Page 1

AMP-204C / AMP-208C

Advanced DSP Pulse Motion Controller

for 4/8 Axis

User Manual

Manual Rev.: 2.00

Revision Date: July 25, 2014

Part No: 50-15089-1000

Advance Technologies; Automate the World.

Page 2

Revision History

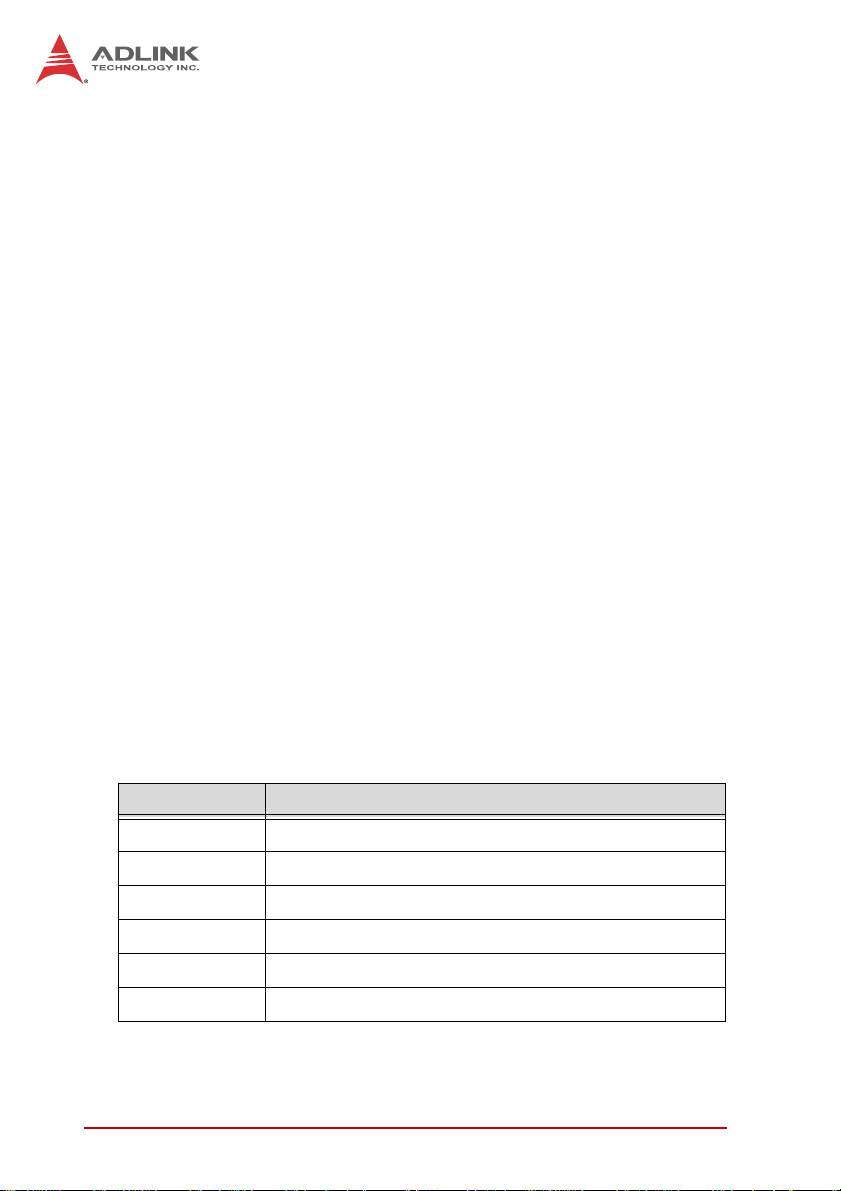

Revision Release Date Description of Change (s)

2.00 2014-07-25 Initial release

ii

Page 3

AMP-204C / AMP-208C

Preface

Copyright 2014 ADLINK Technology, Inc.

This document contains proprietary information protected by

copyright. All rights are reserved. No part of this manual may be

reproduced by any mechanical, electronic, or other means in any

form without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

Under no circumstances will ADLINK be held liable to this

document.

In no event will the manufacturer be liable for direct, indirect,

special, incidental, or consequential damages arising out of the

use or inability to use the product or documentation, even if

advised of the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the

European Union's Restriction of Hazardous Substances (RoHS)

directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products,

manufacturing processes, components, and raw materials have as

little impact on the environment as possible. When products are at

their end of life, our customers are encouraged to dispose of them

in accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered

trademarks of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

reference to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE

NOTE

Information to prevent minor physical injury, component

damage, data loss, and/or program corruption when trying to

CAUTION

WARNING

complete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

iv Preface

Page 5

AMP-204C / AMP-208C

Contents

Revision History...................................................................... ii

Preface.................................................................................... iii

List of Figures........................................................................ ix

List of Tables........................................................................ xiii

1 Introduction ........................................................................ 1

1.1 Product Specifications ......................................................... 4

1.2 Software Support ................................................................. 8

Software Support Library ................................................ 8

MotionCreatorPro 2 ........................................................ 8

1.3 Terminal Board .................................................................... 8

2 Getting Start with The Installation.................................... 9

2.1 Package Contents ............................................................... 9

2.2 AMP-204C / AMP-208C Exterior Profile Diagram ............. 10

2.3 Hardware Installation ......................................................... 12

Hardware Configuration ................................................ 12

Installation Procedures ................................................. 12

Troubleshooting ............................................................ 13

2.4 Software Installation Procedure......................................... 14

2.5 Definitions to Key Connector Signal .................................. 16

AMP-204C:P1 Connector ............................................. 16

AMP-208C:P1-A/B Connector ...................................... 18

AMP-204C/208C:P2 Connector .................................... 21

2.6 DIP Switch ......................................................................... 23

SW2: Card ID Switch .................................................... 23

2.7 IDE 44p – DSUB 37p Bus.................................................. 24

2.8 Exclusive Board - DIN-825-GP4 ........................................ 25

Contents v

Page 6

Definitions to Connector ............................................... 26

P1 Connector: For Connecting to PCI-8254 / PCI-8258 /

AMP-204C / AMP-208C ................................................ 28

S1, S2: EDO/ALM_RST Selection Switch .................... 37

3 Signal Connection ............................................................ 39

3.1 Pulse Command ................................................................ 40

3.2 Encoder Input, EA & EB & EZ............................................ 43

3.3 Emergency Stop Input ....................................................... 45

3.4 PEL/MEL Input................................................................... 46

3.5 ORG Input.......................................................................... 48

3.6 INP Input ............................................................................ 49

3.7 ALM Input .......................................................................... 50

3.8 SVON Output ..................................................................... 51

3.9 Comapre & Trigger Output:................................................ 52

3.10 Digital Output/Input ............................................................ 54

4 Motion Control Theory ..................................................... 59

4.1 Motion Control Mode and Interface Overview.................... 60

4.1.1 Motion Control Interface ........................................... 60

4.1.2 Control Cycle ............................................................ 66

4.2 Motion Control Operations ................................................. 68

4.2.1 Coordinated System ................................................. 68

4.2.2 Unit Factor ................................................................ 69

4.2.3 Acc/Deceleration Profile ........................................... 72

4.3 Home Move........................................................................ 78

4.3.1 OGR Signal Homing - Home Mode = 0 .................... 81

4.3.2 EL Signal Homing - Home Mode 1 ........................... 88

4.3.3 Single EZ Signal Homing.......................................... 91

4.4 Velocity Move..................................................................... 94

4.5 Jog Move ........................................................................... 97

4.6 Point-to-Point Move ......................................................... 101

4.6.1 Point-to-Point Move ................................................ 101

vi Contents

Page 7

AMP-204C / AMP-208C

4.6.2 Synchronous Start .................................................. 102

4.6.3 On The Fly Change ................................................ 103

4.6.4 Continuous PTP Move............................................ 103

4.7 Interpolation ..................................................................... 106

4.7.1 Linear Interpolation................................................. 106

4.7.2 Arc Interpolation ..................................................... 108

4.7.3 Continuous Interpolation......................................... 116

4.8 Motion Status Monitoring ................................................. 122

4.8.1 Motion Status.......................................................... 123

4.9 Application Functions....................................................... 132

4.9.1 Electronic Gearing .................................................. 132

4.9.2 High Speed Position Compare Trigger................... 134

4.9.3 PWM Control (Laser Control) (VAO Table Control)140

4.9.4 Motion Control and I/O Sampling Function............. 148

4.9.5 Simultaneous Movement ........................................ 153

4.9.6 Point Table Movement............................................ 156

4.10 Safety Protection ............................................................. 161

4.10.1 Hardware Protection ............................................... 161

4.10.2 Software Protection ................................................ 164

4.11 Host Interrupt ................................................................... 168

Important Safety Instructions............................................ 176

Getting Service.................................................................... 178

Contents vii

Page 8

viii Contents

Page 9

AMP-204C / AMP-208C

List of Figures

Figure 1-1: AMP-204C/208Csystem block diagram...................... 2

Figure 1-2: System installation flow chart ..................................... 3

Figure 2-1: AMP-204C exterior profile diagram .......................... 10

Figure 2-2: AMP-208C exterior profile diagram .......................... 11

Figure 2-3: Exterior of DIN-825-GP4 .......................................... 25

Figure 2-4: Exterior of DIN-825-GP4 .......................................... 26

Figure 3-1: Line Driver type pulse control command signal

connection example41

Figure 3-2: Open-Collector type pulse control command signal

connection example42

Figure 3-3: Line driver type encoder input signal connection example

44

Figure 3-4: Emergency stop signal connection example ............ 45

Figure 3-5: Mechanical limit switch signal connection example.. 47

Figure 3-6: Original position switch signal connection example . 48

Figure 3-7: In-position signal connection example...................... 49

Figure 3-8: Servo alarm signal connection example................... 50

Figure 3-9: Servo-on signal connection example........................ 51

Figure 3-10: Line Driver type compare trigger signal connection

example52

Figure 3-11: Open-Collector type compare trigger signal connection

example53

Figure 3-12: General purpose digital I/O signal connection example

55

Figure 3-13: General purpose digital I/O signal connection example

58

Figure 4-1: Format of pulse signal .............................................. 61

Figure 4-2: Control cycle............................................................. 67

Figure 4-3: Controller coordinates system block......................... 68

Figure 4-4: Relation of trapezoidal speed profile's

speed/acceleration/jerk VS time72

Figure 4-5: Maximum speed by auto-planning............................ 73

Figure 4-6: Relation of S-curve speed profile's

speed/acceleration/jerk VS time74

Figure 4-7: Auto-planning the maximum velocity........................ 76

Figure 4-8: Home mode 0 (Case: ORG) .................................... 82

Figure 4-9: Home mode 0 (Case: ORG) .................................... 84

Figure 4-10: Home mode 0 (Case: ORG+EZ) ............................. 85

List of Figures ix

Page 10

Figure 4-11: Home mode 0 adverse (Case: ORG+EZ)................ 86

Figure 4-12: Home mode 0 decelerate to stop (Case: ORG)....... 87

Figure 4-13: Home mode 1 (Case: EL) ........................................ 88

Figure 4-14: Home mode 1 (Case: EL+EZ) ................................. 90

Figure 4-15: Home mode 2 (Case: EZ)........................................ 92

Figure 4-16: Home mode 2 adverse (Case: EZ) .......................... 93

Figure 4-17: Relation between V-T chart of JOG movement and

JOG-ON signal97

Figure 4-18: Jog step mode .......................................................... 98

Figure 4-19: T-curve V-T chart.................................................... 101

Figure 4-20: Dynamically change position and velocity .............. 103

Figure 4-21: Continuous three position V-T chart ....................... 104

Figure 4-22: Continuous three position V-T chart

(auto speed connection (1)104

Figure 4-23: Continuous three position V-T chart

(auto speed connection (2)104

Figure 4-24: Continuous three position V-T chart

(auto speed connection (3)105

Figure 4-25: Continuous three position V-T chart

(auto speed connection (4)105

Figure 4-26: Two-dimension straight line interpolation ............... 107

Figure 4-27: Three-dimension arc interpolation (method 1)........ 109

Figure 4-28: Defining spatial normal vector ................................ 110

Figure 4-29: Determining arc direction in space ......................... 110

Figure 4-30: Three dimension arc interpolation (method 2)........ 111

Figure 4-31: Three dimension arc interpolation example............ 112

Figure 4-32: Three dimension spiral interpolation (method 1) .... 113

Figure 4-33: Three-dimension spiral interpolation (method 2) .... 114

Figure 4-34: Illustration on continuous interplotation (Buffer)

movement116

Figure 4-35: Velocity blending (method 1) .................................. 117

Figure 4-36: Velocity blending (method 2) .................................. 118

Figure 4-37: Velocity blending (method 3) .................................. 118

Figure 4-38: Velocity blending (method 4) .................................. 119

Figure 4-39: Velocity blending (method 5) .................................. 119

Figure 4-40: Velocity blending (method 6) .................................. 120

Figure 4-41: Velocity blending (method 7) .................................. 120

Figure 4-42: Continuous interpolation examples......................... 121

Figure 4-43: Motion status monitoring process ........................... 122

Figure 4-44: Relation of different motion signals VS motions ..... 125

xList of Figures

Page 11

AMP-204C / AMP-208C

Figure 4-45: Relation of motion done (MDN) signal VS motion .. 126

Figure 4-46: Relation of motion done (MDN), In-homing (HMV) signals

VS motion127

Figure 4-47: Relation of WAIT signals VS motion....................... 128

Figure 4-48: Relation of JOG and motion done(MDN) signals VS

motion129

Figure 4-49: Relation of ASTP VS motion .................................. 129

Figure 4-50: Relation of blending (BLD) signal VS motion ......... 130

Figure 4-51: Relation between pre- and post-distance event signals

and movement131

Figure 4-52: Adjust electronic gear's auto engagement speed... 133

Figure 4-53: Compare trigger block diagram .............................. 135

Figure 4-54: Linear compare trigger example ............................. 137

Figure 4-55: Table compare trigger example .............................. 138

Figure 4-56: Table compare trigger block diagram ..................... 139

Figure 4-57: Signal sampling structure diagram ......................... 148

Figure 4-58: Interruption flow chart ............................................. 168

List of Figures xi

Page 12

xii List of Figures

Page 13

AMP-204C / AMP-208C

List of Tables

Table 1-1: Cross-reference table of exclusive cables for pulse servo

drive8

Table 4-1: Encoder input format ..................................................... 63

Table 4-2: Encoder input format ..................................................... 63

Table 4-3: Board parameter table ................................................. 146

Table 4-4: Motion kernel signal table ............................................ 149

List of Tables xiii

Page 14

xiv List of Tables

Page 15

AMP-204C / AMP-208C

1 Introduction

The AMP-204C / AMP-208C, is a fully in-house developed

DSP-based advanced motion control card from ADLINK. It

supports 4/8 axis pulse type signal commands, provides

open-loop circuit control options, and supports position commands

for several different servo drives.

