Page 1

NuDAQ

6208/6216 Series

Multi-channel Analog Output Cards

User’s Guide

Recycle Paper

Page 2

Page 3

©Copyright 2002 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 3.22: September 13, 2002

Part No.: 50-12201-005

The information in this document is subject to change without prior notice

in order to improve reliability, design and function and does not represent

a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special,

incidental, or consequential damages arising out of the use or inability to

use the product or documentation, even if advised of the possibility of such

damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

NuDAQ, NuIPC, DAQBench are registered trademarks of ADLINK

Technology Inc.

Other product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered trademarks of

their respective companies.

Page 4

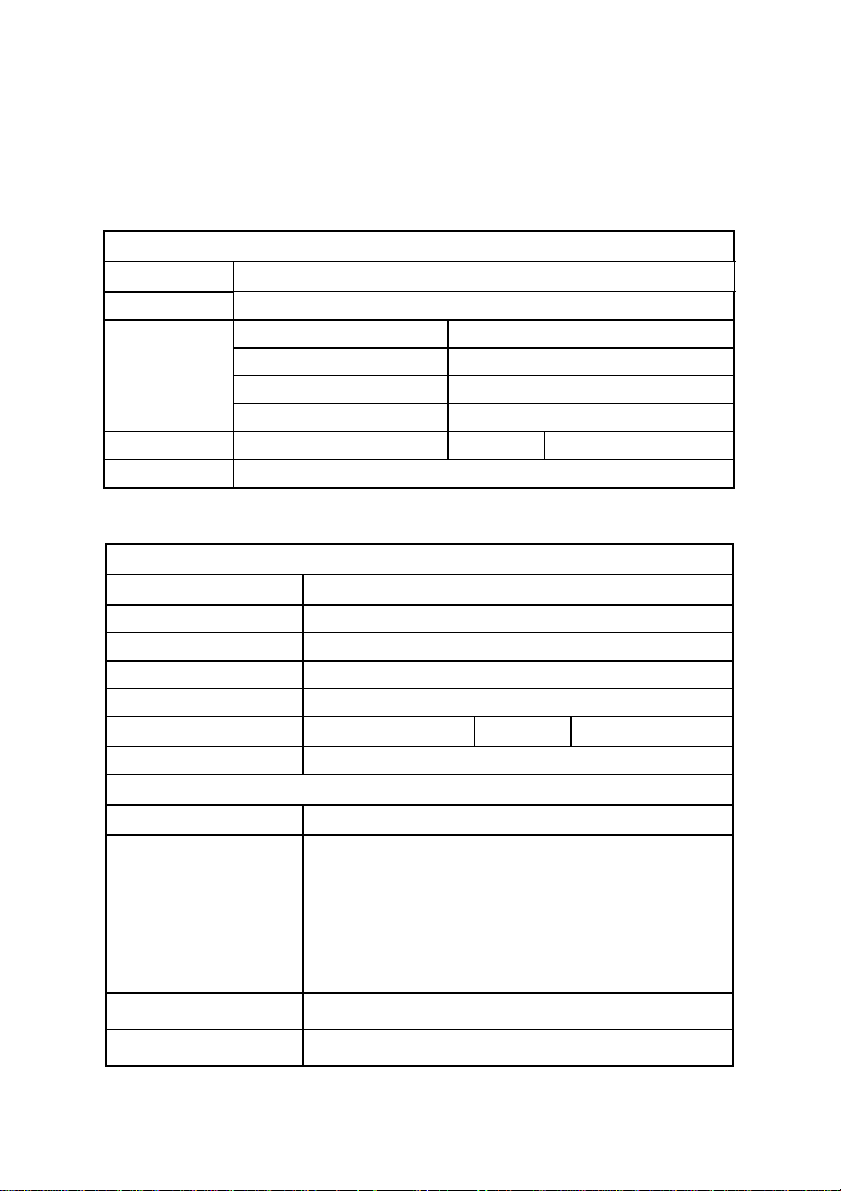

Getting service from ADLINK

• Customer Satisfaction is the most important priority for ADLINK Tech

Inc. If you need any help or service, please contact us.

ADLINK Technology Inc.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

NuDAQ + USBDAQ nudaq@adlinktech.com

Technical

Support

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan.

• Please email or FAX us of your detailed information for a prompt,

satisfactory and constant service.

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL

Web Site

Product Model

Environment to Use

Detail Description

Automation automation@adlinktech.com

NuIPC nuipc@adlinktech.com

NuPRO / EBC nupro@adlinktech.com

Detailed Company Information

FAX

Questions

OS:

Computer Brand:

M/B: CPU:

Chipset: BIOS:

Video Card:

Network Interface Card:

Other:

Suggestions to ADLINK

Page 5

Table of Contents

Tables and Figures ......................................................iii

How to Use This Guide................................................iv

Introduction...................................................................1

1.1 Features............................................................................. 2

1.2 Applications........................................................................ 2

1.3 Specifications..................................................................... 2

1.4 Supporting Software ..........................................................5

1.4.1 Programming Library........................................................ 5

1.4.2 PCIS-LVIEW: LabVIEW® Driver .......................................6

1.4.3 PCIS-VEE: HP-VEE Driver...............................................6

1.4.4 DAQBenchTM: ActiveX Controls........................................ 6

1.4.5 DASYLabTM PRO.............................................................. 6

1.4.6 PCIS-DDE: DDE Server and InTouchTM..........................6

1.4.7 PCIS-ISG: ISaGRAFTM driver ...........................................7

1.4.8 PCIS-ICL: InControlTM Driver............................................7

1.4.9 PCIS-OPC: OPC Server...................................................7

Getting Started..............................................................8

2.1 What You Have.................................................................. 8

2.2 Unpacking.......................................................................... 9

2.3 PCB Layout...................................................................... 10

2.4 Connector Pin Assignment ..............................................15

2.5 Hardware Installation Outline........................................... 16

2.6 Device Installation for Windows Systems........................ 17

2.7 Termination Board Connection........................................ 17

Registers......................................................................18

