Page 1

CoreModule

TM

430

(PC/104 Single Board Computer)

Reference Manual

P/N 50-1Z006-1010

Page 2

Notice Page

DISCLAIMER

ADLINK Technology, Incorporated makes no representations or warranties with respect to the contents of

this manual or of the associated ADLINK products, and specifically disclaims any implied warranties of

merchantability or fitness for any particular purpose. ADLINK shall under no circumstances be liable for

incidental or consequential damages or related expenses resulting from the use of this product, even if it has

been notified of the possibility of such damages. ADLINK reserves the right to revise this publication from

time to time without obligation to notify any person of such revisions. If errors are found, please contact

ADLINK at the address listed below on the Notice page of this document.

TRADEMARKS

CoreModule and the Ampro logo are registered trademarks, and ADLINK, Little Board, LittleBoard,

MightyBoard, MightySystem, MilSystem, MiniModule, ReadyBoard, ReadyPanel, ReadySystem, and

RuffSystem are trademarks of ADLINK Technology, Inc. All other marks are the property of their

respective companies.

REVISION HISTORY

Revision Reason for Change Date

A, A Initial Release Oct/08

1.0 Added U9 chip to table 2-1; revised description of U7 chip in table 2-1;

revised JP7 default to pins 2-3 in table 2-3; changed document p/n from

5001840 to 50-1Z006-1000; changed rev to 1.0

1010

Changed pitch of J4 header in Tables 2-2 and 3-5 to 0.079

rev of this document from 1.0 to 1010; changed pin 9 in Tabl e 3 -10

from 3.6/4.0V to 3.0V max; added BIOS Setup Screens section to ch 4;

replaced EOL, U14 video memory in Tab le 2- 1 with new component;

changed definition of SPI Flash device

"; changed

Oct/09

June/12

ADLINK Technology, Incorporated

5215 Hellyer Avenue, #110

San Jose, CA 95138-1007

Tel. 408 360-0200

Fax 408 360-0222

http://www.adlinktech.com

© Copyright 2008, 2009, 2010, 2011, 2012 ADLINK Technology, Incorporated

Audience

This manual provides reference only for computer design engineers, including but not limited to hardware

and software designers and applications engineers. ADLNK Technology, Inc. assumes you are qualified to

design and implement prototype computer equipment.

ii Reference Manual CoreModule 430

Page 3

Contents

Chapter 1 About This Manual ....................................................................................................1

Purpose of this Manual ....................................................................................................................1

References ......................................................................................................................................1

Chapter 2 Product Overview.....................................................................................................3

PC/104 Architecture ........................................................................................................................3

Product Description..........................................................................................................................4

Module Features ........................................................................................................................4

Block Diagram ............................................................................................................................7

Major Components (ICs) .................................................................................................................8

Header, Connector, and Socket Definitions ..................................................................................10

Jumper Header Definitions .......................................................................................................11

Specifications.................................................................................................................................12

Physical Specifications .............................................................................................................12

Mechanical Specifications ........................................................................................................12

Power Specifications ................................................................................................................13

Environmental Specifications....................................................................................................13

Thermal/Cooling Requirements ...............................................................................................13

Chapter 3 Hardware..................................................................................................................15

Overview ........................................................................................................................................15

CPU ..............................................................................................................................................16

Graphics ........................................................................................................................................16

Memory ..........................................................................................................................................16

System Memory .......................................................................................................................16

Video Memory ..........................................................................................................................16

SPI Flash .................................................................................................................................16

Memory Map ..................................................................................................................................17

Interrupt Channel Assignments .....................................................................................................18

I/O Address Map ...........................................................................................................................19

Parallel Interface (LPT) .................................................................................................................20

Serial Interface ..............................................................................................................................21

USB Interface ................................................................................................................................23

Utility Interface ..............................................................................................................................24

Keyboard ..................................................................................................................................24

Mouse .......................................................................................................................................24

Battery ......................................................................................................................................24

Reset Switch.............................................................................................................................24

Speaker ....................................................................................................................................24

Ethernet Interface .........................................................................................................................25

Video (TTL/VGA) Interface ...........................................................................................................26

Serial Peripheral Interface (SPI) ....................................................................................................28

Low Pin Count Interface (LPC) ......................................................................................................28

Miscellaneous ................................................................................................................................28

Real Time Clock (RTC) ............................................................................................................28

User GPIO Interface ................................................................................................................29

Oops! Jumper (BIOS Recovery) ...............................................................................................29

CoreModule 430 Reference Manual iii

Page 4

Contents

Remote Access ...................................................................................................................... 30

Remote Access Setup ........................................................................................................ 30

Hot (Serial) Cable .............................................................................................................. 30

Watchdog Timer....................................................................................................................... 30

Power Interface ............................................................................................................................ 31

Chapter 4 BIOS Setup .............................................................................................................. 33

Introduction.................................................................................................................................... 33

Entering BIOS Setup (Local Display) ....................................................................................... 33

Entering BIOS Setup (Remote Access) ................................................................................... 33

OEM Logo Utility .......................................................................................................................... 34

Logo Image Requirements....................................................................................................... 34

BIOS Setup Screens ..................................................................................................................... 35

BIOS Main Setup Screen ........................................................................................................ 35

BIOS Advanced Setup Screen................................................................................................. 36

BIOS PCIPnP Setup Screen .................................................................................................... 38

BIOS Boot Setup Screen ......................................................................................................... 40

BIOS Security Setup Screen.................................................................................................... 41

BIOS Chipset Setup Screen..................................................................................................... 42

BIOS Exit Setup Screen........................................................................................................... 45

Appendix A Technical Support .................................................................................................. 47

Index ................................................................................................................................................. 49

List of Figures

Figure 2-1. Stacking PC/104 Modules with the CoreModule 430 .............................................. 3

Figure 2-2. Block Diagram ......................................................................................................... 7

Figure 2-3. Component Locations (Top Side)............................................................................ 9

Figure 2-4. Connector Pin Identifications................................................................................. 10

Figure 2-5. Header Locations (Top Side) ................................................................................ 11

Figure 2-6. Mechanical Dimensions (Top Side)....................................................................... 12

Figure 3-1. RS-485 Serial Port Implementation....................................................................... 21

Figure 3-2. Oops! Jumper........................................................................................................29

Figure 3-3. Hot Cable Jumper ................................................................................................. 30

Figure 4-1. BIOS Main Setup Screen ...................................................................................... 35

Figure 4-2. BIOS Advanced Setup Screen .............................................................................. 36

Figure 4-3. BIOS PCIPnP Setup Screen ................................................................................. 38

Figure 4-4. BIOS Boot Setup Screen....................................................................................... 40

Figure 4-5. BIOS Security Setup Screen ................................................................................. 41

Figure 4-6. BIOS Chipset Setup Screen.................................................................................. 42

Figure 4-7. BIOS Exit Setup Screen ........................................................................................ 45

List of Tables

Table 2-1. Major Components (Chips) Descriptions and Functions ......................................... 8

Table 2-2. Header, Connector, and Socket Descriptions ....................................................... 10

Table 2-3. Jumper Settings .................................................................................................. 11

Table 2-4. Weight and Footprint Dimensions ......................................................................... 12

Table 2-5. Power Supply Requirements ................................................................................. 13

Table 2-6. Environmental Requirements ................................................................................ 13

Table 3-1. Memory Map - Vortex 86SX/DX Processor........................................................... 17

Table 3-2. Interrupt Channel Assignments ............................................................................. 18

iv Reference Manual CoreModule 430

Page 5

Contents

Table 3-3. DMA Map ...............................................................................................................18

Table 3-4. I/O Address Map ....................................................................................................19

Table 3-5. Parallel (LPT) Interface Pin/Signal Descriptions (J4) .............................................20

Table 3-6. Serial Ports 1 & 2 Interface Pin/Signal Descriptions (J3, J9) .................................22

Table 3-7. Serial Ports 3 & 4 Interface Pin/Signal Descriptions (J13, J14) .............................22

Table 3-8. USB0 Interface Pin/Signal Designations (J10) ......................................................23

Table 3-9. USB1 Interface Pin/Signal Designations (J17) ......................................................23

Table 3-10. Utility Interface Pin/Signal Descriptions (J5) ..........................................................24

Table 3-11. Ethernet Interface Pin/Signal Descriptions (J2) .....................................................25

Table 3-12. Video Interface Pin/Signal Descriptions (J11)........................................................26

Table 3-13. SPI Interface Pin/Signal Descriptions (J19) ...........................................................28

Table 3-14. LPC Interface Pin/Signal Descriptions (J20)..........................................................28

Table 3-15. User GPIO Interface Pin/Signal Descriptions (J8) .................................................29

Table 3-16. Power Interface Pin/Signals (J7)............................................................................31

Table 4-1. BIOS Setup Menus ................................................................................................35

Table A-1. Technical Support Contact Information..................................................................47

CoreModule 430 Reference Manual v

Page 6

Contents

vi Reference Manual CoreModule 430

Page 7

Chapter 1 About This Manual

Purpose of this Manual

This manual is for designers of systems based on the CoreModule™ 430 PC/104 single board computer

(SBC) module. This manual contains information that permits designers to create an embedded system

based on specific design requirements.

Information provided in this reference manual includes:

• CoreModule 430 SBC Specifications

• Environmental requirements

• Major chips and features implemented

• CoreModule 430 SBC connector/pin numbers and definitions

• BIOS Setup information

Information not provided in this reference manual includes:

• Detailed chip specifications

• Internal component operation

• Standard interface pin-out tables

• Internal registers or signal operations

• Bus or signal timing for industry standard busses and signals

References

The following list of references may be helpful for you to complete your custom design successfully. Some

of these references are also available on the Ampro By ADLINK web page. The web page was created for

embedded system developers to share ADLINK’s knowledge, insight, and expertise.

Specifications

• PC/104 Specifications Revision 2.5, November 2003

For latest revision of the PC/104 specifications, contact the PC/104 Consortium, at:

Web site: http://www.pc104.org

Major Integrated Circuit (Chip) Specifications

The following chip specifications are used in the CoreModule 430 processor module:

• DMP Electronics Inc. and the Vortex 86SX/DX CPU

Web site: http://www.vortex86sx.com/

• Winbond Electronics and the W25Q16BV SPI Flash memory

Web site: http://www.winbond.com/hq/enu/ProductAndSales/ProductSearch/?partno=w25q16bv

• Samsung Electronics and DDR2 on-board System Memory

Web site: http://www.samsung.com/global/business/semiconductor/

• Hynix Semiconductor, Inc. and DDR2 on-board Video Memory

Web site: http://www.hynix.com/gl/products/consumer/consumer_info.jsp

NOTE If you are unable to locate the datasheets using the links provided, search the

internet to find the manufacturer’s web site and locate the documents you need.