AMP-204C / AMP-208C exchanges data with operating system

through high speed PCI bus including motion control command,

feedback data, parameter, etc. Used with the ADLINK exclusive

Softmove kernel, it offers scores of move control functions

including T/S speed profile planning, point-to-point movement,

multi-dimension interpolation, and master/slave motion.

The AMP-204C / 208C, see Figure 1 below for its system functions,

uses one digital signal processor (DSP) from Texas Instrument (TI)

as its main computing unit and integrates high speed large volume

Field Programmable Gate Array (FPGA) to provide high speed

encoder output, 2/4 high speed position compare and trigger output,

move & general purposed I/O and logic control. It separates

isolation circuit into exclusive terminal board DIN-825-GP4 to

prevent the burning out of AMP-204C/208C from incorrect wiring.

Thanks to full range of flexing resistant wires from ADLINK, it

connects with market avaialble popular servo dirves easily.

Introduction 1

Page 16

SCSI 100P

PCI Bus

PCI Bus

Isolation

DSUB 37P

DIN-825-GP4

Figure 1-1: AMP-204C/208Csystem block diagram

Graphical motion control interface – MotionCreatorPro 2 is a

Windows-based motion control software development tool for

motion control and I/O status monitoring. It captures motion curves

and data at the same time for analysis. Its Setup Wizard guides

you through the hardware installation and wiring as well as

single-axis manipulation step-by-step. This saves your

development time and cost.

2Introduction

Page 17

AMP-204C / AMP-208C

The Windows Programming Libraries supports Windows coding

environment including: Visual Studio C++ 6.0, Microsoft .NET

framework based VB.NET and C++, and Borland's C++ Builder.

There are sample programs available in the installation folders.

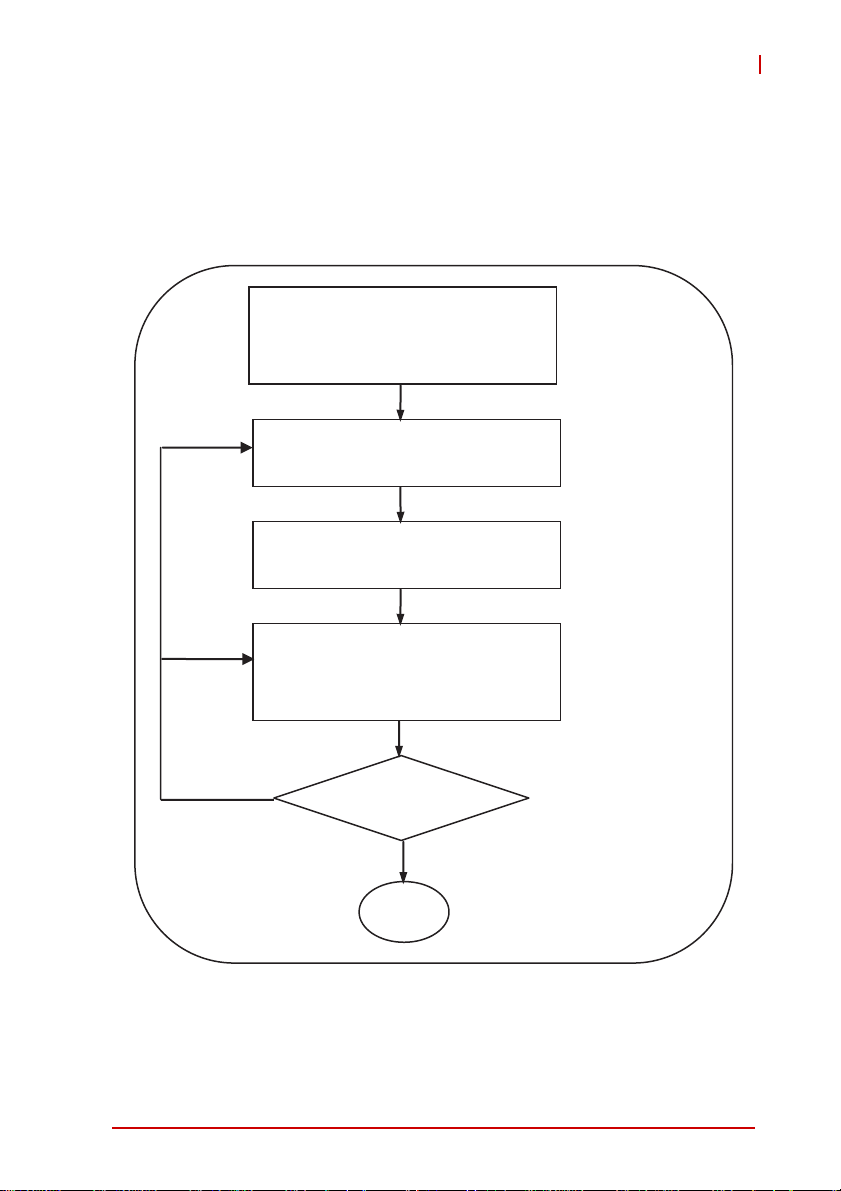

The flow chart below will guide you in using this manual as well as

help you to locate any required information effectively.

Hardware installation

Wiring and jumper setup

Set up card and adjust axis parameters

with MotionCreatorPro 2

Control axis with MotionCreatorPro 2

Develop application with APS library

No

Is the system running

successfully?

Yes

Chapter II and III

MotionCreatorPro 2

User's Manual

Chapter IV

MotionCreatorPro 2

User's Manual

APS and ADCNC

library

End

Figure 1-2: System installation flow chart

Introduction 3

Page 18

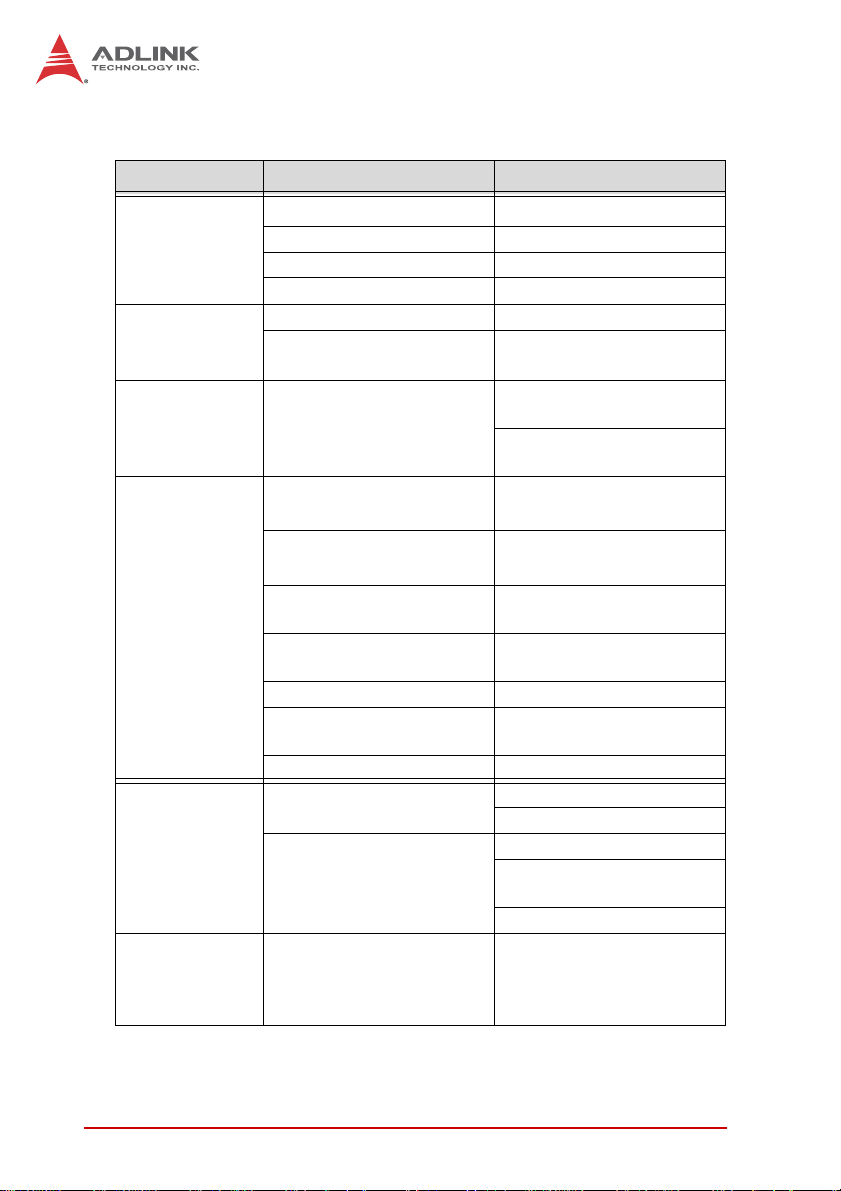

1.1 Product Specifications

Item Description

Bus information PCI Rev. 2.2, 33MHz

System

DSP

Board-to-board

interface

Motion control

I/O interface

General

purpose digital

I/O

PCI bus width 32-bit

PCI bus voltage 3.3V, 5V

PCI bus IRQ settings Assigned by PCI controller

Model TI 375MHz floating DSP

Memory (for program and

data)

Connector

Number of axes supported

Track update rate

Position / speed command

range

Acceleration / deceleration

range

Encoder input frequency 20 MHz @ 4x AB

Encoder input mode

Encoder input interface ±12 volts, TTL compatible

Motion control relevant I/O

Drive relevant I/O

General purpose I/O

DDR2 SDRAM: 64Mx16bit

Flash ROM: 16M-bit

1x SCSI-II 100P for

AMP-204C

1x Dual SCSI VHDCI 100P

AMP-208C

for

4/8 axis for AMP-204C /

AMP-208C

500us, 1ms, 2ms

(programmable)

32 bit

32 bit

CW/CCW, 1x/2x/4x AB

Phase

Plus/Minus end limitsignal

Zero-position for each axis

Servo ON

In-position signal /

Zero-Speed detection

Alarm

20/24-CH input & 20/24-CH

TTL output (optical

isolation design for

DIN-825-GP4)

4Introduction

Page 19

Motion control

function

AMP-204C / AMP-208C

Item Description

Speed Profile Planning

Trajectory Planing

Linear interpolation:

2-6 axes

Home Return

Trapezoidal Curve and

S-Curve

Jogging

Point-to-point movement

Online position/speed

change

3 axes arc interpolation

3 axes spiral interpolation

3 axes helix interpolation

User customization (see

zero-position, limit switch,

EZ signals for reference)

Introduction 5

Page 20

Industrial

application

Interrupt

Position

comparison

&

trigger output

Item Description

Each axis supports 50

points buffer memory

(BUFs)

Supports

Point table

Motion Status Monitoring

Synchronous move

Master-client axes control

Data sampling

System error diagnostics Watchdog timer

Motion status event/error

alarm/in position/

emergency stop

Pulse output interface Difference output

Trigger channel

Pulse logic

Trigger output frequency

Minimum pulse width 100ns programmable

Position comparison mode

FIFO capacity

point-to-point/line/arc and

spiral interpolation

Supports dwell function

Supports pause/resume

function

Supports DO function

Motion control relevant I/O

monitoring

Motion status monitoring

4/8 axes corresponding

AMP-204C / AMP-208C

Up to 4/8 axis (including

ganty control)

Motion speed profile/

motion status/motion

control relevant I/O

Planning in accordance

with the manual

2/4 corresponding

AMP-204C / AMP-208C

Programmable active-high

or active-low

Linear compare trigger:

1MHz

FIFO compare trigger:

255K ~ 1MHz

FIFO and linear

comparison

255 points (channel

independent)

6Introduction

Page 21

Item Description

PWM control

Maximum number of

channels

Control modes

Resolution 16 bit

Environment condition

Working

ambient

temperature

Storage

ambient

temperature

Working

ambient

humidity

0~55°C

-20~75°C

10~90%RH, without condensation

AMP-204C / AMP-208C

2/4 CH correspondence

AMP-204C / AMP-208C

● Fixed frequency,

variable duty cycle ratio

● Variable frequency, fixed

duty cycle ratio

● Variable frequency,

variable duty cycle ratio

Item

Storage

ambient

humidity

Noise

impedance

Environment

condition

Cooling

condition

Power

consumption

Introduction 7

10~90%RH, without condensation

Noise voltage 1500VPP noise frequency 25~60Hz using

noise simulator

Minimal corrosive gas, dust

Self-cooling

+3.3V @ 0.8A typical

+5V @ 0.8A typical

+/-12V @ 0.5A typical

Page 22

1.2 Software Support

1.2.1 Software Support Library

AMP-204C / AMP-208C supports Windows XP/7 32/64 bit

operating system and provides a complete function library and

DLL files for easy application development by users.

