®

,167$//$7,21,16758&7,216

GENERAL INFORMATION

The Quest 2260SN is a Microwave/PIR polling loop motion detector

that offers unmatched levels of operation with the advanced

features listed below.

This detector is designed for use with control panels that support

serial number polling loop devices . It is not for use with panels that

support only DIP switch addressing.

Accu-Trak environmental test feature allows the installer to

•

check for environmental disturbances on both the PIR and

microwave channels at the same time.

Conditional Microwave Mode saves current in large installations.

•

Automatic adaptation to environmental disturbances.

•

Rejection of fluorescent light disturbance.

•

Continuous supervision of both PIR and microwave.

•

Advanced dual-slope temperature compensation assures optimal

•

detection.

Vertical and horizontal pattern adjustability.

•

Tampered front cover and back case.

•

This detector is shipped with its standard wide-angle lens installed

to provide coverage of 60 ft x 75 ft.

Optional swivel-mounting bracket is available under part number

998SB.

K5510 12/00

4XHVW61

0LFURZDYH3,53ROOLQJ/RRS0RWLRQ6HQVRU

37.5'

(11.5 m)

0

MICROWAVE

PATTERN

SPECIFICATIONS

Detection Method: Dual-technology Microwave/PIR

Coverage: Standard Lens 60' x 75' (18.3m x 22.9m)

Detection Zones: Standard Lens: 38 zones (11 long range, 11

over 6 intermediate,5 over 5 short range, 1

Look-Down Zone)

Pulse Processing: Standard or Intermediate, selectable via a

DIP Switch

Detectable Walk Rate: 0.5-10 ft/sec (0.15-3m/sec)

Mounting Height: 7-8 ft (2.1-2.4m),

Indicator: Red and Green LED (see LED

INDICATIONS); enabled/disabled via

a DIP switch

Input Voltage: 9-13VDC at polling loop terminals with

reverse polarity protection

Current: 3mA nom. (Conditional Microwave mode)

6mA nom. (Normal mode), with LED

disabled

8mA nom. (alarm, with LED enabled)

Up to 8mA nominal during warm-up

Standby: Power source should be capable of at least

4 hours of battery standby

Operating Temp: -14°F to +122°F (-10°C to +50°C)

(0°C to +50°C for UL installations)

Operating Humidity: Up to 95% RH (max.), non-condensing

Dimensions: 2.8"W x 5.2"H x 2.2"D

(71mm x 132mm x 56mm)

