Page 1

cPCI-3615 Series

3U CompactPCI® Dual-Core Intel® Atom™

Processor Blade

User’s Manual

Manual Rev.: 2.01

Revision Date: June 13, 2012

Part No: 50-15077-1010

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

2.00 2011/04/29 Initial release

Correct Atom N455 frequency, board layout; add

2.01 2012/06/13

DB-3610CF removal instructions; correct J2 pin

def’n

Page 3

cPCI-3615

Preface

Copyright 2011-12 ADLINK Technology Inc.

This document contains proprietary infor mation protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufa cturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Using this Manual

Audience and Scope

The cPCI-3615 User’s Manual is intended for hardware

technicians and systems operators with knowledge of installing,

configuring and operating CompactPCI systems.

Manual Organization

This manual is organized as follows:

Chapter 1, Introduction: Introduces the cPCI-3615, its features,

block diagrams, and package contents.

Chapter 2, Specifications: Presents detailed specification infor-

mation, power consumption, and technical drawings.

Chapter 3, Functional Description: Describes the cPCI-3615

main functions.

Chapter 4, Board Interfaces: Describes the cPCI-3615 board

interfaces.

Chapter 5, Getting Started: Describes the installation of compo-

nents to the cPCI-3615 and rear transition modules.

Chapter 6, Driver Installation: Provides information on how to

install the cPCI-3615 device drivers.

Chapter 7, Utilities: Describes the utilities of the cPCI-3615

Series.

Chapter 8, BIOS Setup: Describes basic navigation for the

AMIBIOS®8 BIOS setup utility.

Important Safety Instructions: Presents safety instructions all

users must follow for the proper setup, installation and usage of

equipment and/or software.

Getting Service: Contact information for ADLINK’s worldwide

offices.

iv Preface

Page 5

cPCI-3615

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component damage, data loss, and/or program corruption when trying to com-

CAUTION:

WARNING:

plete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

Preface v

Page 6

This page intentionally left blank.

vi Preface

Page 7

cPCI-3615

Table of Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Figures........................................................................ xi

List of Tables........................................................................ xiii

1 Introduction ........................................................................ 1

1.1 Overview.............................................................................. 1

1.2 Features............................................................................... 2

1.3 Block Diagram ..................................................................... 3

1.4 Product List............................. ... .......................................... 4

1.5 Package Contents ............................................................... 5

2 Specifications..................................................................... 7

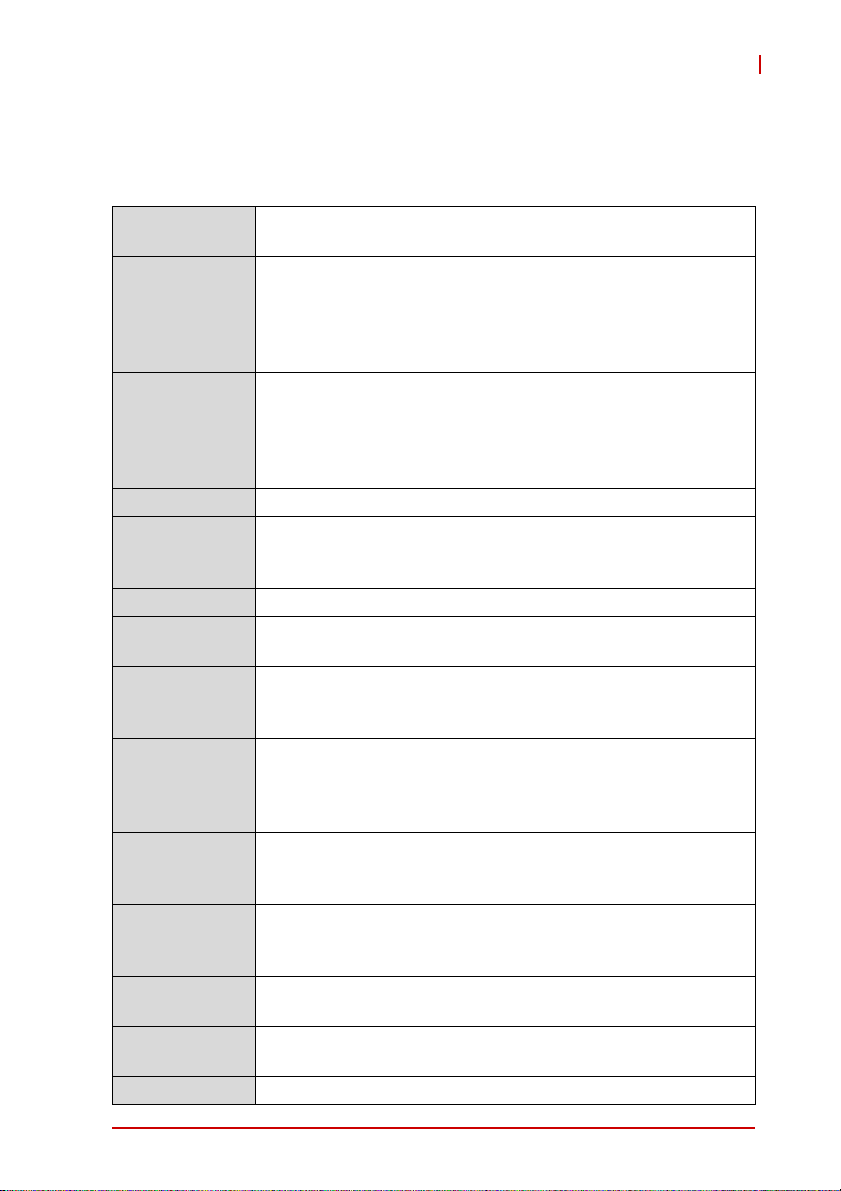

2.1 cPCI-3615 Specifications........... ... ... .... ... ... ... ... .... ... ... ... .... ... 7

2.2 I/O Connectivity Table ......................................................... 9

2.3 Power Requirements.................... ... .... ... ... ... ... .... ... ... ... .... . 10

3 Functional Description .................................................... 13

3.1 Processor........................................................................... 13

3.2 Chipset............................................................................... 16

3.3 Super I/O ........................................................................... 16

3.4 Battery ............................................................................... 17

3.5 PMC/XMC.......................................................................... 17

4 Board Interfaces............................................................... 19

4.1 cPCI-3615 Blade Board Layout......................................... 19

4.2 cPCI-3615 Blade Assembly Layout ................................... 20

4.3 cPCI-3615D Blade Assembly Layout................................. 21

4.4 cPCI-3615P Blade Assembly Layout................................. 22

vii

Page 8

4.5 cPCI-3615 Series Front Panel Layout ............................... 23

4.6 cPCI-R3610T RTM Board Layout...................................... 25

4.7 cPCI-R3610(T) RTM Front Panel ...................................... 26

4.8 Connector Pin Assignments............................................... 27

4.9 Switch and Jumper Settings .............................................. 41

5 Getting Started.................................................................. 47

5.1 CPU and Heatsink ............................................................. 47

5.2 Hard Drive Installation........................................................ 48

5.3 PMC/XMC Card Installation............................................... 55

5.4 Removing the DB-3610CF Daughter Board ...................... 59

5.5 Installing the cPCI-3615 to the Chassis............................. 62

5.6 RTM Installation - cPCI-R3610(T)...................................... 63

6 Driver Installation.............................................................. 65

7 Utilities............................................................................... 67

7.1 Watchdog Timer................................................................. 67

7.2 Preboot Execution Environment (PXE).............................. 72

8 BIOS Setup........................................................................ 73

8.1 Starting the BIOS............................................................... 73

8.2 Main Setup......................................................................... 77

8.3 Advanced BIOS Setup....................................................... 77

8.3.1 CPU Configuration.........................................................79

8.3.2 IDE Configuration ..........................................................81

8.3.3 Super IO Configuration..................................................82

8.3.4 Hardware Health Configuration .....................................83

8.3.5 USB Configuration.........................................................84

8.3.6 AHCI Configuration.......................... .... ... ... ... ... ..............86

8.3.7 Remote Access Configuration .......................................87

8.4 Advanced PCI/PnP Settings.............................................. 89

viii

Page 9

cPCI-3615

8.5 Boot Settings ..................................................................... 90

8.5.1 Boot Settings Configuration............ ... ... ... ... .... ... ... ... .... .. 91

8.6 Security Setup ................................................................... 92

8.7 Chipset Setup.................................................................... 94

8.8 Exit Menu........................................................................... 95

Important Safety Instructions.............................................. 97

Getting Service...................................................................... 99

ix

Page 10

This page intentionally left blank.

x

Page 11

cPCI-3615

List of Figures

Figure 1-1: cPCI-3615 Series Functional Block Diagram...................3

Figure 4-1: cPCI-3615 Blade Board Layout.....................................19

Figure 4-2: cPCI-3615 Assembly Layout .........................................20

Figure 4-3: cPCI-3615D Board Layout.............................................21

Figure 4-4: cPCI-3615, cPCI-3615D Front Panel Layout................. 23

Figure 4-5: cPCI-3615P Front Panel Layout.................................... 24

Figure 4-6: cPCI-R3610T RTM Board Layout..................................25

Figure 4-7: cPCI-R3610(T) RTM Front Panel ..................................26

List of Figures xi

Page 12

This page intentionally left blank.

xii List of Figures

Page 13

cPCI-3615

List of Tables

Table 4-1: cPCI-3615 Front Panel System LED Descriptions ........ 24

Table 4-2: USB Connector Pin Definition........................................27

Table 4-3: VGA Connector Pin Definition.................... .... ... ... ... .... .. 27

Table 4-4: GbE Connector Pin Definitions...................................... 28

Table 4-5: Ethernet Status LED Definitions........... ... ... .... ... ... ... .... .. 28

Table 4-6: PS/2 Keyboard/Mouse Connector Pin Definition...........29

Table 4-7: DB-9 Serial Port Connector Pin Definition..................... 29

Table 4-8: cPCI-R3610(T) Serial Port Pin Header Definition..........30

Table 4-9: Serial ATA Connector on RTM Pin Definition................ 30

Table 4-10: Serial ATA Connector on DB-3610L2 Pin Definition......31

Table 4-11: CompactFlash Connector Pin Definition........................32

Table 4-12: DB-3610CF Connector Pin Definition............................33

Table 4-13: DB-3610L2 Connector Pin Definition............................. 34

Table 4-14: DB-3UMC Connector Pin Definition...............................35

Table 4-15: PMC Connector Pin Definitions..................................... 36

Table 4-16: XMC Connector Pin Definition.................... .... ... ... ... .... .. 38

Table 4-17: CompactPCI J1 Connector Pin Definition...................... 39

Table 4-18: CompactPCI J2 Connector Pin Definition...................... 40

Table 4-19: VGA/GPIO Mode Switch Settings.............. .... ... ... ... .... .. 41

Table 4-20: COM1 Mode Selection Switch Settings.........................42

Table 4-21: COM2 Mode Selection Switch Settings.........................43

Table 4-22: COM3 Mode Selection Switch Settings.........................44

Table 4-23: XMC VPWR Select Jumper Settings.............................45

Table 4-24: PMC V(I/O) Select Jumper Settings............................ .. 45

List of Tables xiii

Page 14

This page intentionally left blank.

xiv List of Tables

Page 15

1 Introduction

1.1 Overview

The cPCI-3615 Series is a 3U CompactPCI single board computer

in single-slot (4HP), dual-slot (8HP) or triple-slot (12HP) width

form factor featuring the Intel® Atom™ N455 or D525 processor

with ICH8M I/O Controller Hub. The cPCI-3615 provides single

channel DDR3-800 soldered onboard memory up to 4GB, integrated graphics on the CPU, IDE CompactFlash slot, and

2.5” SATA HDD (cPCI-3615D/P) and one PMC/XMC site

(cPCI-3615P). Front panel I/O includes 2x USB, 2x GbE, VGA,

and additional 2x USB, COM, KB/MS, and line-in/out for the

8(12)HP cPCI-3615D(P) models.

