Page 1

cPCI-9116®/cPCI-9116R®

64 Ch, 16 bit, 250KS/s

Analog input Card

For 3U CompactPCI

User’s Guide

Recycled Paper

Page 2

Page 3

©Copyright 2002 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 1.10: April 28, 2003

Part No: 50-15002-101

The information in this document is subject to change without prior n otice in

order to improve reliability, design and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental,

or consequential damages arising out of the use or inability to use the product

or documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

NuDAQ®, NuIPC® are registered trademarks of ADLINK Technology Inc.

Other products names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective

companies.

Page 4

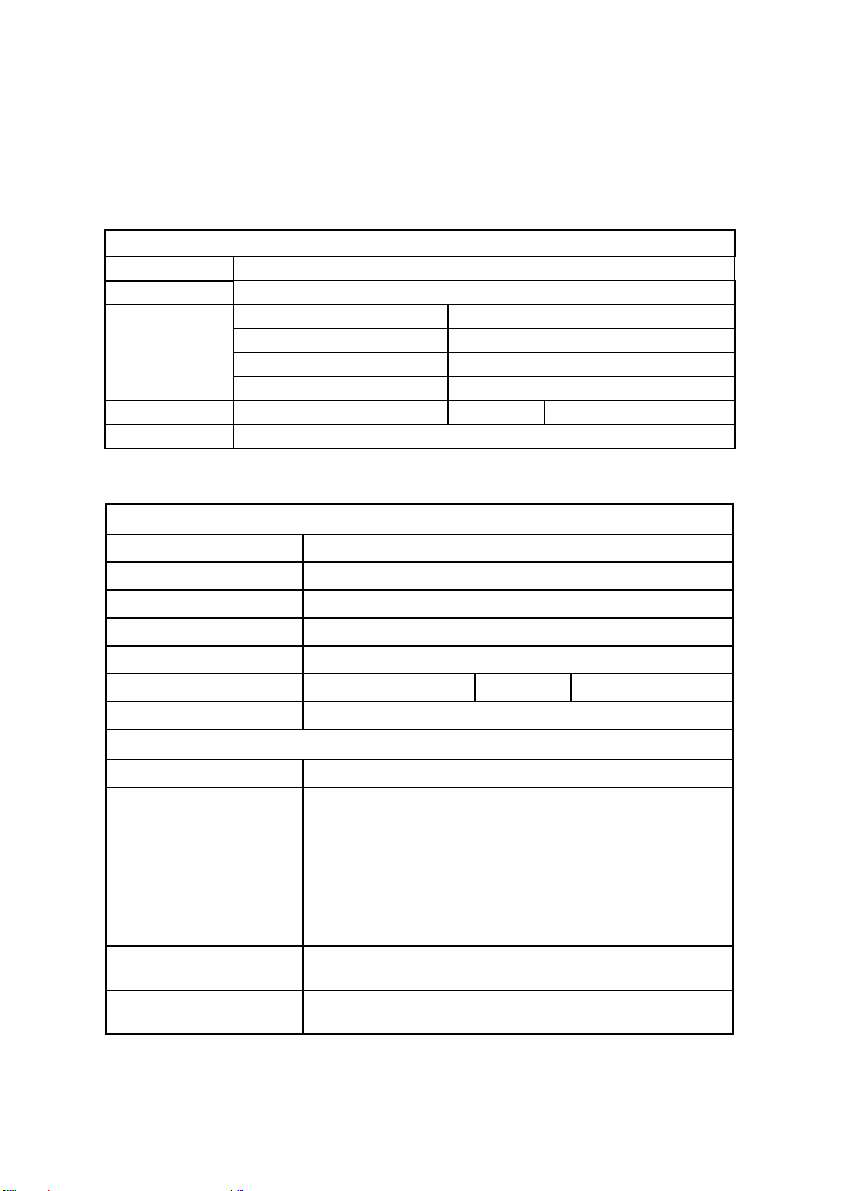

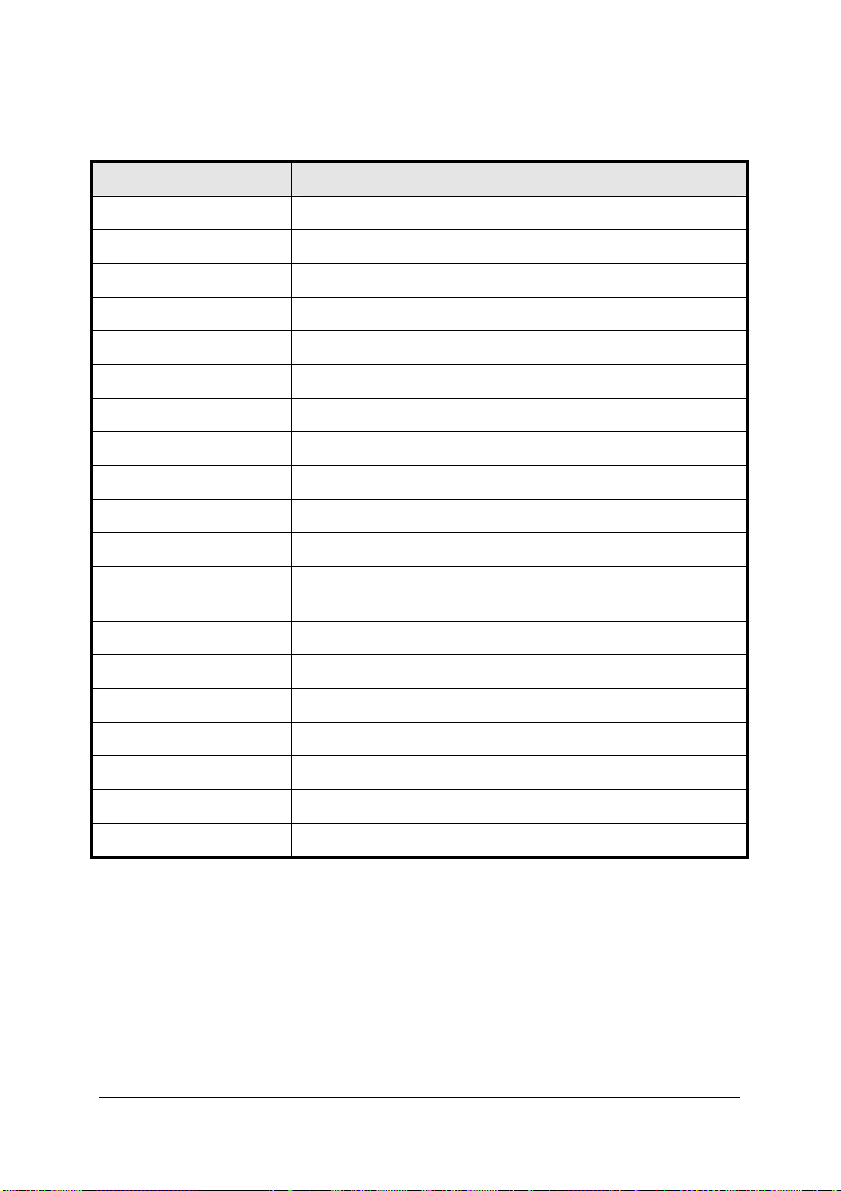

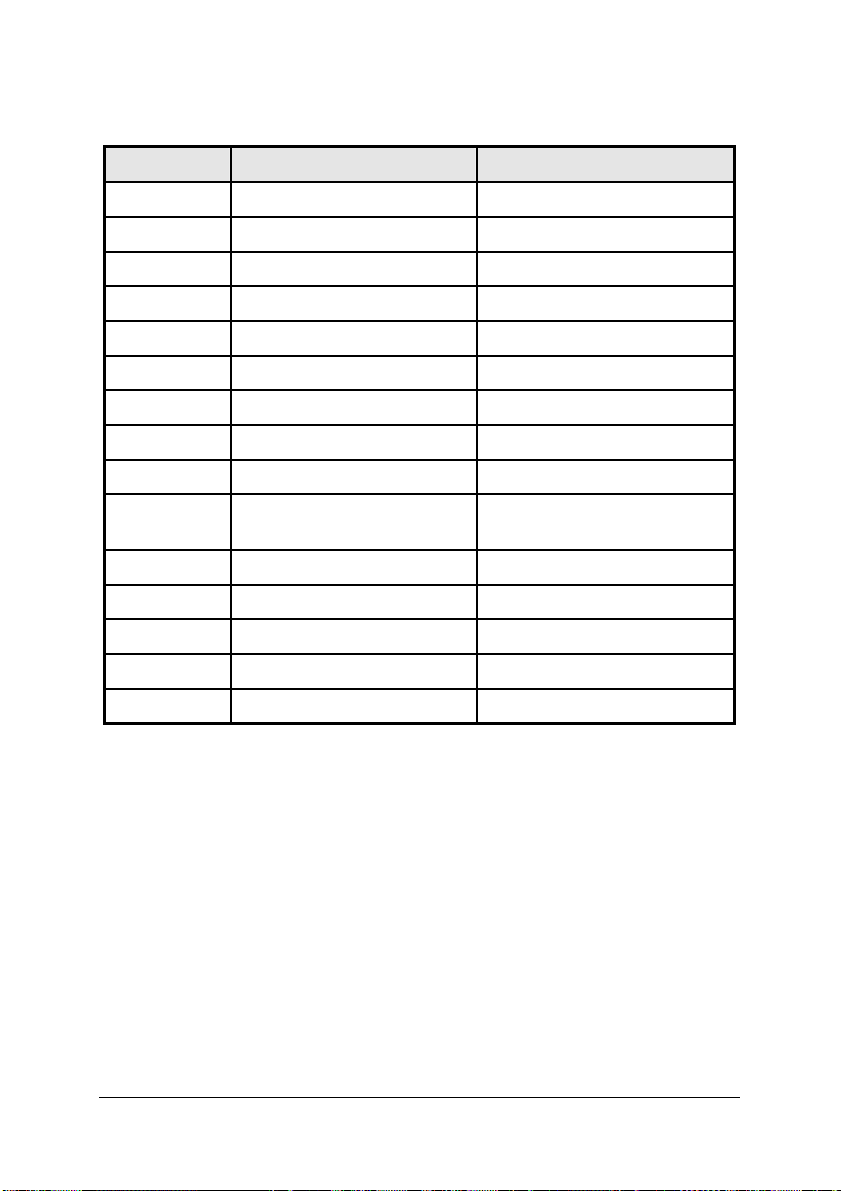

Getting service from ADLINK

Customer Satisfaction is the most important priority for ADLINK Tech Inc. If

you need any help or service, please contact us.

ADLINK Technology Inc.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

NuDAQ + USBDAQ nudaq@adlinktech.com

Technical

Support

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan.

Please email or FAX us of your detailed information for a prompt, satisfactor y

and constant service.

