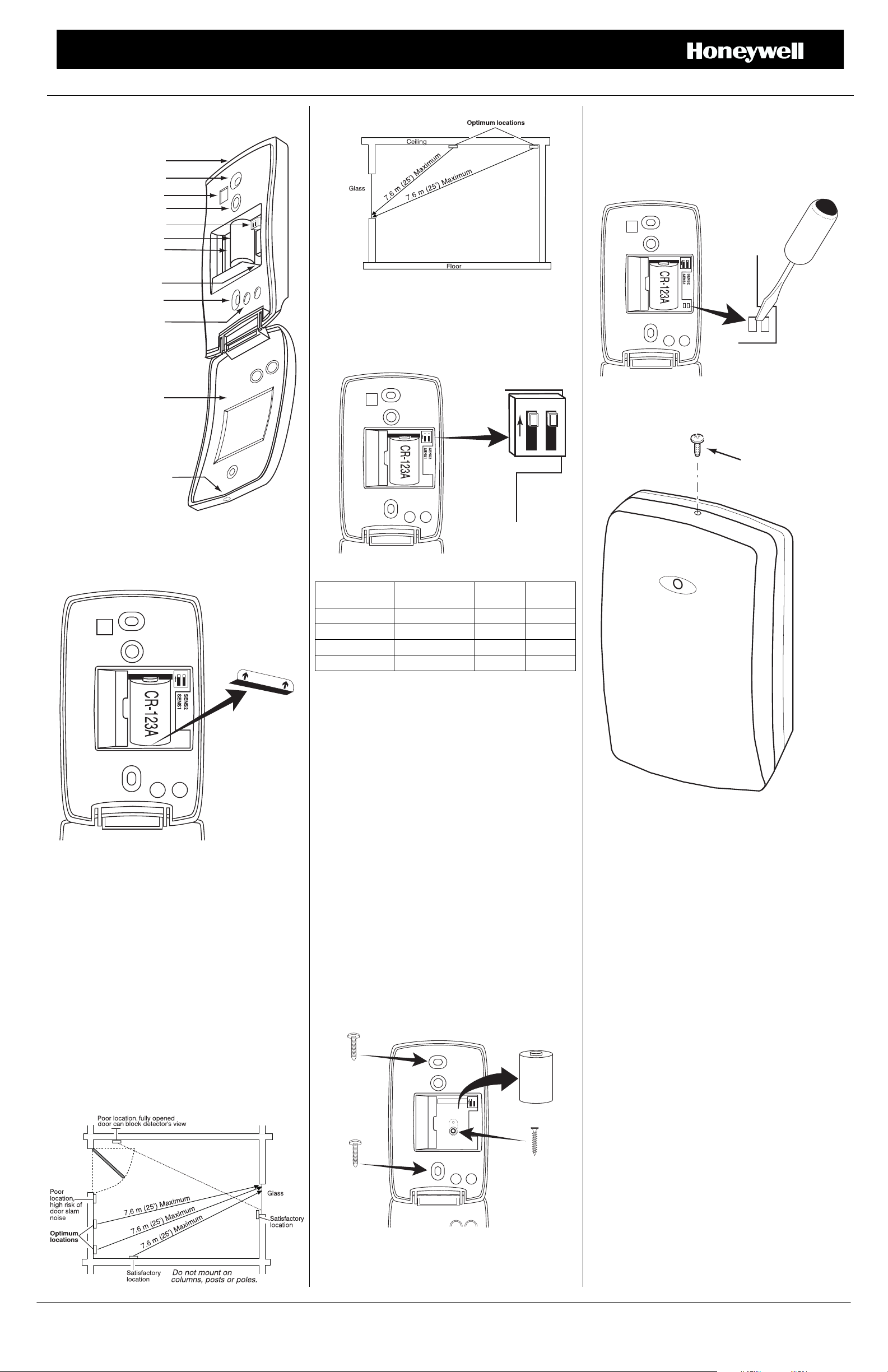

Ademco 8DL5853 4 Users Manual

CR-123A

Mounting Hole

Mounting Hole

Battery

Front Tamper Switch

LED Indicators

Microphone

Sensitivity Switches

Wall Tamper (behind battery)

