Ademco 8DL5816OD User Manual

AGENCY STATEMENTS ARE

AT THE BOTTOM OF PAGE 2

5816OD Wireless Outdoor Sensor – Quick Installation Guide

For Online Support visit: http://www.security.honeywell.com/hsc/resources/MyWebTech/

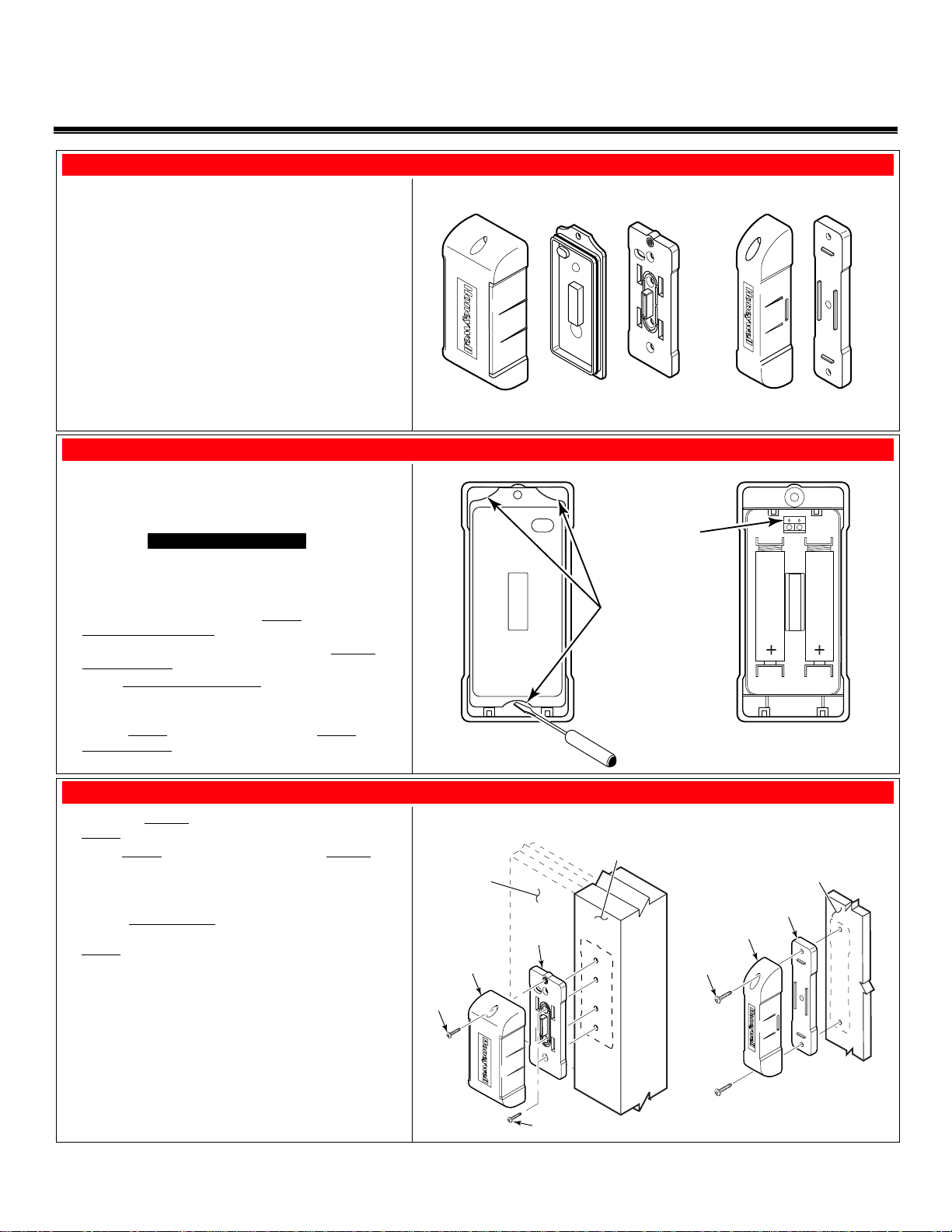

General Information and Component Identification

The Honeywell 5816OD Wireless Outdoor Sensor (referred

to as the sensor) brings the convenience of wireless

technology to the outdoors. The major features are:

Weatherized security protection for an outdoor

environment. Great for sheds, barns, garages, pool

gates, fences, and rural mailbox (notifications).

Versatile mounting options on flat and round materials.

Cover and rear tamper detection.

Can be painted to coordinate with mounting surface.

Operating temp: – 40 to + 50° C (– 40 to +122° F) at

RH of 100% (rain, snow).

