Page 1

AdeptSix 300CR Robot

Instruction Handbook

Page 2

Page 3

AdeptSix 300CR Robot

Instruction Handbook

P/N 01600-000

Rev. A

August 2002

3011 Triad Drive • Livermore, CA 94550 • USA • Phone 925.245.3400 • Fax 925.960.0452

Otto-Hahn-Strasse 23 • 44227 Dortmund • Germany • Phone (49) 231.75.89.40 • Fax(49) 231.75.89.450

41, rue du Saule Trapu • 91300 • Massy • France • Phone (33) 1.69.19.16.16 • Fax (33) 1.69.32.04.62

Page 4

The information contained herein is the property of Adept Technology, Inc., and shall not be reproduced in whole or in part without prior written approval of Adept Technology, Inc. The information herein is subject to change without notice and should not be construed as a commitment by

Adept Technology, Inc. This manual is periodically reviewed and revised.

Adept Technology, Inc., assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation

of future documentation. Please email your comments to: techpubs@adept.com.

Copyright

2002 by Adept Technology, Inc. All rights reserved.

The Adept logo, CHAD, the CHAD logo, and Soft Machines

are registered trademarks of Adept Technology, Inc.

ActiveV, Adept, Adept 1060, Adept 1060+, Adept 1850, Adept 1850 XP, Adept 540, Adept 560,

Adept C40, Adept C60, Adept CC, Adept CHADIQ, Adept CHADIQh, Adept CHADIQt, Adept

Cobra 550, Adept Cobra 550 CleanRoom, Adept Cobra 600, Adept Cobra 800, Adept DeskTop,

Adept Digital Workcell, Adept FFE, Adept FlexFeeder 250, Adept IC, Adept Impulse Feeder, Adept

LineVision, Adept MC, Adept MV, Adept MV-10, Adept MV-19, Adept MV4, Adept MV-5, Adept

MV-8, Adept NanoBonder EBS, Adept NanoBonder LWS, Adept NanoCell, Adept NanoStage

L1P2, Adept NanoStage L3, Adept NanoStage L3P2, Adept OC, Adept SmartAmp, Adept

SmartAxis, Adept SmartController CS, Adept SmartController CX, Adept SmartModule, Adept

SMIF-EZ, AdeptAlign 650, AdeptAtlas, AdeptCartesian, AdeptForce, AdeptFTP, AdeptGEM,

AdeptModules, AdeptMotion, AdeptMotion Servo, AdeptMotion VME, AdeptNet, AdeptNFS,

AdeptOne, AdeptOne-MV, AdeptOne-XL, AdeptRAPID, AdeptSix 300, AdeptSix 300CR,

AdeptTCP/IP, AdeptThree, AdeptThree-MV, AdeptThree-XL, AdeptTwo, AdeptVicron,

AdeptVicron 300S, AdeptVicron 310D, AdeptVision, AdeptVision AVI, AdeptVision AGS,

AdeptVision GV, AdeptVision I, AdeptVision II, AdeptVision VME, AdeptVision VXL,

AdeptVision XGS, AdeptVision XGS II, AdeptWindows , AdeptWindows Controller,

AdeptWindows DDE, AdeptWindows Offline Editor, AdeptWindows PC, AIM, AIM Command

Server, AIM Dispense, AIM PCB, AIM VisionWare, A-Series, AutoCal, AutoTune, AutoWidth,

CCM, CCMII, CGM, CHAD ACM, CHAD ACT, CHAD AF, CHAD AutoClinchMaster, CHAD

BLT, CHAD CH, CHAD ClinchMaster, CHAD ClinchMaster II, CHAD CS, CHAD CSII, CHAD

ECA, CHAD GuideMaster, CHAD HT, CHAD LGM, CHAD LLG, CHAD MGE, CHAD MixTech,

CHAD MTM, CHAD OFM, CHAD PIE, CHAD QCB, CHAD RC, CHAD SGE, CHAD TM, CHAD

VT, CimStation, CimStation Robotics, FlexFeedWare, HexSight, HyperDrive, Microenvironment,

MicroV

SMIF-C, SMIF-EZX, SMIF-Z, SMIF-ZX, SoftAssembly, S-Series, UltraOne, V, V

+

, MotionWare, ObjectFinder, ObjectFinder 2000, PackOne, PalletWare, Production PILOT,

SILMA CellFLEX, SILMA CellPRO, SILMA PaintPRO, SILMA PressPRO, SILMA SpotPRO,

+

, and VisionTeach

are trademarks of Adept Technology, Inc.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Printed in the United States of America

Page 5

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2 Overview of Typical System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Read Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Controller and PA-4 Power Chassis . . . . . . . . . . . . . . . . . . . . . 14

Installing System Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adding End of Arm Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Turning On the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3 Checking Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Locating the Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5 How Can I Get Help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.6 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.7 Knowledge Express . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 Dangers, Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Precautions and Required Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Definition of a Manipulating Industrial Robot . . . . . . . . . . . . . . . . . . . . . . . 20

Safety Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Risk Assessment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Severity of Injury . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Avoidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control System Behavior Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4 Intended Use of the Robots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.5 Robot Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Acceptable Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unacceptable Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.6 AdeptSix 300CR Hazards and Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.7 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.8 Safety Requirements for Additional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.9 Working Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.10 Qualification of Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.11 Safety Equipment for Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.12 Protection Against Unauthorized Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

AdeptSix 300CR Robot Instruction Handbook, Rev. A 5

Page 6

Table of Contents

2.13 Safety Aspects While Performing Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 30

2.14 Risks That Cannot Be Avoided . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.15 Risks Due to Incorrect Installation or Operation . . . . . . . . . . . . . . . . . . . . . . . . 30

2.16 What to Do in an Emergency Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3 Robot Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.1 Safety Guard Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Safety Standard Information (ISO10218) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 Transporting Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Using the Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Using the Forklift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3 Shipping Bracket and Jig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4 Installing Cover Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5 Types of Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6 Mounting Procedures for Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

When the Robot and Mounting Fixture are

Installed on a Common Installation Base . . . . . . . . . . . . . . . . . . . . . . . . . . 37

When the Robot is Mounted Directly on the Floor . . . . . . . . . . . . . . . . . . . . 38

3.7 Axis Naming Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.8 Grounding the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.9 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4 System Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1 System Cable Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Adept MV Controller System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Adept SmartController System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2 Cable Connections from Robot to PA-4 Power Chassis . . . . . . . . . . . . . . . . . . . 43

Connection to the Robot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connection to the PA-4 Power Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3 Cable Connections to MV Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Installing the MV Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cable Connections to MV Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connecting User-Supplied Safety and I/O Equipment. . . . . . . . . . . . . . . . . 46

4.4 Cable Connections to SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installing the SmartController. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cable Connections to SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting User-Supplied Safety and I/O Equipment. . . . . . . . . . . . . . . . . 47

5 End of Arm Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1 Allowable Wrist Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 7

Table of Contents

5.2 Wrist Tool Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3 End of Arm Tooling Load Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 Calculating the Moment of Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5 Mounting Equipment - Allowable Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.6 User Electrical Lines and Air Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 System Operation - MV Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mechanical Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

AC Power to Adept Components Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Board and Cable Installation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

