Adler 580 Installation Manual

Manual, complete

580

Double-chainstitch buttonhole automat

Single-chainstitch automat for stitched eyelets

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon + 49 (0) 5 21 / 9 25-00 • Telefax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 10/2005 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 580001

580

Manual, complete

Contents

Operating Instructions

Installation Instructions

Service Instructions

Interconnection-diagram

9890 580001 B

Index Page:

Part 2: Installation Instructions cl. 580

1. Scope of delivery .................................................3

2. General notes and securing devices .....................................3

3. Table plate with dimensioning ........................................4

4. Ring bolt ......................................................5

5. Assembly of the main sw itch .........................................5

6. Assembly of the control ............................................6

7. Potential equalization ..............................................7

8. Assembly of the waste container .......................................8

9. Installation of the automatic buttonholer

9.1 Adjustingtheworkingheight...........................................9

9.2 Attachingthethreadstand............................................9

9.3 Connecting the pedal ..............................................10

9.4 Securingthestand................................................10

9.5 Connecting the maintenance unit .......................................11

9.6 Adjusting the operating pressure ........................................11

10. Lubrication

10.1 Filling the oil reservoirs .............................................13

11. Installing the sew ing s oftware

11.1 General .......................................................14

11.2 Loading the program ...............................................14

11.3 Setting the sewing equipment .........................................15

11.4 Dongle-Update via the Internet ........................................15

2

12. Sewing test ....................................................16

4

1

3

6

2

5

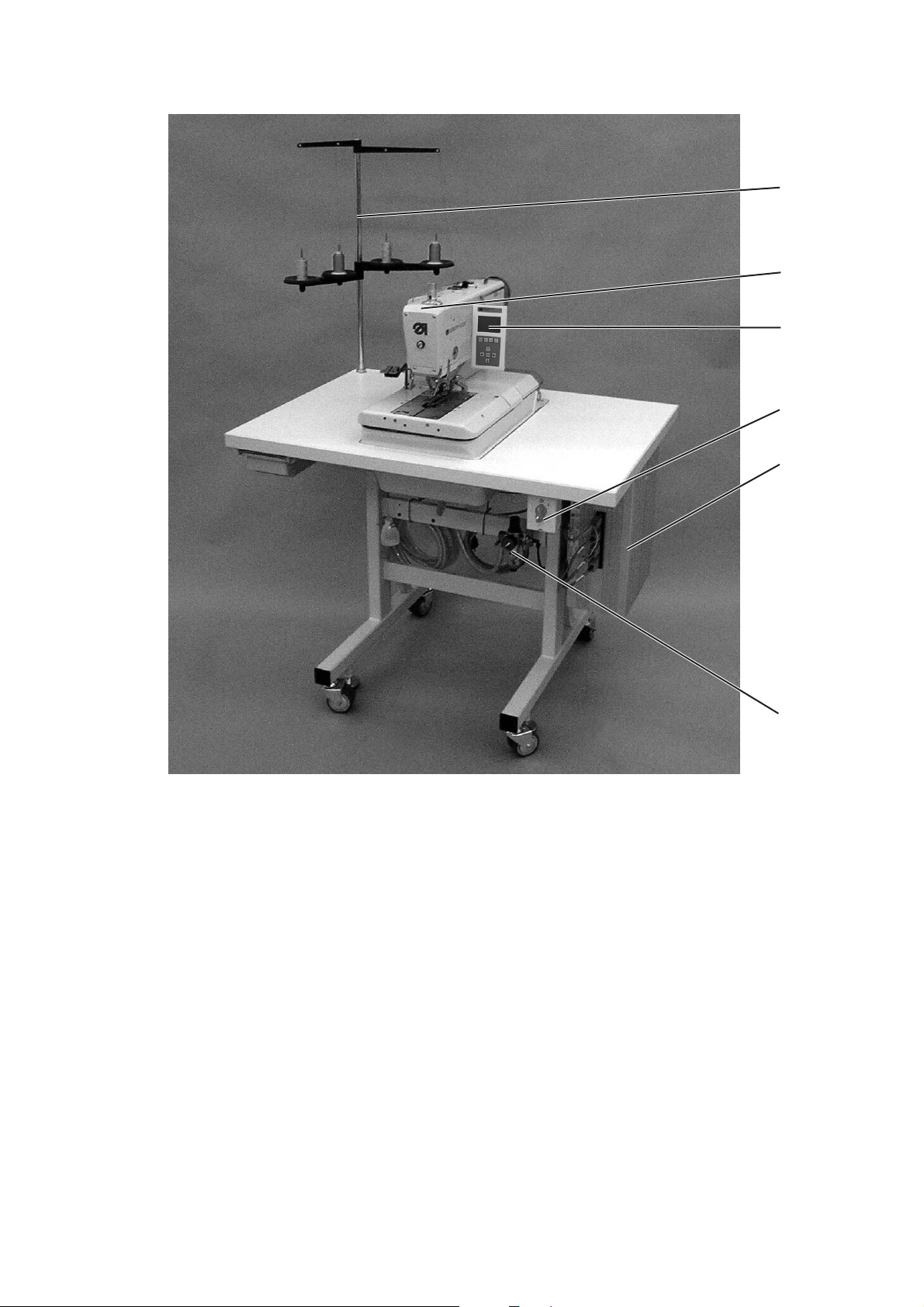

1. Scope of delivery

The scope of delivery is dependent on your order. Please check before

the assembly whether all required parts are available.

