NIBP Controller

Owner’s Guide

This document was, as far as possible, accurate at the time of release. However,

changes may have been made to the software and hardware it describes since

then. ADInstruments Pty Ltd reserves the right to alter specifications as

required. Late-breaking information may be supplied separately.

Trademarks of ADInstr uments

PowerLab

®

, LabTutor® and MacLab® are registered trademarks of ADInstruments

Pty Ltd. The names of specific recording units, such as PowerLab 8/30, are

trademarks of ADInstruments Pty Ltd. LabChart, Chart and Scope (application

programs) are trademarks of ADInstruments Pty Ltd.

Other Trademarks

Apple, Mac and Macintosh are registered trademarks of Apple Computer, Inc.

Windows, Windows XP and Windows Vista are either registered trademarks or

trademarks of Microsoft Corporation.

All other trademarks are the property of their respective owners.

Product: ML125 NIBP Controller

Document Number: U-ML125-OG-003B

Part Number: 4375

Copyright © February 2008 ADInstruments Pty Ltd.

Unit 13, 22 Lexington Drive, Bella Vista, NSW 2153, Australia

All rights reserved. No part of this document may be reproduced by any means

without the prior written permission of ADInstruments Pty Ltd.

Web: www.adinstruments.com

Technical Support: support.au@adinstruments.com

Documentation: documentation@adinstruments.com

ADInstruments Pty Ltd. ISO 9001:2000 Certified Quality Management System

Reg. No. 1053

ii

NIBP Controller Owner’s Guide

Contents

Safety Notes 5

1 Overview 13

Checking the NIBP Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

The Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

The Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cuff Pressure Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pulse Input Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Filter Switch (Pulse Range). . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Start/Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

The Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

I2C Input and Output Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure Signal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pulse Signal Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Max mmHg Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Gain Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Trigger In Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Trigger Out Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Contents

2 Using the Controller 17

Connecting the NIBP Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting to PowerLab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Optional Trigger Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting to Other ADInstruments Front-ends . . . . . . . . . . . . . . . 19

Power-up Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Recording with the NIBP Controller . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting Pulse Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Indirect Blood Pressure Measurements in Small Animals using Tail Cuffs. . . 21

Background Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Protocol Development Guidelines . . . . . . . . . . . . . . . . . . . . . . . 22

iii

A Technical Details 25

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Circuit Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pump Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pressure and Pulse Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . 27

The Pulse Input Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

B Specifications 29

Cycle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Manual Start/Stop Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remote Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Trigger Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pressure Output (Cuff Pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pulse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Physical Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Index 31

iv

NIBP Controller Owner’s Guide

Safety Notes

Statement of Intended Use

All products manufactured by ADInstruments are intended for use in

teaching and research applications and environments only.

ADInstruments products are NOT intended to be used as medical

devices or in medical environments. That is, no product supplied by

ADInstruments is intended to be used to diagnose, treat or monitor a

subject. Furthermore no product is intended for the prevention, curing

or alleviation of disease, injury or handicap.

Safety Notes

Where a product meets IEC 60601-1 it is under the principle that:

• it is a more rigorous standard than other standards that could be

chosen, and

• it provides a high safety level for subjects and operators.

The choice to meet IEC 60601-1 is in no way to be interpreted to mean

that a product:

• is a medical device,

• may be interpreted as a medical device, or

• is safe to be used as a medical device.

5

Safety Symbols

Devices manufactured by ADInstruments that are designed for direct

connection to humans are tested to IEC 601-1:1998 (including

amendments 1 and 2) and 60601-1-2, and carry one or more of the

safety symbols below. These symbols appear next to those inputs and

output connectors that can be directly connected to human subjects.

!

BF symbol: Bodyprotected equipment

The three symbols are:

• BF (body protected) symbol. This means that the input connectors

are suitable for connection to humans provided there is no direct

electrical connection to the heart.

• CF (cardiac protected) symbol. This means that the input

connectors are suitable for connection to human subjects even

when there is direct electrical connection to the heart.

• Warning symbol. The exclamation mark inside a triangle means

that the supplied documentation must be consulted for operating,

cautionary or safety information before using the device.

Further information is available on request.

CF symbol: Cardiacprotected equipment

Warning symbol: ‘see

documentation’

Bio Amp Safety Instructions

The Bio Amp inputs displaying any of the safety symbols are

electrically isolated from the mains supply in order to prevent current

flow that may otherwise result in injury to the subject. Several points

must be observed for safe operation of the Bio Amp:

6

NIBP Controller Owner’s Guide

• All Bio Amp front-ends (except for the ML138 Octal Bio Amp) and

PowerLab units with a built-in Bio Amp are supplied with a 3-lead

or 5-lead Bio Amp subject cable and lead wire system. The ML138

Octal Bio Amp is supplied with unshielded lead wires (1.8 m). Bio

Amps are only safe for human connection if used with the

supplied subject cable and lead wires.

• All Bio Amp front-ends and PowerLab units with a built-in Bio

Amp are not defibrillator-protected. Using the Bio Amp to record

signals during defibrillator discharges may damage the input

stages of the amplifiers. This may result in a safety hazard.

• Never use damaged Bio Amp cables or leads. Damaged cables and

leads must always be replaced before any connection to humans is

made.

Isolated Stimulator Safety

Instructions

The Isolated Stimulator outputs of a front-end signal conditioner or

PowerLab with a built-in isolated stimulator are electrically isolated.

However, they can produce pulses of up to 100 V at up to 20 mA.

