Page 1

E

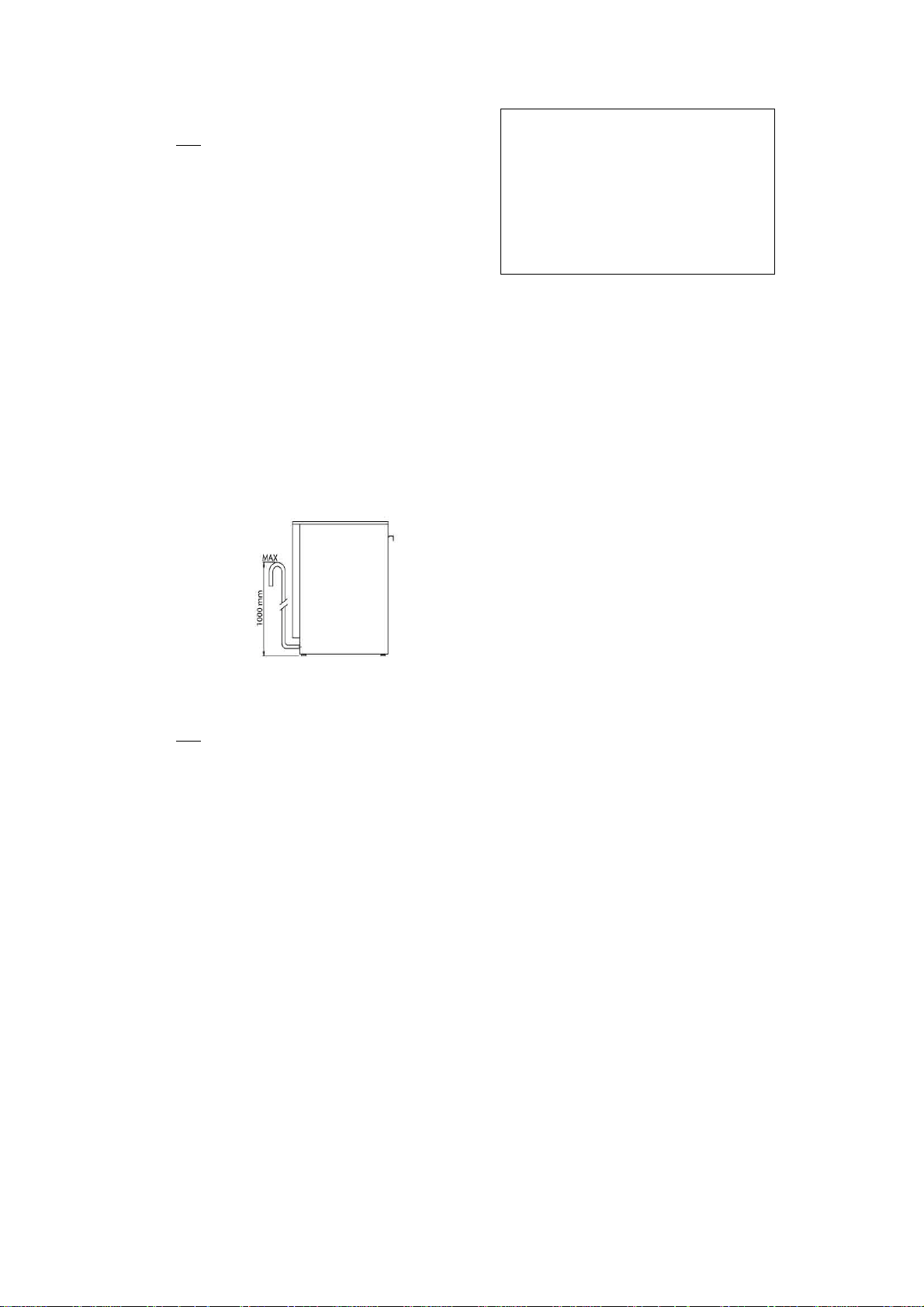

DISHWASHER

INSTALLATION, OPERATION AND MAINTENANCE Page 4

LAVASTOVIGLIE

INSTALLAZIONE, USO E MANUTENZIONE Pagina 21

GESCHIRRSPÜLER

INSTALLATION, BEDIENUNG UND WARTUNG Seite 38

LAVE-VAISSELLE

INSTALLATION, EMPLOI ET ENTRETIEN Page 57

LAVAVAJILLAS

INSTALACIÓN, USO Y MANTENIMIENTO Página 74

(REV 08/2014)

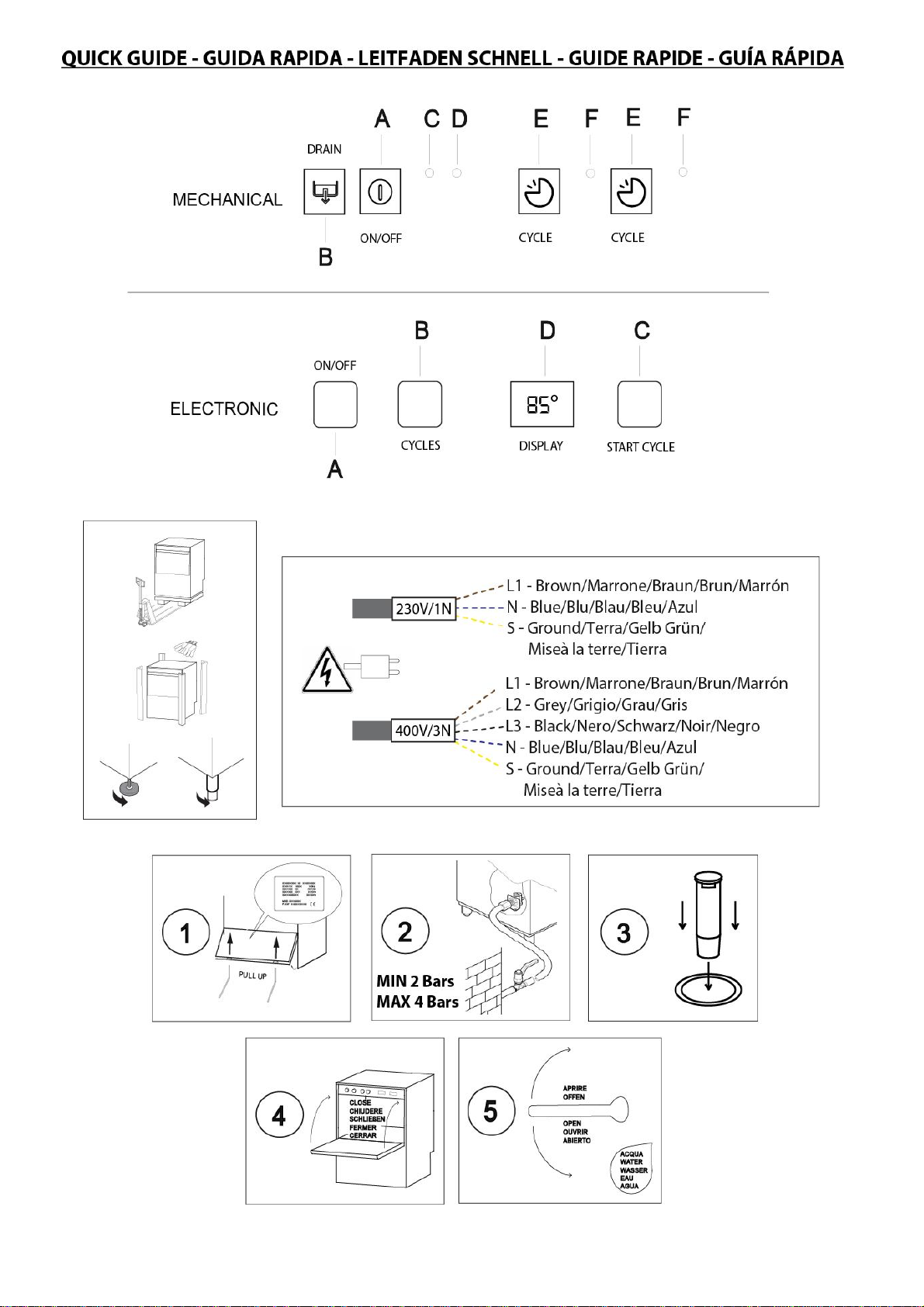

Page 2

1

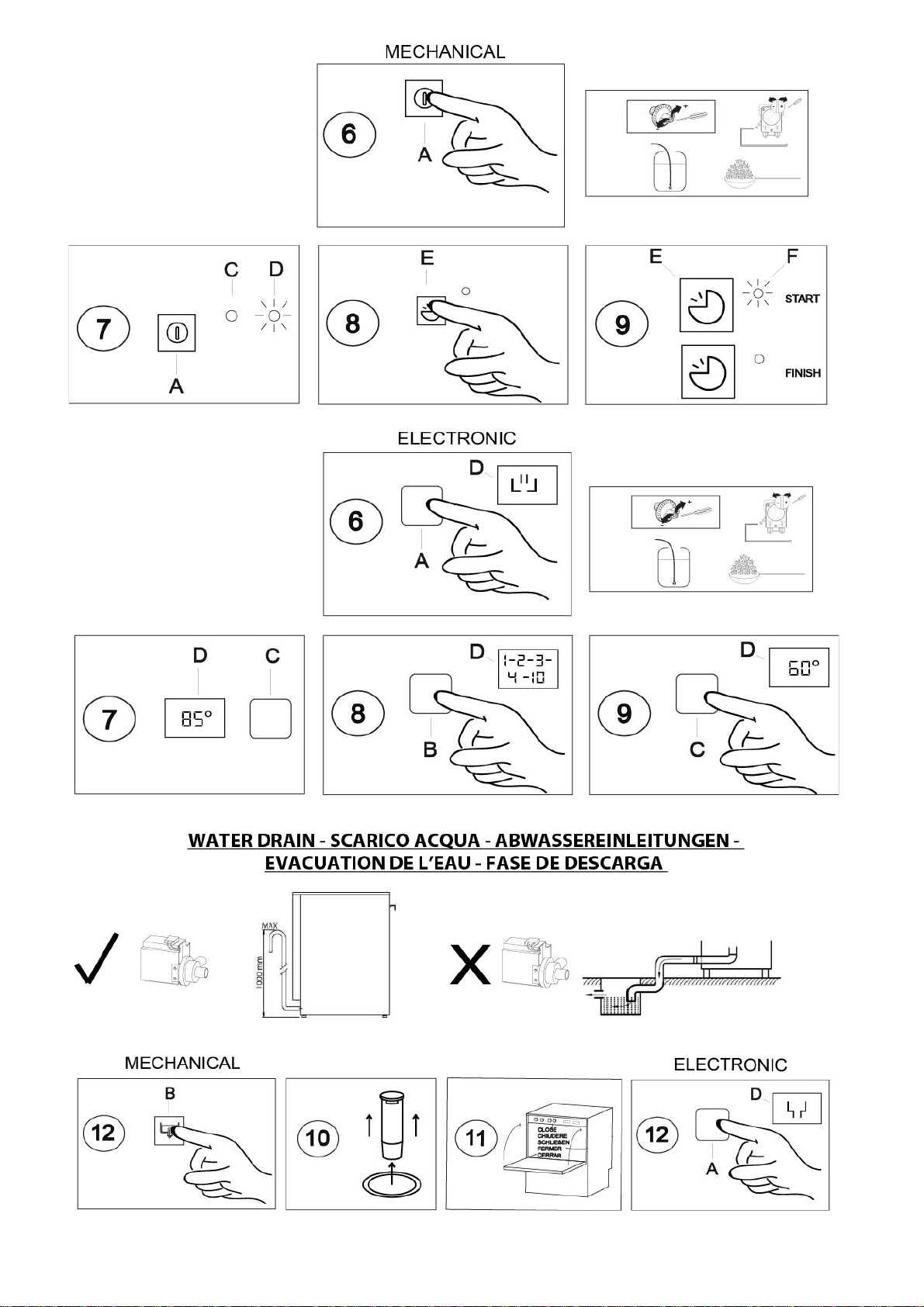

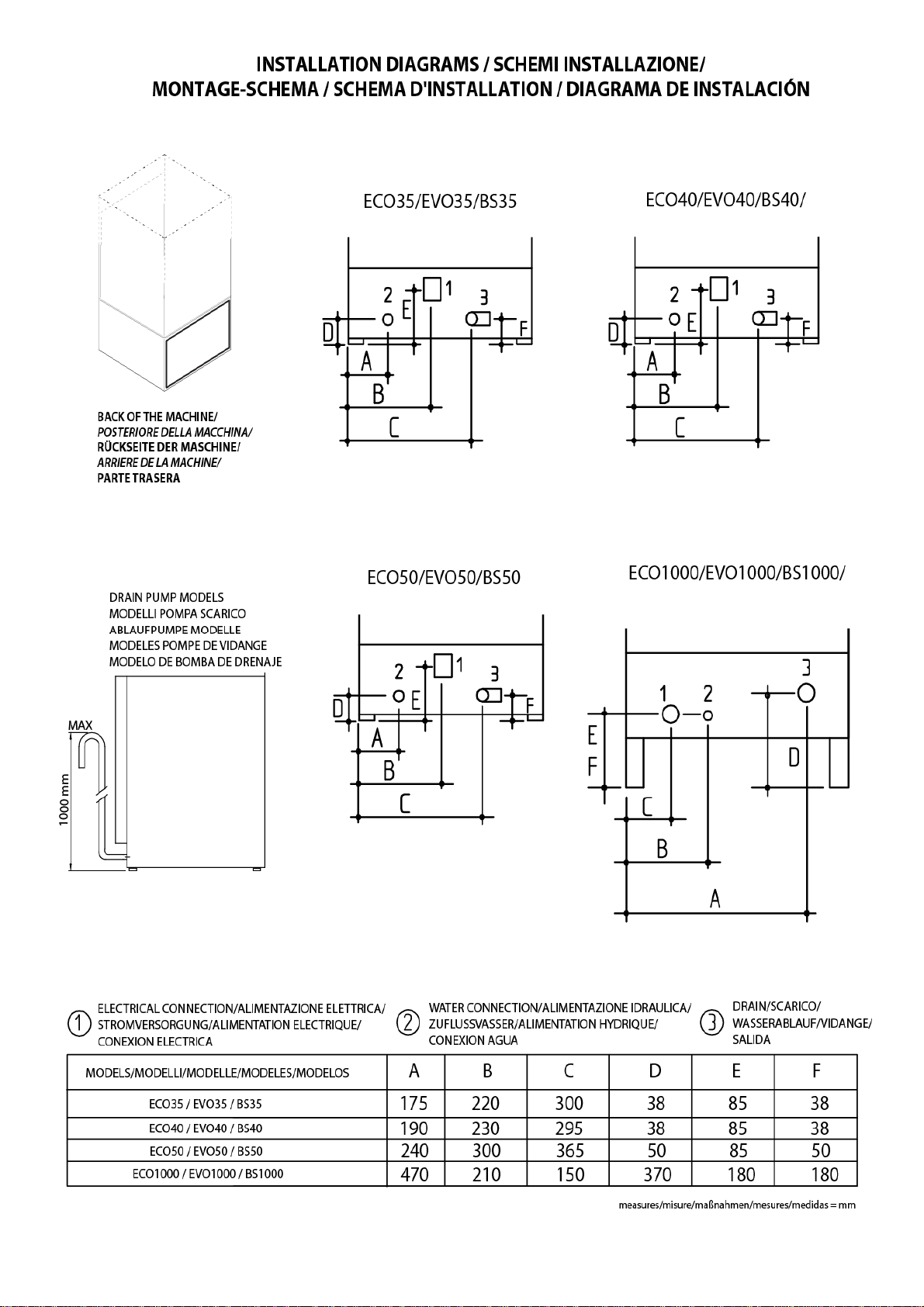

Page 3

2

Page 4

3

Page 5

INDEX

1 - GENERAL RECCOMMENDATIONS .………………...……………………... p.5

1A - HANDLING ……………………………………………………………...…... p.5

1B - UNPACKING …………….………………………………….……………….. p.5

1C - DISPOSAL …………………………………….……………………………... p.6

1D - TECHNICAL DATA …………………………………..…………………….... p.6

2 - INSTALLER AND MAINTENANCE PERSON INSTRUCTIONS ……...…...... p.7

2A - WATER CONNECTION ……………………….………………………............. p.7

2B - ELECTRICAL CONNECTION …………….………………………….……...… p.8

2C - WARNING MESSAGES DISPLAYED ON THE CONTROL PANEL …………..… p.9

2D - DETERGENT AND RINSE AID DISPENSERS AND SETTINGS …….…….……. p.10

2E - MANTEINANCE ………………………………………………….………..... p.11

2F - UNINSTALL (long period of inactivity)……….............…….……………….. p.11

3 - USER INSTRUCTIONS ……………..…..………………………………..... p.12

3A - GENERAL RECCOMENDATIONS AND WARRANTY ……….………............... p.12

3B - STARTING / WASH CYCLES (ELECTRONIC version) …………………............... p.13

3C - STARTING / WASH CYCLES (MECHANICAL version)……............................…..... p.15

3D - DAILY CLEANNING / END OF WORK ……….....................………………....... p.16

3E - UNDERCOUNTER DISHWASHER WITH BUILT- IN WATER SOFTENER ….... p.17

3F - WARNING MESSAGES DISPLAYED ON THE CONTROL PANEL …………..... p.19

4 - TROUBLESHOOTING …………………....……………………….……..... p.20

4

Page 6

1

-

GEN

ERAL RECOMMENDATIONS

ATTENTION

Carefully read this instructions booklet, as it

contains important advice for safe installation,

operation and maintenance. Keep this booklet to

hand in a safe place for future reference by other

operators.

Installation, use and service of the machine can

be performed only by qualified personnel,

especially trained to follow instructions:

WARNING!

The manufacturer cannot be held

responsible for injuries or damages of any

kind occurred to persons, machine or

others, due to lack of conformity with the

operation instructions indicated in this

documentation and for abuse, misuse and

lack of conformity with the instructions

indicated in this documentation as well as

installation, uninstall, service, tune-up,

maintenance requiring the removal of the

safety barriers not performed BY TRAINED

AND AUTHORISED SPECIALISTS, will result

in the IMMEDIATE LOSS OF THE WARRANTY.

Loss of warranty will result also from any

service performed to the machine, when:

Safety barriers are removed without

disconnecting the power line and the water

supply. When any safety provision of the

machine has been bypassed, removed or

excluded.

Machine is installed in provisional,

improper or unsafe conditions for lack of

compliance with safety provisions (fuses,

main breaker, ground line, or water inlet

and discharge valves).

When unauthorized modifications or

additions of devices which modify the

operation cycles indicated on the data chart

delivered with the machine.

When not genuine spare parts are used.

Installation or storage in inadequate spaces

according to the indications of

manufacturer.

