Page 1

cPCI-R6700

6U CompactPCI® Rear Transition Module

with ATI Radeon™ E4690 GPU

User’s Manual

Manual Rev.: 2.00

Revision Date: November 2, 2012

Part No: 50-15084-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

2.00 2012/11/02 Initial release

ii Revision History

Page 3

cPCI-R6700

Preface

Copyright 2012 ADLINK Technology, Inc.

This document contains proprietary infor mation protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufa cturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Using this Manual

Audience and Scope

The cPCI-R6700 User’s Manual is intended for hardware

technicians and systems operators with knowledge of installing,

configuring and operating industrial grade computer systems.

Manual Organization

This manual is organized as follows:

Chapter 1, Introduction: Introduces the cPCI-R6700, its features,

block diagrams, and package contents.

Chapter 2, Specifications: Presents detailed specification infor-

mation.

Chapter 3, Board Interfaces: Describes the cPCI-R6700 co nnec-

tors and switches.

Chapter 4, Getting Started: Describes the installation of the

cPCI-R6700 to the system and driver installation.

Chapter 5, VBIOS Update: Provides information on how to

update the cPCI-R6700 VBIOS.

Important Safety Instructions: Presents safety instructions all

users must follow for the proper setup, installation and usage of

equipment and/or software.

Getting Service: Contact information for ADLINK’s worldwide

offices.

iv Preface

Page 5

cPCI-R6700

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component damage, data loss, and/or program corruption when trying to com-

CAUTION:

WARNING:

plete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

Preface v

Page 6

This page intentionally left blank.

vi Preface

Page 7

cPCI-R6700

Table of Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Figures........................................................................ ix

List of Tables.......................................................................... xi

1 Introduction ........................................................................ 1

1.1 Overview.............................................................................. 1

1.2 Features............................................................................... 2

1.3 Block Diagram ..................................................................... 3

1.4 Package Contents ............................................................... 4

2 Specifications..................................................................... 5

2.1 cPCI-R6700 General Specifications .................................... 5

2.2 I/O Connectivity ................................................................... 6

2.3 GPU..................................................................................... 6

2.4 Power Consumption ............................ ... ... ... ... .... ... ... ... .... ... 7

3 Board Interfaces................................................................. 9

3.1 cPCI-R6700(D) Assembly Layout........................................ 9

3.2 cPCI-R6700 Board Layout................................................. 10

3.3 Connector Pin Assignments .............................................. 12

3.4 Switch Settings .................................................................. 20

4 Getting Started ................................................................. 23

4.1 Installing a 2.5" SATA Drive............................................... 23

4.2 Auxiliary Power Cord......................................................... 28

4.3 Installing the cPCI-R6700.................................................. 29

4.4 Driver Installation................................................. ... ... ... .... . 30

vii

Page 8

5 VBIOS Update.................................................................... 31

Important Safety Instructions............................................... 33

Getting Service...................................................................... 35

