Page 1

NuDAQ®

ACL-8111

16-bit High Resolution

Data Acquisition Card

User’s Guide

Recycled Paper

Page 2

Page 3

©Copyright 1995~2001 ADLINK Technology Inc;

All Rights Reserved.

Manual Rev. 2.60: April 28, 2003

Part No: 50-11010-102

The information in this document is subject to change without prior notice in

order to improve reliability, design and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special,

incidental, or consequential damages arising out of the use or inability to use

the product or documentation, even if advised of the possibility of such

damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

NuDAQ is a registered trademark of ADLINK Technology Inc.,

Other product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective

companies.

Page 4

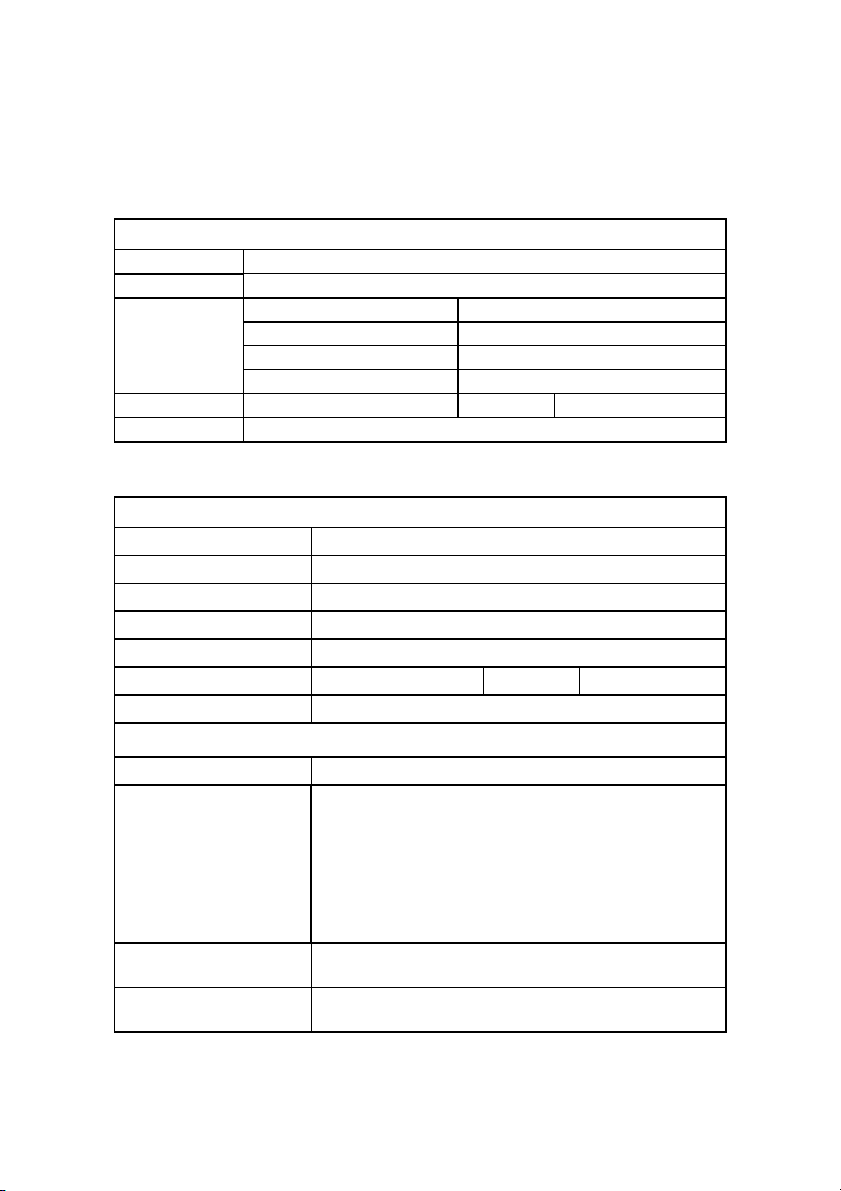

Getting service from ADLINK

Customer Satisfaction is the most important priority for ADLINK Tech Inc. If

you need any help or service, please contact us.

ADLINK Technology Inc.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

NuDAQ + USBDAQ + PXI nudaq@adlinktech.com

Technical

Support

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan.

Please email or FAX us of your detailed information for a prompt, satisfactory

and constant service.

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Product Model

Environment to Use

Automation automation@adlinktech.com

NuIPC nuipc@adlinktech.com

NuPRO / EBC nupro@adlinktech.com

Detailed Company Information

Questions

OS:

Computer Brand:

M/B: CPU:

Chipset: BIOS:

Video Card:

Network Interface Card:

Other:

Detail Description

Suggestions to ADLINK

Page 5

Table of Contents

Chapter 1 Introduction ..................................................... 1

1.1 Features ................................................................................. 2

1.2 Applications............................................................................ 3

1.3 Specifications ......................................................................... 4

1.4 Software Supporting ..............................................................7

1.4.1 ACLS-DLL2 .........................................................................7

1.4.2 ACLS-LVIEW.......................................................................7

Chapter 2 Installation ....................................................... 8

2.1 Unpacking ..............................................................................9

2.2 What You Have...................................................................... 9

2.3 PCB Layout.......................................................................... 10

2.4 Base Address Setting ..........................................................11

2.5 D/A Reference Voltage Setting ............................................ 13

2.6 Connectors Pin Assignments...............................................14

2.7 Daughter Board Connection ................................................16

2.7.1 Connect with ACLD-9137 ..................................................16

2.7.2 Connect with ACLD-9182 ..................................................16

2.7.3 Connect with ACLD-9185 ..................................................16

2.7.4 Connect with ACLD-9188 ..................................................17

Chapter 3 Registers Format .......................................... 18

3.1 Registers Address Map........................................................ 18

3.2 A/D Data Registers ..............................................................19

3.3 A/D Channel Multiplexer Register........................................ 20

3.4 A/D Input Range Control Register .......................................21

3.5 Mode and Interrupt Control Register ...................................22

3.6 Interrupt Status Register ......................................................23

3.7 Software Trigger Register ....................................................23

3.8 Digital I/O register ................................................................24

3.9 D/A Output Register.............................................................24

Table of Contents • i

Page 6

Chapter 4 Operation Theorem ....................................... 26

4.1 A/D Conversion.................................................................... 26

4.1.1 A/D Conversion Procedure................................................27

4.1.2 A/D Clock Sources (Trigger Modes)..................................27

4.1.3 A/D Data Transfer Modes..................................................29

4.2 D/A Conversion.................................................................... 30

4.3 Digital Input and Output .......................................................32

Chapter 5 C/C++ Library for DOS.................................. 33

5.1 DOS Software Library Installation........................................ 34

5.1.1 Installation .........................................................................34

5.1.2 Running Utility ...................................................................34

5.1.3 Example Programs............................................................34

5.2 _8111_Initial......................................................................... 35

5.3 _8111_Switch_Card_No ...................................................... 36

5.4 _8111_DI..............................................................................37

5.5 _8111_DI _Channel .............................................................38

5.6 _8111_DO............................................................................ 39

5.7 _8111_DA ............................................................................40

5.8 _8111_AD_Set_Channel .....................................................41

5.9 _8111_AD_Set_Gain ........................................................... 42

5.10 _8111_AD_Set_Mode..........................................................43

5.11 _8111_AD_Soft_Trig ...........................................................44

5.12 _8111_AD_Aquire................................................................45

5.13 _8111_CLR_IRQ .................................................................46

5.14 _8111_AD_INT_Start...........................................................47

5.15 _8111_AD_INT_Status ........................................................ 48

5.16 _8111_AD_INT_Stop...........................................................48

5.17 _8111_AD_Timer.................................................................49

Chappter 6 Calibration ................................................... 50

6.1 What do you need................................................................50

6.2 VR Assignments...................................................................51

6.3 D/A Calibration..................................................................... 51

6.4 A/D Calibration..................................................................... 52

Appendix A. Demo. Programs....................................... 53

Warranty Policy .................... Error! Bookmark not defined.

ii • Table of Contents

Page 7

1

Introduction

The ACL-8111 is a multi-function, high performance, and general-purpose

data acquisition card for the IBM Personal Computer and compatible

computers. The registers map is fully compatible with PCL-711B.

The ACL-8111 is designed to combine all the data acquisition functions, such

A/D, D/A, D/O, and D/I in a single board, The high-end specifications of the

card makes it ideal for wide range of applications in industrial and laboratory

automation.

