Page 1

FCR 200

Operator Guide

Page 2

Copyright Notice

© Copyright ADIC 1998, 1999

The information contained in this document is subject to change without notice.

This document contains proprietary information which is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced, or translated to another language without prior written

consent of ADIC.

ADIC shall not be liable for errors contained herein or for incidental or consequential damages (including lost

profits) in connection with the furnishing, performance or use of this material whether based on warranty,

contract, or other legal theory.

Copyright Notice (Europe)

© Copyright ADIC Europe 1998, 1999

All rights reserved. No part of this document may be copied or reproduced in any form or by any means,

without prior written permission of ADIC Europe, ZAC des Basses Auges, 1 rue Alfres de Vigny, 78112

Fourqueux, FRANCE.

ADIC Europe assumes no responsibility for any errors that may appear in this document, and retains the right

to make changes to these specifications and descriptions at any time, without notice.

This publication may describe designs for which patents are pending, or have been granted. By publishing

this information, ADIC Europe conveys no license under any patent or any other right.

ADIC Europe makes no representation or warranty with respect to the contents of this document and

specifically disclaims any implied warranties of merchantability or fitness for any particular purpose. Further,

ADIC Europe reserves the right to revise or change this publication without obligation on the part of ADIC

Europe to notify any person or organization of such revision of change.

Every effort has been made to acknowledge trademarks and their owners. Trademarked names are used solely

for identification or exemplary purposes, any omission are made unintentionally.

ADIC and ADIC Europe are trademarks of Advanced Digital Information Corporation.

Advanced Digital Information Corporation ADIC Europe

Shipping Address: 11431 Willows Road NE ZAC des Basses Auges

Redmond, WA 98052 1, rue Alfred de Vigny

Mailing Address: PO Box 97057 78112 FOURQUEUX, FRANCE

Redmond, WA 98073-9757 Telephone: 33.1.3087.5300

Telephone: (425) 881-8004 Fax: 33.1.3087.5301

Fax: (425) 881-2296

Customer Assistance: 1-888-809-3052

World Wide Web: http://www.adic.com

Document number: 62-9301-01 Rev A

First published: February 1999 Printed in the USA

ii

62-9301-01

Page 3

Contents

1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Explanation of Symbols and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Federal Communication Commission Notice (US Only) . . . . . . . . . . . . . . . . . . . . . . .1-5

IEC Statement (Worldwide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Canadian Notice (Avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

European Union Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

VCCI Statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Page 4

2

Description

Introducing the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

FCR200 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Fibre Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

SCSI Bus Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Configuration Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Management Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

FCR200 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Non-operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

FCR200 Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Point-to-Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Single Initiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Multiple Initiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

How the FCR200 Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Operating as Both a SCSI and Fibre Channel Device . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

The SCSI Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

The Fibre Channel Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Mapping Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Processing SCSI Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Processing Fibre Channel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

3

Safety

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

iv Contents

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

62-9301-01

Page 5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

German Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Schutzerdung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wartung/Instandsetzung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Certification and Classification Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Usage Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

4

Installation

Installing the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Unpacking the Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Mounting the FCR200 in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Materials Needed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Required tools: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Ear Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Slide Rail Mounting (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Interfaces and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Fibre Channel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

SCSI Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Serial Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Autobaud Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Connecting the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Management Information Base (MIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

MIB Fibre Channel Interface Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Contents v

Page 6

MIB SCSI Interface Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

MIB Ethernet and Serial Interfaces Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

5

Understanding the Configuration

Understanding the FCR200 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

General Fibre Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Soft Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Hard Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

General SCSI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Fibre Channel Host to SCSI Target Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Indexed Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Auto Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

SCC Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

SCSI Host to Fibre Channel Target Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

6

Configuration

Configuring the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Operation Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Host Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Device Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

vi Contents

Communicating with the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Setting Up Serial Port Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

62-9301-01

Page 7

Power Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Perform Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Baud Rate Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Fibre Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

SCSI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Fibre Channel-to-SCSI Mapping Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Changing the Fibre Channel-to-SCSI Mapping Mode . . . . . . . . . . . . . . . . . . . . .6-14

SCSI-to-Fibre Channel Mapping Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Trace Settings Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Save Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Restore Last Saved Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Reset Configuration to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Display POST Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Display Trace and Assertion History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Download Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

To Download Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Configuring the FCR200’s Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

SNMP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Toggle Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

SNMP Configuration with Traps Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

GET and SET Community Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

IP Address for Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Trap Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

7

Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Basic Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Verify SCSI Bus Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Verify Fibre Channel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Verify SCSI Devices in NT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Verify Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Verify Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Contents vii

Page 8

Verify Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Verify Host Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Verify HBA Device Driver Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

RS-232 Port Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

A

Ethernet Assignments

RJ-11 Serial and RJ-45 Ethernet Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B

Fibre Channel Interface and Commands

Fibre Channel Interface and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Download Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Report LUNs Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

PRLI Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

C

SCSI Interface and Commands

SCSI Interface and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

SCSI Inquiry Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

viii Contents

62-9301-01

Page 9

D

Addressing, Structures, and Operation

Addressing, Structures and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

SCC Addressing Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Indexed Addressing Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Auto Assigned Addressing Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

E

Reference Standards

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-3

Glossary

Index

Contents ix

Page 10

x Contents

62-9301-01

Page 11

Figures

Figure 2-1 Front panel of the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Figure 2-2 Back panel of the FCR200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3 Single Initiator to Single Target. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Figure 2-4 Single Initiator to Multiple Targets. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Figure 2-5 Multiple Initiators to Single or Multiple Targets . . . . . . . . . . . . . . . . 2-7

Figure 2-6 Fibre Channel-to-SCSI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-7 Information processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Figure 4-1 Materials Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-2 Cage Nut Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Figure 4-3 Mounting at Front of rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Figure 4-4 Mounting at back of Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Figure 4-5 Front of Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Figure 4-6 Attaching the Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Figure 4-7 Attaching Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Figure 4-8 Attaching Side Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Figure 4-9 Port Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-10 Configuration with Tape library. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Figure 4-11 Fibre Channel Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Figure 4-12 Removal of GBIC Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Figure 4-13 FCR200 SCSI Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Figure 4-14 SCSI Terminator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Figure 4-15 FCR200 Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

xi

Page 12

Figure 4-16 FCR200 Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Figure 4-17 FCR200 Power Switch and Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Figure 5-1 Configuration with tape library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Figure 6-1 FCR200 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Figure A-1 RJ-11 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Figure A-2 RJ-45 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

xii Figures

62-9301-01

Page 13

Tables

Table 5-1 Indexed Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Table 5-2 SCSI-to-Fibre Target:Channel Address Mapping. . . . . . . . . . . . . . . 5-8

Table 6-1 Connection Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Table B-1 Download Write Command Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Table B-2 Report LUN Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-3 Report LUN Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-4 FCR200 PRLI Response Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Table C-1 FCR200 Inquiry Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Table D-1 SCC Addressing Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Table D-2 Peripheral Device Addressing LUN Structure . . . . . . . . . . . . . . . . . D-3

Table D-3 SCC Logical Unit Addressing LUN Structure. . . . . . . . . . . . . . . . . . D-4

Table D-4 Address Method Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Table D-5 Arbitrated Loop Node Number to ALPA Lookup Table . . . . . . . . D-4

Table D-6 Example of Fibre Channel-to-SCSI Mapping . . . . . . . . . . . . . . . . . . D-6

xiii

Page 14

xiv Tables

62-9301-01

Page 15

1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Explanation of Symbols and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Federal Communication Commission Notice (US Only) . . . . . . . . . . . . . . . . . . . . . . .1-5

IEC Statement (Worldwide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Canadian Notice (Avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

European Union Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

VCCI Statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Page 16

1-2 Introduction

62-9301-01

Page 17

Overview

This manual contains information and instructions necessary

for the safe operation of the FCR200 Fibre Channel-to-SCSI

Routers. The topics discussed in this chapter are:

•Overview

• Intended Audience

• Organization

• Associated Documents

• Explanation of Symbols and Notes

• Assistance

Intended Audience

This guide is intended for operators, trained customer

specialists, and maintenance personnel of the service partner

who interact with the FCR200.