viii

Page 9

cPCI-R6700

List of Figures

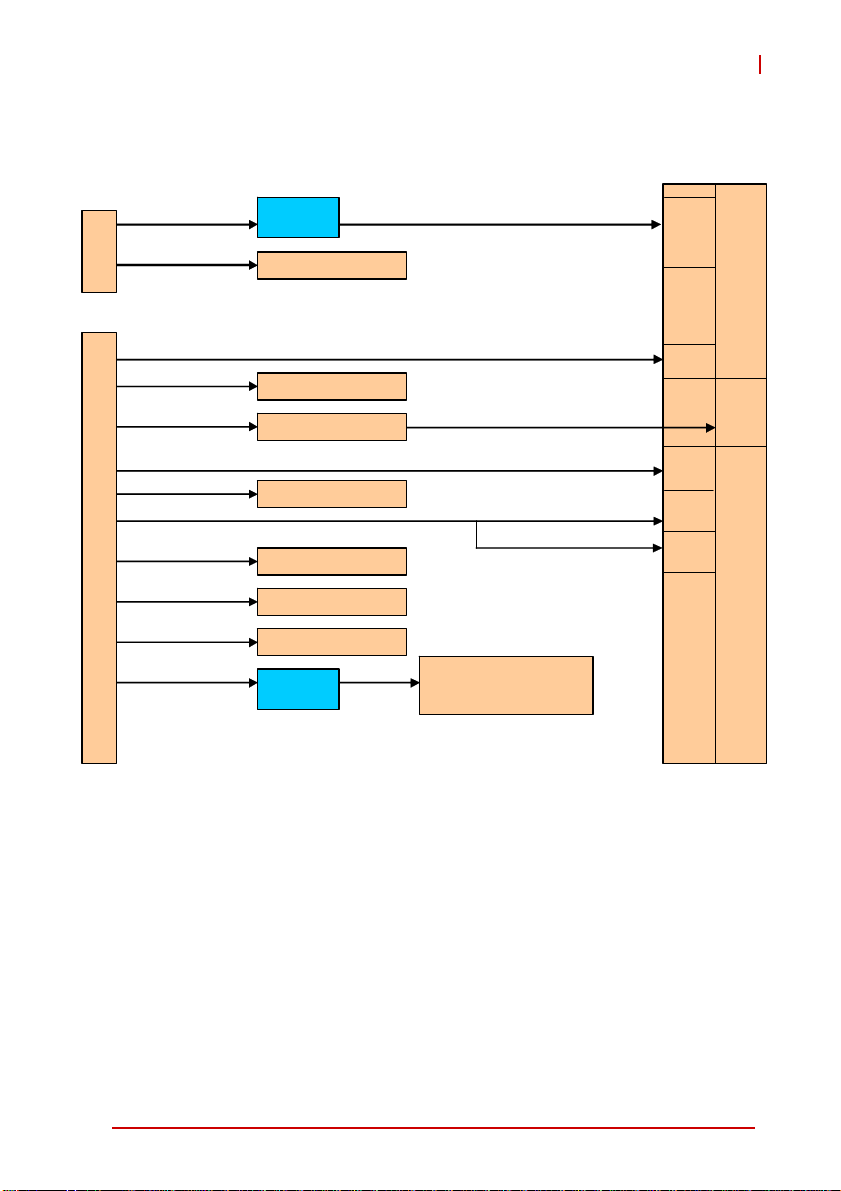

Figure 1-1: cPCI-R6700 Functional Block Diagram ...........................3

Figure 2-1: cPCI-R6700 General Specifications ................................5

Figure 3-1: cPCI-R6700(D) Assembly Layout....................................9

Figure 3-2: cPCI-R6700 Board Layout - Component Side............... 10

Figure 3-3: cPCI-R6700(D) Board Layout - Solder Side..................11

List of Figures ix

Page 10

This page intentionally left blank.

xList of Figures

Page 11

cPCI-R6700

List of Tables

Table 2-1: cPCI-R6700(D) I/O Connectivity......................................6

Table 2-2: cPCI-R6700 Power Consumption................................ ... . 7

Table 3-1: DVI-I Connector Pin Definition.......................................12

Table 3-2: CompactPCI J3 Connector Pin Definition...................... 18

Table 3-3: CompactPCI J5 Connector Pin Definition...................... 19

Table 3-4: COM2 Mode Switch Settings.........................................20

Table 3-5: LAN Control Switch Settings..........................................21

List of Tables xi

Page 12

This page intentionally left blank.

xii List of Tables

Page 13

1 Introduction

1.1 Overview

The cPCI-R6700 Series is 6U CompactPCI rear transition module

(RTM) designed for use with ADLINK 6U CompactPCI CPU

blades. The cPCI-R6700 is an RTM equipped with the ATI Radeon™ E4690 graphics processor unit (GPU) to provide additional

graphics performance for embedded applications and supports

comprehensive rear I/O functionality. The Radeon™ E4690 GPU

features an integrated 600 MHz engine clock, 700 MHz memory

clock, 128-bit memory interface and 512MB GDDR3 VRAM. Dual

independent display output is via two DVI-I ports and an onboard

Realtek ALC262 High Definition Audio Codec provides analog

audio output from the audio controller on the CPU blade. The

cPCI-R6700 requires a compatible 6U CompactPCI backplane

with rear I/O support and correctly configured CPU blade.

Two models are available: the cPCI-R6700 (4HP) and

cPCI-R6700D (8HP). The cPCI-R6700 is a 4HP RTM equipped

with two DVI-I ports, two GbE ports, three USB Type A ports, and

one COM port (RS-232/422/485 selectable) on the faceplate.

Onboard I/O includes one 5-pin USB pin header, one 10-pin USB

box header, one 10-pin Mic-in/Line-in/Line-out box header, one

10-pin COM box header (TX/RX only), one 10-pin PS/2 box

header and three SATA 7-pin connectors for external storage

device. The cPCI-R6700D is an 8HP RTM that provides a PS/2

keyboard/mouse Mini-DIN port on the faceplate and space to

mount a 2.5" SATA drive for onboard storage requirements.