Introduction • 1

Page 8

1.1 Features

The ACL-8111 Enhanced Multi-function Data Acquisition Card provides the

following advanced features:

• 8 single-ended 12-bit analog input channels

• On-chip sample & hold

• Variable input range: ± 5V, ±2.5V, ±1.25V, ±0.625V, and ±0.3125V

• One 12-bit monolithic multiplying analog output channel

• 16 digital output channels

• 16 digital input channels

• Three A/D trigger modes: Software trigger, Programmable pacer and

external trigger

• Programmable IRQ level for A/D data transfer

• Rugged 37-pin D-sub connector

• Compact size PCB

2 • Introduction

Page 9

1.2 Applications

• Industrial and laboratory ON/OFF control

• Energy management

• Annunciation

• 16 TTL/DTL compatible digital input channels

• Security controller

• Product test

• Period and pulse width measurement

• Event and frequency counting

• Waveform and pulse generation

Introduction • 3

Page 10

1.3 Specifications

Analog Input (A/D)

♦

Converter:

•

type

Resolution:

•

Number of channels:

•

Programmable Gain:

•

ADS-774 or equivalent one, successive approximation

12-bit

8 single-ended

1, 2, 4, 8, 16 (programmable)

Input Range:

•

Bipolar: ±5V, ± 2.5V, ±1.25V, ±0.625V, and ±0.3125V

Conversion Time:

•

Maximum Sampling Rate: ≤ 50

•

Over-voltage protection:

•

Accuracy:

•

Input Impedance:

•

AD Clock Sources (trigger modes):

•

pacer, and external pulse trigger

Data Transfer Modes:

•

Analog Output (D/A)

♦

Converter:

•

Number of channel:

•

Resolution:

•

Output Range:

•

Internal reference: (unipolar) 0~5V or 0~10V

External reference: (unipolar) max. +10V or -10V

Settling Time:

•

(programmable)

8 µ sec

0.015% of reading ± 1 Bit LSB

10 MΩ

DAC7548 or equivalent, monolithic multiplying

1 double-buffered analog outputs

12-bit

30 µ sec

KHz

Continuous ± 35V maximum

Software trigger, internal timer

Polling and Interrupt

Linearity:

•

Output driving capability:

•

4 • Introduction

±1/2 bit LSB

5mA max.

±

Page 11

Digital I/O (DIO)

♦

Number of channel:

•

Input Voltage:

•

• Low: Min. 0V; Max. 0.8V

• High: Min. +2.0V

Input Load:

•

• Low: +0.5V @ -0.2mA max.

• High: +2.7V @+20 uA max.

Output Voltage:

•

• Low: Min. 0V; Max. 0.4V

• High: Min. +2.4V

Output Driving Capacity:

•

• Low: Max. +0.5V at 8.0mA (Sink)

• High: Min. 2.7V at 0.4mA(Source)

Programmable Counter

♦

Device:

•

A/D pacer Source:

•

together) with a 2MHz time base

82C54

16 DI & 16 DO (TTL compatible)

32-bit timer (two 16-bit counter cascaded

Pacer Output:

•

General Specifications

♦

I/O Base Address

•

Interrupt IRQ

•

Connector

•

Operating Temperature

•

Storage Temperature

•

Humidity

•

Power Consumption

•

: 37-pin D-type connector

: 5 ~ 95%, non-condensing

0.00046 Hz ~ 100K Hz

: 16 consecutive address location

: IRQ 2,3,4,5,6,7 (programmable)

: 0°C ~ 55°C

: -20°C ~ 80°C

:

Introduction • 5

Page 12

• +5 V @ 440 mA typical

• +12V @ 60 mA typical

Dimension:

•

158mm X 108mm

6 • Introduction

Page 13

1.4 Software Supporting

The ACL-8111 is programmed using simple 8-bit I/O port commands. Users

can use high level language, such as BASIC, C, or PASCAL, or low- level

language, such as assembly to program the board. For the programming

under Windows or LabView, please contact your dealer to purchase ACLSDLL2 or ACLD-LVIEW.

1.4.1 ACLS-DLL2

For easily program the board under Windows environment, we also provide

ACLS-DLL2

DLL2, you can use compilers such as VB, VC/C++, or Delphi. ACLS-DLL2 is

included in ADLINK CD. It need license.

1.4.2 ACLS-LVIEW

For easily link the ACL-8111 with LabView of National Instrument, the ACLSLVIEW includes the Vis of the ACL-8111 under for Windows 3.1/95/98 and

NT. ACLS-LVIEW is included in ADLINK CD. It need license.

, which include the DLL for Windows 95/98/NT. With ACLS-

Introduction • 7

Page 14

2

Installation

This chapter describes how to install the ACL-8111. The following list shows

the installation procedures:

1. Unpacking and check what you have.

2. Check the PCB and the location of jumper and switch.

3. Setup the jumpers according to the system and applications setting.

4. Installation the external termination boards.

5. Wiring with signals according to the connector pin assignments.

8 • Installation

Page 15

2.1 Unpacking

The ACL-8111 card contains sensitive electronic components that can be

easily damaged by static electricity.

The card should be done on a grounded anti-static mat. The operator should

be wearing an anti-static wristband, grounded at the same point as the antistatic mat.

Inspect the card module carton for obvious damage. Shipping and handling

may cause damage to your module. Be sure there are no shipping and

handing damages on the module before processing.

After opening the card module carton, extract the system module and place it

only on a grounded anti-static surface component side up.

Again inspect the module for damage. Press down on all the socketed IC's to

make sure that they are properly seated. Do this only with the module place

on a firm flat surface.

Note:

DO NOT APPLY POWER TO THE CARD IF IT HAS BEEN

DAMAGED.

You are now ready to install your ACL-8111.

2.2 What You Have

In addition to this User's Manual, the package includes the following items:

• ACL-8111 multi-function data acquisition card

• ADLINK Software CD

If any of these items is missing or damaged, contact the dealer from whom

you purchased the product. Save the shipping materials and carton in case

you want to ship or store the product in the future.

Installation • 9

Page 16

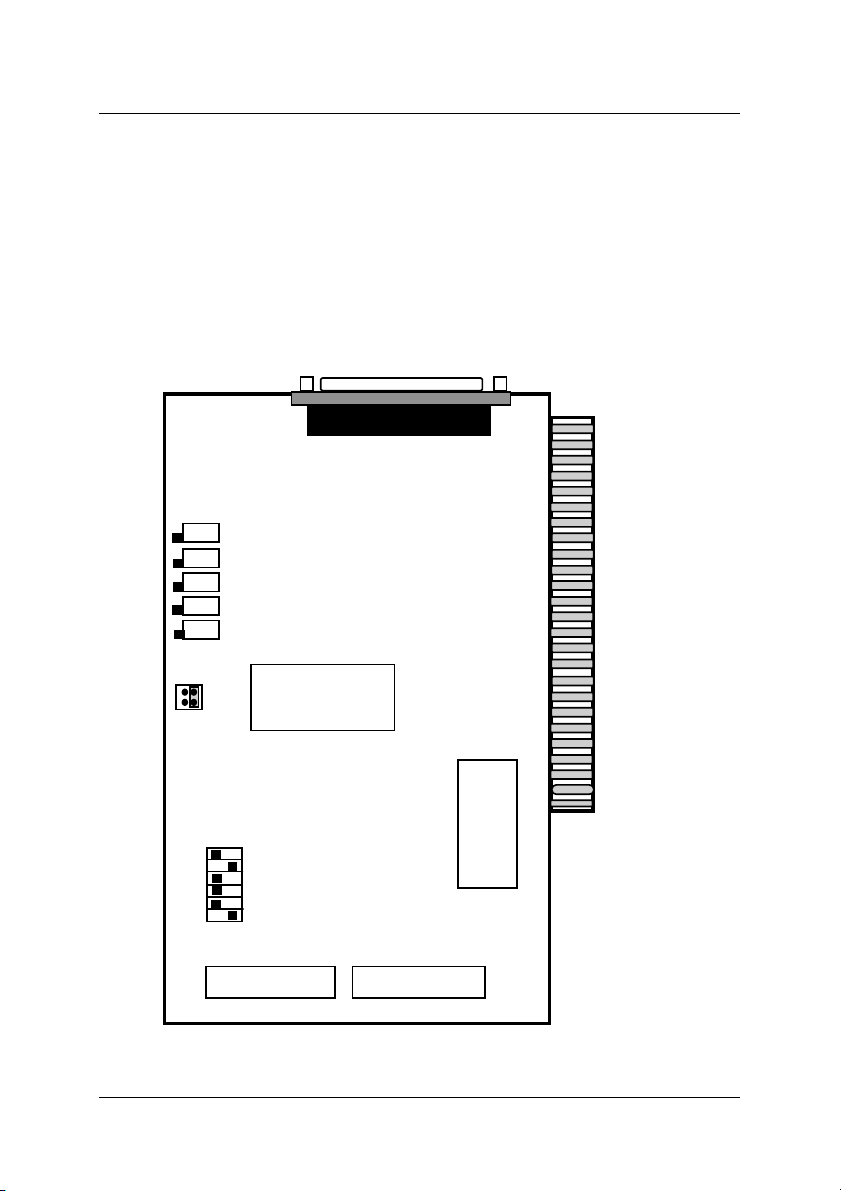

2.3 PCB Layout

In ACL-8111, there are three connectors (CN1~CN3), one switch (SW1), one

jumper (JP1) and 5 variable resistors (VR1~VR5). Please refer Figure 2.3 to

identify the location these components.

