Page 1

33-00446EFS-01

Controller Kit Installation Manual

controller

MHK2

Installation guide for:

• Wireless Receiver and Cable

• Remote Controller

DISCONNECT POWER BEFORE BEGINNING INSTALLATION.

Can cause electrical shock or equipment damage.

Must be installed by a trained, experienced technician.

Read these instructions carefully. Failure to follow these instructions can damage the

product or cause a hazardous condition.

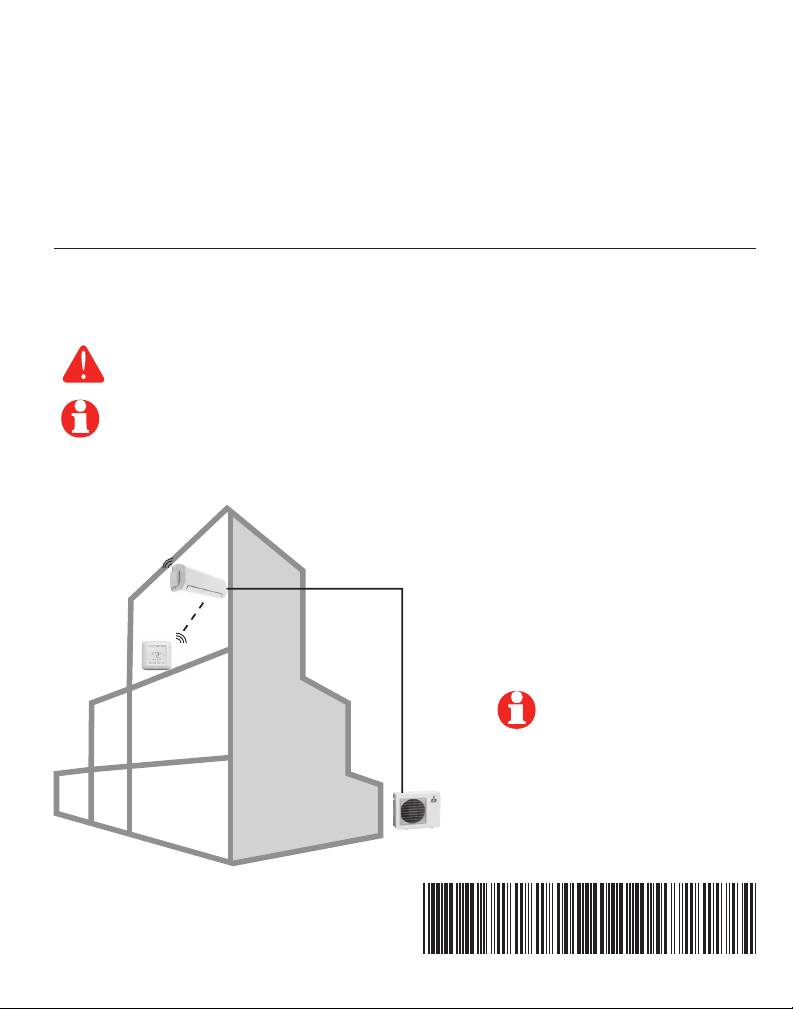

Installation at a glance

This document covers linking

and installation procedures for

the Mitsubishi Ducted Systems'

RedLINK™ control devices.

Before you begin, you must attach

the cable to the CN105 connector

on the indoor unit control board,

then follow the steps in this

document.

Remote

controller

Wireless

receiver

Remote controllers are

linked to specific indoor

units. Each indoor unit must

have a dedicated remote

controller and wireless

receiver.

M32309A

© 2019 Mitsubi shi Elect ric & Elec tronic s USA, Inc.

Suwanee, G A 30024 All R ights Re served .

