Page 1

Contents page:

Preface and general safety instructions

Part 1: Operating instructions class 579

Program version 579A04

1. Product description

1.1 Designated use ..................................................5

1.2 Brief description..................................................5

1.3 Subclasses.....................................................7

1.4 Product structure .................................................8

2. Technical data ..................................................9

3. Operation

3.1 Needles, yarns and gimps ...........................................10

3.2 Removing and replacing the clamp plates..................................11

3.3 Changing the needle ..............................................12

3.4 Threading the upper thread ..........................................13

3.5 Threading the bobbin thread..........................................14

3.6 Threading the gimp thread (versions 579-121000, 579-141000 and 579-151000 only) .......15

4. Thread tensions

4.1 Needle- and bobbin-thread tension......................................16

4.2 Bobbin-thread-tensioning spring .......................................17

5. Changing the cutting blocks ........................................18

6. Spreading the workpiece...........................................19

7. Hand switches .................................................19

1

8. Switching on - Switching off - Firm hold

8.1 Switching on ...................................................20

8.2 Switching off ...................................................20

8.3 Firm hold .....................................................20

8.4 Switching threading mode on and off.....................................21

9. Controller

9.1 General ......................................................21

9.2 Operating the controller ............................................22

9.3 Changing parameter values ..........................................23

9.3.1 Numerical values ................................................23

Page 2

Contents page:

9.3.2 Selecting a parameter .............................................23

9.4 Sewing process .................................................24

9.4.1 Switching on ...................................................24

9.4.2 Sequence mode and single-button mode ..................................24

9.4.2.1 Selecting a sequence (sequence mode)...................................24

9.4.2.2 Selecting a buttonhole (single-button mode) ................................24

9.4.3 Changing buttonhole parameters .......................................25

9.4.4 Automatic or manual operation (can only be set in sequence mode) ..................25

9.5 Sewing ......................................................26

9.5.1 Fast switch-off ..................................................26

9.6 Changing a buttonhole program........................................28

9.7 Buttonhole sequence ..............................................31

9.7.1 Selecting a buttonhole sequence .......................................31

9.7.2 Changing the buttonhole sequence......................................31

9.8 Piece counter ..................................................32

9.9 Buttonhole and sequence programming: a brief description ......................33

9.9.1 Selecting a buttonhole number ........................................33

9.9.2 Entering parameters ..............................................33

9.10 Setting buttonhole sequences: a brief description .............................34

9.10.1 Selecting a buttonhole sequence .......................................34

9.10.2 Changing a sequence..............................................34

10. Error messages

10.1 Pressure monitor ................................................35

10.2 Firm hold .....................................................35

10.3 Error messages .................................................35

10.4 Needle not in starting position.........................................35

10.5 Handwheel turned manually .........................................35

10.6 Sewing-start side not correct .........................................35

11. Maintenance

11.1 cleaning ......................................................36

11.2 Lubrication ....................................................37

Page 3

1. Product description

1.1 Designated use

Die DÜRKOPP ADLER 579 is an automatic sewing machine designed

for sewing buttonholes in light to medium-heavy material.

Such material, which is generally made of textile or synthetic fibres, is

used in the clothing industry. This sewing machine can also be used to

produce so-called technical seams. In this case, however, the operator

must assess the possible dangers which may arise (with which

DÜRKOPP ADLER would be happy to assist), since such applications

are on the one hand relatively unusual and, on the other, they are so

varied that no single set of criteria can cover them all. The outcome of

this assessment may require appropriate safety measures to be taken.

Generally only dry material may be sewn with this machine. The

material may be no thicker than 8mmwhen compressed by the

lowered upper material clamps.

The material may not contain any hard objects. The machine may only

be operated with finger and eye protection. The seam is generally

produced with sewing threads of gauge up to 80/2 Nm (synthetic

threads with or without cotton covering). Before using any other thread

the possible dangers arising must be assessed and appropriate safety

measures taken if necessary. This machine may be set up and

operated only in dry, well-maintained premises. If it is used in other

premises which are not dry and well-maintained it may be necessary to

take further precautions (which should be agreed in advance - see EN

60204-31: 1999). As manufacturers of industrial sewing machines we

proceed on the assumption that personnel who work on our products

will have received training at least sufficient to acquaint them with all

normal operations and with any hazards which these may involve.

1

1.2 Brief description

Depending on the subclass, the DÜRKOPP ADLER 579 is a

double-chainstitch buttonhole machine or a single-thread chainstitch

eyelet machine with CNC step motor for fabric feed and rotating

sewing mechanism.

As a buttonhole machine it works with two chainstitch loopers, the left

one carrying the thread, sewing buttonholes with or without an eye,

with taper, round or cross tacks.

As an eyelet machine it works with two chainstitch dummy loopers,

sewing single-thread eyelets.

The various subclasses of the 579 are fitted with different

thread-trimming systems.

Technical features

The machine is driven by a positioning drive built into the machine arm.

The movements of the X, Y and Z axles are driven by a step motor.

These drives are controlled by a DAC 2 electronic controller in

conjunction with various pneumatic machine functions.

The BF 2A operating panel is mounted in a visible location on the

machine arm and is thus easily accessible to the operator. This

drive-and-controller system has the following advantages:

–

Variable sewing speed depending on parameters such as the upper

thread, bobbin thread, material, seam width) up to a maximum of

2200 stitches/min.

–

Very quiet operation because there is no mechanical connection

and disconnection.

Additional noise reduction from the new needle-bar and looper

drive.

5

Page 4

–

The use of step motors confers great versatility. No use of control

cams.

–

One-pedal operation for the following functions:

- close/open clamps

- switching on the sewing process

- rapid halt with needle lift

–

Pneumatically-operated thread-trimming system with short drive

distances for precise operation.

–

Pneumatic buttonhole slit.

–

Central oil-wick lubrication from two oil reservoirs.

–

Simple cutting-block replacement.

–

Seam-width alteration in the cross tack.

–

The special design of the machine arm permits the use of a

different material holder (optional extra) enabling the material to be

placed lengthwise.

–

Smooth design with casing. A gas-pressure spring helps to swing

the machine up and ensures that the head does not swing down

too quickly.

–

Vertically-operating cutting-block holders mean that no finishing-off

work is necessary even with different cutting-block heights.

–

After the material has been released a display setting enables the

cloth carrier plate to move to the starting position for the next

buttonhole, which improves visibility for material positioning.

Controller

–

A counter, shown in the display, counts the number of buttonholes

sewn.

–

A number of parameters can be set on the BF 2A operating panel,

depending on the subclass and buttonhole shape. These include

the following:

- with or without eye

- speed max. 2200 rpm

- buttonhole length, various ranges depending on the subclass

- cut before or after sewing

- no cutting

- stitch count in the eye

- stitch distance

- taper tack overlap

- taper tack length

- overlap in round tacks and eyelets

- overlap in the round tack

- number of stitches in the round tack

- stitch distance in the cross tack

6

Page 5

1.3 Subclasses

579-112000 With short trimmer for the upper and bobbin threads. The

bobbin-thread trimmer is located in the throat plate, enabling the

thread to be severed very close to the material. For taper, round and

cross tacks. Can also be used for double-chainstitch eyelets in

conjunction with appropriate sewing apparatus.

Fitted as standard with an electropneumatic upper thread catcher.

No lower gimp.

579-121000 With short trimmer for the upper thread and long

trimmer (thread length ca. 30 mm) for bobbin thread and gimp. Cutting

before or after sewing, with or without taper, round or cross tack.

The bobbin thread and gimp can thus be either pulled tight or passed

through to sew a lockstitch tack afterwards.

After the cross tack has been sewn they are short-trimmed by hand.

For cut lengths up to 38 mm: fitted as standard with electropneumatic

thread catcher and gimp guide. This grasps the upper thread as soon

as it is severed, holds it clamped and inserts it into the right side to

sew the next buttonhole. This means:

- a secure seam start, even in light, loose weaves - tight starting

stitches

- a clean buttonhole underside, hence no need for trimming.

1

579-141000

With short trimmer for the upper thread, bobbin thread and lower gimp.

The material is not released by the material clamps until the

thread-trimming process is complete, which means that the lower

thread and lower gimp are trimmed very short .

Cutting before or after sewing, with or without taper, round or cross

tack.

On this machine the buttonhole length, cut length and taper-tack length

can be altered by fitting different clamp-plate sets.

Clamp-plate sets for five groups of cut lengths exist.

L1 for cut lengths of 12-16 mm in 2 mm increments

L2 for cut lengths of 16-20 mm in 2 mm increments

L3 for cut lengths of 20-24 mm in 2 mm increments

L4 for cut lengths of 24-28 mm in 2 mm increments

L5 for cut lengths of 28-32 mm in 2 mm increments.

Within these cut-length groups various taper-tack lengths are possible.

With thread catcher and gimp guide.

579-151000

With short trimmer for the upper thread.

A universal machine for buttonholes with cut lengths of 10-50 mm in

materials of various qualities and thicknesses, available with or without

lower gimp depending on sewing apparatus. Can also be used for

single-chainstitch eyelets in conjunction with appropriate sewing

apparatus.