Test Mode pads (on PCB)

Front Cover

Latch

Break out flash

for cover screw

2

1

ON

OFF

5853-1_001-V0

BATTERY

5853-1_002-V2

Wall Mount

(Top View)

WallMnt-001 -V0

Ceiling Mnt-001-V0

Ceiling Mount: (Side View)

SENS2

SENS1

5853-1_004-V2

ON

OFF

SENSITIVITY

APPROXIMATE

SENS1

SENS2

OFF OFF

ON OFF

OFF ON

ON ON

CR-123A

SENS2

SENS1

(Screw not supplied.)

3.5 mm x 38 mm

(#6 x 1-1/2")

3.5 mm x 38 mm

(#6 x 1-1/2")

#6 (3.5 mm) screw for

Optional Rear Tamper

*3.5 mm (#6)

screws works best

with the screw

retention feature.

To work properly, the back tamper

screw must be screwed into a

framing stud or a heavy-duty

hollow-wall anchor, such as a

#8 self-tapping anchor. This type

of back tamper is not suitable for

use on acoustic ceiling tile.

SENS2

SENS1

5853-1_005-V2

TEST

TEST

5853_006-V1

2.9 mm (#4) screw,

6 mm (1/4-in.) long

FlexGuard® 5853 Wireless Glassbreak Detector – Installation Instructions

5853 Glassbreak Detector Internal Parts

NOTE: If the device is ceiling mounted, the end with the

hole (Microphone end) should face the protected glass.

Set Sensitivity (Range)

Test Detector Installation

Enter Test Mode using a FlexGuard FG-701

Glassbreak Simulator (see Testing the Detector on the

next page). To enter Test Mode manually, short the

Test Mode pads (as shown below).

Connect Battery

Remove pull tab to connect battery.

NOTE: Constant exposure to high or low temperature or high

humidity may reduce battery life.

Install Cover Screw (optional)

SENS1 & SENS2 configure sensitivity

RANGE

MAX 7.6m (25 ft)

MEDIUM 4.6m (15 ft)

LOW 3m (10 ft)

LOWEST 1.5m (5 ft)

NOTE: Ranges are approximate and vary with each

room’s acoustic properties. Always verify range with a

FlexGuard FG-701 Glassbreak Simulator.

Select Mounting Location

For the best detector performance, select a mounting

location that is:

• within 7.6 m (25 feet) of the protected glass;

• within clear view of the protected glass;

• at least 2 m (6.5 feet) from the floor;

• at least 1 m (3.3 feet) from forced air ducts;

• at least 1 m (3.3 feet) from sirens or bells greater

than 5 cm (2 inches) in diameter.

• between the protected glass and any heavy

window coverings that may be present.

Alternatively, when heavy window coverings are

present, the detector can be mounted on the frame of

the window.

Avoid mounting the detector on the same wall as the

protected glass, on free-standing posts or pillars, or in

rooms with noisy equipment (air compressors, bells,

power tools, etc.), if this equipment is operated when

the detector is armed.

Enroll Detector

Refer to text and control panel's installation

instructions.

When programming the transmitter, specify:

• Input Type = 3 (Supervised RF)

• Loop Number = 1

Mount Detector

• Use mounting holes as a template to mark

mounting locations on ceiling or wall.

• If using the optional back tamper, remove the

battery, then mark the wall tamper location

through its mounting hole.

• Mount detector using appropriate hardware.

NOTE: A screw capture feature designed to

make ceiling mounting easier will cause some

resistance when inserting the screw into the

plastic.

• Close detector cover when finished.

*The screw retention feature simplifies installation: A

rib in the screw cavity lightly holds the screw in place

when installing the detector.

Ê800

-

12481V1ÀÀ1Š

SENSITIVITY

APPROX.