The three diamond logo is a registered trademark

of Mitsubishi Electric Corporation

www.mitsubishipro.com

Page 2

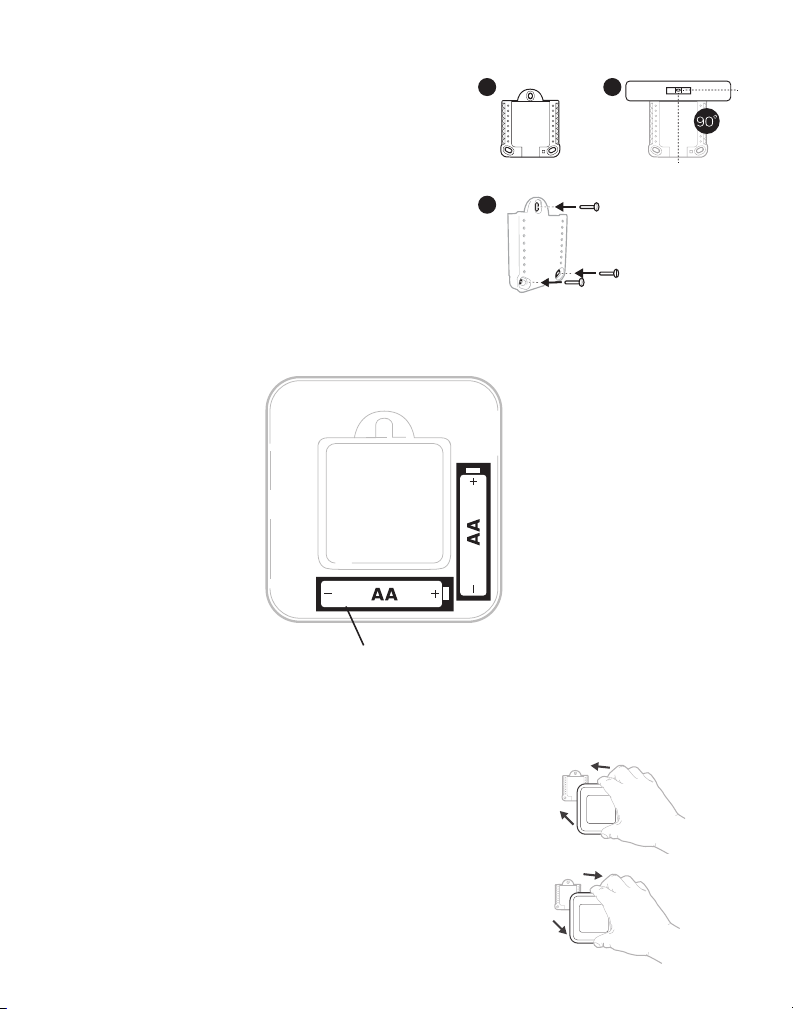

Mounting Wall Plate

1. Open package to find the Wall Plate. See Figure 1.

2. Position the Wall Plate on the wall. Level and mark

hole positions. See Figure 2.

Drill holes at marked positions, and then lightly tap

supplied wall anchors into wall using a hammer.

‒ Drill 7/32” holes for drywall.

3. Place the Wall Plate over the wall anchors. Insert and

tighten mounting screws supplied with the Wall Plate.

Do not overtighten. Tighten until the Wall Plate no

longer moves. See Figure 3.

Install batteries

Insert AA batteries

1 2

3

Use 3x supplied

screws #8 1-1/2”

Mounting MHK2 Controller

1 Align the Wall Plate with the MHK2 Controller and

push gently until the MHK2 snaps in place.

2 If needed, gently pull to remove the MHK2 Controller

from the Wall Plate.