1.2.2 MotionCreatorPro 2

MotionCreatorPro 2 is a user interface exclusively developed for

ADLINK motion control products in common Windows

environment. You may easily set up card and axis parameters with

the help of MotionCreatorPro 2. Its Setup Wizard guides you

through the hardware installation and wiring as well as single-axis

manipulation in couple of minutes. MotionCreatorPro 2 not only

effectively reduces your development time but also enables you to

concurrently validate the overall mechanism and electric design

with all its single axis and interpolation motion operation pages.

1.3 Terminal Board

ADLINK's exclusive terminal board DIN-825-GP4 for

AMP-204C/208C can connect with market available servo drivers

with special cables, e.g. Mitsubishi's J3A and Yaskawa's Sigma V

series, or with third party's servo or stepper drivers by single

ended open cables. Brands with exclusive cables support are

listed below:

Pulse command:

Cable Supported brands

HSL-4XMO-DM Mitsubishi J2S series

4XMO-DM-J3 Mitsubishi J3A series

HSL-4XMO-DP Panasonic A4 and A5 series

HSL-4XMO-DY Yaskawa Sigma V series

4XMO-DA Delta A2 series

4XMO-OPEN General purpose

Table 1-1: Cross-reference table of exclusive cables for pulse servo drive

8Introduction

Page 23

AMP-204C / AMP-208C

2 Getting Start with The Installation

This chapter teaches you how to install AMP-204C / AMP-208C

hardware and software as well as its I/O wiring.

• Package Contents

• Hardware installation

• Software installation

• I/O wiring

2.1 Package Contents

In addition to this manual you shall find the following item in the

product package box:

• One AMP-204C or AMP-208C card

• IDE 44p – DSUB 37p flat cable x 1

• Product warranty card x 1

Should there be any item missed or damaged, please consult with

your dealer immediately. Please keep the product along with items

included in its package for easy replacement or repair.

Getting Start with The Installation 9

Page 24

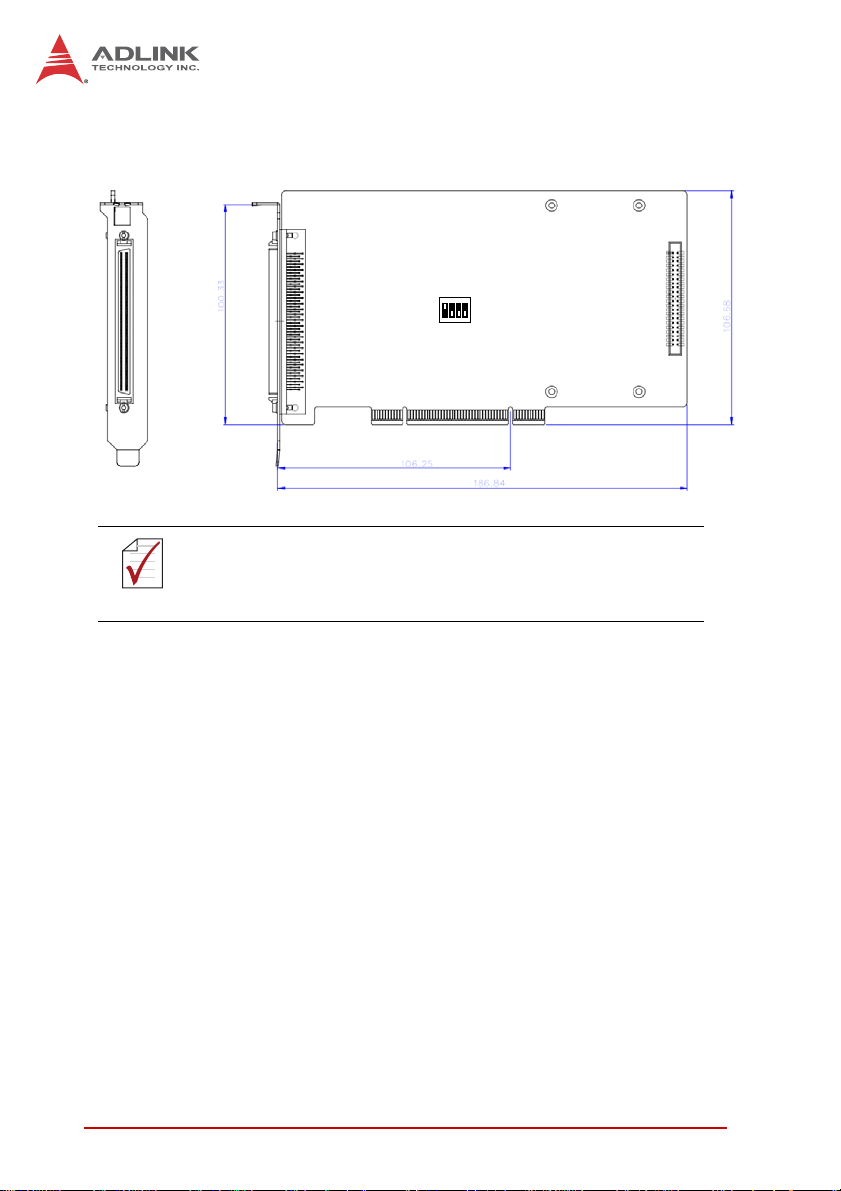

2.2 AMP-204C / AMP-208C Exterior Profile Diagram

SW2

P1

P2

Dimension in unit of millimeter (mm).

NOTE

NOTE

Figure 2-1: AMP-204C exterior profile diagram

P1: for Motion control command, Position feedback, and Servo I/O

feedback. (with SCSI 100-PINS connector)

P2:

for 16 channel digital TTL I/O. (with DSUB 37-PINS connector)

SW2:

Card ID setup (0-15)

10 Getting Start with The Installation

Page 25

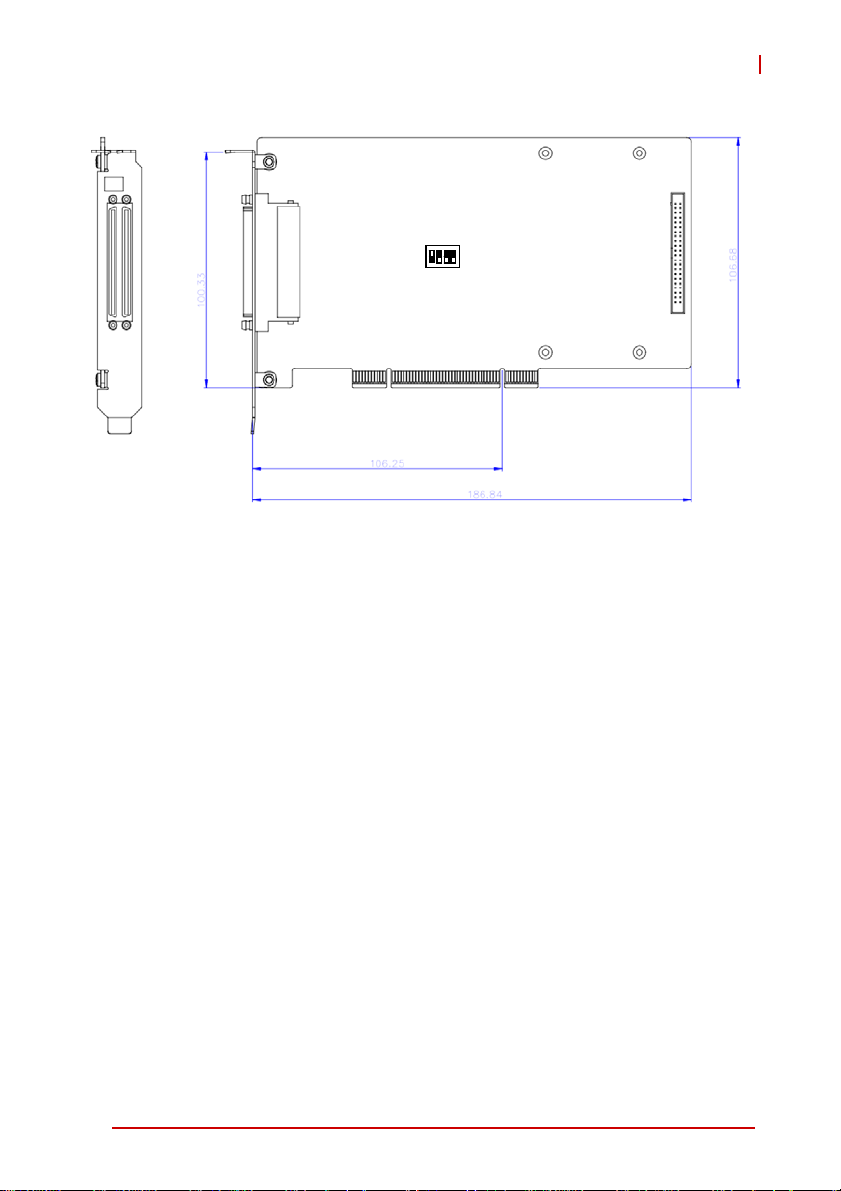

AMP-204C / AMP-208C

P1

SW2

P2

Figure 2-2: AMP-208C exterior profile diagram

P1: for Motion control command, Position feedback, and Servo I/O

feedback. (with SCSI-VHDCI 200-PINS connector)

P2:

for 16 channel digital TTL I/O. (with DSUB 37-PINS connector)

SW2: Card ID setup (0-15)

Getting Start with The Installation 11

Page 26

2.3 Hardware Installation

2.3.1 Hardware Configuration

AMP-204C/208C employs PCI Rev. 2.2 bus. System BIOS can

auto configure memory and IRQ channel.

Exclusive terminal board DIN-825-GP4 provides isolation circuit

and indicator lights for easy connections to varieties of servo drive

and stepper drive.

2.3.2 Installation Procedures

1. Please read this manual carefully and set up signal I/O in

proper mode.

2. Turn off power of your computer and all relevant terminal

boards, insert your AMP-204C/208C to any 32-bit PCI

slot in your computer. (The slot is usually in white color.)

(Please make sure you have proper ESD (Electrostatic

discharge) protection.)

3. Connect AMP-204C/208C and DIN-825-GP4 with SCSI

100p cable

4. Set up motion control relevant limit switch on

DIN-825-GP4 board, servo signal and general purpose

digital signal wiring

5. Set up servo or stepper drive connection

6. Turn on system power including computer power,

terminal board relevant powers, and 24Vdc power

7. Verify all I/O signal and servo operation correctness with

MotionCreatorPro 2

Please ground the shielding end of the power terminal to the

earth to reduce risk of electric shock and ensure product

CAUTION

CAUTION

12 Getting Start with The Installation

operation of your electric appliances.

Please disconnect the motor drive from its load before using

the card for the first time to protect your safety. Do not connect

the motor drive to any mechanical devices before the

completion of the installation and fine tuning of the control

system. Connect the system only after the board is adjusted

and the drive parameters can control the motor. Serious

damage may be resulted in otherwise.

Page 27

AMP-204C / AMP-208C

2.3.3 Troubleshooting

If the computer cannot power on normally or the motion control

system operates abnormally after system installation, please

follow steps described below for troubleshooting. If the problem

persists after you have taken steps described, please consult the

dealer where your product is purchased for technical services.

