Page 1

American DJ®

Accu Roller 250™

Table of Contents

Unpacking......................................................................3

Introduction....................................................................3

Customer Support......................................................................3

Safety Precautions......................................................................4

Handling Precautions..................................................................5

Discharge Lamp Warnings..........................................................5

Registration......................................................................6

Features.........................................................................6

Controls and Functions..............................................................7

Set-Up.............................................................................10

System Menu............................................................................13

Editing Program.........................................................................25

Operating Modes.......................................................................30

Fuse and Lamp Replacement...................................................32

DMX Traits.................................................................................34

Gobos..................................................................................35

Gobo Replacement...................................................................37

Cleaning..................................................................38

Trouble Shooting.......................................................................38

Warran ty....................... ..... ............................. ..... ...39

Specifications....................................................................40

Rev. 11/04

User Instructions

4295 Charter Street

Los Angeles CA. 90058

www.americandj.com

American DJ®

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 2

Page 2

Accu Roller 250™ General Information

Accu Roller 250™ Safety Precautions

Unpacking: Thank you for purchasing the Accu Roller 250™ by Amer-

ican DJ®. Every Accu Roller 250™ has been thoroughly tested and has

been shipped in perfect operating condition. Carefully check the shipping carton for damage that may have occurred during shipping. If the

carton appears to be damaged, carefully inspect your fixture for any

damage and be sure all equipment necessary to operate the unit has

arrived intact. In the event damage has been found or parts are missing, please contact our toll free customer support number for further

instructions. Please do not return this unit to your dealer without contacting customer support first.

Introduction: The Accu Roller 250™ is a eight channel, intelligent

DMX barrel scanner. The fixture can operate in three different operating modes; stand alone, sound

tion. The Accu Roller 250™ comes with several built in programs and

is best used in multiples of four. When used as a stand alone unit or

when used in multiples linked in a master/slave configuration. For best

results use fog or special effects smoke to enhance the beams projections.

During the initial start-up or use of this product a light smoke or

smell may arise from the unit. This is a normal process and is

cause by the heat associated with the lamp.

-active, or in a Master/Slave configura-

Customer Support: American DJ® provides a toll free customer

support line, to provide help and to answer any question should you

encounter problems during your set up or initial operation. You may

also visit us on the web at www.americandj.com for any comments or

suggestions. Service Hours are Monday through Friday 9:00 a.m. to 5:

00 p.m. Pacific Standard Time.

Voice: (800) 322-6337

Fax: (323) 582-2610

E-mail: support@americandj.com

To purchase parts online visit http://parts.americandj.com

Warning! To prevent or reduce the risk of electrical shock or fire, do

not expose this unit to rain or moisture.

Warning! This may cause severe eye damage. Avoid looking directly

into the light source at all times!

For Your Own Personal Safety, Please Read and Understand This

Manual Completely Before You Attempt To Install Or Operate

This Unit!

• To reduce the risk of electrical shock or fire, do not expose this unit

rain or moisture

• Do not spill water or other liquids into or on to your unit.

• Be sure that the local power outlet match that of the required volt age for your unit.

• Do not attempt to operate this unit if the power cord has been

frayed or broken.

• Do not attempt to remove or break off the ground prong from

the electrical cord. This prong is used to reduce the risk of electrical

shock and fire in case of an internal short.

• Disconnect from main power before making any type of connection.

• Do not remove the cover under any conditions. There are no user

serviceable parts inside.

• Never operate this unit when it’s cover is removed.

• Always be sure to mount this unit in an area that will allow proper

ventilation. Allow about 6” (15cm) between this device and a wall.

• Do not attempt to operate this unit, if it becomes damaged.

• This unit is intended for indoor use only, use of this product out doors voids all warranties.

• Always mount this unit in safe and stable matter.

• Power-supply cords should be routed so that they are not likely to

be walked on or pinched by items placed upon or against them,

paying particular attention to cords at plugs, convenience recep tacles, and the point where they exit from the appliance.

• Cleaning -The fixture should be cleaned only as recommended by

the manufacturer. See page 38 for cleaning details.

• Heat -This fixture should be situated away from heat sources such

as radiators, heat registers, stoves, or other appliances (including

amplifiers) that produce heat.

• The fixture should be serviced by qualified service personnel when:

A. Objects have fallen, or liquid has been spilled into the appliance.

B. The appliance has been exposed to rain or water.

C. The appliance does not appear to operate normally or exhibits a

marked change in performance.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 4American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 3

Page 3

Accu Roller 250™ Handling Precautions

Accu Roller 250™ General Instructions

Caution! There are no user serviceable parts inside this unit. Do not

attempt any repairs yourself, doing so will void your manufactures

warranty. In the unlikely event your unit may require service please

contact American DJ®.

During operation the housing may become extremely hot. Avoid

touching the unit with bare hands while in use.

American DJ

caused by the non-observance of this manual or any unauthorized

modification to this unit.

Accu Roller 250™ Discharge Lamp Warning

This unit emits intense UV radiation which is harmful to the eyes and

skin. The intense luminance of the lamp can cause severe damage

to the retina. Never operate this unit without it’s covers, these covers

have been specially designed to shield against UV radiation.

Epileptic Warning: Those suffering from epilepsy should avoid looking

directly into the lamp at all times.

Avoid switching the fixture on and off repeatedly in short intervals as

this will reduce lamp life and intensity.

To achieve the intensity associated with discharge lamps, these lamps

use gas sealed in a high pressure environment to emit a brilliant output.

Due to the high pressure involved with the construction of the lamp,

the lamp may explode during prolonged extensive use. This risk is

increased with age, added care is encouraged when dealing with older

lamps. Extreme caution should be used when operating this or any

fixture fitted with a gas discharge lamp. Never open this unit while in

use.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 5

® will not accept any liability for any resulting damages

This fixture is fitted with a discharge lamp which

is highly susceptible to damage if improperly

handled. Never touch the lamp with your bare fin

gers as the oil from your hands will shorten lamp

life. Also, never move the fixture until the lamps

have had ample time to cool. Remember, lamps

are not covered under warranty conditions.

To optimize the performance of this product, please read these operating

instructions carefully to familiarize yourself with the basic operations of

this unit. These instructions contain important safety information regarding the use and maintenance of this unit. Please keep this manual with

the unit, for future reference.

Accu Roller 250™ Product

Registration

The Accu Roller 250™ carries a one year limited warranty. Please fill

out the enclosed warranty card to validate your purchase. All returned

service items whether under warranty or not, must be freight pre-paid

and accompany a return authorization (R.A.) number. The R.A. number

must be clearly written on the outside of the return package. A brief

description of the problem as well as the R.A. number must also be

written down on a piece of paper and included in the shipping carton.

If the unit is under warranty, you must provide a copy of your proof of

-

purchase invoice. You may obtain a R.A. number by contacting our

customer support team on our toll free customer support number. All

packages returned to the service department not displaying a R.A.

number on the outside of the package will be returned to the shipper

at the shippers cost.