7

Page 6

1.4 Product structure

Subclasses

Equipment Material number

machine 0579 990001 X

machine 0579 990002 X

machine 0579 990003 X

machine 0579 990004 X

accessory kit 0791 579501 X X X X

Optional extras:

lengthways positioning kit 0579 590074 O O O

upper thread catcher 0579 590564 X X X O

pneumatic connection pack 0797 003031 O O O O

halogen tripod sewing lamp 9822 510000 O O O O

table clamp for halogen tripod sewing lamp 9822 510011 O O O O

key 9880 579001 O O O O

gimp-thread advancing device 0579 590334 X O O

hind-trouser holder 0579 590324 O

(in sewing apparatus E151 for 579-112000 and

sewing apparatus E551 for 579-151000)

positioning aids

buttonhole-to-buttonhole distance stop 0579 590344 O O O O

buttonhole-to-edge distance stop 0579 590104 O O O O

579-112000

579-141000

579-121000

579-151000

stands

MG58-13 MG58 400084 X* X* X* X*

stand with attachment fittings and table

plate 1060x750 inc. maintenance unit and rollers

MG58-13 MG58 400094 X* X* X* X*

stand with attachment fittings and table plate 620x750

inc. maintenance unit and rollers

support table for working standing up 0579 590134 O O O O

(inc. key 9880 579001)

holder for hind-trouser facings 0579 590654 O O O O

(pocket pouch open) inc. stop

right and left for pocket opening

laser mark lamp inc. power pack 0579 590674 O O O O

X = Standard equipment

O = Optional extras

* = Narrow or wide stand supplied at purchaser’s option

8

Page 7

2. Technical data

Head: class 579

Stitch type: double chainstitch

Number of needles: 1

Needle system: 579

Needle thickness: max. Nm 125

(depending on the subclass)

Upper-thread thickness: max. Nm 50

Bobbin-thread thickness: max. Nm 30

Max. Speed: 2200 rpm

Stitch distance: 0.5-2mm

Max. sewing length: 38 mm (subclass 579-112000)

(depending on 38 mm (subclass 579-121000)

sewing apparatus) 38 mm (subclass 579-141000)

50 mm (subclass 579-151000)

Max. cut length: 38 mm (subclass 579-112000)

(depending on 38 mm (subclass 579-121000)

sewing apparatus) 36 mm (subclass 579-141000)

50 mm (subclass 579-151000)

1

Operating pressure: 6 bar ± 0.5 bar

Air consumption: approx. 5 NL per working cycle

Rated power: 1.4 kVA

Rated voltage: 1 x 190-240 V, 50/60 Hz

on delivery: 1 x 230 V, 50-60 Hz

Dimensions: 1060 x 750 x 1030 mm (LxWxH)

Working height: 750...895 mm (upper edge of table plate)

Weight: approx. 170 kg

Rated noise value: Lc = 79 dB (A)

Workplace-related emission value in accordance with

DIN 45635-48-B-1

(sewing cycle 6s ON and 1s OFF)

Stitch length: 1.2 mm

speed: 2200 rpm

material: double denim 509g/m²

9

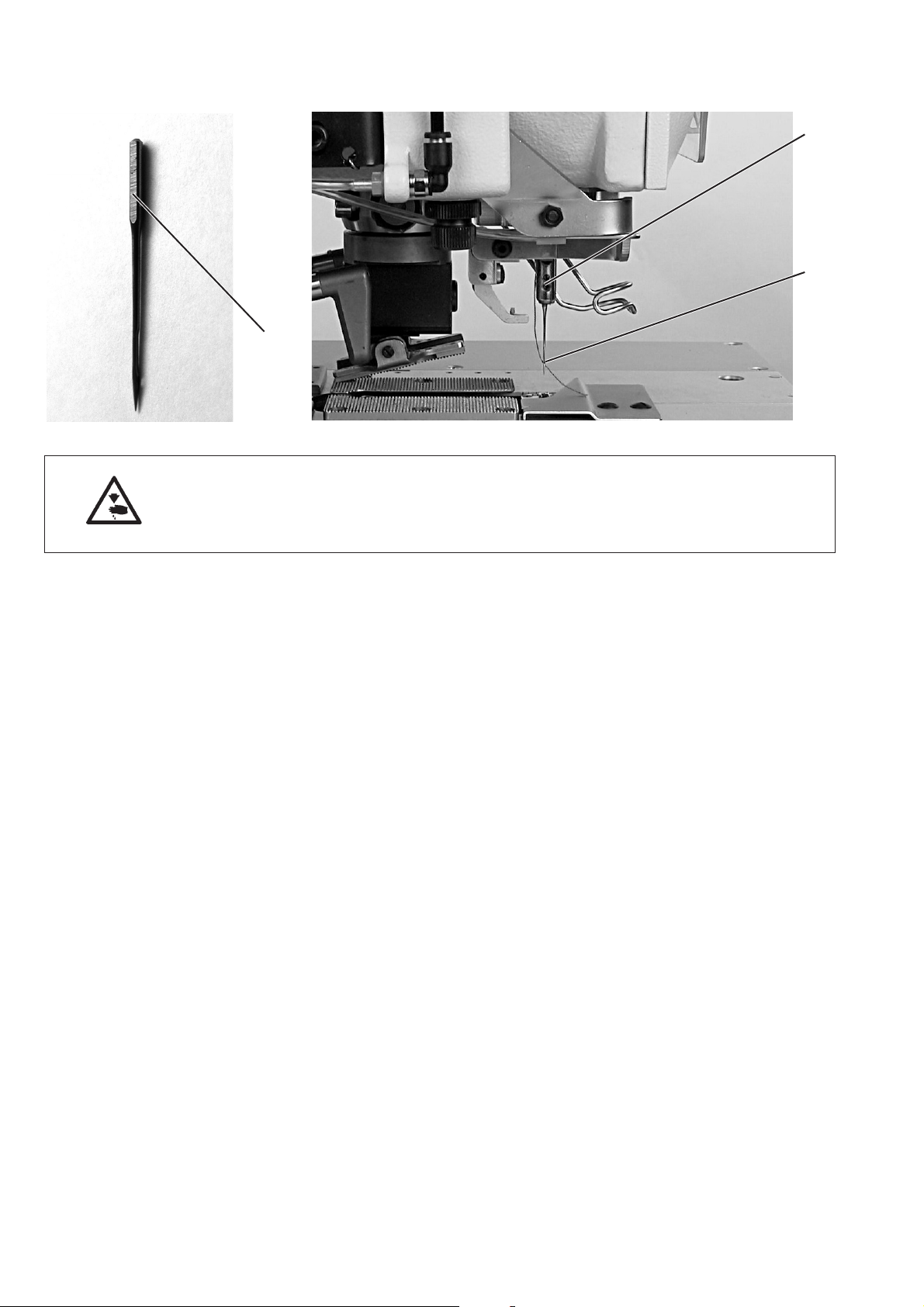

Page 8

3. Operation

3.1 Needles, yarns and gimps

Needles

Needle system: 579

Needle thicknesses: Nm 90-125

The needle thickness to be used for each machine and its sewing

apparatus (E no.) is given on the nameplate.

Yarns

The appearance of the buttonhole is greatly affected by the yarn used.

Synthetic-fibre yarns or even silk yarn can be used as the needle and

bobbin threads.

The appearance of the buttonhole is greatly affected by

–

–

Gimps

The gimp stabilises the buttonhole and at the same time gives it a

plastic shape.

It should have the following characteristics:

–

–

depending on the type of thread and material and the

sewing apparatus (E no.).

the yarn used

the use of different thicknesses for the needle and bobbin threads.

not too thick, but supple and strong

constant diameter.

The recommended yarns in the following table are only guidelines.

Other yarns and yarn thicknesses may be required, depending on the

sewing apparatus (E no.) and the material.