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Product Model

Environment to Use

Automation automation@adlinktech.com

NuIPC nuipc@adlinktech.com

NuPRO / EBC nupro@adlinktech.com

Detailed Company Information

Questions

OS:

Computer Brand:

M/B: CPU:

Chipset: BIOS:

Video Card:

Network Interface Card:

Other:

Detail Description

Suggestions to ADLINK

Page 5

Table of Contents

Tables..........................................................................................................iv

Figures.........................................................................................................v

Outline of Chapters.................................................................................... vi

Chapter 1 Introduction................................................................................1

1.1 Features..............................................................................................2

Applications ........................................................................................2

1.2

1.3 Specifications......................................................................................3

1.4 Software Support................................................................................6

1.4.1 Programming Library.............................................................6

1.4.2 PCIS-LVIEW: LabVIEW® Driver............................................6

1.4.3 DAQBenchTM: ActiveX Controls.............................................7

Chapter 2 Installation..................................................................................8

2.1 What You Have...................................................................................8

2.2 Unpacking...........................................................................................9

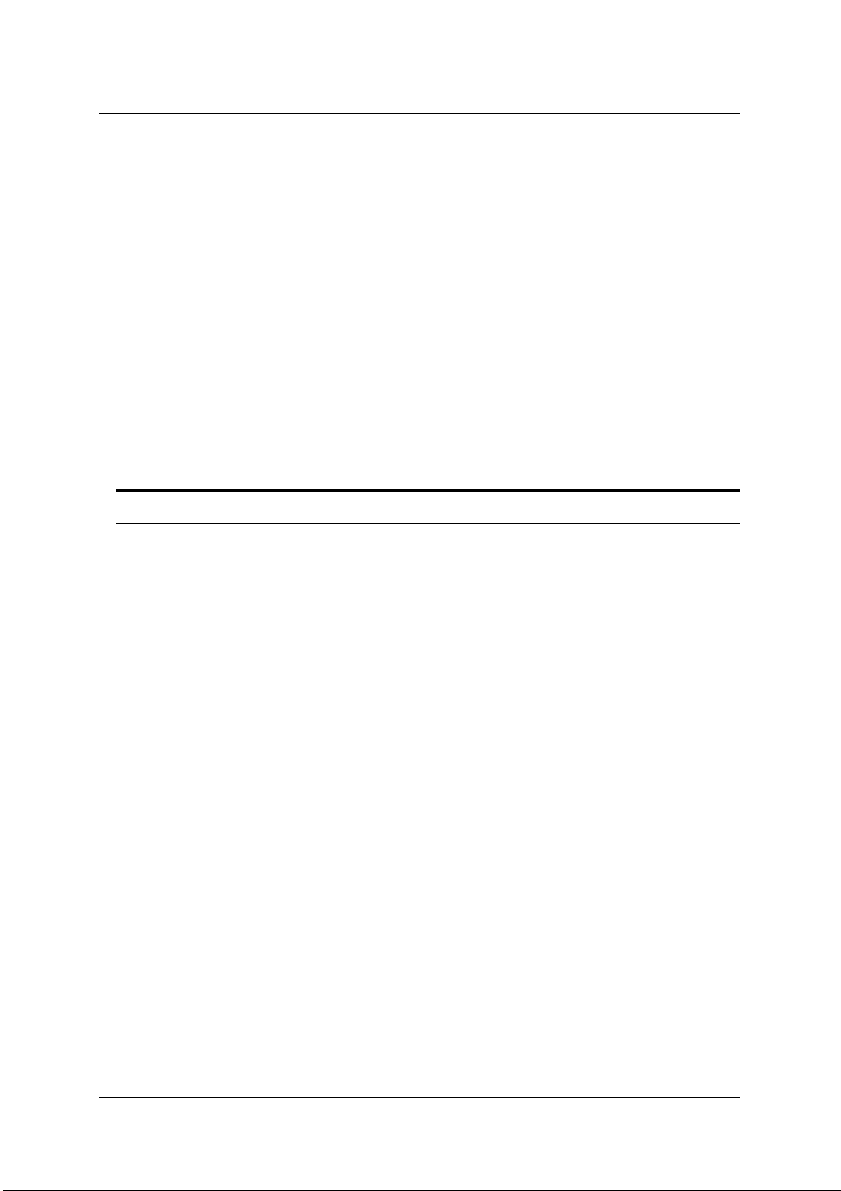

2.3 cPCI-9116 and cPCI-9116R Layout..................................................10

2.4 PCI Configuration..............................................................................12

Chapter 3 Signal Connections.................................................................13

3.1 Connectors and Pin Assignment.......................................................13

3.1.1 100-pin SCSI-type connector (J1) .......................................14

3.1.2 Legend of J1........................................................................15

3.2 Analog Input Signal Connection........................................................16

3.2.1 Types of signal sources.......................................................16

3.2.2 Input Configurations ............................................................16

3.3 Digital I/O Connection....................................................................... 18

Chapter 4 Registers..................................................................................19

4.1 I/O Port Address ...............................................................................19

4.2 Internal Timer/Counter Register........................................................21

4.3 General Purpose Timer/Counter Register.........................................22

4.4 General Purpose Timer/Counter Control Register............................22

4.5 A/D Data Registers...........................................................................24

4.6 Channel Gain Queue Register..........................................................24

4.7 A/D & FIFO Control Register ............................................................26

4.8 A/D & FIFO Status Register..............................................................27

4.9 Digital I/O register.............................................................................29

4.10 A/D Trigger Mode Register ...............................................................30

4.11 Interrupt Control Register..................................................................31

4.12 Interrupt Status Register...................................................................33

Table of Contents • i

Page 6

Chapter 5 Operation Theory.....................................................................34

5.1 A/D Conversion.................................................................................34

5.1.1 A/D Conversion Procedure..................................................34

5.1.2 Software conversion with polling data transfer acquisition

mode (Software Polling)......................................................35

5.1.3 Programmable scan acquisition mode.................................36

5.1.4 A/D Data Transfer Modes....................................................47

5.2 Digital Input and Output....................................................................48

5.3 General Purpose Timer/Counter Operation ......................................49

Chapter 6 C/C++ Library...........................................................................51

6.1 Libraries Installation..........................................................................51

6.2 Programming Guide..........................................................................52

6.2.1 Naming Convention.............................................................52

6.2.2 Data Types..........................................................................52

6.2.3 Sample Programs List (DOS)..............................................53

6.3 Initial functions..................................................................................54

6.3.1 _9116_Initial........................................................................ 54

6.3.2 _9116_AD_Clr_DFIFO........................................................55

6.4 DIO functions....................................................................................56

6.4.1 _9116_DI.............................................................................56

6.4.2 _9116_DO...........................................................................56

6.5 AD Channel Gain Queue configuration functions..............................57

6.5.1 _9116_AD_Clr_CFIFO........................................................57

6.5.2 _9116_AD_Set_CFIFO .......................................................58

6.5.3 _9116_AD_CFIFO_SetDone...............................................60

6.6 AD Software-Polling functions...........................................................61

6.6.1 _9116_AD_Acquire .............................................................61

6.7 AD Trigger control functions .............................................................62

6.7.1 _9116_AD_Trig_Ctrl............................................................62

_9116_AD_Set_TrigMode...................................................62

_9116_AD_Set_TrigPol.......................................................62

_9116_AD_Set_Timebase ..................................................62

_9116_AD_Set_Delay_SRC ...............................................62

_9116_AD_Set_M_enable ..................................................62

6.8 AD Counter setting functions ............................................................64

6.8.1 _9116_AD_Set_SC.............................................................64

6.8.2 _9116_AD_Set_SI...............................................................65

6.8.3 _9116_AD_Set_SI2.............................................................65

6.8.4 _9116_AD_Set_DIV............................................................66

6.8.5 _9116_AD_Set_DLY1.........................................................66

6.8.6 _9116_AD_Set_M...............................................................67

6.8.7 _9116_AD_Set_Retrig.........................................................68

ii • Table of Contents

Page 7

6.9 AD one-shot scan data acquisition with DMA transfer functions.......69

6.9.1 _9116_AD_DMA_Start........................................................69

6.9.2 _9116_AD_DMA_Status .....................................................70

6.9.3 _9116_AD_DMA_Stop........................................................71

6.10 AD one-shot scan data acquisition with interrupt- transfer functions.72

6.10.1 _9116_AD_INT_Start..........................................................72

6.10.2 _9116_AD_INT_Status........................................................73

6.10.3 _9116_AD_INT_Stop ..........................................................74

6.11 AD continuous scan data acquisition with double-buffered DMA

transfer functions ..............................................................................75

6.11.1 _9116_DblBufferMode........................................................75

6.11.2 _9116_DblBufferTransfer ....................................................76

6.11.3 _9116_GetOverrunStatus....................................................77

6.12 General Purpose Timer/Counter functions........................................77

6.12.1 _9116_GP0_Set_Mode.......................................................77

6.12.2 _9116_GP0_Set_Count ......................................................78

6.12.3 _9116_GP0_Set_CLK.........................................................78

6.12.4 _9116_GP0_Set_GATE_SRC.............................................79

6.12.5 _9116_GP0_Set_UPDOWN_SRC......................................79

6.12.6 _9116_GP0_Set_UPDOWN................................................80

6.12.7 _9116_GP0_EN ..................................................................80

6.12.8 _9116_GP0_Read_Count ...................................................81

Chapter 7 Software Utility & Calibration.................................................82

7.1 Running 9116util.exe program..........................................................82

7.2 Calibration.........................................................................................83

7.2.1 What do you need ...............................................................83

7.2.2 VR Assignment....................................................................84

7.2.3 A/D Adjustment ...................................................................84

7.3 Functional Testing.............................................................................85

Warranty Policy.........................................................................................87

Table of Contents • iii

Page 8

Tables

Table 1. Legend of J1 Connector......................................................15

Table 2. I/O Port Address..................................................................20

Table 3. Timer/Counter Register Address.........................................21

Table 4. General Purpose Timer/Counter Register...........................22

Table 5. General Purpose Timer/Counter Control Register...............22

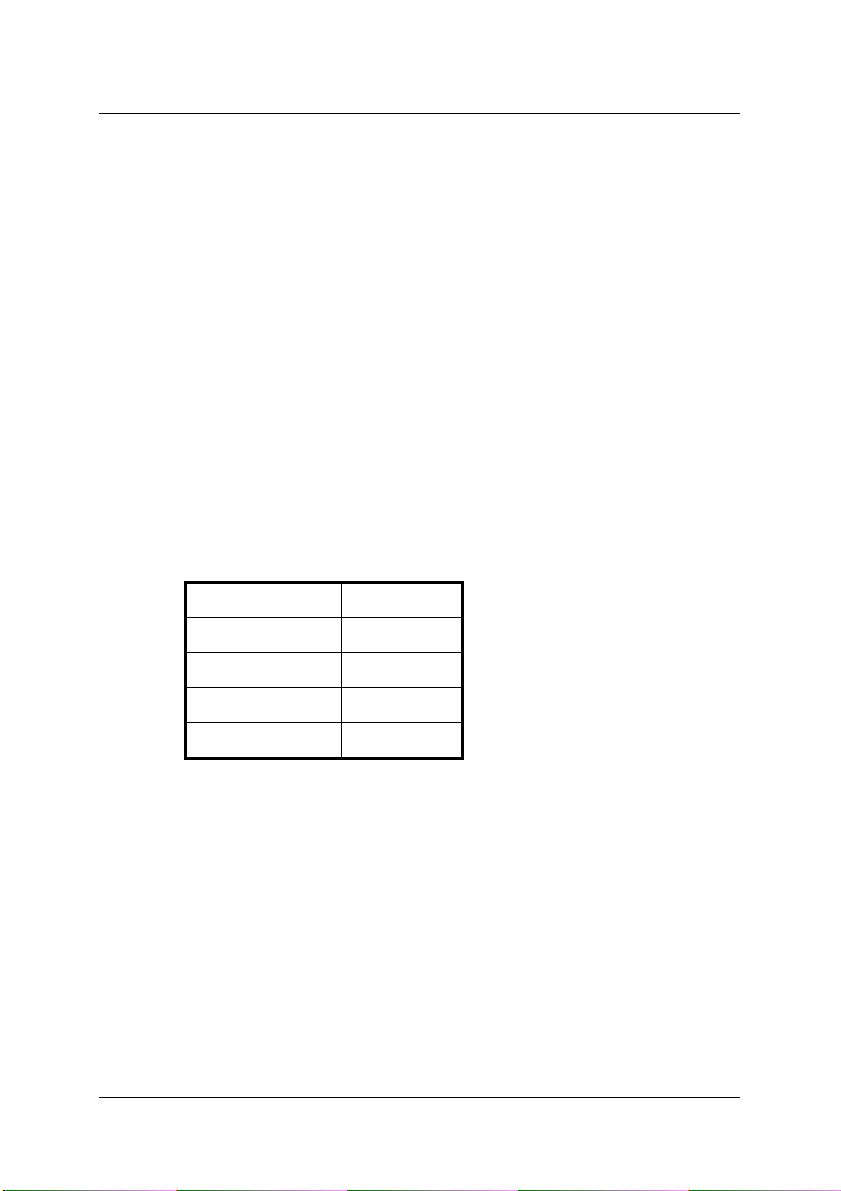

Table 6. GPTC0’s Mode selection.....................................................23

Table 7. A/D Data Registers..............................................................24

Table 8. Channel Gain Queue Register ............................................24

Table 9. Gain Selection Bits..............................................................25

Table 10. A/D & FIFO Control Register...............................................26

Table 11. A/D & FIFO Status Register ................................................27

Table 12. Digital I/O register (Read)....................................................29

Table 13. Digital I/O register (Write)....................................................29

Table 14. A/D Trigger Mode Register..................................................30