1-

Organization

This publication contains chapters detailing the operation of

the FCR200. The chapters topics include:

Chapter 1 Introduction - Describes the overview,

Chapter 2 Description - Describes general information

Chapter 3 Safety - Describes the hazard symbols,

Chapter 4 Installation - Describes the functional

Chapter 5 Understanding the Configuration - Describes

Chapter 6 Configuration - Describes the configuration

intended audience, organization,

associated documents, explanation of

symbols and notes, and how to obtain

additional assistance.

about the FCR200.

messages, safety features, and operational

considerations for the safe operation of the

FCR200.

installation of the FCR200.

the configuration considerations for the

FCR200.

of the FCR200.

Overview 1-3

Page 18

Chapter 7

Appendix A

Appendix B

Appendix C SCSI Interface and Commands - Describes

Appendix D

Appendix E

Glossary

Index

Troubleshooting

techniques and hints.

Ethernet Assignments

cable connections.

Fibre Channel Interface and Commands

Describes specific commands supported by

the FCR200.

specific information about the SCSI Inquiry

command.

Addressing, Structures, and Operation

Describes various addressing schemes for

devices.

Reference Standards

standards.

Associated Documents

- Describes troubleshooting

- Outlines the Ethernet

-

-

- List applicable

None.

Explanation of Symbols and Notes

The following symbols and highlighted passages note

important information.

Detailed explanations for the above symbols are provided in

Safety Instructions

<1> + <2> Press these keys simultaneously.

Italics

Bold Special Term, e. g., Utilities.

Courier Terms appearing on the operating panel,

on page 3-3.

Headline, e. g., Chapter Name,

switch position, e. g., ON, OFF

Description

1-4 Introduction

62-9301-01

Page 19

Federal Communication Commission

Notice (US Only)

The Federal Communications Commission (in 47 CFR 15.105)

has specified that the following notice be brought to the

attention of the users of this product.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct

the interference at personal expense.

IEC Statement (Worldwide)

This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user

may be required to take adequate measures.

Canadian Notice (Avis Canadien)

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet appareil numerique de la classe A respecte toutes les

exigences du Reglement sur le materiel brouilleur du Canada.

European Union Notice

Products with the CE Marking comply with both the EMC

directive (89/336/EEC) and the Low Voltage Directive

(73/23/EEC) issued by the Commission or the European

Community. Compliance with these directives implies

conformity to the following European Norms (in brackets are

equivalent international standards):

EN55022 (CISPR 22) Electromagnetic Interference

EN50082-1 (IEC801-2, IEC801-3, IEC801-4)

Electromagnetic Immunity

Federal Communication Commission Notice (US Only) 1-5

Page 20

EN60950 (IEC950) Product Safety

VCCI Statement (Japan)

1-6 Introduction

62-9301-01

Page 21

2

Description

Introducing the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

FCR200 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Fibre Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

SCSI Bus Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Configuration Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Management Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

FCR200 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Non-operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

FCR200 Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Point-to-Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Single Initiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Multiple Initiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

How the FCR200 Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Operating as Both a SCSI and Fibre Channel Device . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

The SCSI Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

The Fibre Channel Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Mapping Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Processing SCSI Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Processing Fibre Channel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Page 22

2-2 Description

62-9301-01

Page 23

Introducing the FCR200

The FCR200 is a member of the Fibre Channel-to-SCSI Router

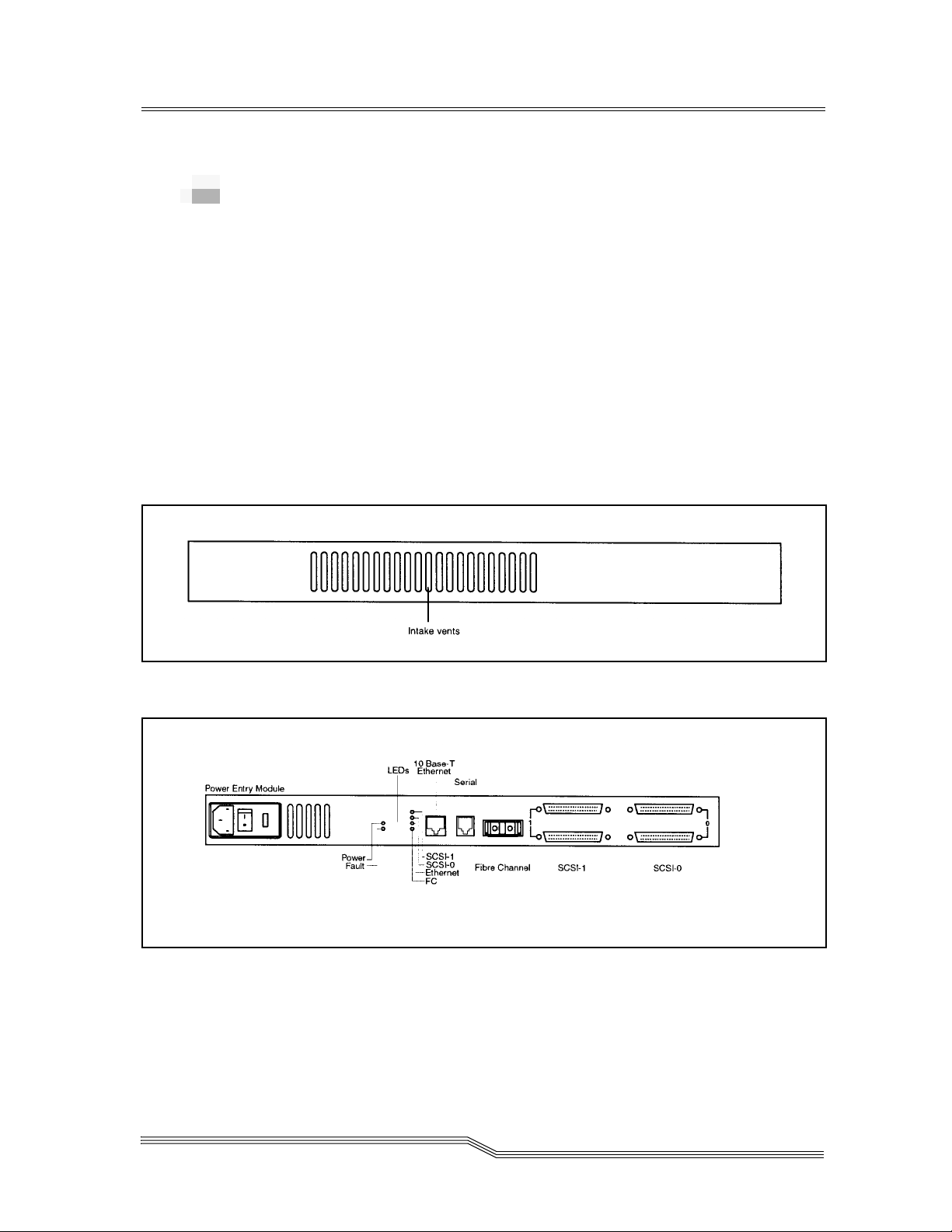

product family. See Figure 2-1 and Figure 2-2.

The FCR200 provides connectivity between a Fibre Channel

Switched Fabric (FC-SW) or Arbitrated Loop (FC-AL), and

two Fast/Wide/Ultra SCSI buses.