COVERAGE & LOCATION CONSIDERATIONS

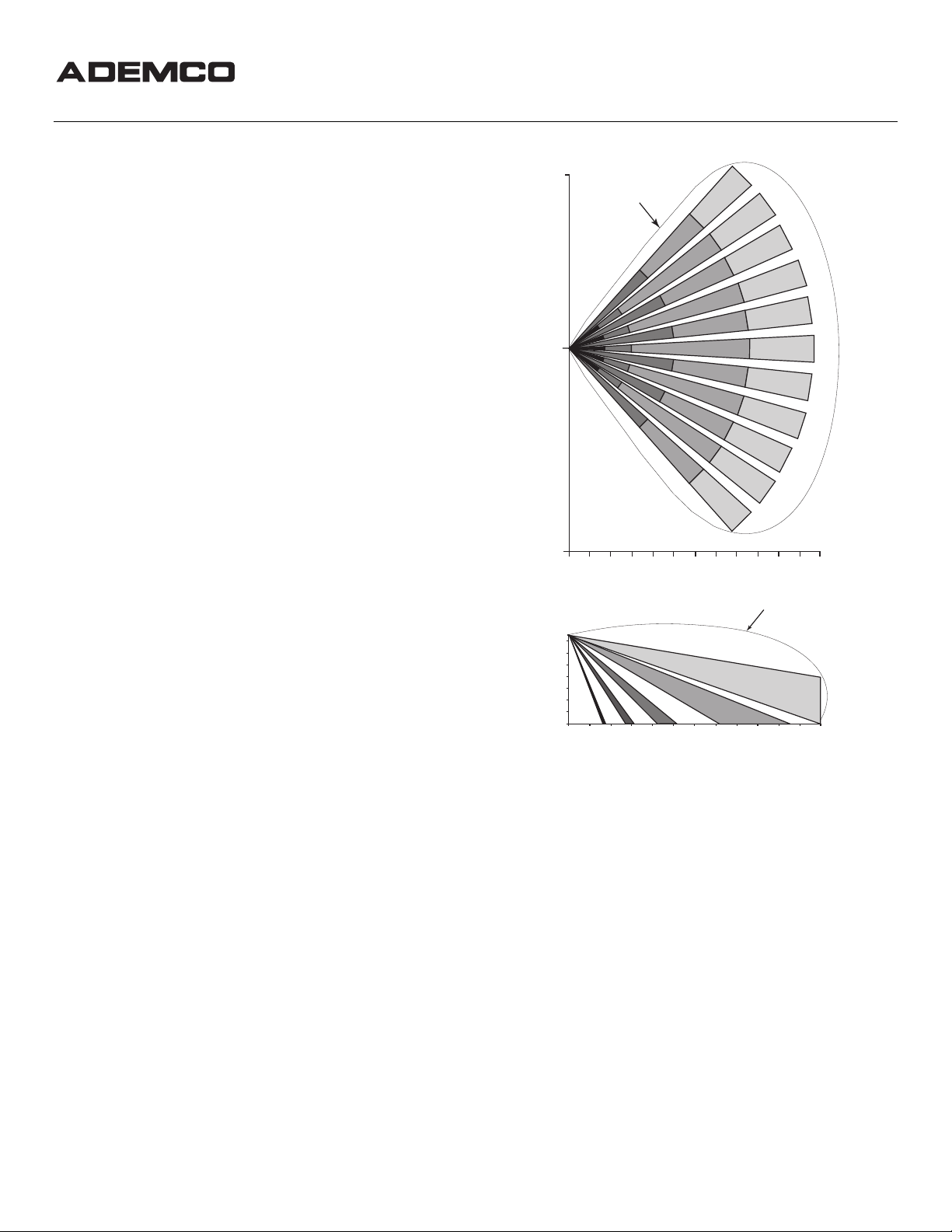

Combined protective patterns are shown in Figure 1 for a nominal

mounting height of 7.5 ft (2.3m). The microwave detection pattern

shown in Figure 1 represents coverage in open space. In practical

application, when the detector is bounded by ceiling, floor, and

walls, reflections can occur.

SELECTING A MOUNTING LOCATION

The detector responds to changes in energy that occur when an

intruder moves into the combined protection pattern. Best coverage

will be obtained if the mounting site is selected so that the likely

direction of intruder motion is generally across the pattern and

angle s slight ly towar d the detector.

37.5'

(11.5 m)

7.5' (2.3m)

7' (2.1m)

6' (1.8m)

5' (1.5m)

4' (1.2m)

3' (1.0m)

2' (0.6m)

1' (0.3m)

5'

0

10'

(1.5m)

(3m)

(4.5m)

5'

10'

0

(1.5m)

(3m)

(4.5m)

25'

30'

35'

15'

20'

(7.5m)

(6m)

TOP VIEW

25'

15'

20'

(7.5m)

(6m)

SIDE VIEW

(9m)

(9m)

(10.5)

30'

35'

(10.5)

40'

50'

45'

(12m)

(15m)

(13.5)

MICROWAVE PATTERN

40'

50'

45'

(12m)

(15m)

(13.5)

55'

(16.5)

55'

(16.5)

60'

(18m)

60'

(18m)

2260SN-001-V0

INSTALLATION HINTS

The detector is remarkably resistant to false alarm hazards, but the

following recommendations should be observed.

Never install the detector in an environment that causes a

•

disturbance in one technology. Good installations start with both

LEDs OFF when in the Accu-Trak environmental test mode and there

is no target motion.

Do not mount on an unstable surface. Locate the unit on a sturdy

•

inside wall whenever possible. Avoid sources of vibration such as loose

fitting doors and walls that shake when heavy traffic exists.

Do not install on or close to metal structures such as metal door

•

frames, shelves, etc.

Do not include space heaters in the protective pattern whenever

•

possible, to avoid rapid temperature changes and vibrations from

fans.

ALL microwave transmission penetrates most building materials

•

(except metal, which reflects transmission). Moving objects outside of

the protected area may be detected unless the microwave sensitivity

control is kept at as low a setting as possible, to minimize penetration.

Make sure the detection area does not have obstructions (curtains,

•

screens, large pieces of furniture, plants, etc.) that may block the PIR

portion of the coverage pattern.