The optional Rear Transition Module (RTM) provides 2x SATA,

2x GbE, 1x USB, 2x COM, and VGA ports. One PCI-Express x1

port, GPIO and SMBus signals are routed to the J2 connector. The

cPCI-3615 Series is ideally suited for transportation, factory automation, and other industrial applications.

cPCI-3615

Introduction 1

Page 16

1.2 Features

X 3U CompactPCI blade in 4HP, 8HP or 12HP width form factor

X Supports Dual-Core or Single-Core Intel® Atom™ processor,

up to 1.8 GHz

X Graphics and memory controllers integrated in processor

X ICH8M I/O Hub

X Single channel DDR3-800 SDRAM soldered onboard, up to

4GB

X 32bit/33MHz CompactPCI Interface based on PCI specifica-

tions

X Optional 32bit/66MHz PMC or PCI-Express x1 XMC site

X VGA port on front or switchable to RTM

X Two PCI-Express® Gigabit Eth ernet egress ports , configurable

to RTM by software

X One IDE CompactFlash socket

X Line-in and Line-out ports on front panel

X 2.5” SATA HDD onboard on 8HP/12HP blade and two 7-pin

SATA ports on RTM

2Introduction

Page 17

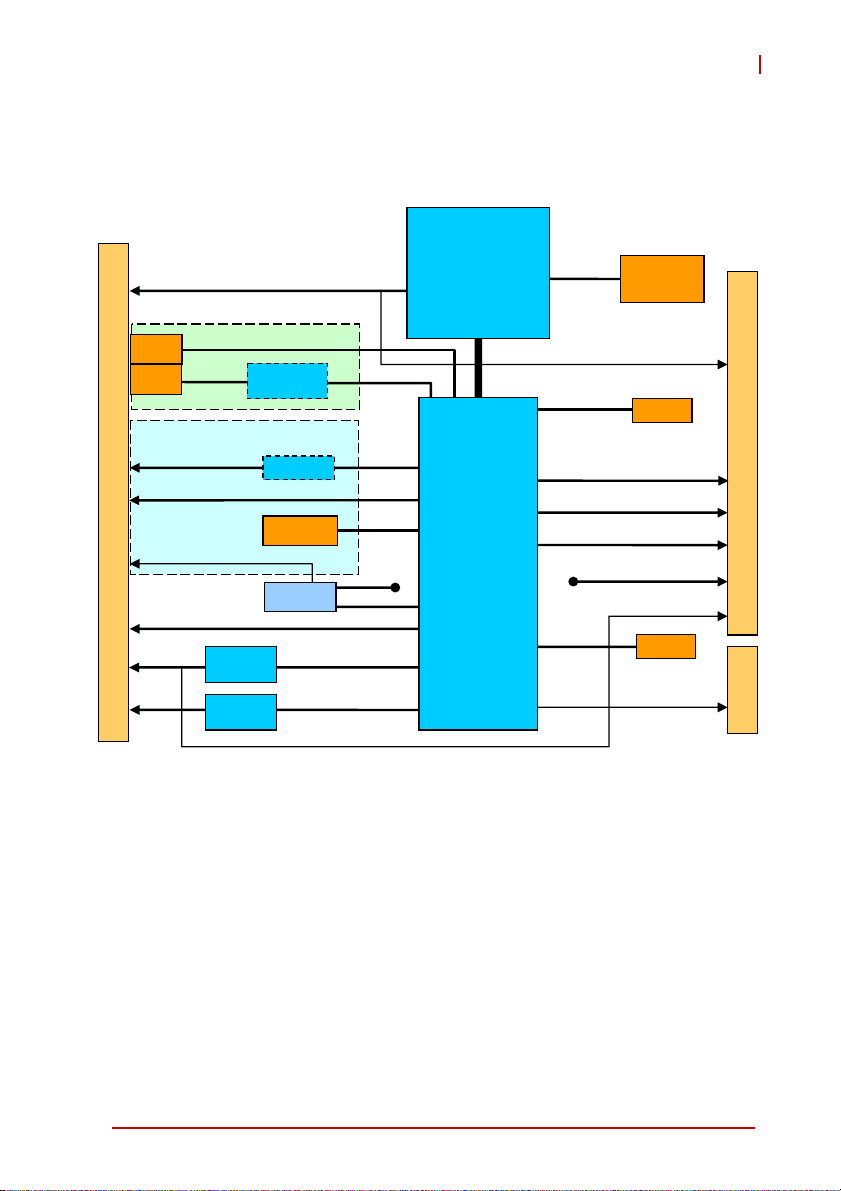

1.3 Block Diagram

C

RGB

Intel® Atom™

Processor

N455/D525

DDR3-800

cPCI-3615

Soldered

Up to 4GB

XMC

PMC

F

R

O

N

Line-in, Line-out

T

USB 3/4

P

A

N

E

COM1, KB/MS

L

USB 1/2

GbE 2

GbE 1

DB-3UMC

32b/66M

I

P

PCIe x1

PCIe-to-PCI

Bridge

PCIe x1

DMI

IDE

DB-3610L2

HD

SATA 1

COM2/3

LPC

Intel®

ICH8M

PCIe x1, GPIO, SMBus

SATA 2/3

1x USB

COM2,COM3

GbE 1/2

SPI

PCI 32b/33M

Intel

82574L

Intel

82574L

Codec

2.5” HDD

IT8783F

PCIe x1

PCIe x1

Figure 1-1: cPCI-3615 Series Functional Block Diagram

RGB

CF

J2

BIOS

J1

Introduction 3

Page 18

1.4 Product List

Products in the cPCI-3615 Series include:

Processor Blade

X cPCI-3615: 4HP width (single-slot) 3U CompactPCI featur-

ing Atom™ N455 or D525 processor; 1GB, 2GB or 4GB

memory soldered onboard; CompactFlash slot; 2x USB;

2x GbE; VGA.

X cPCI-3615D: 8HP width (dual-slot) 3U CompactPCI featur-

ing Atom™ N455 or D525 processor; 1GB, 2GB or 4GB

memory soldered onboard; CompactFlash slot; 2x USB; 2x

GbE; VGA. The DB-3610L2 riser card onboard provides 2x

USB, COM, PS/2 KB/MS, Line-in, Line-out ports.

X cPCI-3615P: 12HP width (triple-slot) 3U CompactPCI fea-

turing Atom™ N455 or D525 processor; 1GB, 2GB or 4GB

memory soldered onboard; CompactFlash slot; 2x USB; 2x

GbE; VGA. The DB-3610L2 riser card onboard on the 2nd

layer provides 2x USB, COM, PS/2 KB/MS, Line-in,

Line-out ports. The DB-3UMC riser card on the 3r d layer

provides one PMC/XMC site.

X Extended Temperature: -20°C to 70°C operating tempera-

ture range is supported by the cPCI-ET3615,

cPCI-ET3615D and cPCI-ET3615P

X Extreme Temperature: -40°C to 85°C operating tempera-

ture range is supported by the cPCI-EX3615,

cPCI-EX3615D and cPCI-EX3615P

Rear Transition Module

X cPCI-R3610: 8HP width, 50mm depth Rear Transition Mod-

ule with 2x COM, USB, 2x GbE, 2x SATA, VGA

X cPCI-R3610T: 8HP width, 80mm depth Rear Transition

Module with 2x COM, USB, 2x GbE, 2x SATA, VGA

4Introduction

Page 19

cPCI-3615

1.5 Package Contents

The cPCI-3615 is packaged with the following components. If any

of the items on the contents list are missing or damaged, retain the

shipping carton and packing material and contact the dealer for

inspection. Please obtain authorization before returning any product to ADLINK. The packing contents of the cPCI-3615 Series are

non-standard configurations and may vary depending on customer

requests.

Processor Blade

X The cPCI-3615 Series Processor Blade

Z CPU, RAM specifications will differ depending on

options selected

Z Thermal module is assembled on the board

X Y-cable for PS/2 combo port (8HP/12HP version only)

X 2.5” HDD accessory pack (8HP/12HP version only)

X ADLINK All-in-One CD

X User’s manual

Rear Transition Module

X cPCI-R3610: 8HP width, 50mm depth Rear Transition Mod-

ule with 2x COM, USB, 2x GbE, 2x SATA, VGA

X cPCI-R3610T: 8HP width, 80mm depth Rear Transition

Module with 2x COM, USB, 2x GbE, 2x SATA, VGA

The contents of non-standard cPCI-3615 configurations may

vary depending on the customer’s requirements.

NOTE:

NOTE:

This product must be protected from static discharge and physical shock. Never remove any of the components except at a

CAUTION:

static-free workstation. Use the anti-static bag shipped with the

product when putting the board on a surface. Wear an

anti-static wrist strap properly grounded on one of the system's

ESD ground jacks when installing or servicing system components.

Introduction 5

Page 20

This page intentionally left blank.

6Introduction

Page 21

2 Specifications

2.1 cPCI-3615 Specifications

cPCI-3615

CompactPCI®

Standards

Mechanical • Standard 3U CompactPCI®

Processor • µFC-BGA Intel® Atom™ Processor N455

Chipset • Intel® ICH8M I/O Controller Hub (ICH)

Memory

BIOS • AMIBIOS8® 16Mbit SPI flash memory

CompactPCI

Bus

Gigabit

Ethernet

Graphics • In te grated in Intel® Atom™ Processor

Serial Ports • Up to three 16C550 compatible RS-232/422/485/485+

Storage

Interface

PMC/XMC • On e 32bit/66MHz PMC or PCI-Express x1 XMC site

Audio • Line-in and Line-out ports on front panel (8HP/12HP only)

BIOS • AMIBIOS8® 16Mbit SPI flash memory

1

• P ICMG® 2.0 CompactPCI® Rev. 3.0

• P ICMG® 2.1 Hot Swap Specification Rev.2.0

• B oard size: 100mm x 160mm

• Single-slot (4HP, 20.32mm); Dual-slot (8HP, 40.64mm),

Triple-slot (12HP, 60.96mm) width

• CompactPCI® connectors with J1, J2

1.66 GHz, 512KB L2 cache, TDP 6.5W

• µFC-BGA dual-core Intel® Atom™ Processor D525

1.8 GHz, 1MB L2 cache, TDP 13W

• Passive heatsink

• Single channel unbuffered DDR3-800 SDRAM soldered

onboard

• Up to 2GB for N455 processor, 4GB for D525 processor

• PCI 32bit/ 33MHz; 3.3V, 5V universal V(I/O)

• Supports operation in system slot only

• Two PCI-Express x1 Intel® 82574L GbE controllers

• Two egress 10/100/1000BASE-T ports, configurable to J2

(RTM) by software setting

• DB-15 VGA port on front panel, switchable to J2 (RTM)

• Analog monitor support up to QXGA 2048x1536 @60Hz

32-bit

serial ports from Super I/O IT8783

• One DB-9 port on front panel, two DB-9 ports on rear panel

• CompactFlash Type II socket onboard

• 2.5” SAT A HDD connector onboard

• Two 7-pin SATA signal connectors on RTM

(12HP version only)

• Realtek ALC262 High Definition Audio Codec

(8HP/12HP version only)

Specifications 7

Page 22

Faceplate I/O

4HP (cPCI-3615):

• 2x USB 2.0 ports

• 2x 10/100/10 00BASE-T Ethernet ports

• Analog DB-15 VGA port

8HP (cPCI-3615D):

• 4x USB 2.0 ports

• 2x 10/100/10 00BASE-T Ethernet ports

• Analog DB-15 VGA port

• DB-9 RS-232/422/485/485+ port

• PS/2 Keyboard/ Mouse combo port

• Line-in and Line-out ports

cPCI-R3610(T):

• 2x USB 2.0 ports

• 10/100/1000BASE-T Ethernet port

• 2x DB-9 RS-232 serial ports

OS

Compatibility

• Mi crosoft Windows XP Professional, x64 Editio n

• Mi crosoft Windows Vista x64 Edition

• Mi crosoft Windows 7 x86 Edition

• Red Hat Enterprise Linux 5.3

• Fedora 12

• Other OS supp ort upon request

Environmental • Operating Temperature (with forced air flow)2:

- Standard: 0°C to 60°C

- Extended: -20°C to 70°C

- Extreme Extended temperature: -40°C to 85°C

• Storage Temperature: -40°C to 85°C

• Humidity: 90% @ 60°C non-condensing

• Shock: 15G peak-to-peak, 11ms duration, non-operating

•Vibration1: Operating 1.88Grms, 5-500Hz, each axis w/o HDD

EMI • CE EN55022

• FCC Cla ss A

Specifications are subject to change without prior notice.

1. Hard drive limits operational vibration. When application requires

higher vibration specification, it is recommended to use a flash disk.

2. ADLINK-certified thermal design. The thermal performance is

dependent on the chassis cooling design. Forced airflow with

3.2 m/s is required. Temperature limit of optional mass storage

devices may affect the thermal specification.

8 Specifications

Page 23

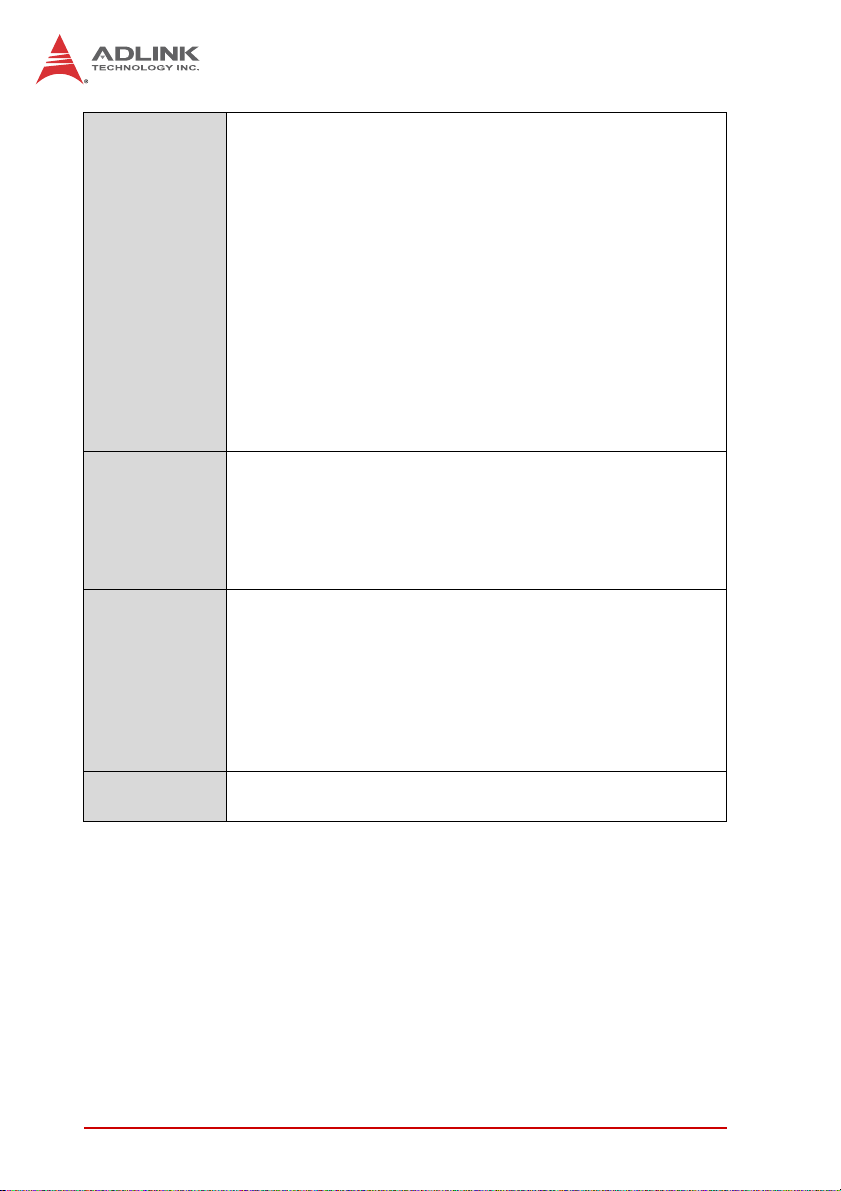

2.2 I/O Connectivity Table

cPCI-3615

Function

Gigabit

Ethernet

COM

USB 2.0

VGA

Serial

ATA

CF

PS/2

KB/MS

Line-in

Line-out

PMC/

XMC

GP LED

Reset

Btn.