Machine utilization different from the scope

foreseen as written in the documentation

(ex. Dishes of type or sizes different from

specified).

Utilization of dispensers with corrosive

products, not pure or dry.

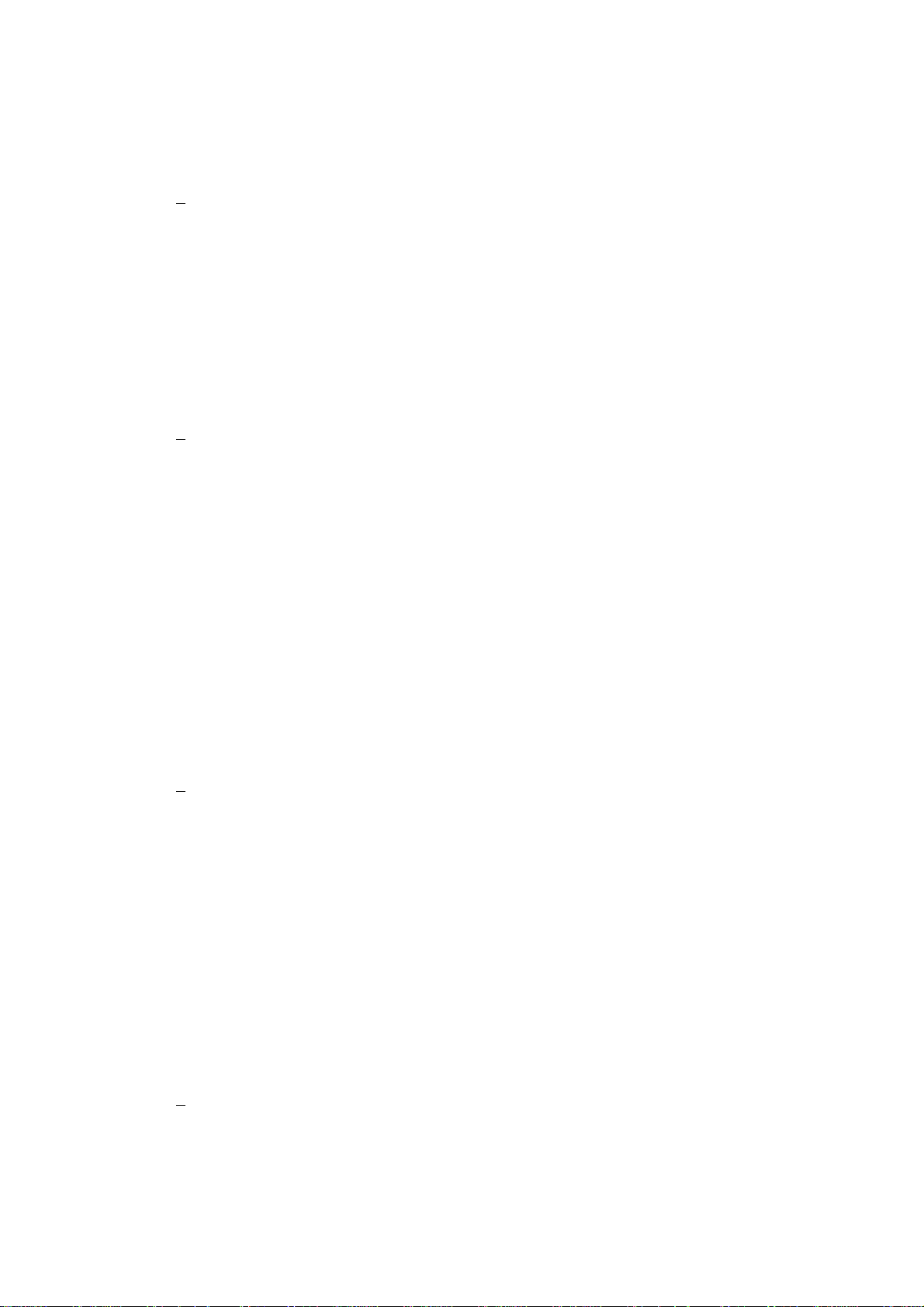

1A – HANDLING

Use suitable means to move the appliance: a

lift truck or fork pallet trucks (the forks should

reach more than halfway beneath the

appliance).

1B – UNPACKING

Before opening the boxes, verify the

conditions and in case indicates damages on

delivery slip. After unpacking, check the

machine conditions, in case the machine is

damaged, communicate immediately to the

dealer.

Do not proceed with the installation if

damages are relevant to operate safely and

wait for qualified and authorized assistance

person. Save boxing components (plastic

bags, expanded polystyrene, nails, etc.)

outside the reach of children for safety

reasons.

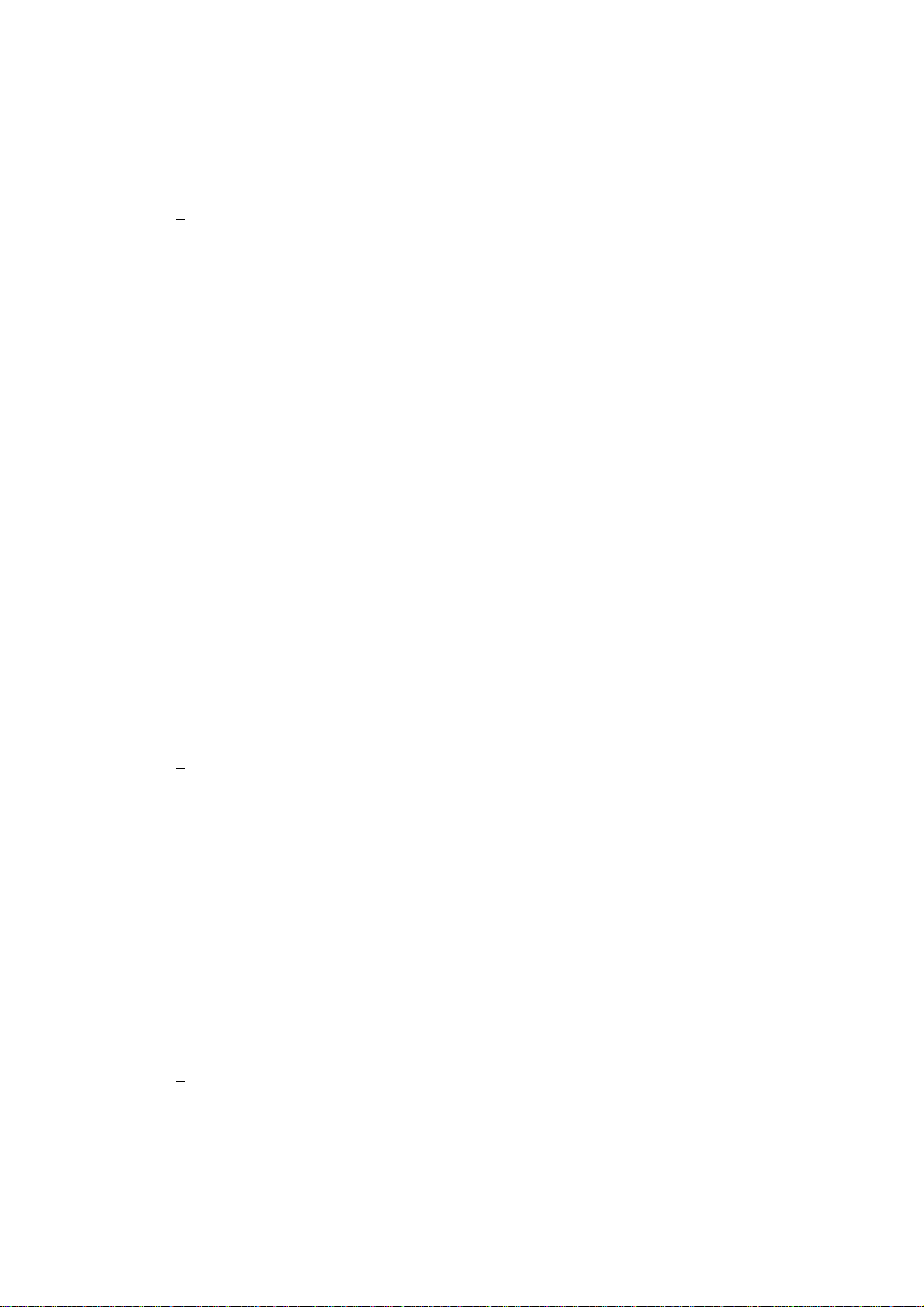

1- Wear protective gloves to unpack the

appliance from the boxing. (Fig. 1)

Fig.1

2- Lift the appliance using a lift truck. (Fig. 2)

Fig.2

3- Remove the protection film of the

appliance. (Fig. 3)

Fig.3

5

Page 7

Temperature

°C

50

Bar

2 - 5

Hardness

°f

7 - 14

°e

5 - 9,5

ppm

70 - 140

Conductivity

µ

S/cm

300 / 400

Operating

°C

5 - 35

Temperature

°F

50 - 158

1C – DISPOSAL

This appliance is marked according to the

European directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE). By

ensuring this product is disposed of correctly,

you will help prevent potential negative

consequences for the environment and human

health, which could otherwise be caused by

inappropriate waste handling of this product.

The symbol:

on the product, or on the documents

accompanying the product, indicates that this

appliance may not be treated as household

waste. Instead it shall be handed over to the

applicable collection point for the recycling of

electrical and electronic equipment. Disposal

must be carried out in accordance with local

environmental regulations for waste disposal.

For more detailed information about treatment,

recovery and recycling of this product, please

contact your local city office, your household

waste disposal service or the shop where you

purchased the product.

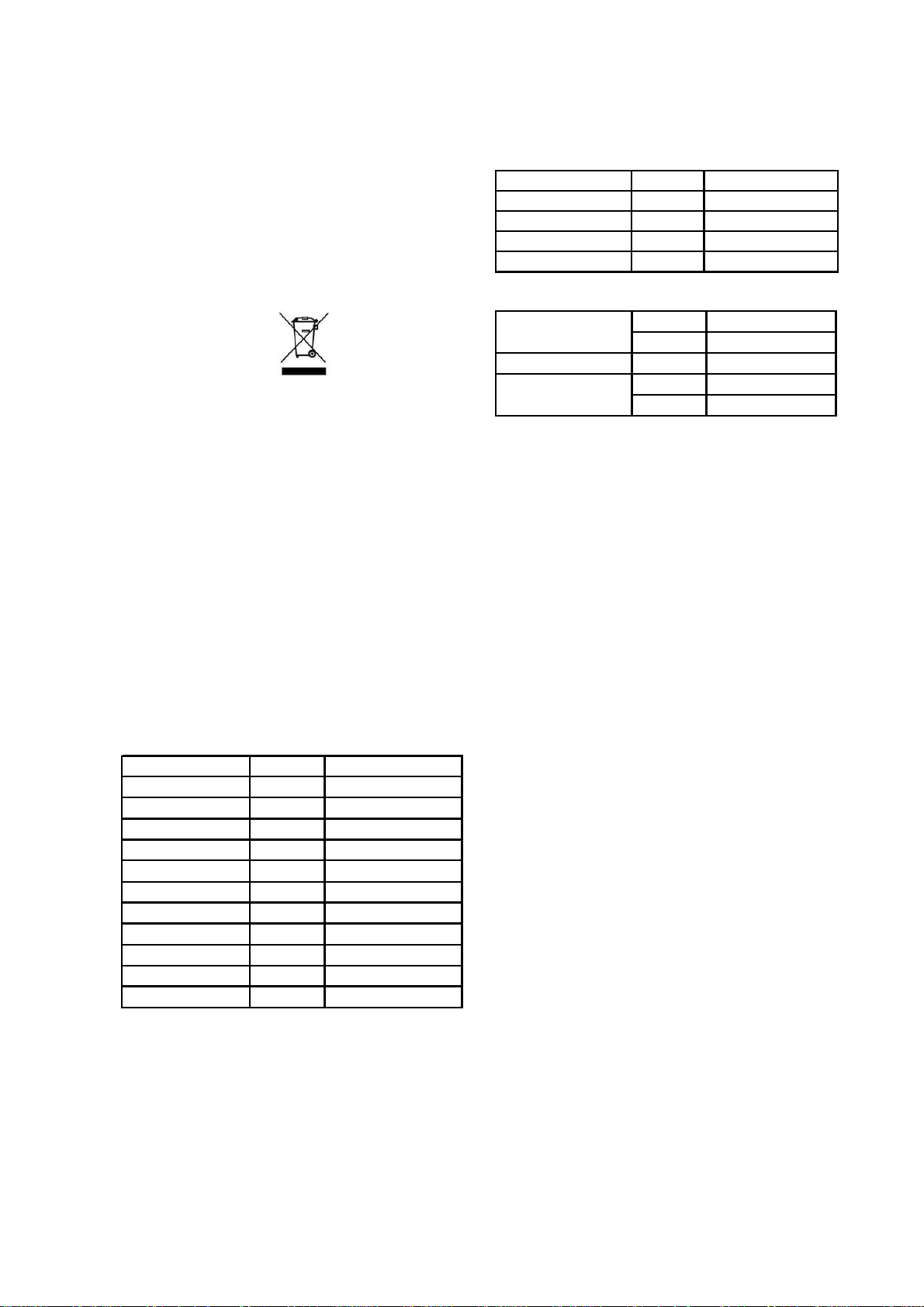

1D – TECHNICAL DATA

WATER CONNECTION

°F 122

Pressure kPA 200 - 500

ELECTRICAL CONNECTION

Voltage V ± 6 %

Frequency Hz ± 1 %

Wash Cycle °C 55

Rinse Cycle °C 85

INSTALLATION ENVIRONMENT

Temperature °F 41 - 95

Storage °C 10 - 70

1D1– NOISE LEVEL

Environment noise level cannot exceed the

values as per Standards of place of

installation. The noise of the machine,

measured at the manufacturer site, has been

less than 70dB, approximately 58dB.

When using the machine following data

must be complied with the storage,

transportation, utilization and maintenance

of the machine. Values of this documentation

can be updated according to the state-ofthe-art and manufacturer can reserve the

rights to modify present values.

PSI 29 - 72

Flow Lt/min 20 - 30

°dH 4 - 7,5

Mineral residues mg/l 300 / 400

6

Page 8

2

-

INSTALLER AND MAINTENANCE PERSON INSTRUCTIONS

ATTENTION

Specialists that install the machine are

foreseen to train the operators about

machine utilization and safety procedures to

be followed. They must provide a real

“demonstration” and verify that machine

instructions are available to the operators.

Following attentions should be taken:

WARNING!

DO NOT OPEN THE DOOR QUICKLY IF CYCLE

IS NOT ENDED.

DO NOT DIP BARE HANDS IN WASHING

SOLUTION.

DO NOT TAKE OFF THE MACHINE PANELS IF

THE MACHINE HAS NOT BEEN DISCONNECTED

FROM THE POWER AND WATER SUPPLY.

DO NOT BYPASS THE MACHINE PROTECTIONS

(MICROSWITCHES, PANELS, OR OTHERS)

PROVIDED BY THE MACHINE MANUFACTURER

IF NOT AT THE PRESENCE OF TRAINED

SPECIALISTS THAT CAN TAKE PROPRER

CAUTIONS.

DO NOT UTILISE THE MACHINE TO WASH

GOODS OUTSIDE THE SCOPE FOR WHICH IS

PROVIDED FOR, OBJECTS OF SHAPE, TYPE,

SIZE, AND MATERIAL NOT COMPATIBLE.

DO NOT OPERATE THE MACHINE IF NOT

PROPERLY CONNECTED, ACCORDING TO THE

SPECIFICATIONS AND REQUIREMENTS OF THE

LOCAL LAW AND PRESCRIPTION OF

MANUFACTURER, MAKING SURE THAT ALL

SAFETY DEVICES ARE OPERATIVE.