3.1 PCI PnP Registers........................................................... 18

3.2 I/O Address Map.............................................................. 19

3.3 Analog Output Status Register ........................................20

3.4 Digital Output Register..................................................... 20

3.5 Digital Input Register........................................................ 20

Table of Contents • i

Page 6

Operation Theory........................................................21

4.1 Voltage Output................................................................. 21

4.2 Current Output .................................................................22

C\C++ Library...............................................................23

5.1 Libraries Installation......................................................... 23

5.2 Programming Guide......................................................... 24

5.2.1 Naming Convention........................................................ 24

5.2.2 Data Types......................................................................24

5.3 _6208_Initial..................................................................... 25

5.4 _6208_Software_Reset ...................................................26

5.5 _6208_DA........................................................................ 27

5.6 _6208_Get_DA_Status.................................................... 28

5.7 _6208_DI.......................................................................... 29

5.8 _6208_DO........................................................................ 30

5.9 _6208_I2V_Control.......................................................... 31

Utility / Calibration ......................................................32

6.1 Running the 6208util.exe................................................. 32

6.1.1 Functional Testing...........................................................33

6.1.2 Calibration....................................................................... 34

6.2 Calibration of Analog Output Channel ............................. 35

6.2.1 What You Need...............................................................35

6.2.2 VR Assignment of cPCI/PCI-6208 and PCI-6216...........36

6.2.3 Voltage Output Calibration.............................................. 37

6.2.4 Current Output Calibration.............................................. 37

Warranty Policy...........................................................38

ii • Table of Contents

Page 7

Tables and Figures

Tables

Table 1. I/O Address Map .......................................................19

Table 2. Digital Value Vs Analog output voltage..................... 21

Table 3. Current Output and Range Control........................... 22

Table 4. Data types and it range............................................. 24

Table 5. VR Assignment.......................................................... 36

Figures

Figure 1: PCI-6208 REV: A3 Layout......................................... 10

Figure 2: PCI-6208 REV: B1 Layout......................................... 11

Figure 3: cPCI-6208 Layout...................................................... 12

Figure 4: cPCI-6208V/R Layout................................................ 13

Figure 5: cPCI-R6216DB Rear I/O Adapter for cPCI-6208V/R,

cPCI-6208A/R and cPCI-6216V/R............................ 14

Figure 6: cPCI-6208V(A)/R and cPCI-6216V/R Front Panel

(Left to Right)............................................................. 14

Figure 7: Pin Assignment of CN1 connector ............................ 15

Figure 8: Current Output Circuits.............................................. 22

Figure 9: Main selection Menu .................................................32

Figure 10: Function Testing Menu Window................................ 33

Figure 11: 6208V Testing Window ............................................. 33

Figure 12: 6208 Calibration Window .......................................... 34

Figure 13: Channel Selection Menu........................................... 35

Figure 14: Calibration Procedures Window................................ 35

Tables and Figures • iii

Page 8

How to Use This Guide

This manual is designed to help you use the 6208 series products. It

describes how to modify and control various functions of the products to

achieve your requirements. It is divided into six chapters:

Chapter 1, “Introduction”, gives an overview of the product

features, applications, and specifications.

Chapter 2, “Getting Started”, describes how to install the 6208

series products. The layout of 6208 series products is

shown, as well as the connectors’ specifications.

Chapter 3, “Registers”, describes the details of registers of the

6208 series product, the information is useful for the

programmers who want to control the hardware with

low-level programming.

Chapter 4, “Operation Theorem”, describes more detail concept

about 6208’s functions, including analog output and

range control systems.

Chapter 5, “Software Library”, describes the software libraries

for programming the 6208 series cards. The software

libraries for DOS and Windows 95 are provided. It

assist users program and control the 6208 series cards

with high-level programming languages.

Chapter 6, “Utility/Calibration”, describes how to run the utility

program included in the software CD. And how to

calibrate the 6208 series cards for accurate

measurements and operations.

iv • How to Use This Guide

Page 9

1

Introduction

The 6208 series products are multi-channel analog output cards. They

include the following three products:

• cPCI/PCI-6208V: 8-CH voltage output card for cPCI/PCI interface

• cPCI/PCI-6208A: 8-CH voltage and current output card for

cPCI/PCI interface

• PCI-6216V: 16-CH voltage output card for PCI interface

cPCI-6208V, PCI-6208V:

cPCI/PCI-6208V is a high-density analog output card with 8 identical

voltage output channels. Each channel is equipped with B.B PCM56U,

which is a state-of-the-art fully monotonic, digital to analog converter. This

device employs ultra-stable nichrome (NiCr) thin-film resistors to provide

monotonicity, low distortion, and low differential linearity error over long

period of time.

cPCI-6216V, PCI-6216V:

cPCI/PCI-6216V is a high-density analog voltage output card, it is a

combination of the cPCI/PCI-6208V series card and an EXP-8V daughter

board. The EXP-8V is an extension board, which includes 8 extra voltage

output channels.

cPCI-6208A, PCI-6208A:

cPCI/PCI-6208A is a high-density current source output card, it is a

combination of the cPCI/PCI-6208V and an EXP-8A daughter board. The

EXP-8A includes 8 precision voltage-to-current converters, which convert

voltage outputs from the cPCI/PCI-6028V to current sources.

Introduction • 1

Page 10

1.1 Features

• 32-bit cPCI/PCI-Bus, Plug and Play

• 16-bit high resolution voltage outputs

• Output Range: ±10V (14 -bit resolution guarantee) for cPCI/PCI-

6208V and PCI-6216V only

• Output Range: 0-20mA, 4-20mA, 5-25mA (14-bit resolution

guaranteed) for cPCI/PCI-6208A only

• Differential Linearity Error: 0.001% of FSR typical

• Fast 2 µs voltage settling time (-10V~+10V)

• On board DC-to-DC converter to provide stable power and

current source for analog outputs

1.2 Applications

• Industrial Process Control

• Pressure/Temperature Transmitter

• Current Source for Testing Equipment

• Function Generator

1.3 Specifications

Voltage Output

♦

• Numbers of channel:

P 8 channels for cPCI/PCI-6208V and cPCI/PCI- 6208A

P 16 channels for PCI-6216V

• Converter: B.B PCM56U or equivalent

• Conversion type: Monolithic multiplying

• Resolution: 16-bit (14-bit guarantee)

• Voltage output ranges: ±10V

• Voltage output driving capability: ± 5mA max.