cPCI-3615

(4HP)

Front I/O Onboard Front I/O Onboard Front I/O Onboard Front I/O Onboard

Y x2 – Y x2 – Y x2 –

–Y–Y–Y x2–

Y x2 – Y x4 – Y x4 – Y –

Y– Y – Y –

–– –

–Y – Y – Y – –

––Y–Y–––

––Y–Y–––

––Y–Y–––

–– – – –Y– –

Y x2 – Y x2 – Y x2 – – –

Y–Y–Y–––

cPCI-3615D

(8HP)

(2.5” HD)

cPCI-3615P

(12HP)

Y

–

Y

(2.5” HD)

cPCI-R3610(T)

Y x2

Y

(1)

(1)

–

–

–

Yx2

(7-pin)

1. Software switchable from front port(s).

Specifications 9

Page 24

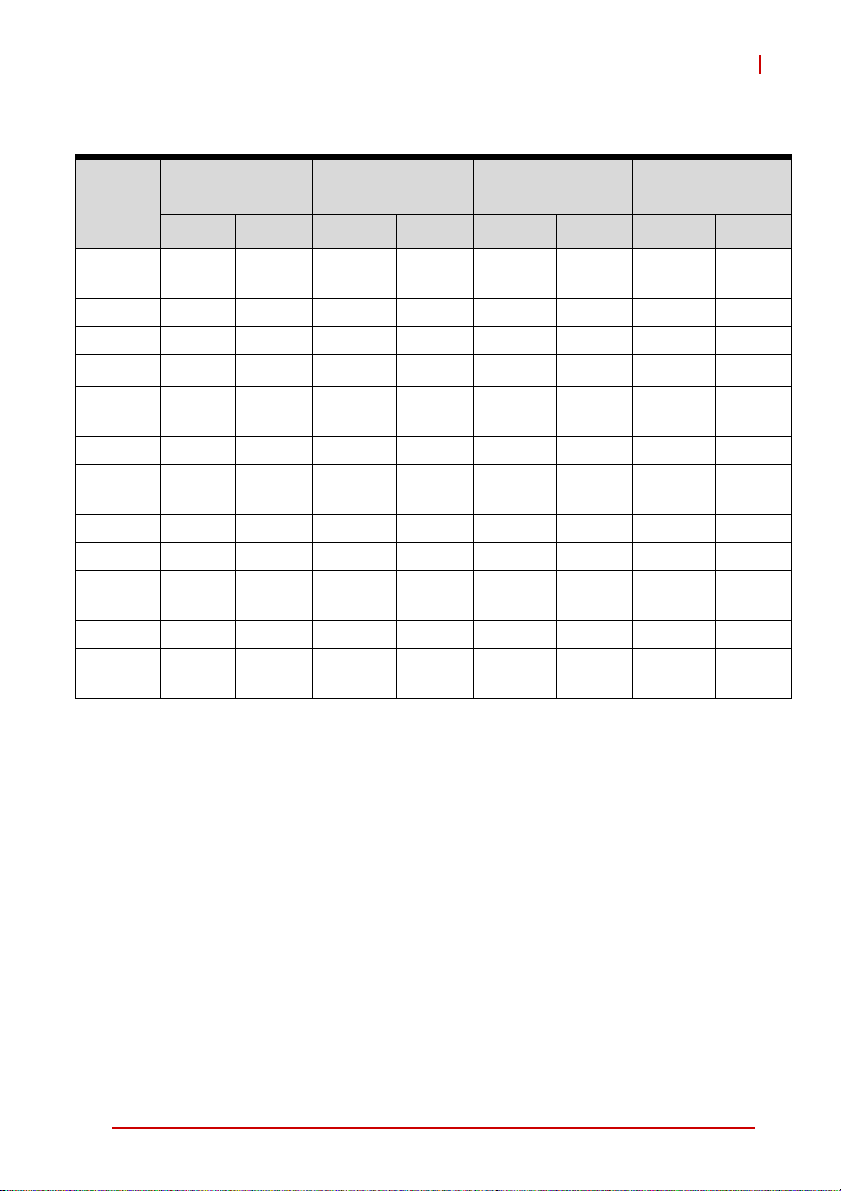

2.3 Power Requirements

In order to guarantee stable operation of the system, it is recommended that significantly more power be provided than required.

An industrial power supply unit should be able to provide at

least twice as much power as the entire system requires of

each voltage. An ATX power supply unit should be able to provide

at least three times as much po wer as the entire syst em requires

of each voltage.

The tolerance of the voltage lines described in the CompactPCI

specification (PICMG 2.0 R3.0) is +5%/-3% for 5, 3.3 V and ±5%

for ±12V. This specification is for power delivered to each slot and

it includes both the power supply and the backplane tolerance.

Voltage

5V +5.0 VDC +5% / -3% 50 mV

3.3V +3.3 VDC +5% / -3% 50 mV

+12V +12 VDC +5% / -5% 240 mV

-12V -12 VDC +5% / -5% 240 mV

V I/O (PCI I/O

Buffer Voltage)

GND

Nominal

Value

+3.3 VDC or

+5 VDC

Tolerance

+5% / -3% 50 mV

Max. Ripple

(P - P)

10 Specifications

Page 25

cPCI-3615

Power Consumption

This section provides information on the power consumption of

cPCI-3615 Series when using Intel® Atom™ processors with 1GB

soldered DDR2 memory and onboard 80GB SATA hard drive. The

cPCI-3615 is powered by 5V only. Power consumption at 100%

CPU usage was measured using PassMark BurnInTest 6.0.

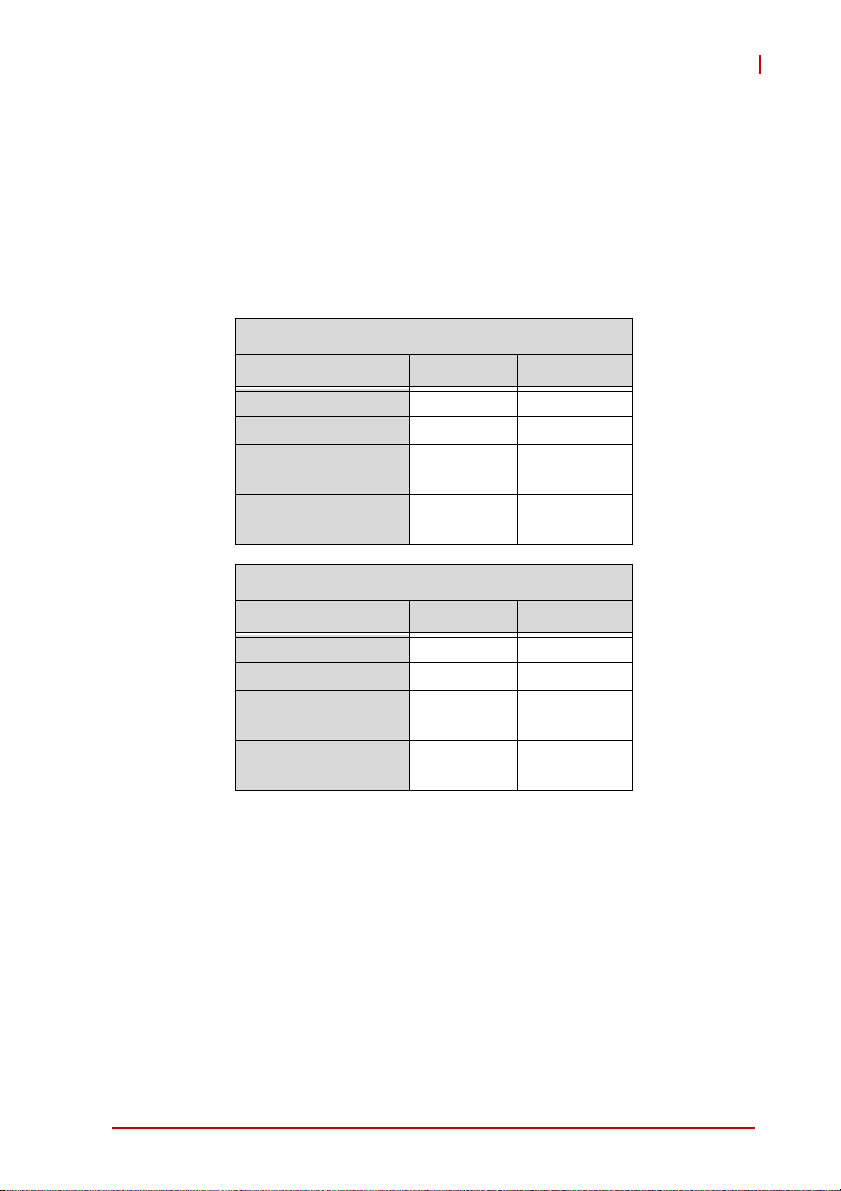

Intel® Atom™ Processor N455

OS/Mode Current 5V Total Power

DOS/Idle mode 2.94A 14.7W

Linux/Idle mode 2.54A 12.7W

Windows XP/

Idle mode

Windows® XP,

100% CPU Usage

Intel® Atom™ Processor D525

OS/Mode Current 5V Total Power

DOS/Idle mode 2.99A 14.9W

Linux/Idle mode 2.79A 13.9W

Windows XP/

Idle mode

Windows® XP,

100% CPU Usage

2.95A 14.7W

3.02A 15.1W

3.04A 15.2W

3.48A 17.4W

Specifications 11

Page 26

This page intentionally left blank.

12 Specifications

Page 27

3 Functional Description

The following sections describe the cPCI-3615 Series features

and functions.

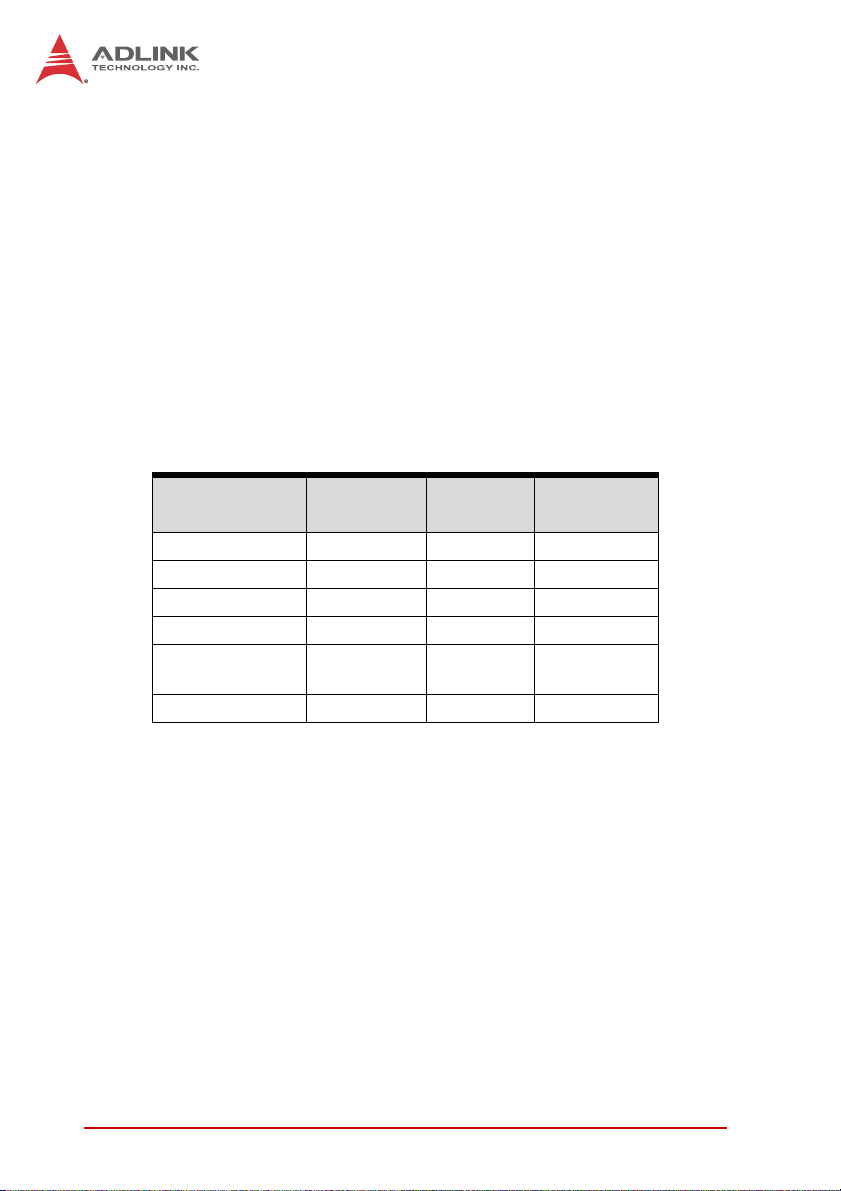

3.1 Processor

cPCI-3615

The cPCI-3615 Series supports the

Intel® Atom™ Processor N400,

D400 and D500 Series processors built on 45-nm Hi-K process

technology. The processor is designed for a two-chip platform as

opposed to the traditional three-chip platforms (processor, GMCH,

and ICH). The two-chip platform consists of a processor and the

chipset and enables higher performance, lower cost, easier validation, and improved x-y footprint.

