Page 1

Contents Page:

Home

Preface and General Safety Standards

Part 1: Operating Instructions cl. 577-1 1 11

1. Product description

2. Normal use

3. Technic al data

4. Operation

4.1 Threading the needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Winding the hook thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Inserting the bobbin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 Changing the needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Lifting the sewing cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6 Regulating the sewing cage pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.7 Setting the buttonhole length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.8 Setting the number of stitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.9 Changing and adjusting the knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.10 Thread tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5. Control and control panel

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Keys on the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Changing parameter values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. Sewing

6.1 Normal sewing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Interruption of th4e sewing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Monitoring the hook thread by counting the buttonholes . . . . . . . . . . . . . . . . . . . . . . . . 23

7. Maintenance

7.1 Cleaning and checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8. Auxiliary equipment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3

Page 2

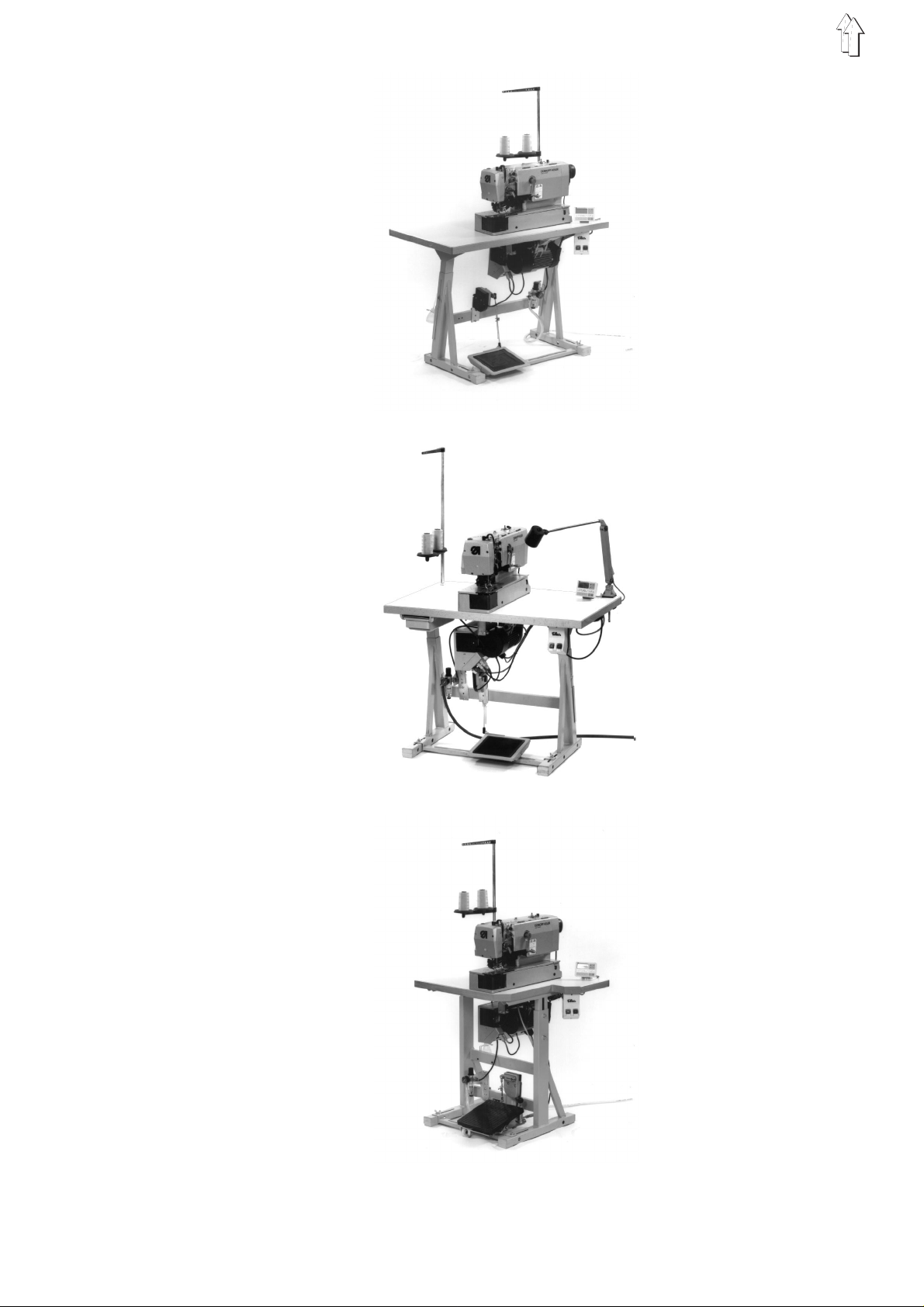

Stand set for longitudinal installation

Stand set for transversal installation

Stand set for transversal/longitudinal operation

4

Page 3

1. Product description

2. Normal use

DÜRKOPP ADLER 577-1111

The

machine with bottom and top fe ed fo r s ewing buttonhol es w i th two

straight bars.

Normal sewing mo de :

During the sewi n g p roc e s s th e f ab r ic fa c e ( t he fa c e se en ) ) i s up .

The machine c a n b e supplied in thre e i n s ta l l at i on v ari a nt s ( see on the

left ).

is an automatic double lockstitch

The automatic sewing machine

designed for s ew i ng l igh t t o m i dd l e-h ea v y we i gh t m at eri a l , a s us e d i n

the apparel industry.

Such materi al co ns i s t s ge ne ral l y o f t ex t i l e o r s y nt he ti c f i bre s .

Furthermore, the machine lends itself for producing so-called technical

seams. In this case, the user must estimate any possible dangers

(contact dürkopp adler ag for help), Technical seams are seldom, but

they may be very versatile. Proper safety precautions, depending on

the result of s uc h an estimation, mus t b e t ak e n. G en er a ll y, only dry

material sh ou l d b e sewn on this machin e. An d th e ma te r ial s ho ul d not

exceeded the thickness of

4 mm

when compress e d b y th e l o we r ed sew i ng fo ot .

The material should not contain any hard objects, because otherwise it

would be necess a ry to pr o te ct t he ey e s du r i ng th e se wi n g p roc e s s..

