Ademco 8DL5800SS2 Users Manual

5800SS1

FCC / IC STATEMENTS ARE IN THE MIDDLE OF PAGE 2

5800SS1

5800SS1 5800SS1

Wireless Shock Sensor

Wireless Shock Sensor ---- Installation Guide

Wireless Shock Sensor Wireless Shock Sensor

GENERAL INFORMATION

The 5800SS1 is a wireless shock sensor

intended for use in systems that support 5800

series devices. Each transmitter has its own

unique serial number, assigned during

manufacture, which must be “enrolled” in the

control panel before the device can be used

with the system. Refer to the control panel's

Installation and Setup Guide for programming

details.

One 5800SS1 is required for each pane of

glass protected. (Do not use more than one

sensor per pane.)

Types of Glass Protection

• Tempered

• Ordinary Plate

• Laminated Type

• Wired

• Coated

*

• Sealed Insulated

* Not for use in UL installations.

Note: It is not necessary to remove the case

cover during installation.

ENROLLING THE 5800SS1

You must enroll the 5800SS1 serial number

in the control panel during zone

programming. The control panel's Installation

and Setup Guide provides detailed

programming procedures. Before

programming, perform the following:

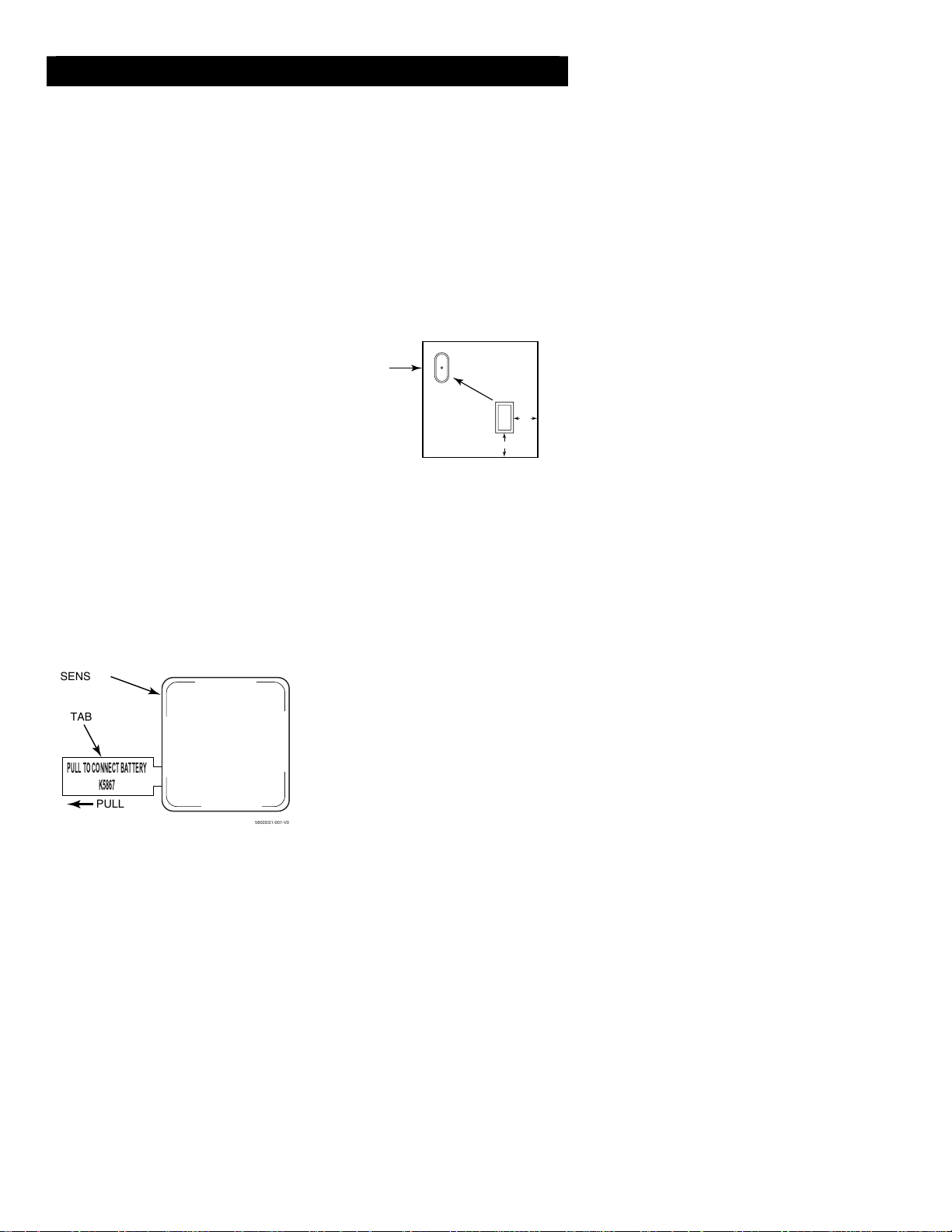

1. To cause the transmitter to transmit,

remove the “PULL TO CONNECT

BATTERY” tab (see Figure 1). (For

additional transmissions, lightly tap on

the base of the sensor with a

screwdriver.)

SENSOR

TAB

PULL TO CONNECT BATTERY

K5867

PULL

5800SS1-001-V0

Figure 1

2. When programming the shock