Features Atom™N455 Atom™D525

Clock 1.66 GHz 1.8 GHz

L2 cache 512KB 1MB

No. of Core(s) 1 2

Max. Power (TDP1)

T

junction, MAX

1. The high est expected sustainable power while running known

power intensive applications. TDP is not the maximum power

that the processor can dissipate.

2. The maximum supported operating temperature.

2

6.5W 13W

100°C 100°C

Intel® Atom™ Processor N455

Included in this family of processors is an integrated memory controller, integrated graphics processing unit and integrated I/O

(such as DMI) on a single silicon die.

The following list outlines the key features of this processor:

X One die, primary 32-kB instructions cache and 24-kB

write-back data cache

X Intel® Hyper-Threading Technology (2 threa ds)

X On die 512-kB, 8-way L2 cache

X Support IA 32-bit and Intel® 64 architecture

X Intel® SSE2 and SSE3 and SSSE3 support

Functional Description 13

Page 28

X Micro-FCBGA8 packaging technologies

X Thermal management support via Intel® Thermal Monitor 1

(TM1) and Intel® Thermal Monitor 2 (TM2)

X Enhanced Intel® SpeedStep Technology (EIST)

X Support L2 dynamic cache sizing

The following list outlines the key features of system memory support:

X One channel DDR3 memory

X Memory DDR3 data transfer rates of 800 MT/s

X Non-ECC, unbuffered DDR3

X 512Mb. 1-Gb,and 2-Gb DDR3 DRAM technologies supported

X Maximum of 2-GB memory capacity supported

X Maximum 2GB memory capacity on one SO-DIMM or Mem-

ory Down

The following list outlines the key graphics features:

X The integrated graphics controller contains a refresh of the

3rd generation graphics core

X Intel® Dynamic Video Memory Technology 4.0

X Directx* 9 compliant Pixel Shader v2.0

X 200-MHz render clock frequency

X Analog RGB display output up to resolution up to

1400x1050 @ 60Hz

Intel® Atom™ Processor D525

The following list provides some of the key features of this processor:

X One die, primary 32-kB instructions cache and 24-k B

write-back data cache

X Intel® Hyper-Threading Technology (2 threads per core)

X On die 2x512-kB, 8-way L2 cache

X Support IA 32-bit and Intel® 64 architecture

X Intel® SSE2 and SSE3 and SSSE3 support

X Micro-FCBGA8 packaging technologies

X Thermal management support via Intel® Thermal Monitor 1

(TM1)

14 Functional Description

Page 29

cPCI-3615

The following list outlines the key features of system memory support:

X One channel DDR3 memory

X Memory DDR3 data transfer rates of 800 MT/s

X Non-ECC, unbuffered DDR3

X I/O Voltage of 1.8V for DDR3

X 512Mb. 1-Gb,and 2-Gb DDR3 DRAM technologies supported

The following list outlines the key graphics features:

X The integrated graphics controller contains a refresh of the

3rd generation graphics core

X Intel® Dynamic Video Memory Technology 4.0

X Directx* 9 compliant Pixel Shader v2.0

X 400-MHz render clock frequency

X Analog RGB display output up to resolution up to

2048x1536 @ 60Hz

Functional Description 15

Page 30

3.2 Chipset

Intel® ICH8 Mobile I/O Controller Hub

The ICH8M provides extensive I/O support. Functions and capabilities include:

X Provides 6 PCI Expressx1 ports, supporting the PCI

Express Base Specification, Revision 1.1. Each Root Port

supports 2.5GB/s bandwidth in each direction. The

cPCI-3615 utilizes two PCI Express x1 ports for two Gigabit

Ethernet controllers; routes two PCI Express x1 ports to the

board-to-board connector and one PCI Express x1 port to

the J2 connector for expansion capability.

X Enhanced DMA controller, interrupt controller, and timer functions

X Integrated Serial A TA host controller with independent DMA

operation on three ports

X Integrated IDE controller supports Ultra ATA100/66/33

X System Management Bus (SMBus) Specification, Version

2.0 with additional support for I2C devices

X Supports Intel® Matrix Storage Technology

X PCI Local Bus Specification, Revision 2.3 support for

33MHz PCI operations

3.3 Super I/O

The ITE IT8783F Super I/O is on a Low Pin Count interface supporting PS/2 keyboard/mouse; three 16C550-compatible serial

ports; hardware monitor function to monitor CPU voltage, CPU

temperature, power supply voltages and system temperature; and

Watchdog Timer with time resolution from minimum 1 second or

minute to maximum 65635 seconds or minutes on the cPCI-3615.

16 Functional Description

Page 31

cPCI-3615

3.4 Battery

The cPCI-3615 is provided with a 3.0V “coin cell” lithiu m battery

for the Real Time Clock (RTC). The battery socket is equipped on

the DB-3610CF daughter board. The lithium battery must be

replaced with an identical battery or a battery type recommended

by the manufacturer. The cPCI-3615 is equipped with a Rayovac

BR2032 by default, and can be optionally equipped with a Gold

Capacitor.

3.5 PMC/XMC

The cPCI-3615P Series supports one PMC or XMC site for front

panel I/O expansion. The PMC site provides a maximum 32bit/

66MHz PCI bus link using a Pericom PI7C9X110

PCI-Express-to-PCI bridge and PCI-Express x1 link. The PMC site

supports +3.3V and +5V signaling. The XMC site provides a PCI

Express x1 port.

Functional Description 17

Page 32

This page intentionally left blank.

18 Functional Description

Page 33

4 Board Interfaces

This chapter illustrates the board layout, connector pin

assignments, and jumper settings to familiarize users with the

cPCI-3615 Series.

4.1 cPCI-3615 Blade Board Layout

cPCI-3615

LAN

VGA

USB0

USB1

CPU Intel® Atom processor USB0/1 USB 2.0

SB South Bridge Intel® ICH8M CN4 DB-3610L2 connector

LAN GbE Controller Intel® 82574L CN2 DB-3610CF connector

RAM DDR2 SDRAM SW1 VGA/GPIO Mode Switch

CN1 Dual RJ-45 GbE ports

CN2 VGA connector CompactPCI connectors

LAN

LAN

CN4

Figure 4-1: cPCI-3615 Blade Board Layout

RAM

CPU

SB

(SW3 on solder side)

CN2

SW1

J2

J1

Board Interfaces 19

Page 34

4.2 cPCI-3615 Blade Assembly Layout

This section describes the final as sembly layout of the single slot

cPCI-3615 (4HP).

DB-3610CF

Battery

Heat sink

CF socket

Figure 4-2: cPCI-3615 Assembly Layout

20 Board Interfaces

Page 35

cPCI-3615

4.3 cPCI-3615D Blade Assembly Layout

The dual-slot width cPCI-3615D (8HP) is comprised of the

cPCI-3615 single-slot main board and the DB-36 10L2 r i ser ca rd to

expand I/O connectivity with PS/2, COM, 2x USB, Line-in, and

Line-out ports.

DB-3610L2

COM1

USB2

USB3

PS2

SATA0

2.5” SATA HDD

CN6

CN8

CN7

COM1 DB-9 COM port CN7 DB-3UMC connector

USB2/3 USB connectors CN6 Line-in port

PS2 PS/2 KB/MS combo port CN8 Line-out port

SATA0 22-pin SATA connector

Figure 4-3: cPCI-3615D Board Layout

Board Interfaces 21

Page 36

4.4 cPCI-3615P Blade Assembly Layout

The triple-slot width cPCI-3615P (12HP) is comprised of the

cPCI-3615D dual-slot assembly and the DB-3UMC riser card to

provide a PMC/XMC slot for front I/O expansion.

JN3

JN1

JN2

DB-3UMC

DB-3UMC

JN1/2 PMC connectors JN3 XMC connector

22 Board Interfaces

Page 37

4.5 cPCI-3615 Series Front Panel Layout

cPCI-3615

cPCI-3615

WDT LED

Reset button

cPCI-3615D

WDT LED

Reset button

GbE 1/2

12

Power LED

COM1

12

Power LED

USB 2.0

VGA

PS/2

KB/MS

VGA

USB 2.0

Line-in

Line-out

USB 2.0

Figure 4-4: cPCI-3615, cPCI-3615D Front Panel Layout

Board Interfaces 23

Page 38

cPCI-3615P

COM1

USB 2.0

PS/2

KB/MS

Line-in

Line-out

PMC/XMC

WDT LED

VGA

Reset button

Power LED

USB 2.0

Figure 4-5: cPCI-3615P Front Panel Layout

Optional 2-slot version with PMC/XMC as shown below is avail-

able by request. Please contact your ADLINK sales representative.

PMC/XMC

System LEDs

LED Color Condition Indication

Power Green

WDT Red

OFF System is off

ON System is on

OFF No Watchdog event

Blinking Watchdog event alert

Table 4-1: cPCI-3615 Front Panel System LED Descriptions

24 Board Interfaces

Page 39

4.6 cPCI-R3610T RTM Board Layout

SATA1

SATA2

cPCI-3615

rJ2

LAN

COM2

SW1-4

COM3

USB 5

VGA1

SW5-8

COM2/3 COM ports LAN Dual Ethernet port

SATA1/2 SATA ports USB5 USB port

rJ2 CompactPCI connector SW1-8 Switches

VGA1 VGA connector

Figure 4-6: cPCI-R3610T RTM Board Layout

Board Interfaces 25

Page 40

4.7 cPCI-R3610(T) RTM Front Panel

COM3

VGA

Figure 4-7: cPCI-R3610(T) RTM Front Panel

COM2

12

USB GbE x2

26 Board Interfaces

Page 41

4.8 Connector Pin Assignments

USB Connectors

Pin # Signal Name

1Vcc

2UV03UV0+

4GND

Table 4-2: USB Connector Pin Definition

VGA Connector (DB-15)

Signal Name Pin # Pin # Signal Name

Red 1 2 Green

Blue 3 4 N.C.

GND 5 6 GND

GND 7 8 GND

+5V. 9 10 GND

N.C. 11 12 CRTDATA

HSYNC 13 14 VSYNC

CRTCLK 15

cPCI-3615

Table 4-3: VGA Connector Pin Definition

Board Interfaces 27

Page 42

Gigabit Ethernet Connectors (RJ-45)

Pin #

1 TX+ BI_DA+

2 TX- BI_DA3 RX+ BI_DB+

4— BI_DC+

5 — BI_DC6 RX- BI_DB7— BI_DD+

8 — BI_DD-

Ta ble 4-4: GbE Connector Pin Definitions

Status

Network link is not established

or system powered off

10 Mbps

100 Mbps

1000 Mbps

10BASE-T/

100BASE-TX

Link OFF ON

Active OFF Blinking

Link Green ON

Active Green Blinking

Link Amber ON

Active Amber Blinking

1000BASE-T

81

Speed LED

(Green/Amber)

OFF OFF

Activity LED

(Yellow)

Ta ble 4-5: Ethernet Status LED Definitio ns

28 Board Interfaces

Page 43

PS/2 Keyboard/Mouse Connector

Pin # Signal Function

1 KBDATA Keyboard Data

2MSDATA Mouse Data

3 GND Ground

4+5V Power

5 KBCLK Keyboard Clock

6 MSCLK Mouse Clock

T able 4-6: PS/2 Keyboard/Mouse Connector Pin Definition

Serial Port DB-9 Connector (COM1)

Pin # RS-232 RS-422 RS-485(+)

1 DCD-L TXD- TXD2RXDTXD+TXD+

3TXDRXD+ —

4 DTR-L RXD- —

5 GND GND GND

6DSR-L — —

7RTS-L — —

8CTS-L — —

9RI-L — —

cPCI-3615

Table 4-7: DB-9 Serial Port Connector Pin Definition

Board Interfaces 29

Page 44

cPCI-R3610(T) Serial Port Pin Header (COM2/3)

Pin # RS-232 RS-422 RS-485(+)