Injury can still occur from careless use of these devices. Several points

must be observed for safe operation of the Isolated Stimulator:

Safety Notes

• The Isolated Stimulator output must only be used with the

supplied bar stimulus electrode.

• The Isolated Stimulator output must not be used with individual

(physically separate) stimulating electrodes.

• Stimulation must not be applied across the chest or head.

• Do not hold one electrode in each hand.

• Always use a suitable electrode cream or gel and proper skin

preparation to ensure a low-impedance electrode contact. Using

electrodes without electrode cream can result in burns to the skin

or discomfort for the subject.

• Subjects with implantable or external cardiac pacemakers, a

cardiac condition, or a history of epileptic episodes must not be

subject to electrical stimulation.

• Always commence stimulation at the lowest current setting and

slowly increase the current.

• Stop stimulation if the subject experiences pain or discomfort.

7

• Do not use faulty cables, or those that have exhibited intermittent

faults.

• Do not attempt to measure or record the Isolated Stimulator

waveform while connected to a subject using a PowerLab input or

any other piece of equipment that does not carry the appropriate

safety symbol (see Safety Symbols above).

Always check the status indicator on the front panel. It will always

flash green each time the stimulator delivers a current pulse. A yellow

flash indicates an ‘out-of-compliance’ (OOC) condition that may be

due to the electrode contact drying up. Always ensure that there is

good electrode contact at all times. Electrodes that are left on a subject

for some time need to be checked for dry contacts. An electrode

impedance meter can be used for this task.

• Always be alert for any adverse physiological effects in the subject.

At the first sign of a problem, stimulation must be stopped, either

from the software or by flicking down the safety switch on the

front panel of any built-in Isolated Stimulator or the ML180

Stimulus Isolator.

• The ML180 Stimulus Isolator is supplied with a special

transformer plug pack. The plug pack complies with medical

safety requirements. Therefore, under no circumstances should

any other transformer be used with the Stimulus Isolator. For a

replacement transformer plug pack please contact your nearest

ADInstruments representative.

General Safety Instructions

To achieve the optimal degree of subject and operator safety,

consideration should be given to the following guidelines when

setting up a PowerLab system either as stand-alone equipment or

when using PowerLab equipment in conjunction with other

equipment. Failure to do so may compromise the inherent safety

measures designed into PowerLab equipment. The following

guidelines are based on principles outlined in the international safety

standard IEC60601-1-1: General requirements for safety - Collateral

standard: Safety requirements for medical systems . Reference to this

standard is required when setting up a system for human connection.

8

NIBP Controller Owner’s Guide

PowerLab systems (and many other devices) require the connection of

a personal computer for operation. This personal computer should be

certified as complying with IEC60950 and should be located outside a

1.8 m radius from the subject (so that the subject cannot touch it while

connected to the system). Within this 1.8 m radius, only equipment

complying with IEC60601-1 should be present. Connecting a system

in this way obviates the provision of additional safety measures and

the measurement of leakage currents.

Accompanying documents for each piece of equipment in the system

should be thoroughly examined prior to connection of the system.

While it is not possible to cover all arrangements of equipment in a

system, some general guidelines for safe use of the equipment are

presented below:

• Any electrical equipment which is located within the SUBJECT

AREA should be approved to IEC60601-1.

• Only connect those parts of equipment that are marked as an

APPLIED PART to the subject. APPLIED PARTS may be

recognized by the BF or CF symbols which appear in the Safety

Symbols section of these Safety Notes.

• Only CF-rated APPLIED PARTS must be used for direct cardiac

connection.

• Never connect parts which are marked as an APPLIED PART to

those which are not marked as APPLIED PARTS.

• Do not touch the subject to which the PowerLab (or its peripherals)

is connected at the same time as making contact with parts of the

PowerLab (or its peripherals) that are not intended for contact to

the subject.

• Cleaning and sterilization of equipment should be performed in

accordance with manufacturer’s instructions. The isolation barrier

may be compromised if manufacturer’s cleaning instructions are

not followed.

• The ambient environment (such as the temperature and relative

humidity) of the system should be kept within the manufacturer’s

specified range or the isolation barrier may be compromised.

• The entry of liquids into equipment may also compromise the

isolation barrier. If spillage occurs, the manufacturer of the affected

equipment should be contacted before using the equipment.

Safety Notes

9

• Many electrical systems (particularly those in metal enclosures)

depend upon the presence of a protective earth for electrical safety.

This is generally provided from the power outlet through a power

cord, but may also be supplied as a dedicated safety earth

conductor. Power cords should never be modified so as to remove

the earth connection. The integrity of the protective earth

connection between each piece of equipment and the protective

earth should be verified regularly by qualified personnel.

• Avoid using multiple portable socket-outlets (such as power

boards) where possible as they provide an inherently less safe

environment with respect to electrical hazards. Individual

connection of each piece of equipment to fixed mains socketoutlets is the preferred means of connection.

If multiple portable socket outlets are used, they are subject to the

following constraints:

• They shall not be placed on the floor.

• Additional multiple portable socket outlets or extension cords

shall not be connected to the system.

• They shall only be used for supplying power to equipment which

is intended to form part of the system.

10

Cleaning and Sterilization

ADInstruments products may be wiped down with a lint free cloth

moistened with industrial methylated spirit. Refer to the

manufacturer’s guidelines or the Data Card supplied with transducers

and accessories for specific cleaning and sterilizing instructions.

Preventative Inspection and

Maintenance

PowerLab systems and ADInstruments front-ends are all

maintenance-free and do not require periodic calibration or

adjustment to ensure safe operation. Internal diagnostic software

performs system checks during power up and will report errors if a

significant problem is found. There is no need to open the instrument

for inspection or maintenance, and doing so within the warranty

period will void the warranty.

