Page 1

Contents Page

Home

General safety instructions

1. Set of gauges and handwheel positions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Parts of the set of gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Adjustments in the different handwheel positions . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Adjusting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Adjustment disk with respect to the arm shaft crank . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Lower timing belt pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Rocker bolt for the looper drive and left bottom shaft bearing . . . . . . . . . . . . . . . . . 8

2.4 Looper drive housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Looper avoid (width of the elliptic looper path) . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Symmetry of the looper motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Looper in the looper holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8 Loop stroke and needle bar height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9 Needle guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.10 Thrust motion for the feed dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11 Stroke motion for the feed dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12 Retaining spring at the looper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.13 Looper thread take-up cam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.14 Thread trimming device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.15 Sewing foot stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.16 Setting the stitch lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Setting the top puller feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1 Synchronisation of the bottom feed and top puller feed . . . . . . . . . . . . . . . . . . . . 22

3.2 Distance between the puller and needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Raising stroke of the puller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Puller pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5 Fabric keep-off plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.6 Timing belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.7 Replacing the puller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.8 Raising and lowering functions of the puller . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4. Adjusting the synchronizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Page 2

1. Set of gauges and handwheel positions

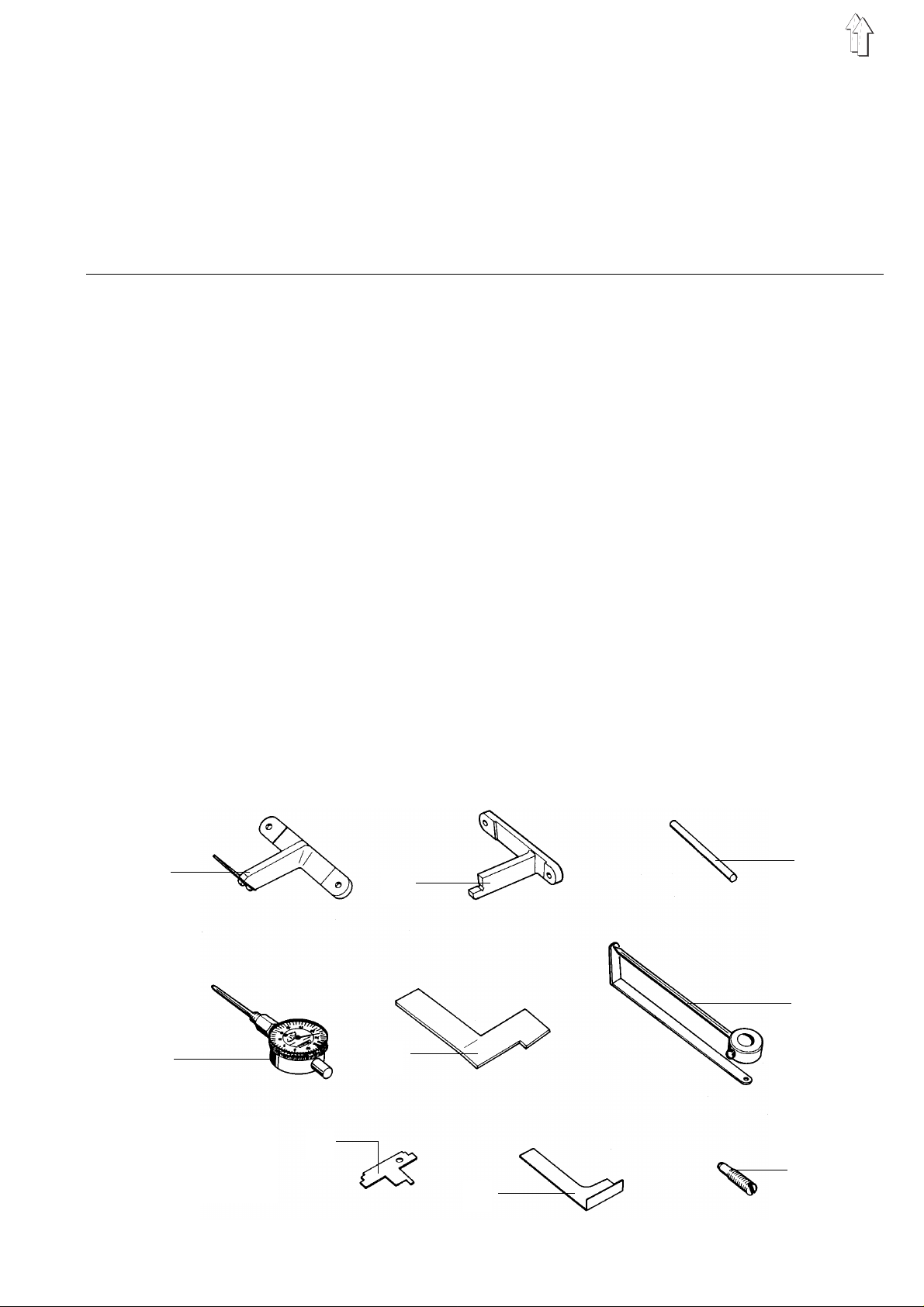

1.1 Parts of the set of gauges

The gauges li sted below enab l e t he ac c u rate adjusting a nd c he c k i ng of th e c l a s s es 1 71 an d 1 73.

The timing pi n 3 i s i n c orp or a te d i n the accessor i es of every deliv e red machine. It c an be used to lock th e

handwheel po s iti ons A - F that are required for the ma c hi n e ad j us t me nts.

Gauges Order no. Adjustment

Gauge 1 933 735 – Position of the rocker bolt in the looper drive housing

Gauge 2 933 739K – Position of the looper drive housing

Timing pin 3

(accessories bag)

Metering clock 4 171 981 – To measure the looper avoid ( width of the elliptic

Gauge 5 171 975 – Looper inclined by 89° 30

Gauge 6 933 80192 – Symmetrical looper motion

Gauge 8 933 740 – Height of the looper thread take-up cam

Gauge 9

(accessories bag)

Screw 10 933 716 – Spreading s cr ew fo r r ep lac i n g t he ar m s ha ft c ran k , e g

791 1152 – Locking the handwheel positions A - F

looper path) .

Should you already have a metering clock, you will

just need the clamping sleeve 171 984 and the

measuring pin 933 748.

’