Accu Roller 250™ Features

• Micro-Stepping Motors for Smooth Color and Gobo Transitions

• DMX-512 Protocol Compatible (Uses Eight DMX Channels)

• Independent Gobo and Color Wheels

• 7 Rotating Gobos w/ Shake, 1 Dichroic and 1 beveled gobo +

Spot - All Replaceable

• 9 Colors, Plus White - With Rainbow

• 3 Operating Modes - Master/Slave; Stand Alone; Sound Active

• Internal Microphone

• ZB-MSD250 Discharge Lamp, 250w 2000 Hours

• Edit and Save Scenes into the Memory

• Manual Focus Lens

• Variable Strobe (1-12 fps)

• 156˚ Pan Movement

• 45˚ Tilt Movement

• Digital Display for Address and Function Setting

• Mini/C Input Jack for Blackout Function

(Mini/C Controller Not Included)

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 6

Page 4

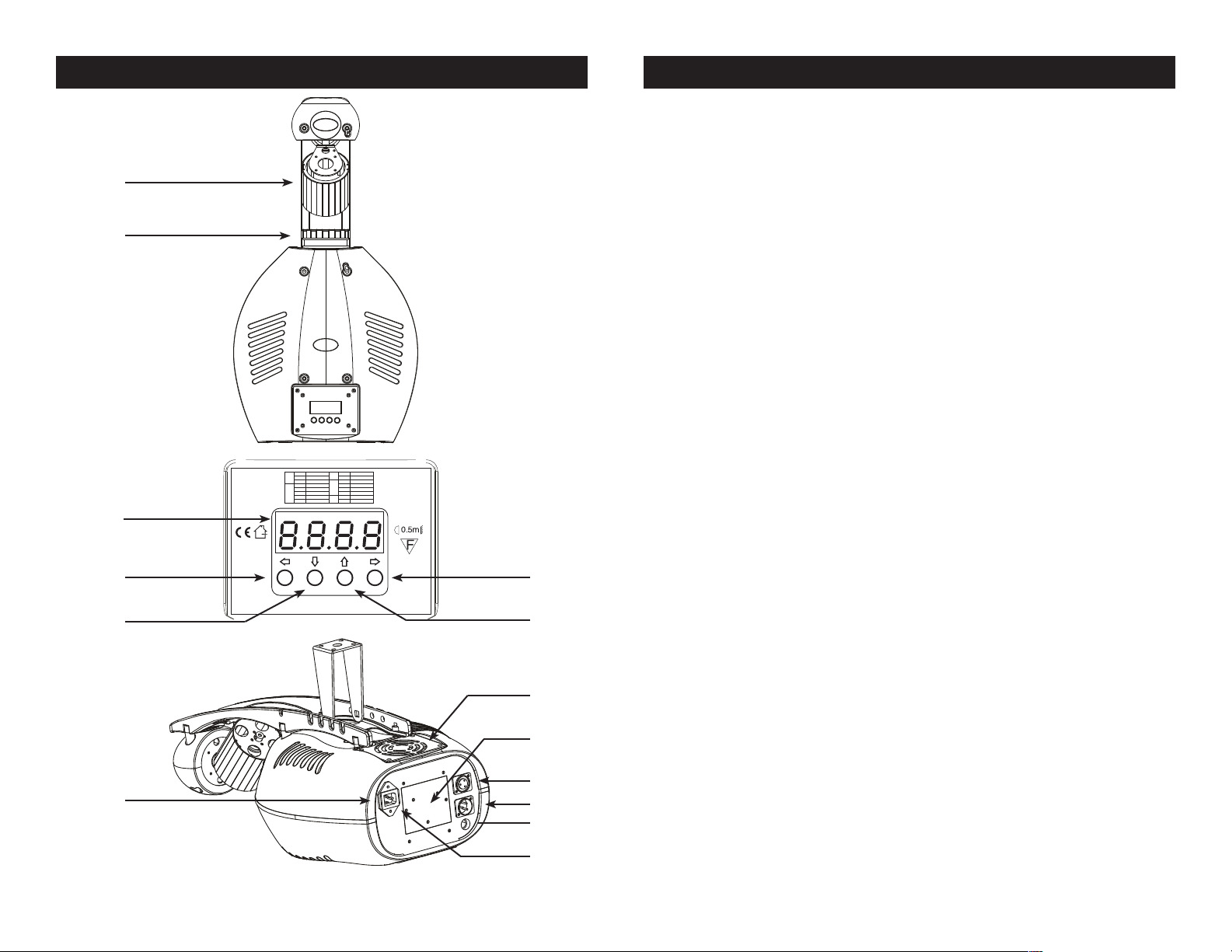

Accu Roller 250™ Controls and Functions Accu Roller 250™ Controls and Functions

MODE/ENTER DOWN UP EXIT

1. Barrel Mirror - This is a highly reflective surface mirror specifically

designed to optimize and enhance beam output. Never use glass

cleaner that contain ammonia to clean the surface of the mirror (such

as Windex).

1

2

3

2. Lens Assembly - This high quality lens is a fully focusing. Focus

the lens by manually turning the lens in a clockwise or counter-clockwise direction until the desired effect is achieved.

3. Digital Display - This display shows the menu and operating functions that you can choose from.

4. Mode/Enter Button - This button is used to select and confirm a

function when working in the system menu. It is also used to exit certain menus.

5. Down Button - This button is used to scroll backwards when navigating through the system menu.

6. Fuse Holder - This housing stores a 8 amp (4 amp 220v) GMA protective fuse. Never defeat the fuse, the fuse is designed to protect the

electronics in the event of severe power fluctuations. Always be sure

to replace the fuse with an exact match as the one being replaced,

unless otherwise told to do so by an authorized American DJ® service

technician.

4

5

6

14

13

12

11

10

9

8

7

7. Power Cord Inlet - This unit is equipped with a removable I.E.C.

power cord. Be sure to only use the power cord included with the

unit, this cord is designed to match the electrical requirements of the

unit. Other cords may cause the unit to overheat or malfunction. Voltage may vary from venue to venue, when connecting this unit to a

power supply be sure to connect to a matching power outlet. Never

use this fixture if the ground prong has been removed or broken off.

The ground prong is designed to reduce the risk of fire or electrical

shock in the event the unit suffers from an internal short.

8. MINI/C Controller Jack - This jack is for use with the optional

MINI/C controller only. This controller is used to control the blackout

function. Do not attempt to connect an audio signal to this jack, this

will damage the PC board and void your manufactures warranty!

9. XLR DMX Input Jack - This jack is used to receive an incoming

DMX signal or Master/Slave signal.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 8American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 7

Page 5

Accu Roller 250™ Controls and Functions

10. XLR Output Jack - This jack is used to transmit the incoming

DMX signal to another DMX fixture, or transmit a Master/Slave signal

to the next Accu Roller 250™ in the chain. For best results in DMX or

Master/Slave mode terminate this jack if it is the last unit in the chain.

See “Terminator” on page 11.

11. Lamp Assembly and Access Plate

- This plate accesses the lamp

socket assembly. The unit includes a spring mounted ZB-MSD250

250w discharge lamp. Be sure to only replace with same type lamp.

After replacing a lamp be sure the lamp is centered in the reflector. See

page 32 for details on installing and optimizing replacement lamps.

Never operate this unit with the lamp exposed, this lamp emits strong

UV radiation.

12

. Cooling Fan - This unit is equipped with three high velocity vari-

able fans to aid in the cooling process. These fans are designed to

vary their velocity at different operating temperatures, to provide

better cooling when the unit reached higher operating temperatures

associated with long usage. Be sure to never obstruct the cooling fans

during normal usage. Also, be sure to keep the vents clean at all times.

