Page 1

cPCIS-ET2600 Series

4U Height Wide Temperature Range

Subsystem for 3U CompactPCI Modules

User’s Guide

Page 2

Copyright 2013 ADLINK Technology, Inc.

All Rights Reserved.

Manual Rev. 1.00, January 2, 2013

Part No.: 50-15088-2000

The information in this document is subject to change without prior notice in

order to improve reliability, design and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental,

or consequential damages arising out of the use or inability to use the product

or documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

Product names mentioned herein are used for identification purposes only and

may be trademarks and/or registered trademarks of their respective companies.

Page 3

Table of Contents

How to Use This Manual................................................................v

1 Introduction ....................................................................................1

1.1 Product Definition ......................................................................1

1.2 Mechanical Drawing ..................................................................2

1.3 Configurations............................................................................3

1.4 Customized Systems.................................................................3

2 Getting Started ...............................................................................5

2.1 Shipping Contents .....................................................................5

2.2 CompactPCI Board & PSU Installation cPCIS-ET2600 Series

models with CompactPCI PSU(s) .......................................................

2.3 RTM (Rear Transition Module) Installation................................9

2.4 Powering Up the System...........................................................9

3 Backplane .....................................................................................10

3.1 cBP-3208[R] Backplane...........................................................10

Specifications .....................................................................10

Mechanical Drawing...........................................................11

Pin Assignment...................................................................13

3.2 cBP-3206[R] Backplane...........................................................17

Specifications .....................................................................17

Mechanical Drawing...........................................................18

Pin Assignment...................................................................19

3.3 cBP-3061 Power Backplane....................................................23

Specifications .....................................................................23

Mechanical Drawing...........................................................23

Pin Assignment...................................................................24

3.4 cBP-3062 Power Backplane....................................................27

Specifications .....................................................................27

Mechanical Drawing...........................................................27

Pin Assignment...................................................................28

5

4 Cooling System............................................................................31

4.1 Removing and Replacing the Air Filters cPCIS-ET2600 Series

models with CompactPCI PSU(s) .....................................................

4.2 Fan Alarm: Fan Removal and Replacement...........................33

Table of Contents • iii

31

Page 4

4.3 Temperature Alarm..................................................................34

4.4 Fan Specifications ...................................................................34

Mechanical Drawing...........................................................34

5 Power Supply Unit .......................................................................35

5.1 CompactPCI: cPS-P325/AC....................................................35

Features .............................................................................35

Specifications .....................................................................35

Input Characteristics...........................................................36

Output Characteristics........................................................36

6 Specifications...............................................................................39

6.1 Features...................................................................................39

6.2 Mechanical...............................................................................39

6.3 Environmental..........................................................................40

6.4 System Alarm Board................................................................40

Important Safety Instructions ...................................................43

Getting Service...............................................................................45

iv • Table of Contents

Page 5

How to Use This Manual

This manual is designed to help you use the cPCIS-ET2600 series 3U

CompactPCI Subsystem . It is divided into six chapters:

Chapter 1: Introduction

Chapter 2: Getting Started,

and configuration of the subsystem .

Chapter 3: Backplane

used in the cPCIS-ET2600 Series subsystems.

Chapter 4: Cooling System

subsystem air filters, fan and temperature alarm conditions

and the hot swappable fans used to cool the subsystem .

Chapter 5: Power Supply Unit

ET2600 Series subsystems.

Chapter 6: Specifications

specifications.

, gives an overview of the product features.

describes the unpacking procedure, setup

, gives a detailed description of the backplanes

, describes how to remove and replace the

, describes the PSUs of the cPCIS-

, describes the subsystem's detailed

How to Use This Manual • v

Page 6

This page intentionally left blank.

vi • Introduction

Page 7

1 Introduction

1.1 Product Definition

The cPCIS-ET2600 wide temperature range subsystem is rack mountable,

4U in height, and designed for 3U CompactPCI cards and modules. They ar e

ideal for industrial or transport applications where small chassis size with

multi-functionality are important, and provide maximum cooling efficienc y, a

guarded power on/off button, ample power capacity, a hot swap backplane

and easy maintenance. Their ability to handle a wide range of temperatu res

and excellent shock and vibration characteristics make them suitable for

operating in a rigorous environment. An embedded alarm board monitors

temperature & fan status to maximize continuous operation. The cPCISET2600 Series allows for custom configuration, giving system integrators

maximum flexibility to build in specialized functionality.

This user’s manual provides unpacking, operating, and maintenance

information for the cPCIS-ET2600 3U CompactPCI subsystem. The cPCISET2600 subsystem is assembled using the following components:

Components:

• Chassis: cPRK-2600ET

• Power Supply: 3U CompactPCI

• Backplane: PICMG 2.0 R3.0 Hot Swap compatibility

• Cooling: 5 hot swappable, push-in fans with removable air filters

cPCIS-ET2632R shown

Introduction • 1

Page 8

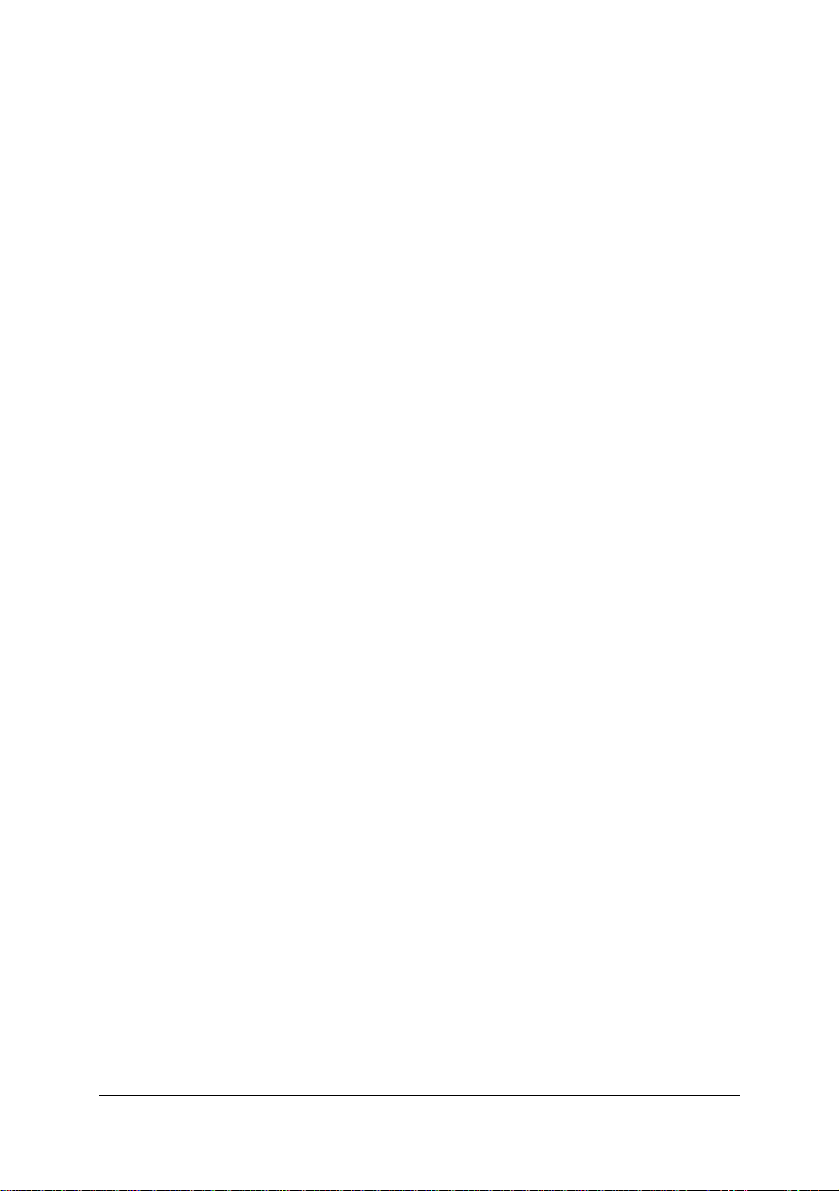

1.2 Mechanical Drawing

R

2 • Introduction

Page 9

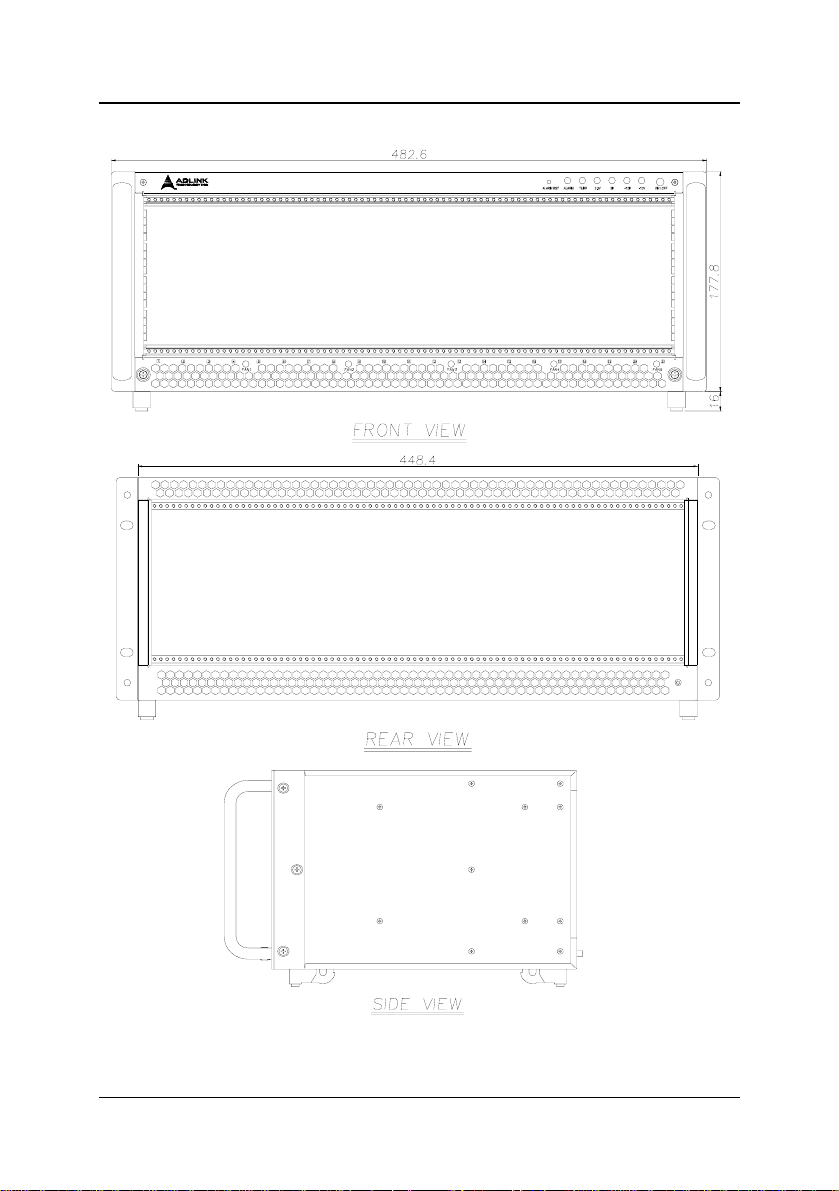

1.3 Configurations

The cPCI-ET2600 Series comes in the following configuration:

cPCIS-

ET2632[R]

*cPCIS-ET2632 is available with rear I/O backplanes for Rear Transition

Modules (RTMs) and is indicated by an “R” suffix on the model name .

system

slots

peripheral

slots

1 7

250W cPCI

PSU(s) monitor PICMG

(1 + 1)

— 2.0, 2.1, 2.11

1.4 Customized Systems

Subsystem s can also be customized to meet individual nee ds. To customize

a subsystem please contact an ADLINK dealer. For complete systems, users

must order CPU modules in addition to the subsystem .

Introduction • 3

Page 10

This page intentionally left blank.

4 • Introduction

Page 11

2 Getting Started

In this chapter, we will describe the unpacking procedure of the subsystem

and CompactPCI board and power supply unit (PSU) installation procedures

for cPCIS-ET2600 Series models with CompactPCI PSU(s) only.

2.1 Shipping Contents

Check the shipping carton for any damage. If the shipping carton and

contents are damaged, please notify the dealer for a replacement. Ret ain

the shipping carton and packing material for inspection by the deal er. Obtain

authorization before returning any product to ADLINK.

Check that the following items are included in the package. If there are any

missing items, please contact your dealer:

• One cPCIS-ET2600 Series subsystem

• This User’s Manual

• Power cord (either N. American or European)

2.2 CompactPCI Board & PSU Installation

cPCIS-ET2600 Series models with CompactPCI PSU(s)

The CompactPCI connectors are rigid and require careful handling when

inserted and removed. Improper handling of cards can easily damage the

backplane.

The PSU slot also has an obvious indicator such as a green card guide rail in a

standard CompactPCI chassis (see photo below).

Backplane • 5

Page 12

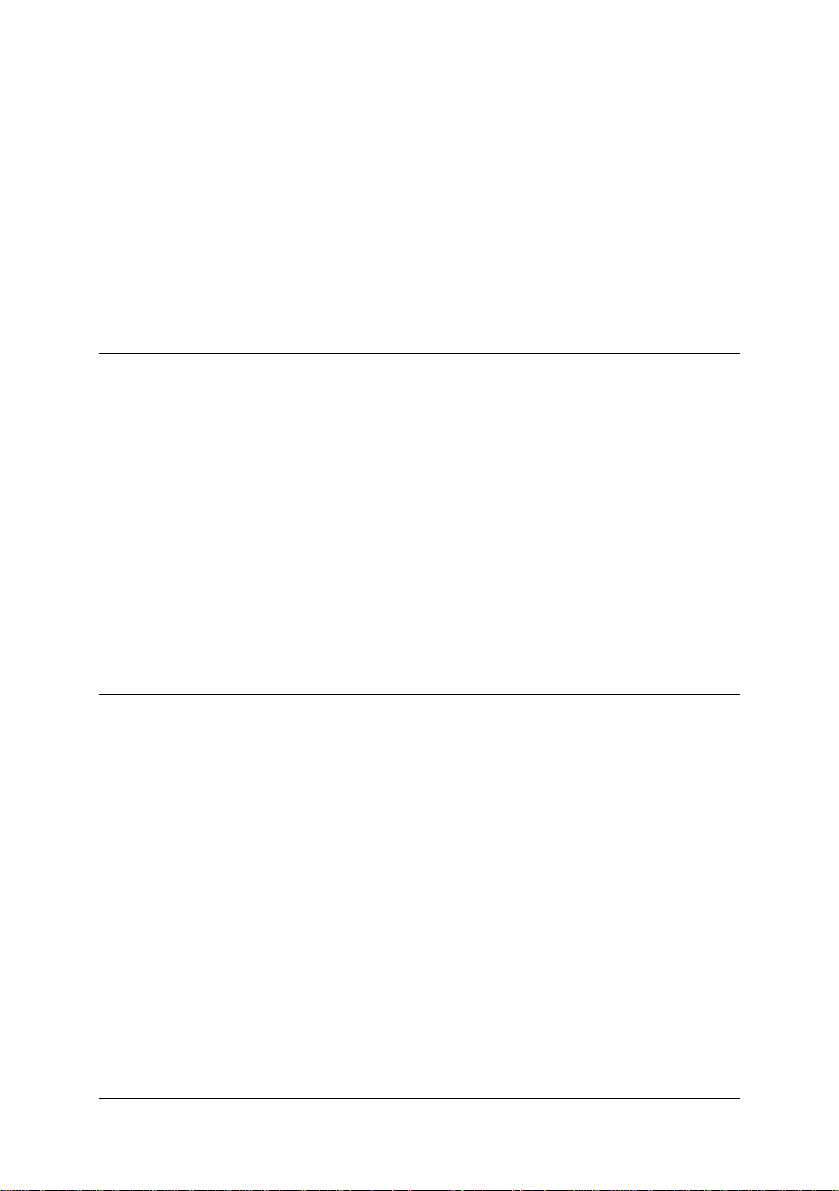

PSU Slot

System slots usually have obvious indicators (e.g. red card guide rail, triangle

mark enclosing the slot number on the backplane, etc.) System cards can only

be installed in a system slot. Do not insert a system card into any other slot, or

insert any peripheral card into system slot.

