Page 1

Contents: Page:

Home

Foreword and general safety instructions

Part 1: Operation manual classe 171 • 173

1. Product specifications

1.1 Sho rt de scri ption and use for the intended purpose . . . . . . . . . . . 5

1.2 Technic al data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Opt iona l equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Machine elements and their functions

2.1 Elements at the m achine head . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Elements at the stand . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Operating

3.1 Threading t he needle thread . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Threading t he lo oper thread . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Adjusti ng the th read tensions . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Amount of ne edle thread f or se cure stitch formation . . . . . . . . . . 12

3.5 Adjusti ng the lo oper thread t ake- up . . . . . . . . . . . . . . . . . . . . 14

3.6 Setting the feeding length . . . . . . . . . . . . . . . . . . . . . . . . . 15

a) B ottom feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

b) Top pu ller feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

4. Maintenance

4.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5. Information on sewing with monofilament threads . . . . . . . . . 18

Page 2

The following patents and registered designs apply:

Status October 1992

DE 86 20 593

JP Sho-62-108358

TW 40 985

Page 3

1. Product specifications

1.1 Short description and use for the intended purpose

The 171 and 173 are double chainstitch (stitch type 401) sewing machines in single or

twin needle version.

The loopers are across the line of sewing (Crossline).

Class 171 with drop oscillation feed.

Class 173 with drop oscillation feed and intermittent top puller feed.

The feeding lengths of feed dog and puller are independently a dj ustable at separate

dials. When changing over to stitch condensing, the feeding length of the puller is

automatically reduced accordingly.

In accordance with the intended purpose, the machines must only be used for sewing

materials made of textile f ibres and leath er.