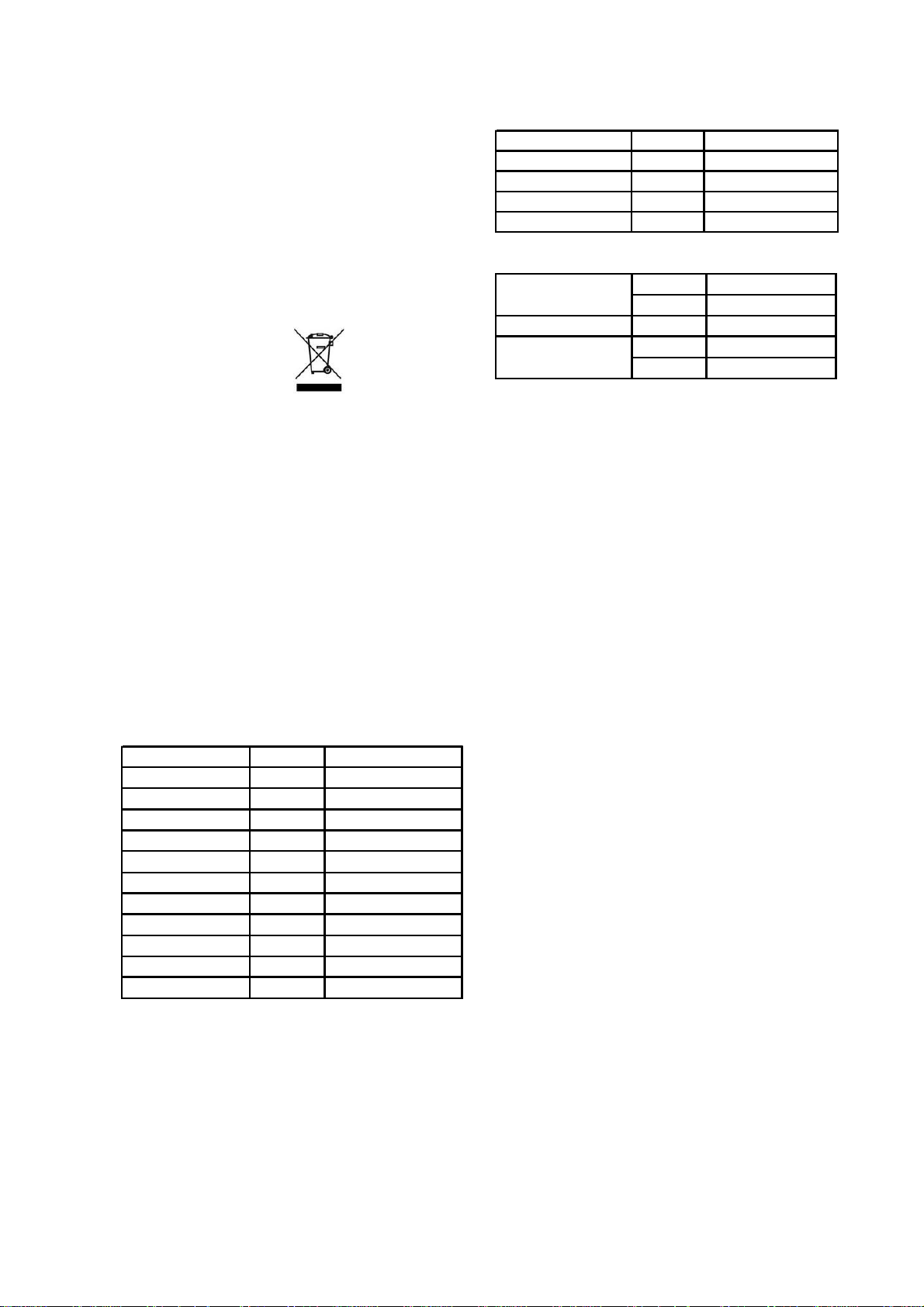

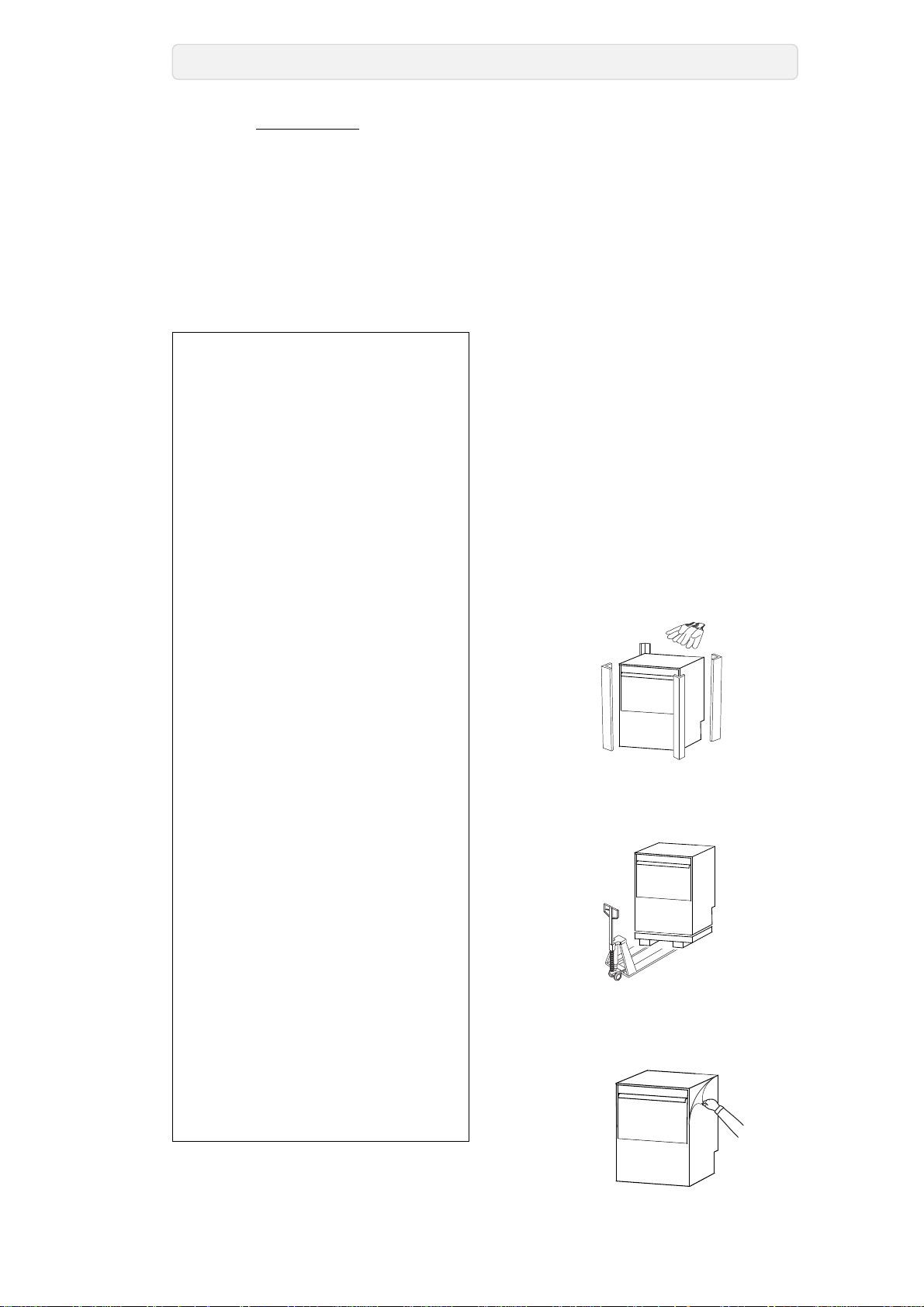

ID/RATING/DATA PLATE

ID/Rating plate of the appliance contains

identification and technical data and is located

on the front inside panel.

- Extract the front panel with Allen tool or

similar by inserting it inside the holes on the

inferior part of the panel. Pull up the panel

carefully. For Hoodtype models, unscrew the two

screws located on the bottom of the panel.

(Fig.4)

Fig.4

2A – WATER CONNECTION

N.B.

Shut-off valve, single direction, spool,

sphere, lid control type, which can shut

water supply off quickly and totally,

selected to assure water pressure and flow

as requested in the data diagram supplied

with each machine.

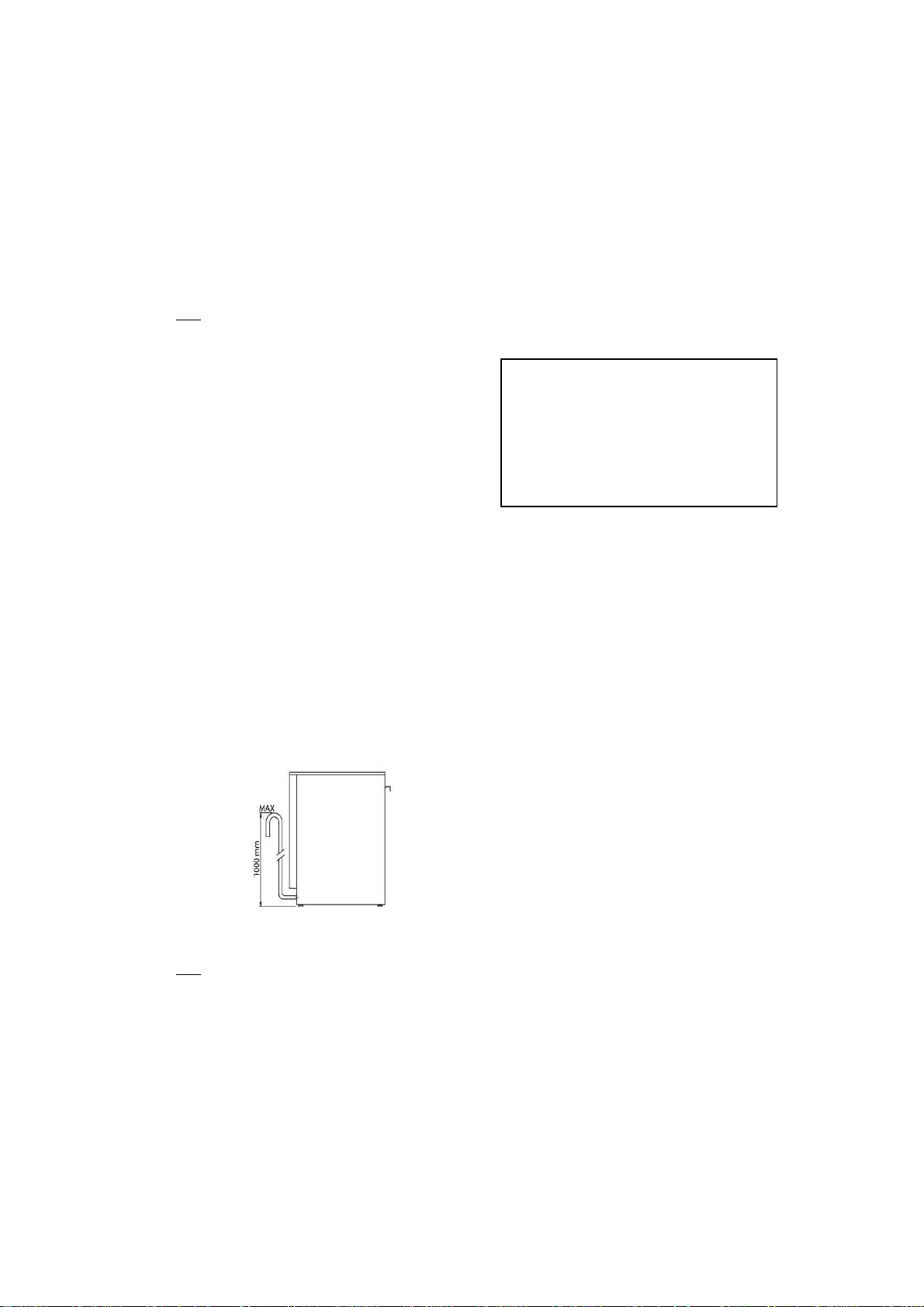

1- Position the dishwasher and level the

appliance by turning the relative heightadjustable feet. (Fig.5)

Fig. 5

2- Connect the solenoid valve, which feed

the machine, to water shut valve, using a

flexible line. (Fig.6) Each machine must

have its own water line supply.

Fig. 6

2A1 – WATER SUPPLY PRESSURE

Check that dynamic water supply pressure,

measured between the appliance and the

main, is between 200 and 500kPa. If the

pressure is too high, fit a suitable pressure

reducer on the inlet pipe. If the pressure is

low, install an additional external

pressure motor pump. (par.1D – Technical

Data)

- In case of new or long term appliance

inactivity, drain the water line to eliminate air

bubbles and foreign bodies present in new

or unused water lines, which can damage the

machine.

2A2 – WATER HARDNESS

If water hardness is higher than acceptable,

install a water softener if in the machine is

not provided with an internal one, of

adequate size prior the feed solenoid valve.

(par.1D – Technical Data)

If there is a high concentration of mineral

residues in the water or high conductivity,

we recommend installing the

demineralization filter for 5/7° f.

7

Page 9

2A3 – MODELS WITH FREE FALL DRAINAGE

N.B.

The drainage line consists of a sump pit, free

flow, of proper size capable to dispose twice

the water flow indicated on the data diagram.

It must be close to the drain pipe of the

machine without bending, stretching,

jointing the pipe.

- Drain line must reach sump pit with free flow

without constraints, stretching, bends, kinks, or

being forced.

- Connect the waste outlet pipe to the main

drain pipe, fitting a trap, or place the outlet pipe

over an “S” trap set into the floor.

2A4 – MODELS WITH DRAIN PUMP

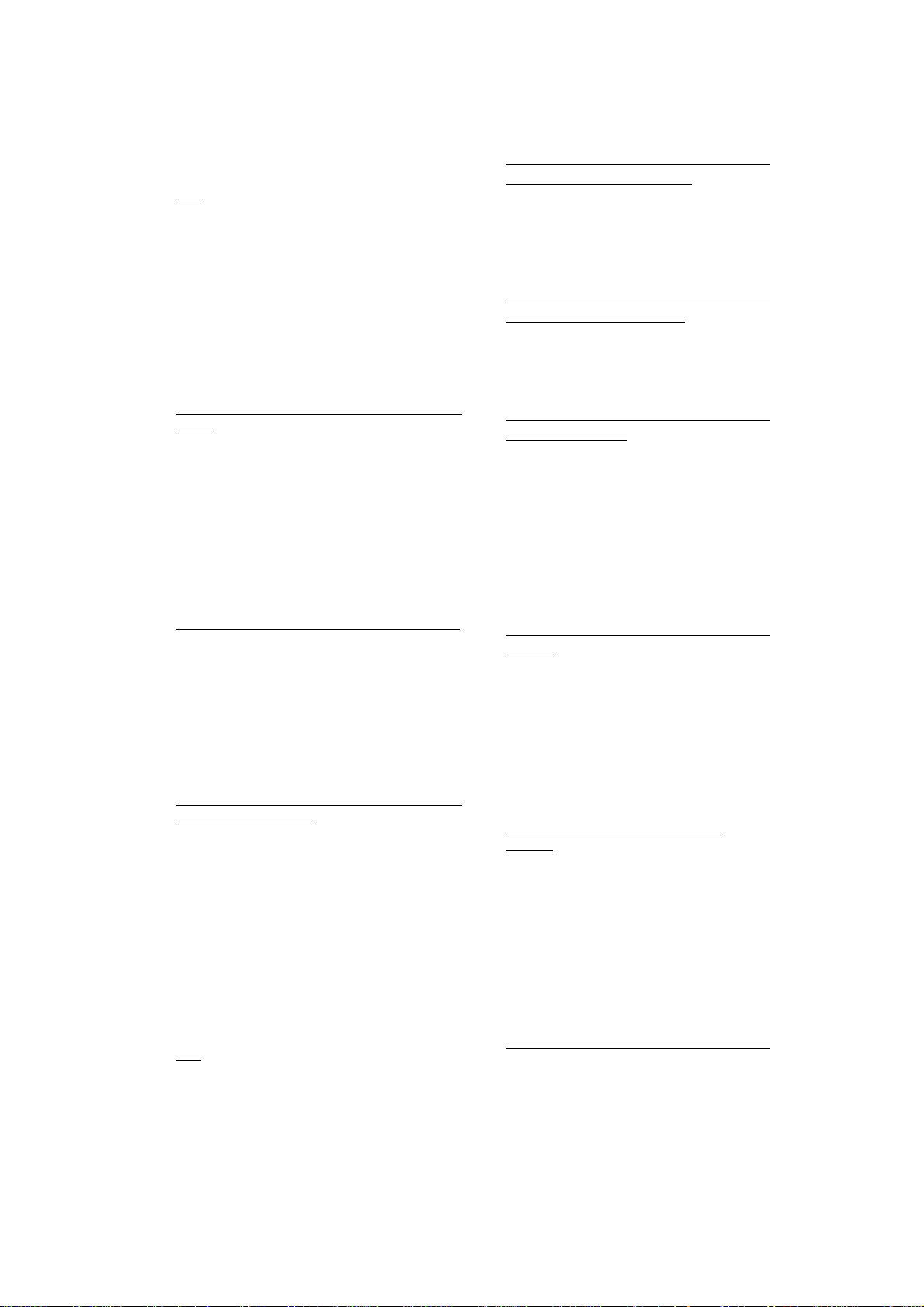

- Position the outlet pipe at a height anywhere

between 750 and 1000mm from the floor. (Fig.7)

Fig. 7

2B - ELECTRICAL CONNECTION

N.B.

All contacts must be mechanically open,

ground line included, min. distance between

contacts 3 mm, with magnetic overload or

fuses, calibrated for a max, sustained current

agree with machine plat. It must be installed

outside the machine but close to it. It must

feed one machine only at time.

Machine cannot be connected to mains using

adapters, plug, cables or cable extensions not

properly sized and adequate to the machine

power requirements.

- Verify main specifications must comply with

indicated requirements on the data plate located

inside of the front bottom panel of the machine

(par. ID/RATING/DATA PLATE), that exists for the

connection, a main breaker with proper size

suitable for the machine and a proper ground

system.

THE MANUFACTURER IS NOT

RESPONSIBLE FOR DAMAGES OR INJURIES

CAUSED FOR IMPROPER GROUNDING. THE

GROUND AND THE ELECTRICAL

CONNECTIONS SHOULD BE IN

COMPLIANCE WITH NATIONAL

REGULATIONS.

The line cable can be replaced only with a

spare cable supplied by the manufacturer.

For replacement indicate machine type,

machine serial number and possible

modifications of the installation. Power cable

cannot be stretched kinked, pressed, during

normal operation, service or anytime.

Earth equilibrating point on machine must

be connected to nearest appliance terminal

according to Safety Standards using a 2.5 –

10 mm.

WARNING!

8

Page 10

2C – WARNING MESSAGES

DISPLAYED ON THE CONTROL PANEL

(Electronic version only)

N.B.

If the machine is in OFF mode, warning

messages are not displayed. Turn ON the

machine to visualize the type of warning

message on the appliance.

Following warning messages on the display are

provided:

ntcb

E-01 BOOSTER TEMPERATURE PROBE

Booster temperature probe not connected or

faulty.

Verify that the probe is correctly and well

connected to the electronic board.

Verify that the probe is correctly positioned

inside the booster and there is not presence of

limestone on it.

ntcu

E-02 TANK TEMPERATURE PROBE

Tank temperature probe not connected or faulty.

Verify that the probe is correctly and well

connected to the electronic board.

Verify that the probe is correctly positioned

inside the tank and there is not presence of

limestone on it.

fill

E-03 WATER FILL

Water fill not completed during the available

maximum time (10min).

Verify that water supply is correctly connected,

opened and free of obstructions.

Verify that solenoid valve filter is free of possible

obstructions and deposit.

Verify that water supply pressure is adequate

(par.1D – Technical Data).

Verify that machine’s door is completely closed

and the overflow device is correctly positioned

inside the tank.

N.B.

If water fill timing expires or in case of water

level signal is not respected solenoid valve is

automatically interrupted. To restart solenoid

valve press any button on the control panel.

Tbo

E-04 BOOSTER TEMPERATURE LIMIT

Booster temperature maximum set point

reached (set point +14°C / 57°F).

SUBSTITUE THE ELECTRONIC BOARD

TUA

E-05 TANK TEMPERATURE LIMIT

Tank temperature maximum set point

reached (set point +7°C / 44°F).

SUBSTITUE THE ELECTRONIC BOARD

drA

E-06 DRAIN ANOMALY

Drainage not completed on the maximum

programmed timing.

Verify that the overflow device is completely

removed and not obstructions are present on

the water drain line.

Verify that drain wires is correctly connected

to the electronic board.

Bnot

E-07 BOOSTER HEATING

Maximum booster heating time reached

(15min).

Verify that heater element wires are

correctly connected to the electronic board.

Verify that heater element works correctly

and there is not presence of limestone on it.

Unot

E-08 TANK HEATING

Maximum tank heating time reached

(30min).

Verify that heater element wires are

correctly connected to the electronic board.

Verify that heater element works correctly

and there is not presence of limestone on it.

SEruICE

E-09 PARAMETERS ERROR OR

DAMAGED BOARD

Memory parameters error or damaged board.

SUBSTITUE THE ELECTRONIC BOARD

ACTIONS FOLLOWED TO THE WARNINGS:

Booster and tank heating elements are

interrupted, all loads are disactivated, the

electronic board displays warning codes and

it is inactivated. All control panel leds are Off.

Cycle is interrupted “hold mode” until the -

9

Page 11

breakdown is reseted. It is always possible to

turn Off and On the appliance trought the

button.

SAFETY THERMOSTAT

All machines are provided with a safety

heatswitch that shuts machine off in case of

overheating (120°C/248°F). To reset the

thermonstat device press the push-button

behind the control panel of the thermostat.