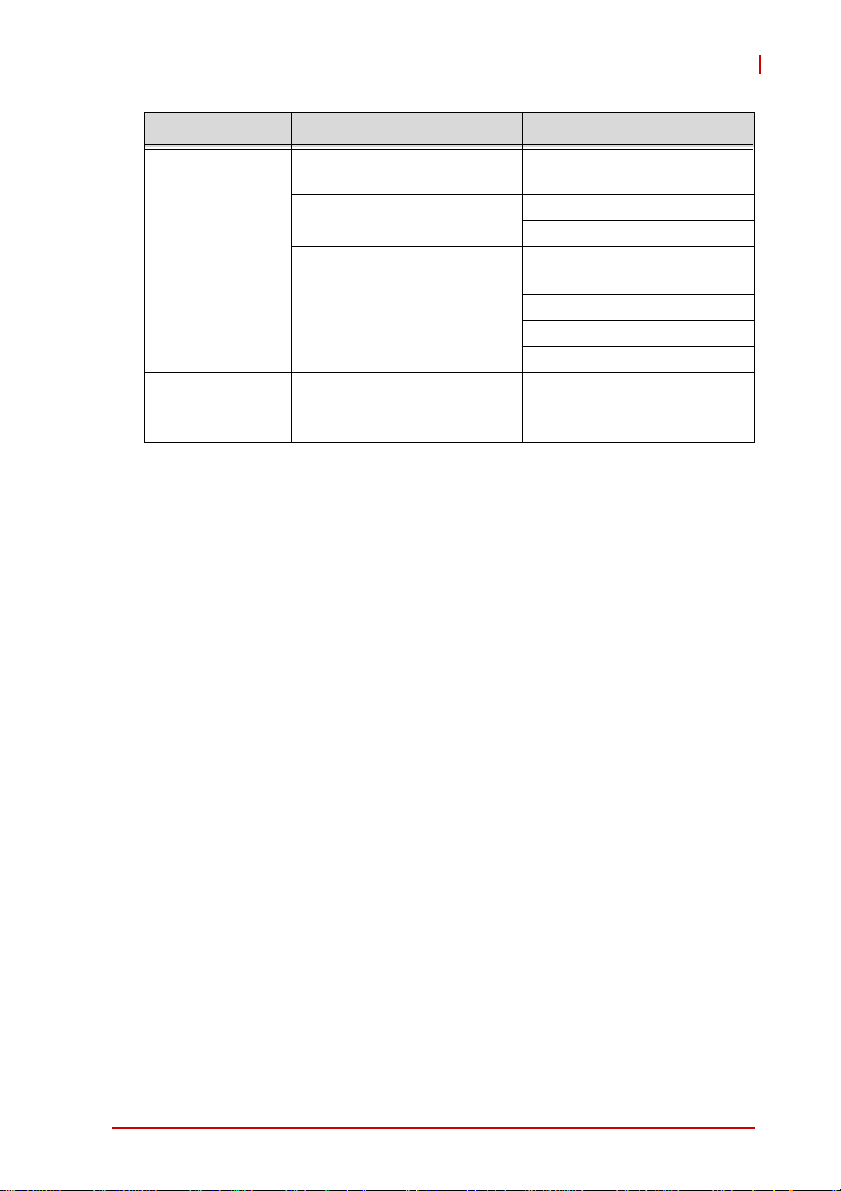

Abnormalities you

encountered

The card does not show up in

Windows Device Manager

after its driver has been

installed

MotionCreatorPro2 cannot

open after installing driver in

computer.

The without signal indicator on

MotionCreatorPro2 lights up

after the motor is connected

and the motor does not work.

When using the

MotionCreatorPro2 all the

control indicators of the drive

light correctly but the drive

warns

Value of output command

differ from the feedback value

from encoder

If motion control, the motor

moves only in one direction

rather than back and forth two

way movement

Potential causes

Please turn off your computer,

ensure the card is properly in PCI

slot and the driver is properly

installed by cheking its proper

installation in Windows Control

Panel's "Add remove programs"

Ensure .NET framework v3.5 or later

version has been installed in your

system

Please ensure a 24Vdc power is

connected to the terminal board

Please ensure correctness of the

axis parameter setup, alarm logic

(ALM) and the EMG loop

configuration

Please ensure feedback signal

(CW/CCW, 1xAB, 2xAB, 4xAB)

settings comply with that of the drive

Please ensure setting of signal pattern

(CW/CCW, OUT/DIR) comply with that

of the motor

drive

Getting Start with The Installation 13

Page 28

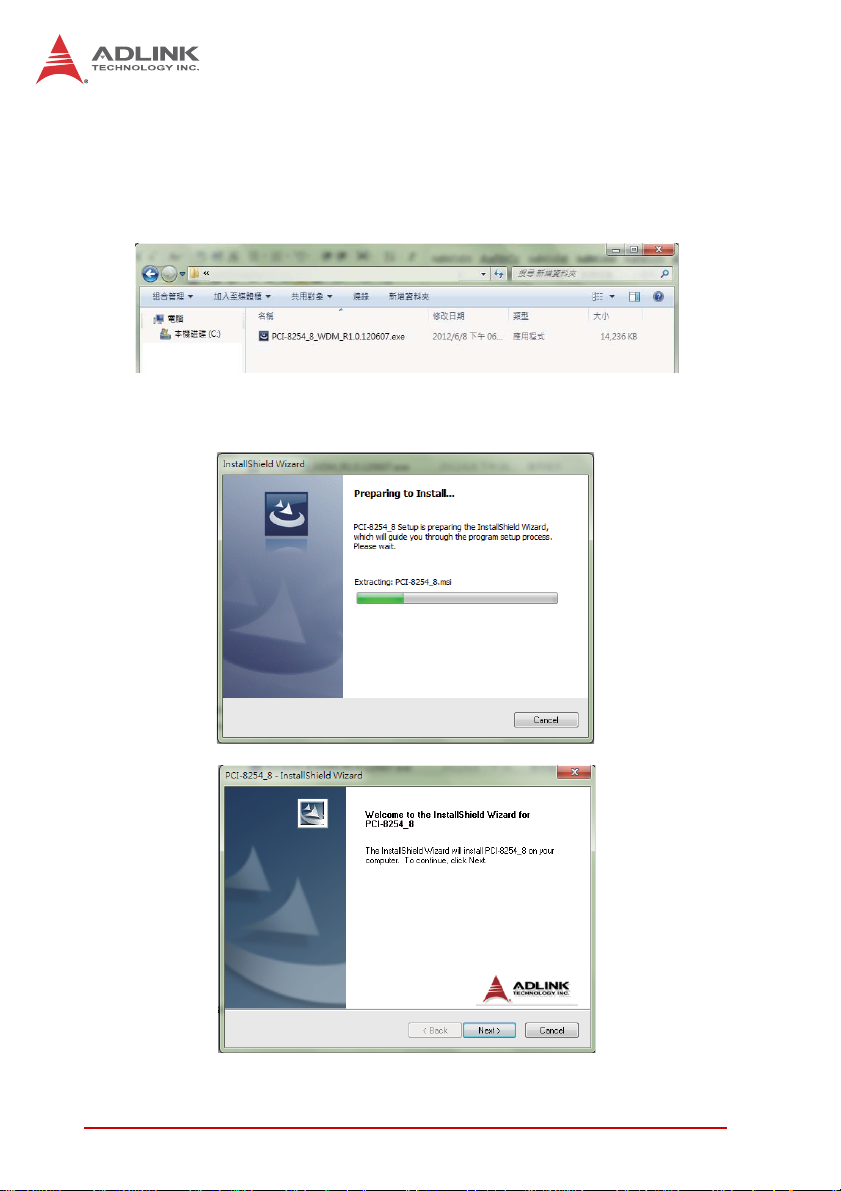

2.4 Software Installation Procedure

Windows driver installation procedure:

Step 1. Execute AMP-204C / AMP-208C WDM file and run

installation procedure automatically.

Step 2. Click "Next" as prompted to complete the installation

process.

14 Getting Start with The Installation

Page 29

AMP-204C / AMP-208C

Step 3. Restart your computer after installation is completed.

Step 4. Ensure the Windows Device Manager identify your

AMP-204C / AMP-208C correctly.

Recommendations: Please download latest installation software

from ADLINK official website to maintain the optimum operation

environment.

(http://www.adlinktech.com/Motion-Control/index.php

)

Getting Start with The Installation 15

Page 30

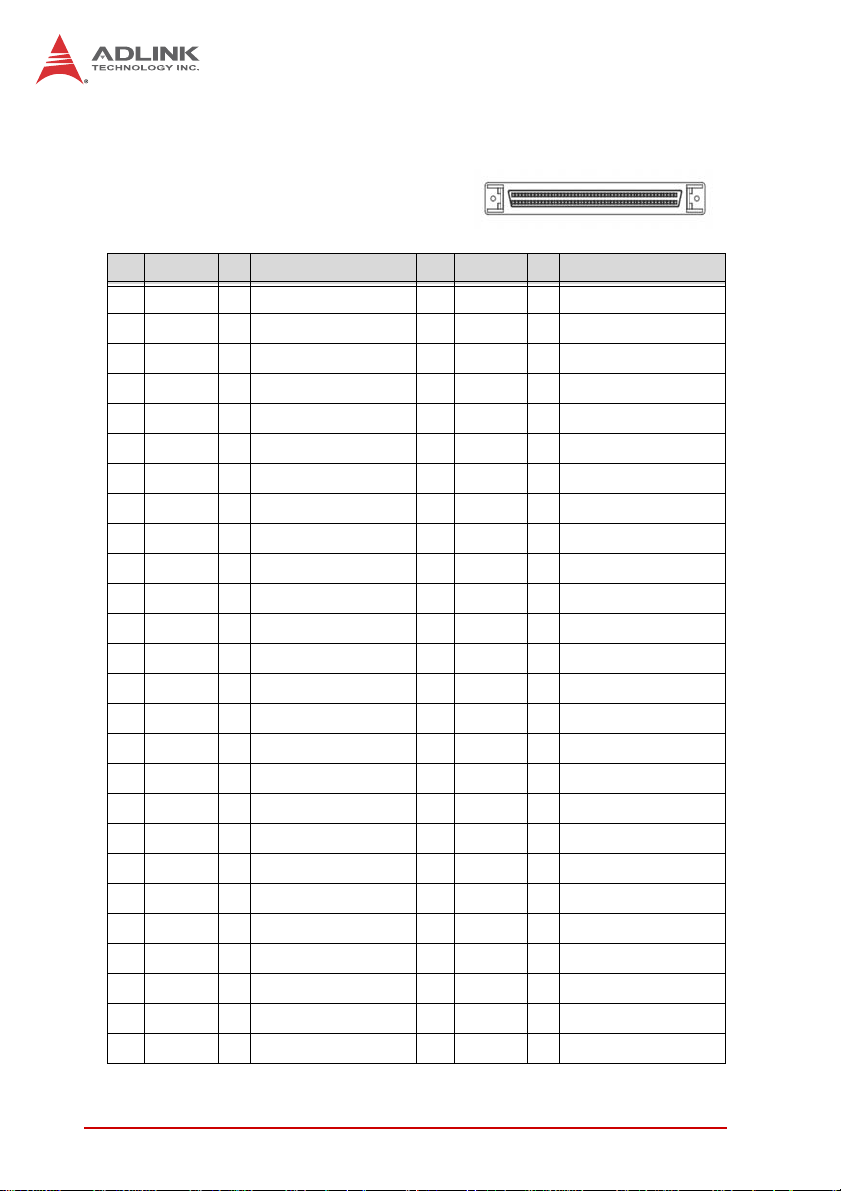

2.5 Definitions to Key Connector Signal

2.5.1 AMP-204C:P1 Connector

•P1

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Digital ground 51 IEMG I Emergency stop input