CoreModule 430 Reference Manual 1

Page 8

Chapter 1 About This Manual

2 Reference Manual CoreModule 430

Page 9

Chapter 2 Product Overview

PC/104 Module

CoreModule 430

PC/104 Module

Stackthrough

Expansion

Bus Headers

4-40 nut (4)

0.6 inch spacer (4)

0.6 inch spacer (4)

4-40 screw (4)

PC/104 Module

CM430stack

This introduction presents general information about the PC/104 architecture and the CoreModule 430

Single Board Computer (SBC). After reading this chapter you should understand:

• PC/104 architecture

• CoreModule 430 product description

• CoreModule 430 features

• Major components

• Header definitions

• Specifications

PC/104 Architecture

The PC/104 architecture affords a great deal of flexibility in system design. You can build a simple system

using only a CoreModule Single Board Computer (SBC), with input/output devices connected to its serial or

parallel ports and a Compact Flash card in the Compact Flash socket. To expand a simple CoreModule

system, simply add self-stacking ADLINK MiniModules or 3rd party PC/104 expansion boards to provide

additional capabilities, such as:

• Additional I/O ports

• Analog or digital I/O interfaces

PC/104 expansion modules can be stacked with the CoreModule 430 avoiding the need for card cages and

backplanes. The PC/104 expansion modules can be mounted directly to the PC/104 bus connector of the

CoreModule 430. PC/104-compliant modules can be stacked with an inter-board spacing of ~0.66" (16.7

mm) so that a 3-module system fits in a 3.6" x 3.8" x 2.4" space. See Figure 2-1.

One or more MiniModule products or other PC/104 modules can be installed on the CoreModule expansion

connectors. When installed on the PC/104 headers, the expansion modules fit within the CoreModule outline

dimensions. Most MiniModule products have stack through connectors compatible with the PC/104 Version

2.5 specification. Several modules can be stacked on the CoreModule headers. Each additional module

increases the thickness of the package by 0.60" (15 mm). See Figure 2-1.

Figure 2-1. Stacking PC/104 Modules with the CoreModule 430

CoreModule 430 Reference Manual 3

Page 10

Chapter 2 Product Overview

Product Description

The CoreModule 430 SBC is an exceptionally high integration, x86-based PC compatible system in the

PC/104 form factor. This rugged and high quality single board system contains all the component

subsystems of a PC/AT motherboard plus the equivalent of several PC/AT expansion boards.

In addition, the CoreModule 430 SBC includes a comprehensive set of system extensions and enhancements

that are specifically designed for embedded systems. These enhancements ensure fail-safe embedded system

operation, such as a watchdog timer. The CoreModule 430 is designed to meet the size, power consumption,

temperature range, quality, and reliability demands of embedded applications. The CoreModule 430 requires

a single +5V power source.

The CoreModule 430 SBC is particularly well suited to either embedded or portable applications. Its

flexibility makes system design quick and easy. It can be stacked with ADLINK MiniModules or other

PC/104-compliant expansion boards, or it can be used as the computing engine in a fully customized

application.

Module Features

• CPU

Provides x86 based DMP Vortex SX (300 MHz) or DX (800 MHz) microprocessor

Provides integrated Northbridge and Southbridge

Fully supports PC compatible architecture

Provides 8 kB Unified Instruction and Data Cache

Provides Parallel Processing Integrated Floating Point Unit (only in DX version)

Provides Low Power and System Management Modes

• Memory

Provides up to 256 MB standard DDR2 system RAM (soldered on the board)

Provides up to 32 MB standard DDR2 video RAM (soldered on the board)

Supports Memory Bus Speeds of 166 MHz on the SX CPU and 333 MHz on the DX CPU

• PC/104 Bus Interface

Provides standard PC/104 connector

Supports clock speeds up to 8 MHz ISA

• IDE Interface

Provides one IDE channel

Supports two enhanced IDE devices

Provides Fast ATA-capable interface for high-speed PIO modes

(PIO modes 0 to 4)

Supports ATAPI and DVD peripherals

Supports IDE native and ATA compatibility modes

• Compact Flash Socket

Provides Compact Flash socket (Type I or II)

Supports IDE Compact Flash cards

Attached to Primary IDE bus

4 Reference Manual CoreModule 430

Page 11

Chapter 2 Product Overview

• Serial Ports

Provides two 10-pin headers and four buffered RS-232 serial ports with full handshaking and

modem capability

Provides 16C550 or 16C552 UARTs, each with a built-in 16-byte FIFO buffer

Supports RS-232 or RS-485 operation on ports 1 and 2

Supports programmable word length, stop bits, and parity

Supports 16-bit programmable baud-rate generator and an interrupt generator

• Parallel Port (LPT)

Provides parallel port header

Supports standard printer port

Supports IEEE standard 1284 protocols, including SPP, EPP, and ECP modes

Supports 16 byte FIFO for ECP mode

• Ethernet

Supports IEEE 802.3 10BaseT/100BaseT compatible physical layer

Supports Auto-negotiation for speed, duplex mode, and flow control

Supports full duplex or half-duplex mode

• Full-duplex mode supports transmit and receive frames simultaneously

• Supports IEEE 802.3x Flow control in full duplex mode

• Half-duplex mode supports enhanced proprietary collision reduction mode

• Utility Interface

PS/2 Keyboard and Mouse Interface

Supports external battery for Real Time Clock operation

Supports standard external 8 speaker interface

Supports external reset switch

• USB Ports

Provides one root USB hub

Provides two USB ports

Supports USB v2.0 and Universal UHCI v1.1

• Video (TTL/VGA) Display

Enhanced 2D graphics controller

Supports BitBLT implementation for all 256 raster operations for Windows support

Provides hardware command queue

Supports all BLT transparency modes

• Bitmap transparency

• Pattern transparency

• Source transparency

• Destination transparency

Supports rectangle clipping

Supports fast line draw engine with styled pattern

CoreModule 430 Reference Manual 5

Page 12

Chapter 2 Product Overview

Supports fast rectangle fill engine

Supports 64x64x2 bit-mapped mono hardware cursor

Supports 256MB frame buffer with linear addressing

VGA Interface (DB15)

VGA Controller with 135 MHz triple RAMDACs for 1280 x 1024 x 75 Hz display

Supports 24-bit pixel depth

Interlaced or non-interlaced output

TTL Interface

Supports VESA Flat Panel Display interface

Supports programmable panel size up to 1600x1200 pixel display resolution

Supports internal CRT controller for display mode settings

Supports 12-, 18-, and dual 12-bit interface (1 Pixel/Clock)

Supports 3.3V or 5V LCD panels; jumper selectable

• Miscellaneous

Provides Real Time Clock and CMOS RAM, with support for battery-free operation

Provides General Purpose I/O (GPIO) interface

Supports Oops! Jumper (BIOS Recovery)

Supports Remote Access (Console Redirection)

Supports customizable Splash Screen

Supports Watchdog Timer (WDT)

Provides 16 Mbits of virtual floppy drive capacity

6 Reference Manual CoreModule 430

Page 13

Chapter 2 Product Overview

SPI Header

SPI Flash

(Virtual Floppy)

USB0 and USB1

Header

Ethernet

Transformer

10/100 Ethernet

Header

CRT and TTL

Header

DDR2

Video Memory

DDR2

System Memory

DDR2

System Memory

SiS

Volari

TM

Z9s

PCI Graphics

Controller

DMP Vortex

86DX/SX

CPU

GPIOs (8)

Header

PCI Bus

Parallel (LPT)

Header

PC/104 Connector

Compact Flash

Socket

44-Pin IDE

Header

ISA Bus

Utility Interface

Header

LPC

Header

RTC

COM3 & COM4

Header

COM1 & COM2

Header

RS232

Transceiver (X2)

RS422/485

Transceiver (X1)

COM1 & COM2

Header

RS232

Transceiver (X1)