Table 15. Trigger Mode Selection Bits ................................................31

Table 16. Interrupt Control Register....................................................31

Table 17. Interrupt Status Register......................................................33

Table 18. Functions of VRs.................................................................84

iv • Tables

Page 9

Figures

Figure 1: PCB Layout of the cPCI-9116 .............................................10

Figure 2: PCB Layout of cPCI-9116R and Rear I/O adaptor .............. 11

Figure 3: J1 Pin Assignments.............................................................14

Figure 4: Single-ended Mode and Floating sources...........................16

Figure 5: Ground-referenced source and differential input .................17

Figure 6: Floating source and differential input...................................17

Figure 7: Ground-referenced source and User Common Mode

connections.........................................................................18

Figure 8: Digital I/O Connection..........................................................18

Figure 9: Scan Timing ........................................................................37

Figure 10: Pre-trigger (trigger occurs after M scans)............................40

Figure 11: Pre-trigger (trigger with scan is in progress)........................40

Figure 12: Pre-trigger with M_enable = 0 (trigger occurs before M

scans)..................................................................................41

Figure 13: Pre-trigger with M_enable = 1 ............................................. 42

Figure 14: Middle trigger with M_enable = 1.........................................43

Figure 15: Middle trigger (trigger with scan is in progress)...................44

Figure 16: Post trigger..........................................................................44

Figure 17: Delay trigger........................................................................45

Figure 18: Post trigger with re-trigger...................................................46

Figure 19: General-purpose Timer/Counter model...............................49

Figure 20: Mode 0 Operation................................................................50

Figure 21: Mode 1 Operation................................................................50

Figure 22: CPCI-9116 Utility Main Screen............................................83

Figure 23: A/D Adjustment menu Screen.............................................84

Figure 24: cPCI-9116 Function Testing Screen....................................86

Figures • v

Page 10

Outline of Chapters

This manual is designed to help you use the 9116 series. The manual

describes how to modify various settings on the card to meet your

requirements. It is divided into seven chapters:

Chapter1, “Introduction”,

applications, and specifications.

Chapter 2, “Installation”,

layout of 9116 series is shown.

Chapter 3, “Signal Connection”,

assignment and how to connect external signal and devices

to the 9116 series card.

Chapter 4, “Registers”,

structure. This information is important for programmers

who want to control the hardware with low-level

programming.

Chapter 5, “Operation theory”,

9116 series card. The A/D, DIO and timer/counter functions

are introduced. Also, some programming concepts are

specified.

Chapter 6, “Software Utility & Calibration”,

utility program included in the software CD and how to

calibrate the 9116 series card for accurate measurements.

gives an overview of the product features,

describes how to install the 9116 series. The

describes the connectors' pin

describes the details of the registers and its

describes the working theory of the

describes how to run the

vi • Outline of Chapters

Page 11

1

Introduction

The cPCI-9116 series products are advanced data acquisition cards based on

the 32-bit CompactPCI architecture. The 9116 series include:

cPCI-9116: 16-bit 250KHz DAS card for 3U CompactPCI

•

cPCI-9116R: 16-bit 250KHz DAS card for 3U CompactPCI

•

with Rear I/O connector

The 9116 series DAS cards use state-of-the-art technology making it an ideal

for data logging and signal analysis applica tions in medical, process control,

etc.

Introduction • 1

Page 12

1.1 Features

The 9116 series CompactPCI Advanced Data Acquisition Card provides the

following advanced features:

32-bit PCI-Bus, plug and play

•

Up to 64 single-ended inputs or 32 differential inputs, mixing

•

of using SE and DI analog signal sources

16-bit analog input resolution

•

On-board A/D 1K FIFO memory

•

512 words analog input Channel Gain Queue spaces

•

Sampling rate up to 250KS/s

•

Bipolar or Unipolar input signals

•

Programmable gain of x1, x2, x4, x8

•

Jumper-less and software configurable

•

Five A/D trigger modes: software trigger, pre-trigger,

•

post-trigger, middle-trigger and delay-trigger

Software Polling, Interrupt and Bus-mastering DMA data

•

transfer available

8 digital input and 8 digital output channels

•

100-pin D-type SCSI-II connector for cPCI-9116

•

100-pin D-type SCSI-II connector on a rear I/O transition

•

board for cPCI-9116R

Compact size: standard compact PCI 3U size

•

1.2 Applications

Automotive Testing

•

Cable Testing

•

Transient signal measurement

•

ATE

•

Laboratory Automation

•

Biotech measurement

•

2 • Introduction

Page 13

1.3 Specifications

Analog Input (A/D)

♦

Converter:

•

Number of channels: (programmable)

•

64 single-ended (SE)

3

32 differential input (DI)

3

Mixing of SE and DI analog signal between channel allowed

3

A/D Data FIFO Buffer Size:

•

Channel Gain Queue Length:

•

Resolution:

•

Input Range:

•

Bipolar:

3

Unipolar:

3

CMRR (DC to 60 Hz, typical)

•

Input Range CMRR

LT1606 (or equivalent) 250KHz

16-bit

(Controlled by Channel Gain Queue)

± 5V, ±2.5V, ±1.25V, ±0.625V

0~10V, 0~5V, 0~2.5V, 0~1.25

1024 locations

512 words configurations

±5, 0~10V

±2.5, 0~5V

±1.25, 0~2.5V

±0.625, 0~1.25V

Overvoltage Protection:

•

Accuracy:

•

Input Impedance:

•

Time-base source:

•

3

3

Programmable scan interval and sampling rate (divided from

•

0.01% of FSR

Internal 24MHz

External clock Input (fmax: 24MHz, fmin: 1MHz)

87dB

90dB

92dB

93dB

Continuous ± 35V maximum

100 MΩ | 6pF

time-base source)

Introduction • 3

Page 14

Trigger Mode:

•

Software-trigger.

3

Pre-trigger.

3

Post-trigger.

3

Middle-Trigger.

3

Delay Trigger

3

Data Transfer:

•

Polling.

3

EOC interrupt transfer.

3

FIFO half-full Interrupt transfer.

3

Bus-mastering DMA.

3

Data Throughput:

•

Digital I/O (DIO)

♦

Channel:

•

Input Voltage:

•

3

3

Output Voltage:

•

3

3

General Purpose Timer/ Counter

♦

Number of channel:

•

Clock Input:

•

8 TTL compatible digital inputs and outputs

Low: VIL=0.8 V max. IIL=0.2mA max.

High: VIH=2.0V max. IIH=0.02mA max

Low: VOL=0.5 V max. IOL=8mA max.

High: VOH=2.7V min; IOH=400μA

Internal 24MHz or External CLK input up to 20MHz

250KHz (maximum)

One 16-bit Up/Down Timer/Counter

4 • Introduction

Page 15

General Specifications

♦

Connector:

•

Operating Temperature:

•

Storage Temperature:

•

Humidity:

•

Power Consumption:

•

+5V @ 560mA typical

3

+3.3V@ 100mA typical

3

15V (pin35, pin85) Output Current (max):

±

•

+5V(pin49, pin99) Output Current (max):

•

Dimension:

•

100-pin D-type SCSI-II connector

0° C ~ 60° C

-20° C ~ 80° C

5 ~ 95%, non-condensing

Standard Compact PCI 3U size

5mA

500mA

Introduction • 5

Page 16

1.4 Software Support

ADLINK provides versatile software drivers and packages for users’ different

approach to building a system. We not only provide programming libraries

such as DLL for many Windows systems, but also provide drivers for other

software packages such as LabVIEW®.

All software options are included in the ADLINK CD. Non-free software drivers

are protected with licensing codes. Without the software code, you can install

and run the demo version for two hours for trial/demonstration purposes.

Please contact ADLINK dealers to purchase the formal license.

1.4.1 Programming Library

For customers who are writing their own programs, we provide function

libraries for many different operating systems, including:

PCIS-DASK: Include device drivers and DLL for Windows

•

98, Windows NT and Windows 2000. DLL is binary compati bl e

across Windows 98, Windows NT and Windows 2000. That

means all applications developed with PCIS-DASK are

compatible across Windows 98, Windows NT and Windows

2000. The developing environment can be VB, VC++, Delphi,

BC5, or any Windows programming language that allows calls

to a DLL. The user’s guide and function reference manual of

PCIS-DASK are in the CD. Please refer the PDF manual files

under \\Manual_PDF\Software\PCIS-DASK

PCIS-DASK/X: Includes device drivers and shared library for

•

Linux. The developing environment can be Gnu C/C++ or any

programming language that allows linking to a shared librar y.

The user's guide and function reference manual of

PCIS-DASK/X are in the CD.

(\Manual_PDF\Software\PCIS-DASK-X.)

The above software drivers are shipped with the board. Please refer to the

“Software Installation Guide” for installation procedures.

1.4.2 PCIS-LVIEW: LabVIEW® Driver

PCIS-LVIEW contains the VIs, which are used to interface with NI’s

LabVIEW® software package. The PCIS-LVIEW supports Windows

95/98/NT/2000. The LabVIEW® drivers is shipped free with the board. You

can install and use them without a license. For more information about

PCIS-LVIEW, please refer to the user’s guide in the CD.

(\\Manual_PDF\Software\PCIS-LVIEW)

6 • Introduction

Page 17

1.4.3 DAQBenchTM: ActiveX Controls

We suggest customers who are familiar with ActiveX controls and VB/VC++

programming use the DAQBenchTM ActiveX Control component library for

developing applications. The DAQBenchTM is designed under Windows

NT/98. For more information about DAQBench, please refer to the user’s

guide in the CD. (\\Manual_PDF\Software\DAQBench\DAQBench

Manual.PDF).

Introduction • 7

Page 18

2

Installation

This chapter describes how to install the 9116 series cards. The contents of the

package and unpacking information that you should be aware of are described

first.

The 9116 series cards perform an automatic configuration of the IRQ, port

address, and BIOS address. You do not need to set these configurations, as

you would do in ISA form factor DAS cards. Automatic configuration allows

your system to operate more reliable and safe.

2.1 What You Have

In addition to this User's Guide, the package should also include the following

items:

cPCI-9116 or cPCI-9116R with rear I/O adaptor Analog input

•

Data Acquisition Card

ADLINK All-in-one Compact Disc

•

Software Installation Guide

•

If any of these items are missing or damaged, contact the dealer from

whom you purchased the product. Save the shipping materials and carton

in case you want to ship or store the product in the future.

8 • Installation

Page 19

2.2 Unpacking

The card contains electro-static sensitive components tha t can be easily be

damaged by static electricity.

Therefore, the card should be handled on a grounded anti-static mat. The

operator should be wearing an anti-static wristband, grounded at the same

point as the anti-static mat.

Inspect the card module carton for obvious damages. Shipping and handling

may cause damage to your module. Be sure there are no shipping and

handling damages on the modules carton before continuing.

After opening the card module carton, extract the system module and place it

only on a grounded anti-static surface with component side up.

Again, inspect the module for damages. Press down on all the socketed IC's to

make sure that they are properly seated. Do this only with the module place on

a firm flat surface.

Note:

DO NOT APPLY POWER TO THE CARD IF IT HAS BEEN DAMAGED.

You are now ready to install your cPCI-9116/R.

Installation • 9

Page 20

2.3 cPCI-9116 and cPCI-9116R Layout

10 • Installation

Figure 1: PCB Layout of the cPCI-9116

Page 21

Figure 2: PCB Layout of cPCI-9116R and Rear I/O adaptor

Installation • 11

Page 22

2.4 PCI Configuration

1. Plug and Play:

As a plug and play component, the board requests an interrupt number via a

system call. The system BIOS responds with an interrupt assignment based on

the board information and on known system parameters. These system

parameters are determined by the installed drivers and the hardware load seen

by the system.

2. Configuration:

The board configuration is done on a board-by-boar d basis for all PCI form

factor boards on your system. Because configuration is controlled by the

system and software, so there is no jumpers for base-address, DMA, and

interrupt IRQ need to be set by the user.

The configuration is subject to change with every boot of the s ystem as new

boards are added or boards are removed. So, there is no idea what‘s going on

to be installed.

3. Trouble shooting:

If your system doesn’t boot or if you experience erratic operation with your PCI

board in place, it’s likely caused by an interrupt conflict (perhaps because you

incorrectly configured the BIOS setup). In general, the solution, once you

determine it is not a simple oversight, is to consult the BIOS documentation

that came with your system.