A blocked or malfunctioning cooling system may shorten lamp life and

unit reliability.

13. Up Button

- This button is used to scroll forward when navigating

through the system menu.

14. Exit Button

- This button is used to exit menus and to scroll back-

wards through certain menus only.

Accu Roller 250™ Set Up

Power Supply: Before plugging your unit in, be sure the source volt-

age in your area matches the required voltage for your American DJ®

™

Accu Roller 250.™ The American DJ® Accu Roller 250

is available in

a 120v and 220v version. Because line voltage may vary from venue

to venue, you should be sure your unit voltage matches the wall outlet

voltage before attempting to operate you fixture. Also be sure to only

use the included I.E.C. power cable supplied with the unit, this cable

matches the voltage and current requirements of the unit.

DMX-512: DMX is short for Digital Multiplex. This is a universal pro-

tocol used by most lighting and controller manufactures as a form of

communication between intelligent fixtures and controllers. A DMX

controller sends DMX data instructions from the controller to the fix

ture. DMX data is sent as serial data that travels from fixture to fixture

via the DATA “IN” and DATA “OUT” XLR terminals located on all DMX

fixtures (most controllers only have a DATA “OUT” terminal).

DMX Linking: DMX is a language allowing all makes and models

of different manufactures to be linked together and operate from a

single controller, as long as all fixtures and the controller are DMX

compliant.

several DMX fixtures try to use the shortest cable path possible. The

order in which fixtures are connected in a DMX line does not influence

the DMX addressing. For example; a fixture assigned a DMX address

of 1 may be placed anywhere in a DMX line, at the beginning, at the

end, or anywhere in the middle. Therefore, the first fixture controlled

by the controller could be the last fixture in the chain. When a fixture

is assigned a DMX address of 1, the DMX controller knows to send

DATA assigned to address 1 to that unit, no matter where it is located

in the DMX chain.

To ensure proper DMX data transmission, when using

-

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 9

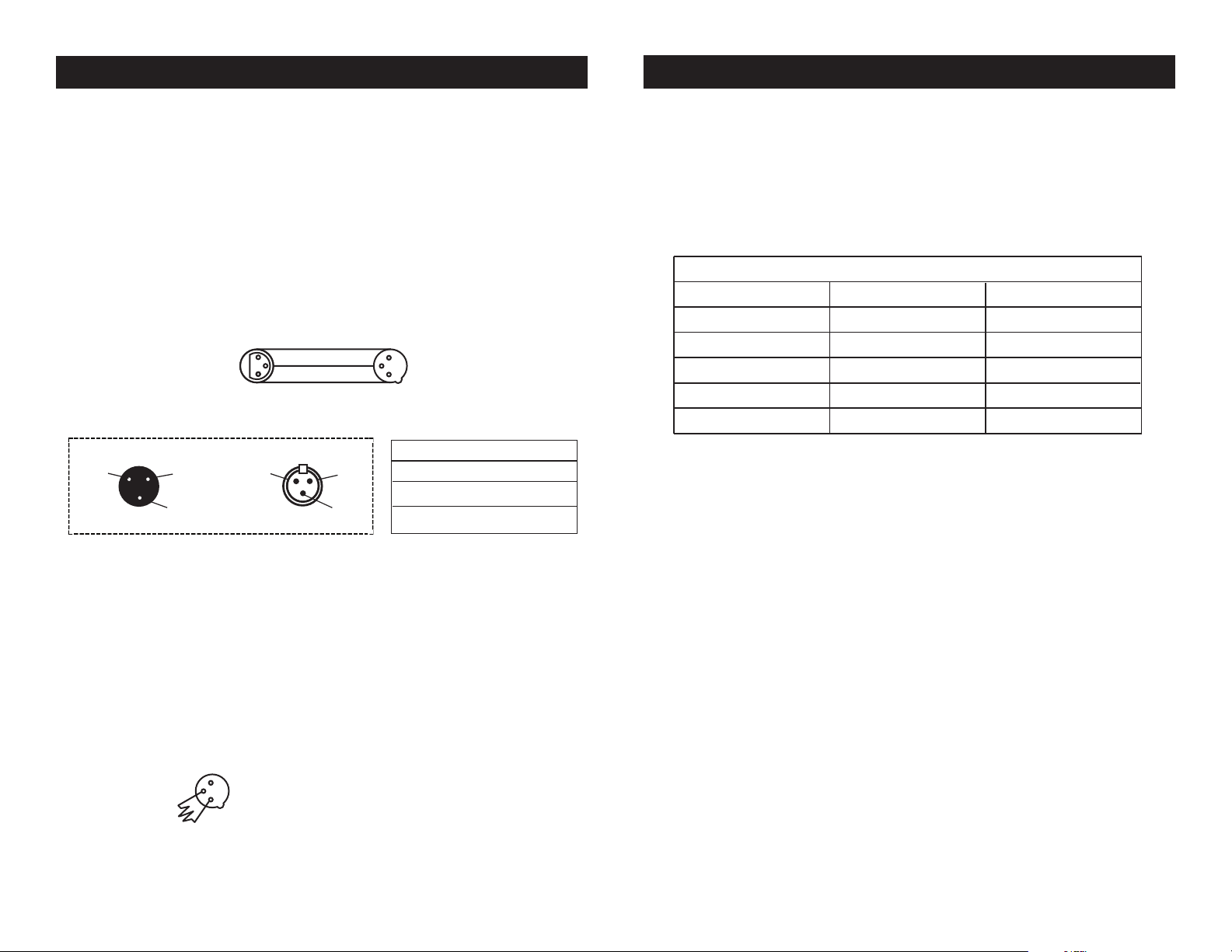

Data Cable (DMX Cable) Requirements (For DMX

and Master/Slave Operation):

The Accu Roller

250™ can be controlled via DMX-512 protocol.

The Accu Roller 250™ is a eight channel DMX unit.

The DMX address is set electronically using the

controls on the side panel of the unit. Your unit and

your DMX controller require a standard 3-pin XLR

connector for data input and data output (Figure

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 10

Figure 1

Page 6

Accu Roller 250™ Set Up

DMX512 IN

3-PIN XLR

REMOTE

CONTROL

INPUT

POWER

INPUT OUTPUT

SOUND

REMOTE

CONTRO

L

INPU

T

POWER

INPUT OUTPUT

SOUND

REMOTE

CONTRO

L

INPU

T

POWER

INPUT OUTPUT

DMX512

DMX+,DMX-,COMMON

1

2

3

Terminatio n re duces signal errors and

avo ids signal tran smis sion problem s

and interference. It is always advisable

to connect a DMX terminal, (Resistance

120 Ohm 1/4 W) between PIN 2 (DMX-)

and PIN 3 (DMX +) of the l ast fixture.

1

2

3

1

2

3

DMX +

DMX -

COMMON

DMX512 OUT

3-PIN XLR

POWER

SOUND

REMOTE

CONTRO

L

INPU

T

POWER

INPUT OUTPUT

1

2

3

Terminatio n re duces signal errors and

avo ids signal tran smis sion problem s

and interference. It is always advisable

to connect a DMX terminal, (Resistance

120 Ohm 1/4 W) between PIN 2 (DMX-)

and PIN 3 (DMX +) of the l ast fixture.

