Contents: Page:

Home

Preface and General Safety Information

Descriptio n of pr oper us e or pro pe r app lic ati on

Part 1: Operating Instructions Cl. 195

1. Product Desc ription . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Short Description and Proper Use . . . . . . . . . . . . . . . . . 5

1.2 Sub-Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Technical Speci ficat ion . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Operating Elements and Their Function . . . . . . . . . . . . 7

2.1 Elements at the Sewing Head . . . . . . . . . . . . . . . . . . . . 7

2.2 Elements on the Frame . . . . . . . . . . . . . . . . . . . . . . . 11

3. Operating the Sewin g Machi ne . . . . . . . . . . . . . . . . . . 13

3.1 Threading the Needle Thread . . . . . . . . . . . . . . . . . . . . 13

3.2 Needle Thread Quantity for Sure Stitch Formation . . . . . . . . 14

3.3 Threading the Bobbin Thread . . . . . . . . . . . . . . . . . . . . 15

3.4 Setting the Thread Tensions . . . . . . . . . . . . . . . . . . . . . 16

3.5 Setting the Bobbin Thread Take-Up . . . . . . . . . . . . . . . . . 17

3.6 Setting the Pressure Foot Stroke . . . . . . . . . . . . . . . . . . 18

3.7 Edge tr immer shut-on and shut-off . . . . . . . . . . . . . . . . . 19

4. Maintenanc e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Following Patents and R eg ist er e d Ut ilit y Mod el s ap ply:

Status April 1994

DE 30 43 141 JP 1 258 920

IT 209 238 JP 1 339 944

KR 24 686 JP 1 803 181

TW 31 498 JP 1 931 464

US 4 116 145

US 4 446 803

1. Product Description

1.1 Short Description and Proper Use

The special sewing machine 195 is a single needle-double chain stitch

machine with lower transport and an upper transport with alternating

pressure feet. The hook of the 195 is set crosswise to the direction of sewing

(Crossline). With the part s set 195 5002 it can be converted to a two-n eedle

sewing machine.

The machines are designed and may only b e used for sewing materials of

textile fiber and leathe r.

As of 11/95 Class 195-171110 is equipped at the factory so that thread

thicknesses great er th an 25/3 N m ca n be sewn (ai r bag pr o du ct ion) .

For this, the machine and the pa rts kit 195 50 02 eac h have a second hoo k,

this means that:

The single needle machi ne can be equipped with

hook 195 4753 for threads up to 25/3 Nm or with

hook 195 4753a for threads thicker than 25/3 Nm as required.

The dual n e edle machine can be equipped with the

hooks 195 4753 and 195 5055 for threads up to 25/3 Nm or with

hooks 195 4753a an d 19 5 50 55 a for threa ds thicker than 25/ 3 Nm as requ ir e d.

Attention!

The hook or hooks not inserted in the machine are enclosed with the machine.

1.2 Sub-Classes

195-171110 Execution without thread trimmer.

195-171521 Execution with electropneumatic

Electropn eu ma ti c li ft in g of the

pressure foot

thread trimmer for needle and

bobbin thread, electropneumatic

automatic interlock and

pressure foot stroke

5

1.3 Tec hnical Specification

Needle system: 933

Maximum number of stit ches : 4000 rpm

Maximum stitch len gt h: Upper transport 10 mm

Maximaler pressure foot stroke: 2-7 mm

Clearance under the pressure feet:

when sewing: 10 mm

when raised: 17 mm

Maximum thread thickness: 20/3 Nm

Operating press ur e : 6 +/- 0,5 bar

Line pressure: 7-10 bar

Air consumption per work cycle:

-171110 0,05 Nl

-171521 0,1 Nl

Through-feed area : 280 x 132 mm

dependent on pressure foot stroke

and stitch length

Lower transport 8 mm

1.4 Optional Equipment

195 5002 Parts set for converting a single-needle

Z 133 601 Reflecting light barrier for recognizing

Z 132 1501 Needle cooling from above.

to a two-needle machine. Max. needle

pitch 14 mm dependent on the E-Nr.

Not

for 195-171521.

the seam end.