System Card Slot

Peripheral Card Slots

6 • Backplane

Page 13

The handle on CompactPCI cards and PSUs ensures simple and safe

installation and removal. Please follow the procedures below to install a

CompactPCI module into a cPCIS-ET2600 Series chassis with CompactPCI

PSU(s):

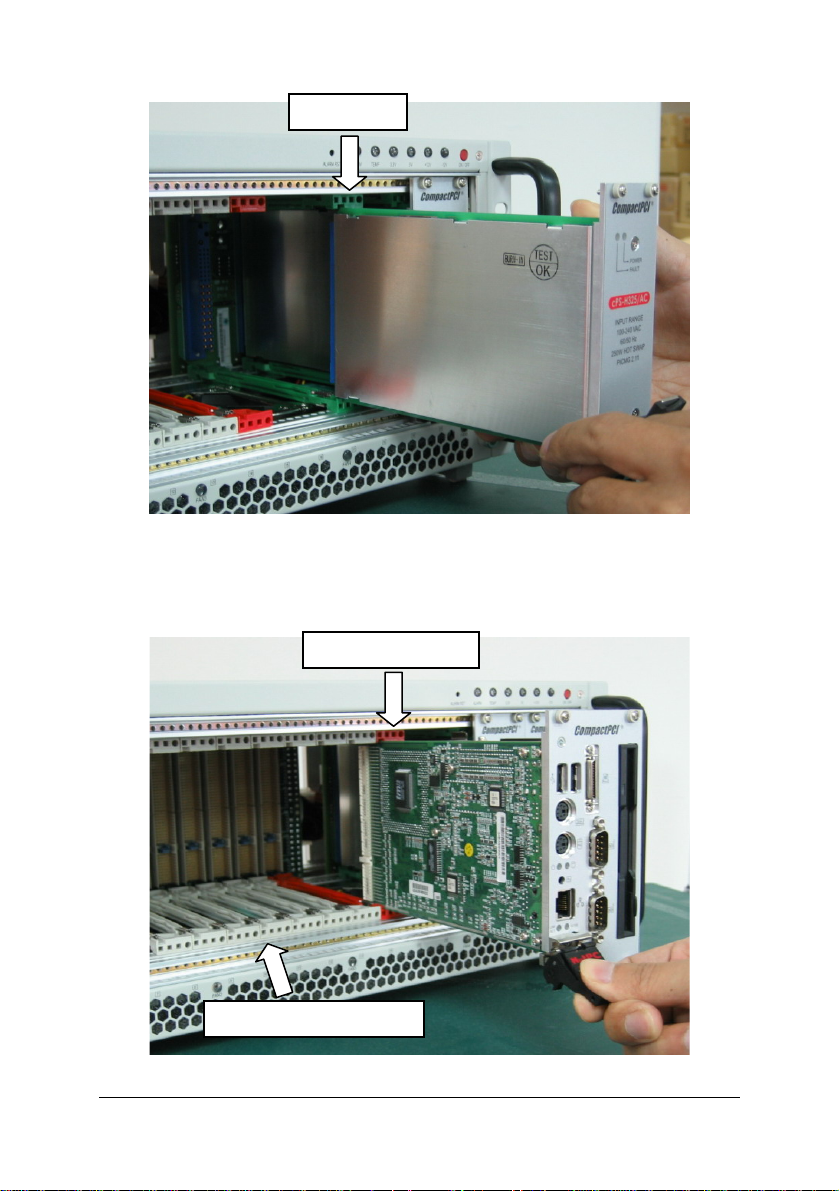

CompactPCI Card Installation/Removal Procedure

1. Place the subsystem on a level surface or rackmount it. Remove the

blanking plates where required by undoing the retaining screws at each

end. Retain the blanking plates for possible future use. The system should

not be put into use without blanking plates for all empty slots, otherwise the

EMC and cooling performance will be compromised

2. Hold the SBC module, peripheral card or PSU module vertically. For PSU

modules, make sure that the handle is unlatched (i.e. that it is pulled

downwards) by first pressing on the locking button with your thumb.

Insert Module

Locking Button

Unlatched

3. Carefully insert the module into the desired slot by sliding the edges of the

board into the appropriate card guide rail. Take care to ensure correct

alignment of the card with the chassis during insertion to prevent damage

to the card and/or backplane.

4. Continue inserting the card until the handle engages with the chassis.

5. Pull upwards on the handle for final insertion. For PSU modules, ensure

that the locking button on the handle is fully latched into positi on.

Backplane • 7

Page 14

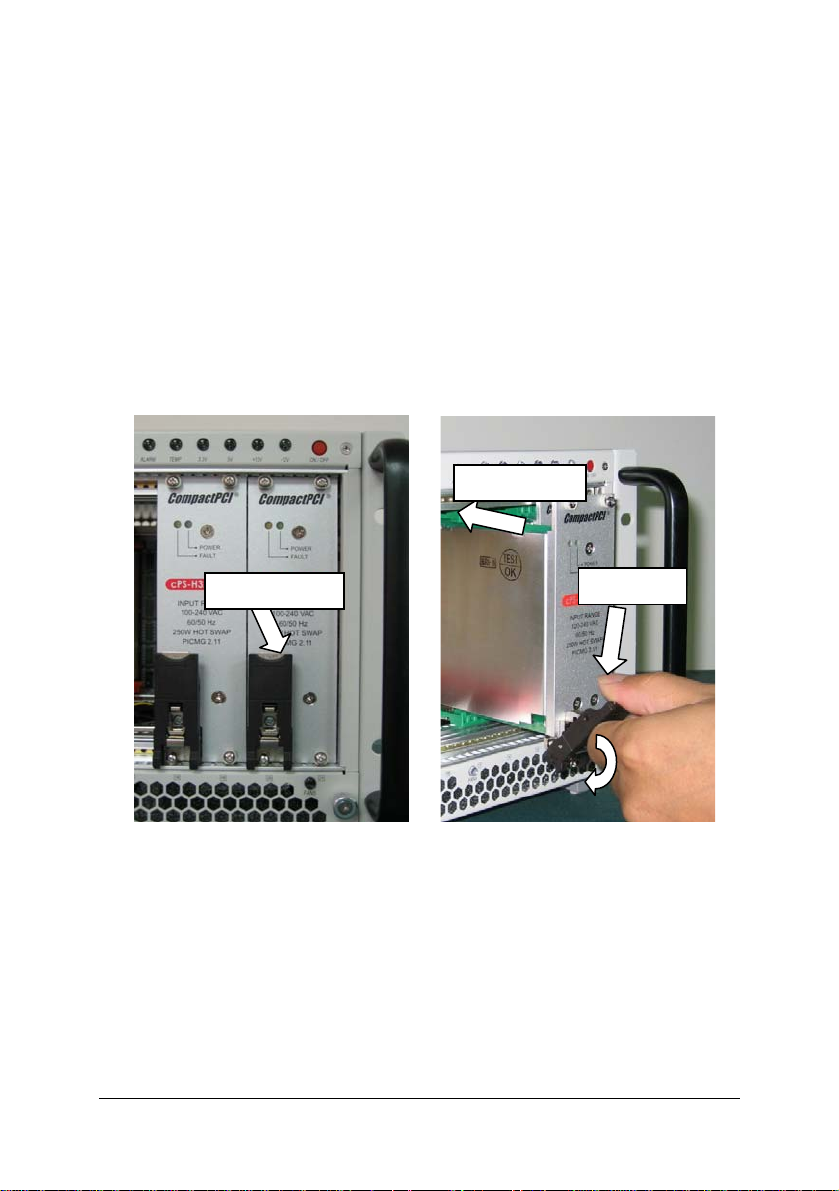

y

Fully Latched

Handle Engages

with Chassis

System Card

Full

Inserted

To remove the module, press the release button (if necessary), and reverse

steps 1 through 5 above.