1 DCD-L TXD- TXD2DSR-L — —

3 RXD TXD+ TXD+

12

4RTS-L — —

5 TXD RXD+ —

6CTS-L — —

910

7 DTR-L RXD- —

8RI-L — —

9GNDGNDGND

10———

Table 4-8: cPCI-R3610(T) Serial Port Pin Header Definition

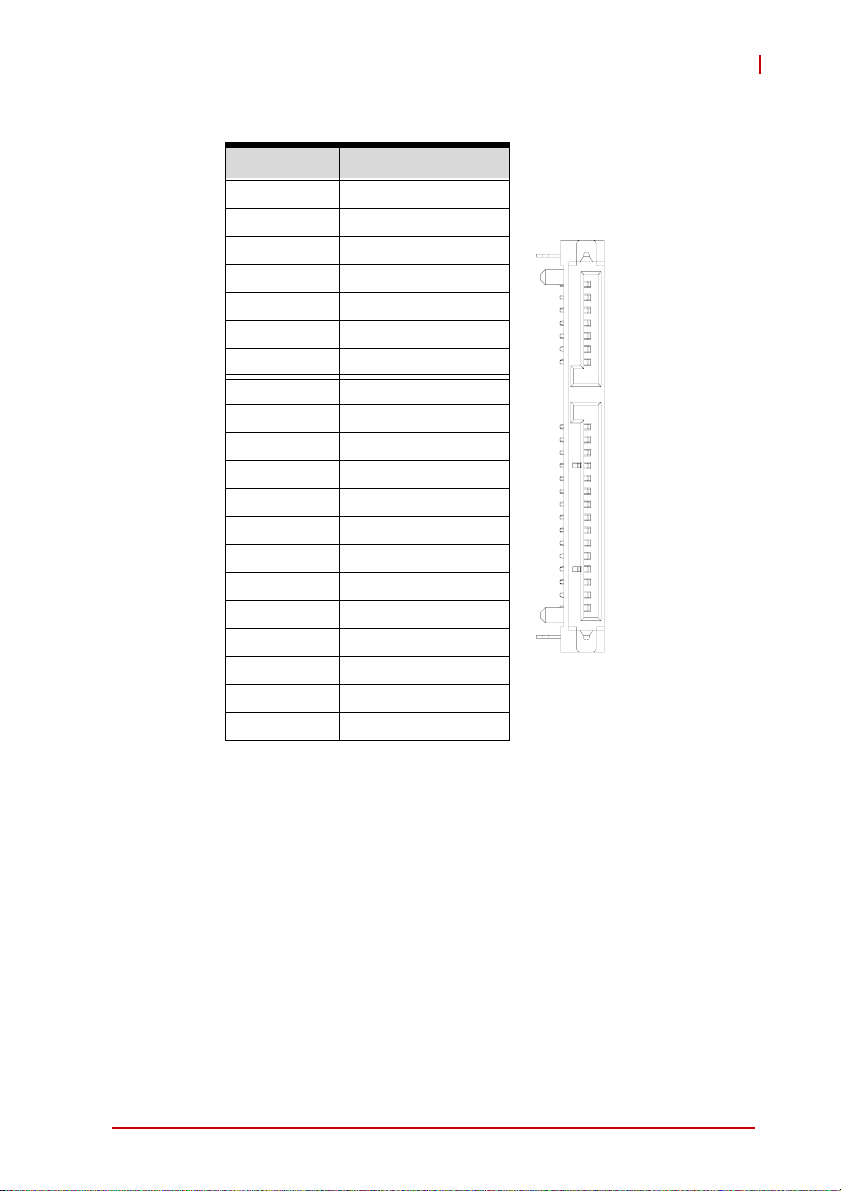

Serial ATA Connectors on RTM

Pin # Signal

1GND

2TX+

3TX4GND

5RX6RX+

7GND

Table 4-9: Serial ATA Connector on RTM Pin Definition

1

7

30 Board Interfaces

Page 45

Serial ATA Connector on DB-3610L2

Pin # Signal

S1 GND

S2 TX+

S3 TXS4 GND

S5 RXS6 RX+

S7 GND

P1 NC

P2 NC

P3 NC

P4 GND

P5 GND

P6 GND

P7 5V

P8 5V

P9 5V

P10 GND

P11 NC

P12 GND

P13~P15 NC

cPCI-3615

S1

Signal

S7

P1

Power

P15

Table 4-10: Serial ATA Connector on DB-3610L2 Pin Definition

Board Interfaces 31

Page 46

CompactFlash Connector on DB-3610CF

Signal Name Pin# Pin# Signal Name

GND 1 26 GND

DD3 2 27 DD11

DD4 3 28 DD12

DD5 4 29 DD13

DD6 5 30 DD14

DD7 6 31 DD15

CS1J 7 32 CS3J

GND 8 33 GND

GND 9 34 SDIORJ

GND 10 35 SDIOWJ

GND 11 36 5V

GND 12 37 IRQ15

5V 13 38 5V

GND 14 39 PCSEL

GND 15 40 NC

GND 16 41 BRSTDRVJ

GND 17 42 SDIORDY

DA2 18 43 NC

DA1 19 44 SDACKJ

DA0 20 45 IDEACTJ

DD0 21 46 DIAG

DD12247DD8

DD22348DD9

IOIS16J 24 49 DD10

GND 25 50 GND

Table 4-11: CompactFlash Connector Pin Definition

32 Board Interfaces

Page 47

DB-3610CF Connector (CN2)

cPCI-3615

Signal Name Pin # Pin # Signal Name

IDE_D7 1 2 IDE_D8

IDE_D6 3 4 IDE_D9

IDE_D5 5 6 IDE_D10

IDE_D4 7 8 IDE_D11

IDE_D3 9 10 IDE_D12

IDE_D2 11 12 IDE_D13

IDE_D1 13 14 IDE_D14

IDE_D0 15 16 IDE_D15

GND 17 18 GND

IDE_REQ-L 19 20 IDE_66DECT

IDE_IOW-L 21 22 IDE_RST-L

IDE_IOR-L 23 24 SPKR

IDE_IORDY 25 26 SIO_SPKR

IDE_ACK-L 27 28 GND

IDE_IRQ 29 30 VCC_RTC

IDE_A1 31 32 GND

IDE_A0 33 34 USB4-P

IDE_A2 35 36 USB4-N

IDE_CS1-L 37 38 P5V

IDE_CS3-L 39 40 P5V

40 39

2

1

Table 4-12: DB-3610CF Connector Pin Definition

Board Interfaces 33

Page 48

DB-3610L2 Connector (CN4)

Signal Name Pin # Pin # Signal Name

USB2-N 1 2 -12V

USB2-P 3 4 +12

GND 5 6 GND

USB3-N 7 8 HDA_SDIN0

USB3-P 9 10 HDA_R_SDOUT

GND 11 12 GND

SATA_ICH_RX-N0 13 14 HDA_R_SYNC

SATA_ICH_RX-P0 15 16 HDA_R_BIT_CLK

GND 17 18 GND

SATA_TX-P0 19 20 CK_L2_PCIE1-P

SATA_TX-N0 21 22 CK_L2_PCIE1-N

GND 23 24 GND

PCIE_TXN5 25 26 CK_L2_PCIE2-P

PCIE_TXP5 27 28 CK_L2_PCIE2-N

GND 29 30 GND

PCIE_RXN5 31 32 HDA_R_RST-L

PCIE_RXP5 33 34 SPKR

GND 35 36 L2_PCIE_RST-L

PCIE_RXN4 37 38 NC

PCIE_RXP4 39 40 USB_2_3_OC-L

GND 41 42 COM1_DCD-L

PCIE_TXN4 43 44 COM1_RI-L

PCIE_TXP4 45 46 COM1_CTS-L

GND 47 48 COM1_DTR-L

MSCLK 49 50 COM1_RTS-L

MSDATA 51 52 COM1_DSR-L

KBCLK 53 54 COM1_SOUT

KBCDATA 55 56 COM1_SIN

P5V 57 58 +3.3V

P5V 59 60 +3.3V

60

12

59

Table 4-13: DB-3610L2 Connector Pin Definition

34 Board Interfaces

Page 49

DB-3UMC Connector (CN7)

Signal Name Pin # Pin # Signal Name

NC 1 2 -12V

NC 3 4 +12V

GND 5 6 GND

NC 7 8 NC

NC 9 10 NC

GND 11 12 GND

NC 13 14 NC

NC 15 16 NC

GND 17 18 GND

NC 19 20 CK_PCIE1_P

NC 21 22 CK_PCIE1_N

GND 23 24 GND

PCIE_TXN2 25 26 CK_PCIE2_P

PCIE_TXP2 27 28 CK_PCIE2_N

GND 29 30 GND

PCIE_R_RXN2 31 32 NC

PCIE_R_RXP2 33 34 NC

GND 35 36 PCIE_RST#

PCIE_R_RXN1 37 38 NC

PCIE_R_RXP1 39 40 NC

GND 41 42 NC

PCIE_TXN4 43 44 NC

PCIE_TXP4 45 46 NC

GND 47 48 NC

NC 49 50 NC

NC 51 52 NC

NC 53 54 NC

NC 55 56 NC

+5V 57 58 +3.3V

+5V 59 60 +3.3V

cPCI-3615

60

12

59

Table 4-14: DB-3UMC Connector Pin Definition

Board Interfaces 35

Page 50

PMC Connector (JN1/2)

Pin# JN1 Signal JN2 Signal

1 PMC_TCK P12V

2 N12V PMC_TRST-L

3 GND PMC_TMS

4 PCIX_INTA-L NC (PMC_TDO)

5 PCIX_INTB-L PMC_TDI

6PCIX_INTC-L GND

7PMC_MOD-L1 GND

8P5V NC

9PCIX_INTD-L NC

10 NC NC

11 GND PMC_MOD-L2

12 P3V3_PMCAUX P3V3

13 CLK66_PCIX_PMC PMC_RST-L

14 GND PMC_MOD-L3

15 GND P3V3

16 PCIX_GNT-L0 PMC_MOD-L4

17 PCIX_REQ-L0 PMC_PME-L

18 P5V GND

19 PMC_VIO PCIX_AD30

20 PCIX_AD31 PCIX_AD29

21 PCIX_AD28 GND

22 PCIX_AD27 PCIX_AD26

23 PCIX_AD25 PCIX_AD24

24 GND PCIX_AD23

25 GND PMC_IDSEL

26 PCIX_CBE-L3 PCIX_AD23

27 PCIX_AD22 P3V3

28 PCIX_AD21 PCIX_AD20

29 PCIX_AD19 PCIX_AD18

30 P5V GND

31 PCIX_FRAME-L PCIX_AD16

32 PCIX_AD17 PCIX_CBE-L2

6364

12

Table 4-15: PMC Connector Pin Definitions

36 Board Interfaces

Page 51

Pin# JN1 Signal JN2 Signal

33 PCIX_FRAME-L GND

34 GND NC

35 GND PCIX_TRDY-L

36 PCIX_IRDY-L P3V3

37 PCIX_DEVSEL-L GND

38 P5V PCIX_STOP-L

39 PCIX_PCIXCAP PCIX_PERR-L

40 PCIX_LOCK-L GND

41 NC P3V3

42 NC PCIX_SERR-L

43 PCIX_PAR PCIX_CBE-L1

44 GND GND

45 PMC_VIO PCIX_AD14

46 PCIX_AD15 PCIX_AD13

47 PCIX_AD12 PCIX_M66EN

48 PCIX_AD11 PCIX_AD10

49 PCIX_AD9 PCIX_AD8

50 P5V P3V3

51 GND PCIX_AD7

52 PCIX_CBE-L0 NC

53 PCIX_AD6 P3V3

54 PCIX_AD5 NC

55 PCIX_AD4 NC

56 GND GND

57 PMC_VIO NC

58 PCIX_AD3 NC

59 PCIX_AD2 GND

60 PCIX_AD1 NC

61 PCIX_AD0 PCIX_ACK64-L

62 P5V P3V3

63 GND GND

64 PCIX_REQ64-L NC

Table 4-15: PMC Connector Pin Definitions (cont’d)

cPCI-3615

Board Interfaces 37

Page 52

XMC Connector (JN3)

