Page 1

cPCI-6S10 Series

6U CompactPCI Switch Blade

User’s Manual

Manual Rev. 0.10

Revision Date: March 31, 2014

Part No: 50-15099-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

0.10 31/03/2015 Preliminary release

ii Revision History

Page 3

cPCI-6S10

Preface

Copyright 2015 ADLINK Technology Inc.

This document contains proprietary infor mation protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufa cturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component damage, data loss, and/or program corruption when trying to com-

CAUTION:

WARNING:

plete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

iv Preface

Page 5

cPCI-6S10

Table of Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Tables......................................................................... vii

List of Figures........................................................................ ix

1 Overview ............................................................................. 1

1.1 Block Diagram ..................................................................... 2

1.2 Package Contents ............................................................... 3

2 Specifications & Board Interfaces.................................... 5

2.1 cPCI-6S10 Specifications .................................................... 5

2.2 Board Layout ...................................................................... 6

2.3 Front Panel Layout .............................................................. 7

2.4 Connector Pinouts............................................................... 9

2.5 Switch Settings .................................................................. 17

3 Hardware Platform Management .................................... 19

3.1 Platform Management Overview ....................................... 19

3.2 IPMI Commands................................................................ 20

3.3 Controller Specific OEM/Group Commands...................... 59

4 Getting Started ................................................................. 65

4.1 Heatsink............................................................................. 65

4.2 Installing the cPCI-6S10 .................................................... 65

4.3 Configuring the cPCI-6S10................................................ 65

5 Software Management..................................................... 75

5.1 Introduction........................................................................ 75

5.2 Broadcom Network Switching Software SDK............... .... . 75

5.3 Commands ........................................................................ 76

Table of Contents v

Page 6

Important Safety Instructions............................................... 79

Getting Service...................................................................... 81

vi Table of Contents

Page 7

cPCI-6S10

List of Tables

Table 2-1: cPCI-6S10 Specifications ......................................... 5

Table 3-1: NetFn codes ........................................................... 20

Table 3-2: Response Codes .................................................... 21

Table 3-3: Required Message Length for IPMI 1.5 .................. 22

Table 3-4: cPCIS-3300BLS Chassis Slots ............................... 23

List of Tables vii

Page 8

This page intentionally left blank.

viii List of Tables

Page 9

cPCI-6S10

List of Figures

Figure 1-1: cPCI-6S10 Series Block Diagram........................... ... 2

Figure 2-1: cPCI-6S10 Board Layout........................................... 6

List of Figures ix

Page 10

This page intentionally left blank.

xList of Figures

Page 11

1Overview

The ADLINK cPCI-6S10 is a fully managed CompactPCI Gigabit

Ethernet switch blade supporting up to twenty four 1GbE ports and

two 10GbE SPF+ uplink ports. On the front panel are three GbE

ports, two 10GbE SFP+ uplink ports, one COM port and one

10/100 RJ-45 management port. Twenty GbE ports are routed to

rear I/O and an IPMI interface is provided to monitor and control

system health.

The ADLINK cPCI-6S10 integrates Broadcom BCM56150 switch

silicon along with an ARM Cortex-A9 processor and one Broadcom BCM54685 Octal port 1000BASE-T PHY. The cPCI-6S10 is

ideal for CompactPCI platform adopters who require high speed

and high bandwidth data transport interco nnect s for packe t switching management.

The ADLINK cPCI-6S10 supports ADLINK PacketManager, a software suite with an extensive feature set and integration capabilities that enables powerful networking functionality for the Base

Interface. It also provides comprehensive device management

capabilities for network administrators.

cPCI-6S10

Overview 1

Page 12

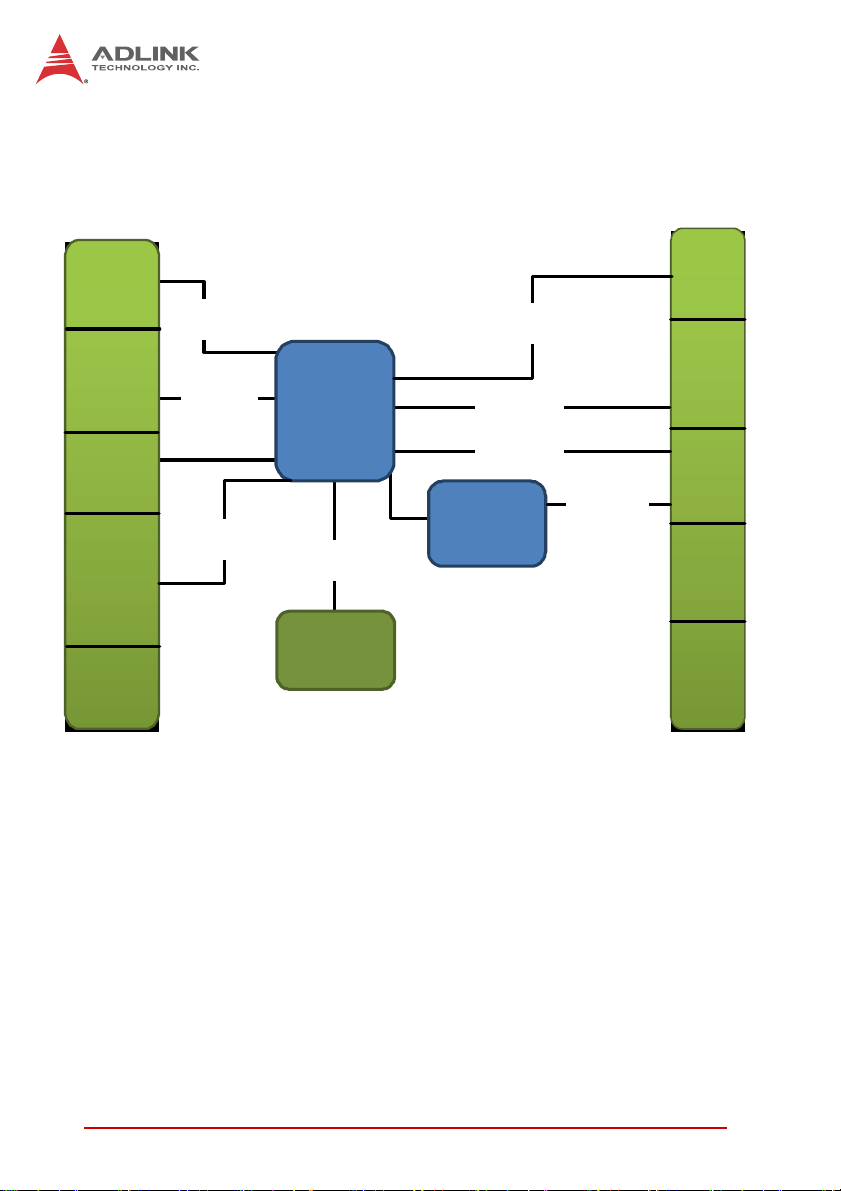

1.1 Block Diagram

Front Panel

CompactPCI

Conn.

GbE x3

10G

SFP+ x2

Mgt x1

RJ-45

COM x1

LED

MDI x3

SFI x2

UART

Figure 1-1: cPCI-6S10 Series Blo ck Diagram

BCM56150

UART

Atmel

IPMC

MDI x11

MDI x1

MDI x1

BCM54685

J5

J4

J3

MDI x8

J2

J1

2Overview

Page 13

cPCI-6S10

1.2 Package Contents

The cPCI-6S10 is packaged with the components listed below

(RTMs and adapter kits are optional). If any of the items in the

contents list are missing or damaged, retain the shipping carton

and packing material and contact the dealer for inspection. Please

obtain authorization before returning any product to ADLINK. The

packing contents of non-standard configurations may vary

depending on customer requests.

X cPCI-6S10 CompactPCI switch blade

X RJ-45 to DB-9 adapter for UART port

The contents of non-standard cPCI-6S10 Series configurations

may vary depending on customer requests.

NOTE:

NOTE:

This product must be protected from static discharge and physical shock. Never remove any of the components except at a

CAUTION:

static-free workstation. Use the anti-static bag shipped with the

product when putting the board on a surface. Wear an

anti-static wrist strap properly grounded on one of the system's

ESD ground jacks when installing or servicing system components.

Overview 3

Page 14

This page intentionally left blank.

4Overview

Page 15

2 Specifications & Board Interfaces

2.1 cPCI-6S10 Specifications

Standards and Interfaces

CompactPCI

Standard

Switch Fabric,

PHY

Networking

Front Panel IO

Rear IO 20x 10/100/1000BASE-T ports to J3 and J5

PICMG 2.0 CompactPCI Rev. 3.0

PICMG 2.9 System Management Bus Rev. 1.0

PICMG 2.16 Packet Switching Backplane Rev.1.0

• Broadcom BCM56150 24-port Gigabit Ethernet switch with

two 10G SFP+ uplink ports

• Broadcom BCM54685 Octal-port 10/100/1000BASE-T PHY

• Broadcom BCM5221 10/100BASE-TX management port

• 3x 10/100/1000BASE-T ports to front panel (BCM56150)

• 20x 10/100/1000BASE-T ports to rear (BCM56150, 9x to J3,

11x to J5)

• 1x inter-switch link 1000BASE-T

• 2x 10G SFP+ ports for uplink through BCM56150

• 1x 10/100BASE-TX for management

3x 10/100/1000BASE-T RJ-45 ports

2x 10G SFP+ interfaces for uplink interface

1x 10/100 RJ-45 management port

1x UART port via RJ-45

cPCI-6S10

Mechanical & Environmental

Dimensions 233.35mm x 160mm (L x W), 6U 4HP single slot

Operating

Temp.

Storage Temp. -50°C to 100°C

Humidity 95% non-condensing

Shock 15G peak-to-peak, 11ms duration, non-operating

Vibration Non-operating: 2G rms, 5 to 500 Hz, each axis

Compliance CE, FCC Class A

Power

Consumption

NOTE:

NOTE:

Specifications & Board Interfaces 5

Standard: 0°C to 60°C

ETT version upon request

TBD

Table 2-1: cPCI-6S10 Specifica tions

Specifications are subject to change without prior notice.