User-Supplied Safety Equipment on JUSER and JSIO Connector Checks . 63

6.3 Applying Power to the Adept Control System . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 Checks After Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.5 Calibrate Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.6 Turning Off the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.7 Learning to Operate/ Program the AdeptSix 300CR Robot . . . . . . . . . . . . . . . 66

7 System Operation - SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.2 Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Mechanical Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Power to the Adept Components Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Board and Cable Installation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

User-Supplied Safety Equipment on XUSR Connector Checks . . . . . . . . . . 69

E-Stop Button and Switch Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3 Applying Power to the Adept Control System . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.4 Checks After Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.5 Calibrate Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.6 Turning Off the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.7 Learning to Operate/ Program the AdeptSix 300CR Robot . . . . . . . . . . . . . . . 72

8 Using the Manual Control Pendant (MCP) . . . . . . . . . . . . . . . . . . . . . . 73

8.1 MCP Usage for Six-Axis Robots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Joint Mode (Single-Axis Movement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

AdeptSix 300CR Robot Instruction Handbook, Rev. A 7

Page 8

Table of Contents

WORLD Coordinate System (WORLD Mode on the MCP) . . . . . . . . . . . . . . 75

TOOL Coordinate System (TOOL Mode on the MCP) . . . . . . . . . . . . . . . . . 76

Coordinate System Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9 Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

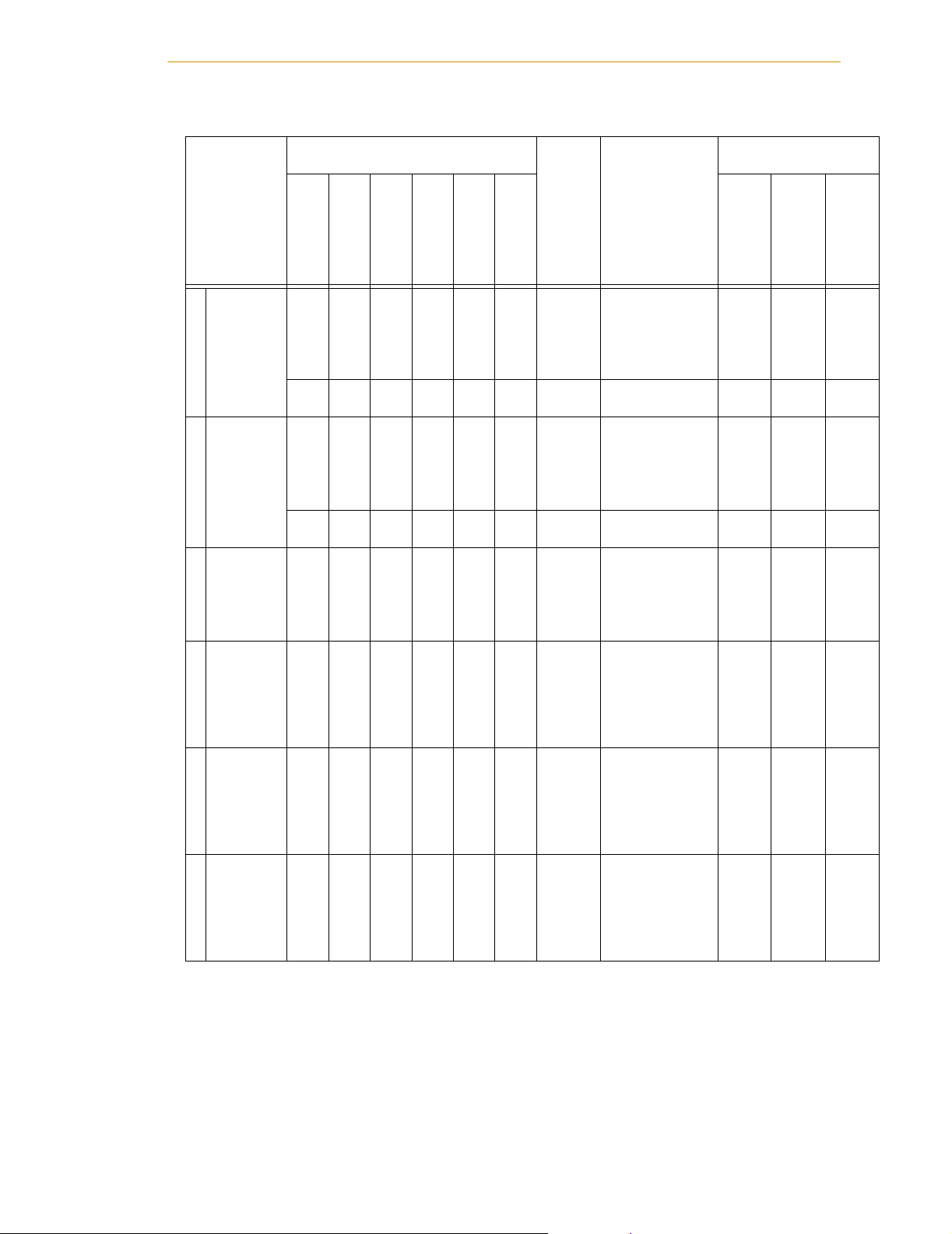

9.1 Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.2 Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Battery Unit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Grease Replenishment for Axis 1 Speed Reducer . . . . . . . . . . . . . . . . . . . . 84

Grease Replenishment for Axis 2 Speed Reducer. . . . . . . . . . . . . . . . . . . . . 85

Grease Replenishment for Axis 3 Speed Reducer. . . . . . . . . . . . . . . . . . . . . 86

Grease Replenishment for Axis 4 and Axis 5 Speed Reducers . . . . . . . . . . 87

Grease Replenishment for Axis 6 Speed Reducer. . . . . . . . . . . . . . . . . . . . . 88

Notes for Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Installing and Using Brake Release Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

9.3 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.1 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.2 Robot Cleanroom Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.3 Part Names and Working Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.4 Baseplate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.5 Dimensions and Working Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.6 Axis 5 Working Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.7 Axis 2 and 3 Effect on Axis 4 Working Range . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 9

List of Figures

Figure 1-1. Robot ID Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2-1. AdeptSix 300CR — Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3-1. Transporting Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 3-2. Using the Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 3-3. Installing Cover Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 3-4. Mounting the Robot Baseplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 3-5. Direct Mounting on the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 3-6. Grounding Method for Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 4-1. System Cable Diagram with Adept MV Controller . . . . . . . . . . . . . . . . . . . . 41

Figure 4-2. System Cable Diagram with Adept SmartController . . . . . . . . . . . . . . . . . . 42

Figure 4-3. Interconnect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 4-4. Interconnect Cable Connection to the Robot . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 4-5. PA-4 Power Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 5-1. Moment Arm Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 5-2. Wrist Tool Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 5-3. Center of Gravity: Calculating Tool Load Information . . . . . . . . . . . . . . . . . 51

Figure 5-4. Moment of Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 5-5. Center of Gravity: Sealing Gun Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 5-6. Moment of Inertia for Hexahedron and Cylinder . . . . . . . . . . . . . . . . . . . . . 54

Figure 5-7. Center of Gravity: Large Tool and Workpiece Example . . . . . . . . . . . . . . . 55