For the time b ei n g, no s uch eye guard is av a i l ab le. The seams are

produced gene r al ly w i th th r ea ds u p t o 6 5/ 2 Nm ( cotton-cov e red

synthetic threads or synthetic threads ) Before using any other threads

it is necessary, also in this case, to estimate the consequential

dangers and to take, if necessary, the respective safety measures.

This automat i c sewing unit shou l d b e i n s ta l led and operated onl y in

dry and proper rooms. Otherwise, further precautions (to convene)

may be needed , ( s i e he E N 6 02 04 - 3-1:1990 ). We.manuf ac t ur e rs of

industrial sewing machines, assume, that our machines will be

operated at le as t by a we l l trained staff, know i ng al l u s ua l con tr o l s an d

any possible dangers.

DÜRKOPP ADLER 577-1111

has been

5

Page 4

3. T echnical data

Machine head s: Class 577-1111

Needle system: System 265, needle point slightly rounded off

Needle thi ck ne s s : 70 - 100, Standard 80

Threads: Synthetic threads, and cotton-coated

synthetic threads

Up to 65/2 Nm

Stitch type: Double lockstitch

Speed: up to. 4000 rpm ( a dj u s ta bl e )

Number of stitches

Per seam pattern: 76 - 510

Buttonhol e length: 10 - 48 mm

Buttonhol e w i dt h: 0 - 6 mm

Cut length: max. 38 mm

Motor type: EFKA DC1600/DA82GL

Nominal pe rfo r ma nc e : 0,75 kW

Speed: 4000 U/min

Service pressure: 6 bar

Air consumption: about 4 NL per working cycle

Nominal vol t ag e: 1 ~ 230 V, 50/60 Hz

1~ 190 - 240 V, 50/60 Hz

Dimensions:

Longitudinal stand: 1060 x 620 x 1250 mm ( L x B x H )

Longitudinal/transversal

stand: 800 x 650 x 1250 mm ( L x B x H )

(Machine hea d w i th ou t s t an d: 180 x 600 x 450)

Working level : 750...895 mm ( Table top )

Weight: ca. 135 kg ( wi t h s t an d )

Rated noise level:

Lc = .... dB (A)

