Page 1

CoreModule® 920

Single Board Computer

Reference Manual

P/N 50-1Z144-1020

Page 2

Notice Page

DISCLAIMER

ADLINK Technology, Incorporated makes no representations or warranties with respect to the contents of

this manual or of the associated ADLINK products, and specifically disclaims any implied warranties of

merchantability or fitness for any particular purpose. ADLINK shall under no circumstances be liable for

incidental or consequential damages or related expenses resulting from the use of this product, even if it has

been notified of the possibility of such damages. ADLINK reserves the right to revise this publication from

time to time without obligation to notify any person of such revisions. If errors are found, please contact

ADLINK at the address shown at the bottom of this page.

TRADEMARKS

CoreModule and the Ampro logo are registered trademarks, and ADLINK, Little Board, LittleBoard,

MightyBoard, MightySystem, MilSystem, MiniModule, ReadyBoard, ReadyBox, ReadyPanel,

ReadySystem, and RuffSystem are trademarks of ADLINK Technology, Inc. All other marks are the

property of their respective companies.

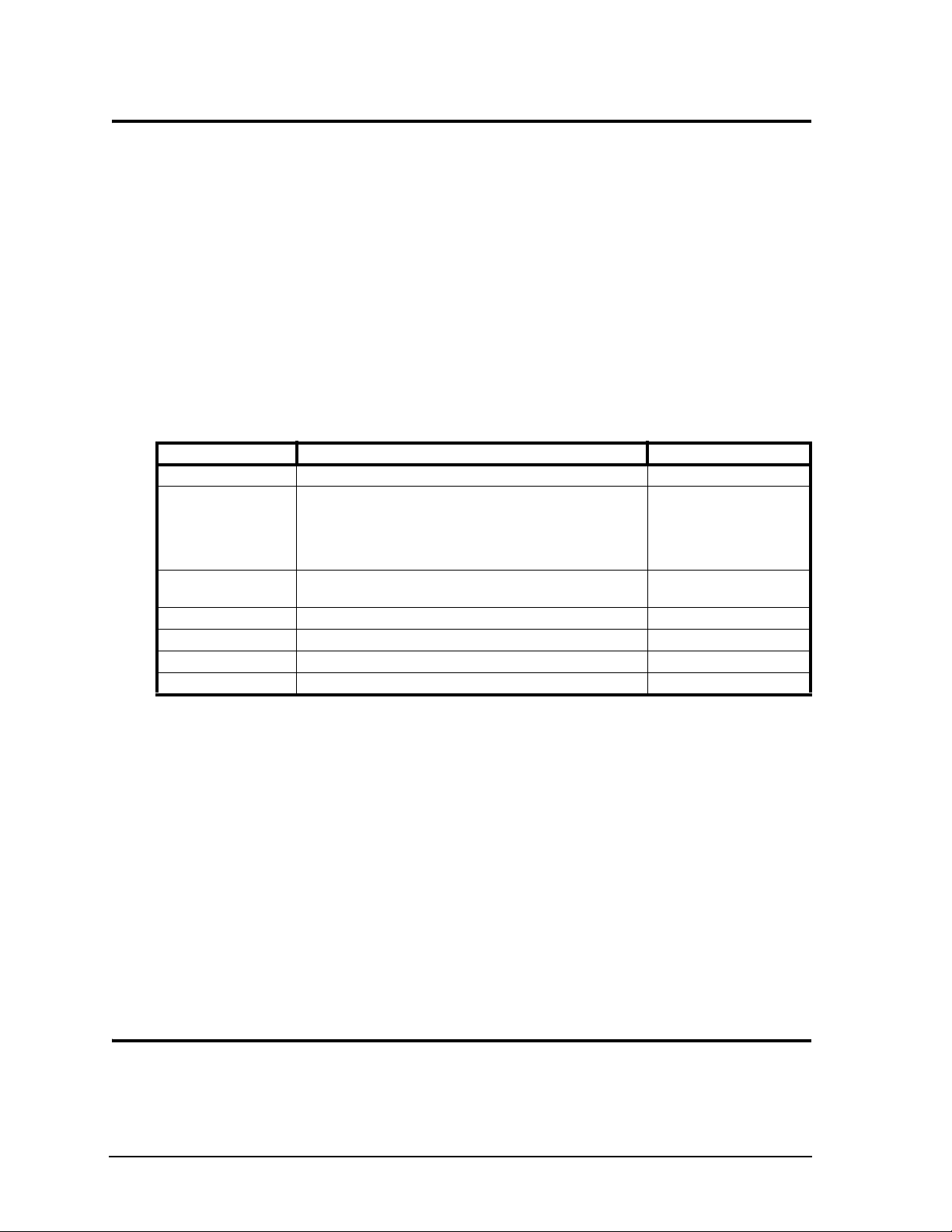

REVISION HISTORY

Revision Reason for Change Date

1000 Initial Release Jan/13

1010 Revised PCIe confiuration settings on page 21; changed battery

voltage from 3.3 to 3.0 in Tab le 3- 17 ; added header

manufacturer P/Ns to Tables 2-2 and 2-3; changed descriptions of J6

in Figure 2-4 and J5 in Figure 2-6 from PCI/104-Express to

PCIe/104; and made other minor changes

3.0 Revised mechanical dimension drawing on page 29; changed

revision of this manual from 1010 to 3.0

Jun/13

Mar/14

ADLINK Technology, Incorporated

5215 Hellyer Avenue, #110

San Jose, CA 95138-1007

Tel. 408 360-0200

Fax 408 360-0222

www.adlinktech.com

© Copyright 2013, 2014 ADLINK Technology, Incorporated

Audience

This manual provides reference only for computer design engineers, including but not limited to hardware

and software designers and applications engineers. ADLINK Technology, Inc. assumes you are qualified to

design and implement prototype computer equipment.

ii Reference Manual CoreModule 920

Page 3

Contents

Chapter 1 About This Manual ....................................................................................................1

Purpose of this Manual ....................................................................................................................1

References ......................................................................................................................................1

Chapter 2 Product Overview.....................................................................................................5

PCI/104-Express Form Factor ........................................................................................................5

Product Description .........................................................................................................................6

Module Features ........................................................................................................................7

Block Diagram .........................................................................................................................10

Major Component (ICs) Definitions ..............................................................................................11

Header, Connector, and Socket Definitions...................................................................................14

Jumper Header Definitions ...........................................................................................................16

Specifications ..............................................................................................................................17

Physical Specifications ..........................................................................................................17

Mechanical Specifications ........................................................................................................18

Power Specifications ...............................................................................................................19

Environmental Specifications ...................................................................................................20

Thermal/Cooling Requirements ...............................................................................................20

Chapter 3 Hardware .................................................................................................................21

Overview ........................................................................................................................................21

CPU ...............................................................................................................................................22

Graphics ........................................................................................................................................22

Memory .........................................................................................................................................22

Interrupt Channel Assignments .....................................................................................................23

Memory Map .................................................................................................................................23

I/O Address Map ...........................................................................................................................24

Serial Interfaces ............................................................................................................................25

USB Interface ................................................................................................................................27

Ethernet Interfaces ........................................................................................................................28

Video Interfaces ............................................................................................................................29

Power Interface .............................................................................................................................31

User GPIO Interface .....................................................................................................................32

Utility Interface ..............................................................................................................................33

Power Button ...........................................................................................................................33

Reset Switch ............................................................................................................................33

Speaker ...................................................................................................................................33

System Fan ..................................................................................................................................33

Battery............................................................................................................................................34

External LEDs (Ethernet) ..............................................................................................................34

Miscellaneous ................................................................................................................................35

SSD (Solid State Drive) ............................................................................................................35

Real Time Clock (RTC) ............................................................................................................35

Oops! Jumper (BIOS Recovery) ............................................................................................35

Serial Console .........................................................................................................................35

Serial Console Setup...........................................................................................................35

Hot (Serial) Cable .............................................................................................................35

Hardware Voltage and Temperature Monitor ..........................................................................36

Watchdog Timer ......................................................................................................................36

CoreModule 920 Reference Manual iii

Page 4

Contents

Chapter 4 BIOS Setup .............................................................................................................. 37

Introduction.................................................................................................................................... 37

Entering BIOS Setup (Local Video Display) ............................................................................. 37

Entering BIOS Setup (Serial Port Console) ............................................................................ 37

OEM Logo Utility .......................................................................................................................... 38

Logo Image Requirements....................................................................................................... 38

BIOS Setup Menus ....................................................................................................................... 39

Main BIOS Setup Screen ........................................................................................................ 39

Advanced BIOS Setup Screen ................................................................................................ 40

Chipset BIOS Setup Screen .................................................................................................... 46

Boot BIOS Setup Screen ........................................................................................................ 49

Security BIOS Setup Screen ................................................................................................... 50

Save & Exit BIOS Setup Screen ............................................................................................. 51

Appendix A Technical Support .................................................................................................. 53

Index ................................................................................................................................................. 57

List of Figures

Figure 2-1. Stacking PCI/104-Express Modules with the CoreModule 920 ............................... 6

Figure 2-2. Functional Block Diagram ..................................................................................... 10

Figure 2-3. Component Locations (Top Side).......................................................................... 13

Figure 2-4. Component Locations (Bottom Side) .................................................................... 13

Figure 2-5. Connector Pin Sequence ..................................................................................... 15

Figure 2-6. Header, Connector, and Socket Locations (Top Side) .......................................... 16

Figure 2-7. Jumper Header Locations (Top Side) ................................................................... 17

Figure 2-8. Mechanical Overview (Top Side) .......................................................................... 18

Figure 2-9. i7-3517UE Peak In-Rush Current and Duration .................................................... 19

Figure 2-10. Stack Heights of Cooling Assemblies .................................................................. 20

Figure 3-1. Oops! Jumper Serial Port (DB9)............................................................................ 35

Figure 3-2. Serial Console Jumper .......................................................................................... 35

Figure 4-1. Main BIOS Setup Screen ...................................................................................... 39

Figure 4-2. Advanced BIOS Setup Screen .............................................................................. 40

Figure 4-3. Chipset BIOS Setup Screen.................................................................................. 46

Figure 4-4. Boot BIOS Setup Screen....................................................................................... 49

Figure 4-5. Security BIOS Setup Screen ................................................................................. 50

Figure 4-6. Save & Exit BIOS Setup Screen ........................................................................... 51

List of Tables

Table 2-1. Major Component Descriptions and Functions ..................................................... 11

Table 2-2. Module Header and Connector Descriptions ........................................................ 14

Table 2-3. Jumper Settings .................................................................................................... 16

Table 2-4. Weight and Footprint Dimensions ......................................................................... 17

Table 2-5. Power Supply Requirements ................................................................................. 19

Table 2-6. Environmental Requirements ................................................................................ 20

Table 3-1. Interrupt Channel Assignments ............................................................................. 23

Table 3-2. Memory Map ......................................................................................................... 23

Table 3-3. I/O Address Map ................................................................................................... 24

Table 3-4. Serial 1 (COM1) Interface Pin Signal Descriptions (J18) ...................................... 25

Table 3-5. Serial 2 (COM2) Interface Pin Signal Descriptions (H16) ..................................... 26

Table 3-6. USB0 and USB1 Interface Pin Signals (H15)........................................................ 27

iv Reference Manual CoreModule 920

Page 5

Contents

Table 3-7. USB2 and USB3 Interface Pin Signals (J25) .........................................................27

Table 3-8. GLAN1 Interface Pin Signal Descriptions (H11) ....................................................28

Table 3-9. GLAN2 Interface Pin Signal Descriptions (J14) .....................................................29

Table 3-10. VGA Interface Pin Signal Descriptions (J17) .........................................................30

Table 3-11. LVDS Video Interface Pin Signals (J23) ................................................................30

Table 3-12. Power Interface Pin Signals (J24)..........................................................................31

Table 3-13. User GPIO1 Interface Pin Signal Descriptions (J26) .............................................32

Table 3-14. User GPIO2 Interface Pin Signal Descriptions (J27) .............................................32

Table 3-15. Utility Interface Pin Signals (J21) ...........................................................................33

Table 3-16. System Fan Pin Signals (J22) ...............................................................................33

Table 3-17. External Battery Input Header (J12) .....................................................................34

Table 3-18. GLAN1 External LED Pin Signals (J2)...................................................................34

Table 3-19. GLAN2 External LED Pin Signals (J3)...................................................................34

Table 4-1. BIOS Setup Menus ................................................................................................39

Table A-1. Technical Support Contact Information..................................................................53

CoreModule 920 Reference Manual v

Page 6

Contents

vi Reference Manual CoreModule 920

Page 7

Chapter 1 About This Manual

Purpose of this Manual

This manual is for designers of systems based on the CoreModule® 920 Single Board Computer (SBC). This

manual contains information that permits designers to create an embedded system based on specific design

requirements.

Information provided in this reference manual includes:

• Product Overview

• Hardware Specifications

• BIOS Setup information

• Technical Support Contact Information

Information not provided in this reference manual includes:

• Detailed chip specifications (refer to the References section of this chapter)

• Internal component operation

• Internal registers or signal operations

• Bus or signal timing for industry-standard busses and signals

• Pin-signal definitions for industry-standard interfaces

References

The following list of references may help you successfully complete your custom design.