• Settling time: 2µ second (-10V to +10V)

• Gain error: ± 0.2 % (max, without trimming)

2 • Introduction

Page 11

• Differential Linearity Error: ± 0.001 % Full Scale Range

• Output initial status: 0V (after RESET or POWER-ON)

• Data Transfer: Programmed I/O

Current Output

♦

• Numbers of channel: 8 channel for cPCI/PCI-6208A

• Current output range: (programmable) 0~20mA, 4~20mA,

5~25mA.

• Voltage to current converter: B.B XTR110 or equivalent

• Settling time: 17 µ second (from 0 to 20mA)

• Slew rate: 1.3 mA / µs

• Non-linearity: ± 0.01 % of Span

• Span error: 0.3% of initial Span

• Output resistance: 10x109 Ohms Typical

• Output initial status: 0mA (after RESET or POWER-ON)

Digital I/O

♦

• Channel: 4 TTL compatible inputs and outputs

• Input Voltage:

P Low: Min. 0V; Max. 0.8V

P High: Min. +2.0V; Max. 5.5V

• Input Load:

P Low: +0.8V @ -0.2mA max.

P High: +2.7V @ +20mA max.

• Output Voltage:

P Low: Min. 0V; Max. 0.4V

P High: Min. +2.4V; Max. 5.5V

• Driving Capacity:

P Low: Max. +0.5V at 8.0mA (Sink)

P High: Min. 2.7V at 0.4mA (Source)

Introduction • 3

Page 12

General Specifications

♦

• Operating temperature: 0° ~ 50°C

• Storage temperature: -20° ~ 80°C

• Humidity: 5~95% non-condensing

• Connector: 37-pin D-sub connector (female)

• Bus interface: 32-bit slave PCI bus

Power consumption:

♦

• PCI-6208V:

P +5VDC @ 580mA typical

P +12VDC @ 70mA typical

• PCI-6208A:

P +5VDC @ 670mA typical

P +12VDC @ 90mA typical or +12VDC @ 380mA (when all

current output channel is 20mA)

• PCI-6216V:

P +5VDC @ 1.20 typical

P +12VDC @ 110mA typical

• cPCI-6208V:

P +5VDC @ 560mA typical

P +12VDC @ 70mA typical

• cPCI-6208A:

P +5VDC @ 650mA typical

P +12VDC @ 90mA typical or +12VDC @ 370mA (when all

current output channel is 25mA)

PCB Dimension:

♦

• Half-sized

PCI series: 175 mm x 105 mm

P

cPCI series: 160 mm x 100 mm

P

4 • Introduction

Page 13

1.4 Supporting Software

ADLINK provides versatile software drivers and packages for users’

different approach to building a system. ADLINK not only provides

programming libraries such as DLL for most Windows based systems, but

also provide drivers for many software package such as LabVIEW®, HP

VEETM, DASYLabTM, InTouchTM, InControlTM, ISaGRAFTM, and so on.

All software options are included in the ADLINK CD. Non-free software

drivers are protected with licensing codes. Without the software code, you

can install and run the demo version for two hours for trial/demonstration

purposes. Please contact ADLINK dealers to purchase the formal license.

1.4.1 Programming Library

For customers who are writing their own programs, we provide function

libraries for many different operating systems, including:

• DOS Library: Borland C/C++ and Microsoft C++. Functional

descriptions are included in this user’s guide.

• Windows 95 DLL: For VB, VC++, Delphi, and BC5. Functional

descriptions are included in this user’s guide.

• PCIS-DASK: Include device drivers and DLL for Windows 98,

Windows NT and Windows 2000. DLL is binary compatible

across Windows 98, Windows NT and Windows 2000. That

means all applications developed with PCIS-DASK are

compatible across Windows 98, Windows NT and Windows

2000. The developing environment can be VB, VC++, Delphi,

BC5, or any Windows programming language that allows calls to

a DLL. The user’s guide and function reference manual of PCISDASK are in the CD. Please refer the PDF manual files under

\\Manual_PDF\Software\PCIS-DASK

• PCIS-DASK/X: Includes device drivers and shared libraries for

Linux. The developing environment can be Gnu C/C++ or any

programming language that allows linking to a shared library.

The user's guide and functional reference manual for the PCISDASK/X are in the CD. (\Manual_PDF\Software\PCIS-DASK-X.)

The above software drivers are shipped with the board. Please refer to

the “Software Installation Guide” for installation procedures.

Introduction • 5

Page 14

1.4.2 PCIS-LVIEW: LabVIEW® Driver

PCIS-LVIEW contains the VIs, which are used to interface with NI’s PCISLVIEW contains the VIs, which is used to interface with NI’s LabVIEW®

software package. The PCIS-LVIEW supports Windows 95/98/NT/2000.

The LabVIEW® drivers is shipped free with the board. You can install and

use them without a license. For more information about PCIS-LVIEW,

please refer to the user’s guide in the CD. (\\Manual_PDF\Software\PCISLVIEW).

1.4.3 PCIS-VEE: HP-VEE Driver

The PCIS-VEE includes user objects, which are used to interface with the

HP-VEE software package. PCIS-VEE supports Windows 95/98/NT. The

HP-VEE drivers are shipped free with the board. You can install and use

them without a license. For more information about PCIS-VEE, please

refer to the user’s guide in the CD. (\\Manual_PDF\Software\PCIS-VEE).