Magnet Gap (Wood): 2 inches

Magnet Gap (Metal): 1.75 inches /no Magnet Spacer

Magnet Gap (Metal): 2 inches /with Magnet Spacer

Installing / Replacing the Batteries

IMPORTANT:

Change both batteries at the same time. Do not mix

weak batteries with new batteries.

Use two (2) lithium 1.5VDC AA cells. (For best life, use

Eveready's

Energizer Ultimate LITHIUM

AA batteries,

Honeywell part number 462)

OBSERVE BATTERY POLARITY.

Battery Replacement:

1. Remove cover screw and swing Sensor

Sensor Mounting Plate

.

to remove from

2. Use screwdriver in any pivot point and pry Battery

Chamber Cover off. Replace batteries.

3. Orient Battery Chamber Cover

so the screw hole line s

up with the screw hole in the sensor cover, and press to

close.

4. Engage Sensor

tabs into mating holes in Sensor

Mounting Plate and swing closed. Secure with cover

screw.

Mounting Guidelines

Mount the Magnet on the magnet sensing side of the

Sensor

as indicated by the ribs on the Sensor.

Mount Sensor

moveable surface.

When used on wooden sheds and barns, mount the

sensor and magnet on the inside of the structure.

Use the Magnet Spacer

surfaces; or if needed to achieve proper alignment with

Sensor

Flat Surfaces:

Use screws suitable for the material being fastened to.

on stationary surface, and Magnet on

when mounting on metal

.

COMPONENT IDENTIFICATION

BATTERY

SENSOR

CHAMBER

COVER

FLAT SURFACES

FENCE

SENSOR

MOUNTING

PLATE

SENSOR

COVER

SCREW

SENSOR

MOUNTING

PLATE

TERMINAL BLOCK

FOR EXTERNAL

CONTACT SWITCH

PRY

POINTS

FENCE

POST

MOUNTING

SCREW (2)

MAGNET

MAGNET

+

MAGNET

SPACER

MAGNET

SPACER

+

5816OD-002-V0

GATE

5816OD-001-V0

MOUNTING

SCREW (4)