Figure 5-8. Center of Gravity: Dual End Effector Example . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 5-9. Installing Peripheral Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 5-10. User Electrical and Air Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 5-11. Detailed Drawing of Connector Pin Numbers . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 8-1. Joint Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 8-2. World Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 8-3. Tool Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 8-4. Right Hand Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 9-1. Inspection Parts and Inspection Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 9-2. Battery Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 9-3. Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 9-4. Axis 1 Speed Reducer Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 9-5. Axis 2 Speed Reducer Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 9-6. Axis 3 Speed Reducer Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 9-7. Axis 4 and Axis 5 Speed Reducers Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 9-8. Axis 6 Speed Reducer Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 9-9. Encoder Connector Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 9-10. Manual Brake Release Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 10-1. Part Names and Working Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

AdeptSix 300CR Robot Instruction Handbook, Rev. A 9

Page 10

List of Figures

Figure 10-2. Baseplate Dimensions (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 10-3. Dimensions and Working Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 10-4. Axis 5 Working Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 10-5. Axis 2 and Axis 3 Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 11

List of Tables

Table 1-1. Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 2-1. Sources for International Standards and Directives . . . . . . . . . . . . . . . . . . . . .22

Table 2-2. Partial List of Robot and Machinery Safety Standards . . . . . . . . . . . . . . . . . . .23

Table 3-1. Maximum Repulsion Forces of the AdeptSix 300CR . . . . . . . . . . . . . . . . . . . . .37

Table 3-2. Axis Naming Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 5-1. Moment and Total Inertia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 6-1. LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Table 9-1. AdeptSix 300CR Maintenance Schedule and Inspection Items . . . . . . . . . . .78

Table 9-2. Inspection Parts and Grease Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Table 10-1. Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

AdeptSix 300CR Robot Instruction Handbook, Rev. A 11

Page 12

Page 13

1.1 Product Description

The AdeptSix 300CR is a compact, high-performance cleanroom robot that provides the

application flexibility of six axis articulation running on the Adept platform. The arm

design provides superior reach capability with a very small footprint to maximize system

flexibility and minimize cell layout size. The AdeptSix 300CR is available with either the

Adept MV controller or the Adept SmartController.

Adept software and controllers simplify integration of the robot by combining all of the

functions found in a typical robot work cell, which is common across the extensive Adept

Product Line. Available options for the AdeptSix 300CR include integral AVI vision,

adaptive Force Sensing, and real-time Conveyor Tracking.

The overall reach of the AdeptSix 300CR is 677 mm with a footprint of 300 mm. Maximum

payload is 3 kg. The AdeptSix 300CR comes standard with the ability to be mounted

either in a tabletop, side or overhead position providing maximum application flexibility.

Applications include assembly, packaging, machine load/unload, quality inspection,

sorting and other high performance tasks.

Introduction 1

1.2 Overview of Typical System Installation

This section provides an overview of the installation process for a typical AdeptSix 300CR

system.

Read Safety Information

1. Read Chapter 2 to understand general safety information about the AdeptSix

300CR robot system.

Installing the Robot

1. Prepare for installation, including installing safeguards, by following Section 3.1

to Section 3.3.

2. Mount the robot according to procedures described in Section 3.4. to Section 3.6

3. Install grounding cable on the robot. See Section 3.8.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 13

Page 14

Chapter 1 - Introduction

Installing the Controller and PA-4 Power Chassis

Adept MV Controller

1. Refer to the AdeptSix Controller Installation Guide to install the Adept MV

controller and the PA-4 power chassis.

2. Install the AdeptWindows PC user interface according to instructions in the

controller manual.

Adept SmartController

1. Refer to the AdeptSix Controller Installation Guide to install the SmartController

and the PA-4 power chassis.

2. Install the AdeptWindows PC user interface according to instructions in the

controller manual.

Installing System Cables

1. Connect the system cables between the robot, controller, and PA-4 power chassis.

See Chapter 4.

2. See Figure 4-1 on page 43 for the system cable diagram for an Adept MV

controller.

3. See Figure 4-2 on page 44 for the system cable diagram for an SmartController.

Adding End of Arm Tooling

Refer to Chapter 5 for complete information on adding end of arm tooling to the robot.

Turning On the System

Refer to Chapter 6 for an Adept MV controller or Chapter 7 for an SmartController. These

chapters contain checklists to verify the installation is correct and to test all safety circuits

before using the robot.

1.3 Checking Package Contents

When the package arrives, check the contents for the following standard items (check any

other options ordered, as well):

• AdeptSix 300CR Robot

• Adept MV controller or SmartController

• Adept PA-4 power chassis

• Manual Control Pendant (MCP) (optional)

• Controller Interface Panel (CIP2) or Adept Front Panel

• Interconnect cables between controller and robot

14 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 15

WARNI NG: Confirm that the robot and the controller have

the same serial number. Special care must be taken when

more than one robot is to be installed. If the numbers do

not match, robots may not perform as expected and cause

injury or damage.

1.4 Locating the Serial Number

The ID serial number of the AdeptSix 300CR robot corresponds to the ID number of the

controller. You can check the controller ID using the V+ ID command. The robot’s ID serial

number is located on a label on the robot base. See Figure 1-1.

Locating the Serial Number

Location

of serial

label

Figure 1-1. Robot ID Serial Number

AdeptSix 300CR Robot Instruction Handbook, Rev. A 15

Page 16

Chapter 1 - Introduction

1.5 How Can I Get Help?

Refer to the How to Get Help Resource Guide (Adept P/N 00961-00700) for details on

getting assistance with your Adept software and hardware.

Additionally, you can access the following information sources on Adept’s corporate web

site:

• For Contact information: http://www.adept.com/main/contact/index.html

• For Product Support information: http://www.adept.com/main/services/index.asp

• For general information about Adept Technology, Inc.: http://www.adept.com

1.6 Related Manuals

This manual covers the installation and maintenance of an AdeptSix 300CR system. There

are additional manuals that cover programming the system, reconfiguring installed

components, and adding other optional components. The following manuals (available on

the Knowledge Express CD-ROM provided with each system) provide information on

advanced configurations and system specifications.

Table 1-1. Related Manuals

Manual Title Description

AdeptSix Controller

Installation Guide

Adept MV Controller User’s

Guide

Adept SmartController

User’s Guide

AdeptWindows Installation

Guide

AdeptWindows User’s

Guide

Instructions for Adept

Utility Programs

V+ Operating System User’s

Guide

V+ Language User’s Guide Describes the V

Describes the installation process for the Adept MV controller

and the Adept SmartController.

Describes the configuration and interface options for all

Adept-supplied processor boards and components that can be

installed in an Adept control system.

Contains complete information on the operation of the Adept

SmartController and the optional sDIO product.

Describes the basic installation process for the AdeptWindows

PC user interface.

Describes complex network installations, installation and use

of NFS server software, the Adept Windows Offline Editor, and

the AdeptWindows DDE software.

Describes the utility programs used for advanced system

configurations, system upgrades, file copying, and other

system configuration procedures

Describes the V

operations, monitor commands, and monitor command

programs.

control system.

+

operating system, including disk file

+

language and programming of an Adept

16 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 17

1.7 Knowledge Express

In addition to the Knowledge Express CD-ROM containing Adept manuals, you can find

Adept product documentation on the Adept web site in the Knowledge Express area. The

Knowledge Express search engine allows you to locate information on a specific topic.

Additionally, the Library menu provides a list of available product documentation.

To access Adept’s Knowledge Express, type the following URL into your browser:

http://www.adept.com/Main/KE/DATA/adept_search.htm

or, select the Knowledge Base link from the Services area of the Adept web site.