Pin# A B C D E F

1 RXP RXN 3.3V NC NC VPWR

2 GND GND Not used GND GND PCIE_RST-L

3 NC NC 3.3V NC NC VPWR

4 GND GND Not used GND GND Not used

5 NC NC 3.3V NC NC VPWR

6 GND GND Not used GND GND +12V

7 NC NC 3.3V NC NC VPWR

8 GND GND Not used GND GND -12V

9 NC NC Not used NC NC VPWR

10 GND GND Not used GND GND GA0

11 TXP TXN Not used NC NC VPWR

12 GND GND GA1 GND GND Not used

13 NC NC 3.3V NC NC VPWR

14 GND GND GA2 GND GND Not used

15 NC NC Not used NC NC VPWR

16 GND GND Not used GND GND Not used

17 NC NC Not used NC NC NC

18 GND GND Not used GND GND Not used

19 CK-P CK-N Not used Not used Not used Not used

Table 4-16: XMC Connector Pin Definition

38 Board Interfaces

Page 53

cPCI-3615

CompactPCI J1 Connector

Pin Z A B C D E F

25 GND +5V REQ64# ENUM# +3.3V +5V GND

24 GND CPCI_AD1 +5V CPCI_VIO CPCI_AD0 ACK64# GND

23 GND P3V3 CPCI_AD4 CPCI_AD3 P5V CPCI_AD2 GND

22 GND CPCI_AD7 GND P3V3 CPCI_AD6 CPCI_AD5 GND

21 GND P3V3 CPCI_AD9 CPCI_AD8 CPCI_M66EN CPCI_CBE-L0 GND

20 GND CPCI_AD12 GND VIO CPCI_AD11 CPCI_AD10 GND

19 GND P3V3 CPCI_AD15 CPCI_AD14 GND CPCI_AD13 GND

18 GND CPCI_SERR-L GND P3V3 CPCI_PAR CPCI_CBE-L1 GND

17 GND P3V3 NC NC GND CPCI_PERR-L GND

16 GND CPCI_DEVSEL-L CPCI_PCIXCAP VIO CPCI_STOP-L CPCI_LOCK-L GND

15 GND P3V3 CPCI_FRAME-L CPCI_IRDY-L NC CPCI_TRDY-L GND

12-14 Key

11 GND CPCI_AD18 CPCI_AD17 CPCI_AD16 GND CPCI_CBE-L2 GND

10 GND CPCI_AD21 GND P3V3 CPCI_AD20 CPCI_AD19 GND

9 GND CPCI_CBE-L3 NC CPCI_AD23 GND CPCI_AD22 GND

8 GND CPCI_AD26 GND VIO CPCI_AD25 CPCI_AD24 GND

7 GND CPCI_AD30 CPCI_AD29 CPCI_AD28 GND CPCI_AD27 GND

6 GND CPCI_REQ-L0 GND P3V3 CPCI_CLK0 CPCI_AD31 GND

5 GND NC NC CPCI_RESET-L GND CPCI_GNT-L0 GND

4 GND NC CPCI_HEALTHY-L VIO NC NC GND

3 GND CPCI_IRQA-L CPCI_IRQB-L CPCI_IRQC-L P5V CPCI_IRQD-L GND

2 GND cPCI_TCK-L P5V cPCI_TMS-L NC cPCI_TDI-L GND

1 GND P5V NC cPCI_TRST-L P12V P5V GND

Ta ble 4-17: CompactPCI J1 Connecto r Pin De fini tion

Board Interfaces 39

Page 54

CompactPCI J2 Connector

Pin Z A B C D E F

22 GND GA4 GA3 GA2 GA1 GA0 GND

21 GND CLK6 GND LAN1_TXDP0 LAN1_TXDN0 CK_ PCIE-N GND

20 GND CLK5 GND LAN1_TXDP2 GND CK_ PCIE-P GND

19 GND GND GND LAN1_TXDN2 LAN1_TXDP1 LAN1_TXDN1 GND

18 GND PCIE_TXP2 LAN1_TXDP3 LAN1_TXDN3 GND P3V3 GND

17 GND PCIE_TXN2 GND PRSTJ REQ6# GNT6# GND

16 GND GPIO0 PCIE_ RXP2 NC GND PCIE_RST# GND

15 GND RGB_BLUE PCIE_ RXN2 NC REQ5# GNT5# GND

14 GND GPIO1 NC USB_5_OC# SATA_TX-N1 COM2_RI# GND

13 GND LAN2_TXDP0 GND SATA_TX-P1 COM2_DTR# COM2_CTS# GND

12 GND GPIO2 LAN2_TXDN0 USB5-P SATA_RX-N1 COM2_SOUT GND

11 GND LAN2_TXDP1 GND SATA_RX-P1 COM2_RTS# COM2_SIN GND

10 GND GPIO3 LAN2_TXDN1 USB5-N GND COM2_DSR# GND

9GND

8GND

7GND RGB_RED GND +5V COM3_CTS# COM3_SOUT GND

6GND

5GND

4GND V(I/O) SATA_RX-P2 SATA_RX-N2 SATA_TX_P2 COM3_DCD# GND

3 GND CLK4 GND GNT3# REQ4# GNT4# GND

2 GND CLK2 CLK3 SYSEN# GNT2# REQ3# GND

1 GND CLK1 GND REQ1# GNT1# REQ2# GND

VSY/

GPIO4

HSY/

GPIO5

DDC_CLK/

GPIO6

DDC_DAT/

GPIO7

GND RGB_GREEN COM2_DCD# COM3_RI# GND

LAN2_TXDP2 LAN2_TXDN2 GND COM3_DTR# GND

LAN2_TXDP3 LAN2_TXDN3 GND CON3_RTS# GND

GND SATA_TX_N2 COM3_SIN COM3_DSR# GND

Table 4-18: CompactPCI J2 Connector Pin Definition

COM port

VGA (shared w/ GPIO pin 4-7 by switch selection)

Serial ATA

USB port

PCI-Express x1

Ethernet port

40 Board Interfaces

Page 55

4.9 Switch and Jumper Settings

Clear CMOS Switch (SW4)

The cPCI-3615 comes with a Clear CMOS switch to reset the

CMOS values to default. The switch is located on solder side of

the board, under the "CE" logo. Press the switch to clear the

CMOS and reset the values to default.

VGA/GPIO Mode Switches (SW1, SW3)

The VGA and GPIO 4~7 signals to J2 share the same pins and

are selected by switch settings. SW1 is located on the

cPCI-3615 component side (see “cPCI-3615 Blade Board Layout” on page 19 and “Removing the DB-3610CF Daughter

Board” on page 59) and SW3 is located on the solder side

behind SW1. When the switches are set to VGA mode, the

VGA signals are available to J2, and there are only four GPIO

signals connected to J2 (GPIO 0~3). When the switches are

set to GPIO mode, there are eight GPIO signals connected to

J2 and VGA output to the RTM is not available. The switches

are set to VGA mode by default.

cPCI-3615

SW1 SW3

Mode SW1 SW3

VGA (default) All OFF All ON

GPIO 4~7 All ON All OFF

Table 4-19: VGA/GPIO Mode Switch Settings

To enable VGA output on the RTM, Onboard VGA Output Select

must be set to Rear in the BIOS Advanced Chipset Settings.

NOTE:

NOTE:

Board Interfaces 41

Page 56

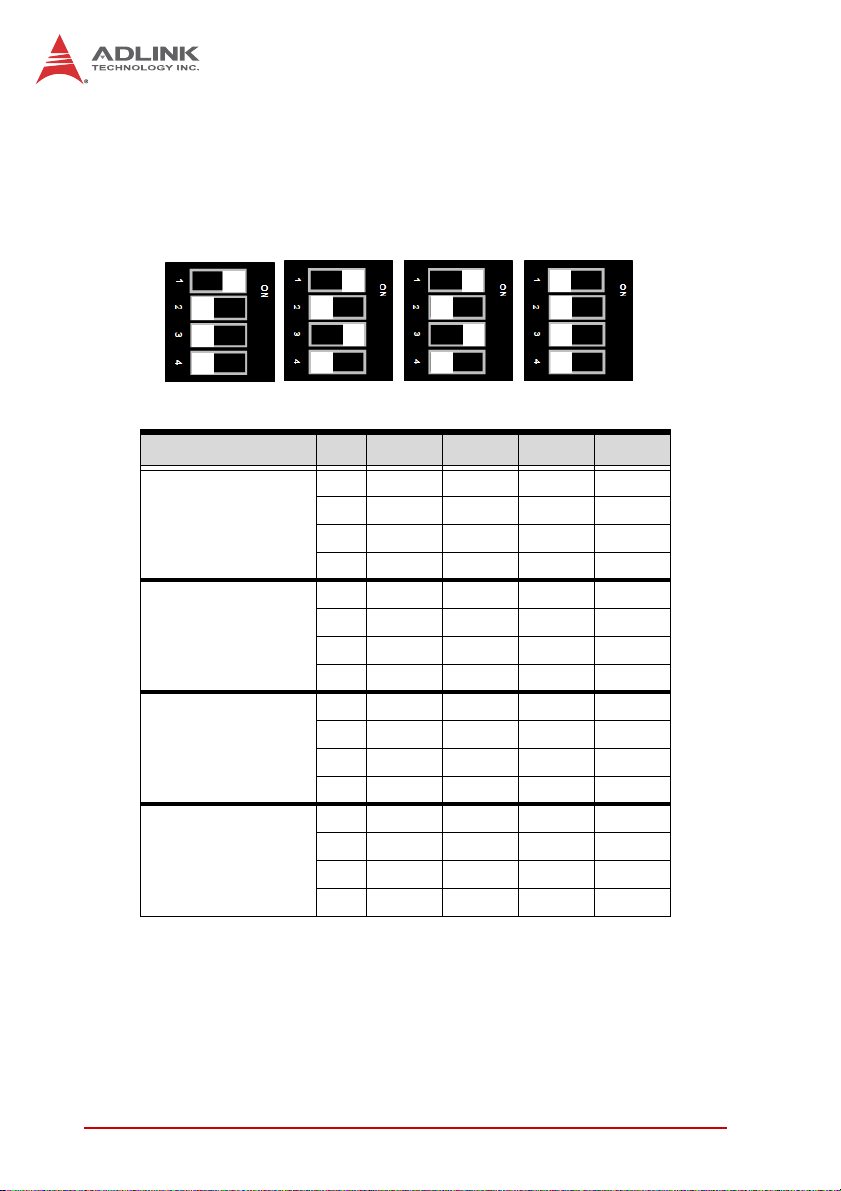

COM1 Mode Selection Switches (SW1~SW4)

These switches select COM1 (cPCI-3615D/P front panel) to be

RS-232 full modem, RS-422, RS-485, or RS-485+ half-duplex

mode. Switches SW1~SW4 are located on the top edge of the

DB-3610L2 board. RS-232 full modem is set by default.

SW1 SW2 SW3 SW4

Mode Pin SW1 SW2 SW3 SW4

1ONONONOFF

RS-232

RS-422

RS-485

RS-485+

Table 4-20: COM1 Mode Selection Switch Settings

2 OFF OFF OFF OFF

3 OFF ON ON OFF

4 OFF OFF OFF OFF

1 OFF OFF OFF ON

2ONONONOFF

3 OFF OFF OFF ON

4 OFF ON ON OFF

1 OFF OFF OFF ON

2 OFF ON ON OFF

3ONOFFOFFON

4 OFF ON ON OFF

1 OFF OFF OFF OFF

2 OFF ON ON ON

3ONOFFOFFOFF

4 OFF ON ON ON

42 Board Interfaces

Page 57

cPCI-3615

COM2 Mode Selection Switches on RTM (SW1~SW4)

These switches on the RTM select COM2 to be RS-232 full

modem, RS-422, RS-485, or RS-485+ half-duplex mode.

RS-232 full modem is set by default. See “cPCI-R3610T RTM

Board Layout” on page 25 for switch locations.

SW1 SW2 SW3 SW4

Mode Pin SW1 SW2 SW3 SW4

1 OFF ON ON ON

RS-232

RS-422

RS-485

RS-485+

Table 4-21: COM2 Mode Selection Switch Settings

2OFFOFFOFFOFF

3 OFF ON ON OFF

4OFFOFFOFFOFF

1ONOFFOFFOFF

2 OFF ON ON ON

3ONOFFOFFOFF

4 OFF ON ON OFF

1ONOFFOFFOFF

2 OFF ON ON OFF

3ONOFFOFFON

4 OFF ON ON OFF

1OFFOFFOFFOFF

2ON ON ONOFF

3 OFF OFF OFF ON

4ON ON ONOFF

Board Interfaces 43

Page 58

COM3 Mode Selection Switches on RTM (SW5~SW8)

These switches on the RTM select COM3 to be RS-232 full

modem, RS-422, RS-485, or RS-485+ half-duplex mode.

RS-232 full modem is set by default. See “cPCI-R3610T RTM

Board Layout” on page 25 for switch loc at ion s.

SW5 SW6 SW7 SW8

Mode Pin SW5 SW6 SW7 SW8

1 OFF ON ON ON

RS-232

RS-422

RS-485

RS-485+

Table 4-22: COM3 Mode Selection Switch Settings

2 OFF OFF OFF OFF

3 OFF ON ON OFF

4 OFF OFF OFF OFF

1ONOFFOFFOFF

2 OFF ON ON ON

3ONOFFOFFOFF

4 OFF ON ON OFF

1ONOFFOFFOFF

2 OFF ON ON OFF

3ONOFFOFFON

4 OFF ON ON OFF

1 OFF OFF OFF OFF

2ONONONOFF

3 OFF OFF OFF ON

4ONONONOFF

44 Board Interfaces

Page 59

cPCI-3615

XMC VPWR Select Jumper on DB-3UMC (JPX1)

This jumper is located on the DB-3UMC board near JN1/2 and

selects the XMC VPWR setting. 5V is set by default.

Mode Connection JPX1

+5V (Default) 1 – 2

+12V 2 – 3

Table 4-23: XMC VPWR Select Jumper Settings

PMC V(I/O) Select Jumper on DB-3UMC (JPX2)

This jumper is located on the DB-3UMC board near JN1/2 and

selects the PMC V(I/O) setting. 3.3V is set by default.

Mode Connection JPX2

+5V 1 – 2

+3.3V (Default) 2 – 3

Table 4-24: PMC V(I/O) Select Jumper Settings

Board Interfaces 45

Page 60

This page intentionally left blank.

46 Board Interfaces

Page 61

5 Getting Started

This chapter describes the installation procedures for the

cPCI-3615 and rear transition module:

X 2.5” SATA Hard Drive Disk installation

X PCI Mezzanine Card installation

X cPCI-3615 installation to chassis

X RTM installation to chassis

5.1 CPU and Heatsink

The cPCI-3615 Series come with a BGA CPU soldered onboard

and heatsink pre-installed. Removal of heatsink/CPU by users is not

recommended. Please contact your ADLINK service representative

for assistance.

cPCI-3615

Getting Started 47

Page 62

5.2 Hard Drive Installation

The cPCI-3615D/P 2/3 slot versions provide space to install a slim

type 2.5” Serial-ATA hard drive.

Installing a Hard Drive - cPCI-3615D

1. Attach the mounting brackets to the hard drive with four

M3 screws provided.

2. Align the hard drive assemby with the mounting points

on the cPCI-3615D and insert it into the onboard Serial

ATA connector until it is properly seated.

48 Getting Started

Page 63

cPCI-3615

3. Secure the hard drive assemby to the cPCI-3615D using

four M2.5 screws provided.

Getting Started 49

Page 64

Installing a Hard Drive - cPCI-3615P

1. To install a hard drive on the cPCI-3615P, the front panel

and DB-3UMC daughter board must first be disassembled.

Remove the front panel by unscrewing

securing it to the PCB assembly (arrows), the four standoffs securing the VGA and COM connectors (circles),

and one screw under the ejector handle.

the four screws

50 Getting Started

Page 65

cPCI-3615

2. Detach the faceplate from the PCB assembly.

3. Loosen the five screws securing DB-3UMC riser card to

the PCB assembly.