Accu Roller 250™ Set Up

1). If you are making your own cables, be sure to use standard two

conductor shielded cable (This cable may be purchased at almost all

professional sound and lighting stores). Your cables should be made

with a male and female XLR connector on either end of the cable. Also

remember that DMX cable must be daisy chained and cannot be split.

Notice: Be sure to follow figures two and three when making your own

cables. Do not use the ground lug on the XLR connector. Do not connect the cable’s shield conductor to the ground lug or allow the shield

conductor to come in contact with the XLR’s outer casing. Grounding

the shield could cause a short circuit and erratic behavior.

Figure 2

XLR Male Socket

1 Ground

Figure 3

2 Cold

3 Hot

XLR Female Socket

2 Cold

1 Ground

3 Hot

XLR Pin Configuration

Pin 1 = Ground

Pin 2 = Data Compliment (negative)

Pin 3 = Data True (positive)

5-Pin XLR DMX Connectors.

Some manufactures use 5-pin XLR

connectors for DATA transmission in place of 3-pin. 5-pin XLR fixtures

may be implemented in a 3-pin XLR DMX line. When inserting standard 5-pin XLR connectors in to a 3-pin line a cable adaptor must be

used, these adaptors are readily available at most electric stores. The

chart below details a proper cable conversion.

3-Pin XLR to 5-Pin XLR Conversion

Conductor 5-Pin XLR Male (In)3-Pin XLR Female (Out)

Ground/Shield

Data Compliment (- signal)

Data True (+ signal)

Not Used

Not Used

Pin 1

Pin 2

Pin 3

Pin 1

Pin 2

Pin 3

Pin 4 - Do Not Use

Pin 5 - Do Not Use

Special Note: Line Termination.

used, you may need to use a terminator on the last unit to avoid erratic

behavior. A terminator is a 90-120 ohm 1/4 watt resistor which is connected between pins 2 and 3 of a male XLR connector (DATA + and

DATA -). This unit is inserted in the female XLR connector of the last

unit in your daisy chain to terminate the line. Using a cable terminator

(ADJ part number Z-DMX/T) will decrease the possibilities of erratic

behavior.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 11

When longer runs of cable are

Figure 4

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 12

Page 7

Accu Roller 250™ System Menu

Accu Roller 250™ System Menu

ADDRESS MENU -

AOO1 - A511 (Value) - This is where you set the DMX address of

the unit.

TEST MENU -

T-01 - T-XX (Test) - Tests the functions of each channel. There

are eight channels, but only channels 1,2,3,4, and 6 can be

tested.

AUDI MENU -

MAST (Master) - Runs the unit as master in sound active mode.

ALON (Alone) - Runs the unit stand alone, sound active mode.

RESE (RESET) MENU -

ALL - Resets all the motors in the unit.

SCAN - Resets the motors that control pan/tilt.

COLR (Color) - Resets the color motors.

ADDR A001~A511 Indicate the staring DMX address

A001 also is the setting for slave

TEST T-01~T-XX Automatically test the function

AUDI MSTR Runs fixture as “master” for audio

ALON Runs fixture as “alone” for audio

RESE ALL ON/OFF Reset all motors and returns fixture to home

SCAN ON/OFF Reset only motors for pan/tilt

COLR ON/OFF Reset only motors for colors

GOBO ON/OFF Reset only motors for gobo and rotation

SHTR ON/OFF Reset only motors for shutter and/or dimmer

TIME LIFE 0000~9999 Displays the total fixture running time

LAMP 0000~9999 Displays a lamps running time

CLMP ON/OFF Clear lamp running time

RPAN ON/OFF Reverses the pan movements

RTLT ON/OFF Reverses the tilt movements

DISP VALU D–XX D-00 (DXXX) Display the DMX512 value of each channel

D ON ON/OFF Display on/off

FLIP ON/OFF This function will reverse the display 180

SPEC SPOT ON/OFF Lamp optimization

DFSE ON/OFF Resets all the fixture functions to default

VER V1.0~V9.9 Software version

EDIT RUN ON/OFF Run your desired program

STEP S–01 ~ S–48 Set the amount of steps in your program

SCXX SC01 - SC30 Scenes that can be edited in your program

C–01 - C-08 01-08 XX(00~FFH) Fixture DMX channel

TIME T – XX(01~FFH) Time of each scene

CEDT ON/OFF Controller Editing

GOBO - Resets the gobo motors.

SHTR - Resets the shutter motors.

TIME MENU -

LIFE - Displays the fixtures total running time.

LAMP - Displays the lamp running time.

CLMP - Clears the lamp running time.

RPAN (RE

VERSE PAN) MENU -

ON/OFF - When “On” is chosen it will reverse the pan.

RTILT (REVE

RSE TILT) MENU -

ON/OFF - When “On” is chosen it will reverse the tilt.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 14American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 13

Page 8

Accu Roller 250™ System Menu

Accu Roller 250™ System Menu

DISPLAY MENU -

VALU (DMX-512 Value) - Display the DMX-512 value of each

channel.

D ON (Display On) - Turns digital display on and off.

FLIP - “Flips” the digital display 180º.

SPEC MENU -

SPOT - This provides a spot beam for better lamp optimization.

REST (Reset) - Resets the unit to default.

VER (Version) - Software version 2.2

EDIT MENU -

RUN - This will run your own custom program.

STEP (S-01 - S-48) - These are the steps slots that you write

your programs into. There are at total of 48 steps. See edit program, page 27.

SCXX (SC01 - SC30) - These are the scenes that are stored in

your program. There are a total of 30 scenes.

C-01 - C-08 (Channel 1 - Channel 08) - The channels of each

scene that can be edited. See page 27.

TIME (Time) - Running time of the entire program. See page 27.

On-Board System Menu.

easy to navigate system menu. This next section will detail the functions of each command in the system menu.

Enter Button -

button (4) on the front of the unit. Press this button to activate the

system menu. Tap the UP button (13) until you reach function you wish

to change. When you reach the function you wish to change tap the

MODE/ENTER button. When a function is selected the menu will begin

to flash, use the UP button to change the function. Once your changes

are made tap the MODE/ENTER button again to lock the change in the

system. To exit without making any changes tap the EXIT button (14).

To access the main menu locate the MODE/ENTER

The Accu Roller 250™ comes with an

ADDR MAIN MENU -

ADDR DMX Address Setting via control board -

1. Access the main menu.

2. Tap the UP button until “ADDR” is displayed, press ENTER.

4. Now the display will show “A001”. Adjust the DMX address

by pressing the UP or DOWN buttons.

5. Press MODE/ENTER to confirm.

6. Press the EXIT button to return to the main menu.

When the display is on “A001”, you can directly press the UP

or DN buttons to change the DMX start address.

CEDT - Edit program using a external controller. See page 29.

TEST MAIN MENU -

TEST - This will test the functions of each channel.

1. Access the main menu.

2. Tap the UP button until “TEST” is displayed, press ENTER.

3. The display will show “T-01”. You can now press the up

button and test the different channels. For example: If you

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 16American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 15

Page 9

Accu Roller 250™ System Menu

Accu Roller 250™ System Menu

press the up button until “T-03” is displayed, the unit will test

the color channel, changing the color one by one and show the

rainbow effect with different speeds. There are eight channels,

but only channels 1,2,3,4, and 6 can be tested.

5. Press MODE/ENTER or EXIT to exit.

AUDI MAIN MENU -

MSTR Define the unit as the master, in master/slave mode-

1. Access the main menu.

2. Tap the UP button until “AUDI” is displayed, press MODE/

ENTER.