For applications requiring reduced power consumption, the graphics engine clock can be changed by VBIOS update. When the

cPCI-R6700 is used with a CPU blade that consumes over 50W of

power or under extended temperature conditions (>60°C), additional power supply must be supplied to the RTM using an auxiliary power cord provided in the package.

cPCI-R6700

Introduction 1

Page 14

1.2 Features

X 6U CompactPCI RTM in 4HP or 8HP width form factor

X Compliant with CompactPCI Specification 2.0, Rev. 3.0

X Compliant with CompactPCI Packet Switching Backplane

Specification PICMG 2.16 Rev. 1.0

X 64-bit/66 MHz CompactPCI interface based on PCI specifica-

tions

X ATI Radeon™ E4690 embedded GPU

X Integrated 128-bit memory interface and 512MB GDDR3

VRAM

X Up to 600MHz engine clock and 700MHz memory clock

X Supports DirectX 10.1 and OpenGL 3.x

X Supports display resolutions up to 3840x2400 per display out-

put

X Engine clock can be changed by VBIOS update

X Realtek ALC262 HD Audio codec

X Two DVI-I ports for dual independent displays

X One DB-9 serial port support RS-232/422/485

X Three USB Type A ports

X Two Gigab it Ethernet ports from CPU board

X One PS/2 keyboard mouse on faceplate (cPCI-R6700D only)

X One 5-pin USB 2.0 pin header and one 10-pin USB 2.0 box

header onboard

X One onboard 10-pin COM box header support RS-232, TX/RX

only

X One onboard 10-pin PS/2 keyboard mouse box header on

cPCI-R6700

X One onboard 10-pin audio box header (Mic-in, Line-in,

Line-out)

X Three SATA 7- pin connectors

X 2.5" drive space on 8HP version (cPCI-R6700D only)

2Introduction

Page 15

1.3 Block Diagram

r

r

/

r

A

-

cPCI-R6700

rJ5

rJ3

PCIE x4

SATA 0

TX , R X, G ND

PS/2 KB/MS

USB 4/7

USB 5

SATA 2

SATA 1

HD

ATI E4690

SAT A 7-pin connecto

RS-232 10-pin heade

KB/ MS 10-pi n header

USB x2 10-pin header

USB 5-pin header

SAT A 7-pin connecto

SAT A 7-pin connector

ALC262

RS-232/422/485

PS/2 KB/MS

USB 6

LAN x2 (PICMG 2.16)

Mic -i n, Line-out Line-i n,

10-pin header

8/9

DVI-I

DVI-I

DB

LAN

LAN

9

PS/2

KB/MS

L1 L2

Figure 1-1: cPCI-R6700 Functional Block Diagram

Introduction 3

Page 16

1.4 Package Contents

The cPCI-R6700 is packaged with the following components. If

any of the items on the contents list are missing or damaged,

retain the shipping carton and packing material and contact the

dealer for inspection. Please obtain authorization before returning

any product to ADLINK.

X cPCI-R6700 module

X 2.5" drive bracket kit (cPCI-R6700D only)

X Auxiliary power cord (4-pin Molex to 6-pin RTM onboard

connector, 20cm)

X ADLINK All-in-One DVD

X User's manual

This product must be protected from static discharge and

physical shock. Never remove any of the components

CAUTION:

except at a static-free workstation. Use the anti-static bag

shipped with the product when putting the board on a surface. Wear an anti-static wrist strap properly grounded on

one of the system's ESD ground jacks when installing or

servicing system components.

4Introduction

Page 17

cPCI-R6700

2 Specifications

2.1 cPCI-R6700 General Specifications

Standards • CompactPCI® Specification 2.0, Rev. 3.0

• CompactPCI® Packet Switching Backplane Specification

PICMG 2.16 Rev. 1.0

Form Factor • Standard 6U CompactPCI® Rear Transition Module

• Board size: 233.35mm x 80mm

• Single-slot (4HP, 20.32mm) or dual-slot (8HP, 40.64mm)

• CompactPCI® connectors rJ3 and rJ5

GPU • ATI Radeon™ E4690 embedded GPU

• Integrated 128-bit memory interface and 512MB GDDR3

• 600 MHz engine clock and 700 MHz memory clock

• Supports DirectX 10.1 and OpenGL 3.x

• Supports resolutions up to 3840x2400 per display output

• Engine clock changeable by VBIOS update

• PCI Express x4 lane interface

Audio • Realtek ALC262 HD Audio codec

Faceplate I/O • 2x 10/100/1000BASE-T Ethernet ports

• 3x USB 2.0 Ty pe A ports

• 1x DB-9 COM port (RS-232/422/485)

• 2x DVI-I ports from onboard ATI E4690 GPU

• 1x PS/2 Mini-DIN keyboard/mouse (cPCI-R6700D only)

Onboard

Peripherals

OS

Compatibility

Environmental • Operating Temperature: 0 °C to +60 °C

• 3x 7-pin SATA connectors

• 1x RS-232 10-pin box header (Tx, Rx signals only)

• 1x KB/MS 10-pin box header (cPCI-R6700 only)

• 1x USB 10-pin box header (2 ports)