Page 16

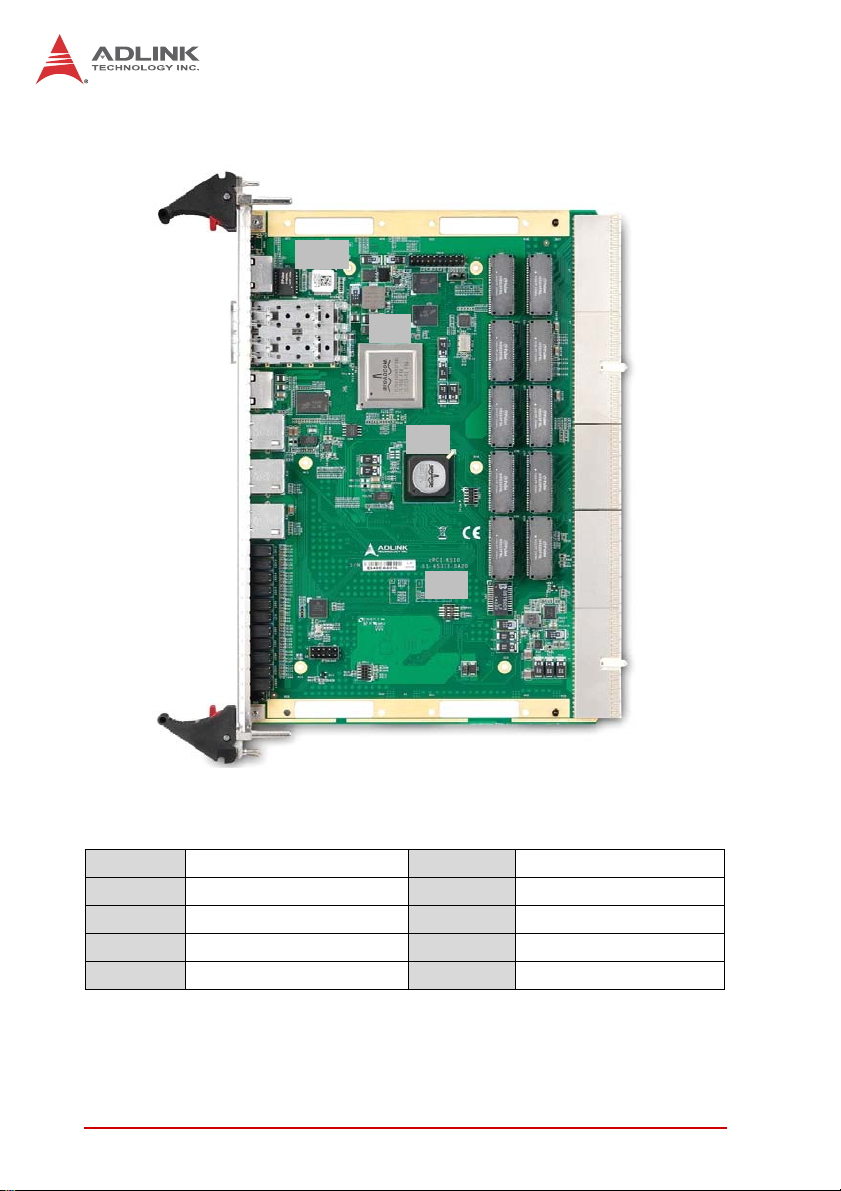

2.2 Board Layout

RJ4

CN23

CN22

CN6

RJ1

RJ3

RJ2

U100

U67

U66

SW6

J5

J4

J3

J2

J1

Figure 2-1: cPCI-6S10 Board Layout

U100 BCM5221 RJ1-3 10/100/1000 GbE

U67 BCM56150 RJ4 10/100 Mgmt GbE

U66 BCM54685 CN6 UART Port

J1-J5 CompactPCI connectors CN22-23 SFP+ Uplink ports

SW6 Standalone mode switch

6 Specifications & Board Interfaces

Page 17

cPCI-6S10

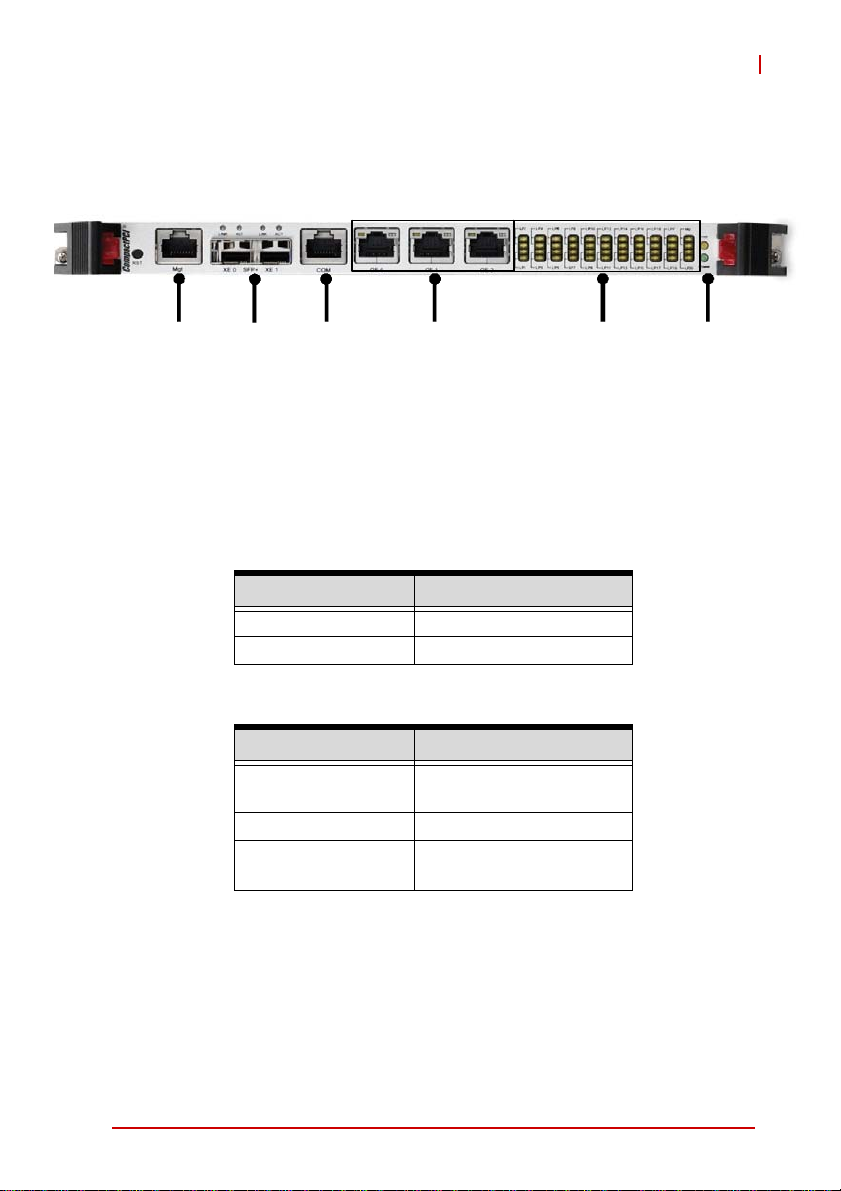

2.3 Front Panel Layout

Management

Port

SFP+ COM GbE x3 LED x22 HW LE D

Power LED

The following section describes the behavior of the LEDs on the

front panel.

Power LED

Power LED (Green) Status

On Power status normal

Off Power off

HW LED (Hardware Health)

HW LED (Yellow) Status

On

Blinking TBD

Off

Specifications & Board Interfaces 7

POST and sensor status

of IPMC is normal

POST and sensor status

of IPMC is abnormal

Page 18

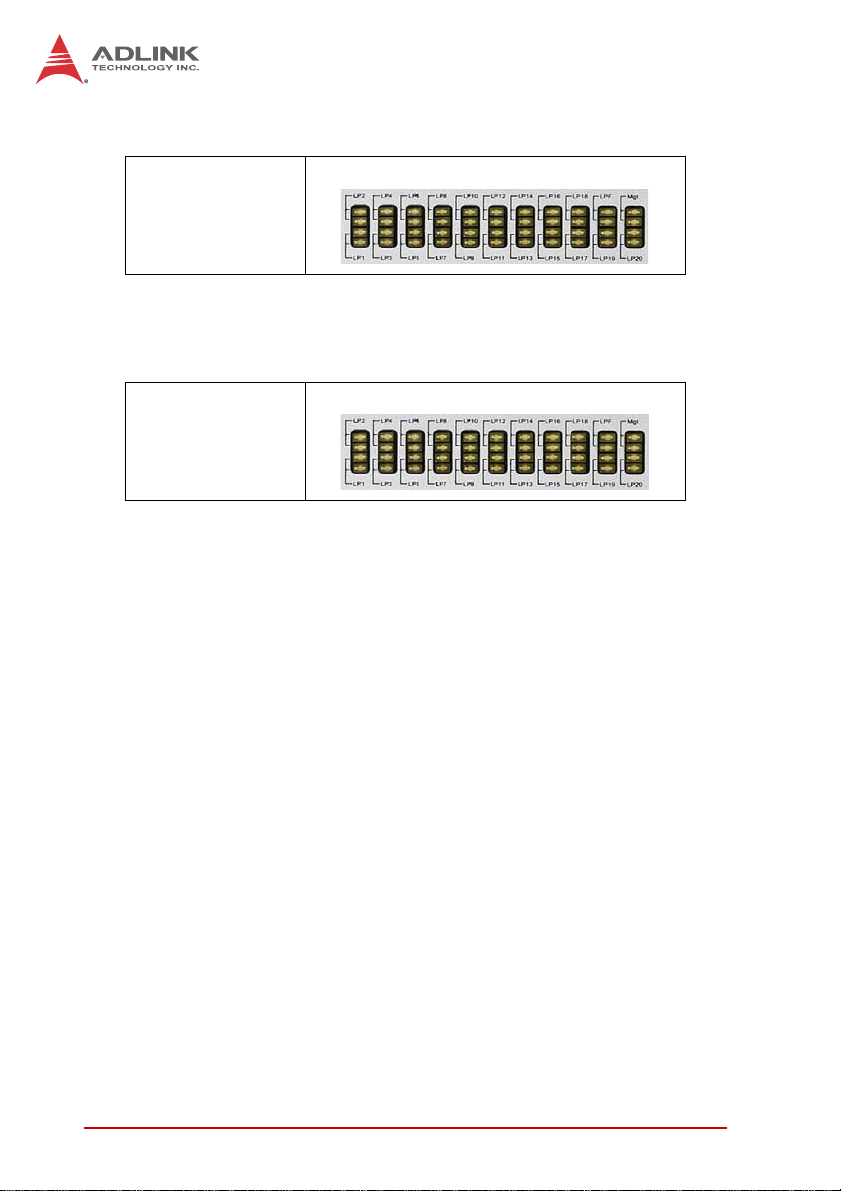

Rear IO GbE Status LEDs (LP1 - LP20)

Upper LED

On: Link up

Off: Link down

Lower LED

Blink: Packet Activity

SFP+ Status LEDs (XE 0 - XE 1)

Link LED (Green)

ON: Link up

OFF: Link down

Act LED (Orange)

Blink: Packet Activity

8 Specifications & Board Interfaces

Page 19

2.4 Connector Pinouts

UART COM Connector (CN6)

Set SW21 to IPMI or BCM56150 UART MUX debug port

cPCI-6S10

Pin #

1NC

2NC

3NC

4 IPM_DBG_TX

5 IPM_DBG_RX

6GND

7NC

8NC

10BASE-T/

100BASE-TX

18

RJ-45 10/100BASE-T Mgmt. Ethernet Connector (RJ4)

Pin #

1NC

2NC

3NC

4 IPM_DBG_TX

5 IPM_DBG_RX

6GND

7NC

8NC

10BASE-T/

100BASE-TX

18

Specifications & Board Interfaces 9

Page 20

RJ-45 Gigabit Ethernet Connectors ((RJ1/2/3)

Pin # 1000BASE-T

1 LAN_TX0+

2LAN_TX03 LAN_TX1+

4 LAN_TX2+

5LAN_TX26LAN_TX17 LAN_TX3+

8 LAN_TX3+

GbE Status LEDs

Left LED

On: Link up

Off: Link down

Right LED:

Blink: Packet Activity

Link Activity

18

10 Specifications & Board Interfaces

Page 21

SFP+ 10Gigabit Ethernet Connector (CN22/23)

Pin # 1000BASE-T

1GND

2SFP_TX_FAULT

3 SFP_TX_DISABLE

4SFP_SDA

5SFP_SCL

6 SFP_MOD_ABS

7GND

8 SFP_RX_LOS

9GND

10 GND

11 GND

12 SRDS_RX-N

13 SRDS_RX-P

14 GND

15 SFP_V3P3_R

16 SFP_V3P3_T

17 GND

18 SRDS_TX-P

19 SRDS_TX-N

20 GND

11

cPCI-6S10

1120

10

SFP+ 10GbE Status LEDs

Link LED: Yellow (Left)

Act LED: Green (Right)

Specifications & Board Interfaces 11

Page 22

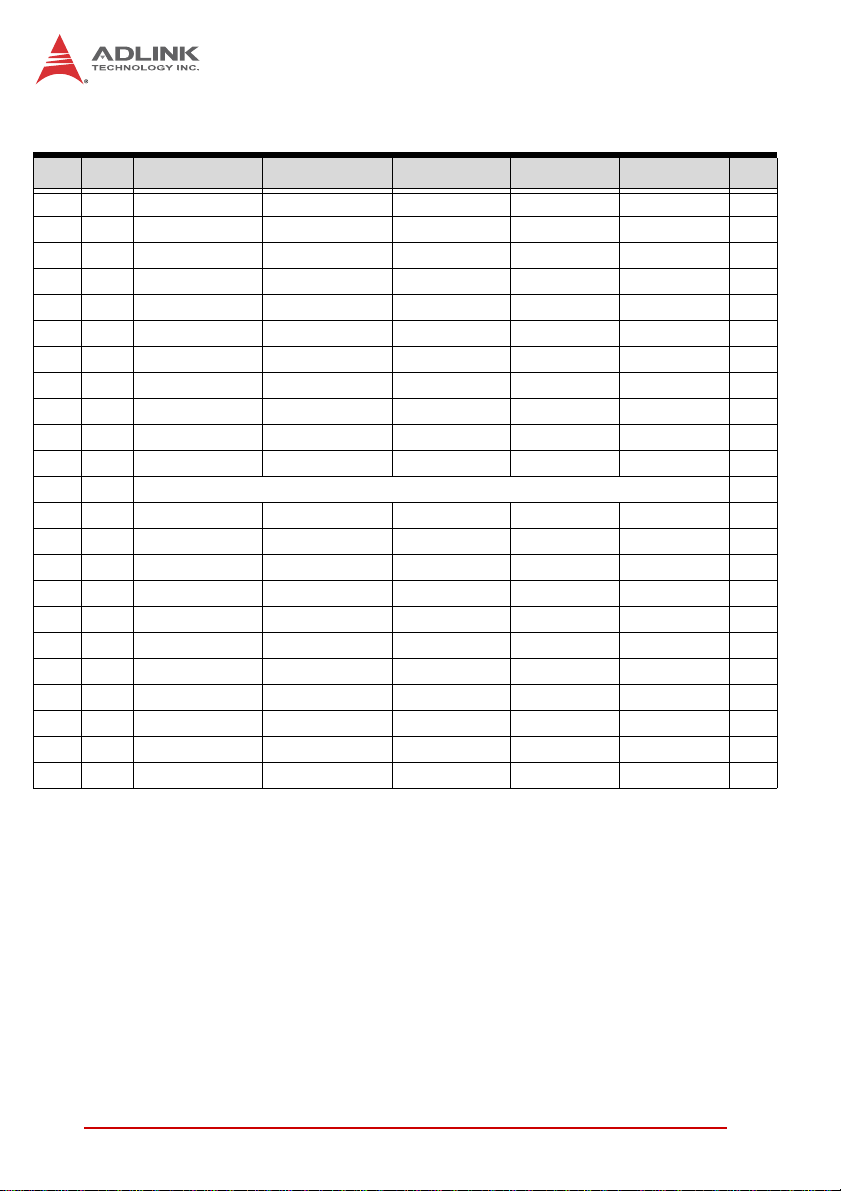

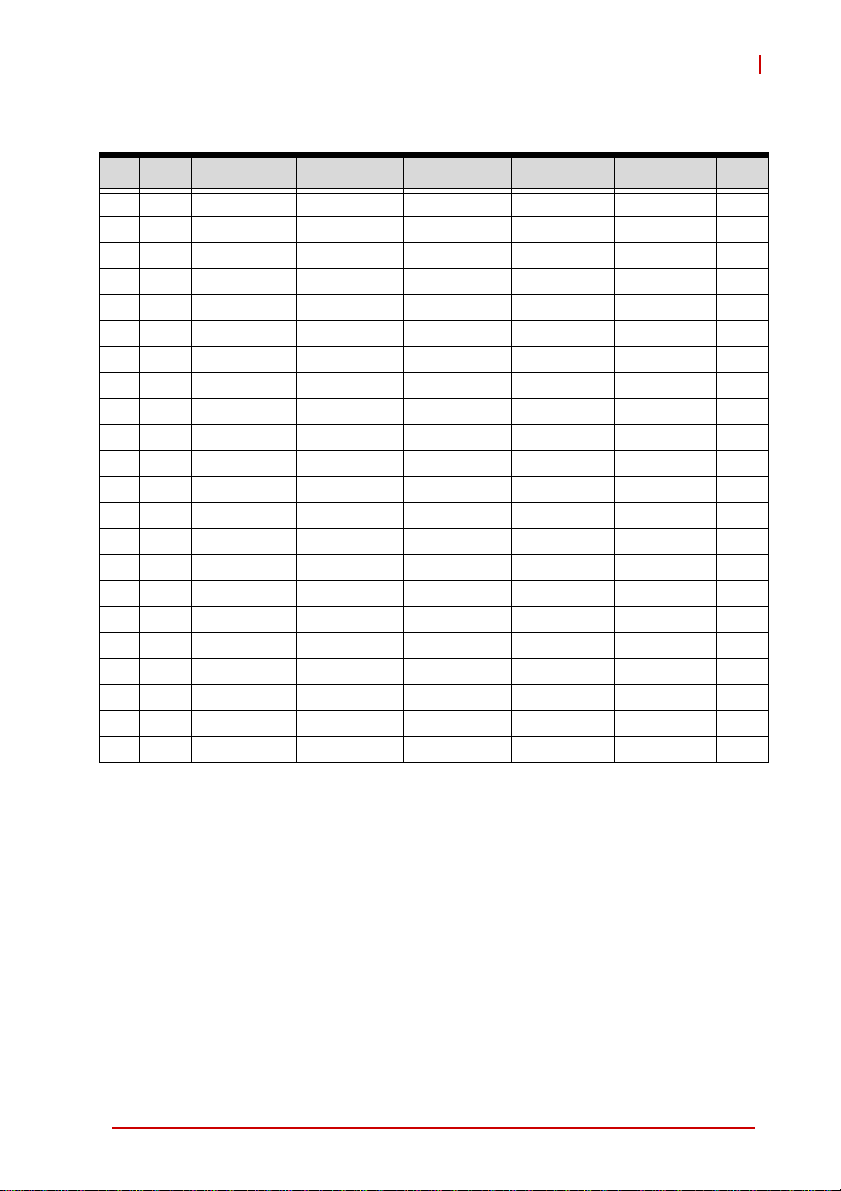

CompactPCI J1 Connector Pin Assignment

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND AD1 +5V V(I/O) AD0 ACK64# GND