6

2. Operating Elements and Their Function

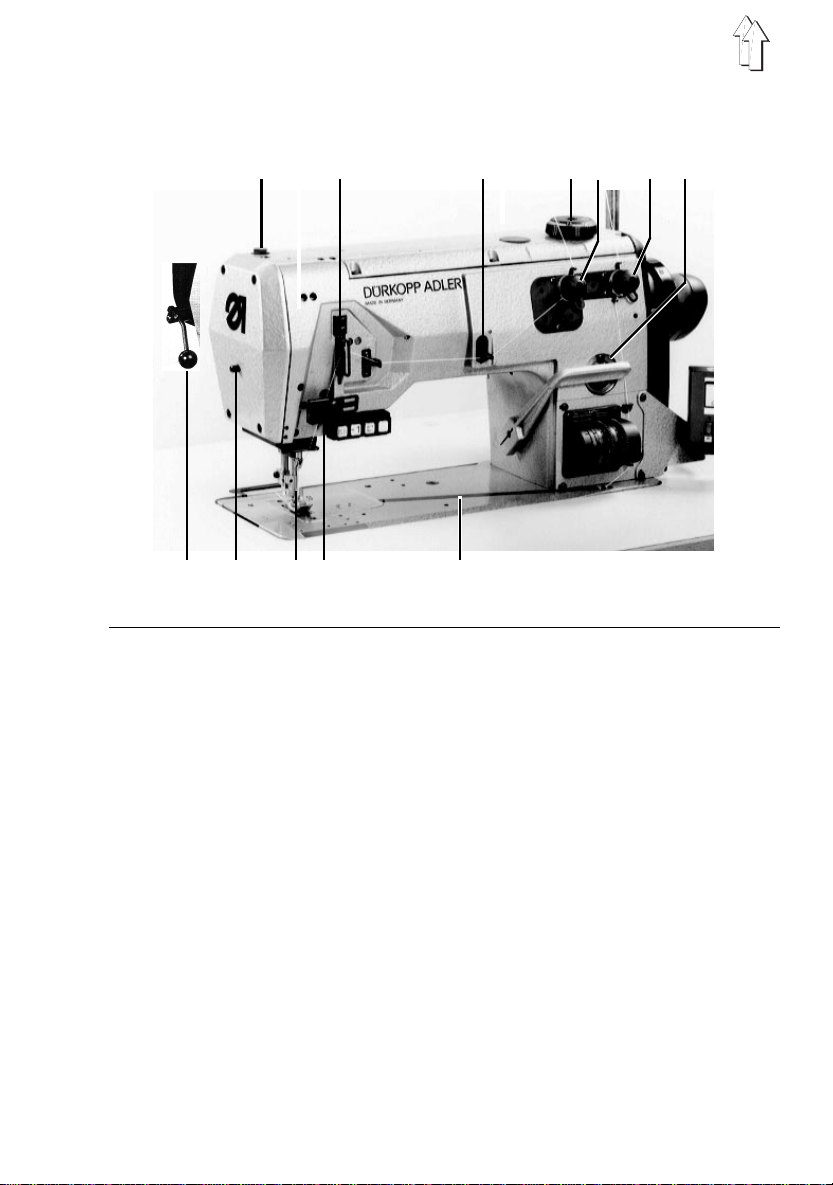

2.1 Elements on the Sewing Head

1

234567

12

Element Function

1 - Screw - This screw for the pressure foot pressure is

2 - Thread regulator - Setting the correct needle thread quantity

3 - Needle thread puller - For formation clean stitches at the beginning of

4 - Adjustment wheel - Setting pressure foot stroke.

5 - Contr ol knob - Setting needle thread tension.

6 - Control knob - Setting bobbin thr ea d te ns io n.

7 - Viewing glass - Show the oil level in the reservoir. The oil level

with fill opening must be kept above "MIN". If necessary fill

8 - Plate - Bobbin thread guide

9 - Light barri er - Recognition of the mater i al edg e an d ther e by the

10 - Needle - 933, Needle thicknesses depending on the sewing

11 - Knob - Lock the pressure foot in the raised position.