6

Page 5

4. Operation

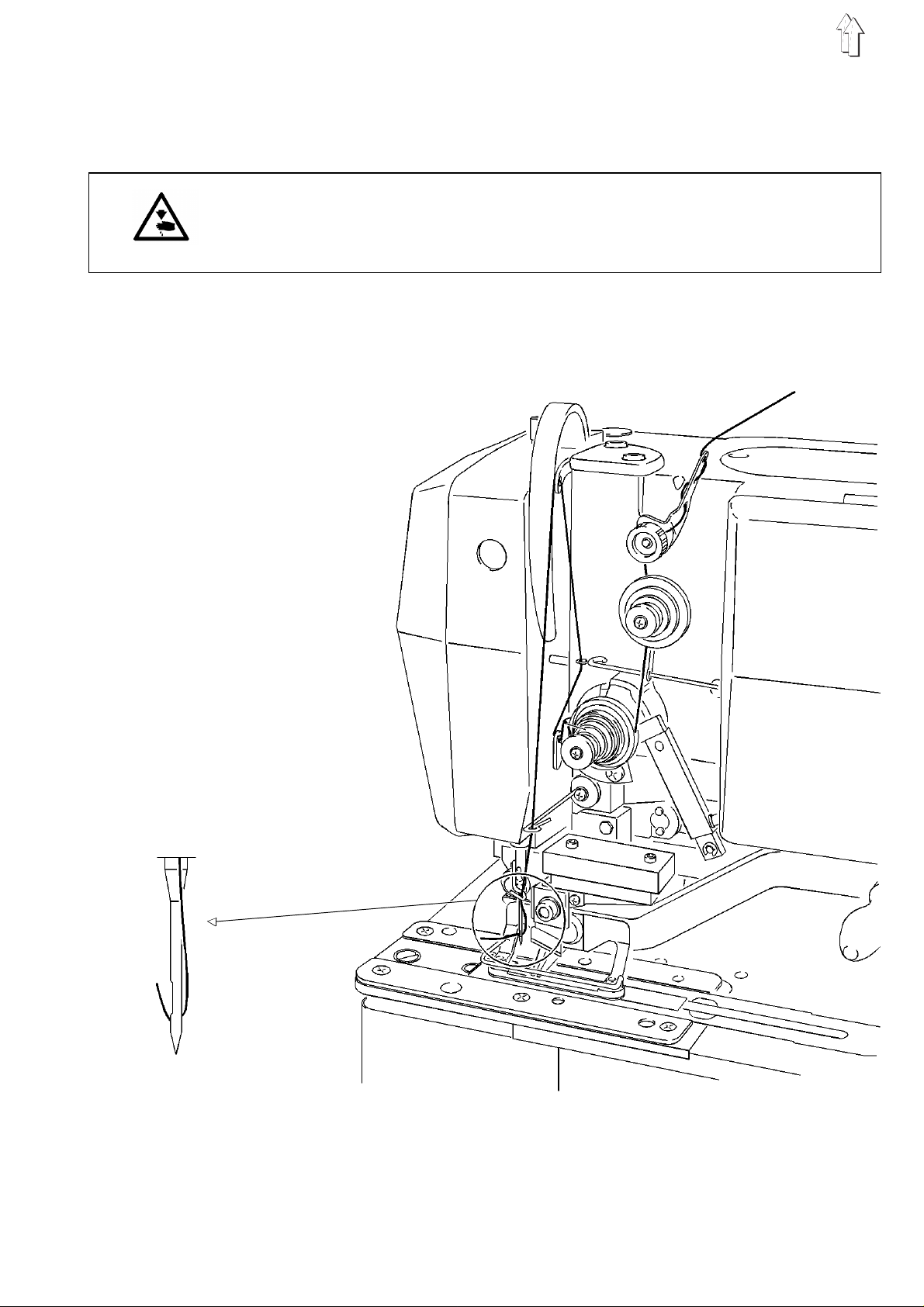

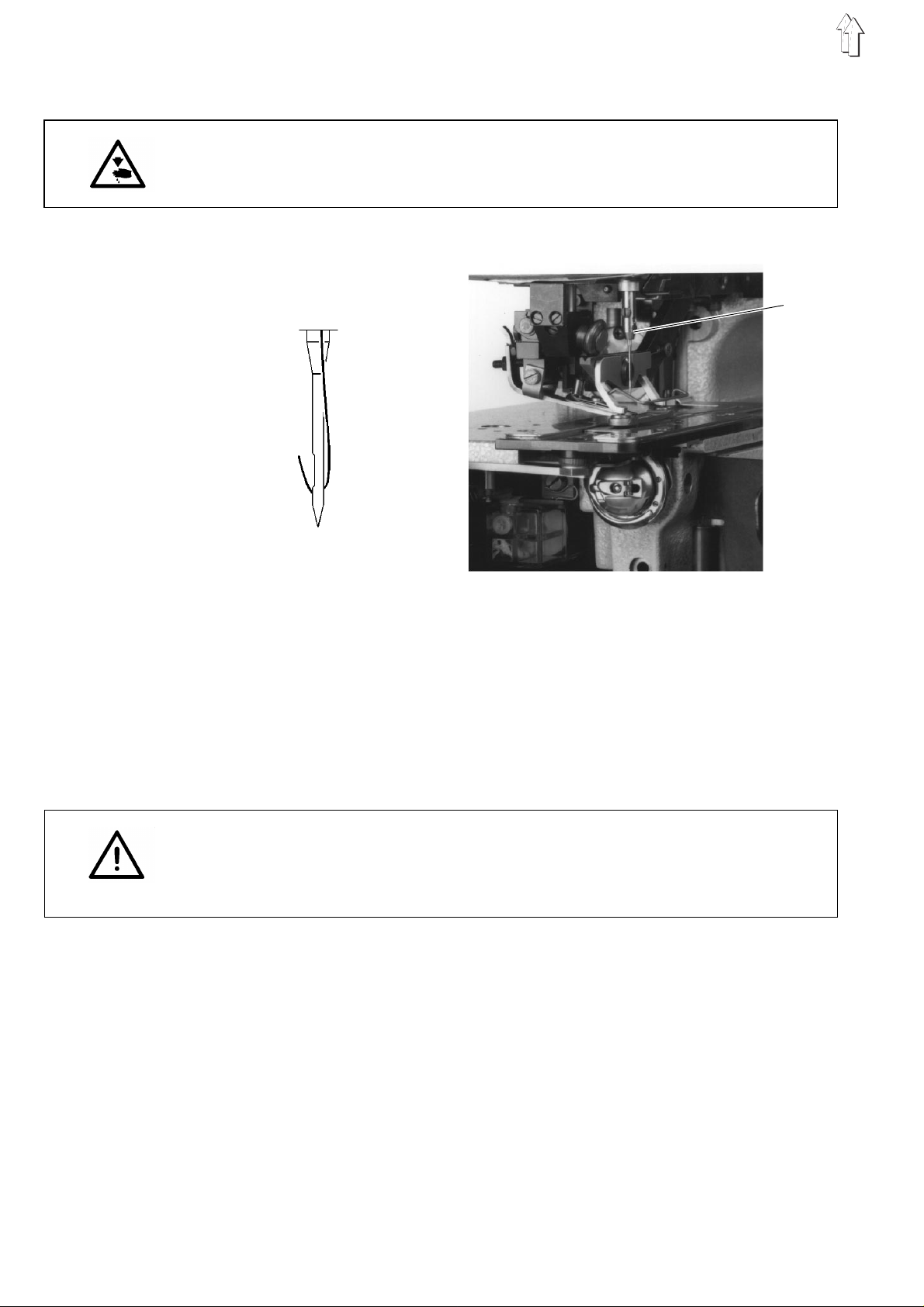

4.1 Threading the needle

CAUTION: DANGER OF ACCIDEN T S !

Turn off main switch!

Switch off the machine before threading the needle.

–

Thread then needle according to the illustration.