sensor, note the following:

• Input Type = 3 (Supervised RF)

• Loop Number = 1

3. When prompted for the serial number,

you can transmit by lightly tapping on

the base of the sensor with a

screwdriver or by manually entering

the serial and loop number.

MOUNTING

1. Determine the optimum mounting

location. For best sensitivity, the

sensor should be mounted one-inch

from the corner edge of the window

frame (see Figure 2).

STRIKE AT

FURTHEST

OPPOSITE

CORNER WITH

SCREWDRIVER

HANDLE

Figure 2

2. Before the transmitter is permanently

mounted, conduct Go/No Go tests (see

control’s instructions) to verify adequate

signal strength from the mounting

location.

3. Always verify range by holding the

sensor in the approximate mounting

location and tapping at the base. The

panel (in test mode) should respond to

the transmissions. If not, find a more

suitable mounting location.

4. Clean the glass, where the sensor will be

mounted, with a mixture of water and

isopropyl alcohol.

5. Once the glass has dried, remove the

tape backing paper and firmly press the

sensor in the desired mounting location.

6. Verify operation by striking the furthest

opposite corner of the glass with the

handle of a large screwdriver. Always

check the alarm panel keypad to verify

that the zone has tripped.

7. Apply optional “WARNING” label to the

outside glass surface opposite the tape

side of the 5800SS1.

10 FT. RADIUS

MAXIMUM

COVERAGE

1in.

1in.

MOUNT 1 INCH FROM CORNER

OF WINDOW FRAME.