Supported devices include:

• Initiator Devices – Fibre Channel and SCSI hosts

• Direct Access Devices – RAID Controllers, Disk drives,

JBODs

• Sequential Access Devices – Tape drives

• Changer Devices – Tape and Magneto-Optical Libraries

2-

Figure 2-1

Figure 2-2

Front panel of the FCR200

Back panel of the FCR200

Introducing the FCR200 2-3

Page 24

FCR200 Features

Fibre Channel Features

• Fibre Channel initiator and target modes

• Single 1.0625 Gbps port

• Fibre Channel Arbitrated Loop (FC-AL) and Switched

Fabric (FC-SW) topologies

• Private Loop Direct Attach (PLDA) profile compliant

• Class 3 connection with SCSI-FCP protocol

• Optical GBIC

• FC-Tape Compliant

SCSI Bus Features

• SCSI initiator and target modes

• Two auto-negotiating SCSI buses (Narrow, Wide, Fast,

Ultra)

• Ultra Wide SCSI for data transfer up to 40 MB/s per bus

• Connection for up to 30 devices (15 per bus)

• Simultaneous commands, tagged command queuing and

disconnect/reconnect

• Middle of bus configuration with external termination

• SCSI-2 and SCSI-3 protocols

• 68-pin D shell, P type connectors

• Differential or single-ended

• Disk, tape, optical and changer devices

• SCC, Indexed and Automatic addressing modes

2-4 Description

Configuration Features

• Serial RJ-11 connector for terminal access

• Ethernet RJ-45 connector for FTP, Telnet and Web

browser access

• Easy field-upgradable firmware

Management Features

• Out-of-band Ethernet TCP/IP

• SNMP with private MIB support

62-9301-01

Page 25

FCR200 Specifications

Physical Specifications

• Internal power supply with power switch and detachable

power cord

• Fibre Channel activity LED

• SCSI Bus 1 activity LED

• SCSI Bus 0 activity LED

• Ethernet activity LED

• Power LED

• Fault LED

• Airflow with internal fan

• Rack mount or desktop enclosure

Physical Dimensions

• Width 43.18cm (17.00 inches)

• Depth 22.82cm (8.98 inches)

• Height 4.31cm (1.70 inches, 1U)

• Weight 3.18 kg (7 lbs)

Operating Environment

• 5 to 40 °C

• 5 to 80% Relative Humidity (non-condensing)

Non-operating Environment

• -40 to +55 °C

• 0 to 92% Relative Humidity (non-condensing)

Power

• 100 - 240 VAC, Auto Sensing

• 50/60 Hz, 1.0 Amps

FCR200 Specifications 2-5

Page 26

FCR200 Benefits

Point-to-Point

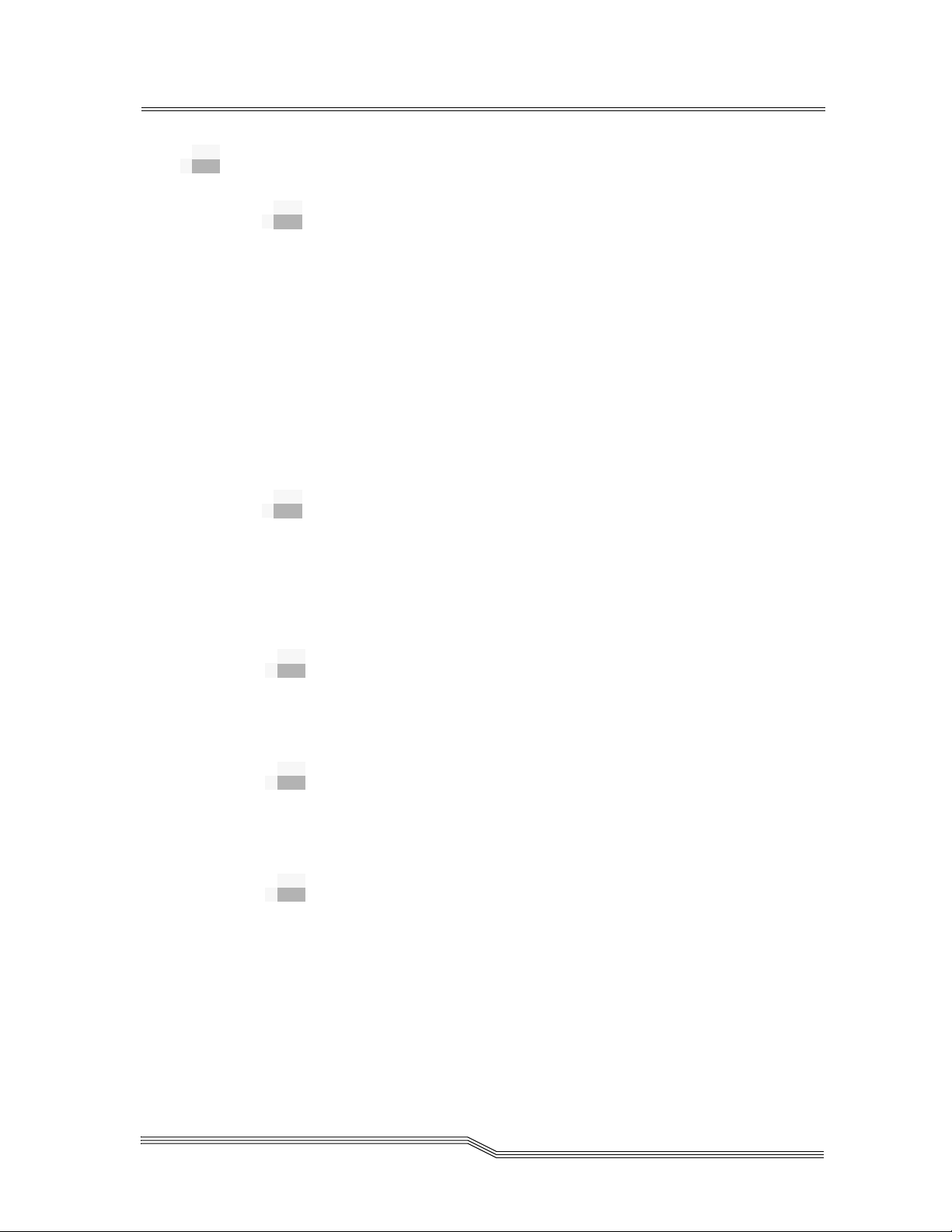

See Figure 2-3 for a point to point illustration.

Figure 2-3 Single Initiator to Single Target

Single Initiator

See Figure 2-4 for a single initiator to multiple target

illustration.