2

Page 3

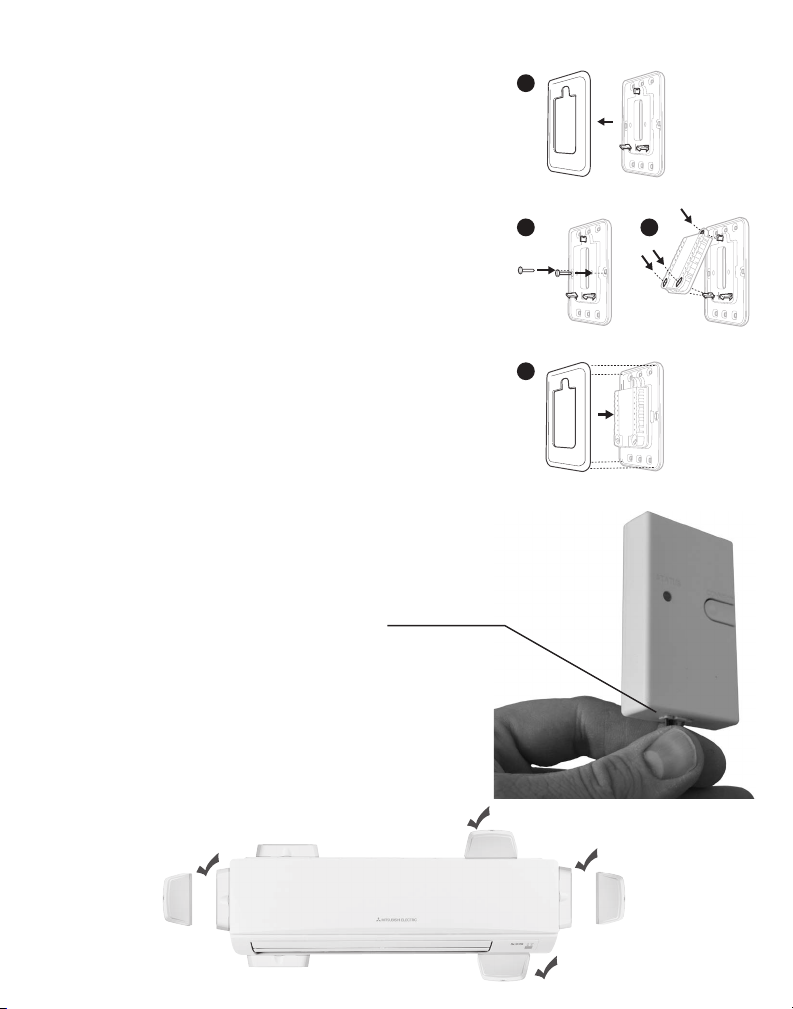

Optional Decorative Cover Plate installation

MCR31400

Use the Optional Cover Plate when you need to cover

paint gap from the old control.

4. Separate the Junction Box Adapter from the Cover

Plate. See Figure 4.

5. Mount the Junction Box Adapter to the wall or an

electrical box using any of the eight screw holes.

Insert and tighten mounting screws supplied with

Cover Plate Kit. Do not overtighten. Make sure the

Adapter Plate is level. See Figure 5.

6. Attach the Wall Plate by hanging it on the top hook

of the Junction Box Adapter and then snapping the

bottom of the Wall Plate in place. See Figure 6.

7. Snap the Cover Plate onto the Junction Box Adapter.

See Figure 7.

4

5

Use 2x

supplied

screws #6

5/8”

7

Install cable and receiver

1. Before mounting indoor unit, connect cable to the

5-pin CN105 connector on the control board in the

indoor unit.

2. Mount indoor unit. Route cable to preferred location of

the wireless receiver.

3. Attach the 5 pin connector to the receiver.

4. Push the excess cable back through the indoor unit or

behind the wireless receiver. Do not cut or modify the

cable. Use zip tie connections on back of receiver if

needed.

5. Mount wireless receiver next to the indoor unit (see

below) or in a remote location.

Mount in the orientations shown. Do not block vents.