CM430blkdiag_c

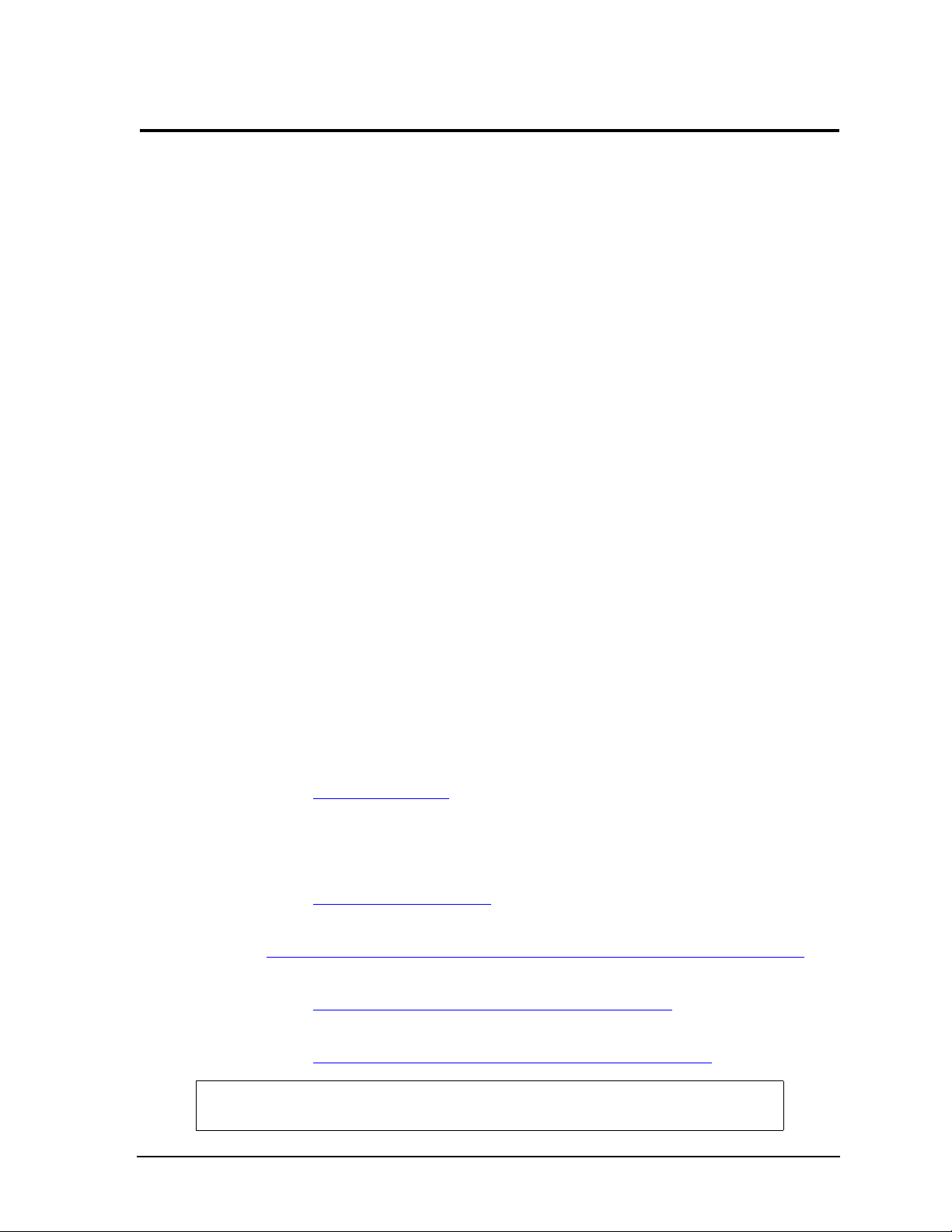

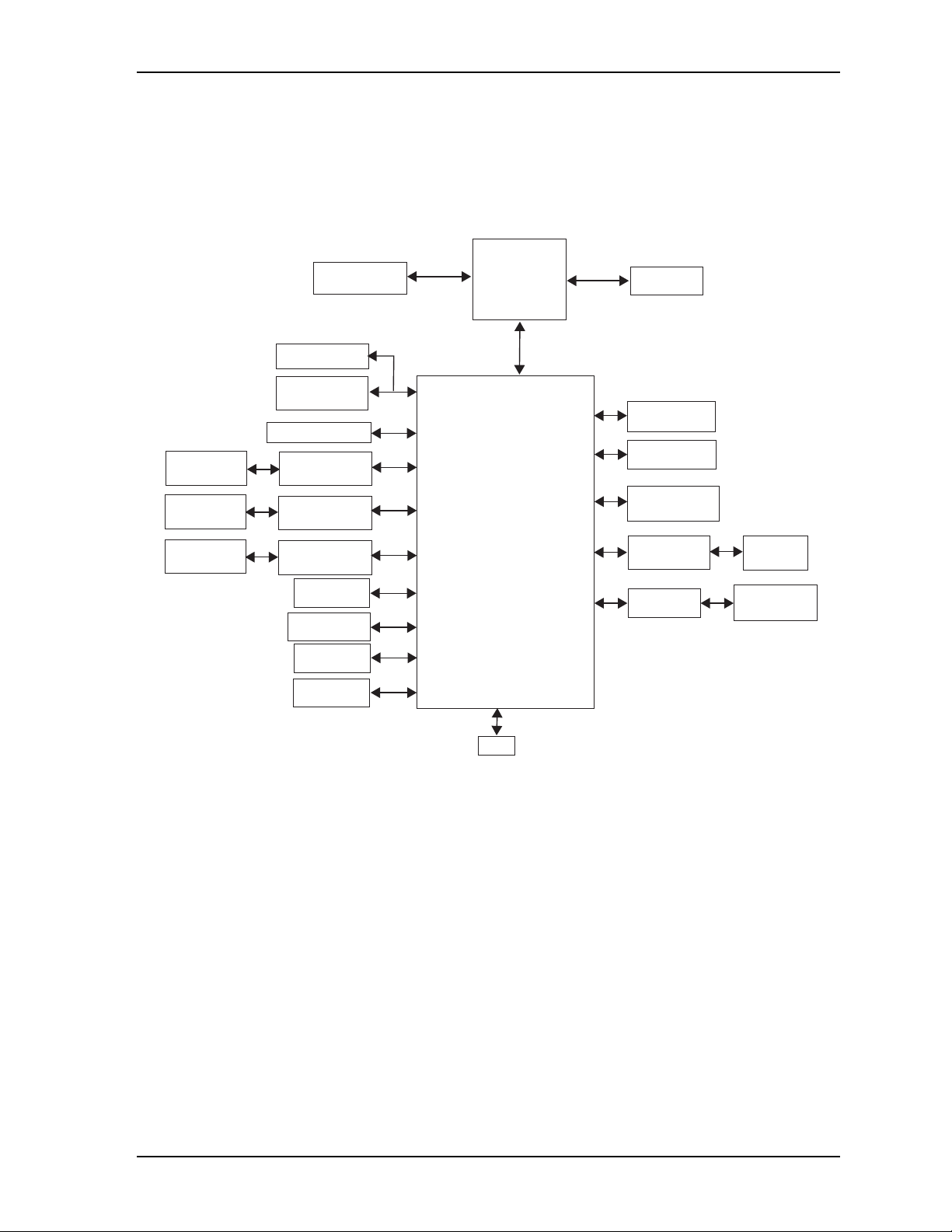

Block Diagram

Figure 2-2 shows the functional components of the module.

Figure 2-2. Block Diagram

CoreModule 430 Reference Manual 7

Page 14

Chapter 2 Product Overview

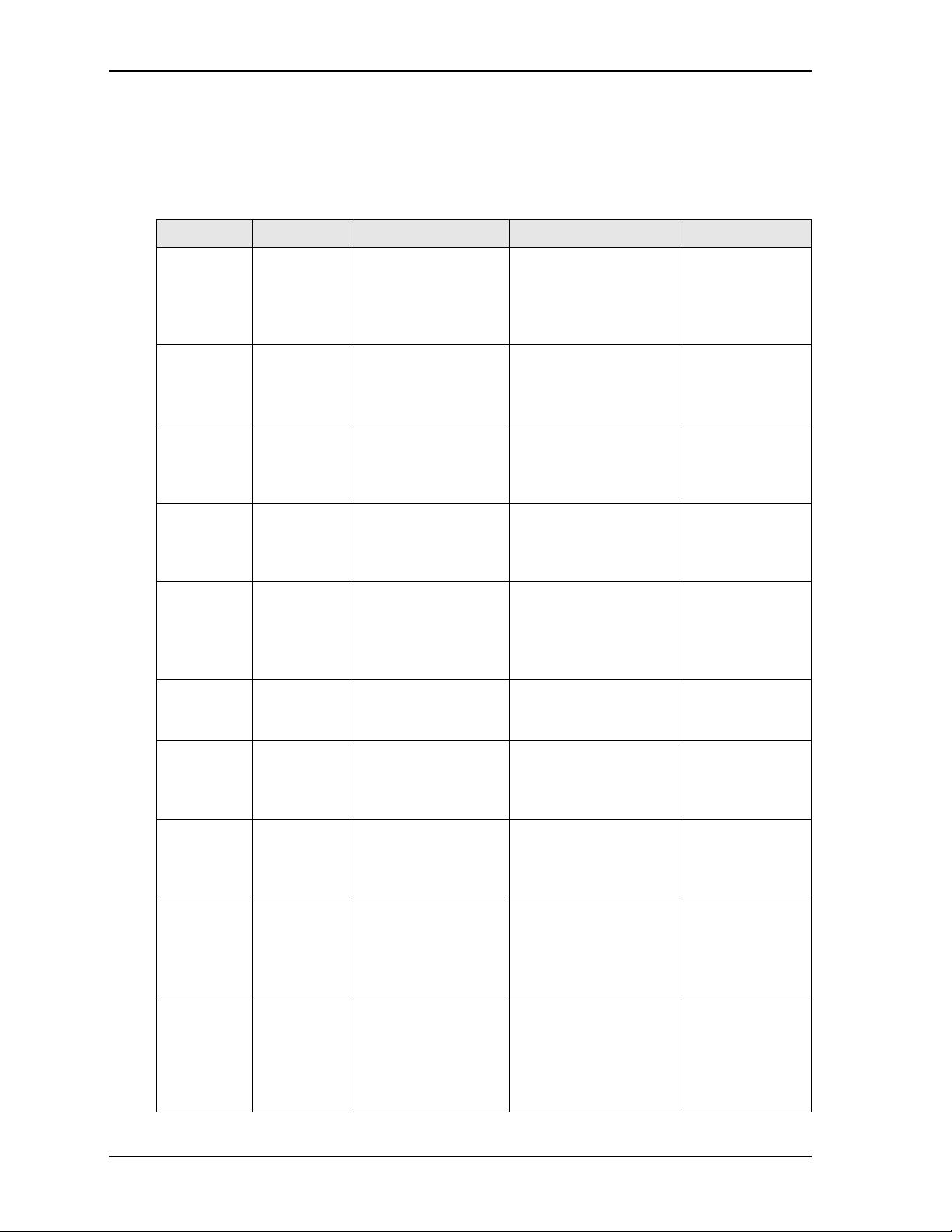

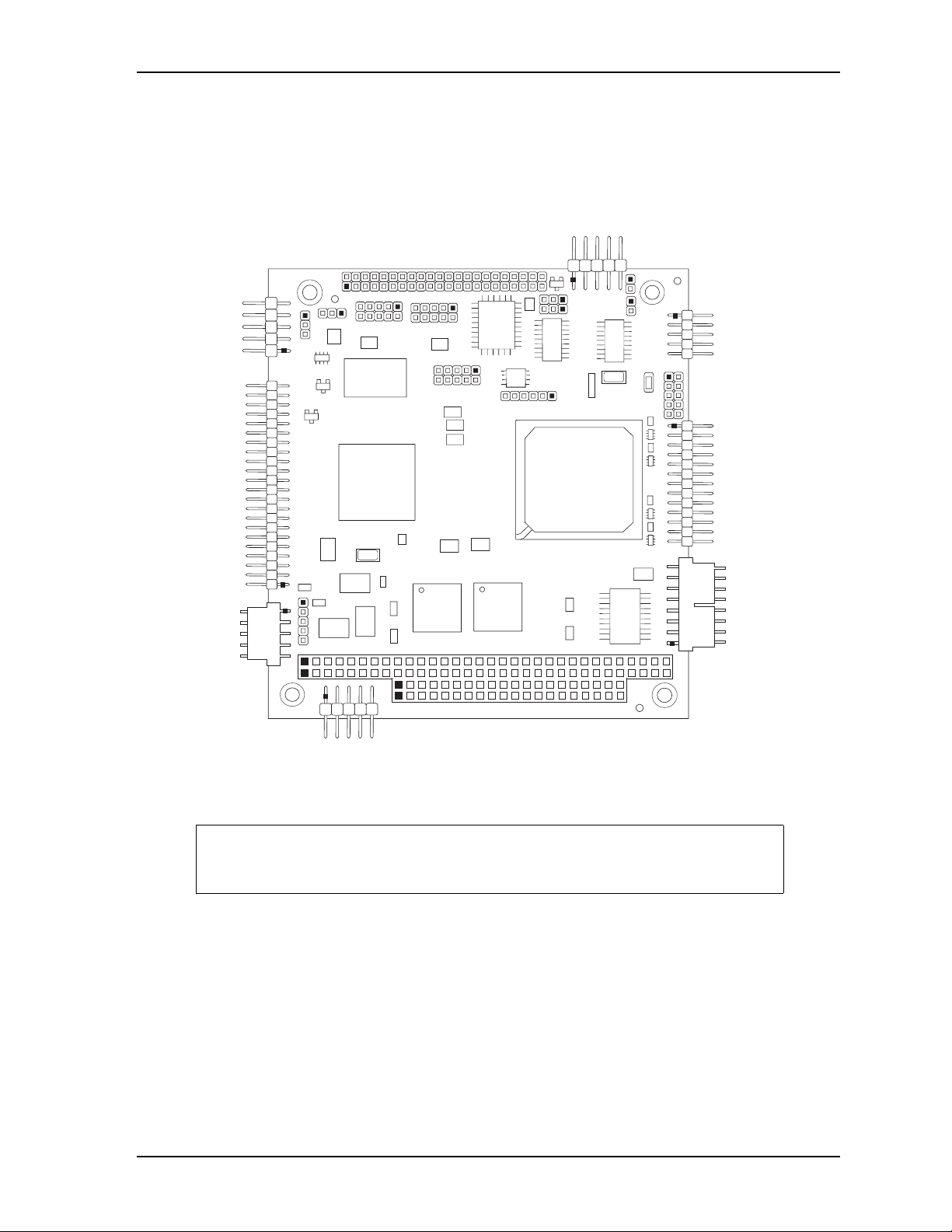

Major Components (ICs)

Table 2-1 describes the major integrated circuits (ICs) on the CoreModule 430, and Figure 2-3 shows the

locations of the major ICs on the board.

Table 2-1. Major Components (Chips) Descriptions and Functions

Chip Type Mfg. Model Description Function

CPU (U1) DMP

Electronics,

Inc.