Industry Standard Specifications

• PCI/104-Express Specification, Revision 2.0, February, 2011

Web site: http://www.pc104.org/pci104_Express_specs.php

• PCI-104 Specification

Web site: http://www.pc104.org/pci_104_specs.php

• PCI Express Specification, Revision 2.0, January, 2007

Specification (for members): http://www.pcisig.com/specifications/pciexpress/base2/#b21

• PCI Specification, Revision 2.3, March 29, 2002

Web site: http://www.pcisig.com

• LPC Specification Version 1.1

Web site: http://www.intel.com/design/chipsets/industry/lpc.htm

• USB Specification Version 2.0

Web site: http://www.usb.org/developers

• SATA Specification Version 3.0

Web site: http://www.sata-io.org/

• Ethernet IEEE802.3 Specifications

Web site: http://standards.ieee.org/about/get/802/802.3.html

CoreModule 920 Reference Manual 1

Page 8

Chapter 1 About This Manual

• SMBus Specification Version 2.0

Specification: http://smbus.org/specs/

• AMI BIOS Aptio TSE User’s Guide

Data sheet: http://www.ami.com/support/doc/AMI_TSE_User_Manual_PUB.pdf

Chip Specifications

The following integrated circuits (ICs) are used in the CoreModule 920 SBC.

• Intel Corporation and the Mobile 3rd Generation Core™i7 CPU integrated processor core and

graphics memory hub

Web site: http://www.intel.com/p/en_US/embedded/hwsw/hardware/core-hm76/hardware

• Hynix Semiconductor, Inc. and the H5TQ2G83BFR-H9, DDR3 on-board System SDRAM

Web site: http://www.hynix.com/gl/products/consumer/consumer_info.jsp

• Intel Corporation and the BD82QM67, 6 Series Express chipset, featured as the Platform Controller

Hub (PCH)

Datasheet: http://www.intel.com/Assets/PDF/datasheet/324645.pdf

• Intel Corporation and the 82574IT, Gigabit Ethernet controller

Data sheet: http://

download.intel.com/design/network/datashts/82574.pdf

• Intel Corporation and the 82579LM, Gigabit Ethernet PHY (physical layer) transceiver

Data sheet: http://www.intel.com/content/www/us/en/ethernet-controllers/ethernet-controllers.html

• Atmel Corporation and the AT25128B-SSHL-B, Ethernet EEPROM

Data sheet: http://www.atmel.com/dyn/resources/prod_documents/doc8535.pdf

• Fintek, Inc. and the F81216AU-I, LPC to 4 UART Controller

Data sheet: http://www.fintek.com.tw/files/productfiles/F81216_V032P.pdf

• Texas Instruments and the XIO2001IPNP, PCIe-to-PCI bridge

Web site:

http://www.ti.com/sitesearch/docs/universalsearch.tsp?searchTerm=XIO2001IPNP&linkId=1

• Texas Instruments and the TR3253EIRSMR RS-232, serial transceiver

Web site: http://www.ti.com/lit/ds/slls850b/slls850b.pdf

• Greenliant and the GLS85LS1008P Solid State NANdrive

Data sheet: http://www.greenliant.com/products/solid_state_storage.dot#sn

• ON Semiconductor and the ADT7490-D, Hardware Monitor

Data sheet: http://www.onsemi.com/pub_link/Collateral/ADT7490-D.PDF

• Winbond Corporation and the W25Q64BVSSIG SPI Flash BIOS chip

Web site: http://www.winbond.com/hq/enu

• ST Microelectronics and the STHDLS101TQTR, HDMI Level Shifter

Web site: http://www.st.com/internet/com/home/home.jsp

• Atmel Corporation and the AT24C02C for SPD and PCIe-to-PCI Bridge EEPROMs

Web site: http://www.atmel.com/devices/at24c02c.aspx?tab=documents

• Wurth Elektronik Company and the 7490200110, Gigabit Ethernet Transformers

Data Sheet: http://katalog.we-online.de/pbs/datasheet/749020011.pdf

2 Reference Manual CoreModule 920

Page 9

Chapter 1 About This Manual

NOTE If you are unable to locate the datasheets using the links provided, search the internet

using the name of the manufacturer or component model and locate the documents

you need.

CoreModule 920 Reference Manual 3

Page 10

Chapter 1 About This Manual

4 Reference Manual CoreModule 920

Page 11

Chapter 2 Product Overview

This overview presents general information about the PCI/104-Express form factor and the CoreModule 920

Single Board Computer (SBC). After reading this chapter you should understand the following points with

regard to the CoreModule 920.

• PCI/104-Express From Factor

• Product Description

• Major Components (ICs)

• Headers, Connectors, and Sockets

• Product Specifications

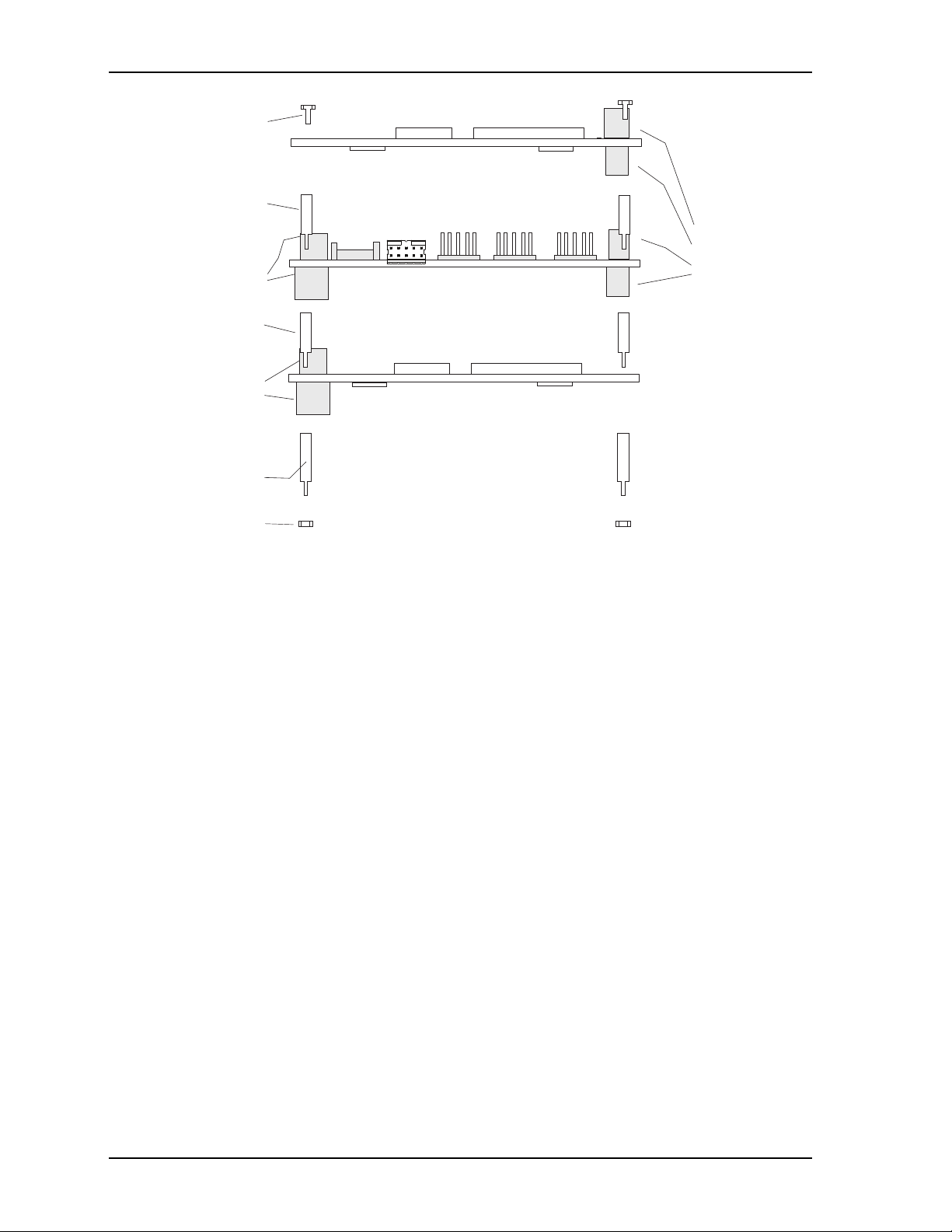

PCI/104-Express Form Factor

This product is based on PCI Express architecture and the PCI/104-Express form factor. The PCI/104Express form factor affords a great deal of flexibility in system design. You can build a simple system using

only a CoreModule SBC, input/output devices connected to serial, USB, or SATA ports, and the on-board

storage device. To expand a simple CoreModule system, simply add self-stacking expansion modules to

provide additional capabilities, such as:

• Additional serial and parallel ports

• Analog or high-speed digital I/O

Data Acquisition (Analog In/Out)

USB 2.0 expansion modules

IEEE 1394 (FireWire) expansion modules

Standard VGA video output

PCI/104-Express-compliant expansion modules can be stacked with a CoreModule SBC, avoiding the need

for large, expensive card cages and backplanes. These expansion modules can be mounted directly to the

expansion connectors of the CoreModule, with inter-board spacings of ~0.6 inches, so that a 3-module

system fits in a 4.6" x 3.8" x 2.0" space. See Figure 2-1.

One or more PCI/104-Express-compliant modules can be installed on the CoreModule SBC expansion

connectors so that the expansion modules fit within the CoreModule outline dimensions. The PCI/104Express form factor allows for several modules to be stacked up or down from the CoreModule expansion

connectors with each additional module increasing the thickness of the package by ~17mm (0.6"). See

Figure 2-1.

CoreModule 920 Reference Manual 5

Page 12

Chapter 2 Product Overview

CM920stackthru_a

Nuts (4)

or Chassis Standoffs

PCIe Bus

Stackthrough

Connectors

(active heastsink

exceeds height

limit for stack-up

capability on the

CoreModule 920)

Expansion

0.6 inch Spacers (4)

PCI Bus Stack

Connectors

through

Screws (4)

0.6 inch Spacers (4)

PCIe/104 Module

0.6 inch Spacers (4)

PCI Bus Stack

Connectors

through

PCI-104 Module

CoreModule 920

Figure 2-1. Stacking PCI/104-Express Modules with the CoreModule 920

Product Description

The CoreModule 920 SBC is a highly integrated, high-performance, Intel Core™ i7 processor based

system, compliant with PCI Express architecture and the PCI/104-Express form factor. This rugged and high

quality single-board system contains all the component subsystems of an ATX motherboard, plus the

equivalent of several PCI and PCI Express expansion boards.

The Intel Core i7 series CPU integrates a multiple execution core with a Graphics and Memory Controller

Hub (GMCH), providing a high-performance processor, a memory controller for up to 2GB of DDR3 onboard memory, and a graphics controller that provides VGA, LVDS, and HDMI ports driven by the PCH

(Platform Controller Hub) and one PCIe x16 Graphics (PEG) port driven by the CPU.

Each CoreModule 920 incorporates an Intel BD82QM67 PCH, providing the controller hub for a range of

common user interfaces including six USB 2.0 ports, two serial ports, two SATA 3.0 ports, one SATA 2.0

port dedicated for the SSD, four PCIe x1 lanes, as well as interfaces for GPIO and RTC battery. The

CoreModule 920 provides a Solid State Drive through the SATA2 port for storage up to 8GB, a Hardware

Monitor chip to control temperature and voltage levels, and a Utility interface for Power button, Reset

switch, and Speaker output. The PCH connects to two 10-pin Gigabit Ethernet interfaces through two PCIe

x1 lanes.

The CoreModule 920 can be expanded through the PCIe expansion bus using the PCI-104 and PCIe/104

interfaces for additional system functions. These interfaces offer compact, self-stacking, modular

expandability. The PCI-104 interface implements a PCI bus available on a 120-pin (4 rows of 30 pins) PCI

expansion bus connector. The PCIe/104 interface includes the PCIe signal set plus SMBus and USB 2.0

signals available on top and bottom-side, 156-pin high-speed PCIe connectors. The PCI bus operates at a

clock speed of up to 33MHz, and the PCIe bus operates at a clock speed of up to 100MHz.

The CoreModule 920 is particularly well suited to either embedded or portable applications and meets the

size, power consumption, temperature range, quality, and reliability demands of embedded system

applications. It can be stacked with ADLINK expansion modules or other PCI/104-Express-compliant

expansion modules, or it can be used as a powerful computing engine. The CoreModule 920 requires a

single +5V AT power source.