12 - Lever - Ed ge tr im me r shu t-o n an d sh ut- of f. (195-671110)

91011

screwed in completely at the factory.

Do not alter the scr ew posi ti on !

the seam pull out su ff ic ie nt thr e ad .

"Esso SP NK 10" oil up the the "MA X" marking.

precise position of the stitch condensation at

the seam end.

garrangement. Caution Risk of Injury!

8

7

Element Function

13

bac1415161718

13 - Operating field - See motor manufacture r ’s instruct io ns

14 - Bobbin thread- - For formation a clean stitch at the seam beginning

puller pull out suffic ie nt thr e ad .

15 - Adjustment wheel - Setting the stitch length of the upper t ransport.

16 - Adjustment wheel - Setting the stitch length of the lower transport.

17 - Screw - Setting the stitch condensation

18 - Hand lever - Continuous adjustm ent of the stitch length.

8

Note: For thread tri m m in g wit h th e su b- c la ss

171521 the thread wiper on the threa d

trimming key must also always be turned on.

Diodes a and b must be lit.

The upper diode c must be lit on the "S titch

Condensation at the Seam End" key.

(Length of the stitches).

1617181920

Element Function

16 - Block of Keys

17 - Key - Ke y not j ust.

18 - Key - Suppression of stitch condensation at seam

19 - Key - Sew single stitches

20 - Key - Bring the needle alternatingly in position

beginning

high/low, stitch condensation at any de si r ed

seam position during sewing.

9

Element Function

20 - Dip stick - Measuring the oil level in the hook drive

21 - Screw To che ck the oi l level screw out sc rew 21

22 - Thread take-up - Automa ti c ad ap ti on of th e bo bbi n thr ea d qu an ti ty

housing . Dip stick is in the enclosed packag e.

and place the dip stick 20 in the opening. The

oil level must be between the mar ki ng s.

Fill only Esso SP NK 10-type oil.

Attention!

When overfilling the excess oi l w il l co me

out of the ventilation hole in screw 21.

to the set stitch length. Settings for tight,

normal and highly elastic seams see

Section 3.5.

UMB 2.2

20

22

10

21

2.2 Elements on the Frame

4

3

2

1

Element Function

1 - Main switch - Switch the machine on and off.

2 - Screw - Compensation for floor irregularities

3 - Pedal

Rest position - No function

Position forward - Sewing with desired rpm

Position "half back" - Raise pressure foot when machine at rest

Position "full back" - Thread trimming and raise pressure foot

4 - Screws - Adju stin g th e work height

11

Maintenanc e Uni t

11 10 9 8 7 6 5

Element Function

7 - Oil mister - With the regulating screw 5 set approx. 1 drop

8 - Air filter and - Before the water level reaches the filter, screw

water trap in screw 9 far enough to drain water.

10 - Pressure Regu la to r - To set to 6 bar pull the bushi ng 11 up

for 10 work cycles. To fill interrupt the

compressed air feed and vent the system with

screw 9. Screw out screw 6 and fill

"Esso SP NK 10"-type oil up to the groove in

the glass.

Do

not

interrupt th e co mp ressed air suppl y.

and turn ap pro priately.

UMBRUCH =

12

3. Operating the Sewing Machine

3.1 Threading the Needle Thread

1

Caution Risk of Injury!

Turn off main switch before threading.

- Thread the needle thread as shown in the

illustrations.

Important!

By machines with thread trimming it is

essential that the nee dl e th r ea d be thr e ad ed

through the pre-tensioners (1).

13

3.2 Needle Thread Quantity for Sure Stitch Formation

1

a)

b)

With elastic sewing thr e ad s, e.g. synthetic fiber

threads, a certain needle thread quantity must be

pulled out for sure stitch formation.

This occurs in the low posi ti on of th e take-u p lever

in conjunctio n wit h th e th rea d r eg ul ator 1.

For this the thread regulator is set as follows:

–

Bring the thread regulator into its lowest

position.

–

Adjust the thread regulator.

With elastic th rea ds :

The thread hole must be visible below the thread

regulator.

Thread the needle to the

With non-elast ic thr e ads, e.g. cotton:

Thread hole should be visible above the thread

regulator.

