Page 1

Isolated Analog Output Card

NuDAQ®

ACL-6128A

2-CH 12-bit

User’s Guide

Page 2

Page 3

©Copyright 1995, 2003 ADLINK TECHNOLOGY INC.

All Rights Reserved.

Manual Rev. 1.00: August 12, 2003

Part No: 50-11032-100

The information in this document is subject to change without prior notice in

order to improve reliability, design and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental,

or consequential damages arising out of the use or inability to use the product

or documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

ACL-6128A is registered trademarks of ADLINK TECHNOLOGY INC.

Other product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective

companies.

Page 4

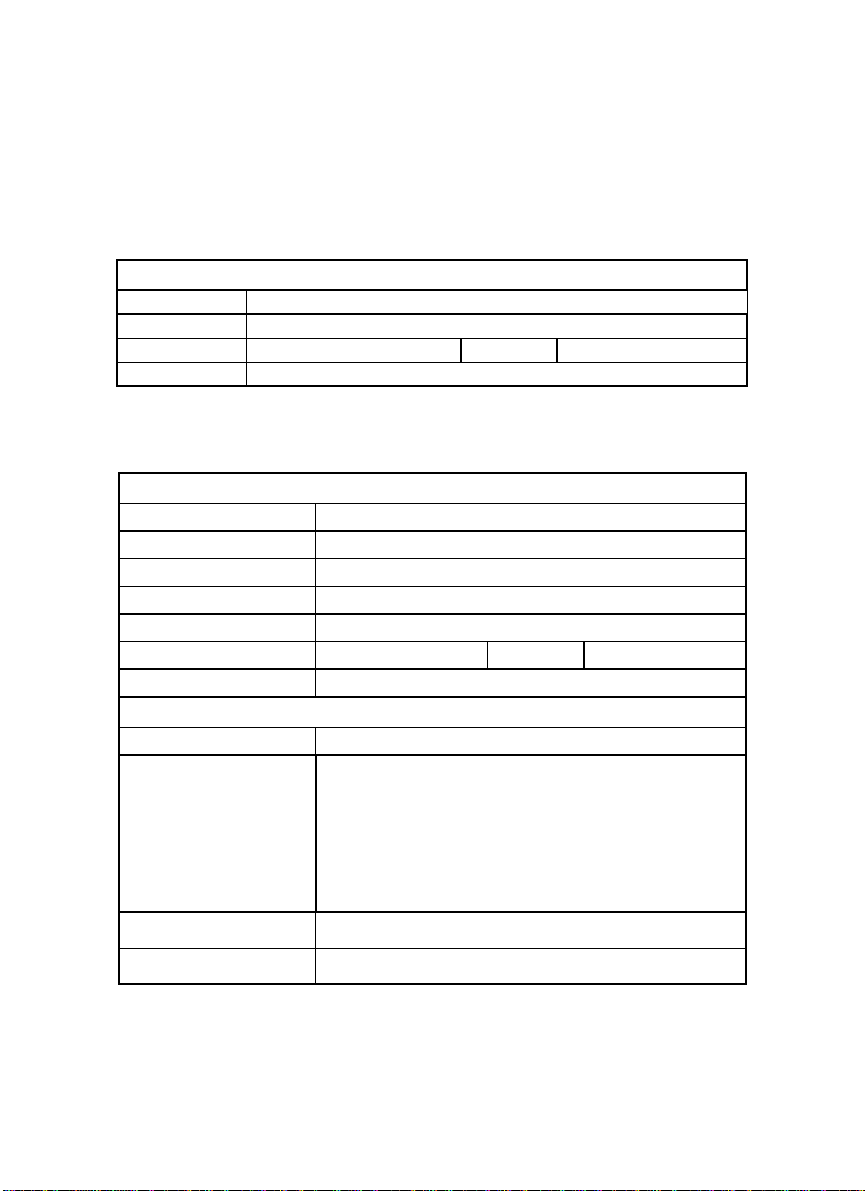

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK TECHNOLOGY INC. If you

need any help or service, please contact us.

ADLINK TECHNOLOGY INC.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan

Please email or FAX your detailed information for prompt, satisfactory, and

consistent service.

Detailed Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Questions

Product Model

OS:

Computer Brand:

M/B: CPU:

Environment

Detail Description

Chipset: BIOS:

Video Card:

NIC:

Other:

Suggestions for ADLINK

Page 5

Table of Contents

Chapter 1 Introduction.......................................................1

1.1 Features................................................................................... 2

1.2 Applications.............................................................................. 2

1.3 Specifications........................................................................... 3

1.4 Software Support..................................................................... 4

1.4.1 Programming Library............................................................4

1.4.2 LabView Driver.....................................................................4

Chapter 2 Installation.........................................................5

2.1 What’s Included ....................................................................... 5

2.2 Unpacking................................................................................ 6

2.3 ACL-6128A's Layout................................................................ 7

2.4 Jumper and DIP Switch Description........................................ 7

2.5 Base Address Setting .............................................................. 8

2.6 Selecting D/A Range and Functions...................................... 10

2.6.1 Reference Source Setting……………………………………..10

2.6.2 Output Range Setting………………………………………….11

2.6.3 Summary………………………………………………………..13

2.7 Current Sink Range Setting................................................... 15

2.8 Connector Pin Assignment.................................................... 16

2.9 Signal Connection.................................................................. 17

2.9.1 Voltage Output Connection……………………………………17

2.9.2 Current Sink Connection………………………………………17

2.9.3 Floating Load without external power supply……………….18

Chapter 3 Low-Level Programming ................................ 19

3.1 I/O Port Address Map ............................................................ 19

3.2 D/A Data Format.................................................................... 20

3.3 Converted Data Representation............................................ 21

3.3.1 Unipolar Numbering……………………………………………21

3.3.2 Bipolar Numbering……………………………………………..21

3.4 D/A Conversion Sequence .................................................... 22

Chapter 4 High-Level Programming................................23

4.1 Installation.............................................................................. 24

4.3 C Language Library ............................................................... 25

Chapter 5 Calibration ....................................................... 27

Table of Contents • i

Page 6

5.1 What is Needed ..................................................................... 27

5.2 VR Assignment...................................................................... 28

5.3 Internal Reference Source Adjustment.................................. 28

5.4 Unipolar Output Calibration .................................................. 29

5.5 Bipolar Output Calibration..................................................... 30

5.6 Current Sink Calibration......................................................... 30

Warranty Policy.................................................................31

ii • Table of Contents

Page 7

How to Use This Guide

This manual is written to help users understand the ACL-6128A. Descriptions

of how to modify various settings on the ACL-6128A are provided in the

chapters below to meet your application specific requirements.

Chapter 1

Overview of product features, applications, and specifications.

Chapter 2

Installation instructions of the ACL-6128A with layout jumper

Chapter 3

Details register structure and programming for analog output in

Chapter 4

Describes programming for analog output using a high-level C

Chapter 5

Explains how calibration procedures for the ACL-6128A.

Introduction

Installation

settings, reference voltage source, D/A output ranges, pin

assignments, and signal connections.

Low-Level Programming

basic I/O primitive functions.

High-Level Programming

language library.

Calibration

How to Use This Guide • iii

Page 8

Page 9

1

Introduction

The ACL-6128A is an ideal cost effective analog output card with two separate

D/A converters In addition to 12-bit resolution and 16kHz throughput on each

DAC, supporting both voltage and current outputs for industrial applications.

The ACL-6128A provides high voltage isolation on each analog output channel.

Opto-isolators give 2500 V

from damage due to high voltages on the inputs. After powering on or resetting

the PC system, both channels will reset the output voltage to 0V in unipolar or

bioplar output range.

The ACL-6128A is fully compatible with the Advantech PCL-728, ensuring an

easy learning curve for customers familiar with Advantech products as well as

an easy replacement with addition functionality. Extra enhancements include

remarkable reliability and performance, surface mount components design, and

single +5V power consumption.

isolation to protect both the PC and peripherals

RMS

Introduction • 1

Page 10

1.1 Features

The ACL-6128A 2-channel Isolated D/A Card provides the following advanced

features:

• Fully compatible with ADLINK ACL-6128 and AdvantechPCL-728

• Two independent 12-bit analog output channels

• 2500 V

• 12-bit resolution, multiplying D/A converter

• Multiple output ranges

• Bipolar: ±10V, ±5V

• Unipolar: 0-10V, 0-5V

• Sink: 0-20mA, 4-20mA current loop

• Integral DC-to-DC converter for stable output operations

• Compact, half-size PCB

• 4-layer PCB with an integral ground plane

Isolation (channel-to-channel, input-to-output)

RMS

1.2 Applications

• Arbitrary waveform generation

• Control of values, switches, relays

• Programmable voltage source

• Servo Control

• Programmable current sink

2 • Introduction

Page 11

1.3 Specifications

The ACL-6128A provides the following specifications:

Analog Output (D/A)

♦

Output Channel:

•

Resolution:

•

Settling Time:

•

Output Range:

•

Bipolar Voltage:

•

Unipolar Voltage:

•

Current Loop (sink) :

•

Reference voltages

•

Internal:

External:

Output Drive Current:

•

Current Loop Excitation Voltage:

•

20mA.

Isolation Voltage:

•

Accuracy:

•

Linearity:

•

Data Transfer:

•

Temperature coefficient

•

2 Isolated channels

12-bit, multiplying D/A converter

≤ 30 μs

(Jumper selectable)

±10V, ±5V

0-10V, 0-5V

0-20mA, 4-20mA

-5V and -10V

DC or AC, ± 10V (max.)