6

X

OR

UPDATE

OR

IMAGE

X

3

Page 4

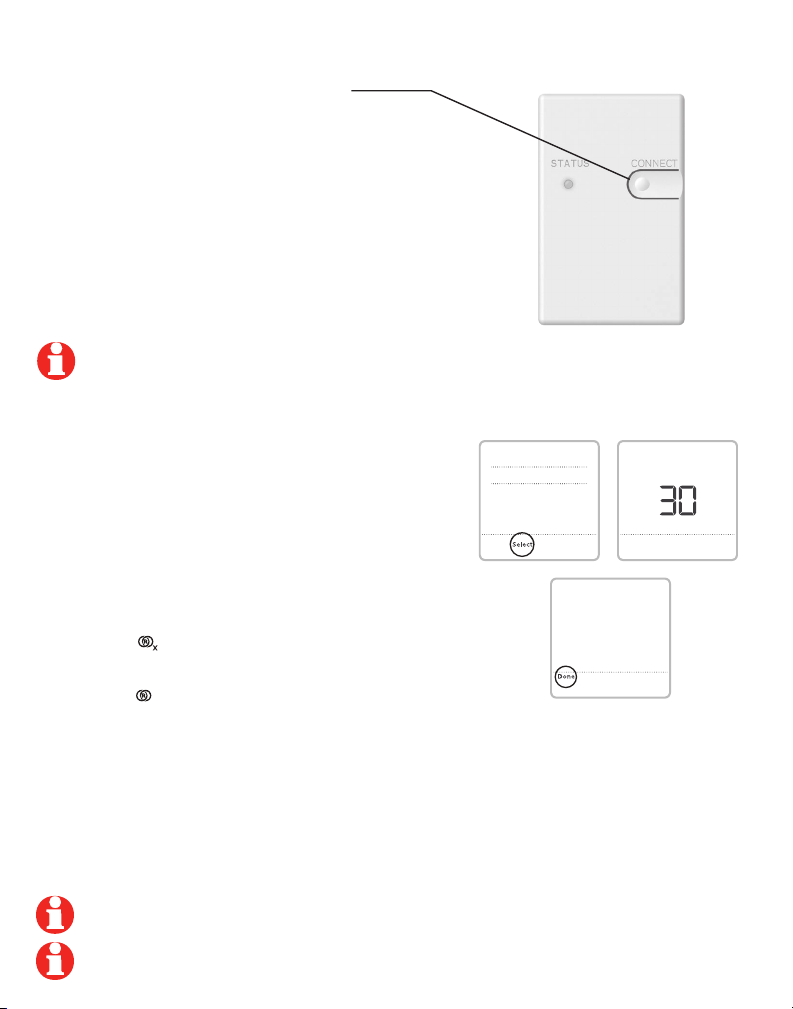

Link all devices to wireless network

1. Press and release the CONNECT button.

2. If CONNECT light does not flash, another receiver or

RedLINK wireless adapter may be in wireless setup

mode. Exit wireless setup at the other device.

CONNECT LED

• Flashing Green: In wireless setup mode.

• Solid Green: At least one Redlink device is enrolled

onto the receiver.

• Yello w: Please wait.

• Red: RedLINK device is not communicating.

• Off: No RedLINK devices are enrolled onto the

receiver.

Flashing status light times out after 15 minutes of

inactivity. Press CONNECT again if necessary.

Link remote controller to wireless network

1. Press CONNECT to establish a link to the wireless

network.

2. After a brief pause, the confirmation screen at

right should be displayed to verify that the wireless

connection has been established.

3. Press DONE to display the home screen.

4. The MHK2 Controller will display a "WAIT" screen

while it receives data from the air conditioner. While on

the "WAIT" screen:

• If the controller shows the RedLINK disconnected

icon at the top-right, the controller has lost

connection with the receiver.

• If the controller shows the RedLINK connected

icon , the controller is waiting for the air

conditioning to connect.

• To unenroll the receiver, press and hold the

bottom-center of the controller's screen for

5 seconds. The controller will then be unenrolled

regardless if the receiver is on or off.

CONNECT RECE CONNECTING

SUCCESS

Exit wireless setup

Press and release the CONNECT button at the wireless receiver to exit wireless setup (light should

stop flashing and remain solid). Replace cover on wireless receiver.

Note: The wireless receiver will automatically exit wireless setup after 15 minutes of

inactivity.

Note: If installing more than one receiver, you must exit wireless setup on previous receiver

before attempting wireless setup of subsequent controllers/receivers.

4

Page 5

Initial installer setup

After the MHK2 Controller has communicated with

the A/C correctly, MHK2 Controller will change

from the "Wait" screen to the "Initial Installer

Setup" screen and show START SETUP.

1. The MHK2 will search for A/C support. If it

finds A/C support, the controller will load the

Function Code setup. See page 6 for a full

list of Function Codes options. If the controller

does not find A/C support, the controller will

load the Installer Set Up (ISU). See page 7

for a full list of ISU options.

2. Touch or to toggle between Function

Code/ISU options.

3. Touch Edit or touch text area, and then touch

or to edit default setup option.

4. Touch Done or touch text area to confirm the

setting or press Cancel.

5. Touch or to continue to setup another

ISU option.

6. To finish setup and save your settings, scroll

to the FINISH SETUP screen at the end of the

ISU list.

Note: To see a list of all setup parameters, go to

"Installer setup options (ISU) – advanced menu"

on page 7. The MHK2 Controller displays the

ISU name and the ISU number.

ISU option and

name (scrolling)

ISU option blinking

Saves selected ISU

option moves on to

the next ISU screen

View ISU

Arrow buttons

used to scroll

through ISUs

Edit ISU

ISU #

Arrow buttons

used to scroll

through ISU

options

Cancels ISU option

selection, go back to

view ISU

Installer setup – advanced menu (after initial installation)

To access the advanced menu, press and hold the Menu button for 5 seconds.