23 GND P3V3 CPCI_AD4 CPCI_AD3 P5V CPCI_AD2 GND

22 GND CPCI_AD7 GND P3V3 CPCI_AD6 CPCI_AD5 GND

21 GND P3V3 CPCI_AD9 CPCI_AD8 CPCI_M66EN CPCI_CBE-L0 GND

20 GND CPCI_AD12 GND VIO CPCI_AD11 CPCI_AD10 GND

19 GND P3V3 CPCI_AD15 CPCI_AD14 GND CPCI_AD13 GND

18 GND CPCI_SERR-L GND P3V3 CPCI_PAR CPCI_CBE-L1 GND

17 GND P3V3 IPMB_CLK IPMB_DAT GND CPCI_PERR-L GND

16 GND CPCI_DEVSEL-L GND VIO CPCI_STOP-L CPCI_LOCK-L GND

15 GND P3V3 CPCI_FRAME-L CPCI_IRDY-L NC CPCI_TRDY-L GND

12-14 GND Key Area Key

11 GND CPCI_AD18 CPCI_AD17 CPCI_AD16 GND CPCI_CBE-L2 GND

10 GND CPCI_AD21 GND P3V3 CPCI_AD20 CPCI_AD19 GND

9 GND CPCI_CBE-L3 NC CPCI_AD23 GND CPCI_AD22 GND

8 GND CPCI_AD26 GND VIO CPCI_AD25 CPCI_AD24 GND

7 GND CPCI_AD30 CPCI_AD29 CPCI_AD28 GND CPCI_AD27 GND

6 GND CPCI_REQ-L0 GND P3V3 CPCI_CLK0 CPCI_AD31 GND

5 GND NC NC CPCI_RESET-L GND CPCI_GNT-L0 GND

4 GND P5V_IPMB

3 GND CPCI_IRQA-L CPCI_IRQB-L CPCI_IRQC-L P5V CPCI_IRQD-L GND

2 GND cPCI_TCK-L P5V cPCI_TMS-L NC cPCI_TDI-L GND

1 GND P5V N12V cPCI_TRST-L P12V P5V GND

CPCI_HEALTHY-L

VIO NC NC GND

12 Specifications & Board Interfaces

Page 23

cPCI-6S10

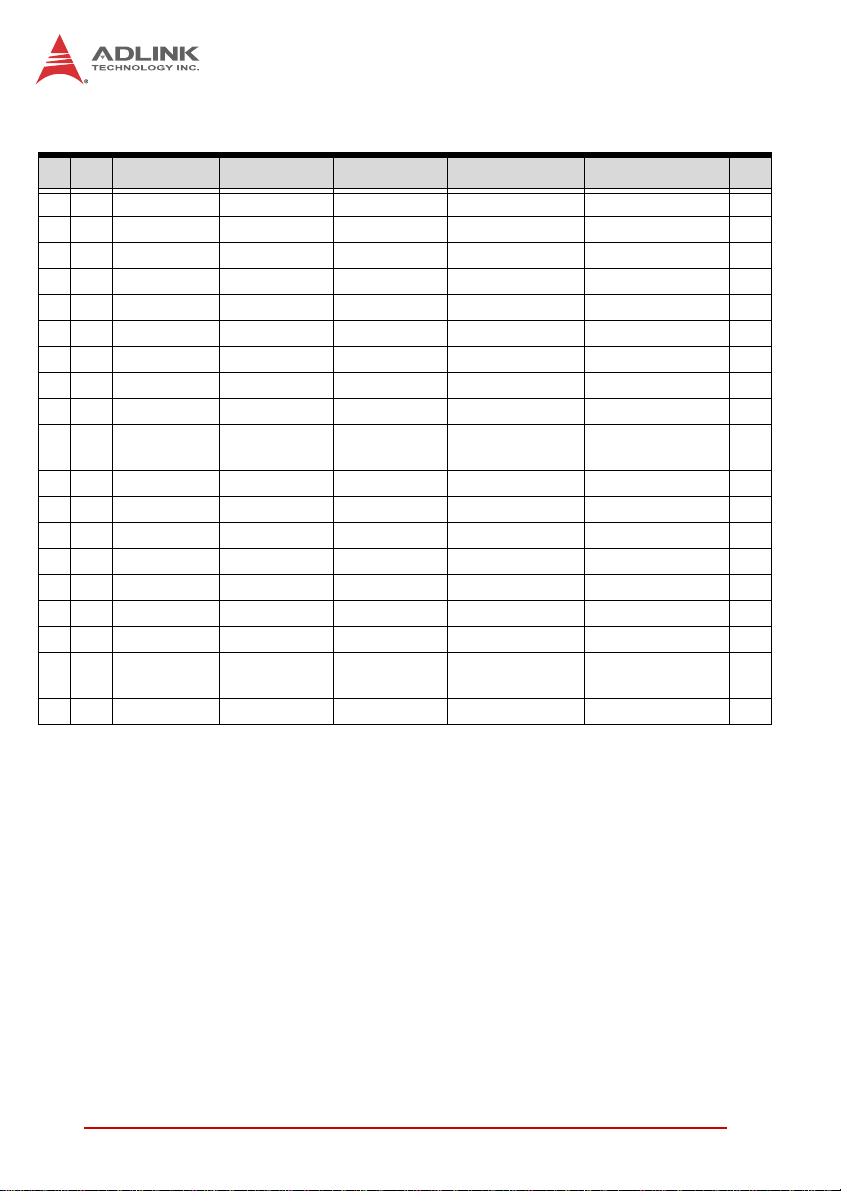

CompactPCI J2 Connector Pin Assignment

Pin Z A B C D E F

22 GND GA4 GA3 GA2 GA1 GA0 GND

21 GND CLK6 GND NC NC NC GND

20 GND CLK5 GND NC GND NC GND

19 GND GND GND NC NC NC GND

18 GND NC NC NC GND NC GND

17 GND NC GND RSTBTN# REQ6# GNT6# GND

16 GND NC NC DEG# GND NC GND

15 GND NC GND FAL# REQ5# GNT5# GND

14 GND AD35 AD34 AD33 GND AD32 GND

13 GND AD38 GND V(I/O) AD37 AD36 GND

12 GND AD42 AD41 AD40 GND AD39 GND

11 GND AD45 GND V(I/O) AD44 AD43 GND

10 GND AD49 AD48 AD47 GND AD46 GND

9 GND AD52 GND V(I/O) AD51 AD50 GND

8 GND AD56 AD55 AD54 GND AD53 GND

7 GND AD59 GND V(I/O) AD58 AD57 GND

6 GND AD63 AD62 AD61 GND AD60 GND

5 GND CBE5# GND V(I/O) CBE4# PAR64 GND

4 GND V(I/O) NC CBE7# GND CBE6# GND

3 GND CLK4 GND GNT3# REQ4# GNT4# GND

2 GND CLK2 CLK3 SYSEN# GNT2# REQ3# GND

1 GND CLK1 GND REQ1# GNT1# REQ2# GND

Specifications & Board Interfaces 13

Page 24

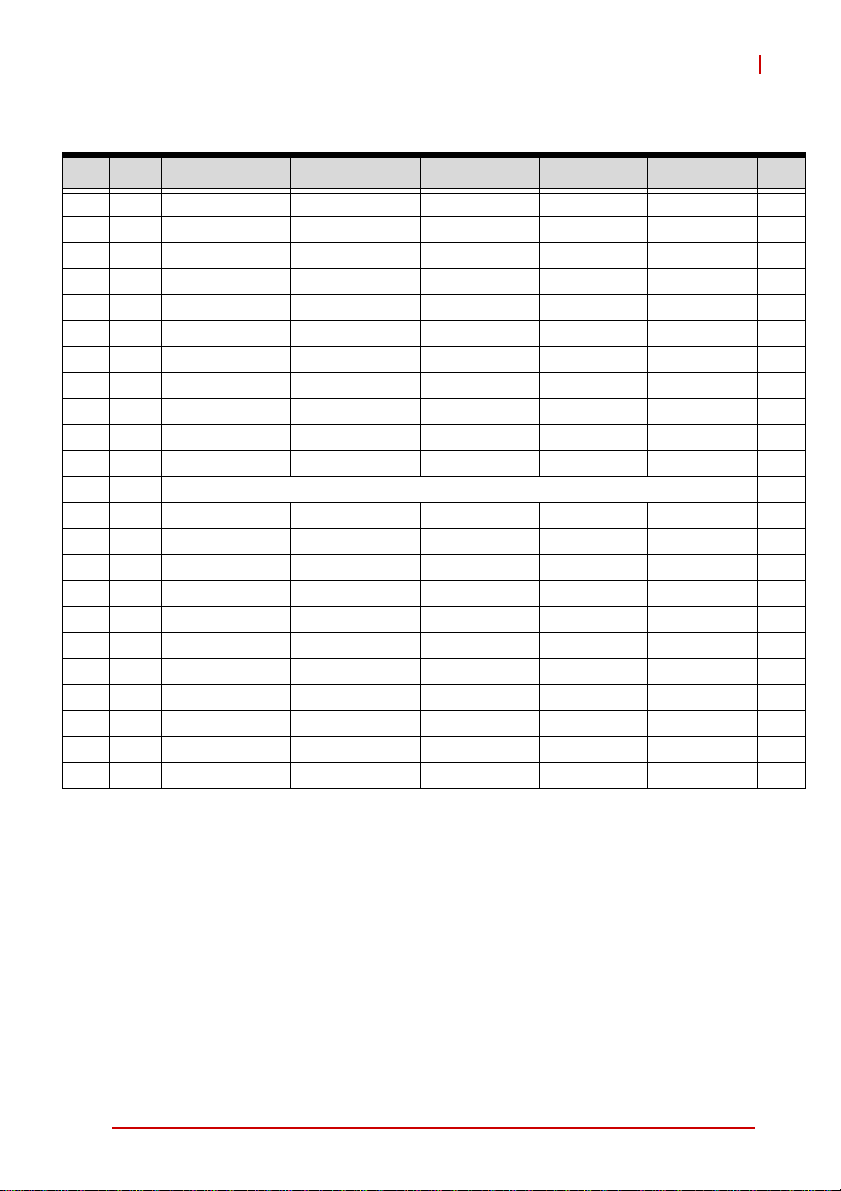

CompactPCI J3 Pin Assignment

Pin Z A B C D E F

19 GND P5V P5V P12V P5V P5V GND

18 GND LAN3_TXDP0 LAN3_TXDN0 GND LAN3_TXDP2 LAN3_TXDN2 GND

17 GND LAN3_TXDP1 LAN3_TXDN1 GND LAN3_TXDP3 LAN3_TXDN3 GND

16 GND LAN4_TXDP0 LAN4_TXDN0 GND LAN4_TXDP2 LAN4_TXDN2 GND

15 GND LAN4_TXDP1 LAN4_TXDN1 GND LAN4_TXDP3 LAN4_TXDN3 GND

14 GND USB_OC45-L USB_OC6 USB_OC7 USB_OC8 USB_OC9 GND

13 GND USB8-P USB8-N GND USB9-P USB9-N GND

12 GND USB6-P USB6-N GND USB7-P USB7-N GND

11 GND USB4-P USB4-N GND USB5-P USB5-N GND

10 GND USB_OC45-L

9 GND COM2_CTS-L COM2_RI-L CRT_BLUE CRT_RED CRT_GREEN GND

8 GND COM2_RX COM2_TX COM2_DTR-L COM2_DSR-L COM2_RTS-L GND

7 GND COM3_TX COM3_RX COM2_DCD-L IPMB_CLK IPMB_DAT GND

6 GND SATA_RXP1 SATA_RXN1 GND SATA_RXP0 SATA_RXN0 GND

5 GND GND GND NC GND GND GND

4 GND SATA_TXP1 SATA_TXN1 GND SATA_TXP0 SATA_TXN0 GND

3 GND KBDATA KBCLK NC MSDATA MSCLK GND

2 GND AUD_SDIN1 AUD_SDIN2 NC

1 GND AUD_RST-L AUD_SYNC AUD_BIT_CLK AUD_SDOUT AUD_SDIN0 GND

CRT_DDC_

CLK

CRT_DDC_

DATA

CRT_HSYNC CRT_VXYNC GND

AUD_DOCK_

EN-L

AUD_DOCK_

RST-L

GND

14 Specifications & Board Interfaces

Page 25

cPCI-6S10

CompactPCI J4 Connector Pin Assignment

Pin Z A B C D E F

25 GND BP(I/O) (1,3) BP(I/O) (1,3) BP(I/O) (1,3) BP(I/O) (1,3) BP(I/O) (1,3) GND

24 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

23 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