• 1x Mic-in/Line-out 10-pin box header

• 1x USB 5-pin header

• Microsoft Windows XP Professional 32-bit

• Microsoft Windows 7 64-bit

• Microsoft Windows Server 2003 32-bit

• Microsoft Windows Server 2008 64-bit

• Red Hat Enterprise Linux 6.0 64-bit

• Extended Temperature: -20 °C to +70 °C

Figure 2-1: cPCI-R6700 General Specifications

Specifications 5

Page 18

2.2 I/O Connectivity

Function

LAN Y x2 - Y x2 -

USB Y x3 Y x2 Y x3 Y x2

COM Y x1

DVI-I Y x2 - Y x2 -

Serial A TA -Y x3-Y x3

Audio -Y x1-Y x1

KB/MS - Y x1 Y x1 (PS/2) -

2.5” drive space ---Y x1

Table 2-1: cPCI-R6700(D) I/O Connectivity

cPCI-R6700 cPCI-R6700D

Faceplate Board Faceplate Board

Y x1 (RS-232

TX/RX)

Y x1

Y x1 (RS-232

TX/RX)

2.3 GPU

The following sections describe the ATI Radeon E4690 embedded

GPU features and functions.

X Integrated 512MB GDDR3 and 128-bit memory interface

X Fully DirectX 10.1 compliant

X Support for OpenGL® 3.0

X Dual independent display controllers support true 30-bpp

throughout the display pipe

X Support for display resolutions up to 3840x2400 per disp lay

output

X Dual RGB output

X Maximum pixel frequency of 400 MHz for RGB

X Fully compliant with PCI Express Base Specification Rev.

2.0.

X Supports PCI-Express x1, x2, x4, x8, and x16 lane widths.

X Full ACPI 1.0b, OnNow, and IAPC (Instantly Available PC)

power management.

6 Specifications

Page 19

cPCI-R6700

2.4 Power Consumption

The power consumption data of the cPCI-R6700 was measured

using 3D Mark06 at different engine clock frequencies (memory

clock fixed at 700MHz).

Configuration

Test Tool Futuremark® 3DMark06 Professional Edition 1.1.0

CPU Blade ADLINK cPCI-6210 w/ Core™ i7-2710QE

Backplane ADLINK cBP-6402R

Power Supply Sunpower SPX-6500P1

Power Consumption

Clock

Engine

600 MHz

400 MHz

300 MHz

100 MHz

Voltage (V) Current (A) Power (W)

+5 V 4.24 A 21.2 W

+12 V 1.42 A 17.04W

+5 V 3.83 A 19.15 W

+12 V 1.1 A 13.2 W

+5 V 3.3 A 16.5 W

+12 V 1.01 A 12.12 W

+5 V 2.8 A 14 W

+12 V 0.85 A 10.2 W

Total Power

(W)

38.24

32.35

28.62

24.2

Table 2-2: cPCI-R6700 Power Consumption

Due to limited available power from the CompactPCI backplane, it is advised to use the auxiliary power cord provided in

NOTE:

NOTE:

the package to supply additional power when the CPU blade

power consumption exceeds 50W or if used under extended

temperature conditions (>60°C). Please refer to 4.2 Auxiliary

Power Cord on page 28.

Specifications 7

Page 20

This page intentionally left blank.

8 Specifications

Page 21

3 Board Interfaces

This chapter illustrates the board layout, connector pin

assignments, and switch settings to familiarize users with the

cPCI-R6700.

3.1 cPCI-R6700(D) Assembly Layout

Heatsink

Heatsink

Fan

Fan

cPCI-R6700

Drive Bracket

cPCI-R6700 cPCI-R6700D

Figure 3-1: cPCI-R6700(D) Assembly Layout

Board Interfaces 9

Page 22

3.2 cPCI-R6700 Board Layout

rJ5

U1

DVI-I

CN8

rJ3

PS/2

COM1

USB2

HDA

USB1

SW4

SW3

CN3

FAN1

CN2

CN9

CN4

DVI-I

COM2

USB x3

GbE b

GbE a

DVI-I DVI-I connectors HDA Audio box header

CN2/3/4 SATA connectors PS/2 PS/2 KB/MS box header

CN8 Aux. Power connector rJ3/rJ5 cPCI connectors

CN9 SATA power connector SW3/SW4 LAN control switches

COM1 COM box header U1 ATI E4690 GPU

COM2 COM2 connector USB1 USB5 5-pin header

FAN1 Fan power connector USB2 USB4/7 box header

GbE a/b LAN RJ-45 connectors USB x3

USB Type A connectors

(USB6/9/8)