2D – DETERGENT AND RINSE AID

DISPENSERS AND SETTINGS

Before starting a new cycle the dispenser and its

pipe must be completely filled. Check the level of

the detergent or rinse aid and eventually fill-up

the tank.

N.B.

The level in the detergent or rinse aid tank

must not get empty or filled with corrosive or

inadequate products. The warranty does not

cover damages caused by improper use of

dispenser. The dispenser is calibrated at

manufacturer site: dispenser settings after

installation can be performed only by

qualified specialists.

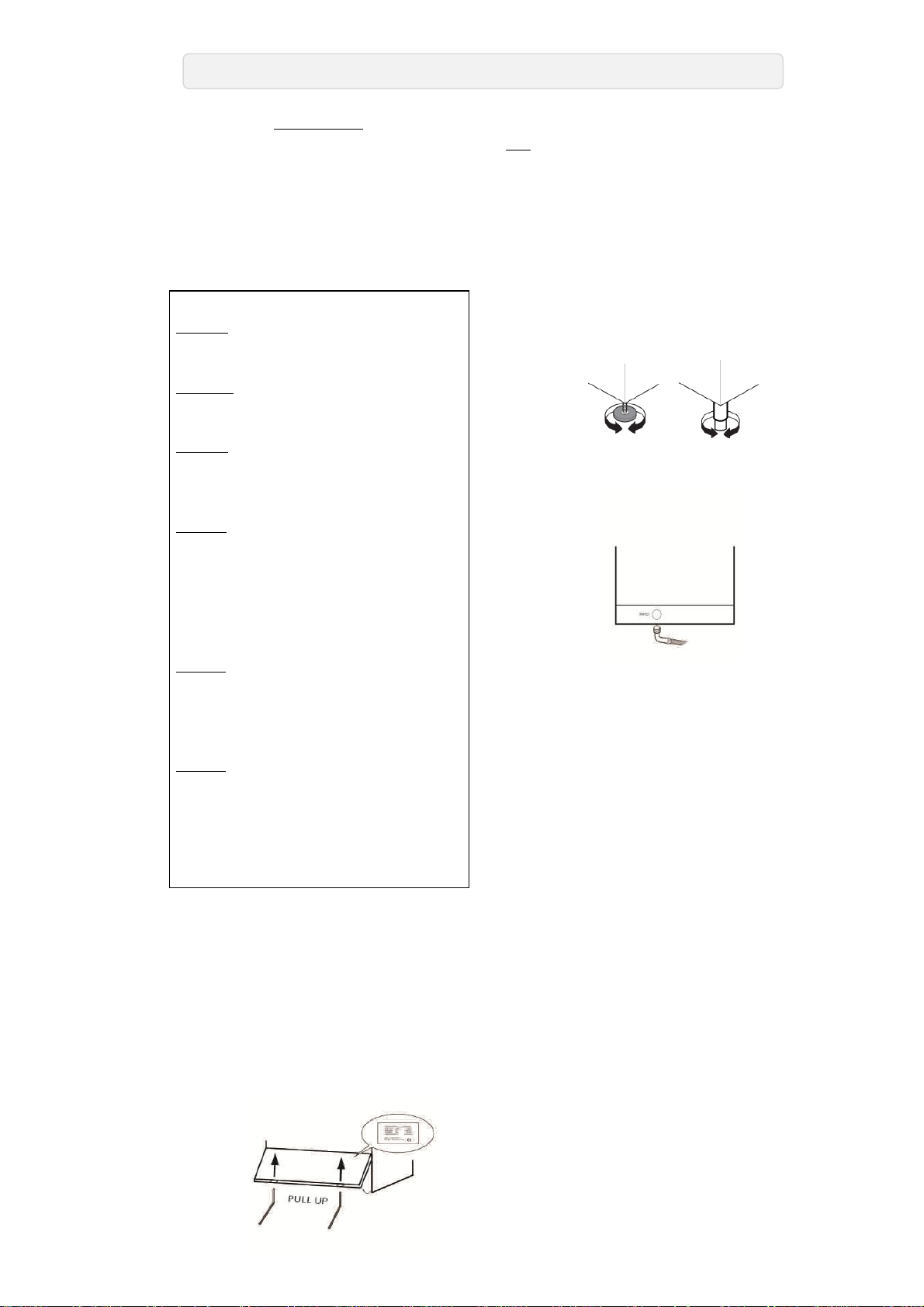

1- Extract the front panel with Allen tool or

similar by inserting it inside the holes on the

inferior part of the panel. Pull up the panel

carefully. For Hoodtype models, -

unscrew the two screws located on the

bottom of the panel. (Fig.8)

Fig.8

Before removing the front panel make sure the

machine is disconnected from the main

breaker.

2- Insert included dispenser tube inside the

detergent or rinse aid tank. (if available).

(Fig.9)

Fig.9

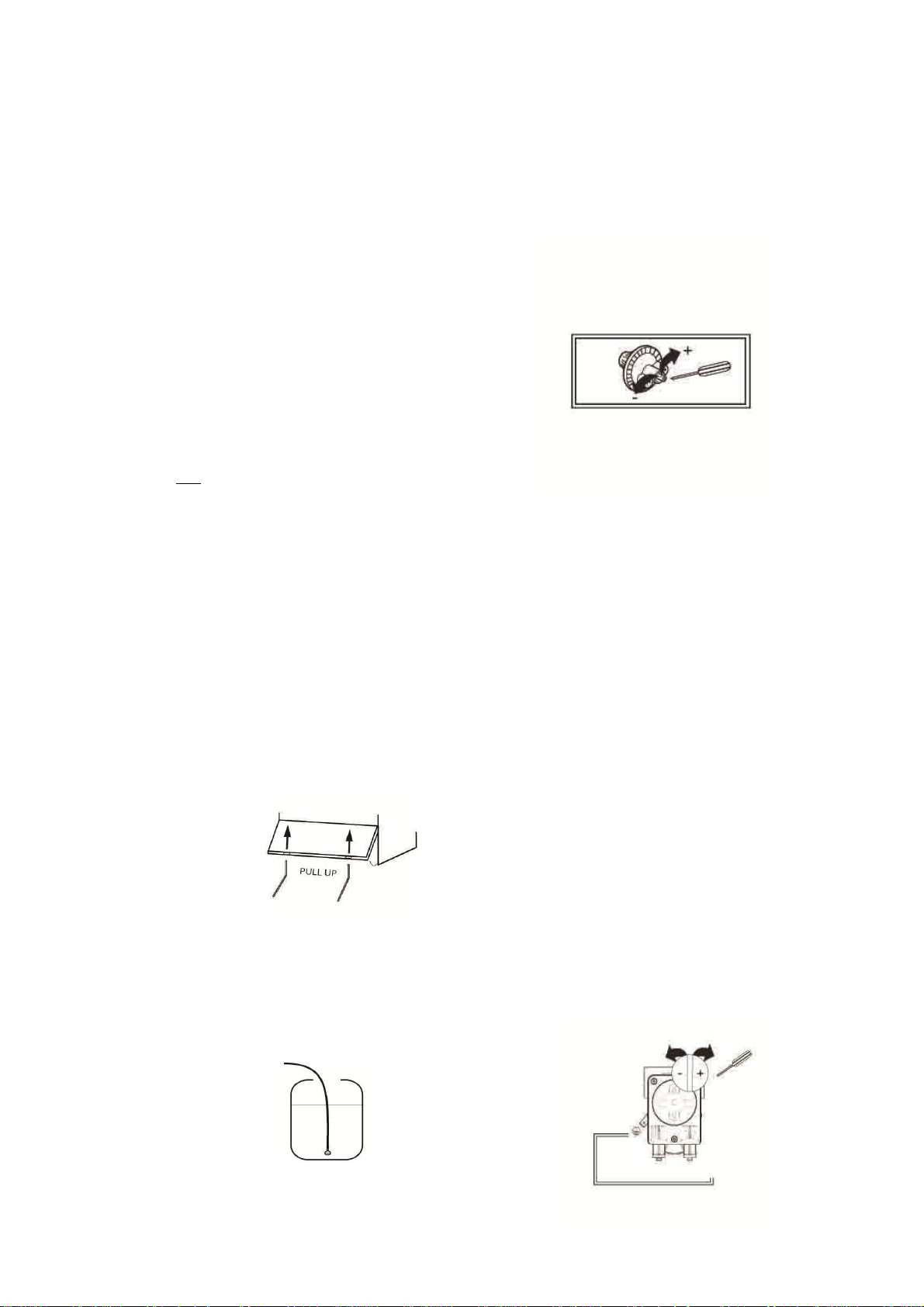

2D1 – PRESSURE RINSE AID DISPENSER

Setting of rinse aid dispenser is perfomed

acting on the screw accessible after removal

of front panel, under the tank door. (see

Fig.8)

1- Close gently all the way down the

dispenser by screwing anticlockwise the

needle valve of the dispenser.

2- Open up until reached necessary

quantity by screwing clockwise the needle

valve of the dispenser. (Fig.10)

Fig.10

Quantity for the first setting should be

according to the installator after

evaluating the hardness of the water and

the type of rinse aid used. Recommended

vacum standard quantity of rinse aid from

the included tube 4 x 6 correspond to

approximately 4 cm = 0,5cc = 0,5 gr. for

each 50 x 50 standard rack machine.

Otherwise, approximately 2,5 cm = 0,3 =

0,3 gr. for 35 x 35 and 40 x40 standard

rack glasswasher. Maximum dosing

permit is approximately 25,8 cm = 3,6 cc =

3,6 gr.

After first setting rinse aid dosage must be

optimize by evaluating washing results after

few cycles.

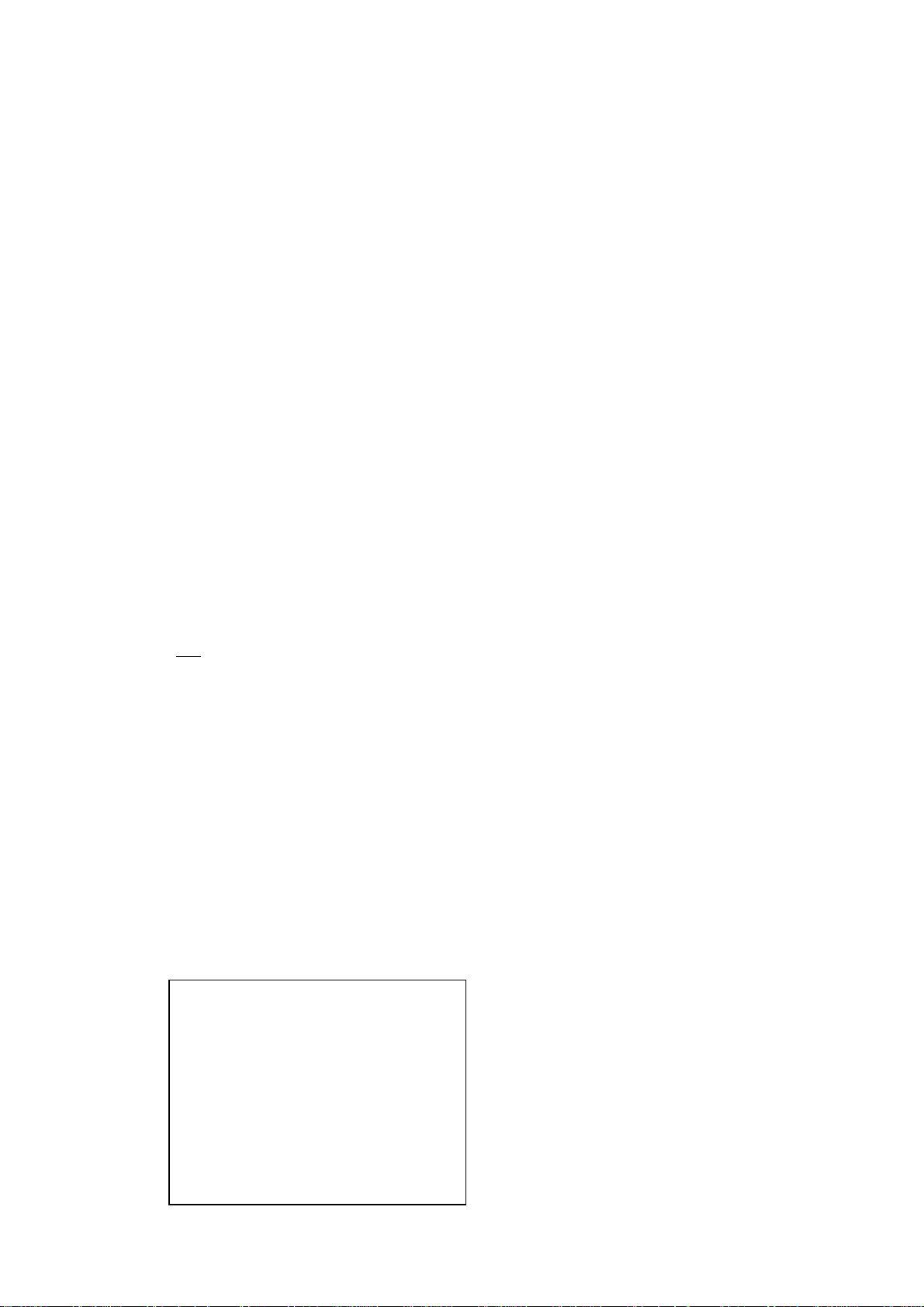

2D2 – PERISTALTIC RINSE AID AND

DETERGENT DISPENSER

Setting of rinse aid dispenser is perfomed

acting on the screw accessible after removal

of front panel, under the tank door. (see

Fig.8)

1- Close gently all the way down the

dispenser by screwing anticlockwise the

needle valve of the dispenser.

2- Open up until reached necessary

quantity by screwing clockwise the

needle valve of the dispenser. (Fig.11)

Fig.11

10

Page 12

Quantity for the first setting should be according to

the installator after evaluating the hardness of the

water and the type of rinse aid used. Recommended

rinse aid standard quantity is 0,16 gr/sec that

correspond to the maximum flow rate of the

dispenser. Recommended detergent standard

quantity is 0,77 gr/sec that correspond to the

maximum flow rate of the dispenser.

SUGGESTION

To check the effectivness of the rinse aid, look at

freshly washed glasses against the light. Drops of

water remaining on the glass indicate an

insufficient amount while streaks indicate an

excess. (next page)

In case of light coated presence that block

dispenser functions, remove the coat by soaking

the dishes for 30 minutes in a solution water

soap (1:10) before starting machine cycle.

2D3 – DISHWASHERS WITHOUT DETERGENT

DISPENSER

Manually add recommended detergent quantity

from the supplier every 5 cycles. Doses differ

depending on water hardness and soiled

quantity that remain on the dishes.

N.B.

All dishwashers are ready to be installed

external dispenser or specific dispenser kit

through injector and relative tube or through

the hole with relative cap located on the tank

of the machine. If changing to a different

detergent or rinse aid type (even one by the

same manufacturer), you must rinse the

suction and pressure hoses with fresh water

before connecting the new detergent or rinse

aid container. Otherwise, the mixing of

different types of detergent or rinse aid will

cause cristallisation, which may result in a

breakdown of the dosing pump. Failure to

observe this condition will invalidate the

guarantee and product liability.

WARNING!

DETERGENT SELECTION AND DOSAGE ARE

FUNDAMENTAL FOR WASHING GOOD

RESULTS AND TO MANTAIN MACHINE

PERFORMANCES FOR LONG TIME AND

EXTENDED LIFE. FOLLOW ALWAYS THE

INSTRUCTIONS OF THE MANUFACTURER OF

CLEANNING AGENTS. IMPROPER DOSAGES

RESULT IN UNSATISFACTORY WASHING

RESULTS AND REPRESENT SOURCES OF

RIVERS AND SEAS POLLUTION. DO NOT USE

CORROSIVE OR POLLUTANT PRODUCTS

TO PROTECT AND MAINTAIN

MACHINE, NEVER EXCEED DOSAGES

INDICATED BY DETERGENT

MANUFACTURER. NEVER LEAVE THE

DISPENSER DRY OR CHARGED WITH

CORROSIVE OR FOREIGN PRODUCTS

WHICH WILL RESULT IN LOSS OF

WARRANTY.

2E – MAINTENANCE

1- Descale the boiler, the internal surface of

the tank and the appliance water piping

once or twice a year.

2- Descale the rinse and wash jets every

month using vinegar or a descaling

agent.

3- The internal hose of the rinse aid and

detergent peristaltic dispenser should

undergo periodic maintenance (once or

twice a year).

4- Clean solenoid valve filter by extracting it

from the inside of the valve and by

unplugging the water inlet tube.

2F – UNINSTALL (Long period of

inactivity)

Machine can be taken out of operation

only by trained specialists authorized for

the purposes, who will provide for:

1- Shut water line off (water valve) and

electric supply (main breaker).

2- Completely drain the tank.

3- Remove and carefully clean the filters.

4- Completely drain the incorporated

dispenser hoses, removing them from

the containers.

5- Drain the detergent and rinse aid nozzles

with fresh water first and after with water

and glycerine (50% - 50%) taking care

that nozzles remain clean and lubrified

inside.

6- Drain completely the booster by

removing the screw located under the

machine.

7- Spread a thin film of vaseline oil over all

the stainless steel surfaces.

INSTALLATOR REMARKS

INSTALLATION DATE:________________________

INSTALLATION PLACE:_______________________

INSTALLATOR NAME:________________________

MACHINE SERIAL NUMBER:___________________

SIGNATURE:_______________________________

11

Page 13

3

-

USER INSTRUCTIONS

3A – GENERAL RECCOMENDATIONS

AND WARRANTY

Our appliances have been studied and optimised

to give high performance. This appliance must

be used exclusively for the purpose for which it

has been designed, i.e. for washing dishes with

water and specific detergent. Any other use is to

be considered improper.

WARNING!

BEFORE ANY CLEANING OR MAINTENANCE

OPERATION, DISCONNECT THE DISHWASHER

BY SWITCHING OFF THE ELECTRICITY AT THE

MAINS OR PULLING THE PLUG OUT.

DO NOT LEAVE THE DISHWASHER SWITCHED

ON UNNECESSARLY.

IF ANY FAULT IS DETECTED, DISCONNECT THE

DISHWASHER FROM THE MAINS, CLOSE THE

MAIN WATER SUPPLY AND CALL

IMMEDIATELY THE SERVICE ASSISTANCE.

DO NOT USE THE DISHWASHER OPEN DOOR

PULLING THE TOP FRONTWARDS.

DO NOT USE THE DISHWASHER IN A

EXPLOSIVE ATMOSPHERE.

DO NOT WAS OR CLEAN THE MACHINE WITH

DIRECT BOLT OF WATER AND/OR WITH

HURTFUL MATERIAL.

AVOID THE MACHINE IS EXPOSED TO HEAT

AND/OR HUMIDITY SOURCES.

DO NOT USE THE MACHINE IF THE SUPPLY

CABLE IS DAMAGED.