6 Reference Manual CoreModule 920

Page 13

Chapter 2 Product Overview

Module Features

• CPU

Provides a 1.7GHz (17W) Intel Core i7 3517UE Processor Core and Graphics Memory Controller

Hub

Provides a DMI (Direct Media Interface) with 2 GB/s of bandwidth in each direction

Provides an FDI (Flexible Display Interface) for carrying display traffic to the PCH

Provides Enhanced Intel SpeedStep® Technology (EIST)

Supports Hyper-Threading Technology

Provides up to 8MB on-die L3 cache

Provides 3D graphics engine

Provides dual-channel DDR3 memory controller (only one channel connected on board)

• Memory

Provides 2GB of +1.5V DDR3 soldered, on-board memory

Provides double data rate interface

Supports 32-bit data bus

Supports DDR3 1333MHz memory

• Expansion Buses

PCI bus version 2.3 at 33MHz

PCIe bus version 2.0 at 100MHz

• SATA Interface

Supports two SATA 3.0 ports from the BD82QM67 PCH

Supports up to 6Gb/second data transfer rate

Supports independent DMA operation

Supports Native Command Queuing

Provides Auto Activate for DMA

Supports Hot Plug features

Provides two standard SATA 3.0 connectors

Supports one SATA 2.0 port dedicated for the SSD (Solid State Drive)

• Serial Interface

Provides two buffered serial ports (COM1-2) with full handshaking

Provides two 10-pin headers

Provides 16550-equivalent controllers with 16-byte FIFO modes

Supports full-duplex buffering and full status reporting

Supports full modem capability

Supports programmable word length, stop bits, and parity

Provides programmable baud-rate generator

CoreModule 920 Reference Manual 7

Page 14

Chapter 2 Product Overview

• USB 2.0 Interface

Provides two root USB 2.0 hubs

Provides up to six USB 2.0 ports

Supports USB bootable devices

Supports USB Keyboard and Mouse

Supports USB v2.0 EHCI and v1.1 UHCI

Supports over-current detection status

• Ethernet Interface

Provides two fully independent Gigabit Ethernet ports

Provides integrated LEDs on each port (Link/Activity and Speed)

Provides one Intel 82574IT controller chip and one 82579LM PHY transceiver chip

Provides two 10-pin headers for Gigabit Ethernet user interface

Provides two headers for GLAN LED signals

Supports IEEE 802.3 10/100BaseT and 10/100/1000BaseT compatible physical layers

Supports Auto-negotiation for speed, duplex mode, and flow control

Supports full-duplex or half-duplex mode

• Full-duplex mode supports transmit and receive frames simultaneously

• Supports IEEE 802.3x Flow control in full-duplex mode

• Half-duplex mode supports enhanced proprietary collision reduction mode

• Video Interfaces (VGA, HDMI, LVDS, and PEG)

Provide VGA outputs

• Resolutions up to 2048x1536 pixels at 75Hz

• Integrated 340.4MHz RAMDAC with 32-bit color

• RGB output provided by three 8-bit DACs

• HSYNC and VSYNC output

Provide HDMI outputs

• Resolutions up to 3840x2160 pixels at 30Hz

• Pixel clock rates from 25MHz to 340MHz

• Support for DVD-Audio and Audio Return Channel

Provide LVDS flat panel outputs

• Single channel capability

• Resolutions up to 1400x1050 at 60Hz

• Pixel clock rates of 25MHz to 112MHz

• Pixel color depths of 18 and 24 bits

Support PCI Express graphics (PEG)

• External high-performance PCI Express graphics cards

• General-purpose PCI Express devices

• Theoretical bandwidth of up to 8GT/s

• PCIe Gen3 compliance

8 Reference Manual CoreModule 920

Page 15

Chapter 2 Product Overview

• GPIO Interface

Provides two 6-pin interface headers

Supports a total of eight GPIO ports

Supports sample code in BSP QuickDrive

• Utility Interface

Power Button

Reset Switch

Speaker

• Miscellaneous

Real Time Clock (RTC) with external replaceable battery

Battery-free boot

Oops! Jumper support

Serial Console support

Watchdog Timer

Logo Screen (Splash)

SSD (Solid State Drive)

Hardware Monitor (voltage and temperature)

CoreModule 920 Reference Manual 9

Page 16

FDI

DMI

1333MHz,

1.5V, 2GB

PCH

Intel

BD82QM67

Intel

82574IT

MAC & PHY

Controller

USB 0-1

Header

USB 2-3

Header

PCIe x1

PCIe x1, Lanes 1-4

PCIe x1

SATA 3.0, Port 0

SATA 3.0, Port 1

SATA 2.0, Port 2

32-bit PCI

33 MHz

COM1

COM2

SPI

BIOS

VGA VGA

Header

HDMI

Connector

PCI-104

Connector

HDMI

Level

Shifter

HDMI TMDS

24-bit LVDS

LVDS

Header

SATA0

Connector

SATA1

Connector

SSD

PCIe-to-PCI

Bridge

PCIe/104

Connector

GPIO

GPIO

Header

GPIO

GPIO

Header

LPC

Serial

Header

RS232

Transceiver

RS232

Transceiver

Serial

Header

LPC to UART

Controller

F81216

SMBus

USB 2.0, Ports 4-5

USB 2.0, Ports 0-1

USB 2.0, Ports 2-3

VBAT

CPLD

Battery

Header

Utility

Header

Intel

82579LM

PHY

Transceiver

GLAN1

LED

Header

GLAN2

LED

Header

GLAN1

Header

Transformer

Transformer

PCIe x1

GLAN2

Header

CM920_blk_diag_a

CPU

Intel

Core i7 3517UE (Dual-Core) 1.7GHz (17W)

(with integrated Processor Core

and Graphics Memory Hub)

PCIe x16 Graphics (1) [PEG],

1x16; 2x8; 1x8 & 2x4

Memory Bus

8x DDR3 SDRAM

System Memory

(2Gb each)

1x DDR3 SDRAM

System Memory (ECC)

(2Gb each)

Hardware

Monitor

SPD

EEPROM

PCIe-to-PCI

Bridge

EEPROM

Chapter 2 Product Overview

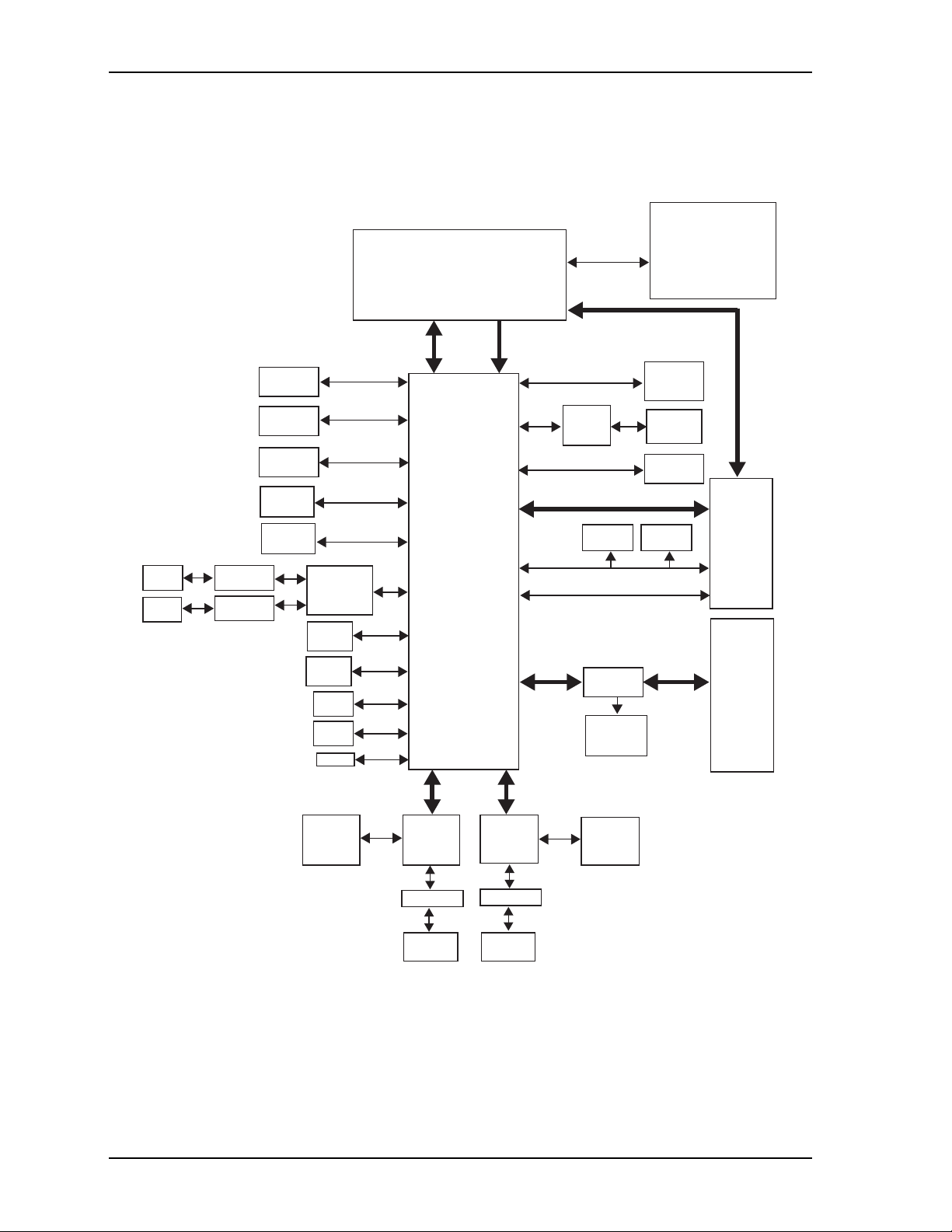

Block Diagram

Figure 2-2 presents a functional representation of the CoreModule 920.