Figure 2-4 Single Initiator to Multiple Targets

2-6 Description

62-9301-01

Page 27

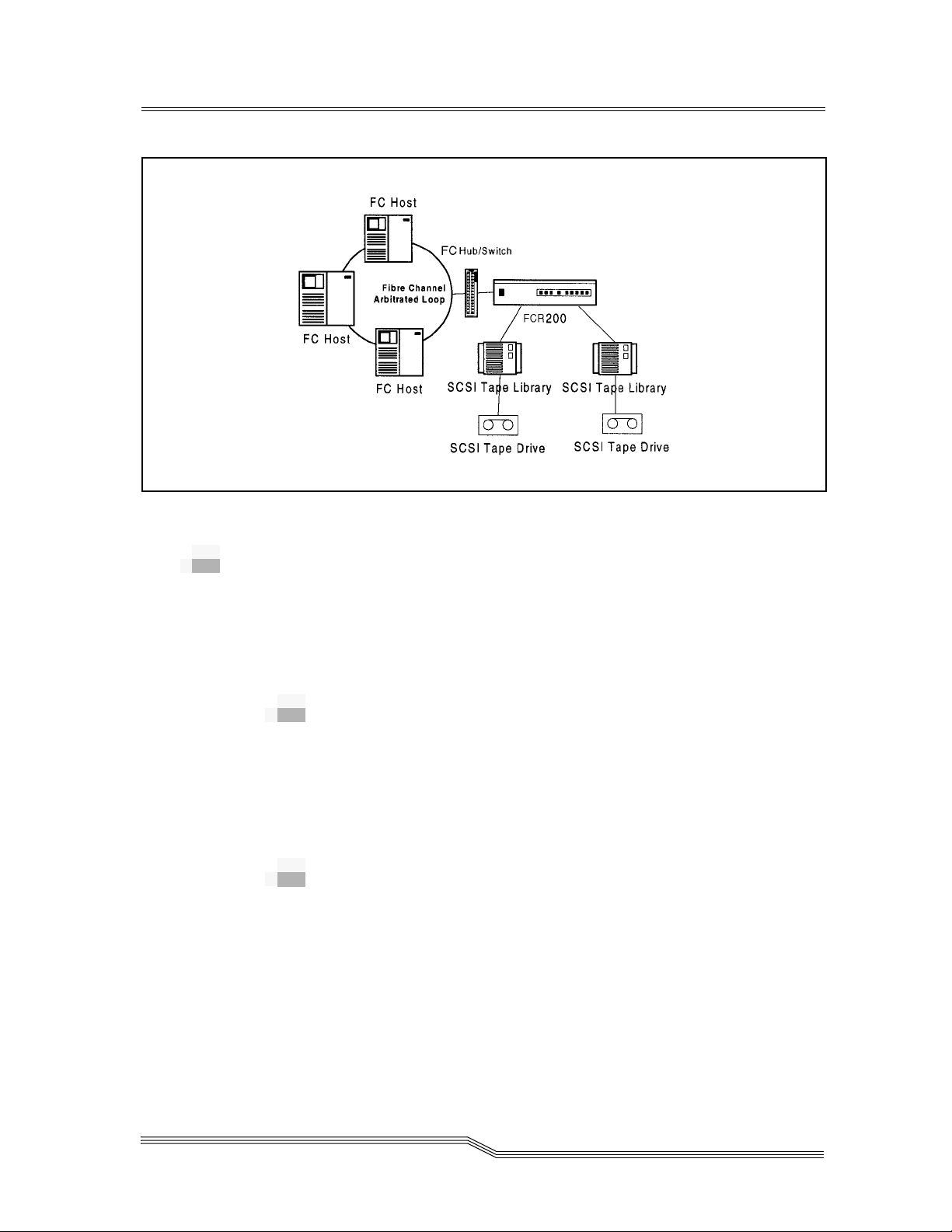

Multiple Initiators

See Figure 2-5 for multiple initiators to single or multiple

targets illustration.

Figure 2-5 Multiple Initiators to Single or Multiple Targets

Availability With two units, dual loop attachment

provides redundancy and no single point

of failure.

Connectivity SCSI devices may be attached to Fibre

Channel storage networks to share data

and increase address space.

Distance SCSI cable length from hosts to devices is

increased from 25m to 10,000m, facilitating

remote or disaster tolerant sites.

Performance 100 Mbytes/sec Fibre Channel (200

Mbytes/sec bi-directional) offers increased

bandwidth when distributing data across

multiple SCSI devices.

Reliability Low error rates, robust error recovery and

flow control provide an enterprise with

reliable data delivery.

Scalability Point-to-point links can be expanded to

multi-initiator links supporting

interconnected servers, tape drives, tape

libraries, disk drives and disk arrays.

Flexibility Allows Fibre Channel initiators to

communicate with SCSI targets, as well as

SCSI initiators to communicate with Fibre

Channel targets, simultaneously.

FCR200 Benefits 2-7

Page 28

Consolidation Allows multiple servers to share storage

resources, including tape drives, tape

libraries, disk drives and disk arrays.

Centralization Enables existing storage to be moved to a

central location to simplify management

and maintenance, and to improve security.

Lower TCO Improving storage management,

maintenance and security can lower Total

Cost of Ownership (TCO) for enterprise

storage.

How the FCR200 Works

The FCR200 is a storage router that translates Fibre Channel

Protocol (FCP) to and from two SCSI buses so devices on these

two types of media can communicate with each other. It

attaches to either a Fibre Channel or SCSI host, and transfers

the command, data, and status information to SCSI or Fibre

Channel targets. The host passes packets to SCSI or Fibre

Channel targets as if the FCR200 were just another device

along the path.

The FCR200 provides connections for two SCSI buses and a

Fibre Channel Arbitrated Loop or Switched Fabric. It takes

advantage of Fibre Channel’s ability to encapsulate SCSI

protocol packets to allow a host with a FC or SCSI adapter to

access SCSI or FC peripheral devices transparently over a FC

connection.

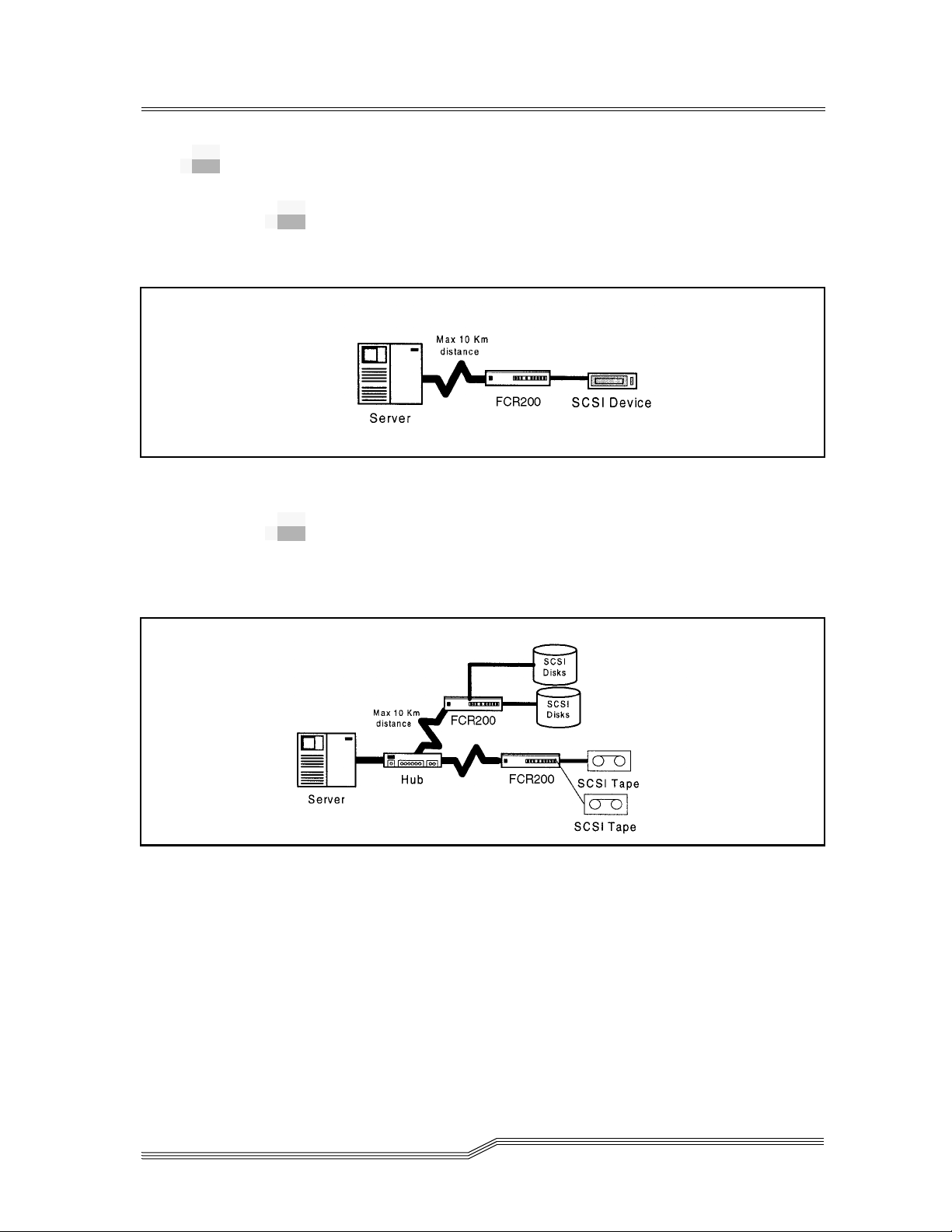

Figure 2-6 on page 2-9 shows a Fibre Channel-to-SCSI

configuration. Through the FCR200 router, any host on the

Fibre Channel loop can access the tape drive and library on

each SCSI bus.