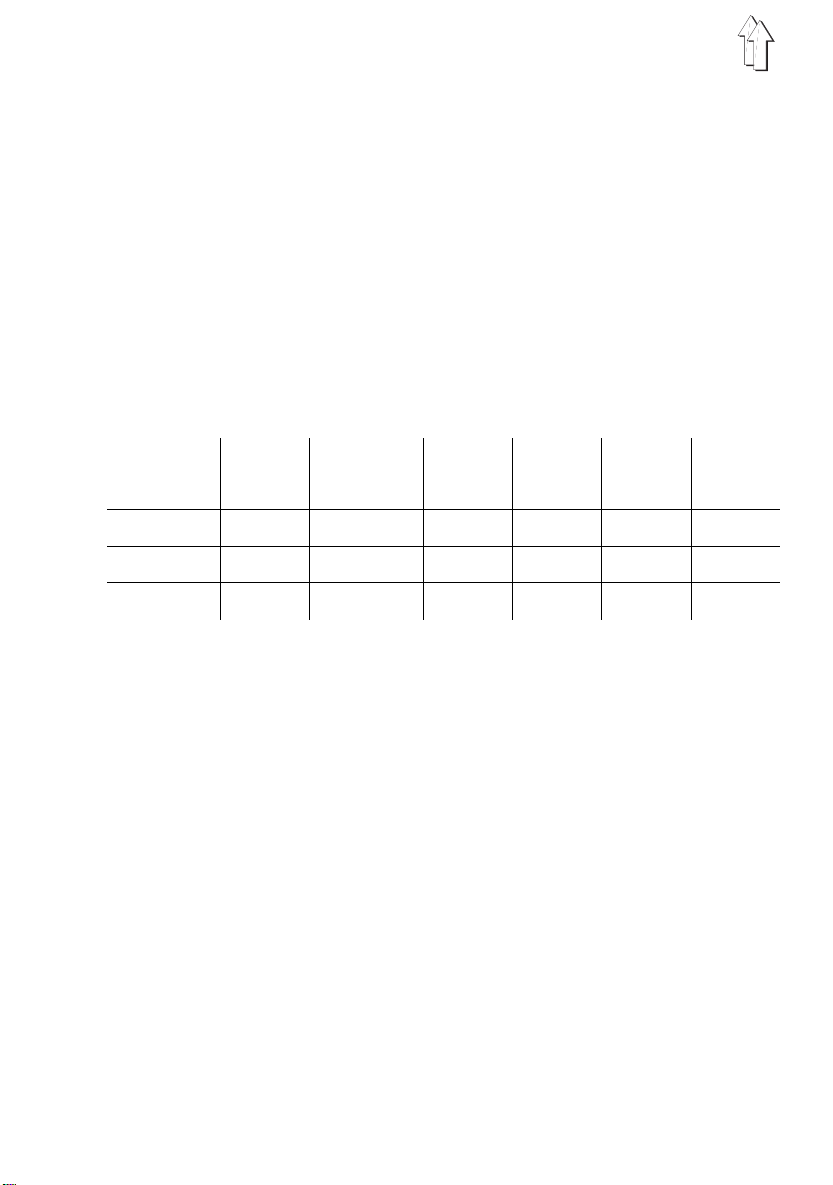

1.2 T echnical data

Feeding length of the top puller feed: max. 7 mm

Standard puller width: 9 mm

Subclasses Stitch

length

171-131110 1-4 mm 6600 / 7000 27 mm

173-141110 1-4 mm 5800 / 6000 30 mm

173-141521 1-4 mm 5800 / 6000 30 mm

Maximum clearance under the sewing foot:

When lifting: 5 mm with the needle 934 SIN

When sewing: 4 mm

Operating pressure: 6+/-0.5 bar

Air consumpti on: On the -161120 0.05 NL per work cy cl e

On the -1 41521 0.1 NL per work cycle

Speed

at work/ max.

Needle

stroke

934 SIN or 933 depending on the sewing

equipment (E-Nr.)

10 mm with the needle 933

Stitch

condensati

Foot lifting Thread

on

•••

cutter

N

e

e

d

l

e

s

y

s

t

e

m

:

1.3 Optional equipment

Order numbers

1713502 Set of parts for converting a single nee dl e- into a twin ne edle double

chainstitch sewing m achine. Max. needle dista nce 1 4 mm depe ndin g on the

E-Nr. Not f or su bclass 173-141521.

933 5736 Steel puller 1 mm tooth ed, 9-mm-wide

933 5737 Steel puller 1 mm tooth ed, 15-mm-wide

933 5738a Steel puller 2 mm saw-toothed, 15-mm-wide

The steel pullers must not touch, the distance to the throat plate must be 0.5 mm.

For the adjustm ent see the servic e m anual. 16-mm-wi de asymmetric Vulcollan puller

and a hook kni f e are contained i n the accessor i es. The position of the puller wi th

respect to the seam or fabric fold may be varied depending on how it is mounted.