NIBP Controller Owner’s Guide

Your PowerLab system can be periodically checked for basic safety by

using an appropriate safety testing device. Tests such as earth leakage,

earth bond, insulation resistance, subject leakage and auxiliary

currents and power cable integrity can all be performed on the

PowerLab system without having to remove the covers. Follow the

instructions for the testing device if performing such tests.

If the PowerLab system is found not to comply with such testing you

should contact your PowerLab representative to arrange for the

equipment to be checked and serviced. Do not attempt to service the

device yourself.

Environment

Electronic components are susceptible to corrosive substances and

atmospheres, and must be kept away from laboratory chemicals.

Storage Conditions

• Temperature in the range 0–40 °C

• Non-condensing humidity in the range 0–95%.

Operating Conditions

• Temperature in the range 5–35 °C

• Non-condensing humidity in the range 0–90%.

Disposal

• Forward to recycling center or return to manufacturer.

Safety Notes

11

12

NIBP Controller Owner’s Guide

1

Overview

The ADInstruments ML125 NIBP (Non-Invasive Blood Pressure)

Controller performs non-invasive blood pressure measurement on rats

and mice using specialised tail cuffs.

This Owner’s Guide covers the features of the NIBP Controller and its

operation with your ADInstruments PowerLab

software.

®

and LabChart

Chapter 1 Overview

13

Start

Pulse Input Pulse Range (BPM)Cuff

40 - 150

90 - 420

240 - 600

Status

Power

Stop

Checking the NIBP Controller

The unit passes quality control inspection before leaving the factory.

However, there is a small chance that damage may occur in transit.

1. Check there are no obvious signs of damage to the outside casing.

2. Check there are no obvious signs of internal damage (like rattling).

If you find a problem, please contact your ADInstruments distributor

immediately.

The Front Panel

Figure 1–1

The front panel of the

NIBP Controller

Cuff connection Filter setting switch

NIBP Controller

Status indicator Pulse Input connectorPower indicator

Start/Stop button

The Power Indicator

The Power indicator will light when the unit is on. If not, check that

the unit is properly connected to the PowerLab, and that the

PowerLab is properly connected to a power socket and is switched on.

Status Indicator

The Status indicator light can be in one of three states:

• Off: Idle, no measurement in progress

• Green: Inflating cuff

• Orange: Deflating cuff

14

Cuff Pressure Connection

This port has a luer lock fitting and is where the tail cuff is attached.

The NIBP system can be purchased with either a cuff suitable for rats

or a cuff suitable for mice. The pressure is measured by way of an

internal pressure transducer. Output is from the ‘Pressure Output’.

NIBP Controller

Owner’s Guide

Pulse Input Connector

The pulse transducer is attached here. The signal is amplified and

filtered inside the NIBP Controller. Output is from the ‘Pulse Output’.

Filter Switch (Pulse Range)

This three position switch adjusts the filtering of the pulse signal.

Details of the frequency response are in Appendix B. For mice, use the

240–600 BPM setting. For rats, 90–420 BPM is usually appropriate.

Start/Stop Button

The NIBP Controller measurement cycle is started by pushing the

Start/Stop button. This begins an inflation and deflation cycle. To stop

the measurement cycle (during either inflation or deflation) push the

button again. This will stop the cycle and immediately deflate the cuff.