22 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

21 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

20 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

19 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

18 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

17 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

16 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

15 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

12-14 GND Key Area Key

11 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

10 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

9 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

8 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

7 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

6 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

5 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

4 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

3 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

2 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

1 GND BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) BP(I/O) (1,16) GND

Specifications & Board Interfaces 15

Page 26

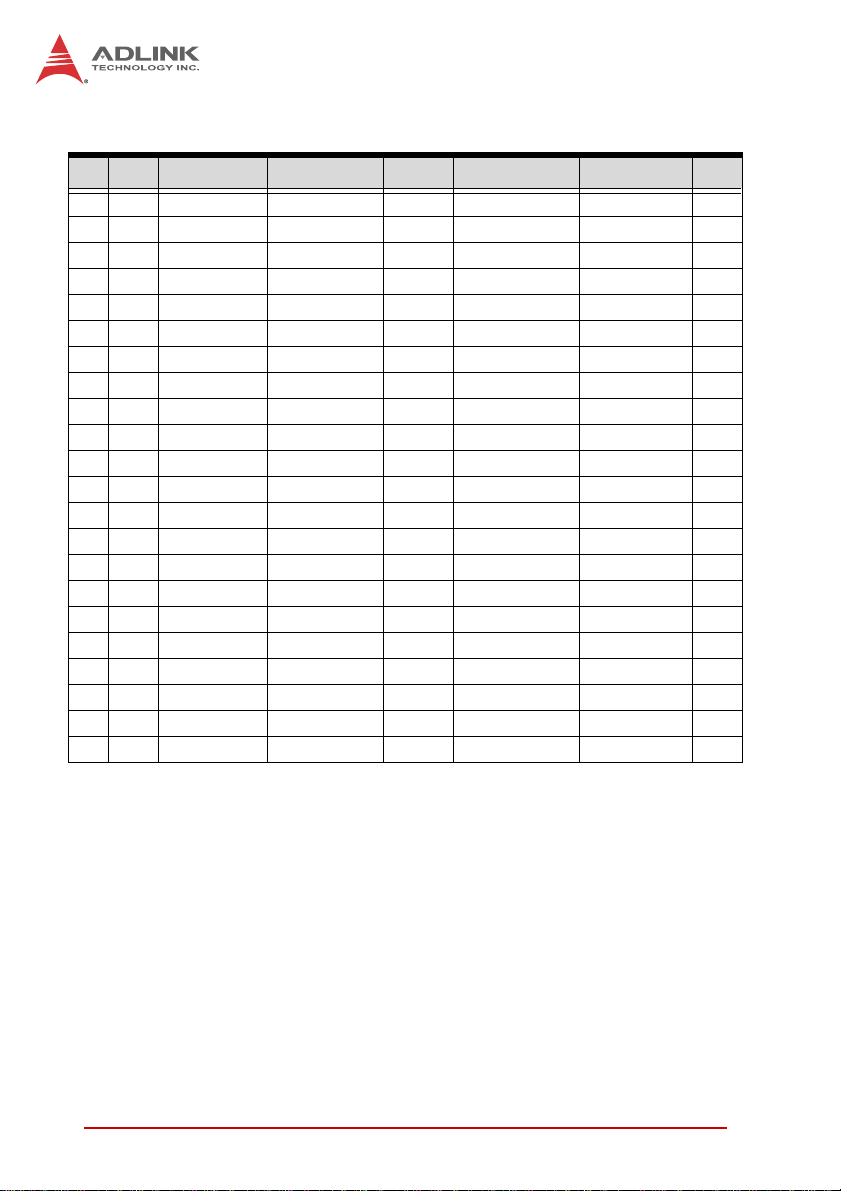

CompactPCI J5 Pin Assignment

Pin Z A B C D E F

22 GND LP19_DA+ LP19_DA- GND LP19_DC+ LP19_DC- GND

21 GND LP19_DB+ LP19_DB- GND LP19_DD+ LP19_DD- GND

20 GND LP18_DA+ LP18_DA- GND LP18_DC+ LP18_DC- GND

19 GND LP18_DB+ LP18_DB- GND LP18_DD+ LP18_DD- GND

18 GND LP17_DA+ LP17_DA- GND LP17_DC+ LP17_DC- GND

17 GND LP17_DB+ LP17_DB- GND LP17_DD+ LP17_DD- GND

16 GND LP16_DA+ LP16_DA- GND LP16_DC+ LP16_DC- GND

15 GND LP16_DB+ LP16_DB- GND LP16_DD+ LP16_DD- GND

14 GND LP15_DA+ LP15_DA- GND LP15_DC+ LP15_DC- GND

13 GND LP15_DB+ LP15_DB- GND LP15_DD+ LP15_DD- GND

12 GND LP14_DA+ LP14_DA- GND LP14_DC+ LP14_DC- GND

11 GND LP14_DB+ LP14_DB- GND LP14_DD+ LP14_DD- GND

10 GND LP13_DA+ LP13_DA- GND LP13_DC+ LP13_DC- GND

9 GND LP13_DB+ LP13_DB- GND LP13_DD+ LP13_DD- GND

8 GND LP12_DA+ LP12_DA- GND LP12_DC+ LP12_DC- GND

7 GND LP12_DB+ LP12_DB- GND LP12_DD+ LP12_DD- GND

6 GND LP11_DA+ LP11_DA- GND LP11_DC+ LP11_DC- GND

5 GND LP11_DB+ LP11_DB- GND LP11_DD+ LP11_DD- GND

4 GND LP10_DA+ LP10_DA- GND LP10_DC+ LP10_DC- GND

3 GND LP10_DB+ LP10_DB- GND LP10_DD+ LP10_DD- GND

2 GND LP9_DA+ LP9_DA- GND LP9_DC+ LP9_DC- GND

1 GND LP9_DB+ LP9_DB- GND LP9_DD+ LP9_DD- GND

16 Specifications & Board Interfaces

Page 27

cPCI-6S10

2

2.5 Switch Settings

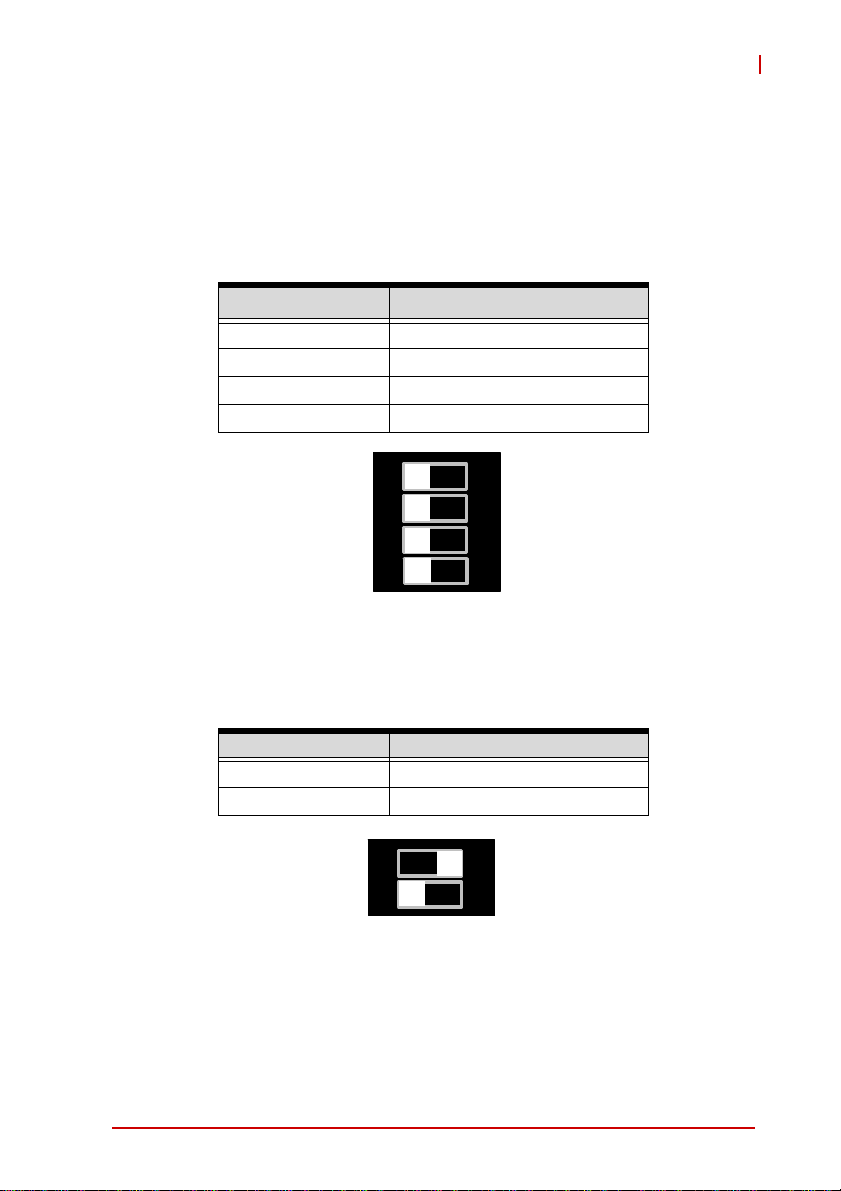

Standalone/CMM Mode Switch (SW6)

The cPCI-6S10 comes with SW6 for user to set the blade to standalone mode or CMM mode. The cPCI-6S10 can boot without CMM

in standalone mode.

Pin Function

All off Stand alone mode (default)

2 ON CMM Disable

3 ON SYSTEM# ENABLE

4 ON EJECT Close

1

3 4

ON

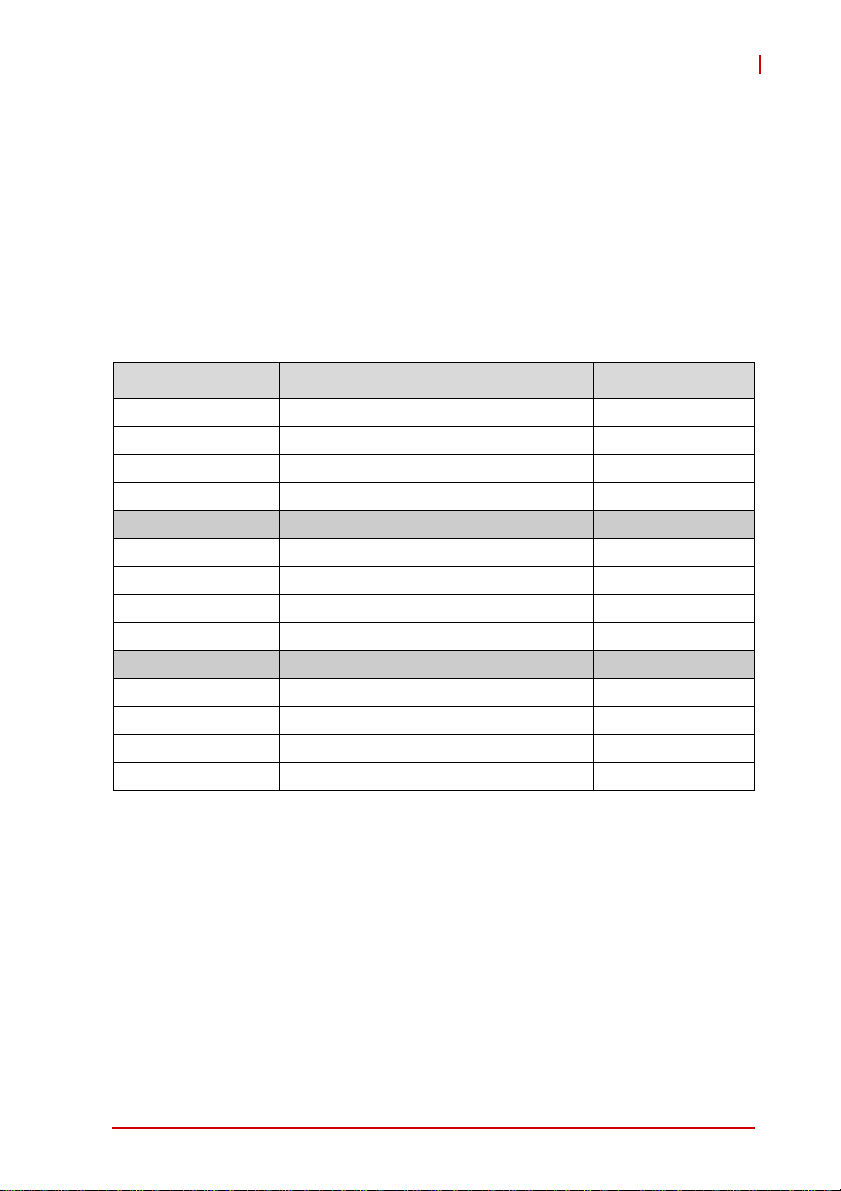

Boot Select Switch (SW13)

SW13 switch is to select boot from either SPI flash or NAND flash

Pin Function

1 ON Boot from SPI flash (Default)

2 ON Boot from nand flash

1 2

ON

.

Specifications & Board Interfaces 17

Page 28

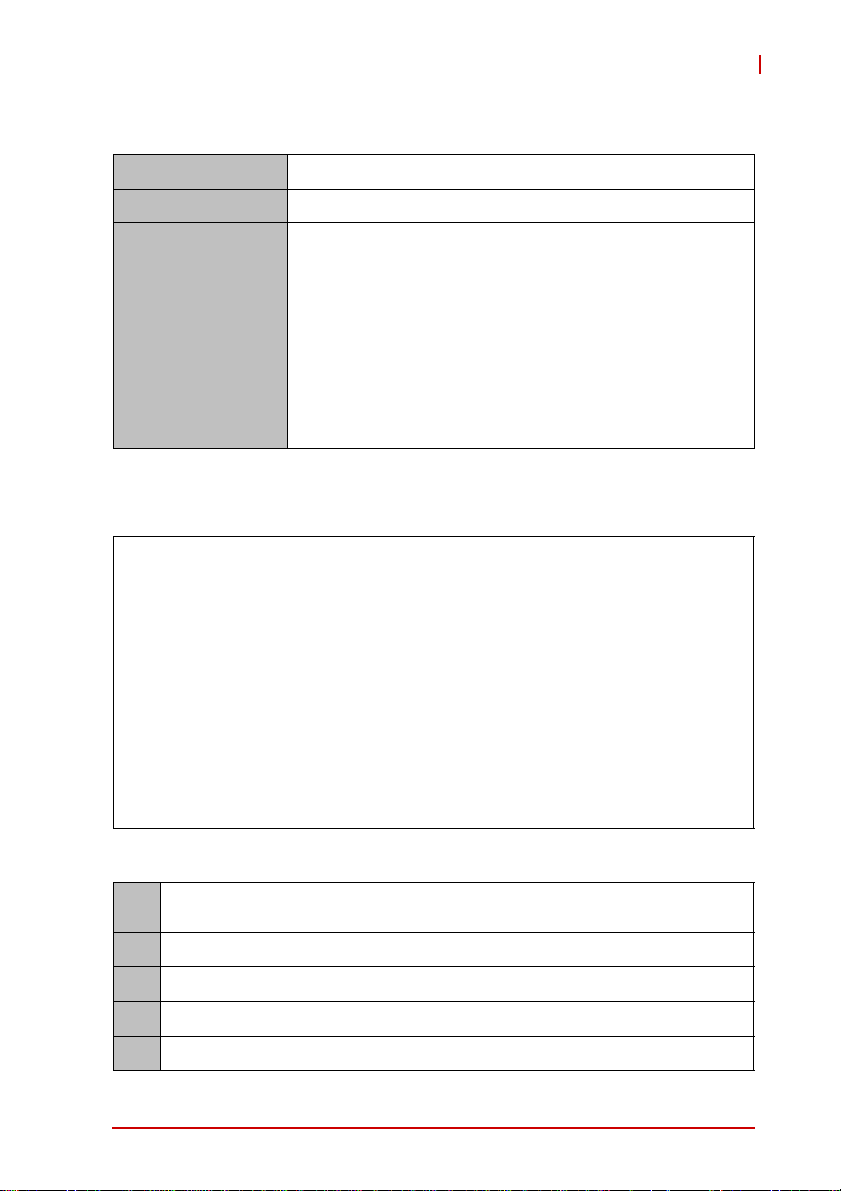

NAND Flash Boot Mode Switch (SW14)

SW14 switch sets either Auto or Manual mode for boot from

NAND flash

Pin 1 Pin 2 Function

Off (no effect) Auto mode (default)

On On Manual mode: Select NAND 0

On Off Manual mode: Select NAND 1

1 2

ON

Console Port Switch (SW21)

SW21 switch sets the console port to either BCM5615 0 or to IPMC.