PCI

Graphics

Controller

(U13)

DDR2

System

Memory

(U2 and U3)

DDR2

Vid eo

Memory

(U14)

RS232

Transceiver

(U4 - on

back of the

board)

RS232

Transceiver

(U5)

SPI Flash

(U6)

RS232

Transceiver

(U7)

RS422/485

Transceiver

(U9 - on

back of the

board)

Ethernet

Transfomer

(U12)

SiS

Corporation

Fluctuating Fluctuating On-board DDR2

Fluctuating Fluctuating On-board DDR2

Analog

Devices

Analog

Devices

Winbond W25Q16BV Serial Peripheral

Analog

Devices

Linear LTC1334CG#PBF RS422/485 Transceiver

Pulse H1102NL-T 10/100BaseT Ethernet

Vortex 86SX/DX x86 32-bit processor Integrates

Processor Core,

Memory

Controller, and

I/O Hub

Volari Z9S PCI graphics controller Integrates 2D

Engine and PCI

controller

Provides high128Mx8 System

memory

32Mx16 Video memory

ADM213EARSZ RS232 Transceiver for

COM3

ADM213EARSZ RS232 Transceiver for

COM4

Interface 16 Mbit Flash

Memory

ADM213EARSZ RS232 Transceiver for

COM1 and COM2

for COM1 and COM2

Magnetics

speed data

transfer

Provides high-

speed data

transfer

Transmits and

receives RS232

signals for COM3

Transmits and

receives RS232

signals for COM4

Stores data in

flash memory,

emulating a

floppy drive

Transmits and

receives RS232

signals for COM1

and COM2

Transmits and

receives

RS422/485

signals for COM1

and COM2

Provides

electrical isolation

for Ethernet

controller

contained in the

CPU

8 Reference Manual CoreModule 430

Page 15

Chapter 2 Product Overview

U1

U2

U14

U3

U13

CM430_comp_top_c

U7

U5

U12

Key:

U1 - CPU

U2 - DDR2 SDRAM - System Memory

U3 - DDR2 SDRAM - System Memory

U5 - RS232 Transceiver - COM4

U6 - SPI Flash - Data Storage

U7 - RS232 Transceiver - COM1 and COM2

U12 - 10/100 Ethernet Transformer

U13 - PCI Graphics Controller

U14 - DDR2 SDRAM - Video Memory

U6

NOTE Pin 1 is shown as a black pin (square or round) on vertical headers or connectors

in all illustrations. Black dots on right-angle headers or connectors indicate pin

2.

Figure 2-3. Component Locations (Top Side)

CoreModule 430 Reference Manual 9

Page 16

Chapter 2 Product Overview

20-pin, two rows,

Consecutive, (1, 11)

Or

1

234

5

678910

20

19

124

15 1120

10

53

20-pin, two rows,

Odd/Even, (1, 2)

CM430_ConNum_a

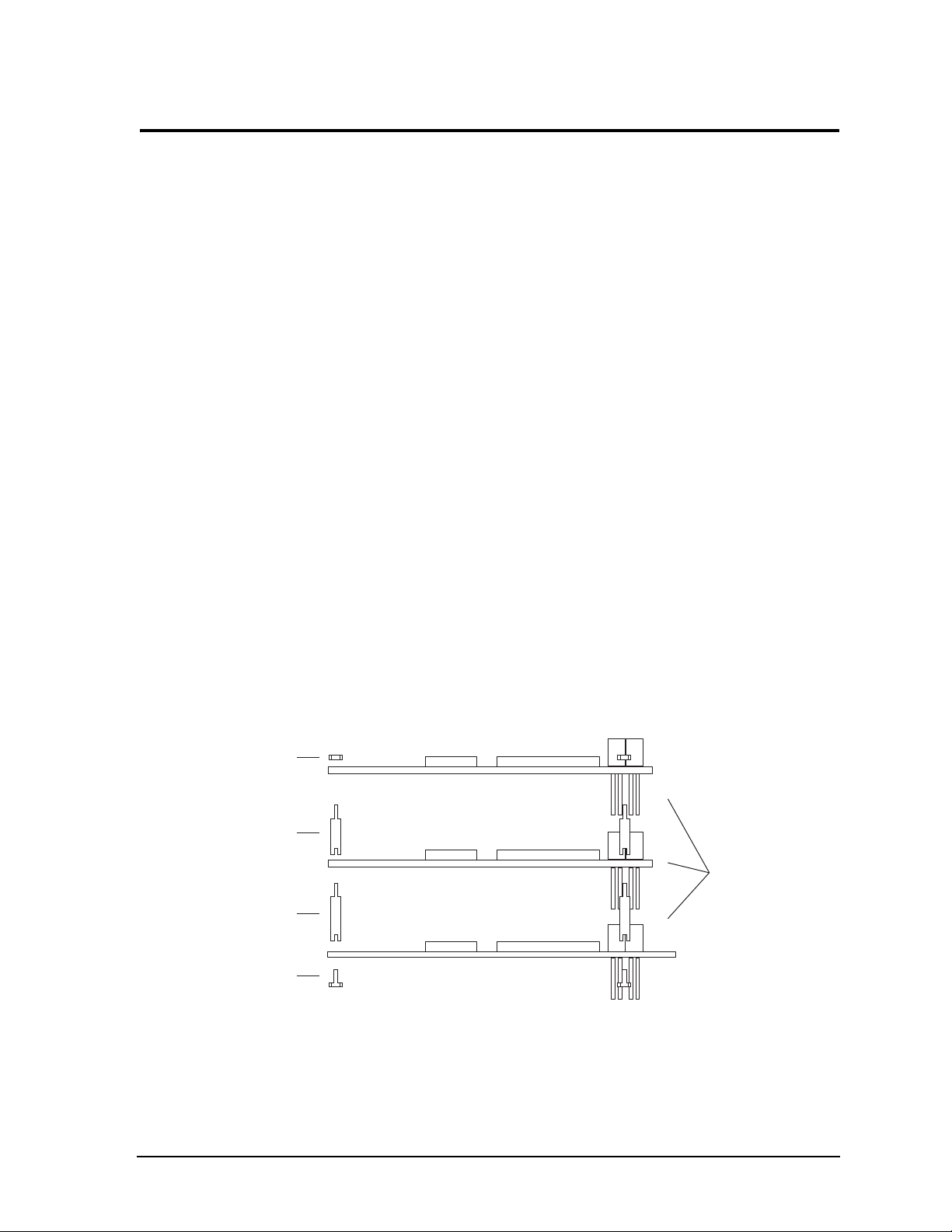

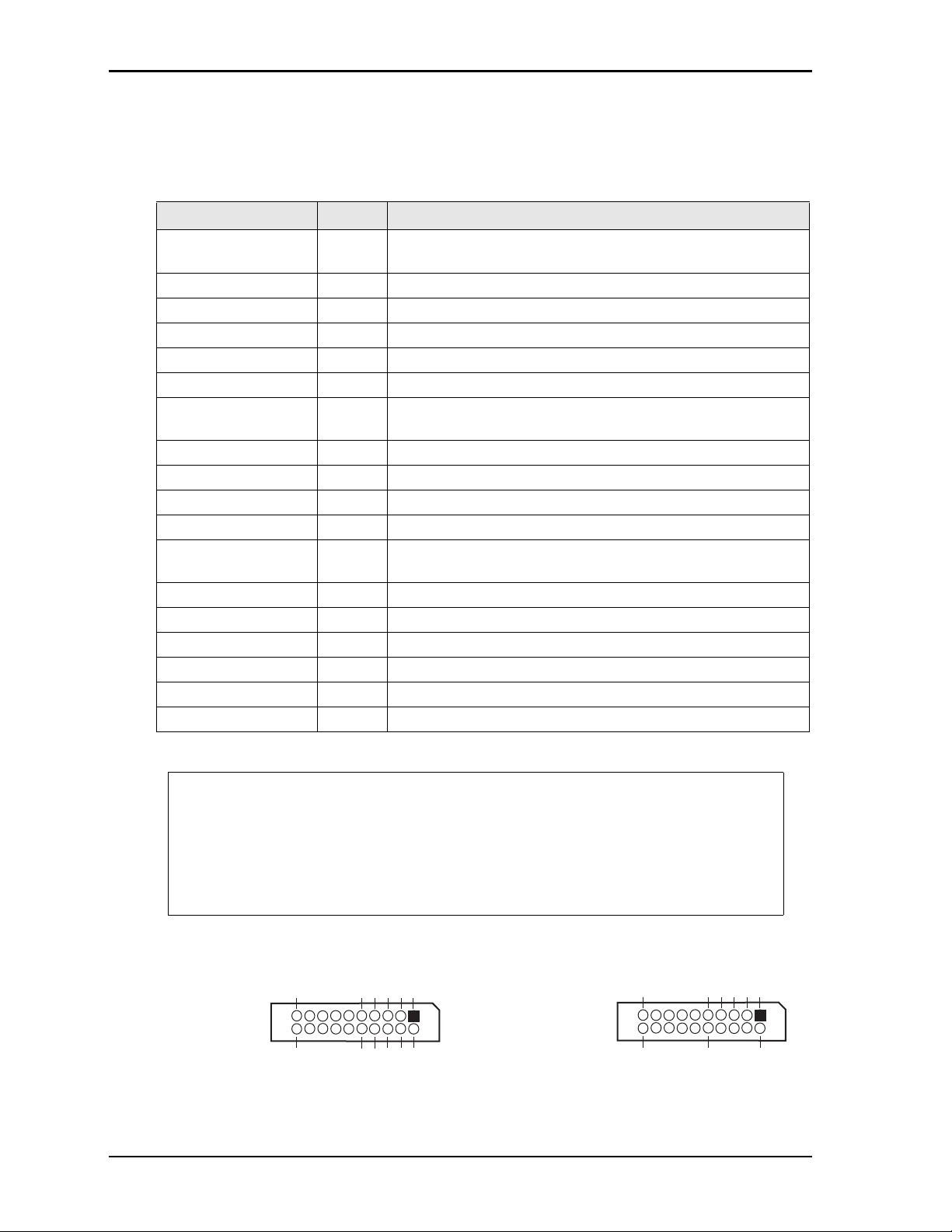

Header, Connector, and Socket Definitions

Table 2-2 describes the headers shown in Figure 2-5.

Table 2-2. Header, Connector, and Socket Descriptions

Jack/Plug # Access Description

P1A/1B & P1C/1D –

PC/104 Bus

J2 – Ethernet Top 8-pin, 0.100" (2.54mm), right-angle header for Ethernet interface

J3 – Serial 1 (COM1) Top 10-pin, 0.100" (2.54mm), right-angle header for Serial 1 interface

J4 – Parallel (LPT) Top 26-pin, 0.079" (2mm), right-angle header for Parallel interface

J5 – Utility Top 10-pin, 0.100" (2.54mm), right-angle header for Utility interface

J6 – IDE Top 44-pin, 0.079" (2mm) header for IDE interface

J7 – Power Top 10-pin, 0.100" (2.54mm), right-angle header for Power

J8 – GPIO (User) Top 10-pin, 0.079" (2mm) header for User defined GPIO signals

J9 – Serial 2 (COM2) Top 10-pin, 0.100" (2.54mm), right-angle header for Serial 2 interface

J10 – USB0 Top 5-pin, 0.100" (2.54mm), right-angle header for USB0 interface

J11 – Video Top 44-pin, 0.079" (2mm), right-angle header for LCD/CRT interface

J12 – Compact Flash Bottom 50-pin, 0.050" (1.27mm) socket for Type I or II Compact Flash

J13 – Serial 4 (COM4) Top 10-pin, 0.100" (2.54mm) header for Serial 4 interface

J14 – Serial 3 (COM3) Top 10-pin, 0.100" (2.54mm) header for Serial 3 interface

J15 – DNP Top Do not populate

J17 – USB1 Top 5-pin, 0.079" (2mm) header for USB1 interface

J19 – SPI Top 6-pin, 0.100" (2.54mm) header used for SPI Flash programming

J20 – LPC Top 10-pin, 0.079" (2mm) header for LPC signals

Top/

Bottom

104-pin, 0.100" (2.54mm) connectors for PC/104 (ISA) bus

connection

cards

NOTE The pinout tables in Chapter 3 of this manual identify pin sequence using the

following methods: A 10-pin header with two rows of pins, using odd/even

numbering, where pin 2 is directly across from pin 1, is noted as 10-pin, 2 rows, odd/

even (1, 2). Alternately, a 20-pin connector using consecutive numbering, where pin

11 is directly across from pin 1, is noted in this way: 20-pin, 2 rows, consecutive (1,

11). The second number in the parenthesis is always directly across from pin 1. See

Figure 2-4.