MOUNTING

LENS HOLDER ASSEMBLY

(REMOVE FOR ACESS

tO LENS)

HOLDING T ABS

(2 EACH SIDE)

BEND INWARD TO

RELEASE LENS

HOLDER

LENS

(BEHIND LENS

HOLDER ASSEMBLY)

2260SN-004-V0

0

4

PCB SHOWN POSITIONED

FOR A SETTING OF "1"

PCB

SCREW

SCALE

0-4

USE AS

MARKER

2260SN-005-V0

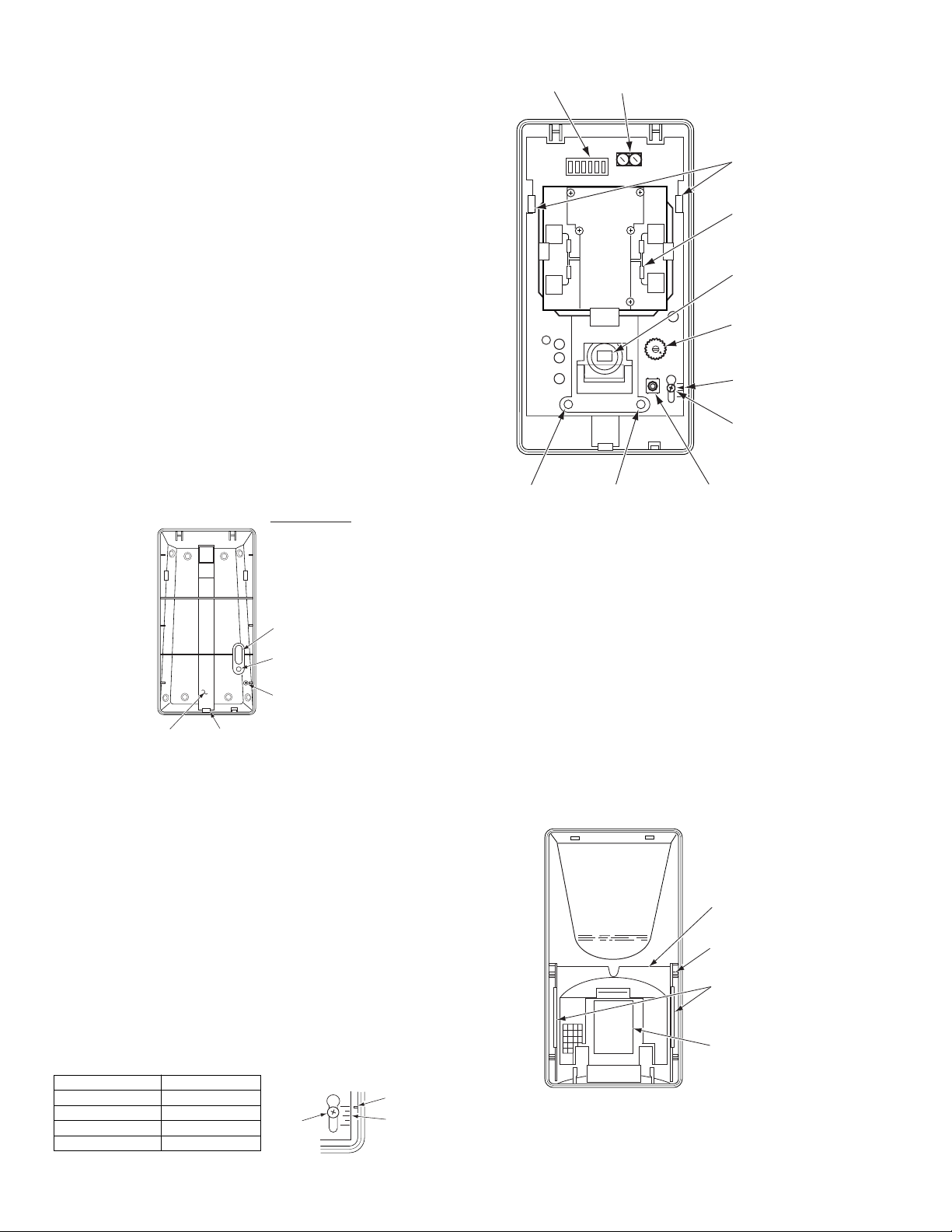

Mount the unit to a firm vertical surface. The wall wiring hole

should be no more than 5/16" (8mm) diameter.