1.4.4 DAQBenchTM: ActiveX Controls

We suggest users who are familiar with ActiveX controls and VB/VC++

programming use the DAQBenchTM ActiveX Control components library

for developing applications. The DAQBenchTM is designed under Windows

NT/98. For more information about DAQBench, please refer to the user’s

guide in the CD. (\\Manual_PDF\Software\DAQBench\DAQBench

Manual.PDF)

1.4.5 DASYLabTM PRO

DASYLab is an easy-to-use software package, which provides easy

setup instrument functions such as FFT analysis. Please contact ADLINK

to purchase a copy of DASYLab PRO, which include DASYLab and

ADLINK hardware drivers.

1.4.6 PCIS-DDE: DDE Server and InTouchTM

DDE stands for Dynamic Data Exchange. The PCIS-DDE includes the PCI

cards’ DDE server. The PCIS-DDE server is free and is included in the

ADLINK CD. The DDE server can be used in conjunction with any DDE

client under Windows 98/NT/2000.

6 • Introduction

Page 15

1.4.7 PCIS-ISG: ISaGRAFTM driver

The ISaGRAF Workbench is an IEC1131-3 SoftPLC control development

environment. The PCIS-ISG includes ADLINK product drivers for

ISaGRAF under Windows NT environment. The PCIS-ISG is included in

the ADLINK CD. It is not free. Please contact ADLINK dealers or ADLINK

to purchase the license.

1.4.8 PCIS-ICL: InControlTM Driver

PCIS-ICL is the InControl drivers that support Windows NT. The PCISICL is included in the ADLINK CD. It needs license.

1.4.9 PCIS-OPC: OPC Server

PCIS-OPC is an OPC server, which can be used to link with other OPC

clients. There are many software packages on the market that can provide

the OPC clients. The PCIS-OPC supports Windows 98, NT, and 2000. It

is not free. Please contact ADLINK dealers or ADLINK to purchase the

license.

Introduction • 7

Page 16

2

Getting Started

This chapter describes how to install and setup the cPCI/PCI-6208. The

contents in the package and unpacking information that you should be

aware of are outlined first.

2.1 What You Have

In addition to the User’s Manual, the package should include the following

items:

• 6208 Series Card

• ADLINK CD

• Software Installation Guide

If any of these items are missing or damaged, contact ADLINK or the

dealer from whom you purchased the product. Save the shipping materials

and carton in case you want to ship or store the product in the future.

8 • Getting Started

Page 17

2.2 Unpacking

The 6208 card contains electro-static sensitive components that can be

easily be damaged by static electricity.

Therefore, the card should be handled on a grounded anti-static mat. The

operator should be wearing an anti-static wristband, grounded at the same

point as the anti-static mat.

Inspect the card module carton for obvious damages. Shipping and

handling may cause damage to your module. Be sure there are no

shipping and handling damages on the modules carton before continuing.

After opening the card module carton, extract the system module and

place it only on a grounded anti-static surface with component side up.

Again, inspect the module for damages. Press down on all the socketed

IC's to make sure that they are properly seated. Do this only with the

module place on a firm flat surface.

Note: DO NOT ATTEMPT TO INSTALL A DAMAGED BOARD IN THE

COMPUTER.

You are now ready to install your card.

Getting Started • 9

Page 18

2.3 PCB Layout

10 • Getting Started

Figure 1: PCI-6208 REV: A3 Layout

Page 19

Figure 2: PCI-6208 REV: B1 Layout

Converter

Optional

DC-DC

Getting Started • 11

Page 20

12 • Getting Started

Figure 3: cPCI-6208 Layout

Page 21

Figure 4: cPCI-6208V/R Layout

Getting Started • 13

Page 22

Figure 5: cPCI-R6216DB Rear I/O Adapter for cPCI-6208V/R, cPCI-

6208A/R and cPCI-6216V/R

Figure 6: cPCI-6208V(A)/R and cPCI-6216V/R Front Panel (Left to Right)

14 • Getting Started

Page 23

2.4 Connector Pin Assignment

+5V

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

The pin assignment of the 6208 series card is shown in Figure 2.2

DI3

DI2

DI1

DI0

GND

+15V

A.GND

V14(A6)

V12(A4)

V10(A2)

V6

A.GND

V4

A.GND

V2

A.GND

V8(A0)

V0

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

Figure 7: Pin Assignment of CN1 connector

The analog output pin are specified as Vn or An, where

Vn: Means the voltage output of channel number n.

For cPCI/PCI-6208V, n=0~7

For PCI-6216V, n =0~15

An: Means the current output of channel number n

For cPCI/PCI-6208A only, n =0~7

The digital input and output pin names are specified as DIn and DOn

respectively, where n =0~3.

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

(28)

(29)

(30)

(31)

(32)

(33)

(34)

(35)

(36)

(37)

DO3

DO2

DO1

DO0

GND

-15V

A.GND

V15(A7)

V7

A.GND

V13(A5)

V5

A.GND

V11(A3)

V3

A.GND

V9(A1)

V1

Getting Started • 15

Page 24

2.5 Hardware Installation Outline

Hardware configuration

The PCI cards (or CompactPCI cards) are equipped with plug and play

PCI controllers, it can request base addresses and interrupts according to

the PCI standard. The system BIOS will assign the system resources

based on the PCI cards’ configuration registers and system parameters

(which are set by the system BIOS). Interrupt assignment and memory

usage (I/O port locations) can only be assigned by the system BIOS.

These system resource assignments are done on a board-by-board basis.

It is not suggested to assign the system resource by any other methods.

PCI slot selection

The PCI card can be inserted into any PCI slot without any configuration of

the system resources. The CompactPCI card can also be inserted into

any CompactPCI I/O slot.

Installation Procedures

1. Turn off your computer

2. Turn off all accessories (printer, modem, monitor, etc.) connected

to your computer.

3. Remove the cover from your computer.

4. Setup jumpers on the PCI or CompactPCI card.

5. Select a 32-bit PCI slot. PCI slot are shorter than ISA or EISA slots,

and are usually white or ivory.