Figure 2-4. Connector Pin Identifications

10 Reference Manual CoreModule 430

Page 17

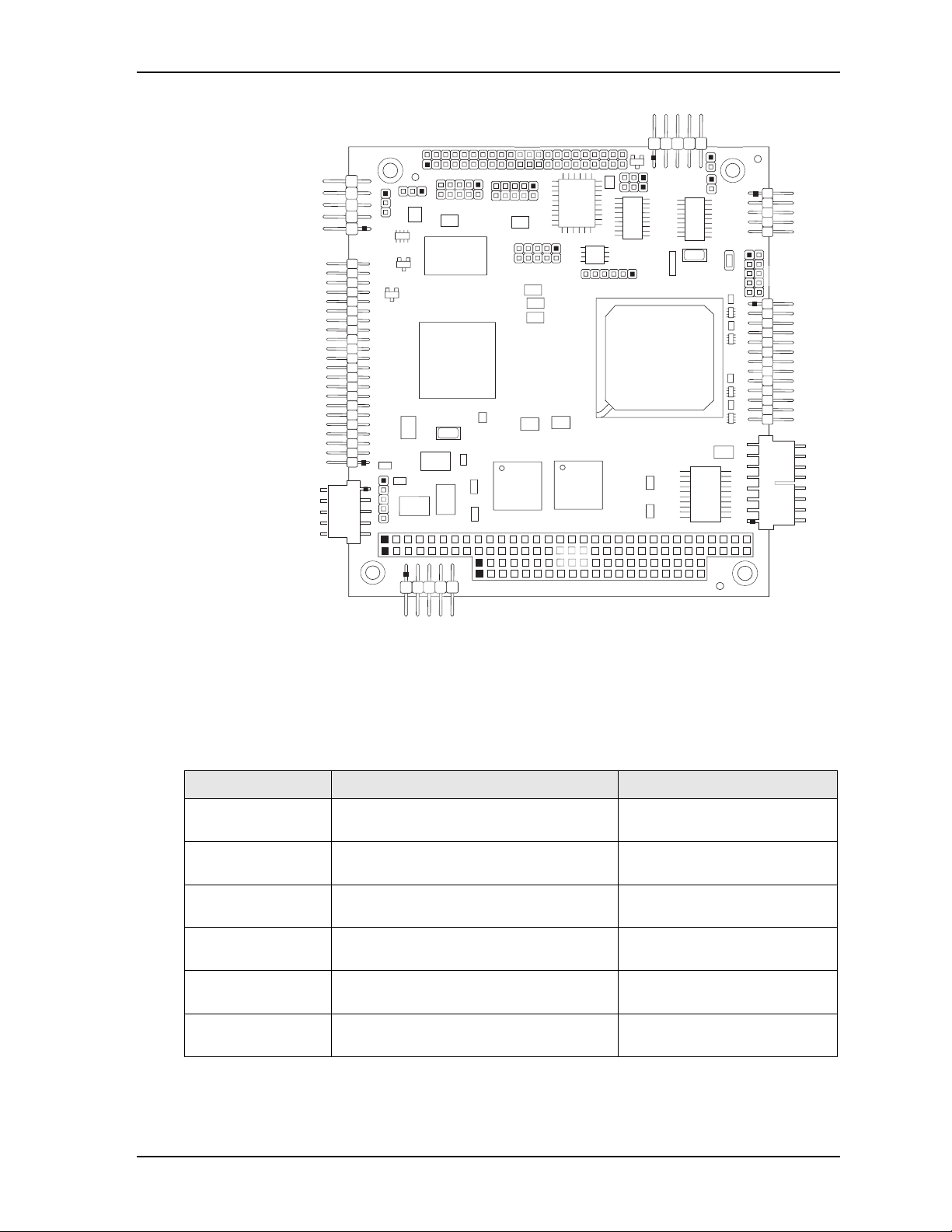

Chapter 2 Product Overview

CM430_conn_top_c

J6

J17

J13

J14

J9

J11

J10

P1

J7

J2

J4

J8

J19

J20

J3

J5

JP2

AB

DC

JP1

JP8

JP5

JP6

JP7

Key:

J2 - Fast Ethernet

J3 - COM1

J4 - Parallel

J5 - Utility

J6 - IDE

J7 - Power

J8 - GPIO

J9 - COM2

J10 - USB0

J11 - TTL and VGA Video

J13 - COM4

J14 - COM3

J17 - USB1

J19 - SPI 16 Mbit Data Storage

JP1 - See jumper table

JP2 - See jumper table

JP5 - See jumper table

JP6 - See jumper table

JP7 - See jumper table

JP8 - See jumper table

P1 - PC/104

Jumper Header Definitions

Table 2-3. Jumper Settings

CoreModule 430 Reference Manual 11

Figure 2-5. Header Locations (Top Side)

Table 2-3 describes the jumper headers shown in Figure 2-5.

(Removed) Default setting

(Removed) Default setting

Jumper # Installed Removed/Installed

JP1 – Serial Port 2

Termination

JP2 – Serial Port 1

Termination

JP5 – Backlight

Enable RS-485 Termination (Pins 1-2) Disable RS-485 Termination

Enable RS-485 Termination (Pins 1-2) Disable RS-485 Termination

+5 Volts (Pins 1-2) +12 Volts (Pins 2-3) Default

Voltage Select

JP6 – Flat Panel

Voltage Select

JP7 – Compact Flash

+3.3 Volts (Pins 1-2) Default +5 Volts (Pins 2-3)

+5 Volts (Pins 1-2) +3.3 Volts (Pins 2-3) Default

Voltage Select

JP8 – IDE Select Enable HDD master, CF slave (Pins 1-2)

Default

Note: All jumper headers use 0.079" (2mm) pitch.

Enable HDD slave, CF master

(Pins 2-3)

Page 18

Chapter 2 Product Overview

CM430_mech_dwg_top_b

0

0.200

3.575

3.775

0

0.200

3.350

3.550

0.350

3.250

Specifications

Physical Specifications

Table 2-4 shows the physical dimensions of the module and Figure 2-6 shows the mounting dimensions.

Table 2-4. Weight and Footprint Dimensions

Item Dimension

Weight 0.10 kg. (0.20 lbs.)

Height (upper surface) 10.99mm (0.43")

See Note on page 13.

Width 90.2mm (3.6")

Length 95.9mm (3.8")

Mechanical Specifications

NOTE Height is measured from the

upper board surface to the

highest permanent component

(PC/104 connector) on the

upper board surface. This does

not include the heatsink.

Figure 2-6. Mechanical Dimensions (Top Side)

12 Reference Manual CoreModule 430

Page 19

Chapter 2 Product Overview

NOTE All dimensions are given in inches. Pin 1 is shown as a black pin (square or

round) on vertical headers or connectors in all illustrations. Black dots on rightangle headers or connectors indicate pin 2.

The Compact Flash socket (J12) exceeds the PC/104 height limitation by 0.2

inches.

Power Specifications

Table 2-5 provides the power requirements for the 300 MHz and 800 MHz versions of the CoreModule 430.

Table 2-5. Power Supply Requirements

Parameter Characteristics for 300 MHz CPU Characteristics for 800 MHz CPU

Input Type Regulated DC voltages Regulated DC voltages

Peak In-rush Current 14.80A (74.00W) 14.86A (74.30W)

Idle Current 1.30A (6.51W) 1.42A (7.12W)

BIT Current (Typical) 1.32A (6.58W) 1.44A (7.19W)

Operating configurations:

• In-rush operating configuration includes CRT video, 256MB DDR RAM, and power.

• Idle operating configuration includes the in-rush configuration as well as on-board Compact Flash with

64MB card, and one keyboard.

• BIT = Burn-In-Test. Operating configuration includes idle configuration as well as two serial port loop-

backs, one Ethernet connection, and four USB Compact Flash readers with 64MB Compact Flash.

Environmental Specifications

Table 2-6 provides the operating and storage condition ranges required for this module.

Table 2-6. Environmental Requirements

Parameter Conditions

Temperature

Operating –20° to +70° C (–4° to +158° F)

Extended (Optional) –40° to +85° C (–40° to +185° F)

Storage –55° to +85° C (–67° to +185° F)

Humidity

Operating 5% to 90% relative humidity, non-condensing

Non-operating 5% to 95% relative humidity, non-condensing

Thermal/Cooling Requirements

The CPU is the primary source of heat on the board. The 800 MHz version of the CoreModule 430 CPU is

designed to operate at its maximum speed and requires a heatsink (provided). The 300 MHz version of the

CoreModule 430 CPU does not require a heatsink.

CoreModule 430 Reference Manual 13

Page 20

Chapter 2 Product Overview

14 Reference Manual CoreModule 430

Page 21

Chapter 3 Hardware

Overview

This chapter discusses the chips and connectors of the module features in the following order:

• CPU

• Graphics

• Memory

System Memory

Vid e o Memory

SPI Flash

• Memory Map

• Interrupt Channel Assignments

• I/O Address Map

• Serial

• Parallel (LPT)

• Utility

Keyboard

Mouse

Battery

Reset Switch

Speaker

• Ethernet

• USB

• Vid eo

• SPI

• LPC

• Miscellaneous

Time of Day/RTC

User GPIO

Oops! Jumper (BIOS Recovery)

Watchdog timer

• Power

CoreModule 430 Reference Manual 15

Page 22

Chapter 3 Hardware

NOTE ADLINK Technology, Inc. only supports the features and options listed in this

manual. The main components used on the CoreModule 430 may provide more

features or options than are listed in this manual. Some of these features/options

are not supported on the module and will not function as specified in the chip

documentation.

Only the pinout tables of non-standard headers and connectors are included in

this chapter. This chapter does not include pinout tables for standard headers and

connectors such as PC/104, 44-pin IDE, and Compact Flash.

CPU

The CoreModule 430 offers two versions of an embedded microprocessor—the DMP Vortex 86SX and

86DX—operating at 300 and 800 MHz, respectively, combining a powerful x86 core and a selection of

peripheral interfaces onto one chip. The 86SX and 86DX integrate CPU, Northbridge, and Southbridge

functions. This single chip supports logic including PC/104, EIDE controllers and combines these with

standard I/O interfaces to provide a PC compatible subsystem on a single chip.

Graphics

The CoreModule 430 provides a single PCI graphics controller chip which integrates a 2D engine and a PCI

controller. The graphics controller incorporates a configurable 3.3V/2.5V DVO interface to support a third

party TMDS transmitter and achieves high 2D performance with a DDR2 memory interface supporting a

bandwith of up to 1 GB (DDR2 @ 250 MHz.)

Memory

The CoreModule 430 memory consists of the following element(s):

• System Memory

• Vid e o Memory

• SPI Flash

System Memory

The CoreModule 430 provides two 16-bit, DDR2 memory chips of up to 128MB each for a total of up to

256MB of system memory soldered to the module and operating at 166MHz.

Video Memory

The CoreModule 430 provides one 16-bit, DDR2 memory chip of 32MB of video memory soldered to the

module and operating at 166MHz.