8 • Backplane

Page 15

2.3 RTM (Rear Transition Module) Installation

The installation and removal procedures for a RTM are the same as those for

CompactPCI boards. Because they are shorter than front boards, pay careful

attention when inserting or removing RTMs. Only models with an “R” at the end

of the model number support RTMs.

Note: We strongly recommended the use of RTMs with AB type connectors

to prevent damaging the backplane during RTM installation.

2.4 Powering Up the System

Connect the supplied power cord to the socket on the back of the chassis. All

supplied PSUs are full range 90-240VAC and do not require input voltage

setting. Insert a system module into the appropriate card slot.

The cPCIS-ET2600 Series subsystems feature a guarded po wer switch. Use

a suitably shaped object (such as a pen) to actuate the power switch. All

LEDs will light up to indicate normal operating conditions.

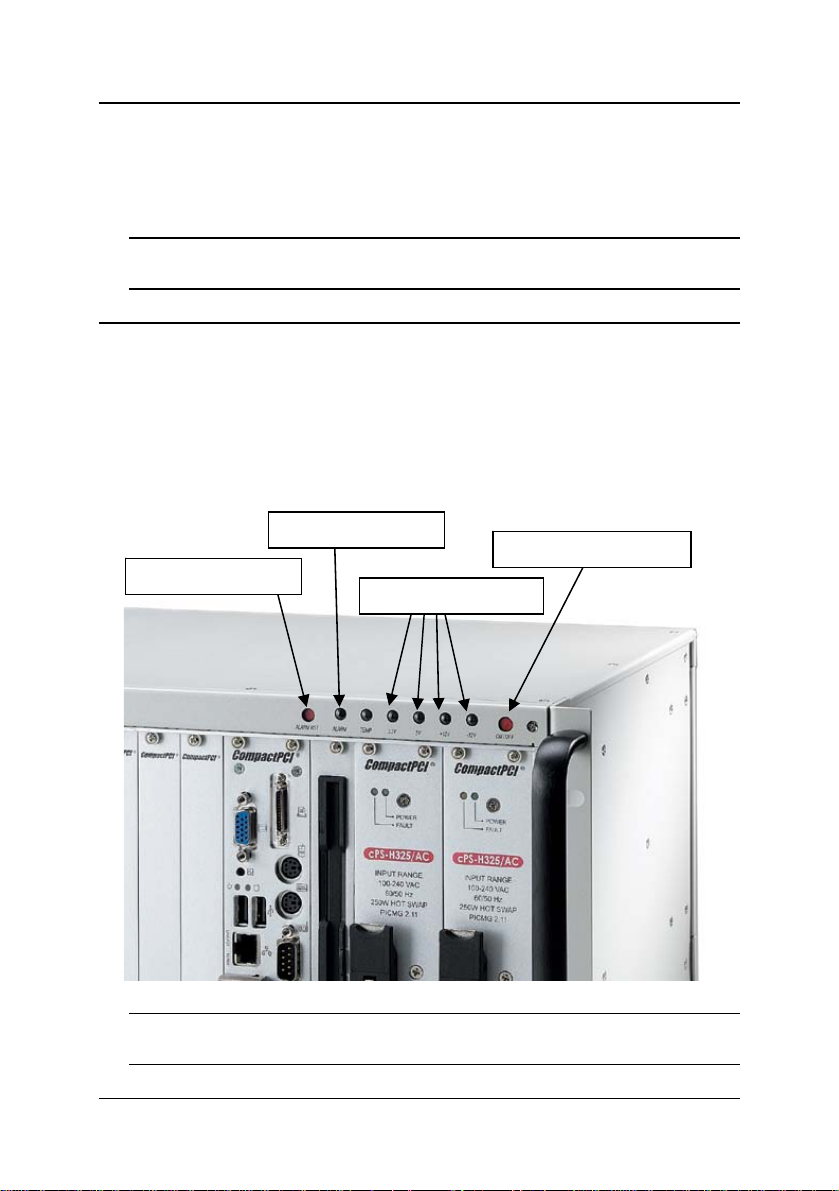

Alarm LED

Alarm reset switch

Voltage Status LEDs

Guarded Power Switch

Note: If there are any faults with the power supply,

the appropriate Voltage Status LED will turn off to notify the user.

Backplane • 9

Page 16

3 Backplane

In this chapter, we will describe the backplane for the cPCIS-ET 2600 Series

subsystems. The following table specifies the backplane(s) that corres pond

to each model.

backplane slots

cPCIS-ET2632[R] cBP-3208[R] 8 cBP-3062A

power

backplane

3.1 cBP-3208[R] Backplane

The cBP-3208[R] is a 3U CompactPCI 32-bit backplane with optional rear I/O

(designated by an “R” suffix). It is used by the cPCIS-2630 / 2631 / 2632 /

2650 / 2651[R].

Specifications

• Standard CompactPCI height for 3U cPCI cards

• CompactPCI Compliancy

o PICMG 2.0 CompactPCI core specification R3.0

o PICMG 2.1 CompactPCI hot swap R2.0

• Dimensions: 141.3 x 128.7 mm

• PCI bus clock: up to 32-bit/33MHz

• System Slot: one R-hand side dual-slot

• System Slot Rear I/O: P2 rear I/O with AB-type shroud

• Peripheral slots: 7

• Peripheral Slots Rear I/O: P2 rear I/O with AB-type shroud (optional)

• Power Connectors: ATX connector x2, DC screw terminals

• V (I/O): 3.3V or 5V selectable, default 5V

• Other connectors: INH#, Reset, PWR_FAL#

10 • Backplane

Page 17

Mechanical Drawing

8 - P2

8 - P1

cBP-3208[R]Front View

1 - P2

1 - P1

Backplane • 11

Page 18

1 - P2

Optional Rear I/O: 2 - P2 to 8 - P2

12 • Backplane

cBP-3208[R] Rear View

Page 19

Pin Assignment

¾ [1 – P1] System Slot

Pin Z A B C D E F

GND +5V REQ64#

25

GND AD[1] +5V V(I/O)

24

GND +3.3V AD[4] AD[3] +5V AD[2] GND

23

GND AD[7] GND +3.3V AD[6] AD[5] GND

22

GND +3.3V AD[9] AD[8] M66EN C/BE[0]# GND

21

GND AD[12] GND V(I/O)

20

GND +3.3V AD[15] AD[14] GND AD[13] GND

19

GND SERR# GND +3.3V PAR C/BE[1]# GND

18

GND +3.3V IPMB_SCL

17

GND DEVSEL# GND V(I/O)

16

GND +3.3V FRAME# IRDY# BDSEL TRDY# GND

15

12-14 Key

GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

11

GND AD[21] GND +3.3V AD[20] AD[19] GND

10

GND C/BE[3]# IDSEL AD[23] GND AD[22] GND

9

GND AD[26] GND V(I/O)

8

GND AD[30] AD[29] AD[28] GND AD[27] GND

7

GND REQ# GND +3.3V CLK AD[31] GND

6

GND Reserved

5

GND IPMB_PWR HEALTHY# V(I/O)