Getting Started 51

Page 66

4. Remove the DB-3UMC riser card, taking care to lift it

from the board-to-board connector indicated below.

5. Attach the mounting brackets to the hard drive with four

M3 screws provided.

52 Getting Started

Page 67

cPCI-3615

6. Align the hard drive assemby with the mounting points

on the cPCI-3615P and insert it into the onboard Serial

ATA connector until it is properly seated.

7. Secure the hard drive assemby to the cPCI-3615P using

four M2.5 screws provided.

Getting Started 53

Page 68

8. Re-attach the DB-3 UMC riser card to the PCB assembly,

taking care to press down firmly on the board-to-board

connector.

9. Re-attach the faceplate to the cPCI-3615P by fastening

the four screws and four standoffs removed in Step 1

above.

54 Getting Started

Page 69

cPCI-3615

5.3 PMC/XMC Card Installation

The cPCI-3615P provides one PMC/XMC slot designed to suppo rt

3.3V or 5V V(I/O) (default 3.3V) and 5V or 12V VPWR (default

5V). Before you install the PMC/XMC card on the cPCI-3615P,

please make sure that the PMC V(I/O) jumper JPX2 and XMC

VPWR jumper JPX1 have been correctly set (see page 45).

1.

To install a PMC/XMC card on the cPCI-3615P, the front

panel and DB-3UMC daughter board must first be disassembled. Remove the front panel by uns crewing

securing it to the PCB assembly (arrows), the four standoffs securing the VGA and COM connectors (circles),

one screw under the ejector handle.

the four screws

and

Getting Started 55

Page 70

2. Remove the DB-3UMC daughter board by unscrewing

the four screws as shown below.

3.3V Key

3. There is a 3.3V key on board by de fault, if the PMC/XMC

This page intentionally left blank.

card you wish to install is 5V signaling, please remove

the key and set the PMC V(I/O) jumper JPX2 to the 5V

setting.

4. Align the male connectors of the PMC/XMC card (component-side down) to the female connectors of the

DB-3UMC and press down.

56 Getting Started

Page 71

cPCI-3615

5. Secure the PMC/XMC card to the DB-3UMC by attach-

ing four screws (provided with the card) from the underside of the daughter board.

6. Align the male board-to-board connector (CN1) of the

PMC/XMC assembly to the female board to board connector (CN7) of the DB-3610L2 riser card and press

down.

Getting Started 57

Page 72

7. Secure the PMC/XMC assembly to the DB-3610L2 riser

card using the four screws removed in Step 2 above.

8. Remove the PMC filler faceplate from the front panel.

9. Assemble the front panel to the cPCI-3615P by reversing Step 1.

58 Getting Started

Page 73

cPCI-3615

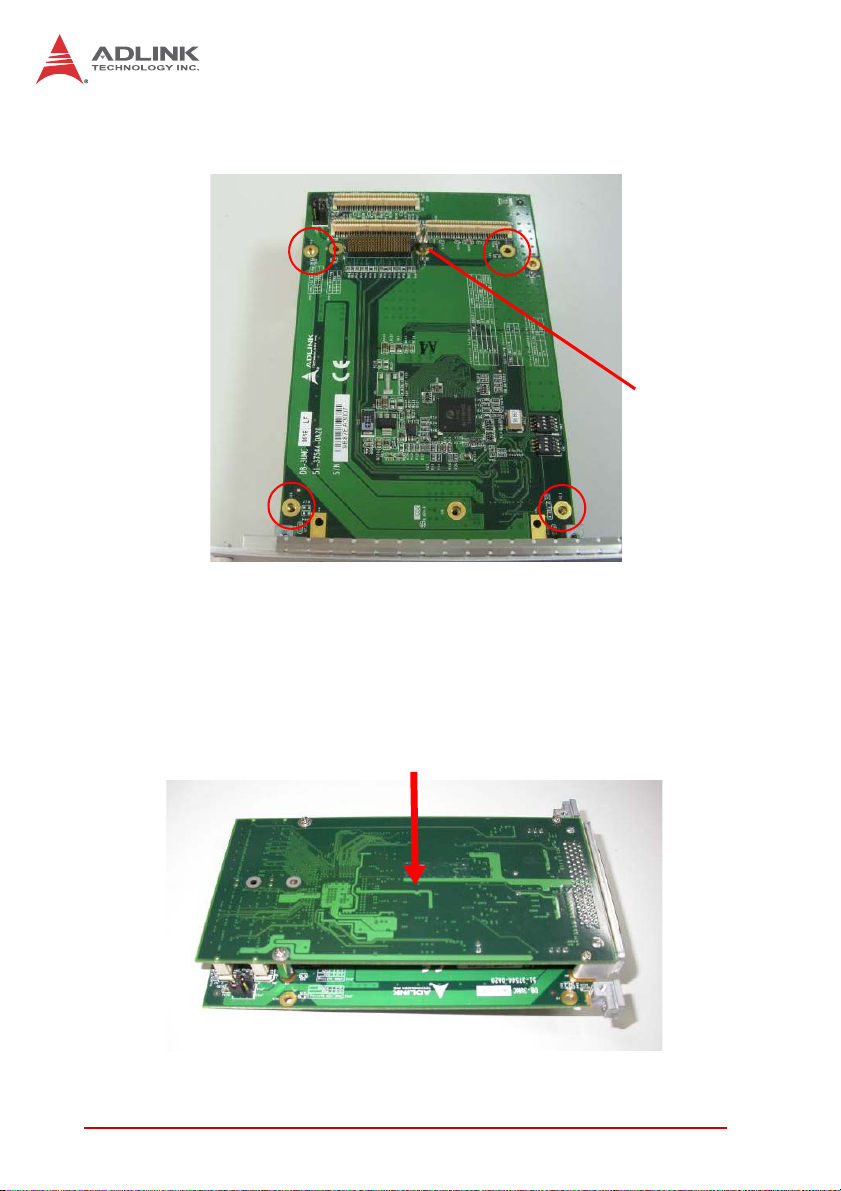

5.4 Removing the DB-3610CF Daughter Board

To access SW1 (VGA/GPIO Mode Switch) which is under the

DB-3610CF Daughter Board, follow the steps below (see

“cPCI-3615 Blade Assembly Layout” on page 20 for DB-3610CF

location).

1.

Remove the front panel from the blade assembly by

unscrewing

version shown).

2.

Remove the Layer 2 daughter board by unscrewing the five

screws as shown below (not required fo r single-slot version).

the screws and standoffs as shown (dual-slot

Getting Started 59

Page 74

3. Remove the screw securing the DB-3610CF from the

component side of the blade as shown.

4. Remove the screw securing the DB-3610CF from the

solder side of the blade as shown.

5. Remove the DB-3610CF from the blade assembly.

60 Getting Started

Page 75

cPCI-3615

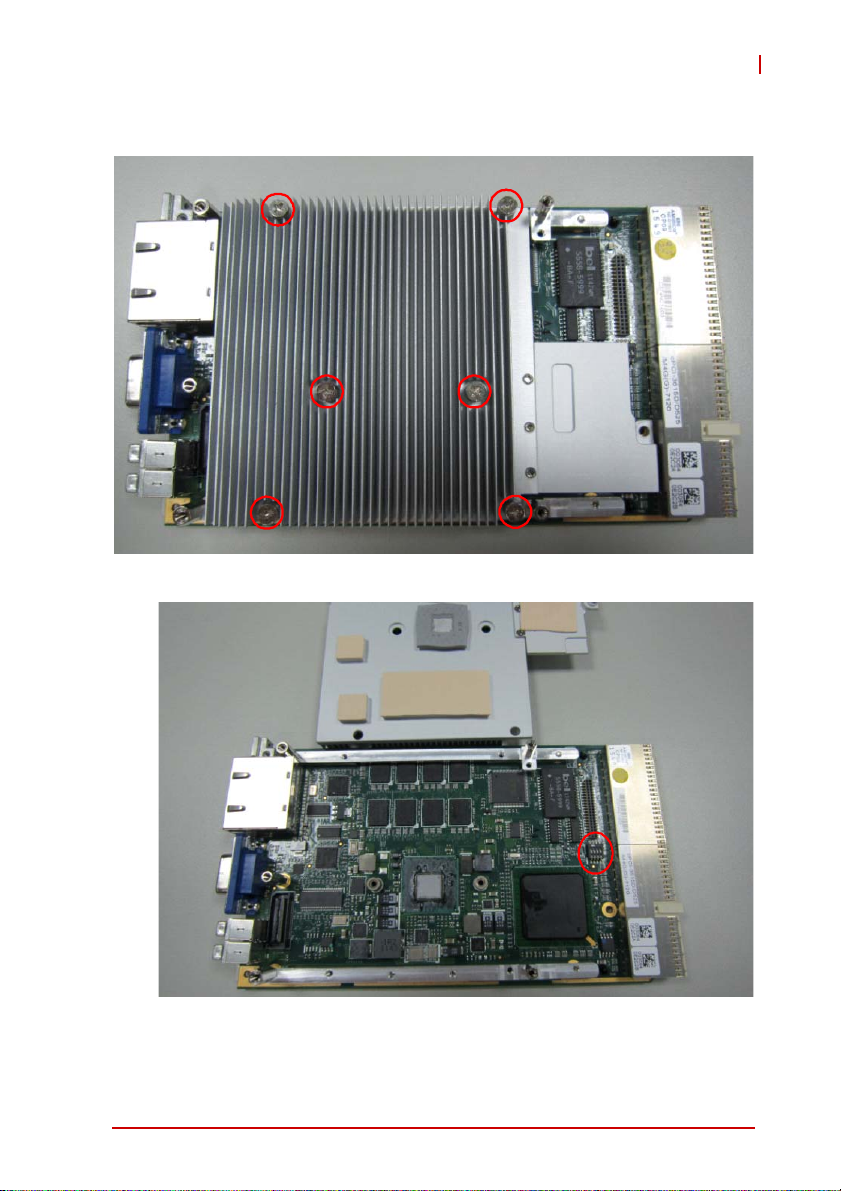

6. Remove the six screws securing the heatsink to the

blade assembly

7. Remove the heatsink to access SW1.

To reassemble the cPCI-3615 blade, reverse Steps 1~7 above.

Getting Started 61

Page 76

5.5 Installing the cPCI-3615 to the Chassis

The cPCI-3615 may only be installed in a system slot of a 3U

CompactPCI chassis. These instructions are for reference only.

Refer to the user guide that comes with the chassis for more information.

1. Be sure to select the correct slot depending on the operational purpose of the module. The system power may

now be powered on or off.

2. Remove the blank face cover from the selected slot, if

necessary.

3. Press down on the release catches of the cPCI-3615

ejector handles.

4. Remove the black plastic caps securing the mounting

screws to the front panel.

5. Align the blade’s top and bottom edges to the chassis

card guides, and then carefully slide the blade into the

chassis. A slight resistance may be felt when inserting

the blade. If the resistance it too strong, check if there

are bent pins on the backplane or if the board’s connector pins are not properly aligned with connectors on the

backplane. Then push the board until it is completely

flush with the chassis.

6. Push the ejector handle outwards to secure the blade in

place, and then fasten the screws on the front panel.

7. Connect the cables and peripherals to the board, and

then turn the chassis on if necessary.

62 Getting Started

Page 77

cPCI-3615

5.6 RTM Installation - cPCI-R3610(T)

The installation and removal procedures for a RTM are the same

as those for CompactPCI boards. Because they are shorter than

front boards, pay careful attention when inserting or removing

RTMs.

Refer to previous sections for peripheral connectivity of all

I/O ports on the RTM. When installing the cPCI-3615 Series and

related RTMs, make sure the RTM is the correct matching model.

You must install the correct RTM to enable functions (I/O interfaces) on the rear panel. Installation of non-compatible RTMs

NOTE:

NOTE:

may damage the system board and/or other RTMs.

Getting Started 63

Page 78

This page intentionally left blank.

64 Getting Started

Page 79

6 Driver Installation

The cPCI-3615 drivers are available from the ADLINK All-In-One

CD at X:\cPCI\cPCI-3615\, or from the ADLINK website

(http://www.adlinktech.com). This section describes the driver

installation procedures for Windows® 7.

1. Install the Windows operating system before installing

any driver. Most standard I/O device drivers are installed

during Windows installation.

2. Install the chipset driver by running the program

...\Chipset\Intel_INF_Update_Utility_All_WinOS

v9.1.1.1023.zip.

3. Install the VGA driver and utilities by running the program

...\Graphics\

Intel_Graphics_Adapter_Win7_64_v8.14.10.2230.zip.

4. Install the LAN driver by running the program

…\LAN\Intel_Network_Adapter_Win7_64_v11.4.7.0.zip.

5. Install the Audio driver by running the program

…\Audio\Win2KXP2003_32_64_ bits.exe

We recommend using the drivers provided on the ADLINK

All-in-One CD or downloaded from the ADLINK website to ensure

compatibility. Please download the VxWorks BSP from the

ADLINK website.

cPCI-3615

Driver Installation 65

Page 80

This page intentionally left blank.

66 Driver Installation

Page 81

7 Utilities

7.1 Watchdog Timer

This section describes the operation of the cPCI-3615’s watchdog

timer (WDT). The primary function of the WDT is to monitor the

cPCI-3615's operation and to reset the system if a software application fails to function as prog rammed. The following WDT functions may be controlled using a software application:

X enabling and disabling

X reloading timeout value

The cPCI-3615 custom WDT circuit is implemented using the

internal I/O of the ITE SuperIO IT8783 which is at 2Eh of LPC. The

basic functions of the WDT include:

X Starting the timer countdown

X Enabling or disabling WDT

X Enabling or disabling WDT countdown LED ON

X Reloading the timeout value to keep the watchdog from tim-

ing out

X Setting the range of the timeout period from 1 second or minute

to maximum 65635 seconds or minutes

X Sending a RESET signal to the system when the watchdog

times out

cPCI-3615

Using the Watchdog in an Application

The following section describes using the WDT functions in an

application. The WDT reset function is explained in the previous

section. This can be controlled through the registers in the

cPCI-3615's SuperIO.