Subclass upper thread type bobbin thread type lower gimp thread type

and thickness and thickness and thickness

579-112000 polyester-fibre yarn, polyester-fibre yarn not required

schappe schappe

70/3 70/3

80/2 80/2

579-121000

-141000 poly-poly 80/2 poly-poly 80/2 poly-schappe 15/3

-151000

10

Page 9

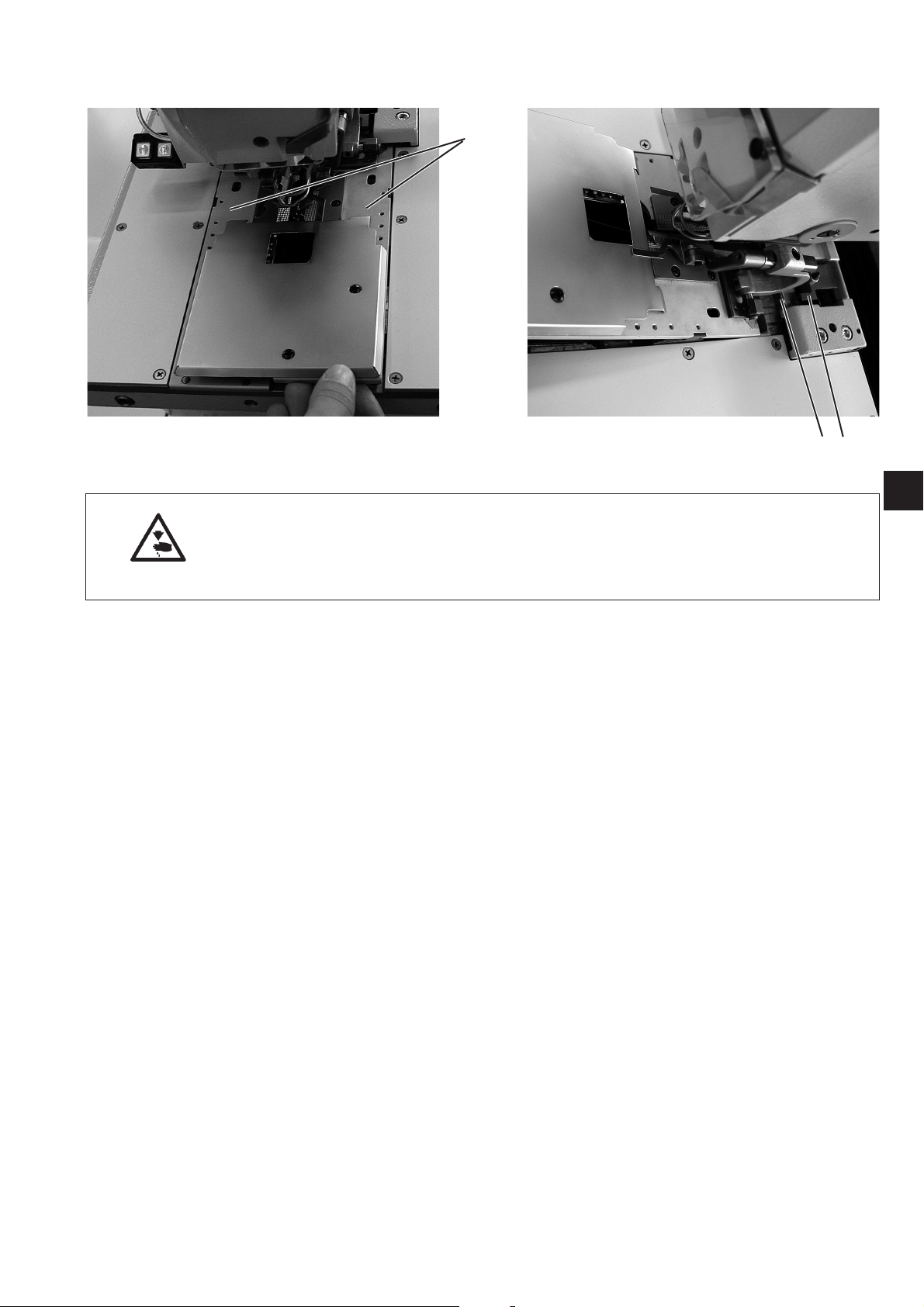

3.2 Removing and replacing the clamp plates

1

Caution: danger of injury

The clamp plates 1 must be removed and replaced with the machine

switched off or in the “firm hold” position. Inadvertently operating the

pedal with the main switch turned on may lead to damage or injury.

23

1

Removing the clamp plates

–

Slightly raise the right or left (depending on the subclass) clamp

plate 1 and remove it forwards.

–

Slightly raise the other clamp plate 1 and remove it forwards.

Fitting the clamp plates

–

First fit the left or right clamp plate 1.

The pin 2 must engage in the jaws 3.

–

Then fit the second clamp plate 1.

The pin 2 must engage in the jaws 3.

11

Page 10

3.3 Changing the needle

1

2

3

Caution: danger of injury

The needle must be changed with the machine switched off or in the

“firm hold” position.

–

Undo screw 1.

–

Pull the needle 2 out of the needle bar.

–

Push the new needle as far as it will go into the hole in the needle

bar.

–

Align the needle 2 so that its throat points forward and the surface

3 on the needle piston to the left (in the direction of the attachment

screw 1).

–

Tighten screw 1.

12

Page 11

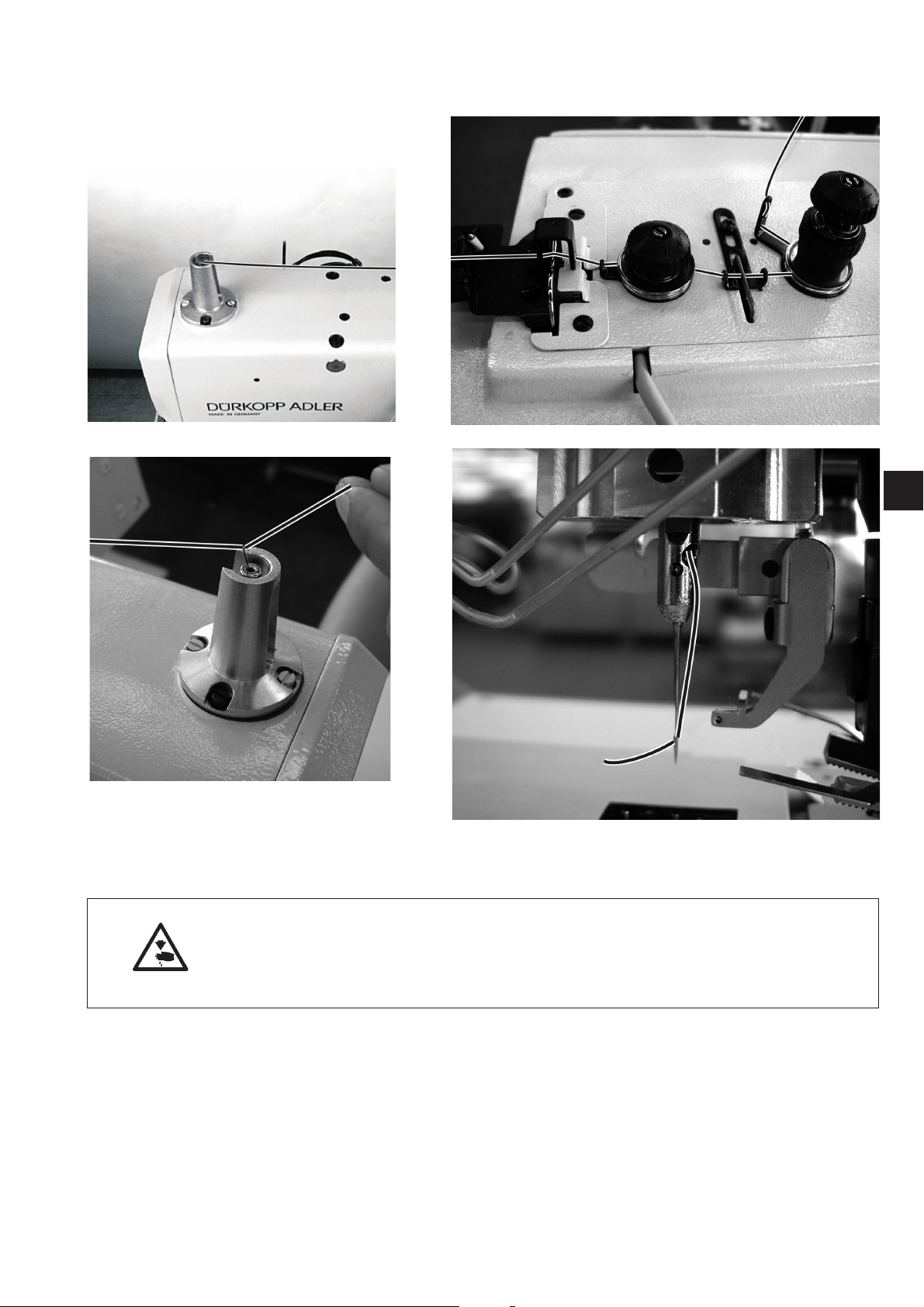

3.4 Threading the upper thread

1

Caution: danger of injury

The upper thread may only be threaded with the machine switched off

or in threading mode (see “threading mode” section).

–

Thread the upper thread as shown in the illustrations.

–

To thread the upper thread insert the threading wire (in the

accessory kit) upwards through the hollow needle bar 1 from below.

–

Place the top end of the upper thread in the hook.

–

Pull the upper thread down with the wire.

–

Thread the upper thread into the needle by drawing it forwards.