6. Before handling the PCI cards, discharge any static buildup on

your body by touching the metal case of the computer. Hold the

edge and do not touch the components.

7. Position the board into the PCI slot you selected.

8. Secure the card in place at the rear panel of the system.

16 • Getting Started

Page 25

2.6 Device Installation for Windows Systems

Once Windows 95/98/2000 has started, the Plug and Play functions of the

Windows system will find and locate the new NuDAQ/NuIPC card. If this is

the first time a NuDAQ/NuIPC card is installed in your Windows system,

you will be prompted to input the device information source. Please refer

to the “Software Installation Guide” for installation procedures of the

device drivers.

2.7 Termination Board Connection

The 6208 series boards are equipped with a DB-37 connector. The

available termination boards include:

ACLD-9137: A general purposed 37-pin screw terminal. The ACLD-9137

is designed with a male DB-37 connector, which is used to

directly attach to the PCI-6208.

ACLD-9188: A general purposed 37-pin screw terminal, which is equipped

with heavy-duty screw terminal

DIN-37D: A general purposed 37-pin screw terminal with a DIN-socket.

DIN-37D is shipped with a 37-pin cable

Getting Started • 17

Page 26

3

Registers

The detailed descriptions of the registers format are specified in this

chapter. This information is quite useful for the programmers who wish to

handle the card by low-level programming. However, we suggest user

have to understand more about the PCI interface then start any low-level

programming. In addition, the contents of this chapter can help users

understand how to use software driver to manipulate this card.

3.1 PCI PnP Registers

This PCI card functions as a 32-bit PCI target device to any master on the

PCI bus. There are three types of registers: PCI Configuration Registers

(PCR), Local Configuration Registers (LCR) and PCI-6208 registers.

The PCR, which is PCI-bus specifications compliant, is initialized and

controlled by the plug & play (PnP) PCI BIOS. Users may obtain more

information on the PCI BIOS specification to better understand the

operation of the PCR. Please contact PCISIG to acquire the specifications

of the PCI interface.

The PCI bus controller PCI-9050 is provided by PLX technology Inc.

(www.plxtech.com). For more information about the LCR, please visit PLX

technology’s web site to download relative information. It is not necessary

for users to fully understand the details of the LCR if the software library

provided is used. The PCI PnP BIOS assigns the base address of the

LCR. The assigned address is located at an offset of 14h from the PCR.

The PCI-6208 registers are discussed in the next section. The base

address, which is also assigned by the PCI PnP BIOS, is located at an

offset of 18h from the PCR. Therefore, users can read the address 18h

from the PCR to obtain its base address by using the BIOS function call.

Do not attempt to modify the base address and interrupt that have been

assigned by the PCI PnP BIOS, it may cause resource conflicts with your

system.

18 • Registers

Page 27

3.2 I/O Address Map

Depending on which card is used, either the cPCI/PCI-6208V or PCI6216V, there are 8 or 16 voltage output channels respectively. For the

cPCI/PCI-6208A, there are 8 voltage and current output channels; the

voltage output controls the current source. The programming methods of

all analog output channels are identical. For the three different models of

the analog output cPCI/PCI cards, the programming methods are

compatible.

The 6208 registers are all 16 bits. Users can access these registers with

16-bit I/O instructions. The following table shows the address of every

analog output port relative to the base address. Note that the base

address is assigned by the PCI BIOS. The current output control for the

cPCI/PCI-6208A is described in Section 3.4.

Offset

Address

0x00 V0 V0 V0 / A0

0x02 V1 V1 V1 / A1

0x04 V2 V2 V2 / A2

0x06 V3 V3 V3 / A3

0x08 V4 V4 V4 / A4

0x0A V5 V5 V5 / A5

0x0C V6 V6 V6 / A6

0x0E V7 V7 V7 / A7

0x10 -- V8 -0x12 -- V9 -0x14 -- V10 -0x16 -- V11 -0x18 -- V12 -0x1A -- V13 --

0x1C -- V14 --

0x1E -- V15 --

CPCI/PCI-

6208V

Table 1. I/O Address Map

PCI-6216V

cPCI/PCI-

6208A

Registers • 19

Page 28

3.3 Analog Output Status Register

The DAC uses a series bus architecture hence it will take time for digital

value to be sent out. The data transfer rate for every DA data write takes

2.2µs, therefore the software driver must wait 2.2µs before sending any

other data to any analog output port. While the DA value is sending, the

Data_Send bit is ‘H’. The software driver should check this bit before

writing any data to the output port. This register is read only.

Offset Address D16~D1 D0

0x00 X Data_Send

3.4 Digital Output Register

D0~D3 is the digital output signal written to the output channels. D4~D7

are don’t cares.

Offset Address D7 D6 D5 D4 D3 D2 D1 D0

0x40 X X X X DO3 DO2 DO1 DO0

3.5 Digital Input Register

D4~D7 is digital input signal from CN1.

D0~D3 is read back signal from digital output channel.

Offset Address D7 D6 D5 D4 D3 D2 D1 D0

0x40 DI3 DI2 DI1 DI0 DO3 DO2 DO1 DO0

20 • Registers

Page 29

4

Operation Theory

In this chapter, the operation theory of the 6208 series cards is described.

Before programming or applying the 6208 series cards to your applications,

please go through this chapter to understand the features of the functions.

4.1 Voltage Output

The DA converter used in the cPCI/PCI-6208 is a Burr-Brown PCM-56U.

The DAC has a 16-bit resolution with bi-polar output. The voltage output

range is +/-10V. Therefore, the data registers are all 16-bits sign values.

The digital value ranges from -32768 (0X8000) to +32767 (0x7FFF)

corresponding to -10 Volt to +10 Volt. Table 2 shows the relation between

the digital value and the analog output voltage.