Figure 3-2: cPCI-R6700 Board Layout - Component Side

10 Board Interfaces

Page 23

SW1

SW2

cPCI-R6700

SW1/2 COM2 mode switches

Figure 3-3: cPCI-R6700(D) Board Layout - Solder Side

Board Interfaces 11

Page 24

3.3 Connector Pin Assignments

Faceplate Connectors

DVI-I Connectors

Pin # Signal Pin # Signal

1 TMDS Data2- 16 Hot Plug Detect

2 TMDS Data2+ 17 TMDS Data03 GND 18 TMDS Data0+

4NC19GND

5 NC 20 TMDS Data56 DDC Clock [SCL] 21 TMDS Data5+

7 DDC Data [SDA] 22 TMDS Clock Shield

8 Analog vertical sync 23 TMDS Clock +

9 TMDS Data1- 24 TMDS Clock 10 TMDS Data1+ C1 Analog Red

11 GND C2 Analog Green

12 NC C3 Analog Blue

13 NC C4 Analog Horizontal Sync

14 +5 V Power C5 Analog GND Return

15 GND

Ta bl e 3-1: DVI-I Connector Pin Definition

12 Board Interfaces

Page 25

COM2 RS-232/422/485 Connector

Pin # RS-232 RS-422/485+ RS-485

1 DCD TXD- Data2RXD TXD+ Data+

3 TXD RXD+ --

6

1

4 DTR RXD -5 GND GND GND

5

6 DSR -- -7 RTS -- -8 CTS -- -9 RI -- --

See “COM2 Mode Switches (SW1, SW2)” on page 20.

NOTE:

NOTE:

USB6/9/8 Type A Connectors

cPCI-R6700

Pin # Signal Name

1Vcc

2 USB_D3USB_D+

4GND

Board Interfaces 13

Page 26

GbE a/b RJ-45 Connectors

Pin #

1TX+ LAN_TXP0

2TX- LAN_TXN0

3RX+ LAN_TXP1

4 -- LAN_TXP2

5 -- LAN_TXP2

6RX- LAN_TXN1

7 -- LAN_TXP3

8 -- LAN_TXN3

Network link is not established

or system powered off

10 Mbps

100 Mbps

1000 Mbps

10BASE-T/

100BASE-TX

Status

Active OFF Blinking

Active Green Blinking

Active Amber Blinking

1000BASE-T

Speed LED

(Green/Amber)

OFF OFF

Link OFF ON

Link Green ON

Link Amber ON

81

Speed Activity

Activity LED

(Amber)

PS/2 Keyboard/Mouse Port (cPCI-R6700D only)

Pin # Signal Function

1 KB_DATA Keyboard Data

2 MS_DATA Mouse Data

3 GND Ground

4KM_VCC Power

5 KB_CLK Keyboard Clock

6 MS_CLK Mouse Clock

14 Board Interfaces

Page 27

Onboard Connectors

SATA Connectors (CN2~4)

Pin # Signal

1GND

2TX+

3TX4GND

5RX6RX+

7GND

Auxiliary Power Connector (CN8)

(6-pin, 2.5 mm pitch Wafer)

1

cPCI-R6700

1

7

Pin # Signal

1P12V

2GND

3GND

4P5V

5P5V

6P5V

SATA Powe r Connector (CN9)

Pin # Signal

1P5V

2 P12V

1

Board Interfaces 15

3NC

4GND

5GND

Page 28

COM1 RS-232 Box Header (COM1)

(2x5-pin, 2.0 mm pitch Wafer)

Pin # RS-232 Signal

1NC

2NC

2

3RXD

1

4NC

5TXD

6NC

7NC

8NC

9 IsoGND

10 NC

Fan Power Connector (FAN1)

Pin # Signal

1GND

1

2 P12V

3NC

Audio Box Header (HDA)

(2x5-pin, 2.0 mm pitch Wafer)

Pin # Signal Pin # Signal

2

16 Board Interfaces

1

2 L_OUT_L 1 GND

4 GND 3 L_OUT_R

6L_IN_L5 GND

8 GND 7 L_IN_R

10 MIC_LR 9 GND

Page 29

PS/2 Keyboard/Mouse Box Header (PS/2)

(2x5-pin, 2.0 mm pitch Wafer)

Pin # Signal Pin # Signal

2

1

2 KB_CLK 1 KB_DATA

4MS_CLK3MS_DATA

6GND5KM_VCC

8 GND 7 GND

10 NC 9 GND

USB5 Header (USB1)

(5-Pin, 2.54 mm pitch)

Pin # Signal

1

1+5V

2USB5D3 USB5D+

4GND

5NC

cPCI-R6700

USB 4/7 Box Header (USB2)

(2x5-pin, 2.0 mm pitch Wafer)