The card's jumpers and switches are preset at the factory. Please setup the

switch and jumper according to the system setting and the application

requirements.

A jumper is closed (sometimes referred to as "shorted") with the plastic cap

inserted over two pins of the jumper. A jumper is open with the plastic cap

inserted over one or no pin(s) of the jumper.

CN1

VR5

VR3 VR4

VR1 VR2

JP2

JP1

-5V

-10V

SW1

. .

8111

10 • Installation

ADS574

CN3

. .

. .

. .

. .

. .

. .

. .

. .

CN2

. .

. .

. .

. .

. .

. .

Figure 2.3 ACL-8111‘s PCB layout

8253

. .

Page 17

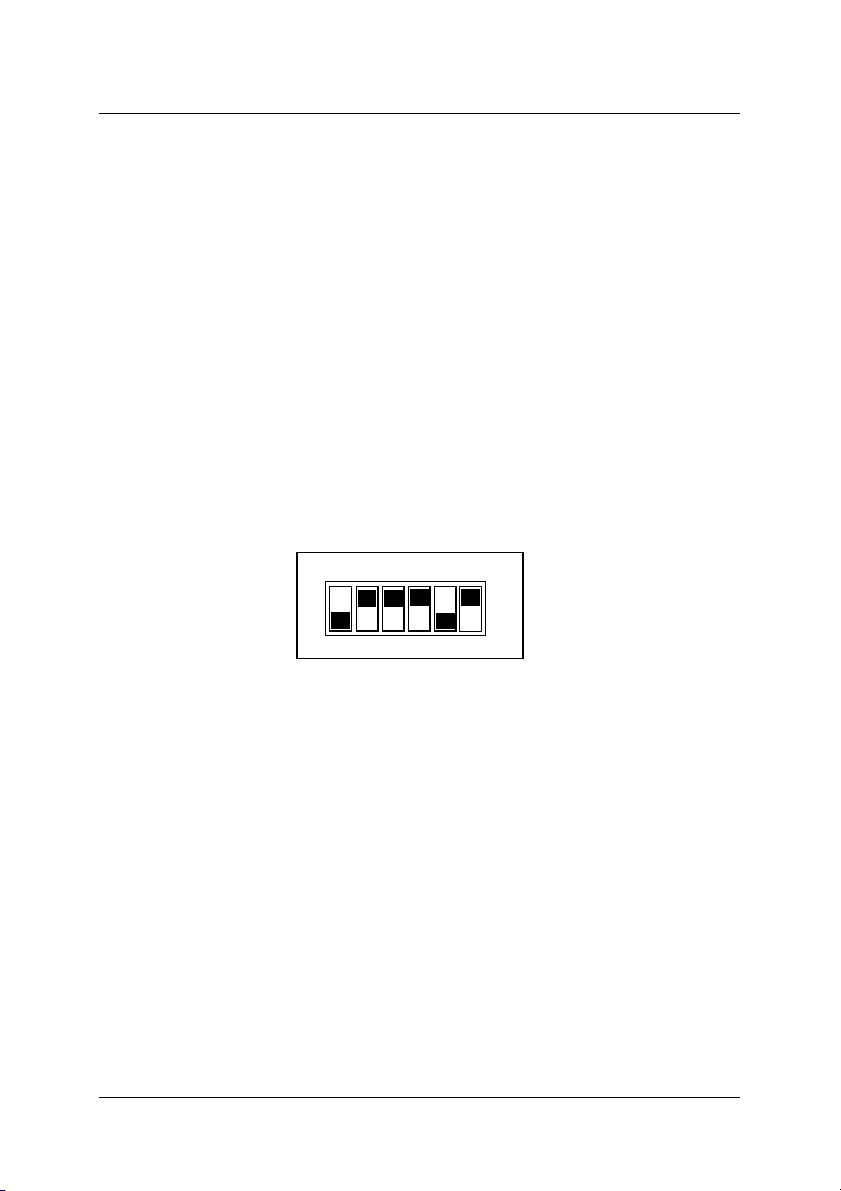

2.4 Base Address Setting

A

The ACL-8111 requires 16 consecutive address locations in I/O address

space. The base address of the ACL-8111 is restricted by the following

conditions.

1.

The base address must be within the range Hex 200 to Hex 3FF.

2.

The base address should not conflict with any PC reserved I/O address.

See Appendix A.

3.

The base address must not conflict with any add-on card on your own

PC. Please check your PC before installing the ACL-8111.

The ACL-8111's base address is selected by a 6 position DIP switch

SW1.The default setting of base address is set to be HEX 220. All possible

base address combinations are listed as Table 2.2. You may modify the

base address if the address HEX 220 has been occupied by another add-on

card.

SW1 : Base Address = Hex 220

ON

23456

1

( 9 8 7 6 5 4 )

DIP

Figure 2.4 Default Base Address Setting

Installation • 11

Page 18

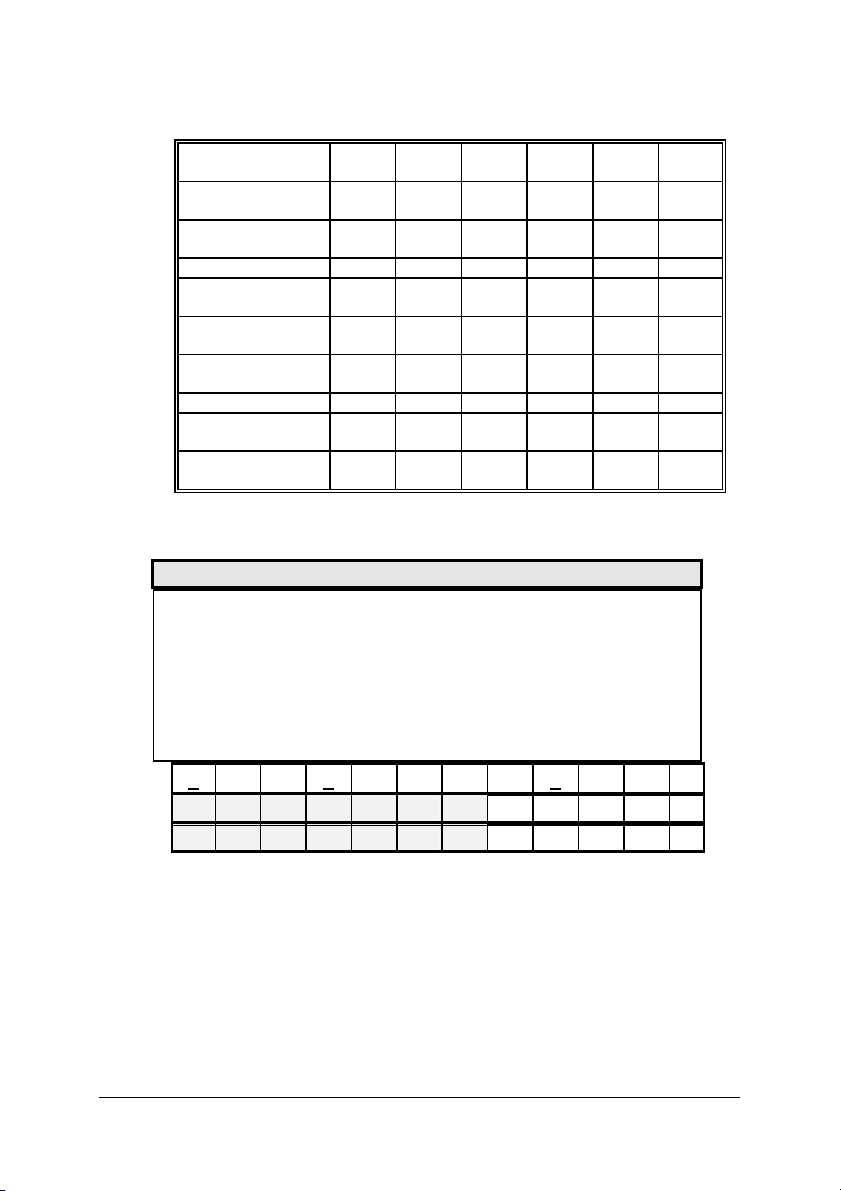

I/O port

address(Hex)

000-00F

100-10F

:

200-20F

210-21F

220-22F

(default)

:

300-30F

3F0-3FF

1

A9

ON

(0)

ON

(0)

OFF

(1)

OFF

(1)

OFF

(1)

OFF

(1)

OFF

(1)

2

A8 3 A7

ON

(0)

OFF

(1)

ON

(0)

ON

(0)

ON

(0)

OFF

(1)

OFF

(1)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

OFF

(1)

4

A6

ON

(0)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

OFF

(1)

ON: 0 OFF: 1.

A4 ... A9 are correspond to PC address lines.