5816OD-003-V0

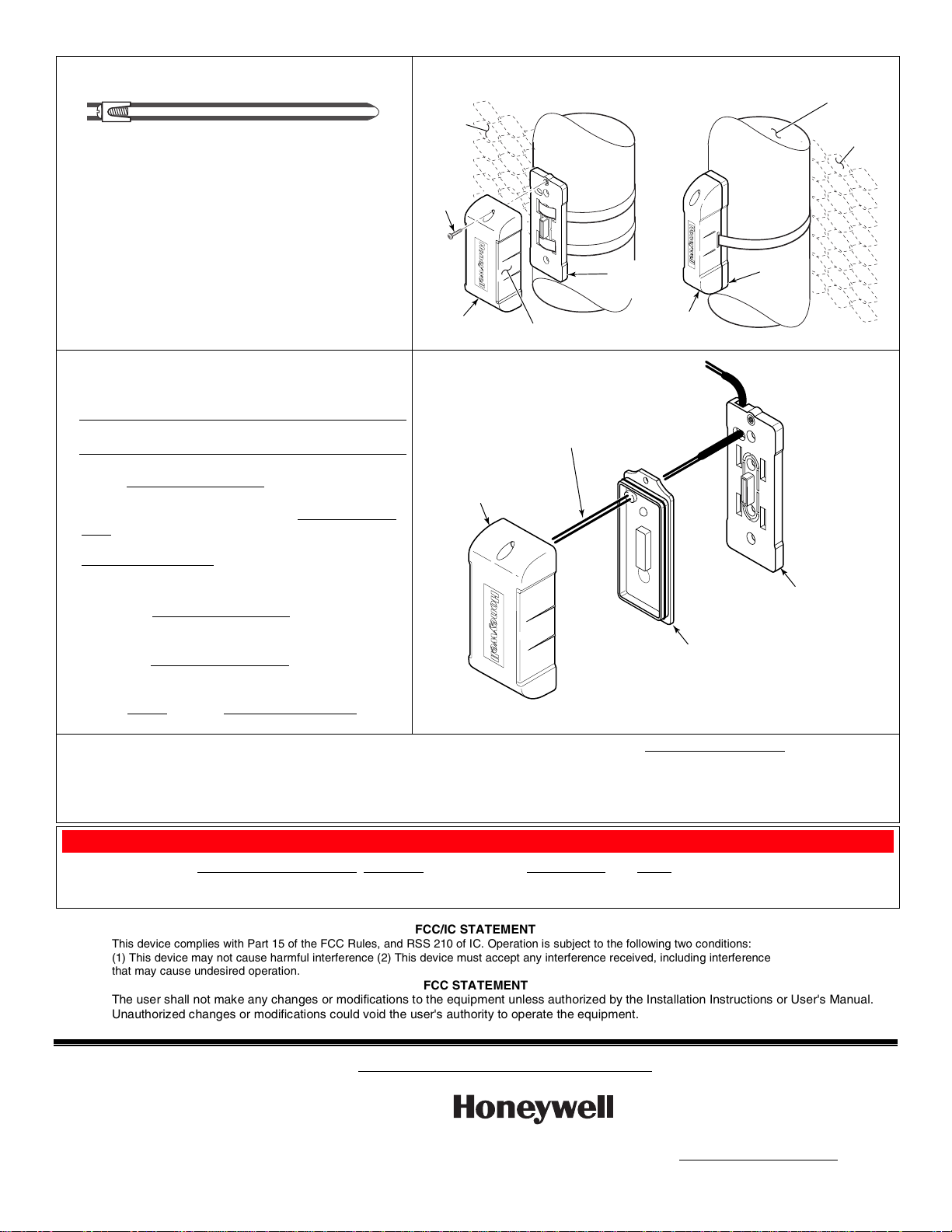

Curved Surfaces:

Mount using self locking stainless steel strap ties.

5816OD-005-V0

Self Locking Stainless Steel Strap Tie

Alternately you can use extra heavy duty Nylon 6/6

UV and Temperature Rated cable ties

(0.5 inch wide).

If desired you may use screws in addition to the ties.

CURVED SURFACES

FENCE

COVER

SCREW

GATE

POST

GATE

MAGNET

SPACER

5816OD-004-V0

ROUTING EXTERNAL WIRING (Optional for use with

external closed contact switches):

SENSOR

MAGNET

SENSING

SLIDE

SENSOR

MOUNTING

PLATE

MAGNET

TO EXTERNAL

CONTACT SWITCH

Note: Use minimum of 22AWG jacketed cable. The

contact switch must be a normally closed type.

UL – The wired contact must be less than 3 feet from

the transmitter.

CONNECT WIRES

TO TERMINAL BLOCK

IN BATTERY CHAMBER

1. Strip cable jacket back 4-inches to allow enough slack to

remove Battery Chamber Cover

batteries.

when changing

SENSOR

2. Pass cable through the access hole in Sensor Mounting

Plate. Use cable notch on mounting plate to pass

jacketed portion of cable through. Then attach the

Sensor Mounting Plate

3. Route cable to the external contact switch and fasten at

intervals to secure cable.

4. Remove the Battery Chamber Cover

through the rubber wire seal.

5. Connect wires to terminal block in battery chamber,

and replace Battery Chamber Cover

.

SENSOR

MOUNTING

PLATE

and thread wires

BATTERY

CHAMBER

. (Note, orient the

COVER

cover so the screw hole lines up with the screw hole in

the sensor cover, and press to close.)

6. Engage Sensor

tabs into Sensor Mounting Plate mating

5816OD-006-V0

holes and swing closed. Secure with cover screw.

PAINTING THE SENSOR:

The sensor and magnet may be painted to coordinate its color with the mounting surface. Use

only paints that are made for plastic and follow the manufacturers directions for preparing the

plastic and applying the paint. Note, the required drying and curing times.

DO NOT USE METALLIC PAINT COLORS.

Recommended Paints

:

Krylon® "Fusion for P lastic"

Rust-Oleum® "Plastic"

Dupli-Color® "Vinyl & F abric Coating"

Programming the Control Panel

You must program the transmitter's serial number, input type (RF Supervised), response type, and loop # in the control panel. (Either or both

loops may be used. Loop # 2 is for the magnet sensing, and Loop # 1 is for the external contact switch.) Refer to the control panel’s instructions

for further details. Note: The transmitter's serial number may be found on the carton, and in the Battery Chamber.

This device complies with Part 15 of the FCC Rules, and RSS 210 of IC. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference (2) This device must accept any interference received, including interference

that may cause undesired operation.

The user shall not make any changes or modifications to the equipment unless aut horized by the Installation Instructions or User's Manual.

Unauthorized changes or modifications c ould void the user's authority to operate the equipment.

WARRANTY For the latest warranty information go to: http://www.security.honeywell.com/hsc/resources/wa/

FCC/IC STATEMENT

FCC STATEMENT

Ê800-04494UŠ

800-04494 11/09 Rev. A

2 Corporate Center Drive, Suite 100

P.O. Box 9040, Melville, NY 11747

Copyright 2009 Honeywell International Inc.

www.honeywell.com/security

Loading...

Loading...