4

GND INTA# INTB# INTC# +5V INTD# GND

3

GND TCK

2

GND +5V -12V TRST#

1

Reserved PCIRST# GND GNT# GND

+5V TMS

Pin Z A B C D E F

ENUM# +3.3V +5V GND

AD[0] ACK64# GND

AD[11] AD[10] GND

IPMB_SDA GND PERR# GND

STOP# LOCK# GND

AD[25] AD[24] GND

INTP INTS GND

TDO TDI

+12V +5V GND

GND

Backplane • 13

Page 20

¾ [1 – P2] System Slot

Pin Z A B C D E F

22 GND GA4

21 GND CLK6 GND NC NC NC GND

20 GND CLK5 GND NC NC NC GND

19 GND GND GND NC NC NC GND

18 GND NC NC NC NC NC GND

17 GND NC NC PRST# REQ6# GNT6# GND

16 GND NC NC DEG# NC NC GND

15 GND NC NC FAL# REQ5# GNT5# GND

14 GND NC NC NC NC NC GND

13 GND NC NC NC NC NC GND

12 GND NC NC NC NC NC GND

11 GND NC NC NC NC NC GND

10 GND NC NC NC NC NC GND

9 GND NC NC NC NC NC GND

8 GND NC NC NC NC NC GND

7 GND NC NC NC NC NC GND

6 GND NC NC NC NC NC GND

5 GND NC NC NC NC NC GND

4 GND V(I/O) NC NC NC NC GND

3 GND CLK4 GND GNT3# REQ4# GNT4# GND

2 GND CLK2 CLK3 GND GNT2# REQ3# GND

1 GND CLK1 GND REQ1# GNT1# REQ2# GND

Pin Z A B C D E F

GA3 GA2 GA1 GA0 GND

14 • Backplane

Page 21

¾ [2 – P1] / [8 – P1] Peripheral Slot

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND AD[1] +5V V(I/O) AD[0] ACK64# GND

23 GND +3.3V AD[4] AD[3] +5V AD[2] GND

22 GND AD[7] GND +3.3V AD[6] AD[5] GND

21 GND +3.3V AD[9] AD[8] M66EN C/BE[0]# GND

20 GND AD[12] GND V(I/O) AD[11] AD[10] GND

19 GND +3.3V AD[15] AD[14] GND AD[13] GND

18 GND SERR# GND +3.3V PAR C/BE[1]# GND

17 GND +3.3V IPMB_SCL IPMB_SDA GND PERR# GND

16 GND DEVSEL# GND V(I/O) STOP# LOCK# GND

15 GND +3.3V FRAME# IRDY# GND TRDY# GND

12-14 Key

11 GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

10 GND AD[21] GND +3.3V AD[20] AD[19] GND

9 GND C/BE[3]# IDSEL AD[23] GND AD[22] GND

8 GND AD[26] GND V(I/O) AD[25] AD[24] GND

7 GND AD[30] AD[29] AD[28] GND AD[27] GND

6 GND REQ# GND +3.3V CLK AD[31] GND

5 GND NC NC PCIRST# GND GNT# GND

4 GND IPMB_PWR HEALTHY# V(I/O) INTP INTS GND

3 GND INTA# INTB# INTC# +5V INTD# GND

2 GND TCK +5V TMS TDO TDI GND

1 GND +5V -12V TRST# +12V +5V GND

Pin Z A B C D E F

¾ [2 – P2] / [8 – P2] Peripheral Slot

Pin Z A B C D E F

22 GND

1-21 GND NC NC NC NC NC GND

GA4

GA3 GA2 GA1 GA0

GND

Backplane • 15

Page 22

¾ CN1 / CN2 – ATX Power Connector

1

11

¾ JP7 – connector

1

¾ JP8 – connector

1

¾ JP9 – connector

1

¾ JP10 – connector

1

¾ JP1- V (I/O), default: +5V

1

8

16 • Backplane

Pin Signal Pin Signal

1 +3.3V 11 +3.3V

2 +3.3V 12 -12V

3 GND 13 GND

4 +5V 14 PS_ON_L

5 GND 15 GND

6 +5V 16 GND

7 GND 17 GND

8 POWER

9 5V STB 19 +5V

10 +12V 20 +5V

Pin # Signal Name

1

2

Pin # Signal Name

1

2

Pin # Signal Name

1 PRST#

2 GND

Pin # Signal Name

1 FAL#

2 GND

Pin # Signal Name Pin # Signal Name

1 +12V 2 GND

3 -12V 4 GND

5 +3.3V 6 GND

7 +5V 8 GND

18 -5V

GOOD

+12V

-12V Sense

INH#

GND

Page 23

3.2 cBP-3206[R] Backplane

The cBP-3206[R] is a 3U CompactPCI 32-bit backplane with optional rear I/O

(designated by an “R” suffix). The cPCIS-2642[R] uses two of these backplanes.

Specifications

• Standard CompactPCI height for 3U cPCI cards

• CompactPCI Compliancy

o PICMG 2.0 CompactPCI core specification R3.0

o PICMG 2.1 CompactPCI hot swap R2.0

• Dimensions: 100.7 x 128.7 mm

• PCI bus clock: up to 32-bit/33MHz

• System Slot: one R-hand side dual-slot

• System Slot Rear I/O: P2 rear I/O with AB-type shroud

• Peripheral slots: 5

• Peripheral Slots Rear I/O: P2 rear I/O with AB-type shroud (optional)

• Power Connectors: ATX connector x2, DC screw terminals

• V (I/O): 3.3V or 5V selectable, default 5V

• Other connectors: INH#, Reset, PWR_FAL#

Backplane • 17

Page 24

[R]

Mechanical Drawing

6 - P2

6 - P1

1 - P2

1 - P1

JP8 - JP10

CN1

cBP-3206

1 - P2

Front View

Opt. Rear I/O:

2 - P2 to 6 - P2

CN2

cBP-3206[R]Rear View

18 • Backplane

Page 25

Pin Assignment

¾ [1 – P1] System Slot

Pin Z A B C D E F

GND +5V REQ64#

25

GND AD[1] +5V V(I/O)

24

GND +3.3V AD[4] AD[3] +5V AD[2] GND

23

GND AD[7] GND +3.3V AD[6] AD[5] GND

22

GND +3.3V AD[9] AD[8] M66EN C/BE[0]# GND

21

GND AD[12] GND V(I/O)

20

GND +3.3V AD[15] AD[14] GND AD[13] GND

19

GND SERR# GND +3.3V PAR C/BE[1]# GND

18

GND +3.3V IPMB_SCL

17

GND DEVSEL# GND V(I/O)

16

GND +3.3V FRAME# IRDY# BDSEL TRDY# GND

15

12-14 Key

GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

11

GND AD[21] GND +3.3V AD[20] AD[19] GND

10

GND C/BE[3]# IDSEL AD[23] GND AD[22] GND

9

GND AD[26] GND V(I/O)

8

GND AD[30] AD[29] AD[28] GND AD[27] GND

7

GND REQ# GND +3.3V CLK AD[31] GND

6

GND Reserved

5

GND IPMB_PWR HEALTHY# V(I/O)

4

GND INTA# INTB# INTC# +5V INTD# GND

3

GND TCK

2

GND +5V -12V TRST#

1

Reserved PCIRST# GND GNT# GND

+5V TMS

Pin Z A B C D E F

ENUM# +3.3V +5V GND

AD[0] ACK64# GND

AD[11] AD[10] GND

IPMB_SDA GND PERR# GND

STOP# LOCK# GND

AD[25] AD[24] GND

INTP INTS GND

TDO TDI

+12V +5V GND

GND

Backplane • 19

Page 26

¾ [1 – P2] System Slot

Pin Z A B C D E F

22 GND GA4

21 GND CLK6 GND NC NC NC GND

20 GND CLK5 GND NC NC NC GND

19 GND GND GND NC NC NC GND

18 GND NC NC NC NC NC GND

17 GND NC NC PRST# REQ6# GNT6# GND

16 GND NC NC DEG# NC NC GND

15 GND NC NC FAL# REQ5# GNT5# GND

14 GND NC NC NC NC NC GND

13 GND NC NC NC NC NC GND

12 GND NC NC NC NC NC GND

11 GND NC NC NC NC NC GND

10 GND NC NC NC NC NC GND

9 GND NC NC NC NC NC GND

8 GND NC NC NC NC NC GND

7 GND NC NC NC NC NC GND

6 GND NC NC NC NC NC GND

5 GND NC NC NC NC NC GND

4 GND V(I/O) NC NC NC NC GND

3 GND CLK4 GND GNT3# REQ4# GNT4# GND

2 GND CLK2 CLK3 GND GNT2# REQ3# GND

1 GND CLK1 GND REQ1# GNT1# REQ2# GND

Pin Z A B C D E F

GA3 GA2 GA1 GA0 GND

20 • Backplane

Page 27

¾ [2 – P1] – [6 – P1] Peripheral Slot

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND AD[1] +5V V(I/O) AD[0] ACK64# GND