5

Page 4

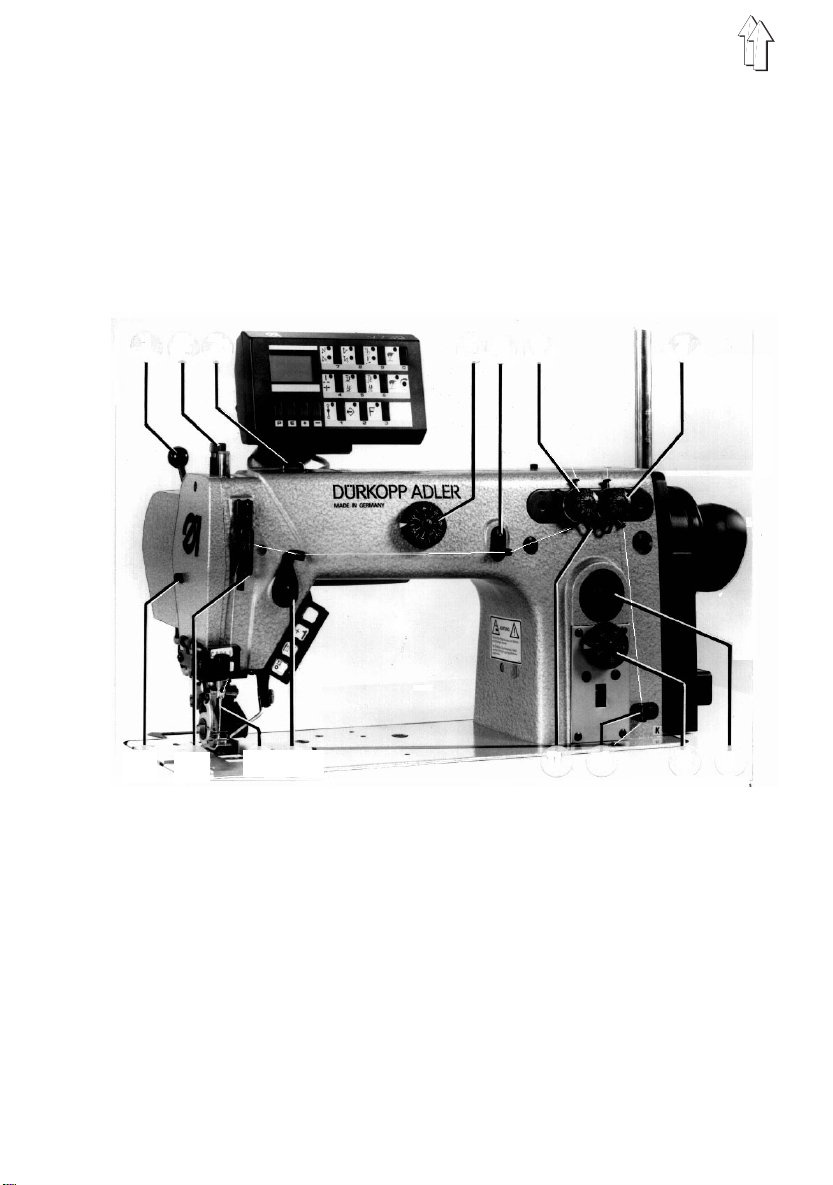

2. Machine elements and their funct ions

2.1 Elements at the machine head

Element Function

Hand lever 1

Screw 2

Oil check tube 3

Dial 4

Needle thread puller 5

(Only subclass -141521)

Needle thread tension 6

Looper thread tension 7

Oil reservoir 8 with

inlet opening

Dial 9

Looper thread puller 10

(Only subclass -141521)

–

Swinging up the puller. It is swung out of the working

area.- Sewing wi th bottom feed only.

–

Regulating the sewing foot pressure depending on the

material.

–

Monitoring the oil circulation for the lubrication of t he

front arm shaft bearing. The oil flow must not be

interrupted while the machine is running. If necessary,

check the oil level in the reservoir 8 or top up with oil.

Only ESSO SP-NK 10 or an oil of the same quality

must be used.

–

Feeding length for the top feed puller.

–

Initial thread for the stitch formation at the seam

beginning after the threads are trimmed.

–

One revolution of the turning button with num erals

covers the entire tension range. Thus, the tension

values can be easily reproduc ed.

–

Same as 6, but w i th a weaker tension spring.

–

The oil level must not drop below "MIN". If necessary,

top up with ESSO SP-NK 10 oil to "Max".

–

Setting the stitch length for the bottom feed.

–

Initial thread for the stitch formation at the seam

beginning after the threads are trimmed.

Release lever 11 for

the thread tensions

Thread guide 12

Needle 13

Thread regu l ator 14

Locking button 15

6

–

Pulling out the threads by hand, eg when threading

–

Basic adjustm ent centre of t he elongated hole.

–

System 934 SIN or 933.- Needl e sizes Nm 80-130

depending on the sewing equipment (E-Nr.).

To exchange t he needle, al ways turn off the

main swi tch! - Danger of injury!

–

For secure sti tch formation i n the case of elastic

threads, such as eg synthe tic spun threads and

monofilament threads. For the adjustment see

section 3.4.

–

Locking the f oot in its lifted position.

Page 5

1 2 3

4 5 6

7

15 14

13 12

11 10

9 8

7

Page 6

Element Function

Key 17

Key 18

Key 19

Key 20

Control pane l 21

(Only subclasses -141521

and -161120)

Knee lever 22

Infrared reflecting

light barrier 23

Looper drive housing 24

–

Undefined

–

Single stitches

–

Needle up or down at machine standstill. During

sewing condensed stitches may be sewn anywhere within the seam.

–

Raising or lowering the puller.

–

See instructions of the motor manufacturer.

Note: To enable thread trimming on the subclass 141521, not only the key "thread trimming", bu t also

the key "thread wiping" at the control panel must be

always switched on. Diodes a and b must be luminous.

–

Prior to tilting the machine head backwards, TURN

OFF the main switch and remove the knee l ever. To unhook, make the m otions 1 and 2 an d to hook up, make

the motions 3 and 4.

–

To sense the fabric edge and thus, the correct

position of t he condensed st i tches at the sea m end.

–

With the machine head tilted backwards the oil level

must not drop below the lower long mark.