Figure 2-2. Functional Block Diagram

10 Reference Manual CoreModule 920

Page 17

Chapter 2 Product Overview

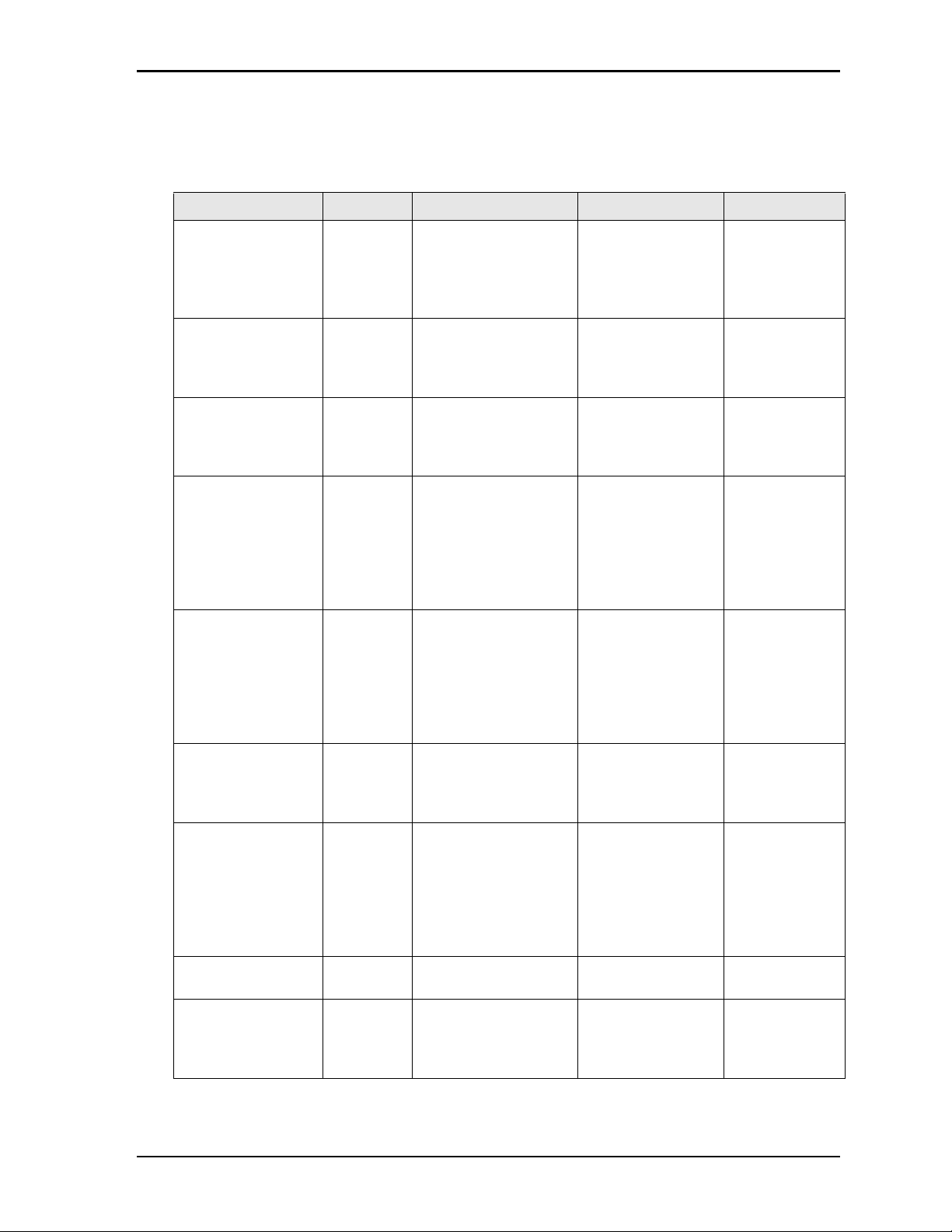

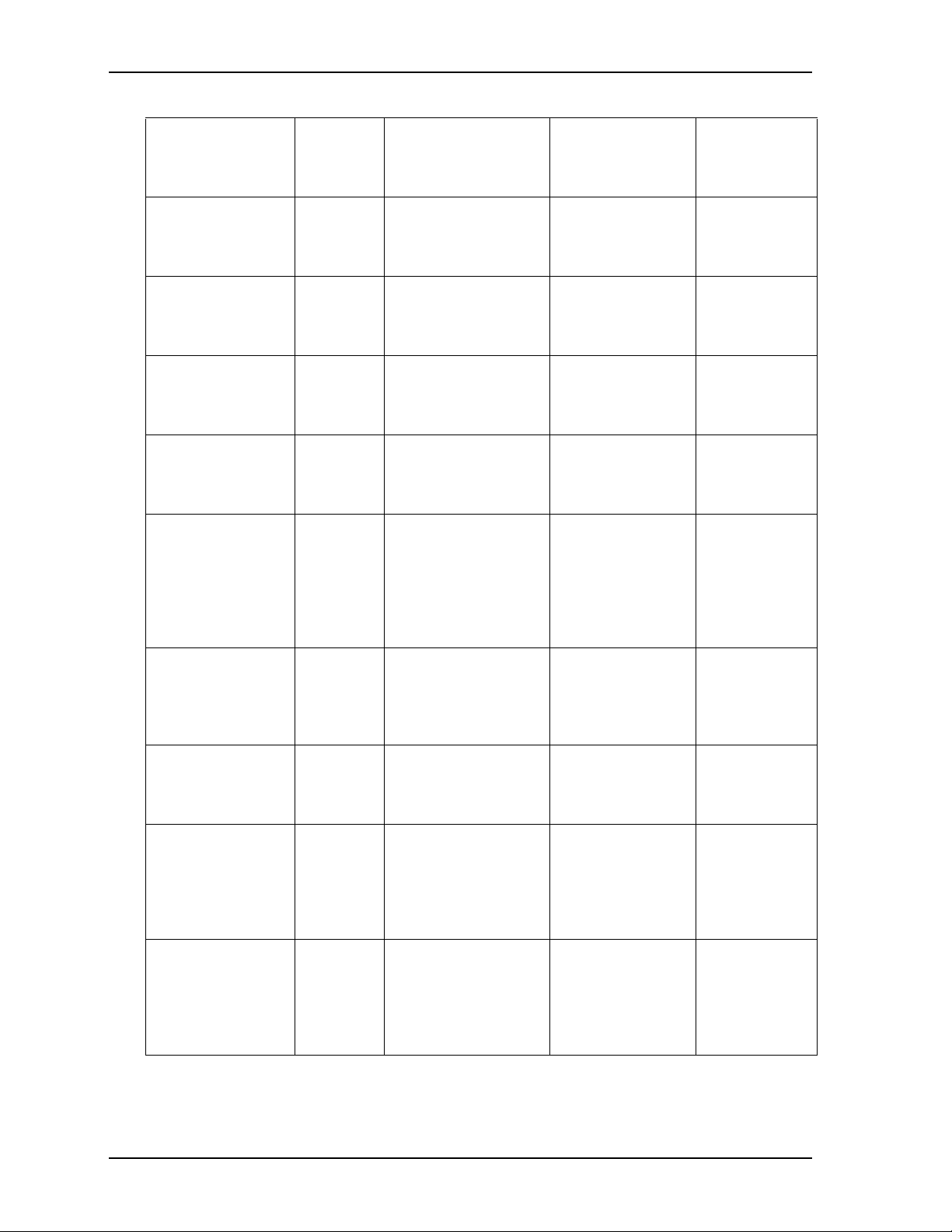

Major Component (ICs) Definitions

Table 2 -1 lists the major ICs, including a brief description of each, on the CoreModule 920. Figures 2-3 and

2-4 show the locations of the major ICs.

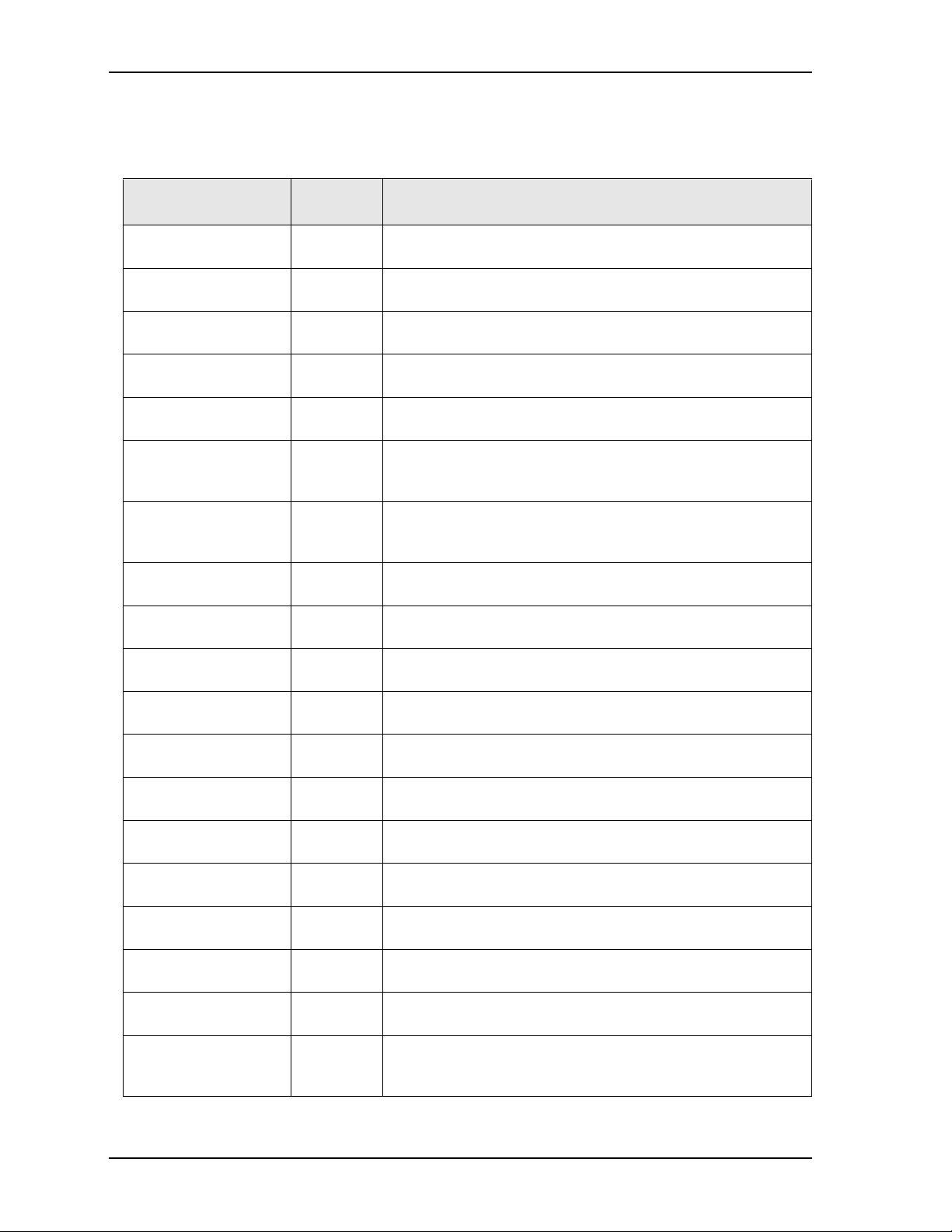

Table 2-1. Major Component Descriptions and Functions

Chip Type Mfg. Model Description Function

CPU (U1) Intel Core i7, 3517UE,

1.7GHz (17W)

DDR3 SDRAM

(U3, U5, U8, U10,

U11 [to enable

ECC])

DDR3 SDRAM

(U4, U6, U7, U9 - on

bottom side [see

Figure 2-4])

PCH [Platform

Controller Hub

(U12)]

Gigabit Ethernet

PHY Transceiver

(U14)

Gigabit Ethernet

Controller (U15)

Ethernet EEPROM

(U16)

PCIe-to-PCI Bridge

(U17)

LPC-to-UART

Controller (U18)

Hynix H5TQ2G83BFR-H9 On-board DDR3

Hynix H5TQ2G83BFR-H9 On-board DDR3

Intel BD82QM67

(PCH)

Intel 82579LM Single-port Gigabit

Intel 82574IT Gigabit Ethernet

Atmel AT25128B-SSHL-B Three-Wire Serial

Texas

Instruments

Fintek F81216AU-I Serial

XIO2001IPNP PCIe-to-PCI

Central Processing

Unit with 2

execution cores and

up to 8MB L3 cache

256M x 8 System

Memory

256M x 8 System

Memory

I/O Hub for

common user

interfaces

Ethernet PHY

Transceiver for

GLAN1 interface

controller for

GLAN2 interface

EEPROM for

Gigabit Ethernet

Controller

interface

communication

controller

Integrates

Processor Core

and Graphics

Memory

Controller Hub

Provides highspeed data

transfer

Provides highspeed data

transfer

Provides

Southbridge

interfaces and

off loads some

Northbridge

functions from

the CPU

Provides a

standard IEEE

802.3 Ethernet

interface for

Ethernet transfer

rates up to 1000

Mb/s

Generates PCIe

10T/100TX/

1000T Ethernet

signals

Provides storage

for MAC

addresses, serial

numbers, and

pre-boot

configuration

data

Migrates legacy

PCI interfaces

Provides 4

UART ports

through the LPC

bus

CoreModule 920 Reference Manual 11

Page 18

Chapter 2 Product Overview

Table 2-1. Major Component Descriptions and Functions (Continued)

RS-232 Transceiver

(U20)

Texas

Instruments

TR3253EIRSMR Transceiver for

Serial 1 RS-232

signals

Transmits and

receives RS-232

signals for

COM1

RS-232 Transceiver

(U21)

Texas

Instruments

TR3253EIRSMR Transceiver for

Serial 2 RS-232

signals

Transmits and

receives RS-232

signals for

COM2

Solid State Drive

[SSD] - SATA (U22)

- on bottom side [see

Figure 2-4])

Hardware Monitor

(U27) [on bottom

side; see Figure 2-4]

Greenliant GLS85LS1008P Industrial-grade

soldered solid-state

storage module

ON

Semicondu

ctor

ADT7490-D Remote Voltage and

Temperature

Monitor and Fan

Provides solid

state storage

through SATA

port 2

Provides system

thermal

protection

Controller

SPI Flash (U28) Winbond W25Q64BVSSIG Serial Peripheral

Interface Flash

Stores BIOS in

Flash Memory

Memory chip (for

firmware)

HDMI Level Shifter

(U48)

ST

Microelectr

onics

STHDLS101TQTR HDMI level-shift IC

for HDMI video

Converts HDMI

differential input

from the PCH to

TMDS

differential

output for the

HDMI interface

EEPROM, DDR3

(U66 - on bottom

side [see Figure 2-4])

Atmel AT24C02C Two-Wire Serial

EEPROM for SPD

(Serial Presence

Detect)

Provides storage

for System

Memory

configuration

data

EEPROM,

PCIe-to-PCI Bridge

(U67 - on bottom

side [see Figure 2-4])

Transformer Gigabit Ethernet

(T1)

Atmel AT24C02C Two-Wire Serial

EEPROM for PCIeto-PCI Bridge

Wurth

Elektronik

7490200110 Gigabit Ethernet

Magnetics

Stores PCIe-to-

PCI bridge

configuration

data

Provides

electrical

isolation for

Gigabit Ethernet

PHY transceiver

(GLAN1)

Transformer Gigabit Ethernet

(T2)

Wurth

Elektronik

7490200110 Gigabit Ethernet

Magnetics

Provides

electrical

isolation for

Gigabit Ethernet

controller

(GLAN2)

12 Reference Manual CoreModule 920

Page 19

Chapter 2 Product Overview

CM920_Top_Comp_a

Key:

U1 - CPU

U3 - DDR3 SDRAM

U5 - DDR3 SDRAM

U8 - DDR3 SDRAM

U10 - DDR3 SDRAM

U11 - DDR3 SDRAM (ECC)

U12 - PCH

U14 - Gigabit Ethernet PHY Transceiver

U15 - Gigabit Ethernet MAC & PHY Controller

U16 - Gigabit Ethernet EEPROM

U17 - PCIe to PCI Bridge

U48 - HDMI Level Shifter

U1

U3

U5

U11

U8

U10

U16

U17

U12

U48

U15

U14

CM920_Bottom_Comp_b

Key:

T1 - Gigabit Ethernet 1 Transformer

T2 - Gigabit Ethernet 2 Transformer

U4 - DDR3 SDRAM

U6 - DDR3 SDRAM

U7 - DDR3 SDRAM

U9 - DDR3 SDRAM

U18 - LPC to UART Controller

U20 - RS-232 Transceiver - COM1

U21 - RS-232 Transceiver - COM2

U22 - SSD (Solid State Drive)

U27 - Hardware Monitor

U28 - BIOS

U66 - EEPROM, DDR3 SPD

U67 - EEPROM, PCIe to PCI Bridge

J6 - PCIe/104

(See Header and Connector table)

SW1 - PCI Express x16 Configuration Switch

(See Header and Connector table)

T1

T2

U22

U9

U7

U6

U4

U28

SW1

U27

U66

U21

U20

U67

U18

ON

1 2

J6

CoreModule 920 Reference Manual 13

Figure 2-3. Component Locations (Top Side)

Figure 2-4. Component Locations (Bottom Side)