933 758 – Thrust eccentric for the feed dog

when modifying the needle bar stroke

1

2

3

6

4

5

8

10

9

5

Page 3

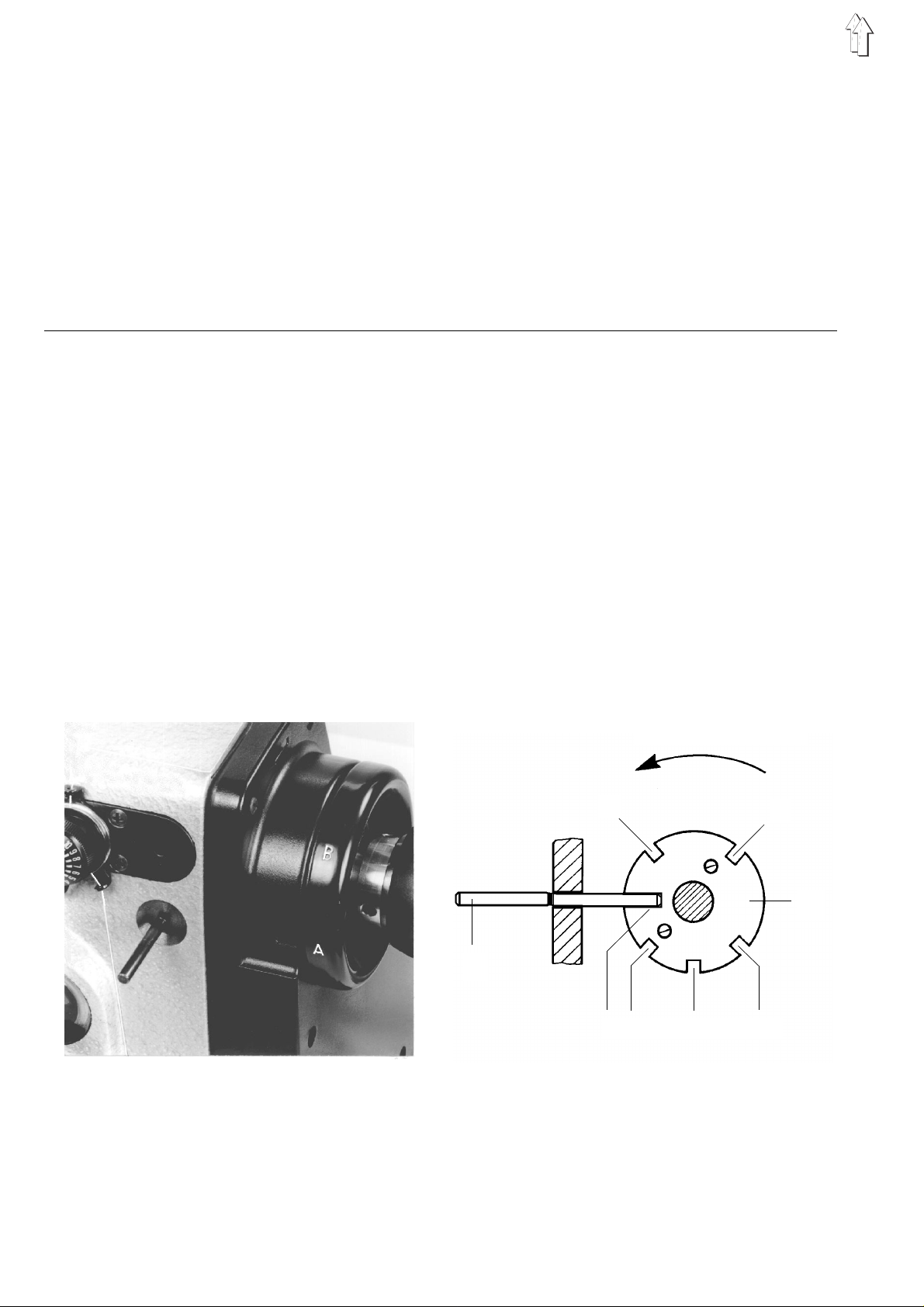

1.2 Adjustments in the different handw heel positions

For some adjustments the machine must be set in a certain position.

This position is marked by letters on the handwheel and can be locked as follows:

– Turn the handwhee l i nt o t he po s i tion defined for t he ad j us t me nt .

– Slide the ti m i ng pi n 4 i n to th e h ol e of th e machine housin g.

– Turn the handwhee l sl i gh tl y f or w ard and backward un ti l the timing pin 4 c a n b e sl i d i nt o t he r es p ec t i v e

slot of the adjustment disk 1.

– Slot A of the adjustment disk is cut out the deepest.

The depths of t he slots B - F are eq ua l .

Slot Adjustment

A

B – Symmetrical looper motion that is, when turning the handwheel in

C – Position of the lower timing belt pulley

D – Stroke and thrus t e cc en tr i c of the feed dog o n ri g ht - ha nd ma c hi n es

E – Looper thread take-up cam

F – Stroke an d t hr u s t e cc en tr i c of the feed dog o n l e ft -ha nd machines

– The deepest slot A of the adjustment disk at the upper timing belt

pulley is aligned with the groove in the arm shaft crank

reverse direction, the needle point must also be located at the centre

of the needle l ik e i n s l ot C

– Loop strok e

– Needle ba r height

– Eccentr ic fo r th e t op pu l l er feed

Operating dire ct io n

B

4

A F E D

Please note!

Depending on the needle bar stroke, the following adjustment disks are built-in:

Class / Subclass Needle bar stroke Adjustment disk

171-131110 27 mm 171 1012

173-141110 30 mm 171 1512

173-141521 30 mm 171 1512

173-161120 32 mm 171 2012

C

1

6

Page 4

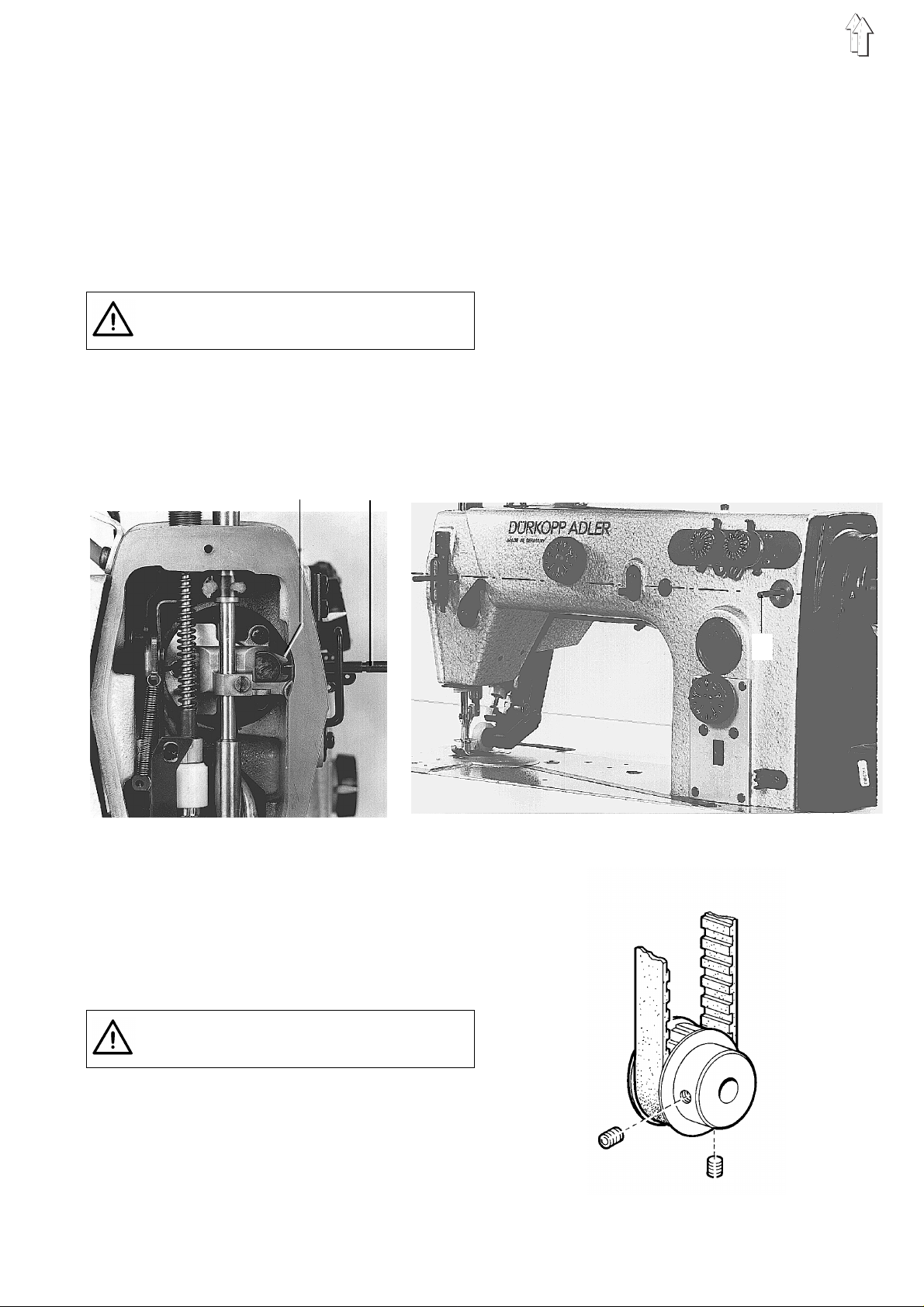

2. Adjusting the machine

2.1 Adjustment disk with respect to the

arm shaft crank

The deepest slot A of the adjustment disk 1 should

be aligned w i th th e g roo v e 2 i n t he ar m s ha ft c ran k .