1. Remove the front cover by twisting a screwdriver blade in the

groove between cover and base at the bottom edge of the case

and then lifting the cover off.

2. Remove the circuit board: Loosen (do not remove) the vertical

adjustment screw, slide the PC board down, then spread the

PCB holding tabs (see Figure 3), and remove the PC board.

3. Break out desired mounting and wire entry holes in the back

case. Refer to Figure 2. Knockout screw holes “A” in the back

case are for normal surface mounting on a wall. Knockout screw

holes “B” are for corner mounting.

Also break out the wire entry hole marked X in Figure 2. If

surface wiring is to be used, break out the section at the bottom

of the back case, and run the wiring up the wiring channel at

the back of the case to hole “X”.

If the back case tamper is to be used, use an additional screw

through hole C to secure the back case to the mounting surface.

4. Feed wiring (unpowered) coming from the wall through the wire

access hole near the top of the detector case back. If surface

wiring is used, use bottom access hole and use the wiring

channel in the case ba ck for routin g the wires.

5. Mount the base and reinstall the PC board.

6. Vertically align the PC board in accordance with Table 1

(Vertical Pattern Adjustment section below) before

tightening the vertical adjustment screw.

7. Refer to WIRING CONNECTIONS section before replacing cover.

X

B

A

A

C

A

A

B

WIRING

CHANNEL

BREAK - OUT

SECTION (BEHIND)

FOR SURFACE

WIRING

BREAK - OUT HOLES

"A" FOR NORMAL SURFACE

MOUNTING (4)

"B" FOR CORNER

MOUNTING (4)

B

"C" SCREW HOLE FOR BACK

CASE TAMPER

"X" FOR WIRING ENTRY

ACTS AS BACK CASE

TAMPER

AFTER MOUNTING, USE

ADDITIONAL SCREW

HERE FOR TAMPER

B

USED TO SECURE

PC BOARD

(DO NOT REMOVE)

2260SN-002-VO

Figure 2. CASE BACK

WIRING CONNECTIONS

All wires shou ld have been fed thro ugh the wire access s lot at the

top of the detector base near the terminal block. Connect polling

loop wiring to the screw terminals as shown in Figure 3. Seal any

openings in the base with foam or RTV (not supplied) to prevent

drafts and insects from enteri ng t he un i t. Apply power only aft er all

connections have been made and are inspected.

DIP

SWITCH

POLLING

LOOP

CIRCUIT BOARD

HOLDING T ABS

(BEND OUTWARD TO

RELEASE BOARD)

1 2 3 4 5 6

12

+-

MICROWAVE

DETECTOR

PIR

DETECTOR

MICROWAVE SENSITIVITY

(TURN CLOCKWISE TO

INCREASE SENSITIVITY)

MIN MAX

0

4

MARKER

PCB SCREW

(LOOSEN TO CHANGE

VERTICAL PATTERN

USING SCALE AT RIGHT)

RED

LED

GREEN

LED

FRONT COVER

TAMPER SWITCH

2260SN-003-V1

Figure 3. INTERIOR OF DETECTOR

HORIZONTAL PATTERN ADJUSTMENT

The protection pattern can be moved to the left or right by horizontal

adjustment of the lens, as follows.

1. Remove the front cover as indicated in step 1 of the MOUNTING

section.

2. Remove the lens holder in the front cover by squeezing the two outer

sides of the holder together, releasing it from the side clips (see

Figure 4). Then pull the holder out, exposing the lens.

3. Slide the lens slightly to the left or right to change the horizontal

pattern as desired.

4. Reinstall the lens holder. It should snap firmly in place beneath the

holding tabs on each side.

5. Replace the front cover.

IMPORTANT: After any adjustment, conduct a walk test to ensure

proper coverage of the area to be protected. See the

Test Procedures section.

VERTICAL PATTERN ADJUSTMENT

The protection pattern can be moved up or down by vertical

adjustment of the lens as follows.

1. Remove the front cover as indicated in step 1 of the

MOUNTING section.

2. Loosen the PCB screw on the lower right of the board (s ee Fig.

3), and slide the board into the appropriate position, using the

scale to the right of the screw. Use Table 1 which shows the

proper setting for the de s ired range.

Table 1. Vertical Adjustment Settings

Desired Range PCB Position

30 ft (9.1m) position 4

40 ft (12.2m) posit i on 2

50 ft (15.2m) posit i on 1

60 ft (18.3m) posit i on 0

– 2 –

Figure 4. ACCESSING THE LENS

ADJUSTMEN TS AND SELECTIONS

Microwave Sensitivity Control

Turn the potentiometer clockwise to increase sensitivity.