12 • Installation

Page 23

3

Signal Connections

This chapter describes the connectors of the 9116 series. The signal

connections between the 9116 series cards and external devices are also

outlined.

3.1 Connectors and Pin Assignment

The cPCI-9116 is equipped with one 100-pin SCSI-type connector (J1).

J1 is used for digital input/output, analog input, and timer/counter signals. The

pin assignment for the connector is illustrated in the Figure 3.1.

With the REAR I/O adaptor specifically designed for the cPCI-9116R, the

cPCI-9116R connector pin assignments are identical to that of the cPCI-9116.

The red LED positioned on the front panel is used as a power indicator.

Signal Connections • 13

Page 24

3.1.1 100-pin SCSI-type connector (J1)

U_CMMD 1 51 AGND

AIH0 AI0 2 52 AI32 AIL0

AIH1 AI1 3 53 AI33 AIL1

AIH2 AI2 4 54 AI34 AIL2

AIH3 AI3 5 55 AI35 AIL3

AIH4 AI4 6 56 AI36 AIL4

AIH5 AI5 7 57 AI37 AIL5

AIH6 AI6 8 58 AI38 AIL6

AIH7 AI7 9 59 AI39 AIL7

AIH8 AI8 10 60 AI40 AIL8

AIH9 AI9 11 61 AI41 AIL9

AIH10 AI10 12 62 AI42 AIL10

AIH11 AI11 13 63 AI43 AIL11

AIH12 AI12 14 64 AI44 AIL12

AIH13 AI13 15 65 AI45 AIL13

AIH14 AI14 16 66 AI46 AIL14

AIH15 AI15 17 67 AI47 AIL15

AIH16 AI16 18 68 AI48 AIL16

AIH17 AI17 19 69 AI49 AIL17

AIH18 AI18 20 70 AI50 AIL18

AIH19 AI19 21 71 AI51 AIL19

AIH20 AI20 22 72 AI52 AIL20

AIH21 AI21 23 73 AI53 AIL21

AIH22 AI22 24 74 AI54 AIL22

AIH23 AI23 25 75 AI55 AIL23

AIH24 AI24 26 76 AI56 AIL24

AIH25 AI25 27 77 AI57 AIL25

AIH26 AI26 28 78 AI58 AIL26

AIH27 AI27 29 79 AI59 AIL27

AIH28 AI28 30 80 AI60 AIL28

AIH29 AI29 31 81 AI61 AIL29

AIH30 AI30 32 82 AI62 AIL30

AIH31 AI31 33 83 AI63 AIL31

AGND 34 84 AGND

+15V out 35 85 -15V out

N/C 36 86 N/C

DI0 37 87 DO0

DI1 38 88 DO1

DI2 39 89 DO2

DI3 40 90 DO3

DI4 41 91 DO4

DI5 42 92 DO5

DI6 43 93 DO6

DI7 44 94 DO7

ExtTimeBase 45 95 N/C

ExtTrg 46 96 GP_TC_CLK

SSH_OUT 47 97 GP_TC_GATE

GP_TC_OUT 48 98 GP_TC_UPDN

+5V Out 49 99 +5V out

DGND 50 100 DGND

Figure 3: J1 Pin Assignments

14 • Signal Connections

Page 25

3.1.2 Legend of J1

Signal Name Definition

U_CMMD User Common Mode

AIn Analog Input Channel n (single-ended)

AIHn Analog High Input Channel n (differential)

AILn Analog Low Input Channel n (differential)

DIn Digital Input Signal Channel n

DOn Digital Output Signal Channel n

ExtTimeBase External Timebase Clock Input

ExtTrg External Digital Trigger Signal

SSH_OUT SSH Output Signal

GP_TC_CLK General Purpose Timer/Counter Clock Input

GP_TC_GATE General Purpose Timer/Counter Gate Input

GP_TC_UPDN

GP_TC_OUT General Purpose Timer/Counter Output

+5V OUT +5V Output

+15V OUT +15V Output

-15V OUT -15V Output

AGND Analog Ground

DGND Digital Ground

N/C No Connection

Purpose Timer/Counter Up/Down Control Input

(0:down, 1:up)

Table 1. Legend of J1 Connector

Signal Connections • 15

Page 26

AInA

A

3.2 Analog Input Signal Connection

The 9116 series provides up to 64 single-ended or 32 differential analog input

channels. You can set and fill the Channel Gain Queue to get the desired

combination of the input signal types. The analog signals can be converted to

digital value by the A/D converter. To avoid ground loops and to obtain

accurate measurements from the A/D conversion, it is quite important to

understand the signal source type and how to choose the analog input modes:

Single-ended, Differential, or User Common Mode.

3.2.1 Types of signal sources

Floating Signal Sources

A floating signal source means it is not connected in any way to the buildings

ground system. A device with an isolated output is a floating signal sour ce,

such as optical isolator outputs, transformer outputs, and thermocouples

Ground-Referenced Signal Sources

A ground-referenced signal means it is connected in some way to the buildings

system. That is, the signal source is already connected to a common ground

point with respect to the 9116 card, assuming that the computer is plugged into

the same power system. Non- isolated outputs of instruments and devices that

plug into the buildings power system are ground-referenced signal sources.

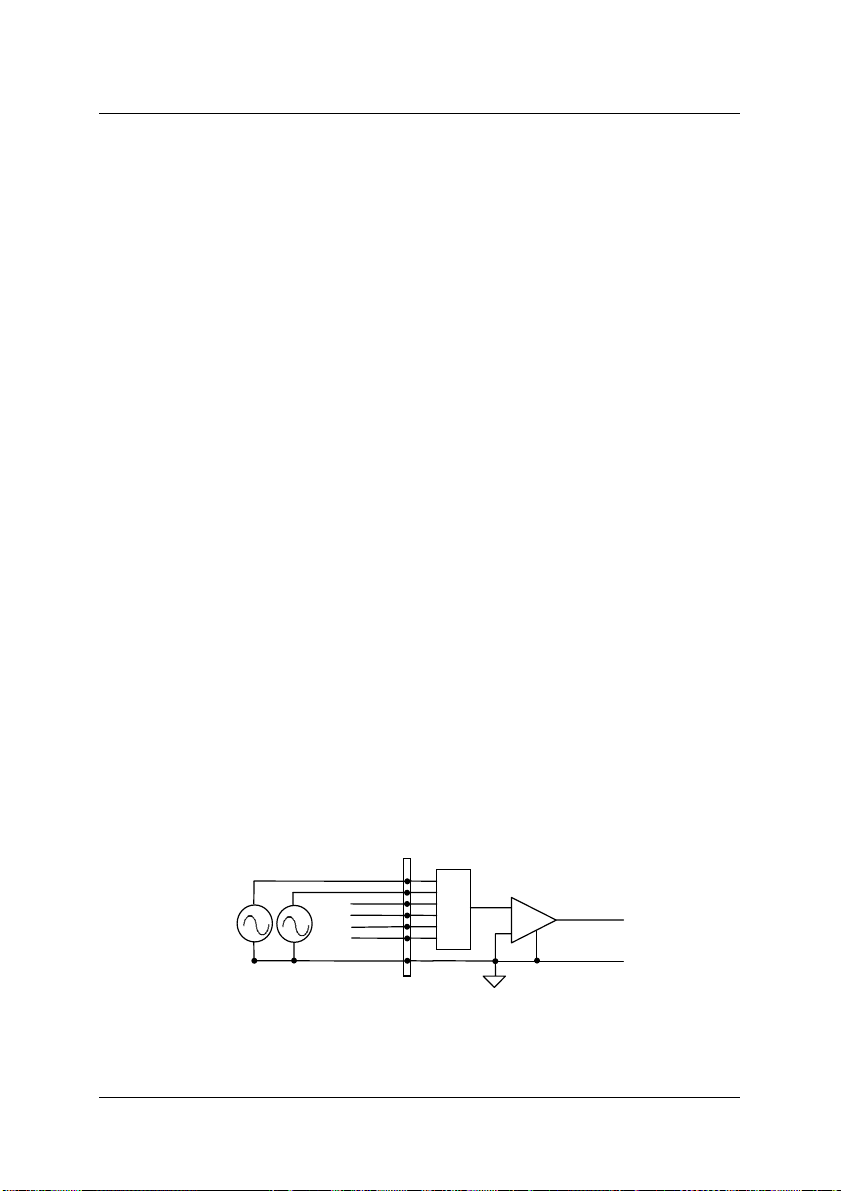

3.2.2 Input Configurations

Single-ended Mode

In single-ended mode, all input signals are connected to g round provided by

the 9116 card. It is suitable for connections with floating signal sources. Figure

4 illustrates single-ended connection. Note that when more than t wo floating

sources are connected, these sources will be referenced to the same common

ground.

Floating

Signal

Source

V1

n = 0, ...,63

V2

J1

Input Multipexer

GND

Instrumentation

mplifier

-

To A/D

Converter

-

Figure 4: Single-ended Mode and Floating sources

16 • Signal Connections

Page 27

A

A

x

A

A

r

A

A

x

A

A

r

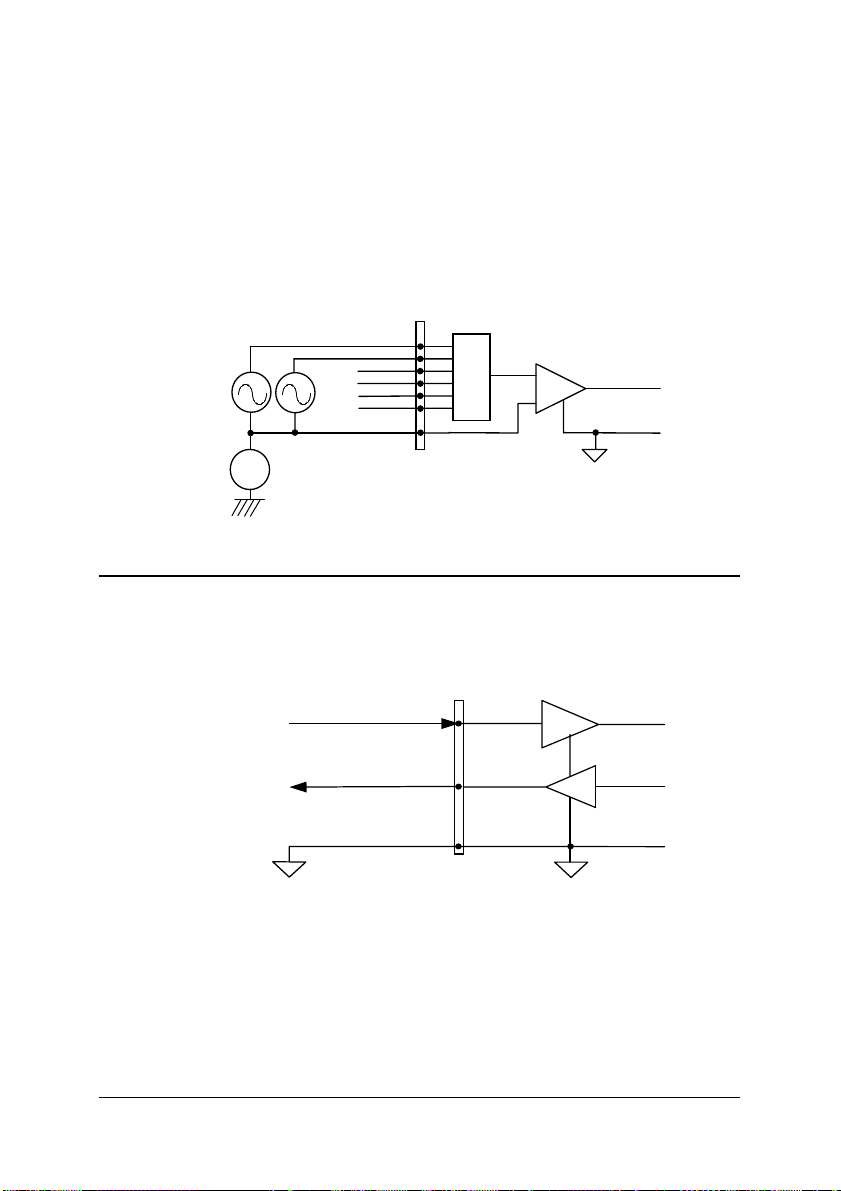

Differential input mode

The differential input mode provides two inputs that respon d to signal voltage

differences between them. If the signal source is ground- referenced, the

differential mode can be used for common-mode noise rejection. Figure 5

shows the connection of ground-referenced signal sources under different ial

input mode.