2-8 Description

62-9301-01

Page 29

Figure 2-6 Fibre Channel-to-SCSI Configuration

Operating as Both a SCSI and Fibre

Channel Device

The router is both a SCSI and Fibre Channel device operating

on a SCSI bus and Fibre Channel network simultaneously.

The SCSI Side

On a SCSI bus, the FCR200 acts as a SCSI initiator passing

requests from hosts on the Fibre Channel network to target

devices on the SCSI bus. Each FCR200 SCSI bus uses a single

SCSI ID. The default ID is 7 and can be changed when

configuring the FCR200.

The Fibre Channel Side

In a Fibre Channel loop, the FCR200 is identified by a single

Arbitrated Loop Physical Address (AL_PA) or a fabric

assigned Source ID. Once the address is acquired, any host on

the Fibre Channel loop can access the devices on a SCSI bus

transparently over a FC connection.

Operating as Both a SCSI and Fibre Channel Device 2-9

Page 30

Mapping Devices

To allow Fibre Channel and SCSI devices to address each

other, the FCR200 creates a table that maps device identifiers

between Fibre Channel and SCSI. During FCR200

configuration, you can choose the mapping method and, in

certain cases, customize the device mappings. See

for more information about address modes and their

configurations.

Processing SCSI Information

The following describes how the router processes SCSI

information. Refer to Figure 2-7 on page 2-11.

1 A FC host issues a command. The FC host

encapsulates the command in the FCP protocol and

sends the packet to the FCR200.

2 The FC port in the FCR200 receives the packet,

interprets the FC information, and places the

packet in buffer memory.

Chapter 5

3 The FCR200’s processor interprets the information

and programs a SCSI controller to process the

transaction.

4 The SCSI controller sends the command to the SCSI

device (target).

5 The target interprets the command and prepares to

either read or write data.

2-10 Description

62-9301-01

Page 31

Figure 2-7 Information processing

6 Data flows between the host and target through

DirectFlow payload buffers.

7 Response information flows from the SCSI target

back to the FC host.

Processing Fibre Channel Information

The FCR200 processes information from the SCSI bus host by

requesting operations of targets on a Fibre Channel Storage

Area Network (SAN). The information is processed using the

same method as described in the previous section, except it

begins with the SCSI host bus issuing commands and the

information passing through the FCR200 to the FC SAN.

Processing Fibre Channel Information 2-11

Page 32

2-12 Description

62-9301-01

Page 33

3

Safety

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

German Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Schutzerdung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wartung/Instandsetzung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Certification and Classification Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Usage Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Page 34

3-2 Safety

62-9301-01

Page 35

Safety Instructions

WARNING

A WARNING denotes a hazard that can cause

personal injury.

3-

CAUTION

Grounding

Servicing

A CAUTION denotes a hazard that can cause

hardware or software damage.

This product is a Safety Class 1 product and has a protective

earthing terminal. There must be an uninterruptible safety

earth ground from the main power source to the product’s

input wiring terminals, power cord, or supplied power cord

set. Whenever it is likely that the protection has been

impaired, disconnect the power cord until the ground has

been restored.

Any servicing, adjustment, maintenance, or repair must be

performed only by authorized service-trained personnel.

There are no operator serviceable parts in this product.

Warranty

If you have any questions about the warranty of this product,

contact a sales representative.

Safety Instructions 3-3

Page 36

German Statements

Sicherheitshinweise

WARNUNG

Eine WARNUNG bezieht sich auf eine Gefahr,

die zu Verletzung von Personen fuehren kann.

ACHTUNG

Ein ACHTUNG bezieht sich auf eine

Gefahr, die zu Schaden am Geraet oder

Verlust von Daten fuehren kann.

Schutzerdung

Dieses Produkt ist ein Schutzklasse I Geraet und hat einen

Anschluss fuer Schutzerdung. Ein ununterbrochener

Schutzleiter von der Stromquelle zum Schutzleiteranschluss

des Geraetes oder dem Netzkabel ist unbedingt notwendig.

Bei Anzeichen von Beeintraetigung dieser Schutzeinrichtung,

trennen Sie die Netzzufuehrung bis die Schutzerdung wieder

einwandfrei ist.

Wartung/Instandsetzung

Jegliche Wartung, Instandsetzung oder Einstellung muss

durch einen qualifizierten, authorisierten Fachmann

durchgefuehrt werden. Das Geraet enthaelt keinerlei zu

wartende Teile fuer den Benutzer.

3-4 Safety

WARNUNG

Oeffnen Sie niemals das Gehaeuse! Gefahr

des Elektrischen Schlages!

62-9301-01

Page 37

WARNUNG

WARNUNG

WARNUNG

Das Netzteil ist bestimmt und zertifiziert fuer

einen Netzspannungsbereich von 100 – 240 V ~.

Die Geraetesicherung darf nur mit einer

Sicherung des gleichen Typs und Nennwerten

ersetzt werden.

Zur Vermeidung der Gefahr eines Elektrischen

Schlages, oeffnen Sie das Gehaeuse unter

keinen Umstaenden.

Laser Safety

Certification and Classification

Information

This product uses Gigabit Interface Converters (GBIC) to

interface with Fibre Channel links. Optical GBICs shipped

with this product contain internal lasers. In the USA, all

optical GBICs shipped with this unit are certified as Class 1

laser products and conform to the requirements contained in

the Department of Health and Human Services (DHHS)

regulation 21 CFR Subchapter J.

Outside the USA, all GBICs are certified as Class 1 laser

components that conform to the requirements contained in

the International Electrotechnical Commission (IEC) standard

825 (1994) and Amendment 1 (1990) along with the CENELEC

(European Committee for Electrotechnical Standardization)

European Normalization standard EN 60825 (1992).

Laser Safety 3-5

Page 38

If other then the shipped optical GBICs are used with this

product then the user is required to insure that the optical

GBIC being used meets all of the above requirements. If the

GBIC is not certified then this product’s laser safety

certification becomes null-and-void.

Certifications include one or more of the following:

• Recognized Component by Underwriters Laboratories

• Certified by the Canadian Standard Association

• Certified by VDE (Germany) and/or Certified by Statens

Provningsanstalt (SP) in Sweden

The following shows the Class 1 information label specified in

IEC 825 and CENELEC HD 482 51. This label is attached to

this product.

Class 1 Laser Product

Laser Klasse 1

Luckan 1 Laserlaite

The following information provides the typical operational

parameters for the Optical Laser GBIC included with the

FCR200.

Parameter Shortwave Longwave

Nomenclature 100-M5-SN-I 100-SM-LC-L

Spectral Centre Wavelength 770-850nm 1300nm

Operating Range 2-500m 2-10km

Launch Power Max 1.3 dBm -3 dBm

Launch Power Min -7 dBm

Receive Power Min -13 dBm -20 dBm

Receive Power Max 1.3dBm -3 dBm

Extinction Ratio 6 dB 9 dB

TX Deterministic Jitter 20 ps 20 ps

Fibre Diameter 50um 9um

3-6 Safety

Class Multi-mode Single-mode

62-9301-01

Page 39

Parameter Shortwave Longwave

Nominal Bit Rate 1061.5 Mbaud 1062.5 Mbaud

OFC none none

Class 1 Laser Products are not considered hazardous.