THE MANUFACTURE DECLINES ANY LIABILITY

FOR DAMAGES TO PERSONS AND/OR THINGS

DUE AND TO AN IMPROPE, WRONG AND/OR

UNREASONABLE USE OF THE MACHINE.

NEVER CLOSE THE WATER COCK WHILE THE

MACHINE IS WORKING.

DO NOT DISCONNECT THE SUPPLY PLUCKING

THE SUPPLY CABLE BUT DISCONNECT

SEIZING THE PLUG.

USE ONLY PROFESSIONAL DETERGENTS AND

RINSE AID AND STORE THEM IN A

COOL AND DRY PLACE, OUT OF THE

REACH OF CHILDREN.

DO NOT REMOVE ANY PROTECTION

AND/OR PANELS REQUIRING A TOOLING

TO BE REMOVED.

THE MACHINE IS EQUIPPED WITH SAFETY

MICROSWITCH TO STOP THE OPERATION

IN CASE THE DOOR WOULD BE OPENED

DURING THE PRECESS. MOTOR PUMP IS

EQUIPPED WITH A THERMICAL PROBE TILL

160°C (320°F) TO AVOID THE

OVERHEATING. IMPOSSIBILITY TO BE IN

CONTACT WITH ELECTRICAL PARTS

WITHOUT USING A TOOL.

TO AVOID VIBRATIONS, THE MACHINE IS

EQUIPPED WITH FOUR ADJUSTABLE FEET.

12 months warranty – Mechanical Parts

6 months warranty – Electrical Parts

N.B.

Damages, breakdown based on lack of

conformity with the operation

instructions indicated in this

documentation and for abuse, misuse and

lack of conformity with the instructions

indicated in this documentation or service

by unauthorized and non specialist

persons will result in the IMMEDIATE LOSS

OF THE WARRANTY.

3A1– SUGGESTION BEFORE USING THE

DISHWASHER

- Carry out a couple of cycles without dishes

to flush out any industrial grease which has

remained in the tank and piping.

- Avoid washing decorated dishes.

- Do not allow silverware to come in contact

with other metals.

- Do not allow food to dry on the dishes.

- Remove large food scraps from the dishes

to prevent clogging the filters.

- Pre-wash the dishes by spraying them with

cold or lukewarm water, without using any

detergent.

- To have best washing results place all

cutlery in the cutlery basket with the handles

downwards paying attention to avoid

potential injuries.

- Use automatic dispenser for the detergent.

- If there is no automatic dispenser, put nonfoaming detergent into tank when the water

has reached the washing temperature.

12

Page 14

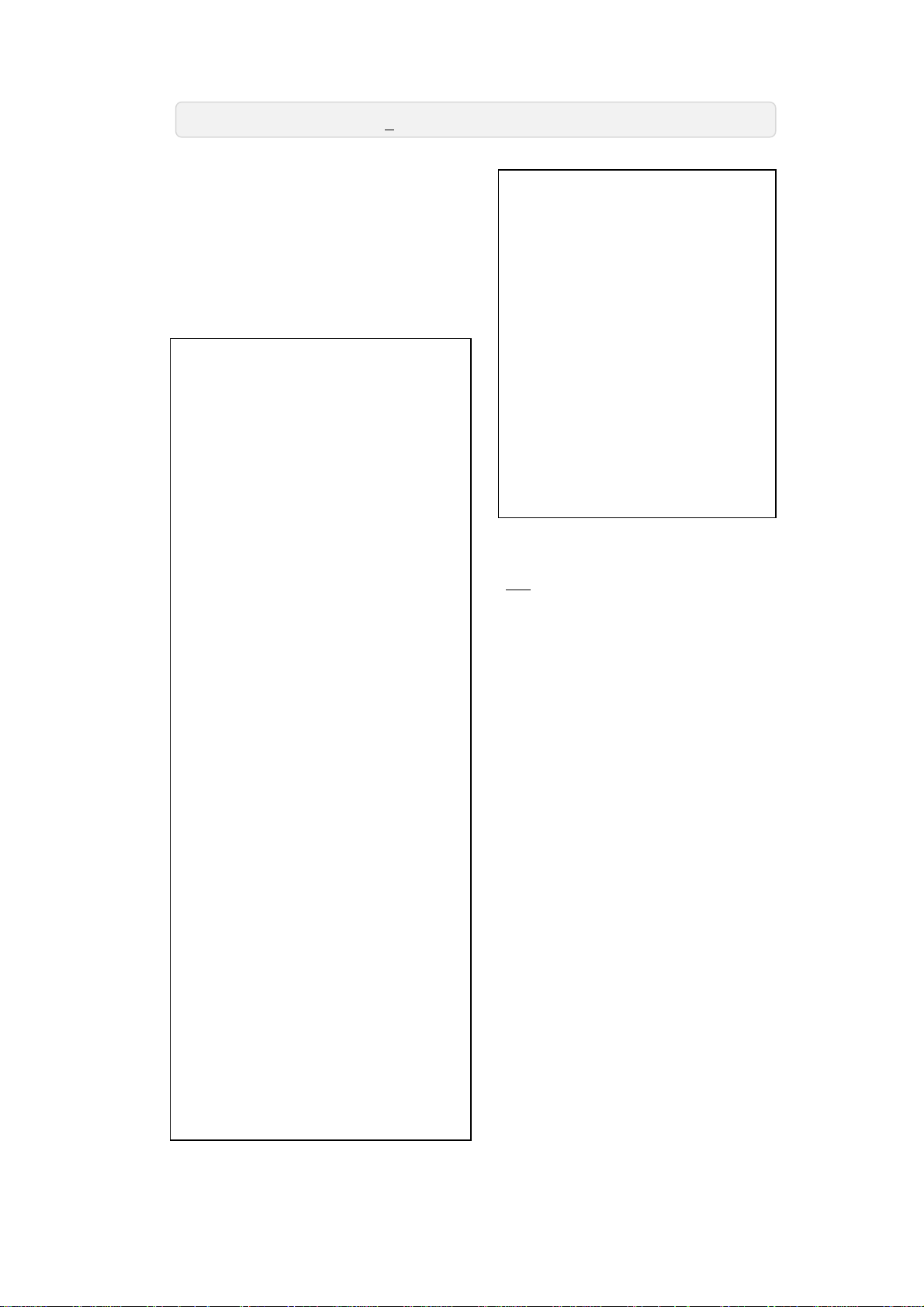

CONTROL PANEL VERSION

LEGENDA

3B – STARTING / WASH CYCLES

(ELECTRONIC version)

A = On/Off

B = Cycle Selection

C = Start Washing Cycle

D = Display

N.B.

The control panel represented above is full version.

Some versions may have not all the indicated functions.

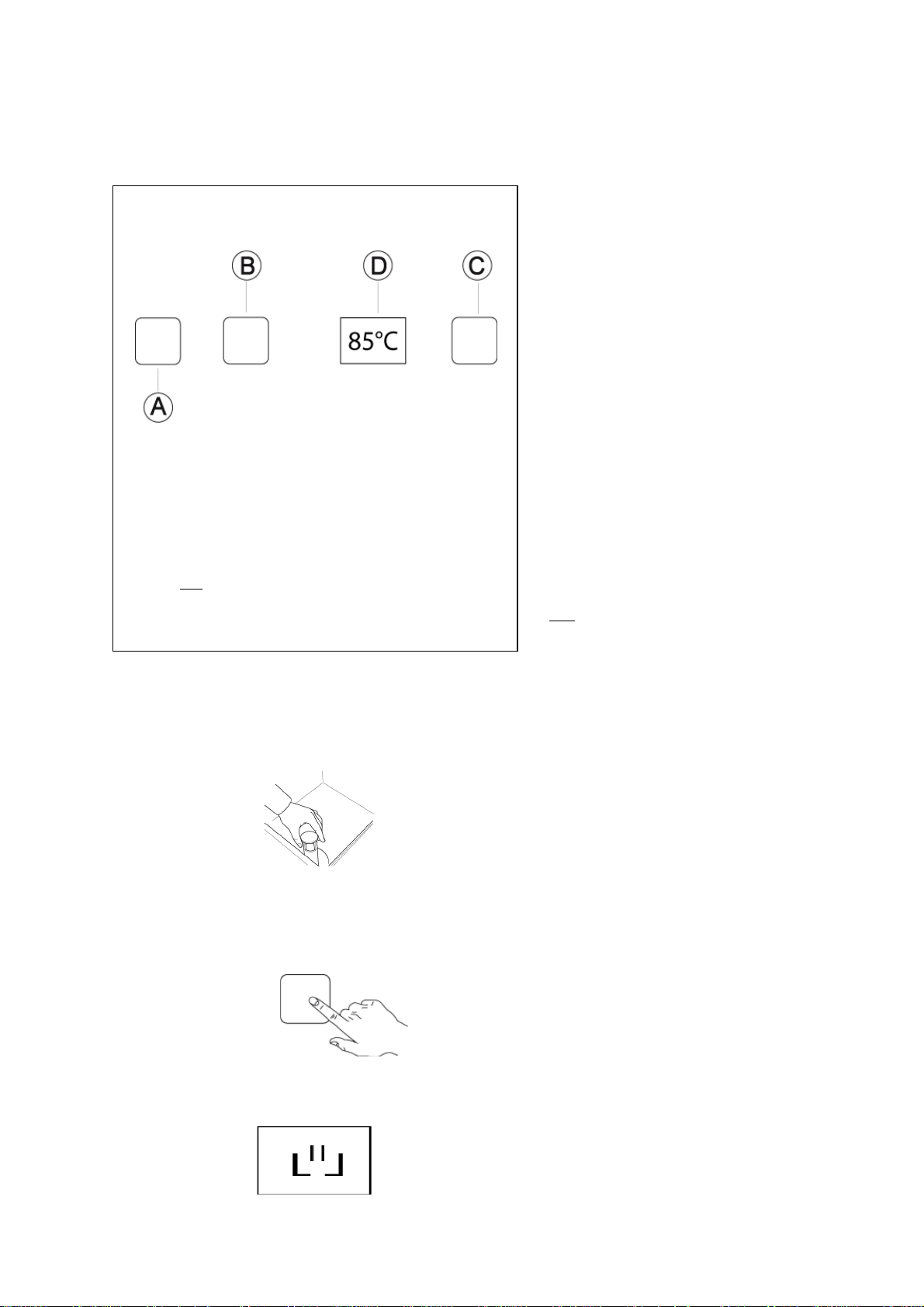

3B1 – STARTING THE MACHINE

1- Open the door and verify that all internal

components, water flow device included,

are in the correct position. (Fig.12)

Fig.12

2- Open main water supply cock.

3- Switch on at the mains.

4- Close the door and press button “A” to turn

ON the machine. (Fig.13)

A

Fig.13

- During water fill process filling

icon is displayed. (Fig.14)

Fig.14

- If during this process door is

opened, display is blinking.

Consequently close the door.

- During filling and water heating

process AMBER indicator light is

visualized on button “C”.

- After water heating process is

finished and the temperature is

reached, indicator light is visualized

on button “C” machine READY to use.

3B2 – DETERGENT FILLING

PROCESS (versions without

automatic detergent pump only)

Glasswasher Models:

- Begin filling the tank with 3

detergent spoons and 1 spoon in

betwenn 2/3 washing cycles.

Dishwasher Models:

- Begin filling the tank with 5/6

detergent spoons and 1 spoon in

between 2/3 washing cycles.

N.B.

All dishwashers are pre-set for

electrical connection of external

automatic detergent pump or

automatic detergent pump kit

through the injector and related

tube or by the hole located on the

back tank of the machine.

THIS MODIFICATION, IF REQUIRED,

MUST BE CARRIED OUT BY

QUALIFIED TECHNICIAN ONLY.

3B3 – WASHING CYCLE

The wash cycle includes one wash

with hot water and detergent at 60°C

(140°F) and one rinse cycle with hot

water and rinse aid at 85°C (185°F).

When the machine reaches the

correct temperature and it is ready to

start a new cycle, GREEN indicator

light is visualized on button “C”, then:

(next page)

1- Open the door.

2- Add recommended quantity of

detergent inside the tank – only

models without automatic

dispenser included – (see par.

3B2)

13

Page 15

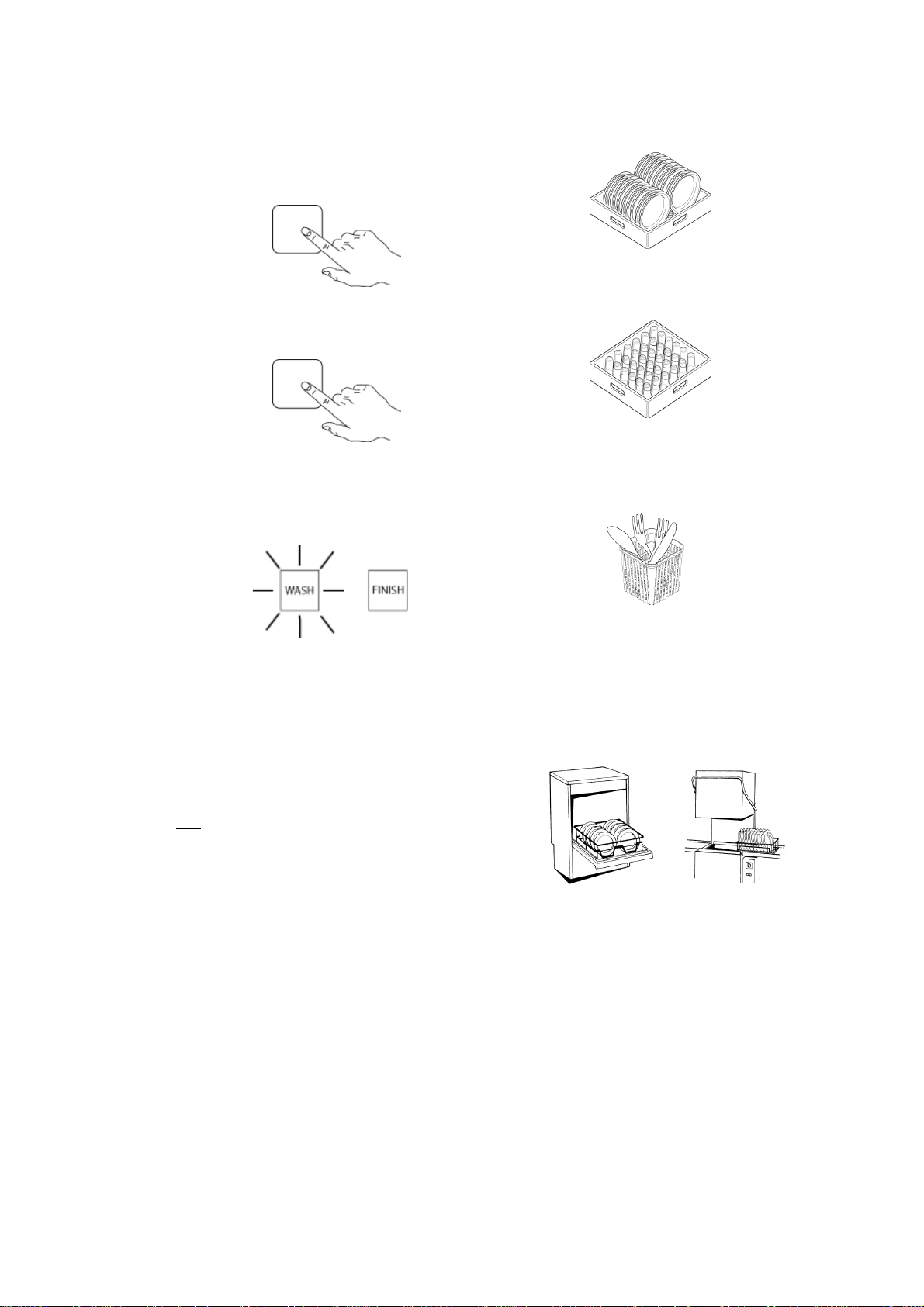

3- Insert dirty loaded dishes basket and close

the door.

4- Press one of the available cycles by pressing

button “B”. (Fig.15)

B

Fig.15

5- Press button “C” start washing cycle. (Fig.16)

C

Fig.16

6- Wait until the end of the cycle when button

“C” will stop blinking, open the door and

download clean dishes basket. (Fig.17)

Fig.17

- During washing cycle light is blinking on

button “C”.

- If during this process door is opened,

washing cycle is interrupted and button “C” is

blinking. To start a new cycle press button “C”

start cycle.

N.B.

The machine is equipped with different kind

of washing cycles. Use short cycle for light dirt

dishes. Medium cycle for medium dirt dishes

and long cycle for heavy dirty dishes.

3B4 – THERMO STOP VERSION

This system allows the machine to final rinse

always at minimum temperature 85°C to satisfy

norms of each country.

Machines with THERMO STOP system may have

cycle time longer than standard machine in case

minimum booster temperature water is not

enough hot for the final rinse. This device

ensures correct final sanitization on the dishes.

