Installation and Operations Guide

AZW-5000

© Honeywell AZW-5000 Rev. 0001BETA

Important safety information and installation

!

precautions

Read all instructions

Failure to follow all instructions may result in equipment damage or a hazardous condition. Read all instructions

carefully before installing equipment.

Local codes and practices

Always install equipment in accordance with the National Electric Code and in a manner acceptable to the local

authority having jurisdiction.

Electrostatic sensitivity

This product and its components may be susceptible to electrostatic discharge (ESD). Use appropriate ESD

grounding techniques while handling the product. When possible, always handle the product by its non-electrical

components.

High voltage safety test

Experienced electricians, at first contact, always assume that hazardous voltages may exist in any wiring system. A

safety check using a known, reliable voltage measurement or detection device should be made immediately before

starting work and when work resumes.

Lightning and high-voltage dang er

Most electrical injuries involving low-voltage wiring result from sudden, unexpected high voltages on normally

low-voltage wiring. Low-voltage wiring can carry hazardous high voltages under unsafe conditions. Never install or

connect wiring or equipment during electrical storms. Improperly protected wiring can carry a fatal lightning surge

for many miles. All outdoor wiring must be equipped with properly grounded and listed signal circuit protectors,

which must be installed in compliance with local, applicable codes. Never install wiring or equipment while standing

in water.

Wiring and equipment separations

All wiring and controllers must be installed to minimize the possibility of accidental contact with other potentially

hazardous and disruptive power and lighting wiring. Never place 24VAC or communications wiring near other bare

power wires, lightning rods, antennas, transformers, or steam or hot water pipes. Never place wire in any conduit,

box, channel, duct or other enclosure containing power or lighting circuits of any type. Always provide adequate

separation of communications wiring and other electrical wiring according to code. Keep wiring and controllers at

least six feet from large inductive loads (power distribution panels, lighting ballasts, motors, etc.). Failure to follow

these guidelines can introduce electrical interference and cause the system to operate erratically.

Warning

This equipment (FCC ID: HS9AZWDGL) has been tested and found to comply with the limits for a class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference, in which case the user will be required to correct the interference at his own

expense.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) This device must accept any interference received,

including interference that may cause undesired operation.

FCC Caution: Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate this equipment.

This equipment should be installed and operated with minimum distance 20 cm between the radiator & your bod y.

© 2009 Honeywell. All Rights Reserved.

6670 185th AVE NE

Redmond, WA 98052 USA

Phone: (425)869-8400 FAX: (425)869-8445

Web Site: www.alerton.com

All information in this document is provided as is without warranty of any kind. Honeywell reserves the right to

change any information herein without prior notice. No guarantees are given as to the accuracy of information.

Trademarks and trade names may be used in this document to refer to either the entities claiming the marks and

names or their products. Alerton, BACtalk, and their logos are registered trademarks and VisualLogic is a trademark

of Honeywell. Honeywell disclaims any proprietary interest in trademarks and trade names other than its ow n.

2

LTBT-TM-AZWIOG Rev. 0001BETA © Honeywell

Contents

Installation and Operations Guide

About AZW-5000 4

Dimensions 4

Power rating 4

AZW-5000 network topology 5

About this document and related publications 6

General installation guidelines 7

Using terminal blocks 7

Power supply guidelines and requirements 7

MS/TP LAN wiring 9

Configuration 11

Commissioning 12

Installation 14

Mounting 14

Attaching an external antenna (optional) 14

Wiring 15

Checking proper operation 16

Checking network operation 18

Adding Alerton Wireless Temperature Sensors 19

WTS AVs and BVs 19

Maintaining an AZW-5000 20

Updating the real-time operating code (ROC) file 20

Replacing an AZW-5000 20

Viewing commissioning data 21

Troubleshooting 22

Troubleshooting weak reception 22

Troubleshooting RSSI flash sequences 22

Troubleshooting devices not found by device scan 23

Troubleshooting erroneous WTS temperature readings 23

Appendix A: AZW-5000 AVs and BVs 24

Appendix B: AZW-5000 Commissioning Record 30

Contents

|

© Honeywell LTBT-TM-AZWIOG Rev. 0001BETA 3

Installation and Operations Guide

About AZW-5000

Alerton’s AZW-5000 is a wireless communications device designed to replace

MS/TP and wall sensor cabling in instances where cabling is cost-prohibitive. It

allows you to add a small (up to 15 controllers or devices) wireless subnetwork

to a wired network.