SENS1

SENS2

OFF OFF

ON OFF

OFF ON

ON ON

CONDITION

GREEN LED

RED LED

Nominal Thickness

Minimum

Maximum

Plate

Tempered

Laminated

1

, 3

Wired

Coated

2, 3

Sealed Insulating

1, 3

P.O. Box 9040, Melville, NY 11747

1. General Information

The 5853 Wireless Glassbreak detector with

Transmitter senses the sound of breaking plate,

tempered, laminated, wired, coated and sealed

insulating glass. The self-contained detector includes a

transmitter that can send alarms, tamper signals, and

low battery messages to the control panel. The sensor

is compatible with 5800-series wireless hardware*, and

is designed for continuous operation using one 3V

lithium battery (CR-123A or equivalent; included).

Prior to installation, you must:

• Connect its battery by removing the tab,

• Adjust the detector’s sensitivity, and

• “Enroll” the detector’s serial number.

Refer to the following sections to install the 5853.

This detector is both UL and ULC listed.

*

Compatible control units for use in Canada require the use of

listed RF receivers that have been subjected to compatibility

analyses by Underwriters’ Laboratories of Canada. Refer to the

Installation Instructions for the control unit before installing

burglar alarm components.

2. Connecting Battery/Initial Power Up

To connect the battery, remove the tab from the end of

the battery holder. The detector will start its power up

sequence, in which both the LED indicators will

illuminate for one second. (The LED indicators are

described later in these instructions.)

3. Adjusting Detector Sensitivity (Range)

The 5853 has four sensitivity settings, which are set

using the SENS1 and SENS2 DIP switches. The

settings are: 1) maximum; 2) medium; 3) low; and 4)

lowest. By default, sensitivity is set to MAXIMUM.

To change the detector’s sensitivity, use a small

screwdriver to adjust the SENS1 and SENS2 switches,

as shown in the table below:

RANGE

MAX 7.6m (25 ft)

MEDIUM 4.6m (15 ft)

LOW 3m (10 ft)

LOWEST 1.5m (5 ft)

4. Enrolling Detector Into 5800-Series Receiver

Before the control panel will recognize the 5853, you

must program the device's serial number into the

control panel. This process, ("enrolling") is described in

detail in the control panel's installation instructions.

When programming the transmitter, specify:

• Input Type = 3 (Supervised RF)

• Loop Number = 1

You can transmit the device’s serial number

automatically or enter it manually. To transmit the

number automatically, momentarily activate the front

tamper switch. To enter the serial number manually,

refer to the control panel’s instructions to enroll the serial

ID number which appears on the product.

5. Selecting Installation Location

The 5853 can be mounted on the ceiling or the wall.

Choose a mounting location that is at least 2.1m (7

feet) from floor and no more than 7.6m (25 feet) from

the farthest protected glass. Be sure the detector has

an unobstructed line-of-sight to the protected glass!

Before mounting the detector permanently, test it to

ensure that it functions satisfactorily in the chosen

mounting location. Verify that the detector can detect

glassbreak sounds, following the directions in the

“Testing the Detector” section. Ensure that the 5853 is

within range of the receiver, following the instructions

for the signal-strength test found in the control panel’s

installation instructions. (To send the signal required by

the test, activate the detector's front tamper switch.) If

the detector fails, relocate it and repeat both tests.

6. Mounting the Detector

NOTE: If using wall tamper and installing on dry wall

(sheet rock), position the detector so that the wall

tamper is over a wall stud or ceiling joist, or use a

drywall anchor so the tamper screw will not pull out.

NOTE: If the device is ceiling mounted, the end with

the hole (Microphone end) should face the protected

glass.

For the latest warranty information, please go to:

www.honeywell.com/security/hsc/resources/wa

For the latest documentation and online support information, please go to:

https://mywebtech.honeywell.com/

For patent information, see www.honeywell.com/patents

To mount the detector:

1. Using the 5853 mounting holes as a template,

mark mounting locations on the ceiling or wall.

2. If using the optional wall tamper, remove

the battery, then mark the wall tamper location

through its mounting hole. The tamper screw

must be securely mounted. See details on

page 1.

3. If required by the mounting location, install

wall anchors for the mounting screws.

4. Secure the 5853 to the wall or ceiling, oriented

so the microphone has the best line-of-sight to

the protected glass.