3B5 – STANDARD LOADING RACKS

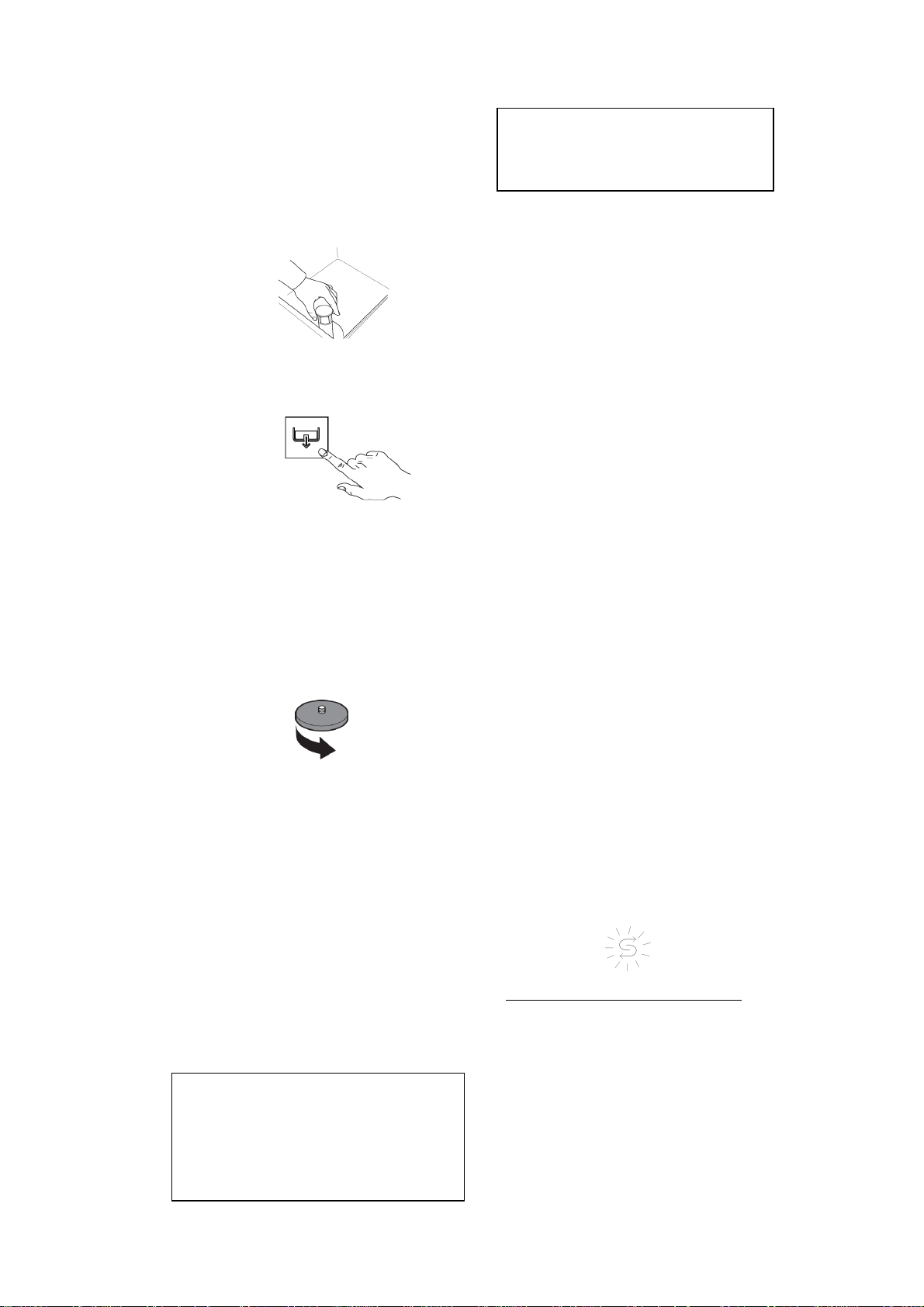

1- Load plates in frontal position. (Fig.22)

Fig.22

2- Load glasses and bowls in upside down

position. (Fig.23)

Fig.23

3- Load cutlery vertically inside its

containers. (Fig.24)

Fig.24

4- Load rack machine with dishes as

described on the figure. For undercounter

models load the rack front side. For

hoodtype models load the rack front side or

sideways (if necessary switch rack support

clockwise). (Fig.25)

Fig.25

14

Page 16

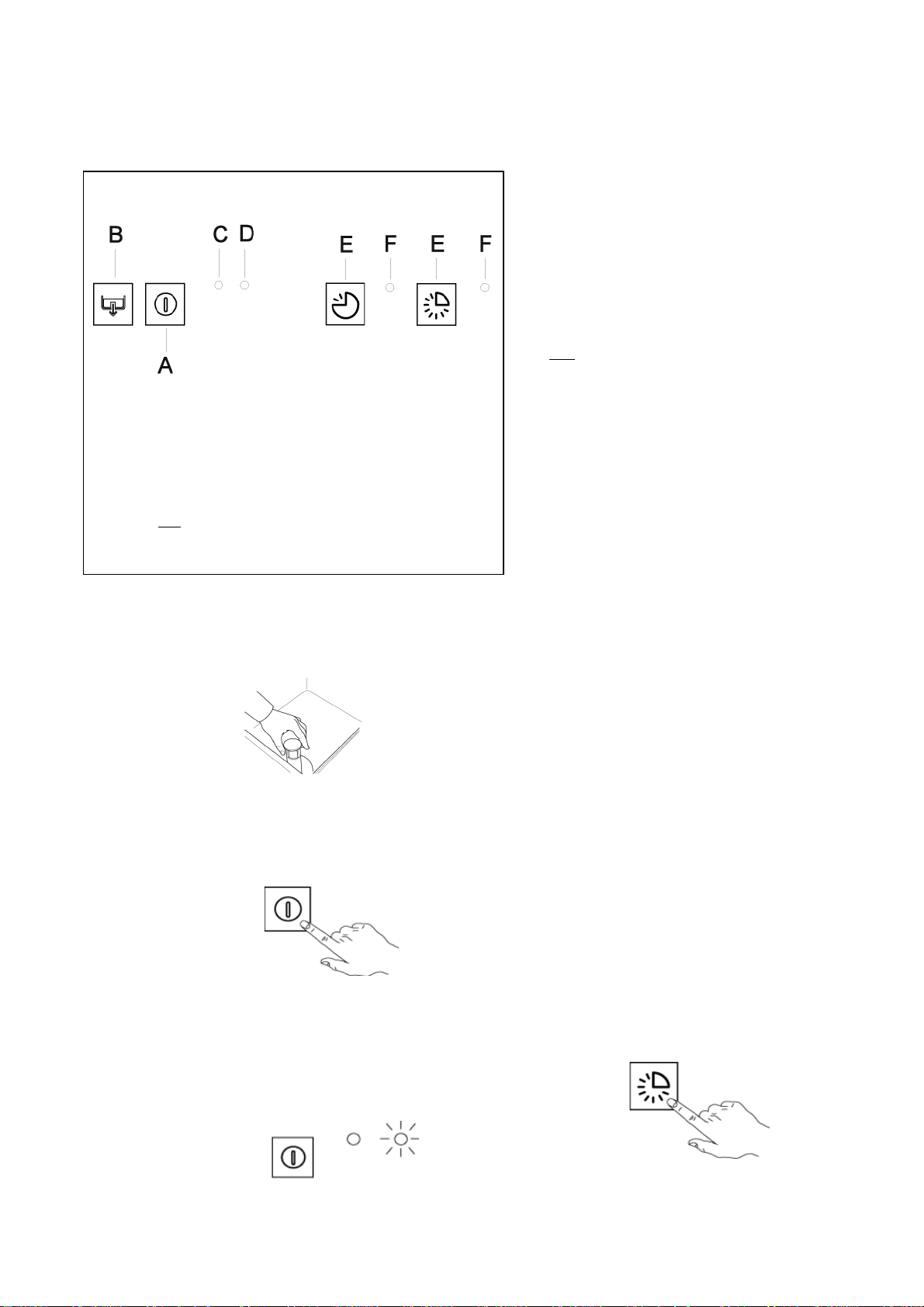

CONTROL PANEL

LEGENDA

3C – STARTING / WASH CYCLES

(MECHANICAL version)

A = On/Off

B = Drain Water Tank

N.B.

The control panel represented above is full version.

Some versions may have not all the indicated functions.

1- Open the door and verify that all internal

Fig.26

2- Open main water supply cock.

3- Switch on at the mains.

4- Close the door and press button “A” to turn

A

Fig.27

- If during this process door is opened, the

filling water tank process is interrupted. To

continue filling process close the door.

- After water heating process is finished and

the temperature is reached, indicator light is

visualized on position “D” machine READY to

use. (Fig.28)

Fig.28

C = On Machine Indicator Light

D = Machine Ready Indicator Light

E = Start Cycle

F = Washing Cycle Indicator Light

3C1 – STARTING THE MACHINE

components, the water flow device included,

are in the correct position. (Fig.26)

ON the machine. Indicator light “C” is ON.

(Fig.27)

3C2 – DETERGENT FILLING

PROCESS (versions without

automatic detergent pump only)

Glasswasher Models:

- Begin filling the tank with 3

detergent spoons and 1 spoon in

betwenn 2/3 washing cycles.

Dishwasher Models:

- Begin filling the tank with 5/6

detergent spoons and 1 spoon in

between 2/3 washing cycles.

N.B.

All dishwashers are pre-set for

electrical connection of external

automatic detergent pump or

automatic detergent pump kit

through the injector and related

tube or by the hole located on the

back tank of the machine.

THIS MODIFICATION, IF REQUIRED,

MUST BE CARRIED OUT BY

QUALIFIED TECHNICIAN ONLY.

3C3 – WASHING CYCLE

Washing cycle is composed by one

hot cycle with detergent at 60°C

(140°F) and one hot final rinse with

rinse aid at 85°C (185°F).

When the machine reaches the

correct temperature and it is ready to

start a new cycle, indicator light is

visualized on position “D”, then:

1- Open the door.

2- Add recommended quantity of

detergent inside the tank – only

models without automatic

dispenser included – (see

par.3C2).

3- Insert dirty loaded dishes basket

and close the door. (next page)

4- Press button “E” start washing

cycle. Indicator light “F” is ON for

the entire period of washing.

(Fig.29)

E

Fig.29

15

Page 17

5- Wait until indicator light “F” is OFF. Open the

door and download clean dishes basket.

- If during this process door is opened, the

washing cycle is interrupted until door is closed.

To continue and finish washing cycle you must

close the door.

WARNING!

THE APPLIANCE WILL NOT REMOVE BURNT

FOOD DEPOSITS FROM DISHES. DISHES WITH

BURNT-ON FOOD DEPOSITS SHOULD BE

CLEANED MECHANICALLY/CHEMICALLY (FOR

EXAMPLE, PRE-WASH UNDER RUNNING

WATER) BEFORE PUTTING THEM IN THE

DISHWASHER.

THE USE OF “FOAMING” AND NOT SPECIFIC

DETERGENTS OR IN ANY CASE DETERGENTS

USED IN DIFFERENT WAYS FROM THAT

PRESCRIBED BY THE MANUFACTURER OR

FAILURE TO REMOVE THE RESIDUALS OF

DETERGENT POSSIBLY USED FOR MANUAL

PREWASH CAN CAUSE MALFUNCTIONING OF

THE DISHWASHER AND COMPROMISE

WASHING RESULTS.

3C4 – STANDARD LOADING RACKS

1- Load plates in frontal position. (Fig.34)

Fig.34

2- Load glasses and bowls in upside down

position. (Fig.35)

Fig.35

3- Load cutlery vertically inside its containers.

(Fig.36)

Fig.36

4- Load rack machine with dishes as

described on the figure.

For undercounter models load the rack front

side. For hoodtype models load the rack

front side or sideways (if necessary switch

rack support clockwise). (Fig.37)

Fig.37

3D – DAILY CLEANNING / END OF

WORK

In order to have excellent washing results

and a cleaned tank, it is recommended to

change the water of the machine at least

twice a day and clean accurately all the

filters inside the tank. Filters must be

removed only once all the water is

drained out of the machine.

3D1 – WATER DRAIN (MECHANICAL

MACHINE WITHOUT DRAIN PUMP

INCLUDED)

1- Turn OFF the machine by pressing

button “A” On/Off.

2- Open the door and remove the water

flow device and close the door. (Fig.38)

Fig.38

3- Wait until all the water is completely

drained out from the tank and turn OFF

the machine by pressing button “A”.

3D2 – WATER DRAIN (ELECTRONIC MACHINE)

1- Turn OFF the machine by pressing

button “A” On/Off.

2- Open the door and remove the water

flow device and close the door. (Fig.39)

Fig.39

3- On the display will appear water drain

message during process. (Fig.40)

Fig.40

16

Page 18

4- Wait until all the water is completely drained

out from the tank. The machine will turn OFF

automatically after completing drain process.

3D3 – WATER DRAIN (MECHANICAL MACHINE

WITH DRAIN PUMP INCLUDED)

1- Open the door and remove the water flow

device and close the door. (Fig.41)

Fig.41

2- Press button “B” to start drain out the water

and wait until all the water is completely

drained out from the tank. (Fig.42)

B

Fig.42

3- Turn OFF the machine by pressing button “A”

On/Off.

3D4 – FILTERS CLEANNING

1- Turn OFF the machine by pressing button “A”

On/Off.

2- Manually remove side or central filters or by

unscrewing the ferrule located on the top

rounded filter inside the tank. (Fig.43)

Fig.43

3- Wash and clean filters accurately on running

fresh water.

4- Repositionated all filters and components

inside the machine.

3D5 – EXTERNAL SURFACES CLEANNING

Before carrying out any cleanning operations,

turn off the power at the mains.

To reduce the emmission of pollutants into the

enviroment, clean the appliance (externally

and where necessary internally) with

products having a biodegradability of over

90%.

WARNING!

CLEAN STAINLESS STEEL SURFACES BY USING

WARM SOAPY WATER; NEVER USE

DETERGENT CONTAINING ABRASIVE

SUBSTANCES NOR STEEL SCRAPERS,

COMMON WIRE WOOL, BRUSHES OR

SCRAPES; RINSE THOROUGHLY USING A

WET CLOTH AND CAREFULLY WIPE DRY.

DO NOT WASH THE APPLIANCE BY USING

DIRECT OR HIGH PRESSURE WATER JETS.

3D6 – TURNING OFF THE MACHINE

1- Drain out completely the water from the

tank. (see par.3D1/2/3)

2- Turn OFF the machine by pressing

button “A” On/Off.

3- Close the door and turn off the power at

the mains.

3E – UNDERCOUNTER

DISHWASHER WITH BUILT- IN

WATER SOFTENER

These models have continuous softener in

the dishwasher water circuit. By means of

special resins, this device removes the

calcareous substance from the feed water,

supplying decalcified water for washing.

Automatic watersoftener works properly if

the resins are regenerated periodically, with

frequency depending on the hardness of the

water and the number of wash cycles carries

out.

3E1 – SALT CONTAINER / FILLING

The water can be only softened if there is salt

in its container. The salt container must be

filled when the dishwasher is used for the

first time and before starting a new cycle.

3E2 – MECHANICAL VERSIONS

It is necessary to fill the salt container

approximately every 5 watersoftener

regenerations.

3E3 – ELECTRONIC VERSIONS

If available, fill salt container everytime the

message “Add SALt” is displayed or during

blinking button on the control panel.

N.B. (Mechanical / Electronic Versions)

It is not possible to start a new

watersoftener regeneration if salt

container is empty. Watersoftener

regeneration process must be made only

after draining out completely the water

inside the tank. Salt container has always

water on its inside; however it is normal if

some water comes out of salt container

while filling it.

Add

ADD SALT

SALt

17

Page 19

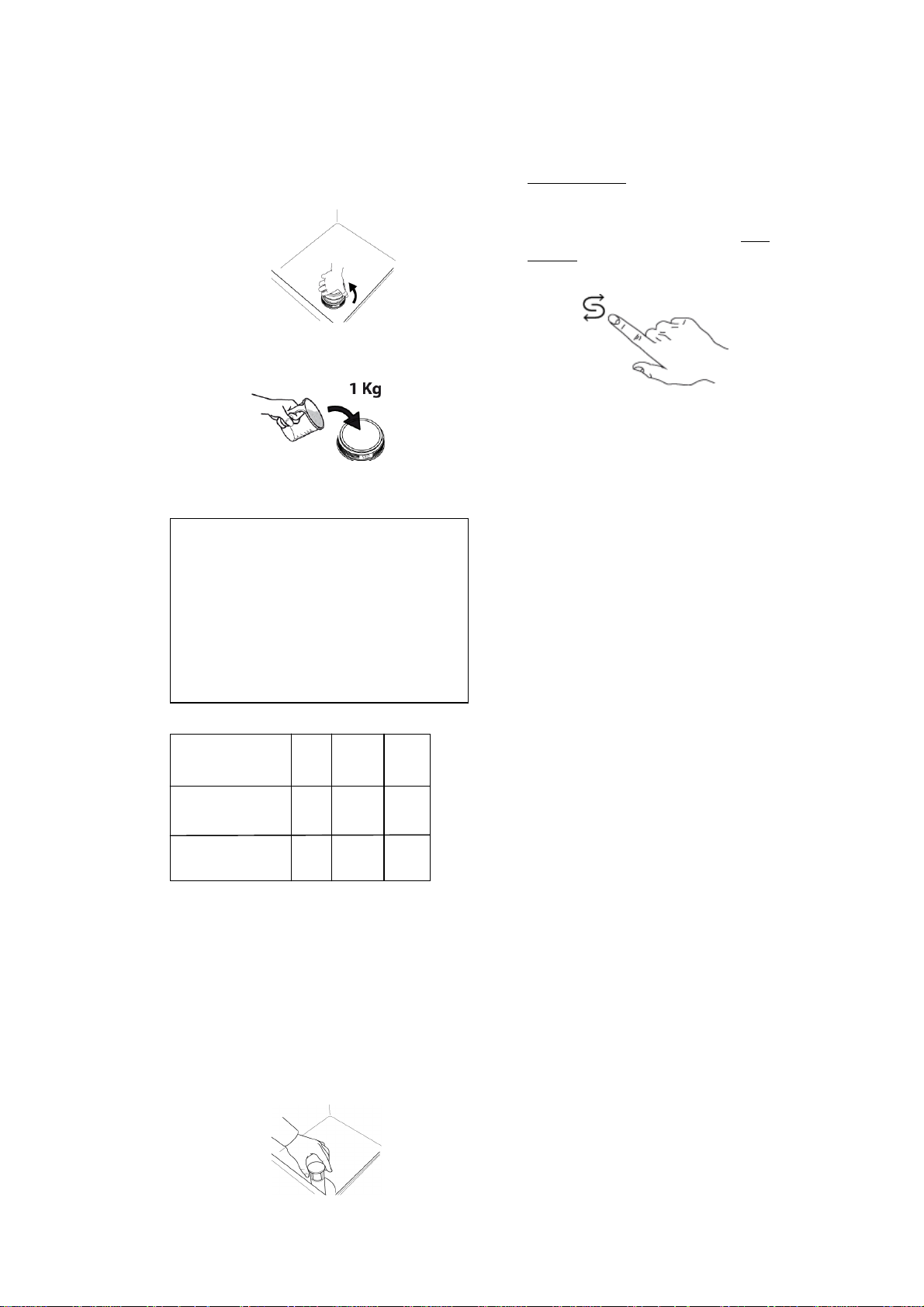

3E4 – ALL MODELS

1- Turn OFF the machine by pressing button “A”

On/Off.

2- Unscrew the cap of salt container located

inside the tank by turning it anticlockwise.

(Fig.44)

Fig.44

3- Pour approx. 1 kg of coarse salt [NaCI] in the

container. (Fig.45)

Fig.45

4- Screw the cap of salt container by

turning it clockwise.

WARNING!

ONLY SALT MUST BE PLACED INSIDE THE

SALT CONTAINER. DO NOT INTODUCE ANY

OTHER CHEMICAL SUBSTANCES SUCH AS

DETERGENT, RINSE AIS OR DESCALING

AGENT, SINCE THESE WOULD INEVITABLY

DAMAGE THE APPLIANCE. SUCH DAMAGE

INVALIDATES ANY WARRANTY AND RELIEVES

THE MANUFACTURER OF ALL LIABILITY.

3E5 – RESINS CHART RANGE

Water Hardness 20°F 30°F 40°F

(french degrees)

Water Liters 240 150 120

Treatment

Cycles Number 120 75 60

3E6 – WATERSOFTENER REGENERATION

It is important to follow the Resins Chart Range

in order to have correct regeneration with the

watersoftener.