(The adjustment disk must be in this posit i on to

assure that a l l ot he r adjustments to be ma de i n t he

other slots are c or re c t. )

Turn off main switch!

- Danger of injury -

Initially, check the factory adjustment using two

locking pins (as an alternative 5-mm-twist drills).

2 3

– Loosen the clamping screws of the clamping

ring. (The clamping ring is located on the left of

the upper tim i ng be l t p ul l e y ).

– Slide the pin 3 into the groove 2 of the arm

shaft crank.

– Turn the handwheel until the timing pin 4 can

be slid into the deepest slot A of the adjustment

disk.

– Push the ar m s h af t c ra nk t o t he r i gh t s o i t is

dead against the arm shaft bearing.

Tighten the screws of the clamping ring.

2.2 Lower timing belt pulley

Turn off main switch!

- Danger of injury -

When positioning the timing belt, make sure that

both screws in slot C are positioned as shown in

the drawing and are thus acce s s ibl e wi t h a

screwdrive r.

4

7

Page 5

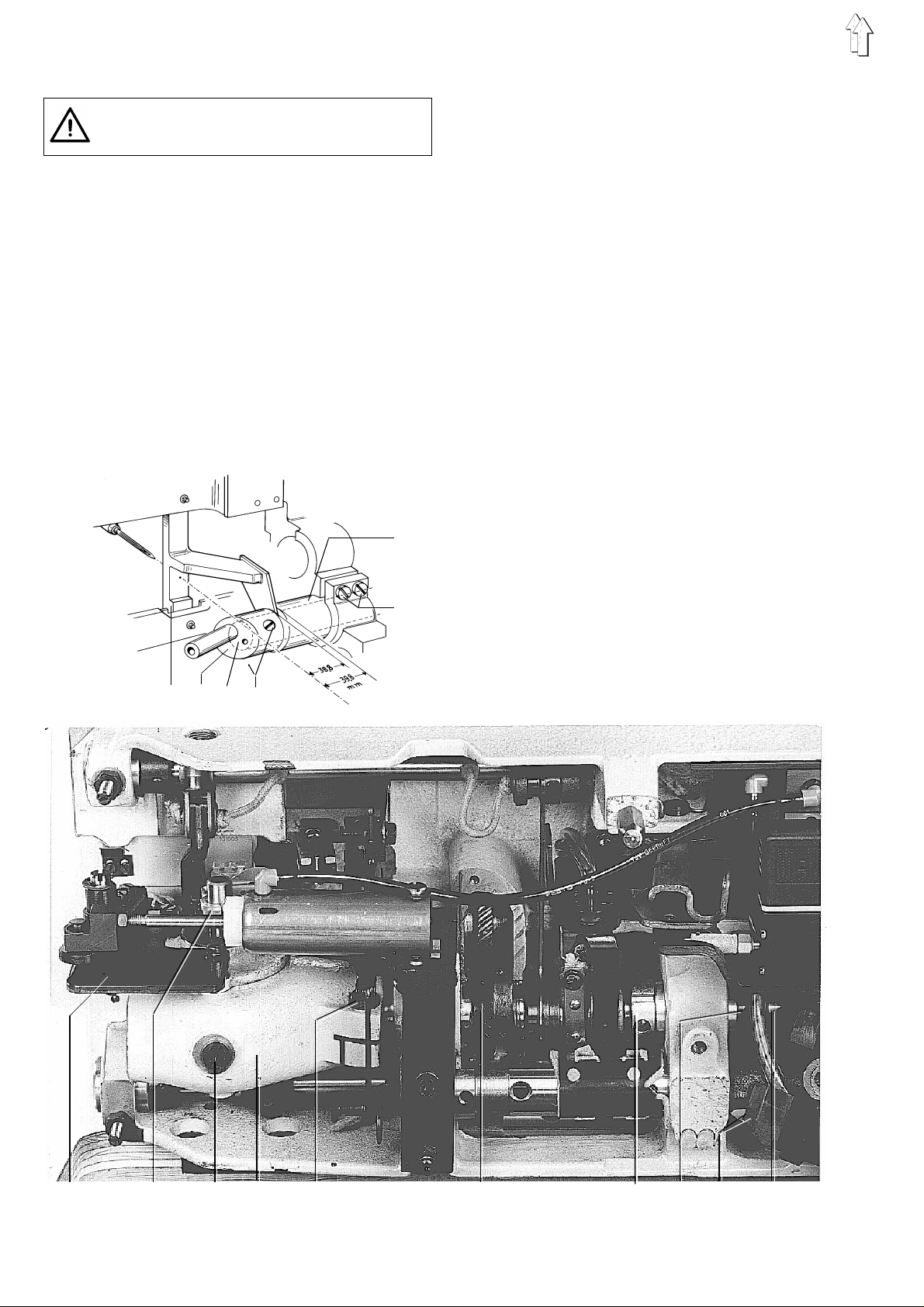

2.3 Rocker bolt for the looper drive and left bottom shaft bearing

Turn off main switch!

- Danger of inj ury -

The distanc e be tw ee n t he centre of the n ee dl e an d

the beginning of the left bottom shaft bearing 6

should be 39.8 mm and between the centre of the

needle and the end of the rocker bolt 38.8 mm.

The rocker b ol t 2 m us t be fl u s h w i th th e f ac e 3 o f

the bottom s ha ft .

– Unscrew the screw 9 and drain the oil in the

housing. Set the machine int o t he up r i gh t

position.

– Remove th e n ee dl e , n ee dl e gu ar d , l o op er

holder 8 with th e l o op er a nd th e t hr e ad

trimming device 7.

– Loosen th e cl a mp i ng s c rew 11.

– Carefully remove the looper drive housing 10.

At the same t i me sl owly turn the bo tt om s ha ft 3.

6

5

– Screw on the gauge 1, order no. 933 735.

Loosen the clamping screws 5.

– Push the bottom shaft bear i n g 6 be s i de th e

gauge. Tighten the cl a mp i ng scr e ws 5.

– Loosen the screws 4.

Check, whethe r th e r o ck er b ol t 2 i s d ead

against the face 3 of the bottom shaft.

– Remove th e g rease cover and th e o i l dri p pa n

15.

– Loosen th e e cc en tr i c 1 3, adjusting ri ng 14 an d

the gearwheel 12 .