SPI Flash

The CoreModule 430 features an on-board 16Mbit SPI Flash device, operating as a virtual Floppy Disk

Drive. The board supports both the SPI Flash and an SPI header on the external SPI Bus. Enable the SPI

Flash through the Boot screen of the BIOS Setup Utility. Refer to the Chapter 1 for a link to the SPI Flash

data sheet.

16 Reference Manual CoreModule 430

Page 23

Chapter 3 Hardware

Memory Map

The following table provides the common PC/AT memory allocations. These are DOS-level addresses. The

OS typically hides these physical addresses by way of memory management. Memory below 000500h is

used by the BIOS.

Table 3-1. Memory Map - Vortex 86SX/DX Processor

Base Address Function

00000000h - 0009FFFFh Conventional Memory

000A0000h - 000AFFFFh Graphics Memory

000B0000h - 000B7FFFh Mono Text Memory

000B8000h - 000BFFFFh Color Text Memory

000C0000h - 000C7FFFh Standard Video BIOS

000D0000h - 000DFFFFh Reserved for Extended BIOS

000E0000h - 000EFFFFh Extended System BIOS Area

000F0000h - 000FFFFFh System BIOS Area (Storage and RAM Shadowing)

00100000h

FFFC0000h [for SX

processor]

- Top of

DRAM

FFFFFFFFh System Flash

Main DRAM Range

FFE00000h [for DX

processor]

CoreModule 430 Reference Manual 17

Page 24

Chapter 3 Hardware

Interrupt Channel Assignments

The interrupt channel assignments are shown in Table 3-2.

Table 3-2. Interrupt Channel Assignments

Device vs IRQ No. 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Timer X

Keyboard X

Secondary Cascade X

COM1 D

COM2 D O

COM3 O O O D

COM4 O O D O

Parallel O D

RTC X

IDE D

Math Coprocessor

(only in DX

processor)

PS/2 Mouse X

PCI INTA Automatically Assigned

PCI INTB Automatically Assigned

PCI INTC Automatically Assigned

PCI INTD Automatically Assigned

USB Automatically Assigned

VGA Automatically Assigned

Ethernet Automatically Assigned

X

Legend: D = Default, O = Optional, X = Fixed

NOTE The IRQs for the Ethernet, Video, and Internal Local Bus (ISA) are

automatically assigned by the BIOS Plug and Play logic. Local IRQs assigned

during initialization can not be used by external devices.

Table 3-3. DMA Map

DMA # Use

0-1, 5, 6, 7 Direct Memory Access

3 LPT 1, only in ECP mode (configurable)

4 DMA 1 cascade

18 Reference Manual CoreModule 430

Page 25

Chapter 3 Hardware

I/O Address Map

Table 3-4 shows the I/O address map. These are DOS-level addresses. The OS typically hides these physical

addresses by way of memory management.

Table 3-4. I/O Address Map

Address (hex) Subsystem

0000-000F Primary DMA Controller (#1)

0020-0021 Master Interrupt Controller (#1)

0040-0043 Programmable Interrupt Timer (Clock/Timer)

0060 Keyboard Controller

0061 ISA Standard Port B

0063 ISA Standard Port B alias

0064 Keyboard Controller

0065 ISA Standard Port B alias

0067 ISA Standard Port B alias

0069 ISA Standard Port B alias

006B ISA Standard Port B alias

006D ISA Standard Port B alias

006F ISA Standard Port B alias

0070-0071 RTC/ NMI enable

0080-008F DMA Page

00A0-00A1 Slave Interrupt Controller (#2)

00C0-00DF Secondary DMA Controller (#2)

00F0-00FF Math Coprocessor (only in the DX processor)

01F0-01F7 IDE 0 (can be disabled)

02E8-2FF Serial Port 4 (COM4) (base configuration @

3F8h/2F8h/3E8h/2E8h/10)

02F8-02FF Serial Port 2 (COM2) (base configuration @

3F8h/2F8h/3E8h/2E8h/10)

0378-037F LPT 1 (only in EPP modes, with default base address)

03E8-3EF Serial Port 3 (COM3) (base configuration @

3F8h/2F8h/3E8h/2E8h/10)

03F6 IDE 0 (see 1F0)

03F8-03FF Serial Port 1 (COM1) (base configuration @

3F8h/2F8h/3E8h/2E8h/10)

0778-077A LPT 1 (only in EPP modes, with default base address)

0CF8 PCI Configuration Address

0CFC-0CFF PCI Configuration Data

CoreModule 430 Reference Manual 19

Page 26

Chapter 3 Hardware

Parallel Interface (LPT)

The Vortex x86 processor chip provides the Parallel Port interface. The Parallel Port supports the standard

parallel, Bi-directional, Standard Printer Port (SPP), Enhanced Parallel Port (EPP), and Enhanced

Capabilities Port (ECP) protocols.

Table 3-5 describes the pin signals of the Parallel interface, which uses a 26-pin, right-angle header with 2

rows, odd/even sequence (1, 2), and 0.079" (2mm) pitch.

Table 3-5. Parallel (LPT) Interface Pin/Signal Descriptions (J4)

Pin # Signal Description

1 Strobe* Strobe* – This is an output signal used to strobe data into the printer. I/O pin in

ECP/EPP mode.

2 AutoFD* Auto Feed* – This is a request signal into the printer to automatically feed one

line after each line is printed.

3 PD0 Parallel Port Data 0 – These pins (0 to 7) provides parallel port data signals.

4 ERR* Error – This is a status output signal from the printer. A Low State indicates an

error condition on the printer.

5 PD1 Parallel Port Data 1 – Refer to pin-3, PDO for more information.

6 INIT* Initialize* – This signal is used to Initialize printer. Output in standard mode,

I/O in ECP/EPP mode.

7 PD2 Parallel Port Data 2 – Refer to pin-3, PDO for more information.

8 SLIN Select In – This output signal is used to select the printer. I/O pin in ECP/EPP

mode.

9 PD3 Parallel Port Data 3 – Refer to pin-3, PDO for more information.

10

11 PD4 Parallel Port Data 4 – Refer to pin-3, PDO for more information.

12

13 PD5 Parallel Port Data 5 – Refer to pin-3, PDO for more information.

14

15 PD6 Parallel Port Data 6 – Refer to pin-3, PDO for more information.

16

17 PD7 Parallel Port Data 7 – Refer to pin-3, PDO for more information.

18

19 Ack* Acknowledge* – This is a status output signal from the printer. A Low State

20

21 Busy* Busy* – This is a Status output signal from the printer. A High State indicates

22

23 PE Paper End – This is a status output signal from the printer. A High State

24

25 Slct Select – This is a status output signal from the printer. A High State indicates it

26 Key/NC Key Pin/Not Connected

GND Ground

GND Ground

GND Ground

GND Ground

GND Ground

indicates it has received the data and is ready to accept new data.

GND Ground

the printer is not ready to accept data.

GND Ground

indicates it is out of paper.

GND Ground

is selected and powered on.

Note: The shaded table cells denote power or ground. The * symbol indicates the signal is Active Low.

20 Reference Manual CoreModule 430

Page 27

Chapter 3 Hardware

CM430RS485jump_b

Or

1

35

7

9

24

6810

Serial Ports (J3, J9)

(COM1 or COM2)

Side View

Standard DB9 Serial

Port Connector (Female)

Rear View

5

4

3

2

1

9

8

7

6

Serial Interface

The Vortex CPU contains the circuitry for all four serial ports. The CoreModule 430 provides serial ports 1

and 2 through transceivers U7 and U9 (headers J3 and J9), serial port 3 through transceiver U4 (header J14)

and serial port 4 through transceiver U5 (header J13). The serial ports support the following features:

• Programmable word length, stop bits and parity

• 16-bit programmable baud rate generator

• Interrupt generator

• Loop-back mode

• 16-bit FIFOs for each port

• Ports 1, 2, 3, and 4 are supported by the Vortex processor and are 16C550/16C552 compatible

Serial 1 (J3, COM1) supports RS-232/RS-485 with full modem operation

Serial 2 (J9, COM2) supports RS-232/RS-485 with full modem operation

Serial 3 (J14, COM3) supports RS-232 with full modem operation

Serial 4 (J13, COM4) supports RS-232 with full modem operation

NOTE The RS-232/RS-485 mode for Serial Port 1 (COM1) and Serial Port 2 (COM2)

are selected in BIOS Setup Utility. However, the RS-232 mode is the default

(Standard) for any serial port.

RS-485 mode termination is selected with jumper JP2 Serial 1 (COM1) and JP1

Serial 2 (COM2) on the module. Refer to Table 2-3 for more information.

To implement the two-wire RS-485 mode on either serial port, you must tie the equivalent pins together for

the selected port.

For example, you must tie pin 3 (Rx Data –) to 5 (Tx Data –) and pin 4 (Tx Data +) to 6 (Rx Data +) at Serial

Port 1 or 2 (J3 or J9) for the two-wire interface. As an alternate, you may short the equivalent pins on the

DB9 connector attached to respective serial port, as shown in Figure 3-1. Refer also to the following tables

for the specific pins on the connectors. The RS-422 mode uses a four-wire interface and does not require

combining pins for its operation, but you must select RS-485 in BIOS Setup.

Figure 3-1. RS-485 Serial Port Implementation

Table 3-6 provides the signals for the corresponding pins of the two independent serial interfaces (Serial 1 &

2), and Table 3-7 provides the signals for the corresponding pins of two independent serial interfaces (Serial

3 & 4). Both interfaces use 10-pin, right-angle headers with 2 rows, odd/even sequence (1, 2), and 0.100"

(2.54mm) pitch.

CoreModule 430 Reference Manual 21

Page 28

Chapter 3 Hardware

Table 3-6. Serial Ports 1 & 2 Interface Pin/Signal Descriptions (J3, J9)

Pin # Signal DB9 # Description

1 DCD* 1 Data Carrier Detect – Indicates external serial device is detecting a

carrier signal (i.e., a communication channel is currently open). In direct

connect environments, this input is driven by DTR as part of the DTR/

DSR handshake.

2 DSR* 6 Data Set Ready – Indicates external serial device is powered, initialized,

and ready. Used as hardware handshake with DTR for overall readiness.

3RXD

2 Receive Data – Serial port receive data input is typically held at a logic 1

(mark) when no data is being transmitted, and is held “Off” for a brief

interval after an “On” to “Off” transition on the RTS line to allow the

transmission to complete.

Rx Data –

4RTS*

7 Request To Send – Indicates serial port is ready to transmit data. Used as

Serial Port 1 or 2 – If in RS-485 mode, this pin is Rx Data Negative.

hardware handshake with CTS for low level flow control.

Tx Data +

5TXD

3 Transmit Data – Serial port transmit data output is typically held to a

Serial Port 1 or 2 – If in RS-485 mode, this pin is Tx Data Positive.

logic 1 when no data is being sent. Typically, a logic 0 (On) must be

present on RTS, CTS, DSR, and DTR before data can be transmitted on

this line.

Tx Data –

6CTS*

8 Clear To Send – Indicates external serial device is ready to receive data.

Serial Port 1 or 2 – If in RS-485 mode, this pin is Tx Data Negative.

Used as hardware handshake with RTS for low level flow control.

Rx Data +

Serial Port 1 or 2 – If in RS-485 mode, this pin is Rx Data Positive.

7 DTR* 4 Data Terminal Ready – Indicates serial port is powered, initialized, and

ready. Used as hardware handshake with DSR for overall readiness.