Page 20

Chapter 2 Product Overview

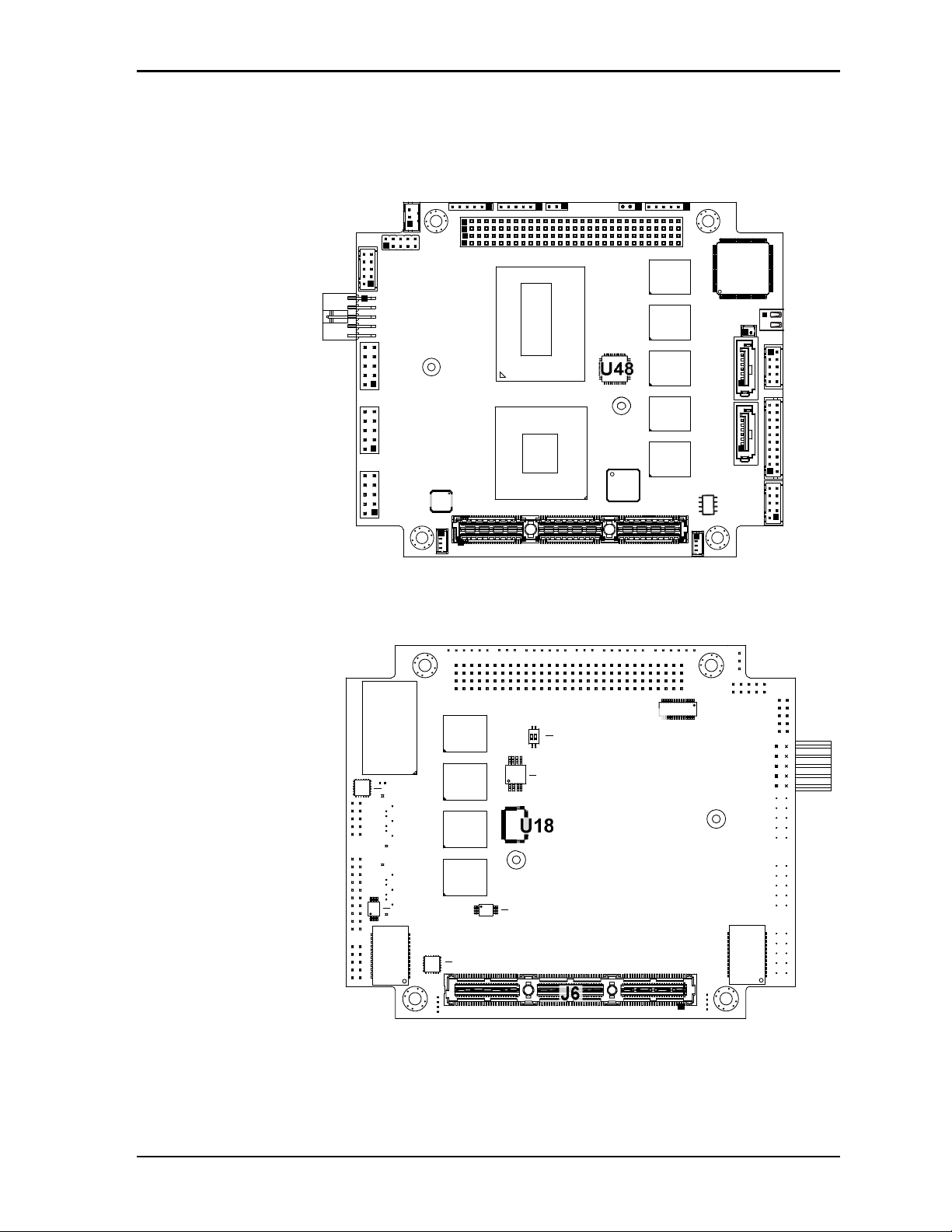

Header, Connector, and Socket Definitions

Table 2 -2 describes the headers, connectors, and socket of the CoreModule 920 shown in Figure 2-6.

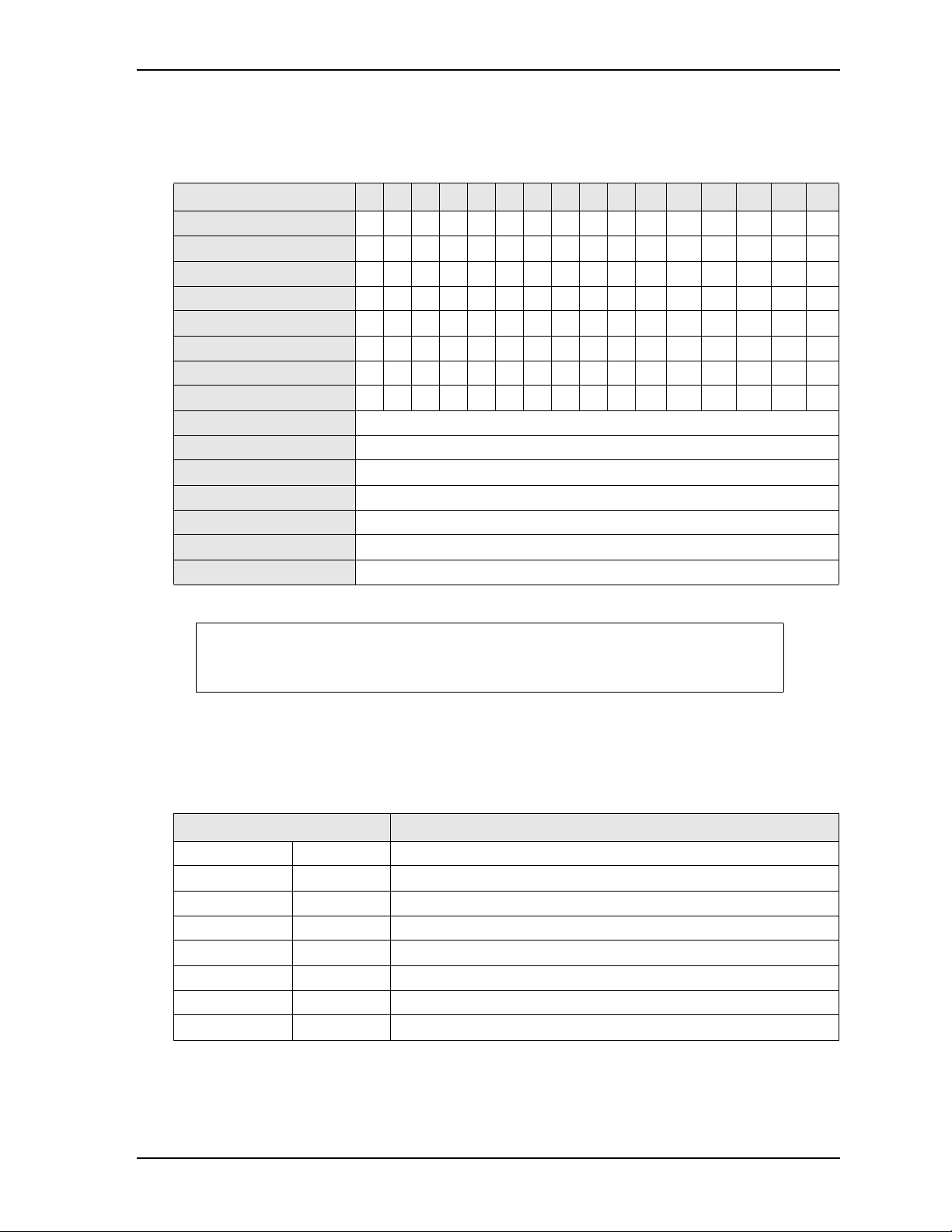

Table 2-2. Module Header and Connector Descriptions

Header # Board

Access

H11 – GLAN1 Top 10-pin, 0.100" (2.54mm) header for Gigabit Ethernet port 1

H15 – USB (0-1) Top 10-pin, 0.100" (2.54mm) header for USB 2.0 ports 0-1

H16 – COM2 Top 10-pin, 0.100" (2.54mm) header for serial port 2

J2 – LED - GLAN1 Top 4-pin, 0.049" (1.25mm) shrouded, single-row header for Gigabit

J3 – LED - GLAN2 Top 4-pin, 0.049" (1.25mm) shrouded, single-row header for Gigabit

J5 – PCIe/104 Top 156-pin, 0.025" (0.64mm) standard PCI Express connector for

J6 – PCIe/104 Bottom 156-pin, 0.025" (0.64mm) standard PCI Express connector for

J7 – PCI-104 Top/Bottom 120-pin, 0.079" (2mm) standard PCI-104 connector for PCI

J8 – HDMI (Micro) Top 19-pin, 0.016" (0.04mm), standard micro-connector for HDMI

J10 – SATA0 Top 7-pin, 0.050" (1.27mm) standard connector for SATA 3.0 port 0

J12 – Battery Top 2-pin, 0.049" (1.25mm) shrouded header for power from external

J13 – SATA1 Top 7-pin, 0.050" (1.27mm) standard connector for SATA 3.0 port 1

J14 – GLAN2 Top 10-pin, 0.079" (2mm) shrouded header for Gigabit Ethernet port 2

J17 – VGA Top 10-pin, 0.079" (2mm) header for VGA video port

J18 – COM1 Top 10-pin, 0.079" (2mm) shrouded header for serial port 1

J21 – Utility Top 6-pin, 0.079" (2mm) single-row header for Power Button, Reset

J22 – Fan Top 3-pin, 0.079" (2mm) shrouded header for power to external fan

J23 – LVDS Top 20-pin, 0.079" (2mm) shrouded header for LVDS video port

J24 – Power Top 10-pin, 0.100" (2.54mm) shrouded, right-angle header for

Description

(JIH JVE, 21N22564-10S10B-01G-6/3-G)

(JIH JVE, 21N22564-10S10B-01G-6/3-G)

(JIH JVE, 21N22564-10S10B-01G-6/3-G)

Ethernet port 1 LED (SMP Technology, W125-0410-310-Z)

Ethernet port 2 LED (SMP Technology, W125-0410-310-Z)

SMBus, USB 2.0, PCIe x1, and PCI interfaces

(SAMTEC, ASP-129637-03)

SMBus, USB 2.0, PCIe x1, and PCI interfaces

(SAMTEC, ASP-129646-03)

interfaces (EPT, 264-60303-12)

video port (MOLEX, 46765-0001)

(WIN WIN, WATM-07DBN4B2B8UW)

battery (REGO, 830-1251-02STD-3.2)

(WIN WIN, WATM-07DBN4B2B8UW)

(HIROSE, DF11-10DP-2DSA)

(JIH, 21N22050-10S10B-01G-4/2.8-G)

(HIROSE, DF11-10DP-2DSA)

Switch, and Speaker (SAMTEC, TMM-106-03-L-S)

(NELTRON, 2417SJ-03)

(HIROSE, DF11-20DP-2DSA)

supplying external power to the board

(FCI, 78207-210HLF)

14 Reference Manual CoreModule 920

Page 21

Chapter 2 Product Overview

ON

1 2

(OFF)

(ON)

Switch Positions

1

234

5

678910

10-pin, two rows,

Odd/Even, (1, 2)

CM920_ConNum_a

Table 2-2. Module Header and Connector Descriptions (Continued)

J25 – USB 2-3 Top 10-pin, 0.079" (2mm) shrouded header for USB 2.0 ports 2-3

(HIROSE, DF11-10DP-2DSA)

J26 – GPIO1 Top 6-pin, 0.079" (2mm) single-row header for GPIO1

(SAMTEC, TMM-106-03-L-S)

J27 – GPIO2 Top 6-pin, 0.079" (2mm) single-row header for GPIO2

(SAMTEC, TMM-106-03-L-S)

SW1 – PCIe x16 Lane

Configuration Switch

(see Figure 2-4 on

page 13.)

Bottom 4-pin dip switch for selecting CPU PCIe x16 lane configurations

(WIN WIN, DHN-02-T-V-T/R)

Switch Positions

Lane Configurations

1-OFF, 2-OFF = 1x16 [Default]

1-OFF, 2-ON = 2x8

1-ON, 2-OFF = Reserved

1-ON, 2-ON = 1x8, 2x4

NOTE The pinout tables in Chapter 3 of this manual identify pin sequence using the

following method: A 10-pin header with two rows of pins, using odd/even

numbering, where pin 2 is directly across from pin 1, is noted as 10-pin, 2 rows, odd/

even (1, 2). See Figure 2-5.

Figure 2-5. Connector Pin Sequence

CoreModule 920 Reference Manual 15

Page 22

Chapter 2 Product Overview

CM920_Top_Conn_b

Key:

H11 - GLAN1

H15 - USB 0-1

H16 - COM2

J2 - LED, GLAN1 (PHY Transceiver)

J3 - LED, GLAN2 (Gb Controller)

J5 - PCIe/104

J6 - PCIe/104 (see Bottom Component View)

J7 - PCI-104

J8 - HDMI (Micro)

J10 - SATA0

J12 - Battery

J13 - SATA1

J14 - GLAN2

J17 - VGA

J18 - COM1

J21 - Utility

J22 - Fan

J23 - LVDS

J24 - Power

J25 - USB 2-3

J26 - GPIO 5-8

J27 - GPIO 1-4

JP1 - LVDS Voltage (see jumper table)

JP2 - PCI-104 Voltage (see jumper table)

SW1 - PCIe x16 Configuration Switch (see Bottom Component View)

J26

J14

J3

J2

H11

H15

H16

J24

J25

J17

J22

J12

J23

J18

J21JP1

J8

JP2

J27

J13

J10

J5

J7

Figure 2-6. Header, Connector, and Socket Locations (Top Side)

NOTE Black square pins on headers and connectors represent pin 1. Black square pins on

right-angle headers represent pin 2.

