ADEMCO 5

PLEASE GO TO THE BOTTOM OF PAGE 4

FOR THE FCC AND IC STATEMENTS

ADEMCO 5870API

Wireless Indoor Asset Protection Device

Wireless Indoor Asset Protection Device

Wireless Indoor Asset Protection DeviceWireless Indoor Asset Protection Device

ADEMCO 5ADEMCO 5

INSTALLATION AND SETUP GUIDE

K14379 4/07 Rev. A

870API

870API870API

GENERAL INFORMATION

The ADEMCO 5870API is a wireless, supervised asset

protection device that uses patented Micro-ElectroMechanical System (MEMS) technology, which references

the Earth’s gravitational field. When affixed to a

protected high-value asset the device will trigger an

alarm if an attempt is made to move or disturb the asset.

ADEMCO VISTA P-series control panels (VISTA-10P,

15P and 20P) provide configurable zone types that allow

the installer to customize a zone for asset protection (i.e.,

24 hour supervisory alarm, trouble by day/alarm by night,

etc.) Refer to the control panel installation instruction for

full details.

The 5870API is intended for use in systems that support

5800 series devices. Each transmitter has its own unique

serial number, assigned during manufacture, which must

be “enrolled” in the control panel before the device can be

used with the system. Refer to the control panel's

Installation and Setup Guide for programming details.

One 5870API is required for each asset that will be

protected.

Typical Protected Assets

The 5870API can be used for many residential and

commercial applications such as:

Residential Commercial

• Electronic equipment • Office Equipment

• Jewelry boxes • Museum Art

• Paintings and Art • Laboratory Equipment

• Entertainment devices

• House or Gun Safe

• Antiques and Collectables

The 5870API sensor is for use on objects that do not

move frequently or vibrate. Mounting the sensor near

sources of vibration may cause false alarm

!

conditions to occur.

Operating Modes

The 5870API is equipped with three programming

options. A three minute inhibit prevents excessive RF

transmissions and preserves battery life by transmitting

alarm signals three minutes apart.

Short Travel Time Detection (Loop 1) – This is a

high-security, minimum movement mode in which the

sensor detects the movement of the device over a short

time period and sends an alarm signal after one second of

continuous movement. When the motion has stopped for

period of three seconds, a restore signal is sent.

Long Travel Time Detection (Loop 2) – The sensor

detects the movement of the device over a longer time

period in this mode and sends an alarm signal after five

seconds of continuous movement. When the motion has

stopped for period of three seconds, a restore signal is

sent.

Open/Close Sensor (Loop 3) – This mode is intended

for boxes with lids that can be opened (e.g.; jewelry boxes).

The sensor detects tilt with respect to the horizon. If the

unit is tilted more than 30° of tilt with respect to the

Earth the sensor will send an alarm signal. If the unit is

tilted back to less than 15° a restore signal will be sent.

The 5870API is not watertight, and therefore should

not be used in damp locations. Do not use the device

in applications that may be exposed to moisture. The

device may be used in garages, sheds, etc., as long

as it is not at risk from rain, snow, humidity or

!

condensation. The device should not be installed in

locations where temperatures may drop below 14° F.

OPERATION

Upon initial battery power up, the unit will transmit

every time it is faulted or restored, which enables you to

program and test the device. To conserve battery life the

sensor’s normal operating mode has a three-minute

lockout on Loops 1, 2 and 3. Once a restore has been sent

on any loop, further transmissions on that loop are

inhibited for three minutes. Other loops are not affected.

The sensor automatically switches from installer test

mode to normal mode after the first supervisory

transmission is sent. This will occur approximately 72

minutes after the last fault/restore message has been

sent.

To return to the installer test mode remove and reinstall

the battery.

TAMPER SUPERVISION

The 5870API tamper supervision feature (Loop 4) causes

a trouble signal to be sent to the control if the sensor is

removed from the asset being protected or if the unit’s

cover is removed from the base. The tamper switch is

also used to program the unit’s serial number and loop

assignments to the control panel.