13

Page 12

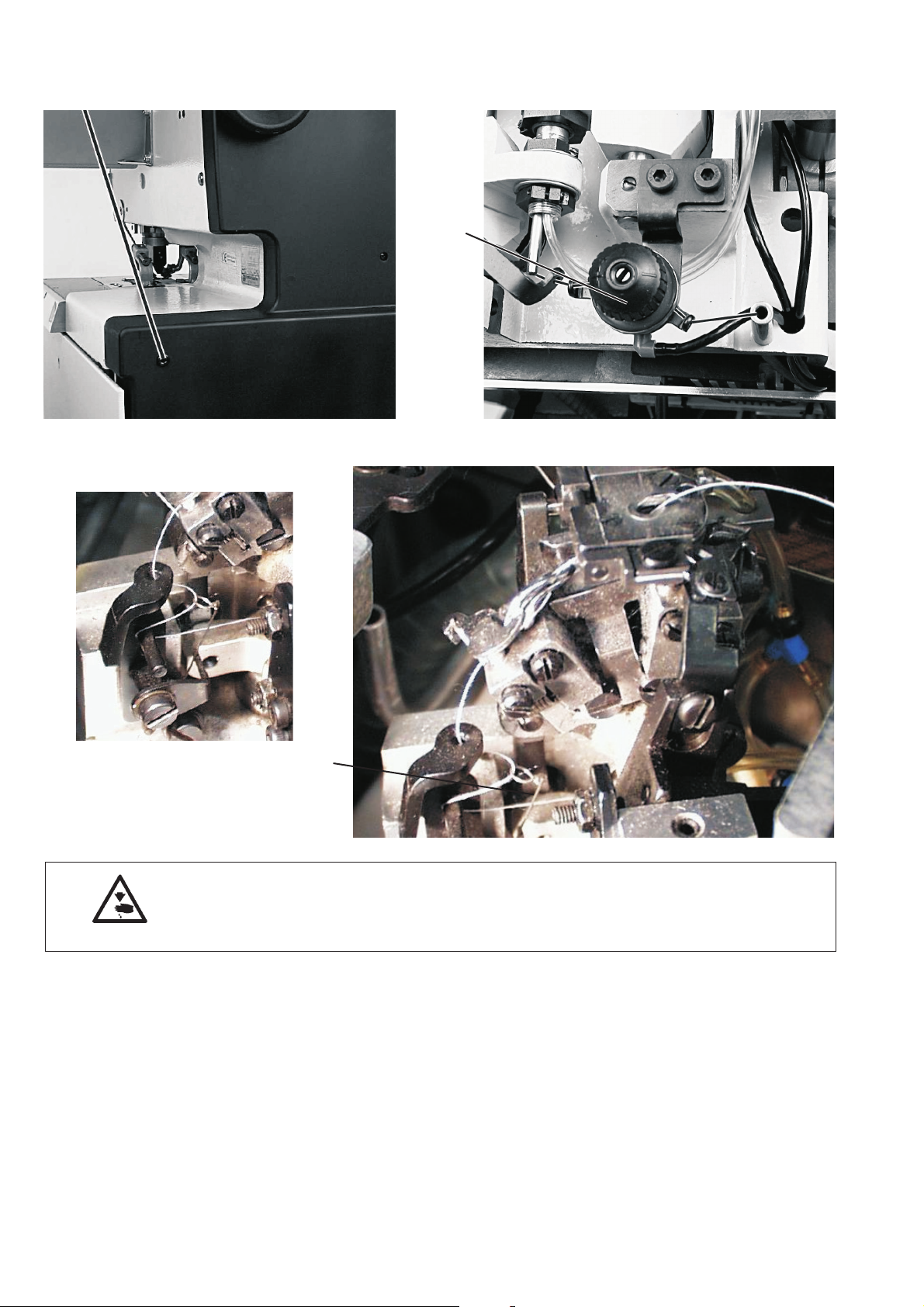

3.5 Threading the bobbin thread

1

2

Caution: danger of injury

The bobbin thread may only be threaded with the machine switched off or in

threading mode (see “threading mode” section).

The machine must be in its final position, i.e. the hook turret with

loopers must point forwards.

–

Remove clamp plates (see section 3.2).

–

Swing machine up.

–

Use the threading wires in the accessory kit to thread the bobbin

thread as shown in the illustrations.

NB: The thread must be threaded above the thread tensioner 1 and

behind the thread-tensioning spring 2.

–

Leave about 25 mm of bobbin thread hanging out of the stitch hole

in the throat plate.

–

Fit the clamp plates (see section 3.2).

14

Page 13

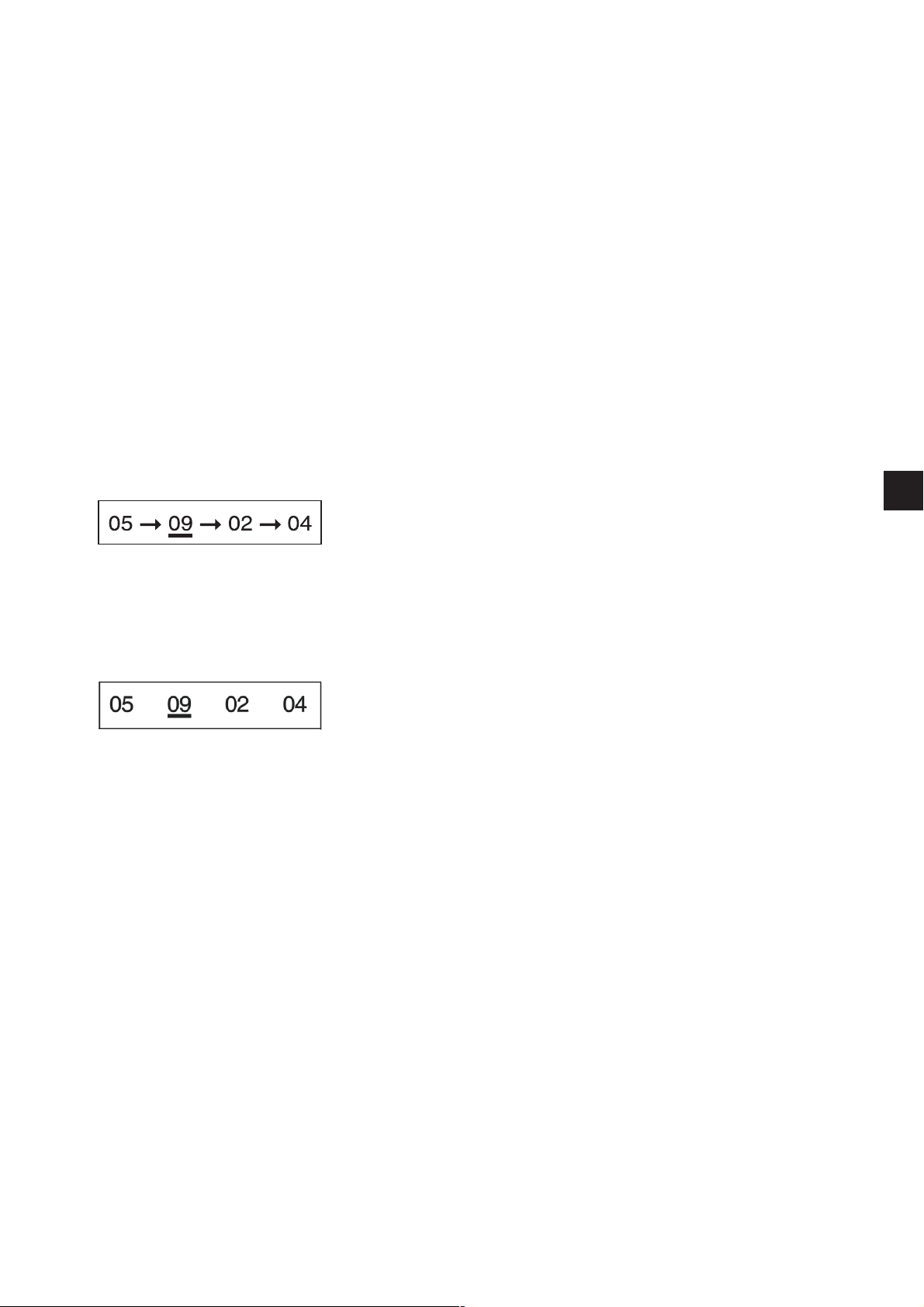

3.6 Threading the gimp thread (subclasses 579-121000, 579-141000 and 579-151000

only)

1

579-121000 and 579-151000 579-141000

Caution: danger of injury

The gimp thread may only be threaded with the machine switched off or in

threading mode (see “threading mode” section).

–

Thread the gimp thread as shown in the illustrations.

–

Leave about 25 mm of bobbin thread hanging out of the gimp hole

in the throat plate.

15

Page 14

4. Thread tension

4.1 Needle and bobbin-thread tension

The thread tensions depend on the type and quality of the yarn and

material. The thread tension should be the minimum at which the

appearance of the buttonhole is satisfactory.

With thin material excessive thread tensions may cause unwanted

gathering and thread breakage.

1

2

3

4

Upper-thread tension

The upper-thread tension must generally be set higher than the

bobbin-thread tension. The upper-thread tension consist of two

components the main tension for the sewing process and a residual

tension to keep the upper thread taut for the cut beneath the throat

plate.

The upper thread hanging out of the needle must be long enough to

ensure that the first stitch is securely executed. The residual tension

required to achieve this depends on the elasticity of the upper thread

used.