2 DGND -- Digital ground 52 Rsv. -- Reserved

3 Rsv. -- Reserved 53 Rsv. -- Reserved

4 Rsv. -- Reserved 54 Rsv. -- Reserved

5 Rsv. -- Reserved 55 Rsv. -- Reserved

6 Rsv. -- Reserved 56 Rsv. -- Reserved

7 Rsv. -- Reserved 57 Rsv. -- Reserved

8 Rsv. -- Reserved 58 Rsv. -- Reserved

9 Rsv. -- Reserved 59 Rsv. -- Reserved

10 Rsv. -- Reserved 60 Rsv. -- Reserved

11 EA5V -- 5V Power 61 DGND -- Digital ground

12 EA5V -- 5V Power 62 DGND -- Digital ground

13 OUT1+ c Pulse output (+), (1) 63 OUT3+ c Pulse output (+), (3)

14 OUT1- c Pulse output (-), (1) 64 OUT3- c Pulse output (-), (3)

15 DIR1+ c Direction output (+), (1) 65 DIR3+ c Direction output (+), (3)

16 DIR1- c Direction output (-), (1) 66 DIR3- c Direction output (-), (3)

17 OUT2+ c Pulse output (+), (2) 67 OUT4+ c Pulse output (+), (4)

18 OUT2- c Pulse output (-), (2) 68 OUT4- c Pulse output (-), (4)

19 DIR2+ c Direction output (+), (2)

20 DIR2- c Direction output (-), (2) 70 DIR4- c Direction output (-), (4)

21 TG1+ c Trigger output (+), (1) 71 TRG2+ c Trigger output (+), (2)

22 TRG1- c Trigger output (-), (1) 72 TRG2- c Trigger output (-), (2)

23 EA1+ | Encoder A-phase (+),(1) 73 EA3+ | Encoder A-phase (+),(3)

24 EA1- | Encoder A-phase (-),(1) 74 EA3- | Encoder A-phase (-),(3)

25 EB1+ | Encoder B-phase (+),(1) 75 EB3+ | Encoder B-phase (+),(3)

26 EB1- | Encoder B-phase (-),(1) 76 EB3- | Encoder B-phase (-),(3)

69 DIR4+ c Direction output (+), (4)

16 Getting Start with The Installation

Page 31

AMP-204C / AMP-208C

No. Name I/O Function of Axis No. Name I/O Function of Axis

27 EZ1+ | Encoder Z-phase (+),(1) 77 EZ3+ | Encoder Z-phase (+),(3)

28 EZ1- | Encoder Z-phase (-),(1) 78 EZ3- | Encoder Z-phase (-),(3)

29 EA2+ | Encoder A-phase (+),(2) 79 EA4+ | Encoder A-phase (+),(4)

30 EA2- | Encoder A-phase (-),(2) 80 EA4- | Encoder A-phase (-),(4)

31 EB2+ | Encoder B-phase (+),(2) 81 EB4+ | Encoder B-phase (+),(4)

32 EB2- | Encoder B-phase (-),(2) 82 EB4- | Encoder B-phase (-),(4)

33 EZ2+ | Encoder Z-phase (+),(2) 83 EZ4+ | Encoder Z-phase (+),(4)

34 EZ2- | Encoder Z-phase (-),(2) 84 EZ4- | Encoder Z-phase (-),(4)

35 ALM1 | Servo alarm,(1) 85 ALM3 | Servo alarm,(3)

36 ORG1 | Home limit, (1) 86 ORG3 | Home limit, (3)

37 SVON1 c Servo-ON, (1) 87 SVON3 c Servo-ON, (3)

38 PEL1 | Positive limit, (1) 88 PEL3 | Positive limit, (3)

39 INP1 | In-Position (1) 89 INP3 | In-Position (3)

40 MEL1 | Negative limit, (1) 90 MEL3 | Negative limit, (3)

41 ALM2 | Servo alarm,(2) 91 ALM4 | Servo alarm,(4)

42 ORG2 | Home limit, (2) 92 ORG4 | Home limit, (4)

43 SVON2 c Servo-ON, (2) 93 SVON4 c Servo-ON, (4)

44 PEL2 | Positive limit, (2) 94 PEL4 | Positive limit, (4)

45 INP2 | In-Position (2) 95 INP4 | In-Position (4)

46 MEL2 | Negative limit, (2) 96 MEL4 | Negative limit, (4)

47 EDO1 c Digital Output, (1) 97 EDO3 c Digital Output, (3)

48 EDI1 | Digital Input, (1) 98 EDI3 | Digital Input, (3)

EDO2 c Digital Output, (2) 99 EDO4 c Digital Output, (4)

49

50 EDI2 | Digital Input, (2) 100 EDI4 | Digital Input, (4)

Getting Start with The Installation 17

Page 32

2.5.2 AMP-208C:P1-A/B Connector

•P1-A

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Digital ground 51 IEMG | Emergency stop input

2 DGND -- Digital ground 52 Rsv. -- Reserved

3 Rsv. -- Reserved 53 Rsv. -- Reserved

4 Rsv. -- Reserved 54 Rsv. -- Reserved

5 Rsv. -- Reserved 55 Rsv. -- Reserved

6 Rsv. -- Reserved 56 Rsv. -- Reserved

7 Rsv. -- Reserved 57 Rsv. -- Reserved

8 Rsv. -- Reserved 58 Rsv. -- Reserved

9 Rsv. -- Reserved 59 Rsv. -- Reserved

10 Rsv. -- Reserved 60 Rsv. -- Reserved

11 EA5V -- 5V power 61 DGND -- Digital ground

12 EA5V -- 5V power 62 DGND -- Digital ground

13 OUT1+ c Pulse output (+), (1) 63 OUT3+ c Pulse output (+), (3)

14 OUT1- c Pulse output (-), (1) 64 OUT3- c Pulse output (-), (3)

15 DIR1+ c Direction output (+), (1) 65 DIR3+ c Direction output (+), (3)

16 DIR1- c Direction output (-), (1) 66 DIR3- c Direction output (-), (3)

17 OUT2+ c Pulse output (+), (2) 67 OUT4+ c Pulse output (+), (4)

18 OUT2- c Pulse output (-), (2) 68 OUT4- c Pulse output (-), (4)

19 DIR2+ c Direction output (+), (2)

20 DIR2- c Direction output (-), (2) 70 DIR4- c Direction output (-), (4)

21 TG1+ c Trigger output (+), (1) 71 TRG2+ c Trigger output (+), (2)

22 TRG1- c Trigger output (-), (1) 72 TRG2- c Trigger output (-), (2)

23 EA1+ | Encoder A-phase (+),(1) 73 EA3+ | Encoder A-phase (+),(3)

24 EA1- | Encoder A-phase (-),(1) 74 EA3- | Encoder A-phase (-),(3)

25 EB1+ | Encoder B-phase (+),(1) 75 EB3+ | Encoder B-phase (+),(3)

26 EB1- | Encoder B-phase (-),(1) 76 EB3- | Encoder B-phase (-),(3)

27 EZ1+ | Encoder Z-phase (+),(1) 77 EZ3+ | Encoder Z-phase (+),(3)

28 EZ1- | Encoder Z-phase (-),(1) 78 EZ3- | Encoder Z-phase (-),(3)

69 DIR4+ c Direction output (+), (4)

18 Getting Start with The Installation

Page 33

AMP-204C / AMP-208C

No. Name I/O Function of Axis No. Name I/O Function of Axis

29 EA2+ | Encoder A-phase (+),(2) 79 EA4+ | Encoder A-phase (+),(4)

30 EA2- | Encoder A-phase (-),(2) 80 EA4- | Encoder A-phase (-),(4)

31 EB2+ | Encoder B-phase (+),(2) 81 EB4+ | Encoder B-phase (+),(4)

32 EB2- | Encoder B-phase (-),(2) 82 EB4- | Encoder B-phase (-),(4)

33 EZ2+ | Encoder Z-phase (+),(2) 83 EZ4+ | Encoder Z-phase (+),(4)

34 EZ2- | Encoder Z-phase (-),(2) 84 EZ4- | Encoder Z-phase (-),(4)

35 ALM1 | Servo alarm,(1) 85 ALM3 | Servo alarm,(3)

36 ORG1 | Home limit, (1) 86 ORG3 | Home limit, (3)

37 SVON1 c Servo-ON, (1) 87 SVON3 c Servo-ON, (3)

38 PEL1 | Positive limit, (1) 88 PEL3 | Positive limit, (3)

39 INP1 | In-Position (1) 89 INP3 | In-Position (3)

40 MEL1 | Negative limit, (1) 90 MEL3 | Negative limit, (3)

41 ALM2 | Servo alarm,(2) 91 ALM4 | Servo alarm,(4)

42 ORG2 | Home limit, (2) 92 ORG4 | Home limit, (4)

43 SVON2 c Servo-ON, (2) 93 SVON4 c Servo-ON, (4)

44 PEL2 | Positive limit, (2) 94 PEL4 | Positive limit, (4)

45 INP2 | In-Position (2) 95 INP4 | In-Position (4)

46 MEL2 | Negative limit, (2) 96 MEL4 | Negative limit, (4)

47 EDO1 c Digital Output, (1) 97 EDO3 c Digital Output, (3)

48 EDI1 | Digital Input, (1) 98 EDI3 | Digital Input, (3)

49 EDO2 c Digital Output, (2) 99 EDO4 c Digital Output, (4)

EDI2 | Digital Input, (2) 100 EDI4 | Digital Input, (4)

50

•P1-B

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 Rsv. -- Reserved 51 Rsv. -- Reserved

2 Rsv. -- Reserved 52 Rsv. -- Reserved

3 Rsv. -- Reserved 53 Rsv. -- Reserved

4 Rsv. -- Reserved 54 Rsv. -- Reserved

5 Rsv. -- Reserved 55 Rsv. -- Reserved

6 Rsv. -- Reserved 56 Rsv. -- Reserved

Getting Start with The Installation 19

Page 34

No. Name I/O Function of Axis No. Name I/O Function of Axis

7 Rsv. -- Reserved 57 Rsv. -- Reserved

8 Rsv. -- Reserved 58 Rsv. -- Reserved

9 Rsv. -- Reserved 59 Rsv. -- Reserved

10 Rsv. -- Reserved 60 Rsv. -- Reserved

11 EA5V -- 5V power 61 DGND -- Digital ground

12 EA5V -- 5V power 62 DGND -- Digital ground

13 OUT5+ O Pulse output (+), (5) 63 OUT7+ O Pulse output (+), (7)

14 OUT5- O Pulse output (-), (5) 64 OUT7- O Pulse output (-), (7)

15 DIR5+ O Direction output (+), (5) 65 DIR7+ O Direction output (+), (7)

16 DIR5- O Direction output (-), (5) 66 DIR7- O Direction output (-), (7)

17 OUT6+ O Pulse output (+), (6) 67 OUT8+ O Pulse output (+), (8)

18 OUT6- O Pulse output (-), (6) 68 OUT8- O Pulse output (-), (8)

19 DIR6+ O Direction output (+), (6) 69 DIR8+ O Direction output (+), (8)

20 DIR6- O Direction output (-), (6) 70 DIR8- O Direction output (-), (8)

21 TRG3+ O Trigger output (+), (3) 71 TRG4+ O Trigger output (+), (4)

22 TRG3- O Trigger output (-), (3) 72 TRG4- O Trigger output (-), (4)

23 EA5+ I

24 EA5- I

25 EB5+ I

26 EB5- I

27 EZ5+ I

28 EZ5- I

29 EA6+ I

30 EA6- I

31 EB6+ I

32 EB6- I

33 EZ6+ I

34 EZ6- I

35 ALM5 I Servo alarm,(5) 85 ALM7 I Servo alarm,(7)

36 ORG5 I Home limit, (5) 86 ORG7 I Home limit, (7)

37 SVON5 O Servo-ON, (5) 87 SVON7 O Servo-ON, (7)

Encoder A-phase (+),(5)

Encoder A-phase (-),(5)

Encoder B-phase (+),(5)

Encoder B-phase (-),(5)

Encoder Z-phase (+),(5)

Encoder Z-phase (-),(5)

Encoder A-phase (+),(6)

Encoder A-phase (-),(6)

Encoder B-phase (+),(6)

Encoder B-phase (-),(6)

Encoder Z-phase (+),(6)

Encoder Z-phase (-),(6)

73 EA7+ I Encoder A-phase (+),(7)

74 EA7- I Encoder A-phase (-),(7)

75 EB7+ I Encoder B-phase (+),(7)

76 EB7- I Encoder B-phase (-),(7)

77 EZ7+ I Encoder Z-phase (+),(7)

78 EZ7- I Encoder Z-phase (-),(7)

79 EA8+ I Encoder A-phase (+),(8)

80 EA8- I Encoder A-phase (-),(8)

81 EB8+ I Encoder B-phase (+),(8)

82 EB8- I Encoder B-phase (-),(8)

83 EZ8+ I Encoder Z-phase (+),(8)

84 EZ8- I Encoder Z-phase (-),(8)

20 Getting Start with The Installation

Page 35

AMP-204C / AMP-208C

No. Name I/O Function of Axis No. Name I/O Function of Axis

38 PEL5 I Positive limit, (5) 88 PEL7 I Positive limit, (7)

39 INP5 I In-Position (5) 89 INP7 I In-Position (7)

40 MEL5 I Negative limit, (5) 90 MEL7 I Negative limit, (7)

41 ALM6 I Servo alarm,(6) 91 ALM8 I Servo alarm,(8)

42 ORG6 I Home limit, (6) 92 ORG8 I Home limit, (8)

43 SVON6 O Servo-ON, (6) 93 SVON8 O Servo-ON, (8)

44 PEL6 I Positive limit, (6) 94 PEL8 I Positive limit, (8)

45 INP6 I In-Position (6) 95 INP8 I In-Position (8)

46 MEL6 I Negative limit, (6) 96 MEL8 I Negative limit, (8)

47 EDO5 O Digital Output, (5) 97 EDO7 O Digital Output, (7)

48 EDI5 I Digital Input, (5) 98 EDI7 I Digital Input, (7)

49 EDO6 O Digital Output, (6) 99 EDO8 O Digital Output, (8)

50 EDI6 I Digital Input, (6) 100 EDI8 I Digital Input, (8)

2.5.3 AMP-204C/208C:P2 Connector

•P2

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 Rsv. - - Reserved 20 VDD | +5V power supply input