How to Define a Base Address for the ACL-8111?

The DIP1 to DIP6 in the switch SW1are one to one corresponding

to the PC bus address line A9 to A4. A0, A1, A2, and A3 are

always 0. If you want to change the base address, you can only

change the values of A9 to A4 (shadow area of below table). The

following table is an example, which shows you how to define the

base address as

Hex 220

.

Base Address:

Hex 220

2 2 0

1 0 0 0 1 0 0 0 0 0

A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

5

A5

ON

(0)

ON

(0)

ON

(0)

ON

(0)

OFF

(1)

ON

(0)

OFF

(01

6

A4

ON

(0)

ON

(0)

ON

(0)

OFF

(0)

ON

(0)

ON

(0)

OFF

(1)

12 • Installation

Page 19

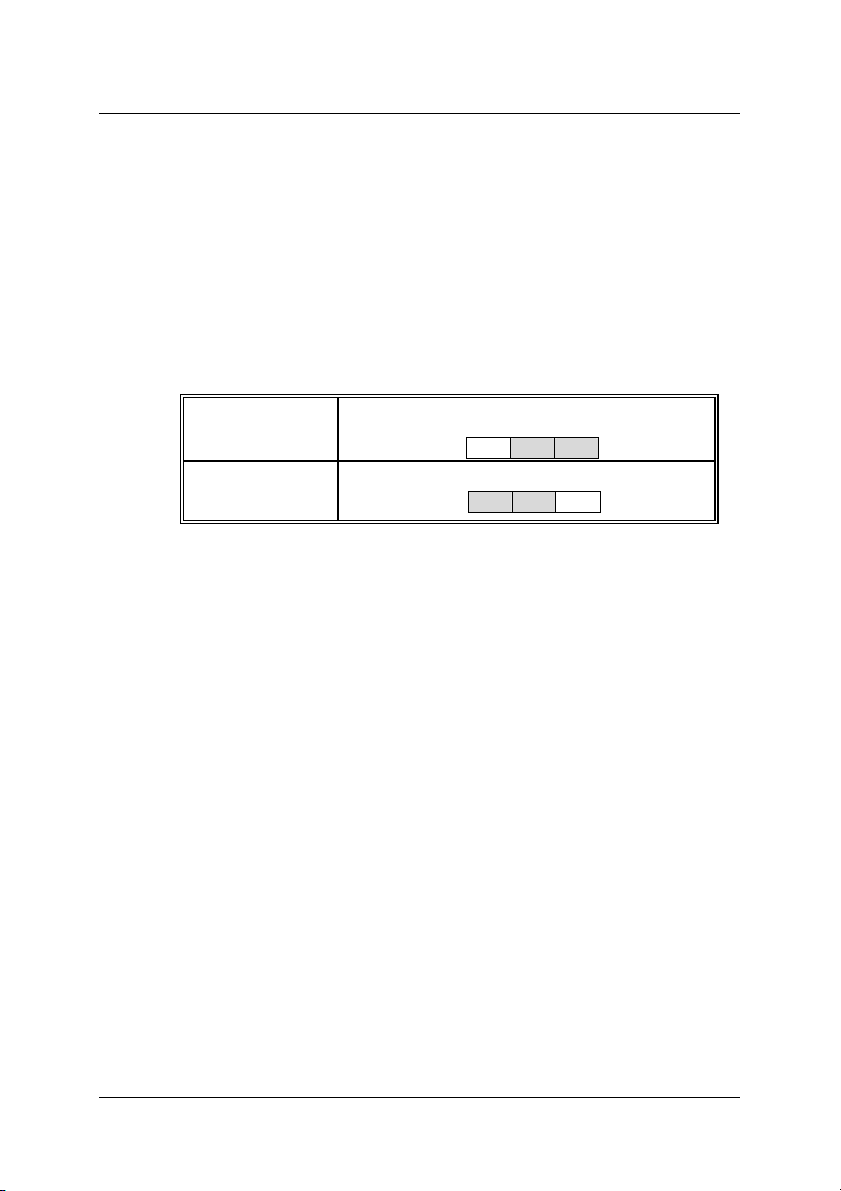

2.5 D/A Reference Voltage Setting

The analog output range of ACL-8111 depends on the reference voltage,

which is selected by JP1. There are two range of reference voltages can be

assigned as either -5V or -10V, that will generate output range 0V ~ +5V or

0V ~ +10V, respectively.

The setting of D/A reference voltage is specified as following:

When you select -10V for the D/A reference voltage, you should be very

careful the analog output. Because the -10 V voltage source is supplied from

your PC system, and it may be up to 11.5V only. Therefore, it will cause you

analog output is less than +10V.

Reference Voltage

is -5V

(default)

Reference Voltage

is -10V

-10V -5V

-10V -5V

JP1

h h h

JP1

h h h

Installation • 13

Page 20

2.6 Connectors Pin Assignments

The ACL-8111 has three connectors: one 37-pin D-type connector (CN1) and

two 20-pin insulation displacement connectors (CN2 and CN3).

CN1 is for analog input and analog output signals. CN2 is for digital input

signal. CN3 is for digital output signal. The pin assignments for each

connector are illustrated in the Figure 3.1 ~ Figure 3.3.

CN1: Analog input/output

(1)

AI0

(2)

AI1

(3)

AI2

(4)

AI3

(5)

AI4

(6)

AI5

(7)

AI6

(8)

AI7

(9)

-(10)

-(11)

-(12)

-(13)

-(14)

-(15)

DGND

(16)

-(17)

-(18)

-(19)

+5V

Figure 3.1. Pin Assignment of CN1

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

(28)

(29)

(30)

(31)

(32)

(33)

(34)

(35)

(36)

(37)

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

--

-AO1

--

--

--

--

--

--

--

Legend:

AIn : Analog Input Channel n (single-ended)

AO : Analog Output Channel

A.GND : Analog Ground

D.GND : Ground

+5V : +5V from system power supply

14 • Installation

Page 21

CN 2: Digital Input Signals (DI 0 - 15)

2

2

DI 0

DI 2

DI 4

DI 6

DI 8

DI 10

DI 12

DI 14

GND

+5V

CN 3: Digital Output Signals (

DO 0 - 15)

DO 0

DO 2

DO 4

DO 6

DO 8

DO 10

DO 12

DO 14

GND

+5V

CN2

1

3 4

5 6

7 8

9 10

11 1 2

13 14

15 16

17 18

19 20

CN3

1

3 4

5 6

7 8

9 10

11 1 2

13 14

15 16

17 18

19 20

DI 1

DI 3

DI 5

DI 7

DI 9

DI 11

DI 13

DI 15

GND

Strobe

DO 1

DO 3

DO 5

DO 7

DO 9

DO 11

DO 13

DO 15

GND

+12V

Legend:

DO n : Digital output signal channel n

DI n : Digital input signal channel n

GND : Digital ground

+12V : +12V power from system

Strobe : Digital input strobe signal

Installation • 15

Page 22

2.7 Daughter Board Connection

The ACL-8111 can be connected with five different daughter boards ACLD9137, 9182, 9185, and 9188. The functionality and connections are specified

as following:

2.7.1 Connect with ACLD-9137

The ACLD-9137 is a direct connector for the card, which is equipped with 37pin D-sub connector. This board provides a simple way for connection. It is

very suitable for the simple applications that do not need complex signal

condition before the A/D conversion is performed.

2.7.2 Connect with ACLD-9182

The ACLD-9182 is a 16 channel isolated digital input board. This board is

connected with CN2 of ACL-8111 via 20-pin flat cable. The advantage of this

board is a 500Vdc isolation voltage is provided, and it can protect your PC

system from damage when an abnormal input signal is occurred.

2.7.3 Connect with ACLD-9185

The ACLD-9185 is a 16 channel SPDT relay output board. This board is

connected with CN3 of ACL-8111 via 20-pin flat cable. By using this board,

you can control outside device through the digital output signals.

ACLD-9185

ACLD-9182

16 • Installation

CN3

CN2

ACL-8111

Page 23

2.7.4 Connect with ACLD-9188

ACLD-9188 is a general-purpose terminal board for the entire card, which

comes equipped with 37-pin D-sub connector.

CN3

CN1

CN2

ACLD-9188

ACL- 8111

Installation • 17

Page 24

3

Registers Format

The chapter specifies the detailed descriptions of the register format. This

information is useful for the programmers who wish to handle the card by

low-level program.

3.1 Registers Address Map

The ACL-8111 requires 16 consecutive addresses in the I/O address space.

The following table (Table 3.1) shows the location of each register relative to

the base address and register descriptions.