Touch or to go through the options in the advanced menu.

Advanced menu options

Function Codes: This is used to access the

device Function Code settings.

Device Setup: This is used to access the device

ISU settings.

Screen Lock: The thermostat touch screen can be

set to fully lock.

System Test: Test the wireless communication or

heating and cooling equipment.

Unenroll Device: Remove a connected receiver or

controller.

5

Reset: Access all reset options

on the MHK2 Controller. This is

the only place to access factory

reset.

72

Auto

HeatHeat

Home

VaneVane

Page 6

Note: Default settings for Function Codes 1-28 are automatically determined by the HVAC equipment. It may take up to 40 seconds to enter

setup, and 30 seconds to exit setup.

Function # Name Options Notes

1 Power Failure

2 Temperature Sensing

3 Ventilation Air 1 = Not sup por ted

4 Power Vo lta ge 1 = 230V

5 Indoo r Unit Automatic

7 Change Fil ter Dur ation 1 = 100 H ours

8 Auto F an (Spe ed

6

9 Numbe r of Air O utle ts

10 High Performance

11 Airflow Direction

15 Frost Prevention

23 Airflow Oscillate Mode 1 = Not Availab le

24 Heat Mo de

25 Heat Mode Fan Option 1 = Ex tra Low

27 Cooling Mode Fa n

28 Display System Error 1 = Enable

Automatic Recovery

Location

Operation

Set ting)

(PLA Only)

Filter Installed

Settings

Temperature Offset

Temperature Offset

Option

1 = Disa bled

2 = Enabled

3 =Not s uppor ted

1 = Avera ge

2 = Sens e at Indoor Uni t

3 = Not sup por ted

2 = Indoo r Unit doesn’ t int ake ou tdoor air thr ough LO SSNAY

3 = Indoo r Unit does in take o utdo or air th rough LOSSN AY

2 = 208V

3 = not sup por ted

1 = On

2 = Off

3 = Not sup por ted

2 = 2500 Hours

3 = Not Us ed

1 = Quie t

2 = Standard

3 = High Ceiling

1 = 4 directio ns

2 = 3 directio ns

3 = 2 directio ns

1 = Not Sup por ted

2 = Suppo rte d

3 = Not Sup por ted

1 = No Vane s (or Vane # 3 f or PL A)

2 = Vane # 1 se tting

3 = Van # 2 settin g

1 = 36°F (2°C)

2 = 37°F (3 °C)

3 = Not Sup por ted

2 = Avail able

3 = Not Sup por ted

1 = On

2 = Off

3 = Not Sup por ted

2 = Stop

3 = Sele cta ble Fa n Spee d

1 = Sele cta ble Fa n Spee d

2 = Stop

3 = Not Sup por ted

2 = Disa ble

3 = Not Sup por ted

Unit Funct ion Option defaulted t o most c ommon s etting at power up by

Gate way (vi a Indo or Unit)

Eith er set ting 1 or 3 could be use d when t he unit does not supp ort t his fe atur e.

Function Code options – advanced menu

Page 7

ISU # ISU Name ISU Options (defaults in bold) Notes

134 Central Controller

136 Residential/

139 Fahrenheit

142 System Type 0 = Heat & C ool (heat pump)

144 Auto Changeover 0 = Manual Changeover

145 Deadband 3 to 8°F (in 1°F increments)

7

146 Drying Mode 0 = Disabled

150 Schedule Owner 0 = Cont roller

151 Schedule Type 0 = No Schedule

152 Schedule Of f

160 Full Lockout 0 = Disabled

161 Lockout S ystem On 0 = Disabled

162 Lockout S ystem Off 0 = Disabled

163 Lockout Mode 0 = Disabled

164 Lockout Fan Speed 0 = Disabled

Present

Commercial

Celsius

Periods

0 = Not installed

1 = Installed

0 = Residential

1 = Commercial

0 = Fahr enheit

1 = Celsius

1 = Cool only

1 = Auto Changeover

3 = Auto changeover Single S etpoint

2.0 to 4.5° C (in .5°C increments)

1 = Enabled

1 = Kumo Cloud

1 = Mo-Su

2 = Mo-Fr/Sa-Su

3 = Mo-Fr/Sa /Su

4 = M/T/W/T/F/S/S

0 = Disabled

1 = Enabled

1 = Enabled

1 = Enabled

1 = Enabled

1 = Enabled

1 = Enabled

The control determines the correct setting based on whether the central

controller was linked to the system. If the central controller is Installed in the

system, then the device will function as a non-programmable device and only

single setpoint will be suppor ted. When the central control is not install ed the

ISU options for "Schedul e Format", "Scheduled Of f", "Power Off Timer" and

"Perm Hold Lock" are displayed in the ISU menu.