Jumper Header Definitions

Table 2 -3 describes the jumper headers shown in Figure 2-7. Both jumper headers provide 0.079" (2mm)

pitch.

Table 2-3. Jumper Settings

Jumper Header Installed Moved

JP1 – LVDS Voltage Selection

(HIROSE, A4B-3PA-2DSA)

JP2 – PCI-104 Voltage Selection

(HIROSE, A4B-3PA-2DSA)

16 Reference Manual CoreModule 920

Enable +3.3V (1-2) (Default) Enable +5V (2-3)

Enable +3.3V (1-2) (Default) Enable +5V (2-3)

Page 23

Chapter 2 Product Overview

CM920_Top_jmpr_a

Key:

JP1 - LVDS Voltage

JP2 - PCI-104 Voltage

JP2

JP1

Specifications

Physical Specifications

Table 2-4. Weight and Footprint Dimensions

Figure 2-7. Jumper Header Locations (Top Side)

Table 2 -4 provides the physical dimensions of the CoreModule 920.

Item Dimension

Weight 0.12 kg (0.25 lbs)

Height (overall) 9.525mm (0.375 inches)

Board thickness 2.362mm (0.093 inches)

Width 96.01 mm (3.78 inches)

Length 102.87 mm (4.05 inches)

NOTE Overall height is measured from the

upper board surface to the top of the

highest permanent object (PCI-104

connector) on the upper board surface.

This does not include the cooling

solution, which is required on all

versions of the board and may increase

the height of the board. Component

height should not exceed 0.345"

(8.763mm) from the upper surface of the

board and 0.190" (4.826mm) from the

lower surface of the board. See

Figure 2-10 on page 20 for the stack

heights of the cooling solutions on the

board.

CoreModule 920 Reference Manual 17

Page 24

Chapter 2 Product Overview

0.0mm 0.0in

0.0mm 0.0in

0.0mm 0.0in

12.7mm 0.5in

7.62mm 0.3in

5.08mm 0.2in

8.89mm

0.35in

59.05mm 2.32in

82.55mm

3.25in

85.09mm 3.35in

90.17mm 3.55in 90.17mm 3.55in

102.87mm 4.05in

5.08mm

0.2in

8.26mm 0.33in

87.63mm

3.45in

90.81mm 3.58in

95.89mm 3.78in

5.08mm

0.2in

8.26mm

0.33in

40.81mm

1.61in

51.31mm 2.02in

87.63mm

3.45in

90.81mm 3.58in

95.89mm 3.78in

3.45

i

3.58

i

3

.78

i

n

CM920_Top_dmn_b

Mechanical Specifications

n

n

Figure 2-8. Mechanical Overview (Top Side)

NOTE All dimensions are given in millimeters and inches.

18 Reference Manual CoreModule 920

Page 25

Chapter 2 Product Overview

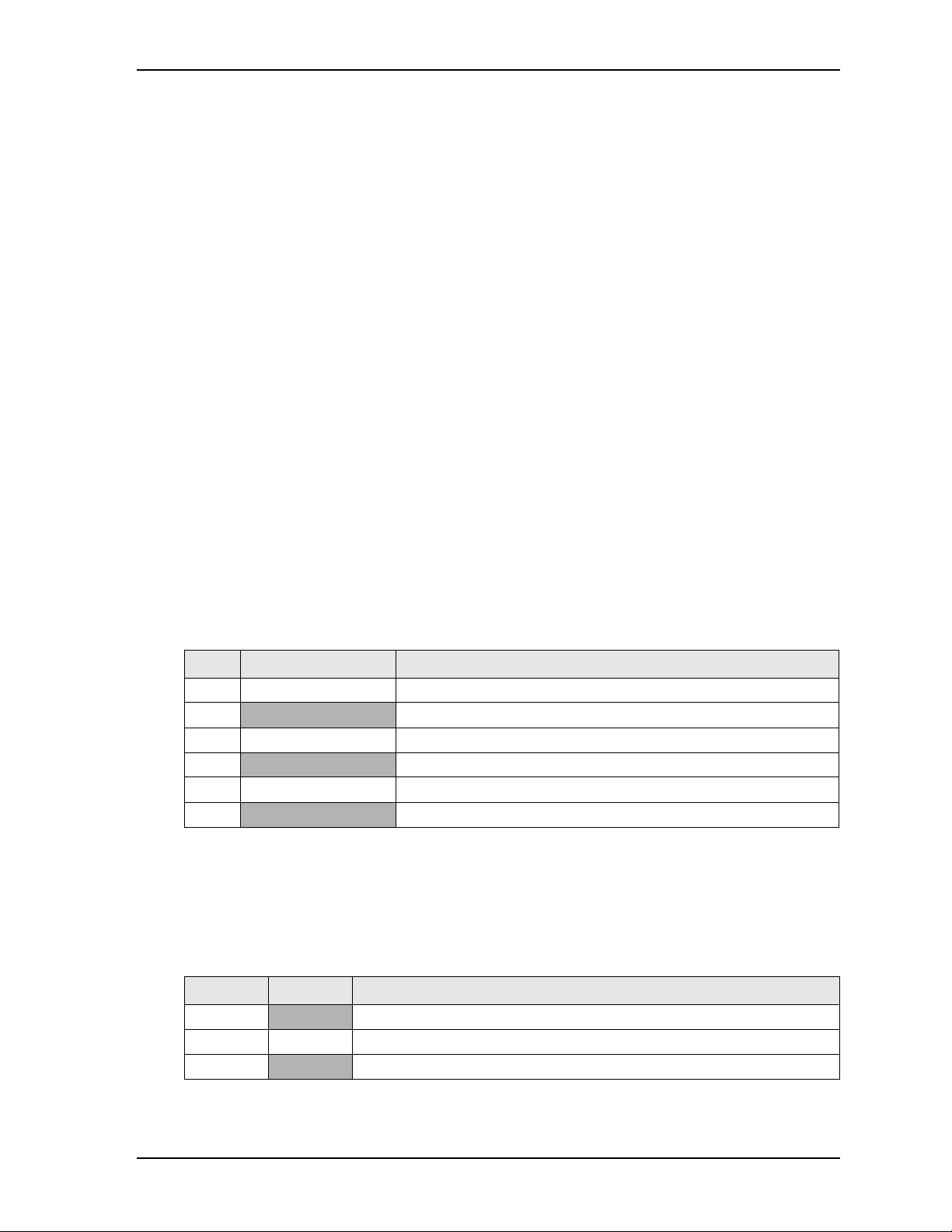

Power Specifications

Table 2 -5 provides the current measurements for the CoreModule 920.

Table 2-5. Power Supply Requirements

Parameter 1.7GHz CPU (3517UE)

Input Type Regulated DC voltages

In-Rush Peak Current and

Duration

Typical Idle Current and

Power

BIT Current and Power 4.41A (22.06W)

Operating configurations:

See Figure 2-9

1.68A (8.41W)

• In-rush operating configuration includes CRT monitor, 2GB memory, and power.

• Idle operating configuration includes In-rush configuration as well as one SATA 3.5" hard drive with

Windows XP, one USB mouse, and one USB keyboard.

• BIT (Burn-In-Test) operating configuration includes Idle configuration as well as two USB thumb

drives, two serial COM ports with loop backs, a second SATA hard drive as slave, and two Ethernet

ports.

Figure 2-9. i7-3517UE Peak In-Rush Current and Duration

CoreModule 920 Reference Manual 19

Page 26

Chapter 2 Product Overview

2.53

1.45

0.22

0.38

Passive Heat Sink

Active

Heat Sink

Fan

Heat Spreader

CM920_Cooling_Ht_b

Environmental Specifications

Table 2 -6 provides the most efficient operating and storage condition ranges required for this module.

Table 2-6. Environmental Requirements

Parameter Conditions

Temperature

Standard –20° to +70° C (–4° to +158° F)

Extended (Optional) –40° to +85° C (–40° to +185° F)

Storage –55° to +85° C (–67° to +185° F)

Humidity

Operating 5% to 90% relative humidity, non-condensing

Non-operating 5% to 95% relative humidity, non-condensing

Thermal/Cooling Requirements

The CPU is the primary source of heat on the board. The CoreModule 920 is designed to operate at the

maximum speed of the CPU and requires an active heatsink for extended temperatures (optional). A passive

heatsink is available (optional) and allows maximum speed operation within the Standard temperature range.

The passive heatsink will allow operation in the Extended temperature range if the CPU speed is locked at

800MHz. To lock the CPU speed at 800MHz, use the Power Consumption setting field in the CPU/PPM

Configuration submenu of the “Advanced BIOS Setup Screen” on page 40. See Figure 2-10 for height

measurements of the cooling assemblies.

Figure 2-10. Stack Heights of Cooling Assemblies

NOTE All heights are given in inches.

20 Reference Manual CoreModule 920

Page 27

Chapter 3 Hardware

Overview

This chapter discusses the chips and interfaces of the module in the following order:

• CPU

• Graphics

• Memory

• Interrupt Channel Assignments

• Memory Map

• I/O Address Map

• Serial Port Interfaces

• USB Interfaces

• Ethernet Interface

• Video Interfaces

VGA

LV DS

HDMI

PEG

• Power Interface

• GPIO Interface

• Utility Interface

Power Button

Reset Switch

Speaker

• System Fan Interface

• Battery Interface

• Ethernet LED Interface

• Miscellaneous

SSD (Solid State Drive)

Time of Day/RTC

Oops! Jumper (BIOS Recovery)

Serial Console

Hot Cable

Hardware Temperature and Voltage Monitor

Watchdog Timer

CoreModule 920 Reference Manual 21

Page 28

Chapter 3 Hardware

NOTE ADLINK Technology, Inc. only supports the features and options listed in this

manual. The main components used on the CoreModule 920 may provide more

features or options than are listed in this manual. Some of these features and

options are not supported on the module and will not function as specified in the

chip documentation.

The pin-out tables only of non-standard headers and connectors are included in

this chapter. This chapter does not include pin-out tables for standard headers,

connectors, and sockets such as SATA, PCI-104, and PCIe/104. Refer to

references in Chapter 1 for PCI-104 and PCIe/104 pin outs.

CPU

The CoreModule 920 features one version of the Intel Core™ i7 series CPU—the i7-3517UE—operating

at 1.7GHz. The CPU integrates a high-performance 64-bit, x86 Processor Core with Memory Controller and

3D Graphics Engine. This single chip is based on 22-nm process technology and provides two execution

cores, an Intel Flexible Display Interface, and a Direct Media Interface for high-speed connectivity to the

PCH. The CPU also supports Intel Hyper-Threading Technology and up to 3.2GB of DDR3 SDRAM

memory at 1333MHz for high overall performance.

Graphics

The CPU provides a refresh of the seventh generation graphics core, which features a substantial gain in

performance and a decrease in power consumption. The next generation Intel Clear Video HD Technology

includes a collection of video playback and enhancement features that improve the end user’s viewing

experience including Encode/Transcode HD content, HD content playback, and superior image quality.

Other graphics features of the CPU include support for DirectX 11.0, OpenGL 3.1, DirectX Video

Acceleration (DXAV), Advanced Scheduler 2.0, 1.0, and XPDM.

Memory

The CoreModule 920 employs one 1333MHz memory channel with one rank of eight system memory chips

(and one additional chip for ECC). The board provides up to 2GB of extended memory using 2Gb DDR3

SDRAM chips. The CPU features Intel FMA (Fast Memory Access) technology, providing Just-in-Time

Scheduling for issuing concurrent requests, Command Overlap for issuing multiple overlapping commands,

and Out-of-Order Scheduling to re-order requests made to the same open page.