SETTING THE OPERATING MODE

You must enroll the 5870API serial number in the control

panel during zone programming. The control panel's

Installation and Setup Guide provides detailed programming procedures. Table 1 provides a list of the various

operating modes of the 5870API with the respective Loop

numbers for each. Before programming, perform the

following:

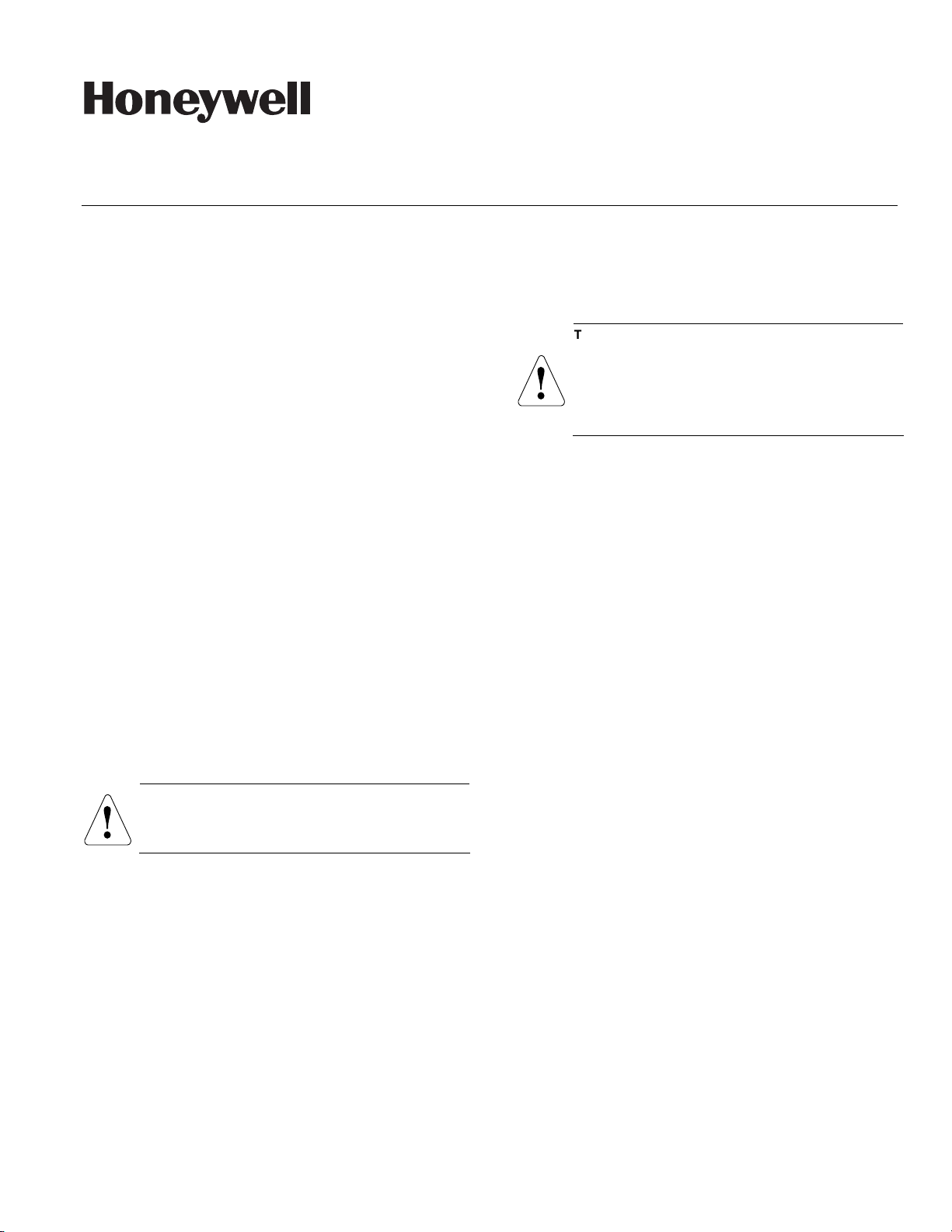

1. To cause the transmitter to transmit, remove the

“PULL TO CONNECT BATTERY” tab (see Figure 1).