DIP Switch Setti ngs

No. Position Function and Explanation

1 Supervision Failure Mode

ON: SUSPEND PIR: In case of microwave channel failure,

OFF (default): REVERT TO PIR: In case of microwave channel failure,

2 Fluorescent F ilter Mode

ON: 50Hz FLTR: Digital fluorescent light filter set for 50Hz.

OFF (default): 60Hz FLTR: Digital fluorescent light filter set for 60Hz.

3 LED Enable/Disable

ON (default): ENABLE: LEDs are enabled.

OFF: DISABLE: LEDs are disabled.

4Microwave Operation Mode

ON (default): NORMAL: Microwave channel always on.

OFF: CONDITIONAL: Microwave channel on only when PIR

5 Signal Processing Mode

ON: INTERMEDIATE: Use this setting in normal

OFF (default): STANDARD: Use this setting for maximum false alarm

6 Accu-Trak Environmental Test Mode

ON: ENV TEST: Accu-Trak environmental test is enabled.

OFF (default): NORMAL: Accu-Trak environmental test is disabled.

LED INDICATIONS

(use a small pointed tool to move the switch handle)

the unit becomes non-operat ional.

the unit reverts to the PIR only mode.

activity is detected.

environments.

immunity. This setting tolerates environmental

extremes and is the recommended setting.

(when LEDs are enabled)

MODE LED INDICATIONS

Power Up Red LED is ON for 30 seconds

Alarm Red LED ON

Accu-Trak Green LED flashes for microwave detection

Test Mode Red LED flashes for PIR detection

Supervision Red LED flashes for PIR failure once per 3 sec.

Failure Green LED flashes for microwave failure once per 3 sec.

SERIAL No. ID

This unit does not utilize DIP switches to set its zone number (ID).

Each unit has a unique factory-assigned serial number which must

be entered into the control panel during the zone programming

procedure. Therefore, this motion sensor can be used only with a

control that supports serial number devices.

Note that this motion sensor’s unique factory-assigned serial

number can be found on the bar code label on its PC board.

The motion sensor’s serial number can be entered by one of the

following methods:

A. Downloading (Zone Definition screen of Compass software).

Recommended for large installations and installations where

foot traffic cannot be controlled.

B. Entering through the keypad at the “INPUT S/N” prompt

during manual zone programmin g (see Impor t ant note below).

C. Activating the detector twice while at the “INPUT S/N” prompt

during manual zone programming.

If entering manually, be sure that other polling loop sensors are not

activated so that they cannot send a signal to the control while this

motion sensor is being programmed (mask motion sensors, don't

open/close doors, etc.).

To be sure that other polling loop devices are not activated when

entering serial numbers manually, power the system down,

disconnect the polling loop at the control, power back up again, and

immediately enter the program mode. Then proceed to Step 1 in the

following section. Remember to reconnect the polling loop when

programming is complete, powering the system down first.

IMPORTANT

To enter the unit's serial number

1. Using the control panel’s keypad, enter Zone Programming mode.

2. Enter t he Zone number, Zone Ty pe, and other zo ne information for

the motion sensor, pressing [∗] to advance from prompt to prompt.

3. At the "Input Type" prompt, enter "6" for SL (Serial Polling Device)

and press [∗].

4. At the “INPUT S/N” prompt, either enter the serial number manually

(and a "1" for the loop number), or fault the motion sensor (the keypad

will "beep" to confirm signal), then wait 3-6 seconds and fault the

motion sensor again (the keypad should beep again to confirm). The

motion sensor should now be enrolled. A "1" should appear under the

"L" on the zone summary screen. If it does not, press [∗] and enter the

loop number manually at the next screen.

5. Press [∗] to continue programming other devices, or enter “00” to quit.

For detailed information, refer to the Zone Programming section in the

control panel’s Installation Instructions.

TAMPER

Removal of the cover causes a front cover tamper switch to open.

Removal of the detector from the wall caus es the back tamper s witch to

open (if back case is tampered using a screw through the tamper hole;

see Figure 2). The control panel is automatically notified via the polling

loop when either of these events occur.