Digital Value HEX value Output Voltage

32767 0x7FFF +9.99969V

16384 0x4000 +5.00000V

8192 0x2000 +2.50000V

1 0x0001 0.00031V

0 0x0000 0.00000V

-1 0xFFFF -0.00031V

-8192 0xE000 -2.50000V

-16384 0xC000 -5.00000V

-32767 0x8001 -9.99969V

-32768 0x8000 -10.00000V

Table 2. Digital Value Vs Analog output voltage

Operation Theory • 21

Page 30

4.2 Current Output

The precision voltage-to-current converter XTR110 implements the current

output. The current output channel n (An) is control by the voltage of

channel n (Vn). The block diagram of the current output channels is shown

in Fig 5.

Figure 8: Current Output Circuits

The cPCI/PCI-6208A provides an on board +15V power supply. Each

current output channel is a current source, which is controlled by the

voltage of the corresponding channel. For example, voltage output

channel 3 control the current source of channel 3. The output current

range is programmable. All 8 current channels on the cPCI/PCI-6208A are

controlled by one control register. The control voltage range is always unipolar 0~10V. There are three kinds of output current ranges. Refer to the

following table and Section 5.2.8 for programming information.

Mode

1 0~10V 0~20 mA

2 0~10V 4~20 mA

3 0~10V 5~25 mA

Table 3. Current Output and Range Control

Caution: The Current Output Module accepts only POSITIVE control

voltage; applying negative voltage may permanently damage the

module or your device.

22 • Operation Theory

Input Voltage

Range

Output Current

Range

Page 31

5

C\C++ Library

This chapter describes the software libraries for operating this card. Only

the functions in the DOS library and Windows 95 DLL are described.

Please refer to the PCIS-DASK function reference manual, which is

included in the ADLINK CD, for descriptions of Windows 98/NT/2000 DLL

functions.

The function prototypes and useful constants are defined in the header

files located in LIB (DOS) and INCLUDE (Windows 95) directories. For

Windows 95 DLL, the developing environment can be Visual Basic 4.0 or

above, Visual C/C++ 4.0 or above, Borland C++ 5.0 or above, Borland

Delphi 2.x (32-bit) or above, or any Windows programming language that

allows calls to a DLL.

5.1 Libraries Installation

Please refer to the “Software Installation Guide” for information

regarding how to install the software libraries for DOS, Windows 95 DLL,

or PCIS-DASK for Windows 98/NT/2000.

The device drivers and DLL functions for Windows 98/NT/2000 are

included in the PCIS-DASK. Please refer to the PCIS-DASK user’s guide

and function reference, which is included in the ADLINK CD, for

programming information.

C/C++ Library • 23

Page 32

5.2 Programming Guide

5.2.1 Naming Convention

The functions of the NuDAQ PCI or NuIPC CompactPCI card software

drivers uses full-names to represent the functions' real meaning. The

naming convention rules are:

In DOS Environment:

_{hardware_model}_{action_name}. e.g. _6208_Initial().

All functions in the PCI-6208 driver uses 6208 as {hardware_model}

In order to recognize the differences between DOS library and Windows

95 library, a capital "W" is placed at the start of each function name for

Windows 95 DLL drivers, e.g. W_9112_Initial().

5.2.2 Data Types

We have defined some data type in Pci_6208.h (DOS) and Acl_pci.h

(Windows 95). These data types are used by NuDAQ Cards’ library. We

suggest you to use these data types in your application programs. The

following table shows the data type names and their range.

Type Name

U8 8-bit ASCII character 0 to 255

I16 16-bit signed integer -32768 to 32767

U16 16-bit unsigned integer 0 to 65535

I32 32-bit signed integer -2147483648 to 2147483647

U32

F32

F64

Boolean Boolean logic value TRUE, FALSE

24 • C/C++ Library

Description Range

32-bit single-precision

floating-point

32-bit single-precision

floating-point

64-bit double-precision

floating-point

Table 4. Data types and it range

0 to 4294967295

-3.402823E38 to 3.402823E38

-1.797683134862315E308 to

1.797683134862315E309

Page 33

5.3 _6208_Initial

@ Description

This function is used to initialize the 6208 series cards. You must call

this function to initialize all 6208 series cards plugged into your system

first, before calls to other function to perform operations on the cards

can proceed.

@ Syntax

C/C++ (DOS)

U16 _6208_Initial (U16 *existCards, PCI_INFO

*pciInfo)

C/C++ (Windows 95)

U16 W_6208_Initial (U16 *existCards, PCI_INFO

*pciInfo)

Visual Basic (Windows 95)

W_6208_Initial (existCards As Integer, pciInfo

As PCI_INFO) As Integer

@ Argument

existCards: number of 6208 cards inserted

pciinfo: relative information of the 6208 cards

@ Return Code

ERR_NoError

ERR_BoardNoInit

ERR_PCIBiosNotExist

C/C++ Library • 25

Page 34

5.4 _6208_Software_Reset

@ Description

This function is used to reset the I/O ports configuration. Note that this

function will not re-start the PCI bus and all the hardware settings won’t

be changed either.

@ Syntax

C/C++ (DOS)

void _6208_Software_Reset (U16 cardNo)

C/C++ (Windows 95)

void W_6208_Software_Reset (U16 cardNo)

Visual Basic (Windows 95)

W_6208_Software_Reset (ByVal cardNo As Integer)

@ Argument

cardNo: The card number of the 6208 card

initialized. (The first card in the most

significant PCI slot is assign cardNo = 0).

@ Return Code

ERR_NoError

26 • C/C++ Library

Page 35

5.5 _6208_DA

@ Description

This function is used to write data to the D/A converters. There are 8 or

16 Digital-to-Analog conversion channels depending on which card is

used. The resolution of each channel is 16 bits with sign; i.e. the digital

value range from -32768 (0x8000) to +32767 (0x7FFF).

@ Syntax

C/C++ (DOS)

U16 _6208_DA (U16 cardNo, U16 chn, I16 DAData)

C/C++ (Windows 95)

U16 W_6208_DA (U16 cardNo, U16 chn, I16

DAData)

Visual Basic (Windows 95)

W_6208_DA (ByVal cardNo As Integer, ByVal chn

As Integer, ByVal DAData As Integer) As Integer

@ Argument

cardNo: The card number of the 6208 card

initialized. (The first card in the most

significant PCI slot is assign cardNo = 0).