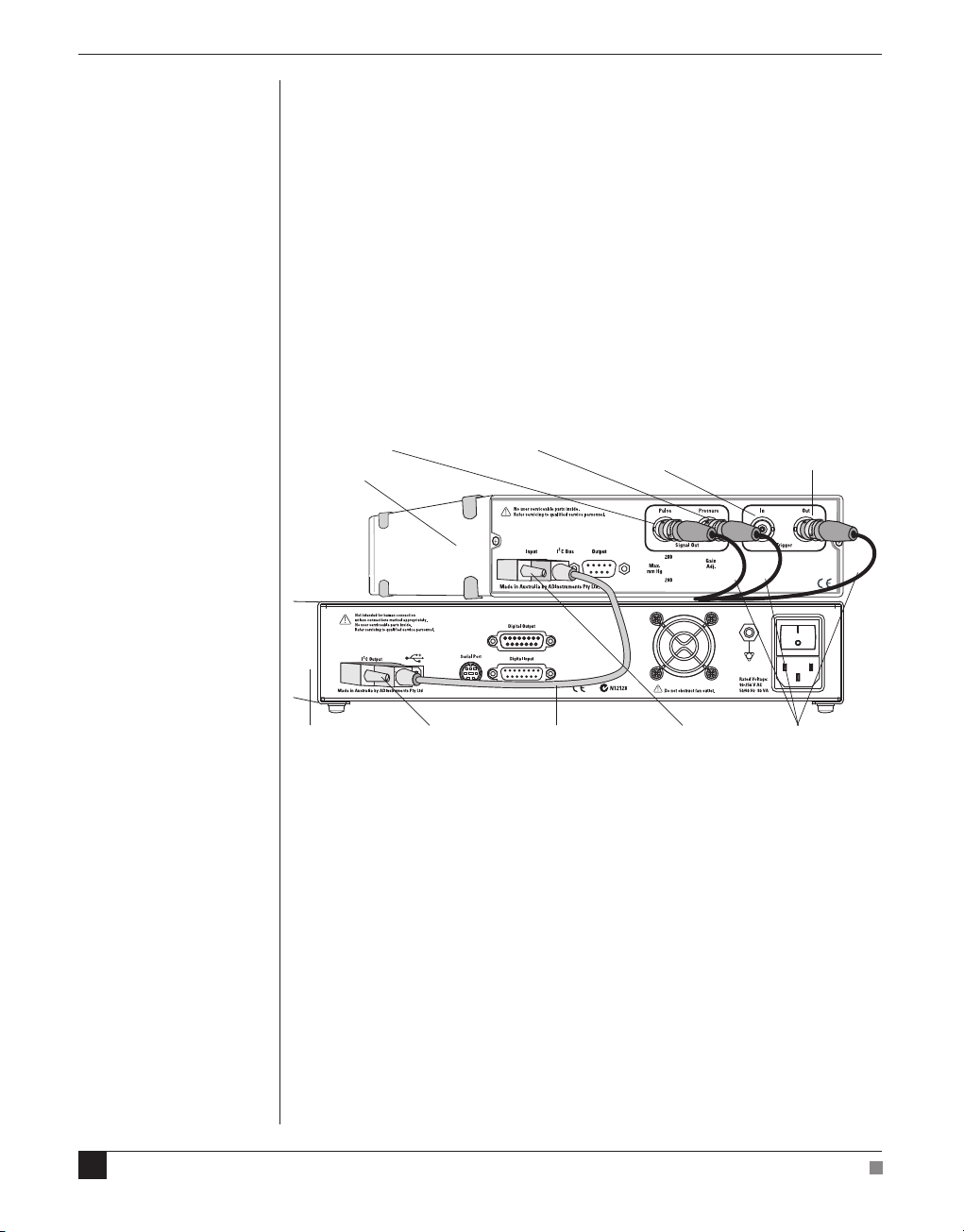

The Back Panel

Figure 1–2

The back panel of the

NIBP Controller

Pulse Output Pressure Output Trigger Input

I2C Input I2C Output

2

I

C Input and Output Sockets

Trigger OutputGain AdjustMaximum Cuff Pressure Switch

The NIBP Controller is designed to receive power and control signals

from an ADInstruments PowerLab. These are supplied by an ‘I

2

C Bus’

(a ‘bus’ is simply information-transmission circuitry such as cables

and connectors). These I

independently with one PowerLab. The I

Controller connects to the I

front-end in the system. The I

2

C sockets allow many front-ends to be used

2

C Output of the PowerLab or a previous

2

C Output socket of the NIBP Controller

2

C Input socket of the NIBP

allows connection of further ADInstruments front-ends to the system,

in series (the input of the next connects to the output of the previous).

Chapter 1 Overview

15

Pressure Signal Output

Connect this output to a PowerLab input channel to record pressure.

This signal is proportional to the cuff pressure and is precalibrated to

produce 1 V per 300 mmHg. By using Units Conversion in LabChart

you can easily display the cuff pressure in mmHg (or similar units).

Pulse Signal Output

Connect this output to a PowerLab input channel to record the pulse.

This pulse signal is used to determine the points at which the pressure

signal will be read to calculate systolic pressures.

Max mmHg Switch

This switch sets the maximum cuff inflation pressure, which will

occur immediately before deflation takes place. Two settings are

available: 200 and 280 mmHg.

Gain Adjust

This control allows an increase or decrease in the amplification of the

signal to suit the type of pulse transducer being used. It will have

been factory set, and you should not find it necessary to make further

adjustment. The adjustment of this control is described in Chapter 2.

Trigger In Connector

This trigger connector provides a means to start and stop the NIBP

measuring cycle from an external device that is providing a TTL

compatible signal. This input can be connected to the analog output of

a PowerLab so that the LabChart recording software can send a

trigger signal (use a 3–5 V pulse when setting up triggering in

LabChart) to start a measurement cycle.

Trigger Out Connector

This connector provides a signal that can be used by the LabChart

software to make data recording take place only during the

measurement cycle. This is useful if you are performing multiple

measurement cycles at, say, 30 minute intervals, and do not want to

record the unwanted signals between cycles. This output is connected

to the External Trigger input of a PowerLab.

The signal is TTL compatible (zero or 5 V) and indicates 5 V when a

measurement cycle is taking place.

16

NIBP Controller

Owner’s Guide

2

Using the

Controller

This chapter guides you through connecting your NIBP Controller to

your PowerLab and performing a power-up test to make sure there

are no problems. This chapter also covers setting up the NIBP

Controller in a typical system, and calibrating the pressure signals.

IMPORTANT: Always make sure that the PowerLab is turned off

before you connect or disconnect the NIBP Controller. Failure to do so

may damage the PowerLab and/or the NIBP Controller.

Chapter 2 Using the Controller

17

Connecting the NIBP Controller

Connecting to PowerLab

To connect the NIBP Controller to your PowerLab system, first make

sure that the PowerLab is turned off. Connect your PowerLab to the

computer and power, as detailed in your PowerLab Owner’s Guide.

Note: the PowerLab should remain off while making connections to it

as hardware may be damaged if the PowerLab is on.

Connect the I2C Output of the PowerLab to the I2C Input of the NIBP

Controller. Additional ADInstruments front-ends may be connected to

the system by connecting to the I2C Output of the NIBP Controller.