5mA

±

+8V min, 36V max for 0-20mA or 4-

2500V

RMS

±0.012% of FSR

1/2 LSB

±

Programmable I/O

5ppm typical, 15ppm maximum

General Specifications

♦

Bus Type:

•

Connector:

•

Operating Temperature:

•

Storage Temperature:

•

Humidity:

•

Power Consumption:

•

Dimension:

•

PC/AT Bus

Two 9-pin D-sub female connector

5 - 95%, non-condensing

0°C - 55°C

-20°C - 70°C

+5V @ 780mA typical, 1A max

163 mm (L) x 107 mm (M)

Introduction • 3

Page 12

1.4 Software Support

1.4.1 Programming Library

A MS-DOS Borland C/C++ programming library is included for customers

writing application specific programs,

ACLS-DLL2 is a Development Kit for NuDAQ ISA bus cards with analog I/O for

Windows 3.1/9x/NT/2000. ACLS-DLL2 can be used with most programming

environments, such as Visual C++, Visual Basic, and Delphi. ACLS-DLL2 is

included in the ADLINK CD and requires a license.

1.4.2 LabView Driver

The ACLS-LVIEW LabView driver includes the ACL-6128A VIs to interface with

LabView. ACLS-LVIEW supports Windows 9x/NT/2000/XP. ACLS-LVIEW is

included in the ADLINK CD and requires a license.

4 • Introduction

Page 13

2

Installation

This chapter describes how to unpack and install the ACL-6128A. Package

contents and unpacking information should be careful reviewed. Jumper and

switch settings for the ACL-6128A's base address, reference voltage sources,

and output voltage range are also specified.

2.1 What’s Included

In addition to this User's Manual, the package includes:

• ACL-6128A 2-channel Isolated Analog Output Card

• ADLINK CD

If the card is missing or damaged, contact an ADLINK dealer. Save the

shipping materials and carton to ship or store the product in the future.

Installation • 5

Page 14

2.2 Unpacking

The ACL-6128A card contains sensitive electronic components that can be

easily damaged by static electricity.

Prepare a grounded anti-static mat. The operator should be wearing an antistatic wristband, grounded at the same point as the anti-static mat.

Inspect the card module carton for obvious damage. Shipping and handling

may cause damage to the module. Be sure there is no obvious damage due to

shipping and handing by examining the shipping box.

After opening the card module carton, extract the system module and place it

only on a grounded anti-static surface, component side up.

Again inspecting the module for damage. Press down on all the docketed IC's

to make sure they are properly seated. Do this only with the module place on a

firm flat surface.

Note:

DO NOT APPLY POWER TO THE CARD IF IT HAS BEEN

DAMAGED.

You are now ready to install your ACL-6128A.

6 • Installation

Page 15

2.3 ACL-6128A's Layout

VR5V

JP1 JP2

SW1

JP7

JP8

VR7 VR8

TB2

VR9

JP9

VR10

JP10

VR11

VR12

CN2

Figure 2.1 ACL-6128A‘s Layout

JP3

JP4

TB1

VR3

JP6

VR1

VR2

VR4

R6

6128A Isolated 2CH D/A ACRD

JP5

CN1

2.4 Jumper and DIP Switch Description

You can change the ACL-6128A's channels and base address by setting

jumpers and DIP switches on the card. The card's jumpers and switches are

preset at the factory. Under normal circumstances, these settings should not

need to be changed.

A jumper switch is closed or "shorted" with the plastic cap inserted over two

pins of the jumper. A jumper is open when the plastic cap inserted over one or

no pin(s) of the jumper.

Installation • 7

Page 16

2.5 Base Address Setting

The ACL-6128A requires 16 consecutive address locations in I/O address

space. The base address of the ACL-6128A is restricted by the following

conditions:

1.

The base address must be within the range 200hex to 3F0hex.

2.

The base address should not conflict with any PC reserved I/O address

(see Appendix A).

The ACL-6128A I/O port base address is selectable by an 8 position DIP switch

SW1 (refer to Figure 2.1). The address setting for the I/O port is from Hex 200

to Hex 3F0 is described in Table 2.1 below. The default base address (Hex

2C0) of the is illustrated in the Figure 2.2 below.

SW1 : Base Address = 2C0H

ON DIP

X

1 2 3 4 5 6 7

8

A ( 9 8 7 6 5 4 3 X )

Figure 2.2 Default Base Address Setting

I/O port

address(hex) 1 A9 2 A8 3 A7 4 A6 5 A5 6 A4 7 A3 8 X

200-20F

210-21F

:

(*) 2C0-2CF

:

300-30F

:

3F0-3FF

8 • Installation

OFF

OFF

OFF

OFF

OFF

(1)

ON

ON

ON

ON

(1)

(0)

(0)

(0)

(1)

(0)

(0)

ON

(0)

OFF

(1)

ON

(0)

OFF

(1)

OFF

(1)

ON

(0)

ON

(0)

(1)

ON

OFF

ON

OFF

(1)

(1)

(1)

OFF

(1)

OFF

(1)

(0)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

OFF

(1)

ON

(0)

ON

(0)

OFF

(1)

Table 2.1

ON

(0)

ON

(0)

ON

(0)

ON

(0)

ON

(0)

X

X

X

X

X

Page 17

(*) : default setting ON : 0

X : don't care OFF : 1

Note : A3-A9 correspond to PC bus address lines.