Shift the bo tt om s ha ft 3 s u c h t ha t t he di s t an c e

between the bo ttom shaft beari n g 6 an d t he

rocker bolt 2 is 1 mm or the rocker bolt rests

against the gauge.

– Set the ad j usting ring 14 an d t he ec ce ntric 13

tight and align the gearwheel 12. Tighten the

screws.

– Check the r u nn i ng of th e timing belt on th e

bottom timi ng be l t p ul le y. If necessar y, align the

bottom timi ng be l t p ul le y.

– Screw in the screw 9.

Re-mount the looper drive housing and fill with

ESSO SP-NK 10 oil to the upper mark of the

sight glass.

– To adjust the housing, looper, needle guard and

the thread tri m me r, see sect i on s 2.4, 2.5, 2.6,

2.7 and 2.14.

2.4 Looper drive housing

1 2 3 4

7 8 9 10 11

8

12

13 14 15 3

Page 6

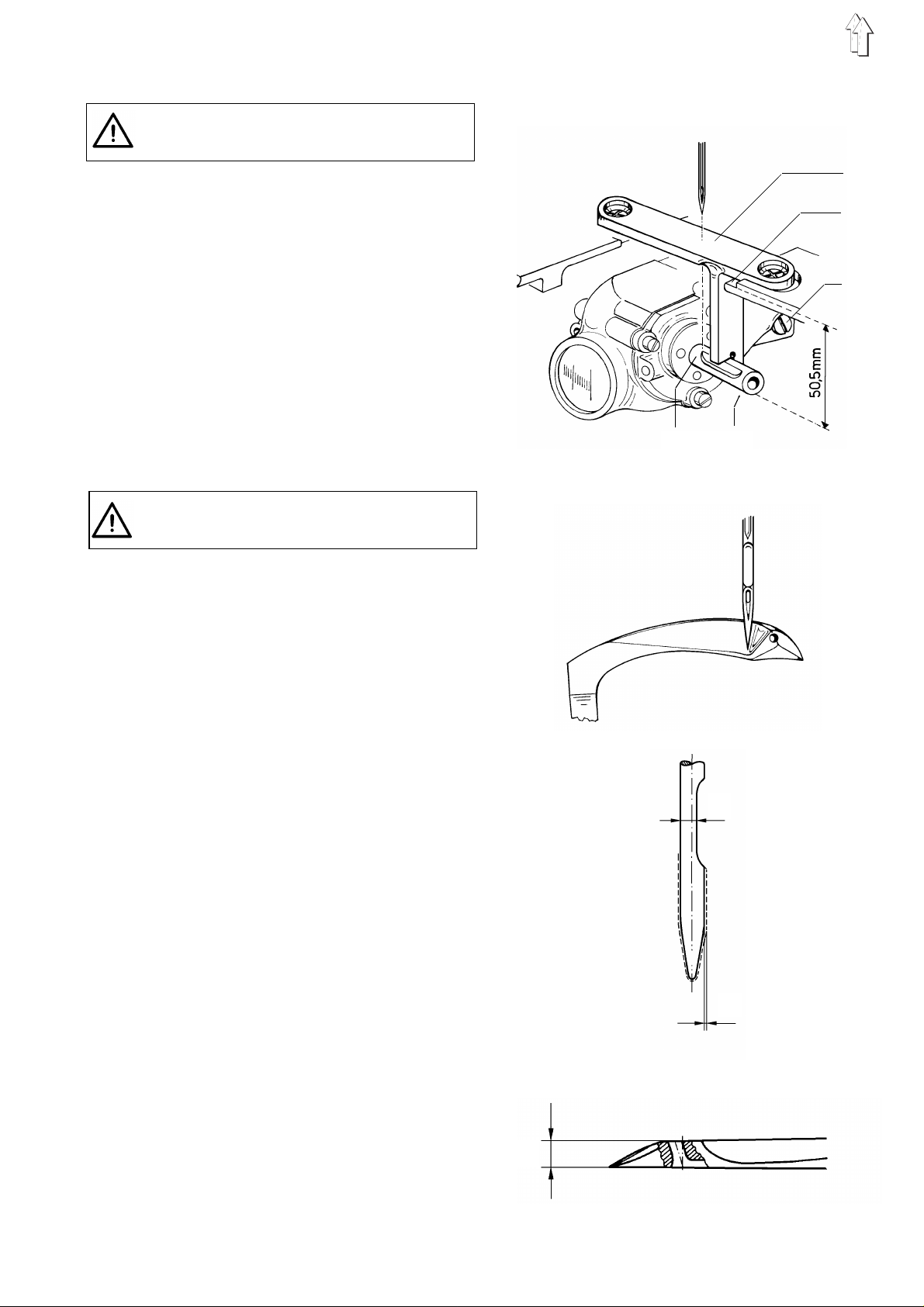

2.4 Looper drive housing

Turn off main switch!

- Danger of injury -

The needle point should point to the centre of the

looper shaft 5 and the bottom edge of the looper

shaft should be pa r al l e l to th e t hroat plate

underside.

1

2

This corresp on ds t o a di s t an c e o f 5 0. 5 m m

between the l oo pe r s ha ft bo tt om ed ge 4 and the

throat plate rest 2.

Remove the throat plate and looper holder with the

looper. Loosen the clamping screw 3.

Align the lo op er d ri v e h ou s i ng suc h th at the looper

shaft rests in the cutout of the gauge 1.

Tighten the clampin g s c rew 3.

2.5 Looper avoid (width of the elliptic looper path)

Turn off main switch!

- Danger of injury -

The looper avo i d m otion is adjust ed c or re c tl y, when

the clearanc e be tw ee n t he l oo pe r po i nt an d n ee dl e

is 0.1 mm during the right-to-left looper motion.

During the left-to-right lo op er m ot i on the point of

the descendi ng needle must rest against the bac k

of the looper, when the l oo pe r an d n ee dl e ar e

positioned as shown in the sketch opposite.

The exact amount of the avoid motion depends on

the needle system and needle size. It must thus be

computed according to the following formula:

E = a + b +0.1 + X

3

5 4

Example for a 9 34 S IN /Nm 110 needle

____________ __ __ __ __ __ ______________ __ __ __

Needle size " a" = 0.7 mm

Looper thick n ess " b " = 1.4 mm

Looper point - n ee dl e c lea r an c e = 0.1 mm

For greater ne ed l e s iz e 110 Nm "X" * = 0.1 mm

Width of the elliptic looper path "E" = 2.3 mm

*X=greater measure "a" for greater needle sizes.

X for Nm 100 = 0 mm

X for Nm 110 and 120 = 0.1 mm

X for Nm 130 = 0.2 mm

To adjust, shift the bottom shaft axially.