Chn: D/A channel number

DAData: D/A converted value

@ Return Code

ERR_NoError

C/C++ Library • 27

Page 36

5.6 _6208_Get_DA_Status

@ Description

This function is used to check the DA data sending status. Because the

data transfer time for every DA data takes 2.2 µs, the software driver

must hold for 2.2µs before sending more data to any of the analog

output ports. This function should be called before writing any data to

the output port. While the DA value is sending, the returned value is “1”,

otherwise the returned value is “0”.

@ Syntax

C/C++ (DOS)

U16 _6208_Get_DA_Status (U16 cardNo)

C/C++ (Windows 95)

U16 W_6208_Get_DA_Status (U16 cardNo)

Visual Basic (Windows 95)

W_6208_Get_DA_Status (ByVal cardNo As Integer)

As Integer

@ Argument

cardNo: The card number of the 6208 card

initialized. (The first card in the most

significant PCI slot is assign cardNo = 0).

@ Return Code

0 (low): no DA value is sending

1 (high): the DA value is sending

28 • C/C++ Library

Page 37

5.7 _6208_DI

@ Description

This function is used to read data from the digital input ports. There are

4 digital input channels on the 6208 series cards. The retrieved value is

stored in DIData. However the returned value needs to be further

process by including the following code in your program: DIData =

(DIData & 0xF0) >> 4

@ Syntax

C/C++ (DOS)

U16 _6208_DI (U16 cardNo, U16 *DIData)

C/C++ (Windows 95)

U16 W_6208_DI (U16 cardNo, U16 *DIData)

Visual Basic (Windows 95)

W_6208_DI (ByVal cardNo As Integer, DIData As

Integer) As Integer

@ Argument

cardNo: The card number of the 6208 card

initialized. (The first card in the most

significant PCI slot is assign cardNo = 0).

DIData: the value read from the digital input

port, please refer to the above descriptive

paragraph to obtain the correct DI data

@ Return Code

ERR_NoError

C/C++ Library • 29

Page 38

5.8 _6208_DO

@ Description

This function is used to write data to digital output ports. There are 4

digital output channels on 6208 series card, i.e. the output value ranges

from 0 to 15.

@ Syntax

C/C++ (DOS)

U16 _6208_DO (U16 cardNo, U16 DOData)

C/C++ (Windows 95)

U16 W_6208_DO (U16 cardNo, U16 DOData)

Visual Basic (Windows 95)

W_6208_DO (ByVal cardNo As Integer, ByVal

DOData As Integer) As Integer

@ Argument

cardNo: The card number of the 6208 card

initialized. (The first card in the most

significant PCI slot is assign cardNo = 0).

DOData: the value written to the digital

output port

@ Return Code

ERR_NoError

30 • C/C++ Library

Page 39

5.9 _6208_I2V_Control

@ Description

This function is used to set the cPCI/PCI-6208A voltage-to-current

mode control. There are three range modes for the cPCI/PCI-6208A.

Please refer to section 4.2 for description of voltage to current

conversion.

@ Syntax

C/C++ (DOS)

U16 _6208_I2V_Control (U16 cardNo, U16 ctrl)

C/C++ (Windows 95)

U16 W_6208_DO (U16 cardNo, U16 DOData)

Visual Basic (Windows 95)

W_6208_I2V_Control (ByVal cardNo As Integer,

ByVal ctrl As Integer) As Integer

@ Argument

cardNo: The card number of the 6208 card

initialized. (The first card in the most

significant PCI slot is assign cardNo = 0).

ctrl: the voltage-to-current mode, the valid

modes are shown in table 3 of Operation theory.

The constants are defined in Pci_6208.h (DOS)

and Acl_pci.h (Windows 95).

@ Return Code

ERR_NoError

C/C++ Library • 31

Page 40

6

Utility / Calibration

The software CD provides a utility program, 6208util.exe, and is intended

for calibration and functional testing. The utility is a menu-driven design

and operates under the DOS environment. The text messages gives

operating guidance, with graphics to indicate correct hardware

configuration and location. The utility is described in the following sections.

6.1 Running the 6208util.exe

After finishing the DOS installation, you can execute the utility by typing

the following command. (Assuming your utility is located in

\ADLINK\DOS\6208\Util directory), the following command should be

entered at the DOS prompt.

C> cd \ADLINK\DOS\6208\Util

C> 6208UTIL

The following diagram will be displayed on your screen. The message at

the bottom of each window guides you through the selected item.

32 • Utility/Calibration

Figure 9: Main selection Menu

Page 41

6.1.1 Functional Testing

This function is used to test the D/A functions of the cPCI/PCI-6208V

/6208A /6216V.

When you choose one of the testing functions from the functions menu, a

channel selection menu is displayed on the screen. Move the cursor and

press <Enter> to select the channel you want to test. After you have

selected a channel from the channel selection menu, a testing window

appears. Figures below are the function testing menu window.

Figure 10: Function Testing Menu Window

Figure 11: 6208V Testing Window

Utility/Calibration • 33

Page 42

6.1.2 Calibration

This function guides you through on how to calibrate the 6208 series card.

The calibration program can serve as a useful test for the 6208 series D/A

functions and can aid in troubleshooting if problems arise.

Note: For an environment with frequent fluctuation in temperature and

vibration, a 3 months re-calibration interval is recommended. For

laboratory conditions, 6 months to 1 year is acceptable

When you choose the calibration function from the main menu list, a

calibration sub-menu is displayed on the screen. After selecting a

calibration item from the list of options, a calibration procedure window will

appear. The instructions will guide you through the calibration process

step by step.

If you select 1, the following figure displays on the screen:

Figure 12: 6208 Calibration Window

34 • Utility/Calibration

Page 43

Figure 13: Channel Selection Menu

After you have selected a channel from the channel selection menu, a

calibration procedures window appears. The figure below outlines the

calibration procedure for the 6208V.