How to Define a Base Address for the ACL-6128A ?

DIP1 to DIP7 in switch SW1 are one-to-one corresponding to the PC bus

address lines A9 through A3. A0, A1, and A2 are always 0. To change

the base address, change the values of A9 to A3 (shadow area of below

diagram). The following table shows how to define the base address as

Hex 2C0.

Base Address : Hex 2C0

2 C 0

1 0 1 1 0 0 0 0 0 0

A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

Installation • 9

Page 18

2.6 Selecting D/A Range and Functions

There are two factors will effect the output voltage of ACL-6128A: reference

source and output range

2.6.1 Reference Source Setting

The ACL-6128A D/A converter reference voltage source can be internally

generated or an external reference voltage from the Reference Voltage Input

(REF.IN) of connectors CN1 and CN2. The settings of the reference sources

for CH1 and CH2 are controlled by jumpers JP4 and JP8, respectively. The

default setting is Internal Reference for both CH1 and CH2, and is illustrated

below.

CH1

CH2

.

Internal Reference

( Default )

JP4

EXT

INT

JP8

EXT

INT

External Reference

Voltage

JP4

EXT

INT

JP8

EXT

INT

Figure 2.3 Reference Source Setting

After setting as internal reference source, two fixed precision internal -5V and 10V reference sources are provided by ACL-6128A. The source selection is set

by JP3 (CH1) and JP7 (CH2), and the default setting of internal reference

voltage is -5V, which is illustrated as Figure 2.4 below:

10 • Installation

Page 19

Channel No.

CH1

CH2

Figure 2.4 Internal Reference Voltage Setting

If users choose the external reference, both AC and DC voltage sources can

be used by the external reference. The maximum input voltage is +/- 10V. The

voltage sources can be input through Pin 3 of the CN1 and CN2 connectors.

Internal -5V

( Default)