Knowledge Express

AdeptSix 300CR Robot Instruction Handbook, Rev. A 17

Page 18

Page 19

Safety 2

2.1 Dangers, Warnings, Cautions, and Notes

There are four levels of special alert notation used in this manual. In descending order of

importance, they are:

DANGER: This indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNI NG: This indicates a potentially hazardous

situation which, if not avoided, could result in serious

injury or major damage to the equipment.

CAUTION: This indicates a situation which, if not avoided,

could result in minor injury or damage to the equipment.

NOTE: This provides supplementary information, emphasizes a point or

procedure, or gives a tip for easier operation.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 19

Page 20

Chapter 2 - Safety

2.2 Precautions and Required Safeguards

This manual must be read by all personnel who install, operate, or maintain Adept

systems, or who work within or near the workcell.

CAUTION: Adept Technology strictly prohibits installation,

commissioning, or operation of an Adept robot without

adequate safeguards. These must be compliant with applicable

local and national standards. Installations in EU and EEA

countries must comply with EN 775/ISO 10218, especially

sections 5,6; EN 292-2; and EN 60204-1, especially section 13.

Definition of a Manipulating Industrial Robot

The definition of a manipulating robot according to (ISO 10218:1992(E)) is as follows:

“A manipulating robot is an automatically controlled, reprogrammable, multipurpose,

manipulative machine with several degrees of freedom, which may be either fixed in

place or mobile for use in industrial automation applications.”

Safety Barriers

Safety barriers must be provided that prevent personnel from entering the workcell

whenever power is applied to the equipment. Adept systems are computer-controlled and

may activate remote devices under program control at times or along paths not

anticipated by personnel. It is critical that safeguards be in place to prevent personnel

from entering the workcell whenever power to the equipment is present.

The robot system integrator (user or operator) must ensure that adequate safeguards,

safety barriers, light curtains, safety gates, safety floor mats, etc., are installed. The robot

workcell must comply with applicable local and national standards (see Section 2.8 on

page 28).

The height and the distance of the safety fence from the robot must ensure that personnel

cannot reach the danger zone of the robot.

The Adept control system has features that aid the user in constructing system safeguards,

including customer emergency stop circuitry and digital input and output lines. The

emergency power-off circuitry is capable of switching external power systems and can be

interfaced to the appropriate user-supplied safeguards. See the AdeptSix Controller

Installation Guide for additional information.

Impact and Trapping Points

Adept robots are capable of moving at high speeds. If a person is struck by a robot

(impacted) or trapped (pinched) serious injury could occur. Robot configuration, joint

speed, joint orientation, and attached payload all contribute to the total amount of energy

available to cause injury.

20 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 21

Precautions and Required Safeguards

Hazards From Expelling a Part or Attached Tooling

The maximum joint tip speeds that can be achieved by the AdeptSix 300CR robot are

listed in Table 10-1 on page 95. Any tooling, fixtures, end effectors, etc., mounted to the

user flange, or one of the other axes of the robot must be attached by sufficient means to

resist being expelled from the robot. Additionally, any payload must be held by the end

effector in a manner that prevents the payload from being expelled accidentally.

The safety fence or barrier constructed around the robot must be designed to withstand

the impact of any item expelled accidentally from the robot. Projectile energy can be

calculated using the formula E = mv

2

1

.

--2

NOTE: In the Projectile energy formula above:

•E = Energy

•m = Mass

•v = Velocity

Additional Safety Information

The standards and regulations listed in this handbook contain additional guidelines for

robot system installation, safeguarding, maintenance, testing, startup, and operator

training. Table 2-1 on page 22 lists some sources for the various standards.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 21

Page 22

Chapter 2 - Safety

Table 2-1. Sources for International Standards and Directives

SEMI International Standards

3081 Zanker Road

San Jose, CA 95134

USA

Phone: 1.408.943.6900

Fax: 1.408.428.9600

http://www.semi.org/web/wcontent.nsf/url/stds_home

BSI Group (British Standards)

389 Chiswick High Road

London W4 4AL

United Kingdom

Phone +44 (0)20 8996 9000

Fax +44 (0)20 8996 7400

http://www.bsi-global.com

DIN, Deutsches Institut für Normung e.V.

German Institute for Standardization

Burggrafenstrasse 6

10787 Berlin

Germany

Phone.: +49 30 2601-0

Fax: +49 30 2601-1231

http://www.din.de

American National Standards Institute (ANSI)

11 West 42nd Street, 13th Floor

New York, NY 10036

USA

Phone 212-642-4900

Fax 212-398-0023

http://www.ansi.org

Document Center, Inc.

1504 Industrial Way, Unit 9

Belmont, CA 94002

USA

Phone 415-591-7600

Fax 415-591-7617

http://www.document-center.com

Global Engineering Documents

15 Inverness Way East

Englewood, CO 80112

USA

Phone 800-854-7179

Fax 303-397-2740

http://global.ihs.com

http://www2.beuth.de/ (publishing)

IEC, International Electrotechnical Commission

Rue de Varembe 3

PO Box 131

CH-1211 Geneva 20

Switzerland

Phone 41 22 919-0211

Fax 41 22 919-0300

http://www.iec.ch

Robotic Industries Association (RIA)

900 Victors Way

PO Box 3724

Ann Arbor, MI 48106

USA

Phone 313-994-6088

Fax 313-994-3338

http://www.robotics.org

22 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 23

Risk Assessment

2.3 Risk Assessment

Without special safeguards in its control system, the AdeptSix 300 robot could inflict

serious injury on an operator working within its work envelope. Safety standards in

several countries require appropriate safety equipment to be installed as part of the

system. Table 2-2 lists some of the safety standards that affect industrial robots. It is not a

complete list. Safeguards must comply with all applicable local and national standards for

the location where the robot is installed.

Table 2-2. Partial List of Robot and Machinery Safety Standards

International USA Canada Europe Title of Standard

ISO 10218 EN 775 Manipulating Industrial Robots -

Safety

ANSI/RIA

R15.06

Adept has performed a Risk Assessment for this product, based on the intended

applications of the robot. The conclusions are summarized below.

CAN/CSAZ434-94

Industrial Robots and Robot

Systems - Safety Requirements

EN 292-2 Safety of Machinery - Basic

Concepts, General Principles for

Design

EN 954-1 Safety Related Parts of Control

Systems - General Principles for

Design

EN 1050 Safety of Machinery - Risk

Assessment

Exposure

When arm power is on, all personnel must be kept out of the robot work envelope by

interlocked perimeter barriers. The only permitted exception is for teaching the robot in

Manual Mode by a skilled programmer (see “Qualification of Personnel” on page 29),

who must wear safety equipment (see “Safety Equipment for Operators” on page 29)

and carry the Manual Control Pendant (MCP). Therefore, exposure of personnel to

hazards related to the robot is limited (seldom and/or short exposure time).

Severity of Injury

Provided that skilled personnel who enter the AdeptSix 300CR robot work envelope are

wearing protective headgear, eyeglasses, and safety shoes, it is likely that any injuries

caused by the robot would be slight (normally reversible).