–

Adjust the main tension for the sewing process with the knurled

nut 1.

–

Adjust the residual tension to keep the upper thread taut when it is

cut with the sleeve 2.

If the residual tension is changed the main tension should be

corrected accordingly.

NB:

Adjusting the thread clamp 4 does not alter the upper-thread tension.

Only the clamping force can be adjusted on the thread clamp.

Bobbin-thread tension

–

Swing the head up.

–

Adjust the bobbin-thread tension with the tensioner 3.

–

Swing the head down.

16

Page 15

4.2 Bobbin-thread-tensioning spring

1

2

3

4

5

Caution: danger of injury

The thread-tensioning spring may only be adjusted with the machine

switched off or in the firm hold position.

The deflection and pre-tensioning force of the thread-tensioning spring

1 affect the bobbin-thread tension and thus the shape and purling of

the buttonhole.

Adjusting the deflection:

–

Undo screw 2.

–

Twist bracket 3.

–

Tighten screw 2.

Adjusting the pre-tension:

–

Undo screw 5.

–

Twist bracket 4.

–

Tighten screw 5.

1

17

Page 16

5. Changing the cutting blocks

1

2

The cut length can be changed by switching cutting blocks.

Caution: danger of injury

Cutting blocks may only be switched with the machine switched off or

in the firm hold position.

Removing the cutting-block holder

–

Remove clamp plates (see section 3.2).

–

Press button 1.

–

Pull the cutting-block holder 2 downwards and remove.

Fitting the cutting-block holder

–

Press button 1.

–

Insert the cutting-block holder in the cutting-block mounting.

–

Release button 1.

–

Check that the cutting-block holder is firmly seated in its mounting.

–

Fit clamp plates (see section 3.2).

18

Page 17

6. Spreading the workpiece

Where cutting precedes sewing the incision opens to enable the

piercing needle to sew the left and right seam rows cleanly without

piercing the cut edge of the material.

On machines where cutting follows sewing the material is kept taut for

the sewing process.

A spread of 1.5 mm is normally sufficient.

The workpiece is spread just before sewing begins. The clamp plates

are forced apart by the two pins 1.

The left and right sides must be evenly adjusted so that both clamp

plates execute an equal lateral movement.

1

2

1

3

1

7. Hand switches

Caution: danger of injury

The material spread must only be adjusted with the machine switched

off or in the firm hold position.

Adjustment

The stop screws 2 can be reached through the holes 3 on both sides of

the machine with an Allen key.

–

Adjust the stop screws on both sides so that the required spread is

achieved.

The hand switch controls the clamps and initiate the sewing process.

Their function depends on the service-menu setting (see Servicing

instructions).

Setting 1:

–

button 1: opens and closes the clamps

–

button 2: initiates the sewing process provided the clamps are

closed.

Setting 2:

–

button 1: opens and closes the clamps

–

button 2: lowers the clamps if they are not already lowered. The

sewing process begins.

19

Page 18

8. Switching on - Switching off - Firm hold

12

8.1 Switching on

–

The sewing-drive switch 1 must be in position 1.

–

Turn on the main switch 2.

The Dürkopp Adler logo briefly appears.

The opening screen appears.

8.2 Switching off

8.3 Firm hold

–

Turn off the main switch 2.

All drives and the controller are immediately disconnected from the

power supply.

Before any work is carried out on the machine it must be switched off

or the firm-hold mode activated.

Push the pedal back.

–

Turn switch 1 to position “0".

The machine is in firm-hold mode.

This message appears, flashing.

The sewing drive is disconnected from the mains.

The buttonhole blade is switched off.

–

To resume the sewing process proceed as follows:

Turn switch 1 to position “1".

After a short pause the machine is again ready for operation. The

sewing process is resumed at the point where firm hold was

activated.

If the symbol appears in reverse, firm hold was switched on before the

pedal was pushed back.

To clear proceed as follows:

–

Turn switch 1 to position “1".

–

Push the pedal back.

–

Turn switch 1 to position “0".

The machine is in firm-hold mode.

20

Page 19

8.4 Switching threading mode on and off

Caution: danger of injury

For threading either the machine must be switched off or threading

mode must be activated.

–

Push the pedal back.

The hook turret is rotated to the optimum threading position.

The thread tensioners are opened.

–

Turn switch 1 to position “0".

This message appears.

–

Thread the upper or bobbin thread.

–

Turn switch 1 to position “I”.

After a short pause the machine switches to sewing mode.

The machine is ready for operation.

9. Controller

1

9.1 General

The class 579 buttonhole machine is equipped with a programmable

controller. Up to 50 different buttonholes can be defined. The

buttonholes can be programmed in up to 25 sequences. Each

sequence can contain up to 5 buttonholes. During operation the

machine can switch among the programmed buttonholes either

automatically or manually.

The following buttonhole shapes are available for selection:

–

buttonholes with taper tack

–

buttonholes with round tack

–

buttonholes with cross tack

–

buttonholes without tack

–

eyelets.

The various buttonhole properties such as length and eye shape can

be set for all shapes.

CAUTION:

Not all buttonhole shapes and variants can be sewn on every subclass

and with every sewing apparatus.

21

Page 20

9.2 Operating the controller

Display

Entry field

OK key

key function

ïð In the main menu: switch from one buttonhole program

to another

If an entry field is activated:

switch from one position to another.

Where functions have a number of selection possibilities:

switch from one to another, e.g. from “cut before

sewing” to “cut after sewing” or “no cut ”.

òñ If no entry field is activated:

switch from one menu line to another. The selected

line appears on a dark background.

If an entry field is activated:

Increase or reduce the value of the selected position.

OK-key If no entry field is activated:

activate the entry field. The value can be changed with the

“ñ” and “ò” keys.

If an entry field is activated:

the value set is accepted.

ESC If an entry field is activated:

an entry is abandoned. The previous value is retained.

If no entry field is activated:

the menu is closed or the clamp opened.

P The controller switches to buttonhole-programming mode.

Buttonhole parameters can be changed in this mode.

S The controller switches to buttonhole sequence mode.

Buttonhole sequences can be changed

in this mode.

F The controller switches to the service menu. Access to the

service menu requires the entry of a code number.

RST Close clamps and initiate the sewing process.

During operation:

stop and re-start the sewing process.

22

Page 21

9.3 Changing parameter values

9.3.1 Numerical values

Numerical values can be changed in the following way:

–

–

–

–

–

Use the ñ and ò cursor keys to select the line containing the value

you wish to change.

Press the enter key.

The cursor flashes under one digit of the numerical value.

Use the ï and ð cursor keys to move from one digit to another.

Use the ñ and ò cursor keys to increase or reduce the value of the

selected digit.

Where parameters are limited to certain values (e.g. eye shape),

pressing the ñ and ò cursor keys displays another possible

parameter value.

Press OK.

The set value is accepted.

If the set value is not to be accepted, press “ESC”.

The original value is restored.

9.3.2 Selecting a parameter

Some parameters allow selection among a number of possibilities.

These parameters can be changed in the following way:

–

Use the ñ and ò cursor keys to select the line containing the

parameter or value to be changed.

–

Press OK.

–

Use the ñ and ò cursor keys to switch from one possibility to another.

The selected symbol appears in the display.

Exception:

to switch cut mode use the ï and ð cursor keys.

–

Press the enter key.

The set parameter or value is accepted.

–

If the set parameter or value is not to be accepted, press “ESC”.

The original parameter or value is restored.