7

Page 6

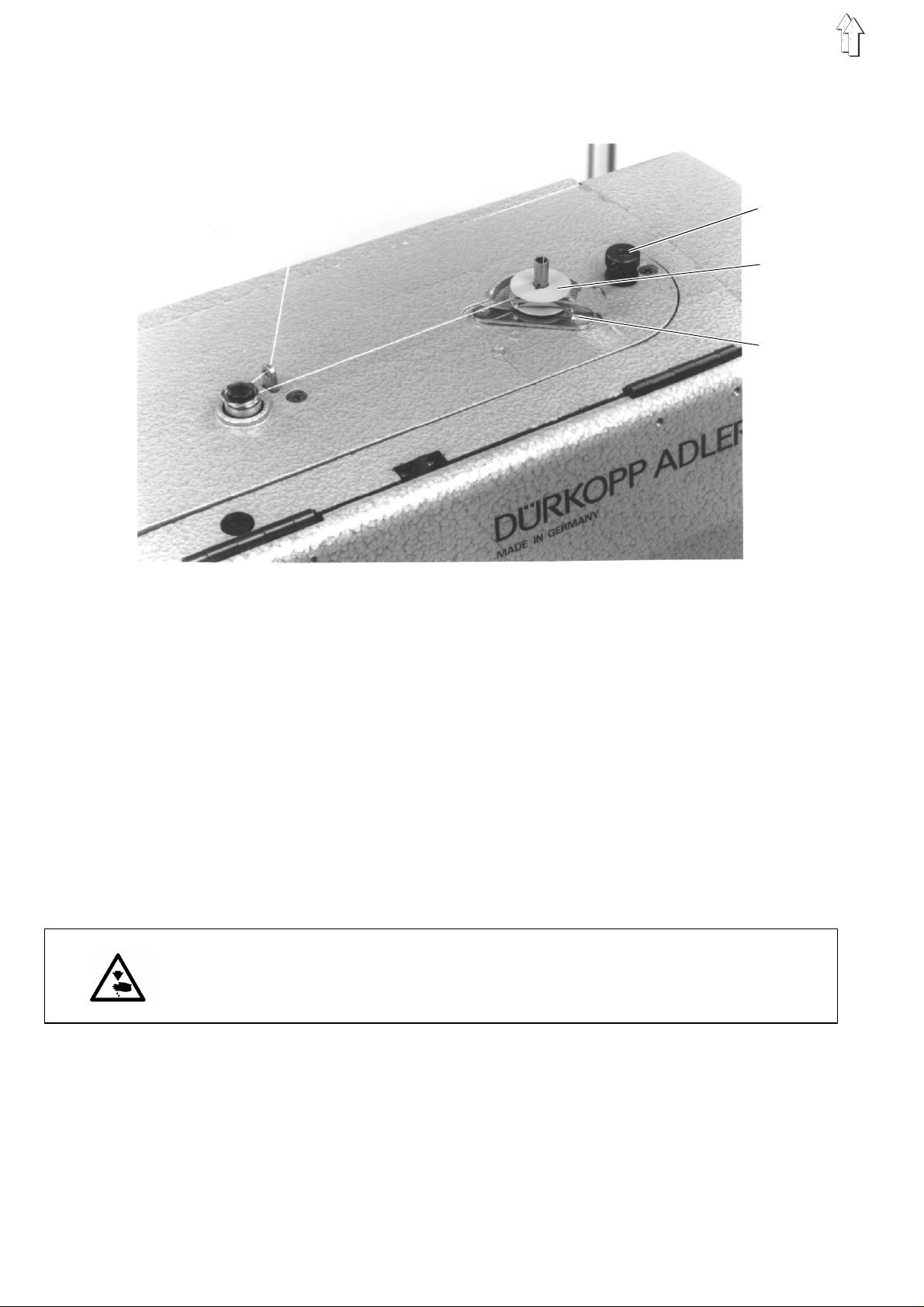

4.2 Winding the hook thread

3

1

2

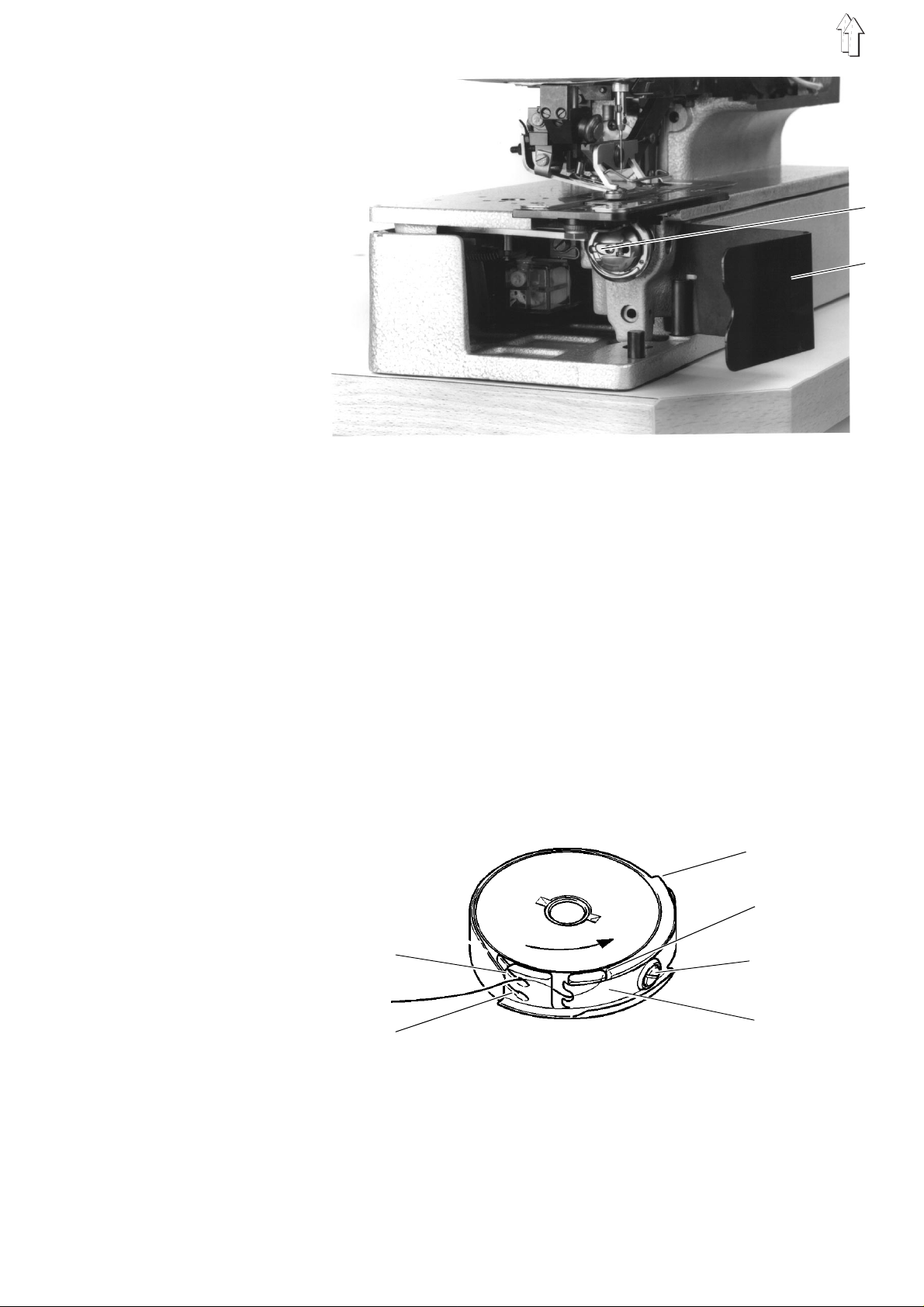

4.3 Inserting the bobbin

–

Slip the ree l on to i ts st and.

–

Thread the hook according to the illustration.

–

Slip the bobb i n o nto the bobbin w inder 1 .

–

Wind the hook thread clockwise about 5 times around the bobbin

core.

–

Swing bobbin winder lever 2 towards the bobbin and let i t s na p.

–

The thread will be wound during the sewing process.

–

The bobbin wi nd er l e v er 2 will stop the winding process as soon as

the bobbin is full.

–

Following the winding process, tear off the bobbin thread at the

thread clam p 3.

CAUTION: DANGER OF ACCIDENTS !

Turn off main switch!

Switch off th e m ac h ine before changing the bobbin!

Removing empty bobbin.

–

Open hook space cover 4.