Address Read Write

Base + 0 Counter 0 Counter 0

Base + 1 Counter 1 Counter 1

Base + 2 Counter 2 Counter 2

Base + 3 Not Used Counter Control

Base + 4 A/D low byte D/A low byte

Base + 5 A/D high byte D/A high byte

Base + 6 DI low byte Not Used

Base + 7 DI high byte Not Used

Base + 8 Not Used Clear Interrupt Request

Base + 9 Not Used Gain Control

Base + 10 Not Used Multiplexer Scan Control

Base + 11 Not Used Mode Control

Base + 12 Not Used Software A/D trigger

Base + 13 Not Used DO low byte

Base + 14 Not Used DO high byte

Base + 15 Not Used Not Used

18 • Registers Format

Table 3.1 I/O Port Address Map

Page 25

3.2 A/D Data Registers

ACL-8111 provides 8 single-end A/D input channels. The 12 bit A/D data is

put in two 8-bit registers. The low byte date (8 LSBs) is at address BASE+4

and the high byte data (4 MSBs) is at address BASE+5. The DRDY bit is

used to indicate the status of A/D conversion. DRDY goes to low-level

means A/D conversion is completed.

Address : BASE + 4 and BASE + 5

Attribute: read only

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+4 AD7 AD6 AD5 AD4 AD3 AD2 AD1 AD0

BASE+5 0 0 0

AD11. AD0: Analog to digital data. AD11 is the Most Significant Bit (MSB).

AD0 is the Least Significant Bit (LSB).

DRDY: Data Ready Signal.

1: A/D data is not ready

0: A/D conversion is completed.

It will be set to 1 after reading out the low byte data

DRDY

AD11 AD10 AD9 AD8

Registers Format • 19

Page 26

3.3 A/D Channel Multiplexer Register

This register is used to control the A/D channels number to convert. It's a

write only register. When the channel number is written to the register, the

multiplexer switches to the new channel and waits for conversion.

Address: BASE + 10

Attribute:

Data Format:

BASE+10 X X X X X CL2 CL1 CL0

CLn: multiplexer channel number.

CL2 is MSB, and CL0 is LSB.

Where CL2, CL1, and CL0 are multiplexer channel selection:

write only

Bit 7 6 5 4 3 2 1 0

Channel NO. CL2 CL1 CL0

0 0 0 0 Power Up Setting

1 0 0 1

2 0 1 0

3 0 1 1

4 1 0 0

5 1 0 1

6 1 1 0

7 1 1 1

20 • Registers Format

Page 27

3.4 A/D Input Range Control Register

The gain control register is a write-only register using address Base + 9. It is

used to adjust the gain of the analog input programmable amplifier. The data

format is specified as follows:

Address: BASE + 9

Attribute:

Data Format:

BASE+9 X X X X X G2 G1 G0

Where G2, G1, and G0 are Gain selection:

G2 G1 G0 GAIN Input Range (V)

The relationship between input voltage range, maximum input voltage and

gain is specified as the equation:

write only

Bit 7 6 5 4 3 2 1 0

0 0 0 x1

0 0 1 x2

0 1 0 x4

0 1 1 x8

1 0 0 x16

1 0 1 Invalid X

1 1 0 Invalid X

1 1 1 Invalid X

± 5V

± 2.5V

± 1.25V

± 0.625V

± 0.3125V

Power Up Setting

Analog Input Range = Maximum Input Voltage / Gain

Registers Format • 21

Page 28

3.5 Mode and Interrupt Control Register

The Mode and Interrupt control register is a write-only register. This register

control the AD operating modes and the IRQ level of the ACL-8111. The AD

operation modes include the AD clock source and the AD data transfer

method.

Address: BASE + 11

Attribute:

Data Format:

BASE+11 X IR2 IR1 IR0 X M2 M1 M0

Where M0, M1, and M2 are mode selection:

M2 M1 M0 Description

write only

Bit 7 6 5 4 3 2 1 0

0 0 0 Software trigger with program polling

0 0 1 (No interrupt generated)

0 1 0 External trigger with program polling

0 1 1

1 0 0

1 0 1 Not Used

1 1 0

1 1 1 Not Used

External trigger with interrupt polling

(With End-of-conversion “EOC” interrupt)

Internal time pacer trigger and polling

(No interrupt generating)

Internal timer pacer trigger with interrupt data

transfer(With End-of-conversion “EOC” interrupt)

Note

: The external trigger signal comes from the DI 0 (pin-1 of CN2).

Where IR0, IR1, and IR2 are interrupt IRQ level settings:

IR2 IR1 IR0 IRQ Level

0 0 0 IRQ2

0 0 1 Not Used

0 1 0 IRQ2

0 1 1 IRQ3

1 0 0 IRQ4

1 0 1 IRQ5

1 1 0 IRQ6

1 1 1 IRQ7

22 • Registers Format

Page 29

3.6 Interrupt Status Register

The Interrupt Status Register is used to clear the interrupt status for next new

interrupt can be generated. If the ACL-8111 is in interrupt data transfer mode,

a hardware status flag will be set after each A/D conversion. You have to

clear the status flag by just writing any data to this register, let the ACL-8111

can generate next interrupt if a new A/D conversion is happen.

Address : BASE + 8

Attribute:

Data Format:

BASE+8 X X X X X X X X

write only

Bit 7 6 5 4 3 2 1 0

3.7 Software Trigger Register

If you want to generate a trigger pulse to the ACL-8111 for A/D conversion,

you just write any data to this register, and then the A/D converter will be

triggered.

Address: BASE + 12

Attribute:

Data Format:

BASE+12 X X X X X X X X

write only

Bit 7 6 5 4 3 2 1 0

Registers Format • 23

Page 30

3.8 Digital I/O register

There are 16 digital input channels and 16 digital output channels are

provided by the ACL-8111. The address Base + 6 and Base + 7 are used for

digital input channels, and the address Base + 13 and Base + 14 are used for

digital output channels.

Address : BASE + 6 & BASE + 7

Attribute:

Data Format:

Base + 6 DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

Base + 7 DI15 DI14 DI13 DI12 DI11 DI10 DI9 DI8

Address: BASE + 13 & BASE + 14

Attribute: write only

Data Format:

Base + 13

Base + 14

read only

Bit 7 6 5 4 3 2 1 0

Bit 7 6 5 4 3 2 1 0

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

DO15 DO14 DO13 DO12 DO11 DO10 DO9 DO8

3.9 D/A Output Register

The D/A converter will convert the D/A output register data to the analog

signal. The register data of the address Base + 4 and Base + 5 are used for

D/A conversion.

Address: BASE + 4 & BASE + 5

Attribute:

Data Format:

Base + 4 DA7 DA6 DA5 DA4 DA3 DA2 DA1 DA0

Base + 5 X X X X DA11 DA10 DA9 DA8

DA0 is the LSB and DA11 is the MSB of the 12 bit data.

X: don't care

24 • Registers Format

write only

Bit 7 6 5 4 3 2 1 0

Page 31

Note: The D/A registers are "double buffered" so that the D/A analog

output signals will not updated until the second (high) byte is written.

This can insure a single step transition when the D/A conversion.

Registers Format • 25

Page 32

4

Operation Theorem

The chapter describe the operation theorem of ACL-8111. The functions

include the A/D conversion, D/A conversion, and digital I/O. The operation

theorem can help you to understand how to manipulate and to program the

ACL-8111.

4.1 A/D Conversion

Before programming the ACL-8111 to perform the A/D conversion, you

should understand the following issues:

• A/D conversion procedure

• A/D trigger mode

• A/D data transfer mode

• Signal Connection

26 • Operation Theorem

Page 33

4.1.1 A/D Conversion Procedure

The A/D conversion is starting by a trigger source, then the A/D converter will

start to convert the signal to a digital value. The ACL-8111 provides three

trigger modes, see section 4.1.2.

The DRDY bit in the A/D data register (Base+5) will become to 0 once the

A/D conversion is completed and data on the Base+4 and Base+5 are ready.

A read data command on BASE+4 will automatically reset the DRDY bit to be

1 which means data is not ready on the Base+4 and Base+5. The A/D data

should be transferred into PC's memory for further using. The ACL-8111

provides three data transfer modes that allow users to optimize the DAS

system. Refer to section 4.1.3 for data transfer modes.

4.1.2 A/D Clock Sources (Trigger Modes)

In the ACL-8111, two Internal or one external clock sources can trigger A/D

conversion. The two internal sources are the software trigger and the timer

pacer trigger, which is controlled by the A/D operation mode control register

(BASE+11). The A/D operation modes combine the AD clock sources and

the data transfer mode together. Please also refer to the next section for

detail data transfer modes. The available operation modes include:

• Software trigger and software polling transfer

• Internal timer pacer and interrupt transfer

• Internal timer pacer and software polling transfer

• External trigger and interrupt transfer

• External trigger and software polling transfer

Three AD clock sources (or trigger sources) are available in the ACL-8111.

Software trigger

The trigger source is software controllable in this mode. That is, the A/D

conversion is starting when any value is written into the software trigger

register (BASE+12). Under this mode, the timing of the A/D conversion is

fully controlled by software, it is suitable for low speed A/D conversion.