TEST PROCEDURES

On power-up, testing must not begin until the LED extinguishes after

first applying power to signify warm-up is complete, about 30 seconds. If

the LED begins to flash at a constant rate, refer to the section on

SUPERVISION.

Accu-Trak Environmental Test Mode

ADEMCO’s unique Accu-Trak environmental test feature easily provides

an environmental check for potential false alarm sources on both the

PIR and microwave channels. Simply set DIP Switch #6 to ON.

Both microwave and PIR information are viewable simultaneously on

the two LEDs, providing crisp, immediate feedback (see below).

NOTE: When Accu-T rak environmental test mode is selected, an

alarm signal is reported to the control panel to prevent leaving

the detector in the test mode.

TEST L ED ACCU-TRAK LED INDICATIONS

PIR RED LED flashes when potential false alarm source is

detected, such as fans or heating duct.

Microwave GREEN LED is ON when potential false alarm source is

detected, such as a fan or mylar balloon.

IMPORTANT:

Detection coverage can only be verified by walk-testing in the normal

operating mode (DIP Switch #6 set to OFF).

Testing in Normal Operating Mode

After testing with the unique Walk-Test mode, the detector should be

tested in the Normal Operating Mode with the following steps:

1. Remove the front cover and ensure that DIP Switch #6 is set to OFF

for Normal Operating Mode.

2. Set DIP Switch #5 to the Pulse Processing Option that will be used for

this installation.

3. Enable the LED by setting DIP Switch #3 ON.

4. Replace the front cover and walk through the protective zones,

observing that the detector’s red LED lights whenever motion is

detected. If necessary, re-adjust the microwave sensitivity to the

minimum level required for satisfactory detection and repeat the

Walk Test.

5. After Walk-Testing is complete, the LED may be disabled, if desired

(DIP Switch #3 OFF).

– 3 –

SUPERVISION

This motion sensor is equipped with advanced supervision of both

the PIR and microwave channels. If a microwave channel failure

occurs, the sensor will continue to operate as a dual-element PIR

sensor (when DIP switch #1 is set to ON) in Standard Signal

Processing mode regardless of the processing option chosen. Even

though some operation is maintained, the unit should be replaced

as soon as possible. If a PIR failure occurs, the unit becomes nonoperational.

Supervision Failure Indications

If a supervision failure occurs, it will be indicated by the

appropriate LED flashing once every 3 seconds, provided the LED

enable option was chosen by DIP switch #3. If a PIR failure occurs,

the RED LED will flash; if a microwave failure occurs, the GREEN

LED will flash. If the unit has defaulted to PIR-only operation as a

result of a microwave failure (DIP switch #1 is set to ON), the RED

LED will light when an alarm occurs while the GREEN LED

continues to flash.

All troubles above will be reported to the control panel.

MAINTAINING PROPER OPERATION

In order to maintain the detector in proper working condition, it is

important that the user observe the following:

1. Power should be provided at all times. Loss of power to the unit

will result in the alarm contacts reverting to an alarm state.

The units DC source should have standby power available for at

least 4 hours of operation during emergencies.

2. Units should never be re-aimed or relocated without the advice

or assistance of the alarm service company.

3. The physical surroundings of the protected area should not be

changed. If furniture or stock is moved, or air conditioning or

additional heating is installed, the system may have to be

readjusted by the alarm service company.

4. Walk tests should be conducted frequently (at least weekly) to

confirm proper coverage by each detector.

TO THE INSTALLER

Regular maintenance and inspection (at least annually) by the

installer and frequent testing by the user are vital to continuous

satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and

offering a regular maintenance program to the user, as well as

acquainting the user with the proper operation and limitations of

the alarm system and its component parts.

Recommendations must be included for a specific program of

freque nt testing (at least we ekly) to ens ure the sys tem’s ope ration

at all times.

FEDERAL COMMUNICATIONS COMMISSION

(FCC) STATEMENT

This device complies with Part 15 of FCC Rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including

interference that may cause undesired operation.

165 Eileen Way, Syosset, New York 11791

Copyright © 2000 PITTWAY CORPORATION

MICROWAVE/PASSlVE INFRARED MOTION DETECTOR

WARNING! THE LIMITATIONS OF YOUR

While the Intrusion Detector is a highly reliable intrusion detection device, it does not

offer guaranteed protection against burglary. Any Intrusion Detection device is

subject to compromise or failure to warn for a variety of reasons:

•

These Motion Detectors can only detect intr usion within the designed ra nges as

diagrammed in this install ation manual.