–

Lift the bow 5 and remove bobbi n c ase to p t og et he r wit h t he

bobbin.

–

Remove the em pt y bo bb i n f rom the bobbin case to p.

8

Page 7

Threading the bobbin

–

Insert the full bobbin into the bobbin case top. When unwinding the

thread, the bobbin must turn clockwise.

–

Pass the hook thread through the slit 6 and under the spring 7.

–

Depending on the buttonhole to be sewn, pass the hook thread

through the slit 9 for a

advanced across the hook ba ck ) ) or through the sl i t 10 for a

buttonhole ( l e s s th rea d ) .

–

Cut then the t hr e ad , p as s e d a s de sc r i be d, by t he k nife 11.

raised

buttonhole ( more thread will be

5

4

flat

Adjusting the hook thread tension

–

Adjust the hook thread tension by turning the screw 12 so that,

when holding t he th rea d a t i t s en d, th e b ob bin c ase de s c en ds b y

its own weight.

11

6

9

12

7

10

Inserting the bobbin case top

–

Place the bo bb i n c a s e t op to ge th er w i th th e b ob bi n on to the bobbin

case bottom an d e nsu r e t ha t t he bo w 5 snaps (what you should

hear).

–

Close the bobbin space cover 4.

9

Page 8

4.4 Changing the needle

CAUTION: DANGER OF ACCIDENTS !

Turn off main switch!

Switch off th e m ac h ine before changing the needle!

1

Knife side

–

Loosen the sc r ew 1.

–

Remove the neel d e f rom i ts b ar.

–

Introduce the new needle as deep as possible into its bar a.

–

Adjust the needle so that its furrow is located on the other side of

the knife.

–

Tighten the screw 1.

NOTE !

The factory- s e t d i st a nce between the hook a nd th e n ee dl e ap pl i e s to

the needles having a thickness of 80.

When inserting a needle having a different thickness it may be

necessary to correct the distance ( see the Service Instructions ).

10

Page 9

4.5 Lifting the sewing cage

The sewing cage 2 will be lifted only if the main switch is turned on

and if following conditions exist:

–

Sewing cage in initial position ( rear p. )

–

Thread take-up lever in top dead-center position ( needle in upper

position )

If the thread ta ke- u p l e v er d oe s no t s t an d i n i ts t op de ad - c en te r

position ( error message in the display of the control panel:

the machine will automatically turn into this position after turning on

the main switch.

After turning on the main switch, following message will be presented

on the displa y of th e c o nt r ol p an el :

not stand in its initial position Turn then the crank until the sewing

cage stands i n th e p r op er p os i t i on an d c a n b e l i f te d. B y tre ad i ng th e

pedal forwar ds i n to i ts 1

without starting the sewing process.

st

position, the sewing cage will be lowered

"_0 1"

. if the sewing cage does

"_0 1 0"

),

The sewing cage can be lifted and lowered by the

panel. Then i t i s n ec e ss ar y to switch on the par a me te r

the operator l e v el ( s e e c h ap te r 4.9 ).

3

2

key 3

on the control

"F - 020"

on

4.6 Regulating the sewing cage pressure

–

The sewing ca ge pre s s ure c an be r eg ula te d b y th e s cr e w 3.

11

Page 10

4.7 Setting the buttonhole length

CAUTION: DANGER OF ACCIDENTS !

Turn off main switch!

Turn off the machine before changing the buttonhole length!

2

1

–

Remove the crank 1.

–

Open the cover 2 completely.

–

Loosen the sc r ew 3.

–

Reset the lever 4 in the crank.

–

Tighten the screw 3.

–

Release the support 5 and close the c ov e r 2.

–

Install the crank 1.

5

3

12

4

Page 11

4.8 Setting the number of stitches

CAUTION: DANGER OF ACCIDENTS !

Turn off main switch!

Switch of the machine before changing the number of stitches!

–

Remove the crank.

–

Open the cov er 2.completely

–

Change the gears

–

Release th e su pport 5 and close the cover.

–

Install the crank.

6 in pairs according to the table

.

2

6

Number of

stitches

76

81

86

91

97

102

108

114

120

127

134

141

149

157

165

173

182

192

Number of

at top/at bottom

teeth

22 / 57

23 / 56

24 / 55

25 / 54

26 / 53

27 / 52

28 / 51

29 / 50

30 / 49

31 / 48

32 / 47

33 / 46

34 / 45

35 / 44

36 / 43

37 / 42

38 / 41

39 / 40

5

Number of

stitches

202

212

223

235

247

261

274

289

305

321

339

358

379

401

425

451

479

510

Number of

teeth

at top / at bottom

40 / 39

41 / 38

42 / 37

43 / 36

44 / 35

45 / 34

46 / 33

47 / 32

48 / 31

49 / 30

50 / 29

51 / 28

52 / 27

53 / 26

54 / 25

55 / 24

56 / 23

57 / 22

13

Page 12

4.9 Changing and adjusting the knife

CAUTION: DANGER OF ACCIDENTS !

Turn off main switch!

The sewing c a ge mu s t stand in its in iti a l po s i ti o n, be c au s e o th erwise

the knife will knock against the cage!

Switch on the adjustment aid before installing the knife!

3

Remove the knife

–

Loosen the nu t 1.

–

Pull out the knife 2.

Install the knife

Switch on th e a dj u stment aid, and:

–

Turn on the main swit c h.

( the cage will be lifted. )

–

Press the key

( The menu of the operator level will be called up. )

–

Cross the menu by operating the key until

displayed.

"P"

on the control panel.

1

2

"+" "F - 020"

is

14

–

"oFF"

will appear after pressing the key "E".

–

Press the key

( The display will present

NOTE !

Do not turn t he ha nd wh ee l or t he c ran k wh en us i n g t he ad j us t me nt ai d !

"+"

for switching on the adjustment aid.

"on"

and an arrow above the key 3. )

Page 13

–

Insert new knife ( loosen nut 1 ) and push it first up to th e t op .

NOTE !

It is absolu te l y ne ces s a ry to no te that the distanc e be tw ee n the upper

thread scissors and the knife bottom amounts to

–

Tighten the nut 1.