23 GND +3.3V AD[4] AD[3] +5V AD[2] GND

22 GND AD[7] GND +3.3V AD[6] AD[5] GND

21 GND +3.3V AD[9] AD[8] M66EN C/BE[0]# GND

20 GND AD[12] GND V(I/O) AD[11] AD[10] GND

19 GND +3.3V AD[15] AD[14] GND AD[13] GND

18 GND SERR# GND +3.3V PAR C/BE[1]# GND

17 GND +3.3V IPMB_SCL IPMB_SDA GND PERR# GND

16 GND DEVSEL# GND V(I/O) STOP# LOCK# GND

15 GND +3.3V FRAME# IRDY# GND TRDY# GND

12-14 Key

11 GND AD[18] AD[17] AD[16] GND C/BE[2]# GND

10 GND AD[21] GND +3.3V AD[20] AD[19] GND

9 GND C/BE[3]# IDSEL AD[23] GND AD[22] GND

8 GND AD[26] GND V(I/O) AD[25] AD[24] GND

7 GND AD[30] AD[29] AD[28] GND AD[27] GND

6 GND REQ# GND +3.3V CLK AD[31] GND

5 GND NC NC PCIRST# GND GNT# GND

4 GND IPMB_PWR HEALTHY# V(I/O) INTP INTS GND

3 GND INTA# INTB# INTC# +5V INTD# GND

2 GND TCK +5V TMS TDO TDI GND

1 GND +5V -12V TRST# +12V +5V GND

Pin Z A B C D E F

¾ [2 – P2] – [6 – P2] Peripheral Slot

Pin Z A B C D E F

22 GND

1-21 GND NC NC NC NC NC GND

GA4

GA3 GA2 GA1 GA0

GND

Backplane • 21

Page 28

¾ CN1 / CN2 – ATX Power Connector

Pin Signal Pin Signal

1

¾ JP8 – connector

¾ JP9 – connector

¾ JP10 – connector

11

1 +3.3V 11 +3.3V

2 +3.3V 12 -12V

3 GND 13 GND

4 +5V 14 PS_ON_L

5 GND 15 GND

6 +5V 16 GND

7 GND 17 GND

8 POWER

GOOD

9 5V STB 19 +5V

10 +12V 20 +5V

Pin # Signal Name

1

1

2

Pin # Signal Name

1

1

2

Pin # Signal Name

1

1 FAL#

2 GND

18 -5V

INH#

-12V Sense

PRST#

GND

22 • Backplane

Page 29

3.3 cBP-3061 Power Backplane

The cBP-3061 is a PICMG 2.11 CompactPCI 3U 47-pin power backplane for

one power module. It is used by the cPCIS-2631/2642[R].

Specifications

• CompactPCI Compliancy: PICMG 2.11 CompactPCI Power Interface

• Dimensions: 40.64x 128.7 mm

• Power Module Sockets: one

• AC/DC input screw terminal: yes

• DC output (ATX connector): one

• Cascading voltage Sense: Built-in ATX connector

• INH#/FAL#/DEG# Distribution: Built-in ATX connector

Mechanical Drawing

CN4

CN1

CN9

CN7

CN2

CN3

CN6

CN5

CN8

cBP-3061 [R]RearViewcBP-3061[R]Front View

Backplane • 23

Page 30

Pin Assignment

¾ CN1 – Power Sense Connector

1

¾ CN2 – Power Sense Connector

1

¾ CN3 – connector

1

Pin # Signal Name

1

2

3

4

5

V1_Sense

GND_S

V2_Sense

V3_Sense

NC

Pin # Signal Name

1

2

3

4

5

V1_Sense

GND_S

V2_Sense

V3_Sense

NC

Pin # Signal Name

1

2

INHJ

GND

24 • Backplane

Page 31

¾ CN4 – Modular Power 47P Connector

Pin Signal Pin Signal

47

44

42

47 ACL/-DC IN 31 GA2

46 ACN/+DC IN 30 V1 SENSE

45 CGND 29 V1ADJ

44 V3 SHARE 28 GA1

43 IPMB_PWR 27 EN#

42 +FAL# 26 RESERVED

41 V2 SHARE 25 GA0

23

20

21

19

40 IPMB_SDA 24 RTN

39 INH# 23 RESERVED

38 DEG# 22 RTN

37 IPMB_SCL 21 V4

36 V3 SENSE 20 V3

35 V1 SHARE 19 RTN

34 S RTN 13-18 V2

33 V2 SENSE 5-12 RTN

32 V2ADJ 1-4 V1

2

1

¾ CN5 – Current Share Connector

Pin # Signal Name

1

2

3

4

1

5

¾ CN6 – Current Share Connector

Pin # Signal Name

1

2

3

4

1

5

V1_Share

GND

V2_Share

V3_Share

NC

V1_Share

GND

V2_Share

V3_Share

NC

Backplane • 25

Page 32

¾ CN7 –AC/DC in Let Connector

1

¾ CN8 – IPMB Connector

1

¾ CN9 – ATX Power Connector

Pin Signal Pin Signal

1

11

1 +3.3V 11 +3.3V

2 +3.3V 12 -12V

3 GND 13 GND

4 +5V 14 PS_ON_L

5 GND 15 GND

6 +5V 16 GND

7 GND 17 GND

8 POWER

9 5V STB 19 +5V

10 +12V 20 +5V

Pin # Signal Name

1

2

3

ACN/DC+

ACL/DC-

CGND

Pin # Signal Name

1

2

3

4

5

IPMB_SCL

GND

IPMB_SDA

IPMB_PWR

ALERT

18 -5V

GOOD

26 • Backplane

Page 33

3.4 cBP-3062 Power Backplane

The cBP-3062 is a PICMG 2.11 CompactPCI 3U 47-pin power backplane for

two power modules. It is used by the cPCIS-ET2632[R].