Figure 2–1

Rear view of a NIBP

Controller on a PowerLab,

showing the connections

that have been made

Pulse Signal Out

(to PowerLab Input)

NIBP Controller

PowerLab I2C cableI2C Output I2C Input BNC cables

Pressure Signal Out

(to PowerLab Input)

Optional Trigger input

(from PowerLab

analog Output)

Optional Trigger output

(to PowerLab external

Trigger input)

With BNC cables, connect the Pulse Signal Out socket on the back of

the NIBP Controller to one of the analog inputs on the front of the

PowerLab and connect the Pressure Signal Out socket on the back of

the NIBP Controller to another of the analog inputs of the PowerLab.

Both these connections must be made to determine blood pressure.

Optional Trigger Controls

18

The NIBP Controller has two control signal sockets on the rear panel.

The Trigger In is used to start an NIBP measurement cycle from an

external source such, as the PowerLab. By connecting this input to

either the analog output or digital output (if supported) of your

PowerLab you can get the LabChart or Scope software to

automatically start the NIBP Controller at preset times.

NIBP Controller Owner’s Guide

The Trigger Out is an output from the NIBP Controller that produces a

5 V signal during the measurement cycle. This can be connected to the

Trigger input of the PowerLab to control the duration of recording, or

to start LabChart or Scope recording when the cycle is started.

Both these controls are optional and allow much more automation of

the recording process, if desired or required.

Connecting to Other ADInstruments Front-ends

The NIBP Controller is designed to be used with other ADInstruments

front-ends. The NIBP Controller can be used anywhere in the series of

I2C connections, as long as there are enough analog inputs on your

PowerLab to support the required number of signals of the front-ends.

Power-up Test

Follow these steps to perform a power-up test of the NIBP Controller:

1. Connect your NIBP Controller to your PowerLab, as above.

2. Turn on your PowerLab. The Power indicator should light.

3. The NIBP Controller Power indicator should also light and the

Status indicator should be off.

Recording with the NIBP Controller

Follow these steps to begin recording with the NIBP Controller:

1. Once the NIBP Controller is connected to your PowerLab as

described above and as shown in Figure 2–1, connect the pressure

cuff to the Cuff connection on the front of the NIBP Controller, and

connect the pulse transducer to the Pulse Input connector.

Connect the pressure cuff and pulse transducer to the mouse or

rat. A typical experimental setup is shown in Figure 2–2.

2. Perform a power-up test of the NIBP Controller, described above.

3. Select the appropriate filter setting using the Filter Setting switch

on the front panel of the NIBP Controller, and set your maximum

cuff inflation pressure, by using the switch on the rear panel.

4. Open LabChart on your computer and set it up for the two

channels attached to the NIBP Controller; one channel for the

pulse signal, and the other for pressure. The pulse channel range

should be set to 50 mV. The pressure channel range should be set

to 1 V, and Units Conversion should be set up to give 0 V = 0

mmHg and 1 V = 300 mmHg.

Chapter 2 Using the Controller

19

Figure 2–2

The NIBP Controller and

PowerLab set up for use

with tail cuff, pulse

transducer and animal

restraint cage

A

D

IN

S

T

RU

ME

N

T

S

N

I

B

P C

on

t

r

ol

l

er

C

uf

f

Pu

l

s

e Input

Pu

l

s

e Rang

e

(B

PM)

S

ta

r

t

S

to

p

4

0 -

1

5

St

a

tu

s

Po

w

er

0

9

0 - 420

240

-

6

00

Tail cuffAnimal restraint cage

5. Click the Start button in LabChart to begin recording.

6. Push the Start/Stop button on the front of the NIBP Controller to

begin a measurement cycle. The pump should start and the cuff

should inflate. Observe that the pressure waveform climbs up to

the preset maximum cuff pressure. At some point in the inflation

cycle you should see the pulse signal start to decrease in

amplitude as the cuff starts to occlude the blood flow.