Ground

Referenced

Signal

Source

Commonmode noise &

Ground

potential

Vcm

= 0, ..., 31

Figure 5: Ground-referenced source a nd differential input

Fig 6 shows how to connect a floating signal source to the 9116 card in

differential input mode. For floating signal sources, a resistor is required on

each channel to provide a bias return path. The resistor value should be about

100 times the equivalent source impedance. If the source impedance is less

than 100ohms, simply connect the negative side of the signal to AGND as well

as the negative input of the Instrumentation Amplifier, without any resistors. In

differential input mode, less noise is coupled into the signal connections than in

single-ended mode.

Ground

Reference d

Signal

Source

= 0, ..., 31

IxH

IxL

IxH

IxL

In put Multipexer

+

-

GND

Inpu t Multipexer

+

-

Instrumentation

mplifie

To A /D

Converter

-

Instrumentation

mplifie

To A /D

Converter

-

GND

Figure 6: Floating source and differential input

Signal Connections • 17

Page 28

A

A

User Common Mode (U_CMMD)

To measure ground-referenced signal sources, which are connected to the

same ground point, you can connect the signals in a User-Common-Mode

(U_CMMD) configuration. Fig 7 illustrates the connections. The signal local

ground reference is connected to the negative input of the instrumentation

Amplifier, and the common-mode ground potential to signal ground. The

instrumentation amplifier will now reject the 9116 series ground.

In

U_CMMD

Input Multipexer

-

Instrumentation

mplifier

To A/D

-

Converter

GroundReferenced

Signal Source

Commonmode noise &

Ground

potential

V1

Vcm

V2

n = 0, ...,63

Figure 7: Ground-referenced source a nd User Common Mode connections

3.3 Digital I/O Connection

The 9116 series card provides 8 digital input and 8 digital output channels. The

digital I/O signals are fully TTL/DTL compatible. The details of the digital I/O

signal specification can be found in section 1.3.

74LS244

From TTL Signal

To TTL Devices

Digital Input(DI)

Digital Output(DO)

Digital GND(DGND)

74LS244

Figure 8: Digital I/O Connection

18 • Signal Connections

Page 29

4

Registers

The descriptions of the registers and structure of the cPCI-9116 are outlined in

this chapter. The information in this chapter will assist programmers, who wish

to handle the card with low-level programs.

In addition, the low level programming syntax is introduced. This information

can help beginners to operate the cPCI-9116 in the shortest possible time.

4.1 I/O Port Address

The 9116 series card functions as a 32-bit PCI master device to any master on

the PCI bus. It supports burst transfer to memory space by using 32-bit data.

All data read and write are based on 32-bit transactions. Table 2 shows the I/O

address of each register with respect to the base address. The function of each

register is also shown.

Registers • 19

Page 30

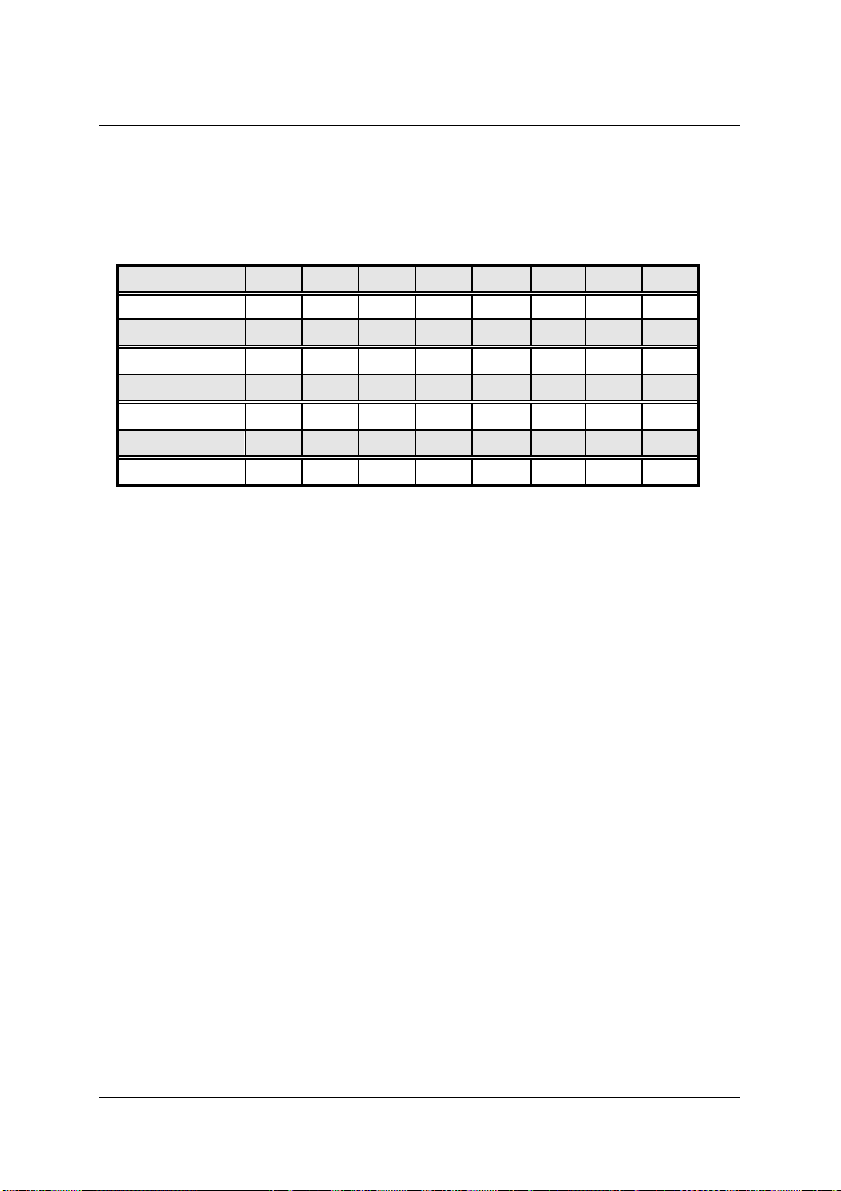

I/O Address Read Write

Base + 0x00 Scan Interval Counter Scan Interval Counter

Base + 0x04 Sample Interval Counter Sample Interval Counter

Base + 0x08 Scan Counter Scan Counter

Base + 0x0C DIV Counter DIV Counter

Base + 0x10 Delay1 Counter Delay1 Counter

Base + 0x14 M Counter M Counter

Base + 0x18 GP Counter/Timer 0 GP Counter/Timer 0

Base + 0x1C X X

Base + 0x20 X GP Counter/Timer Control Reg

Base + 0x24 A/D FIFO Data Reg

Base + 0x28 A/D and FIFO Status Reg. A/D and FIFO Control Reg.

Base + 0x2C X X

Base + 0x30 Digital IN Reg.(Dout) Digital OUT Reg.

Base + 0x34 X A/D Trigger Mode Reg.

Base + 0x38 Interrupt Reason Reg. Interrupt Control Reg.

Table 2. I/O Port Address

Config. Channel Gain Queue

Reg..

20 • Registers

Page 31

4.2 Internal Timer/Counter Register

The 9116 series card basically has 6 counters, which are responsible for the

scan timing of the analog input data acquisition. The 6 counters occupy 6 I/O

address locations in the 9116 card as shown below.

Address: BASE + 0 ~ BASE + 14

Attribute:

Data Format:

Base + 0x00 Scan Interval Count er Register (R/W) 24bit

Base + 0x04 Sample Interval Counter Reg ister (R/W) 16bit

Base + 0x08 Scan Counter Register (R/W ) 24bit

Base + 0x0C DIV Counter Register (R/W) 9bit

Base + 0x10 Delay1 Co unter Register (R/W) 16bit

Base + 0x14 M Counter Register (R/W) 16bit

SI_counter: Scan Interval counter

SI2_counter: Sample Interval counter

SC_counter: total Scan Count counter

DIV_counter: specify the number of samples per scan

DLY1_counter: Delay Interval counter (only used in delay trigger mode)

M_counter: specify the number of scans before a trigger (only used in

read / write

Table 3. Timer/Counter Register Address

pre-trigger and middle-trigger modes)

Registers • 21

Page 32

4.3 General Purpose Timer/Counter Register

One 16-bit, general-purpose timer/counter exists in the 9116 series card.

Writing to this register loads the initial count value into the gen eral-purpose

timer/counter. Reading from this register feedbacks the current count value of

the general-purpose timer/counter

Address:

Attribute:

Data Format:

Bit 7 6 5 4 3 2 1 0

Bit 15 14 13 12 11 10 9 8

Bit 23 22 21 20 19 18 17 16

Bit 31 30 29 28 27 26 25 24

BASE + 0x18

write / read

GP7 GP6 GP5 GP4 GP3 GP2 GP1 GP0

GP15 GP14 GP13 GP12 GP11 GP10 GP9 GP8

--- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- --Table 4. General Purpose Timer/Counter Register

4.4 General Purpose Timer/Counter Control Register

Address:

Attribute:

Data Format:

Bit 7 6 5 4 3 2 1 0

Bit 15 14 13 12 11 10 9 8

--- --- --- --- --- --- ---

Bit 23 22 21 20 19 18 17 16

--- --- --- --- --- --- --- ---

Bit 31 30 29 28 27 26 25 24

--- --- --- --- --- --- --- ---

22 • Registers

BASE + 0x20

write only

Counter

en

Up

Down

Table 5. General Purpose Timer/Counter Control Register

Up

Down

src

Gate_sr

c

Clk_src --- MODE1 MODE0

Page 33

Counter en (bit7): GPTC0 count enable

1: enable GPTC0

0: disable GPTC0

UpDown (bit6): GPTC0’s up/down pin software control

1: Up counter

0: Down counter

UpDown src(bit5): GPTC0’s up/down pin selection bit

1: External input (Pin 98)

0: Software Control

Gate_src (bit4): GPTC0’s gate source

1: External Input (Pin 97)

0: gate controlled by setting the enable (bit7)

Clk_src (bit3): GPT C0’s clock source

1: External Input (Pin 96)

0: Internal Timebase

MODE1~MODE0 (bit1 ~ bit0): GPTC0’s Mode selection

MODE1 MODE0 Description

0 0 General Counter

0 1 Pulse Generation

1 0 X

1 1 X

Table 6. GPTC0’s Mode selection

Registers • 23

Page 34

4.5 A/D Data Registers

The digital converted data is 16-bits and is stored into 32-bit registers.

Address:

Attribute:

Data Format:

Bit 7 6 5 4 3 2 1 0

Bit 15 14 13 12 11 10 9 8

Bit 23 22 21 20 19 18 17 16

Bit 31 30 29 28 27 26 25 24

BASE +24

read

AD7 AD6 AD5 AD4 AD3 AD2 AD1 AD0

AD15 AD14 AD13 AD12 AD11 AD10 AD9 AD8

--- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- ---

Table 7. A/D Data Registers

AD15 ~ AD0: Analog to digital data. AD15 is the Most Significant Bit

(MSB). AD0 is the Least Significant Bit (LSB).

4.6 Channel Gain Queue Register

This register is used to fill the Channel Gain Queue. We recommend users use

our call function to avoid any possible errors from these settings.