If necessary, turn out the screw 26 and top up with oil

ESSO SP-NK 10. The oil must just be filled up to the

upper mark.

Looper thread take-up 25

8

–

It automatically adjusts the amount of looper thread to

the set stitch length.

For adjustments for tight, regular or highly elastic

seams see section 3.5.

Page 7

17

18

19

20

21

a b

23

26

24

22

25

9

Page 8

2.2 Elements at the stand

Element Function

Main switch 1

Pedal 2

Maintenance unit

Air filter with water

separator 7

Pressure regulator 4

Mist lubricator 9

–

Turning on and off t he machine.

Always turn o ff the main switch prior to th reading,

changing the sewing tools ( such as eg needle,

sewing foot, thr oat plate, sl ide plate etc.),

cleaning, when leaving the workplace as well

as for ma intenan ce wo rk.

See also General Safety Instructions.

–

0 Idle position - No function.

1 Sewing foot lift at machine standstill

2 Sewing up to t he maximum speed by pressing down

the pedal accordingly.

3 Stitch condensing - thread trimming* - sewing foot

lift.

* Not on subclass -161120

–

Before the water level reaches the air filter 6, screw in

the screw 8 an d blow off the water under pressure.

–

To set the air pressure of 6 ba r, pull up the knob 4 and

turn it.

Turning to the right = Pressure increase

Turning to the left = Pressure decrease

–

Adjust approx. 1 drop of oil for 10 work cycles using

the regulating screw 11.

10

To top up with oil, vent the pneumatic system. To do

this, turn the knob 4 to the left.

Turn out the screw 10 and fill with ESSO SP-NK 10 oil

up to the gro ove on the oil re servoir 9.

Page 9

1

2

4

11

10

5

96

9

7

8

11

Page 10

3. Operating

3.1 Threading the needle

thread

Turn off main switch.

-Danger of injury! -

For threading the needle thread proceed

as shown in the figures opposite.

3.2 Threading the looper

thread

Turn off main switch.

-Danger of injury! -

For threading the looper thread also

proceed as shown in the figures

opposite. To do this, lift the thread downholder 3 out of its locked position.

3.3 Setting the thread

tensions

The needle thread tension must be

tighter than that of the looper thread.

The looper thread tension 2 is, therefore,

equipped with a spring made of thinner

wire.

Too tight thread tensions ca use compression of the ma terial. A to o l oo se

thread ten si on may lead to ski pped

stitches.

For a larger amount of looper thread

pulled into the seam see sec tion 3.5.

3.4 Needle thread amount for

secure stitch formation

In the case of elastic sewing threads, eg

synthetic spun threads or m onofilament

threads, a certain amount of needle

thread must be pulled to assure a secure

stitch formation.

This takes pl ace when the take-up lever

is in its bottom position in conjunction

with the height adjustment of the thread

regulator 1.

With the take-up lever in bottom position

adjust the thread regulator as follows:

In the case of elastic needle threads the

thread eyelet in the take-up lever should

be visible be l ow the thread regulator.

Pass the needle thread on the left of the

bracket. See fig. a.

With unelasti c threads, such as eg cotton, the th read eyelet should be visible

above the thread regulator. Pass the

thread on the right of the bracket. See fig.

b.

1

a

Abb. / Fig.

b

12

3

Page 11

V

Single needle machines Twin needle machines

Threading through the pre-tensions V only on machines with thread trimmer.

13

2

Page 12

3.5 Adjusting the looper thread take-up

The looper thr ead take-up 1 au t om atically

adjusts the looper thread amount to the

set stitch length.

This means: Always optimum stitch formation and stitch tightening with every stitch

length, and also with condensed stitches.

No seam grinning and seam pu ckering.

The pulled amount of looper thread can

be changed by adjusting the looper

thread take-up cam.

Without chan ge of the thread t ensions

a) tight, b) regular, c) highly elastic

seams (balloon stitch) are yielded.

After loosening the screws 2 and

adjusting t he looper thread take-up 1,

regulate as follows:

In direction 0 = tighter seam

In direction 5 = m ore elastic seam

a)

b)

c)

Important information!

1) In the case of an extreme setting, eg

2) If the stitch length is substantially in-

1

3) If the stitch length is changed on the

2

a stitch length that is as short as

possible and a maximum amount of

thread (elastic seam), be s ure that

the needle does enter the thread

triangle safely.