A scenario where the AZW-5000 would be effective is a school that adds

portable class rooms that need to be tied into the existing school Building

Automation System (BAS). The cost of running cable underground to each

portable is significant. AZW-5000 is an ideal solution to this problem allowing a

wireless network to make the connection for a lower price than the labor and

materials needed to bury a cable.

It will also be useful when retrofitting wireless controllers into places where

wiring or rewiring is prohibitively expensive - buildings with concrete walls, for

example.

The AZW-5000 operates in one of three modes:.

AZW-5000

|

• Coordinator - connects to the committed MS/TP network. Sends and

receives system data to/from transceivers.

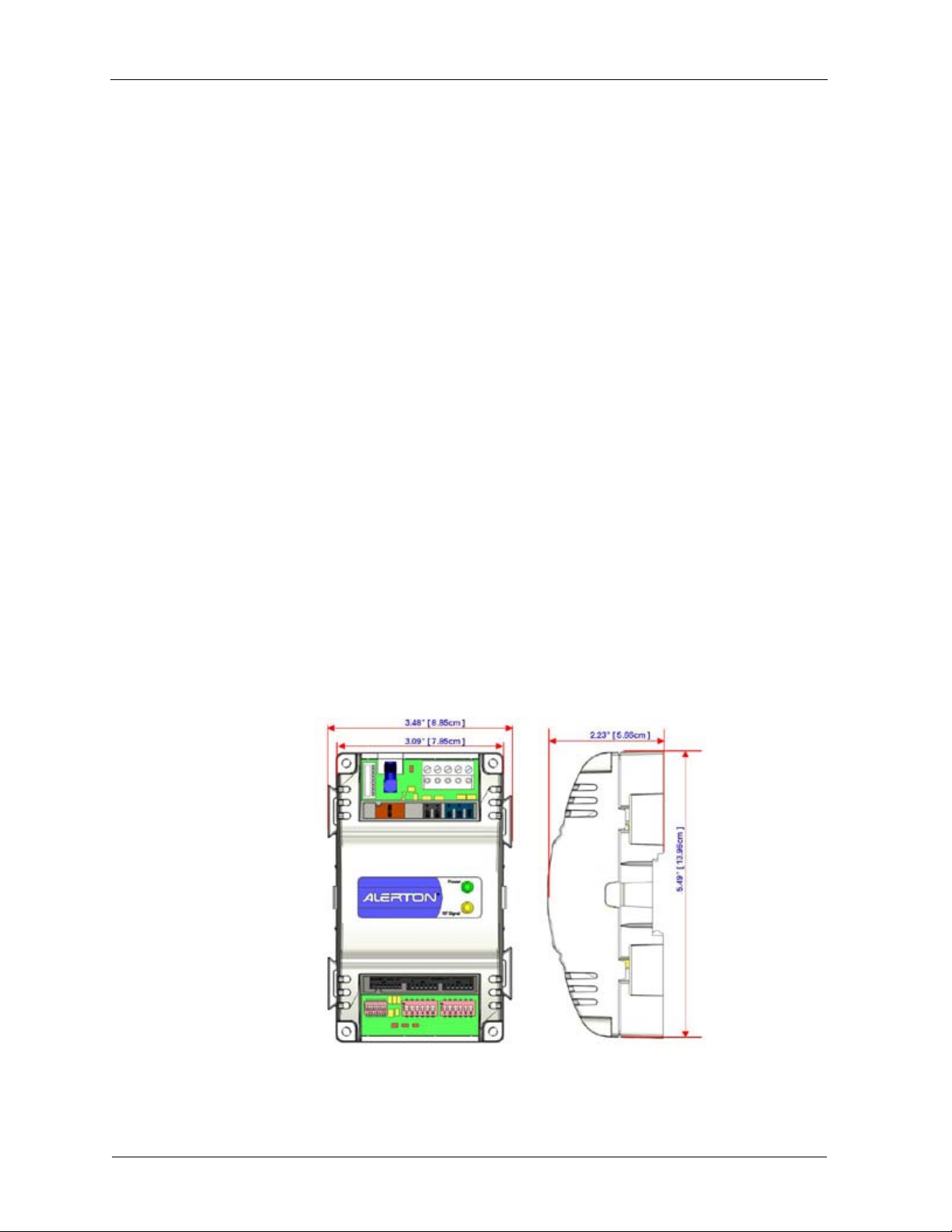

Dimensions

• Transceiver - connects to a unitary controller by an MS/TP cable. Also

supports a wireless sensor by communicating data between the unitary

controller and the wireless sensor. Sends and receives system data

to/from the coordinator.