AdeptSix 300CR Robot Instruction Handbook, Rev. A 23

Page 24

Chapter 2 - Safety

Avoidance

Due to its light payload capacity, it is likely that such personnel could avoid being hit by

the robot even in a high-acceleration, runaway, failure condition. However, the

programmer must always carry the MCP when inside the work envelope, as the MCP

provides both E-Stop and Enabling switch functions.

For normal operation (AUTO mode), user-supplied interlocked guarding must be installed

to prevent any person entering the workcell while Arm Power is on.

DANGER: The Adept-supplied system components

provide a Category 1 control system as defined by EN 954.

The robot system must be installed with user-supplied

interlock barriers. The interlocked barrier should interrupt

the DC and AC supplies to the control system in the event

of personnel attempting to enter the workcell when Arm

Power is enabled, except for teaching in Manual Mode.

Failure to install suitable guarding could result in injury or

death.

The Risk Assessment for teaching this product depends on the application. In many

applications, the programmer will need to enter the robot workcell while Arm Power is

enabled to teach the robot. Other applications can be designed so that the programmer

does not have to enter the work envelope while Arm Power is on. Examples of alternative

methods of programming include:

1. Programming from outside the safety barrier.

2. Programming with Arm Power off.

3. Copying program from another (master) robot.

4. Off-line or CAD programming.

Control System Behavior Category

The following paragraphs relate to the requirements of European (EU/EEA) directives for

Machinery, Electric Safety, and Electromagnetic Compatibility (EMC).

In situations with low exposure consideration factors, European Standard EN 1050

specifies use of a Category 1 Control System per EN 954. EN 954 defines a Category 1

Control System as one that employs Category B components designed to withstand

environmental influences, such as voltage, current, temperature, EMI, and well-tried

safety principles. The standard AdeptSix 300 robot control system described in this

handbook employs hardware components in its safety system that meet or exceed the

requirements of the EU Machinery Directive and Low Voltage Directive.

The standard control system is fully hardened to all EMI influences per the EU EMC

Directive and meets all functional requirements of ISO 10218 (EN 775) Manipulating Robots

Safety. In addition, a software-based reduced speed mode has been incorporated to limit

speed and impact forces on the Operator and production tooling when the robot is

operated in Manual Mode.

24 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 25

The standard AdeptSix 300 robot control system meets or exceeds the requirements

imposed by the EN 954 specified Category 1 level of safety.

2.4 Intended Use of the Robots

The installation and use of Adept products must comply with all safety instructions and

warnings in this manual. Installation and use must also comply with all applicable local

and national requirements and safety standards (see Section 2.8 on page 28).

The AdeptSix 300CR Robot robots are intended for use in parts assembly and material

handling for payloads less than 3 kg. See Chapter 5 for complete information tooling and

payloads.

CAUTION: For safety reasons, it is prohibited to make

certain modifications to Adept robots (see Section 2.5).

Intended Use of the Robots

The Adept controller is a component subassembly of a complete industrial automation

system. The controller subassembly must be installed inside a suitable enclosure. The

controller subassembly must not come into contact with liquids. Additionally, the robot

must not come into contact with liquids.

The Adept equipment is not intended for use in any of the following situations:

• In hazardous (explosive) atmospheres

• In mobile, portable, marine, or aircraft systems

• In life-support systems

• In residential installations

• In situations where the Adept equipment will be subject to extremes of heat or

humidity.

CAUTION: The instructions for operation, installation, and

maintenance given in this Instruction Handbook must be

strictly observed.

Non-intended use of an AdeptSix 300 robot can:

• Cause injury to personnel

• Damage the robot or other equipment

• Reduce system reliability and performance

All persons that install, commission, operate, or maintain the robot must:

AdeptSix 300CR Robot Instruction Handbook, Rev. A 25

Page 26

Chapter 2 - Safety

• Have the necessary qualifications

• Read and follow the instructions in this Instruction Handbook exactly

If there is any doubt concerning the application, ask Adept to determine if it is an

intended use or not.

2.5 Robot Modifications

It is sometimes necessary to modify the robot in order to successfully integrate it into a

workcell. Unfortunately, many seemingly simple modifications can either cause a robot

failure or reduce the robot’s performance, reliability, or lifetime. The following

information is provided as a guideline to modifications.

Acceptable Modifications

In general, the following robot modifications do not cause problems, but may affect robot

performance:

• Attaching tooling, utility boxes, solenoid packs, vacuum pumps, cameras, lighting,

etc., to the robot tool mount flange.

• Attaching hoses, pneumatic lines, or cables to the robot. These should be designed

so they do not restrict joint motion or cause robot motion errors.

Unacceptable Modifications

The modifications listed below may damage the robot, reduce system safety and

reliability, or shorten the life of the robot. The warranty of the entire robot or certain parts

may be voided.

CAUTION: Making any of the modifications outlined

below voids the warranty of any components that Adept

determines were damaged due to the modification. You

must contact Adept Customer Service if you are

considering any of the following modifications:

• Modifying any of the robot harnesses or robot-to-controller cables.

• Modifying any robot access covers or drive system components.

• Modifying, including drilling or cutting, any robot surface.

• Modifying any robot electrical component or printed-circuit board.

• Routing additional hoses, air lines, or wires through the inside of the robot.

• Modifications that compromise EMC performance, including shielding.

26 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 27

AdeptSix 300CR Hazards and Warning Labels

2.6 AdeptSix 300CR Hazards and Warning Labels

Risks from injury are clearly identified on the AdeptSix 300CR by warning labels. The

location of these labels is illustrated in Figure 2-1.

2BC

1BC

3BC

2.7 Transport

Always use adequate equipment to transport and lift Adept products. See Chapter 3 for

more information on transporting, lifting, and installing.

WARNING

Moving parts may

cause injury

WARNING

Do not enter

robot work area

Figure 2-1. AdeptSix 300CR — Warning Labels

AdeptSix 300CR Robot Instruction Handbook, Rev. A 27

Page 28

Chapter 2 - Safety

2.8 Safety Requirements for Additional Equipment

Additional equipment used with the AdeptSix 300 robot (grippers, conveyor belts, etc.)

must not reduce the workcell safeguards.

Emergency stop switches must be accessible at all times.

If the robot is to be used in an EU or EEA member country, all components in the robot

workcell must comply with the safety requirements in the European Machine Directive

89/392/EEC (and subsequent amendments) and related harmonized European,

international, and national standards. For robot systems, these include: EN 775/ISO

10218, sections 5,6; EN 292-2; and EN 60204. For safety fences, see EN 294.

In other countries, Adept strongly recommends, that a similar level of safety be obtained

as well as complying with the applicable local and national regulations, including

SEMI-S2.

In the USA, applicable standards include ANSI/RIA R15.06 and ANSI/UL 1740.

In Canada, applicable standards include CAN/CSA Z434.

2.9 Working Areas

Adept robots have a Manual and an Automatic (AUTO) operating mode. While in

Automatic Mode, personnel are not allowed in the workcell.

In Manual Mode, operators with additional safety equipment (see Section 2.11 on page

29) are allowed to work in the robot workcell. For safety reasons the operator should,

whenever possible, stay outside of the robot work envelope to prevent injury. The

maximum speed and power of the robot is reduced, but it could still cause injury to the

operator.