1

23

Page 22

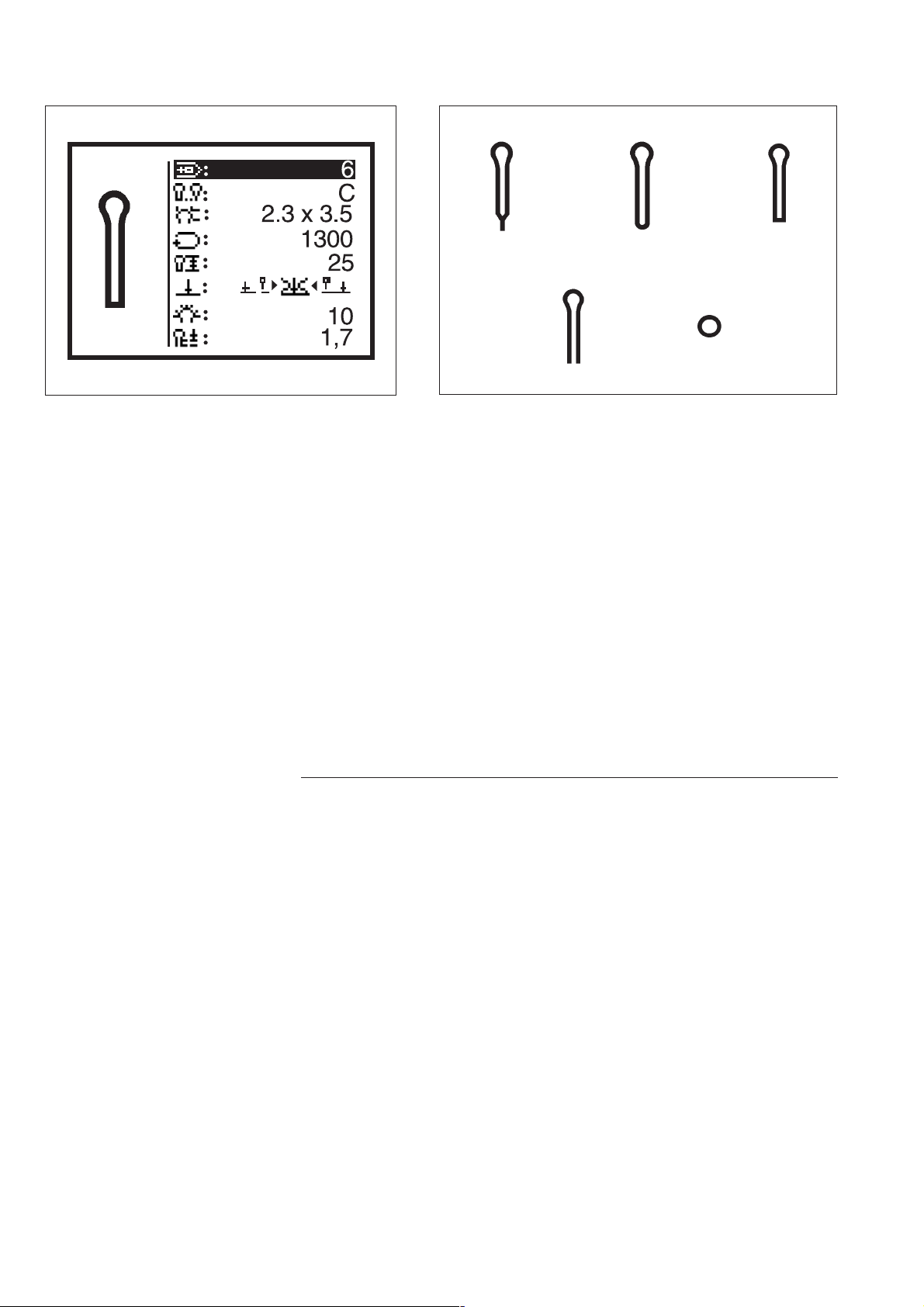

9.4 Sewing process

9.4.1 Switching on

Buttonhole shape

Number of

buttonhole

sequence

Buttonhole

sequence

Rotation speed

buttonhole length

cut mode

Piece counter

–

Turn on the main switch .

The Dürkopp Adler logo briefly appears..

–

The main screen appears.

–

Press the “RST” key on the operating panel.

The machine moves to the insertion position and is ready for

operation.

A sketch of the buttonhole to be sewn first appears in the left half

of the display.

9.4.2 Sequence mode and single-button mode

Depending on the service-menu setting either sequence mode or

single-button mode is available.

9.4.2.1 Selecting a sequence (sequence mode)

After switch-on the top line in the display appears on a dark

background. The last sewing sequence used is selected.

Selecting a different sequence

–

Press OK.

–

Use the ñ and ò cursor keys to switch from one sequence to

another.

9.4.2.2 Selecting a buttonhole (single-buttonhole mode)

If single-button mode is set in the service menu, no sequence can be

activated.

After switch-on the top line in the display appears on a dark

background. The last buttonhole sewn is displayed.

Selecting other buttonholes

–

Press OK.

–

Use the ñ and ò cursor keys to switch from one buttonhole to

another.

24

Page 23

9.4.3 Changing buttonhole parameters

The main parameters of the buttonhole are displayed on the main

screen.

Changing the parameters

–

Use the ñ and ò cursor keys to select the line containing the

parameter to be changed.

–

Press OK.

–

Change the parameter value.

–

Press enter to accept the changed value.

–

If the new value is not to be accepted, press “ESC”.

9.4.4 Automatic or manual operation (can only be set in sequence mode)

Depending on the setting the machine operates either manually or

automatically.

Automatic operation

Arrows are displayed between the buttonhole shapes in the sequence

displayed.

After a buttonhole has been completed the controller switches

automatically to the next shape. After the last buttonhole has been

completed the controller switches back to the first buttonhole in the

sequence.

The current buttonhole is marked with a bar.

1

Manual operation

No arrows are displayed between the buttonhole shapes in the

sequence displayed.

The controller does not switch automatically between the buttonhole

shapes.

The current buttonhole is marked with a bar.

Switching between automatic and manual operation

–

Use the ñ and ò cursor keys to select the line containing the

current sequence.

–

Press OK.

–

Use the ñ and ò cursor keys to switch between the two operating

modes.

The arrows between the buttonhole shapes appear and disappear

accordingly.

Selecting the next buttonhole to be sewn in a sequence

If the sewing menu is shown in the display, you can switch from one

programmed buttonhole to another at any time.

–

Press the ï or ð cursor key.

The next or previous buttonhole shape in the sequence displayed

is selected.

25

Page 24

9.5 Sewing

0

1

2

The sewing process can be controlled with the pedal, the hand

switches or the “RST” and “ESC” keys on the operating panel.

In automatic operation the machine moves to the new insertion position

after each sewing process (sequence mode).

In manual operation it moves to the insertion position of the current

buttonhole (sequence and single-button mode).

Sewing with the pedal

–

Push the pedal back.

The machine moves to the insertion position.

–

Insert the material.

–

Push the pedal forwards to position 1.

The clamps close.

0

R

Releasing the pedal opens them again.

The pedal moves to its rest position.

–

Push the pedal down to position 2

The sewing process is initiated.

–

To carry out another sewing process the pedal must be returned to

its starting (rest) position.

Sewing with the operating-panel keys

–

For the first operation after switch-on press the “RST” key if any

parameters have been changed or another buttonhole shape has

been selected manually.

The machine moves to its starting position and from there to the

insertion position.

–

If you wish the machine to move to its starting position, press the

“ESC” key.

–

Insert the material.

–

Press the “RST” key once.

The clamps close.

–

If you wish the clamps to re-open, Press the “ESC” key.

–

If you wish the sewing process to be initiated, press the “RST” key

again.

After the sewing process the machine returns to the insertion

position.

26

12

Removing material after sewing (subclass 579-151000)

–

Sever the upper gimp, pulling it a little if necessary. The material

can be moved on or removed.

–

To remove the material pass the bobbin thread and lower gimp

under thread clamp 2. Pull both threads from right to left along

blade 1.

The threads are severed.

Page 25

9.5.1 Fast switch-off

The comprehensive safety system on the 579 contains various features

enabling it to be halted immediately in the event of incorrect operation,

needle breakage, thread breakage etc.

–

Push the pedal backwards beyond the rest position, press the

“RST” key or press button 1 or 2 on the hand switches.

The machine halts with the needle raised.

–

If you wish sewing to be resumed, push the pedal forwards, press

the “RST” key again or press button 2 on the hand switches.

The sewing process resumes.

–

If you wish to remove the material, push the pedal back, press the

“ESC” key on the operating panel or press button 1 on the hand

switches.

1

27

Page 26

9.6 Changing a buttonhole program

A

D E

Up to 50 different buttonholes can be programmed in the buttonhole

programming menu.

The various parameters of each buttonhole shape can be changed.

A sketch of the current buttonhole shape is shown in the left half of the display.

If the ñ and ò cursor keys are pressed to switch from one buttonhole

parameter to another in the right half, the current measurement is always

highlighted in the sketch.

If not all adjustable parameters fit in the display, the content can be

shifted up or down by pressing the cursor keys at the top or bottom of

the display.

–

Press “P”.

The controller switches to the buttonhole programming menu.

–

Press “S” to program or alter a sequence.

–

To leave the menu press the “ESC” key.

B

C

The following buttonholes with their parameters can be programmed in

the buttonhole programming menu.

Type Buttonhole shape Adjustable parameters

A taper tack eye shape, speed, buttonhole length,

cut, cut-position correction,

speed in the eye, stitch distance, throw

width in the eye, intermediate fabric

taper tack overlap, taper tack length

B round tack eye shape, speed, buttonhole length,

cut, cut-position correction,

stitch count in the eye, stitch distance,

throw width in the eye, intermediate fabric

overlap, number of stitches in the

round tack

C cross tack eye shape, speed, buttonhole length,

cut, cut-position correction,

stitch count in the eye, stitch distance, throw

width in the eye, intermediate fabric

cross tack length, stitch distance in the cross

tack, lateral cross tack length, seam extension

D without tack eye shape, speed, buttonhole length,

cut, cut-position correction,

stitch count in the eye, stitch distance,

throw width in the eye, intermediate fabric

E eyelet speed, eyelet diameter,

cut, stitch count in the eyelet,

throw width, overlap.

28

Page 27

Measurement / Repère

a stitch distance

d eyelet diameter

kl taper tack length

l length

qb cross tack length

ql lateral cross tack position

qs stitch distance in the cross tack

qv seam extension

x eye shape

y eye shape

NB:

Not all symbols are displayed, only the ones that are important for the

pertinent buttonhole type.