To the right: decreasing the width of the elliptic path

To the left: increasing the width of the elliptic path

For the adjustment see next p ag e.

a

x

b

9

Page 7

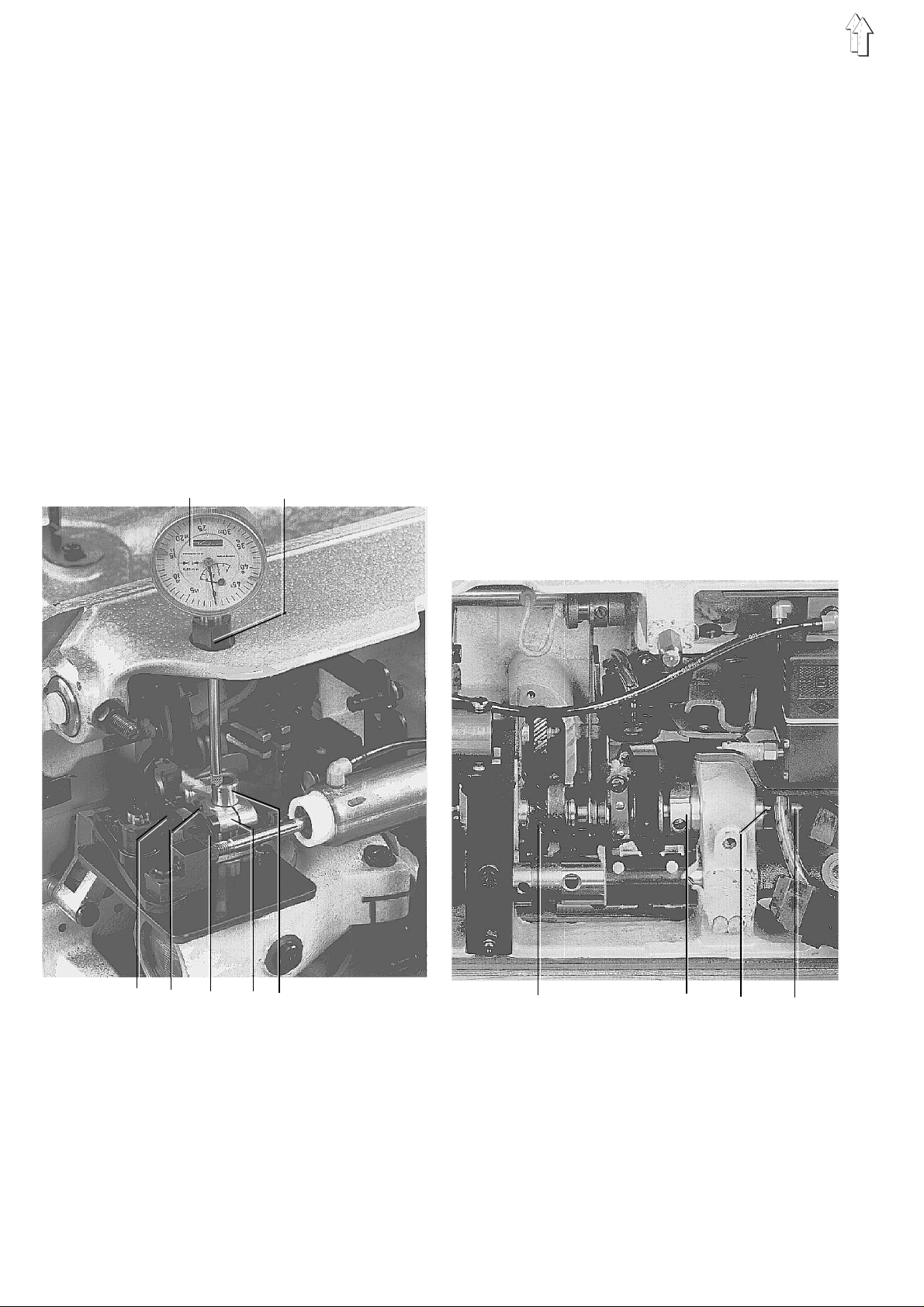

To adjust the width of the elliptic looper path proceed as follows:

– Insert a straight and undamaged needle.

Screw in the clamping bushing 2 and insert the

metering cl ock 1 .

– Turn the handwhee l to s et th e l o op er s h af t 7 at

its lowest point. Set the metering clock at the

measuring v alu e 0.

– Then turn the ha nd wh ee l to set th e l o op er sh af t

at its highes t po i nt .

Read the differen ce o n t he me te ri ng c l ock .

Should the measure not be identical with the

computed width of the elliptic path, the bottom

shaft 11 must be loosened.

– In the case of an adjustment i n a x i al d ir ec t i on

the width of the elliptic path changes with a

ratio of 1:2. When thus the bott om shaft is

shifted eg 0.2 mm, the width of the elliptic path

changes by 0.1 mm.

1 2

– Remove th e t hr o at pl a te an d f ee d d og . Set the

needle guard 3 to th e r e ar.

– Loosen the eccentric 9, adjusting ring 10 and

the gearwheel 8.

Push the botto m sh af t 11 into the respe c tiv e

direction u nt i l th e co mputed measure i s

reached.

– Tighten the eccentric 9 and the ad j ust i ng r i ng

10 so that the bottom shaft 11 is set tight. Align

the gearwheel 8 and tighten.

– Loosen the screw 5 and one of the screws 4.

Set a distanc e of 0.1 mm between th e l o op er

point and the needle by shifting the looper

holder 6 (looper point behind the needle).

Re-tighten th e sc re w s 4 an d 5 .

– Check the r u nn i ng of th e timing belt. I f

necessary, align the lower timing belt pulley.

10

3 4 5 6 7

8 9 10 11

Page 8

2.6 Symmetry of the looper motion

Turn off main switch!

- Danger of injury -

This adjustment means that the looper point is

located at the centre of the needle, when the

machine is locked either in slot C or B.

In slot C the looper point should be behind the

needle, and i n sl ot B i n f r on t o f t he ne edle.

– To enable an accurate adjustment, fasten the

gauge 1 on the looper drive housing and the

pointer 2 on the looper shaft.

– Loosen the sc r ew s of the lower timi ng be lt

pulley.

– Turn the bottom shaft such that in slot C and B

each, the pointer 2 is over the mark of the

gauge.

When turning t he ha nd wh ee l th e p oi n te r mu s t

swing to the l e ft .

– Tighten the screws of the timing belt pulley.

1 2

In operating direction - slot C

2.7 Looper in the looper holder

Turn off main switch!

- Danger of injury -

The looper face should be positioned with respect

to the edge of t he ma c hi n e b ed at an angle of 89°

30’.

In the case of two loopers, first align and securely

tighten the re ar l o op er, and then the front one.

The adjustme nt c an be ma de us i n g t he ga ug e

171 975, as shown in the figure opposite.

In reverse direction - slot B

11

Page 9

2.8 Loop stroke and needle bar height

Turn off main switch!

- Danger of inj ury -

The loop stroke is 3.5 mm. This means that the

looper poin t m us t be at th e c e nt r e o f t he ne edle,

when the needle has risen 3.5 mm from its lower

dead point by turning the handwheel in operating

direction. - Slot C of the adjustment disk.

This adjust ment must also e x is t i n r eve r s e

direction. - Slot B of the adjustment disk. See also

section 2.6 S y mm et r y of the looper mot i on .

When the lo op er e y e i s a t t he c en tre of the needle,

the bottom ed ge of the needle eye an d t he up pe r

edge of the looper eye should be level.

(see Fig.)

– Insert the ne ed l e i n to th e n eedle bar and fas t en .

– Lock the machine in slot C.

– Positio n h oo k po i nt be hi n d t he ne ed l e o n

needle center l i n e.

To do this, loosen the screw 3. Turn the set

screws 2 and 4 accordingly.

Tighten the screw 3.

– Loosen the screw 5.

Adjust the ne edle bar height suc h th at the

lower edge of t hre ad ey e i s al igned with the

upper edge of th e looper’s eye.

Tighten the screw 5.

– Set a distance of 0.1 mm between the looper

point and the c en tre of the needle by s h i ft i ng

the looper holder axially.

Tighten the screw 3. ( s ee Fi g. )

– Check symmetry of looper motion (Pos. B•

and C). See se c ti o n 2 .6 .