(For additional transmissions, move or rotate the

sensor.)

2. When the battery is connected the sensor powers up

in the installer test mode. In this mode the sensor

will transmit fault and restore messages on all loops

when it detects the corresponding motion (or lack

thereof).

SENSOR

TAB

PULL TO CONNECT BATTERY

K5867

PULL

5870API-002-V0

Figure 1 - 5870API Battery Tab

PROGRAMMING THE UNIT

If you are enrolling this device on a LYNXR-Series

control panel refer to the *56 Enhanced Zone

Programming Mode section in the LYNXR Installation

Guide for programming information.

Once you have selected an operating mode you must

enroll the transmitter in the control panel. When

programming the transmitter in the control panel, note

that you must program a separate zone for each loop you

are using on the transmitter. To program:

1. Enter the control’s Zone Programming mode.

2. Enter the zone number to be programmed.

If the asset being protected should not be moved (i.e.,

a painting) it can be programmed as a 24 hour zone

type. If the asset will occasionally be moved, when the

system is disarmed, it can be programmed as a

perimeter zone type .

3. When prompted, enter zone type.

4. When prompted, enter Input Type 03 (3 on some

controls) – Supervised RF Transmitter.

5. When prompted for the serial number, transmit from

the detector by pressing the tamper switch.

6. When the serial number is displayed, transmit from

the detector again by pressing the tamper switch.

The current loop number (4) will begin to flash.

7. Manually change the loop number to the desired loop

number for the zone (according to the application—

see Table 1).

8. If you are enrolling this device on a Vista-series

control, press the * key to skip the confirmation

screen.

9. Exit Programming mode when programming is

complete, and test the detector. Refer to the Testing

section.

MOUNTING

1. Replace the adhesive when relocating the device.

2. Ideal application temperature range of the tape is

70-100°F (21-38°C). Initial tape application to

surfaces below the suggested minimum

temperature is not recommended because the

adhesive becomes too firm to adhere readily.

The 5870API can be permanently or temporarily mounted

directly to the asset to be protected via 3M VHB doublesided tape or removable adhesive double-sided tape. Two

types of tape are provided with the device and the

selections should be based on the end use environment

and conditions. Once cured the black tape (with red

release liner) has a stronger bond, except in low

temperature applications where the gray tape should be

used.

1. Determine the optimum mounting location taking care

to avoid damp locations. To maximize the

transmitter’s range avoid mounting the device to

metal objects, if possible.

2. Temporarily mount the device to the asset to be

protected using masking tape or any suitable method.

3. Before the transmitter is permanently mounted,

conduct Go/No Go tests (refer to the Control Panel’s

instructions) to verify adequate signal strength from

the mounting location.

4. Always verify range by holding the sensor in the

approximate mounting location and moving the asset.

The panel (in test mode) should respond to the

transmissions. If not, find a more suitable mounting

location.

5. If your application (“permanent”) requires the black

tape, remove the gray tape. Clean any fingerprints

and adhesive residue and install the black tape on the

sensor.

Take care to align the hole in the tape with the

device’s tamper switch plunger.

6. Clean the area, where the sensor will be mounted,

with a mixture of water and isopropyl alcohol.

To obtain proper performance with all 3M VHB tapes,

it is important to ensure that the surfaces are dry and

free of condensed moisture.

7. Once the surface has been cleaned, remove the tape

backing paper and firmly press the sensor in the

desired mounting location. Apply pressure for 30

seconds.

Firm application pressure develops better adhesive

contact and helps improve bond strength. After

application, the bond strength will increase. At room

temperature approximately 50% of ultimate bond

strength will be achieved after 20 minutes, 90% after

24 hours and 100% after 72 hours.