–

1 Machine head

–

2 Control

–

3 Control panel

–

4 Thread stand

–

5 Maintenance unit

–

6 Main switch

–

–

–

–

Integral sewing lamp

Spacer (right + left) for the distance between buttonhole

and fabric edge

Tools and small parts in the accessories

Optional equipment (depending on the order) e.g.:

- Stand

- Pneumatic connection package

- Foot switch

2. General notes and securing devices

2

ATTENTION !

The sewing automat must only be assembled by trained specialist

staff.

All work on the electric equipment of the automat must only be

carried out by electricians or correspondingly instructed persons.

The mains plug has to be pulled out.

Securing devices

Before the installation of the sewing automat all securing devices have

to be removed.

–

Remove tapes and battens from the machine head, the machine

table and the stand.

–

Remove screw 1. This screw avoids that the machine head swivels

up during transportation.

–

Remove screws 2.

They will prevent the clamping plates from falling.

1

2

3

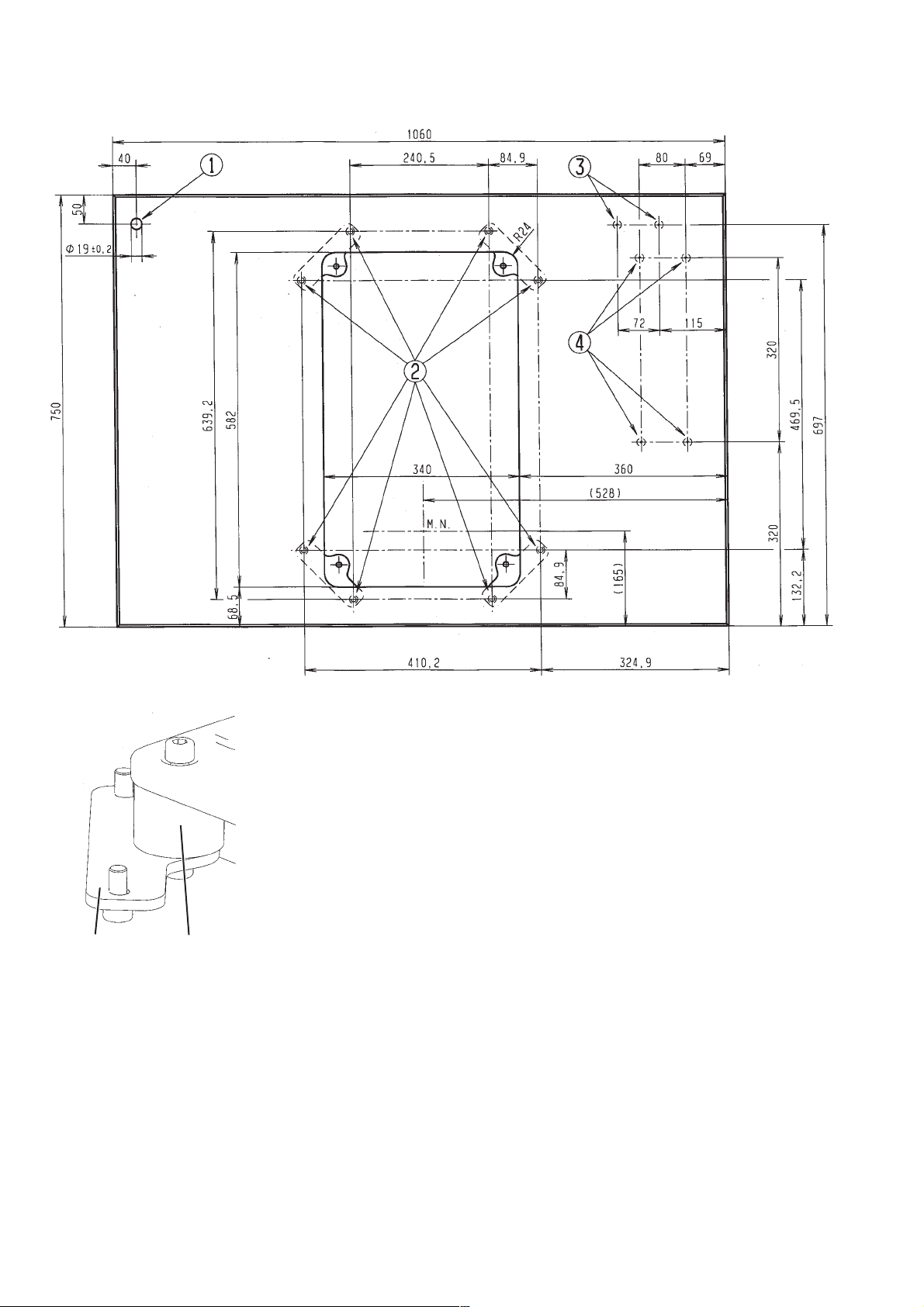

3. Table top with dimensioning

75

If you manufacture the table top yourself, take the above sketch as an

example for the dimensioning. The table top should be approx. 40 mm

thick.

Hole for the thread stand

Positions for screwing on the fish plate.

To fix the machine properly, the screws for

the fish plate should only be screwed into the screwed

inserts M8 x 25 DIN 7965 (the screwed inserts

are not included in the accessories).

Positions for screwing on the protective bracket of the control.

Positions for screwing on the control

The rubber-bonded metal buffers 5 have to be screwed between the

connectors and the machine pedestal, because otherwise vibrations

are transmitted from the automat to the stand.

(all required parts are included in the accessories)

4

Loading...

Loading...