Eyelets and their parameters can only be changed with sewing

apparatus E110, E111, E510 and E511.

Symbol Parameter Meaning

Buttonhole number The number of the buttonhole to be processed.

If a new buttonhole is selected, a * appears

before its number.

Buttonhole type Buttonhole types A to E are available,

depending on the subclass (see also page 27).

Eye shape The external dimensions (x, y) of the eye.

Buttonholes without eyes have dimensions

0.0x0.0. Which buttonhole shapes are possible

depends on the cutting mode set.

When switching from buttonholes with eyes to

buttonholes without eyes the stitch count in the

eye is set to 7. When switching from

buttonholes without eyes to buttonholes with

eyes the stitch count in the eye is set to 10.

The buttonhole display in the left half of the

display alters accordingly.

Speed The speed of the machine.

Length The buttonhole length from the upper end of

the eye up to the beginning of the tack

(measurement l).

Cut

12 3

The following parameters are available:

- cut before sewing (item 1)

- no cut (item 2)

- cut after sewing (item 3).

1

Cut-position

correction

Stitch count in the

eye

Stitch distance The distance between stitches within the side

Throw width in the

side

The distance by which the cut of the blade is

moved lengthwise. Values from -0.3 to +0.3

can be set.

The number of stitches sewn by the machine in

the eye.

of the buttonhole (measurement a).

The value must be between 0.5 and 2 mm.

This parameter changes the throw width in the

side of the buttonhole.

29

Page 28

Symbol Parameter Meaning

Intermediate fabric This parameter changes the

intermediate-fabric type.

Taper tack length In buttonholes with taper tacks, the length from

the tip of the taper to the end of the taper

(measurement kl). The minimum taper tack

length is 2 mm.

When changing the buttonhole length please

ensure that the maximum sewing length is not

exceeded. This can occur with taper-tack

buttonholes as the length of the taper tack

forms part of the sewing length.

When the buttonhole length is increased the

taper tack length is thus automatically adjusted

accordingly.

Taper tack overlap The distance between the two sides in the

straight section of the taper tack. When it is

0.0 mm one side is directly above the other.

Overlap In round tacks and eyelets the overlap can be

adjusted.

Number of stitches

in the round tack

Throw width in the

cross tack

Cross tack length In buttonholes with cross tacks, the overall

Stitch distance in

the cross tack

Lateral cross tack

position

Seam extension In buttonholes with cross tacks the distance

Eyelet diameter The diameter of the eyelet (measurement d).

Stitch count in the

eyelet

In round tack buttonholes, the number of

stitches in the round tack. 4, 6, 8 or 10 stitches

are possible.

This parameter changes the throw width in the

cross tack.

length of the cross tack (measurement qb).

In buttonholes with cross tacks, the gap

between stitches in the cross tack

(measurement qs).

In buttonholes with cross tacks, the position of

the cross tack with respect to the

centre(measurement ql).

- = cross tack left

+ = cross tack right

between the buttonhole side and the cross tack

can be set.

The number of stitches in the eyelet.

30

Page 29

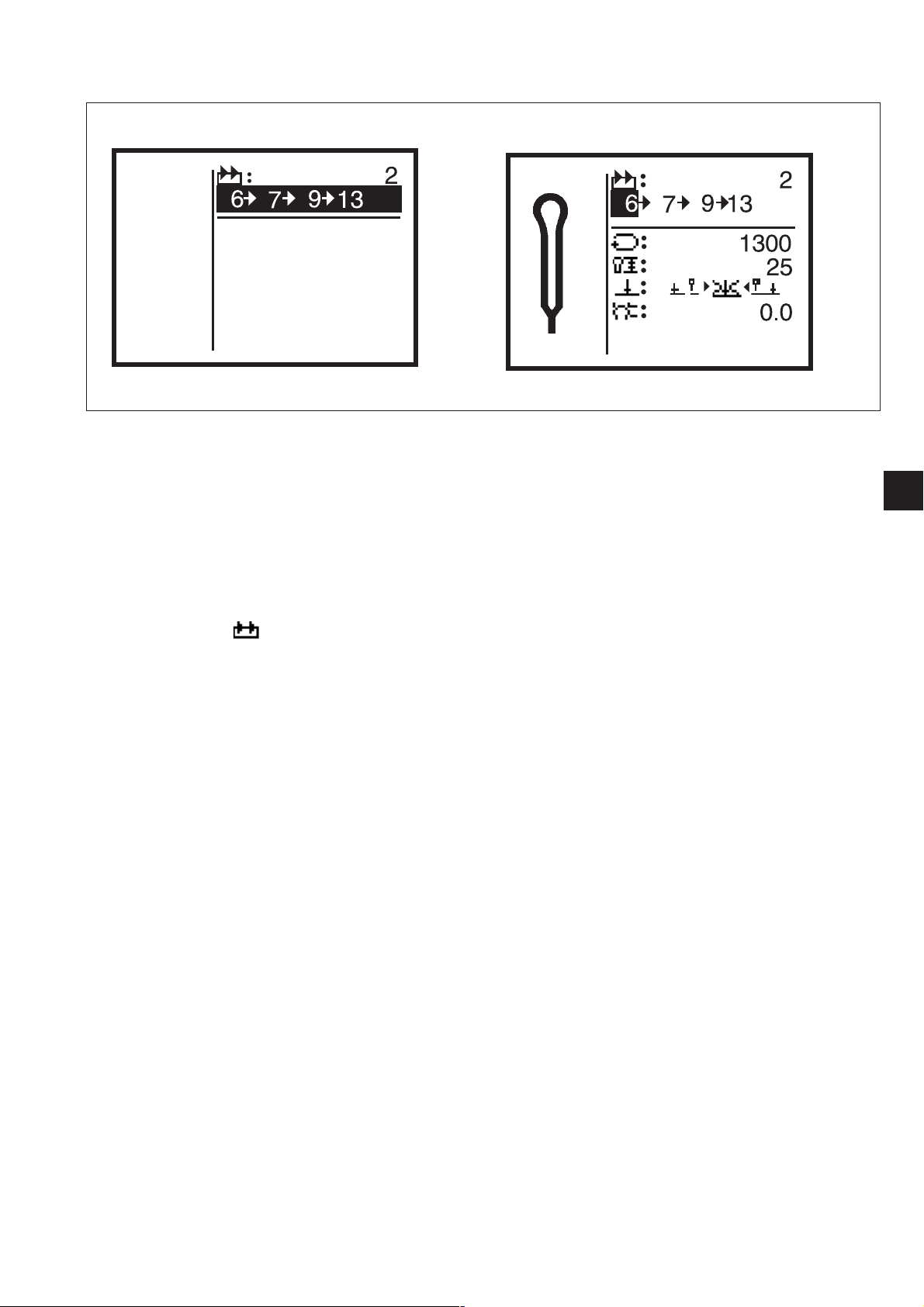

9.7 Buttonhole sequence

The 579 controller can be programmed with up to 25 sequences of

buttonhole shapes. Each sequence can contain up to 5 buttonholes.

–

Press “S”.

The controller switches to the buttonhole-sequence programming

menu.

–

To program or alter a buttonhole shape press “P”.

–

To leave this menu press the “ESC” key.

1

9.7.1 Selecting a buttonhole sequence

–

The number of the selected sequence is displayed behind this

symbol.

The sequence belonging to the sequence number is displayed in

the line below.

–

To switch to another sequence select the top menu line.

–

Press the enter key.

–

Use the ñ and ò cursor keys to select a different sequence.

–

When a new sequence is created a “*” appears before the

sequence number (setting for buttonhole shape of sequence: 1)

9.7.2 Changing the buttonhole sequence

Appending a buttonhole

–

Use the ñ and ò cursor keys to select a buttonhole sequence.

–

Press the enter key.

–

Within the buttonhole sequence use the ð cursor key to select the

point behind the last buttonhole.

“0" appears as the buttonhole shape.

–

Use the ñ and ò cursor keys to select the number of the required

buttonhole shape.

Deleting a buttonhole

–

Use the ñ and ò cursor keys to select a buttonhole sequence.

–

Press the enter key.

–

Within the buttonhole sequence use the ï and ð cursor keys to

select the buttonhole to be deleted.

–

Use the ñ and ò cursor keys to set buttonhole shape “0".

–

Press the enter key.

The selected buttonhole is deleted. Any subsequent buttonholes

move up one place.

31

Page 30

9.8 Piece counter

General

The 579 machine is equipped with a piece counter.

The piece counter counts the number of buttonholes sewn, not the

number of buttonhole sequences sewn. The current piece-counter

value is displayed behind the “Σ” symbol.

Switching the machine off does not affect the piece-counter value. The

piece counter counts up to a maximum of 65000 buttonholes. When

this value is exceeded, counting begins again at 0.

Resetting the piece counter

–

In the sewing menu use the ñ and ò cursor keys to select the

bottom line.

–

Press enter twice.

The piece-counter value is reset to 0.