–

Lower the sewing cage by pressing the key

–

With the adjustment aid still being engaged, it is now possible to

key 4

key 4

. )

lower the kni f e b l oc k b y op er a ti n g t he

( An arrow will appear above the

at least. 1 mm

Ta ste 3

.

.

.

–

Operate the

The knife bl ock c a nn ot be mo v ed do wn by t he

sewing cage is n ot l ow ere d. T he ref or e , f ir st l o we r th e sew i ng ca ge by

key 3

the

locked as long as the knife is in its lower position.

It will be impossible to start the machine as long as the adjustment aid

is engaged.

Adjusting the knife

When the knife block is lowered, the front edge of the knife should

stand

Adjustment:

–

–

–

–

–

The cut of the k n i fe s ho ul d be ab ou t 2 ti s sue threads from t he last

sewn final bartack.

Adjustment:

–

Note:

When the knife block is in its lowered position, the safety distance

between the fr o nt ed ge of the knife and the s l i t in the throat pla te

insert

–

. Also the function of the

about. 2 mm

Lift the sewi n g ca ge .

Loosen slightly the nut 1.

Displace the knife.

Tighten the nut 1.

Check the cutting depth and repeat the process, if required.

Loosen the screw 3 and adjust the distance accordingly.

must

Tighten the screw 3.

key 4

under the bo tt om of th e t hr o at pl a te .

amount to

once again fo r l i ft i ng th e k n i fe bl o ck .

key 4

as long as the

key 3

(lifting the s e wi n g ca ge ) is

0,5 mm

.

End the adjustment aid

For ending the adjustment aid press the key

"P"

on the control panel.

15

Page 14

4.10 Thread tension

The machine he ad ha s be en s et i n t he fa c to r y fo r s ew i ng bu tt on ho l es

with flat bartacks and with raised lips.

4

5

6

Pre-tension

The pre-tension 4 is always active. It serves for stabilising the needle

thread. It sh ould be set to the mi n i mu m v a l ue ( 5- 1 0 g ). The

pre-tension 4 has scarcely any influence on the seam pattern.

Main tension

The main tens i o n 5 is active when sewing both buttonhole lips. But the

main tension 5 it is out of ac t i on wh en ba r ta c k ing and when cutt ing the

threads.

Bartack ten si on

The bartack tension 6 is opened only when cutting the threads. It is

remains clo s ed du r i ng th e e nt i re r e ma i ni n g s e wi n g p roc e s s .

Buttonhole lip tension

The buttonhole lip tension is produced jointly by the main tension

and by the ba rta c k i ng te ns ion

should be produced by the bartacking tension 6.

Adjustment

–

Thread the needle thread so that it does not pass through the main

tension 5.

–

Start the sewing process.

6.

About 1/3 of the buttonhole lip tension

5

16

Page 15

–

Adjust the bartacking tension 6 so that the m axi m um possible

quantity of th e t hre ad unwound is co nsu med during the s ew i ng

process. But ensure that th e t hr e ad do es n ot fl a tt er a bo ve the

pre-tension a nd that it is not to r n.

–

Thread the ne ed l e a c c ord i ng to th e c h ap te r 4. 1.

–

Start the sewing process according to the chapter 6.

–

Adjust the main tension 5 so that a satisfactory seam pattern is

obtained when sewing the buttonhole lips ( regularly raised lips ).

If the seam qual i t y i s wo rs e a ft er a th r ea d ch an ge , p r oce ed to a

correction. Turn onl y th e ma i n te ns io n 5.

Control

–

Use threads of di ffer e nt c ol o urs f or t hr e ad i ng th e n ee dl e an d t he

hook.

–

Carry out a sewing test.

When using two-colour threads, the colour of the needle thread in the

bartacks should be visible only from above.

5. Control unit and control panel

5.1 General

The present Manual describes only the function of the keys and the

change of parameters by the operator.

For a detailed description of th e c o nt r ol u ni t see the attached ac t ua l

Operating In s tru c ti o ns o f t he mo to r ma nu fa c tu r er.

The control panel is used for programming the control unit and for

setting the res p ec t i ve s e am fu nc t i on s .

This is done partly directly by operating the respective keys or by

changing the parameters.

The parameters are entered in the programming mode. The

parameters a nd th e a s si gn ed v al u es a re presented by t he dis p l ay..

In order to avoid any involuntary chages of the pre-set parameters, the

attendance of the control panel is subdivided into different levels (

operator, technician , f i tt er ).

The operator has a direct access to its level.

For having an access to the other levels it is necessary to enter a code

number or it is necessary to press several keys simultaneously.

NOTE !

Do not turn the handwheel or the crank during the parameter change

on the operat or l e v el !

Reset

When the control unit is totally out of adjustment, the technician can,

by means of a Reset Function, reset all adjustment values to the state

existing at the moment of delivery.

The Reset Function is described in the Service Instructions.

17

Page 16

5.2 Keys on the control panel

1 2 3 4 A B

Key

Function

P

E

+

-

Call up/end pro gr a mm ing mo de

( Only in the programming mode )

Displaying the parameter value / Rendering the parameter value for a change

Quitting a parameter entry with a simultaneous change to

the next param et er

Direct function:

Increase the speed

In programming mode:

Change to the nex t pa r amet er o f t he pa ram et er li s t

Increase the displayed parameter value / Switch on the

displayed p ara meter (

Direct function:

Reduce the speed

In the programming mode:

Return to the previous parameter of the parameter list

Reduce the disp l ay e d p ara me te r v al u e / S wi t ch o ff the

displayed p ara meter (

"on"

"oFF"

)

)

Adjustments

18

Key 1

Key 2

Key 3

Soft start

Double cycle

Only when the

"on"

set to

lifting/lowering the sewing cage

Programming mode

"F - 020"

and

on / oFF

on / oFF

are

Page 17

Key

Function

Adjustments

Key 4

Key A

Key B

( Key B )

Only when the

"on"

to

( without functi o n )

Direct function:

Only when the p ar a me te r ad j ustment

to

Short opera ti o n:

Reset the hook thread counter ( after bobbin change )

Operation t i me l on ge r than 1 second:

Connect/disconnect the hook thread counter

Programming mode:

Shift key

( see the Ope rating Instructi o ns o f t he mo tor manufacturer )

connect/disconect the knife

"4"

5.3 Changing parameter values

NOTE !