5800SS1-003-V0

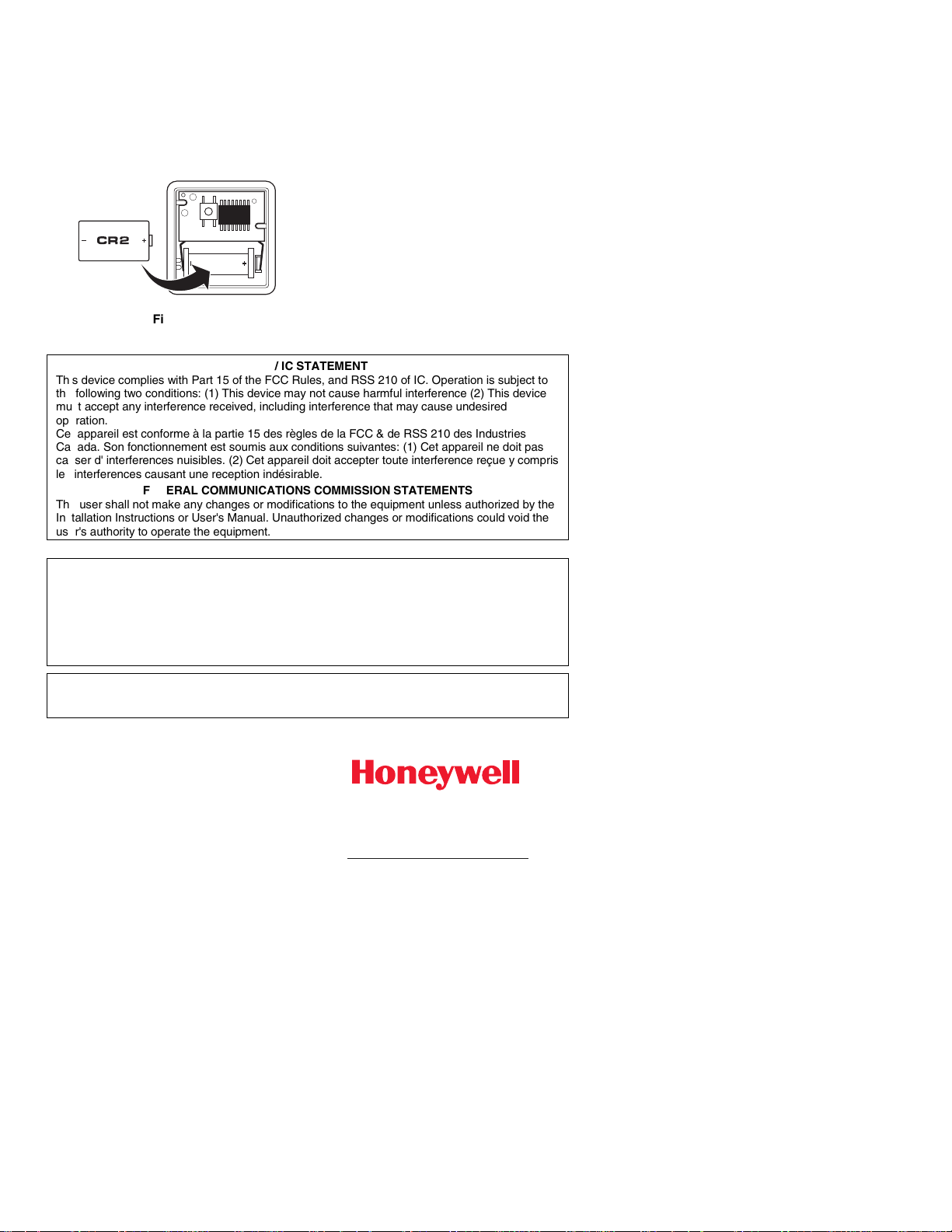

REPLACING THE BATTERY

1. Using a screwdriver, carefully remove

the sensor’s cover.

2. Check the battery polarity orientation

before installing (see Figure 3).

3. Insert the battery securely in the sensor.

4. Snap the sensor cover back in place.

SPECIFICATIONS

Glass Coverage:

Plate, Laminate, Wired, Sealed Insulated,

Coated

* and Tempered glass, with thick-

nesses between 3/32” (2.38mm) and 1/4”

(6.35mm) and up to 10 ft (3.048m) distance

from mounting location. One sensor is

required for each separate pane of glass.

* Not for use in UL installations.

Dimensions:

1.6" H x 1.6" W x 0.8" D (40.64 mm x 40.64

mm x 20.32 mm)

CR2

Power:

Single 3V Panasonic CR2, or Duracell

DLCR2 Lithium Battery

WARNING

5800SS1-001-V0

Figure 3

This device complies with Part 15 of the FCC Rules, and RSS 210 of IC. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference (2) This device

must accept any interference received, including interference that may cause undesired

operation.

Cet appareil est conforme à la partie 15 des règles de la FCC & de RSS 210 des Industries

Canada. Son fonctionnement est soumis aux conditions suivantes: (1) Cet appareil ne doit pas

causer d' interferences nuisibles. (2) Cet appareil doit accepter toute interference reçue y compris

les interferences causant une reception indésirable.

The user shall not make any changes or modifications to the equipment unless authorized by the

Installation Instructions or User's Manual. Unauthorized changes or modifications could void the

user's authority to operate the equipment.

Regular maintenance and inspection (at least annually) by the installer and frequent testing by

the user are vital to continuous satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and offering a regular maintenance

program to the user as well as acquainting the user with the proper operation and limitations of

the alarm system and its component parts. Recommendations must be included for a specific

program of frequent testing (at least weekly) to ensure the system’s proper operation at all times.

FOR WARRANTY INFORMATION AND DETAILS REGARDING THE LIMITATIONS OF THE

ENTIRE ALARM SYSTEM REFER TO THE INSTALLATION INSTRUCTIONS FOR THE

RECEIVER/CONTROL USED WITH THIS DEVICE.

FEDERAL COMMUNICATIONS COMMISSION STATEMENTS

FCC / IC STATEMENT

TO THE INSTALLER

Risk of fire, explosion, and burns. Do not

recharge, disassemble, heat above 212º F

(100º C) or incinerate. Dispose of used

batteries properly. Keep away from children.

ÊK0011V1†Š

K0011V1 1/12 Rev. A

2 Corporate Center Drive, Suite 100

P.O. Box 9040, Melville, NY 11747

Copyright 2011 Honeywell International Inc.

http://www.honeywell.com/security

Loading...

Loading...