2 TDI1 | TTL input, (1) 21 TDO1 c TTL output, (1)

3 TDI2 | TTL input, (2) 22 TDO2 c TTL output, (2)

4 TDI3 | TTL input, (3) 23 TDO3 c TTL output, (3)

5 TDI4 | TTL input, (4) 24 TDO4 c TTL output, (4)

6 TDI5 | TTL input, (5) 25 TDO5 c TTL output, (5)

7 TDI6 | TTL input, (6) 26 TDO6 c TTL output, (6)

8 TDI7 | TTL input, (7) 27 TDO7 c TTL output, (7)

9 TDI8 | TTL input, (8) 28 TDO8 c TTL output, (8)

10 TDI9 | TTL input, (9) 29 TDO9 c TTL output, (9)

11 TDI10 | TTL input, (10) 30 TDO10 c TTL output, (10)

12 TDI11 | TTL input, (11) 31 TDO11 c TTL output, (11)

13 TDI12 | TTL input, (12) 32 TDO12 c TTL output, (12)

Getting Start with The Installation 21

Page 36

No. Name I/O Function of Axis No. Name I/O Function of Axis

14 TDI13 | TTL input, (13) 33 TDO13 c TTL output, (13)

15 TDI14 | TTL input, (14) 34 TDO14 c TTL output, (14)

16 TDI15 | TTL input, (15) 35 TDO15 c TTL output, (15)

17 TDI16 | TTL input, (16) 36 TDO16 c TTL output, (16)

18 DGND - Digital ground 37 DGND - Digital ground

19 VDD | +5V power supply input -- -- -- --

22 Getting Start with The Installation

Page 37

AMP-204C / AMP-208C

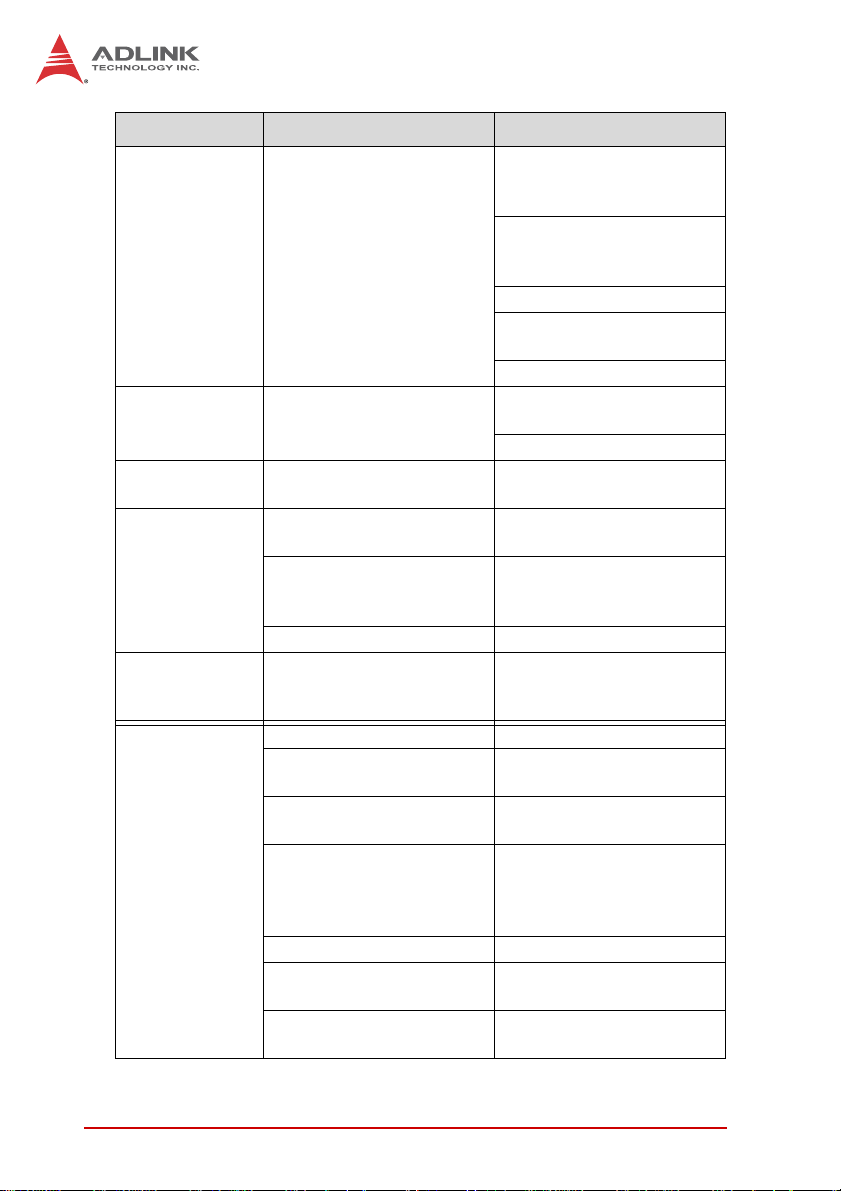

2.6 DIP Switch

2.6.1 SW2: Card ID Switch

This switch is used for adjusting card ID for easy identification in

user application programs. Take example. If you set card ID to

“0-0-0-1” (OFF-OFF-OFF-ON) then

the card ID is “1” and the ID table

should be set up as described below:

Card ID Switch Setting (ON=1)

0 0000

1 0001

2 0010

3 0011

4 0100

5 0101

6 0110

7 0 111

8 1000

9 1001

10 1010

11 1011

12 1100

13 1101

14 111 0

15 1111 ( d efa u lt)

Getting Start with The Installation 23

Page 38

2.7 IDE 44p – DSUB 37p Bus

This card include one IDE cable from IDE 44 pin to DSUB 37 pin.

It is used for AMP-204C / AMP-208C P2 extension 16 channel

digital input and 16 channel digital output.

24 Getting Start with The Installation

Page 39

AMP-204C / AMP-208C

2.8 Exclusive Board - DIN-825-GP4

The "DIN-825-GP4" terminal board is designed for PCI-8254 /

PCI-8258 and AMP-204C / AMP-208C exclusively. It connects

with market available servo drives with special cables, e.g.

Mitsubishi's J3A and Yaskawa's Sigma V series, or third party's

servo or stepper drives with single end open cables.

The DIN-825-GP4 board supports both PCI-8254 / PCI-8258

and AMP-204C / AMP-208C. DO NOT connect it to other

CAUTION

ADLINK's motion controllers as it may be damaged.

Main connector

(to PCI board)

Brake signal

Motion I/O signals

Analog commands

(Torque Control)

Analog input signals

Power &

EMG signal

Pulse commands

(Position Control)

Additional 16 Digital

output signals

Additional 16 Digital

Laser control signals

Figure 2-3: Exterior of DIN-825-GP4

I/O connector

(to PCI board)

input signals

Getting Start with The Installation 25

Page 40

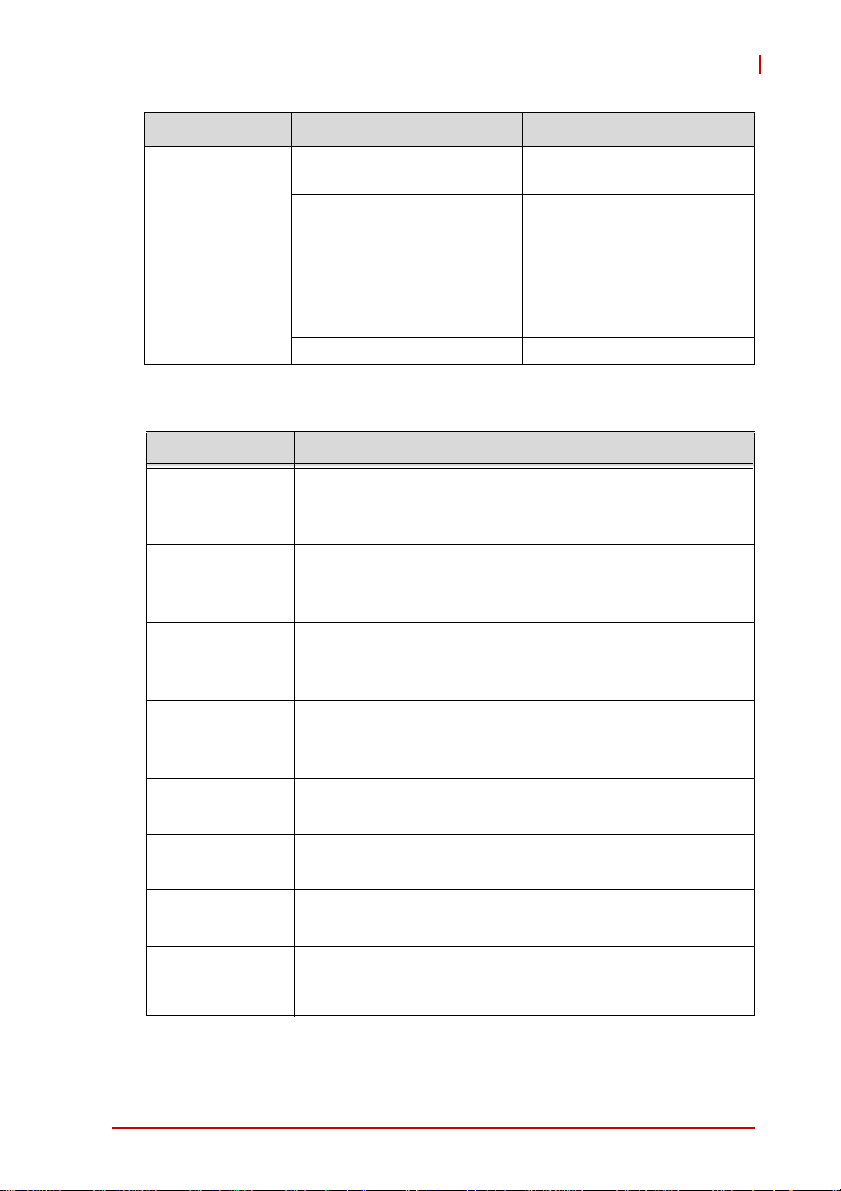

2.8.1 Definitions to Connector

1. P1: This is one SCSI

100-PINS connector for

motion control signals.

2. CMA1–4: These are four

26-PINS connector for

connecting to servo

drive to do S/T mode

control and analog

CMA1

J4

CMA2

CMA3

CMA4

P1

control commands

output.

3. CMP1–4: These are four

26-PINS connectors for

connecting to servo

drive to do P mode

control or stepper drive

CMP1

CMP2

J3

CMP3

CMP4

S1

S2

J6

to output pulse control

commands. It may be

CN1

connected to Mitsubishi

J3A series, Yaskawa

Sigma II, III & V series,

IOIF2

IOIF3

and Panasonic MINAS

A4&A5 with exclusive

cables.

4. J1–J3: These are three

IOIF1

IOIF4

sets of 10-pins screw

lock connectors

(screwed series, Delta

P2

A2 series, or connection

to other servo or stepper

drivers with single end

open cables). It may be

connected to any analog

Figure 2-4: Exterior of DIN-825-GP4

input signal, comparing

trigger signal, plus/minus limit switch and homing signal.

5. J4: This is one 8-PINS connector for connecting to Brake

Signal.

6. J5: This is one 5-PINS connector for connecting to

tenminal board main power and emergency stop signals.

J2 J1

J5

26 Getting Start with The Installation

Page 41

AMP-204C / AMP-208C

7. J6: This is one 5-PINS connector for connecting to four

isolation digital output channel.

8. P2: This is one DSUB 37-PINS connector for connecting

to 16 channel digital input signal and 16 channel digital

output signal in the controller (TTL).

9. IOIF1-IOIF4: These are four 9-PINS connectors for

connecting to 16 channel digital input signal and 16

channel digital output signal for common uses.

10.CN1: This is one 9-pin connector for laser control.

Getting Start with The Installation 27

Page 42

2.8.2 P1 Connector: For Connecting to PCI-8254 / PCI-8258 / AMP-204C / AMP-208C

•P1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Digital ground 51 IEMG | Emergency stop input