It is absolutely necessary to complete a sewing cycle after the

parameter change. It is only then that the modified adjustment will be

definitely memorised. If no sewing is done, the new setting will be lost

by turning off th e m ai n s wi t c h!

Programming mode

"F - 020"

and

"F - 195"

are set

corresponds

on / oFF

For changing o r s wi t c hi n g o n a nd off th e p ar a me te r s pr e s s the keys

"P", "E", "+"

The parameters that can be changed on the operator level are stated

in the following parameter list.

Calling up programming mode

–

Operate the key

The parameter, called up as last one, will appear.. If no parameter

has yet been c al l e d u p a ft er t ur n ing on the main swi t c h, th e d i s pl a y

will present

Selecting the desired parameter

–

Operate the key

displayed

–

The parameter value will be displayed after pressing the key

Changing the displayed parameter

–

For changing the parameter value or for switching on or off the

parameter function press the keys

Memorising the modified parameter value

–

Press the key

The modified parameter value will be memorised. The display will

present the ne x t p ar a me te r on th e o pe rator level.

or:

–

Press the key

The parameter value, modified as last one, will be memorised.

The control system will quit the programming mode.

"-"

and

"F - 000"

"E"

"P"

on the control panel.

"P"

.

.

"+"

or the key

for changing further parameter values.

in order to qu i t t he programming mode .

"-"

.until the desired parameter is

"+"

or

"-"

.

"E"

.

19

Page 18

Parameter list on the operator level

Parameter

F - 000

F - 001

F - 020

Denomination

Buttonhole c o un tin g O n /Off

(This funct i on i s on l y po s s i ble

when the mac hi n e s p ee d d i spl a y,

Parameter

off )

Reset buttonhole counting

Adjustment ai d fo r th e k n i fe an d f or

the thread cu tt er, connect ed mechanically w i th th e se wi n g ca ge .

The following functions are enabled only w hen the needle st an ds

in its upper position and the sewing cage in its rear position .

"+"

Key

Key 3 right arrow On

"F - 139"

on

Sewing cage in upper

position

, is switched

Adjustment

max min Standard

on oFF oFF

on oFF oFF

on oFF oFF

F - 080

F - 081

F - 085

Key 3 right arrow Off

Sewing cage in lower

position

Key 4 right arrow On

Knife

On

Key 4 right arrow Off

Knife

Off

Only one function at a time can be

controlled!

Correction ( + ) of the after-running

stitches a t t he bu ttonhole end

Correction ( - ) of the after-running

stitches a t t he bu ttonhole end

Number of bu tt on ho l es f or the

hook thread monitor

"F - 195" to "1...4"

10 0 0

10 0 0

3000 0 0

20

Page 19

State Display

Display Denomination

InF P1

InF P2

Error in the determination of the after-running stitches.

The number of the after-running stitches is too low.

Error in the determination of the after-running stitches.

The number of the after-running stitches is too high.

The machine ru ns

The hook thre ad mo ni t or c a n b e s w i tc h ed on .

( only when the p ar a me te r

blinking symbol:

The counting for the hook thread monitor has commenced.

Blinking symbol and display of "C D":

The counting ha s en de d, c ha ng e t he bo bbin!

The display of the control panel will present up to 4 different

inadmissible conditions resulting from a number combination.

A

"F - 195"

is set to

"4"

_1 1 1 1

)

Sewing cage not in its initial position (rear pos)

Thread take-up lever not in its top dead centre

position. ( n ee dl e no t i n up pe r po s.)

Needle thread monitor acting

Instant st op ha s been released ( s t op )

A combination of several inadmissible conditions is possible, e.g.:

A

_ 0 1 0 1

Display of the sewn buttonholes.:

B

1 2 3 4 5

The counting for the hook thread monitor has ended.:

C D

1 2 3 4 5

Needle thread monitor active / Sewing cage not in rear

position

max. 65535

21

Page 20

6. Sewing

6.1 Normal sewing process

NOTE !

Do not start sewing with the machine before is has been fully

assembled and before, among others, all the protective devices has

been installed.!

Start the sewing process

–

Turn on the main swit c h.

–

If the sewing ca ge i s no t l if te d, tu r n t he cr an k un til t he s ew i ng cag e

stands in i ts re ar p os i t i on ( i ni t i al p osi t i on ) . T h e sewing cage will

be lifted.

–

Insert the materia l to be s ew n.

–

Start the sewing process by treading the pedal forwards

( the sewing cage will be lowered, the buttonhole will be sewn, the

knife will act, the threads will be cut off and the sewing cage will be

lifted )

–

For being able to start a new sewing process, Before the end of

the sewing process, the pedal must be returned to its neutral

position, in order to enable the start of the next sewing cycle.

6.2 Interruption of the sewing cycle

The sewing cycle can be interrupted as follows:

Interruption by the operator

–

By treading the pedal backwards, the sewing process will be

interrupted within the buttonhole.

–

The error message

–

Turn off main switch an d e l i mi n at e t he c au s e f or t he i nt err u pt i on .

Interruption by thread breakage

–

The error message

–

The sewing cage will be moved, without needle thread, up to the

buttonhole end, the knife and the thread cutter will not act and the

sewing cage will not be lifted.

–

Thread the nee dl e ac co r di n g t o c h ap te r 4. 1.

Following is to be noted after an interruption

–

If the sewing cage stands in its initial position ( rear position ), it

can be lifted by treading the pedal backwards.

–

If the commen ced buttonhole is t o b e c o mp l et ed by a repair seam,

the sewing cage should not stand in its initial position (rear

position) wh en th e m ai n s wi t c h i s t ur n ed on ag ai n , b ec a us e

otherwise it will be lifted.

Before turning on the main switch, take the sewing cage to the

repair point by turning th e cr a nk .

–

If the repair po i nt l i es within the sec o nd ha l f o f t he s ec o nd

buttonhole lip (short before the buttonhole end), a complete

buttonhole will be sewn as a repair seam.

"_1 0 "

"_0 1 0 "

will be displayed.

will be displayed.