8 RI* 9 Ring Indicator – Indicates external serial device is detecting a ring

condition. Used by software to initiate operations to answer and open the

communications channel.

9

GND 5 Ground

10 Key/NC NC Key Pin/Not connected

Note: The shaded table cell denotes ground. The * symbol indicates the signal is Active Low.

Table 3-7. Serial Ports 3 & 4 Interface Pin/Signal Descriptions (J13, J14)

Pin # Signal DB9 # Description

1 DCD* 1 Data Carrier Detect – Indicates external serial device is detecting a

carrier signal (i.e., a communication channel is currently open). In direct

connect environments, this input is driven by DTR as part of the DTR/

DSR handshake.

2 DSR* 6 Data Set Ready – Indicates external serial device is powered, initialized,

and ready. Used as hardware handshake with DTR for overall readiness.

3 RXD 2 Receive Data – Serial port receive data input is typically held at a logic 1

(mark) when no data is being transmitted, and is held “Off” for a brief

interval after an “On” to “Off” transition on the RTS line to allow the

transmission to complete.

22 Reference Manual CoreModule 430

Page 29

Chapter 3 Hardware

Table 3-7. Serial Ports 3 & 4 Interface Pin/Signal Descriptions (J13, J14) (Continued)

4 RTS* 7 Request To Send – Indicates serial port is ready to transmit data. Used as

hardware handshake with CTS for low level flow control.

5 TXD 3 Transmit Data – Serial port transmit data output is typically held to a

logic 1 when no data is being sent. Typically, a logic 0 (On) must be

present on RTS, CTS, DSR, and DTR before data can be transmitted on

this line.

6 CTS* 8 Clear To Send – Indicates external serial device is ready to receive data.

Used as hardware handshake with RTS for low level flow control.

7 DTR* 4 Data Terminal Ready – Indicates serial port is powered, initialized, and

ready. Used as hardware handshake with DSR for overall readiness.

8 RI* 9 Ring Indicator – Indicates external serial device is detecting a ring

condition. Used by software to initiate operations to answer and open the

communications channel.

9

10 Key/NC NC Key Pin – Not connected

Note: The shaded table cell denotes ground. The * symbol indicates the signal is Active Low.

GND 5 Ground

USB Interface

The CoreModule 430 contains one root USB (Universal Serial Bus) hub and two functional USB ports. The

Vortex CPU provides the USB function including the following features:

• Provides one root hub with two USB ports

• Supports USB EHCI v.2.0 and USB OHCI v.1.1

• Provides over-current detection status

• Provides a fuse (F1, 1.5A) on board for over current protection

Table 3-8 describes the pin signals of the USB0 interface, which uses a single-row, 5-pin, right-angle header

with 0.100" (2.54mm) pitch.

Table 3-8. USB0 Interface Pin/Signal Designations (J10)

Pin # Signal Description

1

2 USB0N USB0 Port Data Negative

3 USB0P USB0 Port Data Positive

4

5SHIELDUSB0 Port shield

Note: The shaded table cells denote power or ground.

Table 3-9 describes the pin signals of the USB1 interface, which uses a single-row, 5-pin header with 0.079"

(2mm) pitch.

Table 3-9. USB1 Interface Pin/Signal Designations (J17)

USB0PWR USB Power – VCC (+5V +/-5%) power goes to the port through an on board

fuse. Port is disabled if this input is low.

GND USB0 Port ground

Pin # Signal Description

1

2 USB1N USB1 Port Data Negative

3 USB1P USB1 Port Data Positive

CoreModule 430 Reference Manual 23

USB1PWR USB Power – VCC (+5V +/-5%) power goes to the port through an on board

fuse. Port is disabled if this input is low.

Page 30

Chapter 3 Hardware

Table 3-9. USB1 Interface Pin/Signal Designations (J17) (Continued)

4

5SHIELDUSB1 Port shield

Note: The shaded table cells denote power or ground.

GND USB1 Port ground

Utility Interface

The Utility interface provides various utility and I/O signals on the module and consists of a 10-pin, 0.1"

header. The Vortex CPU drives the signals on the Utility interface, and Table 3-10 provides the signal

definitions.

• PS/2 Keyboard and Mouse

• Battery

• Reset Switch

• Speaker

Keyboard

The signal lines for a PS/2 keyboard are provided from the Vortex CPU to the Utility interface.

Mouse

The signal lines for a PS/2 mouse are provided from the Vortex CPU to the Utility interface.

Battery

An external battery input connection is provided through the Utility interface to support a battery backup for

the CMOS RAM and the RTC (Real Time Clock).

Reset Switch

An external reset switch provides the reset signal through the Utility interface to a reset circuit, which drives

the Vortex CPU.

Speaker

The speaker signal provides sufficient signal strength to drive a 1W 8 “Beep” speaker through the Utility

interface at an audible level. The speaker signal is driven from an on board amplifier and the Vortex CPU.

Table 3-10 describes the pin signals of the Utility interface, which uses a 10-pin, right-angle header with 2

rows, odd/even sequence (1, 2), and 0.100" (2.54mm) pitch.

Table 3-10. Utility Interface Pin/Signal Descriptions (J5)

Pin # Signal Description

1 SPKR Speaker Output

2

3 RESETSW* External Reset Switch signal

4 MDATA Mouse Data input

5 KBDATA Keyboard Data input

6 KBCLK Keyboard Clock input

7

8 KMPWR Keyboard /Mouse power (+5V) output

BATV- Ground return

GND Ground

24 Reference Manual CoreModule 430

Page 31

Chapter 3 Hardware

Table 3-10. Utility Interface Pin/Signal Descriptions (J5) (Continued)

9

10 MCLK Mouse Clock input

Notes: The shaded table cells denote power or ground. The * symbol indicates the signal is Active Low.

BATV+ Real time battery voltage (3.0V Max) input

Ethernet Interface

The Ethernet solution originates from the Vortex 86SX/DX CPU and consists of both the Media Access

Controller (MAC) and the physical layer (PHY) combined into a single component solution. The Vortex Fast

Ethernet Control Unit is a 32-bit PCI controller that features enhanced scatter-gather bus mastering

capabilities, which enables the processor to perform high-speed data transfers over the internal PCI bus. The

bus master capabilities enable the component to process high-level commands and perform multiple

operations, thereby off-loading communication tasks from the CPU. The Ethernet interface offers the

following features:

• Full duplex or half duplex support

• Full duplex support at 10 Mbps or 100 Mbps

• In full duplex mode, the Ethernet controller adheres to the IEEE 802.3x Flow Control specification.

• In half duplex mode, performance is enhanced by a proprietary collision reduction mechanism.

• IEEE 802.3 10/100BaseT compatible physical layer to wire transformer

• Two on board LEDs support the speed and the link & activity status

• IEEE 802.3u Auto-Negotiation support

• Fast back-to-back transmission support with minimum interframe spacing (IFS).

• IEEE 802.3x auto-negotiation support for speed and duplex operation

• 3 kB transmit and 3 kB receive FIFOs (helps prevent data underflow and overflow)

• IEEE 802.3x 100BaseTX flow control support

• On-board magnetics (Ethernet isolation transformer)

Table 3-11 describes the pin signals of the Ethernet interface, which uses a single-row, 8-pin header with

0.100" (2.54mm) pitch.

Table 3-11. Ethernet Interface Pin/Signal Descriptions (J2)

Pin # Signal Description

1 TX+ Analog Twisted Pair Ethernet Transmit Differential Pair – These pins transmit the

2TX-

3 RX+ Analog Twisted Pair Ethernet Receive Differential Pair – These pins receive the

6RX-

4 CT Center Tap – Connected through two 75 ohm resistors in series to center tap of

5CT

7 CT Center Tap – Connected through two 75 ohm resistors in series to center tap of

8CT

serial bit stream through the isolation transformer.

serial bit stream through the isolation transformer.

isolation transformer and then to ground through common 1k PF capacitor.

isolation transformer and then to ground through common 1k PF capacitor.

NOTE The magnetics (isolation transformer, U12) for the Ethernet connector is

included on the CoreModule 430.

CoreModule 430 Reference Manual 25

Page 32

Chapter 3 Hardware

Video (TTL/VGA) Interface

The Volari Z9s graphics controller provides two graphics display ports for video signals to flat panel

displays and traditional glass CRT monitors. The features are listed below:

• Enhanced 2D Graphics Controller

Full BitBLT Implementation for all 256 Raster Operations Defined for Windows

Supports 4 Transparent BLT Modes

• Bitmap Transparency

• Pattern Transparency

• Source Transparency

• Destination Transparency

Rectangle Clipping

Fast Line Draw Engine with styled pattern

Fast Rectangle Fill Engine

256MB frame buffer with linear addressing

64x64x2 bit-mapped mono hardware cursor

• VGA Output (DB15)

Supports 135 MHz triple RAMDACs for 1280 x 1024 x 75 Hz display

Supports 24-bit pixel depth

Supports interlaced or non-interlaced output

• TTL Output

Conforms with VESA Flat Panel Display Interface FPDI-1B

Supports up to 1600x1200 pixel display resolutions

Uses Internal CRT Controller for display modes settings

Supports 12-, 18-, and dual 12-bit Interface (1 pixel/clock)

Table 3-12 describes the pin signals of the Video interface, which uses a 44-pin, right-angle header with 2

rows, odd/even sequence (1, 2), and 0.079" (2mm) pitch.

Table 3-12. Video Interface Pin/Signal Descriptions (J11)

Pin # Signal Description

1 TFTDCLK TFT Shift Clock – This clock signal provides the timing for transferring digital

pixel data.

2 TFTDE TFT Data Enable – This signal indicates valid data on any of the FP [23:0] lines.

3 TFTLP TFT Line Pulse – This signal is the digital monitor equivalent of HSYNC.

4 TFTFrame TFT Frame Marker – This signal is the TFT monitor equivalent of VSYNC.

5

6

7 NC Not connected (FP0 = Panel Data 0)

8 NC Not connected (FP1 = Panel Data 1)

9 FP2 Panel Data 2 – These pins (0 to 23) provides digital pixel data output signals.

10 FP3 Panel Data 3 – Refer to pin 9, FP2, for more information.

11 FP4 Panel Data 4 – Refer to pin 9, FP2, for more information.

GND Ground

GND Ground

26 Reference Manual CoreModule 430

Page 33

Chapter 3 Hardware

Table 3-12. Video Interface Pin/Signal Descriptions (J11) (Continued)

12 FP5 Panel Data 5 – Refer to pin 9, FP2, for more information.

13 FP6 Panel Data 6 – Refer to pin 9, FP2, for more information.

14 FP7 Panel Data 7 – Refer to pin 9, FP2, for more information.

15 NC Not connected (FP8 = Panel Data 8)

16 NC Not connected (FP9 = Panel Data 9)

17 FP10 Panel Data 10 – Refer to pin 9, FP2, for more information.

18 FP11 Panel Data 11 – Refer to pin 9, FP2, for more information.

19 FP12 Panel Data 12 – Refer to pin 9, FP2, for more information.

20 FP13 Panel Data 13 – Refer to pin 9, FP2, for more information.

21 FP14 Panel Data 14 – Refer to pin 9, FP2, for more information.

22 FP15 Panel Data 15 – Refer to pin 9, FP2, for more information.

23 NC Not connected (FP16 = Panel Data 16)

24 NC Not connected (FP17 = Panel Data 17)

25 FP18 Panel Data 18 – Refer to pin 9, FP2, for more information.

26 FP19 Panel Data 19 – Refer to pin 9, FP2, for more information.

27 FP20 Panel Data 20 – Refer to pin 9, FP2, for more information.

28 FP21 Panel Data 21 – Refer to pin 9, FP2, for more information.

29 FP22 Panel Data 22 – Refer to pin 9, FP2, for more information.

30 FP23 Panel Data 23 – Refer to pin 9, FP2, for more information.

31

TFTEnVcc TFT Power (Vcc) – This signal is the power to flat panel displays.