JP3

-10

-5

JP7

-10

-5

Internal -10V

JP3

-10

-5

JP7

-10

-5

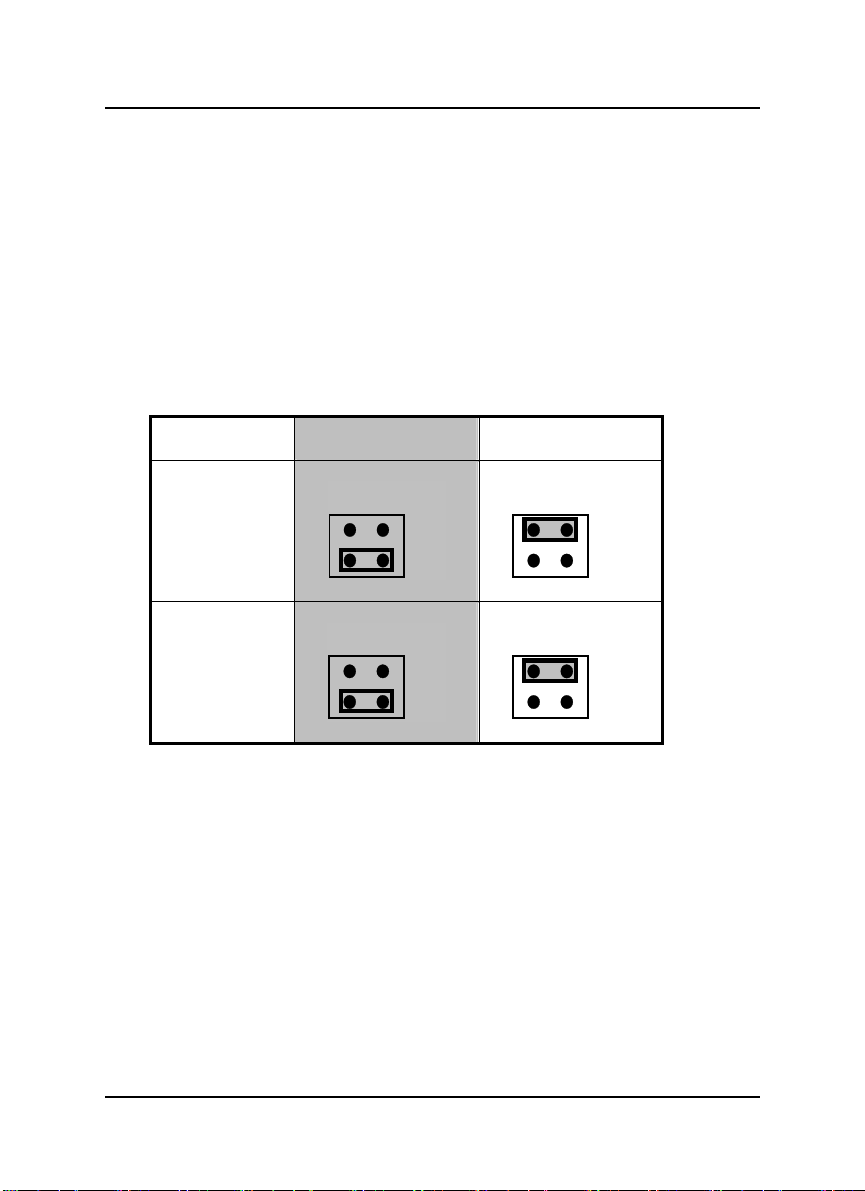

2.6.2 Output Range Setting

The output voltage range of ACL-6128A can be set either Bipolar or Unipolar.

The jumpers, JP1 and JP5 (for CH1), and JP2 and JP9 (for CH2) are used for

the settings as illustrated in Figure 2.5 below (ACL-6128A and ACL-6128

respectively):

ACL-6128A settings (

Jumper settings for the older ACL-6128 are slightly different—see below.)

Channel No.

CH1

CH2

Note

: These settings are for the

Unipolar

( Default )

JP1 JP5

BP

UP

JP2 JP9

BP

UP

UP

BP

UP

BP

ACL-6128A

Bipolar

JP1 JP5

BP

UP

JP2 JP9

BP

UP

UP

BP

UP

BP

Installation • 11

only.

Page 20

ACL-6128 settings (

Jumper settings for the newer ACL-6128 are slightly different—see above. Also,

JP9 on the PCB of the older

and “UP” is the bottom pin.)

Channel No.

CH1

CH2

Note

: These settings are for the older

ACL-6128 ONLY

Unipolar

( Default )

JP1 JP5

BP

UP

JP2 JP9

BP

UP

Figure 2.5 Output Range Setting

is mislabeled. “BP” is the top pin

BP

UP

UP

BP

UP

UP

JP1 JP5

JP2 JP9

ACL-6128

Bipolar

BP

BP

BP

UP

BP

UP

only.

12 • Installation

Page 21

2.6.3 Summary

J

J

Users can configure the output voltage of CH1 and CH2 for application specific

needs according to the reference source and output range settings. can follow

the below table to. Settings are listed in two separate tables for the ACL-6128A

and ACL-6128, respectively.

(JP1, JP3, and JP5 are for CH1. JP2, JP7, and JP9 are for CH2)

ACL-6128A settings (Note: this table is for the ACL-6128A ONLY.)

Jumper

Output Range

0 to +5V

Unipolar

(Default)

0V to +10V

Unipolar

-5V to +5V

Bipolar

-10V to +10V

Bipolar

JP3 for CH1

JP7 for CH2

P3/JP7

P3/JP7

JP3/JP7

P3/JP7

-10

-5

-10

-5

-10

-5

-10

-5

JP1 & JP5 for CH1

JP2 & JP9 for CH2

JP1/JP2 JP5/JP9

BP

UP

JP1/JP2 JP5/JP9

BP

UP

JP1/JP2 JP5/JP9

BP

UP

JP1/JP2 JP5/JP9

BP

UP

UP

BP

UP

BP

UP

BP

UP

BP

Installation • 13

Page 22

ACL-6128 settings (Note: this table is for the older ACL-6128 ONLY. The

ACL-6128 PCB has misprints. Please refer to the chart below for correct

jumper placement.)

Jumper

Output Range

0 to +5V

Unipolar

(Default)

0V to +10V

Unipolar

-5V to +5V

Bipolar

-10V to +10V

Bipolar

JP3 for CH1

JP7 for CH2

P3/JP7

P3/JP7

JP3/JP7

P3/JP7

-10

-5

-10

-5

-10

-5

-10

-5

JP1 & JP5 for CH1

JP2 & JP9 for CH2

JP1/JP2 JP5/JP9

BP

UP

JP1/JP2 JP5/JP9

BP

UP

JP1/JP2 JP5/JP9

BP

UP

JP1/JP2

BP

UP

BP

UP

BP

UP

BP

UP

JP5/JP9

BP

UP

14 • Installation

Figure 2.6 Output Range Summary

Page 23

2.7 Current Sink Range Setting

In addition to voltage output, the ACL-6128A also provides either 0-20mA

or 4-20mA current sink. In order to use the current sink range, set the

output voltage to unipolar. Jumper JP6 corresponds to CH1 and JP10 is

used with CH2. Figure 2.7 shows the settings for the ACL-6128A current

sink range.

Channel No.

CH1

4-20mA

( Default )

JP6

0

0-20mA

0

JP6

CH2

Note :

The current sink can

internal reference with -5V

as

4

JP10

0

4

Figure 2.7 Current Sink Setting

ONLY

be used when the output voltage range set

and

4

JP10

0

4

unipolar mode.

Installation • 15

Page 24

2.8 Connector Pin Assignment

The ACL-6128A is equipped with two D-9 female connectors: CN1 and CN2.