Thread the needle thread to the

Illus. b

left

past the bar. Illus. a

right

past the bar.

14

3.3 Threading the Bobbin Thread

Caution Risk of In ju r y !

Turn off the main switch be fore thre adin g.

–

Lift the thread holder 1 out of its catch.

–

Draw the thread through the holes 2 and 3.

–

Draw the thread through the hook holes.

–

Close the hook holder.

1

2

3

15

3.4 Setting the Thread T ensions

The thread tension of the needle thread must be

higher than that of the bobbin thread. The control

knob for the bobbin thr ea d te ns io n th us has a

spring of thinner wire.

Too high thread tensions cause a puckering of the

material.

Too low bobbin th read tensio ns can caus e faulty

stitches.

For setting a greater thread quantity in the seam

see Sectio n 3.5.

Furth ermore, one ca n work with or without

pneumatic tension opening during the stroke of the

sewing foot.

The tension opening is necessary when the sewing

material with thread is to be pulled forward under

the sewing foot. Here the arm cover must be

removed and the coupli ng plug in se rted into th e

preattache d coupling socket.

Attention!

When sewing corners with sewing foot stroke a

loose stitch results. Thus, pneumatic tension

opening should only be used when there is no

sewing foot stroke during the course of the seam.

16

3.5 Setting the Hook Thread T ake-up

1

2

The thread take-u p 1 pr ovi de s for an aut om at ic

adjustment of the th r ea d qu anti ty to th e se t st itch

length.

Because of this , stitch pull and stitch formation

are always optimal for every stitch length, also for

stitch condensation. The drawn-in thread quantities

can be altered for each type of seam.

Results with ou t al te r i ng the th r ea d te ns io ns ar e:

a) tight

b) normal

c) highly elastic (ballon stitch) seams.

–

Loosen screws 2.

–

Adjust the thr ea d ta ke-u p.

Direction 0 tighter seam

Direction 5 elastic seam.

Important!

1) With extreme settings, e.g. a smallest possible

stitch length and a hi gh es t po ss ible th r ea d quan ti ty

(elastic seam ) , car e mus t be taken th at a pos it ive

stitch of the needle int o th e th rea d de lt a is

possible. Faulty stitches can occ ur by too la rge

hook thread quantities.

2) If the stitch length is greatly increased by the

settings described under 1, it is necessary to set

back the thread guid e in the dir e ct ion 0. Otherwise

the hook thr ead may jump off of the thread take-up

disc.

a)

b)

c)

17

3.6 Setting the Pressure Foot Stroke

Attention!

The machine doe s no t have automa ti c r evolution

reduction. When sewing with a large pressure foot

stroke it is impera ti ve to manua ll y red uc e th e

number of revolutions.

Too high revolutions become obvious through

louder sewing noise.

18

3.7 Edge trimmer activating and deactiv ating

The edge trimmer off Cl. 195-671110 may be

actuated at any time. It’s upper knife is such as

formed that also a save cutting aktion is achieved

at activating while sewing.

1

Attention Danger of injuring

Don’t reach into cutting zone at activating the

trimmer. Remove finger guard only for repair

aktions. immediately replace finger guard at

damages.

For activating of the trimmer pull lever 1

downwardly, for deactivating push lever upwardly

19

4. Maintenance

Caution Risk of Injury !

Turn off the main switch before cleaning the

machine.

At the very latest maintenance work must be

conducted aft er th e num be r of oper at in g hour s

listed in the column " Interval". Shor ter

maintenance intervals may necessary when

working wit h ver y lin ty mat erial.

Procedure Interval Remarks

Head

Removal of lint 8 Particularly at following point s :

accumulations Underside of the stitch plate

Check oil level in the 40 See Subject 2.1

reservoir Element 10

Maintenance Unit

Clean insert in the air filte r 8 500 First vent the system

Transporter stays

Area around th e ho ok

Check oil level in the oil mister 6 180 Do not allow the oil level to fall

Check the oil feed in the oil

mister 180 See Subject 2.2

Check all compressed air lines

for leaks 500

20

the opening in th e su ctio n pi pe

Loading...

Loading...