5. Reinstall the battery if previously removed.

6. Close and secure the detector front cover.

7. Testing the Detector

The detector should be tested at least once each year.

Test the detector with the FlexGuard FG-701 Glassbreak

Simulator. Other simulators will not give accurate

indication of range.

To enter the Test Mode with the FG-701:

1. Stand within 4.6 m (15 feet) of the detector.

2. Switch the FG-701 to ACTIVATE and

MANUAL modes.

3. Point the front [speaker] of the glassbreak

simulator towards the detector and press the

red START button. The simulator buzzes a

short activation code.

When the detector enters Test Mode, the green LED on

the detector flashes about once per second. If the

green LED does not flash, move closer to the detector

and repeat the procedure.

To enter Test Mode manually:

1. Open the front cover.

2. Use a screwdriver to short the Test Mode

pads on the PC board (see diagram on next

page).

3. Close the front cover.

The detector’s green LED blinks approximately once per

second to indicate that it has entered the test mode.

Testing the Detector (flex and audio signals):

To test the 5853, do the following:

1. Place the detector in Test Mode.

2. Set the FG-701 switches to the TEST and

FLEX positions.

3. Position the FG-701 near the farthest point of

the protected glass, and point the speaker

directly at the detector. If window coverings

are present, close them fully and hold the

FG-701 between the coverings and the

protected glass.

4. Press the red START button. The simulator

clicks on and starts an eight-second armed

period.

5. Generate a flex signal by carefully striking the

glass with a cushioned tool. The FG-701

responds with a burst of glassbreak audio.

If the detector receives both the flex and audio signals

properly, its red Alarm LED lights for 5 seconds. (Red

Alarm LED does not latch.)

Testing the Detector (audio signals only):

The FG-701 can also be used to test the detector’s

ability to receive audio signals only. See the FG-701

Operating Instructions for additional information. When

it receives the audio signal, the detector flickers its

green Event LED.

Exiting Test Mode:

When you have finished testing, exit Test Mode by

following the same procedure used to enter Test Mode.

The detector automatically exits Test Mode five minutes

after the last event is detected.

8. LED Indicators

The detector is equipped with two LEDs: a green Event

LED and a red Alarm LED. When the LEDs are

enabled during testing, they light in a variety of patterns

to convey the detector’s operational status. The

following table summarizes the LED messages.

(Please note that the LEDs are only enabled during

Test Mode, and are inactive during normal operation.)

MyWebTech

Warranty

Patents

Power up ON 1 second ON 1 second

Test Mode Flash once per sec OFF

Test Mode, event detected Flicker OFF

Test Mode, alarm Flash once per sec ON 5 seconds

Low Battery * Flash once per sec Flash once per sec

* If battery voltage drops too low, LEDs are no longer visible.

9. Cover Screw

The front cover can be secured after installation. To do

so, remove the cover breakout flash (illustration on next

page) and secure the front cover with a 6 mm (¼-in.), 2.9

mm (#4) screw (supplied).

10. Maintaining Proper Operation

To maintain the 5853 Glassbreak Detector in proper

working order, please observe the following:

Replace the battery when the system indicates a low

battery condition (refer to the control panel’s operating

instructions.) Be sure to replace the battery with the

proper type and voltage. To ensure proper power down

sequence, wait a minimum of 20 seconds before

installing the new battery.

The installer should inform the end user that fans, air

conditioners, blowers, loudspeakers, or other sources of

vibration and sound should not be introduced into the

protected area after installation of glassbreak detectors.

If unavoidable, the end user must contact the alarm

service company to re-adjust/re-test the equipment as

needed. Additionally, this device should not be relocated

without the advice or assistance of the alarm service

company.

11. Protected Glass Types Chart

NOTE: The 5853 is NOT recommended for protection of glass areas

smaller than 27.6 cm x 27.6 cm (10-7/8 inches x 10-7/8 inches).

Glass Type*

2mm (3/32 in.) 10mm (3/8 in.)

3mm (1/8 in.) 10mm (3/8 in.)

3mm (1/8 in.) 14mm (9/16 in.)

6mm (1/4 in.) 6mm (1/4 in.)