• Repeater - Connects only to power. Repeats transmissions in areas of

weak reception. Note that the use of repeaters reduces the overall

bandwidth of the network.

Power rating

4

Figure 1 AZW-5000 dimensions

The AZW-5000 consumes <5VA power at 24VAC 50/60Hz typical.

LTBT-TM-AZWIOG Rev. 0001BETA © Honeywell

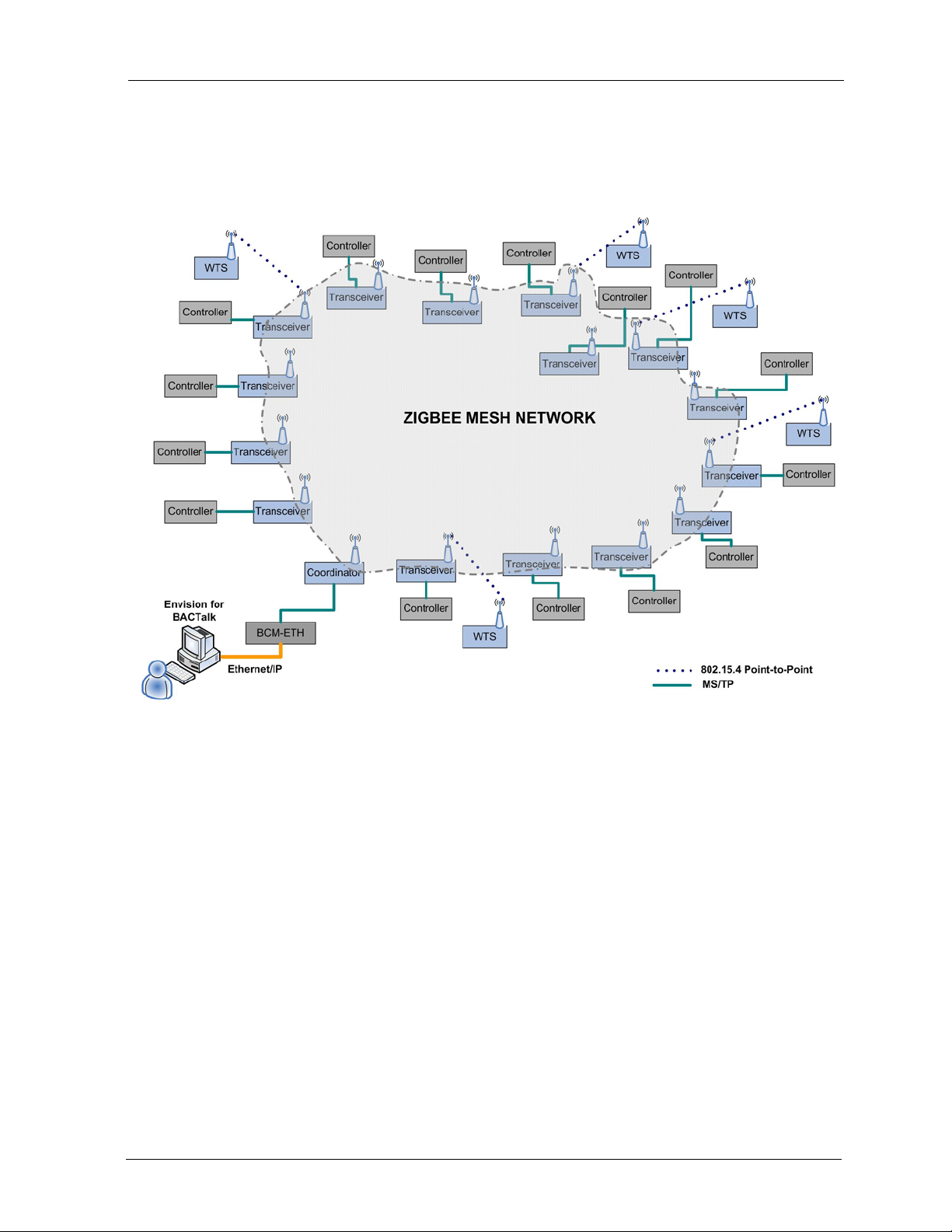

AZW-5000 network topology

Figure 2 shows a typical, stand-alone, AZW-5000 implementation. For examples

of other topologies, see the System Design Guide (LTBT-TM-SYSDSGN).

Installation and Operations Guide

About AZW-5000

|

Figure 2 Typical AZW-5000 implementation

Items to note in relation to Figure 2:

• The maximum number of AZW-5000 devices on a network is 16 (1

coordinator and 15 transceivers/repeaters).

• The AZW-5000 connected to the BCM-ETH must be configured as a

coordinator. This device manages the wireless network.

• The coordinator must have a dedicated BCM-ETH or BCM-MSTP. Do

not connect multiple MS/TP devices to the coordinator’s BCM.

• An Alerton Wireless Temperature Sensor cannot be associated with a

coordinator or a repeater.

• An AZW-5000 transceiver or repeater may be associated with only one

WTS. Both must share the same ZigBee MAC address.

• Locating a transceiver more than 100 feet from the coordinator may

degrade data transfer rates.

© Honeywell LTBT-TM-AZWIOG Rev. 0001BETA 5

Installation and Operations Guide

AZW-5000

|

About this document and related publications

This document provides information about installing and wiring a AZW-5000 to

equipment, power, and communication channels. It also shows how to operate

the device.

IMPORTANT Always install equipment in accordance with the National

Electric Code and in a manner acceptable to the local authority having

jurisdiction (AHJ). No guidelines, instructions, installation practices, or other

information presented in this guide may be interpreted to supersede or modify

the local codes and practices of the AHJ.