Address:

Attribute:

Data Format

Bit 7 6 5 4 3 2 1 0

Bit 15 14 13 12 11 10 9 8

Bit 23 22 21 20 19 18 17 16

Bit 31 30 29 28 27 26 25 24

24 • Registers

BASE + 0x24

write

:

EN3 EN2 EN1 EN0 HL_sel UNIP DIFF U_CMMD

--- --- Gain1 Gain0 CH3 CH2 CH1 CH0

--- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- --Table 8. Channel Gain Queue Register

Page 35

CH3 ~ CH0 (bit11~ bit8): Internal A/D Channel selection bits

EN3 ~ EN0 (bit7~ bit4): Multiplexer Enable selection bits

Gain1~Gain0 (bit13~bit12): Gain selection bits

Gain1 Gain0 Gain

0 0 1

0 1 2

1 0 4

1 1 8

Table 9. Gain Selection Bits

HL_sel(bit3): >31 channel selection (single ended)

1: when channel number is larger than 31

0: when channel number is smaller than or equal to 31

DIFF(bit1): Analog Input Signals Type

1: Differential

0: Single ended

UNIP(bit2): Analog Input Signals Polarity

1: Unipolar

0: Bipolar

U_CMMD(bit0): User Defined Common Mode Selection

1: User Defined Common Mode (Pin 1)

0: Local Ground of 9116 series

Registers • 25

Page 36

4.7 A/D & FIFO Control Register

Address:

Attribute:

Data Format:

Bit 7 6 5 4 3 2 1 0

Bit 15 14 13 12 11 10 9 8

Bit 23 22 21 20 19 18 17 16

Bit 31 30 29 28 27 26 25 24

DMA (Bit8): Write Only. Set for DMA transfer

SC_dis (Bit7): Write Only. Set to disable the SC counter

Clear Channel Gain Queue (Bit6): Write Only

Set done (Bit5): Write Only

Clear DFIFO(Bit4) : Write Only

Clear the Data FIFO:

Clear Trg_det(Bit3) : Write 1 to clear

BASE + 28

Write

Clear

SC_dis

--- --- --- --- --- --- --- DMA

--- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- ---

Channel

Gain

Queue

Table 10. A/D & FIFO Control Register

Clear the Channel Gain Queue

0: no effect on the Channel Gain Queue

1: clear the Channel Gain Queue

0: indicate the Channel Gain Queue is not ready

1: indicate the Channel Gain Queue is OK

0: no effect on Data FIFO

1: clear the Data FIFO

Set

done

Clear

DFIFO

Clear

Trg_det

Clear

SC_TC

Clear

ADOR

Clear

ADOS

26 • Registers

Page 37

Write 1 to clear the trigger status:

0: no effect

1: clear trigger detect status

Clear SC_TC(Bit2) : Write 1 to clear

Write 1 to clear Scan Counter Terminal Count status

0: no effect

1: clear the SC_TC status

Clear ADOR(Bit1) : Write 1 to clear

Write 1 to clear the A/D Overrun Status

0: no effect

1: clear the A/D Overrun status

Clear ADOS(Bit0) : Write 1 to clear

Write 1 to clear the A/D Over Speed Status:

0: no effect

1: clear the A/D Over-Speed status

4.8 A/D & FIFO Status Register

Address:

Attribute:

Data Format:

Bit 7 6 5 4 3 2 1 0

Bit 15 14 13 12 11 10 9 8

Bit 23 22 21 20 19 18 17 16

Bit 31 30 29 28 27 26 25 24

BASE + 28

read

ACQ Full HFull Empty Trg_det SC_TC ADOR ADOS

--- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- ---

--- --- --- --- --- --- --- --Table 11. A/D & FIFO Status Register

Registers • 27

Page 38

ACQ (Bit7): Read Only, set when acquisition is in progress.

Full (Bit6): Read Only A/D FIFO Full status (Fatal Error!)

0: FIFO Full

1: FIFO not Full

HFull(Bit5): Read only A/D FIFO Half Full status

0: FIFO Half Full

1: FIFO not Half Full

Empty (Bit4): Read Only A/D FIFO Empty status

0: FIFO Empty

1: FIFO not Empty

Trg_det (Bit3): Read/ Write 1 to clear External Digital Trigger Status

1: External Digital Trigger

0: No External Digital Trigger

SC_TC(Bit2): Read/ Write 1 to clear Scan Counter Terminal Count Status

1: Scan Counter counts to 0

0: Scan Counter not completed

ADOR(Bit1): Read/ Write 1 to clear A/D Overrun Status (Fatal Error !)

1: A/D Overrun

0: A/D not Overrun

ADOS(Bit0): Read/ Write 1 to clear A/D Over Speed Status (Warning !)

1: A/D Over Speed

0: A/D not Over Speed

28 • Registers

Page 39

4.9 Digital I/O register

There are 8 digital input and 8 digital output channels provided by the 9116

series cards. The address Base + 30 is used to access digital inputs and

control digital outputs.

Address:

Attribute:

Data Format:

Address:

Attribute:

Data Format:

BASE +30

read

Bit 7 6 5 4 3 2 1 0

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

Bit 15 14 13 12 11 10 9 8

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

Bit 23 22 21 20 19 18 17 16

--- --- --- --- --- --- --- ---

Bit 31 30 29 28 27 26 25 24

--- --- --- --- --- --- --- --Table 12. Digital I/O register (Read)

BASE + 30

write

Bit 7 6 5 4 3 2 1 0

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

Bit 15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

Bit 23 22 21 20 19 18 17 16

--- --- --- --- --- --- --- ---

Bit 31 30 29 28 27 26 25 24

--- --- --- --- --- --- --- --Table 13. Digital I/O register (Write)

Registers • 29

Page 40

4.10 A/D Trigger Mode Register

Address:

Attribute:

Data Format:

BASE + 0x34

write only

Bit 7 6 5 4 3 2 1 0

Retrig DLYSRC

Time

Base

TrgP MODE2 MODE1 MODE0

---

Bit 15 14 13 12 11 10 9 8

--- --- --- --- --- softconv ACQ_EN M_enable

Bit 23 22 21 20 19 18 17 16

--- --- --- --- --- --- --- ---

Bit 31 30 29 28 27 26 25 24

--- --- --- --- --- --- --- --Table 14. A/D Trigger Mode Register

softconv (bit10): ADC direct conv ersion control

1: generate 1 convert pulse

0: no effect

ACQ_EN (bit9): Acquisition enable bit

1: enable the acquisition timing

0: disable the acquisition timing

M_enable (bit8): M counter enable bit

1: ignore trigger signals before M counter reaches 0

0: accept the trigger signal anytime

Retrig (bit7): Re-triggerability in an acquisition

1: Re-triggerable

0: trigger only once

DLY SRC (bit6): Delay time unit in delay trigger mode

1: delay in sampling rate (SI2)

0: delay in Timebase

30 • Registers

Page 41

TimeBase(bit5) : The Timebase Selection of 9116 series

1: External Timebase

0: Internal Timebase (24 MHz)

TrgP (bit4): The T r igger polarity selection bit

1: Negative Edge Trigger

0: Positive Edge Trigger

MODE2 ~ 0(bit3 ~ bit1): Trigger Mode Selection Bits

MODE2 MODE1 MODE0 Description

0 0 0 Software Trigger

0 0 1 Post Trigger

0 1 0 Delay Trigger

0 1 1 Pre Trigger

1 0 0 Middle Trigger

Table 15. Trigger Mode Selection Bits

4.11 Interrupt Control Register

Address:

Attribute:

Data Format:

Bit 7 6 5 4 3 2 1 0

--- --- --- Clr_Timer Clr_STTC Clr_Hfull Clr_DTrg Clr_EOC

Bit 15 14 13 12 11 10 9 8

--- --- --- Timer_en STTC_en Hfull_en DTrg_en EOC_en

Bit 23 22 21 20 19 18 17 16

--- --- --- --- --- --- --- ---

Bit 31 30 29 28 27 26 25 24

--- --- --- --- --- --- --- ---

Timer_en (bit12): General Purpos e Timer Interrupt Enable Control

BASE + 0x38

write

Table 16. Interrupt Control Register

1: Enable

0: Disable

Registers • 31

Page 42

SCTC_en (bit11): Trigger Complete Interrupt Enable Control

1: Enable

0: Disable

Hfull_en (bit10): A/D FIFO Half Full Interrupt Enable Control

1: Enable

0: Disable

DTrg_en (bit9): Extern al Digital Trigger Interrupt Enable Control

1: Enable

0: Disable

EOC_en (bit8): End of conversion Interrupt Enable Control

1: Enable

0: Disable

Clr_Timer (bit4): writ e 1 to clear the GPTC Interrupt status

1: clear interrupt from the GPTC

0: no effect

Clr_SCTC (bit3): write 1 to clear the SCTC Interrupt

1: clear the interrupt on terminal count of the Scan counter

0: no effect

Clr_HFull (bit2): write 1 to clear the data FIFO half full interrupt

1: clear the interrupt on the data FIFO half full status

0: no effect

Clr_DTrg (bit1): write 1 to clear the Digital Trigger Interrupt

1: clear the interrupt when trigger happens

0: no effect

Clr_EOC (bit0): write 1 to clear the End of Conversion Interrupt

1: clear the interrupt when EOC

0: no effect

32 • Registers

Page 43

4.12 Interrupt Status Register

Address:

Attribute:

Data Format:

Timer (bit4): GPTC generated Interrupt status

SCTC(bit3): Scan Counter reach Terminal Count Interrupt status

HFull (bit2): data FIFO Half Full Interrupt

DTrg (bit1): Digital Trigger Interrupt status

EOC (bit0): End of Conversion Interrupt status

BASE + 0x38

read

Bit 7 6 5 4 3 2 1 0

--- --- --- Timer STTC Hfull DTrg EOC

Bit 15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

Bit 23 22 21 20 19 18 17 16

--- --- --- --- --- --- --- ---

Bit 31 30 29 28 27 26 25 24

--- --- --- --- --- --- --- --Table 17. Interrupt Status Register

1: Interrupt Occurs

0: Interrupt not Occur

1: Interrupt Occurs

0: Interrupt not Occur

1: Interrupt Occurs

0: Interrupt not Occur

1: Interrupt Occur

0: Interrupt not Occur

1: Interrupt Occurs

0: Interrupt not Occur

Registers • 33

Page 44

5

Operation Theory

The operation theory of the functions on the 9116 series is described in this

chapter. The functions include the A/D conversion, Digital I/O and General

Purpose Counter / Timer. The operation theory can help you better understand

how to configure and program the 9116 series card.

5.1 A/D Conversion

5.1.1 A/D Conversion Procedure

When using an A/D converter, users should beware of the properties of the

signal to be measured. Users can decide which channel to use and where to

connect the signals to the card. Please refer to 3.2 for signal connections. In

addition, users should define and control the A/D signal configurations,

including channels, gains, and A/D signal types.

The A/D acquisition is initiated by a trigger source; users must decide how to

trigger the A/D conversion. The data acquisition will start when a trigger

condition is met.

After the end of the A/D conversion, the A/D data is buffered in a Data FIFO.

The A/D data is then transferred into PC's memory for further processing.

There are two acquisition modes: Software Polling and Scan acquisition. They

will be described separately in the following section, including the timing, signal

source control, trigger mode, and transfer method.

34 • Operation Theory

Page 45

5.1.2 Software conversion with polling data transfer acquisition

mode (Software Polling)

This is the easiest way to acquire a single A/D data. The A/D converter starts a

conversion when the user writes 1 into bit10 of the A/D trigger mode register

(BASE+34). After the software initializes the A/D conversion, the software polls

the FIFO Empty status (bit4) in the A/D & FIFO Status register (BASE+28)

until it changes to active low logic.

If the Data FIFO is empty before an A/D conversion starts, the Empty bit will be

high. After the A/D conversion is completed, the A/D data is written to the Data

FIFO immediately, thus the Empty becomes low. You can consider the Empty

bit as a flag to indicate the converted data ready status. That is, a low Empty

bit meaning the data is ready. The A/D data is now ready to be transferred to

host memory from the FIFO.

This method is suitable for applications that needs to process AD data in r eal

time. Under this mode, the timing of the A/D conversion is fully controlled by

the software. However, it is difficult to control a fixed A/D conversion rate

unless another timer interrupt service routine is used to generate a fixed

conversion rate trigger.

ADLINK’s software driver provides an integral function to acquire a single data

(That is, it will start an A/D conversion, then poll the Empty flag and read the

data back when the data is ready). We also provide individual functions to

allow users to start an A/D conversion only. Users must read it back from the

A/D data register (BASE+24) by themselves. This method makes it possible to

read A/D converted data without polling. The conversion and acquisition time

of the ADC does not exceed 4μs. Hence, after software conversion, the

software need only wait for a maximum of 4μs to read the A/D Data Register

without polling.