Before performing maintenance in the working envelope of the robot, High Power must

be switched off and the power supply of the robot must be disconnected. After these

precautions, a skilled person is allowed to perform maintenance on the robot. See

Section 2.10 for the specifications.

CAUTION: Never remove any safeguarding and never

make changes in the system that will decommission a

physical safeguard.

28 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 29

2.10 Qualification of Personnel

This manual assumes that all personnel have attended an Adept training course and have

a working knowledge of the system. The user must provide the necessary additional

training for all personnel who will be working with the system.

As noted in this handbook, certain procedures should be performed only by skilled or

instructed persons. For a description of the level of qualification, Adept uses the standard

terms:

• Skilled persons have technical knowledge or sufficient experience to enable them

to avoid the dangers, electrical and/or mechanical.

• Instructed persons are adequately advised or supervised by skilled persons to

enable them to avoid the dangers, electrical and/or mechanical.

All personnel must observe industry-prescribed safety practices during the installation,

operation, and testing of all electrically powered equipment. To avoid injury or damage to

equipment, always remove power by disconnecting the AC power from the source before

attempting any repair or upgrade activity. Use appropriate lockout procedures to reduce

the risk of power being restored by another person while you are working on the system.

Qualification of Personnel

WARNI NG: The user must get confirmation from every

entrusted person before they start working with the robot

that the person:

1. Has received the instruction handbook

2. Has read the instruction handbook

3. Understands the instruction handbook

4. Will work in the manner specified by the instruction handbook.

2.11 Safety Equipment for Operators

Operators must wear safety equipment in the workcell. For safety reasons, operators must

wear the following when they are in the robot workcell.

• Safety glasses

• Protective headgear (hard hats)

•Safety shoes

Warning signs should be posted around the workcell to ensure that anyone working

around the robot system knows they must wear safety equipment.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 29

Page 30

Chapter 2 - Safety

2.12 Protection Against Unauthorized Operation

The system must be protected against unauthorized use. The user or operator must

restrict access to the keyboard and the Manual Control Pendant by locking them in a

cabinet or use another adequate method to prevent access to them.

2.13 Safety Aspects While Performing Maintenance

Only skilled persons with the necessary knowledge about the safety and operating the

equipment are allowed to maintain the robot, controller, and power chassis.

CAUTION: During maintenance and repair, the power of

the Adept controller must be turned off. Lockout measures

must be used to prevent unauthorized personnel from

turning on power.

2.14 Risks That Cannot Be Avoided

The AdeptSix 300 robot control system includes devices that disable High Power if a

system failure occurs. However, certain residual risks or improper situations could cause

hazards. The following situations may result in risks that cannot be avoided:

• Failure of software or electronics that may cause high-speed robot motion in

Manual Mode

• Failure of hardware associated with enabling device or E-Stop system

2.15 Risks Due to Incorrect Installation or Operation

Take precautions to ensure that the following situations do not occur:

• Purposely defeating any aspect of the safety E-Stop system

• Improper installation or programming of the robot system

• Unauthorized use of cables other than those supplied or use of modified

components in the system

• Defeating interlock so that operator can enter workcell with High Power ON

• Ejection of workpiece (see “Hazards From Expelling a Part or Attached Tooling”

on page 21).

30 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 31

What to Do in an Emergency Situation

2.16 What to Do in an Emergency Situation

Press any E-Stop button (a red push-button on a yellow background/field) and then

follow the internal procedures of your company or organization for an emergency

situation. If a fire occurs, use CO

to extinguish the fire.

2

AdeptSix 300CR Robot Instruction Handbook, Rev. A 31

Page 32

Chapter 2 - Safety

32 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 33

Robot Installation 3

3.1 Safety Guard Installation

To ensure safety, make sure to install safety guards, which prevent unforeseen accidents

with personnel and damage to equipment. The following standard is noted below for

your information and guidance.

Safety Standard Information (ISO10218)

Responsibility for Safeguarding

The user of a manipulator or robot system shall ensure that safeguards are provided and

used in accordance with Sections 6, 7, and 8 of this standard. The means and degree of

safeguarding, including any redundancies, shall correspond directly to the type and level

of hazard presented by the robot system consistent with the robot application.

Safeguarding may include but not be limited to safeguarding devices, barriers, interlock

barriers, perimeter guarding, awareness barriers, and awareness signals.

WARNI NG: Install the safety guards. Failure to observe

this warning may result in injury or damage.

WARNI NG: Install the robot in a location where the fully

extended arm and end-of-arm tooling will not reach the

wall, safety guards, or controller. Failure to observe this

warning may result in injury or damage.

WARNI NG: Do not start the robot or even turn on the

power before it is firmly anchored. The robot may

overturn and cause injury or damage.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 33

Page 34

Chapter 3 - Robot Installation

WARNI NG: When mounting the robot on the ceiling or

wall, the base section must have sufficient strength and

rigidity to support the weight of the robot. Also, it is

necessary to consider countermeasures to prevent the

robot from falling. Failure to observe these warnings may

result in injury or damage.

WARNI NG: Do not install or operate a robot that is

damaged or lacking parts. Failure to observe this caution

may cause injury or damage.

CAUTION: Before turning on the power, make sure that

the shipping bracket and jig have been removed. Failure to

observe this caution may result in damage to the gear

train, motors, and other key system components.

3.2 Transporting Method

Using the Crane

As a rule, a crane should be used to remove the robot from its package and to move the

robot into position. The robot should be lifted using wire slings threaded through the

attached eyebolts. Make sure the robot is fixed with jigs before transporting, and lift it into

the position shown in Figure 3-1 on page 35. Points A and B in Figure 3-1 identify the

locations of the shipping bracket and jig.

34 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 35

1X Urethane washer

2X M6 Coned disc springs

(anti-corrosive)

2X Urethane washers

2X Urethane washers

2X M5 10 mm Hexagon

socket head cap bolts

(anti-corrosive)

2X M5 Washers

(anti-corrosive)

M6 8 mm Hexagon

socket head cap bolt

(anti-corrosive)

Details of C

2X M6 40 mm Hexagon

socket head cap bolts

(anti-corrosive)

Details of D

Transporting Method

A

C

2X M8 Eyebolts

D

(provided at factory)

B

Details of E

E

Figure 3-1. Transporting Position

WARNI NG: Sling applications via crane or forklift must be

performed by authorized personnel only. Failure to

observe this caution may result in injury or damage.

CAUTION: Avoid excessive vibration or shock during

transporting. The system consists of precision

components, so failure to observe this caution may

adversely affect performance.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 35

Page 36

Chapter 3 - Robot Installation

Using the Forklift

When using a forklift, the robot should be fixed on a pallet with its shipping bracket and

jig, as shown in Figure 3-2. Insert the forklift blades under the pallet and lift it. The pallet

must be strong enough to support the robot. Transportation of the robot must be

performed slowly in order to avoid overturning, slippage, or damage.

4 x M10 Bolts

Pallet

Forklift Blade Entry

Figure 3-2. Using the Forklift

When using the forklift, note the following:

• Check that the eyebolts are securely fastened.

• Use a wire sling that is strong enough to withstand the weight. (The weight of the

robot is approximately 35 kg, including the shipping bracket and jig.)

• Attached eyebolts are designed to support the robot’s weight. Do not use them for

anything other than transporting the robot.