1- Ensure that salt container is full.

2- Turn OFF the machine by pressing button “A”

On/Off.

3- Open the door and remove the water flow

device. (Fig.46)

Fig.46

4- Drain out completely the water from the

tank. For models with Drain Pump see

par. 3D.

5- Keep pressing for few seconds

regeneration button on the control panel

until it starts regeneration process.

(Fig.47) On electronic version, keep

pressing button “C” until Regeration icon

will be on the display.

Fig.47

- The machine automatically complete the

regeneration process in approx. 18 min.

18

Page 20

3F – WARNING MESSAGES

DISPLAYED ON THE CONTROL PANEL

(Elettronic versions only)

N.B.

If the machine is in OFF mode, warning

messages are not visualized on the display.

Turn ON the machine to visualize type of error

or breakdown.

The following warning messages are visualized

on the display:

ntcb

E-01 BOOSTER TEMPERATURE PROBE

Booster temperature probe not connected or

faulty.

CALL TECHNICAL SERVICE ASSISTANCE

ntcu

E-02 TANK TEMPERATURE PROBE

Tank temperature probe not connected or faulty.

CALL TECHNICAL SERVICE ASSISTANCE

fill

E-03 WATER FILL

Water fill not completed during the available

maximum time (10min).

Verify that water supply is correctly connected,

opened and free of obstructions.

Verify that solenoid valve filter is free of possible

obstructions and deposit.

Verify that water supply pressure is adequate

(par.1D – Technical Data).

Verify that machine’s door is completely closed

and the overflow device is correctly positioned

inside the tank.

N.B.

If water fill timing expires or in case of water

level signal is not respected solenoid valve is

automatically interrupted. To restart solenoid

valve press any button on the control panel.

Tbo

E-04 BOOSTER TEMPERATURE LIMIT

Booster temperature maximum set point

reached (set point +14°C / 57°F).

CALL TECHNICAL SERVICE ASSISTANCE

TUA

E-05 TANK TEMPERATURE LIMIT

Tank temperature maximum set point

reached (set point +7°C / 44°F).

CALL TECHNICAL SERVICE ASSISTANCE

drA

E-06 DRAIN ANOMALY

Drainage not completed on the maximum

programmed timing.

Verify that the overflow device is completely

removed and not obstructions are present on

the water drain line.

bnot

E-07 BOOSTER HEATING

Maximum booster heating time reached

(15min).

CALL TECHNICAL SERVICE ASSISTANCE

Unot

E-08 TANK HEATING

Maximum tank heating time reached

(30min).

CALL TECHNICAL SERVICE ASSISTANCE

SEruICE

E-09 PARAMETERS ERROR OR

DAMAGED BOARD

Memory parameters error or damaged board.

CALL TECHNICAL SERVICE ASSISTANCE

FOLLOWING ACTIONS AFTER MACHINE

ERROR OR BREAKDOWN:

Booster and tank heating elements are

interrupted, water load is disactivated,

control panel display visualizes the error and

the electronic card is inactivated. All led

buttons are OFF. Washing cycle is interupted

(stanby mode) and restored if the problem is

solved. It is always possible to turn OFF the

machine by pressing button “A” ON/OFF, and

if the problem is solved, warning messages

are not more displayed.

19

Page 21

4

–

TROUBLESHOOTING

THE DISHWASHER DOES NOT WORK ?

1- Verify inlet main water supply is correctly

connected, open and free from any

obstructions.

2- Verify main electrical supply is working

without any electrical breakdown

connections.

3- Verify the door is properly closed.

DISHWASHER DOES NOT WASH

WELL ?

1- Verify if the filters are cleaned, in case not,

clean them. (see par. 3D4)

2- Verify if the washing water jets on the

washing arms are not obstructed by any solid

residues.

3- Verify if used a correct amount and quality of

detergent and rinse aid. (see par. 3B2/3C2)

4- Verify if the dishes are correctly loaded on

the dishwasher. (see par. 3B6/3C7)

5- Washing cycle used is too short. Use another

cycle (if available) or repeat the washing

cycle.

THE DISHES ARE NOT RINSED WELL?

1- Verify if the rinse water jets on the washing

arms are not obstructed by any solid

residues.

2- Verify solenoid valve filter is free from any

obstructions such as lime or scale.

3- The inlet water pressure is inferior of 2 bar –

200 kPA. Install an external pressure device

to ensure and increase the inlet water

pressure inside the machine.

THE DISHES ARE NOT DRIED WELL ?

1- Ask the assistance service to verify the

instruction for the rinse aid dosing. (see par.

2D)

2- Verify if the rinse aid container is empty. If

yes, fill it with rinse aid product. (see par. 2D)

3- Verify the quality and the quantity of the

rinse aid used and check with the assistance

service. (see par. 2D)

4- Verify the rinsing temperature is between

80°C (176°F) to 90°C (194°F) degrees.

Produced and Built in Italy – P.IVA 00740990163

CONDENSATION ON GLASSES ?

1- Verify if the rinse aid container is empty.

If yes, fill it with rinse aid product. (see

par. 2D)

2- Verify the quality and the quantity of the

rinse aid used and check with the

assistance service. (see par. 2D)

3- Download the glasses rack immediately

after the end of each cycle.

STAINS ON GLASSES ?

1- Use only non foaming products for

professional dishwashers.

EXCESSIVE FOAM IN THE TANK ?

1- Verify washing water temperature is not

less than 50°C (122°F) degrees.

2- Ask the assistance service to verify the

instruction for the rinse aid dosing. (see

par. 2D)

3- Ensure the tank has not been cleaned

with unsuitable cleaners. Drain the tank

and rinse throughly before new wash

cycles.

4- If foaming detergent has been used,

drain and refill the tank with water until

the foam disappears.

SMEARS OR SPOTS ON THE

GLASSES ?

1- Ask the assistance service to verify the

instruction for the rinse aid dosing.

EMERGENCY

IN CASE OF FIRE A POWDER

EXTINGUISHER MUST BE USED.

IN CASE OF DANGER CUT-OFF

IMMEDIATLY THE AUTOMATIC GENERAL

ELECTRICAL SWITCH.

The Manufacturer reserves the right to

modify the appliances presented in this

publication without notice.

20

Page 22

INDICE

1 - AVVERTENZE GENERALI …………………………...…………………..... p.22

1A - TRASPORTO ……………………………………………………………...... p.22

1B - DISIMBALLO …………….………………………………………………..... p.22

1C - SMALTIMENTO ……………………………….…………………………..... p.23

1D - CARATTERISTICHE TECNICHE …………………………………………....... p.23

2 - ISTRUZIONI INSTALLATORE E MANUTENTORE …………………..….. p.24

2A - ALLACCIAMENTO IDRAULICO ……………………………………….......... p.24

2B - ALLACCIAMENTO ELETTRICO ………….…………………………………. p.25

2C - MESSAGGI DI AVVERTIMENTO DISPLAY PANNELLO DI CONTROLLO ….... p.26

2D - PREDISPOSIZIONE E REGOLAZIONE DOSATORI DETERGENTE

E BRILLANTANTE ………………………………………………………...... p.27

2E - MANUTENZIONE ………………………………………………….……...... p.28

2F - DISINSTALLAZIONE (periodo prolungato di inattività)………………….... p.28

3 - ISTRUZIONI UTENTE …………………..…………………………………. p.29

3A - AVVERTENZE GENERALI E GARANZIA ………….………………………..... p.29

3B - AVVIO APPARECCHIO / CICLO DI LAVAGGIO (versione ELETTRONICA) …..p.30

3C - AVVIO APPARECCHIO / CICLO DI LAVAGGIO (versione MECCANICA) ….....p.32

3D - PULIZIA / SPEGNIMENTO APPARECCHIO ………..……………………….. p.33

3E - LAVASTOVIGLIE CON ADDOLCITORE INCORPORATO …………………..... p.35

3F - MESSAGGI DI AVVERTIMENTO DISPLAY PANNELLO DI CONTROLLO …..... p.36

4 - RICERCA GUASTI …………………...…………………………….………. p.37

21

Page 23

1

- AVVERTENZ

E GENERALI

AVVERTENZA

Leggere attentamente il presente libretto in

quanto fornisce importanti indicazioni

riguardanti la sicurezza d’installazione, d’uso e di

manutenzione. Conservare con cura questo

libretto per ogni ulteriore consultazione dei vari

operatori.

L’uso, l’installazione e la manutenzione

dell'apparecchio sono riservate a personale

addestrato che osservi quanto qui indicato:

ATTENZIONE!

Il costruttore declina ogni responsabilità

per danni a cose o persone derivanti

dall’inosservanza delle istruzioni macchina.

Il mancato rispetto di quanto segue può

compromettere la sicurezza

dell’apparecchio e far decadere

IMMEDIATAMENTE la garanzia.

Installazione o disinstallazione,

manutenzione, regolazioni, riparazioni o

qualsiasi tipo d’intervento che comporti la

rimozione dei pannelli di protezione

quando NON EFFETTUATE DA PERSONALE

QUALIFICATO ED AUTORIZZATO CHE

RISPETTI LE INDICAZIONI DEL

COSTRUTTORE o che comunque non

provveda a scollegare elettricamente ed

idraulicamente la macchina prima di tali

interventi o che ometta di prendere le

precauzioni necessarie quando si escludono

le sicurezze predisposte dal costruttore.

Installazioni scadenti o provvisorie o

comunque che non prevedano adeguate

sicurezze sull’alimentazione elettrica (es.

fusibili, interruttore generale, MESSA A

TERRA) ed idrica (es. rubinetto di

intercettazione e scarico).

Modifiche od aggiunte di dispositivi

comunque applicati che cambino il

funzionamento, previsto ed indicato sulla

scheda tecnica allegata alla macchina.

Impiego di ricambi non originali.

Installazione o rimessaggio in ambienti non

rispondenti alle indicazioni del costruttore.

Uso dell'apparecchio diverso da quanto

indicato nella documentazione macchina

(es. stoviglie di tipo o dimensioni diverse da

quelle specificate).

Uso dei dosatori con prodotti

corrosivi, impuri o a secco.

1A – TRASPORTO

Qualsiasi spostamento dell’apparecchiatura deve

avvenire tramite un mezzo idoneo: un carrello

elevatore o transpallets a forche (queste devono

superare la metà della dimensione del prodotto).

1B – DISIMBALLO

Prima di togliere l'imballo verificare che sia

integro, contestando e scrivendo sulla bolla di

consegna dello spedizioniere eventuali danni

riscontrati. Dopo aver tolto l’imballo assicurarsi

che l'apparecchio sia integro, nel caso sia

danneggiato, avvertire tempestivamente il

rivenditore.

Se i danni sono tali da pregiudicare la sicurezza

della macchina non procedere con l'installazione

fino all'intervento di un tecnico qualificato. Gli

elementi di imballaggio (sacchetti in plastica,

polistirolo espanso, chiodi, etc.) non devono

essere lasciati alla portata dei bambini in quanto

fonte potenziale di pericolo.

1- Usare sempre guanti di protezione per

rimuovere l’apparecchio dal suo imballo.

(Fig.1)

Fig.1

2- Sollevare l’apparecchio sul suo bancale con

l’ausilio di un carrello elevatore. (Fig. 2)

Fig.2

3- Rimuovere la pellicola di protezione

dall’apparecchio. (Fig. 3)

Fig.3

22

Page 24

Tempertatura

°C

50

Bar

2 - 5

Durezza

°f

7 - 14

°e

5 - 9,5

ppm

70 - 140

Conducibilità

µ

S/cm

300 / 400

Temperatura

°C

5 - 35

Magazzino

°F

50 - 158

1C – SMALTIMENTO

Questo prodotto è contrassegnato in conformità

alla Direttiva Europea 2002/96/EC, Waste

Electrical and Electronic Equipment (WEEE).

Assicurandosi che questo prodotto sia smaltito in

modo corretto, l’utente contribuisce a prevenire

le potenziali conseguenze negative per

l’ambiente e la salute. Il simbolo

ALIMENTAZIONE ELETTRICA

Tensione V ± 6 %

Frequenza Hz ± 1 %

Ciclo lavaggio °C 55

Ciclo Risciacquo °C 85

AMBIENTE DI INSTALLAZIONE

Esercizio °F 41 - 95

sul prodotto o sulla documentazione di

accompagnamento indica che questo prodotto

non deve essere trattato come rifiuto domestico

ma deve essere consegnato presso l’idoneo

punto di raccolta per il riciclaggio di

apparecchiature elettriche ed elettroniche.

Disfarsene seguendo le normative locali per lo

smaltimento dei rifiuti. Per ulteriori informazioni

sul trattamento, recupero e riciclaggio di questo

prodotto, contattare l’idoneo ufficio locale, il

servizio di raccolta dei rifiuti domestici o il

negozio presso il quale il prodotto è stato

acquistato.

1D – CARATTERISTICHE

TECNICHE

ALIMENTAZIONE IDRAULICA

Temperatura °C 10 - 70

1D1 – RUMOROSITA’

La rumorosità ambientale non può superare i

valori indicati dalle normative vigenti nella

località in cui la macchina viene installata. Il

rumore generato dall’apparecchio è risultato, ai

collaudi del costruttore, inferiori ai 70dB, circa

58dB.

Nell’impiego della macchina si dovrà sempre fare

riferimento ai valori di seguito elencati da

rispettare, conoscere o considerare per

l’immagazzinamento, il trasporto, l’uso e la

manutenzione della macchina. I continui

miglioramenti possono rendere superata la

presente documentazione, il costruttore si

riserva quindi il diritto di modificare in tutto o in

parte i dati qui riportati, che pertanto non sono

impegnativi.

°F 122

Pressione kPA 200 - 500

PSI 29 - 72

Portata Lt/min 20 - 30

°dH 4 - 7,5

Minerali Residui mg/l 300 / 400

23

Page 25

2

-

ISTRUZIONI INSTALLATORE E MANUTENTORE

AVVERTENZA

Il personale che esegue l’installazione e

l’allacciamento elettrico è tenuto a istruire

adeguatamente gli utenti sul funzionamento

dell’impianto e sulle misure di sicurezza da

eseguire. Deve inoltre dare dimostrazioni

pratiche sul modo di utilizzo e accertarsi che

siano in suo possesso le istruzioni allegate

all’apparecchiatura.

ATTENZIONE!

NON APRIRE MAI VELOCEMENTE LA PORTA

MACCHINA SE NON HA FINITO IL CICLO.

NON IMMERGERE MAI LE MANI NUDE NELLA

SOLUZIONE DI LAVAGGIO.

NON RIMUOVERE MAI I PANNELLI MACCHINA

SE NON SI È PRIMA PROVVEDUTO A

SCOLLEGARE ELETTRICITÀ ED ACQUA DALLA

MACCHINA.

NON UTILIZZARE MAI LA MACCHINA SENZA

PROTEZIONI (MICRO CONTATTI PANNELLI OD

ALTRO) PREDISPOSTE DAL COSTRUTTORE SE

NON ALLA PRESENZA DI UN TECNICO

QUALIFICATO CHE PRENDA LE PRECAUZIONI

DEL CASO.

NON UTILIZZARE MAI LA MACCHINA PER

LAVARE OGGETTI DI TIPO, FORMA, MISURA O

MATERIALE NON COMPATIBILI CON QUANTO

INDICATO DAL COSTRUTTORE.

NON UTILIZZARE MAI LA MACCHINA SE NON

SI HA LA CERTEZZA CHE TUTTI GLI

ALLACCIAMENTI SONO STATI EFFETTUATI

CORRETTAMENTE E CHE FUNZIONINO I

DISPOSITIVI DI SICUREZZA.

ETICHETTA IDENTIFICATIVA

La targhetta con apportate sopra le

caratteristiche tecniche ed i dati identificativi

dell’apparecchio è situata all’interno del

pannello frontale o sul fondo all’interno della

macchina.

- Estrarre il pannello frontale con l’ausilio di un

attrezzo a brugola o simile inserendolo negli

appositi fori, tirando il pannello verso l’esterno.

Per i modelli a Capot, svitare le viti nella parte

inferiore del pannello. (Fig.4)

Fig.4

2A – ALLACCIAMENTO IDRAULICO

N.B.

Il rubinetto di alimentazione deve essere

costituito da una valvola di

intercettazione a cassetto, a sfera, od a

saracinesca in grado di sezionare

rapidamente e completamente la linea

dell’acqua, con dimensioni tali da

garantire portata e pressione alla

macchina.

1- Posizionare e livellare l’apparecchio

ruotando i piedini a vite regolabili in

dotazione. (Fig.5)

Fig. 5

2- Collegare l’elettrovalvola di caricamento

al rubinetto di alimentazione, mediante il

tubo flessibile in dotazione. (Fig.6) Ogni

macchina deve disporre di un

rubinetto di alimentazione.

Fig. 6

2A1 – PRESSIONE DI RETE

Controllare la pressione dinamica di

alimentazione dell’acqua, misurata a monte

dell’apparecchiatura. Questa deve essere

compresa tra 200 a 500 kPa. Se la pressione

risultasse superiore ai valori prestabiliti,

installare un riduttore di pressione. Se la

pressione risultasse inferiore ai valori

prestabiliti installare una pompa di

sovrappressione esternamente. (vedi

par.1D – Caratteristiche Tecniche)

- In caso di impianto non usato a lungo o

nuovo far scorrere l’acqua prima di collegare

la macchina spurgando bene eventuali

impurità, bolle d’aria e tutto ciò che potrebbe

sporcare o danneggiare la macchina.

2A2 – DUREZZA DELL’ACQUA

Se dovesse essere superiore ai valori

prestabiliti (vedi par.1D – Caratteristiche

Tecniche) e la macchina non ne avesse uno

interno, è consigliabile l’installazione di un

addolcitore esterno, (segue)

24

Page 26

di dimensioni adeguate, prima

dell’elettrovalvola di alimentazione. Se dovesse

esserci un’alta concentrazione di minerali residui

di acqua o di conducibilità elevate, si consiglia

l’installazione di un impianto di filtraggio e

demineralizzazione tarato per una durezza

residua di 5/7 °f.

2A3 – MODELLI CON SCARICO

GRAVITAZIONALE

N.B.

La linea di scarico consiste in un pozzetto

sifonato libero di dimensioni adeguate a

evacuare almeno una portata doppia rispetto

a quella richiesta per l’alimentazione sulla

scheda tecnica. Deve trovarsi alla portata del

tubo fornito con la macchina senza che

questo sia sottoposto a trazioni, pieghe o

giunte.

- Per consentire uno scarico libero, il tubo

deve poter raggiungere il pozzetto, senza essere

tirato, costretto, piegato, schiacciato, premuto o

forzato da nulla.

- Collegare il tubo di scarico acqua alla

condotta di scarico inserendo un sifone, oppure

posizionare il tubo sopra un pozzetto a piletta

sifoide ricavato nel pavimento.