Pin # Signal Pin # Signal

2

Board Interfaces 17

1

2 +5V 1 +5V

4 USB4_D- 3 USB7_D6 USB4_D+ 5 USB7_D+

8 GND 7 GND

10 NC 9 Key

Page 30

CompactPCI rJ3 Pin Assignment

Pin Z A B C D E F

19 GND P5V P5V P12V P5V P5V GND

18 GND

17 GND

16 GND

15 GND

14 GND

13 GND

12 GND

11 GND

10 GND

9GND

8GND

7GND

6GND

5 GND GND GND NC GND GND GND

4GND

3GND

2GND

1GND

LAN2_TXP0 (b) LAN2_TXN0 (b) GND LAN2_TXP2 (b) LAN2_TXN2 (b) GND

LAN2_TXP1 (b) LAN2_TXN1 (b) GND LAN2_TXP3 (b) LAN2_TXN3 (b) GND

LAN1_TXP0 (a) LAN1_TXN0 (a) GND LAN1_TXP2 (a) LAN1_TXN2 (a) GND

LAN1_TXP1 (a) LAN1_TXN1 (a) GND LAN1_TXP3 (a) LAN1_TXN3 (a) GND

USB-OC4-L USB-OC5-L USB-OC6-L USB-OC7-L USB-OC8-L GND

USB4P YSB4N GND USB5P USB5N GND

USB6P USB6N GND USB7P USB7N GND

USB8P USB8N GND USB9P USB9N GND

USB-OC9-L NC NC NC NC GND

CTS1-L RI1-L NC NC NC GND

SIN1 SOUT1 DTR1-L DSR1-L RTS1-L GND

COM_TXD COM_RXD DCD1-L NC NC GND

SATA3_RXP0 SATA3_RXN0 GND SATA3_RXP1 SATA3_RXN1 GND

SATA3_TXP0 SATA3_TXN0 GND SATA3_TXP1 SATA3_TXN1 GND

KB_DATA KB_CLK NC MS_DATA MS_CLK GND

HDA_SDIN1 HDA_SDIN2 HDA_SDIN3 HDA_EN-L AUD_RST-L GND

HDA_RST-L HDA_SYNC HDA_BIT_CLK HDA_SDOUT HDA_SDIN0 GND

Table 3-2: CompactPCI J3 Connector Pin Definition

High Definition Audio

Keyboard/Mouse

Serial ATA

Serial port

USB port

Ethernet port

18 Board Interfaces

Page 31

cPCI-R6700

CompactPCI rJ5 Pin Assignment

Pin Z A B C D E F

22 GND P1V8_LAN LAN1_LINK-L (a) LAN1_ACT-L (a) LAN2_LINK-L (b) LAN2_ACT-L (b) GND

21 GND NC NC GND NC NC GND

20 GND NC NC GND NC NC GND

19 GND NC NC NC NC NC GND

18 GND NC NC NC NC NC GND

17 GND NC NC NC NC NC GND

16 GND NC NC NC NC NC GND

15 GND NC NC NC

14 GND NC NC GND

13 GND

12 GND NC NC NC NC NC GND

11 GND NC NC GND NC NC GND

10 GND NC NC GND NC NC GND

9 GND NC NC NC NC NC GND

8 GND NC NC GND NC NC GND

7 GND GND GND BAT_RTM GND GND GND

6GND

5 GND GND GND GND GND GND GND

4GND

3GND

2GND

1GND

LAN1_100-L (a) LAN2_100-L (b) NC LAN2_1G-L (b) LAN1_1G-L (a) GND

PCIE_CLKP PCIE_CLKN GND PLTRST-L NC GND

PCIE_TXP4 PCIE_TXN4 GND PCIE_RXP4 PCIE_RXN4 GND

PCIE_TXP3 PCIE_TXN3 GND PCIE_RXP3 PCIE_RXN3 GND

PCIE_TXP2 PCIE_TXN2 GND PCIE_RXP2 PCIE_RXN2 GND

PCIE_TXP1 PCIE_TXN1 GND PCIE_RXP1 PCIE_RXN1 GND

SATA_RXP0 SATA_RXN0 GND

SATA_TXP0 SATA_TXN0 GND

Table 3-3: CompactPCI J5 Connector Pin Definition

PCI-Express x4

Serial ATA

Ethernet port

Board Interfaces 19

Page 32

3.4 Switch Settings

2

COM2 Mode Switches (SW1, SW2)

The COM2 port on the cPCI-R6700 faceplate supports

RS-232/422/485 modes. Switches SW1 and SW2 can be used

to configure the COM2 port to the desired mode using the settings shown below (set to RS-232 by default).