1

5

4

3

2

12

Page 10

2.9 Needle guard

Turn off main switch!

- Danger of injury -

When the looper point

moves to the left and

reaches the needle, the

needle point s h ou l d r e s t

against the

needle guard.

When lateral pressure is

applied to t he ne ed l e, i t

must not be po s si bl e to

press it into the path of the

looper point.

In the lowest n ee dle po sition, half of the needle eye

must remain accessible.

8

2.10 Thrust motion for the feed dog

Turn off main switch!

- Danger of injury -

To assure good stit c h t i gh te ni n g t he fe ed do g

should make a slight "additional thrust motion"

after the needle has passed its upper dead position.

The accurate adjustment is obtained in slot D using

the gauge 2 that is in the accessories bag. Proceed

as follows:

– Loosen the screws of the thrust eccentric 3.

– Lock the handwheel in slot D.

– Slide the gauge 2 into the slot 1 of the thrust

eccentric.

– Turn the thrust eccentric 3 such that the edges

of the gauge r e st o n t he s ti t ch r e gu l at or f rame 4.

– Tighten the screws of the thrust eccentric.

Make sure that th e b ot to m sh af t i s se t t i gh t.

– With maxi mu m f ee di n g l e ng th th e feed dog

must not str i k e t he ed ge s of th e t hr o at pl a te

slots.

– Loosen the sc r ew 7.

Adjust the h ei g ht of the needle guar d ac cordingly.

S

e

e

s

k

e

t

c

h

.

Tighten the screw 7.

– Loosen the screws 8.

Place the needle guard against the needle

point.

Tighten the screws 8.

The needle mu s t n ot be deflected more than is

required.

4

7

3

1

2

Attention exception!

The class 171-131110 without frame shaft, ie with

fixedly adjustable stitch lengths, is an exception as

to adjustments.

The 171-131110 can be retrofitted for the use on

hemming unit s.

Kit 171 1201 for "right-hand machines"

Kit 171 1301 fo r " l ef t- h an d m ac h i ne s"

Please note that the thrust eccentric must be

adjusted differ e nt l y on l ef t- and right-hand

machines.

"Left-hand ma c hi n e" : s l ot F

Set the firs t s cr e w s e en i n o pe r at i ng di re c ti o n o f

the thrust eccentric 3 with its lower edge onto the

upper edge of th e g au ge .

"Right-hand ma c hi n e" : s l ot D

Set the second screw seen in operating direction of

the thrust eccentric 3 with its lower edge onto the

upper edge of th e g au ge . S e e s ketch.

13

Page 11

2.11 Stroke motion for the feed dog

Turn off main switch!

- Danger of inj ury -

When the nee dl e po i nt rea c he s th e t hr o at pl a te

needle hole, the descending tooth points of the

feed dog should be level with the throat plate

surface. This position corresponds to slot D in the

adjustment disk.

– Loosen the screws of the stroke eccentric 3.

– Lock the machine in slot D.

– Turn the stroke eccentric 3 such that seen in

operating di r ection the centr e o f t he fi rs t s c rew

4 and the housing edge 2 have the position

shown in the figure. Align the gearwheel and

tighten the screws of the stroke eccentric.

– At its hi gh es t po i nt of tr a v el t he fe ed do g

should exten d 0 .8 mm above the thro at pl a te

surface.

Attention! Except of class 171-131110

"Right-hand machine": slot D

Set the first screw of the stroke eccentric 3 seen in

operating direction level with the second screw of

the thrust eccentric 1.

"Left-hand machines": slot F

Set the second screw of the stroke eccentric 3

seen in operating direction level with the first screw

of the thrust eccentric 1.

14

4 3 2 1

Page 12

2.12 Retaining spring at the looper (Only class 173-141521 with thread trimmer)

Turn off main switch!

- Danger of injury -

During the right-to-left motion of the loop er t he

needle thread l oop 1 must slide beyond the hold i ng

point 2 betwe en the retaining sp r i ng 3 a nd the

looper 4.

During the left-to-right motion of the loop er t he

needle thread l oop should be hel d at th e holding

point 2 unti l th e d es c e nd i ng ne ed l e has entered the

thread trian gl e on th e l e ft in front of the ne edle

thread loop 1.

As the needle rises to its upper position and the

looper moves to the left, the needle point should

pass the reta i ning spring at a d is ta nc e of ap pr o x .

0.5 mm.

1

To make the adjustment proceed as follows:

– Bend the retaining spring 3 so that it rests flat

against the l o op er. Make als o s ure that the

pressure is greatest in front at the holding

point 2.

– Loosen the screw 5 and shift the spring 3 to

adjust the distance of 0.5 mm.

– The pressur e of th e s p ri ng ag ai n s t t he l oo pe r

must be checked when the machine is

completed and threaded.

To do this, tilt the machine head backward and

rotate the handwheel by hand.

– Check the described stitch formation during the

right-to-left and left-to-right looper motion.

– When the ne ed l e t hread loop is not pu s he d

over the holding point 2, decrease the pressure

of the spring against the looper by bending the

spring, and when the needle thread loop is not

held by the holding point 2 until the needle

enters the thread triangle on the left in front of

the needle t hread loop 1, inc rea s e t he pr e s s ure .

4

2

5

3

2.13 Looper thread take-up cam

Turn off main switch!

- Danger of injury -

With the mach i ne l oc ked in slot E (up pe r de ad

position of the needle bar) the looper thread

take-up cam 6 s ho uld be located 5 mm ab ov e th e

carrier plate 7.

– Loosen the sc r ew s of th e l o op er t hre ad take-up

cam.

– Slide the locking pin into slot E.

– Turn the looper thr e ad ta k e-u p c a m 6

accordingly.

For measurem en ts u s e t he ga ug e 8 .

– Set the cam tight and tight en th e s c rews.

8

7

6

15

Page 13

3

4

10

5

1 4 2 13 16

14 13 12 11 9

7

6

16

9 8

18

17

Page 14

2.14 Thread trimming device

Turn off main switch!

- Danger of injury -

During the trimming process the looper thread

behind the looper and the rear thread of the needle

thread loop mu s t b e c a ug ht by t he po i nt 7 o f t he

movable knife. See sketch.

4. Mounting and end positions of the thread

trimmer

– Unscrew the screws 2 and initially remove the

movable knife.

– Position th e t hr e ad tr im mer such that the k n i fe

holder 13 fits over the ball lever 16.

Tighten the screws 1.

5 6

7

1. Removing the knife

– Unscrew th e s c re w s 2 and remove the mo v ab le

knife 4.

– Then unscrew the screws 1 and remove the

whole thre ad tri m me r ass e mb l y.

2. Manual trimming test

– Initiall y, fasten the m ova bl e k ni f e 4 by

tightenin g t he s cr ew s 2 s li g htly.

The screws 2 should be approx. located at the

centre of the elongated hole of the knife.

– Align the point 7 of the movable knife with

respect to the notch 6 of the stationary knife 5.

Tighten the screws 2 securely.

– Make a trimming test with thread.

If the thread is not trimmed properly, the edges

must be checked or new sharp knives are to be

installed.

– Set the movable knife in cut t in g position by

slightly turning in the pressure screw 3.

The smooth mo ti o n o f t he knife must be

assured.

– If necessary, align the movable knife in cutting

position with respect to the stationary knife.

3. Thread clamping sheet

The thread c l am ping sheet 10 shou l d sl i g ht l y

clamp the thread end to assure a secure seam

beginning.