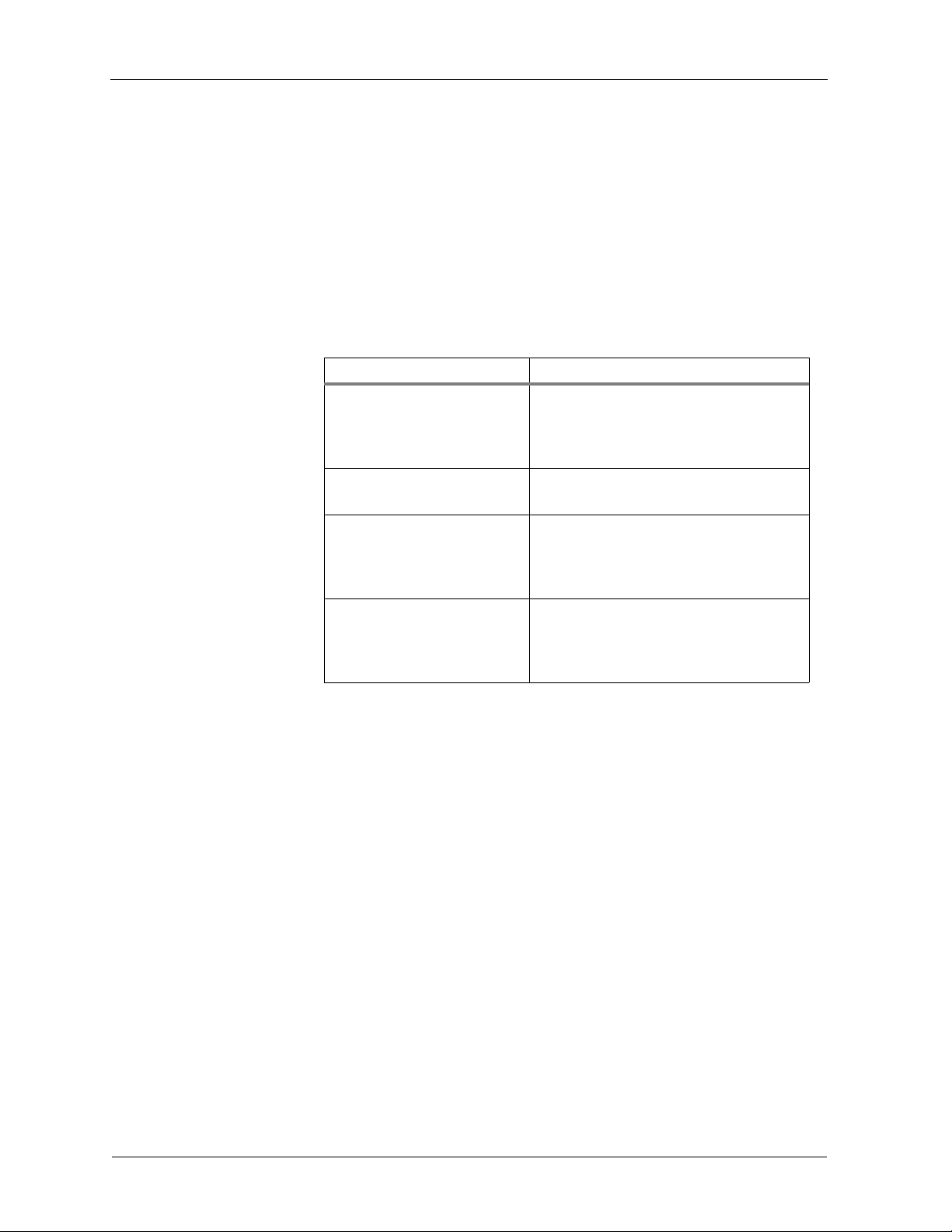

Ta bl e 1 Other documentation related to AZW-5000s

Document (ID) Contains

AZW-5000 Installation

Instructions

(LTBT-AZW-INST)

Data Sheet Single-sheet summary of applications,

System Design Guide Guidelines for BAS systems. Includes a

Alerton Wireless Temperature

Sensor Installation

Instructions

(LTBT-TM-WTS-INST-USA)

Instructions for mounting and wiring the

AZW-5000. Also lists field configuration

settings. A printed copy ships with each

unit.

capabilities, and configuration.

section on wireless networks and Alerton

wireless hardware. includes max trendlogs,

schedules, and alarms supported.

Instructions for installing and operating the

Alerton Wireless Temperature Sensor.

6

LTBT-TM-AZWIOG Rev. 0001BETA © Honeywell

Installation and Operations Guide

General installation guidelines

This section provides guidance for wiring and powering Alerton controllers. For

installation instructions specific to AZW-5000, see “Installation” on page 14.

Using terminal blocks

The AZW-5000 uses header-style termination blocks to simplify field wiring of

power, communications, and I/Os. Terminal blocks accept wire gage from

12–24AWG.

To terminate wire to a AZW-5000

1. Strip approximately 1/8” of the wire jacket from the end of the wire.

2. Use a small screwdriver (1/8” max) to turn the adjustment screw fully

counter-clockwise. The clamps in the wire slot separate as you turn the

screw.

3. Insert the stripped end of the wire into it (try to get the jacket flush with

the terminal block). If using stranded wire, be sure to insert all strands

into the wire slot. If terminating multiple wires, trim wires to same

length and tightly twist exposed wire together.

General installation guidelines

|

4. Hold the wire in place and turn the adjustment screw clockwise to

tighten it until the clamps in the wire slot secure the wire.

5. Tug gently on the wire to ensure it is secure.

Power supply guidelines and requirements

AZW-5000 uses 24VAC power from a UL Listed Class 2 24VAC transformer

(not provided). The AZW-5000 uses a half-wave rectifier to convert the AC

power supply to onboard power. This enables multiple devices with half-wave

power supplies to be powered from a single, grounded transformer. When

sharing a transformer make sure the sum of the MAX loads for all connected

devices does not exceed the Load rating for the transformer. AZW-5000

maximum power consumption is <5VA.

CAUTION Half-wave devices and full-wave devices must not use the same AC

transformer. If a AZW-5000 will share its power supply with another device,

ensure that the other device uses a half-wave rectifier and that polarity of wiring

is maintained. Failure to do so can result in equipment damage.