2 DGND -- Digital ground 52 Rsv. -- Reserved

3 Rsv. -- Reserved 53 Rsv. -- Reserved

4 Rsv. -- Reserved 54 Rsv. -- Reserved

5 Rsv. -- Reserved 55 Rsv. -- Reserved

6 Rsv. -- Reserved 56 Rsv. -- Reserved

7 Rsv. -- Reserved 57 Rsv. -- Reserved

8 Rsv. -- Reserved 58 Rsv. -- Reserved

9 Rsv. -- Reserved 59 Rsv. -- Reserved

10 Rsv. -- Reserved 60 Rsv. -- Reserved

11 EA5V -- 5V power 61 DGND -- Digital ground

12 EA5V -- 5V power 62 DGND -- Digital ground

13 OUT1+ c Pulse output (+), (1) 63 OUT3+ c Pulse output (+), (3)

14 OUT1- c Pulse output (-), (1) 64 OUT3- c Pulse output (-), (3)

15 DIR1+ c Direction output (+), (1) 65 DIR3+ c Direction output (+), (3)

16 DIR1- c Direction output (-), (1) 66 DIR3- c Direction output (-), (3)

17 OUT2+ c Pulse output (+), (2) 67 OUT4+ c Pulse output (+), (4)

18 OUT2- c Pulse output (-), (2) 68 OUT4- c Pulse output (-), (4)

19 DIR2+ c Direction output (+), (2)

20 DIR2- c Direction output (-), (2) 70 DIR4- c Direction output (-), (4)

21 TG1+ c Trigger output (+), (1) 71 TRG2+ c Trigger output (+), (2)

22 TRG1- c Trigger output (-), (1) 72 TRG2- c Trigger output (-), (2)

23 EA1+ | Encoder A-phase (+),(1) 73 EA3+ | Encoder A-phase (+),(3)

24 EA1- | Encoder A-phase (-),(1) 74 EA3- | Encoder A-phase (-),(3)

25 EB1+ | Encoder B-phase (+),(1) 75 EB3+ | Encoder B-phase (+),(3)

26 EB1- | Encoder B-phase (-),(1) 76 EB3- | Encoder B-phase (-),(3)

69 DIR4+ c Direction output (+), (4)

28 Getting Start with The Installation

Page 43

AMP-204C / AMP-208C

No. Name I/O Function of Axis No. Name I/O Function of Axis

27 EZ1+ | Encoder Z-phase (+),(1) 77 EZ3+ | Encoder Z-phase (+),(3)

28 EZ1- | Encoder Z-phase (-),(1) 78 EZ3- | Encoder Z-phase (-),(3)

29 EA2+ | Encoder A-phase (+),(2) 79 EA4+ | Encoder A-phase (+),(4)

30 EA2- | Encoder A-phase (-),(2) 80 EA4- | Encoder A-phase (-),(4)

31 EB2+ | Encoder B-phase (+),(2) 81 EB4+ | Encoder B-phase (+),(4)

32 EB2- | Encoder B-phase (-),(2) 82 EB4- | Encoder B-phase (-),(4)

33 EZ2+ | Encoder Z-phase (+),(2) 83 EZ4+ | Encoder Z-phase (+),(4)

34 EZ2- | Encoder Z-phase (-),(2) 84 EZ4- | Encoder Z-phase (-),(4)

35 ALM1 | Servo alarm,(1) 85 ALM3 | Servo alarm,(3)

36 ORG1 | Home limit, (1) 86 ORG3 | Home limit, (3)

37 SVON1 c Servo-ON, (1) 87 SVON3 c Servo-ON, (3)

38 PEL1 | Positive limit, (1) 88 PEL3 | Positive limit, (3)

39 INP1 | In-Position (1) 89 INP3 | In-Position (3)

40 MEL1 | Negative limit, (1) 90 MEL3 | Negative limit, (3)

41 ALM2 | Servo alarm,(2) 91 ALM4 | Servo alarm,(4)

42 ORG2 | Home limit, (2) 92 ORG4 | Home limit, (4)

43 SVON2 c Servo-ON, (2) 93 SVON4 c Servo-ON, (4)

44 PEL2 | Positive limit, (2) 94 PEL4 | Positive limit, (4)

45 INP2 | In-Position (2) 95 INP4 | In-Position (4)

46 MEL2 | Negative limit, (2) 96 MEL4 | Negative limit, (4)

47 EDO1 c Digital Output, (1) 97 EDO3 c Digital Output, (3)

48 EDI1 | Digital Input, (1) 98 EDI3 | Digital Input, (3)

EDO2 c Digital Output, (2) 99 EDO4 c Digital Output, (4)

49

50 EDI2 | Digital Input, (2) 100 EDI4 | Digital Input, (4)

•P2:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 Rsv. - - Reserved 20 VDD c +5V power supply output

2 TDI1 | TTL input, (1) 21 TDO1 c TTL output, (1)

Getting Start with The Installation 29

Page 44

No. Name I/O Function of Axis No. Name I/O Function of Axis

3 TDI2 | TTL input, (2) 22 TDO2 c TTL output, (2)

4 TDI3 | TTL input, (3) 23 TDO3 c TTL output, (3)

5 TDI4 | TTL input, (4) 24 TDO4 c TTL output, (4)

6 TDI5 | TTL input, (5) 25 TDO5 c TTL output, (5)

7 TDI6 | TTL input, (6) 26 TDO6 c TTL output, (6)

8 TDI7 | TTL input, (7) 27 TDO7 c TTL output, (7)

9 TDI8 | TTL input, (8) 28 TDO8 c TTL output, (8)

10 TDI9 | TTL input, (9) 29 TDO9 c TTL output, (9)

11 TDI10 | TTL input, (10) 30 TDO10 c TTL output, (10)

12 TDI11 | TTL input, (11) 31 TDO11 c TTL output, (11)

13 TDI12 | TTL input, (12) 32 TDO12 c TTL output, (12)

14 TDI13 | TTL input, (13) 33 TDO13 c TTL output, (13)

15 TDI14 | TTL input, (14) 34 TDO14 c TTL output, (14)

16 TDI15 | TTL input, (15) 35 TDO15 c TTL output, (15)

17 TDI16 | TTL input, (16) 36 TDO16 c TTL output, (16)

18 EGND - External power ground 37 EGND - External power ground

19 VDD | +5V power supply input -- -- -- --

•J1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DICOM -- Digital input common 6 EDI4 | Isolated digital input, (4)

2 EDI3 | Isolated digital input, (3) 7 PEL4 | Positive limit, (4)

3 PEL3 | Positive limit, (3) 8 ORG4 | Origin Signal, (4)

4 ORG3 | Origin Signal, (3) 9 MEL4 | Negative limit, (4)

5 MEL3 | Negative limit, (3) 10 DOCOM -- Digital output common

30 Getting Start with The Installation

Page 45

AMP-204C / AMP-208C

•J2:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DICOM -- Digital input common 6 EDI2 | Isolated digital input, (2)

2 EDI1 | Isolated digital input, (1) 7 PEL2 | Positive limit, (2)

3 PEL1 | Positive limit, (1) 8 ORG2 | Origin Signal, (2)

4 ORG1 | Origin Signal, (1) 9 MEL2 | Negative limit, (2)

5 MEL1 | Negative limit, (1) 10 DOCOM -- Digital output common

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

•J3:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Isolated digital ground 6 AGND -- Analog ground

2 TRG2- c Trigger output (-), (2) 7 AI4 | Analog input, (4)

3 TRG2+ c Trigger output (+), (2) 8 AI3 | Analog input, (3)

4 TRG1- c Trigger output (-), (1) 9 AI2 | Analog input, (2)

5 TG1+ c Trigger output (+), (1) 10 AI1 | Analog input, (1)

• J4: Brake Connector

No. Name I/O Function of Axis No. Name I/O Function of Axis

BRAKE 1+

1

BRAKE 1-

2

BRAKE 2+

3

BRAKE 2-

4

Getting Start with The Installation 31

-- Brake signal (+), (1) 6

| Brake signal (-), (1) 7

| Brake signal (+), (2) 8

| Brake signal (-), (2) 9

BRAKE 3+

BRAKE 3-

BRAKE 4+

BRAKE 4-

| Brake signal (+), (3)

| Brake signal (-), (3)

| Brake signal (+), (4)

| Brake signal (-), (4)

Page 46

•J5

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 I24V -- Ext. power supply, +24V 4 DOCOM -- Digital output common

2 IGND -- Ext. power ground 5

3 DICOM -- Digital input common 6 -- -- --

EEMG

| Ext. Emergency signal

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

•J6

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 EDO1 c Digital output, (1) 4 EDO4 c Digital output, (4)

2 EDO2 c Digital output, (2) 5 DOCOM c Digital output common

3 EDO3 c Digital output, (3) 6 -- c --

•IOIF1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DI1 I

2 DI2 I

3 DI3 I

4 DI4 I

5 DI5 I

Additional isolated digital

input, (1)

Additional isolated digital

input, (2)

Additional isolated digital

input, (3)

Additional isolated digital

input, (4)

Additional isolated digital

input, (5)

6 DI6 I

7 DI7 I

8 DI8 I

9 DICOM -- Digital input common

-- -- -- --

32 Getting Start with The Installation

Additional isolated digital

input, (6)

Additional isolated digital

input, (7)

Additional isolated digital

input, (8)

Page 47

AMP-204C / AMP-208C

•IOIF2:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DI9 I

2 DI10 I

3 DI11 I

4 DI12 I

5 DI13 I

Additional isolated digital

input, (9)

Additional isolated digital

input, (10)

Additional isolated digital

input, (11)

Additional isolated digital

input, (12)

Additional isolated digital

input, (13)

6 DI14 I

7 DI15 I

8 DI16 I

9 DICOM -- Digital input common

-- -- -- --

Additional isolated digital

input, (14)

Additional isolated digital

input, (15)

Additional isolated digital

input, (16)

•IOIF3:

No. Name I/O Function of Axis No. Name I/O Function of Axis

※DO1

1

※DO2

2

3 ※DO3 O

※DO4

4

5 ※DO5 O

Additional isolated digital

O

output, (1)

Additional isolated digital

O

output, (2)

Additional isolated digital

output, (3)

Additional isolated digital

O

output, (4)

Additional isolated digital

output, (5)

6 DO6 O

7 DO7 O

8 DO8 O

9 DOCOM -- Digital output common

-- -- -- --

Additional isolated digital

output, (6)

Additional isolated digital

output, (7)

Additional isolated digital

output, (8)

※The digital output current may reach 250mA

NOTE

NOTE

Getting Start with The Installation 33

Page 48

•IOIF4:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DO9 O

2 DO10 O

3 DO11 O

4 DO12 O

5 DO13 O

Additional isolated digital

output, (9)

Additional isolated digital

output, (10)

Additional isolated digital

output, (11)

Additional isolated digital

output, (12)

Additional isolated digital

output, (13)

6 DO14 O

7 DO15 O

8 DO16 O

9 DOCOM --

-- -- --

Additional isolated digital

output, (14)

Additional isolated digital

output, (15)

Additional isolated digital

output, (16)

Digital output common

--

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

• CN1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 EDO4+ O

2 TG1+ O

3 TRG2+ O

4 Rsv. --

5 Rsv. --

Digital output (+), (4)

Trigger output (+), (1)

Trigger output (+), (2)

Reserved

Reserved

6 EDO4- O

7 TRG1- O

8 TRG2- O

9 DGND --

Digital output (-), (4)

Trigger output (-), (1)

Trigger output (-), (2)

Digital ground

34 Getting Start with The Installation

Page 49

AMP-204C / AMP-208C

• CMA1-CMA4 (compatible with PCI-8254/8258

only):

outputsignal

Resetdriversignal/Digital

O

DO

ALM_RST/

10

11 ALM I Servoalarmsignal

12 I24VͲͲExt.powersupply,+24V

13 IGNDͲͲ Ext.powerground

14 BRAKEͲ OBrakesignal(Ͳ)

15 AGNDͲͲ Analogground

16 EBͲ I EncoderBͲphase(Ͳ)

1 SVON O ServoOnsignal19 EMG I Emergencysignal

2 ZSP I Zerospeedsignal20 IGND ͲͲ Ext.powerground

3 Rsv. ͲͲ Reserved21 IGND ͲͲ Ext.powerground

4 Rsv. ͲͲ Reser ved.22 IGND ͲͲ Ext.powerground

5 AOUTͲ O Analogcommandoutput(Ͳ)23 Rsv. ͲͲ Reserved

6 AOUT+ O Analogcommandoutput(+)24 Rsv. ͲͲ Reserved

No. Name I/O Function No. Name I/O Function No. Name I/O Function

7 EAͲ I EncoderAͲphase(Ͳ)25 EZͲ I EncoderZͲphase(Ͳ)

17 EB+ I EncoderBͲphase(+)

18 AGNDͲͲ Analogground

8 EA+ I EncoderAͲphase(+)26 EZ+ I EncoderZͲphase(+)

9 BRAKE+ O Brakesignal(+)

ALM_RST / DO: You may set this signal to general purpose

digital output signal (EDO) or alarm clearance function

NOTE

NOTE

(ALM_RST) by switch S1 or S2.

Getting Start with The Installation 35

Page 50

•CMP1~CMP4:

outputsignal

Resetdriversignal/Digital

O

DO

ALM_RST/

10

11 ALM I Servoalarmsignal

12 I24VͲͲExt.powersupply,+24V

13 IGNDͲͲ Ext.powerground

14 BRAKEͲ OBrakesignal(Ͳ)

15 IGNDͲͲ Ext.powerground

1 SVON O ServoOnsignal19 EMG I Emergencysignal

2 INP I InͲpositionsignal20 IGND ͲͲ Ext.powerground

3 ERC O Dev.ctr,clr.signal21 IGND ͲͲ Ext.powerground

4 RDY I Servoreadysignal22 IGND ͲͲ Ext.powerground

No. Name I/O Function No. Name I/O Function No. Name I/O Function

5 OUTͲ O Pulsesignal(Ͳ)23 DIRͲ O Dir.Signal(Ͳ)

16 EBͲ I EncoderBͲphase(Ͳ)

17 EB+ I EncoderBͲphase(+)

18 IGNDͲͲ Ext.powerground

6 OUT+ O Pulsesignal(+)24 DIR+ O Dir.Signal(+)

7 EAͲ I EncoderAͲphase(Ͳ)25 EZͲ I EncoderZͲphase(Ͳ)

8 EA+ I EncoderAͲphase(+)26 EZ+ I EncoderZͲphase(+)

9 BRAKE+ O Brakesignal(+)

ALM_RST / DO: You may set this signal to general purpose

digital output signal (EDO) or alarm clearance function

NOTE

NOTE

(ALM_RST) by switch S1 or S2.

36 Getting Start with The Installation

Page 51

AMP-204C / AMP-208C

2.8.3 S1, S2: EDO/ALM_RST Selection Switch

Reset servo drive

Reset servo drive

Reset servo drive

Reset servo drive

DIN-825-GP4 is equipped with 4 servo drive reset signals. You

may set up CMA1~CMA4 PIN 10 and CMP1~CMP4 PIN 10 for

servo drive rest or J6 connector DO.1~DO.4 by switch S1 and S2.

Getting Start with The Installation 37

Page 52

38 Getting Start with The Installation

Page 53

AMP-204C/AMP-208C

3 Signal Connection

AMP-204C / AMP-208C must connect to servo or stepper motor

drive with exclusive terminal board DIN-825-GP4. All optical

isolation circuit of mechanical relevant I/O and servo relevant I/O

are set to DIN-825-GP4 to prevent damages to primary controller

AMP-204C / AMP-208C from any invalid signal connection to it.