Pin Function

1/2 On, 3/4 Off Console port to BCM56150 (Default)

1/2 Off, 3/4 On Console port to IPMC

1

2

3 4

ON

18 Specifications & Board Interfaces

Page 29

3 Hardware Platform Management

3.1 Platform Management Overview

The purpose of the hardware platform management system is to

monitor, control, and assure proper operation of CompactPCI

blades. The hardware platform management system wa tches over

the basic health of the system, reports anomalies, and provides

feedback to the chassis management module (CMM) when

needed. The hardware platform management system can retrieve

inventory information and sensor readings as well as receive

event reports and failure notifications from blades and other Intelligent FRUs. The hardware platform management system can also

perform basic recovery operations such as power cycle or reset of

managed entities.

The IPMC controller on the cPCI-6S10 supports an intelligent

hardware management system, based on the Intelligent Platform

Management Interface Specification. The hardware management

system provides the ability to manage the power, cooling, and

interconnect needs of intelligent devices; monitor events; and log

events to a central repository.

cPCI-6S10

Hardware Platform Management 19

Page 30

3.2 IPMI Commands

3.2.1 Standard Commands

In terminal mode, the command is enclosed by square brackets.

Each Hex number is separated by a single blank. This command

group ranges from 0x00, 0x02, 0x04, 0x06, 0x08, 0x0A, to 0x0C in

Netfn list.

Format

Request: [18 00 02]

X Byte 1: NetFn/rsLUN(00b)

X Byte 2: rqSeq/Bridge

X Byte 3: Command

X Byte 4-n: request data

Response: [1C 00 02 00]

X Byte 1: NetFn

X Byte 2: rqSeq

X Byte 3: Command

X Byte 4: Completion code

X Byte 5-n: response data

NetFn Codes:

Request Response Name

00 01 Chassis

02 03 Bridge

04 05 Sensor / Event

06 07 App

08 09 Firmware

0A 0B Storage

0C 0D Transport

0E 2B Reserved

2C 2D Group Extension

2E 2F OEM

30 3F Controller specific OEM/Group

Table 3-1: NetFn codes

20 Hardware Platform Management

Page 31

Response Codes

Description Code

IPMI_SUCCESS 0x00

IPMI_NODE_BUSY 0xC0

IPMI_INVALID_COMMAND 0xC1

IPMI_COMMAND_INVALID_FOR_LUN 0xC2

IPMI_TIMEOUT 0xC3

IPMI_OUT_OF_SPACE 0xC4

IPMI_RESERVATION_INVALID_OR_CANCELED 0xC5

IPMI_REQUEST_DATA_TRUNCATED 0xC6

IPMI_REQUEST_DATA_LENGTH_INVALID 0xC7

IPMI_REQUEST_DATA_LENGTH_LIMIT_EXCEEDED 0xC8

IPMI_PARAMETER_OUT_OF_RANGE 0xC9

IPMI_CANNOT_RETURN_NUMBER_OF_REQUESTED_BYTE

S

IPMI_REQUESTED_DATA_NOT_PRESENT 0xCB

IPMI_INVALID_DATA_IN_REQUEST 0xCC

IPMI_COMMAND_ILLEGAL_FOR_SPECIFIED_OBJECT 0xCD

IPMI_CANNOT_PROVIDE_COMMAND_RESPONSE 0xCE

IPMI_CANNOT_EXECUTE_DUPLICATED_REQUEST 0xCF

IPMI_SDR_REPOSITORY_IN_UPDATE_MODE 0xD0

IPMI_DEVICE_IN_FIRMWARE_UPDATE_MODE 0xD1

IPMI_INITIALIZATION_IN_PROGRESS 0xD2

IPMI_DESTINATION_UNAVAILABLE 0xD3

IPMI_INSUFFICIENT_PRIVILEGE_LEVEL 0xD4

IPMI_COMMAND_NOT_SUPPORTED_IN_PRESENT_STATE 0xD5

IPMI_READ_ONLY_PARAMETER 0x82

IPMI_UNSPECIFIED_ERROR 0xFF

0xCA

cPCI-6S10

T able 3-2: Response Codes

Hardware Platform Management 21

Page 32

Message Length

The IPMI standard overall message for “no-bridging” messages is

specified as 32 bytes, maximum, including slave address. For

bridging messages to other interfaces, Master Write-Read and

Send Message commands are allowed to exceed 32-bytes on

IPMI.

The table below shows the required interface length in IPMI 1.5.

Some interfaces have extra recommended values in the IPMI

specification.

Interface Length(bytes)

KCS/SMIC Input 40

KCS/SMIC Output 38

BT Input 42

BT Output 40

IPMB Input 32

IPMB Output 36

SMBus 2.0 Input 36

SMBus 2.0 Output 36

Private Bus Input 34

Private Bus Output 23

LAN/PPP Input 45

LAN/PPP Output 42

Table 3-3: Required Message Length for IPMI 1.5

3.2.2 IPMItool

IPMItool is an open-source software, which supports several message

interfaces to communicate with IPMI devices. It includes pre-define

commands such like “fru” and “mc”, and can also send raw IPMI commands.

To send IPMI commands to the cPCI-6S10’s IPMC, instead of using IPMItool under Linux login, it is possible to communicate remotely with

cPCI-6S10 IPMC through RMCP protocol, with the help of the IPMItool

utility.

22 Hardware Platform Management

Page 33

Message Interfaces

X Access through Linux driver (on LMP locally): ipmitool

<command>

X RMCP remote client: ipmitool -I lan -H <hostname> [-p

<port>] [-U <username>] [-A <authtype>] <command>

X If bridged command is issued. An extra parameter should

be applied.

Z -t: select target slave address (0xB0 for slot1, 0xB2 for

slot2, etc, in ADLINK Chassis cPCIS-3300BLS).

Slot No. IPMB Address (hex) Type

01 B0 CPU

02 B2 CPU

03 B4 CPU

04 B6 CPU

05 B8 SWH

06 BA CPU

07 BC CPU

08 BE CPU

09 C0 CPU

10 C4 SWH

11 C6 CPU

12 C8 CPU

13 CA CPU

14 CC CPU

cPCI-6S10

T able 3-4: cPCIS-3300BLS Chassis Slots

Examples

Access from local LMP

ipmitool mc info

Get device Information from onboard payload with Linux IPMI

driver.

ipmitool raw 0x06 0x01

Get device id with IPMI raw command.

Access from RMCP remote client, bridged through the BMC

Hardware Platform Management 23

Page 34

ipmitool -I lan -H 172.20.5.225 -U admin -P admin -t 0xB8 raw 0x06

0x01

Remote send raw command “Get device Id” to IPMC

(172.20.5.225) via RMCP protocol with username: admin,

password: admin, and let CMM to bridge it to CPCI-6S10

board plugged in slot 5 (slave address: 0xB8).

Response

X Complete: Completion code is 0x00 and will be skipped,

and only response data be printed.

X Error: More error message will be printed.

3.2.3 IPMItool Pre-defined Commands

X ipmitool raw: Send a raw command request.

X ipmitool mc: Print the management controller status and

global enabled options.

# ipmitool mc

MC Commands:

reset <warm|cold>

info

wdt

selftest

getenables

setenables <option=on|off> ...

recv_msg_intr Receive Message Queue Int.

event_msg_intr Event Message Buffer Full Int.

event_msg Event Message Buffer

system_event_log System Event Logging

oem0 OEM 0

oem1 OEM 1

oem2 OEM 2

X ipmitool fru: Print built-in FRU and scan SDR for FRU loca-

tors.

# ipmitool fru

FRU Device Description: Builtin FRU Device (ID 0)

Board Mfg Date: Tue Sep 16 20:00:00 2014

Board Mfg: ADLINK Technology

24 Hardware Platform Management

Page 35

cPCI-6S10

Board Product: cPCI-6S10

Board Serial: ADLINK-XXXX-XXXX

Board Part Number: cPCI-6S10

Product Manufacturer: ADLINK Technology

Product Name: cPCI-6S10

Product Part Number: cPCI-6S10

Product Version: A2

Product Serial: ADLINK-XXXX-XXXX

Product Asset Tag: N/A

X

ipmitool -I lan -H 172.20.5.225 -U admin -P admin -t 0xB4 sdr:

Print Sensor Data Repository entries and readings.

BMC_WatchDog | no reading | ns

POWER_GOOD | 0 unspecified | cr

P1V | 1.01 Volts | ok

P1V2 | 1.20 Volts | ok

P1V5 | 1.50 Volts | ok

P0V75 | 0.74 Volts | ok

+3.3V | 3.32 Volts | ok

+5.0V | 5.05 Volts | ok

54685_TEMP | 47 degrees C | ok

56150_TEMP | 67 degrees C | nc

3.2.4 Supported IPMItool Commands

Get Device ID

ipmitool ipmitool [parameters] mc info

Te rminal mode [18 00 01]: raw 0x06 01

Description Get device’s id from selected MC.

Example

root@BDSP-A-0-0-1:~# ipmi mc info

Device ID : 18

Device Revision : 0

Firmware Revision : 1.2

IPMI Version : 1.5

Manufacturer ID : 24339

Manufacturer Name : Unknown (0x5F13)

Product ID : 21267 (0x5313)

Hardware Platform Management 25

Page 36

Product Name : Unknown (0x5313)

Device Available : yes

Provides Device SDRs : yes

Additional Device Support :

Sensor Device

FRU Inventory Device

IPMB Event Generator

Aux Firmware Rev Info :

0xa1

0x00

0x00

0x00

Response Data Fields

1 Completion cod e

2 Device ID. 00 = unspecified.

3 Device Revision

4 Firmware Revision 1

5 Firmware Revision 2

6 IPMI version

7 Addition Device support

8:10 Manufacture ID

11:12 Product ID

Cold Reset

ipmitool ipmitool [parameters] mc reset cold

Terminal mode [18 00 02]: raw 0x06 0x02

Description Reset IPMC

26 Hardware Platform Management

Page 37

In IPMC console, cold reset message will be printed.

<_>: BMR-AVR Firmware (v1.0.2), cPCI edition.

<_>: Pigeon Point Systems (c) Copyright 2004.

<_>: boot_type: 0xA3

<_>: Reset type: COLD, reset cause: Software

<_>: app_status: 0x01

<_>: Operating mode: Normal

Response Data Fields

1 Completion code

Reset Watchdog Timer

ipmitool ipmitool [parameters] mc wdt rst

Te rminal mode [18 00 22]: raw 0x06 0x22

Description

Response Data Fields

This command is used to reset IPMC watchdog timer.

The ipmitool supports this command.

cPCI-6S10

1 Completion code

Set Watchdog Timer

ipmitool

Te rminal mode [18 00 24 03 01 00 20 00 01]

Description This command is used to set IPMC watchdog timer.

Hardware Platform Management 27

ipmitool [parameters] raw 0x06 0x24 0x03 0x01 0x00

0x20 0x00 0x01

Page 38

Response Data Fields

Time use

[7] –1b = don’t log

[6] –1b = do not stop timer on set Watchdog Timer command.

[5:3] – reserved

[2:0] – timer use

000b = reserved

1

001b = BIOS FRB2

010b = BIOS/POST

011b = OS Load

100b = SMS/OS

101b = OEM

110b – 111b = reserved

Timer actions

[7] – reserved

[6:4] – pre-timeout interrupt

000b = none

001b = SMI

010b = NMI / Diagnostic Interrupt

011b = Messaging interrupt

2

110b,111b = reserved

[3] – reserved

[2:0] = timeout action

000b = no action

001b = Hard reset

010b = Power down

01 1b = Power cycle

110b,111b = reserved

3 Pre-timeout interval in seconds.

Timer use expiratio n fl a gs clea r

(0b = leave alone, 1b = clear timer use expiration bit)

[7] – reserved

[6] – reserved

[5] – OEM

4

[4] – SMS/OS

[3] – OS/Load

[2] – BIOS/POST

[1] – BIOS FRB2

[0] – reserved

5 Initial countdown value, lsbyte(100ms/count)

6 Initial countdown value, msbyte

28 Hardware Platform Management

Page 39

Get Watchdog Timer

ipmitool ipmitool [parameters] mc watchdog get

Te rminal mode [18 00 25] : raw 0x06 0x25

Description

Response:

root@iProc /root:~# ipmitool mc watchdog get

Timer Use: 0x42 - BIOS/POST

Timer Actions: 0x01 - Hard Reset

Pre-timeout interval: 0x00

Timer Use Expiration: 0x00

Initial Countdown: 360 ms

Present Countdown: 357 ms

Response Data Fields

1 Completion code

Timer use

[7] –1b = don’t log

[6] –1b = timer started.

0b = timer stopped.

[5:3] – reserved

[2:0] – timer use

2

000b = reserved

001b = BIOS FRB2

010b = BIOS/POST

011b = OS Load

100b = SMS/OS

101b = OEM

110b – 111b = reserved

This command is used to get watchdog timer info.

We can use ipmitool command to get this information.

cPCI-6S10

Hardware Platform Management 29

Page 40

Timer actions

[7] – reserved

[6:4] – pre-timeout interrupt

000b = none

001b = SMI

010b = NMI / Diagnostic Interrupt

011b = Messaging interrupt

3

110b,111b = reserved

[3] – reserved

[2:0] = timeout action

000b = no action

001b = Hard reset

010b = Power down

01 1b = Power cycle

110b,111b = reserved

4 Pre-timeout interval in seconds.

Timer use expirati o n fl a gs

(1b = timer expired while associated ‘use’ was selected)

[7] – reserved

[6] – reserved

[5] – OEM

5

[4] – SMS/OS

[3] – OS/Load

[2] – BIOS/POST

[1] – BIOS FRB2

[0] – reserved

6 Initial countdown value, lsbyte(100ms/count)

7 Initial countdown value, msbyte

8 Preset countdown value, lsbyte

9 Preset countdown value, msbyte

30 Hardware Platform Management

Page 41

Master Write-Read

ipmitool Ipmitool [parameters] raw 0x06 0x52 …

Te rminal mode [18 00 52 ….]