Note All Alerton unitary controllers are half-wave devices.

Selecting a transformer

The safest way to size a transformer is to ensure that the maximum VA load

rating of the AZW-5000 is less than 85% of the Nameplate VA rating of the

transformer. Even if all outputs are not presently used, this ensures that each

AZW-5000 has sufficient power for future equipment additions.

CAUTION If an AZW-5000 will share its power supply with another device,

ensure the transformer is rated to handle the combined maximum load. Using

and undersized transformer may damage equipment.

IMPORTANT Transformer sizing should never exceed the maximum UL Class

2 rating.

© Honeywell LTBT-TM-AZWIOG Rev. 0001BETA 7

Installation and Operations Guide

AZW-5000

|

Power supply grounding and wiring

When connecting power to the AZW-5000, ensure that one leg of the VAC

secondary circuit connects to a known earth ground. Also ensure that the GND

terminal on the AZW-5000 connects to the same known earth ground.

Supplying a high-quality ground connection to a AZW-5000 and then properly

connecting the AZW-5000 to the ground is one of the most important things you

can do to ensure a trouble-free installation.

The 24VAC secondary leads are not interchangeable. Once a lead connects to

the GND terminal on the AZW-5000, it is the grounded lead. Observe and

maintain polarity for subsequent connections. The GND terminal provides a

reference ground for the circuit board and communications wiring. Use 18 AWG

cable for best results.

WARNING Ensure that all AZW-5000 power, communications, and I/O

cabling are grounded according to these instructions. Failure to follow these

instructions may result in AZW-5000 operational and communication failures or

equipment damage.

Power supply wire selection

If you are considering long power supply wiring runs, using the right wire size is

critical. If the wire diameter is too small, the resistance may be too high,

resulting in a low voltage supply to the AZW-5000. This is known as line loss.

The wire size is based on the length of the wire run and the current draw of the

AZW-5000. Obtain additional information from the transformer manufacturer.

8

LTBT-TM-AZWIOG Rev. 0001BETA © Honeywell

MS/TP LAN wiring

Installation and Operations Guide

The AZW-5000 coordinator device communicates with the BACnet system over

the MS/TP LAN, which uses the EIA–485 signaling standard. Transceivers

communicate with their associated unitary controllers over

Note This section applies only to the coordinator device.

Ta bl e 2 MS/TP LAN facts

Transmission speed 9.6, 19.2, 38.4, 76.8Kbps (figured at global controller).

At startup, AZW-5000 devices operate at 76.8 Kbps.

Layout Bus.

Cabling BACnet specifies the following. Shielded, twisted-pair

cabling with characteristic impedance between 100 and

130 Ohms. Distributed capacitance between conductors

must be less than 30 pF/foot (100 pF/m). Distributed

capacitance between conductor and shield must be less

than 60 pF/foot (200 pF/m). Foil or braided shield

acceptable.

Segment length Segments between transceivers and controllers/devices

should be kept as short as practical to reduce cable

costs. Longer segments are acceptable to improve radio

signal strength.

The segment between a coordinator and its associated

BCM can be up to 4000 ft. (1071 m.), but will typically

be much shorter.

General installation guidelines

|

Maximum devices

overall

Maximum devices

per segment

MS/TP repeaters Do not use.

Terminating

resistors

Shield grounding Ground transceiver shield drain wires at single point

Terminating MS/TP LAN cabling

MS/TP terminations are located at the top of the AZW-5000. See Fig. 4 on p. 15.

Maintain polarity of the MS/TP wire run throughout the MS/TP LAN.

Note Basic information about MS/TP terminations at the AZW-5000 are

provided here. See the BACtalk System Design Guide (LTBT-TM-SYSDSGN)

for more detailed information and limitations with respect to MS/TP LANs —

distance requirements, unit loads, repeater architectures, and so on.

One coordinator and 15 transceivers/Repeaters.

One transceiver and one controller per subnet.

not applicable

earth (panel) ground, not AZW-5000 ground. Tape off

the shield drain wire at the other end.

Grounding coordinator shield wires is not necessary

unless the coordinator is located more than ten feet

from its associated BCM.

© Honeywell LTBT-TM-AZWIOG Rev. 0001BETA 9

Loading...

Loading...