20

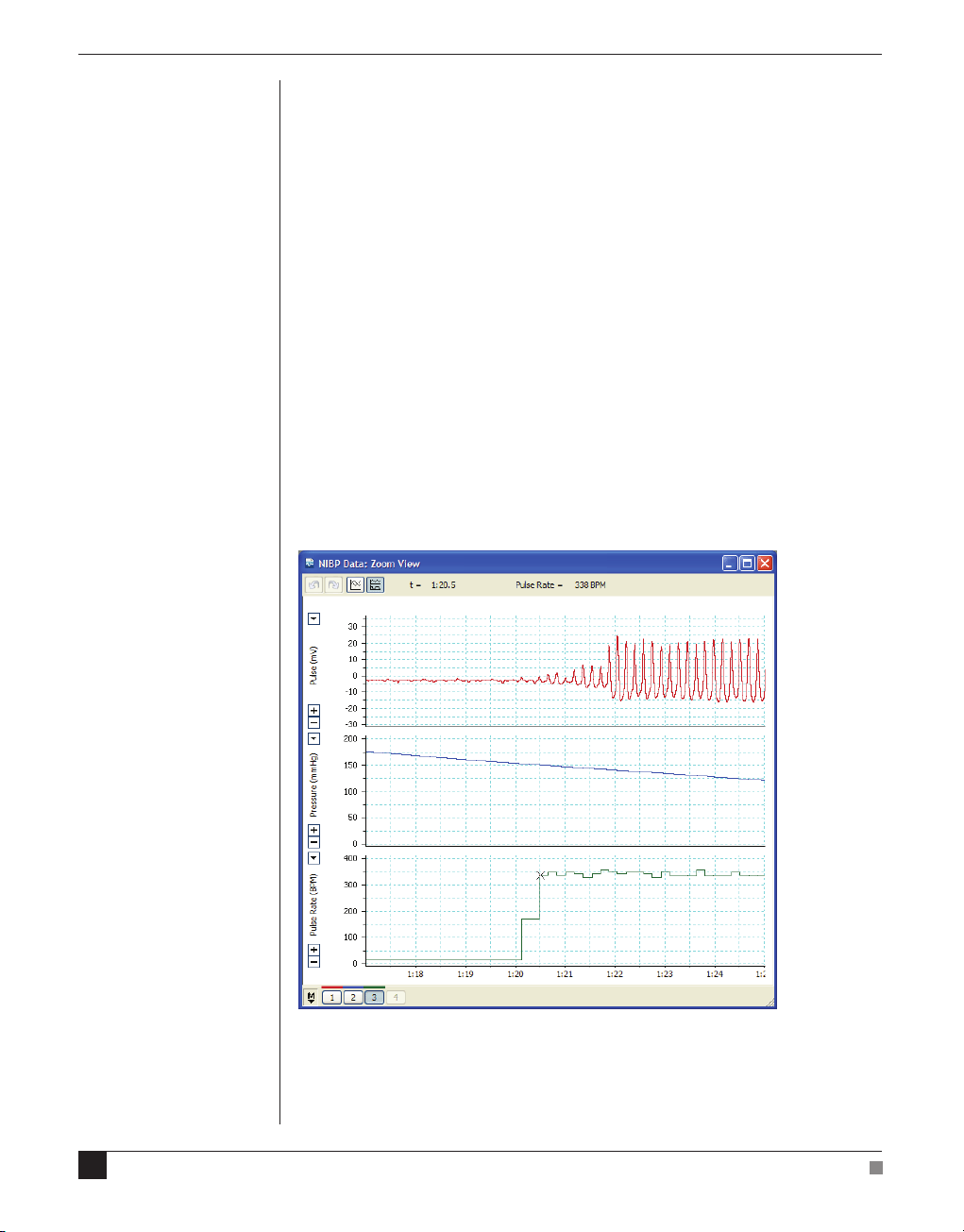

When the maximum cuff pressure is reached, the pump will stop and

the pressure will begin to drop. The pressure will drop until it reaches

about 40 mmHg at which point an valve is opened to release the

remaining air quickly. As the pressure drops the pulse signal will start

to increase again. Typical data is shown in Figure 2–3.

Connecting Pulse Transducers

The Pulse Input connector (Figure 1–1) on the front panel is a 6 pin

DIN type connector allowing attachment of the pulse transducer in

the MLT125M (mice) or MLT125R (rats) Pulse Transducer and

Pressure Cuff assemblies. Your NIBP system will have been purchased

with one of these assemblies. They are also available separately if you

require a replacement, or wish to study both mice and rats.

NIBP Controller Owner’s Guide

Figure 2–3

Typical recording using

LabChart showing the

pulse and pressure signals

Cuff Inflation Cuff Deflation

Indirect Blood Pressure Measurements in Small Animals using Tail Cuffs

Background Information

This technique has been used routinely for the non-invasive

measurement of blood pressure in rats, and more recently in mice. The

technique provides a good estimate of actual systolic pressure.

Although non-invasive, the protocol details related to the technique

(warming, handling, restraint and so on) will inevitably have some

effect on the actual blood pressure. The technique is useful as a

comparative measurement, particularly when carried out on a wellhabituated animal.

The major advantage of the PowerLab approach to this technique is

that it provides an accurate and permanent record of the pulsatile data

recorded from the tail during the measurement cycle. It therefore

makes it possible for scientists to develop protocols and detection

algorithms that correlate with their experiment. We do not offer a

method of estimating diastolic pressure, because to date very little

published data is available on the efficacy of such methods.

Chapter 2 Using the Controller

21

Users are presented with all the information that is typically recorded

by NIBP systems and can implement their own algorithms.

The following guidelines are provided to assist in the development of

protocols and reliable algorithms for the non-invasive measurement of

blood pressure in small animals.

Protocol Development Guidelines

1. Training: Most animals require some training, habituation to the

protocol, and careful handling to produce repeatable results; rats

are more readily trained than mice. Two to three training sessions

may be necessary to acclimatize the animals. Even when the

animal has been trained it may take a few minutes before a distinct

pulse is measurable on the tail.

2. Restraint cages: These are necessary for conscious animals. Ensure

that Perspex restraint cages are selected to fit the animal

comfortably. Place the animal in the Perspex cylinder restraint cage

and adjust the depth to restrict forward and backward movement

within the tube. The tube should prevent the animal from turning

around.

3. External stimuli: Sudden motion and sounds should be restricted

as much as possible, since they cause animal movement. It

sometimes helps to cover the restraint cage with a cloth to reduce

the impact of external stimuli.

22

4. Temperature maintenance: Warming rats and mice improves blood

circulation in the tail and the signal to noise ratio in the recording.

Typically animals should be preheated to 28–30 ˚C and maintained

at that temperature during the test.

5. Tail cuff: The tail cuff is used to occlude blood flow in the tail and

thereby interrupt the pulse that is measurable in the caudal artery.

The tail cuff is positioned at the proximal end of the tail.

6. Pulse transducer positioning: The active site of the pulse

transducer should be located on the ventral surface of the tail,

directly below the caudal artery. The transducer is positioned

directly following the tail cuff. Maximum sensitivity is achieved

when the artery is positioned above the most sensitive position on

the transducer. Movement from this position can reduce the

amplitude of the measured pulses.