Both CN1 and CN2 are located on the rear plate. CN1 and CN2 are the

outputs of CH1 and CH2, respectively. Each connector's pin assignment is

specified as follows:

Legend : V.OUT : Analog Voltage Output

I.SINK : Current Sink

A.GND : Analog Ground

REF.IN : Reference Voltage Input

+15V : +15V output

CN 1: Analog Output for Channel 1

♦

1

V.OUT

A.GND

REF.IN

A.GND

A.GND

CN2 : Analog Output for Channel 2

♦

2

3

4

5

1

V.OUT

A.GND

REF.IN

A.GND

A.GND

2

3

4

5

6

7

8

9

6

7

8

9

A.GND

I.SINK

A.GND

+15V

A.GND

I.SINK

A.GND

+15V

16 • Installation

Page 25

2.9 Signal Connection

A correct signal connection is vital to send data accuracy. This section

illustrates proper signal connection when the ACL-6128A is used.

2.9.1 Voltage Output Connection

ACL-6128A Side

Externa

Side

Rload

-

Amp

2.9.2 Current Sink Connection

ACL-6128A Side

ACL- 6128 Side

I.SINK

Amp

V.OU

A.GND

External

Side

Power

Supply

+

Load

A.GND

Rload

Note : For 4-20mA current sink mode, the output range should be set as

Internal Reference with -5V and Unipolar mode.

Installation • 17

Page 26

r

2.9.3 Floating Load without external power supply

The ACL-6128A provides a +15V power source for systems that do not offer

external power supplies. The connection is as follows:

D/A

Converte

ACL- 6128A Side

Amp

A.GND

+15V

I.SINK

External

Side

Load

18 • Installation

Page 27

3

Low-Level Programming

This chapter describes low-level programming of the ACL-6128A and details

the register format and control procedures. To write applications based on

primitive I/O functions (inportb and outportb) instead of using the ACL-6128A

library, be careful to fully understand the register structure.

3.1 I/O Port Address Map

The ACL-6128A requires only 4 consecutive addresses in the PC I/O address

space. The following table (Table 3.1) shows the location of each register and

driver relative to the base address.

Location Write Read

Base + 0 CH1 High Byte Data Not Used

Base + 1 CH1 Low Byte Data Not Used

Base + 2 CH2 High Byte Data Not Used

Base + 3 CH2 Low Byte Data Not Used

Table 3.1 I/O Register Map

Low-Level Programming • 19

Page 28

3.2 D/A Data Format

The base address from Base+0 to Base+3 is used for D/A conversion. The

analog output channels and its corresponding registers are specified by table

3.2.

CH NO. CHANNEL 1 CHANNEL 2

High byte Base+0 Base+2

Low byte Base+1 Base+3

Table 3.2

Address : BASE + 0 & BASE + 1

Attribute:

Data Format : (for D/A Channel 1)

Address : BASE + 2 & BASE + 3

Attribute:

Data Format: (for D/A Channel 2)

DA11 .. DA0:

DA0

X:

Don't care.

write only

Bit 7 6 5 4 3 2 1 0

Base + 0 X X X X DA11 DA10 DA9 DA8

Base + 1 DA7 DA6 DA5 DA4 DA3 DA2 DA1 DA0

write only

Bit 7 6 5 4 3 2 1 0

Base + 2 X X X X DA11 DA10 DA9 DA8

Base + 3 DA7 DA6 DA5 DA4 DA3 DA2 DA1 DA0

Digital to Analog data.

is the Least Significant Bit, and

DA11

is the Most Significant Bit.

20 • Low-Level Programming

Page 29

3.3 Converted Data Representation

Two analog output range alternatives are provided by the ACL-6128A: Unipolar

and Bipolar. The numbering of the converted data with have different

presentations for different output ranges.

3.3.1 Unipolar Numbering

0 40952048

0000 0000 0000 1000 0000 0000 1111 1111 1111

V.OUT=-Vref*(0/4095) V.OUT=-Vref*(2048/4095) V.OUT=-Vref*(4095/4095)

Example:

Converted Data =2047

Binary Code =0111 1111 1111

Vref =-5V

V.OUT =-(-5 V) * ( 2047/4095) = 2.499 V

3.3.2 Bipolar Numbering

-2048

0000 0000 0000

V.OUT=-Vref*(-2048/2047)

1000 0000 0000

V.OUT=-Vref*(0/2047)

= 0V

Example:

Converted Data =500

Binary Code =1001 1111 0100

Vref =-5V

V.OUT =-(-5 V) * ( 500/2047) = 1.221 V

Low-Level Programming • 21

20470

1111 1111 1111

V.OUT=-Vref*(2047/2047)

Page 30

3.4 D/A Conversion Sequence

In the ACL-6128A, the A/D conversion can only be controlled by software using

the double buffering concept. That is, the converted data should be stored in

High Byte Register first, and then stored the Low Byte Register.