This command is used for low-level I2C write, read, or

Description

Request Fields

Bus ID:

[7:4] channel number

[3:1] bus ID, 0-based (always 000b for public bus)

1

[0] bus type:

0 = public (e.g. IPMB or PCI Management Bus)

1 = private bus

[7:1] - Slave Address

2

[0] - reserved. Write as 0.

Read count. Number of bytes to read, 1 based. 0 = no bytes to read.

The maximum read count should be at least 34 bytes. This allows the

command to be used for an SMBus Block Read. This is required if the

command provides access to an SMBus or IPMB. Otherwise, if FRU

3

SEEPROM devices are accessible, at least 31 bytes must be

supported. Note that an implementation can support fewer bytes can

be supported if none of the devices to be accessed can handle the

recommended minimum.

Data to write. This command should support at least 35 bytes of write

data. This allows the command to be used for an SMBus Block Write

with PEC. Otherwise, if FRU SEEPROM devices are accessible, at

4:N

least 31 bytes must be supported. Note that an implementation is

allowed to support fewer bytes if none of the devices to can handle

the recommended minimum.

write-read access to IPMB or private busses behind a

management controller.

cPCI-6S10

Hardware Platform Management 31

Page 42

Response Data Fields

Completion Code

A management controller shall return an error Completion Code if an

attempt

is made to access an unsupported bus.

1

generic, plus following command specific codes:

81h = Lost Arbitration

82h = Bus Error

83h = NAK on Write

84h = Truncated Read

Bytes read from specified slave address. This field will be absent if the

(2:M)

read count is 0. The controller terminates the I 2 C transaction with a

STOP condition after reading the requested number of bytes.

Set Event Receiver

ipmitool ipmitool [parameters] raw 0x04 0x00 0x20 0x00

Terminal mode [10 00 00 20 00]

Description

Request Data Fields

Set event receiver address, default event receiver is

0x20.

1

Slave address

2 [7:2] = reserved

[1:0] = Event receiver LUN

Note: The commands “Set event receiver” and “Get event

receiver” are used for event delivery between IPMC and BMC.

Other address (except 0x20 to CMM by default) will cause incorrect behavior.

32 Hardware Platform Management

Page 43

Get Event Receiver

ipmitool ipmitool [parameters] raw 0x04 0x01

Te rminal mode [10 00 01]

Description Get event receiver’s slave address

Response Data Fields

1

Completion code

2

Slave address

3 [7:2] = reserved

[1:0] = Event receiver LUN

Note: The commands “Set event receiver” and “Get event

receiver” are used for event delivery between IPMC and CMM.

Other address (except 0x20 to CMM by default) will cause incorrect behavior.

Platform Event

cPCI-6S10

ipmitool

Te rminal mode [10 00 02 04 01 01 01 07 FF FF 48]

Description

ipmitool [parameters] raw 0x04 0x02 0x04 0x01 0x01

0x01 0x07 0xFF 0xFF 0x48

Send event to event receiver. We don’t need to fire this

command directly.

This command can be testing when we test sensor event.

Note: The command “Platform event” is only available from Linux

driver side. IPMC would only accept this command from Addin

card, and drops messages from CMM with bridged format.

Because IPMC only send this command to CMM, IPMC don’t

receive this command coming from outside.

Hardware Platform Management 33

Page 44

We can test IPMC by sending a event to BMC:

root@BCNMB-A:~# ipmitool raw 0x2E 0x88 0x39 0x28

0x00 0x02

39 28 00

root@BCNMB-A:~# ipmitool -I lan -H 172.20.225 -U

admin -P admin sel list last 1

2e | 04/28/2010 | 00:49:19 | Add-in Card #0x9d

| soft reset | Asserted

Get Device SDR Info

ipmitool ipmitool [parameters] raw 0x4 0x20

Terminal mode [10 00 20]

Description Get device sdr information

root@BCNMB-A:~# ipmitool raw 0x4 0x20

0a 01 00 00 00 00

Response Fields

1

Completion code

2

Number of sensors in device for LUN this command was ad d r essed to.

3 Flags:

Dynamic population

[7] – 0b = static sensor population

1b = dynamic sensor population

[6:4] = reserved

Device LUns:

[3] – 1b = LUN 3 has sensors

[2] – 1b = LUN 2 has sensors

[1] – 1b = LUN 1 has sensors

[0] – 1b = LUN 0 has sensors

4:7 Sensor Population Change Indicator LS byte first.

Four byte timestamp or counter. Updated or incremented each time the

sensor population changes. This field is not provided if the flags indicate a

static sensor population.

34 Hardware Platform Management

Page 45

Get Device SDR

ipmitool ipmitool [parameters] sdr list all

Te rminal mode [10 00 21 00 00 00 00 00 FF]

This command is used to get SDR info. SDR format

depends on IPMI spec.

Ipmitool support sdr command to read those data. We

can use “ipmitool sdr” to get those data without pain.

Description

Example:

List all SDR from IPMC (from Device SDR)

root@BCNMB-A:~# ipmitool -I lan -H 172.20.5.225

cPCI-6S10 | Dynamic MC @ B4h | ok

BMC_WatchDog | 0 unspecified | nc

POWER_GOOD | 0 unspecified | cr

P1V | 1.01 Volts | ok

P1V2 | 1.20 Volts | ok

P1V5 | 1.50 Volts | ok

P0V75 | 0.74 Volts | ok

+3.3V | 3.32 Volts | ok

+5.0V | 5.05 Volts | ok

54685_TEMP | 48 degrees C | ok

56150_TEMP | 66 degrees C | nc

If MC support “SDR repository device”, ipmitool will use

“SDR repository” first.

When MC only support “Sensor Device”, this command

has been applied to retrieve SDR.

We fix ipmitool to support list SDR from Device SDR with

“list” command.

-U admin -P admin -t 0xB8 sdr list all

cPCI-6S10

Request Fields

1 Reservation ID. LS Byte. Only required for partial reads with a non-zero

‘Offset into record’ field. Use 0000h for reservation ID otherwise.

2

Reservation ID. MS Byte.

3

Record ID of record to Get LS Byte. 0000h returns the first record

4

Record ID of record to Get, MS Byte.

5

Offset into record

Hardware Platform Management 35

Page 46

6

Bytes to read. FFh means read entire record

Response Fields

1

Completion code

2

Record ID for next record, LS Byte

3

Record Id for next record. MS Byte

4:3+N

Requested bytes from record

Reserve Device SDR Repository

ipmitool ipmitool [parameters] raw 0x04 0x22

Terminal mode [10 00 22]

Description

This command is used to obtain a reservation ID.

Reserve ID is used by “Get Device SDR” command.

Response Fields

1

Completion code

2

Reservation ID, LS Byte 0000h reserved

3

Reservation ID, MS Byte

Set Sensor Threshold

ipmitool

Terminal mode [10 00 26 00 00 00 00 00 00 00 00]

Description

36 Hardware Platform Management

ipmitool [parameters] sensor thres h “sensor id”

<threshold> <setting>

This command is used to set sensor threshold. We can

use ipmitool to fire this command.

Page 47

Command Format:

sensor thresh <id> <threshold> <setting>

id : name of the sensor for which

threshold is to be set

threshold : which threshold to set

unr = upper non-recoverable

ucr = upper critical

unc = upper non-critical

lnc = lower non-critical

lcr = lower critical

lnr = lower non-recoverable

setting : the value to set the threshold to

Example:

Set sensor “56150_TEMP”’s UNR threshold to 88

ipmitool –I lan –H 172.20.5.225 –U admin –P

admin –t 0xB8 sensor thresh “56150_TEMP” unr

88

Request Fields

1

Sensor number( FFh = reserved)

2 [7:6] – reserved

[5] – 1b = set upper non-recoverable threshold

[4] – 1b = set upper critical threshold

[3] – 1b = set upper non- critical threshold

[2] – 1b = set lower non-recoverable threshold

[1] – 1b = set lower critical threshold

[0] – 1b = set lower non- critical threshold

3

Lower non-critical threshold

4

Lower critical threshold

5

Lower non-recoverable threshold

6

Upper non-critical threshold

7

Upper critical threshold

8

Upper non-recoverable threshold

cPCI-6S10

Hardware Platform Management 37

Page 48

Response Fields

1

Completion code

Get Sensor Threshold

ipmitool ipmitool [parameters] sensor get <sensor id>

Terminal mode [10 00 27 00]

Description

Example:

root@BCNMB-A:~# ipmitool -I lan -H 172.20.5.225

Locating sensor record...

Sensor ID : 56150_TEMP (0x8)

Entity ID : 160.96

Sensor Type (Analog) : Temperature

Sensor Reading : 67 (+/- 0) degrees C

Status : Upper Non-Critical

Lower Non-Recoverable : na

Lower Critical : na

Lower Non-Critical : na

Upper Non-Critical : 60.000

Upper Critical : 75.000

Upper Non-Recoverable : 88.000

Assertion Events : unc+

Deassertion Events : lnc- lnc+ lcr- lcr+

Assertions Enabled : unc+ ucr+ unr+

Deassertions Enabled : unc+ ucr+ unr+

This command is used to get threshold. We can use

ipmitool command to get this info.

-U admin -P admin sensor get "56150_TEMP "

lnr- lnr+ unc- ucr- ucr+ unr- unr+

Request Fields

1

Sensor number( FFh = reserved)

38 Hardware Platform Management

Page 49

Response Fields

1

Completion code

2 [7:6] – reserved

[5] – 1b = upper non-recoverable threshold

[4] – 1b = upper critical threshold

[3] – 1b = upper non- critical threshold

[2] – 1b = lower non-recoverable threshold

[1] – 1b = lower critical threshold

[0] – 1b = lower non- critical threshold

3

Lower non-critical threshold

4

Lower critical threshold

5

Lower non-recoverable threshold

6

Upper non-critical threshold

7

Upper critical threshold

8

Upper non-recoverable threshold

Set Sensor Event Enable

cPCI-6S10

ipmitool

Terminal

mode

Description This command is use to enable sensor events.

ipmitool [parameters] raw 0x04 0x28 0x01 0xd0 0x30 0x0c 0x00

0x00

[10 00 28 01 d0 03 0C 00 00]

Example: Enable sensor 1’s assertion for lower non-recoverable

going high, and assertion event for upper non-recoverable going

high.

[10 00 28 01 d0 20 08 00 00]

Hardware Platform Management 39

Page 50

Request Fields

1

Sensor number( FFh = reserved)

2 [7] – 0b = disable all event message from this sensor

[6] – 0b = disable scanning on this sensor

[5:4] – 00b = do not change individual enables

01h = enable selected event messages

10b = disable selected event messages

11b = reserved

3 For sensors with threshold based events:

[7] – 1b = select assertion event for upper non-critical going high

[6] – 1b = select assertion event for upper non-critical going low

[5] – 1b = select assertion event for lower non-recoverable going high

[4] – 1b = select assertion event for lower non-recoverable going low

[3] – 1b = select assertion event for lower critical going high

[2] – 1b = select assertion event for lower critical going low

[1] – 1b = select assertion event for lower non-critical going high

[0] – 1b = select assertion event for lower non-critical going low

For Sensors with discrete event:

[7] – 1b = select assertion event for state bit 7

[6] – 1b = select assertion event for state bit 6

[5 – 1b = select assertion event for state bit 5

[4] – 1b = select assertion event for state bit 4

[3] – 1b = select assertion event for state bit 3

[2] – 1b = select assertion event for state bit 2

[1] – 1b = select assertion event for state bit 1

[0] – 1b = select assertion event for state bit 0

40 Hardware Platform Management

Page 51

4 For sensors with threshold base events:

[7:4] – reserved.

[3] – 1b = select assertion event for upper non-recoverable going high

[2] – 1b = select assertion event for upper non-recoverable going low

[1] – 1b = select assertion event for upper critical going high

[0] – 1b = select assertion event for upper critical going low

For sensors with discrete events:

[7] – reserved

[6] – 1b = select assertion event for state bit 14

[5] – 1b = select assertion event for state bit 13

[4] – 1b = select assertion event for state bit 12

[3] – 1b = select assertion event for state bit 11

[2] – 1b = select assertion event for state bit 10

[1] – 1b = select assertion event for state bit 9

[0] – 1b = select assertion event for state bit 8

5 For sensors with threshold based events:

[7] – 1b = select deassertion event for upper non-critical going high

[6] – 1b = select deassertion event for upper non-critical going low

[5] – 1b = select deassertion event for lower non-recoverable going high

[4] – 1b = select deassertion event for lower non-recoverable going low

[3] – 1b = select deassertion event for lower critical going high

[2] – 1b = select deassertion event for lower critical going low

[1] – 1b = select deassertion event for lower non-critical going high

[0] – 1b = select deassertion event for lower non-critical going low

cPCI-6S10

For Sensors with discrete event:

[7] – 1b = select deassertion event for state bit 7

[6] – 1b = select deassertion event for state bit 6

[5] – 1b = select deassertion event for state bit 5

[4] – 1b = select deassertion event for state bit 4

[3] – 1b = select deassertion event for state bit 3

[2] – 1b = select deassertion event for state bit 2

[1] – 1b = select deassertion event for state bit 1

[0] – 1b = select deassertion event for state bit 0

Hardware Platform Management 41

Page 52

6 For sensors with threshold base events:

[7:4] – reserved.

[3] – 1b = select deassertion event for upper non-recoverable going high

[2] – 1b = select deassertion event for upper non-recoverable going low

[1] – 1b = select deassertion event for upper critical going high

[0] – 1b = select deassertion event for upper critical going low

For sensors with discrete events:

[7] – reserved

[6] – 1b = select deassertion event for state bi t 14

[5] – 1b = select deassertion event for state bi t 13

[4] – 1b = select deassertion event for state bi t 12

[3] – 1b = select deassertion event for state bi t 11

[2] – 1b = select deassertion event for state bi t 10

[1] – 1b = select deassertion event for state bi t 9

[0] – 1b = select deassertion event for state bi t 8

Response Fields

1

Completion code

Get Sensor Event Enable

ipmitool ipmitool [parameters] sensor get <id>

Terminal

mode

Description

[10 00 28 01 00 00 00]

This command is used to get which sensor event is enable or no.