22 Reference Manual CoreModule 920

Page 29

Chapter 3 Hardware

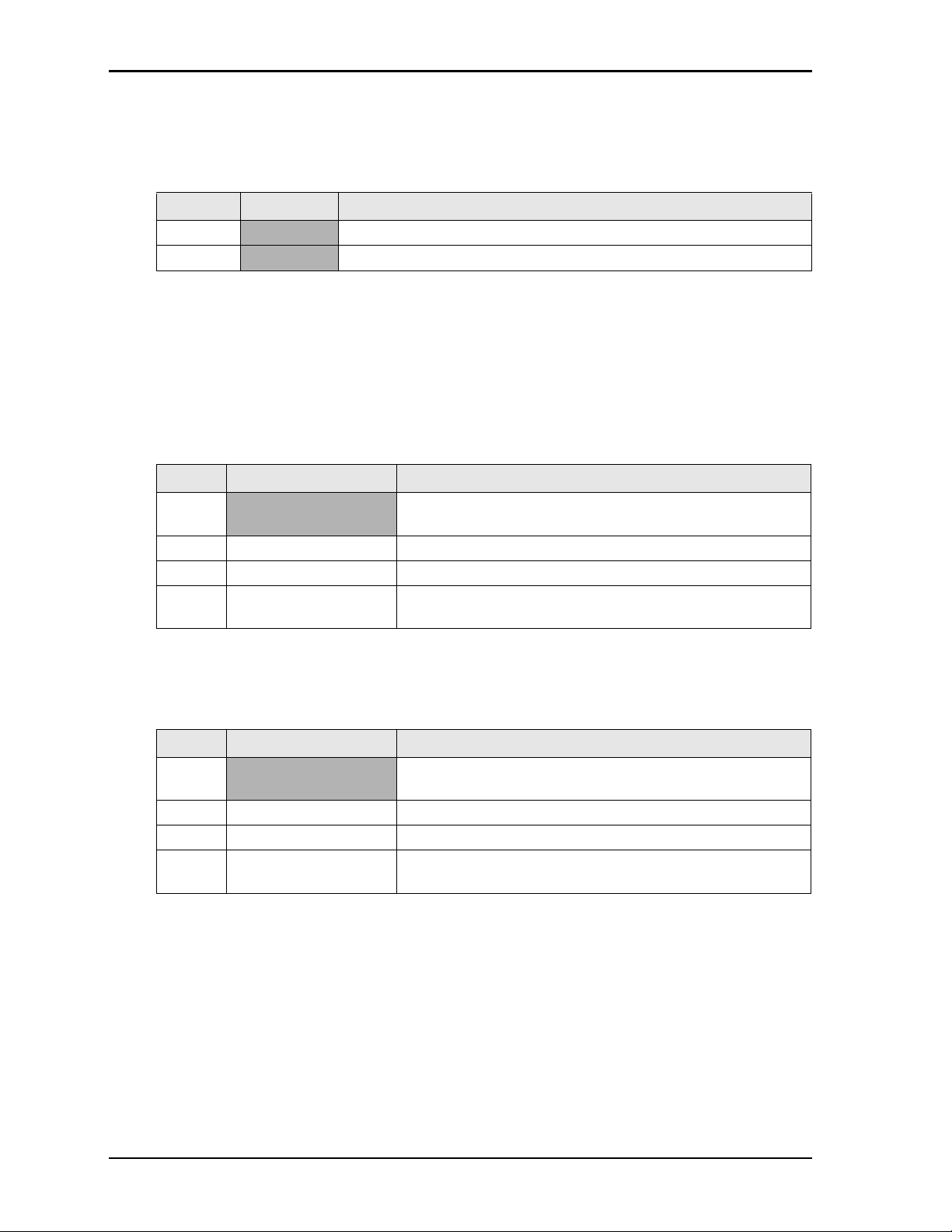

Interrupt Channel Assignments

The interrupt channel assignments are shown in Table 3-1.

Table 3-1. Interrupt Channel Assignments

Device vs IRQ No. 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Timer X

Secondary Cascade X

COM1 O D

COM2 D O

RTC X

Math Coprocessor X

SATA Primary X

SATA Secondary X

PCI INTA Automatically Assigned

PCI INTB Automatically Assigned

PCI INTC Automatically Assigned

PCI INTD Automatically Assigned

USB Automatically Assigned

Video Automatically Assigned

Ethernet Automatically Assigned

Legend: D = Default, O = Optional, X = Fixed

NOTE The IRQs for USB, Video, and Ethernet are automatically assigned by the BIOS

Plug and Play logic. Local IRQs assigned during initialization can not be used

by external devices.

Memory Map

The following table provides the common PC/AT memory allocations. These are DOS-level addresses. The

OS typically hides these physical addresses by way of memory management.

Table 3-2. Memory Map

Base Address Function

00000000h - 0009FFFFh Conventional Memory

000A0000h - 000AFFFFh Graphics Memory

000B0000h - 000B7FFFh Mono Text Memory

000B8000h - 000BFFFFh Color Text Memory

000C0000h - 000CFFFFh Standard Video BIOS

000D0000h - 000DFFFFh DVMT Memory

000E0000h - 000EFFFFh PCI Express Base Memory

000F0000h - 000FFFFFh System Flash and PCI Resources

CoreModule 920 Reference Manual 23

Page 30

Chapter 3 Hardware

I/O Address Map

Table 3 -3 shows the I/O address map. These are DOS-level addresses. The OS typically hides these physical

addresses by way of memory management.

Table 3-3. I/O Address Map

Address (hex) Subsystem

0000-00F Primary DMA Controller

0020-0021 Master Interrupt Controller

0040-0043 Programmable Interrupt Timer (Clock/Timer)

0061 NMI, Speaker control

0063 NMI Controller

0065 NMI Controller

0067 NMI Controller

0070-007F CMOS RAM, NMI Mask Reg, RT Clock

0080 System reserved

0081-0083 DMA Page Registers

0084-0086 System reserved

0087 DMA Page Register

0088 System reserved

0089-008B DMA Page Registers

008C-008E System reserved

008F DMA Page Register

0090-0091 System reserved

0092 Fast A20 gate and CPU reset

0093-009F System reserved

00A0-00A1 Slave Interrupt Controller

00A2-00BF System reserved

00C0-00DF Slave DMA Controller #2

00E0-00EF System reserved

00F0-00FF Math Coprocessor

01F0-01F7 SATA Controller

02F8-02FF Serial Port 2 (COM2)

03B0-03BB Video (monochrome)

03C0-03DF Video (VGA)

03F8-03FF Serial Port 1 (COM1)

0400-041F SMBus Configuration Ports

0500-053F PCH GPIO Configuration Ports

0800-087F PCH Power Management Ports

0CF8-0CFF PCI bus Configuration Address and Data

24 Reference Manual CoreModule 920

Page 31

Chapter 3 Hardware

Serial Interfaces

The CoreModule 920 provides two RS-232 serial ports. The PCH BD82QM67 contains the circuitry for

both serial ports and delivers the signals through two RS-232 transceivers: one transceiver for COM1 and

the second transceiver for COM2. The serial ports support the following features:

• Two individual high-speed NS16C550A-compatible UARTs (COM1 and COM2)

• Programmable word length, stop bits, and parity

• 16-bit programmable baud rate generator

• Loop-back mode

• Two individual 16-bit FIFOs

• Serial Port Headers

J18 - Serial 1 (COM1) supports RS-232 and full modem

H16 - Serial 2 (COM2) supports RS-232 and full modem

Table 3 -4 defines the pins and corresponding signals for serial 1 header (J18), which consists of 10 pins, 2

rows, odd/even sequence (1, 2), and 0.079" (2mm) pitch.

Table 3-4. Serial 1 (COM1) Interface Pin Signal Descriptions (J18)

Pin # Signal DB9

Pin #

1 S1_DCD* 1 COM1 Data Carrier Detect – Indicates external serial device is detecting

2 S1_DSR* 6 COM1 Data Set Ready – Indicates external serial device is powered,

3 S1_RXD 2 COM1 Receive Data – Serial port receive data input is typically held at a

4 S1_RTS* 7 COM1 Request To Send – Indicates serial port is ready to transmit data.

5 S1_TXD 3 COM1 Transmit Data – Serial port transmit data output is typically held

6 S1_CTS* 8 COM1 Clear To Send – Indicates external serial device is ready to

7 S1_DTR* 4 COM1 Data Terminal Ready – Indicates serial port is powered,

8 S1_RI* 9 COM1 Ring Indicator – Indicates external serial device is detecting a

9

10

GND 5 Ground

GND 10 Ground

Description

a carrier signal (i.e., a communication channel is currently open). In

direct connect environments, this input is driven by DTR as part of the

DTR/DSR handshake.

initialized, and ready. Used as hardware handshake with DTR for overall

readiness.

logic 1 (mark) when no data is being transmitted, and is held “Off” for a

brief interval after an “On” to “Off” transition on the RTS line to allow

the transmission to complete.

Used as hardware handshake with CTS for low level flow control.

to a logic 1 when no data is being sent. Typically, a logic 0 (On) must be

present on RTS, CTS, DSR, and DTR before data can be transmitted on

this line.

receive data. Used as hardware handshake with RTS for low level flow

control.

initialized, and ready. Used as hardware handshake with DSR for overall

readiness.

ring condition. Used by software to initiate operations to answer and

open the communications channel.

Note: The shaded table cell denotes ground. The * symbol indicates the signal is Active Low.

CoreModule 920 Reference Manual 25

Page 32

Chapter 3 Hardware

Table 3 -4 defines the pins and corresponding signals for the Serial 2 header, which consists of 10 pins, 2

rows, odd/even sequence (1, 2), and 0.100" (2.54mm) pitch.

Table 3-5. Serial 2 (COM2) Interface Pin Signal Descriptions (H16)

Pin # Signal DB9

Description

Pin #

1 S2_DCD* 1 COM2 Data Carrier Detect – Indicates external serial device is detecting

a carrier signal (i.e., a communication channel is currently open). In

direct connect environments, this input is driven by DTR as part of the

DTR/DSR handshake.

2 S2_DSR* 6 COM2 Data Set Ready – Indicates external serial device is powered,

initialized, and ready. Used as hardware handshake with DTR for overall

readiness.

3 S2_RXD 2 COM2 Receive Data – Serial port receive data input is typically held at a

logic 1 (mark) when no data is being transmitted, and is held “Off” for a

brief interval after an “On” to “Off” transition on the RTS line to allow

the transmission to complete.

4 S2_RTS* 7 COM2 Request To Send – Indicates serial port is ready to transmit data.

Used as hardware handshake with CTS for low level flow control.

5 S2_TXD 3 COM2 Transmit Data – Serial port transmit data output is typically held

to a logic 1 when no data is being sent. Typically, a logic 0 (On) must be

present on RTS, CTS, DSR, and DTR before data can be transmitted on

this line.

6 S2_CTS* 8 COM2 Clear To Send – Indicates external serial device is ready to

receive data. Used as hardware handshake with RTS for low level flow

control.

7 S2_DTR* 4 COM2 Data Terminal Ready – Indicates serial port is powered,

initialized, and ready. Used as hardware handshake with DSR for overall

readiness.

8 S2_RI* 9 COM2 Ring Indicator – Indicates external serial device is detecting a

ring condition. Used by software to initiate operations to answer and

open the communications channel.

9

10

GND 5 Ground

GND 10 Ground

Note: The shaded table cells denote ground. The * symbol indicates the signal is Active Low.

26 Reference Manual CoreModule 920

Page 33

Chapter 3 Hardware

USB Interface

The CoreModule 920 contains two root USB hubs and six functional USB ports. Four of the six USB ports

are routed through two 10-pin headers (H15 and J25), and the other two ports are routed through the

PCIe/104 interface connector. The PCH provides the USB function including the following features:

• Supports USB v.2.0 EHCI and USB v.1.1 UHCI

• Provides over-current detection status

• Provides a fuse on board for over-current protection

Table 3 -6 describes the pin signals of the USB0 and USB1 header which consists of 10 pins, in two rows,

with odd/even (1, 2) pin sequence, and 0.100" (2.54mm) pitch.

Table 3-6. USB0 and USB1 Interface Pin Signals (H15)

Pin # Signal Description

1

2

3 CONN_USB0_N USB0 Port Data Negative

4 CONN_USB1_N USB1 Port Data Negative

5 CONN_USB0_P USB0 Port Data Positive

6 CONN_USB1_P USB1 Port Data Positive

7

8

9

10

USB-PWR_0 USB0 Power – VCC (+5V +/-5%) power goes to the port through an on-

board fuse. Port is disabled if this input is low.

USB-PWR_1 USB1 Power – VCC (+5V +/-5%) power goes to the port through an on-

board fuse. Port is disabled if this input is low.

USB_GND0 USB0 Ground

USB_GND1 USB1 Ground

USB_GND0 USB0 Ground

USB_GND1 USB1 Ground

Note: The shaded table cells denote power or ground.

Table 3 -7 describes the pin signals of the USB2 and USB3 header, which consists of 10 pins in two rows,

with odd/even (1, 2) pin sequence, and 0.079" (2mm) pitch.

Table 3-7. USB2 and USB3 Interface Pin Signals (J25)

Pin # Signal Description

1

2

3 CONN_USB2_N USB2 Port Data Negative

4 CONN_USB3_N USB3 Port Data Negative

5 CONN_USB2_P USB2 Port Data Positive

6 CONN_USB3_P USB3 Port Data Positive

7

8 USB_GND3 USB3 Ground

9

10

Note: The shaded table cells denote power or ground.

USB-PWR_2 USB2 Power – VCC (+5V +/-5%) power goes to the port through an on-

board fuse. Port is disabled if this input is low.

USB-PWR_3 USB3 Power – VCC (+5V +/-5%) power goes to the port through an on-

board fuse. Port is disabled if this input is low.

USB_GND2 USB2 Ground

USB_GND2 USB2 Ground

USB_GND3 USB3 Ground

CoreModule 920 Reference Manual 27

Page 34

Chapter 3 Hardware

Ethernet Interfaces

The CoreModule 920 supports two Gigabit Ethernet interfaces. The first Ethernet interface originates from

the 82579LM PHY transceiver, which occupies one PCI Express lane and supports the internal MAC

(Media Access Controller) in the PCH. The second Ethernet interface is implemented through the 82574IT

Ethernet controller, which occupies one PCI Express lane and generates its own Gigabit Ethernet signals.