Operation Theory • 35

Page 46

5.1.2.1 Specifying Channels, Gains, and input configurations in the

Channel Gain Queue

In both Software Polling and programmable scan acquisition mode, the

channel, gain, and input configuration (single-end, differential, and U_CMMD),

where you want to acquire samples from, can be specified in the

Gain Queue

any order. Therefore, you can control the channel order from which data is

acquired with different gain and input configuration for each channel. The

maximum number of entries you can set is 512 channels. The channel order of

acquisition is the same as the order you set in the Channel Gain Queue. When

the specified channels are sampled from the beginning to the end in the

Channel Gain Queue, the channels in the Channel Gain Queue will be

sampled again until the specified number of samples has been acquired.

. You can set the channel number in the Channel Gain Queue in

Channel

5.1.3 Programmable scan acquisition mode

5.1.3.1 Scan Timing and Procedure

It's recommended that this mode be used, if your application needs a fixed and

precise A/D sampling rate. You can accurately program the period between

conversions of each individual channel in the scan and the period bet ween

conversions of the entire scan. There are 4 counters, which need to be

specified:

SI_counter(24 bit): Specify the Scan Interval = SI_counter / Timebase

SI2_counter(16 bit): Specify the data Sampling Interval =

SI2_counter/Timebase

SC_counter(24 bit): Specify Scan Count Counter after trigger

DIV_counter(9 bit): Specify the number of samples per scan

The acquisition timing and the meaning of the 4 counters are illustrated in

figure 9.

36 • Operation Theory

Page 47

A

A

(

)(

)

Timebase clock source

In scan acquisition mode, all the A/D conversions start on the output of

counters, which use

specify the Timebase to be either an internal clock source (on board 24MHz) or

an external clock input on pin 45 of J1. The external clock is useful when you

want to acquire data at rates not available with the internal A/D sample clock.

The external clock source must generate TTL-compatible continuous cloc ks,

and the maximum frequency is 24MHz while the minimum is 1MHz.

Scan_start

D_conversion

Scan_in_progress

SSH_OUT

cquisition_in_progress

Timebase

as the clock source. With the software you can

3 Scans, 4 Samples per scan

(SC_Counter=3, DIV_Counter=4)

( channel sequences are specified in Channel Gain Queue)

Ch2

Ch3

Ch1

Ch0

Ch2

Ch3

Ch1

Ch0

pin47

Ch2

Ch3

Ch1

Ch0

Sam pling Inte rva l t=

SI2_COUNTER/TimeBase

Scan In te rva l T =

SI_COUNTER/TimeBase

Figure 9: Scan Timing

In the scan acquisition mode, the channel, gain, and input configurations

(single-end, differential, or U_CMMD) must be specified in the hardware

Channel Gain Queue

, please refer to 5.1.3.2 for more details.

There are 5 trigger modes to start the scan acquisition, please refer to 5.1.3.3

details. The data transfer modes will be discussed in 5.1.3.4.

Operation Theory • 37

Page 48

Note:

1. The maximum A/D sampling rate is 250kHz. Therefore, SI2_counter can’t

be smaller than 96 while using the internal Timebase.

2. The SI_counter is a 24-bit counter and the SI2_counter is a 16-bit counter.

Therefore, the maximum scan interval while using the internal Timebase =

24

/24M s = 0.699s, and the maximum sampling interval between 2

2

channels while using the internal Timebase = 2

3. T he scan interval can’t be smaller than the product of the data sampling

interval and the DIV_counter value. The relationship can be represented

as: SI_counter>=SI2_counter*DIV_counter.

Scan with SSH

You can send the SSH_OUT signal on pin 47 of J1 to an external S&H circuits

to sample and hold all signals if you want to simultaneously sample all

channels in a scan, as illustrated in fig 9.

Note: The ‘SSH_OUT’ signal is sent to external S&H circuits to hold the analog

signal. Users must implement external S&H circuits on their own to

carry out the S&H function. There are no on-board S&H circuits.

5.1.3.2 Specifying Channels, Gains, and input configurations in the

Channel Gain Queue

Like software polling acquisition mode, the channel, gain, and input

configurations (single-end, differential, and U_CMMD) must also be specified

in the hardware

Channel Gain Queue

under scan acquisition mode. Please

refer to 5.1.2.1 for details. Note that in scan acquisition mode, the number of

entries in the Channel Gain Queue is normally equivalent to the value of

DIV_counter (that is, the numbers of samples per scan).

Example:

Set

SI2_counter = 240

SI_counter = 960

SC_counter = 3

DIV_counter = 4

Timebase = Internal clock source

Channel entries in the Channel Gain Queue: ch1, ch2, ch0, ch2

16

/24M s = 2.73ms.

38 • Operation Theory

Page 49

Then

Acquisition sequence of channels: 1, 2, 0, 2, 1, 2, 0, 2, 1, 2, 0, 2.

Sampling Interval = 240/24M s = 10 us

Scan Interval = 960/24M s = 40 us

Equivalent sampling rate of ch0, ch1: 25kHz

Equivalent sampling rate of ch2: 50kHz

5.1.3.3 Trigger Modes

There are 5 trigger modes (software-trigger, pre-trigger, post-trigger,

middle-trigger, and delay-trigger) to start the data acquisition described in

5.3.1.1. All but software trigger are external digital triggers. An external digital

trigger event occurs when a rising edge or a falling edge (software

programmable) of a digital signal is detected on pin 46 of J1. They are

described as follows.

Software-Trigger Acquisition

This trigger mode does not need any external trigger source. The data

acquisition starts right after you execute the specified function calls to begin

the operation. The scan timing is the same as fig 9. The total acquired data

length = DIV_counter*SC_counter.

Pre-Trigger Acquisition

Use pre-trigger acquisition in applications where you want to collect data

before an external trigger event. The A/D starts when you execute the

specified function calls to begin the operation, and it stops when the external

trigger event occurs. Users must program the value M in the

to specify the amount of stored scans of data before the trigger event. If the

external trigger occurs after M scans of data are converted, the program only

stores the last M scans of data, as illustrated in fig 10, where M_counter = M =3,

DIV_counter =4, SC_counter = 0. The total stored amount of data =

DIV_counter *M_counter =12.

M_counter

(16bit)

Operation Theory • 39

Page 50

A

A

Aq

A

A

A

Aq

A

(M_counter = M = 3, DIV_counter=4, SC_counter=0)

ExtTrg(pin4 6)

Scan_start

D_conversion

Scan_in_progress

(

SSH_OUT

cquisition_in_progress

)(pin47)

uired data

Operation start

cquired & stored data

(M scans)

Figure 10: Pre-trigger (trigger occurs after M scans)

Note: If an external trigger event occurs when a scan is in progress, the data

acquisition won’t stop until this scan completes, and the stored M scans

of data include the last scan. Therefore, the first stored data will al ways

be the first channel entry of a scan (that is, the first channel entry in the

Channel Gain Queue if the number of entries in the Channel Gain

Queue is equivalent to the value of DIV_counter), no matter when the

trigger signal occurs, as illustrated in Fig 11, where M_counter = M =3,

DIV_counter = 4, SC_counter = 0.

(M_counter = M = 3, DIV_counter =4, SC_counter=0)

ExtTrg(pin46)

Scan_start

D_conversion

Scan_in_progress

(SSH_OUT)(pin47)

cquisition_in_progress

Operation start

uired data

cquired & stored data

(M scans)

Trigger occurs

Data acquisition

won’t stop u ntil a

scan completes

Figure 11: Pre-trigger (trigger with scan is in progress)

40 • Operation Theory

Page 51

A

A

A

When an external trigger signal occurs before the first M scans of data are

converted, the amount of stored data could be fewer than the originally

specified amount of DIV_counter * M_counter, as illustrated in fig 12. This

situation can be avoided by setting

M_enable.

trigger signal will be ignored until the first M scans of data are converted, and it

assures user of obtaining M scans of data under pre-trigger mode, as

illustrated in fig 13. However, if

M_enable

is set to 0, the trigger signal will be

accepted in any time, as illustrated in fig 12. Note that the total amount of

stored data is still always a multiple of DIV_counter (number of samples per

scan) because the data acquisition won’t stop until a scan is completed.

(M_Counter = M = 3 , DIV_Counter=4, SC_Counter=0)

ExtTrg(pin46)

Scan_start

D_conversion

Scan_in_progress

(SSH_OUT)(pin47)

cquisition_in_progress

cquired & stored data

(2 scans)

Operation start

Figure 12: Pre-trigger with M_enable = 0 (trigger occurs before M scans)

M_enable

If

is set to 1, the

Operation Theory • 41

Page 52

A

A

Aq

A

(M_counter = M = 3, DIV_counter=4, SC_counter=0)

ExtTrg(pin46)

Scan_start

D_conversion

Scan_in_progress

(

SSH_OUT

cquisition_in_progress

)(pin47)

The first M scans

Trigger signals which occur in the shadow

region(the first M scans) will be ignored

uired data

Operation start

cquired & stored data

(M scans)

Figure 13: Pre-trigger with M_enable = 1

Note: The SC_counter must be set to 0 in pre-trigger acquisition mode.

Middle-Trigger Acquisition

Use middle-trigger acquisition in applications where yo u want to collect data

before and after an external trigger event. The number of scans stored before

the trigger is specified in M_counter, while the number of scans after the trigger

is specified in SC_counter.

Like pre-trigger mode, the number of stored data can be less than the specified

amount of data (DIV_counter *(M_counter+SC_counter)) if an external trigger

occurs before M scans of data is converted. The M_enable bit in middle-trigger

mode takes the same effect as in pre-trigger mode. If M_enable is set to 1, the

tigger signal will be ignored until the first M scans of data are converted, this

assures user of obtaining M+N scans of data under middle-trigger mode.

However, if M_enable is set to 0, the trigger signal will be accepted at any time.

Fig 14 shows the acquisition timing with M_enable=1.

42 • Operation Theory

Page 53

A

A

Aq

A

(M_ Counter=M =3, DIV_ Coun ter=4, SC_C ounter=N=1 )

ExtTrg(pin46)

Scan_start

D_conversion

Scan_in_progress

(

SSH_OUT

cquisition_in_progress

)(pin47)

The first M scans

Trigger signals which occur in the shadow

region(the first M scans) will be ignored

uired data

Operation start

M scans before

trigger

cquired & stored data

(M+N scans)

N scans

after trigger

Figure 14: Middle trigger with M_enable = 1

If an external trigger event occurs when a scan is in progress, the stored N

scans of data would include this scan.

be the first channel entry of a scan,

And the first stored data will always

as illustrated in Fig 15.

Operation Theory • 43

Page 54

A

A

Acq

A

A

A

A

ExtTrg(pin46)

Scan_start

D_conversion

Scan_in_progress

(SSH_OUT)(pin47)

cquisition_in_progress

(M_Counter=M=2, DIV_C ounter=4, SC_Co unter=N=2)

Trigger occurs when a scan is in progress

uired data

Operation start

M scans before

trigger

(M+N scans)

cquired & stored data

N scans

after trigger

Figure 15: Middle trigger (trigger with scan is in progress)

Post-Trigger Acquisition

Use post-trigger acquisition in applications where you want to collect data after

an external trigger event. The number of scans after the trigger is specified in

SC_counter, as illustrated in fig 16. The total acquired data length =

DIV_counter *SC_counter.

(DIV_Counter=4, SC_Counter=3)

ExtTrg

Scan_start

D_conversion

Scan_in_progress

(SSH_OUT)

cquisition_in_progress

cquired & stored data

(3 scans)

Operation start

Figure 16: Post trigger

44 • Operation Theory

Page 55

A

A

A

Delay Trigger Acquisition

Use delay trigger acquisition in applications where you want to delay the data

collection after the occurrence of a specified trigger event. The delay time is

controlled by the value, which is pre-loaded in the

counter counts down on the rising edge of Delay_counter clock source after

the trigger condition is met. The clock source can be software program med

either Timebase clock (24MHz) or A/D sampling clock (Timebase

/SI2_counter). When the count reaches 0, the counter stops and 9116 c ard

starts to acquire data. The total acquired data length = DIV_counter *

SC_counter.