However, it is difficult to control the fixed A/D conversion rate except a timer

interrupt service routine is used and the software trigger is programmed

inside the interrupt service routines.

Operation Theorem • 27

Page 34

Timer Pacer Trigger

d

An on-board timer / counter chip 8253 provide a pacer trigger source at a

fixed rate. Two counters of the 8253 chip are cascaded together to generate

trigger pulse with precise frequency. It's recommend to use this mode if your

applications need a fixed and precise A/D sampling rate. It can be combined

with the EOC (end-of-conversion) interrupt data transfer.

On the ACL-8111, the 8253 chip for timer pacer trigger source is configured

as below:

The pacer rate of above configuration is determined by the formula:

Pacer rate = 2 MHz / (C1 * C2)

8253 Timer/Counter

Not Use

Counter 0

CLK0

2MHz

Oscillator

Vcc

GATE0

Counter 1

CLK1

GATE1

Counter 2

CLK2

GATE2

OUT0

OUT1

OUT2

Timer Pacer

The maximum pacer signal rate is 2MHz/4=500K, which excess the

maximum A/D conversion rate of the ACL-8111. The minimum signal rate is

2MHz/65535/65535, which is a very slow frequency that user may never use

it.

For example, if you wish to get a pacer rate 2.5 kHz, you can set C1 = 40 and

C2 = 10. That is

2.5KHz = 2Mhz / (40 x 20)

External Trigger

Through the pin-1 of CN2 (DI0), the A/D conversion also can be performed

when a rising edge of external signal is occurred. The conversion rate of this

mode is more flexible than the previous two modes, because the users can

handle the external signal by outside device. The external trigger can

combine with the interrupt data transfer, or even program polling data

transfer. Generally, the interrupt data transfer is often used when external

trigger mode is used.

28 • Operation Theorem

Page 35

4.1.3 A/D Data Transfer Modes

On the ACL-8111, three A/D data transfer modes can be used when the

conversion is completed. The data transfer mode is controlled by the mode

control register (BASE+11). The different transfer modes are specified as

follows:

Software Data Transfer

Usually, this mode is used with software A/D trigger mode. After the A/D

conversion is triggered by software, the software should poll the DRDY bit

until it becomes to high level. Whenever the low byte of A/D data is read, the

DRDY bit will be cleared to indicate the data is read out.

It is possible to read A/D converted data without polling. The A/D conversion

time will not excess 8µs on ACL-8111 card. Hence, after software trigger, the

software can wait for at least 25µs then read the A/D register without polling.

EOC Interrupt Transfer

The ACL-8111 provides hardware interrupt capability. Under this mode, an

interrupt signal is generated at end of A/D conversion (EOC) then the data is

ready to be read. It is useful to combine the interrupt transfer with the timer

pacer trigger mode. Under this mode, the data transfer is essentially

asynchronous with the control software.

When the interrupt transfer is used, you have to set the interrupt IRQ level by

hardware jumper. Please refer section 2.10 for IRQ jumper setting. After the

A/D conversion is completed, a hardware interrupt will be inserted and its

corresponding ISR (Interrupt Service Routine) will be invoked and executed.

The converted data is transferred by the ISR program.

Operation Theorem • 29

Page 36

4.2 D/A Conversion

A

The operation of D/A conversion is simpler than A/D operation. You only

need to write digital values into the D/A data registers and the corresponding

voltage will be output from the AO. The ACL-8111 has one uni-polar analog

output channels. To make the D/A output connections from the appropriate

D/A output, please refer Figure 4.2.

-5 or -10

Ref In

INT or Ext

D/A Converter

-

+

Pin-30 ( AO)

To D/A Output

Pin-20 ( A.GND)

nalog GND

Figure 4.2 Connection of Analog Output Connection

The mathematical relationship between the digital number DAn and the

output voltage is formulated as following:

Vout Vref

=− ×

DAn

4096

Where the Vref is the reference voltage, the Vout is the output voltage, and

the DAn is the digital value in D/A data registers.

Before performing the D/A conversion, users should care about the D/A

reference voltage, which set by the JP1. Please refer section 2.6 for jumper

setting. The reference voltage will effect the output voltage. If the reference

voltage is -5V, the D/A output scaling will be 0~5V. If the reference voltage is

-10V, the D/A output scaling will be 0~10V. The relationship of reference

voltage and output range is summary in the following table.

Reference Voltage DA Output Voltage Range

-5 V 0V ~ +5V

-10 V 0V ~ +10V

30 • Operation Theorem

Page 37

Note that the D/A registers are "double buffered", so that the D/A analog

output signals will not be updated until the high byte is written. When write 12

bits data to D/A registers of the ACL-8111, the low byte must be written

before the high byte. This procedure can insure a single step transition when

the D/A conversion.

Note:

when writing digital data to D/A register,

be written first

released to output. After the high byte is written, both high and low

will add and passed to A/D converter.

, because the register will temporarily hold and not

the low byte data should

Operation Theorem • 31

Page 38

4.3 Digital Input and Output

The ACL-8111 provides 16 digital input and 16 digital output channels

through the connector CN2 and CN3 on board. The digital I/O signal are fully

TTL/DTL compatible. The detailed digital I/O signal specification can be

referred in section 1.3.

74LS244

Digital Input(DI)

From TTL Signal

Digital Output (DO)

74LS373

ACL-8111

Figure 4.3 Digital I/O Connection

To program digital I/O operation is fairly straightforward. The digital input

operation is just to read data from the corresponding registers, and the digital

output operation is to write data to the corresponding registers. Note that the

DIO data channel can only be read or written in form of 8 bits together. It is

impossible to access individual bit channel.

Digital GND (DGND)

Outside Device

To TTL Devices

32 • Operation Theorem

Page 39

5

C/C++ Library for DOS

This chapter describes the DOS software library, which is free supplied. The

DOS library software includes a utility program, C language library, and some

demonstration programs, which can help you reduce the programming work.

To program in Windows environment, please use ACLS-DLL2. The function

reference manual of ACLS-DLL2 is included in the ADLINK CD. It needs

license.

C/C++ Library for DOS • 33

Page 40

5.1 DOS Software Library Installation

5.1.1 Installation

To install the DOS library software and utilities, please follow the following

installation procedures:

1. Put ADLINK CD into the appropriate CD-ROM drive.

2. Type the following commands to change to the card’s directory (X

indicates the CD-ROM drive):

CD \NuDAQISA\8111

X:\>

3. Execute the setup batch program to install the software:

X:\NuDAQISA\8111>

SETUP

5.1.2 Running Utility

After finishing the installation, you can execute the utility by typing as follows:

C>cd ADLINK\8111\DOS\UTIL

C>8111UTIL

5.1.3 Example Programs

Six example programs in C language are supported in the directory

<SAMPLES>, you can refer these samples and modify them for your own

application. They can help you understand the library more quickly.

34 • C/C++ Library for DOS

Page 41

5.2 _8111_Initial

@ Description

An ACL-8111 card is initialized according to the card number and the

corresponding base address. Every ACL-8111 Multi-Function Data

Acquisition Card have to be initialized by this function before calling other

functions.

@ Syntax

int _8111_Initial(int card_number, int base_addresss )

@ Argument:

card_number: the card number to be initialized, only

two cards can be initialized, the card

number must be CARD_1 or CARD_2.

base_address:the I/O port base address of the card,

the default address on the hardware

setting is Hex 220.

@ Return Code:

ERR_NoError

ERR_InvalidBoardNumber

ERR_BaseAddressError

@ Example:

#include "8111.h"

main()

{

int ErrCode;

Errcode = _8111_Initial( CARD_1, 0x210 );

if ( ErrCode != ERR_NoError )

exit(0);

ErrCode = _8111_Initial( CARD_2, 0x220 );

if ( ErrCode != ERR_NoError )

exit(0);

...

}

C/C++ Library for DOS • 35

Page 42

5.3 _8111_Switch_Card_No

@ Description

This function is used on dual-cards system. After two ACL-8111 cards are

initialized by the initial function, you can select one card which you want to

operate.

@ Syntax

int _8111_Switch_Card_No(int card_number)

@ Argument:

card_number: The card number to be initialized, only

two cards can be initialized, the card

number must be CARD_1 or CARD_2.

@ Return Code:

ERR_NoError

ERR_InvalidBoardNumber

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

_8111_Initial( CARD_1, 0x210 );

_8111_Initial( CARD_2, 0x220 );

/* Assume NoError when Initialize ACL-8111*/

_8111_Switch_Card_No( CARD_1 );

/*..... You can perform certain functions

to Card_1 here*/

_8111_Switch_Card_No( CARD_2 );

/*..... You can perform certain functions

to Card_2 here*/

}

36 • C/C++ Library for DOS

Page 43

5.4 _8111_DI

@ Description

This function is used to read data from digital input port. There are 16-bit

digital inputs on the ACL-8111. The bit 0 to bit 7 are defined as low byte

and the bit 8 to bit 15 are defined as the high byte.