When set for residential there is an option for per manent hold and the

Schedule periods are wake, away, home, sleep.

When set for commercial, we have a limited override duration and the schedule options are for occupied and unoccupied.

The control determines the correct setting based on the equipment the

receiver is plugged into.

If Auto Changeover is selected, sys tem mode options will be heat, off, cool,

and auto.

This ISU set ting is not shown when ISU 134 is set to 1 or ISU 142 is se t to 1.

Settings 0 or 1 are shown if ISU 134 is set to 0. Setting 3 is shown if ISU 134

is set to 1.

This ISU is shown if dual auto changeover is selected.

This ISU is shown if dr y mode is supported.

Not shown if wireless interface is NOT present.

If disabled, Schedule Power Off in schedule mode cannot be used.

If full lockout is configured the display will not allow user to adjust mode,

temperature setpoints, etc.

If enabled the display will not allow user to adjust mode from off to on.

If enabled the display will not allow user to adjust mode from on to of f.

If enabled the display will not allow user to adjust mode from current mode to

any other mode.

If user attempts to modify the fan setting, flash Locked segment and revert to

current mode if lockout is enabled.

Installer Setup options (ISU) – advanced menu

Page 8

ISU # ISU Name ISU Options (defaults in bold) Notes

165 Lockout Setpoint 0 = Disabled

167 Lockout Vane

170 Hide Indoor

171 Hide Indoor

172 Hide Outdoor

173 Hide Outdoor

180 Max Heat Setpoin t 40 to 90°F (4.5 to 32°C)

181 Min Cool Setpoint 50 to 99°F (10 to 37°C)

190 Indoor Temperature

191 Indoor Temperature

8

195 Indoor Humidity

196 Indoor Humidity

Direction

Tempera ture

Humidity Display

Tempera ture

Display

Humidity Display

Source

Display Offset

Source

Display Offset

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Ther mos tat

1 = Wall Unit

2 = Sensor

3 = Average

-5°F to 5°F (-2.5°C to 2.5°C)

0 = Ther mos tat

1 = Sensor

2 = Average

-10 % RH to 10% RH

If user attempts to modify the setpoint, fla sh Locked segment and revert to

current setpoint if lockout is enabled.

If user attempts to modify the vane direction, flash Locked segment if lockout

is enabled.

If enabled, indoor temperature is not shown in the display.

If enabled, indoor humidi ty is not shown in the display.

If enabled, outdoor temperature is not shown in the display.

If enabled, outdoor humidity is not shown in the display.

Options 2 and 3 not shown if the IAS is not enrolled.

Options 1 and 2 will not be shown if the IAS is not enrolled.

Installer Setup options (ISU) – advanced menu

Page 9

Performing a system test

You can test the system setup in ADVANCED MENU

under SYSTEM TEST option.

1 Press and hold Menu on the controller for 5

seconds to access ADVANCED MENU options.

2 Touch or to go to SYSTEM TEST.

3 Touch Select or touch text area.

4 Touch or to select system test type. Touch

Select or touch text area.

5 For the heat test, cool test, and fan test use

or to activate equipment.

Note: The clock is used as a timer while heat or cool

is running. The Heat and Cool indicators are displayed

when the system test is running.

Special functions

Schedule Off Periods (Setup Function 152) : Allows the user to schedule a period where the

split-zoning system is completely off and resumes operation at the next scheduled period.

9

Page 10

Key features

System status

information

Cool On, Heat On, Standby.

Schedule information

Following time-based

temperature control.

Desired Temperature

Displays the current desired

temperature setting.

Indoor Temperature

Displays the current indoor

temperature.

Vane

Touch to select air direction:

Auto, Swing, Ceiling, High,

Middle, Low, Floor.

Mode

Select system Mode: Heat,

Cool, Dry, Fan, Auto, Off.

Time, ISU #, or

Alert #

72

HeatHeat

VaneVane

Auto

RedLINK wireless

communication status

Indicates if the controller is

connected to the RedLINK

interface and communicating

correctly.