3. Tap the UP button until “MSTR” is displayed, press MODE/

ENTER.

4. Press EXIT to return to the main menu.

ALON Define the unit as a slave, in master/slave mode -

1. Access the main menu.

2. Tap the UP button until “NODE” is displayed, press ENTER.

3. Tap the UP button until “ALON” is displayed, press MODE/

ENTER to confirm.

4. Press EXIT to return to the main menu.

2. Tap the UP button until “

ENTER.

3. Tap the UP button until “ALL” is displayed, press MODE/

ENTER.

4. The display will show “ON/OFF”. Press the UP button to

select “ON” to reset the color motor. 5. Press MODE/ENTER to

confirm.

6. Press EXIT/DN to return to the main menu.

RESE” is displayed, press MODE/

SCAN - When you activate this reset function, the fixture

will only reset the pan/tilt motor.

1. Access the main menu.

2. Tap the UP button until “RESE” is displayed, press MODE/

ENTER.

3. Tap the UP button until “SCAN” is displayed, press MODE/

ENTER to confirm.

4. The display will show “ON/OFF”. Press the UP button to

select “ON” to reset the pan/tilt motor. Press MODE/ENTER to

confirm.

5. Press EXIT/DN to return to the main menu.

COLR - When you activate this reset function, the fixture

will only reset the color wheel motor.

1. Access the main menu.

RESE MAIN MENU -

ALL - When you activate the reset function, the fixture will

begin the reset motion.

1. Access the main menu.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 17

2. Tap the UP button until “RESE” is displayed, press MODE/

ENTER.

3. Tap the UP button until “COLR” is displayed, press MODE/

ENTER to confirm.

4. The display will show “ON/OFF”. Press the UP button to

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 18

Page 10

Accu Roller 250™ System Menu Accu Roller 250™ System Menu

select “ON” to reset the color motor. Press MODE/ENTER to

confirm.

5. Press EXIT/DN to return to the main menu.

GOBO - When you activate this reset function, the fixture

will only reset the gobo wheel motor.

1. Access the main menu.

2. Tap the UP button until “RESE” is displayed, press MODE/

ENTER.

3. Tap the UP button until “GOBO” is displayed, press MODE/

ENTER to confirm.

4. The display will show “ON/OFF”. Press the UP button to

select “ON” to reset the gobo motor. Press MODE/ENTER to

confirm.

5. Press EXIT/DN to return to the main menu.

SHTR - When you activate this reset function, the fixture

will only reset the shutter/dimmer motor.

LIFE - With this function you can display the total running

time of the unit.

1. Access the main menu.

2. Tap the UP button until “TIME” is displayed, press MODE/

ENTER.

3. Tap the UP button until “LIFE” is displayed, press MODE/

ENTER.

4. Press EXIT to return to the main menu.

LAMP - With this function you can display the running time

of the lamp.

1. Access the main menu.

2. Tap the UP button until “TIME” is displayed, press MODE/

ENTER.

3. Tap the UP button until “LAMP” is displayed, press MODE/

ENTER.

4. Press EXIT to return to the main menu.

1. Access the main menu.

2. Tap the UP button until “RESE” is displayed, press MODE/

ENTER.

3. Tap the UP button until “SHTR” is displayed, press MODE/

ENTER to confirm.

4. The display will show “ON/OFF”. Press the UP button to

select “ON” to restart the shutter/dimmer motor. Press MODE/

ENTER to confirm.

5. Press EXIT/DN to return to the main menu.

TIME MAIN MENU -

CLMP - With this function you can clear the running time of

the lamp. Note Very Important: Please clear the lamp time

every time you replace the lamp.

1. Access the main menu.

2. Tap the UP button until “TIME” is displayed, press MODE/

ENTER.

3. Tap the UP button until “CLMP” is displayed, press MODE/

ENTER.

4. Press MODE/ ENTER, the display will show “ON/OFF”.

5. Press the UP button to select “ON” to activate this function,

or “OFF” to deactivate this function.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 20American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 19

Page 11

Accu Roller 250™ System Menu Accu Roller 250™ System Menu

6. Press MODE/ENTER to confirm.

7. Press EXIT/DN to return to the main menu.

RPAN MAIN MENU -

RPAN - The movement of the Pan will be reversed.

1. Access the main menu.

2. Tap the UP button until “RPAN” is displayed, press MODE/

ENTER.

4. The display will show “ON/OFF”.

5. Press the UP button to select “ON” to activate this function,

or “OFF” to deactivate this function.

6. Press MODE/ENTER to confirm.

7. Press EXIT to return to the main menu.

RTILT MAIN MENU -

DISP MAIN MENU -

VALU Display the DMX-512 value of each channel -

1. Access the main menu.

2. Tap the UP button until “DISP” is displayed, press MODE/

ENTER.

3. Tap the UP button until “VALU” is displayed, press MODE/

ENTER.

4. “VALU” should now be displayed, press MODE/ENTER.

5. The display should show “D-00”. Press the UP button in

order to select the desired channel. If you select “D-05” the

display will only show the DMX value of the 5th channel

6. Press MODE/ENTER to confirm.

7. Press EXIT to return to the main menu.

Now the display will change as per the 5th channel DMX

value.

RTILT - The movement of the Tilt will be reversed.

1. Access the main menu.

3. Tap the UP button until “RTILT” is displayed, press MODE/

ENTER.

4. The display will show “ON/OFF”.

5. Press the UP button to select “ON” to activate this function,

or “OFF” to deactivate this function.

6. Press MODE/ENTER to confirm.

7. Press EXIT to return to the main menu.

D ON Turns the digital display on and off.

1. Access the main menu.

2. Tap the UP button until “NODE” is displayed, press MODE/

ENTER.

3. Tap the UP button until “DISP” is displayed, press MODE/

ENTER.

4. Tap the UP button until “D-ON” is displayed, press MODE/

ENTER.

5. The display will show “ON/OFF”. Press the UP button to

select “ON” to activate this function, or “OFF” to deactivate this

function.

©American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 22American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 21

Page 12

Accu Roller 250™ System Menu Accu Roller 250™ System Menu

DFSE - With this function you can restore the factory

6. Press MODE/ENTER to confirm.

7. Press EXIT to return to the main menu.

settings of the device. All settings will be set back to the

default values. Any edited scenes will be lost. When restoring the factory settings the unit must be set to the address

that the unit was in when you started editing.

FLIP - This function will reverse the display 180º.

1. Access the main menu.

2. Tap the UP button until “DISP” is displayed.

3. Press MODE/ENTER, the display will show “ON/OFF”.

4. Press the UP button to select “ON” to activate this function,

or “OFF” to deactivate this function.

5. Press MODE/ENTER to confirm.

6. Press EXIT to return to the main menu.

SPEC MAIN MENU -

1. Access the main menu.

2. Tap the UP button until “SPEC” is displayed, press MODE/

ENTER.

3. Tap the UP button until “DFSE” is displayed, press MODE/

ENTER.

4. The display will show “ON/OFF”.

5. Press the UP button to display “ON” to activate this function,

or “OFF” to deactivate this function.

6. Press MODE/ENTER to confirm.

7. Press EXIT to return to the main menu.

spot - With this function you can adjust the lamp via

the control board. The shutter opens and the lamp can be

adjusted. In this mode, the device will not react to any control signal.