• Mount the shipping bracket and jig for transporting the robot.

• Avoid exerting force on the arm or motor unit when transporting. Exercise caution

when using transporting equipment other than a crane or forklift, as injury may

occur.

36 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 37

3.3 Shipping Bracket and Jig

The robot is provided with a shipping bracket and jig at points A and B. See Figure 3-3 on

page 38 for details.

• The shipping bracket and jig are painted yellow.

• The number of hexagon socket head cap screws are: A: M6 X 2, B: M5 X 2.

• To prevent the jigs from damaging the paint of the robot, the resin washers are

inserted between the robot and the jigs.

NOTE: Before turning on the power, make sure that the robot is securely

mounted to its mounting base and that the shipping bracket and jig have

been removed. Then store the shipping bracket and jig for future use (in

the event that the robot must be moved again).

NOTE: Remove the protective covers from the 1BC and 2BC connectors

prior to installing the power and signal interconnect cables.

Shipping Bracket and Jig

3.4 Installing Cover Bolts

After mounting the robot, remove the shipping bolts and jigs that were attached when

using the crane, and insert the cover bolts. When transporting the robot again, replace

them with the shipping bolts and jigs. Figure 3-3 illustrates the procedure for installing

the cover bolts

AdeptSix 300CR Robot Instruction Handbook, Rev. A 37

Page 38

Chapter 3 - Robot Installation

A

B

( Attached with shipping products)

2X M8 Eyebolts

Shipping jig

Detail A

Detail B

Shipping jig

Remove shipping jig and

insert the cover bolts

2X M5 Hexagon socket head bolts (anti-corrosive)

2X M5 Washers (anti-corrosive)

2X Urethane washers

Use shipping bolts

Remove shipping jig and

insert the cover bolts

Figure 3-3. Installing Cover Bolts

2X M6 Hexagon socket head bolts (anti-corrosive)

2X Urethane washers

Detail A

Detail B

3.5 Types of Mounting

The robot can be mounted in three different ways: floor-mounted (standard),

wall-mounted, and ceiling-mounted types are available. For wall- and ceiling-mounted

types, contact Adept.

38 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 39

3.6 Mounting Procedures for Robot

The robot should be firmly mounted on a baseplate or foundation strong enough to

support the robot and withstand repulsion forces during acceleration and deceleration.

Construct a solid foundation with the appropriate thickness to withstand maximum

repulsion forces of the robot as shown in Table 3-1.

During installation, if the level of the mounting plane is not right, the robot’s functional

ability may be compromised. The level of the plane of installation must be kept at 0.5 mm

or less. Mount the baseplate in either of the two ways described on page 40.

Table 3-1. Maximum Repulsion Forces of the AdeptSix 300CR

Mounting Procedures for Robot

Maximum horizontal rotating torque

500 N·m (51.0 kgf·m)

(direction of motion Axis 1)

Maximum vertical rotating torque

700 N·m (71.4 kgf·m)

(direction of motion Axes 2 and 3)

When the Robot and Mounting Fixture are Installed on a Common Installation Base

The common base should be rugged and durable to prevent shifting of the robot or the

mounting fixture. The thickness of the common base should be 30 mm or more, and an

M10 size or larger anchor bolt is recommended. Affix the robot by fastening the plate with

the M10 (mm) anchor bolts. The plate is tapped for M10 (35 mm length) bolts. Tighten the

plate fixture, mounting bolts, and anchor bolts securely so that they will not work loose

during operation. See Figure 3-4 for details.

4X M10 35 mm Hexagon socket head cap bolts

(anti-corrosive, provided at factory)

4X M10 Spring washers

(anti-corrosive, provided at factory)

4X M10 Washers

(anti-corrosive, provided at factory)

Details of A

A

Anchor bolts M10 or more

Common installation base

Figure 3-4. Mounting the Robot Baseplate

AdeptSix 300CR Robot Instruction Handbook, Rev. A 39

Page 40

Chapter 3 - Robot Installation

e

When the Robot is Mounted Directly on the Floor

The floor should be strong enough to support the robot. Construct a solid foundation with

the appropriate thickness to withstand maximum repulsion forces of the robot as shown

in Table 3-1 on page 39. As a rough standard, when there is a concrete thickness (floor) of

150 mm or more, the base of the robot can be fixed directly to the floor with M10 anchor

bolts. Before mounting the robot, however, check that the floor is level and that all cracks,

etc. are repaired. Any thickness less than 150 mm is insufficient for mounting, even if the

floor is concrete.

4X M10 35 mm Hexagon

socket head cap bolts (anti-corrosive)

4X M10 Spring washers

(anti-corrosive)

4X M10 Washers

(anti-corrosive)

A

Details of A

150 mm

or more

Figure 3-5. Direct Mounting on the Floor

3.7 Axis Naming Conventions

The robot’s six axes are referred to throughout this documentation as either Axis 1-6 or

Joint (J) 1-6. These terms are used interchangeably. For legacy reasons, these axes are

labelled on the robot as S-axis, L-axis, U-axis, R-axis, B-axis, and T-axis. The table below

shows how these current axis labels correspond to the legacy labels.

Installation base

Grating

Anchor bolts M10 or mor

40 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 41

Table 3-2. Axis Naming Conventions

Grounding the Robot

Current Axis

Labels

Axis 1 (J1) S-axis

Axis 2 (J2) L-axis

Axis 3 (J3) U-axis

Axis 4 (J4) R-axis

Axis 5 (J5) B-axis

Axis 6 (J6) T-axis

See Figure 10-1 on page 96 for a drawing that identifies the various axes.

3.8 Grounding the Robot

Follow local regulations for grounding line size.

NOTE: Do not use this line in common with other ground lines or

grounding electrodes for other electric power, motor power, welding

devices, etc.

Legacy Axis

Labels

NOTE: Where metal ducts, metallic conduits, or distributing racks are

used for cable laying, ground in accordance with Electric Equipment

Technical Standards.

WARNI NG: Ground resistance must be 100 Ω or less.

Failure to observe this warning may result in fire or

electric shock.

WARNI NG: Before wiring, make sure to switch off the

primary power supply, and place a warning sign (for

example, Do not switch on the power). Failure to observe this

warning may result in fire or electric shock.

AdeptSix 300CR Robot Instruction Handbook, Rev. A 41

Page 42

Chapter 3 - Robot Installation

WARNI NG: Wiring must be performed by authorized or

certified personnel. Failure to observe this caution may

result in fire or electric shock.

A

5.5 mm2 or more

Figure 3-6. Grounding Method for Robot

3.9 Environmental Requirements

The environmental conditions of the area in which the robot is installed must satisfy the

conditions listed below:

• Ambient temperature must be from 0° to +45° C

• No moisture should be present (20 to 80% RH)

• Level of the mounting plane for installation must be 0.5 mm or less

• System must be isolated from excessive electrical interference or noise (plasma)

• The area must be free from:

• Dust, soot, and water

• Corrosive gases and liquids, as well as explosive gases

• Excessive vibration (less than 0.5 G)

View A

M8 Bolt - for grounding

(provided at factory)

42 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 43

System Cable Installation 4

ENC

PORTS

1394

ENC

MAI STATUS

DSP STATUS

B

R

A

K

R

S

2

3

X

S

L

V

X

S

L

V

5

C

6

C

3

ON

G/O

O NO

S

SHO

O

ODU

D

D

G

ON

CH2

P

2

C2BC

C

2

-+

4.1 System Cable Diagrams

Adept MV Controller System

CIP (JSLV) to MAI-2 (XSLV1)

AWC IEEE 1394 (Port 1) to

MAI-2 IEEE 1394 (Port 1)

CIP (JAWC) to AWC (CIP)

Ethernet to PC

AWC II

STP

SF

SCR

A

C

B

VME

D

USE ONLY WITH

WARNING:

FOR CONTINUED PROTECTION

250V FUSES

AGAINST RISK OF FIRE,

REPLACE ONLY WITH SAME

TYPE AND RATING OF FUSE.