The Ethernet function supports multi-speed operation at 10/100/1000 Mbps and operates in full-duplex at all

supported speeds or half duplex at 10/100 Mbps while adhering to the IEEE 802.3x flow control

specification. The Ethernet interface offers the following features:

• Full duplex support at 10 Mbps, 100 Mbps, or 1000 Mbps

• Half duplex support at 10 Mbps and 100 Mbps

• In full duplex mode, the Ethernet controller adheres to the IEEE 802.3x Flow Control specification

• In half duplex mode, performance is enhanced by a proprietary collision reduction mechanism

• IEEE 802.3 compatible physical layer to wire transformer

• IEEE 802.3u Auto-Negotiation support

• Fast back-to-back transmission support with minimum interframe spacing (IFS)

• IEEE 802.3x auto-negotiation support for speed and duplex operation

• On-board magnetics (Ethernet isolation transformers)

Table 3 -8 describes the pin signals of the Ethernet GLAN1 interface, which consists of a two-row, 10-pin

vertical header with odd/even (1,2) pin sequence, and 0.100" (2.54mm) pitch.

Table 3-8. GLAN1 Interface Pin Signal Descriptions (H11)

Pin # Signal Description

1 MDI1+ Media Dependent Interface 1 +/-

2MDI1-

3 MDI2+ Media Dependent Interface 2 +/-

4MDI2-

5 MDI0+ Media Dependent Interface 0 +/-

6MDI0-

7 MDI3+ Media Dependent Interface 3 +/-

8MDI3-

9

10 GND

Note: The shaded table cells denote ground.

GND Ground

NOTE The magnetics (isolation transformer, T1) for the Ethernet connector is included

on the CoreModule 920.

28 Reference Manual CoreModule 920

Page 35

Chapter 3 Hardware

Table 3 -9 describes the pin signals of the Ethernet GLAN2 interface, which consists of a two-row, 10-pin

vertical header with odd/even (1,2) pin sequence, and 0.079" (2mm) pitch.

Table 3-9. GLAN2 Interface Pin Signal Descriptions (J14)

Pin # Signal Description

1 MDI1+ Media Dependent Interface 1 +/-

2MDI1-

3 MDI2+ Media Dependent Interface 2 +/-

4MDI2-

5 MDI0+ Media Dependent Interface 0 +/-

6MDI0-

7 MDI3+ Media Dependent Interface 3 +/-

8MDI3-

9

10

Note: The shaded table cells denote ground.

GND Ground

GND

NOTE The magnetics (isolation transformer, T2) for the Ethernet header is included on

the CoreModule 920.

Video Interfaces

The Core i7, 3517UE CPU provides an integrated 2D/3D graphics engine, which supports video decode

such as MPEG2, VC-1, and AVC/H.264 (main, baseline at L3 and High-profile level 4.0/4.1) as well as

video encode such as MPEG2, AVC/H.264 (baseline at L3), and VGA. The PCH supports VGA, LVDS, and

HDMI display ports, permitting simultaneous, independent operation of two displays. The CPU provides

PCIe x16 Graphics signals to the PCIe/104 connector for an external high-performance PCI Express

Graphics card or other general purpose PCI Express devices. The video interface features are listed in the

following bullets. Refer to Table 3-10 for definitions of the VGA pin signals and Tab le 3 -11 for the LVDS

pin signal definitions. The HDMI interface is a standard HDMI micro connector, and those pin signals are

not defined in this manual. The PEG signals are part of the standard PCIe/104 interface and are not defined

in this manual.

VGA:

• Supports resolutions up to 2048x1536 pixels at 75Hz

• Provides integrated 340.4MHz RAMDAC with 32-bit color

• Provides RGB output by three 8-bit DACs

• Supports HSYNC and VSYNC output

LVDS:

• Supports a maximum resolution of 1400x1050 at 60Hz (pixel clock rate up to 112MHz)

• Supports minimum pixel clock rate of 25MHz

• Supports a single channel interface through a 20-pin header

• Supports pixel color depths of 18 and 24 bits

HDMI:

• Supports resolutions up to 3840x2160 pixels at 30Hz

• Supports pixel clock rates from 25MHz to 340MHz

CoreModule 920 Reference Manual 29

Page 36

Chapter 3 Hardware

• Supports DVD-Audio and Audio Return channel

• Provides one 19-pin, standard HDMI micro connector

PEG (PCI Express Graphics):

• Supports external high-performance PCI Express graphics cards

• Supports general-purpose PCI Express devices

• Supports theoretical bandwidth of up to 8GT/s

• Provides PCIe Gen3 compliance

Table 3-10 defines the signals of the VGA interface, which consists of 10 pins, 2 rows, odd/even, (1, 2) with

0.079" (2mm) pitch.

Table 3-10. VGA Interface Pin Signal Descriptions (J17)

Pin # Signal Description

1 VSYNC Vertical Sync – This signal is used for the digital vertical sync (polarity is

programmable) 2.5V output to the VGA display.

2 HSYNC Horizontal Sync – This signal is used for the digital horizontal sync

(polarity is programmable) or “sync interval” 2.5V output to the VGA

display

3 DDC-CLK Display Control Clock

4 RED Red – This is the Red analog output signal to the VGA display.

5 DDC-DATA Display Control Data

6 GREEN Green – This is the Green analog output signal to the VGA display.

7

8 BLUE Blue – This is the Blue analog output signal to the VGA display.

9

10

VDD5V0 Power – This is the +5 volts +/- 5% power signal from the external power

interface.

GND Ground

GND Ground

Note: The shaded table cells denote power or ground.

Table 3-11 lists the pin signals of the LVDS video header, which provides 20 pins, 2 rows, odd/even pin

sequence (1, 2) with 0.079" (2mm) pitch.

Table 3-11. LVDS Video Interface Pin Signals (J23)

Pin # Signal Description

1

2

3

4

5 LVDSA_CLK_P LVDS A Clock Positive

6 LVDSA_CLK_N LVDS A Clock Negative

7 LVDSA_DAT3_P LVDS A DATA Positive Line 3

8 LVDSA_DAT3_N LVDS A DATA Negative Line 3

9 LVDSA_DAT2_P LVDS A DATA Positive Line 2

10 LVDSA_DAT2_N LVDS A DATA Negative Line 2

11 LVDSA_DAT1_P LVDS A DATA Positive Line 1

12 LVDSA_DAT1_N LVDS A DATA Negative Line 1

30 Reference Manual CoreModule 920

+12V +12 volts for flat panel and backlight

VCC_LVDS_CONN JP3 determines LVDS voltage (+3.3V or +5V)

GND Ground

GND Ground

Page 37

Chapter 3 Hardware

Table 3-11. LVDS Video Interface Pin Signals (J23) (Continued)

Pin # Signal Description

13 LVDSA_DAT0_P LVDS A DATA Positive Line 0

14 LVDSA_DAT0_N LVDS A DATA Negative Line 0

15 LBKLT_CTL Panel Backlight Control

16 LVDD_EN Enable Panel Power

17 LDDC_CLK Display Data Channel Clock

18 LDDC_DATA Display Data Channel Data

19 LBKLT_EN Enable Backlight Inverter

20 NC Not Connected

Note: The shaded table cells denote power or ground.

Power Interface

The CoreModule 920 requires one +5 volt DC power source and provides a shrouded 10-pin, right-angle

header with 2 rows, odd/even pin sequence (1, 2), and 0.100" (2.54mm) pitch.

The power input header (J24) supplies the following voltage and ground directly to the module:

• 4.75VDC - 5.0VDC +/- 5%

Table 3-12. Power Interface Pin Signals (J24)

Pin Signal Descriptions

1

2

3

4

5

6

7

8

9 GND Ground

10

Note: The shaded table cells denote power or ground.

GND Ground

+5V +5 Volts

GND Ground

+12V +12 Volts routed to PC/104, PC/104-Plus, and LVDS interfaces

GND Ground

+3.3V_PCI +3.3 Volts routed to PCI

GND Ground

+5V +5 Volts

+5V +5 Volts

CoreModule 920 Reference Manual 31

Page 38

Chapter 3 Hardware

User GPIO Interface

The CoreModule 920 provides GPIO pins for customer use, routing the signals from the PCH chipset to the

J26 and J27 headers. An example test application and source code reside in each BSP directory of the

CoreModule 920 Support Software QuickDrive.

For instructions on using the example applications, refer to the GPIO Readme in each BSP directory of the

QuickDrive. For more information about the GPIO pin operation, refer to the PCH BD82QM67 datasheet at:

http://

www.intel.com/Assets/PDF/datasheet/324645.pdf

Table 3-13 describes the pin signals of the GPIO1 interface, which provides a 6-pin, single-row header with

0.079" (2mm) pitch.

Table 3-13. User GPIO1 Interface Pin Signal Descriptions (J26)

Pin # Signal Description

1 PCH_GPIO71 User defined

2 PCH_GPIO70 User defined

3 PCH_GPIO69 User defined

4 PCH_GPIO68 User defined

5

6

GND Ground

GND Ground

Note: The shaded areas denote ground. All GPIO pins are in the Core Power Well of the PCH.

Table 3-14 describes the pin signals of the GPIO2 interface, which provides a 6-pin, single-row header with

0.079" (2mm) pitch.

Table 3-14. User GPIO2 Interface Pin Signal Descriptions (J27)

Pin # Signal Description

1 PCH_GPIO35 User defined

2 PCH_GPIO36 User defined

3 PCH_GPIO37 User defined

4 PCH_GPIO38 User defined

5

6

Note: The shaded table cells denote ground. All GPIO pins are in the Core Power Well of the PCH.

GND Ground

GND Ground

32 Reference Manual CoreModule 920

Page 39

Chapter 3 Hardware

Utility Interface

The Utility interface provides three I/O signals on the module and consists of a 5-pin, 0.100" (2.54mm),

single-row header (J21). The CPU drives the Power Button and Speaker signals on the Utility interface. A

separate Power Management microprocessor drives the Reset Switch signal. Table 3-15 provides the signal

definitions.

• Power Button

• Reset Switch

• Speaker

Power Button

The Utility header provides a signal for an external Power Button through pins 1 and 2. The Power Button

allows the user to shut down and power on the system. To shut down the system, press and hold the Power

Button for four seconds. Press the Power Button for one second to power on the system.

Reset Switch

Pins 2 and 3 on the Utility header provide the signals for an external reset button, which allows the user to

re-boot the system.

Speaker

The speaker signal provides sufficient signal strength to drive an external 1W 8 “Beep” speaker at an

audible level through pins 4 and 5 on the Utility header. The speaker signal is driven from an on-board

amplifier and the CPU.

Table 3-15 describes the pin signals of the Utility interface, which provides a 5-pin, single-row header with

0.100" (2.54mm) pitch.

Table 3-15. Utility Interface Pin Signals (J21)

Pin # Signal Description

1 PWR_BTN* External Power Button (Pins 1-2)

2

3 RESET SW* External Reset Switch signal (Pins 2-3)

4

5 SPKR_CONN Speaker Output (Pins 4-5)

6

Note: The shaded table cells denote power or ground. The * symbol indicates the signal is Active Low.

GND Ground

5V +5 Volts Power

GND Ground

System Fan

Table 3-16 lists the pin signals of the System Fan header, which provides a single row of 3 pins with 0.079"

(2mm) pitch.

Table 3-16. System Fan Pin Signals (J22)

Pin # Signal Description

1

2 NC Not Connected

3

Note: The shaded table cells denote power or ground.

CoreModule 920 Reference Manual 33

+V_FAN +5.0 volts DC +/- 5%

GND Ground

Page 40

Chapter 3 Hardware

Battery

Table 3-17 lists the pin signals of the External Battery Input header for backup RTC (Real Time Clock),

which provides 2 pins with 0.049" (1.25mm) pitch.

Table 3-17. External Battery Input Header (J12)

Pin # Signal Description

1

2

Note: The shaded table cells denote power or ground. The RTC has an expected current draw of 6A at

room temperature, with +3.0V. The battery is used only when power is not applied to the board.

V_BATT +3.0 volts DC

GND Ground

External LEDs (Ethernet)

These two headers provide signals for two external LEDs that indicate Ethernet links and activity.

Table 3-18 defines the signals for the GLAN1 LED header that indicates Ethernet links and activity using a

single row of 4 pins with 0.049" (1.25mm) pitch.

Table 3-18. GLAN1 External LED Pin Signals (J2)

Pin # Signal Description

1

2 GBE1_ACT_LED Ethernet Activity

3 GBE1_LINK1000_LED Gigabit Ethernet Link

4 GBE1_LINK100_LED Fast Ethernet Link with +3.3 volts power (Pins 3-4 for Bi-Color

V3.3_CONN +3.3 volts – Provides +3.3 volts to external LED (Pins 1-2 for

Green LED)

LED)

Note: The shaded table cell denotes power. Configure Ethernet LEDs for Active Low operation.

Table 3-19 defines the signals for the GLAN2 LED header that indicates Ethernet links and activity using a

single row of 4 pins with 0.049" (1.25mm) pitch.

Table 3-19. GLAN2 External LED Pin Signals (J3)

Pin # Signal Description

1

2 GBE2_ACT_LED Ethernet Activity

3 GBE2_LINK1000_LED Gigabit Ethernet Link

4 GBE2_LINK100_LED Fast Ethernet Link with +3.3 volts power (Pins 3-4 for Bi-Color

Note: The shaded table cell denotes power. Configure Ethernet LEDs for Active Low operation.

V3.3_CONN +3.3 volts – Provides +3.3 volts to external LED (Pins 1-2 for

Green LED)

LED)

34 Reference Manual CoreModule 920

Page 41

Chapter 3 Hardware