8. Verify operation by moving the asset. Always check

the alarm panel keypad to verify that the zone has

tripped.

REPLACING THE BATTERY

A 3-volt lithium battery powers the 5870API. If the

battery voltage gets too low, the device sends a low battery

signal to the control panel.

The 5870API consume less battery power when stationary

than when in motion. Maximum battery life will be

obtained when used on assets that are moved infrequently

(e.g.; televisions, paintings, sculpture, etc.)

Replace the battery with Ademco 469, Sanyo CR2,

Panasonic CR2 or Duracell DLCR2. Use of another

battery may present the risk of fire or explosion

1. Using a screwdriver, release the case’s retaining tabs.

2. Carefully remove the sensor’s cover. (see Figure 2)

- 2 -

INSERT TIP OF

FCC & IC ID No's

SCREWDRIVER.

PUSH IN TO

RELEASE CLIP

CR2

Figure 3 – Replacing the 5870API Battery

5870API-005-V0

Figure 2 – Replacing the 5870API Battery

3. Check the battery polarity orientation before

installing (see Figure 3).

4. Insert the battery securely in the sensor.

5. Snap the sensor cover back in place.

Table 1: 5870API Operating Mode Choices

Operating Mode Loop Faults when… Restores when…

Short Travel Time

Detection

Long Travel Time

Detection

Open/Close Sensor

1 Asset/sensor is moved for 1 (+1, -0)

second.

2 Asset/sensor is moved for 5 (+1, -0)

seconds

3 Asset/sensor is tilted >30 (+/-10)

degrees (with respect to the horizon)

Motion of the asset/sensor has stopped for 3

(+1, -0) seconds.

Motion of the asset/sensor has stopped for 3

(+1, -0) seconds.

Asset/sensor is tilted <15 (+/-5) degrees

(with respect to the horizon).

SPECIFICATIONS

1.7"

Dimensions:

1.8" H x 1.7" W x 0.63" D

(45.72 mm x 43.18 mm x 16.02 mm)

5870API-001-V0

Power:

Single 3V Ademco 469, Panasonic CR2, Sanyo CR2,

or Duracell DLCR2 Lithium Battery

Environmental Conditions:

14° to 122°F (-10° to 50°C)

<90% RH (non-condensing)

- 3 -

1.8"

REPLACE ADHESIVE WHEN RELOCATING THIS DEVICE

5870API

(Rear View)

TAMPER

5870API-003-V1

WARNING

Risk of fire, explosion, and burns. Do not recharge, disassemble, heat above 212º F (100º C) or incinerate. Dispose of used

batteries properly. Keep away from children.

TO THE INSTALLER

Regular maintenance and inspection (at least annually) by the installer and frequent testing by the user are vital to

continuous satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and offering a regular maintenance program to the user as well

as acquainting the user with the proper operation and limitations of the alarm system and its components parts.

Recommendations must be included for a specific program of frequent testing (at least weekly) to ensure the system’s proper

operation at all times.

FCC ID: CFS8DL5870API

The FCC ID may also be found inside the battery compartment of this product, beneath the battery. Refer to "REPLACING

THE BATTERY" above for information on how to remove the battery.

FCC and Industry Canada Statement

This device complies with Part 15 of FCC rules and RSS 210 of Industry Canada. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Unauthorized changes or modifications could void the user's authority to operate the equipment.

FOR WARRANTY INFORMATION AND DETAILS REGARDING THE LIMITATIONS OF THE ENTIRE

ALARM SYSTEM REFER TO THE INSTALLATION AND SETUP GUIDE FOR THE CONTROL PANEL

USED WITH THIS DEVICE.

U.S. Patent Numbers

5,155,469

5,004,999

6,724,316

7,119,681

‡K14379bŠ

K14379 4/07 Rev. A

165 Eileen Way, Syosset, New York 11791

Copyright © 2007 Honeywell International Inc.

www.honeywell.com/security

Loading...

Loading...