An application using the reset fe ature enab les the watch dog func tion, sets the count-down period, and reloads the timeout value

periodically to keep it from resetting the system. If the timer countdown value is not reloaded, the watchdog resets the system hardware after its counter reaches zero.

For a detailed programming sample, refer to the sample code provided in the ADLINK All-In-One CD. You can find it in the following

directory: X:\cPCI\cPCI-3615\WDT.

Utilities 67

Page 82

Sample Code

The sample program written in C shown below offers an interactive way to test the Watchdog Timer under DOS.

#include<stdio.h>

#include<dos.h>

#define IT8783_ID1 0x87

#define IT8783_ID2 0x83

static unsigned int IT8783_ioPort = 0x2e;

//Check index port

void Enter_IT8783_Config(unsigned int flag)

{

if(flag) IT8783_ioPort = 0x4e;

switch(IT8783_ioPort)

{

case 0x2E: //Address port = 0x2E, enter keys =

0x87, 0x01, 0x55, 0x55

outportb(0x2E, 0x87);

outportb(0x2E, 0x01);

outportb(0x2E, 0x55);

outportb(0x2E, 0x55);

break;

case 0x4E: //Address port = 0x4E, enter keys =

0x87, 0x01, 0x55, 0xAA

outportb(0x4E, 0x87);

outportb(0x4E, 0x01);

outportb(0x4E, 0x55);

outportb(0x4E, 0xAA);

break;

default:

break;

}

}

//Exit index port

void Exit_IT8783_Config(unsigned int flag)

{

if(flag) IT8783_ioPort = 0x4e;

68 Utilities

Page 83

cPCI-3615

outportb(IT8783_ioPort, 0x02);

outportb(IT8783_ioPort+1, 0x02);

}

//Check chip

void Get_IT8783_ID(unsigned int &ID1, unsigned int &ID2)

{

outportb(IT8783_ioPort, 0x20);

ID1 = inportb(IT8783_ioPort+1);

outportb(IT8783_ioPort, 0x21);

ID2 = inportb(IT8783_ioPort+1);

}

//WDT and LED program

void IT8783_3_WDTRun(unsigned int count_value, unsigned

int PLEDflag) //for cPCI-3615

{

unsigned long tempCount;

unsigned int registerValue;

outportb(IT8783_ioPort, 0x07);

outportb(IT8783_ioPort+1, 0x07);// Device 7

outportb(IT8783_ioPort, 0xf8);

outportb(IT8783_ioPort+1, 0x00);// PLED mapping to

nothing, disable PLED function

if(PLEDflag == 1)

{

outportb(IT8783_ioPort, 0x2D);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0x01; // set Pin109 is GPIO

function GP60

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0xC5);

registerValue = inportb(IT8783_ioPort + 1);

registerValue &= 0xfe; // set GP60 is alternate

function

Utilities 69

Page 84

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0xCD);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0x01; // set GP60 is output

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0xf8);

outportb(IT8783_ioPort+1, 0x30);// PLED mapping to

GP60

outportb(IT8783_ioPort, 0xf9);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0x02;

registerValue &= 0xfb;

outportb(IT8783_ioPort+1, registerValue);

}

outportb(IT8783_ioPort, 0x71);

registerValue = inportb(IT8783_ioPort + 1);

registerValue |= 0xD0; // set Mouse & Keyboard

interrupt Enable

outportb(IT8783_ioPort+1, registerValue);

outportb(IT8783_ioPort, 0x73);

outportb(IT8783_ioPort+1, count_value); // set WDT

count LSB

tempCount = tempCount >> 8;

outportb(IT8783_ioPort, 0x74);

outportb(IT8783_ioPort+1, count_value); // set WDT

count MSB

if(count_value >= 60)

{

outportb(IT8783_ioPort, 0x72);

registerValue = inportb(IT8783_ioPort+1);

registerValue &= 0x8f;

registerValue |= 0x10; //enable WDT output through

PowerOK!

outportb(IT8783_ioPort+1, registerValue); // set

WDT count is minute

tempCount = count_value / 60;

if((count_value%60) > 30)

70 Utilities

Page 85

tempCount++;

if(tempCount > 65535)

tempCount = 65535;

printf("WDT timeout in %d minutes.\n", tempCount);

}

else

{

outportb(IT8783_ioPort, 0x72);

registerValue = inportb(IT8783_ioPort+1);

registerValue |= 0x80;

tempCount = count_value;

if(tempCount != 0)

{

printf("WDT timeout in %d seconds.\n",

tempCount);

registerValue |= 0x40; //Enable WDT output

through KBRST

}

else

{

printf("WDT is Disabled.\n");

registerValue &= 0xbf; //Disable WDT output

through KBRST

}

cPCI-3615

outportb(IT8783_ioPort+1, registerValue); // set

WDT count is second

}

}

Utilities 71

Page 86

7.2 Preboot Execution Environment (PXE)

The cPCI-3615 Series supports the Intel® Preboot Execution

Environment (PXE) that is capable of booting up or executing an

OS installation through an Ethernet ports. To use PXE, there must

be a DHCP server on the network with one or more servers running PXE and MTFTP services. It could be a Windows® 2003

server running DHCP, PXE, and MTFTP services or a dedicated

DHCP server with one or more additional servers running PXE

and MTFTP services.

To build a network environment with PXE support:

1. Setup a DHCP server with PXE tag configuration

2. Install the PXE and MTFTP services

3. Make a boot image file on the PXE server (i.e. the boot server)

4. Enable the PXE boot function on the client computer

72 Utilities

Page 87

8 BIOS Setup

The following chapter describes basic navigation for the

AMIBIOS®8 BIOS setup utility.

8.1 Starting the BIOS

To enter the setup screen, follow these steps:

1. Power on the motherboard

2. Press the < Delete > key on your keyboard when you

see the following text prompt:

< Press DEL to run Setup >

3. After you press the < Delete > key, the main BIOS setup

menu displays. You can access the other setup screens

from the main BIOS setup menu , such as Chipset and

Power menus.

cPCI-3615

Note: In most cases, the < Delete > key is used to invoke the setup

screen. There are several cases that use other keys, such as

< F1 >, < F2 >, and so on.

BIOS Setup 73

Page 88

Setup Menu

The main BIOS setup menu is the first screen that you can navigate. Each main BIOS setup menu option is described in this

user’s guide.

The Main BIOS setup menu screen has two main frames. The left

frame displays all the options that can be configured. “Grayed”

options cannot be configured, “Blue” options can be.

The right frame displays the key legend. Above the key legend is

an area reserved for a text message. When an option is selected

in the left frame, it is highlighted in white. Often a text message will

accompany it.

Navigation

The BIOS setup/utility uses a key-based navigation system called

hot keys. Most of the BIOS setup utility hot keys can be used at

any time during the setup navigation process.

These keys include < F1 >, < F10 >, < Enter >, < ESC >, < Arrow >

keys, and so on. .

74 BIOS Setup

Page 89

cPCI-3615

Note: There is a hot key legend located in the r ight frame on most

setup screens.

The < F8 > key on your keyboard is the Fail-Safe key. It is not displayed on the key legend by default. To set the Fail-Safe settings

of the BIOS, press the < F8 > key on your keyboard. It is located

on the upper row of a standard 101 keyboard. The Fail-Safe settings allow the motherboard to boot up with the least amount of

options set. This can lessen the probability of conflicting settings.

Hotkey Descriptions

F1 The < F1 > key allows you to display the General Help

screen.

Press the < F1 > key to open the General Help screen.

BIOS Setup 75

Page 90

F10 T h e < F1 0 > key allows yo u to save any changes you have

made and exit Setup. Press the < F10 > key to save your

changes. The following screen will appear:

Press the < Enter > key to save the configuration and exit.

You can also use the < Arrow > key to select Cancel and

then press the < Enter > key to abort this functio n and return

to the previous screen.

ESC The < Esc > key allows you to discard any changes you have

made and exit the Setup. Press the < Esc > key to exit the

setup without saving your changes. The following screen will

appear:

Press the < Enter > key to discard changes and exit. You can

also use the < Arrow > key to select Cancel and then press

the < Enter > key to abort this function and return to the previous screen.

Enter The < Enter > key allows you to display or change the setup

option listed for a particular setup item. The < Enter > key

can also allow you to display the setup sub-screens.

76 BIOS Setup

Page 91

cPCI-3615

8.2 Main Setup

When you first enter the Setup Utility , you will enter the Main setup

screen. You can always return to the Main setup screen by selecting the Main tab. There are two Main Setup options. They are

described in this section. The Main BIOS Setup screen is shown

below.

System Time/System Date

Use this option to change the system time and date. Highlight System Time or System Date using the < Arrow > keys. Enter new values using the keyboard. Press the < Tab > key or the < Arrow >

keys to move between fields. The date must be entered in MM/

DD/YY format. The time is entered in HH:MM:SS format.

Note: The time is in 24-hour format. For example, 5:30 A.M. ap-

pears as 05:30:00, and 5:30 P.M. as 17:30:00.

8.3 Advanced BIOS Setup

Select the Advanced tab from the setup screen to enter the

Advanced BIOS Setup screen. You can select any of the items in

BIOS Setup 77

Page 92

the left frame of the screen to go to the sub menu for that item.

You can display an Advanced BIOS Setup option by highlighting it

using the < Arrow > keys. The Advanced BIOS Setup screen is

shown below.

The sub menus are described on the following pages.

78 BIOS Setup

Page 93

cPCI-3615

8.3.1 CPU Configuration

You can use this screen to select options for the CPU Configuration Settings. Use the up and down < Arrow > keys to select an

item. Use the < + > and < - > keys to change the value of the

selected option. A description of the selected item appears on the

right side of the screen. The settings are described on the following pages. An example of the CPU Configuration screen is shown

below.

Max CPUID Value Limit

When the computer is booted up, the operating system executes the CPUID instruction to identify the processor and its

capabilities. Before it can do so, it must first query the processor to find out the highest input value CPUID recognized. This

determines the kind of basic information CPUID can provide

the operating system. This option allows you to circumvent

problems with older operating systems.

When Enabled, the processor will limit the maximum CPUID

input value to 03h when queried, even if the processor supports a higher CPUID input value. When Disabled, the processor will return the actual maximum CPUID input value of the

processor when queried.

BIOS Setup 79

Page 94

Execute-Disable Bit Capability

Intel’s Execute Disable Bit functionality can help prevent certain classes of malicious buffer overflow attacks when combined with a supporting operating system. Exec ute Disable Bit

allows the processor to classify areas in memory where application code can execute and where it cannot. When a malicious worm attempts to insert code in the buffer, the processor

disables code execution, preventing damage and worm propagation.

Hyper-Threading Technology

This item allow you to enable or disable Hyper-Thread ing Technology.

Intel® Speedstep™ Tech

Intel® SpeedStep Technology allows the system to dynamically

adjust processor voltage and core frequency, which can result

in decreased average power consumption and decreased

average heat production.

Intel® C-State Tech

This option allows you to enable or disable Intel® C-State function.

Enhanced C-State Tech

This option allows you to enable or disable the Enhanced CState function.

80 BIOS Setup

Page 95

cPCI-3615

8.3.2 IDE Configuration

You can use this screen to select options for the IDE Configuration

Settings. Use the up and down < Arrow > keys to select an item.

Use the < + > and < - > keys to change the value of the selected

option.

ATA/IDE Configuration

This item specifies which mode the ATA/IDE channels should

be initialized in. The settings are Disabled, Compatible and

Enhanced.

Configure SAT A as

When running in Compatible mode, SATA channels can be

configured as a legacy IDE channel.

SATA1 does not support Compatible mode due to chipset

limitation.

NOTE:

NOTE:

IDE Master/Slave

Select one of the hard disk drives to configure it. Press

< Enter > to access its sub menu.

BIOS Setup 81

Page 96

8.3.3 Super IO Configuration

You can use this screen to select options for the Super IO settings.

Use the up and down < Arrow > keys to select an item. Use the <

+ > and < - > keys to change the value of the selected option. The

settings are described on the following pages. The screen is

shown below.

Serial Port1/2 Address

Select an address for Serial Port1/2.

Port1 Options: 3F8, 3E8, 2E8, Disabled.

Port2 Options: 2F8, 3E8, 2E8, Disabled.

Serial Port1/2 IRQ

Select an IRQ for Serial Port1/2.

Options: 3, 4, 10, 11.

Serial Port3

Enable or disable Serial Port3 (address/IRQ: 3E8/10).

82 BIOS Setup

Page 97

cPCI-3615

8.3.4 Hardware Health Configuration

This option displays the current status of all of the monitored hardware devices/components such as voltages and temperatures.

The options are Enabled and Disabled.

BIOS Setup 83

Page 98

8.3.5 USB Configuration

You can use this screen to select options for the USB Configuration. Use the up and down < Arrow > keys to select an item. Use

the < + > and < - > keys to change the value of the selected

option. The settings are described on the following pages. The

screen is shown below.

Legacy USB Support

Legacy USB Support refers to USB mouse and keyboard support. Normally if this option is not enabled, any attached USB

mouse or USB keyboard will not become available until a USB