2A4 – MODELLI CON POMPA DI SCARICO

- Posizionare il tubo di scarico ad un’altezza

massima di 1000 mm dal piano d’appoggio.

(Fig.7)

Fig. 7

2B – ALLACCIAMENTO ELETTRICO

N.B.

L’interruttore generale deve essere di tipo

omnipolare, che interrompa tutti i contatti

incluso il neutro, con distanza tra i contatti

aperti di almeno 3 mm, con scatto

magnetotermico di sicurezza o accoppiato a

dei fusibili ed in grado di sopportare la

corrente massima indicata sulla targa

identificativa. Deve trovarsi sulla linea

elettrica vicino all’installazione. Deve servire

esclusivamente un’apparecchiatura alla volta.

Da escludersi assolutamente l’impiego di

adattatori, prese multiple e cavi di sezione

non adeguata o con giunture di prolunga

di qualsiasi tipo.

- Verificare che le caratteristiche della rete

elettrica siano compatibili con le indicazioni

sull’etichetta identificativa dell’apparecchio

posta all’interno del pannello frontale (vedi

par. Etichetta Identificativa), che esista per

il collegamento un interruttore generale e

che sia presente un efficiente impianto di

messa a terra dove collegare la macchina.

ATTENZIONE!

IL COSTRUTTORE NON E’ RESPONSABILE

DEI DANNI DERIVANTI DA UNA

MANCANZA DI MESSA A TERRA

DELL’IMPIANTO. LE CONNESSIONI DI

TERRA ED ELETTRICHE DEVONO ESSERE

CONFORMI ALLE NORMATIVE NAZIONALI.

Il cavo di alimentazione potrà essere

sostituito solamente con un altro fornito dal

costruttore su indicazione del tipo di

macchina, del suo numero di matricola e di

eventuali particolari dell’installazione. Non

può essere messo in trazione o schiacciato da

nulla durante il normale funzionamento o la

manutenzione ordinaria.

Il morsetto di equipotenzialità fissato al

corpo macchina deve essere collegato,

secondo normative, utilizzando un cavo di

sezione compresa tra 2,5 e i 10 mm.

25

Page 27

2C – MESSAGGI AVVERTIMENTO

DISPLAY PANNELLO DI CONTROLLO

(solo versione Elettronica)

N.B.

Se la macchina è spenta (OFF) le segnalazioni

di errore o guasto non saranno visualizzate.

Accendere la macchina (ON) per visualizzare il

tipo di errore o guasto.

Sono previste le seguenti segnalazioni di errore

indicate lampeggiando sul display:

ntcb

E-01 SONDA TEMPERATURA BOILER

Sonda temperatura del boiler in corto o non

collegata.

Verificare che la connessione della sonda alla

scheda sia eseguita correttamente.

Verificare che la sonda sia correttamente

posizionata nella propria sede e non vi sia

presenza di calcare sulla stessa.

ntcu

E-02 SONDA TEMPERATURA VASCA

Sonda temperatura della vasca in corto o non

collegata.

Verificare che la connessione della sonda alla

scheda sia eseguita correttamente.

Verificare che la sonda sia correttamente

posizionata nella propria sede e non vi sia

presenza di calcare sulla stessa.

fill

E-03 CARICO ACQUA

Carico d’acqua non completato nel tempo

massimo programmato (10min).

Verificare che il rubinetto di rete sia

correttamente allacciato, aperto e libero da

ostruzioni.

Verificare che il filtro dell’elettrovalvola sia

libero da possibili incrostazioni e ostruzioni.

Verificare che vi sia un’adeguata pressione nella

rete idraulica (vedi par.1D - Caratteristiche

Tecniche).

Verificare che la porta della macchina sia ben

chiusa e che il troppopieno sia inserito

correttamente nella sua sede.

N.B.

Se viene superato il tempo limite massimo o

in caso di perdita del segnale di livello del

carico acqua l’elettrovalvola viene fermata

automaticamente. Per far ripartire

l’elettrovalvola premere un tasto qualsiasi.

Tbo

E-04 LIMITE TEMPERATURA BOILER

La temperatura del boiler ha superato il

valore massimo previsto (setpoint +14°C /

57°F).

SOSTITUIRE LA SCHEDA

TUA

E-05 LIMITE TEMPERATURA VASCA

La temperatura della vasca ha superato il

valore massimo previsto (setpoint +7°C /

44°F).

SOSTITUIRE LA SCHEDA

drA

E-06 ANOMALIA SCARICO

Anomalia scarico, svuotamento non

compiuto entro il tempo massimo

programmato.

Verificare che sia stato rimosso il

troppopieno e non vi siano ostruzioni nella

linea di scarico.

Verificare che la connessione della pompa di

scarico alla scheda sia eseguita

correttamente.

bnot

E-07 RISCALDAMENTO BOILER

La durata del riscaldamento boiler ha

superato il tempo massimo previsto. (15min)

Verificare che la connessione della

resistenza alla scheda sia eseguita

correttamente.

Verificare che la resistenza del boiler

funzioni correttamente e sia esente da

incrostazioni calcaree.

Unot

E-08 RSCALDAMENTO VASCA

La durata del riscaldamento vasca ha

superato il tempo massimo previsto. (30min)

Verificare che la connessione della

resistenza alla scheda sia eseguita

correttamente.

Verificare che la resistenza della vasca

funzioni correttamente e sia esente da

incrostazioni calcaree.

SEruICE

E-09 ERRORE PARAMETRI O GUASTO

SCHEDA

Errore di memorizzazione parametri o guasto

scheda.

SOSTITUIRE LA SCHEDA

26

Page 28

AZIONI IN SEGUITO ALLA SEGNALAZIONE:

Il riscaldamento di boiler e vasca vengono

interrotti, tutti i carichi sono disattivati, la scheda

visualizza il codice di guasto e non è più

operativa. Tutti i led della tastiera sono spenti. Il

ciclo in corso viene interrotto (“messo in pausa”)

nel punto in cui si trova, per poi eventualmente

riprendere se il guasto viene ripristinato. È

sempre ammessso lo spegnimento della

macchina tramite il tasto ON/OFF, ed in tal caso

la visualizzazione viene annullata.

TERMOSTATO DI SICUREZZA

Tutte le macchine sono dotate di termostato di

sicurezza che in caso di sovratemperatura

eccessiva (120°C/248°F) provvede a sezionare

l’alimentazione delle resistenze. Per ripristinare il

termostato di sicurezza premere il pulsante

situato dietro al dispositivo stesso.

2D – PREDISPOSIZIONE E

REGOLAZIONE DOSATORI

DETERGENTE E BRILLANTANTE

Prima di avviare il ciclo di lavaggio verificare che

sia il dosatore ed il tubetto del brillantante e

detergente (se disponibile) siano pieni.

Controllare che il loro livello sia sufficiente ed

eventualmente ripristinarlo.

N.B.

Il livello nel contenitore non va mai fatto

scendere sino allo svuotamento né

rabboccato con prodotti corrosivi o impuri. La

garanzia non copre danni conseguenti ad un

errato impiego del dosatore. Il dosatore viene

tarato in fabbrica, eventuali registrazioni

dovranno essere effettuate da un tecnico

qualificato.

3- Estrarre il pannello frontale con l’ausilio di un

attrezzo a brugola o simile inserendolo negli

appositi fori e tirando il pannello verso

l’esterno. Per i modelli a Capot, svitare le viti

nella parte inferiore del pannello. (Fig.8)

Fig.8

Prima della rimozione dei pannelli

l’alimentazione va tolta aprendo

l’interruttore generale.

4- Inserire il tubo in dotazione nel recipiente del

brillantante e del detergente (se disponibile).

(Fig.9)

Fig.9

2D1 – DOSATORE BRILLANTANTE CON

MEMBRANA INCORPORATA

La taratura del dosatore va effettuata tramite

la vite accessibile con lo smontaggio del

pannello frontale sotto il portello vasca. (vedi

Fig.8)

1- Chiudere completamente il dosatore

avvitando la regolazione in senso

antiorario fino a fermarla delicatamente.

2- Aprire avvitando in senso orario fino al

raggiungimento della quantità specifica

necessaria. (Fig.10)

Fig.10

La quantità di prodotto da considerare per

la prima taratura dovrà essere valutata

dall’installatore a seconda della durezza

dell’acqua e del tipo di brillantante

utilizzato. La quantità del brillantante

standard consigliata aspirata dal tubetto

4x6 in dotazione corrisponde a 4cm =

0,5cc = 0,5gr. circa per lavastoviglie cesto

50x50. Oppure 2,5cm = 0,3 = 0,3gr. circa

per lavabicchieri con cesto 35x35 e 40x40.

La massima quantità di dosaggio è di

25,8cm = 3,6cc = 3,6gr. circa.

Dopo la prima taratura la regolazione va

rifinita valtuando i risultati di lavaggio

ottenuti con la regolazione dopo aver

effettuato almeno tre cicli.

2D2 – DOSATORE BRILLANTANTE E

DETERGENTE PERISTALTICO

La taratura del dosatore va effettuata tramite

la vite accessibile con lo smontaggio del

pannello frontale sotto il portello vasca. (vedi

Fig.8)

1- Chiudere completamente il dosatore

avvitando la regolazione in senso

antiorario fino a fermarla delicatamente.

2- Aprire avvitando in senso orario fino al

raggiungimento della quantità specifica

necessaria. (Fig.11)

Fig.11

27

Page 29

La quantità di prodotto da considerare per la

prima taratura dovrà essere valutata

dall’installatore a seconda della durezza

dell’acqua e del tipo di brillantante o

detergente utilizzato. La quantità standard

del brillantante consigliata è di 0,16 gr/sec

che corrisponde alla portata massima del

dosatore. La quantità standard di detergente

consigliata è di 0,77 gr/sec che corrisponde

alla portata massima del dosatore.

SUGGERIMENTO

Per verificare l’efficacia del brillantante, osservare

controluce i bicchieri appena lavati e controllare

che non vi siano gocce d’acqua (dosaggio

insufficiente) o striature (dosaggio eccessivo) sul

bicchiere. Nel caso si formasse una leggera

patina di amido che impedisce al brillantante di

svolgere correttamente il suo compito, è

possibile rimuoverla lasciando le stoviglie a

bagno per circa trenta minuti in una soluzione di

acqua e sapone (1:10) prima di lavarle in

macchina.

2D3 – LAVASTOVIGLIE SENZA DOSATORE

DETERGENTE

Aggiungere manualmente ogni 5 cicli di

lavaggio circa la quantità di detergente suggerita

dal fornitore prescelto. I dosaggi possono variare

a seconda della durezza dell’acqua e della

quallità di sporco che resta sulle stoviglie.

N.B.

Tutte le lavastoviglie sono predisposte per

l’installazione di dosatori esterni o kit

dosatori specifici attraverso l’iniettore e

relativo tubo oppure foro con relativo tappo

collocati nella vasca dell’apparecchio.

Se si passa ad un diverso tipo di detergente o

brillantante (anche della stessa marca), è

necessario riasciaquare i tubi di aspirazione e

di mandata con acqua pulita prima di

collegare il nuovo recipiente del detergente brillantante. In caso contrario, la miscelazione

tra tipi diversi di detergente-brillantante

provoca una cristallizzazione, con

conseguente rottura del dosatore. La mancata

osservanza di questa prescrizione annulla la

garanzia e ala responsabilità da parte del

costruttore.

ATTENZIONE!

LA SCELTA ED IL DOSAGGIO DEL DETERGENTE

SONO DETERMINANTI PER UN BUON

RISULTATO DI LAVAGGIO, LA

CONSERVAZIONE E DURATA

DELL’APPARECCHIO. PER LA PROTEZIONE

E LA SALVAGUARDIA DELL’AMBIENTE

NON USARE MAI PRODOTTI CORROSIVI O

INQUINANTI. NON ECCEDERE MAI LE DOSI

INDICATE DAL PRODUTTORE. I DOSATORI

NON DEVONO MAI RESTARE A SECCO E

MAI UTILIZZATI CON PRODOTTI

CORROSIVI PENA LA DECADENZA DELLA

GARANZIA.

2E – MANUTENZIONE

1- Disincrostare una o due volte l’anno il

boiler, le superfici interne della vasca e le

tubazioni della macchina.

2- Ogni mese disincrostare i getti di

risciacquo e lavaggio con bagno d’aceto

o disincrostanti.

3- Il tubicino interno del dosatore

peristaltico brillantante e detergente

deve essere sottoposto a manutenzione

periodica (1 – 2 volte l’anno).

4- Pulire il filtro all’interno dell’elet-

trovalvola estraendolo e svitanto il

raccordo del tubo di carico.

2F – DISINSTALLAZIONE (periodo

prolungato di inattività)

La disinstallazione dovrà essere eseguita solo

da personale tecnico qualificato e autorizzato

che tenga conto di:

1- Chiudere i collegamenti idraulici

(rubinetto di alimentazione) ed elettrico

(interruttore generale).

2- Svuotare completamente la vasca.

3- Rimuovere e pulire con cura i filtri.

4- Svuotare completamente i tubi dei

dosatori incorporati e togliere i tubi dalle

taniche.

5- Spurgare i dosatori di detergente e

brillantante prima con acqua pulita e poi

con acqua e glicerina (50% - 50%),

avendo cura che i dosatori restino

interamente puliti e lubrificati.

6- Svuotare completamente il boiler

svitando la vite collocata sotto alla

macchina sul boiler.

7- Spalmare su tutte le superfici in acciaio

un velo d’olio di vaselina.

NOTE A CURA DELL’ INSTALLATORE

DATA INSTALLAZIONE:________________________

LUOGO INSTALLAZIONE:_______________________

INSTALLATORE:_______________________________

N° MATRICOLA MACCHINA:_____________________

FIRMA:______________________________________

28

Page 30

3

-

ISTRUZIONI UTENTE

3A – AVVERTENZE GENERALI E

GARANZIA

Le nostre apparecchiature sono studiate ed

ottimizzate al fine di ottenere prestazioni e

rendimenti elevati. Questa apparecchiatura è

destinata solo all’uso per il quale è stata

espressamente concepita, e cioè per il lavaggio

di stoviglie con acqua e detergenti specifici. Ogni

altro uso è da ritenersi improprio.

ATTENZIONE!

PRIMA DI QUALSIASI OPERAZIONE DI PULIZIA

O MANUTENZIONE, DISINSERIRE L’APPARECCHIO ELETTRICAMENTE TOGLIENDO LA

SPINA O DISINSERENDO L’INTERRUTTORE

GENERALE.

NON LASCIARE INSERITO L’APPARECCHIO

SENZA NECESSITÀ.

IN CASO DI GUASTO, DISINSERIRE

L’APPARECCHIO ELETTRICAMENTE,

CHIUDERE IL RUBINETTO DELL’ACQUA E

CONTATTARE SUBITO IL SERVIZIO

ASSISTENZA.

NON USARE LA PORTA APERTA COME BASE DI

APPOGGIO E NON PERMETTERE DI SALIRE O

SEDERSI SULLA STESSA.

NON USARE LA MACCHINA IN ATMOSFERA

ESPLOSIVA.

NON LAVARE LA MACCHINA CON GETTI

D’ACQUA DIRETTI O IN PRESENZA DI

SOSTANZE NOCIVE.

EVITARE CHE LA MACCHINA SIA ESPOSTA A

FONTI DI CALORE E UMIDITÀ.

NON UTILIZZARE LA MACCHINA SE IL CAVO DI

ALIMENTAZIONE RISULTA DANNEGGIATO.

IL COSTRUTTORE DECLINA OGNI

RESPONSABILITÀ PER DANNI A PERSONE O

COSE DOVUTE AD USO IMPROPRIO ERRATO O

IRRAGIONEVOLE.

NON CHIUDERE MAI IL RUBINETTO DI

INTERCETTAZIONE IDRICA CON L’APPARECCHIO IN FUNZIONE.

NON SCOLLEGARE L’ALIMENTAZIONE DELLA

MACCHINA TIRANDO IL CAVO, MA ESTRARRE

IMPUGNANDO LA SPINA.UTILIZZARE SOLO

DETERGENTI E BRILLANTANTI

APPOSITAMENTE STUDIATI PER

LAVASTOVIGLIE INDUSTRIALI.

CONSERVANDOLI APPOSITAMENTE IN LUOGO

ASCIUTTO, FUORI DALLA PORTATA DEI

BAMBINI.

NON TOGLIERE LE PROTEZIONI O

PANNELLATURE CHE RICHIEDONO L’USO

DI UTENSILI PER ESSERE RIMOSSE.

LA MACCHINA È DOTATA DI

MICROINTERRUTTORE DI SICUREZZA CHE

ARRESTA LA MACCHINA IN CASO DI

APERTURA DELLA PORTA DURANTE IL

CICLO DI LAVAGGIO. IL MOTORE DELLA

POMPA DI LAVAGGIO È DOTATO DI UN

LIMITATORE TERMICO FINO A 160°C PER

EVITARE SURRISCALDAMENTO DELLO

STESSO E QUINDI IL BLOCCO DELLA

MACCHINA. NON È POSSIBILE VENIRE A

CONTATTO CON PARTI ELETTRICHE SENZA

L’UTILIZZO DI UN UTENSILE.

LA MACCHINA È EQUIPAGGIATA CON

PIEDINI DI GOMMA ANTIVIBRAZIONE.

Garanzia 12 mesi Parti Meccaniche

Garanzia 6 mesi Componenti Elettrici

N.B.

La garanzia decade qualora i guasti siano

provocati da negligenza dell’utente o

manomissioni effettuate da personale non

autorizzato.

3A1 – SUGGERIMENTI PRIMA DI

UTILIZZARE LA LAVASTOVIGLIE

- Effettuare un paio di cicli a vuoto per pulire

la vasca e tutte le condutture da oli di

produzione.

- Evitare il lavaggio di stoviglie decorate.

- Evitare il contatto dell’argenteria con gli

altri metalli.

- Evitare l’essicazione dei residui sulle

stoviglie.

- Asportare dalle stoviglie i residui solidi più

consistenti onde evitare l’intasamento dei

filtri.

- Pretrattare le stoviglie con sola doccia

d’acqua fredda o tiepida, senza l’uso di alcun

detergente.

- Per ottenere migliori risultati, disporre le

posate nell’apposito cestello con i manici

rivolti verso il basso.

- Utilizzare dosatori automatici per il

detersivo.

- In mancanza del dosatore automatico

versare il detersivo, di tipo non

schiumogeno, nella vasca quando l’acqua ha

raggiunto la temperatura di lavaggio.

29

Page 31

PANNELLO DI CONTROLLO

LEGENDA

3B – AVVIO APPARECCHIO/ CICLO DI

LAVAGGIO (versione ELETTRONICA)

N.B.

L’interfaccia rappresentata qui sopra è la versione più completa.