@ Syntax

int _8111_DI( int port_number, unsigned char *data )

@ Argument:

port_number: To indicate which port is read,

DI_LO_BYTE

or DI_HI_BYTE.

DI_LO_BYTE: bit 0 ~ bit 7,

DI_HI_BYTE: bit8 ~ bit15

data: return value from digital port.

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_PortError

@ Example:

See Demo program . Demo Program 'DI_DEMO.C'

C/C++ Library for DOS • 37

Page 44

5.5 _8111_DI _Channel

@ Description

This function is used to read data from digital input channels (bit). There

are 16 digital input channels on the ACL-8111. When performs this

function, the digital input port is read and the value of the corresponding

channel is returned.

Note: channel means each bit of digital input ports.

@ Syntax

int _8111_DI_Channel(int di_ch_no, unsigned int

*data )

@ Argument:

di_ch_no: the DI channel number, the value has to be

set from 0 to 15.

data: return value, either 0 or 1.

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_InvalidDIChannel

@ Example:

#include “8111.h”

main()

{

unsigned int data;

int ch;

_8111_Initial( CARD_1, 0x220 );

/* Assume NoError when Initialize ACL-8111

*/

.

.

.

for( ch=0; ch<16; ch++ )

{

_8111_DI_Channel( ch , &data );

printf( "The value of DI channel %d

is %d.\n" , ch , data );

}

}

38 • C/C++ Library for DOS

Page 45

5.6 _8111_DO

@ Description

This function is used to write data to digital output ports. There are 16

digital outputs on the ACL-8111, they are divided by two ports,

DO_LO_BYTE and DO_HI_BYTE. The channel 0 to channel 7 are defined

in DO_LO_BYTE port and the channel 8 to channel 15 are defined as the

DO_HI_BYTE port.

@ Syntax

int _8111_DO(int port_number, unsigned char data )

@ Argument:

port_number: DO_LO_BYTE or DO_HI_BYTE

data: value will be written to digital output port

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_PortError

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

_8111_Initial( CARD_1, 0x220 );

/* Assume NoError when Initialize ACL-8111

card */

.

.

_8111_DO( DO_LO_BYTE , 0x55 );

printf( "The low byte is now 0x55.\n" );

_8111_DO( DO_HI_BYTE , 0xAA );

printf( "The high byte is now 0xAA.\n" );

}

A more detailed program is Provided in this software 'DO_DEMO.C'

C/C++ Library for DOS • 39

Page 46

5.7 _8111_DA

@ Description

This function is used to write data to D/A converters. There is a Digital-toAnalog conversion channel on the ACL-8111. The resolution is 12-bit, i.e.

the range is from 0 to 4095.

@ Syntax

int _8111_DA(unsigned int data )

@ Argument:

data: D/A converted value, if the value is greater

than 4095, the higher 4-bits are negligent.

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_InvalidDAChannel

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

_8111_Initial( CARD_1, 0x220 );

/* Assume NoError when Initialize ACL-

8111 */

/* if the hardware setting for DA output range

is 0~5V */

_8111_DA( 0x800 );

printf( "The output voltage is 2.5V

\n" );

}

A more complete program is provided in this software. 'DA_DEMO.C'

40 • C/C++ Library for DOS

Page 47

5.8 _8111_AD_Set_Channel

@ Description

This function is used to set AD channel by means of writing data to the

multiplexer scan channel register. There are 8 single-ended A/D channels

in ACL-8111, so the channel number should be set between 0 to 7 only.

The initial state is channel 0 which is a default setting by the ACL-8111

hardware configuration.

@ Syntax

int _8111_AD_Set_Channel( int ad_ch_no )

@ Argument:

ad_ch_no: channel number to perform AD conversion

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_InvalidADChannel

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

_8111_Initial( CARD_1, 0x220 );

/* Assume NoError when Initialize ACL-8111

*/

_8111_AD_Set_Channel( 3 );

printf( "AD channel 3 is now selected.\n" );

...

/* the following A/D's operation is based on channel

3 */

}

C/C++ Library for DOS • 41

Page 48

5.9 _8111_AD_Set_Gain

@ Description

This function is used to set the A/D analog input range by means of writing

data to the A/D range control register. The initial value of gain is “1’ which

is set by the ACL-8111 harware. The relationship between gain and input

voltage ranges is specified by following tables:

The initial value of gain is '1‘ and input type is bipolar, which are pre-set by

the ACL-8111 hardware. The relationship between analog input voltage

range, gain and input mode are specified by following tables:

Input Range (V) Gain Gain Code

±5 V

±2.5 V

±1.25 V

±0.625 V

±0.3125V

@ Syntax

int _8111_AD_Set_Gain( int ad_range )

@ Argument:

ad_range: the programmable range of A/D conversion,

please refer to above tabbs for the

possible values .

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_AD_InvalidRange

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

_8111_Initial( CARD_1, 0x220 );

/* Assume NoError when Initialize ACL-8111

*/

_8111_AD_Set_Gain( AD_GAIN_8 );

printf( "The A/D analog input range is +/-

0.625V now.\n" );

}

X 1 AD_GAIN_1

X 2 AD_GAIN_2

X 4 AD_GAIN_4

X 8 AD_GAIN_8

X 16 AD_GAIN_16

42 • C/C++ Library for DOS

Page 49

5.10 _8111_AD_Set_Mode

@ Description

This function is used to set the A/D trigger and data transfer mode by

means of writing data to the mode control register. The hardware initial

state of the ACL-8111 is set as AD_MODE_1 software( internal) trigger

with program polling data.

A/D Mode Description

AD_MODE_0 Software Trigger, Software Polling Transfer

AD_MODE_1 Software Trigger, Interrupt Transfer

AD_MODE_2 External Trigger, Software Polling Transfer

AD_MODE_3 External Trigger, Interrupt Transfer

AD_MODE_4 Timer Trigger, Software Polling Transfer

AD_MODE_5 Timer Trigger, Interrupt Transfer

@ Syntax

int _8111_AD_Set_Mode(int irq_no, int ad_mode )

@ Argument:

irq_no: interrupt IRQ level

ad_mode: AD trigger and data transfer mode

( please to refer above table.)

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_InvalidMode

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

_8111_Initial( CARD_1 , 0x220 );

/* Assume NoError when Initialize ACL-8111

*/

_8111_AD_Set_Mode( IRQ5, AD_MODE_0 );

printf( "Now, disable internal trigger.\n" );

}

C/C++ Library for DOS • 43

Page 50

5.11 _8111_AD_Soft_Trig

@ Description

This function is used to trigger the A/D conversion by software. When the

function is called, a trigger pulse will be generated and the converted data

will be stored in the base address Base +4 and Base +5, and can be

retrieved by function _8111_AD_Aquire(). Please refer to section 6.11.

@ Syntax

int _8111_AD_Soft_Trig( void )

@ Argument:

None

@ Return Code:

ERR_NoError

ERR_BoardNoInit

@ Example:

Please refer the example in next section.

44 • C/C++ Library for DOS

Page 51

5.12 _8111_AD_Aquire

@ Description

This function is used to poll the AD conversion data. It will trigger the AD

conversion, and read the 12-bit A/D data until the data is ready ('data

ready' bit becomes low).

@ Syntax

int _8111_AD_Aquire( int *ad_data )

@ Argument:

ad_data: 12-bit A/D converted value, the value should

within 0 to 4095.

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_AD_AquireTimeOut

@ Example:

#include “aclerr.h”

#include “8111.h”

main()

{

int ad_data;

int ErrCode;

_8111_Initial( CARD_1, 0x220 );

/* Assume NoError when Initialize ACL-8111

*/

/* Set to software trigger at first*/

_8111_AD_Set_Mode( IRQ5, AD_MODE_1 );

/* then trigger the AD */

_8111_AD_Soft_Trig();

/* wait for AD data ready then read it */

ErrCode = _8111_AD_Aquire( &ad_data );

if( ErrCode == ERR_NoError )

printf( "The AD value is %d.\n", ad_data );

else

printf( "AD conversion error happen\n" );

}

Also see deme program 'AD_DEMO1.C'

C/C++ Library for DOS • 45

Page 52

5.13 _8111_CLR_IRQ

@ Description

This function is used to clear interrupt request which requested by the

ACL-8111. If you use interrupt to transfer A/D converted data, you should

use this function to clear interrupt request status, otherwise no new coming

interrupt will be generated.

@ Syntax

int _8111_CLR_IRQ( void )

@ Argument

None

@ Return Code:

ERR_NoError

ERR_BoardNoInit

46 • C/C++ Library for DOS

Page 53

5.14 _8111_AD_INT_Start

@ Description

The function will perform A/D conversion N times with interrupt data

transfer by using pacer trigger. It takes place in the background which will

not be stopped until the Nth conversion has been completed or your

program execute _8111_AD_INT_Stop() function to stop the process.