We can use ipmitool to get this information.

42 Hardware Platform Management

Page 53

Example:

root@BCNMB-A:~# ipmitool -I lan -H 172.20.5.225

-U admin -P admin sensor get "56150_TEMP "

Locating sensor record...

Sensor ID : 56150_TEMP (0x8)

Entity ID : 160.96

Sensor Type (Analog) : Temperature

Sensor Reading : 67 (+/- 0) degrees C

Status : Upper Non-Critical

Lower Non-Recoverable : na

Lower Critical : na

Lower Non-Critical : na

Upper Non-Critical : 60.000

Upper Critical : 75.000

Upper Non-Recoverable : 88.000

Assertion Events : unc+

Deassertion Events : lnc- lnc+ lcr- lcr+

lnr- lnr+ unc- ucr- ucr+ unr- unr+

Assertions Enabled : unc+ ucr+ unr+

Deassertions Enabled : unc+ ucr+ unr+

Request Fields

cPCI-6S10

1

Sensor number( FFh = reserved)

Response Fields

1

Completion code

2 [7] – 0b = All event messages disabled form this sensor

[6] – 0b = Sensor scanning disabled

[5:0] - reserved

Hardware Platform Management 43

Page 54

3 For sensors with threshold based events:

[7] – 1b = select assertion event for upper non-critical going high

[6] – 1b = select assertion event for upper non-critical going low

[5] – 1b = select assertion event for lower non-recoverable going high

[4] – 1b = select assertion event for lower non-recoverable going low

[3] – 1b = select assertion event for lower critical going high

[2] – 1b = select assertion event for lower critical going low

[1] – 1b = select assertion event for lower non-critical going high

[0] – 1b = select assertion event for lower non-critical going low

For Sensors with discrete event:

[7] – 1b = select assertion event for state bit 7

[6] – 1b = select assertion event for state bit 6

[5 – 1b = select assertion event for state bit 5

[4] – 1b = select assertion event for state bit 4

[3] – 1b = select assertion event for state bit 3

[2] – 1b = select assertion event for state bit 2

[1] – 1b = select assertion event for state bit 1

[0] – 1b = select assertion event for state bit 0

4 For sensors with threshold base events:

[7:4] – reserved.

[3] – 1b = select assertion event for upper non-recoverable going high

[2] – 1b = select assertion event for upper non-recoverable going low

[1] – 1b = select assertion event for upper critical going high

[0] – 1b = select assertion event for upper critical going low

For sensors with discrete events:

[7] – reserved

[6] – 1b = select assertion event for state bit 14

[5] – 1b = select assertion event for state bit 13

[4] – 1b = select assertion event for state bit 12

[3] – 1b = select assertion event for state bit 11

[2] – 1b = select assertion event for state bit 10

[1] – 1b = select assertion event for state bit 9

[0] – 1b = select assertion event for state bit 8

44 Hardware Platform Management

Page 55

5 For sensors with threshold based events:

[7] – 1b = select deassertion event for upper non-critical going high

[6] – 1b = select deassertion event for upper non-critical going low

[5] – 1b = select deassertion event for lower non-recoverable going high

[4] – 1b = select deassertion event for lower non-recoverable going low

[3] – 1b = select deassertion event for lower critical going high

[2] – 1b = select deassertion event for lower critical going low

[1] – 1b = select deassertion event for lower non-critical going high

[0] – 1b = select deassertion event for lower non-critical going low

For Sensors with discrete event:

[7] – 1b = select deassertion event for state bit 7

[6] – 1b = select deassertion event for state bit 6

[5] – 1b = select deassertion event for state bit 5

[4] – 1b = select deassertion event for state bit 4

[3] – 1b = select deassertion event for state bit 3

[2] – 1b = select deassertion event for state bit 2

[1] – 1b = select deassertion event for state bit 1

[0] – 1b = select deassertion event for state bit 0

6 For sensors with threshold base events:

[7:4] – reserved.

[3] – 1b = select deassertion event for upper non-recoverable going high

[2] – 1b = select deassertion event for upper non-recoverable going low

[1] – 1b = select deassertion event for upper critical going high

[0] – 1b = select deassertion event for upper critical going low

cPCI-6S10

For sensors with discrete events:

[7] – reserved

[6] – 1b = select deassertion event for state bit 14

[5] – 1b = select deassertion event for state bit 13

[4] – 1b = select deassertion event for state bit 12

[3] – 1b = select deassertion event for state bit 11

[2] – 1b = select deassertion event for state bit 10

[1] – 1b = select deassertion event for state bit 9

[0] – 1b = select deassertion event for state bit 8

Hardware Platform Management 45

Page 56

Re-arm Sensor Event

ipmitool ipmitool [parameters] raw 0x04 0x2a 0x01 0x00

Terminal

mode

Description This command is used to re-arm a sensor.

[10 00 2a 01 00]

Request Fields

1

sensor number (FFh = reserved)

2 [7] - 0b = re-arm all event status from this sensor. If 0, following

parameter

bytes are ignored, but should still be written as 0, if sent.

[6:0] - reserved. Write as 000_0000b.

(3)* For sensors with threshold based events:

[7] - 1b = re-arm assertion event for upper non-critical going high

[6] - 1b = re-arm assertion event for upper non-critical going low

[5] - 1b = re-arm assertion event for lower non-recoverable going

high

[4] - 1b = re-arm assertion event for lower non-recoverable going low

[3] - 1b = re-arm assertion event for lower critical going high

[2] - 1b = re-arm assertion event for lower critical going low

[1] - 1b = re-arm assertion event for lower non-critical going high

[0] - 1b = re-arm assertion event for lower non-critical going low

For sensors with discrete events :

[7] - 1b = re-arm assertion event for state bit 7

[6] - 1b = re-arm assertion event for state bit 6

[5] - 1b = re-arm assertion event for state bit 5

[4] - 1b = re-arm assertion event for state bit 4

[3] - 1b = re-arm assertion event for state bit 3

[2] - 1b = re-arm assertion event for state bit 2

[1] - 1b = re-arm assertion event for state bit 1

[0] - 1b = re-arm assertion event for state bit 0

46 Hardware Platform Management

Page 57

(4)* For sensors with threshold based events:

[7:4] - reserved. Write as 0000b.

[3] - 1b = re-arm assertion event for upper non-recoverable going

high

[2] - 1b = re-arm assertion event for upper non-recoverable going

low

[1] - 1b = re-arm assertion event for upper critical going high

[0] - 1b = re-arm assertion event for upper critical going low

For sensors with discrete events:

(00h otherwise)

[7] - reserved. Ignore on read.

[6] - 1b = re-arm assertion event for state bit 14

[5] - 1b = re-arm assertion event for state bit 13

[4] - 1b = re-arm assertion event for state bit 12

[3] - 1b = re-arm assertion event for state bit 11

[2] - 1b = re-arm assertion event for state bit 10

[1] - 1b = re-arm assertion event for state bit 9

[0] - 1b = re-arm assertion event for state bit 8

(5)* For sensors with threshold based events:

[7] - 1b = re-arm deassertion event for upper non-critical going high

[6] - 1b = re-arm deassertion event for upper non-critical going low

[5] - 1b = re-arm deassertion event for lower non-recoverable going

high

[4] - 1b = re-arm deassertion event for lower non-recoverable going

low

[3] - 1b = re-arm deassertion event for lower critical going high

[2] - 1b = re-arm deassertion event for lower critical going low

[1] - 1b = re-arm deassertion event for lower non-critical going high

[0] - 1b = re-arm deassertion event for lower non-critical going low

For sensors with discrete events:

(00h otherwise)

[7] - 1b = re-arm deassertion event for state bit 7

[6] - 1b = re-arm deassertion event for state bit 6

[5] - 1b = re-arm deassertion event for state bit 5

[4] - 1b = re-arm deassertion event for state bit 4

[3] - 1b = re-arm deassertion event for state bit 3

[2] - 1b = re-arm deassertion event for state bit 2

[1] - 1b = re-arm deassertion event for state bit 1

[0] - 1b = re-arm deassertion event for state bit 0

cPCI-6S10

Hardware Platform Management 47

Page 58

(6)* For sensors with threshold based events:

[7:4] - reserved. Write as 0000b.

[3] - 1b = re-arm deassertion event for upper non-recoverable going

high

[2] - 1b = re-arm deassertion event for upper non-recoverable going

low

[1] - 1b = re-arm deassertion event for upper critical going high

[0] - 1b = re-arm deassertion event for upper critic al go i ng lo w

For sensors with discrete events :

(00h otherwise)

[7] - reserved. Ignore on read.

[6] - 1b = re-arm deassertion event for state bit 14

[5] - 1b = re-arm deassertion event for state bit 13

[4] - 1b = re-arm deassertion event for state bit 12

[3] - 1b = re-arm deassertion event for state bit 11

[2] - 1b = re-arm deassertion event for state bit 10

[1] - 1b = re-arm deassertion event for state bit 9

[0] - 1b = re-arm deassertion event for state bit 8

Response Fields

1

Completion code

Get Sensor Reading

ipmitool ipmitool [parameters] sensor get <id>

Terminal

mode

Description

[10 00 2d 01]

This command is used to get sensor reading.

We can use ipmitool to read each sensor’s reading value.

Example: Get Tmp421 sensor reading

48 Hardware Platform Management

Page 59

root@BCNMB-A:~# ipmitool -I lan -H 172.20.5.225

-U admin -P admin sensor get "56150_TEMP "

Locating sensor record...

Sensor ID : 56150_TEMP (0x8)

Entity ID : 160.96

Sensor Type (Analog) : Temperature

Sensor Reading : 67 (+/- 0) degrees C

Status : Upper Non-Critical

Lower Non-Recoverable : na

Lower Critical : na

Lower Non-Critical : na

Upper Non-Critical : 60.000

Upper Critical : 75.000

Upper Non-Recoverable : 88.000

Assertion Events : unc+

Deassertion Events : lnc- lnc+ lcr- lcr+

lnr- lnr+ unc- ucr- ucr+ unr- unr+

Assertions Enabled : unc+ ucr+ unr+

Deassertions Enabled : unc+ ucr+ unr+

Request Fields

cPCI-6S10

1

Sensor number( FFh = reserved)

Response Fields

1

Completion code

2

Sensor reading

3 [7] – 0b = all event messages disabled form this sensor

[6] – 0b = sensor scaling disabled

[5] – 1b = reading/state unavailable

[4:0] – reserved

Hardware Platform Management 49

Page 60

4 For threshold-base sensors

Present threshold comparison status

[7:6] – reserved

[5] – 1b = at or above (>=) upper non-recoverable threshold

[4] – 1b = at or above (>=) upper critical threshold

[3] – 1b = at or above (>=) upper non- critical threshold

[2] – 1b = at or above (<=) lower non- recoverable threshold

[1] – 1b = at or above (<=)lower critical threshold

[0] – 1b = at or above (<=)lower non- critical threshold

For discrete reading sensors

[7] – 1b = state 7 asserted

[6] – 1b = state 6 asserted

[5] – 1b = state 5 asserted

[4] – 1b = state 4 asserted

[3] – 1b = state 3 asserted

[2] – 1b = state 2 asserted

[1] – 1b = state 1 asserted

[0] – 1b = state 0 asserted

5 For discrete reading sensors only( optional)

[7] – reserved

[6] – 1b = state 14 asserted

[5] – 1b = state 13 asserted

[4] – 1b = state 12 asserted

[3] – 1b = state 11 asserted

[2] – 1b = state 10 asserted

[1] – 1b = state 9 asserted

[0] – 1b = state 8 asserted

Get Sensor Type

ipmitool ipmitool [parameters] sensor get <id>

Terminal

mode

Description

50 Hardware Platform Management

[10 00 2F 00]

This command is used to get sensor type.

We can use ipmitool to get this information

Page 61

Example:

root@BCNMB-A:~# ipmitool -I lan -H 172.20.5.226

-U admin -P admin sensor get "P1V "

Locating sensor record...

Sensor ID : P1V (0x2)

Entity ID : 3.96

Sensor Type (Analog) : Voltage

Sensor Reading : 1.005 (+/- 0) Volts

Status : ok

Lower Non-Recoverable : 0.945

Lower Critical : 0.965

Lower Non-Critical : 0.985

Upper Non-Critical : 1.105

Upper Critical : 1.125

Upper Non-Recoverable : 1.155

Assertion Events : lnc- lcr Deassertion Events : lnc+ lcr+ lnr- lnr+

unc- unc+ ucr- ucr+ unr- unr+

Assertions Enabled : lnc- lcr- lnr- unc+

ucr+ unr+

Deassertions Enabled : lnc- lcr- lnr- unc+

ucr+ unr+

Request Fields

cPCI-6S10

1

Sensor number( FFh = reserved)

Response Fields

1

Completion code

2

Sensor type

3 [7] – reserved

[6:0] – Event/Reading type code

Hardware Platform Management 51

Page 62

Get FRU Inventory Area Info

ipmitool Ipmitool [parameters] raw 0x0A 0x10 0x00

Terminal

mode

Description Get FRU inventory area info

Request Fields

1 FRU Device ID. ( FFh = reserved)

0 – CMM

32h – PSU1

33h – PSU2

Response Fields

1

Completion code

2

FRU inventory area size in bytes, LS byte

3

FRU inventory area size in bytes, MS byte

4 [7:1] – reserved

[0] – 0b = device is accessed by bytes

1b = device is accessed by words

Note: The command “Get FRU inventory area info” and “Read

FRU data” support customized design on this platform for PSU

FRU eeprom re-direction. However, “write FRU data” is not

acceptable for PSU.