32

Page 31

9.9 Buttonhole and sequence programming: a brief description

9.9.1 Selecting a buttonhole number

–

Push the pedal back:

the cloth carrier plate and hook turret move to their starting

positions

–

Press “P”:

The display switches from sewing mode to buttonhole programming

mode.

In this mode the buttonhole parameters can be changed.

–

The buttonhole number line appears on a dark background.

–

If you wish to change the buttonhole displayed, skip to

section 9.9.2.

–

If you wish to change a buttonhole that is not displayed or program

a new buttonhole, press OK.

–

Use the ñ and ò keys to display buttonholes already programmed.

–

If a new buttonhole is selected, a “*” appears before the buttonhole

number.

–

Select a buttonhole number and press OK to confirm.

9.9.2 Entering parameters

–

Use the ñ and ò keys to select the parameter to be changed.

–

The line containing the selected parameter appears on a dark

background.

–

Press OK.

The cursor flashes under the value of the selected parameter and

only the symbol appears on a dark background.

–

Use the ñ and ò keys to set the required value.

–

Use the ï and ð keys to change the cutting mode.

–

Press OK.

The set value is accepted.

–

If you do not wish to accept the changed value, press the “ESC”

key.

The original value is restored.

–

Use the ñ and ò keys to select and change further parameters.

–

Press the “ESC” key to leave buttonhole programming mode.

The machine is now in sewing mode and thus ready for operation.

1

33

Page 32

9.10 Setting buttonhole sequences: a brief description

9.10.1 Selecting a buttonhole sequence

–

Push the pedal back:

the cloth carrier plate and hook turret move to their starting

positions.

–

Press “S”.

The display switches from sewing mode to sequence mode:

in this mode sequences can be programmed.

The line sequence number appears on a dark background.

–

If you wish to change the sequence displayed, skip to

section 9.10.2.

–

If you wish to change a sequence that is not displayed or program

a new sequence, press OK.

–

Use the ñ and ò keys to display sequences already programmed.

–

If a new sequence is selected a * appears before the sequence

number.

–

Select a sequence number and press OK.

9.10.2 Changing a sequence

–

Use the ò key to select the line containing the buttonhole

sequence and press OK.

Now the buttonhole sequence can be changed.

–

Use the ñ and ò keys to select the buttonhole number be changed.

If you wish to delete a buttonhole from the sequence, select

buttonhole number 0.

–

Use the ï and ð keys to select the column containing the

buttonhole number to be changed.

–

When programming is complete press OK.

–

If the changed sequence is not to be saved, press the “ESC” key.

The original sequence is restored.

–

Pressing the “ESC” key leaves sequence mode. The machine is

now in sewing mode and thus ready for operation.

34

Page 33

10. Error messages

10.1 Pressure monitor

10.2 Firm hold

The pressure monitor monitors the pressure of the air supply. If the

pressure is inadequate this warning message appears in the display.

Fault rectification

–

Switch the machine off.

–

Ensure that the air pressure is adequate.

–

Switch the machine on again.

When the machine is in firm hold mode this warning message appears

in the display.

10.3 Error messages

If an error or fault occurs, a window containing an error code appears.

Error messages are described in the Servicing instructions.

10.4 Needle not in starting position

If the needle is not in its upper starting position when sewing begins,

appears this message appears.

Rectification

–

Turn the handwheel until the message disappears.

10.5 Handwheel turned manually

If the machine is halted during operation and the handwheel turned,

this symbol appears when it is restarted.

The current sewing process must be abandoned.

1

10.6 Seing-start side not correct

If when sewing begins the needle is about to execute the right needle

insertion on subclasses 121, 141 and 151 (or the left needle insertion

on subclass -112), this warning message appears.

To clear the error turn the handwheel until the message disappears.

If the warning message appears straight after switch-on, the RST key

must be pressed when the message has disappeared.

The machine moves to the starting position.

35

Page 34

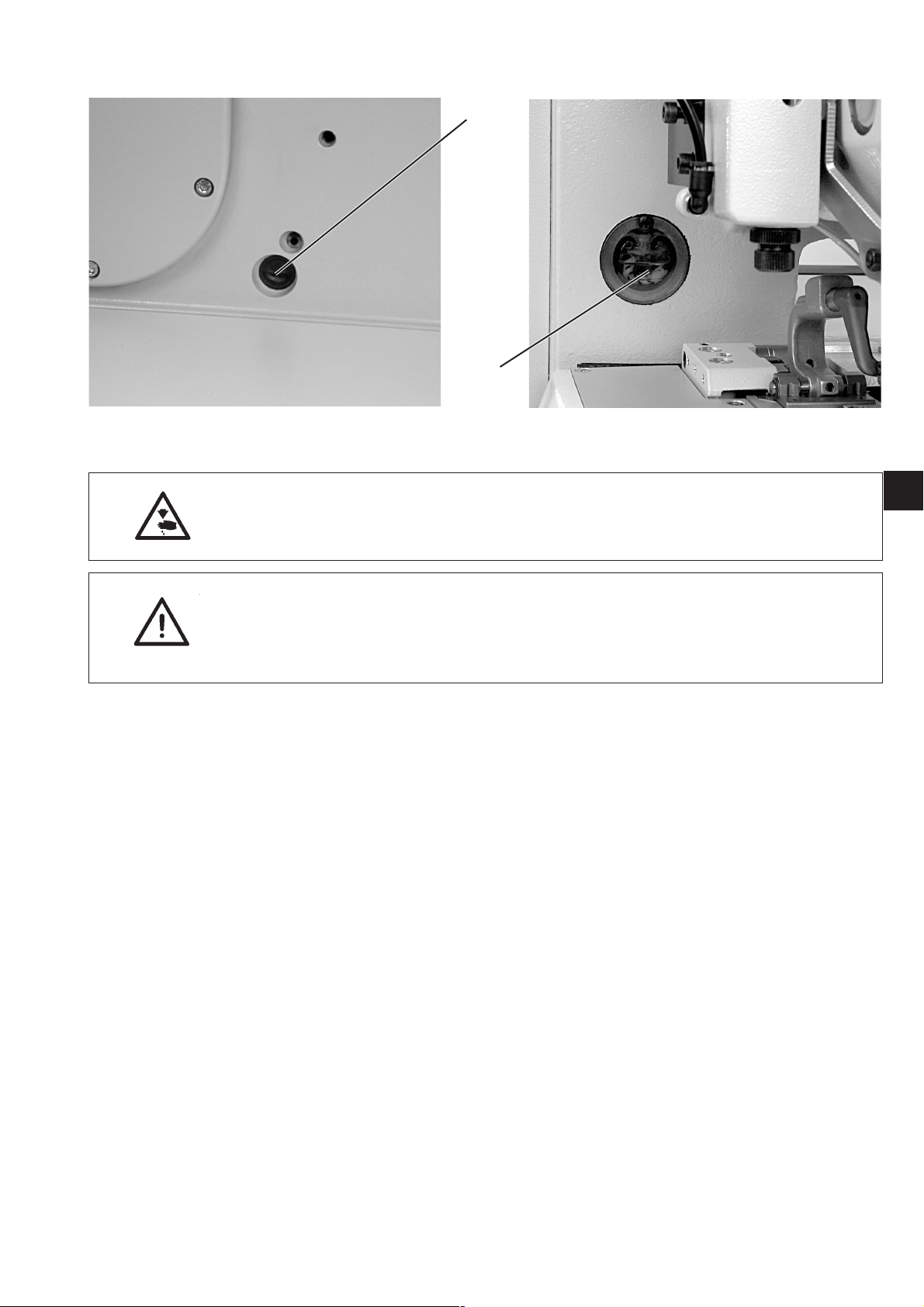

11. Maintenance

11.1 Cleaning

Caution: danger of injury

Maintenance work may only be carried out with the machine switched

off.

The utmost care must be taken when carrying out maintenance work

that requires the machine to be running.

A clean machine is a trouble-free machine.

Daily cleaning:

–

The looper, thread trimmer, throat plate and sewing head areas

must be cleansed daily of lint, pieces of thread and other debris.

1

2

3

–

Check the water level in the pressure regulator every day.

The water level must not rise to the level of the filter cartridge 2.

After screwing in the drain screw 3 blast water under pressure out

of the water separator.

36

Page 35

11.2 Lubrication

1

2

Check the oil level in oil reservoirs 1 and 2 every week.

Caution: danger of injury

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In the event of contact, thoroughly wash the affected area.

CAUTION:

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment. Take care not to spill oil.

Use only ESSO SP-NK 10 lubricating oilor an equivalent oil of the

following specification:

- viscosity at 40°C: 10 mm²/s

- flashpoint: 150° C

to top up the oil reservoirs.

This oil is available from

DÜRKOPP ADLER AGretail outlets under the following part numbers:

- 2-litre container: 9047 000013

- 5-litre container: 9047 000014

1

General

All the machine’s moving parts are lubricated by two oil reservoirs via

an oil-wick system.

No lubrication work is thus required except checking and topping up

the oil reservoirs.

37

Page 36

Notice:

38

Loading...

Loading...