32 TFTEnVee TFT Backlight Enable – This signal enables power to flat panel displays.

33

34

35

36

+PNLVdd Voltage (+3.3 or +5 volts ±5%) depends on setting of JP6.

+12V Out +12 volts ±5%

GND Ground

GND Ground

37 HSYNC Horizontal Sync – This signal is used for the digital horizontal sync output to the

CRT. Also used (with VSYNC) to signal power management state information to

the CRT per the VESA DPMS standard.

38 VSYNC Vertical Sync – This signal is used for the digital vertical sync output to the CRT.

Also used (with HSYNC) to signal power management state information to the

CRT per the VESA DPMS standard.

39

AGNDR Analog Ground for Red

40 RED Red – This pin provides the Red analog output to the CRT.

41

AGNDG Analog Ground for Green

42 GREEN Green – This pin provides the Green analog output to the CRT.

43

AGNDB Analog Ground for Blue

44 BLUE Blue – This pin provides the Blue analog output to the CRT.

Note: The shaded table cells denote power or ground. The * symbol indicates the signal is Active Low.

CoreModule 430 Reference Manual 27

Page 34

Chapter 3 Hardware

Serial Peripheral Interface (SPI)

The CoreModule 430 provides an SPI header for programming the SPI Flash virtual floppy drive.

Table 3-13 describes the pin signals of the SPI header, which provides a single-row of 6 pins with 0.079"

(2mm) pitch.

Table 3-13. SPI Interface Pin/Signal Descriptions (J19)

Pin # Signal Description

1 EXT_CS* SPI Chip Select

2 EXT_CLK SPI Clock

3 EXT_DO SPI Data Out

4EXT_DISPI Data In

5

6

Note: The shaded table cells denote power or ground. The * symbol indicates the signal is Active Low.

V.3.3 +3.3 Volts Power

GND Ground

Low Pin Count Interface (LPC)

The LPC interface provides expansion for custom LPC devices.

Table 3-14 describes the pin signals of the LPC interface, which uses a 10-pin header with 2 rows, odd/even

sequence (1, 2), and 0.079" (2mm) pitch.

Table 3-14. LPC Interface Pin/Signal Descriptions (J20)

Pin # Signal Description

1 AD0 Command, Address, and Data 0

2 SERIRQ Serial Interrupt Request

3 AD1 Command, Address, and Data 1

4 DRQ DMA Request

5 AD2 Command, Address, and Data 2

6 FRAME Frame Signals - indicate start of new cycle or termination of broken cycle

7 AD3 Command, Address, and Data 3

8 CLK_PCI PCI Clock

9

10

Note: The shaded table cells denotes power or ground.

V.3.3 +3.3 Volts Power

GND Ground

Miscellaneous

Real Time Clock (RTC)

The CoreModule 430 contains a Real Time (time of day) Clock (RTC), which can be backed up with an

external cell battery. The CoreModule 430 will function without a battery in those environments which

prohibit batteries. The CoreModule 430 will also continue to operate after the battery life has been

exceeded. Under these conditions all setup information is restored from the on-board Flash memory during

POST along with the default date and time information.

NOTE Some operating systems require a valid default date and time to function.

28 Reference Manual CoreModule 430

Page 35

Chapter 3 Hardware

CM430_Oopsjump_b

Standard DB9 Serial

Port Connector (Female)

Rear View

5

4

32

1

9

87

6

Or

1

35

7

9

24

6810

Serial Port Header

(COM1)

User GPIO Interface

The CoreModule 430 provides GPIO pins for customer use, and the signals are routed to header J8. An

example of how to use the GPIO pins resides in the Miscellaneous Source Code Examples on the

CoreModule 430 Support Software QuickDrive.

The example program can be built by using the make.bat file. This produces a 16-bit DOS executable

application, gpio.exe, which can be run on the CoreModule 430 to demonstrate the use of GPIO pins. For

more information about the GPIO pin operation, refer to the Programming Manual for the Vortex processor

at:

http://www.vortex86sx.com/

Table 3-12 describes the pin signals of the GPIO interface, which uses a 10-pin header with 2 rows, odd/

even sequence (1, 2), and 0.079" (2mm) pitch.

Table 3-15. User GPIO Interface Pin/Signal Descriptions (J8)

Pin # Signal Description

1 GPIO0 User defined

2 GPIO1 User defined

3 GPIO2 User defined

4 GPIO3 User defined

5 GPIO4 User defined

6 GPIO5 User defined

7 GPIO6 User defined

8 GPIO7 User defined

9

10

GND Ground

GND Ground

Note: The shaded table cells denote ground.

Oops! Jumper (BIOS Recovery)

The Oops! jumper is provided in the event you have selected BIOS settings that prevent you from booting

the system. By using the Oops! jumper you can stop the current BIOS settings in the CMOS from being

loaded, allowing you to proceed, using the default settings. Connect the DTR pin to the RI pin on Serial port

1 (COM 1) prior to boot up to prevent the present BIOS settings from loading. After booting with the Oops!

jumper in place, remove the Oops! jumper and go into the BIOS Setup Utility. Change the desired BIOS

settings, or select the default settings, and save changes before rebooting the system.

To convert a standard DB9 connector to an Oops! jumper, short together the DTR (4) and RI (9) pins on the

rear of the connector as shown in Figure 3-2 on the Serial Port 1 DB9 connector.

Figure 3-2. Oops! Jumper

CoreModule 430 Reference Manual 29

Page 36

Chapter 3 Hardware

Standard DB9 Serial

Port Cable Connector

(Female)

Rear View

5

4

32

1

9

8

7

6

Or

1

35

7

9

24

6810

Serial Port Header

(COM1 or COM2)

Remote Access

The CoreModule 430 BIOS supports the remote access (or console redirection) feature. This I/O function is

provided by an ANSI-compatible serial terminal, or the equivalent terminal emulation software running on

another system. This can be very useful when setting up the BIOS on a production line for systems that are

not connected to a keyboard and display.

Remote Access Setup

The remote access feature is implemented by connecting a standard null-modem cable or a modified serial

cable (or “Hot Cable”) between one of the serial ports, such as Serial 1 or 2 (J3 or J9), and the serial terminal

or a PC with communications software. The BIOS Setup Utility controls the remote access settings on the

CoreModule 430. Refer to Chapter 4, BIOS Setup for the settings of the remote access option, the serial

terminal, or PC with communications software and the connection procedure.

Hot (Serial) Cable

To convert a standard serial cable to a Hot Cable, specific pins must be shorted together at the Serial port

header or at the DB9 connector. Short together the RTS (4) and RI (8) pins on either serial port (J3 or J9)

header. As an alternate, you can short the equivalent pins (pins 7 and 9) on the back of the respective DB9

port connector as shown in Figure 3-3.

Figure 3-3. Hot Cable Jumper

Watchdog Timer

The Watchdog Timer (WDT) restarts the system if an error or mishap occurs, allowing the system to recover

from the mishap, even though the error condition may still exist. Possible problems include failure to boot

properly, loss of control by the application software, failure of an interface device, unexpected conditions on

the bus, or other hardware or software malfunctions.

The WDT (Watchdog Timer) can be used both during the boot process and during normal system operation.

• During the Boot process – If the OS fails to boot in the time interval set in the BIOS, the system will

reset.

Enable the Watchdog Timer (sec) field in the Chipset > Southbridge

for a time-out interval in seconds, between 1 and 255, in one second increments. Ensure you allow

enough time for the operating system (OS) to boot. The OS or application must tickle (reset) the WDT

before the timer expires. This can be done by accessing the hardware directly or through a BIOS call.

• During System Operation – An application can set up the WDT hardware through a BIOS call, or by

accessing the hardware directly. Some ADLINK Board Support Packages provide an API to the WDT.

The application must tickle (reset) the WDT before the timer expires or the system will be reset.

• Watchdog Code examples – ADLINK has provided source code examples on the CoreModule 430

Support Software QuickDrive illustrating how to control the WDT. The code examples can be easily

copied to your development environment to compile and test the examples, or make any desired

changes before compiling. Refer to the WDT Readme file in the Sample Code directory on the

CoreModule 430 Support Software QuickDrive.

screen of BIOS Setup. Set the WDT

30 Reference Manual CoreModule 430

Page 37

Chapter 3 Hardware

Power Interface

The CoreModule 430 requires one +5 volt DC power source. If the +5VDC power drops below ~4.65V, a

low voltage reset is triggered, resetting the system.

The power input header (J7) supplies the following voltages and ground directly to the module:

• 5.0VDC +/- 5% @ 1.35 Amps

Table 3-16 describes the pin signals of the Power interface, which uses a 10-pin, right-angle header with 2

rows, odd/even sequence (1, 2), and 0.100" (2.54mm) pitch.

Table 3-16. Power Interface Pin/Signals (J7)

Pin Signal Descriptions

1

2

3

4

5

6 NC Not connected

7

8

9

10

GND Ground

+5V +5 Volts

Key/GND Key Pin on connector/Grounded on board

+12V +12 volts routed to PC/104

GND Ground

GND Ground

+5V +5 Volts

GND Ground

+5V +5 Volts

Note: The shaded table cells denote power or ground.

CoreModule 430 Reference Manual 31

Page 38

Chapter 3 Hardware

32 Reference Manual CoreModule 430

Page 39

Chapter 4 BIOS Setup

Introduction

This chapter assumes the user is familiar with general BIOS Setup and does not attempt to describe the

BIOS functions. Refer to “BIOS Setup Screens” on page 35 in this chapter for a map of the BIOS Setup

settings. If ADLINK has added to or modified any of the standard BIOS functions, these functions will be

described.

Entering BIOS Setup (Local Display)

To access BIOS Setup using a local display for the CoreModule 430:

1. Turn on the display and the power supply to the CoreModule 430.

2. Start Setup by pressing the [Del] key when the following message appears on the boot screen.

Press DEL to run Setup

NOTE If the setting for Quick Boot is [Enabled], you may not see this prompt appear on

screen. If this happens, press the <Del> key early in the boot sequence to enter

BIOS Setup.

3. Follow the instructions on the right side of the screen to navigate through the selections and modify any

settings.

Entering BIOS Setup (Remote Access)

This section describes how to enable the Remote Access in VGA mode and enter the BIOS setup through a

serial terminal or PC.

1. Turn on the power supply to the CoreModule 430 and enter the BIOS Setup Utility in VGA mode.

2. Set the BIOS feature Remote Access Configuration to [Enable] under the Advanced menu.

3. Accept the default options or make your own selections for the balance of the Remote Access fields and

record your settings.

4. Ensure you select the type of remote serial terminal you will be using and record your selection.

5. Select Save Changes and Exit and then shut down the CoreModule 430.

6. Connect the remote serial terminal (or the PC with communications software) to the COM port you

selected and recorded earlier in the BIOS Setup Utility.

7. Turn on the remote serial terminal or PC and set it to the settings you selected in the BIOS Setup Utility.

The default settings for the CoreModule 430 are:

COM1

115200

8 bits

1 stop bit

no parity

no flow control

[Always] for Redirection After BIOS POST