[28 00 10 00]

Read FRU Data

ipmitool Ipmitool [parameters] raw 0x0A 0x11 0x00 0x00 0x00 0x08

Terminal

mode

Description Read FRU data

52 Hardware Platform Management

[28 00 11 00 00 00 08]

Page 63

cPCI-6S10

IPMItool Support:

IPMItool supports “read entire fru record” command. We can use

below command to get entire fru command:

ipmitool fru read 0 fru-data.bin

Then fru with id 0 will save to file fru-data.bin

Example:

IPMC

root@BCNMB-A:~# ipmitool fru read 0

fru-data.bin

Fru Size : 512 bytes

Done

We can print all fru:

root@BCNMB-A:~# ipmitool fru

Board Mfg Date : Tue Sep 16 20:00:00 2014

Board Mfg : ADLINK Technology

Board Product : cPCI-6S10

Board Serial : ADLINK-XXXX-XXXX

Board Part Number : cPCI-6S10

Product Manufacturer: ADLINK Technology

Product Name : cPCI-6S10

Product Part Number : cPCI-6S10

Product Version : A2

Product Serial : ADLINK-XXXX-XXXX

Product Asset Tag : N/A

Request Fields

1 FRU Device ID. ( FFh = reserved)

0 – CMM

32h – PSU1

33h – PSU2

2

FRU inventory offset to read, LS Byte

3

FRU inventory offset to read, MS Byte

4

Count to read – count is ‘1’ based

Hardware Platform Management 53

Page 64

Response Fields

1

Completion code

2

Count returned – count is ‘1’ based

3:2+N

Requested data

Note: The command “Get FRU inventory area info” and “Read

FRU data” support customized design on this platform for PSU

FRU eeprom re-direction. However, “write FRU data” is not

acceptable for PSUs.

[root@iProc /root]# ipmitool -I lan -H 127.0.0.1

-U admin -P admin raw 0xa 0x11 0x0 0x0 0x0

8

08 01 00 01 0c 13 19 00 c6

Write FRU Data

ipmitool Ipmitool [parameters] raw 0x0A 0x12 0x00 0x00 0x00 0x01

Terminal

mode

Description

[28 00 12 00 00 00 01]

This command is used to write raw FRU data to eeprom.

We can use ipmitool to write data more easy.

IPMItool Support:

We can use ipmitool to write entire FRU record.

ipmitool fru write 0 fru-data.bin

Additionally, we can write raw data to eeprom:

ipmitool fru 0 field <section> <index> <string>

<section>: is a string which refers to FRU

Inventory Information

Storage Areas and may be referring to:

c FRU Inventory Chassis Info Area

b FRU Inventory Board Info Area

p FRU Inventory Product Info Area

<index>: specifies the field number. Field

numbering starts on the first ’English text’

54 Hardware Platform Management

Page 65

field type. For instance in the <board> info

area field ’0’ is <Board Manufacturer> and

field ’2’ is <Board Serial Number>; see IPMI

Platform Management FRU Information Storage

Definition v1.0 R1.1 for field locations.

<string> must be the same length as the string

being replaced and must be 8-bit ASCII

(0xCx).

Request Fields

1

FRU Device ID. ( FFh = reserved)

2

FRU inventory offset to read, LS Byte

3

FRU inventory offset to read, MS Byte

4:3+N

Data to write

Response Fields

1

Completion code

2

Count written – count is 1 based

cPCI-6S10

Get SDR Repository Info

ipmitool ipmitool [parameters] sdr info

Terminal

mode

Description Get SDR repository information

Hardware Platform Management 55

[28 00 20]

Page 66

root@BCNMB-A:~# ipmitool -I lan -H 127.0.0.1 -U

admin -P admin sdr info

SDR Version : 0x51

Record Count : 117

Free Space : 33016 bytes

Most recent Addition :

Most recent Erase :

SDR overflow : no

SDR Repository Update Support : non-modal

Delete SDR supported : yes

Partial Add SDR supported : yes

Reserve SDR repository supported : yes

SDR Repository Alloc info supported : yes

Response Fields

1

Completion code

2 SDR Version - version number of the SDR command set for the SDR

Device.

51h for this specification. (BCD encoded with bits 7:4 holding the Least

Significant digit of the revision and bits 3:0 holding the Most Significant

bits.)

3

Record count LS Byte - number of records in the SDR Repository

4

Record count MS Byte - number of records in the SDR Repository

5:6 Free Space in bytes, LS Byte first. 0000h indicates ‘full’, FFFEh

indicates

64KB-2 or more available. FFFFh indicates ‘unspecified’.

7:10

Most recent addition timestamp. LS byte first.

11:14

Most recent erase (delete or clear) timestamp. LS byte first.

56 Hardware Platform Management

Page 67

15 Operation Support

[7] - Overflow Flag. 1=SDR could not be written due to lack of space in

the

SDR Repository.

[6:5] - 00b = modal/non-modal SDR Repository Update operation

unspecified

01b = non-modal SDR Repository Update operation supported

10b = modal SDR Repository Update operation supported

11b = both modal and non-modal SDR Repository Update supported

[4] - reserved. Write as 0b

[3] - 1b=Delete SDR command supported

[2] - 1b=Partial Add SDR command supported

[1] - 1b=Reserve SDR Repository command supported

[0] - 1b=Get SDR Repository Allocation Information command

supported

Get SDR

ipmitool Ipmitool [parameters] raw 0xa 0x23

Terminal

mode

Description

[28 00 23]

Get a SDR record from repository

If get a partial SDR record, user should call “Reserve SDR

repository” to get a valid reservation id.

A partial get command means offset is not 0 or length is not 0xff.

A record id with 0x0000 is first record.

If a MC support both “Sensor Device” and “SDR repository

device”, “SDR repository device” will has been used first.

Ipmitool will check “Get_device_id” command to decide use

which SDR source.

cPCI-6S10

Hardware Platform Management 57

Page 68

Example:

Get SDR use raw command.

root@BCNMB-A:~# ipmitool -I lan -H 127.0.0.1 -U

admin -P admin raw 0xa 0x22

06 00

root@BCNMB-A:~# ipmitool -I lan -H 127.0.0.1 -U

admin -P admin raw 0xa 0x23 0x6 0x0 0 0 0

10

01 00 00 00 51 12 13 20 00 cc 29 00

List all SDR from IPMC (from Device SDR)

root@BCNMB-A:~# ipmitool -I lan -H 172.20.5.225

-U admin -P admin -t 0xB4 sdr list all

BMC_WatchDog | 0 unspecified | nc

POWER_GOOD | 0 unspecified | cr

P1V | 1.01 Volts | ok

P1V2 | 1.20 Volts | ok

P1V5 | 1.50 Volts | ok

P0V75 | 0.74 Volts | ok

+3.3V | 3.32 Volts | ok

+5.0V | 5.05 Volts | ok

54685_TEMP | 34 degrees C | ok

56150_TEMP | 47 degrees C | ok

Request Fields

1 Reservation ID. LS Byte. Only requi red for partial reads with a non-

zero ‘Offset into record’ field. Use 0000h for reservation ID

otherwise.

2

Reservation ID. MS Byte.

3

Record ID of record to Get, LS Byte

4

Record ID of record to Get, MS Byte

5

Offset into record

6

Bytes to read. FFh means read entire record.

58 Hardware Platform Management

Page 69

Response Fields

1

Completion code

2

Record ID for next record, LS Byte

3

Record ID for next record, MS Byte

4:N

Record Data

3.3 Controller Specific OEM/Group Commands

Show Card Version

ipmitool ipmitool [parameters] raw 0x30 0x12

Terminal

mode

Description Show 6S10 Card Version.

Request Data Fields

1

None

[C0 00 12]

cPCI-6S10

Response Data Fields

1

Completion Code

2

Predefined – A5h

3

‘V’– 56h (Version)

4

APP_FIRMWARE_REV (MSB)

5

APP_FIRMWARE_REV (LSB)

6

‘P’ –50h (Product)

7

APP_PRODUCT_ID(MSB)

8

APP_PRODUCT_ID(LSB)

9

‘S’ –53h

10

Reserved – 00h

Hardware Platform Management 59

Page 70

11

Predefined – 5Ah

Example:

Show Card Version

[root@iProc /root]#ipmitool raw 0x30 0x12

a5 56 01 02 50 53 13 53 00 5a

Re-Scan GA Input

ipmitool ipmitool [parameters] raw 0x30 0x22

Terminal

mode

Description Re-Scan the IPMB address from the HW GA Input

Example:

Use this command to read the Card’s IPMB address.

Request Data Fields

1

None

[C0 00 22]

[root@iProc /root]#ipmitool raw 0x30 0x22

b8

Response Data Fields

1

Completion Code

2

IPMB Address – xxh

Report Geography Address

ipmitool

Terminal

mode

description Get 6S10 Geography Address.

60 Hardware Platform Management

ipmitool [parameters] raw 0x30 0xF0

[C0 00 F0]

Page 71

Example:

Use this command to read the Card’s IPMB and Geography

Address.

[root@iProc /root]#ipmitool raw 0x30 0xF0

b8 03 01

Request Data Fields

1

None

Response Data Fields

1

Completion Code

2

IPMB Address – xxh

3

Geography Address – xxh

4

Reserved – 01h

Payload Power Reset

ipmitool ipmitool [parameters] raw 0x30 0xF5

Terminal

mode

Description Reset the Payload when it is in PowerOn state.

[C0 00 F5]

cPCI-6S10

Request Data Fields

1

None

Response Data Fields

1

Completion Code

2

None

Hardware Platform Management 61

Page 72

Power Off the Payload

ipmitool Ipmitool [parameters] raw 0x30 0xF6

Terminal

mode

Description Power Off the Payload.

[C0 00 F6]

Request Data Fields

1

None

Response Data Fields

1

Completion Code

Power On the Payload

ipmitool Ipmitool [parameters] raw 0x30 0xF7

Terminal

mode

Description Power On the Payload.

Request Data Fields

[C0 00 F7]

1

None

Response Data Fields

1

Completion Code

62 Hardware Platform Management

Page 73

Set Boot Flash

ipmitool Ipmitool [parameters] raw 0x30 0x15 0x0

Terminal

mode

Description Set the Boot Flash.

[C0 00 15 00]

Request Data Fields

1

Boot flash number – 0 (Flash #0)/1 (Flash #1)

Response Data Fields

1

Completion Code

Note: This command will not change the physical boot flash CS#

signal until a power-off cycle done.

Get Boot Flash

ipmitool Ipmitool [parameters] raw 0x30 0x16

Terminal

mode

Description Get the Boot Flash No.

[C0 00 16]

cPCI-6S10

Request Data Fields

1

None

Response Data Fields

1

Completion Code

2

Boot flash number – 0/1

Hardware Platform Management 63

Page 74

This page intentionally left blank.

64 Hardware Platform Management

Page 75

4 Getting Started

This chapter describes the installation of the cPCI-6S10:

4.1 Heatsink

The cPCI-6S10 comes with on board BGA BCM 56150 processor

and heatsink pre-installed. Removal of heatsink/CPU by users is not

recommended. Please contact your ADLINK service representative

for assistance.

Handle with caution as the heat sink can get very hot. Do not

touch the heat sink when installing or removing the board. The

CAUTION:

4.2 Installing the cPCI-6S10

Insert the cPCI-6S10 into a PICMG 2.16 backplane with a fabric

slot. The symbol for the switch slot is

board should not be placed on any surface or in any form of

storage container until the board and heat sink have cooled

down to room temperature.

cPCI-6S10

4.3 C onfiguring the cPCI-6S10

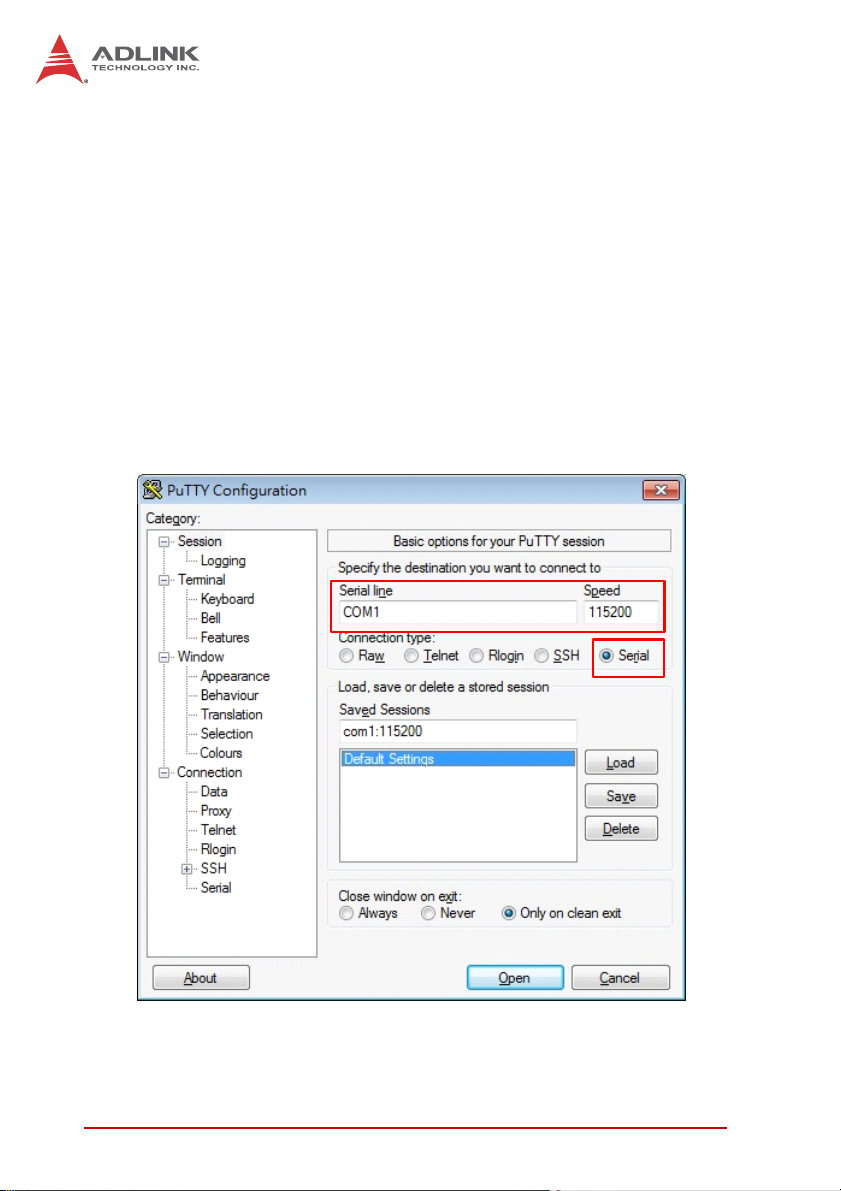

There is a serial port and management port at the front panel of

the cPCI-6S10. Both ports can be used to connect to the

cPCI-6S10 console. Follow the steps below.

User's can connect to the cPCI-6S10 console using "PuTTY".

Download PuTTY from http://www.putty.org. Run the program to

open the PuTTY configuration window.

Serial Port Connection

Connect the RJ-45 to DB-9 adapter cable to the COM port on the

front panel. Set "Serial line" to the COM port of the client PC.