If the clam ping sheet holds th e t hread too

tightly, seam pucker may occur at the seam

beginning.

– Screw the piston rod 12 into the block 11 until it

is flush with the face of the block.

– If the piston rod is moved into its right end

position, t he edge 13 of the kni fe ho l de r an d

edge 14 of the plate should be flush with each

other.

Adjust the end position of the cylinder 9

accordingly (hexagon spanner 2.5 mm) using

the self-locking set screw 8.

– As a pre-adjustment fasten the movable knife

with the screws 2 such that

a) the point 7 points to notch 6 and

b) the cutti ng ed ge s of th e k n i v es o v er l a p

approx. 1 mm.

– During sewing make a trimming test with the

shortest an d l o ng es t s ti t ch l e ng th.

– If necessary, slightly correct the position of the

point 7 so that the threads are caught securely.

5. Thread puller for the looper and needle

thread

During thread trimming the thread tensions are

opened and the thread pullers 18 for the looper

and needle thread are activated. The pulled

tension-free thread is ne ed ed fo r s ec u re s t i tc h

formation at the next seam beginning.

Just the amount of thread needed should be

pulled, as t hi s d et er m i ne s the length of the

thread end at the seam beginning.

– The thread puller 18 is stepped.

By adjusting the stopper 17, more or less

thread can be pu l l ed .

17

Page 15

1 2

3

4

3

9

7

5

1 mm

8

6

5

6

18

Page 16

2.15 Sewing foot stroke

Turn off main switch!

- Danger of injury -

The height of the sewing foot stroke depends on

the needle bar stroke of the respective class and

the needle system used.

With the needle system 934 the sewing foot stroke

is in general 5 mm, and with the needle system 933

it is in general 10 mm.

In the case of higher adjustments and a passage

for thick fabrics make sure that the needle bar or

the needle block must not strike the sewing foot.

Initially, unscrew the stop screws 1 and 2 by some

turns.

The sewing foot sole must rest on the throat plate.

To do thi s, tu r n t he ha nd wh ee l ac c o rdi n gl y.

Adjusting the foot stroke of hinged feet (top

puller feed)

– Place an object, the thickness of which

corresponds t o t he s tr o k e, be tw ee n the sewing

foot sole and throat plate.

– Loosen the sc r ew 9.

Adjust the block 5 on the cloth presser bar so

that the support sheet 4 can just be swung

unhindered under the support nose 7.

– Align the sewing foot with the needle and

tighten the s cr ew 9.

– Remove the object.

When the sewing foot rests on the throat plate,

a distance m us t be be tween the block 5 a nd th e

sleeve 6.

Adjusting the foot stroke of hinged lever feet

– Initiall y, reduce the s ew i ng fo ot pr e s sur e by

screwing the pressure sleeve 3 upwards.

– Loosen the sc r ew 9.

Lower the cl ot h presser bar unti l t he s ew i ng

foot sole re s ts f l at on th e t hr o at pl a te .

– Adjust a distance of approx. 0.5 mm between

the block 5 and the sleeve 6.

– Align the sewing foot with the needle and

tighten the s cr ew 9.

– Re-tighten the pressure sleeve 3.

Make sure that the pressure of the spring is

adjusted clearly higher than that of the hinged

lever foot.

The lowest pos i t ion of th e h i ng ed l eve r fo ot i s

thus determi n ed by t he s l ee v e 6 .

Screw in the s c rew 1 until the dis ta nce between the

angle 8 and the block 5 is approx. 1 mm. The

sewing foot sole must then rest on the throat plate.

Limit the pa th of th e k n ee l eve r bl o c k by s c re wi n g

in the screw 2. - One should just be able to swing

the support sheet 4 unhindered under the support

nose 7.

When the mac hin e i s e qu i pp ed wi t h t he pneumatic

sewing foot lift, the stroke of the cylinder 10, ie the

sewing foot st ro k e, i s to be l imi t ed by the stop

screw 11 accordingly.

10 11

19

Page 17

2.16 Setting the stitch lengths

Regular stitch lengths

If eg a stitch length of 3 mm has been adjusted at

the dial, 11 stitches on thin cardboard mu s t b e

equal to 30 mm.

Loosen the screw 3.

Insert a drift into the hole 1 and turn the frame

shaft 2 accordingly.

1 2

Condensed stitch length of the bottom feed

The minimum condensed stitch length is 1.2 mm.

While adjusting the stitch length, raise the puller.

Make condensed stitches on thin cardboard by

pressing t he bu tt on at th e m ac h i ne he ad .

11 stitches must be equa l to 12 mm.

To mak e t he ad j us t me nt , i n s er t a s cr e wd r i ver i n to

the slot 5.

Loosen the screw 6 and set the stopper 4 higher or

lower accordingly.

3

6 5 4

20

Page 18

Condensed stitch length of the top puller feed

The puller should always feed slightly more than

the bottom feed.

The material i s t hu s te ns i o ne d, th er e by preventing

seam pucker.

When the condensed stitch length of the bottom

feed is eg 1.2 mm, the feed of t he pu l l er i s t o b e

adjusted to 1.3 mm.

Lower the pulle r.

Make condensed stitches on thin cardboard by

pressing th e b ut to n a t t he s ewing head.

11 stitches must be equal to 13 mm.

Adjust the stopper 8 accordingly.

Reduce the sewing foot pressure such that thin

cardboard can j us t pa s s be tw ee n t he s ewing foot

and feed dog.

The lock nut 7 and the stopper 8 are also accessible w i th sc r ew ed on to p c o v er p l at e.

8 7

21

Page 19

3. Setting the top puller feed

Turn off main switch!

- Danger of inj ury -

3.1 Synchronisation of the bottom feed and top puller feed

The bottom feed and top puller feed should be

synchronise d. T he pu ll er m ot i on , ho we v er, must

never be completed earlier than the feed dog

motion.

Thus, the mat eri a l i s te nsi o ne d b et we en th e s e wi n g

foot and the puller so as to prevent seam pucker.

When the machine is locke d i n sl ot E an d the

grooves of the traction rod 1 and the eccentric 2

are congrue nt , t he ab ov e ad j us t me nt i s completed.

– Remove the bobbin winder cover.

– Loosen the screws of the eccentric 2 just

enough that i t c a n b e t ur n ed on th e a r m sh aft

with minimum effort.

– Insert a screwdriver into the groove 3 of the

eccentric.

– Turn the handwhee l to bri n g t he machine to the

position E.

– Tighten the scre ws o f t he ec c e nt r i c 2.

To check t. synchronisation proceed as follows:

– Set the dials for the bottom feed and top puller

feed eg at 3 mm.

– Place two thin cardboard strips under the

sewing foot an d p ul l e r s uc h th at th ei r ends are

adjacent.

– Turn the handwheel. - The distance between

the ends must not change.

– If necessary, correct the setting of t. puller dial

so as to assure synchronous feeding motions.

– Loosen th e g rad ua te d plate of the dia l an d

re-attach suc h th at 3 mm is indicate d.

3

2

1

1

2

3.2 Distance between the puller and

needle

The distance between the puller and centre of the

needle should be 30 mm.

Make sure that the automatically raising puller

does not strike the sewing foot.

To mak e t he ad j us t me nt , l o os e n t he s c rew 4.

4

6

22

30 mm

Page 20

3.3 Raising stroke of the puller

Upper end position

The raised puller must not strike the sewing foot.

Turn the bolt 8 such that its slot is vertical.

Limit the stroke of the piston in the cylinder 9

accordingly using the self-locking set screw 7.