Product Information

Each Fibre Channel communications port consists of a

transmitter and receiver optical subassembly. The transmitter

subassembly contains internally a semiconductor laser diode

in the wavelength of 780 or 1300 nanometers.

WARNING

There are no user maintenance or service

operations or adjustments to be performed on

any of the GBIC modules.

Usage Restrictions

Failure to comply with these usage restrictions may result in

incorrect operation of the system and points of access may

emit laser radiation above the Class 1 limits established by the

IEC and U.S. DHHS.

Product Information 3-7

Page 40

3-8 Safety

62-9301-01

Page 41

4

Installation

Installing the FCR200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Unpacking the Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Mounting the FCR200 in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Materials Needed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Required tools: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Ear Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Slide Rail Mounting (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Interfaces and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Fibre Channel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

SCSI Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Serial Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Autobaud Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Connecting the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Management Information Base (MIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

MIB Fibre Channel Interface Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

MIB SCSI Interface Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

MIB Ethernet and Serial Interfaces Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Page 42

4-2 Installation

62-9301-01

Page 43

Installing the FCR200

Location

Note

The FCR200

contains a cooling

fan mounted in

the rear of the

enclosure and

intake vents on

the front of the

enclosure. The

rear fan vent and

the front intake

vents should

remain clear of

obstructions to

ensure proper

airflow.

4-

This chapter describes how to setup and install the FCR200.

This includes unpacking the FCR200 for the first time, factors

to consider when installing the FCR200, either desktop or rack

installation instructions, and connecting to different types of

devices. Read this chapter carefully and completely before

working with the FCR200.

A number of factors need to be considered in planning the

installation of the FCR200. These factors include the location

of the unit, the use of the unit, and the type of devices to which

the unit will be attached.

The FCR200 Router can be placed on a desktop or mounted in

a standard 19-inch rack depending on the specific

requirements of the installation. The operating environment

should meet the requirements found in Chapter 2. If you plan

to use the router on a tabletop, attach the stick-on feet to the

bottom of the router to protect the surface.

Installing the FCR200 4-3

Page 44

Unpacking the Box

1 Remove all items from the shipping container.

Check each one for damage. Keep the FCR200 in the

protective bag until you are ready to install it.

2 Refer to the packing slip or contents list to make

sure you received all the equipment you ordered. If

an item is missing, contact your sales representative

immediately.

3 Select a location that ensures the front intake vents

and rear fan are clear of obstructions so air flows

freely through the router.

4 Do not connect any devices or cables to the FCR200

until the device is secured in a rack or placed

securely on a flat, level surface.

Mounting the FCR200 in a Rack

Follow the directions below to mount the FCR200 in a

standard rack. Slide rails are optional.

Materials Needed:

Figure 4-1 Materials Needed

4-4 Installation

62-9301-01

Page 45

1 FCR200

2 Left and right mounting rails (optionl)

3 Slide rails (optional)

4 Mounting screws (8 torx screws and 4 phillips

screws) and cage nuts

5 Left and right ears

Required tools:

• Phillips screwdriver

• Standard Torx screwdriver set

Mounting the FCR200 in a Rack 4-5

Page 46

Installation Procedure

Note

Place the FCR200

so the rear fan

vent and the front

intake vents

remain clear of

obstructions to

ensure proper

airflow.

1 Remove the router from the protective bag.

2 Determine where the FCR200 will be mounted.

3 Remove any blanking panels and other equipment

from the chosen rack location.

4 Install the cage nuts on the vertical mounting rails

in the rear of the rack cabinet in accordance with the

desired mounting method.

Figure 4-2 Cage Nut Installation

4-6 Installation

WARNING

Ear Rail Mounting

To reduce injury or equipment damage, the

mounting bracket must be level. If the

brackets are not level, the FCR200 cannot

be installed properly.

If you are mounting the FCR200 in the front of the rack with

the connectors facing the back or in the back of the rack with

the connectors facing the front, attach the mounting ears,

using phillips screws, as shown in Figure 4-3 on page 4-7.

62-9301-01

Page 47

Figure 4-3 Mounting at Front of rack

If you are mounting the FCR200 in the front of the rack with

the connectors facing the front or in the back of the rack with

the connectors facing the back, attach the mounting ears as

shown in Figure 4-4.

Figure 4-4 Mounting at back of Rack

1 Attach each bracket to the mounting rail, using two

torx screw on each side. Tighten the screws

securely.

Installation Procedure 4-7

Page 48

Slide Rail Mounting (Optional)

WARNING

To reduce injury or equipment damage, the

mounting bracket must be level. If the

brackets are not level, the FCR200 cannot

be installed properly.

1 Locate the front of the mounting brackets

Figure 4-5 Front of Mounting Brackets

4-8 Installation

2 Attach the brackets to the front mounting rails,

using two torx screws on each side. Be sure to use

only the top and bottom holes in each bracket. (The

middle holes will be used to attach the front cover

panel after the unit is installed.) Tighten the screws

securely.

62-9301-01

Page 49

Figure 4-6 Attaching the Brackets

Figure 4-7 Attaching Brackets

3 Attach the slide rails to the FCR200 using two torx

screws on each side. Slide the unit back into the rack

and push in on the front tabs until the rails snap into

place.

Installation Procedure 4-9

Page 50

Figure 4-8 Attaching Side Rails

Once the FCR200 is installed, you are ready to connect it to the

other system components.

4-10 Installation

62-9301-01

Page 51

Interfaces and Connections

There are four types of physical interfaces to the FCR200:

• Fibre Channel

•SCSI

• RS-232 (Serial port)

•Ethernet

The RS-232 and Ethernet ports are used primarily for FCR200

configuration and management. MIB information for each

interface is discussed later in this chapter.

Figure 4-9 Port Locations

Interfaces and Connections 4-11

Page 52

Fibre Channel Connection

Before connecting the FCR200 to other Fibre Channel devices,

it is important to understand the configuration requirements

of the environment to which it will be connected. Failure to

correctly configure a Fibre Channel device may impair the

operation of the storage area network to which it is attached.

Typical installations will have the FCR200 connected to either

an Arbitrated Loop or Switched Fabric environment. For an

arbitrated loop, the unit can be directly attached to the Fibre

Channel host bus adapter or target device, in a point to point

fashion. Arbitrated loops also allow for the use of Fibre

Channel hubs, to which the unit can be directly attached. In

Fibre Channel switched environments, the switch is directly

attached to the FCR200.

Figure 4-10 Configuration with Tape library

4-12 Installation

Both switches and hubs may allow for individual ports to be

configured for different media types. The FCR200 must be

connected to the hub or switch port with the appropriate

cabling for the media type in use on both the FCR200 and the

port to which it is connected.

The FCR200 supports various Fibre Channel media types

through the use of an external Gigabaud Interface Converter

(GBIC).

Available media types include:

Copper Support 1.0625 Gbaud HSSDC connector

or 1.0625 Gbaud DB9 connector

62-9301-01

Page 53

Multi-Mode Fiber Support 1.0625 Gbaud Dual SC

connectors

Single-Mode Fiber Support1.0625 Gbaud Dual SC

connectors

To connect the FCR200 to the Fibre Channel Storage Area

Network:

1 Locate the Fibre Channel port on the back of the

FCR200.

Figure 4-11 Fibre Channel Port

2 Remove the rubber protector from the GBIC, as

shown in Figure 4-12, and push the metal latch

down to lock it into place.

Figure 4-12 Removal of GBIC Protector

Fibre Channel Connection 4-13

Page 54

WARNING

The FCR200 has been qualified with a specific

set of GBICs. Using a GBIC that has not been

qualified may cause the FCR200 to operate

improperly or to void approval and certifications

3 With the FCR200 powered off, connect the FCR200

into your Fibre Channel environment using the

appropriate cabling. The connectors on the FCR200

are keyed. Be sure to insert the cable connectors in

the proper orientation.

