheral

cards. The CompactPCI Peripheral Address Mapping Table is

given below.

CompactPCI Peripheral Address Mapping

Geo. Addr. IPMB Addr. Geo. Addr. IPMB Addr.

0Disabled16 D0h

1B0h17D2h

2B2h18D4h

3B4h19D6h

4B6h20D8h

5B8h21DAh

6 Bah 22 DCh

7 BCh 23 DEh

8 BEh 24 E0h

9 Coh 25 E2h

10 C4h 26 E4h

11 C6h 27 E6h

12 C8h 28 E8h

13 CAh 29 EAh

14 CCh 30 ECh

15 CEh 31 Disabled

IPMI User Guide 73

Page 84

9.5 Communications with IPMC

Operating systems need to use a serial port to com municate with

the IPMC. The resource setting of the serial port must be IO:

0x3E8 and IRQ: 3. The communication setting of the serial port