1

ON

1

ON

2

3

4

5

6 7 8

SW1 SW2

3

4

5 6 7

8

Mode RS-232 (default) RS-422 RS-485

SW1

SW2

1, 4, 6 ON

(all others OFF)

1, 3 ON

(all others OFF)

2, 5, 7 ON

(all others OFF)

2, 4, 5, 6 ON

(all others OFF)

3, 5, 7 ON

(all others OFF)

2, 4, 5, 6 ON

(all others OFF)

T able 3-4: COM2 Mode Switch Settings

20 Board Interfaces

Page 33

cPCI-R6700

2

LAN Control Switches (SW3, SW4)

The cPCI-R6700 can route LAN signals from the CPU blade to

either the PICMG 2.16 backplane or to GbE a/b on the faceplate I/O (but not both simultaneously). Switches SW3 and

SW4 can be used to route the LAN signals (set to faceplate

RJ-45 connectors by default).

1

ON

1

ON

2

3

4

5

6 7 8

SW3 SW4

3

4

5 6 7

8

LAN signals routed to SW3 SW4

PICMG 2.16 Backplane All OFF All OFF

Faceplate RJ-45 connectors

(default)

All ON All ON

Table 3-5: LAN Control Switch Settings

Board Interfaces 21

Page 34

This page intentionally left blank.

22 Board Interfaces

Page 35

4 Getting Started

4.1 Installing a 2.5" SATA Drive

The cPCI-R6700D has space onboard to mount a 2.5" storage

device using the bracket kit provided. The kit includes 4x M3 4mm

screws and 4x M3 6mm screws. Follow the steps below to install a

SATA drive on the RTM.

1. Prepare a 2.5" SATA drive and locate the bracket kit in

the package.

cPCI-R6700

2. Align the bracket with SATA power/signal connectors as

shown and mount the drive onto the bracket. Fasten the

bracket to the drive with two of the M3 4mm screws.

Getting Started 23

Page 36

3. Secure the remaining bracket to the other side of the

drive with the two remaining M3 4mm screws. This unit

will be hereafter referred to as the "drive assembly".

24 Getting Started

Page 37

cPCI-R6700

4. Disconnect the PS/2 cable from the onboard connector

as shown as below.

5. Connect the SATA power connector from the drive

assembly to the onboard shown as below.

Getting Started 25

Page 38

6. Pass the SATA signal cable underneath the PS/2 cable

and connect it to the onboard connector as shown.

7. Reconnect the PS/2 cable to the onboard connector.

26 Getting Started

Page 39

cPCI-R6700

8. Align the standoffs on the drive assembly with the 4

screw holes on the PCB as shown.

9. Secure the drive assembly to the RTM using the 4 M3

6mm screws from the solder side of the board.

Getting Started 27

Page 40

4.2 Auxiliary Power Cord

If required, install the Auxiliary Power Cord included in the package.

Additional power supply must be supplied to the RTM using an

auxiliary power cord when the cPCI-R6700 is used with a CPU

CAUTION:

To CN8 onboard

blade that consumes over 50W of power or under extended

temperature conditions (>60°C).

1. Locate the Auxiliary Power Cord (20 cm) in the package.

connector

2. Connect the 6-pin power connector to the cPCI-R6700

RTM (CN8).

To ATX

power supply

3. After the RTM is installed in the chassis (see “Installing

the cPCI-R6700” on page 29 below), connect either the

male or

28 Getting Started

female 4-pin Molex connector to the power supply.

Page 41

cPCI-R6700

4.3 Installing the cPCI-R6700

The cPCI-R6700 may be installed in an RTM slot of a 6U CompactPCI chassis when mated to a compatible CPU blade. See

the6U RTM Blade-to-RTM Compatibility Guide at

http://www.adlinktech.com/cPCI/CompactPCI-Rear-Transition.html.

These instructions are for reference only. Refer to the user guide

that comes with the chassis for more informatio n.

1. Ensure that the cPCI-R6700 is compatible with the CPU

blade and the backplane prior to installation.

2. If required, ensure that the 2.5" SATA drive, Auxiliary

Power Cord, or other peripheral devices are properly

installed.

3. Remove the black plastic caps securing the retaining

screws to the faceplate.

4. Ensure that the system is powered OFF before proceed-

ing.

5. Select the appropriate slot for the cPCI-R6700 RTM as

determined by your application requirements.

6. Align the module's top and bottom e dges to the chassis

card guides, and then carefully slide the module into the

chassis. A slight resistance may be felt when inserting

the module. If the resistance it too strong, check if there

are bent pins on the backplane or if the board's connector pins are not properly aligned with connectors on the

backplane. Then push the board until it is completely

flush with the chassis

7. Push the ejector handles outwards to secure the module

in place, and then fasten the retaining screws on the

module face plate.

8. If required, connect any cables and peripherals to the

board, and then power ON the chassis.

Getting Started 29

Page 42

4.4 Driver Installation

The cPCI-R6700 drivers can be found on the ADLINK All-In-One

DVD at X:\cPCI-R6700\GPU, or at the ADLINK website

(http://www.adlinktech.com). Driver installation procedures for

Windows® XP are described below.