(DIV_Counter=4, SC_Counter=3)

ExtTrg

Scan_start

D_conversion

Scan_in_progress

(

SSH_OUT

cquisition_in_progress

)

Delay_counter

(16bit). The

Delay until

Delay_Counter

reaches 0

Operation start

cquired & stored data

(3 scans)

Figure 17: Delay trigger

Note: When the Delay_counter clock source is set to Timebase, the maximum

delay time = 216/24M s = 2.73ms, and when the source is set to A/D

sampling clock, the maximum delay time = 2

16

* SI2_counter / 24M).

Operation Theory • 45

Page 56

A

A

A

Post-Trigger or Delay-trigger Acquisition with re-trigger

Use post-trigger or delay-trigger acquisition with re-trigger function in

applications where you want to collect data after several external trigger events.

The number of scans after each trigger is specified in SC_count er, and users

could program

illustrates an example. In this example, 2 scans of data is acquired after the

first trigger signal, then the board waits for the re-trigger signal (re-trigger

signals which occur before the first 2 scans of data is acqu ired will be ignored).

When the re-trigger signal occurs, the board scans 2 more scans of data. The

process repeats until the specified amount of re-trigger signals ar e detected.

The total acquired data length = DIV_counter * SC_counter * Retrig_no.

ExtTrg

Scan_start

D_conversion

Scan_in_progress

(SSH_OUT)

cquisition_in_progress

Retrig_no

(DIV_Counter=4, SC_Counter=2, retrig_no=3)

Operation start

to specify the number of re-triggers. Fig 18

cquired & stored data

(6 scans)

Figure 18: Post trigger with re-trigger

46 • Operation Theory

Page 57

5.1.4 A/D Data Transfer Modes

After the end of the A/D conversion, A/D data are buffered into the

memory. The FIFO size on the 9116 series card is 1024 (1K) words. If the

sampling rate is 10 KHz, the FIFO can buffer 102.4 ms of a nalog signal . Aft er

the FIFO is full, any data after this time will be lost.

The data must be transferred to the host memory after the data is ready and

before the FIFO is full. In scan acquisition mode, there are 3 data t ransfer

modes that can be used. They are described below.

EOC Interrupt Transfer

The 9116 series card provides traditional hardware End-Of-Conversion (EOC)

interrupt capability. Under this mode, an interrupt signal is generated when the

A/D conversion has ended and the data is ready to be read into the Data FIFO.

The hardware interrupt will be asserted and its corresponding ISR (I nterrupt

Service Routine) will be invoked and executed. The ISR program can read the

converted data. This method is suitable for data processing applications under

real-time and fixed sampling rate.

FIFO Half-Full Interrupt Transfer

Sometimes, the application does not need real-time processing, cause the

foreground program is busy polling the FIFO data. The FIFO half -full inter rupt

transfer mode is useful for the situation mentioned above.

Under this mode, an interrupt signal is generated when FIFO becomes half-full.

It means that there are 512 words of data in the FIFO ready f or transfer. The

ISR can read the whole block of data when the interrupt occurs. A “block is 512

words long.

Note: In the current version, EOC & FIFO half-full interrupt transfer mode

doesn’t support pre-trigger and middle-trigger mode data acquisition.

Users must use DMA transfer to work with pre-trigger or middle-trigger

data acquisition.

Data FIFO

Operation Theory • 47

Page 58

DMA Transfer

PCI bus-mastering DMA is necessary for high speed DAQ in order to utilize the

maximum PCI bandwidth. The bus-mastering controller, which is built-in into

the AMCC-5933 PCI controller, controls the PCI bus when it becomes the

master on the bus. Bus mastering reduces the size of the on-board memor y

and reduces the CPU loading because data is directly transferred to the

computer’s memory without host CPU intervention.

Bus-mastering DMA provides the fastest data transfer rates on PCI-bus. Once

the analog input operation starts, control returns to your program. The

hardware temporarily stores the acquired data in the on board Data FIFO and

then transfers the data to a user-defined DMA buffer memory in the computer.

Note that even when the acquired data leng th is less than t he Data FIFO, the

AD data will not held in the Data FIFO but directly transferred to the host

memory by bus-mastering DMA.

The DMA transfer mode is very complex to program. We recommend usi ng a

high-level program library to configure this card. If you want to program the

software, which can handle DMA bus master data transf er, please refer to

information about the PCI controller at www.amcc.com.

Note: In DMA transfer mode, the maximum acquired data length in one

acquisition can be up to 64M byte s (32M samples), which is the limit of the

PCI controller. However, the memory that you allocate f or data transfer

must be continuous.

5.2 Digital Input and Output

To program the digital I/O operation is fairly st raightforward. The digital input

(DI) operation is to read data from its corresponding registers, and the digital

output (DO) operation is to write data to its corresponding registers. The digital

I/O registers

reading the DI port. Note that the DIO data channel can only be read or written

to, in the form of 16-bit blocks. It is impossible to access individual bits.

48 • Operation Theory

‘

formats are shown in section 4.9. The DO can be read back when

Page 59

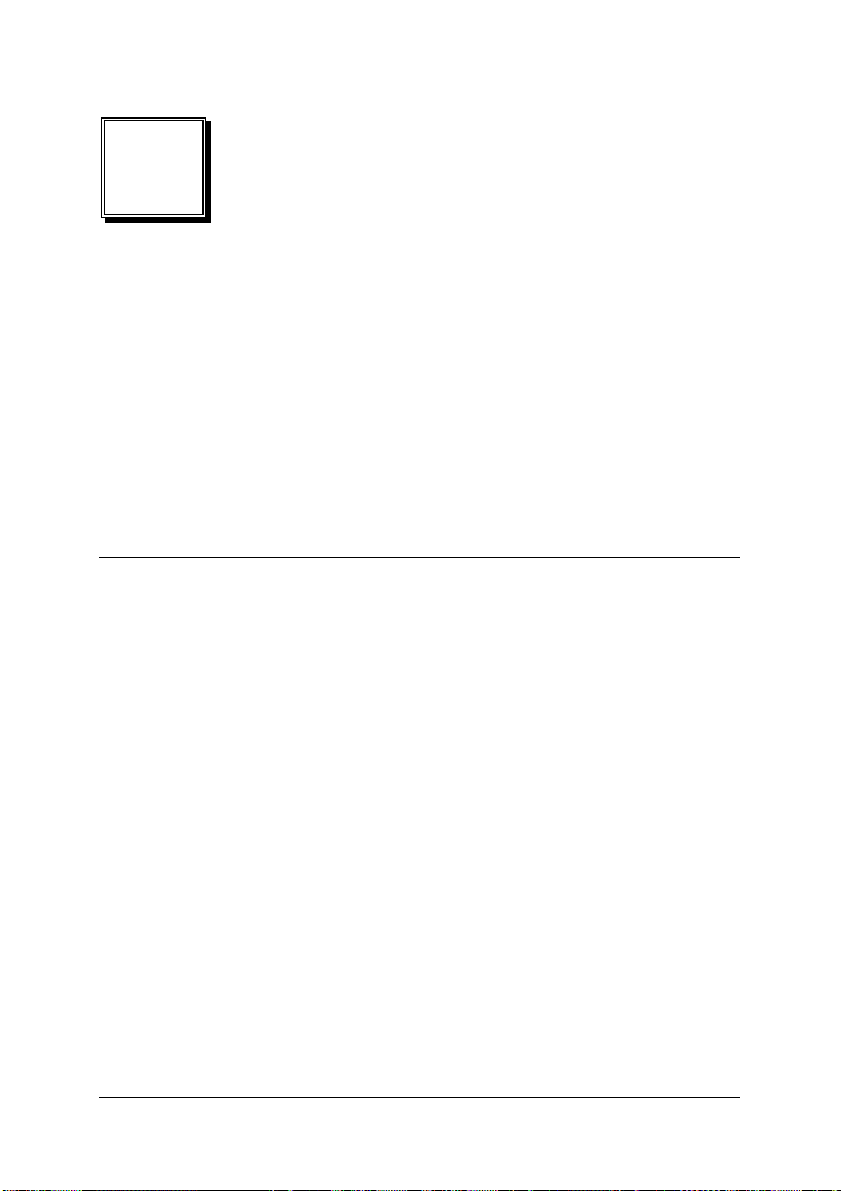

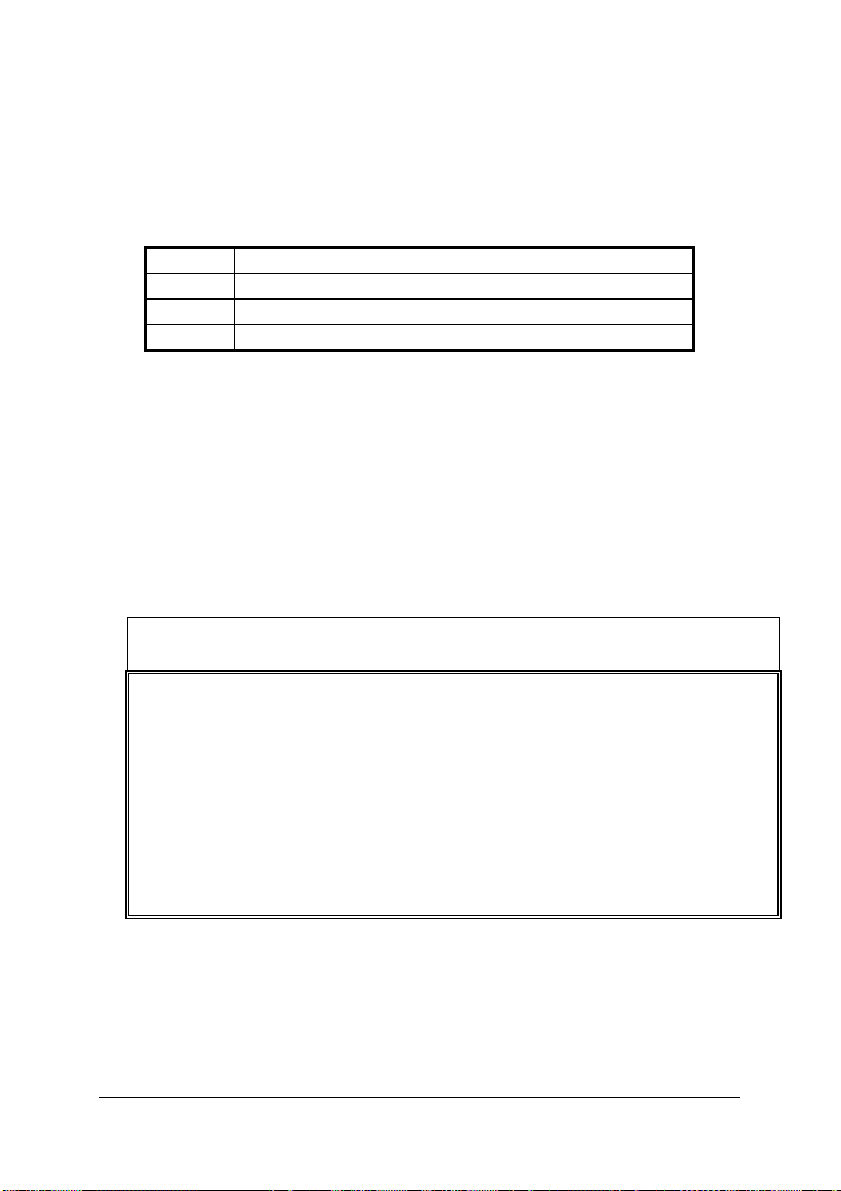

5.3 General Purpose Timer/Counter Operation

An independent 16-bit up/down timer/counter is designed in the FPGA for user

applications. Fig 19 shows a simplified model of the timer/counter on the 9116

series card. It has the following features:

CPCI-9116

Controller

Initial

Count

load

Mode

control

Counter

D0

Count

read back

CLK(pin96)

Gate(pin97)

D15Q0Q15

C

O

G

UP/DOWN(pin98)

OUT(pin48)

Figure 19: General-purpose Timer/Counter model

Count up/Count down controlled by hardware or software

•

(low or 0: counts down, high or 1: counts up)

Programmable counter CLK source selection (Internal

•

24MHz or External CLK input up to 20MHz)

Programmable Gate selection (Internal or External. For

•

Internal control, you can disable counting only by software. For

External gate control, either software or setting Gat e = low on

pin 97 of J1 disables the counting)

Initial Count can be loaded from software

•

Current count value can be read with software without

•

affecting circuit operation

Two programmable timer modes are provided:

•

Operation Theory • 49

Page 60