1. Access the main menu.

2. Tap the UP button until “ADJU” is displayed, press ENTER.

3. Tap the UP button until “LADJ” is displayed, press ENTER.

4. The display will show “ON/OFF”.

5. Press the UP button to select “ON” to activate this function,

or “OFF” to deactivate this function.

6. Press ENTER to confirm.

7. Press EXIT/DN to return to the main menu.

When you exit this function, the unit will begin to reload

data.

VER - Use this function to display the Software version of

the unit.

1. Access the main menu.

2. Tap the UP button until “SPEC” is displayed, press MODE/

ENTER.

3. Tap the UP button until “VER” is displayed, press MODE/

ENTER.

4. The display will show “V-1.0”, the display may also show, “V-

2.0”, “V-9.9” etc.

5. Press ENTER or EXIT/DN to exit.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 24American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 23

Page 13

Accu Roller 250™ Editing Program Accu Roller 250™ Editing Program

EDIT - This menu item allows you to write a program into the

memory (EEPROM) via the control panel or via the external

controller.

RUN With the function “RUN”, you can run your pre-made

program. You can set the number of steps under Step (S-01

- S-48). You can edit the individual scenes under Edit.

1. Access the main menu.

2. Tap the UP button until “EDIT” is displayed, press MODE/

ENTER.

3. Tap the UP button until “RUN” is displayed, press MODE/

ENTER.

4. “AUTO” is displayed. If you press the UP button it will show

“SOUN”. Select which one you want to activate, and press

ENTER.

5. Press UP, to select “ALON” or “NAST”. Which mean stand

alone, and master/slave mode.

5. Press ENTER to save and exit.

SC01 - With this function you can choose the number of

scenes in your Program.

1. Access the main menu.

2. Tap the UP button until “EDIT” is displayed, press MODE/

ENTER.

3. Tap the UP button until “SC01” is displayed.

4. The display shows “SC01”, this stands for the first scene of

your program. You can call up to 30 scenes. For example, if

“SC05”, it means that “Run” will run the first 5 scenes you saved

in “Edit”.

5. Press ENTER to save and exit.

6. Select a mode, and press ENTER to confirm.

7. Press EXIT/DN to return to the main menu.

STEP - With this function you can program the number of

steps in your individual Program.

1. Access the main menu.

2. Tap the UP button until “EDIT” is displayed, press ENTER.

3. Tap the UP button until “STEP” is displayed, press ENTER.

4. The display shows “S-01”, this stands for the first step of

your program. You can call up to 48 scenes in “Run”. For example, if “S-05” is displayed, it means that “Run” will run the first

5 scenes you saved in “Edit”.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 26American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 25

Page 14

Accu Roller 250™ Editing Program Accu Roller 250™ Editing Program

Editing procedure 1: Using the control board only.

1. Access the main menu.

2. Tap the UP button until “EDIT” is displayed. Press MODE/

ENTER.

3. The display will show “SC-01”, this stands for the scene

number. For example, “SC-01” is displayed, it means you will

be editing scene 1, press MODE/ENTER. You can change the

scene number by pressing the UP button.

4. Press MODE/ENTER, the display will show “C-1”, this stands

for the channel number. If “C-01” is displayed, you will be editing channel 1 of your selected scene, press MODE/ENTER. You

can change the channel number by pressing the UP button.

5. The display will show the DMX value for the channel that is

being edited. It will be displayed as “11XX”, it stands for Channel

11 of the editing scene, the DMX value is “XX”.

6. Adjust the DMX value by pressing the UP button, until you

get the expected effect for this channel.

7. Press MODE/ENTER to enter the editing of the other channels of the scene.

11. Adjust the time needed by pressing the UP button.

12. Press MODE/ENTER to save the settings for the scene you

are editing, the display will change to the next scene automati

-

cally.

13. Repeat steps 3-12 to edit other scenes, you can edit and

save 48 scenes maximum.

14. Press EXIT to exit, now you have edited and saved scenes

using the control board. The number of steps can be defined

under “EDIT” and the scenes can be called up under “Run”. To

run the scenes see page 26.

8. Repeat steps 5-8, until you finish setting all the DMX values

for all the channels of this scene, each scene can have 15

channels maximum.

9. Once all the channels are completed, the display will flash

“TIME”, this stands for the time needed to run this scene.

10. Press MODE/ENTER to edit the time needed, the display

shows “T-XX”, “XX” stands for the time needed to run this

scene. For example, “T-02” means scene 1 needs 6 seconds to

run, “T-15” means this scene needs 45 seconds to run.

Note: “XX” is always three seconds not one second.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 28American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 27

Page 15

Accu Roller 250™ Editing Program

Accu Roller 250™ Operation

Editing procedure 2: Using an external controller.

1. Access the main menu.

2. Tap the UP button until “EDIT” is displayed. Press MODE/

ENTER.

3. The display will show “SC01”, this stands for the first scene

number to be edited. For example: If “SC01” is displayed, you

will be editing scene 1.

4. Change the scene number by pressing the UP button.

5. Press MODE/ENTER, the display will show “C-01”, the “1”

stands for the channel number 1.

6. Press the UP button until “CEDT” is displayed, press MODE/

ENTER.

7. The display will show “OFF”, press the UP button so that “ON”

is displayed, press MODE/ENTER.

8. The display shows “SC02”. You have successfully downloaded the first scene.

9. Adjust the Step-time. needed by pressing the UP button.

10. Call up the second scene in your controller now.

11. Repeat steps 3-6 until all desired scenes are downloaded.

12. Press EXIT to exit. The number of steps can be defined

under “Step” and the scenes can be called up under “Run”.

Operating Modes: The Accu Scan 250™ can operate in three

different modes. This next section will detail the differences in

the operating modes.

• Stand alone mode -

The unit will react to sound, chasing through the built-in programs.

• Master/Slave mode -

You can daisy chain up to 16 units together to

light show without the need of an external controller. The units will

react to sound chasing through the several built-in programs.

• DMX control mode -

This function will allow you to control

with a standard DMX

Designer.

™

-512 controller such as the Elation® Show

each individual fixtures traits

get a synchronized

Universal DMX Control: This function allows you to use a uni-

versal DMX-512 controller such as the Elation

or Elation

wheel, gobo wheel, and the shutter (strobe). A DMX controller allows

you to create unique programs tailored to your individual needs.

1. The Accu Scan 250™ uses eight DMX channels. Channel 1 con trols pan, channel 2 controls tilt, channel 3 controls color, channel

4 controls gobo wheel, channel 5 controls gobo rotation, chan nel 6 control the shutter/strobe, channel 7 accesses internal pro grams, and channel 8 controls the speed of the pan/tilt move-

ment. See page 35 for detailed description of the DMX traits.

2. To control your fixture in DMX mode, follow the set-up procedures

on pages 10-14 as well as the set-up specifications that are

included with your DMX controller.

3. Use the controller’s faders to control the various DMX fixture traits.

4. This will allow you to create your own programs.

5. Follow the instruction on page 16 to set the DMX address.

6. For longer cable runs (more than a 100 feet) use a terminator on

the last fixture.

7. For help operating in DMX mode consult the manual included

with your DMX controller.

® Show Designer™ to control head movement, the color

® DMX Operator™

Stand-Alone Operation (Sound Active): This mode allows a single

unit or several units linked together, to run to the beat of the music.