Specifications

• CompactPCI Compliancy: PICMG 2.11 CompactPCI Power

Interface

• Dimensions: 40.64x 128.7 mm

• Power Module Sockets: two

• AC/DC input screw terminal: yes

• DC output (ATX connector): two

• Cascading Current Sharing: yes

• Cascading Voltage Sense: Built-in ATX connector

• INH#/FAL#/DEG# Distribution: Selectable common

INH#/FAL#/DEG# or separated INH# for each power module,

dedicated connector

• PICMG 2.0 IPMB Socket: yes

Mechanical Drawing

CN3

CN1

CN2

CN8

CN10 CN9

CN5

CN4

Backplane • 27

CN7

Page 34

Pin Assignment

¾ CN1 / CN2 – Modular Power 47P Connector

Pin Signal Pin Signal

47

44

23

20

2

¾ CN3 –AC/DC in Let Connector

1

¾ CN4 – Power Sense Connector

1

47 ACL/-DC IN 31 GA2

46 ACN/+DC IN 30 V1 SENSE

45 CGND 29 V1ADJ

44 V3 SHARE 28 GA1

4

43 IPMB_PWR 27 EN#

2

42 +FAL# 26 RESERVED

41 V2 SHARE 25 GA0

40 IPMB_SDA 24 RTN

21

39 INH# 23 RESERVED

19

38 DEG# 22 RTN

37 IPMB_SCL 21 V4

36 V3 SENSE 20 V3

35 V1 SHARE 19 RTN

34 S RTN 13-18 V2

33 V2 SENSE 5-12 RTN

32 V2ADJ 1-4 V1

1

Pin # Signal Name

1

2

3

ACN/DC+

ACL/DC-

Pin # Signal Name

1

2

3

4

V1_Sense

GND_S

V2_Sense

V3_Sense

5

cBP-3062[R]RearViewcBP-3062[R]Front View

CGND

NC

28 • Backplane

Page 35

¾ CN5 – Power Sense Connector

Pin # Signal Name

1

¾ CN6 –Connector

Pin # Signal Name

1

¾ CN7 – Current Share Connector

Pin # Signal Name

1

¾ CN8 – Current Share Connector

Pin # Signal Name

1

1

2

3

4

5

V1_Sense

GND_S

V2_Sense

V3_Sense

NC

1

2

3

4

5

IPMB_SCL

GND

IPMB_DA

IPMB_PWR

ALERT

1

2

3

4

5

V1CS

GND_S

V2 CS

V3 CS

NC

1

2

3

4

5

V1 CS

GND_S

V2 CS

V3 CS

NC

Backplane • 29

Page 36

¾ CN9 / CN10 – ATX Power Connector

Pin Signal Pin Signal

1

¾ JP1 – connector

¾ JP2 – connector

¾ JP3 – connector

¾ JP4 – connector

11

1 +3.3V 11 +3.3V

2 +3.3V 12 -12V

3 GND 13 GND

4 +5V 14 PS_ON_L

5 GND 15 GND

6 +5V 16 GND

7 GND 17 GND

8 POWER

GOOD

9 5V STB 19 +5V

10 +12V 20 +5V

Pin # Signal Name

1

1

2

Pin # Signal Name

1

1

1

2

Pin # Signal Name

1

2

3

4

5

8

6

7

8

Pin # Signal Name

1

1

2

18 -5V

INH#2

GND

INH#1

GND

DEG#1

FAL#1

RSV23A

RSV26A

DEG#2

FAL#2

RSV23B

RSV26B

INH#

GND

30 • Backplane

Page 37

4 Cooling System

The cPCIS-ET2600 Series subsystems with CompactPCI PSUs are

equipped five front-access hot swappable low noise fans on the bottom of the

chassis to provide an effectively cooled environment. The fans are push-in

and ventilate out the rear of the chassis. The chassis is equipped with air

filters that are removable for cleaning and replacement. An embedded alarm

board monitors fan status and initiates a visible and audi ble alarm upon fan

failure.

4.1 Removing and Replacing the Air Filters

cPCIS-ET2600 Series models with CompactPCI PSU(s)

To ensure proper performance, the air filters of cPCIS-ET2600 Series

subsystems with CompactPCI PSUs should be cleaned or replaced as

necessary. Replacement air filters are supplied and can be found in the

Accessory Packet.

Air Filter Removal and Replacement Procedure

1. Remove the screws attaching the front filter cover at the base of the

chassis (2 screws) and remove the cover.

Cooling System • 31

Page 38

2. After cleaning or replacing the filter, place it back in position and reattach the filter cover.

3. Remove the screws attaching the bottom filter cover on the bottom

of the chassis (6 screws – see diagram below).

4. After cleaning or replacing the filter, place it back in positi on and reattach the filter cover.

32 • Cooling System

Page 39

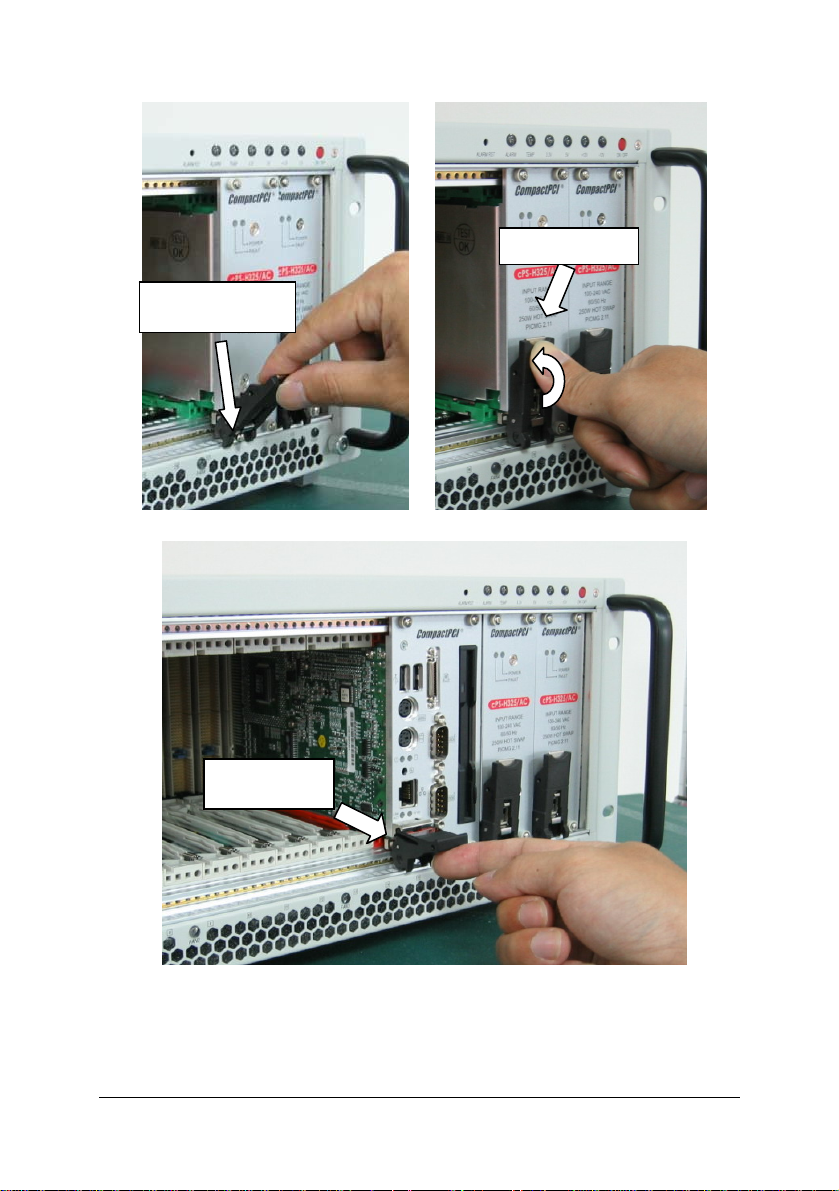

4.2 Fan Alarm: Fan Removal and Replacement

The embedded alarm board monitors temperature & fan status. Should a fan

become disabled, the Alarm LED will light up and an audible warning will be

heard. The LED corresponding to the faulty fan will flash, indicating which fan

needs to be replaced.

To disable the audible warning, press the Alarm RST button. The Alarm LED

will continue to flash until the faulty fan is replaced.

Alarm Reset

Fan Removal and Installation Procedure (cPCI PSU models)

Alarm LED

Temperature LED

1. Remove the screws attaching the front filter cover at the base of the

chassis (2 screws) and remove the cover (see

and Replacement Procedure

above).

Air Filter Removal

2. Pull the faulty fan module out of the fan tray and replace with a

functional fan.

3. Reverse steps 1-2 to replace the filter cover.

For replacement fan modules, please contact your ADLINK distributor.

Cooling System • 33

Page 40

4.3 Temperature Alarm

When the subsystem's internal temperature exceeds 50°C, the TEMP LED

will flash and an audible warning will be heard. To reset the alarm and

disable the audible warning, press the Alarm RST button.

In order to protect the system from damage resulting from overheating, it

should be shut down immediately. Inspect the operating environment for

causes of the overheating condition. After the system has cooled down

sufficiently, power it up and be observant of any future temperature alarm

conditions.

4.4 Fan Specifications

• Model: ADDA AD0812XB-D93GP

• Dimensions: 80 x 80 x 15mm.

• Weight: 63 Gram.

• Type: 12VDC brush-less with ball bearing motor.

• Rated voltage: 12V @ 0.38A.

• Rated power: 4.56 W each.

• Fan speed: 4000 RPM.

• Maximum Air flow: 46.3 CFM each (when zero static pressure).

• Noise: 42.7 dBA each.

Mechanical Drawing

34 • Cooling System

Page 41

5 Power Supply Unit

The cPCIS-ET2600 Series subsystems are equipped with ADLINK’s cPSP325/AC CompactPCI power module.