22

Page 21

Go on sewing

After an interruption, there are three possibilities to continue the

sewing proc es s:

–

Continue the sewing process out of the actual position by treading

the pedal forwards

or

BLICKFANG-STR = Take the sewing cage to the desired point by

turning the c r an k an d r e s ta r t t he s ew i ng pro c es s h ere

or

–

take the sewing cage to its initial position (rear position)by turning

the crank and lift the cage for removing the material.

6.3 Monitoring the hook thread by counting the buttonholes

"C D"

"F - 195"

enter the number of buttonhol es ( 1 - 30 00 ) th at ,

"C D"

will disappear, the buttonhole counting will

has been set to the value

key B

.

When the parameter

technician level, see the Service Instructions ), the bobbin symbol will

appear on the right side of the display

The operator can, by maintaining this position and by using the

parameter

according to t he exp er i e nce , c a n b e se wn wi t h o ne ho ok t hre ad bo bb i n

( see chapter 5.3 ).

For starting the buttonhole counting, press the

second:

–

The bobbin symbol will be blinking during the sewing process.

–

After the num ber of buttonhol es , en te r ed un de r the parameter

085"

–

In addition to the blinking bobbin symbol, the display will present

the blinking letters

–

Lift the sewi n g c a ge by t r ea di n g t he pe da l ba c k wa rds .

–

Change the bo bb i n a c c ord i ng to the chapter 4.3.

–

Reset the bu tt on ho l e c o un ti n g b y a b ri ef operation of the

The letters

remain switched on ( the bobbin symbol will be blinking ) and the

buttonhole counting will be re-started.

–

For switchi n g o ff t he bu tt on ho l e c o un ti n g, press the

than 1 second.

( the bobbin symbol will still be displayed and it will no longer be

blinking. )

"F - 085"

the sewing cage will not be lifted automatically.

"4"

(

, longer than 1

key B

key B

longer

"F -

.

After having completed the pre-set number of buttonholes, further

buttonholes c a n p os s i b l y be s ew n i f the rest of the ho ok t hread on the

bobbin is still sufficient:

–

Lower the pe da l ba c kw a rds .

The sewing cage will be lifted.

–

Lower the pedal forwards.

The buttonhole will be sewn, but the sewing cage will not be lifted.

23

Page 22

7. Maintenance

7.1 Cleaning and checking

CAUTION: DANGER OF ACCIDENTS !

Turn off main switch

Switch off th e m ac h ine before proceed i ng to an y ma i nt en an c e w or k !

The maintena nc e wo r k must be carried ou t a t l e as t at th e i n te r val s

specified in the table ( see the column Service hours ).

1

2

3

Maintenance work to be car ried out

Machine head

Remove sewing du st , th read end s an d

cutting waste.

Sewing motor

Check the cond itio n of the V-belt.

Pneumatic Sys te m

Check and, if requ ir ed , ad just the

air pressure.

Check water lev el in th e pres su re

regulator.

Clean the filt er el em en t.

Explanation

Clean particularly:

- the bottom of the thr oa t pl ate

- the sewing cage

- the space around the hoo k

- the bobbin cas e

- the thread cut te r

The water level sho ul d no t re ac h th e fi lt er ele men t 1.

Drain the water separator 2 under pressure aft er turni ng -i n

the draining screw 3.

The filter element 1 separates dirt and condensed water.

Disconnect the machine from the compressed air line.

Turn-in the draining screw 3. The pneumatic system of the

machine must be pressure-free. Uns crew the water separator 2. Unscrew the filter element 1 and wash the filter tray

and the filter elem ent pe tr ol eu m ben zi ne ( no solv en ts ! )

Bow dry by compress ed air. Re-assembl e an d re -i ns ta ll the

conditioning unit.

Service

hours

8

160

8

40

500

Check the tigh tness of the system.

Auxiliary equipment

Clean the ligh t ba rrie r of the –

thread rest monitor.

24

Clean following element:

- The lens of the ligh t ba rri er

- The light beam pass ag e in the bobb in case

500

8

Page 23

7.2 Lubrication

CAUTION: DANGER OF ACCIDEN T S !

Oil can irritate the s k in !

Avoid long contacts with the skin!

Wash the contaminated skin thoroughly!

NOTE !

The handling an d t he di s p os a l of mi n era l oi l s is s u bj e c t t o l e ga l

regulations.

Deliver waste oil exclusively to an authorized reception center!

Protect your environment, do not spill any oil!

For filling the oil supply containers, used exclusively the lubrication oil

ESSO SP-NK 10

–

Viscosity at 40 °C: 10 mm

–

Point of inflammation: 150°C

or an equivalent oil with the following specification:

2

/s

The oil can be obtained from the sales centres of

DÜRKOPP ADLER AG under the following reference numbers:

–

2-Litre container: 9047 000013

–

5-Litre container: 9047 000014

1

Maintenance work to be carried

out

Hook lubrication

Check oil level in the supply

container 1.

Lubrication of th e mach in e he ad

Check oil level in the supply

container 2.

2

Explanation

Tilt the machine head backwards.

Fill the oil supply container 1 through the resp ec ti ve hol e up to

the mark

The oil level shou ld not dro p be lo w the mark

If required, fil l th e oi l th ro ug h th e hole i n th e si ght gl ass up to

the mark

"max"

"max"

.

"min"

.

Service

hours

8

.

40

25

Page 24

8. Auxiliary equipment

Auxiliary e qu ip m en t

Reference No.. Designation

0577 211324 Vulkollan-coated cloth presser cage

and smooth fa bri c f ee de r fo r E 113/22

0577 211424 Vulkollan-coated cloth presser cage

and smooth fa bri c f ee de r fo r E 114/22

0577 211444 Vulkollan-coated cloth presser cage

and smooth fa bri c f ee de r fo r E 114/35

9822 510000 Stand-type halogen sewing light

9822 510011 Table clamp for stand-type halogen sewing

light

0797 003031 Pneumatic connection package

Loading aids

Reference No.. Designation

0556 002741 Buttonhole spacer and

Edge guide for sewing in longitudinal direction

0556 002656 Collar guide

0556 002654 Cuff guide

0556 002652 Buttonhole spacer;

for transversal sewing, max. 360 mm

0556 002651 Buttonhole spacer;

for transversal sewing, max. 160 mm

0556 002581 Edge guide for longitudinal sewing

26

Loading...

Loading...