1. Install the Windows operating system before installing

any driver. Most standard I/O device drivers are installed

during Windows installation.

2. Install the graphics driver by extracting and running the

file issetup.exe from the archive

ATI_Graphics_WinXP_8.660.0.0.zip, located in

X:\cPCI-R6700\GPU\.

3. Install the audio driver by extracting and running the executable file in the archive

Realtek_WDM_Audio_WinXP32_Win2003_v2.21.zip

located in X:\cPCI-R6700\Audio\Windows XP x32 2003\.

We recommend using the drivers provided on the ADLINK

All-in-One DVD or downloaded from the ADLINK website to

ensure compatibility.

30 Getting Started

Page 43

5 VBIOS Update

For thermal considerations, the engine clock of the cPCI-R6700

can be changed by applying a VBIOS update. ADLINK provides

four VBIOS options (100, 300, 40 0, 600 MHz) for use rs to set the

best performance and thermal combination for their application.

The VBIOS updates can be found on the All-In-One DVD at

X:XMC\cPCI-R6700\VBIOS, or downloaded from the ADLINK

website (http://www.adlinktech.com).

The graphics driver must be installed before applying any

VBIOS updates.

NOTE:

NOTE:

Follow the steps below to update the VBIOS.

1. Create a DOS bootable USB flash drive.

2. Extract the contents of the R6700_VBIOS.zip file

located in X:\cPCI-R6700\VBIOS on the All-In-One DVD

or downloaded from the ADLINK website.

3. Copy the files inside the R6700_VBIOS folder to the

root directory of USB flash drive.

cPCI-R6700

4. Boot the system from the USB flash drive.

5. Type the command "xxx" (without the "...") from the root

directory to update the VBIOS, where "xxx" is the

desired engine clock frequency (e.g. “100”, “300”, “400”,

“600”).

VBIOS Update 31

Page 44

This page intentionally left blank.

32 VBIOS Update

Page 45

cPCI-R6700

Important Safety Instructions

For user safety, please read and follow all instructions,

WARNINGS, CAUTIONS, and NOTES marked in this manual

and on the associated equipment before handling/operating the

equipment.

X Read these safety instructions carefully.

X Keep this user’s manual for future reference.

X Read the specifications section of this manual for detailed

information on the operating environment of this equipment.

X When installing/mounting or uninstalling/removing

equipment:

Z Turn off power and u nplug any power cords/cables.

X To avoid electrical shock and/or damage to equipment:

Z Keep equipment away from water or liquid sources;

Z Keep equipment away from high heat or high humidity;

Z Keep equipment properly ventilated (do not block or

cover ventilation openings);

Z Make sure to use recommended voltage and powe r

source settings;

Z Always install and operate equipment near an easily

accessible electrical socket-outlet;

Z Secure the power cord (do not place any obje ct on /ove r

the power cord);

Z Only install/attach and operate equipment on stable

surfaces and/or recommended mountings; and,

Z If the equipment will not be used for long periods of time,

turn off and unplug the equipment from its power source.

Important Safety Instructions 33

Page 46

X Never attempt to fix the equipment. Equipmen t sho u ld on ly

be serviced by qualified personnel.

A Lithium-type battery may be provided for uninterrupted, backup

or emergency power.

Risk of explosion if battery is replaced with one of an incorrect

WARNING:

type. Dispose of used batteries appropriately.

X Equipment must be serviced by authorized technicians

when:

Z The power cord or plug is damaged;

Z Liquid has penetrated the equipment;

Z It has been exposed to high humidity/moisture;

Z It is not functioning or does not function according to the

user’s manual;

Z It has been dropped and/or damaged; and/or,

Z It has an obvious sign of breakage.

34 Important Safety Instructions

Page 47

Getting Service

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

cPCI-R6700

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Tel: +86-10-5885-8666

Fax: +86-10-5885-8626

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

LiPPERT ADLINK Technology GmbH

Address: Hans-Thoma-Strasse 11, D-68163, Mannheim, Germany

Tel: +49-621-43214-0

Fax: +49-621 43214-30

Email: emea@adlinktech.com

Rm. 801, Power Creative E, No. 1,

Shang Di East Rd., Beijing, 100085 China

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Getting Service 35

Page 48

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1675-12 微汾瘶捒娯 8猻

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: 1st Floor, #50-56 (Between 16th/17th Cross) Margosa Plaza,

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80-23464606

Email: india@adlinktech.com

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

8F Mointer B/D,1675-12, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Singapore 349584

Margosa Main Road, Malleswaram, Bangalore-560055, India

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 6 Hasadna St., Kfar Saba 44424, Israel

Tel: +972-9-7446541

Fax: +972-9-7446542

Email: israel@adlinktech.com

36 Getting Service

Loading...

Loading...