Figure 14: Calibration Procedures Window

6.2 Calibration of Analog Output Channel

6.2.1 What You Need

Before calibrating your 6208 series card, you should prepare a 6 1/2 digital

multi-meter for measuring voltage signals.

Utility/Calibration • 35

Page 44

6.2.2 VR Assignment of cPCI/PCI-6208 and PCI-6216

VR of PCI6208V

There are either 8 or 16 voltage output channels depending on which

model of the card is used. For each channel, two VRs are used to adjust

for the range and offset of the output voltage. The following table shows

the assignment and function of each VR. You can find these designators

on the PCB.

or PCI6216V

VR0-1 Ch #0 full range VR8-1 Ch #8 full range

VR0-2 Ch #0 offset VR8-2 Ch #8 offset

VR1-1 Ch #1 full range VR9-1 Ch #9 full range

VR1-2 Ch #1 offset VR9-2 Ch #9 offset

VR2-1 Ch #2 full range VR10-1 Ch #10 full range

VR2-2 Ch #2 offset VR10-2 Ch #10 offset

VR3-1 Ch #3 full range VR11-1 Ch #11 full range

VR3-2 Ch #3 offset VR11-2 Ch #11 offset

VR4-1 Ch #4 full range VR12-1 Ch #12 full range

VR4-2 Ch #4 offset VR12-2 Ch #12 offset

VR5-1 Ch #5 full range VR13-1 Ch #13 full range

VR5-2 Ch #5 offset VR13-2 Ch #13 offset

VR6-1 Ch #6 full range VR14-1 Ch #14 full range

VR6-2 Ch #6 offset VR14-2 Ch #14 offset

VR7-1 Ch #7 full range VR15-1 Ch #15 full range

VR7-2 Ch #7 offset VR15-2 Ch #15 offset

Function

VR of

PCI6216V

Function

36 • Utility/Calibration

Table 5. VR Assignment

Note: For PCI-6208V/6216V (REV: B1 or later), the designator of VRs

are changed to VRm_n, where m = 0 ~ 15 and n = 1 or 2.

Example VR6-2 on PCI-6208V/6216V REV: A3 will be changed

to VR6_2 on REV: B1 or later.

Page 45

6.2.3 Voltage Output Calibration

Because there is an internal reference voltage for each DA channel, the

calibration process for each channel is independent. The following

procedure, VRn-1 and VRn-2 are used to represent the full range and

offset of the nth channels. The following is the calibration procedure for

the DA output.

Step 1. Connect the n-th DA output (Vn) to DVM (+) of the digital multi-

meter. Connect the AGND signal to DVM (-).

Step 2. Send the digital value ‘0’ to the DA. Roughly adjust the offset

(trim VR n-2) until the DVM value equals zero.

Step 3. Send the digital value ‘-32767’ to the DA. Adjust VRn-2 until the

DVM value equals to –10V.

Step 4. Send the digital value ‘0’ to the DA again. Precisely adjust the

offset (trim VR n-2) until the DVM value equals zero.

Step 5. Repeat Steps 2-4 until the accuracy is within the application‘s

specifications.

6.2.4 Current Output Calibration

The current output calibration is only available to the cPCI/PCI-6208A. As

the current output channels are controlled by its corresponding voltage

output channels, VR n-1 and VR n-2 are also used to calibrate the n-th

current output channel.

Step 1. Connect the n-th current output (An) to the DVM (A+) of the

digital multi-meter. Connect both junctions of the current load

(typical 250Ω) to the DVM (A-) and ground (AGND) respectively.

Step 2. Select the current range with the provided software program.

Example: set the current range to 4~20 mA.

Step 3. Send the digital value ‘0’ to the DA. Adjust the offset (trim VRn-2)

until the current value equals the minimum value of the current

range. Example, adjust to 4mA if the current range is 4~20mA.

Step 4. Send the digital value ‘32767’ to the DA. Adjust for the full range

(trim VR n-1) until the current value equals the maximum value of

the full range. Example, adjust to 20 mA if the current range is

4~20mA.

Step 5. Repeat step 3 and step 4 until the accuracy is within the

application‘s specifications.

Utility/Calibration • 37

Page 46

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all

the after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products, please read the user manual and

follow the instructions exactly. When sending in damaged products for

repair, please attach an RMA application form.

2. All ADLINK products come with a two-year guarantee, free of repair

charge.

• The warranty period starts from the product’s shipment date

from ADLINK’s factory

• Peripherals and third-party products not manufactured by

ADLINK will be covered by the original manufacturers’ warranty

• End users requiring maintenance services should contact their

local dealers. Local warranty conditions will depend on the local

dealers

3. Our repair service does not cover two-year guarantee while damages

are caused by the following:

a. Damage caused by not following instructions on user menus.

b. Damage caused by carelessness on the users’ part during

product transportation.

c. Damage caused by fire, earthquakes, floods, lightening,

pollution and incorrect usage of voltage transformers.

d. Damage caused by unsuitable storage environments with high

temperatures, high humidity or volatile chemicals.

e. Damage caused by leakage of battery fluid when changing

batteries.

f. Damages from improper repair by unauthorized technicians.

g. Products with altered and damaged serial numbers are not

entitled to our service.

h. Other categories not protected under our guarantees

4. Customers are responsible for the fees regarding transportation of

damaged products to our company or to the sales office.

38 • Warranty Policy

Page 47

5. To ensure the speed and quality of product repair, please download

an RMA application form from our company website

www.adlinktech.com. Damaged products with RMA forms attached

receive priority.

For further questions, please contact our FAE staff.

ADLINK: service@adlinktech.com

Test & Measurement Product Segment: NuDAQ@adlinktech.com

Automation Product Segment: Automation@adlinktech.com

Computer & Communication Product Segment: NuPRO@adlinktech.com;

NuIPC@adlinktech.com

Warranty Policy • 39

Loading...

Loading...