The procedure of how to initiate and convert digital data to analog output is

listed below:

1. Define the base address of the ACL-6128A card:

Base_Addr = 0x2C0;

2. Extract the most signification 4 bits from the converted data then write

to Base_Addr + 0:

High_Byte = Data & 0f00;

outportb( Base_Addr + 0, High_Byte);

3. Extract the least signification 8 bits from the converted data then write

to Base_Addr + 1:

Low_Byte = Data & 00ff;

outportb( Base_Addr + 1, Low_Byte);

An example program in low-level programming style called

included in the Utility and Software Library CD for your reference.

6128IO.C

is

22 • Low-Level Programming

Page 31

4

High-Level Programming

A high-level C language programming interface for the ACL-6128A is described

in this chapter. Use the C library to easily and quickly develop customized

applications.

Only three C-language functions are supported by the software library. The

functionality of these function calls can be classified into the following

capabilities:

1. Initialization:

2. D/A conversion:

In addition to the library, some sample programs are also provided. Refer to

them to save programming time.

Initializes the hardware base I/O address and switches

between cards.

performs digital to analog conversion.

High-Level Programming • 23

Page 32

4.1 Installation

To install the DOS library software and utilities, please follow the following

installation procedures:

1. Put the ADLINK CD into an appropriate CD-ROM drive.

2. Type the following commands to change to the card’s directory (

indicates the CD-ROM drive):

X:\>CD \NuDAQISA\6128

3. Execute the setup batch program to install the software:

X:\NuDAQISA\6128>SETUP

After installation, all the files for the ACL-6128A Library & Utility for DOS are

stored in the

C:\ADLINK\6128\DOS

directory.

X

24 • High-level Programming

Page 33

4.3 C Language Library

The ACL-6128A digital-to-analog conversion library was constructed to provide

a simple programming interface for communicating with the ACL-6128A card.

The library provides easy to use functions which allow programmers to use the

features of the card in a high-level way.

The version of this library included in the CD is DOS only.

The detailed function description is specified in the following sections:

4.3.1 _6128_Initial

@ Description

An ACL-6128A card is initialized according to the card number and its

corresponding base address. Every ACL-6128A has to be initialized by this

function before calling other functions.

@ Syntax

int _6128_Initial(int card_number, int base_address)

@ Argument

card_number: The card number to be initialized, up to

base_address: The I/O port base address of the card.

@ Return Code

ERR_NoError

ERR_InvalidBoardNumber

ERR_BaseAddressError

8 cards can be initialized, the card

number must be within the range of 0 and

7.

High-Level Programming • 25

Page 34

4.3.2 _6128_Switch_Card_No

@ Description

This function is used on multi-cards systems. After the ACL-6128A cards

are initialized by the _6128_Initial function, you can use this function

to select which card to operate.

@ Syntax

int _6128_Switch_Card_No(int card_number)

@ Argument

card_number: The card number to be initialized, up to

@ Return Code

ERR_NoError

ERR_InvalidBoardNumber

8 cards can be initialized, the card

number must be within the range of 0 and

7.

4.3.3 _6128_DA

@ Description

This function is used to write data to D/A converters. There are two Digitalto-Analog conversion channel in the ACL-6128A. The resolution of each

channel is 12 bits, providing a range from 0 to 4095.

@ Syntax

int _6128_DA( int da_ch_no, unsigned int da_data )

@ Argument

da_ch_no : The DA channel number, the value has to

da_data : D/A converted value, if the value is

@ Return Code

ERR_NoError

ERR_BoardNoInit

ERR_InvalidDAChannel

be set a 0 or 1.

greater than 4095, the upper 4 bits are

negligent.

26 • High-level Programming

Page 35

5

Calibration

In data acquisition process, how to calibrate your measurement devices to

maintain its accuracy is very important. This chapter will guide you to calibrate

your ACL-6128A to an accurate condition.

5.1 What is Needed

Before calibrating the ACL-6128A card, please prepare the following:

1.

Calibration program: executing this program will walk users through the

calibration steps. The calibration program is located in the

C:\ADLINK\6128\dos\driver\util\6128av.exe

2.

Digital multimeter.

directory:

Calibration • 27

Page 36

5.2 VR Assignment

There are twelve variable resistors (VR) on the ACL-6128A board to allow

users to make accurate adjustment on two D/A channels. VR1 to VR6 belong

to CH1, and VR7 to VR12 belongs to CH2. The detailed functionality of each

VR is listed below:

CH1‘s VR

(-10V) Internal reference

VR1

Gain Adjustment

VR3

Current Sink Offset (4mA)

VR5

CH2‘s VR

(-10V) Internal reference

VR7

Gain Adjustment

VR9

Current Sink Offset (4mA)

VR11

There are two testing points (TP1 and TP2) on the board, which are used for

calibration the ACL-6128A. TP1 is for CH1, and TP2 is for CH2.