To do this, use a 2.5-mm-Allen key.

Lower end position

After the vulcollan puller has lowered onto the

throat plate, the rocker 6 must still be able to

oscillate 2 mm, before the stopper of the hand lever

5 reaches it s en d position. The ma te r i al is thu s

slightly tensioned by the touching down puller.

Loosen the loc k n ut 10 an d turn the thread ed pi n 11

accordingly.

Attention!

Steel pullers must not rest on the throat plate. The

distance bet w e en th e p ul l e r an d p l at e s h ou l d b e

approx. 0.2 mm.

3.4 Puller pressure

The puller pressure can be modified by adjusting

the lever arm for the cylind er f orc e an d c a n t hu s be

adjusted to the respective ma te r ial .

Loosen the sc r ew 13 . C y l i nd er i n

arrow-indicated direction A = higher pressure

arrow-indicated direction B = lower pressure

5

4

7

8

9

10

11

12

3.5 Fabric keep-off plate

The distance between the puller and the fabric

keep-off plate 12 should be as small as possible.

To prevent the material from getting caught in this

gap, the dist a nce needs to be corre c te d d ep en di n g

on the abrasi on of th e p ul l e r.

On machines without thread trimmer the fabric

keep-off plate at the same time serves as trimming

knife for the thread chain.

3.6 Timing belt tension

The timing belts should be tensioned so as to

assure the accurate transmission of the step

lengths of the puller.

A too great belt tension may result in excessive

wear and tear and malfunctioning.

13

B

A

23

Page 21

3.7 Replacing the puller

The following pullers are available for the diverse applications:

Vulcollan puller 9-mm-wide standard on the machine Order no. 933 5725

Vulcollan puller 16-mm-wide asymmetric Order no. 933 5737a

(in the acce ss or ies bag)

Steel puller 9-mm-wide 1-mm-roof-toothed Order no. 933 5736

Steel pull er 1 5-m m- w i de 1-m m-r o of - to ot he d Order no. 93 3 5 73 7

Steel pull er 1 5-m m- w i de 2-m m-s a w- t oo th ed Or d er n o. 93 3 5 73 8a

The asymmetric vulcollan puller that is in the

accessories bag enables to vary the position of the

puller with respect to the seam or fabric fold.

This puller i s to be used on tw in- n ee dl e ma c hi n es.

To rep l ace the puller pro c ee d a s fo l lows:

– Remove th e n ut 14 us i n g a 7-mm-fork spanne r.

(Attention l/h thre ad!) A t th e s ame ti m e hol d the

other end of t he ax le 15 by means of a

screw-driver.

– Steel pullers must not touch the throat plate.

The distance should be 0.2 mm. Therefore,

correct the " Lo w e r en d p os i t i on " of th e p ul l e r as

described in section 3.3 accordingly.

14

15

24

Page 22

3.8 Raising and lowering functions of the puller

Various functions for the puller can be selected at

the Efka V730 c on tr o l pa ne l .

This is done in the parameter F190 / code no.

FFF 001 to 003, preferably according to subclasses

for machines w i th or without thread tr immer. 003

does not contain any functions for double

chainstitc h ma chi n es .

001 preferabl y f or t op puller feed wi thout thread

trimmer with the following functions:

1. At the seam end the puller always remains

lowered to h old the thread chai n.

The thread chain is trimmed by the trimming

knife of the fa bri c k e ep -off pl a te.

2. When the sew i ng fo ot i s l i ft ed wit hi n th e s e am

the puller is raised as well.

3. When sewing is continued, the puller lowers

either immediately or after a delay, depending

on the entere d n um be r of stitches. The

numbers of st i tc h es 0-254 are set in pa r am et er

F191.

3. The puller lo wers at the seam beginning and af ter the sewing foot lift within the seam after the

number of sti tc h es b et we en 0 and 254 entered

in parameter F191 has been sewn.

4. The puller ca n b e r a is ed or lo we r ed wit hi n or

outside the seam at the touch of a button at the

sewing head .

For programming proceed as follows:

1. Hold the key P pressed.

2. Turn on main switc h . - Th e c o de no . C 0000 is

displayed.

3. To enter the "technician level 1" input the Efka

code no. 1907 usi n g the keys 1.... 0.

4. Press key E . - Th e p ar a me te r no . F 10 0 i s

displayed.

4. The puller ca n b e r ai s ed or l o we red wit hi n th e

seam at the touch of a button at the sewing

head.

002 preferabl y f or t op puller feed wi th thread

trimmer with the following functions:

1. After thre ad tr i m mi n g t he pu l l er i s ra i s ed

automatical ly.

2. When the sew i ng fo ot i s l i ft ed wit hi n th e s e am

and the threads are trimmed within the

material, the puller is raised.

5. Enter the parameter no. 190 using the keys

1...0.

6. Press key E. FFF 001, FFF 002 or FFF 003 is

displayed. O ne of th e c o de nu mb er s c a n b e

selected using the + or - key.

7. Press key P twi c e .- Th en th e ad j us t me nt is

completed.

8. Attention! Always sew a seam with thread

trimming or s ewing foot lift . O n l y then the

entered adjus t me nt i s me mo r iz ed .

25

Page 23

4. Adjusting the synchronizer

Prior to the adjustment check whether the

synchronizer is properly fastened on the

handwheel flange.

When the machi n e i s lo ck ed in sl o t A , th e ma rk 11

should be located exactly opposite the groove 12.

This is pos i ti o n 0 , w hi c h i s the starting po int that all

factory se tt i ng s of machine positions depend on .

The machine positions are registered by the

synchroniz e r in s t ep s ( inc r e me nt s ) of 0.7° and are

displayed.

One complete revolution is subdivided into 512

steps (incr e me nt s ).

st

1

position

The machine should stop when the looper has

safely picked up the loop that is, the needle should

rise from its lower dead position until the looper

point has moved to the left by approx. 3 mm

beyond the needle.

This corresponds to the number of increments 214.

101110

12

8

9

7

nd

2

position

Needle bar i n i t s up pe r de ad po s i tio n.

This corresponds to the slot E of the adjustment

disk or the nu mb er o f in c r em en ts 3 84 .

For programming proceed as follows:

1. Hold the key P pressed.

2. Turn on main switc h. - Co de no . C 00 00 i s

displayed.

3. To enter the "technician level 1" input the Efka

code no. 1907 using the keys 1....0.

4. Press key E.- The parameter no. F 100 is

displayed.

5. Enter the p ar a me te r no . F 170 using the k eys

1....0. Press key E.- Service routine 1 (Sr1)

appears. Press key F.- Position 0 is displayed.

6. Turn the handwheel by one complete revolution

in operating direction and lock in position A

using the enclosed timing pin. Press key P

twice.

7. Press key P.- F 170 is displayed.

8. Press key E twice.- The servie routine 2 (Sr2)

and F 171 are displayed.

9. Press key F. - Position 1 and the set number of

increments a re d i s pl a yed. Set the numb er o f

increments 2 14 usi n g the + or - key.

10. Press key E.- Position 2 and the set number of

increments are displayed. Set the number of

increments 384 using the + or - key.

11. Press key P twice. - Now the adjustment is

completed.

12. Attention! Always sew a seam with thread

trimming or s ewing foot lift . O n l y then an

entered adjus t me nt i s de fi n i te l y me morized. If

no seam is sewn , t he ad j ust me nt i s los t wh en

the main switch is turned off.

26

Loading...

Loading...