Connection status

information

Indicates if the wireless

interface is used on the

Mitsubishi unit.

Messaging

Shows device setup options,

menu options, reminders,

schedule overrides.

Schedule period

Shows schedule period:

Wake, Leave, Return, Sleep.

Fan

Select Fan speed.

Menu

Touch to display options. Start here to

set a program schedule.

Note: Long press of Menu button

for 5 seconds to access Advanced

Menu options.

The screen will wake up by pressing the center area of the displayed temperature. The screen

will stay lit for 8 seconds.

10

Page 11

RedLINK™ error codes

128 Duplicate ID

129 Invalid device type

130 Invalid instance

134 Weak signial. Move wireless device to a different location and try again.

137 Maximum number of clients reached.

138 No response

152 Out of order

153 Timeout

For full list of error codes, please refer to your equipment's technical service manual.

Replacing system components

NOTE: Only use Mitsubishi Electric components or other designated components for installation.

Failure to comply may damage the product or cause a hazardous condition.

Remote controller

To replace a remote controller, install batteries and follow the procedures on page 4 to link it to

the wireless network. If necessary, modify settings as needed (see tables on pages 7–8).

Wireless receiver

After installing a new wireless receiver, you must unenroll the remote controller so it can

communicate with the new equipment, as described below.

There are three ways to unenroll the controller from the old receiver:

• Press and hold the Menu button for 5 seconds to enter the Advanced Menu. Touch or to

select UNENROLL DEVICE. Touch Select. Connect the new receiver.

• Enter the Advanced Menu. Touch or to select RESET. Touch Select. Touch or to

select FACTORY. Touch Select. Touch Yes to confirm. Connect the new receiver.

• If the remote controller is on the "Wait" screen, press and hold the bottom-center of the

screen for 5 seconds. Connect the new receiver.

To remove all wireless devices:

1. Press and hold the CONNECT button on the wireless receiver for 10 seconds.

2. To reconnect, see procedure on page 4.

11

Page 12

Regulatory information

FCC Compliance Statement (Part 15.19) (USA only)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1 This device may not cause harmful interference, and

2 This device must accept any interference received, including interference that may cause undesired operation.

FCC Warning (Part 15.21) (USA only)

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate

the equipment.

FCC Interference Statement (Part 15.105 (b)) (USA only)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipme nt into an ou tlet on a circuit d iffere nt from th at to whic h the receiver is co nnect ed.

• Consu lt the dealer or an ex perien ced rad io/ TV technician for hel p.

Wirel ess Rec eiver an d MHK2 Remote C ontro l

To comply with FCC and Industry Canada RF exposure limits for general population/ uncontrolled exposure, the antenna(s)

used for these transmitters must be installed to provide a separation distance of at least 20 cm from all persons and must not be

co-located or operating in conjunction with any other antenna or transmitter.

Section 7.1.3 of RSS- GEN

Operation is subject to the following two conditions:

1 This device may not cause interference, and

2 This device must accept any interference, including interference that may cause undesired operation of the device.

Section 7.1.2 of RSS- GEN

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of type and maximum (or lesser)

gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and

its gain should be so chosen that the equivalent istropically radiated power (e.i.r.p.) is not more than that necessary for successful

communication.

Specifications & replacement parts

Operating Ambient Temperature

• Remote Controller: 32 to 120 °F (0 to 48. 9 °C)

• Wireless Receiver: - 40 to 165 °F (- 40 to 73.9 °C)

Operating Relative Humidity

• Remote Controller: 5% to 90% (non-condensing)

• Wireless Receiver: 5% to 95% (non-condensing)

Physical Dimensions (height, width, depth)

• Remote Controller: 4- 5/ 64" x 4- 5/6 4" x 1-1/16"

(104 mm x 104 mm x 27 mm)

• Wireless Receiver: 3-3/32 x 1-3/4 x 39/64 inches

(74.8 x 44.4 x 15.4 mm)

Accessories & Replacement Parts

Item Part Number

Remote Controller MRCH2

Receiver and Cab le MIFH2

Cable MRC2

© 2019 Mitsubishi Electric & Electronics USA, Inc.

Suwanee, GA 30024 All Rights Reserved.

33-00446EFS—01 M.S. 01-19

Printed in U.S.A.

Loading...

Loading...