(-5V) Internal reference

VR2

Unipolar Offset

VR4

Bipolar Offset

VR6

(-5V) Internal reference

VR8

Unipolar Offset

VR10

Bipolar Offset

VR12

5.3 Internal Reference Source Adjustment

The Internal Reference Source adjustment can ensure that the internal

reference voltages of the ACL-6128A can offer very accurate voltage source—5V and -10V.

1.

Ground the black probe of the voltmeter.

2.

Connect the other probe to TP1 (for testing CH1), or TP2 (for testing

CH2).

Change the jumper to JP3 (for CH1) or JP7 (for CH2), trim

CH1) until the voltmeter reads

voltmeter also reads

3.

Change the jumper to JP3 (for CH1) or JP7 (for CH2), trim

CH1) until the voltmeter reads

voltmeter also reads

-10V

-5V

.

.

-10V

-5V

, trim

, trim

VR7

VR8

(for CH2) until the

(for CH2) until the

VR1

VR2

(for

(for

28 • Calibration

Page 37

5.4 Unipolar Output Calibration

If you choose Unipolar mode for analog output, you have to go through the

Unipolar Output Calibration. There are two steps: Gain Calibration and Offset

Calibration.

Gain Calibration:

1.

Set jumpers JP1 and JP5 (for CH1) or JP2 and JP9 (for CH2) to

unipolar,

2.

Set the digital data as (0000 0000 0000)B, trim VR4 (for CH1) or VR10

(for CH2) until the voltmeter reading is

Offset Calibration:

1.

Set jumpers JP1 and JP5 (for CH1) or JP2 and JP9 (for CH2) to

unipolar

2.

Set the digital data as (1111 1111 1111)B, trim VR3 (for CH1) or VR9

(for CH2) until the voltmeter reading is

and choose an internal reference as

0V

, and choose an internal reference as

5V

-5V

.

.

-5V

.

.

Calibration • 29

Page 38

5.5 Bipolar Output Calibration

If Bipolar mode for analog output is used, use Bipolar Output Calibration to

correctly calibrate. There are two steps involved: Gain Calibration and Offset

Calibration.

Gain Calibration:

1.

Set jumpers

bipolar, and choose an internal reference as

2.

Set the digital data as (1000 0000 0000)B, trim VR4 (for CH1) or VR10

(for CH2) until the voltmeter reading is

Offset Calibration:

1.

Set the internal reference to -5V.

2.

Set the digital data as (0000 0000 0000)B, trim VR6 (for CH1) or VR12

(for CH2) until the voltmeter reading is

JP1

and

JP5

(for

CH1

) or

0V

-5V

.

.

JP2

-5V

and

.

JP9

5.6 Current Sink Calibration

If using current sink output, please do the following:

Use

Follow the below procedures to calibrate the current sink output.

-5V

for internal reference and its reference voltage.

1.

Set the digital data as (0000 0000 0000)B, and internal reference as

5V

, using unipolar output range.

2.

Tr im VR5 (for CH1) or VR11 (for CH2) until there is a constant current

4mA

of

.

(for

CH2

) as

-

30 • Calibration

Page 39

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the

after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow

the instructions exactly. When sending in damaged products for repair,

please attach an RMA application form which can be downloaded from:

http://rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for

products bought in China.

• The warranty period starts on the day the product is shipped from

ADLINK’s factory.

• Peripherals and third-party products not manufactured by ADLINK

will be covered by the original manufacturers' warranty.

• For products containing storage devices (hard drives, flash cards,

etc.), please back up your data before sending them for repair.

ADLINK is not responsible for any loss of data.

• Please ensure the use of properly licensed software with our

systems. ADLINK does not condone the use of pirated software and

will not service systems using such software. ADLINK will not be

held legally responsible for products shipped with unlicensed

software installed by the user.

• For general repairs, please do not include peripheral accessories. If

peripherals need to be included, be certain to specify which items

you sent on the RMA Request & Confirmation Form. ADLINK is not

responsible for items not listed on the RMA Request & Confirmation

Form.

3. Our repair service is not covered by ADLINK's guarantee in the following

situations:

• Damage caused by not following instructions in the User's Manual.

• Damage caused by carelessness on the user's part during product

transportation.

• Damage caused by fire, earthquakes, floods, lightening, pollution,

other acts of God, and/or incorrect usage of voltage transformers.

Warranty Policy • 31

Page 40

• Damage caused by inappropriate storage environments such as

with high temperatures, high humidity, or volatile chemicals.

• Damage caused by leakage of battery fluid during or after change of

batteries by customer/user.

• Damage from improper repair by unauthorized ADLINK technicians.

• Products with altered and/or damaged serial numbers are not

entitled to our service.

• This warranty is not transferable or extendible.

• Other categories not protected under our warranty.

4. Customers are responsible for all fees necessary to transport damaged

products to ADLINK.

For further questions, please e-mail our FAE staff: service@adlinktech.com

Warranty Policy • 32

Loading...

Loading...