After executing this function, it is necessary to check the status of the

operation by using the function 8111_AD_INT_Status(). The function is

perform on single A/D channel with fixed analog input range.

@ Syntax

int _8111_INT_Start( int ad_ch_no, int ad_range,

int irq_ch_no, int count, int *ad_buffer,

unsigned int c1, unsigned int c2)

@ Argument:

ad_ch_no: A/D channel number

ad_range: A/D analog input range, please refer to

section 6.9 for the possible values.

irq_ch_no:IRQ channel number used to transfer AD data,

the possible value is defined in ' 8111.h '

count: the numbers of A/D conversion

ad_buffer:the start address of the memory buffer to

store the A/D data, the buffer size must be

large than the number of A/D conversion.

c1: the 16-bit timer frequency divider of timer

channel #1

c2: the 16-bit timer frequency divider of timer

channel #2

@ Return Code:

ERR_NoError

ERR_InvalidTimerValue

ERR_BoardNoInit

ERR_InvalidADChannel

ERR_AD_InvalidRange

ERR_InvalidIRQChannel

@ Example:

See demo Program 'AD_Demo2.C'

C/C++ Library for DOS • 47

Page 54

5.15 _8111_AD_INT_Status

@ Description

Since the _8111_AD_INT_Start() function executes in background, you

can issue the function _8111_AD_INT_Status to check the status of

interrupt operation.

@ Syntax

int _8111_AD_INT_Status( int *status , int *count )

@ Argument:

status: status of the INT data transfer

0: A/D INT is completed

1: A/D INT is not completed

count: current conversion count number.

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_AD_INTNotSet

@ Example:

See demo program 'AD_Demo2.C'

5.16 _8111_AD_INT_Stop

@ Description

This function is used to stop the interrupt data transfer function. After

executing this function, the internal AD trigger is disable and the AD timer is

stopped. The function returns the number of the data which has been

transferred, no matter whether the AD interrupt data transfer is stopped by

this function or by the _8111_AD_INT_Start() itself.

@ Syntax

int _8111_AD_INT_Stop( int *count )

@ Argument:

count: the number of A/D data which has been

transferred.

@ Return Code:

ERR_NoError

ERR_BoardNoInit

ERR_AD_INTNotSet

@ Example:

See Demo Program 'AD_Demo2.C'

48 • C/C++ Library for DOS

Page 55

5.17 _8111_AD_Timer

@ Description

This function is used to setup the Timer #1 and Timer #2. Timer #1 & #2

are used as frequency divider for generating constant A/D sampling rate

dedicatedly. It is possible to stop the pacer trigger by setting any one of the

dividers as 0. The AD conversion rate is limited due to the conversion time

of the AD converter, the highest sampling rate of the ACL-8111 can not be

exceeded 30 KHz,Thus the multiplication of the dividers must be larger

than 70.

@ Syntax

int _8111_AD_Timer( unsigned int c1 , unsigned int

c2 )

@ Argument:

c1: frequency divider of timer #1

c2: frequency divider of timer #2,

@ Return Code:

ERR_NoError

ERR_BoardNoInitERR_InvalidTimerValue

@ Example:

main()

{

int ErrCode;

_8111_Initial( CARD_1, 0x220 );

/* Assume ERR_NoError when Initialize ACL-

8111 */

_8111_AD_Timer( 100 , 100 );

/* set AD sampling rate to 2MHz/(10*10) */

..

_8111_AD_Timer( 0 , 0 );

/* stop the pacer trigger */

}

C/C++ Library for DOS • 49

Page 56

6

Calibration

In data acquisition process, how to calibrate your measurement devices to

maintain its accuracy is very important. Users can calibrate the analog input

and analog output channels under the users' operating environment for

optimizing the accuracy. This chapter will guide you to calibrate your ACL8111 to an accuracy condition.

Note: Your ACL-8111 board has been carefully calibrated in the factory

before it is shipped to you.

6.1 What do you need

Before calibrating your ACL-8111 card, you should prepare some equipment

for the calibration:

1.

Calibration program: once the program is executed, it will guide you to

do the calibration. This program is included in the delivered package.

2.

One 5 1/2 digit multi-meter (6 1/2 digital multi-meter is recommended).

3.

A voltage calibrator or very stable and noise free DC voltage generator.

50 • Calibration

Page 57

6.2 VR Assignments

There are five variable resistors (VR) on the ACL-8111 board to allow

you making accurate adjustment on A/D and D/A channels. The function

of each VR is specified below:

VR No. Function

VR1 D/A full scale adjustment

VR2 D/A zero offset adjustment

VR3 A/D offset adjustment

VR4 A/D full scale adjustment

VR5 A/D programmable amplifier offset adjustment

6.3 D/A Calibration

The D/A input reference voltage should be connected to for calibration. You

may use the JP1 to select the -5V or -10V reference. The zero offset and full

scale of D/A channel can be turned through VR1 and VR2. The full-scale

gain of D/A is adjusted by VR1, and zero offsets are adjusted by VR2.

Note

: A precision voltmeter to measure the D/A output is very important.

The procedures of calibration are as follows:

Full scale adjustment :

1. Set JP1 to select -5V as reference voltage.

2. Connect VDM (+) to CN1 pin 30 and VDM (-) to A.GND.

3. Write digital data '4095' (0x0FFF) into D/A's digital data Register

(BASE+4 and BASE+ 5).

4. Adjust

(reference voltage with opposite sign).

Offset zero adjustment:

1. Write digital data ' 0' (0x0000) to D/A's digital data register (BASE+4 and

BASE+ 5).

2. Adjust

VR1

until your voltmeter's voltage reading is equal to +5V

VR2

until the your voltmeter's voltage reading is 0V.

Calibration • 51

Page 58

6.4 A/D Calibration

Since the ACL-8111 provides versatile A/D input ranges, the calibration on

one A/D range may cause a small offset on other ranges. It is suggested that

you calibrate the A/D range which you need best accuracy.

The procedures of calibration are as follows:

1. Set the analog input range as: +/- 5V, i.e. the gain = 1.

2. Short the A/D channel 0 (pin 1 of CN1) to ground (GND), and connect

the TP1 (+) and TP2 (-) with your DVM. Trim the variable resister VR5 to

obtain 0 reading in the DVM.

3. Applied a +5V input signal to A/D channel 0, and trim the VR4 to obtain

reading between 4094~4095.

4. Applied a +0V input signal to A/D channel 0, and trim the VR3 to obtain

reading flickers between 2048~2049.

5. Repeat step 2 and step 3, adjust VR3 and VR4.

52 • Calibration

Page 59

Appendix A. Demo. Programs

In this software diskette, there are 6 demonstration programs are provided.

They could help you to program your application by using C Language

Library easily. The description of these programs are specified as follows:

AD_DEMO1.C:

AD_DEMO2.C

AD_DEMO3.C: A/D conversion uses DMA data transfer.

DA_DEMO.C: D/A conversion

DI_DEMO.C: Read data from digital input channels

DO_DEMO.C: Write data to digital output channels

A/D conversion uses software trigger and

program data transfer.

A/D conversion uses interrupt and program

data transfer.

Appendix A. Demo. Programs • 53

Page 60

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the

after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and

follow the instructions exactly. When sending in damaged products for

repair, please attach an RMA application form which can be

downloaded from: http://rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for

products bought in China.

• The warranty period starts on the day the product is shipped from

ADLINK’s factory.

• Peripherals and third-party products not manufactured by ADLINK

will be covered by the original manufacturers' warranty.

• For products containing storage devices (hard drives, flash cards,

etc.), please back up your data before sending them for repair.

ADLINK is not responsible for any loss of data.

• Please ensure the use of properly licensed software with our

systems. ADLINK does not condone the use of pirated software

and will not service systems using such software. ADLINK will not

be held legally responsible for products shipped with unlicensed

software installed by the user.

• For general repairs, please do not include peripheral accessories. If

peripherals need to be included, be certain to specify which items

you sent on the RMA Request & Confirmation Form. ADLINK is not

responsible for items not listed on the RMA Request & Confirmation

Form.

3. Our repair service is not covered by ADLINK's guarantee in the

following situations:

• Damage caused by not following instructions in the User's Manual.

• Damage caused by carelessness on the user's part during product

transportation.

• Damage caused by fire, earthquakes, floods, lightening, pollution,

other acts of God, and/or incorrect usage of voltage transformers.

• Damage caused by inappropriate storage environments such as

with high temperatures, high humidity, or volatile chemicals.

54 • Warranty Policy

Page 61

• Damage caused by leakage of battery fluid during or after change

of batteries by customer/user.

• Damage from improper repair by unauthorized ADLINK technicians.

• Products with altered and/or damaged serial numbers are not

entitled to our service.

• This warranty is not transferable or extendible.

• Other categories not protected under our warranty.

4. Customers are responsible for all fees necessary to transport damaged

products to ADLINK.

For further questions, please e-mail our FAE staff: service@adlinktech.com

Warranty Policy • 55

Loading...

Loading...