1. Access the main menu.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 30American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 29

Page 16

Accu Roller 250™ Operation Accu Roller 250™ Fuse & Lamp Replacement

2. Tap the UP button until “AUDI” is displayed, and Press MODE/

ENTER.

3. Tap UP, to select “ALON” or “NAST”. Which means stand alone,

or master/slave mode. Press MODE/ENTER.

4. “AUTO” is displayed. If you press the UP button it will show

“SOUN”. Select which one you want to activate, and press

MODE/ENTER.

5. Select a mode, and press MODE/ENTER to confirm.

6. Press EXIT to return to the main menu

7. The unit comes with two preprogrammed shows built-in, each

show will react to low frequencies via the internal microphone.

You may change the show or invert the pan and tilt functions by

in the system menu by following the directions on page 21.

Master-Slave Operation (Sound Active): This function will allow

you to link up to 16 units together and operate without a controller. The

units will be sound activated. In Master-Slave operation one unit will

act as the controlling unit and the others will react to the controlling

units programs. Any unit can act as a Master or as a Slave.

1. Using standard XLR microphone cables, daisy chain your units

together via the XLR connector on the rear of the units. Remem ber the Male XLR connector is the input and the Female XLR

connector is the output. The first unit in the chain (master) will use

the female XLR connector only - The last unit in the chain will use

the male XLR connector only. For longer cable runs we suggest a

terminator at the last fixture.

2. Tap the UP button until

“AUDI” is displayed, and Press MODE/

ENTER.

3. Tap UP, to select “ALON” or “NAST”. Which means stand alone,

or master/slave mode. Press MODE/ENTER.

4. “AUTO” is displayed. If you press the UP button it will show

“SOUN”. Select which one you want to activate, and press

MODE/ENTER.

5. Select a mode, and press MODE/ENTER to confirm.

6. Press EXIT to return to the main menu

7. Follow instruction number 7 under Sound Active mode to invert

pan and tilt. Also you can refer to page 21.

Caution: Always replace with the exact same type lamp and fuse,

unless otherwise specified by an authorized American DJ

technician. Replacing with anything other than the specified part can

damage your unit and will void your manufactures warranty.

® service

Warning: If you continue to blow lamps or fuses, STOP using the

unit. Contact customer support for further instructions, you may have

to return the unit for servicing. Continuing to use the unit may cause

serious damage.

Lamp Replacement: Caution! Never attempt to change the lamp

while the fixture is plugged in. Always disconnect the main power

and allow the unit ample time to cool before attempting to replace

the lamp. Lamp replacement has been made simple by incorporating

slide out lamp assembly that is retained by two phillips screws.

1. Be sure to follow the proper handling procedures that deal with

discharge lamps.

2. Remove the two small screws (A,B) on the rear of the unit

3. After removing the screws, gently slide out the socket assembly

from the rear of the unit to expose the lamp.

4. Carefully remove the old lamp and discard it in the trash.

5. Replace the lamp with an exact match and reassemble in reverse

order.

6. After replacing the lamp follow the optimization procedures on the

next page to be sure the lamp is center in the reflector

A

B

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 31 American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 32

Page 17

Accu Roller 250™ Fuse & Lamp Replacement

Accu Roller 250™ DMX Traits

Optimizing Lamp Alignment: This procedure centers the lamp in

the reflector. Proper optimization will increase lamp life and ensure a

bright crisp output. Improper optimization may add a yellow tint to the

lamp output and reduce intensity.

1. Be sure main power is disconnected and allow the unit to cool. If

the you have just installed a new unit you can obviously skip this

step.

2. Make a preliminary adjustment: Turn the three lamp adjustment

thumb screws completely in (clockwise). Then back them each

out (counter-clockwise) about three complete turns.

3. Turn the unit on and allow it to reset.

4. Using either a DMX controller or the control panel on the unit,

strike the lamp and focus the light on a flat surface. Please see

Spot on page 23.

6. Center the hot-spot (the brightest part of the beam) using the 3

adjustment screws. Turn one screw at a time to drag the hot-spot

diagonally across the projected image. If you cannot detect a hot spot, adjust the lamp until the light is even.

7. To reduce a hot-spot, pull the lamp in by turning all three screws

clockwise 1/4-turn at a time until the light is evenly distributed.

8. If the light is brighter around the edge than it is in the center, or if

light output is low, the lamp is too far back in the reflector. “Push”

the lamp out by turning the screws.

Channel Value Function

1 0 - 255 PAN

2 BARRAL CONTROL

0 - 7 NO ROTATION

8 - 127 FORWARD BARRAL ROTATION

FAST SLOW

128 - 135 NO ROTATION

136 - 255 BACKWARDS BARRAL ROTATION

SLOW FAST

3 0 - 199 COLOR

0 - 19 WHITE

20 - 39 RED

40 - 59 BLUE

60 - 79 GREEN

80 - 99 YELLOW

100 - 119 MAGENTA

120 - 139 ORANGE

140 - 159 PURPLE

160 - 179 PINK

180 - 199 LIGHT BLUE

200 - 255 RAINBOW EFFECT

4 GOBO

0 - 13 SPOT

14 - 27 ROTATING GOBO 1 (metal)

Optimizing Screws

Optimizing Screws

28 - 41 ROTATING GOBO 2 (metal)

42 - 55 ROTATING GOBO 3 (dichoric)

Fuse Replacement: Locate and remove the unit’s power cord. Once

the cord has been removed located the fuse holder located inside the

power socket. Insert a flat-head screw driver into the power socket

and gently pry out the fuse holder. Remove the bad fuse and replace

with a new one. The fuse holder has a built-in socket for a spare fuse

be sure not to confuse the spare fuse with active fuse.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 33 American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 34

56 - 69 ROTATING GOBO 4 (metal)

70 - 83 ROTATING GOBO 5 (metal)

84 - 97 ROTATING GOBO 6 (metal)

98 - 115 ROTATING GOBO 7 (metal)

116 - 135 ROTATING GOBO 1 SHAKE

Page 18

Accu Roller 250™ Gobos Accu Roller 250™ DMX Traits cont.

1

765

432

8

Channel Value Function

6 96 - 127 SHUTTER OPEN

128 - 159 PULSE EFFECT

160 - 191 SHUTTER OPEN

192 - 223 RANDOM STROBE

SLOW FAST

224 - 255 SHUTTER OPEN

7 LAMP ON/OFF/RESET/INTERNAL PROGRAMS

0 - 19 COLOR CHANGE NORMAL

Accu Roller 250™ DMX Traits cont.