•

The passive infrared motion sensor in this Motion Detector does not provide

volumetric area protection. It does create multiple beams of protection, and

intrusion can only be detected in unobstructed areas covered by those beams.

•

Passive Infrared Detectors cannot detect motion or intrusion that takes place

behind walls, ceilings, floors, closed doors, glass partitions, glass doors, or

windows.

•

Metal objects (or other reflectors, such as foil faced insulation or water in bottles)

can alter the microwave sensors protection pattern.

•

Mechanical tampering, masking, painting or spraying of any material on the

mirrors, windows or any part of the optical system can reduce the detection ability

of the Passive Infrared Motion Detector.

•

Passive Infrared Detectors sense changes in temperat ure; however, as the am bie nt

temperature of the protected area approaches the temperature range of 90° to

105°F (32° to 40°C), the detection performance can decrease.

•

This Passive Infrared Detector will not operate without appropriate DC power

connected to it or if the DC power is improperly connected (i.e. reversed polarity

connections).

•

Passive Infrared Detectors, like other elect rical devices, are subject to component

failure. Even though they are designed to last as long as 10 years, t he electronic

components could fail at any time.

We have cited some of the most common reasons that a Passive Infrared Motion

Detector can fail to catch intrusion. However, this does not im ply that these are the

only reasons and therefore, it is recom me nded that wee kly test ing of this type of unit,

in conjunction with weekly testing of the entire alarm system, be performed to ensure

that the detectors are working properly.

Installing an alarm system may make the ow ner eligible for a lower insuran ce rate,

but an alarm system is not a substitut e for insurance. Hom eowners, pro perty owners

and renters should continue to act prudently i n pr ot ecting themsel ves an d co ntin ue to

insure their lives and property.

We continue to develop new and improved protection devices. Users of al arm systems

owe it to themselves and their loved ones to learn about these developments.

ADEMCO Limited Warranty

Alarm Device Manufact uring Company, a Division of Pittway Corporation, and its

divisions, subsidiar ies and affiliates ("Seller"), 165 Eilee n Way, Syosset, New York

11791, warrants this detector to be in conformance with its own plans and

specifications and to be free from defects in materials and workmanship under

normal use and service for 36 months from the d ate stamp control on the product.

Seller's obligation shall be limited to replacing, at its option, free of charge for

materials or labor, a detector which is proved not in compliance with Seller's

specifications or proves defective in materi als or workm anship under normal use an d

service. Seller shall have no obligation under t his Limited Warranty or otherwise if

the detector is altered or improperly repaired or serviced by anyone other than

Ademco factory service. In case of defect, return the detector to ADI or an authorized

distributor for an immediate replacement.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, OF

MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE OR

OTHERWISE, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. IN NO CASE SHALL SELLER BE LIABLE TO ANYONE FOR ANY

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF THIS OR ANY

OTHER WARRANTY, EXPRESS OR IMPLIED, OR UPON ANY OTHER BASIS OF

LIABILITY WHATSOEVER, EVEN IF THE LOSS OR DAMAGE IS CA USED BY

THE SELLER'S OWN NEGLIGENCE OR FAULT.

Seller does not represent that its detector may not be compromised or circumvented;

that the detector will prevent any personal injury or property loss by burglary,

robbery, fire or otherwise; or that the detector will in all cases provide adequate

warning or protection. Buyer u nderstands th at a properly installed and maintained

alarm may only reduce the risk of a burglary, robbery, fire or other events occurring

without providing an alar m, but it is not insuranc e or a guara ntee that such will not

occur or that there will be no personal injury or property loss as a result.

CONSEQUENTLY, SELLER SHALL HAVE NO LIABILITY FOR ANY PERSONAL

INJURY, PROPERTY DAMAGE OR OTHER LOSS BASED ON A CLAIM THE

DETECTOR FAILED TO GIVE WARNING. However, if Seller is held liable, whether

directly or indirectly, for any loss or damage arising under this Limited Warranty or

otherwise, regardless of ca use or origin, Seller's maximum lia bility shall not in any

case exceed the purchase price of the DET ECTOR, which sh all be the com plete and

exclusive remedy against Seller. This warranty replaces any previous warranties and

is the only warranty made by Seller on this detector. No increase or alteration,

written or verbal, of the obligations of this Limited Warranty is authorized.

¬.^l

K5510 12/00

Loading...

Loading...