NIBP Controller Owner’s Guide

7. Mechanical vibrations: The transducer used to make the pulse

measurements is very sensitive and subject to vibrations. Ensure

that mechanical vibrations from other laboratory devices do not

affect the transducer.

8. Measured signals: The basic signals recorded by the ML125 NIBP

system are the cuff pressure and the caudal artery pulse.

Cuff pressure is an accurate high level signal with noise of less

than +/– 0.1 mmHg and absolute error of less than +/– 2 mmHg

(after calibration). This data is used in association with the

reappearance of the caudal artery pulse to determine the systolic

pressure.

The caudal artery pulse is a low level pulse requiring significant

amplification—this is particularly true of mice. The signal is

therefore mixed with noise, and subject to movement and

respiratory artifacts. The signal amplitude may alter significantly

as the animal moves and repositions the transducer in relation to

the caudal artery.

A significant feature of the caudal artery pulse is its frequency. For

a conscious rat this is typically in the range 200–500 BPM. For a

given set of circumstances this frequency is relatively constant. The

user should be aware of this frequency, as it will be useful in later

analysis.

A sampling rate in the range of 100 – 1000 samples per second will

be adequate for pulse measurements.

Movement and respiratory artefacts in tail pulse measurements are

particularly disruptive because they often occur at times

coincident with actual measurements. However, it should be noted

that the technique is dependent not on the amplitude of the pulse,

but rather its onset.

9. Systolic measurement: Systolic measurement can normally be

made with relative ease. Systolic blood pressure (SBP) occurs when

the cuff pressure corresponds to the restoration of the first caudal

artery pulse. The presence of noise will inevitably introduce some

uncertainty in this estimate, but typical SBP measurements will be

within 5% of direct blood pressure measurements. Repeat each

measurement five to six times to ensure reproducible results are

being obtained.

Chapter 2 Using the Controller

23

Figure 2–4

Measurement of tail pulse

rate using the Rate function

of Cyclic Measurements.

In Zoom View, the cursor is

used to display a data value

at a specific time point

(the value of the selected

channel is displayed above,

along with the time point)

Although direct observation of the pulse is usually sufficient to

determine the systolic blood pressure point, alternative methods of

detecting the onset of the pulse (by performing certain calculations

in LabChart on the pulse signal) are also available, and may in

some circumstances be used effectively:

a. RMS measurement of pulse: This can be done using the RMS

function in the Data Pad and can be useful in providing a direct

measurement of pulse energy. An averaging period of about 500

ms to 1 second is useful.

b. Cyclic height: The Cyclic Measurements ‘Height’ function allows

an offline measurement of cycle height. This is particularly useful

when the pulse amplitude is modulated by a respiratory artefact.

c. Ratemeter: The Cyclic Measurements ‘Rate’ function can be set up

to accurately measure and display the tail pulse rate, and to

directly indicate the position of the systolic blood pressure point

(as shown in Figure 2–4).

24

NIBP Controller Owner’s Guide

APPENDIX

A Technical

Details

A

This appendix describes some important technical aspects of the NIBP

Controller operation. You do not need to know this material to use the

NIBP Controller. It is likely to be of interest to the technically-minded

and is not intended in any way as a service guide.

It should be noted that any modification or attempt to service your

NIBP Controller voids your rights under the warranty.

Appendix A Technical Details

25

How it Works

The NIBP Controller is a microprocessor controlled pump, designed to

perform the cuff inflation and deflation sequence required for noninvasive blood pressure measurement. Internal amplifiers and filters

are provided to allow monitoring of the cuff pressure and the subject’s

pulse so that systolic and diastolic pressure can be determined.

Circuit Principles

To understand the internal operation of the NIBP Controller, refer to

Figure A–1, which shows a block diagram of the system.

Figure A–1

Block diagram of the

NIBP Controller

Status

indicator

Start/Stop

button

Cuff

Pulse Input

valve

Quick release

Pump

Pressure

Transducer

Internal

valve

Internal cuff

Slow release valve

cuff

Bandpass

filter

Microprocessor

Trigger

Out

Trigger

In

Pressure

Signal

Out

Pulse

Signal

Out

26

Pulse Range

switch

NIBP Controller Owner’s Guide

Pump Control

Control over the cuff inflation and deflation sequence is achieved

using an internal microprocessor. The microprocessor waits until it

detects a start signal either from the front Start/Stop button or from

the external trigger input. It then turns on the internal pump and

starts to fill the cuff. While pumping, it continuously monitors the cuff

pressure and compares it to the maximum cuff pressure set on the

back panel switch (either 200 mmHg or 280 mmHg). When this

maximum cuff pressure is reached, the pump is switched off. The air

in the cuff is allowed to escape at a predefined rate through a small

release valve. The pressure will continue to decrease until it reaches

about 35–40 mmHg, at which point a quick release solenoid will be

opened to quickly release the residual air.

The inflation and deflation cycle can be stopped (or reset) at any time

by pressing the Start/Stop button during the cycle. The

microprocessor then opens the quick release valve and the pressure

will return quickly to atmospheric. This takes about a second.

Pressure and Pulse Monitoring

In order to determine the systolic pressure the NIBP system provides

two analog output signals for animal pulse and cuff pressure.

An internal pressure transducer is used to monitor the air pressure in

the cuff air supply line. The output of the transducer is amplified and

then provided as a signal from the rear panel on the controller. The

NIBP Controller is factory calibrated to produce 1 volt output per

300 mmHg, with zero volts corresponding to zero pressure.