Channel Value Function

4 136 - 155 ROTATING GOBO 2 SHAKE

156 - 175 ROTATING GOBO 3 SHAKE

176 - 195 ROTATING GOBO 4 SHAKE

196 - 215 ROTATING GOBO 5 SHAKE

216 - 235 ROTATING GOBO 6 SHAKE

236 - 255 ROTATING GOBO 7 SHAKE

5 GOBO ROTATION

0 - 7 NO ROTATION

8 - 127 FORWARDS GOBO ROTATION

FAST SLOW

128 - 135 NO ROTATION

136 - 255 BACKWARDS GOBO ROTATION

SLOW FAST

6 SHUTTER/STROBE

0 - 31 SHUTTER CLOSED

32 - 63 DIMMER

64 - 95 STROBE

SLOW FAST

20 - 39 COLOR CHANGE TO ANY POSITION

40 - 79 NO ROTATION

80 - 84 ALL MOTOR RESET

85 - 87 SCAN MOTOR RESET

88 - 90 COLOR MOTOR RESET

91 - 93 GOBO MOTOR RESET

94 - 96 SHUTTER/DIMMER MOTOR RESET

97 - 99 NO ROTATION

100 - 119 INTERNAL PROGRAM 1

120 - 139 INTERNAL PROGRAM 2

140 - 159 INTERNAL PROGRAM 3

160 - 179 INTERNAL PROGRAM 4

180 - 199 INTERNAL PROGRAM 5

200 - 219 INTERNAL PROGRAM 6

220 - 239 INTERNAL PROGRAM 7

240 - 255 SOUND ACTIVE

8 SPEED OF PAN/TILT MOVEMENT

0 - 225 MAX. TO MIN. SPEED

226 - 235 BLACKOUT BY MOVEMENT

236 - 245 BLACKOUT BY WHEEL MOVEMENT

246 - 255 NO FUNCTION

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 36American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 35

Page 19

Accu Roller 250™ Gobo Replacement

Accu Roller 250™ Cleaning

This unit comes with interchangable gobos. Changing the

gobos is a easy procedure. Follow the instructions below.

Caution! Never open the unit when in use. Always disconnect

the main power before attempting to change the gobos.

1. To change the gobo, you must remove the top half of the

units body. The top half of the body has the LED display on it

2. Unscrew the four phillips screws on the front of the body.

Remove the top half shell of the body.

3. When you remove the top shell you will be able to access the

gobo wheel. Turn the wheel with your hand until you come

across the gobo you would like to change.

4. Remove the fixation-ring with a small flat-head screwdriver

or pair of needle nose pliers. Push the gobo out towards the

front. When doing this you do not need a lot of pressure.

5. Change the gobo, replace the fixation-ring, and reassemble

the unit.

Fixture Cleaning: Due to fog residue, smoke, and dust cleaning the

internal and external optical lenses and mirror should be carried out

periodically to optimize light output. Cleaning frequency depends on

the environment in which the fixture operates (I.e. smoke, fog residue,

dust, dew). In heavy club use we recommend cleaning on a monthly

basis. Periodic cleaning will ensure longevity, and crisp output.

1. Use normal glass cleaner and a soft cloth to wipe down the out side casing.

2. Use a brush to wipe down the cooling vents and fan grill.

3. Clean the external optics and mirror with glass cleaner and a soft

cloth every 20 days.

4. Clean the internal optics with glass cleaner and a soft cloth every

30-60 days.

5. Always be sure to dry all parts completely before plugging the unit

back in.

Accu Roller 250™ Trouble Shooting

Trouble Shooting: Listed below are a few common problems that

you may encounter, with solutions.

No light output from the unit;

1. Be sure you have connected your unit into a standard 120v wall

outlet.

2. Be sure the external fuse has not blown. The fuse is located on

the bottom panel of the unit.

3. Remove the lamp holder and be sure the lamp is seated in its

socket properly. Occasionally lamps become loose during ship ping be sure the lamp is push in to its socket all the way.

4. Be sure the fuse holder is completely and properly seated.

Unit does not respond to sound;

1. Low frequencies (bass) should cause the unit to react to sound.

Tapping on the microphone, quiet or high pitched sounds may

not activate the unit.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 37 American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 38

Page 20

Accu Roller 250™ Warranty

Accu Roller 250™ Specifications

1-YEAR LIMITED WARRANTY

A. American DJ® hereby warrants, to the original purchaser, American DJ® products to be

free of manufacturing defects in material and workmanship for a period of 1 Year (365 days)

from the date of purchase. This warranty shall be valid only if the product is purchased

within the United States of America, including possessions and territories. It is the owner’s

responsibility to establish the date and place of purchase by acceptable evidence, at the

time service is sought.

B. For warranty service, send the product only to the American DJ

charges must be pre-paid. If the requested repairs or service (including parts replacement)

are within the terms of this warranty, American DJ

to a designated point within the United States. If the entire instrument is sent, it must be

shipped in its original package. No accessories should be shipped with the product. If any

accessories are shipped with the product, American DJ

for loss of or damage to any such accessories, nor for the safe return thereof.

C. This warranty is void if the serial number has been altered or removed; if the product is

modified in any manner which American DJ

ability of the product; if the product has been repaired or serviced by anyone other than

the American DJ® factory unless prior written authorization was issued to purchaser by

American DJ

the instruction manual.

D. This is not a service contract, and this warranty does not include maintenance, cleaning

or periodic check-up. During the period specified above, American DJ

tive parts at its expense, and will absorb all expenses for warranty service and repair labor

by reason of defects in material or workmanship. The sole responsibility of American DJ

under this warranty shall be limited to the repair of the product, or replacement thereof,

including parts, at the sole discretion of American DJ

ranty were manufactured after January 1, 1990, and bear identifying marks to that effect.

®; if the product is damaged because not properly maintained as set forth in

® will pay return shipping charges only

® shall have no liability whatsoever

® concludes, after inspection, affects the reli-

®. All products covered by this war-

® factory. All shipping

® will replace defec-

Model: Accu Roller 250™

Voltage*: 120v/60Hz or 230v/50Hz

Lamp: ZB-MSD250/2, 250w 2000 Hours

Dimensions: 9”(L) x 11.5”(W) x 22.5”(H)

228mm x 292mm x 571mm

Colors: 9 Plus White

Gobos: 7 Rotating + Spot - All Replaceable

25mm Outside/ 20mm Viewable

Weight: 30 Lbs. / 13.6 kgs.

Fuse: 8A (120v) / 4A (220v)

Duty Cycle: None

DMX: 8 Channels

Sound Active: Yes

Working Position: Any Safe, Secure Position

Warranty: 1 Year (365 days)

*Voltage is preset at the factory and is not user selectable

Please Note: Specifications and improvements in the design

of this unit and this manual are subject to change without any

®

prior written notice.

E. American DJ® reserves the right to make changes in design and/or improvements upon

its products without any obligation to include these changes in any products theretofore

manufactured.

F. No warranty, whether expressed or implied, is given or made with respect to any acces

sory supplied with products described above. Except to the extent prohibited by applicable

law, all implied warranties made by American DJ

ing warranties of merchantability or fitness, are limited in duration to the warranty period

set forth above. And no warranties, whether expressed or implied, including warranties of

merchantability or fitness, shall apply to this product after said period has expired. The

consumer’s and or Dealer’s sole remedy shall be such repair or replacement as is expressly

provided above; and under no circumstances shall American DJ® be liable for any loss or

damage, direct or consequential, arising out of the use of, or inability to use, this product.

G. This warranty is the only written warranty applicable to American DJ® Products and

supersedes all prior warranties and written descriptions of warranty terms and conditions

heretofore published.

H. Lamps are not covered under this or any other warranty, either written or implied.

American DJ® - www.americandj.com - Accu Roller 250™ Instruction Manual Page 39

® in connection with this product, includ-

-

American DJ®

American DJ World Headquarters:

4295 Charter Street Los Angeles, CA 90058 USA

Tel: 323-582-2650 / Fax: 323-582-2610

Web: www.americandj.com / E-mail: info@americandj.com

Loading...

Loading...