4-14 Installation

62-9301-01

Page 55

SCSI Connection

The FCR200 supports Fast/Ultra Wide SCSI. The FCR200 is

factory configured to support either a Single-Ended or

Differential SCSI bus. Four 68-pin D-shell connectors are

located on the rear panel of the unit, allowing the unit to be

attached in the middle or at the end of a SCSI bus. If the

FCR200 is located at one end of the SCSI bus, an external

terminator should be installed. Two terminators are provided

with the FCR200.

Single-Ended SCSI support is indicated by

this symbol on the rear of the FCR200.

Differential SCSI support is indicated by

this symbol on the rear of the FCR200.

The FCR200 supplies termination power (TERMPWR) on each

SCSI bus. A self-resetting fuse is used that will reset after the

fault is cleared.

To connect the FCR200 to a SCSI bus:

1 Power off your SCSI devices.

2 Connect a SCSI cable to one of the SCSI connectors

on the back of the router. If necessary, use a narrowto-wide adapter.

3 Connect the other end of the SCSI cable to the next

SCSI device on the bus.

4 If the FCR200 is at the end of the SCSI bus, place the

terminator provided with the router on the

FCR200’s other SCSI connector on the same bus. If

the router is not at the end of the bus, attach a

second SCSI cable to the other SCSI connector. Use

a narrow-to-wide adapter, if necessary. Connect

this cable to the next device on the bus.

SCSI Connection 4-15

Page 56

Figure 4-13 FCR200 SCSI Connection

5 Make sure that each bus is terminated correctly.

The device at each end of each bus must be

terminated.

Figure 4-14 SCSI Terminator

4-16 Installation

6 Power on your SCSI devices.

7 After all the SCSI devices have completed their

individual POSTs, power on the FCR200.

62-9301-01

Page 57

Ethernet Connection

Note

The FCR200

contains a unique

Ethernet MAC

address that is

assigned during

the

manufacturing

process.

10BaseT Ethernet connectivity is used to provide enhanced

management and configuration capabilities. The RJ-45

connector on the unit can be directly connected to a standard

10BaseT Ethernet network.

Configuration is required to set the IP network address to

allow for use of the configuration capabilities of this port.

Refer to

Chapter 6

Ethernet capabilities include Telnet for configuration, FTP

and TFTP for firmware upgrades, and SNMP for

configuration and management.

for details on setting the IP network address.

Figure 4-15 FCR200 Ethernet Port

Ethernet Connection 4-17

Page 58

Serial Port Connection

The RJ11 connector on the rear panel of the FCR200 provides

an RS-232 connection that can be used to configure the

FCR200, monitor diagnostic status, or to update the program

stored in the FCR200’s Flash memory. A cable is provided

with the unit to connect to a DB-9 serial connection. Further

information on the operations allowed via the RS-232 port is

provided in

The RS-232 port operates with the following settings:

Baud Rate: Autobaud (9600, 19200, 38400, 57600, or

Data Bits: 8

Stop Bits: 1

Parity: None

Flow Control: None

Chapter 6

.

115200)

Figure 4-16 FCR200 Serial Port

4-18 Installation

62-9301-01

Page 59

Autobaud Feature

Note

Hitting the Enter

key before the

POST has

completed has no

effect on the

autobaud feature.

Wait until both

the POST and the

Firmware

Initialization

processes have

completed before

hitting the

ENTER key. This

may take up to 90

seconds.

The autobaud feature automatically configures the baud rate

on the FCR200. Once you set the baud rate in the terminal

emulation program, wait until the FCR200 completes the

Power On Self Test (POST) and then the Firmware

Initialization process. This can take up to 90 seconds. Then

press the Enter key five or six times and the FCR200 will

automatically detect the baud rate and configure the router.

The baud rate is then saved in the FCR200’s configuration and

will be retained through future power cycles.

The baud rate in the terminal emulation program must be set

at 9600, 19200, 38400, 57600, or 115200 for the autobaud

feature to recognize it. The FCR200 will not function properly

at any other baud rate.

Autobaud Feature 4-19

Page 60

Connecting the Power Cord

The power cord shipped with the FCR200 is a 120 VAC threeconductor power cord for use in the United States or Canada.

If you are planning to use another input voltage or if you plan

to use the FCR200 outside of the U.S. or Canada, you must

supply your own power cord.

To connect the power cord to the FCR200:

1 Make sure the FCR200’s power is switched off. See

Figure 4-17 for the location of the power switch on

the back of the router.

2 Connect the female end of the power cord to the

power connector on the back of the FCR200.

3 Plug the male end of the power cord into the power

source.

Figure 4-17 FCR200 Power Switch and Outlet

4-20 Installation

62-9301-01

Page 61

Management Information Base (MIB)

A MIB (Management Information Base) is an element used in

network management with SNMP (Simple Network

Management Protocol) and a management station running a

management application, such as Hewlett Packard’s Open

View. The management application uses GETs and SETs to

get system information and set system environment variables.

The ADIC private MIB can be accessed via Ethernet and is

both a diagnostic and a configuration tool for the FCR200.

The following sections outline what MIB information is

available for each interface type on the ADIC MIB. For more

information on accessing the ADIC MIB, contact a support

representative.

MIB Fibre Channel Interface Information

Fibre Channel data reported includes frame and packet

information, upper layer protocol (ULP) type (FCP or IP), and

other Fibre Channel specific information. Draft MIBs for Fibre

Channel N_Ports and F_Ports are in the public domain.

The ADIC private MIB includes:

• Groups for Fibre Channel configuration

• Fibre Channel port physical table

• Fibre Channel port statistics

• SCSI-to-Fibre Channel mapping

• Fibre Channel-to-SCSI mapping

MIB SCSI Interface Information

The MIB gathers SCSI information for management purposes.

This specific MIB provides information about the following:

• Number of I/O operations per bus

• Number of disconnects

• Abort count

• Number of bus resets

• Vital Product Data (VPD) from Inquiry command for each

SCSI device

• SCSI configuration information

This information can be found in the SCSI Statistics Table,

SCSI Config Group, and the SCSI Product Data Groups of the

ADIC private MIB.

Management Information Base (MIB) 4-21

Page 62

MIB Ethernet and Serial Interfaces

Information

The Ethernet interface is used for configuration and

management, so total traffic flow is relatively low. The basic

Ethernet configuration items are found in the Management

Interfaces (MI) Table.

The serial port is provided for user configuration. The serial

port baud rate will be kept in the MI Table.

4-22 Installation

62-9301-01

Page 63

5

Understanding

the

Configuration

Understanding the FCR200 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

General Fibre Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Soft Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Hard Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

General SCSI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Fibre Channel Host to SCSI Target Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Indexed Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Auto Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

SCC Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

SCSI Host to Fibre Channel Target Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Page 64

5-2 Understanding the Configuration

62-9301-01

Page 65

Understanding the FCR200

Configuration

Of primary importance in configuring the FCR200 is

determining the mode of operation required. The unit can be

configured to support Fibre Channel hosts communicating

with SCSI targets, or SCSI hosts communicating with Fibre

Channel targets. The default configuration of the unit allows

for Fibre Channel hosts to connect to SCSI targets.

Configuration is needed in some cases to modify the method

in which this occurs, as well as to support SCSI hosts

communicating with Fibre Channel targets. Other functions

and features can be configured as well, and are discussed

further in this chapter.