The pulse signal is recorded via the Pulse Input connection on the

front panel of the NIBP Controller. This input connection is designed

to allow different types of pulse transducers to be connected,

depending on the application. For rats and mice the pulse transducer

is incorporated with the tail cuff. The signal from the external pulse

transducer is amplified and then band-pass filtered, before being

passed to the pulse output connector on the rear panel.

Pulse signal filtering is achieved using a band-pass filter with preset

frequencies depending on the Pulse Range setting on the front panel.

The band-pass filter consists of an analog, second order (two pole)

high-pass filter followed by an eighth order (switched capacitance)

low-pass filter.

Appendix A Technical Details

27

The Pulse Input Connector

This connector has provision for two types of analog input: a

differential high-gain signal, or a single-ended low-gain signal. The

differential input is used for small signals typically obtained from

pulse transducers connected to rats and mice. The single-ended low

gain input can be used for other pulse transducers that provide a

larger signal. The pin assignments for the Pulse Input connector are

shown in Figure A–2.

Figure A–2

The Pulse Input connector

pin assignments

Ground

Low gain input

High gain input +

3

2

1

Low gain ground

4

6

5

+ 5V

High gain input –

The Pulse Input connector provides a +5 V power supply (pin 6),

which supplies excitation to the transducer, if required.

For transducers that produce very low level signals, such as those

used for rats or mice, the high-gain differential inputs are used (pins 4

and 5). The output signal from the transducer should not exceed

250 μV. The output of the transducer should be connected between the

high gain input + and high gain input – pins. To minimise noise, pins

1 and 2 should be shorted together.

28

For high output pulse transducers (up to 500 mV) you should use the

single-ended low gain input (pins 1 and 2). If using this connection

you should also ensure that pins 3, 4 and 5 are shorted together.

NIBP Controller Owner’s Guide

B

APPENDIX

B Specifications

Cycle Operation

Max Inflation Pressure: 200 or 280 mmHg (switch-selectable)

Measurement Cycle Time:

40–150 BPM (large animals): 44 s (for 200 mmHg)

90–420 BPM (rats): 22 s (for 200 mmHg)

240–600 BPM (mice): 18 s (for 200 mmHg)

87 s (for 280 mmHg).

41 s (for 280 mmHg).

40 s (for 280 mmHg).

Appendix B Specifications

Cycle Control: Microprocessor based. Performs inflation,

deflation, and fast deflation sequences

automatically.

Operation Indication: Trigger output (normally low, but high during

inflation and deflation cycle).

Front panel Status indicator shows inflation

and deflation operation.

Operation Abort: The cycle can be terminated at any point by

pressing the front panel Start/Stop button

again. Pressure is automatically released.

Fast Release Time: ~1.2 s from 280 to 40 mmHg at 40–150 BPM

~0.5 s from 280 to 40 mmHg at higher ranges.

Control Sources: Front panel push button; External signal source

(voltage level); Remote contact closure.

Manual Start/Stop Input

Operation: Contact the closure input for starting or

stopping measurement cycle. Shorting the

input signal results in a start or stop operation.

Minimum Contact Closure: 1 ms

29

Remote Trigger Input

Operation: Voltage level input for starting or stopping

Input Voltage: 3–5 V

Minimum Trigger Pulse: 1 ms

NIBP cycle. TTL compatible input. High level

operates a start/stop.

Trigger Output

Operation: High (+5V) output level during measurement

cycle. Otherwise zero.

Pressure Output (Cuff Pressure)

Sensitivity: 0–1 V : 0–300 mmHg (factory calibrated)

Frequency Response: DC to 10 Hz

Pulse Input

Input Impedance: Differential Input: 10 GΩ

Input Signal Range: High gain differential input: (0–25 μV) up to

Single-ended Input: 1 MΩ

(0–75 μV), depending on rear panel Gain Adj

setting.

Low gain single-ended input: (0–50 mV) up to

(0–150 mV), depending on rear panel Gain Adj

setting.

30

Bandwidth: 40–150 BPM: 0.7–2.5 Hz

90–420 BPM: 3–7 Hz

240–600 BPM: 4–10 Hz

Pulse Output Max: ± 5 V

Operating Requirements

Power Requirements: PowerLab or MacLab I2C interface:

+9 V @ 100 mA

±18 V @ 50 mA

Operating Conditions: 5–35 °C, 0–90% humidity (non condensing)

Physical Configuration

Dimensions (h × w × d): 65 mm × 200 mm × 275 mm (2.56" × 7.9" × 10.8")

Weight: 1.7 kg

ADInstruments reserves the right to alter these specifications at any time.

NIBP Controller Owner’s Guide

Index

B

back panel 15

block diagram

26

C

circuit principles 26

cleaning

connecting

Cuff pressure connection

10

pulse transducers

to other front-ends

to other recorders

to PowerLab

18

20

19

19

F

filter switch 15

front panel

14

G

gain adjustment 16

H

how it works 26

I

14

M

maintenance 10

maximum cuff pressure switch

P

Power indicator 14

power up testing

PowerLab connection

pressure and pulse monitoring

pressure output connection

Pulse Input connector

pulse input gain adjustment

pulse output connection

Pulse Range switch

pump control

19

18

16

15, 28

16

15, 16

15

27

S

Safety Notes 5–11

Start/Stop button

Status indicator

storage

10

15

14

T

Trigger controls 18

trigger input connection

trigger output connection

16

16

16

27

indicators

Power

14

Status

14

Indirect blood pressure measurements

I2C connection

Index

15

21

U

user modification voids warranty 25

using the NIBP Controller

19

31

32

NIBP Controller Owner’s Guide

Loading...

Loading...