3mm (1/8 in.) 6mm (1/4 in.)

3mm (1/8 in.) [13mm

*

Minimum size for all types is 28cm (11 in.) square; glass must be

framed in the wall or mounted in a barrier at least 0.9m (36 in.) wide.

1

Protected only if both plates in the unit are broken

2

Coated glass with security films up to 0.35mm (14 mils) thick (including films

for solar protection) may be used. Evaluated with the these products: 3M®

SCOTCHSHIELD® SH14CLARL – 0.35mm (14 mils), 4 ply film; Film

Technologies International, Inc.’s GLASS-GARD GGLL 1200 has been

evaluated with this product by Underwriters Laboratories, Inc.

3

In compliance with Underwriters Laboratories of Canada’s Standard for

Intrusion Detection Units (CAN/ULC-S306-M89):

a. Plate glass 3mm (1/8-in.) to 10mm (3/8-in.) can be used.

b. ULC recognizes a maximum range for protecting sealed insulating glass,

1/8” laminated and coated glass of 3.8m (12.5 ft.); sensitivity should be set

to Max.

12. Specifications

Power:

Honeywell #466, Panasonic CR123A, Duracell DL123A (Lithium

Manganese Dioxide) or HUIDERUI CR123A.

Ranges:

protected glass. No minimum range.

Operating Temperature:

For indoor use environment

Dimensions:

Weight:

Accessories:

Compliance:

BATTERY CAUTION

Risk of fire, explosion, and burns. Do not recharge, disassemble,

heat above 212°F (100°C), or incinerate. Dispose of used

batteries properly. Keep away from children.

One 3V Battery (included). Replace only with

Maximum range is 7.6m (25 ft) from farthest

125g (4.41 oz.)

(1/2 in.) overall]

-10° to 50° C (14° to 122° F)

12.5cm (4.95") x 7.8cm (3.09") x 2.8cm (1.1")

FlexGuard FG-701 Glassbreak Simulator

FCC and IC Verified, UL Listed, ULC Listed, C-Tick

6mm (1/4 in.) [19mm

(3/4 in.) overall]

13. NOTICES

FCC/IC STATEMENT

This device complies with Part 15 of the FCC Rules and RSS-210 of Industry

Canada. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference. (2) This device must accept any interference received,

including interference that may cause undesired operation.

Cet appareil est conforme à la partie 15 des règles de la FCC & de RSS-210 des

Industries Canada. Son fonctionnement est soumis aux conditions suivantes: (1) Cet

appareil ne doit pas causer d’interférences nuisibles. (2) Cet appareil doit accepter

toute interférence reçue y compris les interférences causant une réception indésirable.

FEDERAL COMMUNICATIONS COMMISSION STATEMENT

The user shall not make any changes or modifications to the equipment unless

authorized by the installation Instructions or User's Manual.

Unauthorized changes or modifications could void the user's authority to operate the

equipment.

TO THE INSTALLER

Regular maintenance and inspection (at least annually) by the installer and frequent

testing by the user are vital to continuous satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and offering a regular

maintenance program to the user as well as acquainting the user with the proper

operation and limitations of the alarm system and its component parts.

Recommendations must be included for a specific program of testing (at least weekly)

to ensure the system’s proper operation at all times.

REFER TO THE INSTALLATION INSTRUCTIONS FOR THE RECEIVER/ CONTROL

WITH WHICH THIS DEVICE IS USED FOR DETAILS REGARDING WARRANTY

INFORMATION AND LIMITATIONS OF THE ENTIRE ALARM SYST

2 Corporate Center Drive, Suite 100

©2002 Honeywell International Inc. All Rights Reserved

Honeywell, FlexGuard and IntelliSense are registered trademarks of Honeywell International Inc. - All other brands

mentioned are the trademarks or registered trademarks of their respective owners. Specifications subject to change

without prior notice. www.honeywell.com/security

For the latest U.S. warranty information, please go to: www.honeywell.com/security/hsc/resources/wa or

Please contact your local authorized Honeywell representative for product warranty information.

800-12481V1 7/14 Rev B1

Loading...

Loading...