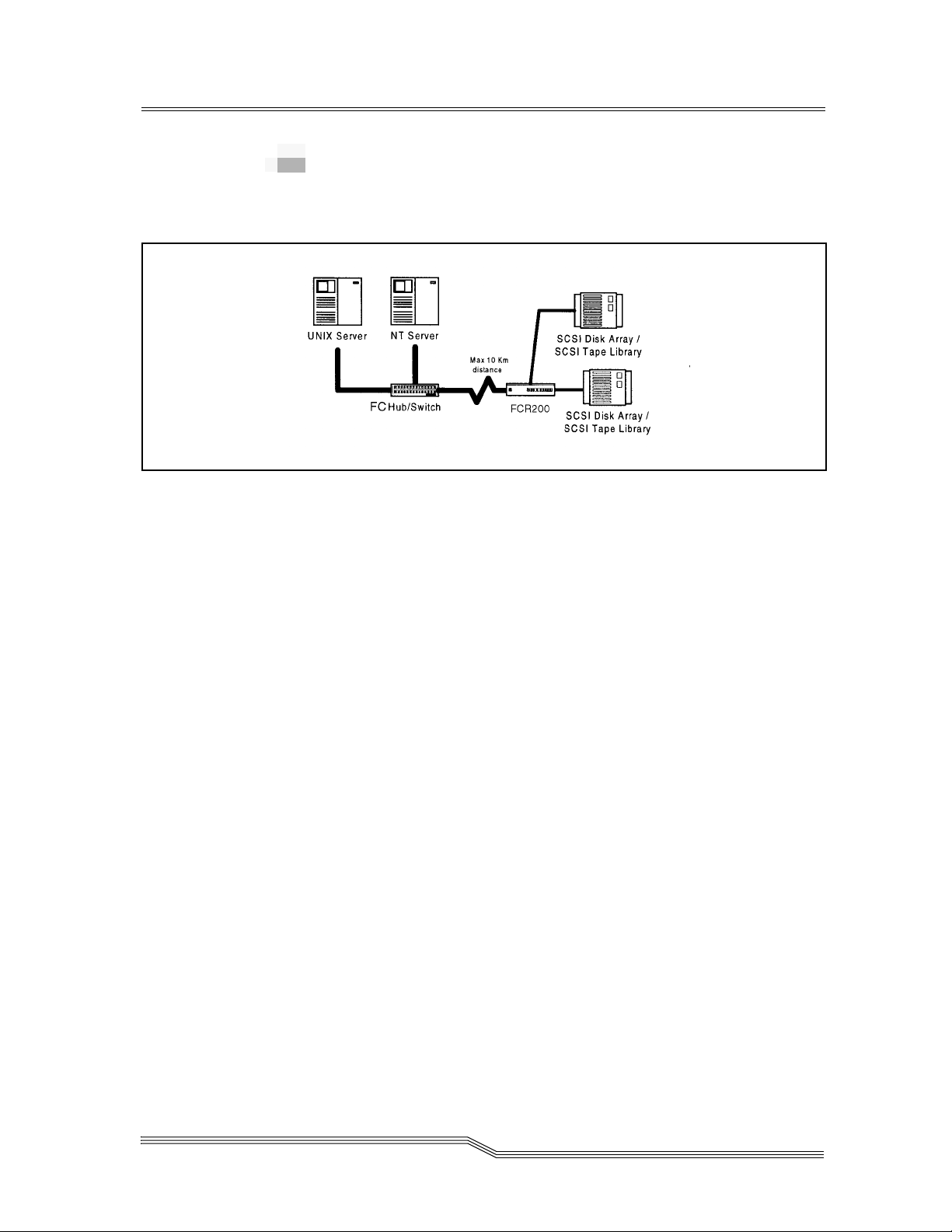

A typical configuration would have a Fibre Channel host

connecting via an arbitrated loop to the FCR200, with SCSI

target devices attached to the FCR200. This configuration,

using a tape library and drives, is represented in Figure 5-1.

The factory default configuration of the unit allows such a

configuration to work without further configuration in most

cases. It should, however, be recognized that more complex

installations or specific application requirements may require

one or more configuration elements to be changed from the

default settings.

5-

Figure 5-1

Configuration with tape library

Understanding the FCR200 Configuration 5-3

Page 66

An understanding of the basic characteristics of Fibre

Channel and SCSI devices is recommended before

configuring the FCR200.

General Fibre Channel Configuration

On a Fibre Channel arbitrated loop, the FCR200 appears at a

single Arbitrated Loop Physical Address (AL_PA). Fibre

Channel devices support two methods for obtaining an

AL_PA, these being soft or hard addressing. The FCR200 can

be configured to use soft addressing (default) or hard

addressing with a selected value.

Soft Addressing

When acquiring a soft address, the FCR200 acquires the first

available loop address starting from address 0. In this mode,

the FCR200 automatically obtains an available address and

participates on the loop, as long as there is at least one address

available on the loop that is connected to the FCR200. Fibre

Channel supports up to 126 devices on an arbitrated loop.

Hard Addressing

When acquiring a hard address, the FCR200 attempts to

acquire the AL_PA value that was specified by user

configuration. If the desired address is not available at loop

initialization time, the FCR200 comes up on the loop in nonparticipating mode. This allows the loop to continue to

operate, although the unit will not be accessible via the Fibre

Channel interface. This would occur when another device on

the arbitrated loop has acquired the same address as that

configured on the FCR200.

Hard addressing is recommended for environments where it

is important that the device addresses do not change. Device

address changes can affect the mapping represented by the

host operating system to the application, and have adverse

effects. An example of such an environment would be a tape

library installation, where the application configuration

requires fixed device identification for proper operation.

Hard addressing will insure that the device identification to

the application will remain constant.

5-4 Understanding the Configuration

62-9301-01

Page 67

When connected to a Fibre Channel Switch, the FCR200 is

identified to the switch as a unique device by the factory

programmed World Wide Name (WWN). No further

configuration is needed, although the WWN can be

configured to a user-defined value through the configuration

interface.

General SCSI Configuration

The FCR200 appears on each SCSI bus as a single initiator. The

default initiator ID is 7, and can be set via configuration to any

valid SCSI address. No other devices on the SCSI bus may use

this address.

The FCR200 provides the capability to reset the SCSI buses

during the boot cycle. This allows the devices on a SCSI bus to

be in a known state. Configuration allows this feature to be

enabled or disabled. This feature is enabled in the default

configuration.

The FCR200 negotiates for the maximum values for transfer

rates and data width on a SCSI bus. If an attached device does

not allow the full rates, the unit will use the rates negotiated

for that device. Negotiation is on a device specific basis, so the

unit can support a mix of device types on the same bus.

Fibre Channel Host to SCSI Target

Configuration

This section describes the configuration of the FCR200 when

acting as a target to a Fibre Channel Initiator, passing FCP

requests through to SCSI target devices.

This is configured as the default, using soft addressing on the

Fibre Channel loop and auto addressing for the target device

mapping. Auto addressing is described further in this section.

The FCR200 automatically detects if it is connected to a loop

or a switch, and will use the appropriate type without further

configuration.

Address Mapping

The FCR200 supports three addressing methods for mapping

SCSI targets to Fibre Channel Hosts:

Indexed Addressing Allows you to edit and maintain a

static address mapping table.

General SCSI Configuration 5-5

Page 68

Auto Addressing Automatically creates a new address

mapping table every time the

FCR200 is power cycled.

SCC Addressing Implements the SCSI-3 Controller

Commands SCSI storage array

addressing to address SCSI devices

attached to the FCR200.

Note

The SCSI bus

number

corresponds to

the physical SCSI

port on the back

of the FCR200.

Indexed Addressing

SCSI Targets are selected by mapping the appropriate values

into the FCP LUN field, and correlating a Fibre Channel LUN

value to a SCSI Bus:Target:LUN value. The FCR200 acts as a

single initiator on each SCSI bus, defaulting to ID 7. All

commands passed through to a SCSI bus originate from this

SCSI ID.

As an example, SCSI bus 0 corresponds to SCSI port 0 on the