This may effectively reduce difficulites and times required in

replacing controller relevant products when doing customer

service maintenance tasks. See sections below for detailed

descriptions on precautions required to connect to various

mechanical I/O and servo I/O signals. Contents:

Section 3.1: Pulse Command Signal

Section 3.2: Encoder Input Signal

Section 3.3: Emergency Stop Signal

Section 3.4: Mechanical Limit Switch Signal

Section 3.5: Original Position Switch Signal

Section 3.6: In-position/Zero Speed Signal

Section 3.7: Servo Alarm Signal

Section 3.8: Servo On Signal

Section 3.9: Comparing Trigger Signal

Section 3.10: General Purpose Digital Input and Output Signal

Signal Connection 39

Page 54

3.1 Pulse Command

AMP-204C / AMP-208C can provide 4/8 pulse control command

channel with each of them supports up to 6.5MHz output

frequency.

In general, you may set the servo driver to P (position) mode for

open-loop control with AMP-204C / AMP-208C pulse control

commands.

In addition to servo drive, the Stepper drive also employs pulse

command interface as the primay control input commands. See

below for corresponding pins of pulse command output against

differential pulse signals to DIN-825-GP4:

CMPx Pin No

(x=1~4)

6OUT+ Pulse signal, (+) (n) 1~8

5OUT- Pulse signal, (-) (n) 1~8

24 DIR+ Dir. Signal, (+) (n) 1~8

23 DIR- Dir. Signal, (-) (n) 1~8

Signal Name

Description

(n=1~8)

AMP-208C requires two DIN-825-GP4 for eight axes motion

control functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

Axis #

40 Signal Connection

Page 55

AMP-204C/AMP-208C

Either servo motor drive or stepper motor drive employs one of the

two input interfaces described below:

1. Line Driver input interface provides better anti noise-resistant

and longer wiring length.

• Signal connection diagram:

Figure 3-1: Line Driver type pulse control command signal connection

example

2. Open-Collector input interface can increase passing

current capacity of signal by adjusting pull-up resistance

value at the shorter wiring length.

Signal Connection 41

Page 56

• Signal connection diagram:

Figure 3-2: Open-Collector type pu lse cont rol c ommand sign al conn ecti on

example

To avoid damages to Line Driver components on controller

casued by invalid wiring please connect the OUT-, DIR- pins of

CAUTION

controller to OUT, DIR pins of motor drive.

The controller employs Line Driver component -26LS31 with

maximum Sink Current at 20mA. Do not use it at current above

CAUTION

this value, the component may be damaged otherwise.

42 Signal Connection

Page 57

AMP-204C/AMP-208C

3.2 Encoder Input, EA & EB & EZ

AMP-204C / AMP-208C provides 4/8 encoder input channels

respectively which accept single end input frequency up to 5MHz

with each channel containing EA, EB, and EZ signal. Each group

of EA, EB, and EZ signal contains a pair of differential signal, e.g.

the EA signal contains EA+ and EA-. See Section 4.1.1.4 for how

to use the encoder. See below for corresponding pins of encoder

input on DIN-825-GP4:

CMAx / CMPx

Pin No

(x=1~4)

8EA+Encoder A-phase (+),(n) 1~8

7EA-Encoder A-phase (-),(n) 1~8

17 EB+ Encoder B-phase (+),(n) 1~8

16 EB- Encoder B-phase (-),(n) 1~8

26 EZ+ Encoder Z-phase (+),(n) 1~8

25 EZ- Encoder Z-phase (-),(n) 1~8

Signal Name

Description

(n=1~8)

AMP-208C requires two DIN-825-GP4 for eight axes motion

control Function

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

The controller employs Line Receiver component -26LS32 with

maximum Sink Current at 20mA@5V. Do not use it at current

CAUTION

above this value, the component may be damaged otherwise.

Axis #

Signal Connection 43

Page 58

• Signal connection diagram:

Figure 3-3: Line driver type encoder input signal connection example

44 Signal Connection

Page 59

AMP-204C/AMP-208C

3.3 Emergency Stop Input

AMP-204C/ AMP-208C provides one hardware input emergency stop

signal (EMG). If the external emergency stop signal is triggered, all

motion control commands will be stopped immediatly. In addition, the

DIN-825-GP4 is designed to transmit external emergency stop signal

to servo/stepper motor drive to stop operation of every motor

immediately. See below for corresponding pins of emergency stop

signal input on DIN-825-GP4:

J5 Pin No Signal Name Description Axis #

5 EEMG

External emergency stop input (external input)

-

CMPx / CMAx

Pin No (x=1~4)

19 EMG(n) Emergency stop (output to drive) 1~8

Signal Name

(n=1~8)

Description Axis #

AMP-208C requires two DIN-825-GP4 for eight axes motion

control functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

• Signal connection diagram:

Figure 3-4: Emergency stop signal connection example

Signal Connection 45

Page 60

3.4 PEL/MEL Input

AMP-204C / AMP-208C provides 4/8 End-limited switch input

channels. The Plus Limited Switch (PEL) is used as the

mechanical protection switch for movement in the positive

direction. When this switch is triggered the AMP-204C /

AMP-208C stops its positive direction movement immediately. The

Minus Limited Switch (MEL) is used as the mechanical protection

switch for movement in the negative direction. When this switch is

triggered, the AMP-204C / AMP-208C stops its negative direction

movement immediately. See below for corresponding pins of

mechanical limit switch signal input on DIN-825-GP4:

J1/J2 Pin No Signal Name Description Axis #

3 PEL(3) / PEL(1) Plus limit switch input (3) / (1) 3 / 1

7 PEL(4) / PEL(2) Plus limit switch input (4) / (2) 4 / 2

5 MEL(3) / MEL(1) Minus limit switch input (3) / (1) 3 / 1

9 MEL(4) / MEL(2) Minus limit switch input (4) / (2) 4 / 2

AMP-208C requires two DIN-825-GP4 for eight axes motion

control Function

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

46 Signal Connection

Page 61

• Signal connection diagram:

AMP-204C/AMP-208C

Figure 3-5: Mechanical limit switch signal connection example

Signal Connection 47

Page 62

3.5 ORG Input

AMP-204C / AMP-208C provides 4/8 original position switch input

channels. Working together with the home movement described in

Section 4.3, this function returns the body to its original position

(also known as the zero position). See below for corresponding

pins of original position switch signal input on DIN-825-GP4:

J1/J2 Pin No Signal Name Description Axis #

4 ORG(3) / ORG(1) Original position switch input (3) / (1) 3 / 1

8 ORG(4) / ORG(2) Original position switch input (4) / (2) 4 / 2

AMP-208C requires two DIN-825-GP4 for eight axes motion

control Function

NOTE

NOTE

• Signal connection diagram:

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

Figure 3-6: Original position switch signal connection example

48 Signal Connection

Page 63

AMP-204C/AMP-208C

3.6 INP Input

AMP-204C / AMP-208C provides 4/8 In-position (INP) input

channels. Working with function described in Section 4.8, it can be

used as the trigger source for in-position events of individual

motion. In general, when servo drive is set to position mode (P

mode), the servo issues a (INP) pulse signal to controller when

movement get into position. See below for corresponding pins of

in-position or zero speed detection signal input on DIN-825-GP4:

CMPx

Pin No (x=1~4)

2INP(n)

Signal Name

(n=1~4)

In-position Input (for pulse output mode only)

AMP-208C requires two DIN-825-GP4 for eight axes motion

control functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

• Signal connection diagram:

Description Axis #

1~4

Figure 3-7: In-position signal connection example

Signal Connection 49

Page 64

3.7 ALM Input

AMP-204C / AMP-208C provides 4/8 servo alarm input channels.

Working with function described in Section 4.11 it can be used as

the trigger source for motion interrupt event. In general, when

abnormality is encountered during servo drive movement, it issues

an (ALM) pulse signal to controller for abnormality occurrence.

See below for corresponding pins of servo alarm input on

DIN-825-GP4:

CMAx / CMPx

Pin No (x=1~4)

11 ALM(n) Servo alarm input 1~4

Signal Name

(n=1~4)

Description Axis #

AMP-208C requires two DIN-825-GP4 for eight axes motion

control functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

• Signal connection diagram:

Figure 3-8: Servo alarm signal connection example

50 Signal Connection

Page 65

AMP-204C/AMP-208C

3.8 SVON Output

AMP-204C / AMP-208C provides 4/8 servo-on output channels

and utilize the servo-on signal to enable servo drive for pulse or

analog commands input. If there is abnormality is encountered

during movement, the AMP-204C / AMP-208C turns off this signal

automatically and stops all motion control commands. See below

for corresponding pins of servo-on signal output on DIN-825-GP4:

CMAx / CMPx

Pin No (x=1~4)

1SVON(n) Servo-on output 1~4

Signal Name

(n=1~4)

Description Axis #

AMP-208C requires two DIN-825-GP4 for eight axes motion

control functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

• Signal connection diagram:

Figure 3-9: Servo-on signal connection example

Signal Connection 51

Page 66

3.9 Comapre & Trigger Output:

AMP-204C / AMP-208C provides 2/4 comparing trigger pulse

output channels. Each comparing trigger channel can output pulse

commands up to 1 MHZ. See Section 4.9.2 for its detail and how

to use it. See below for corresponding pins of pulse command

output against differential pulse signals to DIN-825-GP4:

J3 Pin No Signal Name Description

2 TRG2-/TRG4- Trigger output (-), (2)/(4)

3TRG2+ / TGR4+Trigger output (+), (2)/(4)

4 TRG1-/TRG3- Trigger output (-), (1)/(3)

5 TRG1+/TRG3+ Trigger output (+), (1)/(3)

The compare trigger pulse output channel of AMP-204C /

AMP-208C employs line driver output interface for better noise

NOTE

NOTE

• Signal connection diagram:

signal resistance and wiring length where trigger output (3) &

(4) require #2 DIN-825-GP4 for wiring.

1. Line Driver interface:

Figure 3-10: Line Driver type compare trigger signal connection example

52 Signal Connection

Page 67

AMP-204C/AMP-208C

2. Open-Collector interface:

Figure 3-11: Open-Collector type compare trigger signal connection

example

Signal Connection 53

Page 68

3.10 Digital Output/Input

AMP-204C / AMP-208C provides 20/24 digital output/input

channels. See below for corresponding pins of general purpose

digital input and output signals on DIN-825-GP4:

J1/J2 Pin No. Signal Name Description

2 EDI(3) / EDI (1) General purpose digital input signal (3), (1)

6 EDI(4) / EDI (2) General purpose digital input signal (4), (2)

J6 Pin No. Signal Name Description

1EDO(1)General purpose digital output signal (1)

2EDO(2)General purpose digital output signal (2)

3EDO(3)General purpose digital output signal (3)

4EDO(4)General purpose digital output signal (4)

AMP-208C requires two DIN-825-GP4 for eight axes motion

control Function

NOTE

NOTE

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5~ 8

1. Please connect DICOM to external power

supply (24VDC in general) if possible.

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

54 Signal Connection

Page 69

• Signal connection diagram:

AMP-204C/AMP-208C

Figure 3-12: General purpose digital I/O signal connection example

Signal Connection 55

Page 70

IOIF1 Pin No. Signal Name Description

1~8 DI(1)~(8) General purpose IOIF2 digital input signal (1)~(8)

IOIF2 Pin No. Signal Name Description

1~8 DI(9)~(16) General purpose digital input signal (9)~(16)

IOIF3 Pin No. Signal Name Description Axis #

※1~5

DO(1)~(5)

General purpose digital output signal

(1)~(5)

※The digital output current may reach 250mA

NOTE

NOTE

IOIF3 Pin No. Signal Name Description Axis #

6~8 DO(6)~(8)

General purpose digital output signal

(6)~(8)

-

-

IOIF4 Pin No. Signal Name Description Axis #

1~8 DO(9)~(16)

General purpose digital output signal

(9)~(16)

-

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

56 Signal Connection

Page 71

• Signal connection diagram:

AMP-204C/AMP-208C

Signal Connection 57

Page 72

Figure 3-13: General purpose digi tal I/O signal connection example

58 Signal Connection

Page 73

AMP-204C / AMP-208C

4 Motion Control Theory

This chapter introduces you the motion control function of

AMP-204C / AMP-208C as well as relevant precautions in using

them. Contents:

Section 4.1: Motion Control Mode and Interface Overview

Section 4.2: Motion Control Operations

Section 4.3: Home Move

Section 4.4: Velocity Move

Section 4.5: Jog Move

Section 4.6: Point-to-Point Move

Section 4.7: Interpolation

Section 4.8: Motion Status Monitoring

Section 4.9: Application Functions

Section 4.10: Safety Protection

Section 4.11: Host Interrupt

Motion Control Theory 59

Page 74

AMP-204C / AMP-208C

4.1 Motion Control Mode and Interface Overview

This section describes basic setups of AMP-204C and AMP-208C

before doing motion control and fundamental concepts of its core

operations.

4.1.1 Motion Control Interface

4.1.1.1 Control Mode and Output Interface

You may use the MotionCreatorPro2 application program to set

up these two output interface and save your desired setting in

non-volatile memory, the so-called ROM, of the controller for