Excessive loop er thread may re sult

in skipped stitches.

creased with the adjustment values

described und er 1), eg to 4 mm, t he

thread guide must be set back

toward 0. Oth erwise, the looper

thread might drop off the looper

thread take-up cam.

During the backward motion of the

looper, the looper thread would not

be pulled back by the looper thread

take-up cam, as is required.

171-131110 which has no coulisse

shaft, the take-up lever must be

readjusted manually.

14

Page 13

3.6 Setting the feeding length

a) Bottom feed

The feed dog feeding length is

adjusted at di al 4.

b) Top puller fee d

The feeding length of the puller 9 is

adjustable in dependent of the bottom

feed at dial 3 and can thus be

adapted to the feeding characteristics of the material.

When sewing wit h stitch conden sing

at the seam beginning and se am

end, the puller feeding lengt h automatically adjusts to the feeding

length of the bottom feed.

3

Please note:

–

The puller can b e swung out of the

sewing area us i ng the hand lever, eg

for sewing with the bottom feed only.

–

To raise the pulle r when sewing radii

or corners, operate the lower key 5 at

the sewing he ad.

–

The fabric keep-off plate 8 serves

simultaneously as trimming knife for

the thread chain. (Only on machines

without thread trimmer.)

–

The puller pressure is adjustable to

the material. Loosen the screw 7 and

adjust the cylinder 6:

In direction A = higher pressure

In direction B = lower pressure.

6

5

4

7

8

9

15

Page 14

4. Maintenance

4.1 Cleaning

Turn off main switch.

-Danger of injury! -

A machine kept clean is a safeguard

against malfunctions!

Therefore, specifically clean t he area

under the throat plate, removing the

sewing dust once daily.

It is advisable to do this with an air pistol .

(If exists, remove the knee lever.)

After a certain period of time, the accumulated sewing dust must be removed from

the feed dog rows. To do this, remove the

throat plate.

When the machine is equipped wi t h a

compressed air maintenance unit, the oil

level is to be checked daily.

Before the water level reaches the filter

insert 3, the water must be blown off the

water separator 2. To do this, the

maintenance unit must be under

pressure and the screw 1 must be turned

in (left hand thread).

For checking the oil level see 4.2.

4

3

2

4.2 Lubricating

Turn off main switch.

-Danger of injury! -

For the lubrication of this machine

only use ESSO SP-NK 10 oil or an oil

of the same quality.

The following lubricating points need to

be supplied with oil:

–

Check the oil level in the looper drive

housing 7 and, if necessary refill with

oil.

To do this, turn out the screw 8. With

the machine tilted backwards, the oil

level must not drop below the lower

long mark of th e sight glass. Oil must

only be refilled up to the upper mark.

–

With upright machine, refill oil into the

oil reservoir 9 up to the mark "Max.".

The oil level mus t not drop below the

mark "Min.".

Except for th e l ooper drive, all bearing

points of the machine are supplied by

a central oil wick lubrication out of

reservoir 9.

–

The oil check tube 10 for monit oring

the oil flow to the arm shaft front

bearing is located on the machine

arm. The oil flow must not be interrupted while the machine is running.

Should the oil flow be interrup ted in

5

6

spite of a filled reservoir, immediately

call a service t echnician.

–

If necessary, refill oil into the oil

reservoir 6 of the maintenance unit up

to the groove. To do this, completely

turn off the compressed air by turning

the knob 4 to the left, and then turn

out the screw 5.

16

1

Page 15

8

7

10

9

17

Page 16

5. Information on sewing with monofilament threads

When using monofilament threads,

needle threads and looper threads may

have the same size.

The best resu l ts can be obtained with soft

and elastic threads.

We recommend the following thread

sizes: Lab el-No. 180.

With a needle size of Nm 80 the stitches

per minute must be reduced to 4000.

In the case of needle sizes from Nm 90

the max. stitches per minut e may be

7000.

1

The following is required to assure

reliable sewing:

–

The thread co nt ainers or threa d c ones

must incorporate a silicone impregnated applicato r (felt piece) at t he thread

draw off point.

–

The needle cooler, order no. 933 671,

is required.

–

The edges 1 of the down-holder for

the looper th read must be rounded off

as shown in the figure.

–

Please observe the information on

reliable stitch formation in section 3.4.

18

Loading...

Loading...