5.1 CompactPCI: cPS-P325/AC

Features

• 250W 3U X 8HP Eurocard package

• Meets EN 61000-3-2 active power factor correction

• Internal OR-ing diodes for N+1 redundancy

• Hot-swappable

• Active current sharing

• EMI meets EN 55022 / FCC CLASS A

• CE marking compliance

• Fully compliant with PICMG

Specifications

• Operating Temperature Range: -25°C to +50°C

• Storage Temperature: -40 to +85

• Temperature Coefficient: Typ. ±0.3% /

• Cooling: >400 LFM moving air required to achieve full rate d power

• Dimensions: Eurocard 3U X 8HP X 160mm CompactPCI format

• Efficiency: 81.5-82.6% typical

• Switching Frequency: 135K Hz

• Safety: IEC60950-1,CSA60950-1 & China CCC

• Circuit Topology: Forward circuit

°C

°C

Power Supply Unit • 35

Page 42

Input Characteristics

• Input Voltage: Typ. 90-264VAC

• Power Factor Correction: Meets Harmonic Correction

• Input Connector: CompactPCI 47-pin power connector

• Input Frequency: 47-63Hz

• Inrush Current: Less than 15A@240VAC

• Input Current: 3.6A@230VAC/ 4A@260VAC

• EMI: Meets EN55022 / FCC Class A

• Hold-up Time: 20mS after power fail signal

• Remote ON/OFF: Available at [INH#] & [EN#] pins

• Power Fail Signal: Available at [FAL#] pin

• Status LED: <Green> means valid input voltage; <Amber> means a

critical fault.

• Thermal Protection (OTP): Installed NTC and thermostat for thermal

sensor at [DEG#] pin

• Power OK: Installed at all outputs

• Leakage Current: 1.18mA at 254VAC/60Hz

Output Characteristics

EN 61000-3-2

.

Output

Voltage

5V

3.3V

12V

-12V

• Over Load Protection: Fully protected against output overload or

short circuit. Typical 120% max. load.

• Over Current Protection: Installed at each rail

• Output Wattage: Typ. 250W continuous.

• Output Connector: CompactPCI 47-pin power connector.

• Line Regulation: Max. ±10mV

• Load Regulation: 3.3V & 5V: ± 10mV, +12V: ± 30mV & -12V: -380

mV.

36 • Power Supply Unit

Min. Max. Typ. Peak

Output Current (A)

0 40.0 25.0 –

0 40 20 –

0 5.5 4 –

0 2 1 –

Page 43

• Noise & Ripple: 60 mV@5V and 3.3V output; 120mV@.± 12V

output.

• OVP: Built-in at all outputs.

• Adjustability: Available at VO1, 2 & 3.

• Output Trim: Electrical trim available at VO1/VO2 [ADJ #].

• Remote Sensing: Available at VO1, VO2 & VO3.

• Hot-Swap: Available.

• N+1 Redundancy: Installed with internal OR-ing diodes at all outputs

for N+1 redundancy operation.

• Current Sharing: Third-wire c urrent sharing at VO1,2 &3.

• Power OK Signal: Available for all output.

• Over Current Protection: Installed at each rail.

• Overload Protection: Fully protected against output overload or short

circuit. Typical 120% max. load.

Output power versus temperature T

A

at V

i nom

Power Supply Unit • 37

Page 44

This page intentionally left blank.

38 • Power Supply Unit

Page 45

6 Specifications

6.1 Features

• Standard 19” Rack-mount 3U CompactPCI form factor (4U height).

• Board Space:

o Supports both front and rear access for I/O, CPU, and power supply.

o Standard 3U, 21-slot width chassis.

• Five front-access hot swappable fans with removable air filter for self-

cooling.

• Suitable for both rack-mount and desktop applications.

• Side handles for portability.

• Built-in alarm module to monitor chassis temperature and fan status.

• Comprehensive EMC shielding [EMC gaskets are installed on front rails

(top and bottom), rear rails, and side panels].

• Impact resistant power switch.

• Power status LEDs to easily monitor power status (+12V,-

12V,+5V,+3.3V).

6.2 Mechanical

• CompactPCI Standard: 2.0 R3.0.

• Form Factor: 3U CompactPCI with 50mm depth rear I/O.

• Enclosure: 19” 4U height rack-mount enclosure

o Coated metal plate outer covering.

o Guarded power switch and reset button.

• Dimensions: 448.4mm (W) x 177.8mm (H) x 258mm (D). Width with

rack-mounting kit is 482.6mm (19”).

• Usable width: 21 slots (84HP).

Specifications • 39

Page 46

6.3 Environmental

• Operating Temperature: -20°C to 50°C (Supports operation up to 70°C

but with derating above 50°C. Power efficiency will be derated by 2.5%

for every degree Celsius with only 50% power efficiency at 70°C, i.e.

125W/PSU.)

• Storage Temperature: -40 to 85°C.

• Humidity: 5% - 95%, non-condensed.

• Shock: 15G peak-to-peak, 11ms duration, non-operation.

• Vibration:

o Non-operation:1.88Grms, 5 – 500Hz, each axis.

o Operation: 0.5Grms, 5 – 500Hz, each axis.

6.4 System Alarm Board

• Supports fault alarm for up to 8 fans. If any fan faults, the ALARM LED

will flash and an audible alarm will sound

• Can detect temperature at two different locations.

• Trigger temperature for each sensor can be set independently (50°C,

60°C, 70°C).

• Alarm mute

• LED indicators for fan and temperature status

40 • Specifications

Page 47

Mechanical Drawing

Specifications • 41

Page 48

This page intentionally left blank.

42 • Specifications

Page 49

Important Safety Instructions

Read and follow all instructions marked on the product and in the

documentation before you operate your system. Retain all safety and operating

instructions for future use.

z Please read these safety instructions carefully.

z Please keep this User‘s Manual for later reference.

z The equipment can be operated at an ambient temperature of 50ºC.

z The equipment should be operated only from the type of power source

indicated on the rating label. Make sure the voltage of the power source

when connect the equipment to the power outlet.

z If your equipment has a voltage selector switch, make sure that the

switch is in the proper position for your area. The voltage selector switch

is set at the factory to the correct voltage.

z For pluggable equipment, that the socket-outlet shall be installed near the

equipment and shall be easily accessible.

z Place the power cord such a way that people can not step on it. Do not

place anything over the power cord.

z If the equipment is not use for long time, disconnect the equipment from

mains to avoid being damaged by transient overvoltage.

z All cautions and warnings on the equipment should be noted.

z Please keep this equipment from humidity.

z Do not use this equipment near water or a heat source.

z Lay this equipment on a reliable surface when install. A drop or fall could

cause injury.

z Never pour any liquid into opening; this could cause fire or electrical

shock.

z Openings in the case are provided for ventilation. Do not block or cover

these openings. Make sure you provide adequate space around the

system for ventilation when you set up your work area. Never insert

objects of any kind into the ventilation openings.

z To avoid electrical shock, always unplug all power cables and modem

cables from the wall outlets before removing covers.

Important Safety Instructions • 43

Page 50

z Lithium Battery provided (real time clock battery)

“CAUTION – Risk of explosion if battery is replaced by an incorrect

type. Dispose of used batteries according to the instructions”

z If one of the following situations arises, get the equipment checked by a

service personnel:

A. The power cord or plug is damaged.

B. Liquid has penetrated into the equipment.

C. The equipment has been exposed to moisture.

D. The equipment has not work well or you can not get it work

according to user‘s manual.

E. The equipment has dropped and damaged.

F. If the equipment has obvious sign of breakage.

44 • Important Safety Instruction

Page 51

Getting Service

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: 300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

ADLINK Technology Beijing

Address: Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing, 100085 China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: 2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

LiPPERT ADLINK Technology GmbH

Address: Hans-Thoma-Strasse 11, D-68163, Mannheim, Germany

Tel: +49-621-43214-0

Fax: +49-621 43214-30

Email: emea@adlinktech.com

Getting Service • 45

Page 52

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 8F Mointer B/D,1675-12, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: 1st Floor, #50-56 (Between 16th/17th Cross) Margosa Plaza,

Margosa Main Road, Malleswaram, Bangalore-560055, India

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80- 23464606

Email: india@adlinktech.com

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 6 Hasadna St., Kfar Saba 44424, Israel

Tel: +972-9-7446541

Fax: +972-9-7446542

Email: israel@adlinktech.com

46 • Getting Service

Loading...

Loading...