5AF

~100-240V

50/60HZ

Adept MV

Controller

Dual E Amp #1

Dual E Amp #2

Dual E Amp #3

MAI-2 Module

DUAL E AMP

DUAL E AMP

DUAL E AM

-

D

DO NOT REMOVE OR INSTALL THIS

DO NOT REMOVE OR INSTALL THIS

CH2

adept

technology, i nc.

T REMOVE OR INSTALL THI

MODULE UNLESS HIGH VOLTS LED

M

LE UNLESS HIGH VOLTS LE

IS COMPLETELY DISTINGUISHED

IS COMPLETELY DISTINGUISHE

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

H VOLTS

HIGH VOLTS ON

HI

PWM ON

PWM ON

LOW VOLTS ON

LOW VOLTS

OPEN CKT FAULT

PEN CKT FAULT

HV SA

VER TEMP FAULT

HV SAG/OVER TEMP FAULT

RT FAULT

SHORT FAULT

CH2

CH1

CH2

CH1

A

A

M

M

P

P

L

L

I

I

Þ

F

F

I

I

E

E

R

R

C

C

O

O

N

N

T

T

R

R

O

O

L

L

N

P

G

4

5

CH1

CH2CH1

CH2CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

C

M

N

O

T

2

O

R

P

O

W

E

N

R

P

O

G

U

T

C

1

P

N

2

U

T

2

9

Cable

Arm Power Cable

CN29

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

®

AdeptSix 300CR

Robot

Adept PA-4

Power Chassis

STOP

< 250 mm/s 100%

MCP

CIP-

NET

IP

MCP

Desktop or Laptop PC

Arm

Signal

Cable

1B

User-Supplied

Ground Wire

Figure 4-1. System Cable Diagram with Adept MV Controller

AdeptSix 300CR Robot Instruction Handbook, Rev. A 43

Page 44

Chapter 4 - System Cable Installation

ENC

PORTS

1394

ENC

MAI STATUS

DSP STATUS

B

R

A

K

R

S

2

3

X

S

L

V

X

S

L

V

C

5

C

6

C

3

ON

G/O

T

S

SHO

T

O

T

D

D

G

ON

CH2

P

C

2

Adept

r

(

(

)

el

C

e

STOP

CS

356

*

-+

Adept SmartController System

Controller (XSYS) to MAI-2 (XSLV1)

User-Supplied Ground Wire

Controller

XFP) to

Front Panel

Ethernet to PC

Front Pan

M

P Adapter Cabl

Controller (XMCP) to MCP

Controller SmartServo (Port 1.1) to

MAI-2 IEEE 1394 (Port 1)

User-Supplied Ground Wire

Between PA-4 and SmartController

Adept PA-4

Power Chassis

rtControlle

XFP

*S/N

1-XXXXX

ntroller

24VDC Power from

User-Supplied

Power Supply to

Controller (XDC1)

DUAL E AMP

DO NOT REMOVE OR INSTALL THIS

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

CH1

CH2

A

M

P

F

E

R

C

O

N

T

R

O

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

adept

technology, inc.

User-Supplied

Power Supply

Dual E Amp #1

DUAL E AMP

DO NOT REMOVE OR INSTALL THIS

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

CH1

CH2

A

M

P

L

L

I

I

F

I

I

E

R

C

O

N

T

R

O

L

L

CH2CH1

CH2CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

Dual E Amp #2

Dual E Amp #3

MAI-2 Module

DUAL E AM

-

DO NOT REMOVE OR INSTALL THI

MODULE UNLESS HIGH VOLTS LE

IS COMPLETELY DISTINGUISHE

H VOLTS

HI

PWM ON

LOW VOLTS

PEN CKT FAUL

HV SA

VER TEMP FAUL

RT FAUL

CH1

CH2

A

M

P

L

I

Þ

F

I

E

R

C

O

N

T

R

O

L

N

P

G

4

5

CH1

M

N

O

T

2

O

R

P

O

W

E

N

R

P

O

G

U

T

C

1

P

N

2

U

T

2

9

CN29

Cable

AdeptSix 300CR

Robot

Arm

Power

Cable

MCP

Arm

Signal

Cable

1B

User-Supplied

Ground Wire

Desktop or Laptop PC

Figure 4-2. System Cable Diagram with Adept SmartController

44 AdeptSix 300CR Robot Instruction Handbook, Rev. A

Page 45

Cable Connections from Robot to PA-4 Power Chassis

4.2 Cable Connections from Robot to PA-4 Power Chassis

There are two interconnect cables: the arm signal cable (1BC) and the arm power cable

(2BC). Connect these cables to the robot base connectors and the PA-4 power chassis. Refer

to Figure 4-3 and Figure 4-4 on page 46.

Connection to the Robot

1. Remove the protective covers from the 1BC and 2BC connectors on the back plate

of the robot prior to installing the power and signal cables.

2. Before connecting the two cables described above to the robot, verify the

numbers, 1BC and 2BC, on both interconnect cables and the robot base

connectors.

3. When connecting, adjust the cable connector positions to the main key positions

of the robot, and insert the cables in the following order: Arm Power (2BC), Arm

Signal (1BC).

4. Secure the cables via the locking latch.

CNPG123

CNPG456

Ground

CN29

CN1

CN2

CN3

CN4

CN5

Connection to PA-4 Chassis Connection to the Robot

M3 Bolt

Connector

A

Robot Base Side

B

Robot Base Side

Ground

Connector

Terminal

1BC

1 BC

Arm Signal

Cable

2BC

2BC

Arm Power

Cable

CN6

Motor Output

Connector Clamp

Figure 4-3. Interconnect Cables

AdeptSix 300CR Robot Instruction Handbook, Rev. A 45

Page 46

Chapter 4 - System Cable Installation

C

y

(

)

C

C

1B

1BC2B

onnection details

of the power suppl

robot

cable

Figure 4-4. Interconnect Cable Connection to the Robot

Connection to the PA-4 Power Chassis

Refer to the following information for details on connecting the cabling between the robot

and the Adept PA-4 power chassis, and peripheral equipment. See Figure 4-1 on page 43

or Figure 4-2 on page 44, depending on which controller you are using.

1. Connect the end of the Arm Power cable with the motor output connector clamp

to the six connectors on the three Dual E amp modules.

NOTE: The CH connectors on all the Dual E Amps are labelled CH1 and

CH2. For reference, Figure 4-5 on page 47 matches CN plugs 1 to 6 with

the CH connectors (labelled CH 1 to 6 in the drawing).